From Quarry to City Centre

At OPC Assessment, we are more than test publishers; we’re experts in our field with more than 25 years’ experience supporting our global clients in the rail and transport sector, engineering industry and beyond.

Our psychometric tools help to: recruit top-tier talent develop high-performing employees support career-long growth

Hosted on our user-friendly Candela™ platform, clients can explore our extensive range of innovative assessment tools. Guided by our expert psychologists, we can advise on bespoke recruitment solutions tailored to your specific needs.

From Quarry to City Centre

PUBLISHER

EDITORIAL

EDITOR

Sam Sherwood-Hale editor@railpro.co.uk

DISPLAY ADVERTISING

Jamie Tregarthen sales@railpro.co.uk

RECRUITMENT ADVERTISING recruitment@railpro.co.uk

SUBSCRIPTIONS subscriptions@railpro.co.uk

ADMINISTRATION

Cherie Nugent info@railpro.co.uk

Lisa Etherington admin@railpro.co.uk

DESIGN &

Lukasz Saczek production@railpro.co.uk COVER

EDITOR’S NOTE

Before writing this, I read that Transport Secretary Heidi Alexander announced she would accept all recommendations from the James Stewart review which was published on 18 June. The Stewart Review recommended a fundamental reset of HS2 including new governance structures with clearer Financial Shareholder roles, improved capability and trust between stakeholders, commercial renegotiation of the Main Works Civils Contracts, and enhanced cost control mechanisms.

The Transport Secretary will re-establish the HS2 ministerial taskforce for proper oversight, impose stricter financial delegations on HS2 Ltd, and has appointed Mike Brown as new Chair. She committed £25 billion in the Spending Review to support the reset programme.

Elsewhere in the country, Three Yorkshire mayors have united behind a £20 billion rail investment strategy that could unlock transformative economic growth across a region of 4.6 million people. The White Rose plan, spanning West Yorkshire, South Yorkshire, and York & North Yorkshire, represents the kind of regional collaboration that rail reform advocates have long championed – particularly significant as it emerges from an area where infrastructure underperformance has become a barrier to economic potential.

The proposal addresses stark realities that will resonate across much of the network. Rolling stock averaging 23.6 years old, capacity constraints at major stations, and Leeds ranking as the UK's worst location for rail delays with only 54 per cent of services running on time paint a picture of systematic underinvestment. Yet the mayors' response – a strategy promising 83,000 new jobs and 210,000 new homes alongside network modernisation – demonstrates how targeted rail investment can drive broader economic transformation.

In this month’s issue, I spoke to Bogdan Godziejewski, the 101st President of the Institution of Railway Signal Engineers, about his vision for engaging young professionals in railway signalling's digital transformation and how the next generation can accelerate the adoption of technologies like ETCS and CBTC; Daryn McCombe from Great Western Railway and Network Rail about the pioneering joint control function between the two organisations, exploring how breaking down structural barriers and aligning decision-making processes is delivering better outcomes for passengers whilst preparing the Western Route for the transition to Great British Railways; and Tristan Lloyd-Baker, CEO of RailSense Solutions, about his company's journey to international success with IoT sensors and how remote monitoring technology is transforming railway maintenance from reactive to predictive approaches across global networks.

We also feature articles from Steve Medhurst and William Phillips at RSA on how the rail industry must future-proof against climate-related risks through innovative satellite monitoring and collaborative insurance solutions; Ellis Patents on their successful deployment of the Pegasus® cable hanger system at Cockfosters Depot as part of the Piccadilly Line Upgrade; Andrew Cruttenden from Trainline Partner Solutions on how rail's green credentials can attract high-margin business travellers as companies face increasing pressure to reduce their carbon footprint; and Hannah McDonnell from Oxfordshire & Gloucestershire Community Rail Partnership on the power of making carbon impact relatable through innovative communication strategies like ‘kettle comparators’ to encourage modal shift from car to rail.

SAM SHERWOOD-HALE EDITOR

Specialists in rail depots and infrastructure

(Transport for Greater Manchester wheel lathe by Cairn Cross)

All the latest from Network Rail, Transport for the North and industry responses to the latest Government spending announcements

INTERVIEW

12 Sam Sherwood-Hale spoke to Bogdan Godziejewski, 101st President of the Institution of Railway Signal Engineers, about his vision for engaging young professionals in railway signalling's digital transformation and how the next generation can accelerate the adoption of technologies like ETCS and CBTC

THE CHEEK OF IT

Long distance patronage moves ahead of preCovid levels as British rail passenger numbers continue their steady recovery in the fourth quarter of 2024/25

LAYING DOWN THE LAW Court Expands Building Defects Liability 21 VIEWPOINT

Anwen Robinson, SVP at OneAdvanced discusses the challenges faced by desk free workers in passenger transport

23 VIEWPOINT

Alys Lee, Duty Service Delivery Manager at East Midlands Railway, explains how she found her way into a rail career and why her recent apprenticeship recognition means so much 24 WOMEN IN RAIL

Rail Industry Celebrates the Women in Rail Awards 2025

INTERVIEW

Sam Sherwood-Hale spoke to Daryn McCombe about the pioneering joint control function between Great Western Railway and Network Rail, exploring how breaking down structural barriers and aligning decision-making processes is delivering better outcomes for passengers while preparing the Western Route for the transition to Great British Railways 30

Sam Sherwood-Hale spoke to Mel Burrell about Premier Pits' evolution from subcontractors to prefabrication pioneers, their move into rail, and why the industry must abandon traditional concrete solutions

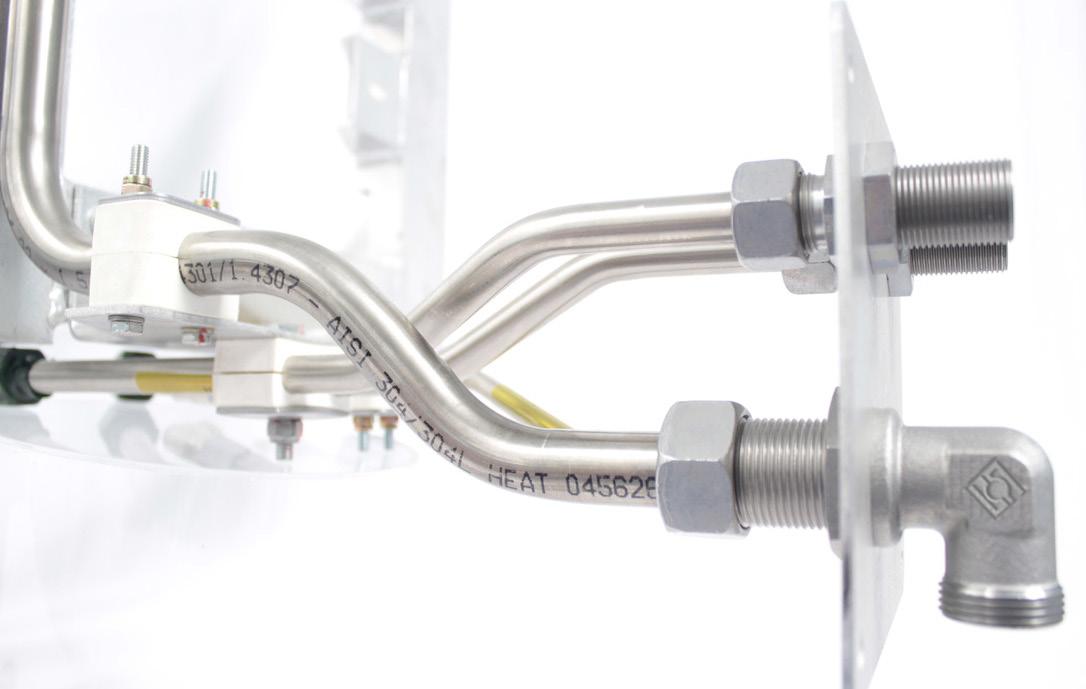

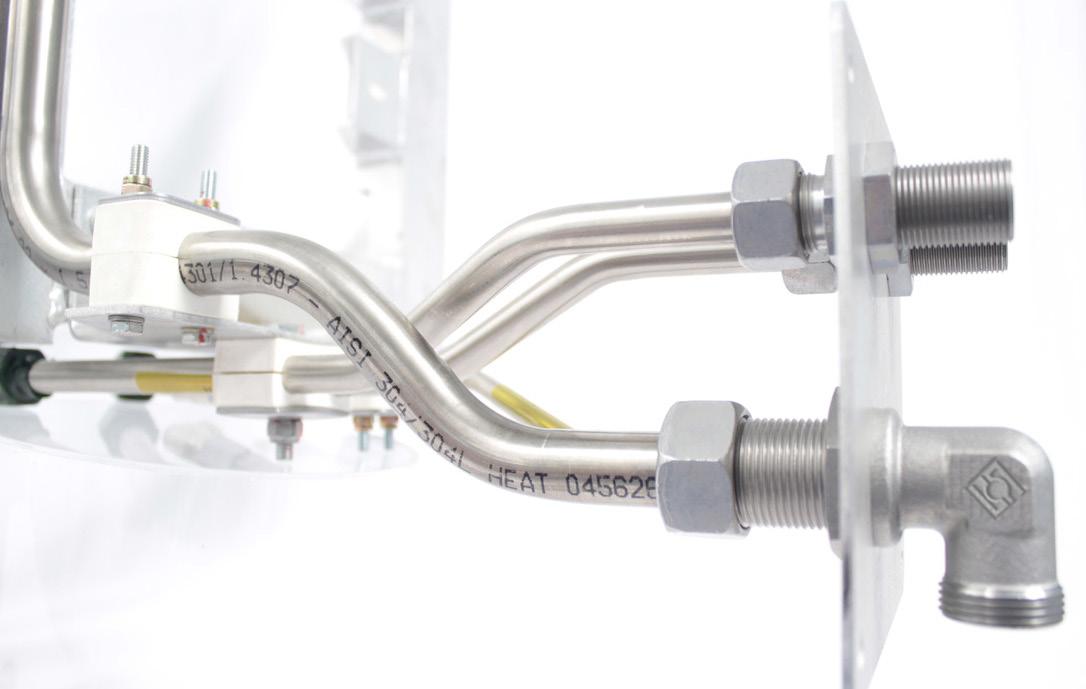

Sam Sherwood-Hale spoke to Chris Showering about IMI's strategic shift from component supplier to systems partner, the challenges of rail electrification, and how building trusted relationships with major OEMs is key

