The Spindles Moulders are mainly for the machining of the polishing, edge rounding, initialline,profile modeling of the surface of the wooden parts and the winding surface

The running speed of the arbor of this moulder is very high,and by transforming the way of connection ,you can have the prograde and backspin of the arbor to meet the using of the polishing knives in different directions. To extend the life of the machine, the highest running speed of this machine you can have is 8000r/min, we propose.

About how to operate this machine and how to take good care of this machine, you can get the details in every chapter, make sure to read and understand the details very carefully to know how to operate and maintain your machine. △Attention! The workers without any experience of operating this machines should not be allowed to operate this machine! Read the details first to learn how to operate to avoid the damagement caused by incorrect ways of using the machine! If there are the death or wound to the operators and the damagement of the spare parts-led by the incorrect ways of operating or incorrect ways of installing, charging and discharging, changing the parts of the machines ,or using non- standard knives,we are not responsible!

You can purchase the spare parts from the retailers ,or call to order from our company straight! When you are to order the spare parts of the machines, please provide us with the following information:

1, the date you bought the machine,and the production date of the machine. 2, the name and the model number of the machine.

3, the name of the accessories(if necessary, please tell us the parts to which the accessories belong)

4, the quantity of the accessories you are to purchase.

Should you have any feedback, just feel free to let us know right away, we will give you the response within two working days!

1. Before you startup this machine,please read the operating details carefully! Check if the earthing is ok or not! Check if every part is normal or not Check if it is bright and clear enough for you to operate the machine! Attention: (the operators must be trained very strictly before they start to use this machine,also,they are advised to read this instruction sheet carefully too).

2. This machine is with the high running speed, after the strict inspection, it is with the good performance of dynamic balancing, if you change the dynamic balancing of the running parts, it will cause big librication,and the long-time shading will lead to the tiring of the machine ,which will cause the damagement of the parts and brings the accident!

3. During your operating this machine,you must have:three tightens: close-fitting clothes, closewaist, tight sleeve; three no: no jewelry, no tie, no glove; one attention: be sure to remember to protect your two bright eyes.

4. Before startup the machine, please pay some attention to the warning stickers on the machine.

5. Check the running directions of the main shaft and the arbor.

6. During the operating, please do not try to be close to the running parts or touch or move the running parts of the machine, also, you are not allow to clean the shatter during the working of the machine. If you want to move or adjust the machine or to clean the shatter, please cut the power first, you are not allowed to do what you want to do till all of the running parts stop running completely!

7. Some time later you use the machine,the arbor will be dull, then you need to change to use the new ones, or try to grind the knife !

8. Do not try to use the machine over its working ability so as to avoid the danger and the damagement to the parts of the machine.

9. If you find something wrong, stop the machine at once to check to find out what wrong is with it!

10. When you leave or the power is stopped, please remember to turn off the main switch of the power.

11. The operators are not allowed to leave until all of the running parts stop running completely.

一,Thetransitionofthe machine:

When you transit the machine ,please be sure to it keep balance.

二,The markingoftheappearanceofthe machineand the parts of the machine:

1, flange 2, check lock lever 3, handle. 4, power switch 5, controlling panel

6, faffle 7, machine stand 8, front door

9, the main shaft (A) 10,the workbench (B)

( 一 )

11,the upwards and downwards supporting of the main shaft (C) 12,motor

13, hold-down plate of the belt

14,hold-down bolts of the belt

15,the boosting pole for the tightening of the belt. 16,the set for adjusting the belt (E)

( 二 )

一、Notice for operating:

1,The operator must be trained to mast the operating rules of this machine

2,Before you startup this machine,make sure to check if the the tighten bolt for the knive impacting iron comes unfastened or not ,or if the screw thread if broken ,please change to use the new tighten bolt for the knive impacting iron.

3,When you are to repairing this machine ,of you are not using it,be sure to remember to cut the power off.

4,keep the machine clean every day! And keep the running parts of the machine lubricate every day !Before you startup the machine,please make sure that there are no the spanner, bolts and something else left on the machine !Check if the knives ,main shaft,upward- downward hand wheel,backup plate and something else are tightened or not to make sure the machine will work normally to ensure the safety of the operators.

5,When you use the allotypic knives,make sure that the overhang ,the tightening grade, and the equilibrium condition meet the safety requirements.

6,When you operate this machine,you must be concentrating! 7,The machine should be managed by the specific operators !

8,When you machine this small workpiece,please choose the proper jig!

9,Only when the running speed of the main shaft meet the standard running speed can you start machining your workpiece!

10,The running parts like the main shaft outer sleeve,upward-down leadscrew and so on should be appened the lube to keep the running parts of the machine lubricate,The main shaft of this machine is hight running part,We have already appened the high-quality lube into the axletree of the main shaft when we install this machine,it meet the requirements of the users due to the test we have the machine had.

