Australia’s forestry and forest products sector will turn its attention to the May 3 Federal Elec-tion campaign after the March 2025-26 Budget which it saw as not delivering anything meaningful in new investment to help the industry.

Australian Forest Products Association CEO Diana Hallam believes the budget did not deliver any meaningful new investment to help forestry industries realise their potential for the climate, economy and communities.

And South Australian Forest Products Association CEO Nathan Paine described the Budget as a “cautious, pre-election fiscal package shaped by the delayed election cycle”.

“For the forest industries, the Budget offers mixed signals. Positive developments in-clude expanded housing and domestic manufacturing investments. However, signifi-cant gaps remain—especially in tailored support for regional infrastructure and housing affordability,” he said.

“The Australian Forest Products Association does, however, welcome a number of small Budget measures and we thank the Albanese Government for that support,” Ms Hallam said. “We will now shift our focus squarely to the Federal Election campaign to se-

cure what our sector needs as outlined in our Platform – Australian Timber. Australia’s Future, to help fix the national housing crisis, strengthen our sovereign capability in timber and wood-fibre and ensure a healthy and well promoted and understood sector,” she said.

“We welcome the additional $20 million for the Buy Australian campaign, but to really drive Australian product in the marketplace, we need the introduction of country of origin labelling to allow consumers to readily choose locally grown timber and wood-fibre. It is currently far too difficult for Australian consumers to discern where timber products come from and we will be campaigning hard for this policy in coming weeks.

“The Budget’s $181.9 million in funding for the Tasmanian Freight Equalisation Scheme (TFES) over the forward estimates is acknowledged, but reform and more work is needed to optimise the transport of timber and wood resources across Bass Strait.”

Ms Hallam said it was also disappointing that the forest products supply chain, as one of Australia’s largest manufacturing sectors, wasn’t included in the Budget announcements around green production credits which went to alu-

minium and iron.

She said that as a sector that was truly carbon positive with innovation potential across a range of nation building products – including bioenergy options from woodchip and timber residues – the sector really should be at the forefront of the Government’s planning in this policy space.

“We also reiterate our support for the $54 million announced for pre-fabricated and modular housing and to assist in certification

for this type of manufacturing that timber and wood-fibre businesses are leading the charge on. It is timely that the Government has acknowledged prefabrication has expanded from just the old donga to include innovative timber panel systems,” she said.

The Tasmanian Forest Products Association welcomed a $181.9 million ongoing com-mitment to the Tasmanian Freight Equalisation Scheme, describing it as a good start for Tasma-

nian businesses.

“Our industry is pleased to see the Federal Government responding to last year’s Senate Inquiry into the TFES, but to ensure the scheme remains fit for purpose the government needs to commit to ongoing review and modernisation of the program,” TFPA Chief Ex-ecutive Officer Nick Steel said. “This scheme was set up almost 50 years ago and it’s clear that, in its current state, it’s no longer working for Tasmania."

Polling conducted for the Australian Forest Products Association in the NSW federal electorate of Gilmore on the State’s south coast, shows voters overwhelmingly back the electorate’s critical native forestry industries, while also expressing strong support for the sector’s contribution to the economy and environment

“These polling results fly in the face of disinformation being spread about Australia’s sustainable native forestry by activists who

live far from the forestry underpinned communities in the seat of Gilmore – and clearly show that the vast majority of voters in electorate regard local forestry and timber operations as critical to support the local economy, local communities and the environment on the NSW South Coast,” , Chief Executive Officer of AFPA, Diana Hallam said. Key findings from the UComms polling of 684 Gilmore residents conducted from February 17th to 20th, include:

• 95 per cent of respondents either ‘agreed’ or ‘strongly agreed’ that timber and timber products sold in Australia should be labelled with their country of origin, whether it’s Australian or from overseas.

• 8 in 10 respondents, including more than half of those who said they’d vote for the Greens this election, either ‘agreed’ or ‘strongly agreed’ that the NSW South Coast should maintain a sustainable native timber industry to produce world class products like home

furnishings, furniture and decking.

• 3 in 4 respondents ‘strongly agreed’ that Australia should grow more timber production trees to fight climate change and secure Australia’s future national timber supply.

• More than 80 per cent believed local forestry and timber industries were important for local jobs and Australia’s economy, while more than 64 per cent said they’d be more likely to vote for a political party or candidate with strong policies

to strengthen Australia’s forestry and timber industries.

The polling also suggests that Liberal candidate Andrew Constance will win the electorate from Labor’s Fiona Phillips with a 52.8 (Liberal) to 47.2 per cent (Labor) two party preferred result returned in the poll.

“Gilmore is just one of many federal electorates where forestry and its supply chain is critical to the local economy and local forest management,” Ms Hallam said.

Issue 2 – Volume 36

Established 1991

News 3-12

Silviculture 13-14

Technology 16, 20-21

Tree felling 16

Milestones 17

Training 18

Forwarders 19

Haulage 22

Feller bunchers 24

Mill profile 26

Front Cover: The newest member of Kesla’s forestry trailer range, the KESLA 165 trailer with a net payload capacity of 16 tons, has just been granted EU167/2013 type approval Story Page 20

Publisher and Chief Executive:

Hartley Higgins

General Manager: Robyn Haworth

Editor:

Bruce Mitchell

b.mitchell@ryanmediapl.com.au

Adelaide Office: (08) 8369 9521

Advertising:

Jamie Richardson

j.richardson@winetitles.com.au

Adelaide Office: (08) 8369 9514

Creative Services:

Robyn Haworth

Trader classifieds:

Jamie Richardson

Adelaide Office: (08) 8369 9514

Subscriptions:

subs@forestsandtimber.com.au

Adelaide Office: (08) 8369 9500

Subcription rates

One-year (6 editions) $44.65

Two-years (12 editions) $77.65

Accounts:

ar@winetitles.com.au

Adelaide Office: (08) 8369 9500

Postal Address: 630 Regency Road, Broadview South Australia 5083

Phone: (08) 8369 9500

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122

Phone: (03) 9810 3262

Website www.timberbiz.com.au

Printed by Lane Print, Adelaide, SA

Conditions

The opinions expressed in Australian Forests & Timber News are not necessarily the opinions of or endorsed by the editor or publisher unless otherwise stated. All articles submitted for publication become the

More than 9000 jobs will go in the hardwood industry if the Great Koala National Park is imposed on north coast communities, say forestry workers.

