CIRAS

reporting app

reporting app

Report it in confidence, on the go.

CIRAS is the confidential safety hotline for transport. Download the CIRAS reporting app on Google Play or the App Store to raise your health, safety and wellbeing concerns. We protect your identity and share your concern with the right people, so they can act.

14|

HS2's underground heroes

Rail Engineer hails the individuals who’ve played a role in one of the high-speed network’s most complex tunnelling operations.

Senceive wireless rockfall monitoring solution

Senceive has developed a rockfall detection system for sites vulnerable to blockage or damage caused by falling rocks and debris.

Geotechnic Minimal Viable Product

Paul Darlington talks to Gerry Manley about how changes to legacy earthworks can be made safely and cost effectively.

22|

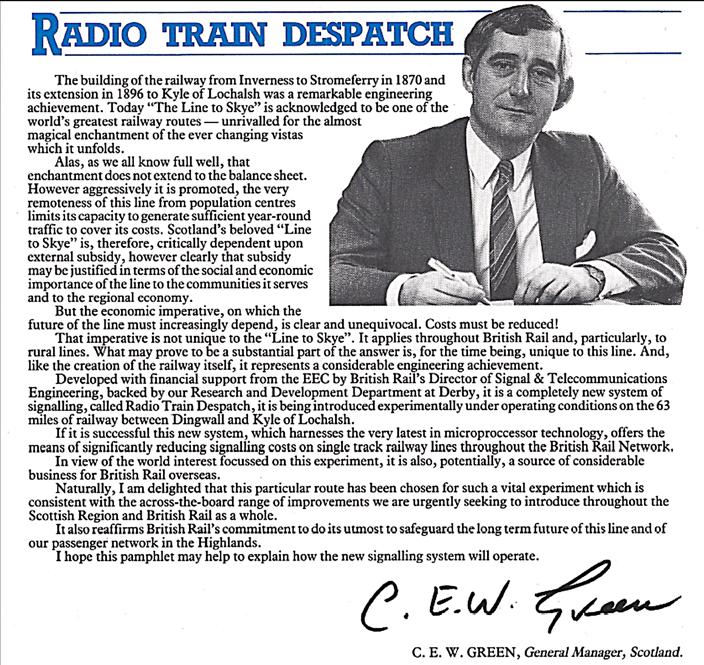

The final of the IMechE Railway Division’s Young Members annual presentation competition was held in London on 8 May.

SPL Powerlines: milestone met at East Kilbride

Regional Director Lee Pounder chats to Rail Engineer about the significant progress made during this 16-week blockade.

Re-imagining and electrifying rail freight

Rail freight has seen little innovative progress in comparison to passenger rail and infrastructure. David Shirres finds out why.

UK electrification: the messages about freight

Freight electrification must be cost-effective, incremental, and prioritised, if we are to achieve net zero, says Peter Stanton.

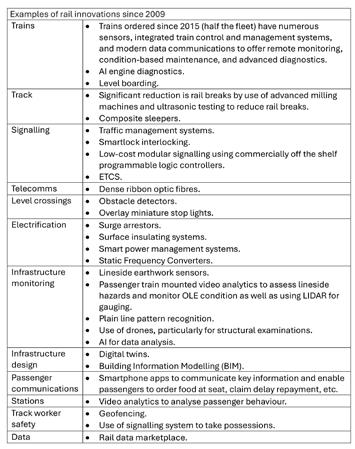

RIA’s promotion of innovation since 2009

RIA’s 16th Innovation Conference featured 61 exhibition stands where new ideas and strategies were showcased to the industry.

GCRE's innovation day

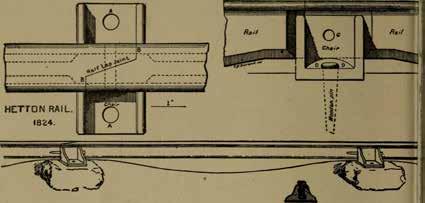

Railway 200: Creating the modern railway

Mark Phillips explores the early innovations in track design and construction that helped lay the groundwork for the modern railway.

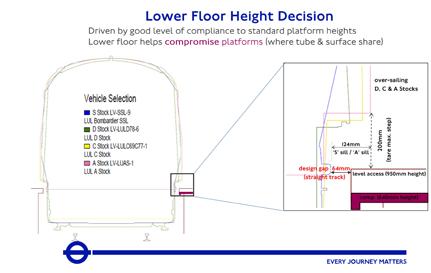

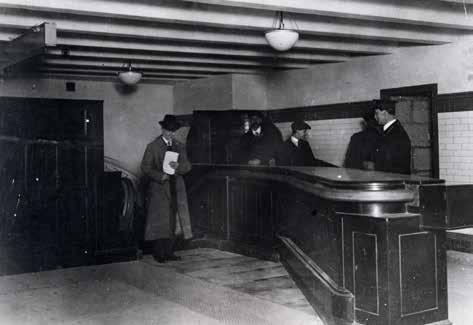

Railway 200: 162 years of the Underground

Malcolm Dobell examines 162 years’ development of the London Underground, which has helped the capital become a world-class city.

Fleet Cyber Security

The Fleet Cyber Security Conference discussed practical measures to reduce cybersecurity risks to rolling stock fleets. Malcolm Dobell reports.

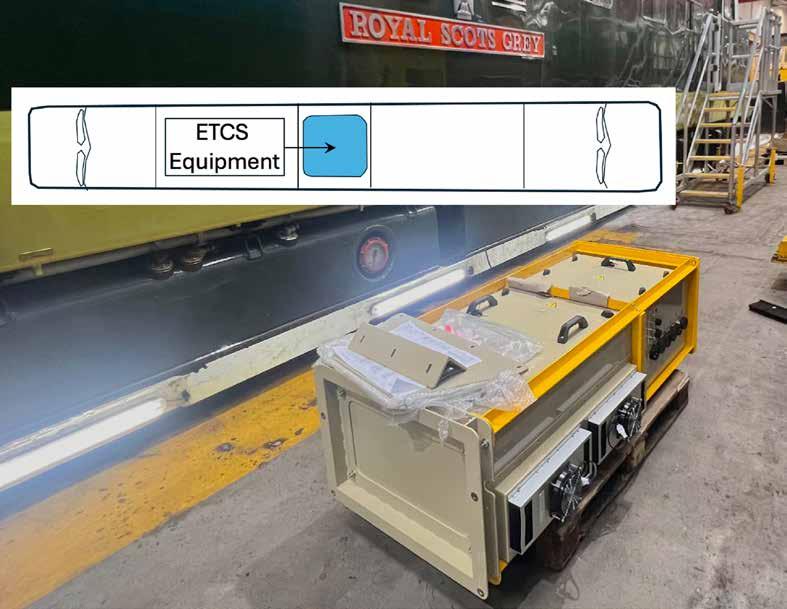

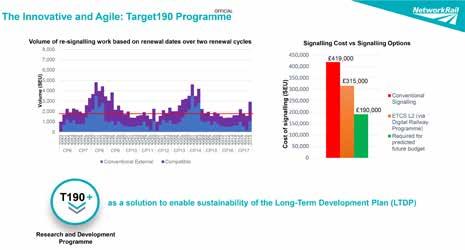

Is ETCS affordable?

David Shirres considers Scotland’s Railway, which sees the cost of retrofitting ETCS to rolling stock as disproportionate.

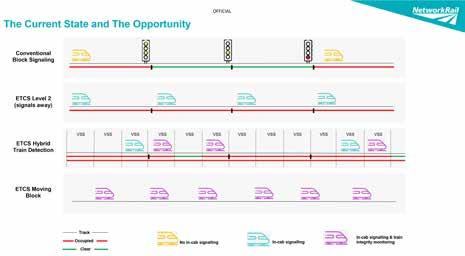

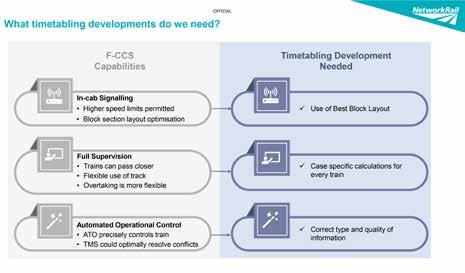

Planning for ERTMS and timetable implications

ERTMS and ETCS offer significant benefits but, asks Clive Kessell, have the practicalities of achieving them been thought through? 42|

An event in March hosted by GCRE highlighted the projects that have been supported through the Railway Construction programme competition.

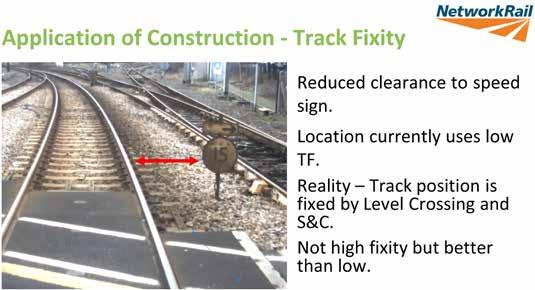

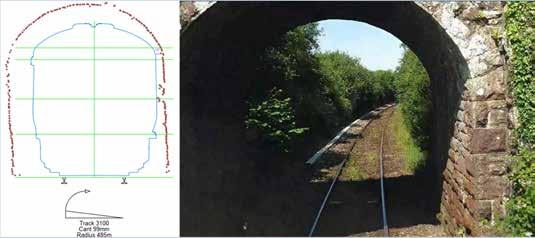

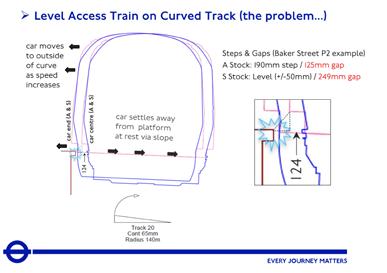

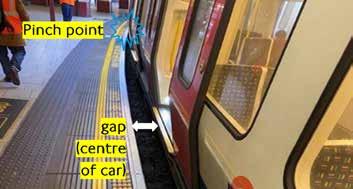

Industry Gauging Seminar 2025

The IMechE’s Railway Division recently hosted a wellattended seminar covering the critical subject of railway gauging. Rail Engineer was there.

