FREEDOM FROM THE ORDINARY

LIBERTY DIVERSIFIED INTERNATIONAL

Liberty Diversified International (LDI) is a 100 + year-old, family-owned company.

Headquartered in Minneapolis, Minnesota, LDI has grown from a small family business to a growing family full of companies that operate within the Plastics, Paper, Packaging, and Furniture industries. As one of the largest privately held companies in the Midwest, we employ nearly 2,000 employees in eighteen facilities within ten states and Mexico.

LIBERTY PLASTICS

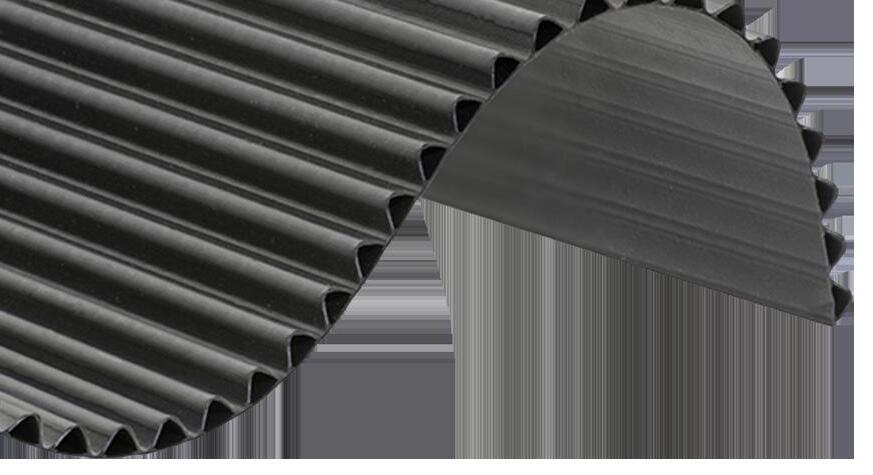

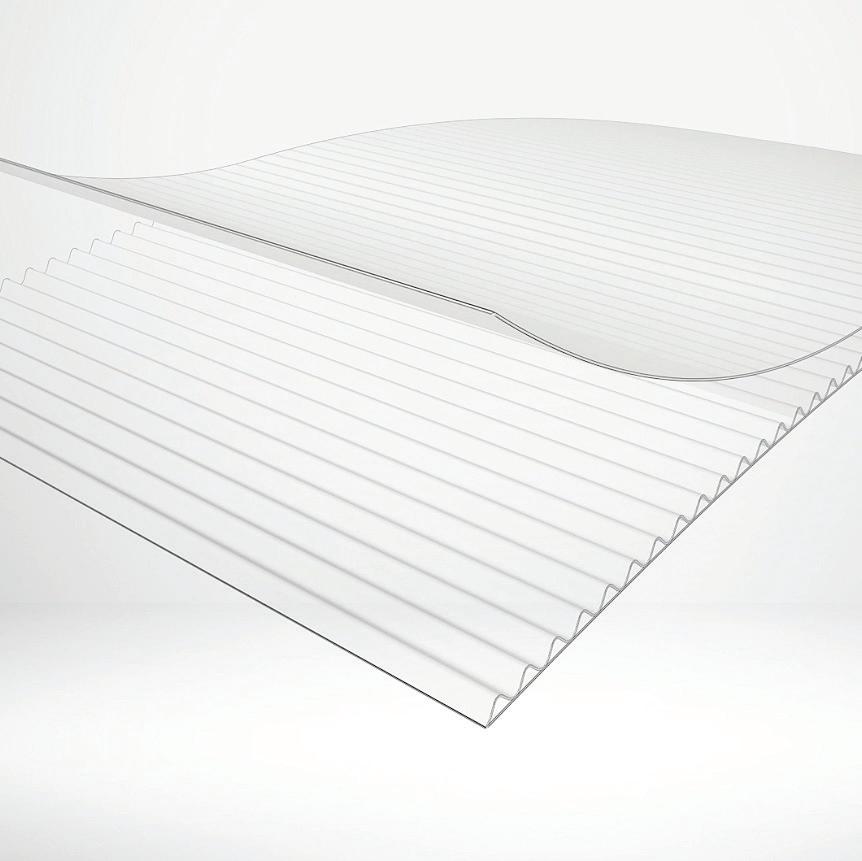

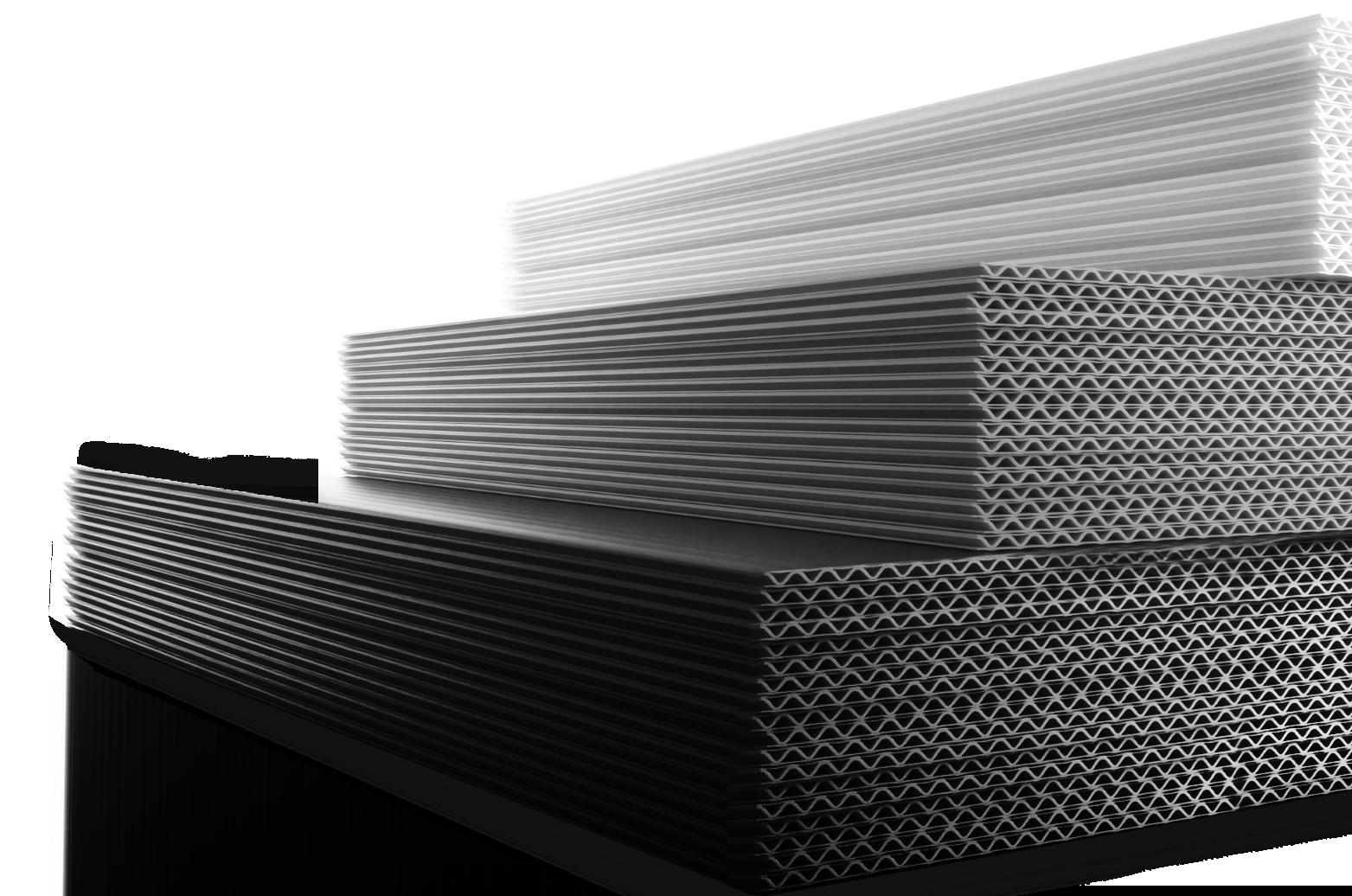

Liberty Plastics offers superior corrugated plastic that stands apart from the ordinary. Our high-performance Wave-Core™ plastic delivers a multitude of benefits from flexibility to reusability – and the liberty for nearly endless applications.

