Toufic Machnouk

1 in 43 quintillion

Liam Henderson

Innovation is the new norm

Richard Carr

GBR can help or hinder innovation

Sponsored by

Showcasing the latest rail innovations and technical developments.

Rail Business Daily (RBD) has always had the objective of being a force for good for the rail industry – providing platforms for any businesses already working in the sector, or for those who are looking to do so, to share their good news, promote their products and services, and encourage participation in their events.

It is therefore fitting that RBD has created this special edition of the popular Rail Director magazine that is specifically designed to allow organisations to celebrate and showcase their latest innovations and technical breakthroughs.

In a world where it is vitally important to implement sustainable solutions and to achieve net-zero targets, rail has a hugely important part to play both in how we travel and how the goods that we use are transported to their destination.

This publication exemplifies the vibrancy and innovation that is taking place right now across

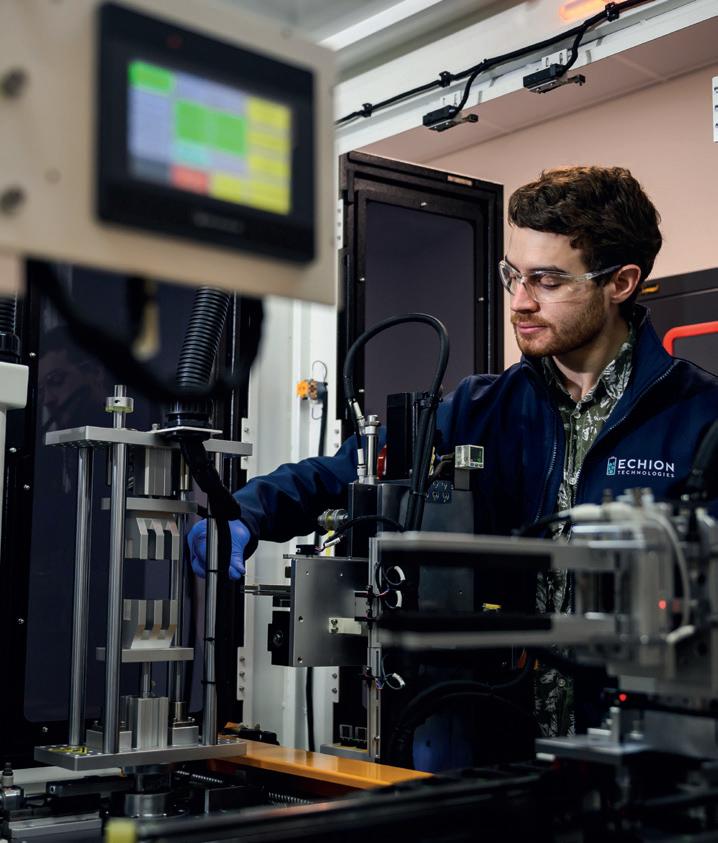

the sector and illustrates some of the exciting developments that lie ahead. It also demonstrates the range of technologies and organisations that are involved in innovation on our railways. From major innovations from the likes of Siemens Mobility and Hitachi Rail to more focused developments from small to medium-sized enterprises (SMEs) such as Echion Technologies’ improved XNO® battery-anode material and Klüber Lubrication’s specialised sustainable lubricants.

2025 has been an exciting time for the rail industry as it celebrates 200 years of operation, and this publication illustrates that, while the sector is celebrating its past, it is most definitely looking forward to the future.

It has been a great privilege working on this special edition magazine and I would like to thank everyone who has contributed and made it possible. No matter which part of the industry you work in, it is hoped that you will enjoy finding out more about the latest

developments and technical breakthroughs. If you would like to tell your story or promote your innovations in Rail Director magazine or in future special editions, please do not hesitate to get in touch.

This publication exemplifies the vibrancy and innovation that is taking place right now across the sector and illustrates some of the exciting developments that lie ahead

Dean Bruce, Managing Director dean@railbusinessdaily.com 07415 063 190 %

Rail Innovation 2025 is a special supplement from Tel: 0113 208 2620 Sales: 07494 529 803

Writers: Nigel Wordsworth, Rosie Crampton

Advertising Sales: Christian Wiles

chrisw@railbusinessdaily.com

Marketing Sales: Sarah Hopton sarah@railbusinessdaily.com

Production Executive: Mia Hargreaves

Design: Dean Wanbon

Published by an asset of the Railway Industry Association. Trading address: c/o 16 Smith Square, Kings Building, London, SW1 3HQ

Printed by Manson Group.

(©) 2025

All rights reserved.

Reproduction of the contents of this publication in any manner whatsoever is prohibited without prior consent from the publisher. The entries contained within the Directory are based on information provided by the respective companies and the publisher cannot be held responsible for any errors or omissions. The views expressed in the articles reflect the author’s opinions and do not necessarily reflect the views of the publisher or editor. The published material, adverts, editorials and all other content is published in good faith.

5 What does a Rubik’s cube teach us about the reality of innovation?

Toufic Machnouk outlines his four principles for successful innovation

8 Innovation that sticks-making change routine

Liam Henderson suggests that innovation should be the new norm

10 Overcoming the barriers to innovation in UK rail

Richard Carr considers the difficulties that the supply chain faces

12 Optimising project delivery at c2c

Sam Fowler and Alex Whybro outline c2c’s innovative approach to project management

14 Unblocking innovation

James Heslop explains some of the steps being taken to speed up innovation

16 UKRRIN: Brilliant minds and excellent facilities

William Powrie describes the relationship between the UK’s top universities and the rail industry

18 Collaboration and commitment: The keys to rail’s innovation

Luisa Moisio considers why rail needs innovation, and how best to deliver it

20 Doing things differently

Kevin Bonanno believes that innovation is a mindset and the sector must embrace change

22 Innovation on a global scale

Innovations from Siemens Mobility will power the trains of the future

24 True innovation brings its own rewards

Alan Barrow considers what is innovation and what isn’t

26 Guiding rail innovation across the Valleys of Death

Some innovations need specialist assistance to get them adopted onto the railway

27 RIN Events: A decade of driving rail innovation and connection

28 Opening the door to innovation

A train’s doors are often taken for granted, but innovation can bring many benefits

30 A new age of opportunity in rail innovation

32 A first for battery power

Hitachi Rail has successfully trialled hybrid battery-powered trains and won its first order

34 The Unipart innovation eco-system

How Unipart delivers innovation through collaboration and expertise

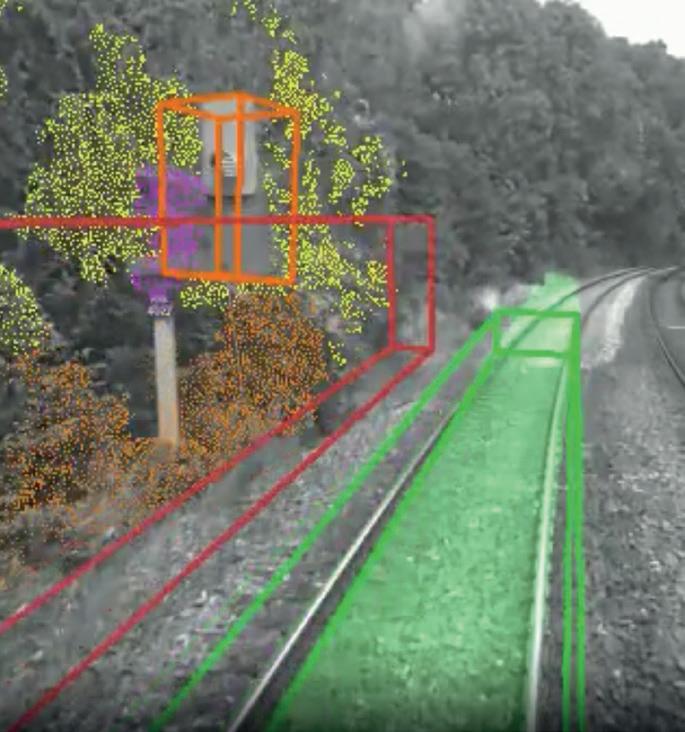

36 Structures inspections from the comfort of an office

Steve Lock reveals that 360° photogrammetry is reducing the cost of inspections

38 Fast-charging the electrification of Britain’s railways

Tyler Andrews considers how XNO® batteries can enhance GWR’s fast-charge findings

40 Ask the right questions

Andy Seccombe says that innovation is simpler once the challenge is properly understood

42 Driving a culture of constant innovation

Infrastructure consultancy Aarvee is continuously raising standards

44 How do you innovate if you are innovating every day?

When innovation is the norm, how will railway engineers go one step further?