Easter works 2025

Major infrastructure renewals and upgrades were delivered over the Easter holiday. We provide a snapshot of this substantial programme.

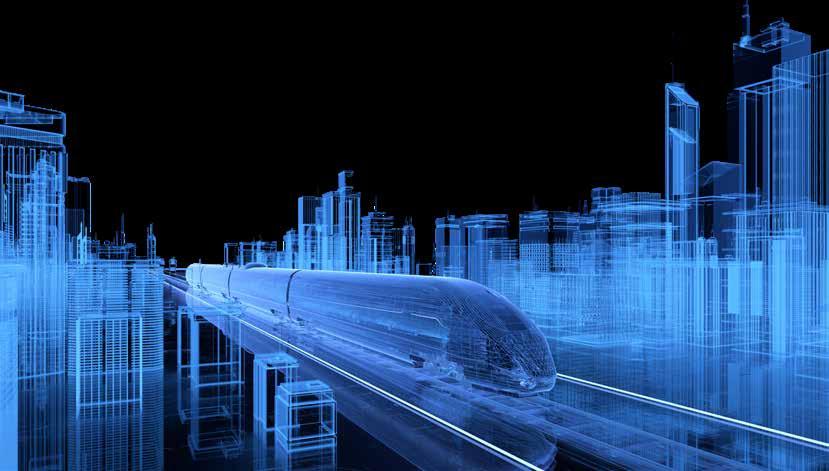

The creation of Great British Railways (GBR) to eliminate industry fragmentation by bringing track and train together has been universally welcomed. Yet it is taking some time to achieve this. Following problems implementing the 2018 timetable, Keith Williams was tasked with recommending a new industry structure. His report recommended the creation of GBR and was published as the Williams-Shapps Report (WSR) in 2021. It is likely that GBR will be created in 2027 after the Government’s Rail Reform Bill becomes law, probably in 2026.

Compared with the WSR, the public sector is to have a greater role. Another difference is that there is no longer a commitment to produce a 30-year long term strategic plan.

This is needed to specify how the newly integrated railway can be best engineered to provide the best service for its passenger and freight customers at the minimum whole life cost. This can only be done by considering trains and infrastructure as a whole system with a full understanding of the whole life costs and benefits of all possible options.

A 1999 Railtrack report on the failure to implement ETCS Level 3 on the West Coast Main Line had a useful table showing how various factors affect capacity on metro and mixed traffic railways. This showed that, while signalling can offer metros significant capacity benefits, on a mixed traffic railway signalling only offers marginal benefits. This is because the primary capacity constraints are infrastructure configuration and the route’s differing train performance and service patterns.

However, recent statements by senior figures indicate that this is not understood. In a recent interview, Lord Peter Hendy wrongly suggested: “wouldn’t you rather do that (invest in ETCS) than build third, fourth, fifth, or six tracks on major main lines.”

Furthermore, there are serious concerns about ETCS’s affordability. Scotland’s Railway, for example, considers that the cost of retrofitting rolling stock is disproportionate. As we describe, this issue is not addressed in Network Rail’s ETCS strategy. Nevertheless, ETCS does offer significant benefits, some of which are described in Clive Kessell’s feature ‘Planning for ERTMS and timetable implications.’

A further misleading statement was made by a Department for Transport (DfT) Permanent Secretary at a recent Transport Select Committee hearing who implied that the only benefit of electrification is decarbonisation. Yet this is just one of electrification’s many benefits, not the least of which is additional capacity. Mixing 110mph passenger trains with diesel-hauled freight trains that struggle to achieve 45mph on gentle gradients creates a significant capacity constraint on the congested southern part of the West Coast Main Line.

Our re-imagining freight feature shows how using electric instead of diesel freight train haulage can save one train path per train. This issue is covered further in Peter Stanton’s feature on freight electrification. This shows how electrification can deliver more capacity than ETCS. Furthermore, the industry is now able to deliver cost effective electrification as shown by Matt Atkin’s feature on the East Kilbride project. This is the latest part of Scotland’s rolling electrification programme which has been shown to reduce electrification and operational costs as well as increasing passenger numbers.

Currently, the Westminster rail investment criteria seems to be minimising capital cost with little account taken of whole life benefits. An example is the promotion of discontinuous electrification using battery trains on lines with freight or 100mph trains for which this is not an appropriate technology.

As highlighted in an article by Malcolm Dobell, gauging also needs to be considered. Although Transport Scotland’s High Level Output Statement (HLOS) devoted three pages to gauging, it is not mentioned in the DfT’s HLOS.

The above shows why GBR needs a whole system engineering strategy. This needs strong engineering leadership that considers all railway engineering disciplines to derive the best whole system approach.

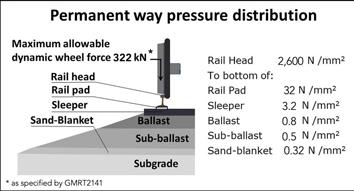

In a Railway200 feature, Mark Phillips describes the early development of railway track. The Stockton and Darlington Railway was a success because it had wrought iron rails. This is an early instance of how the railway is a highly efficient engineered system which offers many benefits, one of which is the way railway track distributes heavy loads. It seems likely that there will still be railways in 200 years time.

Another Railway200 feature outlines the first hundred years of the London Underground since the Paddington to Farringdon line opened in 1863. This shows how the Underground has continually evolved with innovations in tunnelling, electrification, and train design making it a world-class transportation system.

Although the early railways introduced many new technologies, today many consider that the rail industry has a poor record of innovation. Our report on the 2025 Railway Industry Association (RIA)’s innovation conference looks back at previous conferences to consider railway innovations introduced since 2011. Readers can consider for themselves whether this constitutes a poor record of innovation.

Paul Darlington describes 12 innovations that were on show at the recent Global Centre of Rail Excellence (GCRE) innovation demonstration day. These were winners of an ‘Innovation in Railway Construction’ competition, funded by Innovate UK and the Department for Business and Trade, to drive innovation in the rail industry.

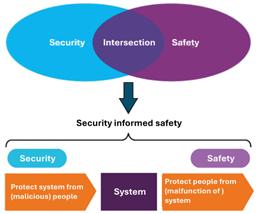

With increasingly complex connected systems that needed to take advantage of such innovations, cyber security is a key issue. Our feature on the Fleet Cyber Security Conference stressed the importance of making assets secure by design.

Work valued at £87 million was delivered over the Easter weekend within 1,190 possessions across the rail network as we

DAVID SHIRRES RAIL ENGINEER EDITOR

A strategy that considers an optimum infrastructure / rolling stock solution.

describe. We also describe the work to complete the first bore of HS2’s 5.8km Bromford tunnel near Birmingham and the people involved in this work. Development of the railway’s future engineers is the aim of the IMechE’s ‘Future of Rail’ competition, which we also cover.

Specifying earthworks in a cost-effective manner is the subject of our feature ‘Geotechnic Minimum Viable Product’ which explains the techniques used to ensure earthworks are safe while budgets are reduced.

An excellent example of railway engineers delivering a cost-effective solution 40 years ago was the introduction of Radio Electronic Token Block (RETB) signalling on Scotland’s Far North line. This cost £400,000 to provide, saved £500,000 in operating costs in its first year, and quite possibly saved the line from closure.

A key test for new technology is whether it can achieve such overall cost reductions. This reinforces the need for an informed engineering strategy that takes full account of all associated costs and benefits.

Editor David Shirres editor@railengineer.co.uk

Production Editor Matt Atkins matt@rail-media.com

Production and design Adam O’Connor adam@rail-media.com

Engineering writers

bob.hazell@railengineer.co.uk

bob.wright@railengineer.co.uk

clive.kessell@railengineer.co.uk

david.fenner@railengineer.co.uk

graeme.bickerdike@railengineer.co.uk

malcolm.dobell@railengineer.co.uk

mark.phillips@railengineer.co.uk

paul.darlington@railengineer.co.uk peter.stanton@railengineer.co.uk

Advertising Craig Smith craig@rail-media.com

Gary Simpkins gary@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK.

Switchboard: 01530 816 444 Website: www.railengineer.co.uk

Rail Engineer Videos http://rail.media/REYouTube

Editorial copy to Email: news@rail-media.com

Free controlled circulation Email: subscribe@rail-media.com

The small print

Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd.

© All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners.

Part of: www.rail-media.com

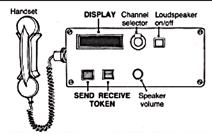

In 1985, Radio Train Despatch, technically known as ‘Radio Electronic Token Block’, was introduced on the single line between Dingwall and Kyle of Lochalsh.

Prior to the introduction of RETB, a driver could not proceed onto a single line section unless the signaller had given him/her a brass key token for the section. RETB replaced this brass token with an electronic token issued by the Dingwall control centre, to a cab display unit which displays the section for which the driver has authority.