The latest CSIRO research from 2024 shows koala populations are stable and thriving with 748,000 of the animals in NSW.

That’s double the number from an outdated 2016 study by Adams-Hosking which estimated populations at 331,000 and led to calls for the establishment of the park.

Hardwood is used for power poles, wharfs, walkways and flooring. Hardwoods are used for these mostly outdoor applications as they are stronger and harder wearing than softwoods.

Softwoods are generally sourced from pine plantations and used for internal ceilings and furniture.

Hardwood sourced from native forest is already heavily restricted. By law no harvesting occurs in old growth forest, and clear felling is also outlawed.

Only a small proportion of trees are harvested and are immediately replanted.

Now 88% of NSW Public

Forests are already protected, and of the remaining 12% only 0.2% are subject to selective timber harvesting.

This scares local people because this is the only job they have...

There are five competing models for the ‘Great Koala National Park’, with Forestry workers supportive of models which don’t endanger forestry communities. Any radical changes to forestry practice in the north will cripple south coast processing facilities where most of NSW’s forestry products are made.

Macleay Valley hardwood worker John Gunst, 65, told the Daily Telegraph the current proposal would kill nearby communities such as Kempsey, Kundabung and Nambucca Heads

which have lived off the timber industry for generations.

“All the timber towns rely on the same thing, if you close the timber industry down, you’re virtually closing the town down,” Mr Gunst said.

“This scares local people because this is the only job they have and if you take away the timber from these regional towns you’re taking away the main source of jobs and income.

“And that’s not including associated industries such as those who make mill machinery and saws, builders and carpenters, they are all going to be out of jobs because the timber is not going to be there.”

Australian Workers’ Union NSW Secretary Tony Callinan says the latest 2024 CSIRO study shows koala populations are thriving and stable.

“The latest CSIRO research shows koala numbers in NSW are stable and thriving and that’s great news,” Mr Callinan said.

“The key here is balancing the need to protect native species while providing future generations the raw materials for housing and infrastructure.

“Nine thousand north

coast locals have jobs in the timber supply chain with their healthy pay cheques going directly into their small communities, it’s imperative we get the balance right or we’ll endanger this $3 billion industry.

“The worst possible scenario would be to get timber from parts of the world with no environmental standards, or to use more climate change intensive products for our power poles, wharves and flooring.

“Timber is quite literally nature’s carbon capture and storage; we should be harnessing it as much as possible while ensuring healthy populations of native species.

“Forestry workers from the north coast are here in NSW Parliament House today to make sure decision makers know we have to get this balancing act right to ensure their communities’ survival.

“They’ve been meeting with Labor Party MPs and telling them not to abandon their core constituency of hard-working Australian families on this issue or they might find themselves an endangered species.”

Page 10 – My View

This year’s Federal Budget was, from a forestry industries point of view, pretty much a dud.

South Australian Forest Products Association CEO Nathan Paine described it as a “cautious, pre-election fiscal package shaped by the delayed election cycle”.

The Australian Forest Products Association was a little more blunt. CEO Diana Hallam simply said the Budget failed to deliver anything meaningful to help the industry, and that the AFPA would simply turn its attention to the May 3 Federal Election.

Astute observations by any standards. The Budget

was little more than a halfhearted attempt to woo voters with tax cuts described, quite accurately, by Opposition Leader Peter Dutton as little more than around 70 cents a day.

His riposte – a 25 per cent cut to the fuel excise for 12 months – did have teeth. Apart from the obvious cost of living bonus the flow-on effect for industry in terms of operating costs would be of huge benefit.

The AFPA is now aimed at

illustrating the role Australian timber can play addressing the current housing crisis and supplying our nation’s future housing needs, the importance of securing the future of Australian grown and recycled timber and wood-fibre to enhance our sovereign capability and promoting healthy and sustainable native and plantation forestry to provide Australians with the timber they need and fight climate change. It has launched forestfacts. com.au aimed at addressing what it sees as the huge amount of disinformation being spread by activists about Australia’s sustainable

and world leading forestry sector.

The election will be a close one, with many observers tipping a Labor minority government. That, by any measure, would not serve the country's timber industry well. Minority government rarely works well.

The AFPA continues, as it should, to play an even hand.

It simply plans to continue to execute its campaign ahead of polling day and work to get all sides of federal politics to show some committment to it.

&

Acomprehensive report into the Limestone Coast timber industry has been released following a five-year review.

The Select Committee on Matters Relating to the Timber Industry in the Limestone Coast released the 83-page document on Wednesday which also provided 17 recommendations.

The recommendations ranged from OneFortyOne’s plantation lease agreement to the pursuit of a National Forest Industry Code of Conduct.

Other main recommendations included the definition of sawlog and pulplog be made consistent throughout the industry and there be a mandatory reporting of monthly export prices by all exporters to a government agency.

The committee first formed about five years ago and despite a shift in committee members, there had been substantial evidence given from across the state.

Throughout the years, 13 submissions were made to the committee as well as about 30 in person witness statements.

Speaking on the outcome of the report, committee chairperson Nicola Centofanti said she was pleased the industry was finally seeing the results of a “significant body of work”.

“The timber industry has had a proud 150-year his-

● The review of the timber industry on the Limestone Coast has recommended the establishment of a parliamentary committee to investigate all aspects of water allocation planning.

tory here in South Australia and is the product of generations of hard working and dedicated innovators, both big and small,” Ms Centofanti said.