Ellis Patents' Cable Hangers at Cockfosters Depot

Phil Judge, Industry Manager – Railways – WAGO UK & Ireland

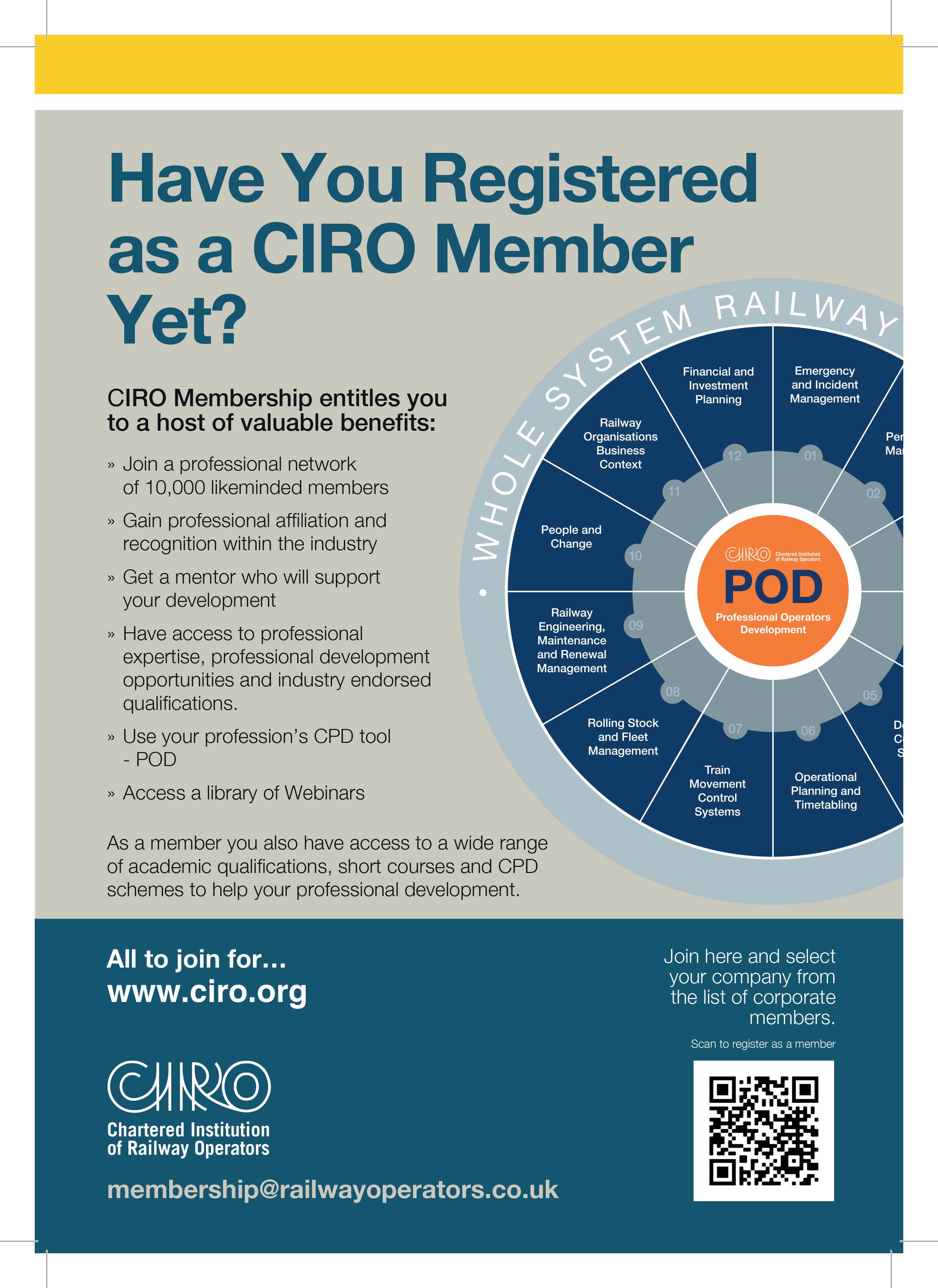

Take Your Next Step

Apply today for Certificate, Diploma or Degree courses with CIRO

If you’re looking to take the next step in your career, a CIRO academic course could be the perfect opportunity.

We offer Certificate, Diploma, and Degree-level courses in Railway Operations Management, taught by industry experts and designed to equip you with the knowledge and skills needed to advance your career.

For more information, get in touch with our academic team, visit ciro.org, or join our virtual open evening to hear from past and present CIRO students during a live Q&A session.

Virtual Open Evenings

We’re delighted to be hosting two online open evenings on June 24th and August 5th for those who are considering a CIRO academic qualification. Whether you have already registered your interest for this year’s intake, or are just curious about the possibilities, come along and speak to the team.

To register, email learning@railwayoperators.co.uk

44 SUSTAINABILITY

Sam Sherwood-Hale spoke to Miça Schultz, RSVT Product Lead at Loop, and Angus Townsend, Director of Social Value at Loop, about the evolution of the Rail Social Value Tool, the challenges of measuring social impact in the rail sector, and how the new Sustainable Rail Blueprint Dashboard integration is helping operators enhance their social value reporting across the industry

INTERVIEW

62 Sam Sherwood-Hale spoke to Tristan Lloyd-Baker about RailSense's journey to international success, their IoT sensors, and how remote monitoring technology is transforming railway maintenance from reactive to predictive approaches across global networks

49

51

Steve Medhurst and Nigel Probert from RSA on the role of claims in risk management and lessons from the Troon station fire recovery

Becky Pullinger, head of land use planning at The Wildlife Trusts on why infrastructure projects must integrate environmental considerations from the outset to avoid costly delays and protect our nature-depleted landscapes

53 SUSTAINABILITY

Andrew Cruttenden, General Manager, Trainline Partner Solutions on how rail's green credentials can attract highmargin business travelers as companies face increasing pressure to reduce their carbon footprint

54 SUSTAINABILITY

Hannah McDonnell, Executive Director, Oxfordshire & Gloucestershire Community Rail Partnership (GoCRP), discusses the power of understanding carbon impact and the role and responsibility of the rail sector in increasing this

56 RAIL LIVE REVIEW

A look back at Rail Live 2025 which took place at the end of June

59 RAIL LIVE REVIEW

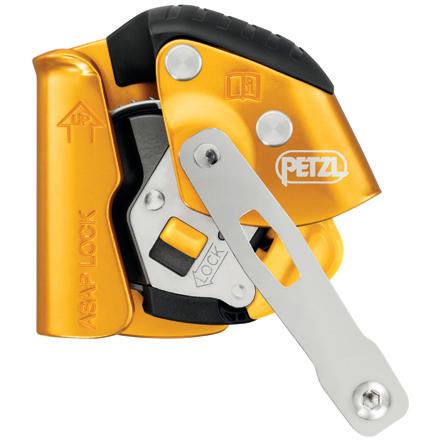

Petzl Work at Height Solutions

NIS Group, a specialist training provider is delivering a tailored ‘bootcamp’ that will give learners the skills they need to gain employment

Cygnus 4+ General Purpose

Ultrasonic Thickness Gauge

3 measuring modes, for accurate, through-coat measurements.

Suitable for extreme corrosion.

Live A-scan, intuitive menu and sequential data logging for easy reporting and analysis.

undergroundElevatedthinking,

Gall Zeidler Consultants celebrates 25 years of innovative solutions and engineering excellence, marking a quarter-century dedicated to advancing tunnelling and underground infrastructure.

We leverage our expertise in transportation, infrastructure, water conveyance, energy, and mining to help clients overcome challenges and deliver world-class infrastructure projects sustainably and responsibly. Over decades, we’ve built a diverse portfolio of major projects, many ranking among the most significant worldwide. With a diverse team, we operate globally through nine offices across Europe, North America, Latin America, and Asia.