46 Innovation spotlight

Three innovators reveal their latest advances

47 Driving smarter, safer, and more sustainable delivery

Ewan Keir looks at innovation on the permanent way

48 The innovation rail needs to protect its workforce

Simon Hochhauser writes about the importance of embracing mobile communications

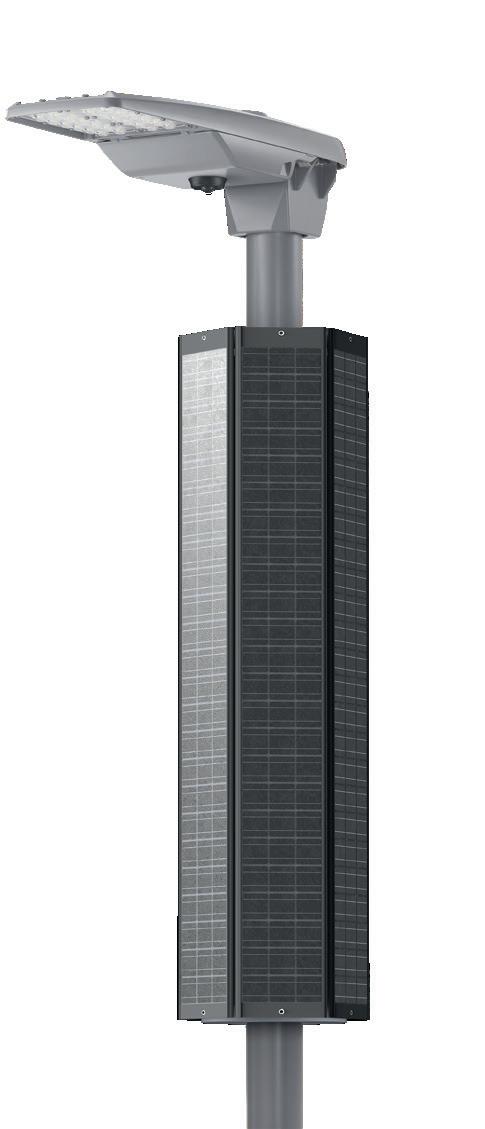

50 Lighting the way in rail innovation

David Woodcock discusses how adopting new lighting technologies can bring major benefits

52 Stay ahead of autumn conditions with LaserTrain

Experience reliable, high-speed rail cleaning designed with the latest laser technology

Toufic Machnouk, Managing Director of GBRX, outlines

his four principles for successful innovation.

have always been fascinated by seemingly impossible things.

As a child, the Rubik’s cube was a hands-on example of such a thing. Like many, I spent hours trying to solve it, frustrated with its difficulty. You solve one bit and then must break it to solve another.

Determined as I am, I learnt the principles and methods and eventually, with lots of practice, I was able to see the patterns quickly enough to solve a randomly scrambled Rubik’s cube in about 30 seconds.

Recently, I realised that the cube, as an inherently complex problem, embodied the practical principles of innovation that we were creating and deploying for the sector through GBRX.

The cube is a system of similar but unique particulars, with interdependent and changing relationships, constraints and freedoms – an unimaginable number of possible permutations – and it manifests the way the world behaves through configuration changes.

So, I demonstrated four of these principles recently during my keynote speech to the Rail Forum Annual Conference while solving a cube at the same time.

I cannot explain enough just how hard it is to do that while talking. But this fun demonstration has captured imaginations and brought some difficult concepts into something we can literally all hold in our hands.

At first glance, reality can seem simple, when it is in fact immeasurably complex. Rubik’s cube only has 26 unique pieces, which doesn’t sound like many. Yet they create 43 quintillion possible combinations. That’s 43 with 18 zeros.

Humans can’t grasp large numbers. To put that in perspective, 43 quintillion is 100 times larger than every second since the beginning of time. Let that sink in for a moment. I can’t even imagine the number of seconds in one lifetime.

In fact, a random scramble has probably never been seen by any human before. So, every starting point is unique, and any system where every starting point is unique is, by definition, complex.

Innovation has principles, models and methods

Toufic Machnouk. Image: Rob Finney/RIA

What does the cube teach us about complex systems?

We know there is virtually no chance of solving it for a desired outcome randomly. This is what an organisation is effectively doing when running random innovation pilots, in the hope that something might just stick.

We know that if you hand this to someone who doesn’t understand it, their odds of solving it are basically zero. That is akin to an organisation asking someone unqualified, or demanding of its people generally, to just innovate.

We know that if you try to solve one side only, which is immeasurably easier to do – we can call this the quick win side – it will create more constraints that then make it impossible to solve the rest. We see this in organisations as an attention deficit, because resources are scarce and their attention is not on the thing that solves the problem, or when a business applies a technology without addressing the complex ecosystem it works within and then wonders why things have become harder rather than simpler.

We also know that, if you try to solve this with the wrong beliefs and methods, you just won’t solve it.

It is effectively the same as trying to do so randomly but with the illusion of a method, which may even have a name. That’s when people say, “We’ve tried innovation before, and it didn’t work.”

So how do you solve a complex problem?

One of the most remarkable innovators in the world, Google X, says this about the question: you must start by loving the problem.

Why is Google X talking about love?

Let’s think about it. When you love something, how do you see it? Is it the same as other things? When you love something, you want to understand everything about it, how it works, how it feels, what constrains it. You are compelled towards it in a different way.

To love this problem is to understand its anatomy, its combinations, and how it changes, how it feels. More important still, to love a problem is to spend time deeply immersed in the problem with insatiable curiosity, exceptional expertise, restless dialogue and time to explore its permutations and limits in different conditions.

Only then can you start to really understand something complex and see what’s actually possible.

So, the first principle is this: the only way to solve complex problems by innovating is to start by loving the problem.

Complex problems can’t be solved in one leap because they have an unimaginable number of permutations and the constraint of inertia, meaning how sticky the status quo is.

You need multiple progressive steps, each revealing new possibilities not there before, but here’s the catch, you must start by solving the hardest one first.

But why the hardest one? Shouldn’t we just bank the easy ones first to make some progress?

Let’s think about this. If you don’t address the hardest problem first, will you ever actually determine if what you are pursuing is even viable? The hardest remains unsolved, and remains very hard, and the easy stuff can just be solved anyway.

So, you pursue the quick wins, then you look back and find no new possibilities were created, but you depleted the attention of your scarce resources on easy things when the hard things need a lot of attention.

Now doing so might have some value in reality, for example in helping some stakeholders engage in change, but that’s not the same as innovation. That needs to be treated as a necessary cost in the art of enabling change.

Google X calls this tackling the monkey first. But why are they talking about monkeys?

The example they give is this: if you need to teach a monkey to read Shakespeare while standing on a stool, what would you do first?

They say, don’t start by building the stool, because that won’t determine if it’s even possible.

Figure out how you’re going to teach the monkey. Learn if anyone has tried this before. If so, what worked and what didn’t. Then start iterating purposefully to determine how you are going to do it, what it’s going to take, what possibilities it will expose,

what false positives it might create, whether you can go all the way or only part of the way, and so on. That is what’s meant by the term ‘fail fast’, which is often used incorrectly.

For the cube, without an omniscient power or a cheat app, you always start with the fixed points first. These are the biggest constraints in this system. If you don’t start with the fixed points first, you will not be able to overcome the constraints of them later down the line.

So, the second principle is this. You must have the resolve to tackle the monkey first, so that each step can determine if what you are trying to do is more or less possible.

The bottom line is this. There is no such thing as innovation without displacement.

To solve this cube, I must displace the pieces, to move and change their configuration.

Every system has a configuration, a status quo, whether you know it or not. To change that system or part of it you must displace pieces out of their current configuration.

Now when dealing with complex problems, the whole process is one of progressive displacement, and each one creates new configurations. Some show you what doesn’t work. Some show you what does. And the skill of innovation is to progressively surface what does work and to move towards it.

So, the third principle is this. You can only say you have innovated if you can say that you have displaced in the current system.

Innovation can be learnt

Innovation is often romanticised in our culture.

When we think of innovation, what might come to mind is wacky ideas, wantonness, just trying stuff, and seeing what sticks. A randomness, or a desirable chaos.

These are cocktails of partial truths. It is not these things.

We also think of great innovators who seem out of this world. Inaccessible. Complete outliers. And yes, there is an outlier nature to innovation. It is not in the average by definition.

You do need to see new possibilities in this immeasurably complex world, and, by definition, you need outlier tenacity.

What does that mean? It means to bring about displacement, you need more tenacity than a meaningful sum of the others in that system who will resist change even if only as a result of their current configuration in it. That’s as fundamental as physics itself.

But here’s the good news. With the right conditions, it is learnable. Innovation has principles, models and methods. How do you think they can be learnt?

Of course, through purposeful action and lots and lots of purposeful practice. We all did this as children naturally.

Children haven’t yet formed their mental models of the world both physically and socially, so they are not yet bound by rigid assumptions and fear of failure. We used to test our mental models of the world repeatedly to find what worked.

By definition almost all new ideas don’t work, that’s exactly the point.

We saw new possibilities, and we were willing to experiment and collaborate in the uncertainty of their viability to see what works.

That’s why, quite remarkably, five-year-olds consistently outperform business executives, business teams and MBA graduates in complex team challenges, like building the tallest possible spaghetti tower that can support the weight of a marshmallow. Take a moment to realise how remarkable that is. Teams of five-year-olds consistently outperform teams of business executives.

So, we were all inherent innovators once. But why do the five-year-olds win?

Because the whole process of becoming an adult is one of forming and solidifying mental models of the world and ourselves. Our brains are predictive machines based on these mental models. Every second of every day our brain is perceiving and predicting. You couldn’t function if you had to rediscover the world and how it behaved every day.

This rigid predictive brain craves certainty, and we harden our mental models of the world with time. Some of us more than others.