11,After you take out the knife,be sure to take out the knives pressing iron or tighten it to avoid the throwing out of the knife pressing iron when the machine starts suddenly.(as per picture shows)

12,when you install the engraving head ,there should be a distance of 20mm between the engraving head and the workbench ,the longest distance should not be over 45mim ,this is to avoid the libration or the rupture of the main shaft .(as per picture shows)

13,The shatter from the work can make the floor slippery ,also there will be the shatter in the machine,be sure to remember to clean it to avoid the accident!

14,During your working,when you encounter the danger,you have to have an emergency stop ,just turn the power switch on the controlling panel to the“0” site !

15,During your working ,if the power stops suddenly ,you should turn of the power switch to avoid the sudden wound which might led by sudden running of the machine after the power comes to you!

1,The selection and maintaining of the belt: a, use “A” form triangle belt!

b,if there are several belts work together, you should not use the old and new belt together !If you find one or two of them break ,change all of the belt and use the new belts right away!

2, keep the proper tightness of the belts is the important factor which affects the life of the main shaft and the belts:

2.1: too much tightness:

a, the burthen of the main axletree increases, the temperature is too high, there will be the big noise when very serious.

b, the shaft end become flexible,the libration becomes stronger. c, the belt is stretched too early.

2.2: too little tightness:

a, the belt becomes too loose,the rated butthen reduces

b, the main shaft and the motor do not stop at the same time when brake ,the belt will be skidded and then damaged.

Usually ,the depth of 15mm is all right when you press the belt with your thumb!

Attention:

1,The standard axial diameter of the main shaft of this Spindles Moulder is 35mm ,the biggest diameter of the knives you use is 120mm ,H=90mm .if you use the knive whose diameter is bigger than 90mm,please remember to turn down the speed to 8000r!If you need to increase the diameter of the knives ,or highten the hight of the knives.you need to order relevant main shaft from our company ,if you repair the knives or the main shaft by yourself and cause any damagement ,we are not responsible!

2,Since the running speed of this machine is too high,and inear velocity is too long ,you are not allowed to use the sawtooth blade ,if you use the sawtooth blade and which causes any.damagement,we are not responsible!

Then installation and adjusting of the machine:

1,The connecting of the dust collector:

There is a Dusting Collecting Hole in the workbench of this machine, which is connected with the Dust Collector through the Dust Collecting Soft Pipe ,You should startup the Dust Collector first before you start operating this machine.(But we do not provide you with the Dust Collector and the Dust Collecting Soft Pipe when you buy this machine)

2,The upward-downward adjusting of the knive shaft:Refer to the picture (picture 十)According to your requirements of machining ,you should have the upward-downward adjusting of the knife shaft.

Loosen the main shaft tightening handle (4)at the side-face ,turn the upwarddownward hand wheel(8),then you finish the upwards and downwards ofthe knife shaft,after the adjust ,tighten the handle.

Attention:during the upwards and downwards,there is a spacing screw which is use for controlling the upward height of the knive shaft,when the knife shaft

(十) upwards some height,the screw will resist the outer sleeve of the main shaft ,then the main shaft stops upwarding.The height of the screw can be adjusted according to your requirement.You can not take away this screw when it works,otherwise,you might be wound when the knife shaft upwards hight to the top!As per(picture 十一)shows.

As per(picture十二)shows.

Loosen the two tightening bolts(B1)in the master plate(B2)first ,then move the mast plate to the necessary site ,be sure to remember to control the cutting depth,then tighten up the two bolts after the adjusting.

Attention during the working.there will be a lot of Shiver which might stick to the surface of the accessories especially the surface of the outer-wear and the sleeve when the main shaft is upwarding and downwarding very slowly .you can append some kerosene or diesel oil ,turn the upward-downward hand wheel to make the main shaft upward and downward for times till it work normally.then clean the corrosive water.If you hear the unnormal noise from the axletree of the main shaft ,change it at once, otherwise.the sleeve of the main shaft will disform some time later.

The installation and adjusting of the machine

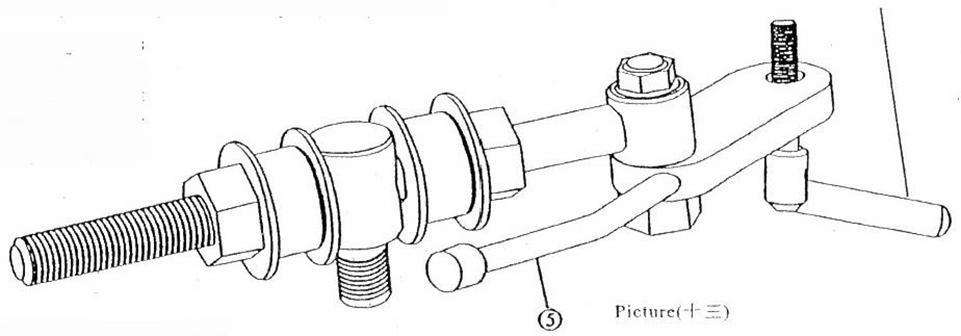

4, The changing of the belt and the adjusting of the tightness :as per(十三)shows:

Some time later after the machine works ,the belt might needs adjusting ,loosen the belt tensioning boosting pole(7),cock the belt tensioning push and pull pole(E5),adjust the bolts(E1)at the two ends of the leadscrew(E4),turn the bolts clockwisely (E1),then the belt will be tensioned :turn the bolt(E1) anticlockwisely,then the belt will be loosened.