This token is coded to ensure it can only be received by the locomotive for which it is intended. Microprocessors control the interlocking and provide the signaller with a visual display of the traffic on the line

It cost £400,000 to introduce this system on the Far North Lines which, by eliminating signalboxes, saved £500,000 in operating costs in its first year.

Rail Engineer is grateful to the Friends of the Far North Line for their permission to reproduce part of the pamphlet issued by ScotRail to mark the introduction of RETB.

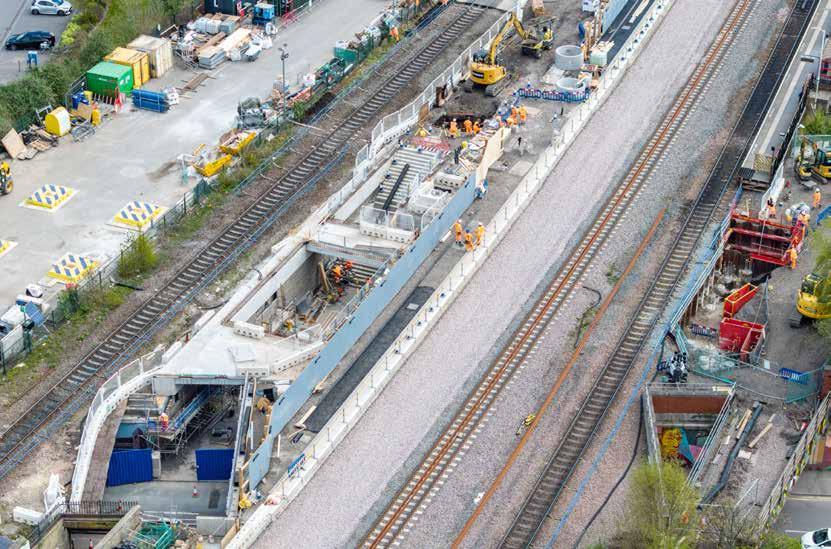

On Thursday 29 May, HS2 revealed the first section of platform to be installed for Britain’s new high-speed railway.

In the underground box at HS2’s Old Oak Common station, engineers have begun installing the platform slabs which passengers will use when boarding or alighting high-speed trains in the future.

Six platforms are being built at the super-hub station in West London for high-speed services. Each will be served by HS2’s fleet of 400-metre trains.

These are being built in advance of a further eight surface-level platforms for Great Western Mainline, Elizabeth Line, and Heathrow Express services.

All six high-speed platforms are being installed at the same time, with construction taking place from either end of the station box. They are laid out as three ‘island’ style blocks.

The platforms are the first to be unveiled anywhere on Britain’s new high-speed railway and give a glimpse of what future passengers can expect when services begin running.

To construct the platforms, 1.59-metre-high invert walls have been poured. 1,960 pre-cast concrete slabs, measuring up to 4 metres by 2 metres, are then lifted into place on top with a void below to allow installation of services.

The pre-cast concrete slabs are being made offsite by Explore Manufacturing in Worksop, Nottinghamshire, an example of how Britain’s manufacturing industry is building for the nation’s future.

The structure of the huge 850-metre-long underground station box at Old Oak Common was completed this year, including the 45,000-square-metre base slab. The station is being constructed by HS2’s station construction partner, Balfour Beatty VINCI SYSTRA (BBVS JV).

Huw Edwards, delivery director for stations and placemaking at HS2 Ltd, said: “The installation of the first passenger platforms represents a real step forward in taking HS2 from purely a construction project to the future of Britain’s railways.

“Whilst there is still much more work to do, standing where passengers will alight HS2 services is a reminder of what this railway will achieve - creating connections between people and places, that will benefit generations to come.”

Steve O’Sullivan, Balfour Beatty VINCI SYSTRA project director at HS2 Old Oak Common station, commented:

“The installation of the first high-speed platforms at Old Oak Common marks a defining moment in the delivery of HS2. It’s a powerful symbol of progress, not just in terms of engineering, but also highlights the change in project focus from the current civil phase of the works to the building, fit-out, and the mechanical, electrical and public health phase of the works. Our teams at BBVS are proud to be laying the foundations of what will become one of the UK’s most important interchange transport hubs.”

Later this year, HS2 will begin installation of the eight platforms that will be used by conventional rail services – the Great Western, Elizabeth Line, and Heathrow Express. The BBVS JV team is also working a level above the base slab where the platform construction is taking place to construct the ground floor level of the station. From there, the superstructure of the station can be built, creating the vibrant station environment.

Tunnelling work to connect the station to the HS2 network is being undertaken by HS2’s London tunnels contractor, Skanska Costain STRABAG JV. In the eastern section of the underground box, the team are preparing to launch two giant tunnelling machines towards Euston.

In the western side of the box, the team will excavate a short tunnel connecting the station to the Victoria Road Crossover Box nearby using the sprayed concrete lining method. From there the new high-speed line will run through the Northolt Tunnel.

The iconic Glenfinnan Viaduct in the Scottish Highlands, made famous worldwide by the Harry Potter films, has undergone an extensive, £3.4 million maintenance programme to safeguard its future for generations to come.

Network Rail, along with principal contractor AmcoGiffen, assessed the condition of the viaduct. Concrete repairs were carried out across the structure sympathetically, taking care to replicate its heritage appearance. New safety handrails for staff working at height were installed, along with renewing ballast retention systems at the ends of the structure.

Engineers also worked in the River Finnan, protecting the piers from erosion caused by the fast-flowing river. Meanwhile, rope access technicians descended from the viaduct, reaching and restoring areas that would otherwise be inaccessible.

Laura Craig, scheme project manager at Network Rail, said: “This project was years in planning due to the complexity of navigating such a large-scale, historic structure. Our highlyskilled team faced numerous challenges, from preserving the viaduct's original integrity to implementing modern engineering solutions. Every step of the process required meticulous attention to detail and a deep respect for its heritage.

“It’s an honour to look after the Glenfinnan Viaduct, knowing how much it’s loved all over the world. We’re proud to see it standing strong and it’s a testament to the dedication and hard work of everyone involved.”

structure

The Glenfinnan viaduct opened in 1901 and is the largest mass concrete viaduct in Scotland, spanning more than 1,000 feet. The build cost £18,904 at the time, around £2 million in today’s money.

Historic Environment

Scotland has designated the structure as Category A, the highest level, meaning it’s of significant architectural and historical interest. As part of its preservation, Network Rail refrains from cleaning off efflorescence marks from the rain as it drains through, ensuring the character of the structure remains.

Ann MacSween, head of planning, consents and advice services at Historic Environment Scotland, said: "We welcome Network Rail's investment into the careful repair of this iconic structure.

“Glenfinnan is the most impressive of several mass concrete railway viaducts and bridges along the West Highland Line, which was built 1897-1901. These bridges were mostly designed with an exposed concrete finish, rather than being faced in stone, and are the earliest railway bridges of this style in Scotland.

“Over a century after it was first built, Glenfinnan Viaduct still stands strong today, in no small part due to Network Rail's excellent care."

The viaduct is an icon of Scottish tourism, drawing thousands of visitors each year. Many pass over the arches aboard ScotRail trains, as well as the ‘Hogwarts Express’ Jacobite steam train operated by West Coast Railways. Countless more tourists make the trip to Glenfinnan to admire the spellbinding views from the ground.

James Shuttleworth, West Coast Railways’ commercial manager, said: "Having run ‘The Jacobite’ for over three decades and celebrated its centenary in 2001, we truly appreciate the historic significance of the viaduct. The recent restoration work has further highlighted its importance, not only as a vital piece of railway heritage, but also as a beloved film star in Harry Potter, for which we

proudly provided The Hogwarts Express."

The restoration of the viaduct is part of a broader programme of work in the Glenfinnan area.

A two-year, industry-leading pilot project enhanced the natural habitat by planting

trees across approximately 200 hectares to protect, restore and expand rainforest and peatland habitats. Additionally, deer fencing has been installed at Ardmolich to safeguard the newly planted native woodlands from overgrazing.

HS2 celebrated another construction milestone on 9 May when the 1,600-tonne tunnel boring machine (TBM), Mary Ann, broke through at Washwood Heath, Birmingham, marking the end of her mission to excavate the first bore of what will soon become the longest railway tunnel in the West Midlands.

The 125-metre-long machine began constructing the 3.5-mile (5.8km) Bromford Tunnel, which starts at the Warwickshire village of Water Orton and extends to the northeast Birmingham suburb of Washwood Heath, in July 2023.

The result of years of meticulous planning, the undertaking required pinpoint precision, flawless preparation, and a highly committed team. Led by HS2’s West Midlands contractor Balfour Beatty VINCI, a 450-strong team worked around the clock for just under two years.

During the 22-month-long mission, the team on board the machine spent 649 days and nights working at depths of up to 40 metres, navigating Mary Ann under the Park Hall Nature Reserve, the M6 motorway, and the River Tame – which crossed the tunnel four times, with a headspace as low as five metres.

It is fitting, then, that we celebrate the magnificent achievements of the individuals who’ve played a role in one of the most complex tunnelling operations on the entire HS2 network. Here we give some of those inspiring individuals a voice and cast a spotlight on their role in the project.

The team was led by Tunnelling Director Jules Arlaud (pictured right). Jules was mobilised to the West Midlands when BBV’s first giant tunnelling machine arrived from Germany. He already had a string of successful worldwide missions under his belt and his next challenge was to join –and eventually lead – the team responsible for constructing two of the five twin-bore tunnels on the HS2 network.

“It’s been a challenging drive beneath critical live infrastructure and through complex ground conditions,” says Jules.