The more open you can be to the possibility that your mental model might be wrong or just incomplete, the more capable you become of enriching your perspective with that of others. We naturally all have slightly different mental models of the world, so one of the best ways to create new possibilities is by working with others. The challenge is that it takes a low ego and deep curiosity about what they see and why they see it that way. That’s what is meant by cognitive diversity.

Now, anyone who’s tried to change a stubborn habit as an adult, and to learn a difficult new habit as an adult, knows all too painfully well that it is as painful as eating glass.

So what’s it like, trying to change the habits of a whole organisation of people?

It takes sound principles, models and methods, and difficult choices, and it takes lots and lots and lots of purposeful painful disciplined practice. Just think of the depth of the mental models you are trying to change. And it still may not work as desired. It’s the same with the cube. I could explain it now in a few paragraphs, but even if you grasped it right away, you still couldn’t do it without the pain threshold to eat glass.

But with that, this seemingly impossible one in 43 quintillion problem, that no one had ever seen before, can be solved by a mere mortal like me.

So the next time you wonder why innovation feels so hard and why there isn’t more of it, just remember this. The distance between you and the solution to a seemingly impossible problem that no one’s ever seen before is the following:

• The capability to love the problem.

• The resolve to tackle the monkey first.

• The outlier tenacity to create displacement in an inherently resisting system that is much bigger than you.

• And the pain threshold to somehow enjoy relentlessly eating glass.

So, it is hard. It is exceptional by nature. But it is real. And it is learnable.

We owe our progress in the world to those who did. And we can choose to be those who do for our time.

It takes lots of purposeful, painful, disciplined practice

Liam Henderson, Chair of The Rail Innovation Group, suggests that innovation should be the new norm.

Innovation in rail is often framed as kit: new trains, faster lines, clever sensors. Useful, but only part of the picture. Equally important are the back-end enablers to innovation: governance, procurement, data and a culture where new ideas take root. Get these right and smaller suppliers can contribute at pace. Get them wrong and even good technology stalls.

I write this as someone who chairs a community of start-ups, digital SMEs (small and medium-sized enterprises) and rail professionals – all advocating for the role that small companies can play in the modernisation of rail. The successful projects I’ve seen within the community have a consistent narrative: small, well-designed steps build evidence and trust. Evidence and trust buy permission to scale.

I’m also conscious that the railway is anchored in heavy engineering, rigorous safety cases and long-life assets that understandably move on more cautious cycles. This piece focuses on the digital layers: systems, data and user-facing information. These are the areas where incremental change can show early value alongside the engineering work.

The railway faces tighter budgets, ageing assets, carbon commitments and rising customer expectations. There is no single project that will answer all of that.

Innovation helps because it allows progress in shorter cycles, measured against outcomes, with scale following evidence. It is a management discipline rather than a hunt for the next transformation.

Applied with care, it reduces risk rather than adding to it.

Innovation lives in the system conditions. Policy that learns, procurement that invites, data treated as infrastructure, and teams that are trained and trusted to improve things a little each time. Technology then has a chance to help, whether that is a better dispatch tool, cleaner accessibility data or an AI assistant that can coordinate help during disruption. The true value of small companies can be harnessed when these

organisations can see a navigable and fair path for their products and their business investment.

To mix a metaphor: if you create a legible landscape, small suppliers can see where their solutions can have most benefit.

If small suppliers help rail to innovate, how can rail enable them?

One challenge in the rail sector is that many briefs still describe the solution in detail. This risks favouring incumbents and locking in yesterday’s interfaces. A problem-first, outcome-based approach opens the door to newer suppliers without putting core operations at risk.

Solving this cycle would start by defining the operational result or user requirement, not the tool itself. Invite suppliers to propose routes to those ends.

Small companies can be specifically targeted through smaller modular lots. Break programmes into interoperable components with clean boundaries and open interfaces. Rail will always rely on large contractors for mega-project delivery, but bite-size

lots would create manageable workloads that can be offered to smaller suppliers. Eventually, the rail sector would benefit from an ecosystem of SMEs in which smaller firms can contribute specialist modules behind stable interfaces.

In a world where Silicon Valley is releasing a new AI product almost every week, the traditional four-year framework list risks locking in obsolescence. It must be possible to design compliant public procurement commissions that can adapt to ever-increasing digital capabilities.

The stakes are rising

Artificial Intelligence (AI) is moving from analysis to action. Agentic tools can plan, replan and trigger support without a person in the loop every minute. In rail, that could mean an assistant that researches, books and manages journeys around disruption, or a system that reconfigures station flows during unexpected events. It might monitor, predict and organise maintenance on a rolling cycle, including moving people and parts to site.

These systems behave well only on clean, accurate, governed data with clear rules for identity, permissions and audit. If feeds are late, the agent hesitates. If authorisation is unclear, it cannot act.

If rail gets this right, the sector will benefit early from faster passenger improvements, better resilience, lower costs and, potentially, more investment.

If contracts, data rights and interfaces remain fragmented, others will move first. Travel retailers, mapping firms and payment platforms will set the customer expectation using their own data products and business model. This will be a lost opportunity for rail.

There’s still time to shape this future: the rail sector should use its coordinating influence to set data

rules and interfaces on its own terms. Initiatives such as the Rail Data Marketplace are already helping to tease out organised datasets and encourage data-led product development by SMEs.

Smaller suppliers bring pace, sharp focus and ideas imported from other sectors. The reason is structural as much as cultural. Small cloud-native companies carry less organisational drag, so decisions travel quickly, and they tend to build on modern, cloud-based stacks making their solutions interoperable from the start.

There is also an ecosystem effect. Where data and interfaces are open, SMEs appear and start solving problems that large suppliers would not prioritise. TfL’s open data programme is the clearest transport example. Deloitte’s study found annual benefits and savings up to £130 million, supported by a developer base in the tens of thousands and hundreds of live apps. The point is not the number. It is that a permissive data platform attracted a competitive market of small builders who delivered features and user experience at a fraction of the cost of doing it in house. This represents an even bigger opportunity for the GB rail network overall. By contrast, heavy reliance on closed frameworks and large, long contracts can suppress competition and make it harder for smaller firms to join mid-stream. The National Audit Office and subsequent parliamentary scrutiny have both warned that overuse of frameworks narrows the field, pushes up bid costs and can reduce transparency. That matters in rail, where innovation often sits in a small module at the edge of a larger programme.

There is good evidence that targeted public programmes, which invite SMEs in early, improve outcomes. Evaluations of the Small Business Research Initiative show positive value for money for government, faster introduction of new products and higher growth for participating firms. Catapult Network studies report stronger employment and turnover growth for SMEs that engage with Catapults. In transport language, this means there is a proven route to bring specialist digital capability into regulated environments without betting the network on it.

The record is not perfect. SMEs have short runways and can be frozen out by long sales cycles, unfunded discovery and payment terms that move risk down the chain. Bid costs and confidence in evaluation can deter smaller suppliers from bidding at all. The fix is not special treatment. It is good market stewardship: clear problem statements, funded discovery, proportionate terms and fast payment on verified milestones. That keeps a broader field of suppliers engaged and raises competitive pressure on quality and price.

So, the case for SMEs is practical. They bring modern development habits that fit modern systems, they adapt quickly when rules change, and they are attracted by open interfaces and clear outcomes. You get faster learning, lower delivery risk and a healthier supplier ecosystem that makes rail more adaptable at reasonable cost.

An outcome-based approach opens the door to new suppliers

Richard Carr, Technical and Innovation Director of the Railway Industry Association (RIA), considers the difficulties that the supply chain faces and how Great British Railways, through GBRX, could help or hinder the process.

he key thing about the railway, for me, is that it is an overly conservative system that is not open to the adoption of innovation. Although examples of best practice can be found, railway innovation as a whole remains underfunded and insufficiently supported. Even modest improvements must navigate long, complex routes to adoption, while transformative, radical innovation is almost entirely shut out.

There is plenty of good practice in R&D being carried out through universities, through organisations such as UKRRIN (the UK Rail Research and Innovation Network) and via Network Rail’s Technical Authority RD&I team. It is getting that research into the system and actually used, deployed and adopted that is the challenge. And if we don’t improve that, we won’t improve the railways.

Moving an innovation from concept to everyday use requires resources, long-term commitment and buy-in from all levels of industry and government. Alongside this, a cross-industry effort is needed to remove barriers to adoption. Policy, procurement rules, cultural habits or structural issues can all block promising innovations from reaching the market. Collaboration is essential.

RIA has examined this challenge from every perspective. By surveying members, studying cross-industry case studies and analysing cultural, commercial, and regulatory barriers, it has built

a clear picture of what holds back innovationand how dismantling those barriers could accelerate decarbonisation, attract private investment, boost UK technology exports, and deliver truly transformative change.

The outlook isn’t entirely bleak. Across the industry, initiatives already demonstrate what is possible. RIA’s Unlocking Innovation programme-delivered with Network Rail, UKRRIN, Telent, and othersbrings together people with ideas and the resources, opportunities, and platforms to realise them. By fostering collaboration across the sector, it nurtures a culture where new thinking doesn’t just take root, it flourishes.