“This report acknowledges some of the challenges and opportunities the forest industry faces and the committee has worked tirelessly to form evidencebased recommendations to government to ensure the continued success of this vital industry.”

Other key areas of concern included water security, calling on the establishment of a parliamentary committee to investigate all aspects of water allocation

planning.

“Water resources are vital for the production of food and fibre and we need to ensure that forestry has equitable access to these resources in order to grow the forestry estate into the future,” Ms Centofanti said.

A National Forest Industry Code of Conduct and further investment into road infrastructure was also highlighted.

Minister for Forest Industries Clare Scriven said she welcomed the conclusion of the committee five years after its establishment in 2020.

“The establishment of the timber select committee was done at a time when the timber industry in South Australia was experiencing a downturn in supply of timber for processors in South Australia,” Ms Scriven said.

“Five years on and the challenges facing the industry have evolved with supply of timber stabilising across the industry.”

She said the industry employs both directly and indirectly about 21,000 South Australians and contributes $3b to the state’s economy each year.

A further 60 per cent of Australia’s agricultural timbers, such as poles, posts and fencing and 48 per cent of the packaging and industrial grade timber originated from the South Australian Forest Industry.

“The state government

understands the forest industry is an enormous contributor to the South Australian economy,” Ms Scriven said.

“As such, I will be considering all the recommendations along with further consulting with industry about the proposed recommendations before considering next steps.”

She said regardless, many of the recommendations which were proposed by the committee were actions the state government were already addressing including further research funding, investment into tree breeding and advocating for the National Forest Industry Code of Conduct.

South Australian Forest Products Association (SAFPA) chief executive Nathan Paine also welcomed the report, stating it was involved in the inquiry.

“We have provided submissions and oral evidence and we are pleased the committee has tabled this report,” Mr Paine said.

“We have not yet had the chance to review it in detail and so we will be doing it in due course but as the industry moves to celebrate its 150-year anniversary of plantation forestry and industry we are pleased to talk about the importance of the forest industry to South Australia.”

He said SAFPA had been working closely with the current government regarding a range of policy

measures including the contribution to the Forestry of Excellence, artificial intelligent cameras at fire towers and the forestry masterplan.

“Any opportunity for our leaders to be talking about forest industries is positive and in this case, primary industries because that is contemplated…the focus really is about the four critical things at the moment which is the current soft economic conditions that the industry is facing and the challenges that has caused,” Mr Paine said.

“If we look forward we are focused on getting more trees on the ground so we have got more resources for processes, getting more support for small to medium processes to improve their recovery rates and be more competitive and driving more use of South Australian grown and processed timber in our built environment.”

He said other items highlighted throughout the report such as education for careers within the forestry industry had already been addressed through the Woodwork campaign launched last year.

“We are a foundational industry, we support the success of other industries and we will be as an association talking to both the government and the opposition as we head into the 2026 election,” Mr Paine said.

- The Border Watch

GLENELG Shire Mayor, Karen Stephens, has been presented with the Inspiring Excellence Award at a Women in Wood Fibre event hosted by Australian Bluegum Plantations in Dunkeld, marking the world-wide event.

Cr Stephens, who is also renowned for her leadership role with the Casterton Kelpie Association and as a former local businesswoman, won the award for her tireless work advocating for the sector over many years.

“I am truly honoured to win this

award,” she said. “The food and fibre industries are major contributors to the Glenelg Shire economy and our role as council is to advocate for them when needed to help them and our Shire to thrive – that advocacy is at all levels of government.

“I would also like to thank Australian Bluegum Plantations for organising such an inspiring event today.”

Hosted by Australian Bluegum Plantations (ABP), more than 100 industry members joined by po-

litical and agricultural leaders enjoyed a High Tea celebration at the Dunkeld Community Centre, recognising the achievements, resilience and contributions of women across the plantation sector and local community.

ABP Human Resources General Manager, Sheri Tarr said the sector was working hard to promote inclusive practices and policies, creating pathways to support female leadership and career progression.

“Creating gender equality starts by achieving a positive workplace

culture, where everyone feels valued and respected,” she said.

“This is a primary objective for ABP and our broader industry which today has 30% of its executive roles filled by women, matched by an ongoing increase in female employees, with a growth rate of 10% per year since 2021.

“It’s important we celebrate this progress whilst recognising there is still more that can be achieved – we must collectively lead and champion this change."

Timber and pulp and paper workers are expected to vote in a demerger ballot which will see them establish their own Union, the Timber, Furnishing and Textiles Union. The secret ballot will end on April 14. The new union will continue to represent workers in the Manufacturing Division’s coverage.

The Governing Council of VFPA has appointed Richard Mulcahy as its inaugural Independent Chair. Mr Mulcahy has had a long involvement in politics and served as Deputy Opposition Leader and Shadow Treasurer, as well as Chair of the Public Accounts Committee in the ACT. He was also Principal Personal Assistant to a former Victorian Premier.

Emeritus Scientist

Professor John Ralph has joined Scion as its newest Emeritus Scientist. He has advised global bioenergy leaders, including the U.S. Department of Energy’s Great Lakes Bioenergy Research Center and the British Royal Society. Prof Ralph holds a B.Sc. (Hons) in Chemistry from Canterbury University, New Zealand (1976), and a Ph.D. in Chemistry and Forestry from the University of Wisconsin-Madison (1982).

FSC appointment

The Forest Stewardship Council ANZ Board has appointed Judy Alexander to the Standards Development Group responsible for revising the Forest Stewardship Standard (FSS) for Australia. Judy, a member of FSC ANZ through her consulting firm Foresa Consulting, brings a well-rounded skill set to the Standards Development Group from her years in the industry including experience developing, implementing, and auditing forestry standards in native and plantation forestry.