“I’m incredibly proud of our entire team, whose expertise, dedication and resilience have made this possible.

“This achievement follows years of design, planning and preparation from BBV, in close collaboration with HS2 and our partners. The team will now move onto the next phase of work inside and outside of the tunnel, while our second TBM, Elizabeth, has completed 60% of the second drive.”

At the coalface

A team of 16 worked the TBM with 61-year-old Lead Miner Steve Rocke in charge. After 43 years on the job, this was his last assignment, after which he returned to his family in Hull, and his beekeeping hobby.

Pilot Harsh, from Kolkata, works in tandem with Steve. They share a tiny office space with three crew members who monitor the technical and mechanical side of the drive. If the cutterhead needed repairing or maintaining, one of the miners must enter the excavation chamber to fix

it. “It can be like working inside a balloon,” says Steve. “So, we calculate to the second how long they’ve got.”

Air pressure levels inside the tunnel determine whether a hyperbaric intervention is required on the miner’s return and Tunnel Agent Josh Knight makes that decision. He assesses the miner’s safe working time and calculates how long he must spend in the decompression chamber afterwards. From a mini submarine-like space inside the TBM, the miner must inhale pure oxygen to avoid the painful decompression sickness, known as the bends.

“Hyperbaric interventions don’t happen often”, explains Josh. “Thankfully, we’ve only had to do it once so far on this mission.”

Around one million tonnes of spoil were excavated during Mary Ann’s 3.5-mile drive, and those at the back of the operation are just as integral to the machine’s daily advance. As the cutterhead rotates, excavated material is extracted and mixed with slurry. The solids and liquid are then separated at an on-site slurry treatment plant.

The treatment plant is where most new starters learn the ropes and is where

21-year-old Dylan Kehoe works alongside his father, Greg. The duo (pictured above) from South Wales moved to nearby Minworth to work on HS2.

Dylan was recruited by Solihull-based Rorcon, as part of the drive to upskill a new generation of tunnellers. After an initial stint as a labourer, the company supported him to achieve his Level 3 Supervisor NVQ, enabling him to climb the ladder to treatment plant operative. The experience has left him hungry for more.

“If you work hard, the progression opportunities are there,” said Dylan. “I’ve worked my way up from being a labourer and hope to progress into mining next, so I can work on the tunnel boring machine.”

During his 40-year career, Dylan’s father Greg has worked on some of the UK’s biggest tunnelling projects, from Crossrail to the London super sewer, Tideway. He, Dylan, and Erdington-based new recruit Edward East worked in sync to keep pace with the TBM’s miners.

Every tonne of excavated earth is compressed to extract the groundwater. Recycled slurry is pumped to the front of the giant digging machine to maintain ground pressure, while the excavated material goes back to the treatment plant and through the slurry circuit. The trio monitors the vast network of machinery that controls the pressing, dilution, and pump process, and are in constant contact with the TBM team underground. The miners need to know the water’s coming and rely on Greg’s analysis of the ground conditions.

“The toughest bit is keeping pace with the mining,” explained Greg. “It’s a balancing act to keep the water tanks at the right level, so we’ve got the volume we need for the machine. Too much, or not enough is never a good thing.”

Subterranean support

There’s little glamour in tunnelling. Whether onboard the giant moving factory, or supporting the machine’s drive from the rear, the team works long, hard hours. Seven 12-hour shifts are rewarded with a three-day break, then it’s another stint of 7/12s before a long awaited fourdays off.

The same is true for the ring builders and grouters who scurry along the metal stairwells and corridors. Excavating the ground is just one part of the job - Mary Ann must also build the tunnel. At peak production, the TBM advanced at around 30 metres per day, lining the tunnel with segments to form precision-placed concrete rings.

Gary Jones (pictured right) and his two-man team dictated the installation of 20,000 of these precision-designed segments, manufactured at Balfour Beatty VINCI’s pre-cast factory at Avonmouth near Bristol.

Crane operators lifted and loaded the huge concrete segments onto an electric vehicle (EV) which was driven into the tunnel. Gavin Davis from Doncaster was at the wheel. Years of experience have earned him the accolade of being the only driver that can manoeuvre the 16-wheel EV in a three-point turn. When he arrived with another haul of segments, Gary and his crew lifted, shifted, and locked them into place.

“On a good shift, we’ll build five or six complete rings,” explains Gary. That 2,971 rings were required in total gives a sense of the scale of the task.

The grout which seals the segments into place is made at the onsite batching plant. Tunnelcraft Apprentice Jevon Lynch, recruited at an HS2 careers fair, was rewarded with a permanent job running the grout batching plant after passing his Tunnelling NVQ.

“I’ve done a bit of everything in my twoyear apprenticeship,” says Jevon,” from helping to build the TBM to working with the crew onboard. Getting a permanent job sets me up for a career in the industry, which is exactly what I need with a baby on the way.”

Despite its most recent success, it’s not the end of the project for our tunnelling heroes. TBM Elizabeth is already hard at work on the second drive of the Bromford

Tunnel and her breakthrough is expected later this year. Once complete, Bromford Tunnel will be the longest railway tunnel in the West Midlands and, in the not-toodistant future, will be used by millions of passengers travelling to Birmingham’s new terminus station – Curzon Street –just two miles away.

The Washwood Heath site, where Mary Ann broke through, and covered by Malcolm Dobell in Issue 208 (MayJune 2024), will become the nerve centre for HS2’s operations. Next to the tunnel portal, HS2’s Depot and Network Integrated Control Centre will be built. From this site, trains will be serviced and stored, and the real time operation of the railway will be controlled.

Rail Engineer celebrates the efforts of all involved and salutes their continued grit and determination under some very difficult conditions. Here’s looking toward the second breakthrough at this critical site.

Engineers at Senceive have developed a rockfall detection system for sites considered vulnerable to blockage or damage caused by falling rocks and debris.

While the UK rail network does not generally face the same degree of risk from rockfall as some European routes, for example those in the Alps and Pyrenees, a significant number of rockfall events each year cause delay, disruption, and danger.

It is 20 years since the Milton Keynes-based remote monitoring specialist pioneered wireless monitoring applications for the rail sector and 10 years since its first successful application of the now widely adopted InfraGuard™ slope monitoring technology at Barnehurst in South London.

The rockfall solution uses intelligent slope monitoring features built into InfraGuard to address the unique challenges posed by rockfall hazards, providing near real-time detection of sudden events, rapid alerts, and high-quality photo verification for quick, actionable insights.

Robust & reliable

Rock slopes, unlike soil slopes, are characterised by the unpredictable movement of individual boulders or localised debris, which can be missed by a typical wireless slope monitoring system because material can fall in between tilt sensor locations. This poses a significant threat to railways, and a bespoke solution was needed. Enter Senceive’s latest development, created in close collaboration with Network Rail, the world’s largest user of wireless slope monitoring technology.

In early 2024, Network Rail commissioned trials at a test site in Switzerland, which allowed Senceive to demonstrate an innovative wireless detection system specifically tailored for rocky slopes. The system revolves around monitoring the effects of rockfall debris impacting fences and barriers and provides a robust, reliable solution with a high detection rate and a minimal incidence of false alarms.

Events can be detected in three ways:

» Rockfall detected by draw wire sensors. This method is based on sensors detecting the extension of draw wires fixed to the fence as a result of loading by rockfall debris. It is particularly sensitive to the gradual accumulation of material over an extended period.

Site trials in a Swiss quarry allowed various boulder impacts and sensor configurations to be evaluated.

Fences, barriers and netting do not always prevent material encroaching on the track.

» Impact on catchfence detected by tilt sensors. This approach is based on impact sensors in the Senceive NanoMacro tilt nodes mounted on catchfence stakes detecting a sudden acceleration or shock. It is ideal for detecting instantaneous events such as a small-to-medium sized boulder hitting the fence.

» Rotation of catchfence stakes detected by tilt sensors. This approach is based on the detection of rotational movement by the highly sensitive tilt sensors in the same NanoMacro nodes described above. Because it requires movement of the catchfence stakes, it is the most reliable way of detecting a large-scale rockfall event that hits the fence with significant force.

An event detected by any of these three methods will trigger the system to accelerate reporting and send high-resolution site images. Equipped with cameras capable of detecting football-sized objects from 50 metres in any lighting conditions, this system enables rapid decision-making, helping to significantly reduce the risk of infrastructure disruption, accidents, and derailments.

Resilient infrastructure

Senceive Nano tilt sensors mounted on a catchfence protecting an Austrian railway.

Built for the most rugged and remote locations, the wireless monitoring solution operates independently, requiring no external power or fixed communications infrastructure. This makes it an ideal choice for deployment in challenging, inaccessible areas where rockfall presents a serious risk to rail infrastructure. It is a modular system and can be fitted to virtually any fence.

A recent deployment in the north of England was achieved within a few hours using plastic mesh fence supported by steel stakes. Tilt nodes were fixed to the stakes, a wireless cellular gateway was added, and the system was reporting data before the team left site.

By integrating these detection capabilities with proven technology, Senceive’s rockfall monitoring system allows operators and engineers to respond quickly and effectively to rockfall hazards, ensuring safer, more resilient infrastructure.

Railway asset engineers and their project colleagues currently face a huge challenge to keep the railway safe and reliable, with a budget said to be 25% less than what is required to maintain the current asset condition.

All asset types face the same challenge, but geotechnical earthworks face another challenge with climate change and the need to keep the assets safe in the extreme weather events we are experiencing. Not only do the existing earthworks need to kept safe, but they also have to support change with for example new electrification schemes. This can require a combination of elements including new Overhead Line Equipment (OLE) structures; bridge works – reconstruction, jacking, and parapet raising; track –lowering, lifting, and slewing; and signalling, with new signals and signal gantries.