5, The machining of the profile modelling of the incurvate workpiece:

Unbolt the mast plate of this machine, you can start the machining of the profile modelling with support from the mast plate ,hold the workpiece that has been machined with the Workpiece Holding Set,the Profile Modelling will be ok slowly when the Master Plate runs.During the machining,make sure the the Master Plate and the Profile Modelling Base joins each other very closely!

When you change the belt.what you need to do first is to loosen The Belt Tightening Boosting Pole (7), then pull the Tightening Pushing and Pulling Pole(B5)to loosen the old belt ,and then fix the new belt ofthe same model!

Screw down the Tightening Handle(4)of the main shaft first to fix the main shaft,loosen the tightening bolt(A25)in the Engraving Head .take away the Insuring Pressing Cover (A24). Pushing Broach Ring(A23). then you can take away the Engraving Head(E22).If you have to change the knife,you can fit on the knife you want to fix,after this,you can then fix the Pushing Broach Ring(A23),Insuring Pressing Cover(A24). tightening bolt(A25).If you need to adjust the height of the knives,you can fix the Pushing Broach Ring(A23)under the knives,if there is the Main Shaft librates after you fit the knives on it. then you need to get the knife you change the dynamic balancing.

DANGEROUS!

1.The tightness of the two belt must be the same! Otherwise,the machine will librate !

2.when you cut too much.you must run the two Belt at the same time!

3.Before you work,you must screw down the tightening bolts to avoid the running out of the Insuring Pressing Cover.

The installation and adjusting of the machine 7 , The changing of the knives:(as十shows)

Attention:the length, thickness, weight of the Three knives you are to fix must be the same!

Loosen the Tightening Bolts(A11)that tighten the Knives Pressing Blade(A10) with the Inner hexagon spanner.

Take away the old knives, then fix the new knives of the same specification.

After the knives are fixed and tightened, please screw down theTightening Bolts for the Knives Pressing Blade

DANGER!! You are not allowed to hit the main shaft with the hammer or anything else!

1.The running diameter can not be bigger than The running diameter 5mm of the knife body,otherwise the knives will break and wound somebody !

2.The length of the knives must be the same as Length of Knives Pressing Blade ,also ,the Knives Pressing Blade Tighten Bolts must be strongly tighten the knives, otherwise , the knives will run out and wound somebody As per 十 七shòws

3,Before you change the knives ,you must cut of the power for the machine first!

4,Make sure to tighten the Knives Pressing Blade Tightening Bolts !When the bolts are stripped ,or you can not screw down the bolts because of the breaking of the screw thread,please change and use the new bolts right away !

Picture(十七)

Knives Knives Pressing Blade

Wrong (The length of the k ife is not the same as the length of the Knife Pressing B.ade,and the Tithgening Bo'ts do not tighten the knife)

8, The adjusting of the positive and negative direction of the bit:

Loosen the Tightening Bolts first,then take away the Insuring Pressing Cover and the Pushing Broach Ring.then turn the bit to the original negative direction can be all right.

Phenomenon

Difficult for the main shaft 1o upward and downward

The libration and the noise

The bits get downslide

After changing the axletree. the main shaft gets heating

The reason of the malfunction

The wood ash enters the sleeveand lock it

1,The assembled bitsare not balance

A,The knife pressing bladeand theknife are in different specification

C,The knives are not fixed properly.

2.The lubrication of the axletree is bad of the axletree is broken.

1,There is the clearance between the upwarddownward clearance when working

2,The handwheel bolts are not screwed down

3,The main shaft sleeve is not tighened

1,The model of the axletree is wrong

Ways of solving

Loosen the tightening bolts in the sleeve base of the main shaft and turn the upward-downward handwheel for times,and clean most of the wood ash,then append some kerosene.

For the same bit,you should use the knife pressing blade and the knives whose specification is the same,

Fix the knives again(please refer to installaion and adjusting in chapter

Append some lube or change the broken axleree

When you adjust the height of the knife, you should obey this rule,first downwards then downwards eliminate the clearance

Tighten the bolts

Tighten the main shaft sleeve after the adjusting every time

Choose to use the correct axleree with the correct mode]

2,The fixing of the axletree is not reasonable Fix the axletree correctly

3,There is the eyewinker enters the axletree during your fixing the axletree Keep the axletree clean when you fix it.