About this Report

This report is the sustainable development report of Pylon Technologies Co., Ltd. (hereinafter referred to as "Pylontech" or "the Company"), which describes Pylontech's management practices and performance in environmental, social and corporate governance in 2024. The aim is to have frank communication with various stakeholders on relevant content and respond to their concerns on various issues.

Organizational scope

The report covers Pylon Technologies Co., Ltd. and its subsidiaries. Unless otherwise specified, the scope of the consolidated financial statements for the same period as the company is consistent.

Time scope

The reporting period is from January 1, 2024 to December 31, 2024. In order to improve the completeness of the report, some information in the report may exceed the aforementioned range.

Reporting period

This report is released once a year, simultaneously with the company's annual report and the specific release time is subject to the current year.

Compilation basis

This report is based on the Guidelines No. 14 of Shanghai Stock Exchange for Self-Regulation of Listed Companies—Sustainability Report (Trial) (hereinafter referred to as the Guidelines) and the preparation process complies with the Global Reporting Initiative's (GRI) Sustainable Development Reporting Standards (2021 Edition) (hereinafter referred to as the "GRI Standards"), while also referencing the United Nations Sustainable Development Goals (SDGs) and key issues of mainstream ESG ratings.

Information and data sources

The information and data disclosed in this report are sourced from official documents, statistical reports and periodic reports within Pylontech and its subsidiaries. Unless otherwise specified, all financial information in this report is presented in Chinese yuan.

Report Confirmation and Disclaimer

The content of this report has been reviewed by the board of directors and confirmed that there are no false records, misleading statements, or significant omissions. However, this report contains some forwardlooking statements and due to the influence of external variables, the future development results or trends implemented may differ from the relevant statements.

Report verification

This report has been independently verified by SGS. The verification statement is attached.

Report

acquisition and response

The Chinese and English versions of this report can be found and downloaded on the company's official website (https://www.pylontech.com.cn).

If you have any suggestions or opinions on this report, please contact the company:

Contact: Xu Chuang

Phone:+86-18018593038

E-mail:xu.chuang@pylontech.com.cn

Message from CEO

In 2024, the 20th anniversary of the release of the United Nations Global Compact (UNGC) Ten Principles on Environment, Social and Corporate Governance coincides with the 15th anniversary of Pylontech's deep cultivation in the energy storage field. At this historic moment, we officially join the UNGC and fully integrate the Ten Principles into our company's operations.

As an important force in promoting sustainable development, Pylontech has written "Liberating Your Energy Sustainably" into its corporate DNA, relying on vertically integrated R&D and manufacturing capabilities and a global service system to provide full scene energy storage solutions for new power systems. We not only provide safe, efficient and reliable products to safeguard the entire life-cycle of clean energy facilities, but also strive to build a sustainable development paradigm for energy transformation.

In the past and future, we will continue to improve our sustainable development plan: optimize every process of R&D and manufacturing, enhance the effectiveness and reliability of the entire product life-cycle and continuously improve the market competitiveness of our products. Inspire the potential of every employee and strive for our collective mission. Strengthen the environmental management system to ensure compliance, even beyond compliance. Accelerate the integration of sustainable procurement into internal governance, effectively prevent and control potential supply chain environmental, social and corporate governance risks. In addition, we will showcase our processes, goals and results through information disclosure and subject them to external audits to achieve visualization, verifiability and optimization of the sustainable development process. In the same year, we won the ESG Information Transparency Award from an international authoritative institution.

As the world moves towards sustainable development, Pylontech will always uphold the original intention of creating value for the world, proactively undertake the social responsibility that enterprises are expected to fulfill , work together with stakeholders, become a firm supporter of customer success and contribute to the sustainable development of the industry with concrete actions.

Mr. Tan Wen CEO of Pylon Technologies Co., Ltd.

Getting to Know Pylontech

Company Profile

Pylon Technologies Co., Ltd.was founded in 2009 and officially listed on the A-share Science and Technology Innovation Board (stock code: 688063) in 2020. As a specialized enterprise in the field of energy storage, Pylontech adheres to the mission of "Liberating Your Energy Sustainably" and focuses on providing energy storage products and solutions to global customers. With over ten years of technological accumulation and market development, Pylontech has achieved business layout in more than 90 countries and regions worldwide, continuously enhancing industry influence and consolidating competitive advantages.

Pylontech has long focused on the field of energy storage, vertically integrating the industry chain and mastering key technologies in the battery module, battery management system, system integration and other key links of the industry chain. The energy storage products and solutions developed and produced by Pylontech cover various scenarios such as households, industrial and commercial areas, new energy generation, data centers and communication base stations.

15+

Dedication to ESS

90+ 13+

2,000,000+

Global Deliveries Production Capacity Only for ESS ESS Globally Served

World's Leading

ESS Provider

Corporate Culture

Mission

Vision

To Energize Billions With Smarter Power

Values

Liberating Your Energy Sustainably Integrity, Responsibility, Accountability Cohesion, Devotion, Accomplishment

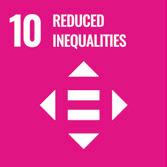

Business Layout

Pylontech actively promotes its global layout, covering multiple countries and regions such as North America and Europe and has established operating entities and production bases in key areas. While consolidating its existing advantageous market, Pylontech has customized and developed energy storage products that meet the needs of users in different countries and regions, achieving significant results.

Sustainability Management

Stakeholder Communication

The cooperation and support of stakeholders are important cornerstones for Pylontech to promote sustainable development practices. Pylontech attaches great importance to communication with stakeholders and has established diversified communication mechanisms for different groups. Through regular and irregular exchanges, it efficiently and comprehensively understands and collects the demands and expectations of all parties and is committed to establishing a cooperative relationship of mutual trust and win-win, providing strong support for sustainable development.

Double Materiality Assessment

• Assessment Process

In 2024, Pylontech has conducted materiality analyses of its sustainability issues in accordance with the Shanghai Stock Exchange's Guidelines, referring to the requirements of the Self-regulatory Guidelines for Listed Companies on the Shanghai Stock Exchange's Science and Technology Innovation Board No. 13- Preparation of Sustainable Development Reports for "issue materiality analyses" and referencing the European Financial Reporting Advisory Committee (EFRAG)'s European Sustainability Reporting Standards, the EFRAG's EFRAG IG 1: Materiality Assessment Implementation Guidance and the Global Sustainability Standards Board's Sustainability Reporting Standards 2021. The analyses has been carried out through four steps: analyses of Pylontech's business background, establishment of an issue list, double materiality assessment and review of assessment results.