The biggest focus that we should have as an industry is around culture and behaviour

I think, to a certain extent, this attitude is endemic throughout the system, but, particularly from an infrastructure perspective, it’s lower down the hierarchy where the problem seems to lie. The Railway Industry Association’s members regularly talk about middle managers as the problem.

Senior management realise what’s needed, but, privately, they admit they are struggling to get behaviours changed.

Skills development and fostering a culture of innovation are critical. Supporting individuals with training, embedding innovation into day-to-day objectives and encouraging continuous improvement will help the railway attract and retain a highly skilled workforce ready to turn ideas into reality.

Which is why I have often said that the biggest focus that we should have as an industry, from an innovation perspective, is around culture and behaviour. It’s not around innovating in technology, because that’s already happening. It’s about changing the culture and the behaviour of the industry to allow that technology to be implemented and adopted.

Is Great British Railways the answer?

While I don’t think Network Rail’s devolution programme has made it worse, I do think that it has made it more complicated and made it more inefficient for the supply chain to engage.

When we first talked about Great British Railways, and RIA formulated its Innovation Strategy in 2022, we had six key asks:

1. Increase Government investment in rail research, development, and innovation.

2. Strengthen support during the innovation rollout phase.

3. Lead a concerted cross-industry effort to identify and overcome barriers to successful adoption.

4. Provide a pathway and funding for radical innovation.

5. The railway must adopt a whole-system and long-term view to enable the right innovation.

6. Support skills development and the creation of an innovation culture.

Great British Railways should be organised so as to be the innovation guiding mind

We also asked that Great British Railways should be organised so as to be the innovation guiding mind, supporting the whole innovation journey through to deployment and benefits realisation, and acting as an enabler to exporting opportunities. This includes adopting the principles of the Rail Technical Strategy – a cross-industry initiative setting out a vision for how technology can be used to create a better railway and giving guidance on how to prioritise existing dedicated railway research and innovation funds.

Great British Railways, through GBRX, should lead the creation of an ecosystem that nurtures innovation and supports innovators throughout the journey from concept to benefits realisation and business as usual.

TfL also states that the Miles per Technical Incident Number (MTIN), which is used to measure the mean distance in miles between service affecting faults of three or more minutes has been, in general, above the target of 10,000 miles. Customer satisfaction ahead of the 29 September meeting gave an overall score of 87.5 per cent, the highest ever score across all the modes of transport, while customer satisfaction for the east

This includes building on the solid foundations of well as backing the development of the Global Centre Network Rail’s Technical Authority RD&I work, as

and west sections was at 77 per cent for Quarter 1.

TfL says that passenger numbers on the Elizabeth line are consistently higher than budgeted for and, excepting strike action, regularly exceed two million per week. Of the 45 million who had travelled by the end of September, some 22 million had used the new section of railway. For example, during the week ending 20 August there were 2.1 million passenger journeys for the whole line.

The TfL chosen BTU partner including the recent Northern Line Extension, Victoria Line and Jubilee Line projects.

PB Design has built its reputation over more than 40 years of designing and manufacturing AC and DC standby systems for many major projects in the UK and overseas.

We manufacture a full range of PADS approved Battery Charges, and also offer full application design facilities through to project management, manufacture, test, installation and site commissioning.

well as backing the development of the Global Centre of Rail Excellence and Network Rail Test Tracks as comprehensive test facilities with open and flexible access for the UK rail sector. GBRX, in collaboration with its regions, should act as the ‘innovation guiding mind,’ supporting the full pathway to deployment, ensuring benefits are realised, and enabling opportunities for export. In addition, they should take responsibility for coordinating the allocation of funds and dedicated teams to support the first deployment of promising innovations.

Passenger numbers across Period 4 (26 June –23 July) reached 4.5 million on the east and west, and 5.1 million passengers travelled in the central section.

In total the frequency through the central section will rise from the current 12 trains per hour (tph) to 22tph during the peak, and 16tph off-peak from 6 November. Trains will also finish running an hour later at 23.30, having already begun operating an hour earlier, from 05.30, on 5 September. The frequency then increases to 24tph from May 2023 and there is capacity for 30tph.

The rail sector stands at a pivotal moment. The drive toward net zero, shifting travel patterns, and the creation of Great British Railways all signal a system in transition and primed for reinvention. Today, rail already contributes £43 billion to the UK economy, supports more than 700,000 jobs, and delivers £2.50 in value for every £1 invested. With a stronger focus on innovation, these benefits could grow significantly.

TfL says that passenger journeys for the Elizabeth line exceeded budgeted figures by 14 million, due to the central section opening five weeks earlier than assumed plus higher than expected passenger numbers across the whole line. This meant that the income from fares was £20 million above budgeted forecasts as a result.

Government will be central to unlocking this potential-not only through funding, but also through policies, procurement practices, and leadership that reward new ideas. The supply chain is ready, ambition is strong, and the blueprint for action is clear.

However, year to date (YTD) direct operating costs were £8 million lower than budgeted and the Net Operating Deficit for the new railway was £101 million, some £28 million favourable to the budget.

If the UK is serious about leading the world in transport innovation, now is the moment to act. By investing in ideas, skills, and collaboration, we can build a railway that is both resilient and sustainable.

Typical applications include:

Substations

Rail Applications

Mass Transit Systems

Power Stations

Data Centres

Shopping Centres

Theatres & Cinemas

Sam Fowler and Alex Whybro oversee c2c’s newly launched project management office (PMO). In this article, they outline its innovative approach to project management – and explain how they are delivering consistency and realising new efficiencies.

Sam Fowler, PMO Lead at c2c, is on a mission to improve the way the industry delivers projects and manages risk. A seasoned rail professional with 10 years of project management experience, he’s truly committed to the task at hand – and hopes this enthusiasm is proving infectious.

“I’m really passionate about it,” said Sam, who first joined c2c as an Information Systems Analyst in 2013. “And that passion hopefully filters through the business. But it’s not about cracking the whip – it’s about working on problems together, being open and honest, and encouraging collaboration.”

Sam runs c2c’s newly launched PMO alongside colleague Alex Whybro, who is Head of Relationships and Programmes at the award-winning regional operator. His “broad” remit includes overseeing the management of the PMO, the operator’s business planning cycle, and its relationships with the Department for Transport and Network Rail. “It definitely keeps me busy!” he laughed.

Alex and Sam share a passion for good project management, and are striving to realise the PMO’s

mission statement – “optimise project delivery”.

It’s no small task – but a year and a half after the function was launched, they’re making steady progress.

“We’ve found that, at many companies around the UK, PMOs come in and out of favour, but we’re really keen to make this one stick,” added Sam.

It’s about ensuring that we do what we set out to dogetting that right and making it as efficient as possible

c2c’s innovative PMO was established in April 2024, the result of a Business Transformation Programme to identify new efficiencies.

“It was one big melting pot of ideas,” remembered Sam. “It gave rise to around 11 major outputs – one of which was the PMO. And now, the PMO itself owns a good chunk of those deliverables.

“Ultimately, the programme was about bringing in more structure and better, more efficient ways of working. The highlight of that work was the PMO.” And already, c2c’s PMO team has introduced much needed-structure and realised new efficiencies, focusing on three areas: projects, corporate risk, and meeting governance.

“Our innovative team love technology, and we also build efficiency solutions,” added Sam. “We’ve created a public relations tracker and worked with the ticket booking team to build a system that allows them to take group bookings, for example.”

Sam explained that PMOs come in all shapes and sizes - adding that at c2c, project delivery is a key focus.

“It’s about ensuring that we do what we set out to do-getting that right and making it as efficient as possible,” he said.

Beyond project delivery, the PMO manages and governs corporate risk. While Sam admits that he and his team are not “risk experts”, they have introduced governance around risk reporting.

And finally, they oversee meeting governance,

bringing structure and consistency to this important area of the business’s operations.

“Two years ago, we didn’t really have terms of reference for our formalised meetings,” Sam revealed.

“People weren’t sure what the agenda was. We set up terms of reference for each meeting, as well as action trackers and risk trackers aligned with our corporate risk.

“And for meetings with external organisations, we created a summary tracker, which meant key information could be captured and disseminated out to the relevant groups.”

Alex added that they had extended this “holistic, consistent” approach to business cases, helping colleagues understand and assess them.

While bringing the “right people” together to interrogate business cases ensures the right decision is reached, he admitted that this approach could make for a “Dragon’s Den-style” experience.

“You’ve got your Head of Engineering asking if you’ve considered accessibility,” he explained.

“And then the Head of Digital asking if they’ve consulted with Supply Chain team about procurement requirements. It’s about ensuring we make the right decisions for the business.”

We’ve found that, at many companies around the UK, PMOs come in and out of favour, but we’re really keen to make this one stick

It’s also about providing a clear view of c2c’s portfolio – something the PMO has achieved via standardised and consistent reporting.

“Previously, project managers were providing updates on Excel, PowerPoint, and even Word,” explained Sam. “It was confusing for the Exec team, so we’ve standardised the reporting process, introducing new templates. This creates one data set, and a clear view of everything from finances to projects and risk.”

This information is available on a single dashboard, which Sam and his team have optimised for ease of use.

Indeed, the duo agree that Smartsheet – an AI-powered work management tool – has played a key role in their success.