NZ-India MOC

New Zealand has signed a new Memorandum of Cooperation with India reinforcing NZ’s commitment to enhancing collaboration in the forestry sector. The MOC includes the development of bilateral forestry cooperation to continue mutual growth.

Dryad Networks, a leader in ultra-early wildfire detection, is setting up its first office in Australia and New Zealand to help tackle the region’s growing bushfire crisis.

Based in Macquarie Park, New South Wales, the new hub strengthens Dryad’s ability to work directly with governments, emergency services, and industry partners to prevent fires before they spread.

Sohan Domingo, who is serving as the Vice President of Sales, Technology, and Operations, is leading the expansion into Australia and New Zealand.

Dryad is starting with a dedicated local team and will scale up as demand grows. Having a local base means working closely with emergency responders, forestry services, and national parks to roll out fire detection solutions tailored to Australia and New Zealand’s unique land-

technology to ANZ to detect fires before flames appear and prevent devastating losses.

Each sensor runs maintenance-free for up to 15 years, powered by a small, integrated solar cell. Designed for rugged conditions, the sensors form a wireless mesh network that provides reliable coverage even in remote areas.

infrastructure, and forests. By reducing fire risk, we’re also cutting carbon emissions and building a more resilient future.”

scapes.

“Australia and New Zealand are on the frontlines of climate adaptation, and early fire detection is critical,” Mr Domingo said.

“With a local team, Dryad can work directly with authorities and land managers to stop fires before they spread.”

Building on success in North America, Europe, and Southeast Asia, the company is bringing its

Detecting fires at the smouldering stage gives emergency services a crucial head start. The system provides real-time fire maps and outperforms spotting towers, infrared cameras, and satellites, which only detect fires once they’ve spread.

“Bushfires don’t just destroy landscapes and communities, they also fuel climate change,” Mr Domingo said.

“Early detection is the key to stopping them before they spread. Dryad’s expansion isn’t just about growth; it’s about protecting lives,

Dryad is also advancing wildfire suppression with Silvaguard, an autonomous artificial intelligence (AI)powered drone that uses acoustic waves to extinguish fires. This innovation will provide a rapid, automated response to fire outbreaks detected by Dryad’s sensors, reinforcing early intervention efforts.

Plans are underway to explore deployment opportunities in Australia and New Zealand, where fastmoving fires pose a critical challenge.

Dryad is partnering with Indigenous Industries Australia (IIAust), Thinxtra, Indicium Dynamics, and New Zealand’s Direct Safety to accelerate deployment.

The Green Triangle Fire Alliance has commended the outstanding efforts of industry brigades, state agencies, and community volunteers as they contend with ongoing heightened fire danger across South Australia and Victoria.

Extreme temperatures, gusty winds, and persistent dry conditions have driven severe fire danger ratings, with firefighting crews responding to more than 100 fires in the past week alone. These incidents resulted in the loss of key plantation estates, farming land, and areas of native forest.

The GTFA’s network of 15 AI-enabled fire detection cameras have been instrumental as a first point of detection for many of these fires, supporting rapid response times and guiding the strategic deployment of

firefighting resources.

GTFA General Manager Anthony Walsh highlighted the crucial role of industryfunded assets, including a dedicated helicopter that was dispatched to 11 fires, providing fast and efficient

aerial suppression, often in rugged and difficult-toaccess terrain.

“Our highly trained industry firefighting crews have been on high alert, working alongside CFA and CFS volunteers and state agencies

to protect our communities and landscapes,” Mr. Walsh said.

“These recent conditions have underscored the value of our AI-driven detection network, which is delivering real-time alerts ahead of traditional human surveillance.

Early detection combined with rapid deployment, strengthened by our industry helicopter, is critical in preventing fires from escalating.”

The GTFA’s Forest Industry Brigade, derived from staff across nine plantation companies, comprises 300 trained firefighting personnel, 150 appliances, and an industry-funded helicopter, supported by strategically placed floating collar tanks for rapid aerial refuelling.

Peak industry body Timber Queensland, in partnership with the Canopy Training and Careers Hub, has launched The Canopy Jobs Board, a free platform for connecting talent with opportunity in Queensland’s dynamic forest and timber industry.

Timber Queensland Strategic Relations & Communications Manager Clarissa Brandt said the new jobs board is a one-stop shop for all jobs related to the local plantation and native forest industry supply chains through to end-use markets for timber products.

“Whether you’re a Queensland forest grower, harvester, sawmiller, merchant, manufacturer, architect, or timber speci-

fier—this is where you’ll find the skilled professionals you need to grow your business,” she said.

Mrs Brandt said the workforce development programs facilitated by the Canopy Hub including industry school tours, pre-employment, and work experience programs plus participation in career expos and school events, has steadily increased the num-

ber of enquiries received by Timber Queensland regarding finding a position in the industry.

“Creating an industry specific jobs board, that’s free for everyone to use, was a solution to connecting these people to local employers both large and small,” said Clarissa.

“In addition, it was a high priority action identified in the 2024 Wide Bay For-

est and Timber Industry Workforce Development plan developed by Timber Queensland in partnership with Jobs Queensland.

“Job seekers will be able to search for roles across all sectors from forest growing, harvest and haulage through to wood processing and secondary manufacturing, product transport, timber construction, wholesaling and merchandising and more.

“They can also post their resumes, create a profile promoting their specific attributes to employers and create job alerts when new jobs match specific search criteria such as job category and location.

“As well as advertising

open roles, employers can search candidates resumes and profiles to find the best match for open positions and use screening questions and applicant tracking to zero in on candidates and keep track of who has applied to each job posting and categorise applicants by hiring status.”

Mrs Brandt said Timber Queensland would be implementing a campaign to promote the jobs board to job seekers and strongly encourages Queensland employers to create an account to utilise its benefits.