Assessment of issue materiality

• Pylontech engages with stakeholders through a combination of regular and irregular methods and conducts a centralized stakeholder opinion survey every two years. In 2024, Pylontech engaged with 222 stakeholders through surveys, evaluating the severity of the impact (scale, scope, irremediable character) and the likelihood of the impact, and taking into account the opinions of internal and external experts to form an impact materiality matrix

• Conduct communication with 26 functional department managers of Pylontech through on-site interviews and surveys, evaluate from two dimensions: "likelihood of impact" and "the potential magnitude of financial effects" and refer to internal and external expert opinions to form a financial materiality matrix

Understand Pylontech's activities and business background

• Understand the competitive landscape of the industry and position Pylontech's sustainable development level within the industry

• Based on this year's policy trends, key concerns in capital market ratings, domestic and international sustainability disclosure standards and management practice requirements, understand the sustainable development background in which Pylontech operates

• Interpret the impact of Pylontech's business on the upstream and downstream of the value chain, identify Pylontech's main stakeholders

Establish a list of issues

• Engage with stakeholders based on the actual situation of Pylontech, analyze the business background of Pylontech, make appropriate adjustments on the basis of the previous year's issue list and preliminarily form an issue list

• Pylontech defines the time horizon for the impact of issues on Pylontech based on its strategic development plan and resource allocation plan. The short-term is less than 2 years, the medium-term is 2 to 5 years and the long-term is more than 5 years

• Analyze the actual and potential impacts, risks and opportunities of Pylontech's sustainability issues in the short, medium and long term based on the judgments of internal and external stakeholders

Issue confirmation and approval

• Reviewed and confirmed by the Board of Directors,, and disclose key issues of high materiality in 2024 in the report

Adjustment of the 2024 Pylontech Issue List

According to the requirements of the Guidelines, adjust the issues expression based on the actual situation of Pylontech

Energy utilization, water resource utilization, pollutant emissions, waste disposal, resource recycling, environmental compliance management, product and service safety and quality, sustainable supply chain, innovation driven, rural revitalization and social contribution, information security and privacy protection, business ethics

According to the requirements of the Guidelines and in combination with policies, peers and ratings, additional issues have been identified

Ecosystem and biodiversity conservation, industry cooperation and development, ESG management, due diligence, intellectual property protection, stakeholder communication

1No additional explanation on issues without changes

• Identification Results Of Double Materiality Issues

Pylontech uses the top 30% of the maximum value set by the financial materiality assessment score as the threshold for determining whether each issue has "financial materiality", and the top 50% of the maximum value set by the impact materiality assessment score as the threshold for determining whether each issue has "impact materiality". Combined with legal and regulatory requirements, the impact materiality of some strong regulatory issues has been adjusted and increased and the materiality analyses results are presented using the issue matrix diagram method.

Based on the comprehensive analyses of impact materiality and financial materiality, among the 26 preliminary identified issues by Pylontech, 5 issues of sustainable supply chain, climate change response, innovation driven, risk management and clean energy opportunities have double materiality. 3 issues of human capital development, product and service safety and quality and customer relationship management only have financial materiality, 15 issues only have impact materiality and 3 issues have neither financial nor impact materiality. For issues identified as financial material, Pylontech conducts in-depth analysis and issues management, enhancing disclosure in the report.

In response to issues of high financial or impact materiality, Pylontech conducts in-depth analyses of the impact paths of stakeholders on the business, comprehensively evaluates the potential effects of these impacts on Pylontech's financial condition, operating results, cash flow and other financial performance over different time periods. By systematically assessing the risks and opportunities of various issues, Pylontech is able to accurately identify potential challenges and development opportunities, providing bases for developing practical and feasible response strategies, ensuring flexibility and competitiveness in dealing with external environmental changes.

The strategy to address climate change can reduce Pylontech's carbon footprint, mitigate climate-related risks, and enhance its reputation for environmental responsibility. By implementing emission reduction measures, Pylontech can actively respond to global climate change challenges and promote sustainable development.

Pylontech seizes opportunities in the green transformation of the market and adopts sustainable technologies, which not only helps improve resource utilization efficiency but also enhances market competitiveness.

Product and service safety and quality directly affect consumer health and satisfaction, impacting brand reputation and market share. Ensuring high safety and quality standards enhances customer trust, strengthens competitiveness, and promotes longterm business growth.

Effective customer relationship management enhances customer loyalty, improves satisfaction, boosts sales performance, and ensures a continuous revenue stream, ultimately strengthening market share and competitiveness.

Extreme climate changes may lead to supply chain disruptions, such as transportation delays or raw material shortages caused by natural disasters or extreme weather. These disruptions may affect the timely production and delivery of downstream operations, resulting in delayed or canceled customer orders and increased operational costs.

By improving product adaptability to extreme climate conditions, Pylontech can attract more customers, especially in regions significantly impacted by climate change. Providing climate-resilient products can open new markets and increase market share.

By increasing investment in clean energy, companies can stabilize energy supply, reduce cost fluctuations, comply with increasingly stringent global environmental regulations, and enhance market competitiveness. At the same time, the increased demand for clean energy products can open up new markets and customer groups for companies. If product R&D projects fail to match market demand, there may be sunk costs for R&D failures.

Pylontech places great emphasis on product safety, implementing strict regular quality inspections to ensure reliability. Providing high-quality and high-safety products strengthens customer trust. In a market increasingly valuing quality and safety, superior products contribute to brand loyalty and market expansion. However, unexpected product safety incidents may lead to negative consequences.

Through refined customer relationship management, Pylontech can better understand customer needs, provide personalized services, and strengthen pre-sales, in-sales, and after-sales management, thereby improving customer satisfaction and loyalty, and enhancing market share and brand influence.

upply chain environmental and social risk management helps ensure that companies comply with environmental and social responsibilities in their supply chains. By proactively managing social risks such as environmental protection and labor rights, companies can enhance their brand reputation and strengthen the trust of consumers and investors.。

An innovation-driven strategy enhances corporate competitiveness and market adaptability. Continuous technological innovation and product R&D enable Pylontech to meet market demands, upgrade business models, maintain leadership, and strengthen brand value and customer loyalty.

Employee development and training directly impact talent retention, innovation capacity, and long-term competitiveness. Providing continuous training and career development opportunities enhances employee skills, productivity, loyalty, and job satisfaction.

Risk management involves identifying, assessing, and responding to potential risks affecting business objectives. Effective risk management reduces financial, reputational, and legal risks, ensuring stable operations in the face of internal and external challenges, supporting long-term sustainability.

The company is improving its sustainable procurement system and strengthening ESG risk control in the supply chain, enhancing downstream customer trust and engagement. However, any non-compliance with domestic and international sustainability standards within the supply chain could result in regulatory penalties or negative market reactions, potentially damaging corporate reputation.

Ongoing technological innovation allows Pylontech to develop more competitive products to meet changing market demands. Innovations in intelligent and green products open new markets and reinforce market leadership.

By increasing investment in employee skill development and career growth, Pylontech improves workforce efficiency and innovation, strengthening core competitiveness, market adaptability, and employer branding.

By refining risk management systems and integrating new technological tools, Pylontech can proactively identify and mitigate risks, reducing losses while enhancing business continuity and market competitiveness.

SDG-Aligned Actions

Pylontech has developed detailed response plans for the risks and opportunities brought to Pylontech by various issues based on the results of the double materiality assessment. By combining the United Nations Sustainable Development Goals (SDGs) as Pylontech's strategic framework for promoting sustainability, Pylontech has taken a series of specific actions aimed at actively addressing environmental, social and governance challenges, while leveraging Pylontech's core strengths to make positive contributions to achieving sustainability goals.