The streamlined software enables teams to record everything from risks to meeting actions. Information is stored in its back office, before being filtered and shared in reports – often with c2c’s Portfolio Board, the operator’s community of team leaders and ‘Heads,’ collaborating on core projects.

“It’s being used in a really clever way, and integrates

with our Microsoft Teams app,” Alex explained. “You can see actions and risks in one place, different meeting dashboards. It means you’re not scrambling to locate meeting notes or terms of reference.”

Sam added that integrating Smartsheet with a familiar tool, Microsoft Teams, made it more user-friendly.

“As soon as we started showing colleagues information in a location they were used to and filtering it to give them exactly what they needed, it got easier,” he said.

The PMO can even analyse data on risks or actions, identifying common themes. As Sam explained, this kind of trend analysis enables c2c to be more proactive. In the future, they hope to employ AI-powered tools like Copilot, interrogating large datasets quickly and easily.

And, when it comes to the bigger picture – project success – the PMO measures three key metrics: are projects on scope, on time, and on budget?

“Again, by having it all in one system, we’re able to effectively track it and show the trend from month-to-month,” Sam explained. “We can identify how many ‘red’ projects we have each month and establish where to focus our efforts.”

Now, c2c is sharing its learnings with industry partners and other train operating companies.

“The system’s been demonstrated to them, and the reaction is usually the same,” Sam said. “‘Oh wow, I didn’t realise it could do that!’ We’re keen to share our knowledge with the industry.”

Within c2c, their work is supporting cross-functional collaboration. Members of the PMO team attend the business’s newly formalised strategy meetings, facilitating conversations – and ensuring vital information is captured – with the right technology. They also work closely with c2c’s finance team, which oversees the annual business planning process.

“The whole business contributes to the business plan, and the tools we have available make capturing all those ideas and putting them together in a response a lot more straightforward,” Alex explained.

And, with its streamlined reporting system and new templates, the PMO is also building a library of lessons learned on major projects. Lessons and actions are captured as a project progresses rather than when it concludes, ensuring they’re not lost.

This collaborative, user-focused approach has enabled Sam and Alex to secure company-wide support for a function that could, under different circumstances, be seen as a “policing force”.

The duo was quick to address this misconception, providing training, gaining key stakeholder support, holding inclusive lunch-and-learns with colleagues, and demonstrating the value of their approach. They were keen that, rather than a bureaucratic, administrative function, the PMO be seen as a strategic project delivery partner.

A clear PMO policy, written by Sam and mandated by the executive team, outlines what is expected of project teams.

“Ultimately, it’s about giving people the tools to make optimising project delivery as straightforward as possible – and in turn, providing a holistic picture of the status of projects across our portfolio,”

Sam explained.

And what does the future hold for c2c’s innovative PMO team? Sam added that it was all about building momentum.

“We’re keen to strengthen our collaboration with the DfT, and look into benefit tracking with the right technology,” he said. “We purposefully started small, got the basics right – but now, we’re looking to build on our progress.”

Network Rail has been accused of being slow to innovate. Head of Strategy James Heslop explains some of the steps being taken to combat this.

t the senior level, Network Rail absolutely understands that it needs to innovate. Doing things the way they have always been done will cost what it always has, so the only way to do more for less, to be more efficient, is to do things differently – and that means innovation. That belief is so strong that Network Rail recently signed memoranda of understanding covering R&D (Research & Development) with Transport for London and SNCF (French national railways), adding to those it already has in place with other international partners and opening the way to collaborate on shared issues related to asset

management, maintenance, safety and environmental sustainability. As part of those agreements, each organisation has developed plans that focus on improved solutions and innovations to change and modernise assets and services.

Speaking of the agreements, Martin Frobisher OBE, Engineering and Safety Director at Network Rail, said: “We share many of the same challenges and, by sharing knowledge and best practices, we can help each other drive innovation and efficiency in asset management, maintenance, and sustainability on our railways, strengthening safety

and performance, for the benefit of passengers.”

So, Innovation on the agenda. However, Network Rail does still have a challenge around the adoption of innovation. Many in the infrastructure supply chain complain that innovation is slowed as Network Rail doesn’t want to run the risk of innovations failing to work.

One of the ways we buy people in is by showing them that a technology works in the rail sector

James Heslop, Network Rail’s Head of Strategy, spoke with Rail Director about the culture of innovation needed to support implementation and how it should focus, throughout the organisation, to support people in developing the capability and capacity to implement fast emerging changes. “Recent studies show that people across Network Rail are keen to support innovation, but they are lacking the capacity to deliver it,” he said.

“Which is understandable but doesn’t promote innovation. Anyone involved in innovation has to be prepared for it to fail, but then has to treat that failure as a learning experience so that next time a similar innovation is introduced, it WILL work.

“Innovation has to have sponsorship throughout the organisation,” James continued. “Often we focus on our senior sponsors – on those people who make the decisions – but actually we need sponsorship throughout the organisation, from people at operator level all the way through to middle and higher management, because they are the people that deploy innovation and act as the champions for the business change.”

The rail industry has relentlessly innovated for 200 years

Network Rail is therefore implementing a three-stage strategy to do this. Firstly, each R&D project that it takes forward has to have the support of regional teams. It has to have sponsors with a clear demand for a successful solution, and it has to move forward in a way that allows that journey for innovation change management to happen.

Secondly, James and his team run Pathfinder Projects. “We are very conservative in our industry, because we have to be,” he explained. “Our job is a very serious job, and we can’t just make sudden changes.

“One of the ways we buy people in is by showing them that a technology works in the rail sector. So, I run Pathfinder Projects. One that Kerry Marchant and the Network Rail Standards Team have just run has been the testing of a large language model with IBM. This uses artificial intelligence to interrogate our railway standards to find confliction and duplication. We know they exist, but today it is a manual activity to identify them. We hope that by including AI tools in the standards digitalisation project, in a safe and secure way, we will become more efficient at updating and reviewing standards.”

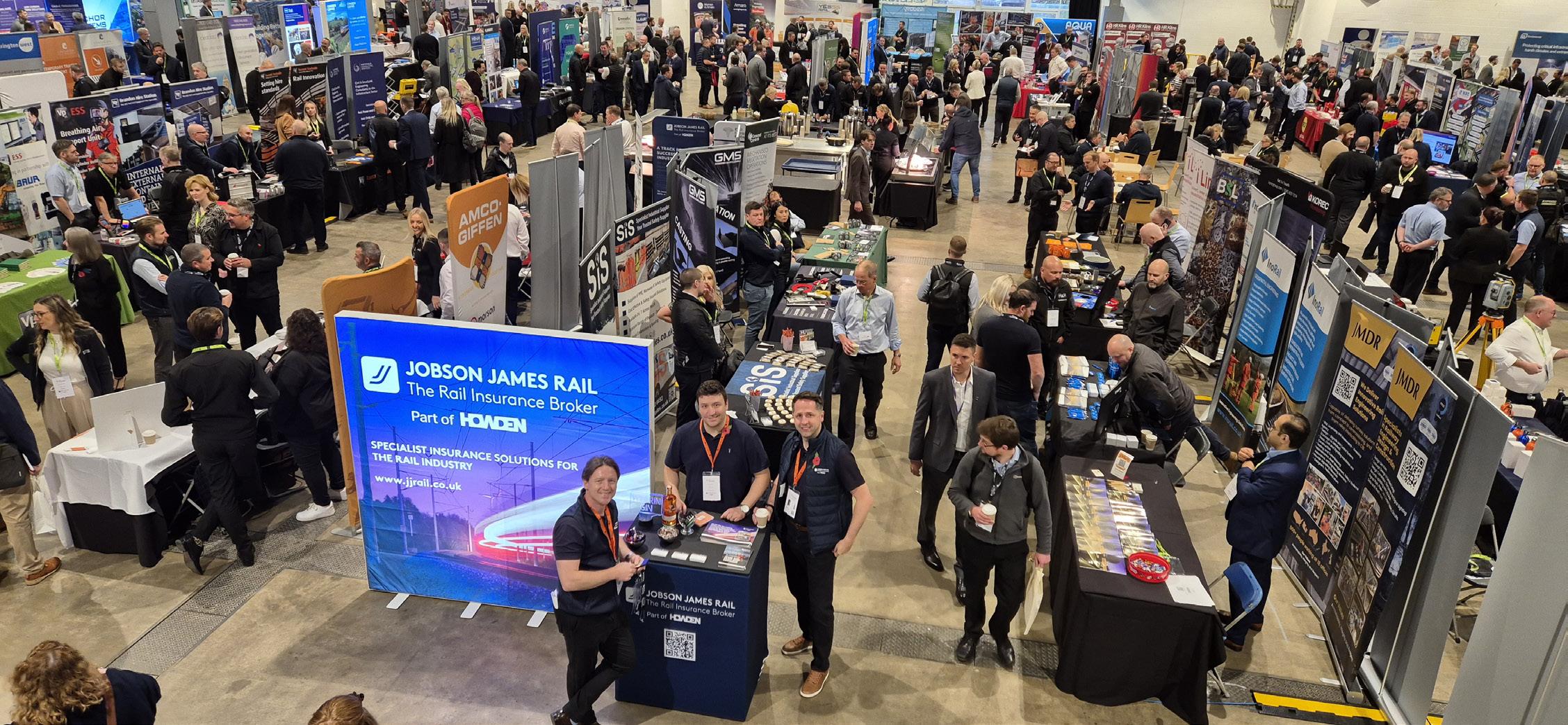

The third and final stage of the strategy utilises the Railway Industry Association’s ‘Unlocking Innovation’ events to show the industry, including Network Rail staff, that the industry is indeed innovative.