“There’s no cost - just create an account and set up a company page to get matched with the right candidate sooner.”

Professor Jeff Morrell has commenced as the first Director of Mount Gambier’s Forestry Centre of Excellence, ready to lead the centre into its next chapter as an international leader in forest industries for research, education, product and market development.

Globally renowned for his distinguished career in wood durability, Professor Morrell was selected following an international search.

Professor Morrell has spent more than three decades leading the durability program at Oregon State University in the United States. He was also the director for the Centre for Timber Durability and Design Life based at the University of the Sunshine Coast in Queensland from 2018 to 2023.

The centre is a collaborative project between the State Government, the University of South Australia

Gambier TAFE – providing a unique opportunity to create an education, training, and research precinct.

Vital research has already been underway including projects on:

• structural timber market access

• improving safety

• fire detection from cameras and satellites

• suppression, recovery, and analysis of digital forestry data using artificial intelligence

• immersive data analytics using VR and AR to understand the implications of climate change on plantation growth yield and water use.

“I’m very pleased to join the team at Mount Gambier to help move the Forestry Centre of Excellence forward and I’m honoured to have been chosen to help direct the centre,” Prof Morrell said.

“It’s an exciting time to be in forestry in Australia with the resurgence in

forests.

“I am excited to work across the discipline to help create a vibrant Forestry Centre of Excellence that builds upon the many excellent projects already underway and contributes to the state.

“I thank (Forestry Minister) Clare Scriven for her very dedicated support for establishing the centre as well as the various advisory bodies that have fostered this process. I look forward to working with her to help make the Centre a credit to the University, Industry and State.”

Ms Scriven said Prof Morrell’s commencement as director is the latest in a series of exciting milestones for the Forestry Centre of Excellence following the successful launch late last year and imminent start of construction on the new facilities.

“The Forestry Centre of Excellence will consolidate the Green Triangle’s

Tigercat durable design

Timed knife arms and triangulated feed

Wireless head communication

Best suited to trees in 40-60 cm diameter range

Dasa D7 fully optimized system (StanForD compatible)

305 cm colour touchscreen (Windows 10)

Back or lower knife option

Introducing the Tigercat 573. A powerful, triangulated three-wheel drive harvesting head with positive control and precise measuring. Versatile for roadside processing and in-stand harvesting. Excellent performance and productivity in medium to large sized timber.

Contact Onetrak today.

www.onetrak.com.au

With the New South Wales State Government poised to announce the creation of a Great Koala National Park, a unique opportunity emerges to balance the establishment of protected koala habitats and the preservation of state forests, offering a win for positive environmental, social, cultural, and economic outcomes.

Whether managed as national park or state forest, science-based active forest management – the thoughtful and deliberate tending of forests – will be crucial to maintaining and enhancing Australia’s forests, responding to climate change and conserving koala habitat.

Simply creating a national park does not guarantee biodiversity conservation.

There is no doubt when managed well, national parks benefit the environment and communities by conserving biodiversity, providing for recreational opportunities and cultural wellbeing, storing carbon and providing clean water. State forests, also provide

all of these values, along with recreation and ecotourism opportunities, timber and non-timber forest products.

The effective conservation benefit provided by state forests has been demonstrated by recent research that shows koala numbers remain high and stable in NSW state forest.

However, this is not a guarantee, for example, in Booderee National Park, severe declines in native animal species have occurred.

Potoroos and bandicoots have had to be re-introduced from nearby state forest after becoming locally extinct within the national park.

In the Pilliga Forest the thriving population of koala declined following conversion of state forest areas to conservation reserves.

This decline is attributed to changes in management that previously encouraged the growth of eucalypt species favoured by koalas.

Given this, it is critical that these lessons be learned and applied if the Great Koala National Park is to truly conserve koala.

Equally, it is important to understand the consequences of removing sustainable, renewable, modest and highly regulated native forest timber supply from state forests when creating the new Great Koala National Park.

Research has shown that when Australian hardwood timber from native forests becomes unavailable, it is mostly replaced by imported timber, concrete, steel or fibre cement – only in relatively few cases is it re-

placed by Australian plantation products.

The products that predominantly replace native forest timber products have high carbon cost, are less environmentally friendly and represent a much greater sovereign risk.

Some groups advocate for Australia to rely solely on plantations for its timber supply. However, claims that such a transition can be done easily are false and oversimplistic.

For now, we simply do not have sufficient plantations to replace the wood products sourced from native forests.

Increasing the plantation estate needs to start today, however even then it will take decades to meet Australia’s growing timber needs. Addressing this is an important task given that every recent global climatechange mitigation strategy highlights the increased use of wood as a substitute for materials with high carbon emissions.

Managing the threat of bushfires is another key consideration. Effective conservation recognises

and embraces the role of year-round fire management in maintaining healthy forests.

The reality is that converting state forest to national park causes a loss of capacity that seriously undermines efforts to prepare for, and respond to, future bushfires.

Lessons from Victoria show the difficulty and high costs of maintaining the skill and capacity of expert fire contractors following closure of the state forest industry that provides their core work.

Deciding which areas become a Great Koala National Park presents the NSW Government with a significant opportunity.

Through striking the right mix of national parks and state forests we can meet the many and varying needs of society and the environment.

By adopting holistic and science-based approaches, the NSW Government can demonstrate that it is possible to simultaneously achieve all the benefits flowing from well managed forests.

Forest & Wood Communities Australia is calling on the New South Wales Government to postpone any decision on the proposed Great Koala National Park until reliable and accurate data on koala populations can be verified.

According to Executive Officer Steve Dobbyns, a veteran forest scientist, the Department of Climate Change, Energy, the Environment and Water has managed to let down both the Premier Mr Minns and communities across the State by grossly exaggerating the number of koalas within some “koala hubs”, by using a count of scats (koala poo) found during surveys, instead of actual

koalas.