Exploring the New Era of Environmental Protection

7.1 Universal access to modern energy

7.2 Increase the global proportion of renewable energy

7.a Promote access to clean energy, technology and investment

12.2 Sustainable management and use of natural resources

12.4 Responsible management of chemicals and waste

12.5 Significantly reduce waste generation

Building New Paradigms of Responsibility

13.3 Establishing knowledge and capacity to address climate change

Pylontech's core goal and mission is to provide sustainable clean energy for everyone and is committed to providing first-class energy storage system solutions

Pylontech has delivered over 2 million sets of energy storage systems to more than 90 countries and regions worldwide, making significant contributions to the use of clean electricity worldwide

Pylontech actively invests in the development of clean energy technologies and infrastructure construction, accelerating the global energy transition

Pylontech promises responsible procurement, selecting durable and reusable materials with long lifespan to improve material selection and purchasing secondary materials (such as waste or recycled feed) or renewable materials to reduce the use of raw materials and non renewable materials

Pylontech follows strict safety standards, conducts product life-cycle environmental impact assessments, improves product cycle life and reduces environmental impact throughout the product life-cycle

Pylontech develops an annual waste reduction plan, which includes detailed and economically feasible reduction plans for waste residues, waste electrolytes, waste packaging materials, physical and chemical sludge, waste activated carbon, etc

Pylontech actively responds to climate change, builds a product carbon footprint management platform, collaborates with universities and research institutes to develop carbon footprint standards for the lithium battery industry and contributes to the sustainable development of the industry

1.4 Equal rights to ownership, basic services, technology and economic resources

Pylontech adheres to the principle of "people-oriented" and safeguards the rights and interests of employees from multiple dimensions. It has established a diverse range of welfare and care systems that prioritize experience and provides free or low-cost accommodation for eligible employees

3.6 Reduce road injuries and deaths

3.9 Reduce diseases and deaths caused by hazardous chemicals and pollution

4.4 Increase the number of people with relevant skills to achieve financial success

4.7 Sustainable development and global citizenship education

Pylontech pays attention to the commuting safety of employees, provides free parking spaces for employees and promptly reminds cyclists to wear helmets to ensure safe travel

Pylontech regularly conducts monitoring of occupational hazards, implements targeted protective measures based on the identified situation and provides necessary labor protection equipment for all employees

Pylontech continues to establish a safety training system, providing employees with abundant learning resources and growth opportunities. In 2024, Pylontech established a Learning and Development Center, which offers courses in four categories: skills, safety, research and development and management. The center comprehensively covers the core areas of employee ability improvement and provides a professional platform support for employee training

Pylontech actively integrates the concept of sustainable development internally, providing employees with awareness and institutional support for sustainable lifestyles, gender equality and anti discrimination

Building New Paradigms of Responsibility

5.1 Eliminating discrimination against women and girls 5.5 Ensure full participation in leadership and decisionmaking

Improving resource efficiency in consumption and production 8.5 Equal pay for equal work and decent work

Pylontech always adheres to the principle of fair and just employment, prohibits any form of

product design and manufacturing considering modularity, disassembly and recyclability, increasing the proportion of renewable materials. The core product has been evaluated by WEEE, with a theoretical recycling rate of

Pylontech advocates a compensation management philosophy centered on valuing talent, performance culture and focusing on cost efficiency and is committed to providing employees with a comprehensive and competitive compensation and benefits system

8.7 Ending modern slavery, trafficking and child labor 8.8 Protecting labor rights and promoting a safe working environment 10.3 Ensuring equal opportunities and eliminating discrimination

Develop sustainable, resilient and inclusive infrastructure

Strengthen research and upgrade industrial technology

Protecting children from abuse, exploitation, trafficking and violence

New Empowerment of Stable Governance

Significantly reduce corruption and bribery

16.6 Establish effective, responsible and transparent institutions

16.7 Ensure responsive, inclusive and representative decision-making

16.8 Promote and enforce non discriminatory laws and policies

Pylontech has established a sound employee file management system by improving the recruitment process, strengthening age verification and identity review of applicants and avoiding the risk of hiring child labor

Pylontech adheres to the occupational health and safety management policy of "people-oriented, safety first", actively eliminates and reduces occupational hazards and fully guarantees the occupational health and safety of employees

Pylontech has formulated Labor and Human Rights Policy that clearly defines the zero-tolerance goal of labor human rights management, ensuring "zero" discrimination and "zero" harassment in all workplaces and eliminating the occurrence of child labor and forced labor

Pylontech actively expands the application scenarios of its products under different extreme conditions and is committed to developing high-quality, reliable, sustainable and disaster resistant infrastructure to support economic development and enhance human well-being

Pylontech actively invests in R&D throughout the entire industry chain, with R&D personnel accounting for 33.73% of the total number of employees and R&D expenses accounting for 17.22% of total revenue

Pylontech has optimized the recruitment process, strengthened age verification and identity verification of applicants, improved the employee file management system and effectively prevented the risk of child labor recruitment

Pylontech adheres to the core values of "Integrity, responsibility and accountability" and always upholds a "zero-tolerance" policy, firmly opposing any form of corruption, bribery and unfair competition

Pylontech has clarified the responsibilities and authorities of the shareholders' meeting, board of directors, supervisory board and senior management, implemented the principle of independent decision-making, execution and supervision and formed an effective balance mechanism to ensure the standardized operation of corporate governance

Pylontech fully recognizes the importance of diversity and independence of the board of directors in company decision-making. Board members have academic backgrounds and practical experience in various fields such as lithium batteries, energy storage systems, law, accounting and financial management, injecting diverse experience and unique insights into company decision-making

Pylontech has formulated a Labor and Human Rights Policy and established a zero-tolerance goal for labor human rights management. It is committed to eliminating discrimination, harassment, child labor and forced labor in all workplaces, actively promoting and implementing non discriminatory laws and policies and promoting sustainable development

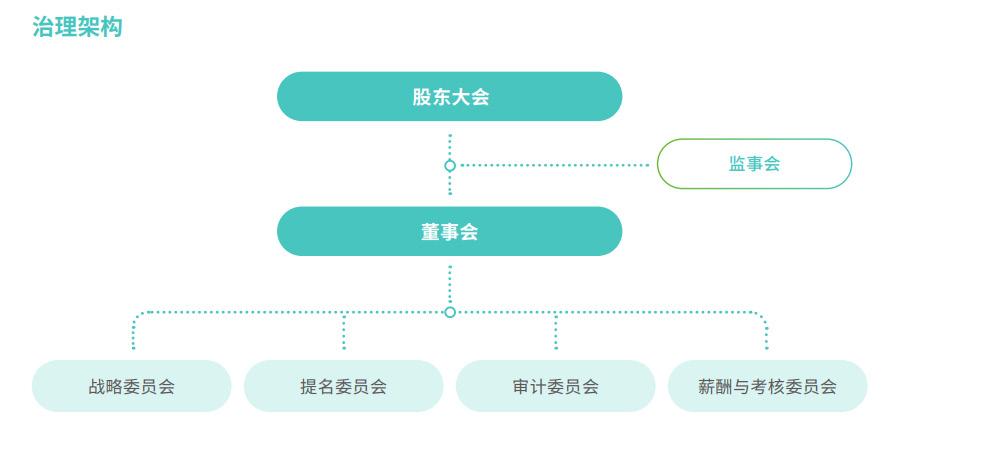

Sustainability Management Architecture

In order to continuously improve the sustainability management level and performance of Pylontech, Pylontech has established a comprehensive sustainability organizational structure and management system, consisting of the board of directors, supervisory board, top management/sustainability leadership group, sustainability working group and liaison personnel from major departments, to achieve supervision, management, coordination and implementation of sustainability work. At the same time, Pylontech focuses on enhancing the professional competence of its top management in the field of sustainability, in order to continuously strengthen its strategic leadership and decision-making capabilities in sustainability management.

During the reporting period, Pylontech officially joined UNGC and pledged to support its ten principles in the areas of human rights, labor, environment and anti-corruption. Pylontech continues to optimize its sustainability management and actions, creating more sustainability value for stakeholders.

Pylontech attaches great importance to risk and opportunity management in sustainability. During the reporting period, Pylontech revised the "Risk and Opportunity Response Management Procedure" and established a comprehensive planning, implementation and evaluation system for risk and opportunity response measures related to sustainable issues. This provided operational guidance for incorporating risk and opportunity management processes into sustainable management systems such as quality, environment and occupational health and safety, ensuring the effectiveness of relevant measures.