“The rail industry has relentlessly innovated for 200 years, starting at my hometown in Darlington,” James concluded. “I believe that, by working together through events such as Unlocking Innovation, we can get innovative organisations closer to the parts of Network Rail that want to support innovation.”

I believe that, by working together through events such as Unlocking Innovation, we can get innovative organisations closer to the parts of Network Rail that want to support innovation

William Powrie, Professor of Geotechnical Engineering at the University of Southampton, describes the relationship between the UK’s top universities and the rail industry, which are working together to innovate and improve our railways.

Innovators drive successful businesses, and applied research underpins innovation. Rigorous science can accelerate product development, focus effort, and speed product acceptance.

But how can businesses secure affordable, top-quality research effort when it’s needed, for as long as it’s needed? How do you complement the bright minds and test facilities you already have in your business?

As far back as 2015, the Rail Delivery Group recognised the need for a new approach. Its report ‘Fast Track for Growth’ concluded: “Existing technology is insufficient; we are moving into a technology-led decade of change and innovation. That means both faster implementation of existing technology, and a relentless drive to spur greater innovation and new technologies.”

The UK is endowed with universities stacked with world-leading researchers and facilities, and the UK Rail Research and Innovation Network (UKRRIN) has simplified access for industry. It comprises key industry players and universities with substantial, generalised and specialist rail-related research capability.

Launched in 2018 with Government support, UKRRIN gives UK industry access to truly practical, applied research, facilitating the development of new products and bringing them quickly to market. University researchers bring enthusiasm and new thinking to bear, using fully equipped laboratories, research quality field measurement techniques, high-powered computing facilities and robust scientific analysis.

And because the universities undertake research across a range of sectors and disciplines, the opportunities for cross-pollination of ideas are huge.

The UK is endowed with universities stacked with world-leading researchers and facilities

There is a symbiotic relationship between industry and academia. Some businesses partner with universities to accelerate product development, for example Sheffield-based SME Tribosonics Ltd has been working with Huddersfield on a Network Rail and Horizon Europe-funded project to develop an ultrasonic track lubrication detection system.

Others take advantage of university testing to support product acceptance, such as the precast concrete manufacturers proving new products in the National Infrastructure Laboratory at Southampton. Major programmes across multiple universities can lead to transformative savings for the whole industry. A good example is the Network Rail-led programme that seeks to reduce the cost of electrification – several industry partners are using the specialist facilities and software at universities including Birmingham, Huddersfield, Sheffield and Southampton.

Other examples include a project at Southampton with Deutsche Bahn, SNCF, Tata Steel and others to develop a cost-effective alternative to field tests for rail dampers. This reduced homologation costs by 90 per cent and the time required from six months to one week, opening the market to SMEs. Meanwhile, the universities can act as a critical friend, supporting industry in problem solving.

Inside the University of Southampton anechoic chamber with a scale track model used to study and improve understanding of noise radiation and absorption of railway rolling noise.

Image: University of Southampton

This can mean developing solutions or providing advice to the people who actually own the problem and are trying to solve it.

Another area for collaboration is in tackling big strategic issues. Climate change is one of the biggest, and Network Rail is working with UKRRIN partners on the challenges of increasing summer temperatures and changing patterns of rainfall (or the lack thereof).

UKRRIN is a partnership between academia and the rail industry. It currently comprises 20 universities, spread around the UK from Heriot-Watt in Edinburgh to Southampton, the two key infrastructure owners – Network Rail and Transport for London – and a number of partners and affiliate members from the industry.

The academic side of UKRRIN is grouped into four Centres of Excellence: Digital Systems, Economics, Policy & Operations, Infrastructure and Rolling Stock. A fifth Centre of Excellence in Testing is led by Network Rail, giving UKRRIN projects preferential access to facilities at Tuxford in Nottinghamshire and Melton Mowbray in Leicestershire.

You don’t have to be a UKRRIN industry partner to benefit from this great resource, and we are always happy to talk. More information can be found on the website www.ukrrin.org.uk/, and guidance on choosing a partner can be had from Centre of Excellence leads, or from RSSB by emailing ukrrin@rssb.co.uk.

Luisa Moisio, Director of

at the Rail

and Standards Board (RSSB), considers why rail needs innovation, and how best to deliver it.

All industries need innovation to continue to improve and meet the evolving needs of their customers and society – that much is clear.

Rail currently has two top priorities: reducing costs and improving reliability. These challenges are not going to be improved easily given the volume and nature of traffic on the network, the characteristics and longevity of some of its assets, and the growing impact of extreme weather.

They need to be tackled by combining short-term, tactical interventions (for example improvement in disruption planning and skills) and longer-term incremental as well as radical developments (for example expanding the use and capabilities of connected driver-advisory systems and traffic management).

There are also opportunities for the railway to pursue, for example – building on its emissions credentials to reduce them further and make better use of existing capacity. Again, the research and innovation communities need to pursue a range of solutions across different time horizons and novelty levels to enable progress on these.

It’s hard to get research and innovation funding to make things better in 10 years from now. Hence the tendency, in some cases, to prioritise research on solutions that can deliver improvements in two or three years.

There are great technologies out there at different readiness levels

We have plenty of near-term impact projects in the RSSB research pipeline, and even more that have been completed and successfully taken up. For example, the extra paths and positive impact on reliability from our recent work on improving the accuracy of sectional running times for freight trains. But we need to be careful that such short-term solutions, aimed at making the most of today’s network, are not the only things we focus on. We need a balanced research portfolio where projects focused on the here and now go together with long-term ambitious developments. The beauty is that the latter can generate early opportunities along the way

For example, at RSSB we are looking at traction-power algorithms to manage available energy. This is because there are pinch points on some parts of the electrified network, where there isn’t enough energy in the wires, and because of the new needs and opportunities that battery-train operations could bring. The long-term vision is to have a real-time management of traction power as part of an intelligent traffic management system. While we are working in that direction, some of this thinking could be used much earlier to allow more flexibility in granting electrical paths.

Another example from RSSB research pipeline is the work on inerters. These are passive mechanical devices that produce a force proportional to the relative acceleration between its ends. RSSB’s initial technology-transfer exercise identified potential applications of this technology in rail. While the journey to have inerters for primary and secondary suspension continues, this work triggered the successful prototyping and testing of an enhanced trailing arm bush (ETAB). And we are now working with Transport for Wales for ETAB to go through the assurance process and be used in the refurbishment of the MK4 fleet planned for 2026.

Pursuing long-term research journeys doesn’t exclude the ability to have impact along the way if one looks for such opportunities, while a too short-termism focus in our research and innovation effort will inevitably restrict the funnel of future improvements.

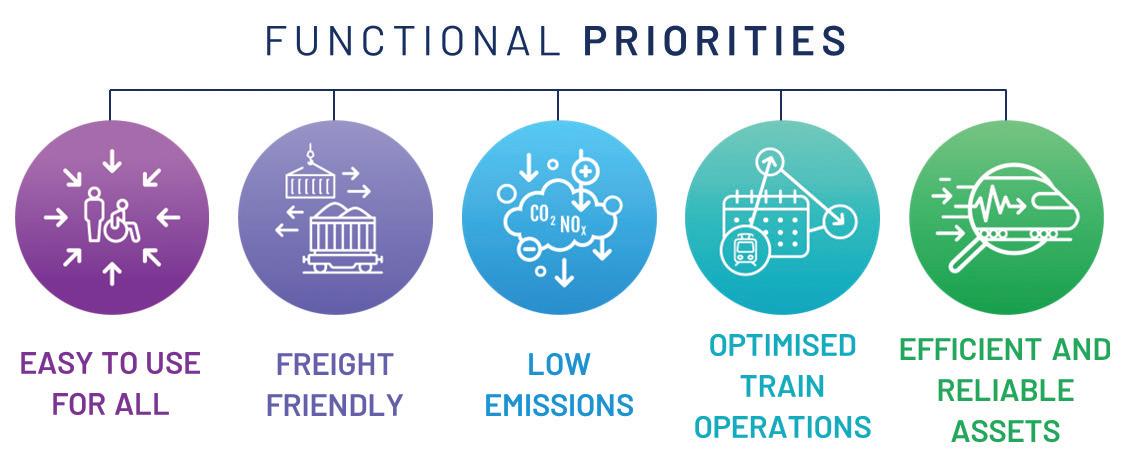

There are great technologies out there at different readiness levels, and they are key to delivering the goals captured in the five priorities of the Rail Technical Strategy. Whether the focus is making the railway ‘easy to use’ and ‘freight friendly’ or on the challenge of working toward ‘more efficient and reliable assets’, we must consider the range of technologies both already at play and new that could bring about the vision.