Scan & SAVE £200*

DISCOUNT CODE RP25

*Only valid when ordering directly from Cygnus Instruments Ltd

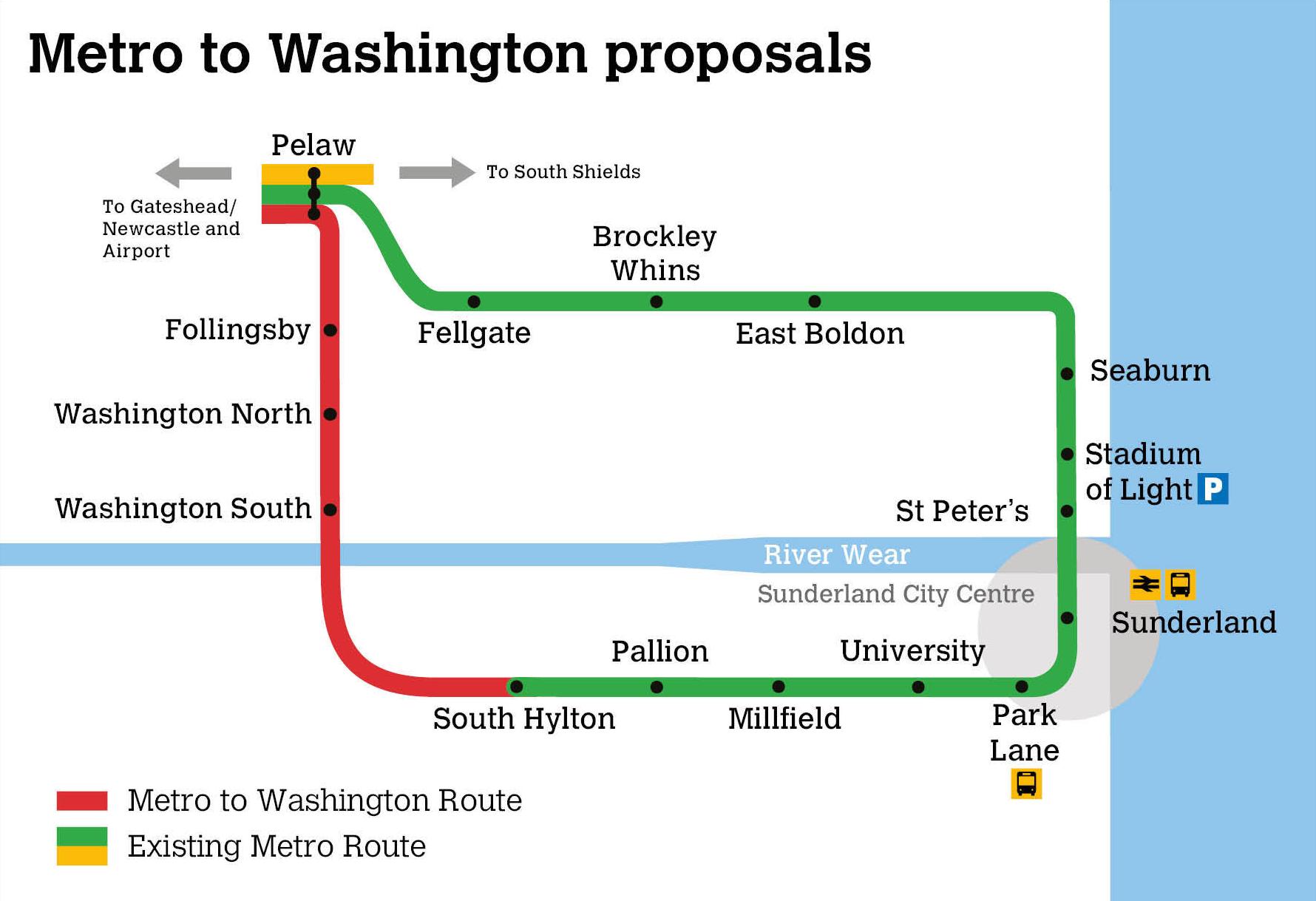

Mayor Announces New Metro Line in ‘Game Changing’ £1.85 Billion Funding Deal

North East Mayor Kim McGuinness today announced the first new Metro line for 30 years will be built as part of a £1.85 billion funding deal agreed with the Government. The new Metro line through Washington stands at the heart of the largest single package of investment ever made in the North East’s transport networks, funding a huge investment in road maintenance, better and safer walking and cycling routes and new bus priority measures.

Mayor McGuinness secured the investment after raising it personally with Chancellor Rachel Reeves and today hailed the deal agreed with Treasury as ‘game changing’ as she delivers on her vision to create the ‘Angel Network’ – a fully integrated sustainable transport network to drive the economy, support new home building and extend opportunity to all.

North East Mayor Kim McGuinness said: ‘When I was elected Mayor I promised voters I would extend the Metro and now, twelve months on, I can today announce that will happen. I am thrilled to say we can now get on with the job of building the first new Metro line for 30 years, at last connecting Washington to the rail network and linking tens of thousands of people to new jobs and opportunity in our growing advanced manufacturing sector.

The Mayor’s deal will provide a major boost towards meeting the total cost of Metro to Washington, with the whole package also expected to include private sector funding. Work to draw up detailed plans for line through Washington is already underway, with the new line, estimated to cost a total of about £900 million, expected to see the first trains run in 2033, just over 30 years since the Metro line through

Sunderland opened. It will serve tens of thousands of homes in Washington, the fourth largest town in England not until now connected to the rail network, and bring people to jobs in the UK’s largest advanced manufacturing zone around the Nissan car factory.

The £1.85 billion announced today will also fund local authority road and public transport projects right across the North East. These include highways maintenance, the roll out of safe and high-quality walking and cycling routes, hundreds of new EV charging points throughout towns and villages, and new bus priority measures to make journey times more reliable. The funding will also take forward the creation of the Angel Network, a fully integrated

sustainable public transport network including contactless travel across bus, Metro and rail and improvements to safety and accessibility where people wait, from bus stops and Metro stations through to large interchanges.

The funding been agreed as the latest phase of the region’s City Region Sustainable Transport Settlement (CRSTS2). It will cover the five-year period from 2027 to 2032.

The agreement is wholly new money and will form part of the North East Combined Authority’s ‘Integrated Settlement’, a fully devolved funding stream that will cover investment in transport, housing investment and economic growth and skills and employment programmes which form the Mayor’s New Deal for North East Workers.

Transport Leaders in the North Plan Rail Devolution

A meeting of Transport for the North's Rail North Committee in Bradford heard that government plans for rail reform offered a huge chance to align the railway to local plan for housing and growth, and enable greater integration with other transport modes such as bus and active travel. The move comes following Chancellor Rachel Reeves announcement last week of more funding to improve transport infrastructure and services in the North's city regions. Political leaders hope Wednesday's Spending Review will build this announcement of billions of pounds of investment to benefit the North's rail network. RNC Chair Mayor Andy Burnham said: ‘This shows that we are serious about taking greater control over our own rail services. For too long decisions have been taken about services and investment by people who don't live in the North and don't use its transport system.

‘Devolution is about correcting that, and making sure that Northerners are at the heart of crucial decision making, so together we can create an accessible, reliable and modern railway.’

The meeting also heard how hundreds of new trains are to be bought for the North's rail network to update the aging fleets currently being used. Northern is to buy up to 450 trains, which could replace two thirds of its existing fleet over the next ten years, while TransPennine Trains (TPT) will buy a further 29 for services across the Pennines linked to the Transpennine Route Upgrade (TRU). Alongside, the Committee reflected on TPT's performance in recent times; cancellations in March dropped to just two per cent and TPT has seen twelve per cent year-on-year passenger growth. The train operating company was brought into public control two years ago due to its poor performance.

Government Allocates £10.2 billion for Rail Enhancements

The Department for Transport has confirmed £10.2 billion of investment for rail enhancements over the next four years, excluding High Speed 2, as part of the government's Spending Review 2025 announcement. The settlement provides a significant boost to inter-city connectivity, with the TransPennine Route Upgrade receiving the largest single allocation of £3.5 billion. The project is expected to reduce journey times between Manchester and Leeds from 55 minutes to 41 minutes, with delivery targeted for the early 2030s. Transport for the North Chief Executive Martin Tugwell welcomed the announcement, saying: ‘We are very pleased with the extra investment in the North's transport infrastructure and services that has been announced. An extra £3.5 billion for the TransPennine Upgrade, support for the reopening of Doncaster Sheffield Airport, and a four-fold increase in local transport grants are all very welcome, especially after last week's announcement of billions for city region transport schemes.’

East West Rail will receive £2.5 billion to continue development of the new railway linking Oxford and Cambridge. The government says this investment will provide new connectivity and unlock growth across the Oxford-Cambridge corridor, supporting housing developments in the region.

Paul Bristow, Mayor of Cambridgeshire and Peterborough, expressed cautious optimism about the East West Rail funding but raised concerns about local priorities: ‘There was silence today on critical upgrades like Ely Junction and the Peterborough Station Quarter. These projects are essential to unlocking growth, jobs, and investment across our region.’

Wales will benefit from £300 million in rail investment, including funding for the Burns Review stations, North Wales Level Crossing improvements, Padeswood Sidings, and Cardiff West Junction. The government has committed to delivering at least £445 million of rail enhancements in Wales to address the country's long-term infrastructure needs.

Leeds station will see a £240 million enhancement programme to improve capacity and relieve congestion at the major Yorkshire hub. The funding forms part of broader improvements to rail infrastructure in northern England.

The spending review also includes provision for progressing the next stage of Midlands Rail Hub West, which will strengthen connections from Birmingham across the West Midlands and to other regions.

Speaking about the Midlands Rail Hub funding, Chancellor Rachel Reeves said: ‘I am providing funding for the Midlands Rail Hub, the region's biggest and most ambitious rail improvement scheme for generations, strengthening connections from Birmingham across the West Midlands and into Wales too.’

Richard Parker, Mayor of the West Midlands, said: ‘The Midlands Rail Hub is about more than trains – it's about opportunity. This investment will unlock thousands of jobs, support new homes and connect our region to faster, greener growth.’

Maria Machancoses, Chief Executive of Midlands Connect, said: ‘This marks a major milestone in this transformational, nationally significant project," adding that it ‘will deliver a step change for passengers, for communities and ultimately for Government's central mission of economic growth.’

Separately, the government has allocated £25.3 billion to progress delivery of High Speed 2 from Birmingham Curzon Street to London Euston. The funding will support what the government describes as a ‘full reset’ of the HS2 programme under new leadership, aimed at addressing longstanding delivery challenges.

The High Speed Rail Group welcomed the news, with a spokesperson saying: ‘This sort of funding agreement creates the platform from which HS2 and its suppliers can carry out the much needed 'reset' of the project and bring clarity on both anticipated costs and programme.’

However, the group warned: ‘We must now work to define what is needed between Birmingham-Crewe to avoid creating Britain's biggest bottleneck in this section of the national railway.’