Pylontech extensively collects risk and opportunity information through various departments and the "Risk and Opportunity Assessment Team" is authorized by the General Manager to conduct assessments and report regularly to the upper management. The top management conducts annual measures and effectiveness verification reviews. This year, Pylontech relied on the analyses of double materiality company issues, coordinated by the CEO's office, combined with the collection of diverse stakeholder opinions, evaluated the dependence and impact of various business processes on resources and capital, identified key risks and opportunities and submitted the analyses results and the management of major sustainable development risks and opportunities to the Board of Directors for review.

Sustainability Governance Architecture Chart of Pylontech

Board of

Board of Supervisors

Those Charged With Governance

Board of directors:The highest decision-making body for Pylontech's sustainability work, approving Pylontech's sustainability strategy, short-term and long-term sustainability plans, supervising the formulation and implementation of sustainability strategies, and making decisions on major issues related to Pylontech's sustainable development.

Management

Top management/Sustainability leading group:Composed of Pylontech's president and department heads, responsible for reviewing Pylontech's sustainability strategy, short-term and long-term sustainability plans, reviewing the achievement of sustainability goals, risk and opportunity assessment results, major issues, and annual sustainability reports.

Sustainability working group:Composed of dedicated sustainability personnel, responsible for building and maintaining the sustainability governance system, regularly reviewing work progress and proposing improvement suggestions. Develop sustainability strategic goals, short-term and medium to long-term plans, systems, and workflows. Continuously tracking global sustainability trends, including policies, regulations, and actions, identifying major sustainability issues and promoting their implementation. Their compensation is linked to Pylontech's sustainability performance.

Execution Level

Each functional department:Each department's sustainability liaison is responsible for promoting the deep integration of sustainability management work with Pylontech's daily operations, ensuring effective implementation of sustainability management work internally and forming a mechanism for top-down and closed-loop management. At the same time, Pylontech clarifies the sustainable development responsibilities of each department, incorporates them into performance evaluations, and implements reward and punishment measures to promote the achievement of sustainability goals.

Responding to Climate Change/26

GREEN FIRST MOVING TOWARDS LOW-CARBON AND HIGH-QUALITY DEVELOPMENT

Responding to Climate Change

Pylontech actively responds to the national strategic goal of "peaking carbon emissions before 2030 and achieving carbon neutrality before 2060" and proactively formulates and implements corporate carbon neutrality plans. By establishing a sound climate change governance system and a comprehensive carbon reduction management mechanism, Pylontech systematically identifies the risks and opportunities brought by climate change, continuously improves its climate governance capabilities and promotes green and low-carbon transformation through practical actions.

Pylontech Climate Change Management System

Climate governance architecture

• Pylontech has established a three-level climate governance framework that organically connects governance, management and implementation, guiding organizations at all levels to carry out orderly efforts to address climate change.

Strategy

• Assess the potential operational and financial impacts of identifying significant risks and opportunities on Pylontech.

• Carry out relevant management actions to reduce the carbon footprint of the entire operational life-cycle.

Risks and opportunities management

• Identify potential risks and opportunities in operational activities based on the risk analysis framework of TCFD and incorporate climate change risks and opportunities as part of overall operational risk management.

Targets and performance

• Actively identify the main sources of greenhouse gas emissions.

• Set greenhouse gas emission reduction targets and disclose greenhouse gas emissions in the sustainability report annually to evaluate Pylontech's performance in Responses to climate change management and develop improvement plans.

Governance

Pylontech has established a comprehensive three-level climate governance system, forming an organic organizational structure that connects governance, management and execution. To ensure the achievement of climate goals, Pylontech will incorporate carbon reduction performance indicators into the assessment system of relevant department heads and establish a dual track mechanism of "incentive enhancement": rewards will be given to teams that achieve emission reduction goals and special capacity building support will be provided to departments that do not meet the standards, continuously improving the organization's climate governance capabilities.

Strategy

Board of directors

Sustainability leadership group

Approve Pylontech's climate transition strategy, short-term and longterm climate plans, supervise the formulation and implementation of climate transition strategies and make decisions on major climate issues for Pylontech

Coordinate Pylontech's climate governance work, including risk and opportunity management, goal setting, cross departmental resource coordination and regularly report on climate management progress to the board of directors

Each department and subsidiary

Implement established emission reduction targets and implementation paths, strictly implement various carbon reduction management measures and ensure the effective implementation and high-quality landing of climate action plans at the operational level

Pylontech systematically identifies and evaluates climate related risks and opportunities in its operations based on industry characteristics and global business layout and constructs a comprehensive climate risk and opportunity assessment matrix accordingly. By quantitatively analyzing the probability of risk occurrence and potential impact, Pylontech prioritizes various risks and opportunities and develops differentiated climate response strategies and implementation plans.

risks

Frequent extreme weather events such as typhoons and floods may lead to safety production accidents, affect factory operations, or cause supply chain disruptions.

• Pay attention to extreme weather warnings and deploy flood and typhoon prevention work in advance. Daily monitoring and maintenance of operational locations susceptible to typhoon weather to prevent water ingress into factories and battery swapping stations.

• Consider power stability factors in site selection, without relying on a single power

• Pre-planning for natural disasters such as typhoons and floods, developing emergency plans, and conducting emergency drills

Physical risks

Material Climate Risks and Opportunities

The increasingly strict climate related requirements may lead to an increase in energy and raw material costs. For example, the emission control costs of China's power generation industry will be transferred to electricity costs, increasing energy costs. The climate compliance costs, supply chain security, and stability of the battery industry supply chain will also lead to an increase in raw material prices, thereby affecting the market competitiveness of Pylontech's products.

• Vigorously promote the construction of self built photovoltaic power stations, increase the use of "self use" green electricity, effectively control the potential risks of rising external energy costs while reducing carbon emissions.

• Establish a new sodium ion battery production project and manage key mineral risk exposures. Successfully developed sodium batteries to replace lead-acid batteries and has abundant patent layouts in the field of sodium batteries.

With the development and innovation of green technologies and the introduction of supportive policies, the accessibility of renewable energy is gradually increasing, and prices may gradually decrease. Actively transforming energy usage can reduce direct energy costs and respond to regulatory pressures and low-carbon goals faced by Pylontech in the end market.

• Pylontech vigorously promotes photovoltaic construction and continues to expand the scale of self-produced renewable electricity use.

• Develop a decision-making tool for green power procurement in enterprises, and determine the proportion of renewable energy in different scenarios based on emission reduction plans.

Climate-related Risk and Opportunity Matrix

With the continuous strengthening of global climate governance, the new energy industry is facing increasingly severe regulatory compliance challenges. For example, laws and regulations represented by the EU's Battery and Waste Battery Regulations have put forward strict requirements for the full life-cycle management of batteries. Enterprises not only need to ensure current compliance, but also need to proactively respond to upcoming regulatory policies.

• Pylontech has established a product compliance transformation team to conduct carbon footprint accounting and declaration for typical products, track the supply chain carbon footprint in accordance with the requirements of the Battery Law for value chain boundaries, and establish a data quality assurance system to ensure compliance with climate related compliance requirements.

In the context of the "dual carbon" goal, green and sustainable products and services will better meet market demand and expectations, further developing and providing climate friendly products can achieve additional business and revenue growth.

• Pylontech establishes a system for identifying and transforming clean energy opportunities, with standardized operation of supporting systems, and builds a matrix style cross departmental collaboration architecture and process to achieve full process tracking and feedback from requirement identification to product realization.

• Organize multi departmental joint research and development, comprehensively improve product energy efficiency, low toxicity, safety, and longer lifespan from structural development, mechanical design, material development, thermal management, and other aspects, to meet the market's demand for sustainable products.

Pylontech has deeply integrated the risks and opportunities related to climate change into its strategy. Based on its medium and long-term development plan, Pylontech has set climate change management goals and regularly reviews them to ensure that its business model aligns with the direction of low-carbon economic transformation.