Take AI. Of course, AI algorithms will be invaluable in integrating a lot more factors into asset or traffic-management-related decisions. If deployed correctly, it will allow a level of ‘intelligence’ that is miles away from what is possible today, for example enabling different priorities for traffic management at different time of the day, or improving the resilience and costs associated with energy use. Such progress needs to go hand in hand with improving our technical capabilities and understanding in many other areas. These range from the aerodynamics of faster freight trains to help with the ‘freight friendly’ priority, to new materials increasing the efficiency and reliability of assets, or wearable technologies to support the health and wellbeing of our workforce. And this is only to name a few.

Research and innovation communities should celebrate success

Innovation benefits tremendously from cross-fertilising new ideas with deep rail expertise. These new ideas can come from academia or be prompted by closer working with other relevant sectors. For example, are we talking enough with the energy sector, both at senior level and at the technical, research and innovation level?

RSSB has always found tremendous value from working with academia, from our long-standing strategic partnership with the University of Huddersfield to close involvement in the UK Rail Research and Innovation Network (UKRRIN). Indeed, UKRRIN is a great vehicle for accelerating innovation in the rail sector, bringing together universities and industrial partners, including SMEs. The inerter/ ETAB journey I mentioned before is only one of its many successes. But are we collectively (public and private funders) using UKRRIN enough? And how can we strengthen it to deliver even more value?

And let’s not forget international collaborations. Whether it’s the World Congress of Rail Research, or bilateral collaborations driven by common challenges and priorities, these can accelerate progress and make research funding go further.

My final thought is that research and innovation communities should celebrate success more robustly. Very often, there is a focus on the negative, and, of course, anyone that works in research and innovation (and not just in rail!) will face many hurdles and failures. But what about all the innovations that happen? There are plenty of new solutions that get adopted and become a new practice, making a big difference on our railway.

Since 2013, when we started to actively focus on facilitating and monitoring implementation of RSSB most successful research outputs, 25 per cent of these have been fully implemented, with an additional 42 per cent at least partially implemented. These are great results on which to build and do even better.

Recent successes include the revised freight gauges (W10 and W12) starting to unlock easier network access for modern freight wagons; data-driven tools informing operations and driver competency; and we are now in the second autumn with variable rate sanders in use on two fleets. All of these successes have been made possible because of commitments and passion from across the industry.

So, my wish is for rail reform to strengthen this commitment and passion with a clear and strong focus on the importance of innovation and of the research and collaboration that underpins it.

We need a balanced research portfolio

Kevin Bonanno, Director of Rail at Telent Technology Services, believes that innovation is a mindset and the sector must shift attitudes and embrace change.

UK Rail is well funded – compared to other sectors, we’re in a strong position. I know it doesn’t feel like it right now, with the current Control Period being challenging for many in the supply chain, but the funding constraints we face won’t be resolved by asking for more. There’s no more money coming.

Our railway is amazing and, after 200 years, is rightly being celebrated. But it is not as resilient or efficient as it needs to be and, together, we must tackle these challenges within the funding we already have.

That’s why I see today’s funding constraints as an opportunity to do things differently. We need to innovate to maintain safety and quality, while improving outcomes for passengers, freight and funders. And we must enable the supply chain to do more of what made the railways worth celebrating over the last 200 years.

At the same time, we need to make a cultural shift. Infrastructure owners should define the outcomes needed, rather than specifying every last detail, and then trust the supply chain to deliver those outcomes. That will be uncomfortable for many, but the UK’s Rail supply chain is capable and ready to take up the challenge.

Moving to an output-driven form of contracting will be difficult for procurement teams – how do you measure one bid versus another? But specifying exactly what

a finished product will be does not invite innovation, doesn’t yield the best price, and doesn’t result in a minimum viable product. If we don’t address the way our industry procures and move away from “best price = best value” thinking, we won’t solve UK Rail’s challenges. Traditional procurement processes stifle innovation, increase cost and prevent different ways of working from being adopted.

We need to make a cultural shift and embrace feeling uncomfortable

Over-specifying is a form of risk aversion, understandable in a safety-critical industry. But leaders – whether in infrastructure owners or in our own organisations – must empower their teams to take calculated risks. Building a culture of innovation means moving away from being risk averse, reducing the fear of failure and empowering individuals and teams to pursue success.

Through procurement – whether from infrastructure owners to us, or us to our suppliers – we need to work together more openly, earlier, and more closely. Early Contractor Involvement (ECI) must be used more widely. Investing in supply chain engagement before issuing a specification, scope or ITT will return significantly improved outcomes – on safety, time,

cost and quality – and will enable different approaches and minimal viable solutions to be explored.

The supply chain will also need to embrace this approach and not hold back its best ideas for the competitive process. Only together can we drive real change.

But I must be clear, when I talk about ECI, I don’t mean Requests for Information (RFI), which have a reputation of being free market consultancy exercises that check the ECI box. They have their place, but they do not facilitate meaningful early engagement.

ECI can remove risk, create a forum to innovate and working differently, as well as drive a change in approach to risk within traditional procurement processes. This is how we’ll get better results.

The smartest people are not in our organisations, or our customer’s, or our suppliers’ organisations –they’re in our collective organisations.

If we don’t collaborate, how will we develop the solutions needed for the industry, passengers, freight and, ultimately, what the Government and the Treasury need us to do?

Together, let’s focus on what needs to be achieved and not how. Let’s empower our teams to take calculated risks. Let’s celebrate success, something we don’t do often enough.

And let’s also celebrate failure, because it’s an opportunity to learn. Failure is a part of the journey to doing things differently and being better. Let’s not forgot how quickly and collectively we adapted during Covid. That proved change is possible in rail and that it can happen at pace, if we work together.

Innovation does not have to be invention, it’s about using what we already have

Building on the theme that the smartest people aren’t always in our organisations, they aren’t always in our sector either. So, let’s bring people in from different sectors. We need to learn from what they’ve already done. Not everyone needs 20 years’ experience in rail to make a difference.

On one project, we had a team full of railway professionals. To avoid repeating past mistakes and to close out strongly, we brought in a Project Manager from outside the sector. They came from a high-assurance background, so still aligned with rail’s governance needs, but without the inhibitions we’d developed over years in the industry.

And the first thing they did, which should be a core skill for anyone, was to build a relationship with the customer. Something that our team hadn’t done, as they were focused on the specification, project challenges and contract clauses.

Hiring from outside of rail is important. Normally, we like to promote from within and build experiences, but we must also look outwards. We need to step out of our comfort zone and embrace ‘different’, even if it feels uncomfortable. Taking the easy option isn’t always the right thing to do.

We often make decisions that feel safe and justifiable. But it’s hard to stand in front of an executive board, or any audience, and say something that makes us feel uncomfortable, because we might be wrong.

Yes, we might be, but if we’ve got a culture that embraces failure as a path to improvement, we should be celebrating – our organisations should be celebrating – the fact that we are trying to do things differently. Trying to enhance our organisations, the project, or the industry.

So, let’s embrace discomfort. Let’s bring in diversity, because diversity from other sectors makes it easier to innovate.

So, what else can we do? We can learn from what’s already been done. Aviation has done an amazing job of collecting data and then using it. UK rail has done a great job of collecting data and putting it into loads of different locations. Then, when needing to answer a challenge, we collect more data because we can’t find what we already have.

At Telent, we recently had outstanding success on a project where the brief I set my team was “you need to use existing data” and “you cannot create or buy more data”. They have done that, and they’ve done that working through an existing partner of Network Rail’s that already generates the data that we needed.

As a result, we’re out on track 80 per cent less than before, using tools that already existed. This is true innovation. This is doing things differently. This is challenging normal ways of working, and it was uncomfortable to start with. We have celebrated this and shared what the team has achieved widely.

Innovation does not have to be invention. In this case, it was about combining what exists today, using what we already have, to drive better safety, time and financial outcomes.

Culture is key. To build innovative organisations, we must empower everyone at every level. We can’t have parts of our organisations that are scared to say: “I know a better way of doing this”, or “can we try this?”

Celebrate failure when things don’t work, it’s how we learn. If you’re not failing, you’re not trying hard enough.

I don’t say this just to the supply chain, or to infrastructure owners, I say this to commercial teams as much as I would say it to procurement, engineering and delivery teams. We need those safe spaces. We need time within our working week to be able to stop and think. We need to try some pilot projects and work in a sandbox environment.

To Network Rail, I would say: “Embrace and trust your talented supply chain. Stop choosing ‘Proofs of Concept’-they only prove that something which already works in another sector can also work in rail. Instead, invest in trialling solutions that have defined outcomes upon success. Let’s do something and, when it works, roll it out. Don’t keep trying new things endlessly, hoping for something better.”

We must encourage collaboration and diversity, bringing together those with different backgrounds, people from outside rail, people from outside our projects. Bringing in individuals who will challenge us, who will ask “why are you doing it like that?”, is one of the most important ways to drive innovation. And it’s not a one-off – we must maintain that momentum, and that requires effort and commitment.

We must recognise and reward innovative thinking, and that doesn’t just mean financially. When we’re talking to our teams, we need to give them a chance to show off what they’re doing and celebrate that success and then share their success more widely. After all, success breeds success!