High Speed 2 spending has been separated from other rail expenditure in the departmental accounts to improve transparency on spending trends over time. Railway Industry Association Chief Executive Darren Caplan said: ‘The Railway Industry Association welcomes the support Chancellor Rachel Reeves announced for UK rail in the Spending Review, and the recognition that the railways are key to delivering economic growth. The Treasury's plans to reassess the Treasury's Green Book investment framework, as social, environmental and regional value are all central to what rail delivers.’

Thomas Knight, Transport Market Lead for UK and Europe at Mott MacDonald, said: ‘Renewed and increased commitment to transport infrastructure investment will deliver transformational projects like East

West Rail, the Midlands Rail Hub and the TransPennine Route Upgrade.’

Richard Whitehead, Chief Executive (Europe and India) at AECOM, said: ‘Having focused on removing planning hurdles and emboldening devolved authorities in its first 12 months in power, this long-term funding cements the government's pledge to accelerate the delivery of essential infrastructure and, in turn, unlock growth opportunities across the UK.’

However, some concerns were raised about delivery capacity. Amish Patel, transport leader at PwC, warned: ‘But investment alone isn't delivery. If we treat each region as an island – tasked with building full delivery and service capacity from scratch – we risk delay, duplication and fragmentation.’

Chris Ball, President – UK & Ireland at AtkinsRéalis, emphasised the broader economic objectives: ‘Infrastructure investment has always been a catalyst for growth and opportunity, but the funding plans today support a clear mission: improve regional connectivity, strengthen energy security, accelerate the build rate of affordable homes and boost socio-economic opportunities.’

Andrew Carter, Chief Executive of Centre for Cities, highlighted the economic potential: ‘The economic underperformance of the UK's largest cities costs the country £50 billion a year. Closing this gap is essential to raising living standards across the country. UK cities lag behind European peers on transport access and economic performance. In Leeds, just 38 per cent of residents can reach the city centre in 30 minutes or less, compared to 87 per cent in Marseille.’

Alasdair Reisner, Chief Executive of the Civil Engineering Contractors Association (CECA), said: ‘The capital investment announced by the Chancellor offers a oncein-a-generation opportunity to revitalise UK infrastructure sector, reinvigorate its supply chains, and create thousands of highly skilled, high-paying jobs.’

Kevin Green, Policy Director at Logistics UK, welcomed the review but cautioned: ‘Nothing, including the economy, moves without logistics. It underpins every sector that our communities and businesses rely on, every day – from keeping the shelves stocked to managing supply chains.’

Daniel Parker-Klein, Director of Policy and Communications for CILT UK, said: ‘Today's announcement recognises the essential role transport, logistics and supply chains play in underpinning Britain's renewal. Electrifying just three miles of railway from London Gateway – the UK's

fastest growing container port – at a cost of less than £10 million, would allow trains to be hauled by electric locomotives all the way to Manchester, Liverpool, Cardiff and Glasgow.’

For London, the government has provided £2 billion of funding between 2026-27 and 2029-30 for Transport for London's capital renewals programme, described as the largest multi-year settlement for the capital in over a decade. London TravelWatch welcomed the fouryear funding settlement as: ‘A welcome step forward in giving greater stability to TfL's finances," but noted disappointment over "the lack of extra funding for key projects such as the DLR and Bakerloo line extensions.’

BusinessForBakerloo called for:

‘Government support and ring-fenced funding to deliver the Bakerloo Line Upgrade and Extension (BLUE)," highlighting the project's potential to deliver ‘up to 107,000 new homes along the route, 150,000 jobs and an additional £1.5 billion in GVA each year.’

Rachel Taylor, government & health industries leader at PwC, noted the wider challenge: ‘To fund the spending choices taken by the Chancellor, substantial savings will have to be made by several departments and wider public services. Salami slicing budgets won't bridge this divide so public bodies will need to make smarter choices, not just cheaper ones.’

The spending review acknowledges the ongoing transfer of rail services into public ownership, which the Department for Transport says will enable the removal of duplication currently spread across 14 train operating companies and create economies of scale.

This transition forms part of the department's commitment to deliver at least five per cent savings and efficiencies, alongside modernisation initiatives and increased use of artificial intelligence in processes.

Beyond national rail projects, the government has committed £15.6 billion by 2031-32 for elected mayors in England's largest city regions to invest in local

transport priorities, including local rail services. City-region transport spending will more than double in real terms by 2029-30 compared with 2024-25.

Jason Prince, Director of the Urban Transport Group, said: ‘The Spending Review –together with the Chancellor's transport funding announcement last week – acknowledges the tireless work of our members in delivering better public transport services, and provides a clear commitment to devolution.’

For strategic long-term rail ambitions in the North of England, the government has allocated funding for further development, with additional details to be set out in the forthcoming ten-year Infrastructure Strategy.

The announcements form part of the government's broader transport strategy, which prioritises investment in northern England and the Midlands whilst giving local areas greater control over how transport funding is allocated and spent.

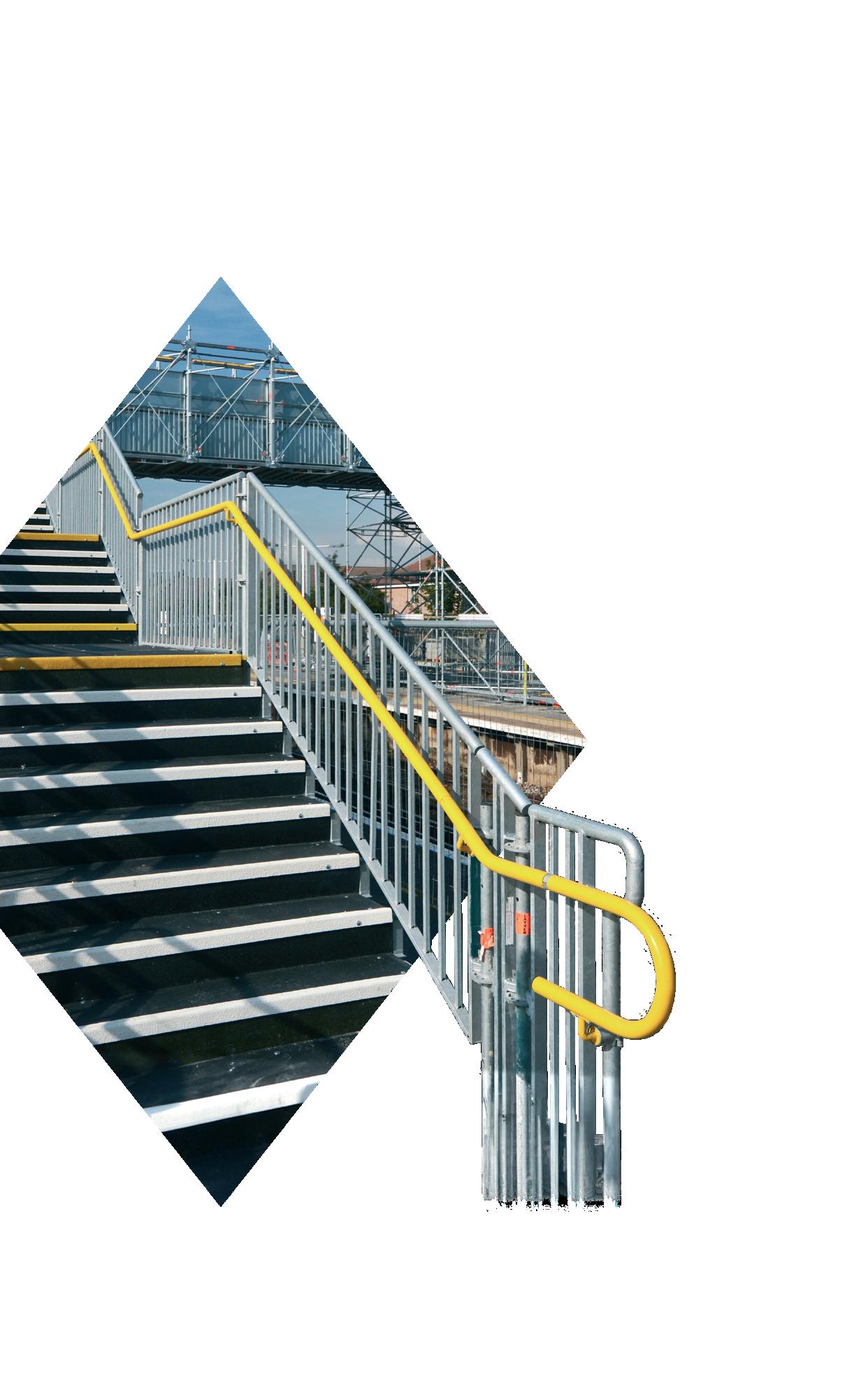

Contract Awarded to Improve Accessibility at Chalkwell Station

Network Rail has awarded a contract to improve accessibility at Chalkwell station to Octavius, to make the station step-free for the first time. Working in collaboration with c2c and Southend City Council, Network Rail and Octavius will install two new lifts, making it easier and safer for all passengers with reduced mobility, pushchairs or heavy luggage to move between street and platform level. The improvements are being funded by the Department for Transport’s

‘Access for All’ scheme which aims to improve accessibility for everyone across the UK’s rail network.

The work will also include the installation of a new modern footbridge and stairs, replacing the existing footbridge and stairs which is coming to the end of its design life. A disused goods lift shaft at the back of the station building, which has not been in operation for over 40 years, will be removed to make space for the new lift to be installed.

Preparatory works are expected to start this summer, which will include the construction of a temporary footbridge and stairs to allow the old footbridge to be removed this autumn.