Risk Management and Response Measures

Pylontech has closely integrated industry characteristics, internal and external development environments and internal and external professional opinions to establish a comprehensive process for managing the impacts, risks and opportunities related to climate change. This process covers four key steps: identification, evaluation, sorting and management, ensuring that Pylontech can systematically address climate challenges and seize transformation opportunities.

• Through multi-dimensional analysis such as policy bench-marking and industry research, clarify the potential impact of climate change on supply chains, production operations and market demand

• Using a combination of quantitative and qualitative methods, conduct in-depth analysis of identified risks and opportunities. Evaluate the likelihood of risk occurrence and its financial impact on the business through financial materiality assessment, while quantifying the potential benefits brought by opportunities

• Based on the severity and urgency of risks and opportunities, as well as their impact on Pylontech's strategic goals, determine priorities and adjust climate management strategies accordingly

• Clarify the main pathways for Responses to climate change and incorporate them into Pylontech's overall strategic planning, establish specialized task force decomposition goals and establish corresponding tracking and assessment mechanisms

Pylontech adheres to the concept of carbon reduction throughout the entire life-cycle and systematically promotes lowcarbon transformation in core links such as design, manufacturing and supply chain, building a multi-level climate change response system. On the design side, Pylontech practices the concept of "source reduction" and reduces the use of non renewable materials. On the manufacturing side, Pylontech continues to optimize its energy structure and promote energy-saving technological transformation projects to achieve operational emissions reduction. On the supply chain side, Pylontech continues to promote the collection and accounting of supplier real-time data and conducts due diligence to promote carbon reduction in raw materials.

In terms of carbon footprint management, Pylontech continues to demonstrate leadership and actively exert influence. At the operational level, we have established a cross departmental carbon management team to comprehensively grasp the energy consumption and carbon emissions of each link in the product life-cycle through independent research and development of internal data collection platforms and modeling accounting tools. As of the end of 2024, Pylontech has completed carbon footprint accounting for 17 core products including the Force series, Powercube series and US series and all accounting results have been verified and certified by third-party authoritative institutions to ensure the accuracy and credibility of the data.

In order to further enhance Pylontech's carbon management capabilities, Pylontech has conducted a series of internal training covering climate risk opportunities, greenhouse gas accounting, product carbon footprint and other issues, striving to popularize carbon management concepts and practical skills to every employee and improve Pylontech's carbon management efficiency.

Pylontech will also expand its sustainable impact to the entire value chain, establish strict management requirements for suppliers and conduct relevant training to ensure that its products meet the sustainability standards of the countries where they are launched. At the same time, we encourage and support suppliers to take more proactive measures to jointly promote the industry towards a higher level of sustainable development.

[Case] Leading the green transformation, the carbon footprint quantification standard for lithium-ion batteries drafted by Pylontech has been released

In December 2024, the group standard T/CQAE 12002-2024 Greenhouse Gas Product Carbon Footprint Quantification Method and Requirements for Lithium Ion Batteries jointly drafted by Pylontech, China Electronics Standardization Institute, Huawei Digital Energy Technology Co., Ltd., Tsinghua University, Kunming University of Science and Technology, etc. was officially released and will be fully implemented from December 27, 2024. This standard aims to standardize the carbon footprint quantification methods and requirements for lithiumion batteries and battery pack products, fill the industry gap and is of great significance for promoting the green transformation and upgrading of China's battery industry.

Indicators and Targets

Pylontech has established a complete value chain (including scope 1, 2 and 3) greenhouse gas emission accounting system, conducted greenhouse gas inventory checks on Pylontech's main operating points for three consecutive years in accordance with ISO14064-1:2018, obtained third-party independent verification statements and effectively controlled and managed greenhouse gas emissions by base and module.

In 2024, Pylontech's scope 1 and 2 (based on location) greenhouse gas emissions were 36,302.40 tons of carbon dioxide equivalent and the unit revenue greenhouse gas (scope 1 and 2) emission intensity was 18.11 tons of carbon dioxide equivalent per million revenue. The total greenhouse gas emissions of scope 1 and 2 decreased by 5.81% compared to the previous year. Pylontech is actively adjusting and updating its existing greenhouse gas emission reduction and carbon neutrality targets.

2

Note: The greenhouse gas emission performance statistics cover Pylontech, Yangzhou Pylontech, and Anhui Pylontech. This report retrospectively adjusts historical data according to the latest verification criteria.

Environmental Compliance Management

Environmental

Management System

Pylontech abides by EnvironmentalProtection Law ofthe People' s Republic ofChina, ISO 14001:2015 EnvironmentalManagement System Requirements andUsage Guide as well as other laws, regulations and relevant standards strictly, formulating EnvironmentalProtection Policy and Environmental, OccupationalHealthandSafety Operation Procedures and other system documents in combination with the actual situation of each operation point to improve the construction of the environmental management system, define the environmental management responsibilities and powers of each level of Pylontech and continuously improve Pylontech's environmental management level and environmental performance on the basis of ensuring environmental compliance. By the end of 2024, Pylontech, Yangzhou Pylontech and Anhui Pylontech have all obtained ISO 14001:2015 environmental management system certification, no major environmental pollution accidents have occurred and no penalties have been imposed by regulatory authorities for environmental violations.

The President's Office of Pylontech is responsible for supervising and making decisions on environmental policies and goals on behalf of the top management and ensuring their effective implementation. Pylontech has established an EHS Committee, which has an EHS Office under the Safety and Environmental Protection Department. Its members include EHS managers and safety managers from various departments. The EHS Committee is mainly responsible for leading and promoting the implementation of environmental protection policies and system construction. the EHS Office is specifically responsible for implementing environmental protection policies and regulations organizing education and training and investigating hidden dangers and other important tasks.

All production bases of Pylontech have established emergency command organizations and regularly conduct environmental emergency plan drills. In 2024, Yangzhou Pylontech and Anhui Pylontech respectively carried out drills for excessive discharge of wastewater under abnormal conditions and emergency drills for chemical leaks.

[Case] Emergency Drill for Chemical Leak at Anhui Pylontech

On November 30, 2024, Anhui Pylontech conducted an emergency drill for a chemical leak outside its chemical warehouse. The simulated scenario involved a minor leak caused by the collapse of chemicals during delivery. Upon discovery, the individual quickly reported it, initiating the emergency response plan. The emergency response team orderly implemented measures such as isolation, medical assistance and cleanup. The drill was completed successfully, enhancing employees' safety awareness and emergency response capabilities.

Pylontech also organizes and carries out various environmental protection training actively. In 2024, Pylontech conducted a total of 4 environmental protection training sessions for all employees, covering the popularization of laws and regulations, safe management of hazardous waste, emergency training for sudden environmental incidents and environmental accident warning education.

In July 2024, Yangzhou Pylontech organized a training session on hazardous waste management for the heads of various workshops. The training covered the definition and types of hazardous waste, standardized operational procedures and comprehensive process management. It also emphasized the importance of proper disposal through case studies, aiming to enhance the company's environmental compliance level.

Environmental Risk Prevention and Control

Pylontech has established a complete emergency response mechanism for sudden environmental incidents to effectively prevent, promptly control and eliminate pollution hazards, improve the ability to respond to sudden environmental incidents and minimize the impact of environmental pollution and ecological damage. 100% of Pylontech's production bases have formulated emergency response plans for sudden environmental incidents. As of the end of 2024, Pylontech, Yangzhou Pylontech and Anhui Pylontech have completed the filing of emergency response plans.