CORPORATE HEADQUARTERS

Golden Valley, MN

MANUFACTURING

FACILITY

Baldwyn, MS

Ride the Wave to New Possibilities

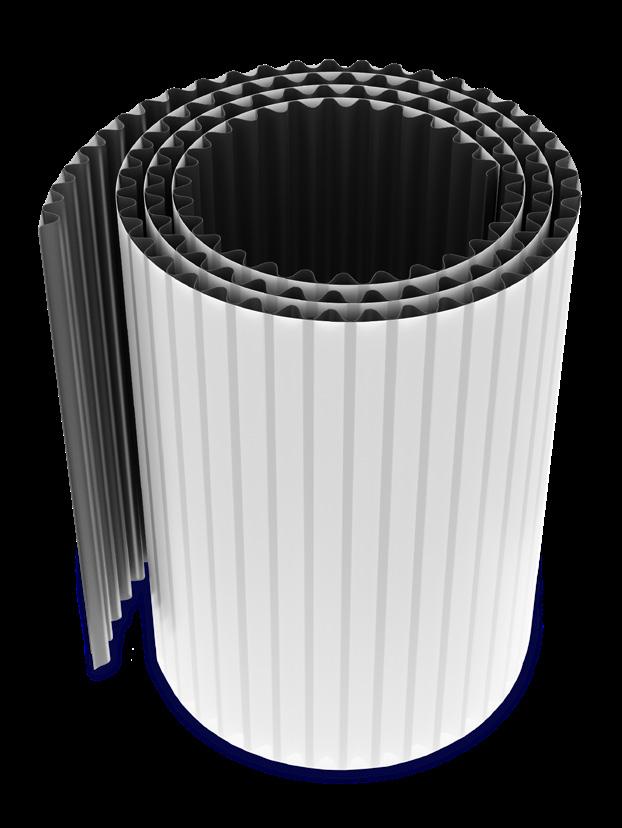

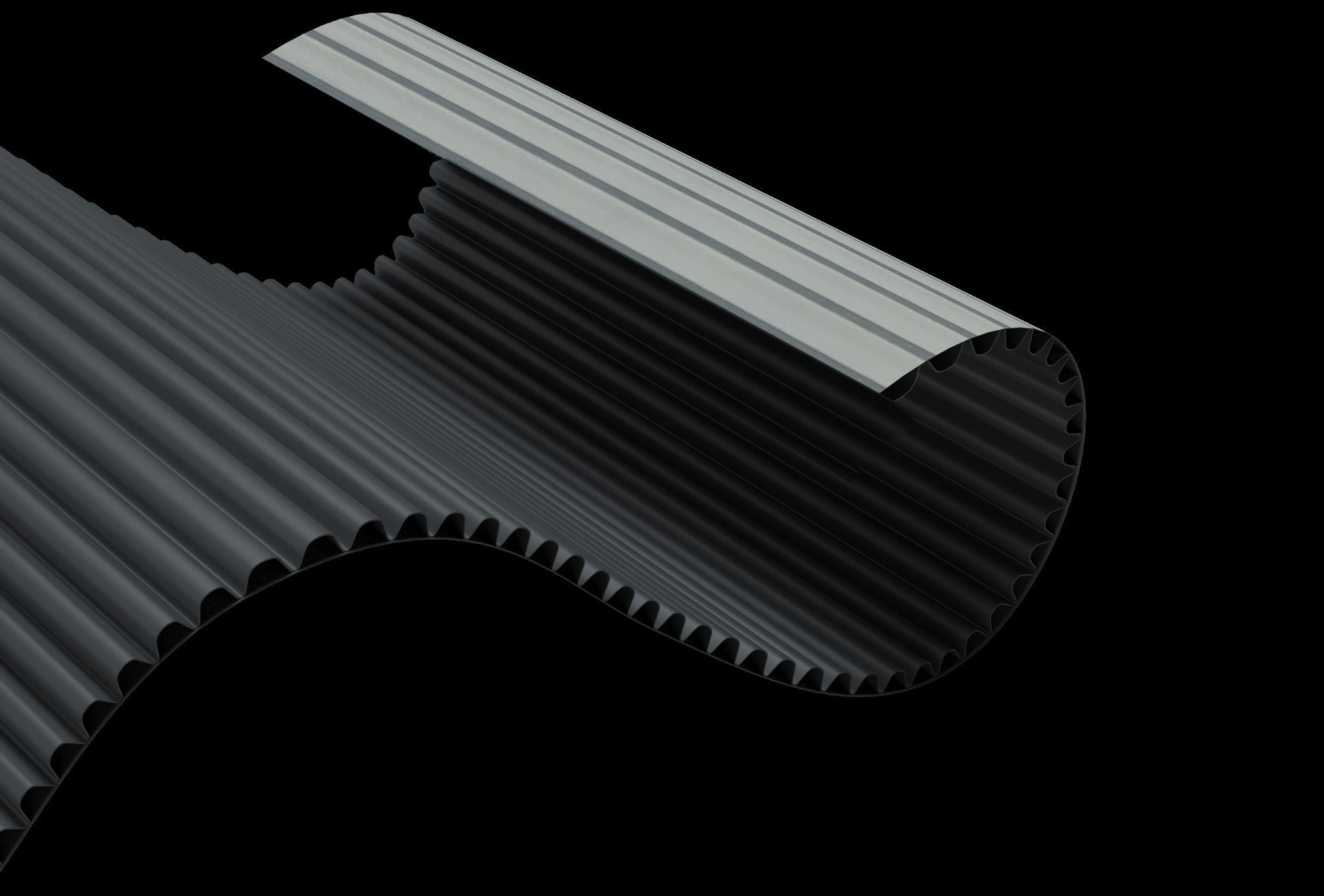

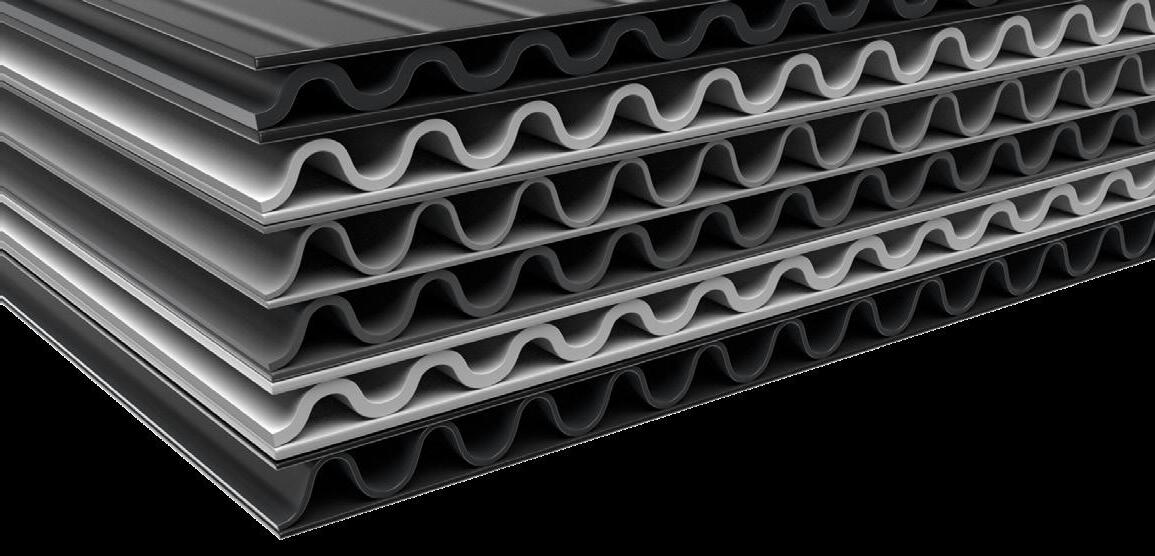

Wave-Core™ corrugated plastic stands apart. It packs all the standard functionality you need, plus the ability to roll, flex and bend. Unmatched in durability, it’s the superior choice for any application. Ride the wave to new possibilities. Wave-Core™ . Three distinct

Corrugated Plastic That Stands Apart

Wave-Core™ is lightweight, made entirely of HDPE, and is impact, moisture and temperature resistant. It’s a sustainable solution that is ultimately, easily recycled. Available in double-layer and triple-layer sheets and rolls.