In summary, there is a real need for change. Innovation is an absolute necessity, so we can’t just beat our teams down and beat costs down to be successful and overcome rail’s challenges. We need to learn from other sectors and, most importantly, build that culture of innovation, within all our organisations.

If you’re not failing, you’re not trying hard enough

Innovations from Siemens Mobility will power the trains of the future, which the company is set to manufacture at its new £240 million UK factory.

While many companies in the railway industry supply chain are involved in innovation, they are often working on one or two innovations at a time. Any more would dilute resources and strain the budget.

However, that’s not a problem for a global technology company such as Siemens Mobility. With research and development laboratories and workshops in many locations around the world, and established businesses involved in train manufacture, signalling, electrification, passenger information systems and more, Siemens engineers are working on too many innovations to list here.

In the UK, the company has about 5,500 UK employees across more than 30 locations, with manufacturing facilities in Chippenham for signalling systems, Ashby de la Zouch for station and passenger information systems and Goole for trains.

Siemens Mobility is currently investing up to £240 million in its Goole Rail Village, bringing up to 1,000 new jobs to East Yorkshire and a further 1,700 in the supply chain, with a further £100 million in its state-of-the-art factory, digital engineering and R&D centre in Chippenham, moving from its current facility to the new site a few miles away.

In terms of innovation, Siemens Mobility invests approximately £20 million per annum in the UK in research and development (more than £100 million in the next five years). This investment is primarily to fund innovation that can help drive down rail costs.

As a measure of its success, Siemens Mobility supports a supply chain of SMEs worth over

£172 million in the UK, making a vital contribution to the industry’s ecosystem and the broader economy. In addition, 50 per cent of the Chippenham and Ashby manufacturing facilities’ production is exported, contributing to the country’s Gross Domestic Product.

The new Goole Rail Village is, as has been well publicised, manufacturing trains for London Underground’s Piccadilly line. Once all 94 trains have been completed, Siemens Mobility hopes to build trains for the Bakerloo line – with the Central and Waterloo & City lines to follow in the future, keeping production lines busy for years to come.

However, the Goole factory is also looking at developing other new train models. The UK is planning to phase out trains powered solely by diesel engines by 2040. Not only will this reduce carbon dioxide (CO₂) emissions, it will also save the country money, as trains that are partially or wholly powered by diesel are more expensive to operate in the long term.

Engineers at Siemens Mobility are also redefining railway electrification with their innovative Sicat SX technology, proving that sustainable rail infrastructure doesn’t have to come with prohibitive costs. This overhead line equipment, which

maintains tension for high-speed lines and has been used in Denmark, has longer span lengths and fewer poles and cantilevers – 10 compared with 14 in traditional systems – bringing down costs over the lifecycle.

This will work hand-in-hand with ‘discontinuous electrification’, with busy routes fully electrified while more lightly used lines, and those areas where electrification isn’t currently feasable, will be served by battery-operated trains that charge off the overhead line when it is present and run off onboard stored battery power in between.

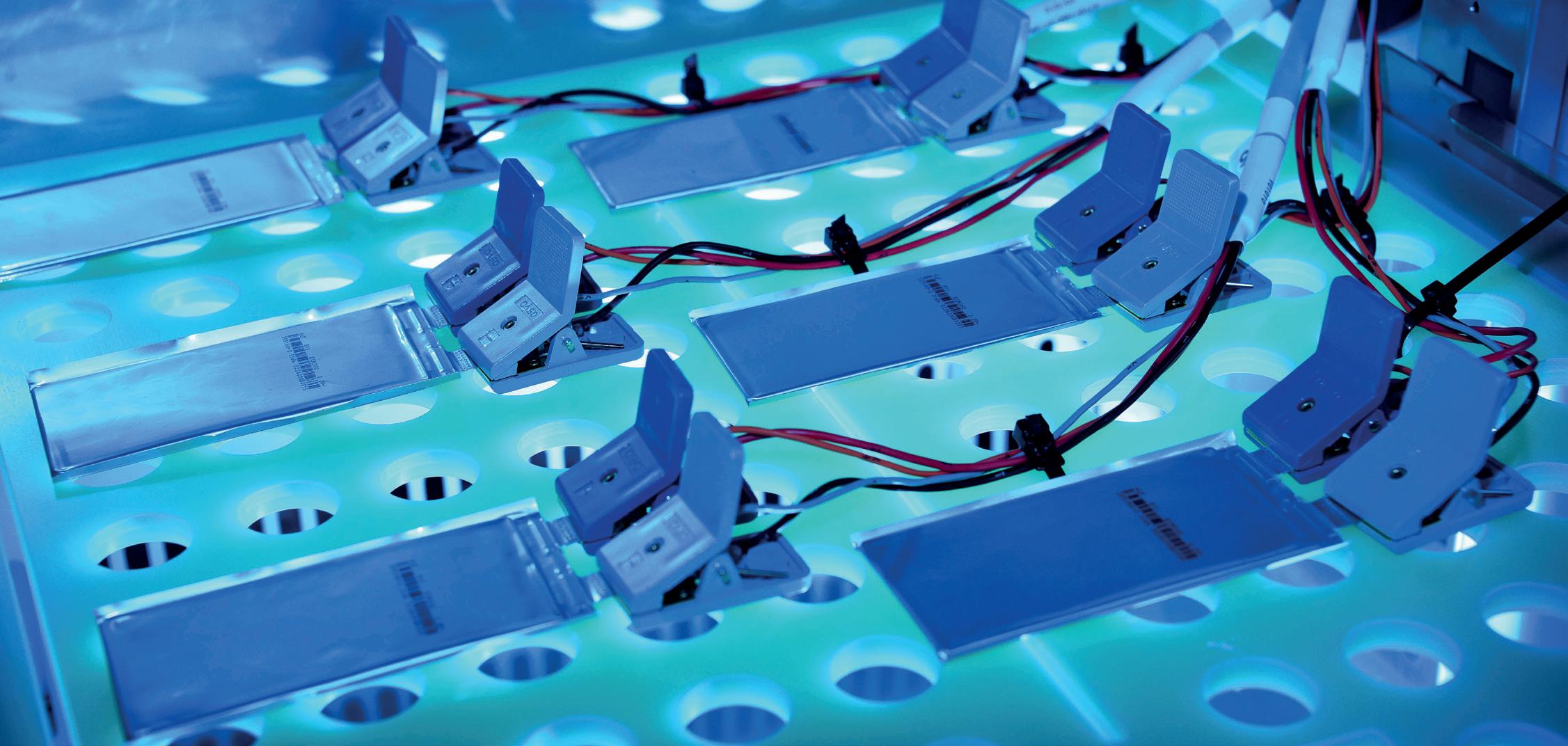

Siemens Mobility has conducted extensive modelling using advanced train performance simulation software to compare using battery bi-mode trains to running diesel or part-diesel powered trains. Desiro Verve battery bi-mode trains, which utilise lithium titanate oxide battery chemistry, can charge their batteries to full capacity in 20 minutes while moving along electrified sections of track or while stopped at stations. The battery technology means that only small sections of track (20-30 per cent) need to be electrified, saving on infrastructure and electrification spend.

In addition to the new battery bi-mode trains which are set to be manufactured at Goole, Siemen’s engineers have come up with the Rail Charging Converter (RCC). This can reduce the time taken to electrify a section of railway from seven years to as little as 18 months when compared with traditional methods, saving further time and cost.

RCCs connect to the local power grid using an 11kV charge, instead of using the high-powered 275/400kV electricity network. The first production

version was installed on Porterbrook’s test track at Long Marston earlier in 2025 and further installations are being planned.

A study of seven routes showed that battery-electric bi-mode trains, alongside electrifying small sections of track (discontinuous electrification) and installing RCCs, can save £3.5 billion and reduce CO₂ emissions by 12 million tonnes over 35 years.

Sambit Banerjee, Joint CEO for Siemens Mobility UK & Ireland, commented: “Britain should never have to buy a diesel passenger train again. Our battery trains, which we’d assemble in our new Goole factory in Yorkshire, can replace Britain’s ageing diesel trains without us having to electrify hundreds of miles more track in the next few years.

“So, on routes from Perth to Penzance, passengers could be travelling on clean, green battery-electric trains by the early 2030s. And the best thing is that this would save the country £3.5 billion over 35 years.”

Siemens Mobility’s continued efforts to transform the UK’s railways are not just about trains, or electrification. Recent analysis has identified as many as 40 rail routes across Britain that still operate with outdated mechanical or electro-mechanical signalling systems and where modular signalling systems would create operational savings which quickly exceed the capital costs.

Siemens Mobility’s modular signalling systems can reduce capital costs by 25 per cent when compared to traditional systems, so the initial investment is much lower. Moreover, they are cheaper to operate and maintain than the existing, outdated systems, cutting operational expenditure by approximately £4 million per route. These savings would cover the capital expenditure in around five years, so would therefore be self-funding in the medium term.

By bringing track and train together through our digital technology, we are helping to transform rail travel and transport

To improve reliability, a new advanced traffic management system, Digital Conflict Resolution, uses an algorithm that analyses the railway’s official timetable and compares it to data from the signalling system. It automatically spots ‘conflicts’, where two or more trains are likely to arrive somewhere at the same time and cause delays, and then it proposes a solution which a human signaller can then accept or reject.