[Case] Hazardous Waste Management Training at Yangzhou Pylontech

Energy Management

The energy involved in Pylontech's production and operation mainly includes electricity, natural gas, gasoline, etc. Pylontech follows the relevant standards such as Energy ManagementSystem Requirements andUsage Guide (GB/T 23331:2020), formulating Energy ManagementManual applicable to Yangzhou Pylontech and Energy Consumption andGreenhouse Gas Emission ManagementProcedure" applicable to all operating points to strengthen the company's energy management system and system construction. In 2024, Yangzhou Pylontech completed the ISO 50001:2018 energy management system review successfully, further reflecting its continuous optimization of energy management.

Pylontech is committed to promoting digital energy management continuously. In 2024, Yangzhou Pylontech Energy Consumption Management System will be fully completed and put into use, realizing real-time monitoring and analyses of water, electricity, gas consumption and load conditions, effectively assisting digital energy consumption management, helping the company to promptly discover energy consumption anomalies and then take targeted measures to optimize and adjust, ensuring efficient and reasonable energy use.

Pylontech actively promotes the clean energy substitution strategies. Starting from 2023, Pylontech will construct a distributed photovoltaic power generation system in three phases, adopting the "self-generation and self-use, surplus power to the grid" operation mode and cooperate with the purchase of green electricity to reduce greenhouse gas emissions during production and operation. In 2024, Pylontech's total photovoltaic power generation will reach 12,981.76MWh, reducing greenhouse gas emissions by approximately 7,602 tons.

At the same time, Pylontech actively carries out energy-saving and consumption-reduction projects in production operations, including boiler waste heat recovery projects, differentiated capacity discharge recovery systems, installation of high-efficiency energy-saving equipment and the use of automatic control systems in air-conditioning rooms, etc., to effectively improve energy utilization efficiency and reduce energy consumption indicators.

In July 2024, Yangzhou Pylontech organized a training session on hazardous waste management for the heads of various workshops. The training covered the definition and types of hazardous waste, standardized operational procedures and comprehensive process management. It also emphasized the importance of proper disposal through case studies, aiming to enhance the company's environmental compliance level.

Pylontech has introduced high-vacuum, contact ovens to replace convection ovens in the baking process. While meeting the standards for moisture control in battery cells, this upgrade has significantly shortened the process time from 38-42 hours to just 7 hours. This has notably improved the production efficiency of battery cells and reduced energy consumption per Unit. Currently, this equipment is widely used in the production of all series of pouch and aluminum-cased products.

1,387

2,495

7,602

In order to further improve the level and professionalism of Pylontech's energy management, Pylontech regularly conducts training on issues such as green factories, energy management and equipment energy efficiency-related regulations to enhance the knowledge reserve of Pylontech's energy management-related personnel. In addition, Yangzhou Pylontech arranged two energy management personnel to participate in the energy management training organized by the Municipal Bureau of Industry and Information Technology, systematically studying energy-saving policies, detection and diagnosis and energy utilization analyses and successfully obtained the energy management certificate to help Pylontech's energy management be carried out effectively.

Yangzhou Pylontech Energy Management Monitoring System

Water

Management

Pylontech abides by Water Law ofthe People' s Republic ofChina and other laws and regulations, formulating the Planned Water ManagementWorkInstructions and strengthens water resources management. In 2024, Pylontech's water sources are all municipal water and no water is taken from areas with water stress and no negative impact is caused on the local communities of the operating points due to water withdrawal.

Pylontech has set a water resource management goal of "Reducing Total Water Intensity by 5% by 2027, with 2022 as the Base Year". In production and operation, Pylontech has adopted measures such as recycling water and reclaimed water through water conservation technology transformation and further identified and optimized water conservation links through water balance and water accounting methods, improved water use efficiency and reduced water waste.

Water-saving Cooling Tower (Application-oriented)

The water-saving cross-flow cooling tower is selected, with an efficient water distribution system and packing structure, which is superior to the counter-flow cooling tower in terms of water evaporation loss, water loss due to drift and watersaving design. The water flow of the cross-flow cooling tower is perpendicular to the air direction, reducing the direct contact time and area between water and air, thereby reducing water evaporation loss and water drift loss. The efficiency of the water temperature drop comparison method can be achieved at ≥100%, the fan efficiency is ≥80% and the water drift rate of the cooling tower is ≤0.001%.

Recycling and Utilization of Steam Condensate Water

Install a steam condensate water recovery system to recycle 95℃ steam condensate water to the insulation water tank and pump it to the boiler room. Then, use the boiler flue gas recovery circulation heating to send it into the boiler, reducing the gas consumption of 1T steam from 80m3 to about 72.5m3. By 2024, 335,940m3 of gas can be saved and approximately 35,000 tons of condensed water can be recycled and reused.

In order to enhance employees' awareness of water conservation and implement water resource management effectively, Pylontech regularly organizes water conservation training. In 2024, Pylontech has carried out special training on water resource protection and cherishing water resources, which has enhanced employees' awareness of the importance of water resources and effectively promoted water resource management.

In addition, Pylontech also actively encourages suppliers to set water conservation goals and formulate practical water conservation measures. To ensure the effective implementation of this measure, Pylontech incorporates water conservation performance into the supplier access standards and annual assessment system to encourage suppliers to actively participate in water resource management and jointly reduce water consumption in the supply chain and transportation links.

Pollutant Emissions and Waste Management

Pylontech strictly abides by Water Pollution Prevention andControlLaw ofthe People s Republic ofChina, Air Pollution Prevention andControlLaw ofthe People s Republic ofChina Law ofthe People' s Republic ofChina on the Prevention andControlofEnvironmental Pollution by SolidWaste as well as the laws, regulations and standards of the operating locations. Based on the actual conditions of each production base, it has formulated Waste ManagementProcedures, Wastewater, Waste Gas andFactory Boundary Noise ManagementProcedures and other procedural documents to achieve comprehensive management of wastewater, waste gas and solid waste generated during production operations.

According to EnvironmentalFactor Identification andEvaluation ManagementProcedure, Pylontech reviews and updates the environmental factor identification and evaluation results of each base at least once a year. In response to the identified pollution factors, Yangzhou Pylontech Equipment Department conducts daily inspections of pollutant treatment facilities and installs electricity monitoring for daily inspections by the Safety and Environmental Protection Department to ensure the normal operation of the treatment facilities and avoid excessive discharge of pollutants. In addition, Pylontech regularly entrusts qualified third-party professional institutions to conduct pollutant testing. In 2024, Pylontech's wastewater, exhaust gas and other related test results will meet the standard requirements.

Emissions and Waste Management Mechanism

Wastewater

Emission types:industrial wastewater such as soft water preparation tail water, boiler periodic drainage, indirect circulating cooling water system drainage, equipment cleaning water, workshop floor cleaning water and domestic sewage.

Emission standards:"PollutantEmission Standardfor Battery Industry".

Treatment process:Acid alkali neutralization and other processes are used to remove heavy metal elements and other pollutants from wastewater.

Treatment method:Domestic sewage from Yangzhou Pylontech is treated in septic tanks and industrial wastewater is pre treated to meet standards before being discharged to the Shikang Sewage Treatment Plant. Pylontech’s Headquarters has no industrial wastewater and domestic sewage is discharged through the sewage pipe network to the sewage treatment plant for standard discharge.

Exhaust Gas

Emission types:organic waste gas from coating process organic waste gas from coating process organic waste gas from liquid injection organic waste gas from wiping section, welding fumes, etc.

Emission standards:"Pollutant Emission Standards for Battery Industry, Odor Pollutant Emission Standards, Boiler Air Pollutant Emission Standards.

Treatment facilities and systems:Treatment facilities and systems: For organic waste gas from coating processes and wiping sections, activated carbon adsorption is used. For organic waste gas from coating process, NMP recovery system + three-stage water absorption system is used for treatment. For the injection of organic waste gas, de-humidification and secondary activated carbon adsorption are used. For welding fumes, a welding fume dust collector is used for treatment.