All this has to be delivered on an asset which in many cases does not comply with modern geotechnic standards. There are

over 190,000 earthwork assets (approximately 19,000km) which were constructed well before the development of geotechnical engineering techniques. Earthwork construction during the 19th century was undertaken on a huge scale, which has left a legacy of over-steep embankments and cuttings, made with questionable construction techniques.

‘Embankments and cuttings on the early railways’ By A.W. Skempton, says that: “Thomas Telford’s report (1829) on a railway embankment, clearly shows they were formed by end-tipping at the full height; a process, moreover, of which Telford specifically disapproved on the grounds of delayed consolidation and an increased tendency for slipping.

“Shortly after opening the line another very similar slip occurred… as a quick first-aid measure Brunel had a row of timber piles driven at the toe of the slope, penetrating 8ft into undisturbed ground”.

To make matters even more challenging, Rail Engineer reported in December 2023 how historic mining features affecting railway earthworks must be managed safely and efficiently to ensure projects such as new electrification can be delivered cost effectively. Rail Engineer recently met up again with Gerry Manley, to learn how changes to earthworks can be made safely and cost efficiently to accommodate electrification work on the Midland Main Line, and the concept of a Minimum Viable Product (MVP).

Minimum Viable Product

There are several ways that mining risk to legacy earthworks can be managed during construction projects, and it is something which can be very time consuming and expensive. The MVP principle

however is that a project can only deliver interventions to meet the client’s requirements, standards, legislation, and budget.

The term MVP came from the production industry and is a version of a product with just enough features for it to be usable. It aims to avoid over engineering products and to minimise cost. It contrasts with the traditional ‘stealth mode’ method of product development, where businesses make detailed plans for products, spanning a considerable time period and incurring huge costs.

Rail needs to be an affordable option for travellers and freight operators, otherwise customers will use other modes of transport which are not as inherently safe or carbon friendly. So, over engineering rail assets can result in increasing the overall societal risk of transport. This is why cost must always be a factor in managing safety and is a fundamental part of So Far As Reasonably Practical (SFARP) legislation and MPV.

The Construction (Design and Management) Regulations 2015 (CDM 2015) also recognise SFARP and say that the principal designer must, as far as reasonably practicable, ensure the elimination of the risks associated with the design. If this is not possible (for instance because of disproportionate costs) then the remaining risks must be reduced or controlled. This is also one of the founding principles behind the management of mining risk for electrification projects and an MVP.

The Midland Main Line (MML) electrification is a significant upgrade to the railway which has been ongoing since 2015. The project involves electrifying sections of the line to allow electric trains to operate, thereby supporting the UK Government's environmental goals and improving the overall efficiency of rail transport.

The electrification is part of a broader initiative to modernise the rail network and reduce reliance on diesel engines. Gerry explained that an early mining report of just one short 2.4km section of Route Section Three from Syston North Junction to Sheet Stores Junction and Trent Sidings, suggested that 100 bore holes would be required to determine the mining risk. This could have cost approximately £4 million and had significant programme impact. However, using the Guidance for Electrification in Mining Risk Areas & Associated Civils (Issue 205, Nov-Dec 2023) and applying MVP avoided the need for the time consuming and costly bore holes, while managing the risks arising from electrification work on the existing assets, including earthworks, in an area with a mining history.

The foundations for new OLE structures can be split into two groups, either laterally loaded piled foundations or vertically loaded pad foundations, including mass gravity foundations.

Laterally loaded piled foundations are the most common, so these should be considered first. These are typically either driven / vibrated Circular Hollow Section (CHS) piles or augered. Augered piles take longer to install and

are more expensive than CHS. Therefore, in the absence of significant mining issues, CHS is generally the more attractive option and offers best value. However, where there are noise or vibrational concerns, augered piles may be more appropriate. If there is evidence to indicate mining void migration and/ or Loss of Surface Support (LoSS) in the area, this needs to be considered and, where appropriate, low vibrational auguring may be considered. Pad foundations are more expensive, time consuming, and disruptive to construct than either CHS or augered piles, but they may be appropriate where shallow bedrock prevents piling or the use of Overhead Line Equipment Master Index (OLEMI) side bearing foundations, for example. On earthworks, pad foundations also impose their load vertically directly onto the top of embankment slopes, where laterally loaded piles have nominal vertical load making them much more appropriate.

Gerry explained that there has been much discussion over the years on whether laterally loaded piles in embankments should be designed to withstand earth pressures in the event of embankment instability. However, this would result in significant increase in size of foundation, and substantial cost escalation, required to essentially allow a failing embankment

to ‘flow’ around the pile foundation. There is little benefit to be gained following a landslip from having a vertical OLE stanchion with the track ‘hanging in the air’. Plus, the prediction of which earthworks will be prone to future instability is not an exact science, but rather sound engineering judgement of what could happen.

So, a leaning OLE stanchion can prove a very useful indicator of potential earthwork instability before any effect on track is evident and impact on the safe operational railway. Therefore, not only would designing piles to accommodate such loads result in substantial cost increase and be contrary to MVP, but it would also remove a potential valuable early indication of earthwork movement.

Trials were undertaken on the Transpennine Route Upgrade West projects looking at the risk of mining to electrification schemes. This established that, where the depth to bedrock exceeds 20 metres, CHS piles were appropriate in similar ground conditions without the need to consider mining risk any further. Where depth to bedrock is less than 20 metres, further consideration of other factors is required, to determine whether CHS piling is within acceptable risk limits. These include: (i) whether the stiff glacial till is ≥ 10 metres thick (a glacial till is a

product of the glacial processes and are complex, hazardous soils); (ii) if multi-seam extractions are present; and (iii) if worked seam strata dip > 20°. The trials also established that auger pile construction vibration was significantly less than that from typical railway traffic.

There are a range of options available for new signal structures. These range from straight post, cantilever, and gantry. There are also various foundation options, from mass gravity pads, screw piles, CHS piles and augered piles.

For cantilever and gantry structures, foundation options are very similar to those for OLE structures, including typically up to six-metre pile length. Generally, on an electrification scheme there are very few new signal structures compared to the number of OLE structures. Therefore, where possible, employing the same foundation type could be advantageous and cost effective as they can be installed with the same resources and in the same time frame.

In cuttings and level ground, and on embankments with sufficient cess width for pad foundation, straight post signal pad foundations do not

typically exceed 1.5 x 1.5 x 1.2 metres deep, and are therefore considered ‘lightweight elements’.

For straight post signals on embankment crests or upper slopes, pad foundations may be difficult to construct, so CHS, augered or screwed piles are likely to be more appropriate.

The concept of a Geotechnic MPV approach for electrification project work is a very welcome initiative to provide a more consistent mature ALARP and effective approach to managing mining risk.

In the years ahead there will need to be significant efforts and resources required to manage earthworks. However, there is likely to be an unprecedented level of competition for funding, between different assets and regions within Network Rail, and competition between railway funding and other public funding. The industry needs to identify new ways of working, like the geotechnic MPV to drive down cost, and it cannot afford to remove every risk on the network. Otherwise, there will be no investment and routes will close.

DAVID SHIRRES

Fareena Saleemi gives her presentation under the watchful eye of George Stephenson.

The final of the Institution of Mechanical Engineers’ (IMechE) Railway Division’s Young Members annual presentation competition – The Future of Rail – was held in London on 8 May. The competitors were winners of heats held at the Railway Division’s centres throughout the UK and were competing for a prize of £1,000.

The competition is open to all young railway engineers including apprentices, undergraduates, and those in the early stages of their career. Entrants must deliver 10-minute presentations about their contribution to work in any aspect of the rail industry and which can describe project work, research, technical developments, or novel technology.

The event started with heats run by the Railway Division’s Scottish, North West, Midlands, South West, and South East Centres in February and March at which over 20 young engineers gave presentations on a diverse range of topics. The final was held at the IMechE’s imposing headquarters at Birdcage Walk in London. It was organised by the Railway Division’s Young Members (RDYM) committee and hosted by its vice-chair, Ellie Smith.

Winner of the North West Centre’s heat was software engineer Kathryn Hurst of Digital Transit. She gave her presentation on the Tram Overspeed Advisory Device (TOAD) which she produced for Blackpool Transport. This enabled the town’s heritage trams to comply with the recommendations of the RAIB report into the Croydon tram crash in respect of an in-cab overspeed warning. To do so, TOAD had to be small and easy to install, be powered from the tram’s 24v DC system, have a speedometer, and provide an in-cab warning.

Kathryn described how geofences were set up and defined in a configuration file so that if a tram approached them at an excessive speed

an alarm would sound. She described how the microprocessor was coded, the components required and how the system was tested. After first producing a proof-of-concept prototype, testing, driver feedback and experience, two further design iterations were required before the design was finalised. However, production of the final design is currently on hold while Blackpool Transport have suspended heritage tram operations.

Ewan Martin, a project engineer from Brodie Engineering (Scotland) described his role in the C8 overhaul of a Class 180 diesel multiple unit. This involved revising block cards to provide more detail to track the work, providing engineering support, liaising with stakeholders and reviewing progress.

As there were only three days to complete the overhaul’s 14 jobs, timely engineering advice was essential, this included clarifying specification of relays and relocating door button earth studs. To communicate this advice, Ewan trialled new ways to improve communication. He felt he had learned much from this project, not the least being that as nothing and nobody is perfect, and processes and people can always be better.