Once complete the improvements will significantly enhance accessibility and make rail travel more convenient for everyone using Chalkwell station. Work is currently planned to be complete and lifts open by the end of 2026.

Bogdan Godziejewski

101st President of the Institution of Railway Signal Engineers

Bogdan Godziejewski serves as Rail Director at Mott MacDonald (Netherlands) and was elected as the 101st President of the Institution of Railway Signal Engineers (IRSE) in 2025. He has accumulated 40 years of experience in railway signalling and control systems since beginning his career in 1985 at the Railway Scientific and Technical Centre in Poland. Since joining Mott MacDonald in 2014, Godziejewski has led the firm's digital signalling and train control competence centre, with particular expertise in European Train Control System (ETCS) development and Communication Based Train Control (CBTC) implementation. His project portfolio spans multiple continents, including work in Europe, Australia, and major North American cities such as Washington, New York, Seattle, and Toronto. Bogdan became an IRSE Fellow in 1999 and has served on the Institution's Council since 2018.

Sam Sherwood-Hale spoke to Bogdan Godziejewski about his vision for engaging young professionals in railway signalling's digital transformation and how the next generation can accelerate the adoption of technologies like ETCS and CBTC

SSH: What are your plans to implement your ‘Engaging Generation Unlimited’ vision during your presidency?

BG: I would like to enable young professionals to present their ideas about where we are and where we should go as a discipline and Institution. The demographics among our members are not different from the average in the railway sector. At the same time, we see a growing number of digital signalling and train control projects overall, not only in the UK but also in Europe and elsewhere.

European Train Control System (ETCS) and Communication Based Train Control (CBTC) are extensively being deployed in both greenfield and brownfield environments. This means that in the next few years, we have to attract enough young professionals to keep pace with the growing number of projects. In my perception, there is no time to lose.

In my opinion, the best way is to engage Generation Unlimited. We don't need to tell them what the future will be. It is much more efficient to facilitate their desires and ideas for the future and show that they are important in the ongoing digital transformation process. This is how you will attract younger people. My plan is to implement this vision by improving the visibility of younger professionals.

SSH: What initiatives are you planning to give young professionals the voice you mentioned they need in shaping the future of railway signalling?

BG: First of all, I will invite young professionals to a series of presidential lectures during my presidential year. These will be dedicated to my theme, which means I would like young professionals to explain their vision for the future of the discipline, and also the role which the IRSE should play in supporting their professional development.

‘There's no longer a place in the consultancy world where you can be only a technical specialist. You must at least understand the implications from organisational, legal and financial perspectives.’

based on their ideas, adjust the strategy of the Institution to facilitate their needs for professional development and their role in improving the efficiency of digital transformation within signalling and train control.

SSH: You mentioned that the conference would be different from a standard conference. What was the decision-making process behind that?

BG: The standard way of presentation, where one person presents and then there are questions and answers, might not be enough. We would like to have more interactive sessions where people can really discuss subjects among themselves. This is the way we observe younger colleagues working together. They are much more connected than we perhaps are, and we would like to facilitate that approach.

I also think sharing knowledge, sharing visions and networking is the best way to get connected, and getting connected is a really important point. Within the organising committee of our Aspect Conference, which is scheduled for Yokohama in December this year, we have decided to give special attention to young professionals. We'll have dedicated interactive sessions for them, which will be different from a standard conference, as well as a networking platform. We will have innovator sessions where young professionals can present their ideas and discuss their theses. To facilitate this, we have decided to offer bursaries for our members under 35 to travel to Japan for the Aspect Conference. These bursaries are using a fund created by Frank Hewlett, a past member of the Institution who made a bequest to the IRSE in his will, and from funds established in honour of Alan Fisher, a past president of IRSE. These efforts will ensure the involvement of younger professionals. We will listen, and

SSH: What obstacles do you think you'll need to overcome to achieve greater engagement from younger professionals?

BG: In my career, I have also worked as a manager, helping young people on their career journey. You encounter various characters in life – introverted people, extroverted people. Some will directly tell you what their expectations are, while others will be much more introverted and wonder: ‘What am I doing here?’

I think we must try to facilitate all those to have a vision, and present it. If you have leaders within the young generation, others will likely join and follow. I believe we should not simply dictate things. It's much better to facilitate and have them as partners, who feel responsible and are respected for their actions.

In my daily job, I work with younger professionals and I treat them as partners. They have the same input as I do, and it's much more dynamic. I bring experience, they bring creativity, which is a good mix.

SSH: When you speak about young people, what age group are you envisioning for these initiatives?

BG: We had a long discussion about who is a ‘young professional’. Someone in their 50s who just joined the discipline could also be considered a young professional in some sense. However, we decided to define the category as people under 35.

SSH: What was the thought process behind that decision?

BG: We're looking for openness and creativity. And while we don't exclude anybody, we have to make some decisions. For instance, if we give bursaries, we need to set some conditions, so the age of 35 was determined to be appropriate.

Our focus is really on Generation Unlimited – young professionals who have joined the discipline and are developing. Normally, it takes about 5-6 years to have a qualified person who knows what the discipline is and what they can do within it. It's a question of facilitating them along the way.

SSH: Based on your experience with projects like ETCS and CBTC globally, how might young professionals' vision differ from conventional approaches?

BG: That's a very interesting question. In my opinion, each generation introduces their own way of dealing with signalling projects. When I started my career in 1985, relay technology was predominant. Together with a couple of younger colleagues, we proposed preparing a standard after seeing developments abroad regarding the implementation of electronic interlockings.

We said: ‘We have to start somehow, so let's prepare a standard for implementing electronic interlockings.’ But this was not really supported by my more experienced colleagues – they were very sceptical and said: ‘Computers in safety applications? That will never happen!’ Today, it's the norm.

I think it's up to younger colleagues to change the paradigm of how we think and do things now. There are many technological developments like cloud-based applications, but this technological change must also be supported by changes in processes – for example, how safety systems are homologated for use in railways, or how they are developed.

Other ideas could involve project preparation itself, where the application of modern tools like Building Information Modelling (BIM) and other modelling tools could become the new normal. We don't have this everywhere yet.

Another often-forgotten area is operational maintenance and the use of data analytics. This, along with predictive and prescriptive maintenance supported by machine learning, will surely change how things are performed today.

‘In my opinion, each generation introduces their own way of dealing with signalling projects. When I started my career in 1985, relay technology was predominant. Together with a couple of younger colleagues, we proposed preparing a standard after seeing developments abroad regarding the implementation of electronic interlockings.’

I've observed, especially within the CBTC domain, more attention being given to properly defining roles and responsibilities and focusing on asset management standards like ISO 55000, that provide structure for how maintenance should be done. I think we are missing this in signalling, and I have a few examples, like in Singapore, where this approach was a breakthrough in maintaining signalling systems.

So, I believe the younger generation can use new technologies to create their own ways of doing things. I see a lot of innovation, new tools being developed, but it will be up to the young generation to determine how to use them.

SSH: When you talk about machine learning tools, do you think this is an area where they would have the most impact? There's a generation that's going to learn how to use these tools, and then there's going to be another generation that will take the technology for granted. Are you concerned about how young people might rely on these tools because they're so effective?

BG: I think the answer is that we don't know yet. It's really up to those coming through. In 1987, when I was developing specifications for electronic interlockings, my older colleagues told me: ‘You will never get safety approval for them.’ Today, the same concern exists about machine learning and AI, with everyone asking: ‘How do you make it safe?’

We'll see – it's still very open. It's a question of changing the paradigm, of thinking about how we can use these tools. We don't want artificial intelligence that gives wrong answers; in a safety environment, that can’t happen. I think in three to five years from now, we'll see a real change in this area.

SSH: Is this something you're working on with Generation Unlimited?

BG: I can tell you about my own practice at Mott MacDonald. I work primarily with younger people. I've helped many of them with their university graduation projects here in the Netherlands, trying to spark their interest in signalling and train control, and many of them stay with me. That's where we create a mix of creativity and experience as we work on various projects. What often happens is that they're assigned to a project and stay on it for several years, which provides good experience as they see the whole life cycle. What I do differently is encourage them to look around while they still have time. I take them to various projects so they can benchmark and see things done in different ways. There's no better or worse approach – just different ones – but through comparison, younger colleagues can learn much faster. Some stay with me, some go to industry partners, but I see them all growing.

SSH: Do you keep in touch with these young people throughout their careers?

BG: Yes, of course. I stay in contact as friends and colleagues. Some stay in the Netherlands, some have gone to Canada and Australia, some went into industry and disappeared into that world, but I still stay in touch.

SSH: What is your personal perspective on signalling and train control projects?

BG: I started my international career as a researcher, working with the European Rail Research Institute, coordinating and managing several teams of 15-20 people on the development of safety applications like ETCS and harmonising functionalities of electronic interlockings at the European level.

I also completed management studies, including an MBA, here in the Netherlands and in the US. Through these studies, I learned that the world is different from just the engineering part. That's why benchmarking and looking beyond just the technical aspects to consider operational, financial, and organisational perspectives, is very important.

In the past, we typically focused primarily on technology and technical aspects, but that's no longer sufficient. You have to take a more comprehensive view to understand the complexity of projects and try to unlock

‘We don't need to tell them what the future will be. It is much more efficient to facilitate their desires and ideas for the future.’

that. My first projects were very technical, then we moved to design-build contracts where lawyers worked alongside us, so things changed dynamically.

There's no longer a place in the consultancy world where you can be only a technical specialist. You must at least understand the implications from organisational, legal and financial perspectives. This is what I want to convey to younger colleagues.

SSH: You mentioned visiting projects to compare approaches. How many of these visits have you done?

