48 | the rail engineer | january 2013

feature Signal processing techniques allow the signal from the bearing defect to be extracted from any background noise, enabling fault identification and classification. An acoustic array of eight microphones positioned 2.5 metres from the rail gives greatly improved spatial discrimination (directionality) and this,

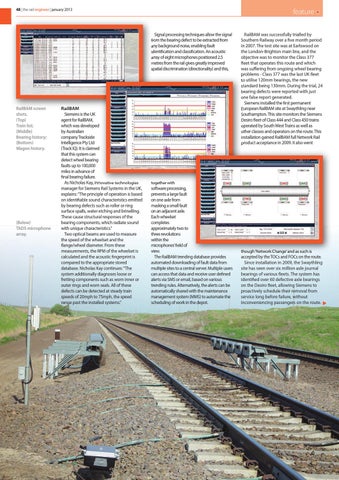

RailBAM screen shots. (Top) Train list; (Middle) Bearing history; (Bottom) Wagon history.

(Below) TADS microphone array.

RailBAM Siemens is the UK agent for RailBAM, which was developed by Australian company Trackside Intelligence Pty Ltd (Track IQ). It is claimed that this system can detect wheel bearing faults up to 100,000 miles in advance of final bearing failure. As Nicholas Kay, innovative technologies manager for Siemens Rail Systems in the UK, explains: “The principle of operation is based on identifiable sound characteristics emitted by bearing defects such as roller or ring surface spalls, water etching and brinelling. These cause structural responses of the bearing components, which radiate sound with unique characteristics.” Two optical beams are used to measure the speed of the wheelset and the flange/wheel diameter. From these measurements, the RPM of the wheelset is calculated and the acoustic fingerprint is compared to the appropriate stored database. Nicholas Kay continues: “The system additionally diagnoses loose or fretting components such as worn inner or outer rings and worn seals. All of these defects can be detected at steady train speeds of 20mph to 75mph, the speed range past the installed systems.”

together with software processing, prevents a large fault on one axle from masking a small fault on an adjacent axle. Each wheelset completes approximately two to three revolutions within the microphones’ field of view. The RailBAM trending database provides automated downloading of fault data from multiple sites to a central server. Multiple users can access that data and receive user defined alerts via SMS or email, based on various trending rules. Alternatively, the alerts can be automatically shared with the maintenance management system (MMS) to automate the scheduling of work in the depot.

RailBAM was successfully trialled by Southern Railway over a five month period in 2007. The test site was at Earlswood on the London-Brighton main line, and the objective was to monitor the Class 377 fleet that operates this route and which was suffering from ongoing wheel bearing problems - Class 377 was the last UK fleet to utilise 120mm bearings, the new standard being 130mm. During the trial, 24 bearing defects were reported with just one false report generated. Siemens installed the first permanent European RailBAM site at Swaythling near Southampton. This site monitors the Siemens Desiro fleet of Class 444 and Class 450 trains operated by South West Trains as well as other classes and operators on the route. This installation gained RailBAM full Network Rail product acceptance in 2009. It also went

though ‘Network Change’ and as such is accepted by the TOCs and FOCs on the route. Since installation in 2009, the Swaythling site has seen over six million axle journal bearings of various fleets. The system has identified over 60 defective axle bearings on the Desiro fleet, allowing Siemens to proactively schedule their removal from service long before failure, without inconveniencing passengers on the route.