TTCI R&D

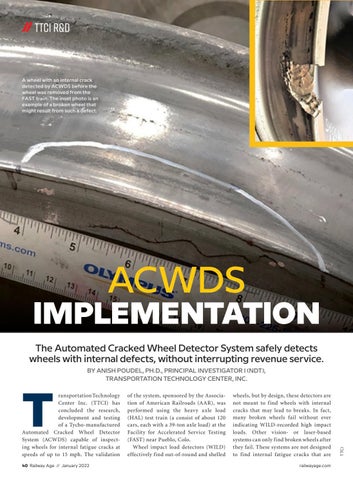

A wheel with an internal crack detected by ACWDS before the wheel was removed from the FAST train. The inset photo is an example of a broken wheel that might result from such a defect.

ACWDS

IMPLEMENTATION The Automated Cracked Wheel Detector System safely detects wheels with internal defects, without interrupting revenue service.

ransportation Technology Center Inc. (TTCI) has concluded the research, development and testing of a Tycho-manufactured Automated Cracked Wheel Detector System (ACWDS) capable of inspecting wheels for internal fatigue cracks at speeds of up to 15 mph. The validation

40 Railway Age // January 2022

of the system, sponsored by the Association of American Railroads (AAR), was performed using the heavy axle load (HAL) test train (a consist of about 120 cars, each with a 39-ton axle load) at the Facility for Accelerated Service Testing (FAST) near Pueblo, Colo. Wheel impact load detectors (WILD) effectively find out-of-round and shelled

wheels, but by design, these detectors are not meant to find wheels with internal cracks that may lead to breaks. In fact, many broken wheels fail without ever indicating WILD-recorded high impact loads. Other vision- or laser-based systems can only find broken wheels after they fail. These systems are not designed to find internal fatigue cracks that are railwayage.com

TTCI

T

BY ANISH POUDEL, PH.D., PRINCIPAL INVESTIGATOR I (NDT), TRANSPORTATION TECHNOLOGY CENTER, INC.