Impact Resistant

Easily Recycled

Moisture Resistant

Temperature Resistant

Industries & Applications

• Manufacturing

• Agrigulture

• Printing

• Material Handling & Storage

• Building & Construction

• Cable, Wire, Coil & Pipe

• Distribution & Transportation

• Food & Beverage

• Bio-Chemical

The Dif ference

FEATURES

WATERPROOF

FLEXIBLE

ROLLABLE

REUSABLE

RECYCLABLE

By The Numbers

FLEX STANDARD ULTRA

• Density (g/m2): 530-730

• Utility grade flexible material

• Uses: Flexible packaging, surface protection, bulk packaging, flexible print media, laminations, underlayment.

• Types: Double-Layer Sheets & Rolls

• Density (g/m2): 780-1070

• Stong, durable material

• Uses: High-value packaging, internal components, reusable/returnable packaging, print media & graphics, point-of-purchase displays, large sheeting needs, totes, boxes, bins.

• Types: Triple-Layer Sheets & Rolls

• Density (g/m2): 1460-2440

• Rigid, sturdy, lightweight material

• Uses: Packaging reinforcement, partitions and dividers, paneling, slip sheets, engineered parts, laminations.

• Types: Triple-Layer Sheets

CONSTRUCTION

FLEX

Double-Layer 535 g/m2

Double-Layer (Flame Retardant) 535 g/m2

Double-Layer (FDA Compliant)

Double-Layer

Double-Layer (Flame Retardant)

535 g/m2

730 g/m2

730 g/m2

Double-Layer (FDA Compliant) 730 g/m2

Protective wrap for piping and pipe edges.

Protection for high-value film and fibers.

Separation/Dunnage for food and produce.

Internal and external protection for trailers and recreational vehicles.

Temporary contruction flooring protection.

Slip sheeting for food conveyance.

STANDARD

High-value packaging, internal components, reusable/returnable packaging, print media & graphics, point-of-purchase displays, large sheeting needs, totes, boxes, bins.

CONSTRUCTION DENSITY SHEETS ROLLS USE CASE EXAMPLES

Triple-Layer

applications: boxes bins and totes. Triple-Layer

Protection in construction projects.

Protection for landscaping stones, signage and printing applications.

for component FR parts.

All Wave-Core™ Products Are 4mm Thick

ULTRA

Packaging reinforcement, partitions and dividers, paneling, slip sheets, engineered parts, laminations.

CONSTRUCTION

Triple-Layer 1460 g/m2

Triple-Layer (Flame Retardant) 1460 g/m2

Triple-Layer (FDA Compliant) 1460 g/m2

Triple-Layer 1950 g/m2

Die-cut component parts.

Commercial component applications.

Protection and transport for food and beverage.

Protection for landscaping stones.

Triple-Layer (Flame Retardant) 1950 g/m2 Sheet protection for high-value machinery.

Triple-Layer (FDA Compliant) 1950 g/m2

Triple-Layer

All Wave-Core™ Products Are 4mm Thick

Protection for biological products.

Custom Capabilities

• Die-Cutting

• Sonic Welding

• Fasteners & Wire Reinforcement

• Printing & Embossing

• FDA Compliant Resin

• Non-Skid Coating

• Color & Logo Customization

• Prototype Design & Fabrication

• A Variety of Resin & Additive Formulations

• Flame Retardant Material

Sustainability

We take great efforts to bring awareness to our customers that our HDPE plastics and products are recyclable and reusable. Our reusable packaging systems eliminate the need for disposable packaging, and provide better product protection with less materials, thus reducing packaging materials, product damage and losses associated with it. During the manufacturing process, we take measures to reduce, reuse, and recycle plastic waste through continuous sustainability efforts.

Stone Manufacturer Solves Landscape Products Breakage

CHALLENGE

A leading manufacturer of concrete and landscaping products was experiencing problems with damage to their high-value stone during shipping and storage.

built-in top flaps

die-cut handles

SOLUTION

The Liberty Plastics design team worked with the client to create an efficient new packaging solution using our Wave-Core™ corrugated plastic.