4 minute read

Recycling: EME

� Pic 1. Glass bottles ready to be put back into the recycling process.

Preheating solutions to improve energy effi ciency in glass plants

With customer interest in energy-saving equipment increasing, the pressure is on suppliers to provide sustainable solutions. EME plans to reduce CO2 emissions and increase energy effi ciency with its investments into batch and cullet preheating systems.

The latest data shows that the majority of glass produced in Europe is recycled.

This result has been obtained through awareness campaigns and strict laws that require manufacturers, and customers, to take responsibility for recycling product packages.

The recycling rate in Germany is high The cullet addition into a melting furnace can be up to 60% for fl int glass and 90% for green glass. The country has policies in place regarding waste management, such as the Packaging Ordinance that obliges manufacturers to collect all their product packages after consumers have used them.

Another legislation, the Closed Substance Cycle and Waste Management Act, demands that manufacturers avoid producing any waste. If waste is inevitable it must be recycled and, when recycling is not an option, it must be disposed of responsibly. Similar regulations are in place in many countries around Europe and the world.

Glass: the material of choice

Glass has retained its position as the most recycled closed-loop packaging material in the world. For new generations, glass will be the material of choice to achieve a more sustainable world (Pic 1).

Advantages of recycled glass

� One kilogram of cullet saves around 1.2 kg of raw materials such as sand, sodium carbonate and limestone. Therefore, recycled glass helps the world to conserve rare, fi nite and renewable resources - diminishing glassmakers’ need for raw material. � As recycled glass has a lower melting temperature, it reduces the production energy consumption; glassmaking feed mixtures with 10% of cullet use 3% less energy. � Glass made from recycled glass reduces air pollution by 20% (it also decreases the exhaust gas concentration) and water pollution by 50% compared to glass made from raw materials. � The reduction in CO2 emissions means that glassmakers need fewer CO2 certifi cates. � Used glass can be reprocessed into new glass products without any quality loss. � Glass has an unlimited lifetime, meaning that it can be melted and recycled infi nitely. � It is a sustainable, environmentally friendly material.

� Limitless availability: glass is abundant. � Glass manufacturers can get it from production scrap; it can be obtained from collection and recycling systems, the construction industry (windows, insulation material, greenhouses), the automotive industry and many more places (screen, cooking hobs, lamps, etc.). � Recycled glass is cheaper than raw materials such as sand, soda, lime, etc and provides a higher melting capacity. � The use of recycled glass as a raw material allows heat recovery in a cullet preheater.

Energy efficiency

EME, a member of the Sorg Group, is improving its systems with energy-saving waste-heat recovery. The heat transfer at combined batch and cullet preheaters can be done by direct or indirect contact between the raw material and the hot flue gases. Flue gases are composed of vapour, small particles, heavy metals, acidic gases and carbon dioxide, amongst other combustion products.

EME created technology that pushes energy efficiency even further, such as the BATCH3 system. The company has also invested in developing technologies that help glassmakers reduce CO2 emissions and increase glass pull.

CO2 reduction

Another trend in the industry is the imperative reduction of CO2 emissions. Although the use of recycled glass reduces greenhouse gas emissions during the manufacturing of a container, the glassmaking process naturally produces carbon dioxide, emitted throughout the melting process (that uses fuel) and during the decomposition of carbonates. As 75% of the CO2 released is due to the use of fossil fuel to heat furnaces, the decrease in the emission rates is highly dependent on energy efficiency increase.

EME’s 100 years of expertise allows the company to create innovative solutions that will contribute to a more competitive industry. The company is continuously investing in the research and development of highly efficient equipment that can reduce energy consumption, as well as particles and CO2 emissions.

Tackling energy waste

In the fight against energy waste and CO2 emissions, the industry can integrate EME’s solutions that include batch and cullet delivery and storage, transport, management, preheating and charging technologies, as well as cullet treatment.

A specialist in batch preparation plants, cullet handling equipment and batch charging technology for the glass industry, EME is always attentive to industry trends. The company’s goals are to provide a seamless service, problemfree equipment and comprehensive solutions for the glass sector.