Next to give a presentation was Fareena Saleemi, a graduate track engineer working for WSP who won the South Eastern Centre’s heat. Her presentation was entitled ‘Optimisation of track alignment with a workflow’. She noted producing an optimum track alignment starts with defining standards and identifying constraints. However, ensuring this is exhaustive while being flexible to changed initial requirements can be quite challenging. Hence her presentation considered how software can simultaneously evaluate multiple track alignment options.

Fareena explained that as constraints are not all absolute, weighted factors such as cost, operational efficiency, safety, and sustainability need to be considered for each alignment option. She illustrated her presentation with

a brief to develop a new 1,000km passenger railway between Quebec City and Toronto which required the analysis of 28,000 square miles of land with lakes, wetland, and rivers for which there were numerous valid alignments. Using automation, the options that best addressed these constraints were quickly identified. Hence, she had no doubt about the benefits of using automation in this way at the early stages of a project lifecycle.

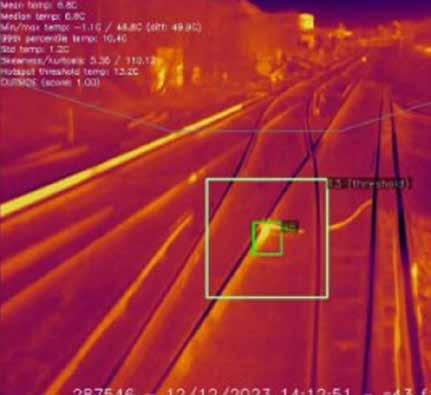

Winner of the South West Centre’s heat was Aamina Shah, a systems engineer from Angel Trains. Her presentation was entitled ‘Hot or Not? The Use of Thermal Cameras in Third Rail Monitoring.’ Aamina advised that thermal imaging cameras can be used to detect loose and defective third rail components, as well as faulty braking equipment on passing trains. When monitored over time thresholds can be developed to allow machine learning to automatically determine the requirement for rapid defect response or preventative maintenance.

Aamina’s presentation explained the practicalities of fitting both removable and fixed front facing thermal imaging cameras to Class 507 and 707 units which concerned power supplies, water ingress, and calibrating them to take account of emissivity of third rail components. These cameras were used in conjunction with a forward-facing video camera and an Automated Intelligent Video Review system to produce the required alerts and reports. It was found that this system effectively detected defects which included a defective lug with a 48°C temperature exceedance.

An everday occurrence

The final contestant was Shahrukh James, a system engineer from Alstom who had won the Midlands Centre’s Future of Rail heat.

His presentation had the intriguing title of ‘An everyday consequence and its impact to the £18.9 billion railway’. The Elizabeth line was the railway concerned, and the everyday occurrence was dropping litter, specifically by train doors. Litter affecting door incidents had caused 87 incidents over a four-month period making this by far the most significant cause of delay.

Shahrukh explained that the first attempt to solve this problem was the provision of a 3D-printed deflector which was only partially successful. Attention was then turned to the door leaf monitor switch which was being activated by litter when the door was open. It was therefore considered that a software change was needed to desensitise this switch so that it would not activate when the door was in the last 300mm of its opening cycle or the first 300mm of its closing cycle. He advised that this combination of hardware and software changes eliminated this door litter problem.

Deliberations and a result

Following the presentations, the judges retired to deliberate. They were: Tom Scott of Angel Trains (RDYM chair); Farzana Hampshire (RD Board); Callum Nicolson of Vanguard STS (last year’s winner); Oliver Joris of Ford Motor Company (IMechE Young Members Board Chair); and Mark Elliot of Network Rail (Railway 200).

Tom Scott commented that, given the quality of the presentations, the judges had had a difficult task choosing the runners up and the winner. Announcing the results in reverse order, the second runner up was Ewan Martin, the first Runner up was Shahrukh James, and the winner was Aamina Shah. As they do every year, the industry’s young engineers excelled themselves throughout the heats and at the London final. Their presentations gave a fascinating insight into the impressive work by young engineers across the country, who are the future of rail.

Any young engineer who would like to enter the 2026 competition should contact their local Railway Division Centre, details of which are available at the very bottom of the link below: https://www.imeche.org/industry-sectors/ railway/railway-division-how-we-are-governed

SPL Powerlines UK (SPL) has just completed a major milestone on the East Kilbride Enhancement project as it prepares to enter into service the latest electrified route in Scotland. Regional Director Lee Pounder took some time out to chat with Rail Engineer about the significant achievements following the completion of the recent 16-week blockade of the branch line.

Quiter, cleaner services

The East Kilbride Enhancement project is a £143 million investment at the centre of the Scottish Government’s Rail Services Decarbonisation Action Plan, the strategic roadmap to eliminate greenhouse gas emissions from Scotland’s domestic passenger rail services by 2045.

A significant aim of the project is to electrify the railway line between East Kilbride and Glasgow Central, enabling the introduction of quieter, cleaner electric trains along the corridor.

At just over 7.5 miles, the branch line plays an important role in enabling passengers in the South Lanarkshire region to

reach Glasgow. Diesel units have served the route for decades but from December 2025, electric traction will replace them. Stage 4 of the project involved a 16-week blockade running from 25 Jan to 18 May 2025, during which an ambitious programme of major works was completed. The work included double-tracking 1.4km of railway between East Kilbride and Hairmyres; the installation of over 22km of overhead electric power lines; the erection of new footbridges at Busby, Clarkston, and Giffnock stations; the renewal of the railway bridge over East Kilbride Road in Busby; and lowering the track under four

key bridges. Industry-leading contractor SPL Powerlines led the project, which involved 23 wire runs, 6.8 miles of earth wire, 364 OLE foundations, 98 booms, 22 switches, and 16 surge arrestors.

Originally scheduled to take place in 2020, like a great many plans around that time the programme was interrupted by the Covid pandemic, and during this period, the original plan was reworked.

“The brand new Hairmyres Station is now significant for intermodal use, and it is also particularly vital for patients, staff, and visitors to Hairmyres Hospital, as well as offering travel opportunities for commuters and leisure passengers,” says Lee.

“There have been upgrades along the line of the route at Giffnock and Clarkston, along with a number of new bridges and structures installed to accommodate electrification.

There have been two access for all schemes along the line of route, 50 new signals installed, and three track lowers removing the requirement to dismantle bridges which is a significantly more efficient way to do electrification.”

Seamless coordination

Years in the planning, the programme of works was executed flawlessly with all contractors working together in parallel, minimising disruption to passengers. As a testament to this high level of integration, SPL Powerlines was able to hand back four additional planned weeks of disruptive access.

“We managed to coordinate track, civils, signalling, and electrification, involving six main contractors and multiple sub-contractors, into a defined timeline. Achieving all this hinges on a long, laborious process of closely examining all the contractor activities – the mileages they’ll be working on, the access points they need to use to on-track people and plant, and deconflict the works safely. By planning the works this way it saves significant time and costs seen on programmes that previously relied on planning works sequentially,” Lee says.

“It’s important to acknowledge that we’ve had the benefit of working with some very good project managers, engineers, construction managers, and programme planners on this project, who have been able to

review and interpret all of the project requirements enabling the integration of all of the works.”

Additionally, the successful execution of the programme could not have been achieved without SPL Powerline’s excellent relationships across the industry.

“We benefit from operating in a region with mature relationships,” says Lee. “We operate under what we call the hub and spoke model, where Network Rail is the ‘hub’ and all of the ‘spoke’ contractors sit on the outside of the wheel. All the contractual relationships go back to Network Rail, and we have informal relationships with all the contractors around the outside of the wheel. Those relationships are at the level where we can have very meaningful conversations. We have a genuinely joined-up way of thinking for the greater good of Scotland’s Railway and its passengers.”

Cutting edge techniques

SPL Powerlines’s success has also been aided by innovative ways of working and the employment of some quite revolutionary technology.

For instance, the majority of OLE masts were prefabricated at its compound, Robslee Drive, and delivered to the site already assembled. This way of working, says Lee, brought many benefits.

“Staff are working safely in a much more controlled environment, with the added benefit of reducing the need for people to be going on the track at night. On the back of that, we get a much better product. When we have people working in a yard similar to a factory, the production line methodology improves quality significantly reducing the need for reworks out on site. Ultimately, that means we become more efficient.

“Given the current cost challenges, these maximal gains are really driving the single track kilometre (STK) rate here in Scotland, so much so that the efficiencies that we’re achieving are now commonly talked about in the industry.”

When it came to wiring, SPL Powerlines used its Zeck wiring unit which enables the contact and catenary wires to be installed at full tension on site. The Zeck wiring unit boasts an automatic wire tensioning system and a control panel with a touch screen display, making it easy to operate and ensuring precise wire installation.

Additionally, the unit is designed to minimise environmental impact and reduce noise levels and carbon emissions.

“I believe it’s one of only two units currently in the UK. It’s been successfully used in England over several years, however this is only the second time it’s been used in Scotland,” says Lee. “It’s been a significant and worthwhile investment for SPL Powerlines which enhances our technical expertise.”

With work on the East Kilbride project underway 24/7 over 16 weeks, the safety and wellbeing of the workforce was at the forefront of SPL’s mind, and the firm employed new technology and innovative strategies to keep workers safe, healthy and happy.

“One of the major innovations was the use of Tended’s geofencing and geotagging system,” says Lee. “We had a geofence around our whole work site, and had all the significant assets tagged including point, marker boards, as well as our compound limits. All our safetycritical staff were geo-tagged as were our plant and engineering trains, so we knew exactly where they were at any given time.