“A look under the hood at the data shows that numerous koala sightings within the koala hubs have impossibly high numbers of koalas, literally hundreds of koalas recorded at a single site, because the Department has not vetted the data,” said Mr Dobbyns.

“That is the quality of maths and science being used by the Department to provide advice to the Minn’s Government about which areas of the proposed Great Koala National Park are important to koalas.”

Whilst the NSW Government described koala hubs as “areas where there is strong evidence of multigenerational, high-density

populations” of koalas, FWCA notes there is no published, peer-reviewed research to support these claims.

FWCA has also identified multiple data entries of the same koala sighting and questioned how the Department could determine if some of the koala hubs had “strong evidence of multigenerational” koala populations.

“Despite koala sightings across the landscape dating back almost a century, the only records of koalas in some of the hubs were from the same point in time. There is no evidence of multi-generational use,” said Mr Dobbyns.

“With more than 8900 jobs

and $2.9 billion injected into our economy each year from our sustainable native forest industry in NSW, it is critical for our State’s future

Nominations are now open for the 2025 Green Triangle Timber Industry Awards.

GTTIA Chair Adrian Flowers has highlighted the importance of recognising and celebrating those within the industry who are driving innovation, safety, sustainability, and leadership.

The GTTIA Gala Dinner will be held on October 24 at The Barn, Mount Gambier, SA. Tickets will go on sale in September

A key feature of this year’s launch was the unveiling of the new online nominations platform, developed in response to industry feedback and designed to make nominating simpler, faster, and more user-friendly.

Key features of the new online nomination portal include:

• Industry Mentor Support –Every award category now has an independent mentor from the committee to assist nominees with guidance on creating strong submissions. These mentors are not involved in judging, ensuring fairness.

• Save & Resume Function – The new system allows nominees to save their progress and receive a secure link via email, making it easy for multiple contributors to collaborate on a single nomination.

• No Word Limits – Unlike previous years, nomina-

tions now allow for detailed submissions without restrictive word counts.

• Unlimited Attachments – Supporting materials, such as images, documents, and testimonials, can be uploaded to strengthen nominations.

• Extended Nomination Period – Historically, nominations opened in May/ June, coinciding with a busy financial period. This year, the earlier launch ensures more time to complete and refine submissions before the deadline.

• Mobile-Friendly & Intuitive – The new platform is designed to be accessible on any device, making it easier than ever to nominate from the office, the field, or home.

The Federal Government’s decision to prioritise an Australian Carbon Credit Units Scheme proposal, which seeks to cease or defer native forest harvesting, has been described an underhanded attack on Tasmanian jobs.

And Tasmania’s Minister for Business, Industry and Resources, Eric Abetz, says it also a direct assault on the environment, ignoring research from the CSIRO’s retired chief research scientist as well as the Intergovernmental Panel on Climate Change.

Mr Abetz said that this “latest sneak raid must be called out for what it is”.

“This is an attack on regional jobs here in Tasmania, plain and simple,” Mr Abetz said.

Designed by the Australian National University (ANU) and NSW Government, the Improved Native Forest Management in Multipleuse Public Forests Method (INFM) would require native forestry to be ended across Australia - including in Tasmania.

However, despite being supported by the Federal Government, it has

been revealed NSW undertook no consultation with the Tasmanian Government before it launched the plan.

Tasmanian Forest Products Association Independent Chair, Sarah Courtney, said the model tries to force the Tasmanian Government to march in lockstep with the radical proposal by the NSW Government.

“The model proposed by the NSW Government, and backed by the Federal Government, would see the end of sustainable native forestry in Tasmania” Ms Courtney said.

“Our industry has bipartisan support in Tasmania. But this looks like another case of a mainland state trying to impose its opinions onto our island.”

Mr Abetz said he had written to Federal Agriculture Minister Julie Collins to express his disappointment.

“And it is important to note that this is a direct assault on jobs in her very own electorate,” he said.

“Wood is renewable, recyclable and at the end of the day bio-degradable and Tasmania’s forest practices are second to none in the world.”

“These awards exist to celebrate the people in our businesses who are achieving great things, driving change, and inspiring those around them,” Mr Flowers said.

“We all know someone in this industry we look up to; that’s the person who needs to be nominated for the 2025

awards. It’s time to shine a spotlight on the exceptional talent that makes the timber industry what it is today.” For full details on award categories and submission guidelines, visit: https://gba. com/2025-award-categories/ Nominate now at https:// gba.com/nomination-form/

Converting woody debris into roading material is proving to be a winner for the environment, both in minimising gravel use and mitigating build-up.

Managing woody debris left after harvesting is a common challenge in forestry. Once it is cleared from the cutover and safely stacked, the key issue remains—how to handle the material.

Transporting it out of the forest is costly, while leaving it piled on landings can pose environmental risks during severe weather events.

With funding from Forest Grower’s Research (FGR), Pan Pac and FGR have been trialling a promising solution – using it as roading material.

Last month around 50 forest industry representatives from across the North Island of New Zealand joined Pan Pac and FGR in Mohaka Forest to get a first-hand look at the shred wood road trial in action.

Compared with metal roads, shredded wood roads offer the environmental advantage of repurposing waste wood while reducing traditional roading material transport distances, thereby lowering the carbon footprint.

Hamish Scown, Pan Pac Forests Operations Technical Coordinator, who has played a key role in running the trial, says the trial has produced some prom-

ising results so far, and has helped to identify the limitations and maintenance requirements of shred wood roads.

“The results so far indicate that shred wood roads could be a viable alternative to metal roads, where the grade is not too steep in wet conditions,” he said.

“In any case, in dry con-

ditions loaded stems units and 50t conventional trucks have been leaving the site uphill loaded at 11.5% with no run up.

“It is likely that a light spread of traction metal will help in wet conditions as per normal wet weather roading operations and that is something we will try next without too much

impact on cost.”