Don’t get left behind

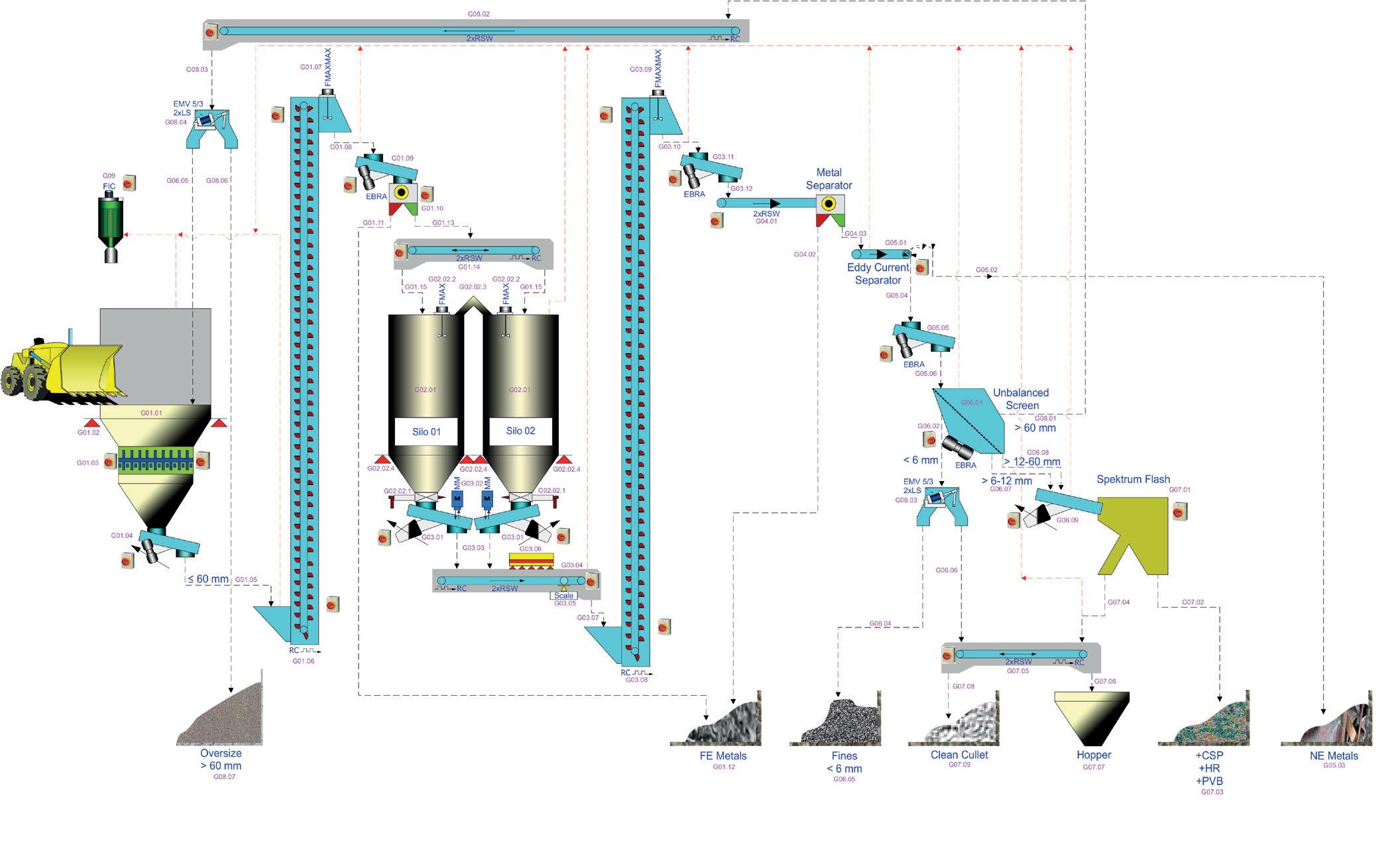

EME has been delivering full planning, execution, and commissioning of internal cold and hot cullet return installation and cullet treatment for over a century. EME’s solutions include dosing, weighing, transport, sorting (magnets, CSP and colour sorting), crushing, dedusting and screening.

The company also supplies preheaters for cullet and raw materials, helping to reduce energy use, and special cullet and batch chargers with doghouse seal. With the demand for more sustainable solutions, glass recycling is more important than ever.

Cullet treatment equipment is an investment in your company’s image and the planet’s future (pic 2). �

*EME GmbH Erkelenz, Germany www.eme.de

� Pic 2. Flow Diagram - Recycling Process.