“If you speak to any of our engineering supervisors, they’ll confess it has totally changed the game. They no longer had to go outside to find out what was happening or make endless calls – instead they had a large monitor in front them showing the whole worksite, and the location of engineering trains, plant and workgroups in real time.

“The technology massively reduced the risk of anybody being in the wrong place at the wrong time. Anyone walking into an area that was out of bounds was immediately alerted by their alarm. It was a game changer and I’m not sure the technology has ever been deployed on a similar scale – it was an incredibly successful deployment of digital innovation” says Lee.

“With regard to health and wellbeing, 16 weeks is a significant amount of time and, as we were working around the clock, we ensured that regular breaks were scheduled,” Lee adds. “We also used that time as an opportunity to monitor staff fatigue. All the contractors went above and beyond in this respect. We ran a health and safety campaign throughout the blockade which saw multiple organisations come along and offer various health checks, both physical and mental. Again, credit is due to all the contractors who were involved in that – it was all very well received by the entire workforce.”

Undoubtably, the latest phase of the East Kilbride project has been a major triumph, but SPL Powerlines is certainly not sitting on its laurels. This is just one key milestone and several more remain, including the reopening of the upgraded East Kilbride station this summer, and the introduction of electric trains at the end of the year.

“While we have broken the back of the construction work, the actual testing, integration works, and final checks and balances you see in any major electrification work all still need to take place,” says Lee. “We need to ensure that when we fully energise the line of route, it’s done in a safe and controlled manner. The end of this blockade means that we are bang on programme, but there’s still a lot of work to do and we can’t afford to be complacent.”

Given SPL Powerline’s success during this latest blockade, this is unlikely to be the case.

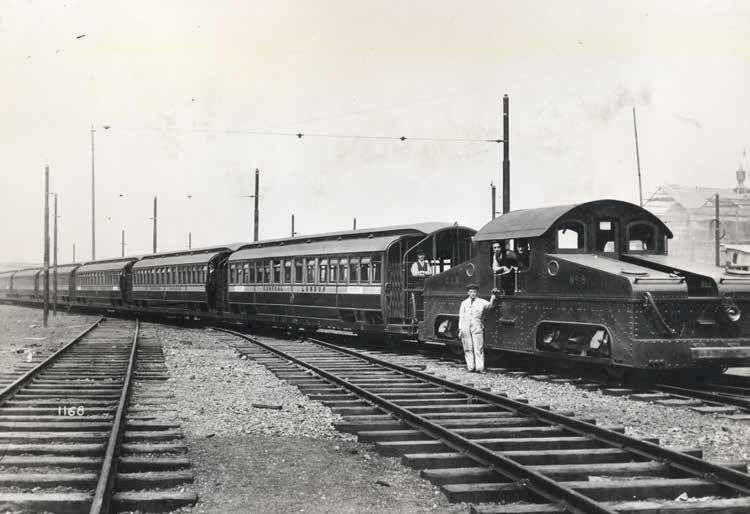

Over the past 20 years the railway has adopted many new technologies on modern passenger trains and infrastructure equipment which have provided significant benefits. However, rail freight has seen little new technology. Most freight trains are hauled by a diesel locomotive introduced in the 1990s. Freight wagons, with no electrical supply, have a maximum speed of 75mph, the speed of the original freightliners when they were introduced in the 1960s. Freight trains are also governed by an operating regime which is little changed since British Rail days.

Though there is an active rail freight research and innovation programme, there are significant opportunities to transform the rail freight sector. To learn more about the potential for such a transformation, Rail Engineer was glad of the opportunity to speak to Karl Watts who led

the introduction of the tri-mode Class 93 locomotive when he was chief executive of the Rail Operations Group.

In his current role as founder and managing director of Railmotive, Karl has produced two papers ‘Rail freight - a path to the future’ and ‘Intermodal Rail freight - a vision of the future’ which form the basis of this feature. The latter paper considers an intermodal freight train operation set in 2032 which takes advantage of the latest operational and technical innovations.

Freight train derailment at Llangennech caused by a wagon’s undetected brake fault.

: 00 CAPTION NOT REQUIRED CREDIT: Network Rail]

Over the past 20 years the railway has adopted many new technologies locomotive introduced in the 1990s. Freight wagons the speed of the original freightliners when they were introduced in the 1960s. Freight trains are also governed by

XM12 in 2032

[IMAGE: 01 CAPTION: Freight train derailment at Llangen Network Rail]

Though there is an active rail freight research and innovation rail freight sector. To learn more about the potential for such a transformation, speak to Karl Watts who led the introduction of the tri -mode Class 93 locomotive when he was chief executive of the Rail Operations Group.

In his current role as founder and managing director of Railmotive future’ and ‘Intermodal Rail freight - a vision of the future’ which form the basis of this feature. intermodal freight train operation set in 2032 which takes advantage of the latest operational and technical innovations.

XM12 is imagined to be an intermodal service from Thames Gateway to Trafford Park which operates in a ‘variable speed’ intermodal path which takes account of a new train classification system. Leaving Thames Gateway, it runs as a Class 6 train to reflect the low speed of the infrastructure. From Wembley, it runs as a Class 4 train to reflect its average speed of 60mph. This gives it a higher priority than Class 5 stopping passenger trains that average 42mph. Along the busy Trent Valley corridor it runs as a Class 3 train to reflect its 90mph maximum speed.

[IMAGE: 02 CAPTION NOT REQUIRED CREDIT: Not applicable]

Intermodal rail freight services.

XM12 is imagined to be an intermodal service from Thames Gateway to Trafford Park which operates in a ‘variable speed’ intermodal path which takes account of a new train classification system Leaving Thames Gateway, it runs as a Class 6 train to reflect the low speed of the infrastructure. From Wembley, it runs as a Class 4 train to reflect its average speed of 60mph. This gives it a higher priority than Class 5 stopping passenger trains that average 42mph. Along the busy Trent Valley corridor it runs as a Class 3 train to reflect its 90mph maximum speed

[IMAGE: 03 CAPTION: Intermodal rail freight services CREDIT: As used in Feb 25 feature on Class 99]

of West Coast Main Line (WCML) slow line running times shows the importance of taking account of average train speed. Although its maximum speed is 110mph, the average speed of a stopping train between Tring and Harrow is 42mph. Yet the average speed of an intermodal train is around 60mph. Thus, the Class 4 train should have a higher priority than the Class 2 train. Furthermore, an intermodal train conveying time-sensitive goods worth £20 million could be considered to have more economic value than a lightly loaded passenger train.

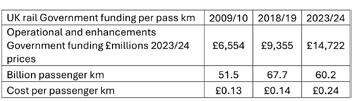

By 2032 the rail industry will have a new AI-powered timetabling system to maximise network utilisation and ensure trains are pathed according to their performance. Train prioritisation for timetabling and regulation will also use a value-based system rather than a system that was introduced in the 1950s in which all passenger trains have priority over freight trains. The difference between these two systems is shown in Table 1

[TABLE]

By 2032 the rail industry will have a new AI-powered timetabling system to maximise network utilisation and ensure trains are pathed according to their performance. Train prioritisation for timetabling and regulation will also use a value-based system rather than a system that was introduced in the 1950s in which all passenger trains have priority over freight trains. The difference between these two systems is shown in Table 1.

Class 2025

XM14 is hauled by a high-powered electric or multimodal locomotive as by this time almost all diesel freight locomotives will have been

2032

1 Express passenger train Passenger, ECS, or parcels over 100mph average speed

2 Ordinary passenger train Passenger, ECS, or parcels over 75mph average speed

3 Specially authorised freight train Parcels train Freight train over 75mph average speed

4 75mph freight train Passenger, ECS, or parcels over 60mph average speed

5 Empty coaching stock (ECS) Freight train over 60mph average speed

6 60mph freight train Passenger, ECS or parcels over 40mph average speed

7 45mph freight train Freight train over 40mph average speed

8 35mph freight train Slow freight or engineering train

9 Class 373 train Exceptional service e.g., test train

0 Light locomotive Light locomotive

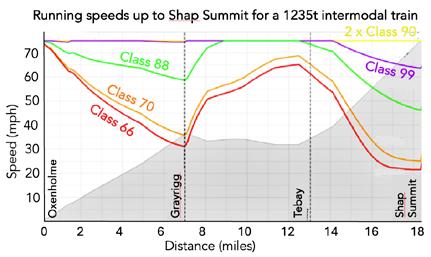

Speed distance graph of different locomotives hauling an intermodal train up Shap summit.

withdrawn. The container flats are 90mph, light weight, articulated, single axle wagons with independently controlled wheels which provide a self-steering vehicle. The wagons can also double the train’s traction power for short periods when accelerating or climbing gradients as each wagon has its own motor powered by a battery which is charged when it brakes.

With such high performance, XM12 can make three end-to-end trips between Thames Gateway and Trafford Park each day running for 19 hours a day – a 90% increase in the train utilisation levels in 2025.

XM12 is operated by the fictitious company Transmodal which is a global freight logistics company specialising in multi-mode freight transport. Rather than trade directly with freight companies, it trades with a logistic company offering a ‘port-to-door’ solution which maximises rail traffic and uses road transport for last-mile deliveries.

Although Railmotive’s vision is for a transformed intermodal freight operation, much of it relates to other freight train operations. The remainder of this feature considers current technology and developments which could deliver this vision.