BG: As a competence centre within Mott MacDonald group for digital signalling and train control systems, we have the opportunity to work in Australia, North America, Europe and the UK. From every project we learn new lessons and compare their efficiency. Although technology stays mostly the same, what matters are ways of procuring, organising and prioritising the signalling projects. With some 50 projects of different sizes and at various stages of implementation, you are able to understand what works and which approach offers the best outcome.

SSH: It sounds like engineers were once more like Renaissance people who needed to know all elements of the job. Do you think people became more specialised over time, and now with these new tools, it's possible to have a more all-encompassing vision of your job?

BG: Exactly. With these tools, the technical part will become less dominant, creating space for a better understanding of the overall project and process.

SSH: Regarding the Tyne and Wear Metro business case, which involves replacing their original signalling system from the 1970s and 1980s, how do you see young professionals reshaping this digital transformation in signalling? What unique perspectives might they bring that experienced engineers might overlook?

BG: The case of Newcastle is special because it's a network that connects with Network Rail, so isn’t a standard solution where you can simply apply CBTC and that's it. You have to think carefully about what to do there.

Each property has its own challenges in dealing with brownfield modernisation, and this applies to Newcastle as well. The key is to look from a lifecycle perspective, and this is where the younger generation can offer a different pace of digital transformation process.

I might be considered a little cautious, but young professionals often don't carry the same historical baggage, so they can think more efficiently about implementation and move beyond old technologies and old operational rules. For example, in New York, they decided to create CBTC overlay systems. We see similar overlay approaches in the UK as well, because infrastructure managers are reluctant to quickly remove old equipment.

However, I think if you apply pure CBTC or pure ETCS, it would be much faster, more efficient, and you would get better results. I believe the younger generation can implement digital transformation much faster than we currently do (typically a brownfield modernisation takes between five to ten years on a metro line), and this is my hope.

If we look at German railways, for instance, they've said that at their current pace, it will take them 60 years to implement ETCS, by which time it will be obsolete. We need to find ways to accelerate implementation, and those entering the industry can help with this in the preparatory phase with better tools, and during testing and commissioning.

Finally, for those further into their career, implementing digital transformation may require a mindset change, but for those starting off in theirs, it is the norm.

SSH: Why do you think younger people learn to use these tools much faster?

BG: Because they are born with the digital technology. If I look at my son, when I'm struggling with my mobile phone settings, he just takes it, looks at it, and fixes it instantly because for him, it's innate – he was born with it.

SSH: What skills do you believe the next generation will need to develop to maintain legacy systems like the one in Newcastle and implement new digital solutions?

BG: You still need time to understand the basics. The fundamentals of signalling have remained largely the same over 200 years of railway history. There are still different technologies and different mindsets about how to translate those basics into modern systems and how to minimise human factor impacts.

This is where I think we still need a mix of experience and knowledge base, which is what IRSE is willing to provide – bringing those basics to young people while also creating platforms for exchanging ideas and collaborative work. With software-based

‘Software-based systems are much more complex, which is why you need cooperation and common understanding... All of this requires a collaborative approach, which I think young professionals can achieve more easily.’

systems, there's no other way but to work collaboratively.

I know people in Europe who work with colleagues from around the world on software-based systems. It's a much more connected environment than having a single specialist working alone to develop something. It's truly collaborative work, completely different from how we did things before.

Previously, we worked in project silos, not only within disciplines but also between disciplines. Now, with software-based applications, these silos are being broken down. In many organisations, I see those developing projects and those operating or maintaining projects as complete silos, whereas with software-based systems, they have to create task forces or common groups to get a comprehensive overview and foster continuous improvement of those involved.

Software-based systems are much more complex, which is why you need cooperation and common understanding – why are you implementing things a certain way, how will operators work with these systems, how will maintainers be able to maintain them, what is the relationship between the property owner and the supplier? All of this requires a collaborative approach, which I think young professionals can achieve more easily.

SSH: How difficult do you think it will be to break down these silos?

BG: My idea is to elevate what they are already doing in their daily work – giving them a platform to talk and explain how organisations should change. This is important not just for infrastructure managers and railway operators, but also for IRSE. I want us to listen to them carefully and draw conclusions about how these organisations should evolve because if we can achieve this, we'll create a platform for collaborative working.

SSH: What was your relationship with IRSE like before becoming President?

BG: It's about people – it's a people's organisation. I joined IRSE in the late 1990s, and because of the job I was doing, I was directly offered Fellow status. Many people I work with internationally, colleagues from the Netherlands and all over the world, are also active members of the IRSE. We meet at conferences, seminars, events, and other occasions, so the organisation brings people together.

I've been on the Council since 2018. To become President, you need to understand how the organisation works, and I think that's a good approach. My colleague Jane Power, who is now Past President, still has a very active role within the Institution. It's a longer trajectory – it takes about ten years if you decide to step into the management level of IRSE, not just one or two years.

SSH: Where are we in your personal vision? Is this year one of ten, or are we halfway through your plan?

BG: For me, the priority during my presidential year is to get things moving. The vision of engaging young professionals is closely linked to the digital transformation of our discipline. This requires continuous improvement and is more about a guiding principle than a time-limited project. I hope that through the various activities during my presidential year, young professionals will become more connected. Later, I will transition into an observer in a supporter role, confident that they will manage things perfectly on their own.

SSH: How do you envision IRSE adapting its licencing, certification, and knowledgesharing processes to prepare young professionals for this increasingly software-driven field?

BG: About a year and a half ago, we started developing a new strategy for the Institution. We created several task-andfinish groups, including a review of the licensing scheme and many others, to understand what's needed for the future. The IRSE licensing scheme has been around for 30 years, and it works well, but with all the changes in this software-driven field, we need to understand what's needed going forward. These strategy groups are working now, and I think by the end of this year, we will be able to consolidate their results.

SSH: What's the feedback process for developing that strategy?

BG: Each task-and-finish group works differently depending on their needs. We have an IT group looking at what instruments are needed within the institution to improve the IT platform for internal and external users. We have a licensing review group that has sent out a

questionnaire to members to see what they like, what they don't like, and what they feel they need for the future.

We're also engaging with large organisations like Network Rail to interview them and understand their vision for future licensing schemes and how they see cooperation with the institution. All these inputs will be brought together into one strategy, which we expect to have ready by the end of this year or early next year. This strategy will prepare the institution for the next five to ten years.

SSH: What role do you see for young professionals in bridging traditional organisational boundaries, and how can IRSE foster these collaborative skills?

BG: Digital signalling and train control systems broke these boundaries long ago. Most of the intelligence of signalling and train control is now on board trains, so the Institution needs to engage train operating companies as well necessitating an even more collaborative approach than before.

We are working to approach train operating companies and see if through this next generation, we can break the silos I spoke of earlier.

SSH: When did your vision for the future of railway signalling first start developing?

BG: I think it's very much related to my work at Mott MacDonald. I've been with the company for more than ten years now. When I arrived, I saw colleagues working independently on projects, and I observed digital signalling and train control gaining momentum.

We started a competence centre here in the Netherlands to support group digital skills. Then I looked around to see who could help me with this and realised there were very few people in the sector, even though it's an engineering field, ready to work with modern systems and available to work for projects abroad.

That's why we approached universities –we work with the Universities of Delft and Twente in the Netherlands – and got the opportunity to help graduates with their final university projects. Many of them stayed, and that's how I built the competence centre team and developed the idea that I really need this younger generation.

SSH: Is this a programme that could be developed EU-wide or even into the UK?

BG: Many colleagues have different approaches, but they face the same problem whether in New York, Singapore, or Amsterdam – how to attract the younger generation. Some created rail academies. Singapore has one, there's one in Europe, and within our company, Mott MacDonald, we also have a special programme for graduates. I think these are good examples of how to attract younger colleagues.

‘I bring experience, they bring creativity, which is a good mix.’

SSH: You mentioned Singapore earlier. Was there a specific example from there that you wanted to reference?

BG: Yes, the LTA (Land Transport Authority) started cooperating with the University of Singapore to organise specific interactive seminars for students and graduates. I am visiting in September this year to join such a seminar and observe how LTA in Singapore works with students and graduates.

Singapore is also a very specific case regarding data analytics. About ten years ago, they had a significant issue with their brownfield environment – they couldn't determine why systems were failing. They assembled a small team of data analytics specialists from the University of Singapore and asked them to look at the vast amount of data from these systems to find failure patterns.

These individuals had no understanding of signalling at first, but supported by SMRT they developed new algorithms and discovered that, for example, thresholds were not properly set – the systems weren't actually failing, but the thresholds were too low. After solving these immediate problems, the digital analytics team was incorporated into the maintenance operations of the SMRT.

They now use various tools for predictive and prescriptive maintenance, and you can see the results in the network's reliability. While we're discussing in Europe how to improve reliability, they only have one or two major failures per year, where a ‘major failure’ means a delay of more than 15 minutes.

I think this demonstrates how you can introduce data analytics without necessarily needing university-trained signalling engineers. You can bring data analytics specialists into the discipline and enrich it that way. There can be various approaches to reaching the goal.

SSH: Does the age of the signalling and train control systems factor into young people's interest? Might they feel closer to newer infrastructure?

BG: I believe it's ultimately about the job itself. For younger people it's important to find work and a work environment where they can experience joy and see real prospects for personal development. It's also a matter of leadership and mentorship – we must engage young professionals and ensure that what they are doing aligns with what they truly want to do.

by Chris Cheek

Winter Warmer from Rail Customers

Long distance patronage moves ahead of pre-Covid levels as British rail passenger numbers continue their steady recovery in the fourth quarter of 2024/25

Demand growth in the British rail industry slowed again during the winter: non Elizabeth Line passenger numbers were 5.6 per cent higher than the same quarter in 2024, reaching another new postCovid high. Including traffic on the recently opened line, growth was 5.9 per cent.