Treatment method:After being treated by exhaust gas treatment facilities and systems, it meets the emission standards.

Hazardous and Non-Hazardous Waste

Types:waste activated carbon, hazardous waste generated by processes, general waste and household garbage.

Control standards:Pollution Control Standards for Hazardous Waste Storage and Management Measures for Hazardous Waste Transfer List.

Storage locations:hazardous waste warehouse, general industrial solid waste warehouse.

Disposal method:Carry out solid waste classification and treatment. For hazardous waste, it shall be transported and disposed of by qualified third-party professional organizations. For recyclable general waste, it is classified and recycled and disposed of internally by Pylontech, manufacturers, service units and waste collection stations. General waste and garbage with no utilization value shall be disposed of by municipal sanitation.

In terms of hazardous and non-hazardous waste reduction, Pylontech achieves effective solid waste reduction and environmentally-friendly treatment through pre-treatment and optimized packaging. In addition, Pylontech regularly conducts waste classification and recycling training to enhance employees' awareness and skills in waste management. In 2024, Pylontech will achieve a total reduction of approximately 12.6 tons of hazardous waste and save approximately RMB 262,600 in costs.

Strict pre-storage evaluation

Pre-processing and classification storage

Unified packaging standards

For raw materials, electrolytes, etc., they need to be confirmed by email that they cannot be recycled and evaluated by R&D/process/safety and environmental assessment as unusable before they can be stored as hazardous waste.

Waste slurry needs to be filtered before being stored to reduce moisture content and ease the difficulty of hazardous waste treatment. The filter element needs to pour out the internal slurry before being stored to achieve effective separation and utilization of resources.

Promote the use of ton bags as unified containers for hazardous waste such as activated carbon and filter cartridges, to improve management efficiency and environmental protection level.

Place ton bags inside the original cardboard boxes and pallets to contain waste and only transfer the ton bags during transfer. Reuse the cardboard boxes and pallets to improve transfer efficiency and reduce pollution.

The positive electrode coating process is equipped with an advanced NMP (N-methylpyrrolidone) recovery system, which has a higher recovery rate and integrates an automatic monitoring device for NMP concentration in the oven, which can more effectively recover and utilize NMP in the waste liquid.

Biodiversity Conservation

Pylontech is committed to protecting biodiversity and species habitats to the greatest extent possible and strives to achieve a balance between business development and ecological protection. Pylontech refers to the LEAP approach framework (locate, evaluate, assess and prepare) proposed by TNFD to conduct a value chain biodiversity risk assessment for its industry system.

In 2024, Pylontech used the Biodiversity Impact Assessment Tool (BIAT) to conduct biodiversity impact assessments on each operating site. According to the assessment results, none of Pylontech's operating sites are located in or adjacent to biodiversity conservation areas and there are no endangered animals listed by the International Union for Conservation of Nature (IUCN) and the Redlist of China's Biodiversity (RCB) or animals protected by the Wildlife Protection Law of the People's Republic of China within a radius of 1 km. There is no negative impact on biodiversity near the operating sites due to production and operation activities.

Recycle packaging

NMP recycling and utilization

Solid Waste Reduction Measures

At the same time, Pylontech strictly abides by relevant domestic and international laws and regulations such as EnvironmentalImpactAssessmentLaw ofthe People' s Republic ofChina and Regulations on EnvironmentalProtection Managementof Construction Projects and thoroughly implements the principles of ecological protection throughout the entire life cycle of engineering construction. It clearly requires that biodiversity protection must be taken into consideration at all stages of project planning, construction and operation and strives to minimize the impact of production operations on the ecological environment and biodiversity. Project Planning

Conduct on-site investigation before site selection, assess the potential environmental impacts of the project site on biodiversity and natural resources and design scientifically reasonable environmental impact control measures based on the assessment results.

Implement Three Points on Simultaneity of environmental protection strictly, ensure synchronous implementation of environmental impact assessment during the construction process and timely completion of relevant acceptance work.

Construction

Conduct environmental hazard inspections regularly, identify and solve potential environmental problems promptly.

Strengthen ecological environment management to ensure that all activities during project operation comply with environmental protection requirements.

Organize extensive ecological environment protection publicity and education activities to enhance employees' awareness of ecological protection.

Based on the results of the environmental impact assessment, targeted ecological restoration work will be carried out to ensure that the ecological environment system in the relevant areas can be restored in a timely and effective manner after the project exits, achieving sustainable utilization of the ecosystem.

Product LCA Management

Pylontech has always integrated the concept of sustainability into the entire life cycle of its products and has continued to explore resource conservation and environmental footprint reduction solutions in the R&D stage, raw material selection stage, production, transportation, product use and end-of-life recycling of products and has continued to promote the construction of a greener, more environmentally-friendly and efficient product system.

Promote the concept of "source reduction" actively, considering modularity, disassembly and recyclability in product design, reducing the use of non renewable materials and improving the recyclability and re-usability of products.

Expand the application of green and environmentally-friendly materials in products and establishing a dedicated material development department to ensure sufficient technical reserves for the selection of green and environmentally-friendly materials.

When importing material suppliers, review their relevant information in accordance with the Regulations on the Management of Hazardous Substances to confirm their compliance.

The laboratory has testing capabilities and conducts sampling and control of materials with different risk levels in accordance with the Management Specification for Sampling and Inspection of Hazardous Substances for RoHS requirements.

Select materials with long lifespan, durability and strong re-usability to improve material selection and prioritize the purchase of secondary materials (such as waste or recycled feed) or renewable materials.

According to REACH requirements, invite authoritative third-party organizations to conduct conformity testing on the product and notify according to regulations when triggering notification requirements.

Adhere to the concept of recyclability in the design of transit packaging materials, adopting a circular packaging design to save material consumption.

By replacing clean energy, carrying out emission reduction projects and strengthening intelligent control, we continuously improve energy efficiency and the proportion of clean energy.

Introduce an automated logistics system within the factory to achieve electrification of vehicles and reduce energy consumption.

Optimize the layout outside the factory, relocate the Kunshan system integration production line to Anhui and Yangzhou according to product categories, significantly reduce the transportation of intermediate goods factories, shorten the distance of the supply chain and reduce the impact of logistics on the environment effectively.

Improve the service life and charge/discharge efficiency of products continuously, enhance their durability and performance as well as reduce resource consumption and waste generation.

Participate in the preparation of the industry standard Technical Requirements for Recycling of Lithium ion Battery Energy Storage Systems actively, promote the standardization of recycling technology, improve the industry's environmental protection level and contribute to the circular economy.

As of the end of 2024, all of Pylontech's self-developed and self-produced battery products have obtained RoHS and REACH compliance reports from third-party professional organizations. Some products have undergone strict WEEE Directive evaluation and their theoretical recycling rate exceeds 94%, demonstrating the product's excellent environmental performance and resource recycling efficiency.

[Case] Pylontech has been awarded the first EU Battery Regulation Conformity Assessment Statement by SGS

At the 7th China International Import Expo, the international certification body SGS issued the first EU Battery Regulation Conformity Assessment Declaration (Module A) for Pylontech's industrial and commercial energy storage products, marking a significant breakthrough in Pylontech's compliance work and providing strong support for the products to penetrate international markets such as the EU.