The trial is currently in Phase One, comparing different sized shred (200mm, 150mm and 200mm with 80mm ‘top dressing’).

The roads are 50m long trial sections originating at the landing loadout bays.

The best-performing particle size mix from Phase One will then be used in

Phase Two, where roads of different depths, preparation and application methods will be put to the test. When complete, Pan Pac and FGR hope to produce a tech note (specifications, application method, and rough costings) on shred wood roads, which will be made available to the wider industry.

The Tasmanian Forest Products Association has welcomed a commitment from the Federal Coalition that, if elected, it will oversee a review of the Tasmanian Freight Equalisation Scheme and support Tasmanian businesses to the tune of $62 million while that review takes place. Following the announcement, TFPA Chief Executive Officer, Nick Steel, said the review into the TFES is a much-needed boost for Tasmanian forestry businesses.

“The TFES model, as it stands, is no longer fit for purpose. This

scheme was set up almost 50 years ago and it’s clear it’s no longer working for Tasmanian businesses,” Mr Steel said.

“The TFPA has long argued that the current indexation model in the scheme is out of date – no longer keeping up with the exponentially increasing costs to move freight to the mainland that we have seen in recent decades.”

“Australia is currently in a cost-ofliving crisis. It’s being particularly felt here in Tasmania, not only by consumers but also by businesses trying to sell to the other states.

“Being an island, Tasmania is at a distinct disadvantage compared to other states when shipping goods to their markets. The Whitlam Government introduced the TFES in the 1970s to go some way to level the playing field between mainland and Tasmanian businesses.

“However, to work properly it’s essential to regularly review the scheme to ensure Its original purpose remains relevant.”

Mr Steel said it was clear the Coalition was listening to the concerns of businesses across the country, and he called on the Federal Labor

to do the same.

“This announcement by the Federal Coalition offers certainty to Tasmanian businesses looking to mainland markets during these tough economic times,” Mr Steel said.

“To ensure Tasmanian businesses can continue to support our local economy, and employ thousands of Tasmanians, the Prime Minister should immediately match this announcement and give our industry the certainty it needs to continue to build a stronger Tasmania.”

Scion scientists looking to establish New Zealand’s largest mixed-species Experimental Forest have sought inspiration from overseas.

Puruki Experimental Forest, south of Rotorua, is a 35-hectare Pinus radiata forest. It was originally established in 1968 as part of a United Nations land use study. With the second rotation approaching harvest, Scion is looking to build on its legacy to create an exciting integrated research platform that underpins the development of new forest systems capable of thriving under climate change.

In March, Scion received support for four exchange projects through a Joint Linkage Call Agreement between INRAE — France’s National Research Institute for Agriculture, Food and Environment — and Science New Zealand.

Among them was an exchange between Scion’s Designing Forests –Mahi Tahi Whaihua Portfolio Lead Yvette Dickinson and INRAE Principal Scientist Hervé Jactel aimed at fostering long-term collaboration on diverse forest plantations. Jactel has been visiting Scion this month after Dickinson’s trip to France in October and his expertise will help inform the future design of trials at Puruki.

His visit is the latest in a long-lasting co-operation between Scion and INRAE which also opens the door to larger collaborative projects.

Jactel has a background in forest ecology and entomology. While working on the largest plantation forest in Europe — a 1-million-hectare pure stand — he started exploring the effect of tree species diversity on resilience to pests and diseases. This led to joining TreeDivNet – an international network of tree diversity experiments, and Jactel developed France’s first experiment comparing pure and mixed stands in planted forests.

The work expanded to include other aspects of forest function such as productivity, carbon sequestration, and biodiversity conservation. He’s also looked at how biotic and abiotic disturbances are combining to increase damage to forest ecosystems.

His visit to Scion covered many areas including field visits, and conversations around current and proposed projects related to mixed forests, pests, diseases and biosecurity.

The most significant project Scion is drawing on Jactel’s expertise for is Puruki Experimental Forest where plans for the forest’s third rotation are being discussed, including the choice of species and the design of

integrated research programmes.

Dickinson’s visit to France included trips to some long-standing tree diversity experiments to gain knowledge to inform the design of Puruki. She says she was able to learn about their experiences mixing species and how to design and manage a tree diversity experiment.

Converting Puruki to a mixed species Experimental Forest also presents the opportunity to be the first New Zealand forest join TreeDivNet, an international network of collaborative experiments. Joining the network will allow access to shared data and knowledge.

Jactel says mixed stands have many advantages.

“Mix species forests are truly more resistant to pests and diseases. They are also associated with a higher level of biodiversity and in most cases, they are also more productive. They are also sequestering more carbon, both in soil and above ground,” he says.

Managing forests for resilience, sustainability and carbon sequestration all align with the Designing Forests – Mahi Tahi Whaihua portfolio Dickinson leads.

“We’re also interested in it from an overyielding perspective. While mixing species can sometimes improve productivity, it doesn’t always happen. Globally we’re trying to understand why it happens in some places and not others,” she says.

“To be able to demonstrate sustainability as a whole, we need to understand all of these different aspects. Puruki is an opportunity to build economics and social sciences alongside the environmental and technological systems.”

The hilly nature of the site could also allow for study into the benefits of tree diversity on erosion, Jactel says.

Tim Barnard who is leading the Puruki work, says the proposed integration of different fields of science on the one site will be novel and building on the legacy of science at Puruki.

“When Puruki was set up it was driven by the United Nations UNESCO programme which was concerned about water quality around the world at the time.

“People had the vision to create that forest 50 years ago and now we’re picking up that legacy to create new forest systems that are going to endure over the next 50 years,” he says.

“It’s not only about diversity, it’s about the need for diversity in the face of climate change.”

Researchers from the Swiss Federal Institute for Forest, Snow and Landscape Research (WSL) and EPFL are spraying water vapour into the crowns of mature pine trees in the Pfynwald forest in the canton of Valais.