Overall, demand rose to 97.4 per cent of pre-Covid levels, according to National Rail Trends statistics, published by the Office of Rail and Road (ORR). However, without the Elizabeth Line, the recovery was limited to 86.5 per cent.

The provisional figures cover the fourth quarter of fiscal year 2024/25, finishing at the end of March: across the network, 429.5 million passenger journeys were made during the twelve-week period, up from 405.7 million in 2023. Between them, they covered 15.8 billion passenger kilometres, 1.3 per cent up, and paid a total of £2.825 billion in fares, 9.5 per cent more than in 2024.

Looking at demand by ticket type, advance tickets were up by 13.6 per cent, taking sales 81.4 per cent higher than before the pandemic. Anytime peak and offpeak fares were up by 6.3 and 4.2 per cent respectively, leaving them 27.0 per cent and 32.0 per cent ahead of the pre-Covid figure. Season ticket holders made 5.6 per cent more journeys than last year, but the 60.1 million total remained 62.5 per cent below the 2019 figure.

Aside from the Elizabeth Line, services in London and South East moved ahead by 4.4 per cent during the quarter, but this was once again the slowest growing sector. Between them, the operators carried 240 million passengers in the twelve weeks, but

slipped back to 18.7 per cent below 2018/19. Amongst individual operators, West Midlands Trains saw the fastest growth on 9.8 per cent, followed by c2c on 7.2 per cent and Chiltern on 7.0 per cent.

The Elizabeth Line carried 59.6 million passengers in its eleventh full quarter of operation, 7.5 per cent up in the year, meaning that the line accounted for 13.9 per cent of the national network’s patronage in the January to March quarter, second only to GTR’s 17.8 per cent.

The long-distance InterCity sector saw demand increase by 7.7 per cent compared with 2024, taking passenger numbers to 36.9 million, 3.7 per cent above 2019 levels. The passenger kilometre figure was 5.3 per cent ahead, leaving it 3.8 per cent short of pre-pandemic levels. Revenue on the InterCity services moved up 9.1 per cent (6.1 per cent after inflation), but remained 19.7 per cent down in real terms on 2018/19. LNER saw the largest growth, on 16.7 per cent, taking the business to 26.3 per cent above pre-Covid levels.

Next came Cross Country on 14.3 per cent, just 1.4 per cent short of 2018/19 levels. Great Western grew by 7.4 per cent, but remained eleven per cent short, whilst EMR grew by 6.7 per cent, taking passenger numbers 20.7 per cent above pre-pandemic levels. Avanti West Coast saw 2.3 per cent growth, still 13.7 per cent down from 2018/19. Caledonian Sleeper, though, saw a 5.2 per cent dip in demand.

Amongst the regional franchises, total patronage was eight per cent up on 2024, but remained 6.3 per cent below 2019 levels. Amongst individual TOCs, TfW led the pack, advancing by 12.6 per cent, but still 4.7 per cent short of its 2019 figures. Northern

bounced back from a drop in the last quarter to be 9.3 per cent up, remaining 7.3 per cent short of full recovery.

TransPennine came next, with passenger numbers up by 8.5 per cent during the quarter, reducing the shortfall against their 2018/19 figure to 6.8 per cent. Merseyrail also bounced back from a loss in the autumn, with a rise of 7.7 per cent, taking demand to 25.2 per cent below on 2018/19. Scotrail saw a 2.2 per cent rise, despite the reimposition of peak fares in October, leaving it 14.6 per cent short of pre-Covid levels.

Amongst the non-franchised operators, First’s operations at Hull Trains saw growth of 8.7 per cent, taking it to 44.8 per cent above pre-Covid levels, but Lumo experienced a small one per cent fall. East Coast rivals Grand Central also saw a small fall, of two per cent, but remained 12.7 per cent ahead of their pre-Covid patronage. Competition from the Elizabeth Line still affected Heathrow Express. Patronage grew by 4.4 per cent on the quarter, partially reversing five quarters of decline. This left patronage on the premium route 28.7 per cent down on 2018/19.

Rolling year figures

The national totals for the twelve months ended 31 March show growth of 7.2 per cent compared with 2023/24, 6.8 per cent excluding the Elizabeth Line. Compared with the last pre-Covid year of 2018/19, the figure was just 1.4 per cent lower at 1,728.7 million. However, excluding the Elizabeth Line, passenger numbers remained 12.7 per cent short of the 2018/19 figure. Passenger kilometres travelled were 7.5 per cent higher at 63 billion, whilst passenger revenue grew by 11.1 per cent to £10.7 billion. Adjusted for inflation, revenue was 4.8 per cent up on the year but remained 16.4 per cent below pre-pandemic earnings.

As in previous quarters, performance varied between the sectors. Passenger journeys in London and South East excluding the Elizabeth Line were 6.7 per cent up on the year, but still 15.6 per cent below 2019 levels. Regional networks saw growth of 9.1 per cent on the year but remained 7.7 short of full recovery. Patronage on the InterCity routes was 8.4 per cent up on the year, and moved past the 2018/19 total by 2.3 per cent, despite a real terms shortfall in revenue of 19.6 per cent.

Comment

This quarter saw some measure of economic growth alongside falls in inflation and interest rates. It was also a relatively mild winter, with fewer severe weather incidents than some past years. A slightly more encouraging context for rail patronage with retail sales rising. All this was before the storms of the second quarter, with Trump tariffs, a new war on the Middle East and the increases in inflation.

The steady recovery in patronage was maintained in all the TOCs bar one, whilst

NEWS IN BRIEF

MOTT

MACDONALD REAPPOINTED AS ADVISOR TO DFT

Mott MacDonald has been reappointed by the UK’s Department for Transport (DfT) to serve as its Futures and Foresight Support Advisor, continuing its support of DfT in embedding ‘futures thinking’ into its strategic planning and decision-making processes, enabling the department to explore long-term trends, uncertainties and emerging challenges. The appointment falls under the DfT’s STARThree framework (Specialist Technical and Commercial Advice for Rail and other transport systems) with Mott MacDonald continuing in its advisory role through to May 2027.

RSSB CARBON LITERACY TRAINING COURSE

The Rail Safety and Standards Board (RSSB) is now accepting registrations for its Carbon Literacy for Rail training program, certified by the Carbon Literacy Project. Scheduled for July 24, 2025, the remote course targets all UK rail sector employees, offering comprehensive climate change education and practical carbon reduction strategies. Participants will develop workplace carbon reduction action plans and learn stakeholder influence techniques. The program includes HS2 case studies and results in official carbon literacy certification upon completion of all assignments and assessments.

there were also small falls in two open access operations – Caledonian Sleeper, Grand Central and Lumo. The winter quarter is the quietest time of the year, especially for leisure traffic, with demand typically dropping by two or three per cent compared with the autumn.

The distinction between the TOCs that traditionally relied on commuters, such as Merseyrail and those in London and the South East, and the rest of the network is becoming clearer. Five of these – Merseyrail, c2c, Chiltern, South Western and South Eastern – remain more than 20 per cent short of their pre-Covid patronage numbers. Meanwhile, the Elizabeth Line continues to power ahead, growing by 6.2 per cent during the year, carrying a total of 234 million passengers.

The contrast with the long distance market is stark. The sector passed the milestone of exceeding 2018/19 passenger journeys during both the quarter and the rolling year – though this is being driven by two operators on the East Coast and Midland Main Line routes, LNER and EMR. LNER’s growth of 16.7 per cent during the quarter was streets ahead of the rest of the network, powering it to a patronage figure no less than 26 per cent ahead of its preCovid peak. The figures for the year show growth of 10.2 per cent, and a total 19.5 per cent ahead of its previous high in 2018/19. Over on the Midland route to Sheffield and Nottingham, EMR’s quarterly growth was less spectacular, at 6.7 per cent, but the total was more than a fifth higher than the same quarter in 2019. The annual growth achieved was 8.9 per cent, exceeding the prepandemic total by 17.9 per cent.

The other long distance operators remained short of full recovery in 2024/25, Avanti West Coast by 11.6 per cent, Cross Country by 7.0 per cent and Great Western by eleven per cent – though the latter comparison continues to be affected by the opening of the Elizabeth Line.

Looking at growth, mention must be made of the strong result achieved in Wales – helped by investment in new

‘LNER's growth of 16.7 per cent during the quarter was streets ahead of the rest of the network, powering it to a patronage figure no less than 26 per cent ahead of its preCovid peak.’

rolling stock, including the tram-trains and the electrification for the Valley Lines. The quarterly growth of 12.6 per cent contributed to an annual growth rate of 19.4 per cent. The annual figure is still 6.4 per cent short of 2018/19, but the trend is clearly in the right direction and represents a strong market response to the investment.

Once again, though, the problem remains revenue. The best example is the InterCity sector, where patronage might be above pre-Covid levels, but revenue most certainly isn’t, being 19.6 per cent behind in real terms.

Looking across the whole network, revenue yields per passenger kilometre are 9.3 per cent down overall, with all ticket types showing a decline, ranging from 12.9 per cent on advance tickets to 3.6 per cent on remaining season ticket sales. The position on advance tickets is particularly surprising given the flexibility to adjust these ticket prices in response to shifts in demand – of which there is no shortage, given the 78 per cent increase in the number of passengers using them since 2018/19. This is surely one area of freedom that should surely be restored to industry managers – a vital change in years to come if the demands on the Treasury for subsidy are to be reduced.

Meanwhile, credit is due to the management teams in both privately and publicly owned TOCs for the huge progress that has been made in recovering the industry’s market position from the dark days of 2020. Problems remain, but it is a huge achievement for which little credit is given by the media or politicians.