Despite a large proportion of the core freight network being electrified, in Britain a mere 2.8% of rail freight traction energy consumption is from electricity. Hence few freight trains benefit from electric traction. As electric locomotives have typically twice the power of a diesel locomotive (electric Class 92 - 5MW, diesel Class 66 - 2.2 MW), they can haul heavier, faster trains.

As shown in the graph, a Class 66 diesel locomotive with a 1,235-tonne intermodal train slows from 60mph to 20mph as it climbs the fivemile 1 in 70 gradient to Shap summit, whereas 2 x electric Class 90 locomotives remain at their maximum speed of 75mph throughout this climb.

This illustrates the benefit of electric freight traction on the steeply graded lines between Lancaster and Glasgow.

However, it is not just the northern fells for which diesel freight is problematic. On the gentle 1 in 300 climb between Willesden and Tring, a Class 66 hauled intermodal freight can manage typically 45mph. This compares with 75mph for an electrically hauled freight which is a higher average speed than the stopping trains which enables electrically hauled freight to precede such trains without delaying them.

Although electric freight currently has higher fuel costs than diesel freight, Karl considers this additional cost is far outweighed by the savings from improved asset utilisation and reduced train crew cost that faster electric freights provide. Moreover, faster electric freight trains offer better use of the network as a slow diesel freight takes up two train paths. Surprisingly, the track access regime does not incentivise the provision of extra paths through the use of electric traction.

One reason for the lack of electrically hauled freight in the UK is the need for infill electrification on freight routes to provide electric haulage for the complete route.

The provision of an all-electric WCML freight service would require power supply upgrades. However, the total power capacity these provide could be minimised by intelligent OLE Supervisory Control and Data Acquisition (SCADA) which, for short periods, could automatically reduce peak locomotive traction demand when there are multiple electric trains in the same section.

On 15 January 2021, Rail Operations (UK) Limited signed a framework agreement with Stadler for the supply of 30 Class 93 tri-mode locomotives. The first of these arrived in the UK in 2023. Ride and static evaluations have now been completed and, after successfully completing initial tests with 400 tonne loads over Shap summit, a 2,000-tonne load test was imminent at the time of writing.

As described in Issue 189 (Mar-Apr 2021), the Class 93 is a tri-mode Bo-Bo locomotive. In electric mode, it can run on 25kV AC overhead lines with a power of 4,000kW. Its Caterpillar C32 engine has a nominal power of 900kW which can be boosted by 400kW for short periods (e.g., while accelerating or going up gradients) by its battery pack when operating on non-electrified lines. Shunting operations can also be powered by the batteries alone.

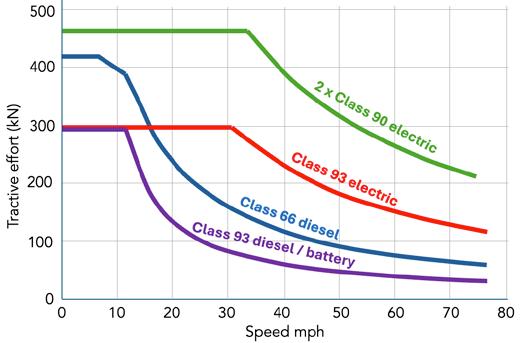

The capabilities of the Class 93 are shown by a comparison of its tractive effort curves with other traction. These curves show how the pulling force of all forms of traction diminishes with speed as power is the product of force and velocity. Diesel traction has a far greater reduction of tractive effort at speed than electric traction. For example, a 2,460kW heavy-haul Class 66 diesel locomotive has a particularly high tractive effort at slow speeds, yet at 40mph it only has 30% of its low-speed pulling power.

In electric mode, the Class 93 has twice the tractive effort of the Class 66 at 75mph. With just a 900kW diesel engine, the Class 93 can manage 60% of a Class 66’s tractive effort at 75mph.

Another new electric locomotive that can operate off the wires is the Class 99 Co-Co locomotive described in Issue 212 (Jan-Feb 2025). Though such locomotives are a solution to the lack of freight infill electrification, the additional costs of such traction over conventional electric locomotives may well be greater than infill electrification. With hundreds of diesel locomotives requiring replacement in the next decade, rail freight companies would no doubt appreciate sight of a longterm electrification strategy.

Railmotive’s intermodal freight paper envisages a train of 12 x three-vehicle articulated sets formed of 10-tonne twin-axle platforms carrying 40-foot,

31-tonne containers at 90mph. Traditionally, such wagons have a 60-tonne payload but in practice the maximum weight of a container on rail is that of the maximum that can be carried on an HGV, which is 31-tonnes. As the wagons are designed for this lower payload they can have single axle suspension, which eliminates the need for bogies and so offers significant weight savings.

It is also envisaged that these wagons would have intelligent on-board systems including wheel flat prevention, brake monitoring, vibration sensors, condition monitoring, GPS, and data transmission like those on the iWagon as reported in Issue 206 (Jan-Feb 2024). However, rather than being powered from axle generator, these intermodal wagons would be powered from the locomotive jumper via a cable throughout the train. As intermodal trains operate in fixed formations, coupling each wagon’s cables together is a more appropriate solution than axle generators.

On the European mainland, it is proposed to introduce Digital Automatic Coupling (DAC) by 2030 for the provision of intelligent wagons and more efficient coupling of freight trains. However, an RSSB report (T1264) estimates that fitting DAC to around 14,000

wagons in the UK would cost £600 million. It concludes that autocoupling offers little benefit as ‘block trains’ are the norm in the UK and that DAC’s main benefit is providing wagons with an electrical supply for which there are more cost-effective solutions.

Railmotive also envisages that wagons will use the ActiWheel system which is being developed by SET. This independently controls each wheel to provide a self-steering vehicle which significantly reduces track forces. This system monitors wheel distance from the track centre then calculates the speed of each wheel for the train to remain centred. It has a permanent magnet synchronous traction motor within the monobloc wheel so does not need a transmission system. Furthermore, as its electric braking works down to zero speed, it does not require friction braking.

This system was successfully demonstrated on a Class 230 unit in 2019. However, introducing such a new radical arrangement will require a robust safety case.

A significant potential benefit of the ActiWheel system is that it could more than double a freight train’s traction power for short periods of time when climbing steep gradients or accelerating.

Freight locomotive tractive effort curves.

This could be done by powering the ActiWheel motors by batteries which are charged when the train brakes.

The Railmotive paper considers how the fictitious global freight and logistics transport company Transmodal offers multi-mode freight transport by trading with a logistics company which is not rail specific as its model considers all container transportation modes to deliver ‘port-to-door’ at any one moment in time. Nevertheless, this is expected to ensure that every train will convey a minimum of 90% payload. Furthermore, this is likely to facilitate the operation of services from ports and terminals with currently unviable low container volumes. This type of operation is that used by iPort Rail. As reported in Issue 201 (Mar-Apr 2023), a Railway Industry Association (RIA) Unlocking Innovation event in Doncaster focused on rail freight and included a visit to iPort Rail which was opened in 2018. As explained at this event, the challenge is to bring

transport elements together for road hauliers to shift their operations from long haul to final mile. For them, using rail freight for long haul with a few short HGV journeys per day is more profitable than long haul HGV operations.

To do this, iPort Rail is working with third party logistics provider Eco2loco to fill the space on its trains and has developed RAILX container booking system to do this. This enables customers to instantly book a container on a train as trainline does for passengers.

Around a fifth of freight train movements are Very ShortTerm Plan (VSTP) movements. Finding the paths for such moves is a cumbersome process as the required data is in various documents that are not well integrated. This is dependant on the experience and skills of planners and has long lead-times making it more difficult for the freight industry to compete with a more dynamic road freight industry. To address this problem, University of Hull’s Logistics Institute has developed NR+ which digitises various documents such as Sectional Appendix, Load Books, RT3973 library, and engineering access statements into a single efficient graphic database. In essence this provides a ‘Google Maps’ for freight train planning.

The University of Hull’s Logistics Institute has also developed the Rail freight Energy and Emissions Calculator (REEC) which uses data from its NR+ system together with other information such as gradient profiles to assess the duration, energy consumption, and emissions of individual freight train moves. It does so by breaking the route into 10 metre segments to which an algorithm is applied. This is based on theoretical equations which have been adjusted and validated using On Train Monitoring Recorder data from hundreds of journeys.

NR+ and REEC are now managed by the University of Hull’s subsidiary Lampada Digital Solutions which, in 2023, won a Network Rail tender to develop the Digital Freight Train Loads book which now has 600 active users.

Much of RSSB’s freight research supports Railmotive’s vision for 2032. Examples of this are:

» Impact of Heavy Axle Weight on infrastructure (Report T1265). In partnership with the University of Southampton, a model was developed to assess future route options for heavy axle weight rail freight traffic on the network.

» Revision W10 and W12 freight gauges (T1327). These gauges were not suitable for some wagon-container combinations for which costly and time-consuming analysis of individual freight vehicles were needed to assess the safe use of new containers on specific trains. This result increased the allowable wagon and container combinations that can run on W10 and W12 cleared routes such as those possible with lower wagons that the ActiWheel system makes possible.

» Optimising freight sectional running times (T1301). This project provided more accurate definition of the maximum trailing load for a freight train by considering a locomotive’s available power and the train’s resistive forces. In all cases studied, it was found that sectional running times (SRT) were too conservative and that heavier freight trains could be run.

» Coupler strength limitations of freight train loads (T1256). The allowable loads for different types of couplers were specified by British Rail in 1969. This research re-examined the engineering principles behind Network Rail’s coupler ‘traction rating’

designation used to set the loading limits and found that they could be re-calculated to allow up to an extra four wagons per train.