Opportunities in Clean Energy*/44

INNOVATION NEVER STOPS AND TECHNOLOGIES ACHIEVE GREEN PRODUCTS

Customer Relationship Management*/65

Supply Chain Management*/53

Intellectual Property Protection/51

Innovation-driven*/47

Product and Service Safety and Quality*/60

Opportunities in Clean Energy*

The global energy transition is accelerating, with energy storage technology emerging as a crucial support for optimizing energy structures and enhancing the stability and flexibility of power systems. Meanwhile, the trend of comprehensive electrification is driving the market to demand higher performance for battery products.

Governance

Adhering to the concept of "Ensuring Smooth Product Planning for Sustained Market Success," Pylontech has established a relatively comprehensive system for identifying and converting opportunities in clean energy. Internally, it has formulated Demand Management Process and Organizational Operation Norms and set up a governance structure led by Pylontech's top management to identify and convert clean energy opportunities, coordinating decision-making and overseeing related work. The Process and Digital Operations Department is responsible for the overall management of market demands and the development of digital tools, ensuring precise and efficient information flow. The Product Planning Department and the Process Management Department specifically carry out demand collection, analyses and conversion, collaborating with various departments to advance demand implementation, forming a closed-loop management mechanism to ensure precise response and efficient implementation of market demands.

Strategy

Pylontech is committed to establishing and improving a standardized system for identifying and converting opportunities in clean energy, covering product planning and demand management, to ensure that R&D quality is quantifiable, traceable and optimizable. By leveraging digital tools, Pylontech optimizes demand collection, analyses and management processes, enhancing information flow efficiency and achieving precise response and efficient implementation. Through systematic training, Pylontech strengthens the understanding and execution capabilities of various functional departments in demand management, promoting collaborative R&D and improving overall quality.

Risk management and response measures

Pylontech is promoting the identification and transformation of clean energy opportunities based on market opportunities, product characteristics and product demands. By 2024, it will integrate into the Integrated Product Development (IPD) process, further improve the matrix based cross departmental collaboration architecture and workflow construction, achieve flexible allocation of manpower and technical strength, promote cross departmental collaboration, ensure efficient information transmission, improve the overall operational efficiency of the demand conversion system, enhance the competitiveness of Pylontech's energy storage solutions and help the industry move towards a more efficient, intelligent and sustainable energy future.

Gathering Analyses

Distribution

Complete the overall planning of opportunities and demands, identify key nodes and control them to ensure effective identification and management of new opportunities in the clean energy field.

Analyze, filter, classify and sort the collected requirements, evaluate market trends, customer needs and technical feasibility and propose priority recommendations for requirements

By distributing and coordinating requirements, ensure that relevant teams accurately receive and implement them and promote the transformation of requirements into concrete actions

Implementation and Verification

Drive product initiation and project approval, develop development plans, adjust and optimize technical solutions and ensure that products meet market and technical requirements

Verify the implementation of requirements continuously to ensure the smooth achievement of goals

Pylontech deploys digital tools actively to promote standardization, intelligence and efficient collaboration in demand management, helping to comprehensively improve R&D efficiency and quality. The introduction of digital tools such as data center, Product Lifecycle Management (PLM) System, data center environmental control, office intelligent platform and industry intelligence center has improved the overall operational efficiency and information integration capability of Pylontech continuously, providing strong support for high-quality mass production product innovation.

Digital Demand Collection Assists in Online Management of Clean Energy Opportunities

In 2024, Pylontech aims to develop an online requirement collection and management tool, facilitating comprehensive digital management of requirements throughout the entire process - from proposal and analyses to distribution and verification. This initiative will guarantee prompt response and precise conversion of requirements, thereby optimizing the information flow mechanism. Additionally, it will enhance the transparency and controllability of requirement tracking, ultimately enabling more scientific and efficient R&D decisions.

Full participation:All employees can submit requirements, enhancing the transparency and participation of requirements

Real time viewing and feedback:The RMT team can view the requirement list online, while analyzing and distributing it at the monthly requirement meeting to ensure timely processing of requirements

Quick response to urgent needs:The system identifies the "emergency analyses" option automatically and configures it through IT automation to ensure that the RMT team responds quickly to urgent needs

Visual management of the entire process of requirements:Each stage of requirements has an independent list, ensuring that responsible parties can view and follow up on the status of requirements at any time, reducing manual communication costs, greatly improving the efficiency of requirements management and helping Pylontech operate efficiently

In order to strengthen the professional capabilities of various departments in transforming clean energy opportunities, Pylontech is gradually constructing a systematic training system that covers key roles in core functional departments such as R&D, marketing and manufacturing, ensuring efficient collection, accurate analyses and effective transformation of demand, enhancing the collaborative ability of the R&D team and improving product R&D efficiency comprehensively.

Indicators and Targets

Pylontech has formulated a series of quantitative management goals around the identification and transformation of clean energy opportunities, covering demand response rate, demand conversion rate, training coverage, etc. At the same time, Pylontech plans to rely on digital management tools to achieve timely supervision of the progress of goal completion and ensure that all work is measurable, traceable and optimizable.

Innovation-driven*

Pylontech regards innovation as the core driving force for high-quality development. With the continuous development of industry technology and the expansion of Pylontech's business scale, as one of the few domestic companies with independent R&D and manufacturing capabilities for core energy storage components such as battery cells, modules, battery management systems and energy management systems, Pylontech continues to increase investment in R&D sites, equipment, instruments and other hardware and software to improve the R&D environment and platform to attract more outstanding talents.

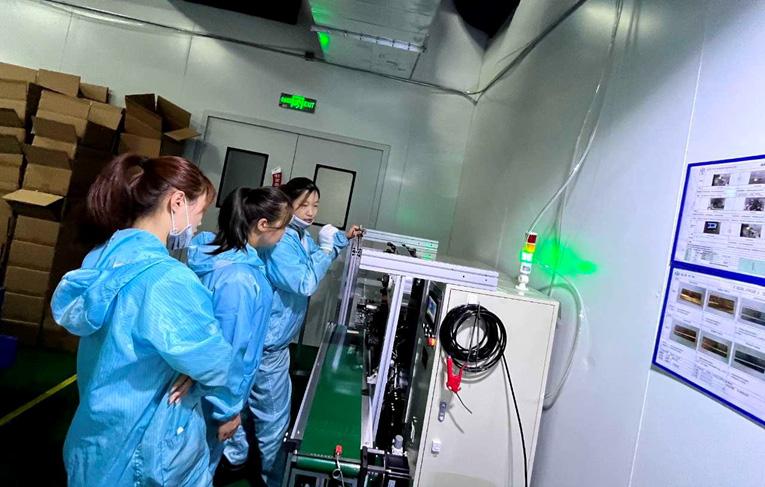

Governance

In 2024, Pylontech will construct a comprehensive R&D center to better integrate R&D resources. The R&D center has 8 departments covering the R&D of various products such as battery cells, modules, battery management systems (BMS) and system integration and centrally configures laboratory testing facilities to optimize the allocation of R&D resources. To ensure the efficient advancement of R&D work, the overall decision-making and supervision of the R&D center are coordinated and guided by Pylontech's top management. At the same time, Pylontech actively invests in the training and introduction of top R&D talents. As of the end of 2024, Pylontech's R&D team has a total of 713 people, demonstrating the professional strength of Pylontech's R&D team. Pylontech's growing R&D investment and continuously strengthened talent strategies will reserve strong momentum for Pylontech's sustainable technological development.

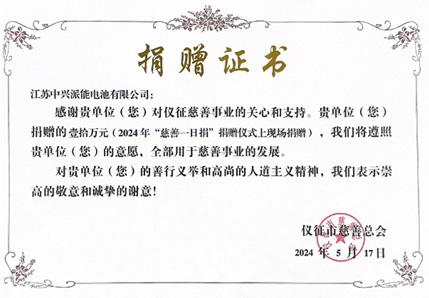

Strategy