LAYING DOWN THE LAW

by Martin Fleetwood

Court Expands Building Defects Liability

The UK’s Supreme Court widens the reach of the defects repair provisions within building safety laws

The Building Safety Act 2022 (the BSA) came into effect on 1 April 2023 and was introduced to focus on improving building safety and accountability, particularly for higher risk buildings which are typically over eleven metres in height and are dwelling places. The Act clarifies the responsibilities of those involved in the design, construction and management of such buildings and was introduced in response to the Grenfell Tower fire.

Within a rail context, new housing often forms part of developments on former city/town centre goods yards and siding complexes and around new station developments. Such developments are often built to provide funding for relevant adjacent railway projects.

The UK Supreme Court (the Court) has recently provided clarity on the reach of the BSA and associated legislation relevant to defects claims in its recent judgement in URS Corporation Ltd v BDW Trading Ltd. The Court was asked to decide how the various construction laws should be interpreted in the light of the BSA, to set the scope of the duties for parties involved in such construction projects and whether parties were entitled to claim certain types of cost related to these duties. The specific facts of the case will be considered at a later date, now that the legal principles have been decided.

Background to the case

After the Grenfell tower fire, BDW Trading Ltd (BDW) conducted investigations into its historic developments and discovered design defects in two sets of multiple highrise residential building developments. To protect itself, BDW decided to carry out

remedial works on the defective buildings, although no claim against BDW relating to the defects had been threatened or made by any third-party owner or occupier.

URS Corporation Ltd (URS) had been appointed by BDW to provide structural design services in connection with the buildings BDW repaired. BDW claimed against URS for the costs of BDW carrying out those remedial works (described as ‘losses’ under the contract). URS challenged the claim on the basis that:

i. the scope of URS’s duties did not extend to covering the losses claimed by BDW; ii. BDW was not entitled to recover those losses because when it carried out the repairs BDW no longer owned the developments; and iii. BDW was not liable for the repairs in any event due to the expiry of a relevant time limit.

The Court dismissed all of the grounds of URS's appeal on the basis detailed below.

Putting the repair works into context

The Court rejected the suggestion that because BDW had decided to repair defects on developments no longer owned by it and without any enforceable legal obligation to do so, such economic losses (incurred by completing repair works) were voluntary and could not be recovered. It concluded that there was ‘a strong case for contending that BDW was not exercising a sufficiently full and free choice so as to be regarded as acting voluntarily in undertaking the repairs’ as:

i. if BDW made no repairs, there was a risk that the defects would cause personal

Martin Fleetwood is a Consultant at Addleshaw Goddard’s Transport practice. The Rail Team has over 30 lawyers who advise clients in both the private and public sectors across a wide range of legal areas. As well as contractual issues, the team advises on operational matters, franchises, concessions, finance, regulatory, property, employment, environmental and procurement issues.

Disclaimer: This article is for informational purposes only and does not constitute legal advice. It is recommended that specific professional advice is sought before acting on any of the information given.

injury to, or the death of, homeowners for which BDW might be legally liable;

ii. BDW had a legal liability to the homeowners under the Defective Premises Act 1972 (DPA) or in contract to incur the cost of repairs, even if no longer enforceable due to limitations in claims legislation; and

iii. potential reputational damage to BDW existed if BDW did nothing once it knew of the danger to homeowners and it was therefore in BDW’s commercial interest to undertake the repairs.

Whether an action is truly voluntary would be based on the specific facts of the case. The Court noted that there was a policy consideration of ‘achieving a fair and reasonable allocation of the risk of the loss that has occurred as between the parties’ in deciding these points. The policy favours incentivising a party in BDW's position to carry out the repairs so as to ensure that relevant dangers to homeowners are removed.

An increased time limit for claims

The Court noted that Section 135 of the BSA increases the time limit for claims under Section 1 of the DPA to 30 years in respect of rights of action which accrued before 28 June 2022 and decided that this extended time limit also applies to claims ‘dependent’ upon Section 1 of the DPA, such as damages for a liability in negligence, or claims for a contribution. This means developers maintain the ability to pursue ‘onward’ claims against responsible parties (whether building contractors, architects, engineers etc).

In reaching this conclusion, the Court carefully considered the policy background

‘Such developments are often built to provide funding for relevant adjacent railway projects’

ii. holding wrongdoers to account will speed up the remediation process and reduce the risks posed by unsafe residential buildings to their residents.

Multiple obligations for a developer

The Court confirmed that a duty under Section 1 of the DPA for defective premises can be both owed to, and owed by, developers. This is because a duty is owed to a person who has ‘ordered’ a dwelling to be built, which can include developers. Developers are covered where they become the ‘first owners’ of a building following the building’s construction, prior to its initial sale.

of money in order for a ‘payment in kind’ to be assessed as a claim for contribution recoverable from a defendant for the purposes of the Civil Liability (Contribution) Act 1978. The fact that the work was done voluntarily, or without a claim from a homeowner, will not generally affect the developer's right to recover a contribution from a party equally liable for the damage.

Impact of the Judgement

to the BSA and the Government policy of making those responsible for building safety defects accountable. The Court took the view that to do otherwise would ‘penalise’ responsible developers who had been proactive in remedying building safety defects in accordance with such Government policy. The decision also supports the Government view that:

i. it is fair for building developers and other contractors responsible for building safety defects to cover the costs of remediation; and

A claim in the courts is not required

The Court decided that BDW was not prevented from bringing a claim for contribution against URS despite there being no judgement against BDW or settlement between BDW and any third party and no third party had ever asserted any claim against BDW. It was sufficient that BDW had made a payment in kind (by performing remedial works) in compensation for the damage suffered by the homeowners.

It was also important that the value of the works could be qualified as a sum

RAIL LIFTING JACKS & PIT EXPERTS

The focus on policy in the judgement, and the consistency of the decisions reached with the overarching policy of the BSA, appears to set the tone for the industry and the approach of the courts in deciding future claims. Such consideration of Government policy behind legislation, rather than simply applying the words of that legislation, has become more prevalent in recent years. Those responsible for defects are expected to rectify those defects to remove risk to homeowners, and the associated cost is to be shared amongst all of those responsible. How such liability is to be shared is likely to become the new focus for claims and there is likely to be some distance still to run on this issue. All parties involved in dwelling developments should remain aware of this still moving area of law.

Anwen

Robinson is SVP at OneAdvanced, a leading UK provider of software solutions.

The Distorted Reality Threatening Passenger Transport

Anwen Robinson, SVP at OneAdvanced, a leading UK provider of software solutions, discusses the challenges faced by deskfree workers in passenger transport, and how leaders are failing to grasp what really matters to their desk-free workforce

The frontline workforce is the beating heart of any business. In the majority of passenger transport businesses, the frontline teams are desk-free (DF). Desk-free workers account for around 80 per cent of the total global working population. They are the people who get the job done, often for low pay, anti-social hours, in testing conditions, and with little recognition.

In passenger transport, you can find a huge range of desk free workers. From drivers and operators, to conductors, guards, ticket collectors, engineers and maintenance staff, it’s an industry that relies on people who work away from a desk. Some of these jobs can be highly skilled and require specialised skills, others are more service based – but all are important to the smooth running of operations.

It is vital that staff feel appreciated, empowered and properly communicated with by their managers and senior leaders. If they are not looked after and do not feel appreciated, businesses risk low morale, which can negatively influence attitudes to work and the management team. In turn, that may seep through into how staff come across to customers.

According to OneAdvanced’s latest research, there’s a growing disconnect between what passenger transport workers actually value and what their managers think they value. That misalignment

could be costing the industry both talent and trust.

It goes without saying that if not addressed properly, these issues can lead to job dissatisfaction and increased staff turnover. This directly impacts the bottom line and leads to a decline in productivity, profit margins, and brand image.

What is the research saying?

Flexibility matters just as much as pay:

• 38 per cent of DF passenger transport workers said that flexible shift patterns were just as important as increased pay when it comes to staying in a job. But only 24 per cent of leaders recognised flexibility as a key factor in retention. Passenger transport was also the only sector in the survey that ranked flexibility the highest as a reason for retention.

• Workload pressures are rising – a huge 75 per cent of workers in passenger transport said they feel overworked. Many blamed poor shift planning and high sickness absence – yet more than half of leaders (53 per cent) said they believe workloads are manageable.

• Training isn't the fix – only four per cent of passenger transport workers said more training would encourage them to stay in their role. However, 24 per cent of managers pointed to training and development as a top retention strategy.

‘Desk-free workers account for around 80 per cent of the total global working population.’

This reveals a clear pattern – while leaders may think they're offering support, the daily experience of desk-free workers in passenger transport tells a different story. Failure to recognise the motivations of employees in their roles, increasing pressures on staff, and ignoring flexible working requirements can quickly create a poor working environment that only further amplifies issues.

Communication breakdown

One of most startling results from our Disenfranchised Workforce Report has to be the huge disconnect between what bosses perceive to be a happy, engaged workforce of DF workers, and the reality of a disenchanted team.

We found that nearly every business with desk-free workers, regardless of industry, grapples with a critical issue –the communication gap between these employees and back-office management. This disconnect exists for many reasons, and it is the silent barrier that keeps organisations from reaching their full potential.

In an era where digital transformation is at the heart of all businesses, desk-free workers are being left behind or forgotten.

Ninety percent of those in the most senior roles – chairpersons, CEOs, and MDs – and 81 per cent of all leaders, believe performance expectations are clearly communicated, but only two thirds (67 per cent) of desk-free workers agree. And while no HR Directors or CEOs admit to any confusion in the ranks, ten per cent of desk-free workers say they often don’t know what’s expected of them.

The flexibility disconnect

The gap in perceptions around flexibility is one of the most revealing parts of the study. While 70 per cent of managers believe their passenger transport teams already have some flexibility, half say they’re tied to fixed hours or shift schedules, although they do note there is flexibility in the types of tasks that need to be completed.