The large-scale experiment is designed to reveal the impact of soil and air drought on forest trees in the context of climate change.

Something peculiar has been happening in the treetops of the Pfynwald forest in the canton of Valais since early summer: numerous high-pressure nozzles mounted on tall frames are spraying water vapour into the 12-metre-high treetops of mature Scots pines.

The installation is part of the ‘VPDrought’ experiment, a world first that aims to unravel the effects of soil and air drought in a natural forest ecosystem.

● The large-scale experiment is designed to reveal the impact of soil and air drought on forest trees in the context of climate change.

understand how hot and dry conditions affect the resilience of forests and which processes lead to the death of trees. The climate is getting hotter and drier, as it already is in many places in the Valais.

The consequences are already being felt: in the canton of Valais and in the neighbouring innerAlpine dry valleys (the region of Innsbruck, Lower Austria, southern Styria, Vintschgau, Aosta Valley), Scots pine trees are dying and being replaced by more drought-tolerant oaks.

The WSL has been studying the processes responsible for this in the Pfynwald forest for 21 years.

thirst’. The warmer the air, the more moisture it can absorb. This means that the heated atmosphere extracts more water from plants and soil. This ‘thirst’ is called vapour pressure deficit (VPD).

VPD is a key factor in how much water trees evaporate through their leaves or needles, and thus has a major influence on the water supply and cooling of the plant. With rising temperatures, it is expected that the VPD will increase exponentially. High VPD values lead to excessive evaporation, which can cause plants to suffer from drought stress.

The water vapour increases the humidity – a sophisticated technique uses high-pressure nozzles to atomise water into tiny droplets that evaporate so quickly that neither the trees nor the ground gets wet.

The project, which is funded by the Swiss National Science Foundation, the WSL, the EPFL and the SwissForestLab, aims to

The Woodsman Pro range offers the ultimate blend of productivity-enhancing tech and brute strength. Designed and built in NZ with over two decades of development in the harshest forestry conditions, Woodsman Pro is now available in Australia factory-direct with total support.

Every night, it waters parts of this forest in order to study the trees with and without drought stress.

Climate change is now adding another worrying environmental factor to the mix: increasing ‘air

In addition to the direct effects on plant physiology, a high VPD accelerates evaporation from soils, creating a vicious cycle of soil drying, land surface warming and drought stress for plants.

The Federal Government is inviting forestry industry and researchers to pitch their ideas for part of $5 million in grant funding.

The Government is investing $300 million in the future of the forestry industry, which includes over $100 million for AFWI.

“After the success of the First Round, I’m excited to see what transformative ideas are proposed through the Second National Open Call,” Australian Forest Products Association CEO Diana Hallam said.

“I encourage anyone with initiatives that will enhance the productivity and profitability of Australia’s forest industries both now and in coming decades to come forward.

“I am confident industry is united in wanting to ensure the $100 million investment called for by AFPA and delivered by

the Australian Government creates the products, jobs and climate solutions needed to decarbonise our economy and turbo charge this great Australian industry,” she said.

Research through this round of funding can include climate change solutions, sustainable forests, and making the most out of our available wood fibre.

Now is the time for industry and researchers to put their heads together and develop industry-driven research proposals with an end-user focus.

The successful projects will have matching funding from industry or other sources.

“Research like this is how we keep our forestry industry competitive, sustainable and able to face challenges head-on,” Minister for Agriculture, Fisheries and Forestry, Julie Collins said.

“Australia’s forestry industry has enormous potential, and I want to see it grow and thrive. The sector is a vital economic contributor and a huge source of jobs in my home state of Tasmania.

“Last year’s projects are researching practical solutions to a range of challenges, from finding Australian timber species for sports flooring and even finding ways to stop pest animals from eating seedlings,” she said.

“I’m looking forward to seeing what the next crop of researchers will discover.”

Last year’s call resulted in eight successful projects sharing the first $5 million grant and unlocking $8.3 million of matching investment from industry and research partners.

The Executive Director of Australian Forest and Wood Innovations Dr Joseph

Designed for Automatic Handling Easy Stacking, Easy Cleaning

TS-45

Tray 385 x 216 x 85 mm

TS-48

Tray 385 x 289 x 100 mm

Lawrence said this call for applications was about funding innovative ideas that can deliver real commercial outcomes and help solve industry challenges.

“We’re looking for research that will make a tangible difference, whether by strengthening local manufacturing, supporting sustainable forestry practices, or driving the transition to a circular bioeconomy,” he said.

“This round introduces a two-stage application process. The first stage invites Expressions of Interest, with selected applicants progressing to a full proposal submission.

“The new process, informed by industry and researcher feedback, is designed to streamline applications, enhance industry alignment, and maximise real-world impact.

“By introducing an EOI stage, we’re ensuring early

engagement with industry and giving applicants an opportunity to refine their proposals before moving to the next step,” Dr Lawrence said.

“This will help attract bold, high-quality ideas that directly address industry needs.”

The next Australian Forest and Wood Innovations (AFWI) National Open Call for forest research is open until 14 April 2025.

Details on the projects supported in the first round are available at Research projects – Australian Forest and Wood Innovations.

For more information on the second round, visit https://www.agriculture.gov. au/agriculture-land/forestry/national/australian-forest-and-wood-innovations or https://www.afwi.au/research/national-open-call/

Bev Betkowski

Awearable camera typically used to record the daring feats of skydivers or other thrill-seekers could also be a practical tool down on the ground, University of Alberta research shows.

By capturing hundreds of images in a short time in a greenhouse experiment, a GoPro was able to monitor the growth of tree seedlings as reliably as humans, according to the study.

“This shows that the GoPro may be a viable alternative to manual measurements, which could provide several benefits to low-tech greenhouses serving the forestry industry,” says Sarun Khadka, who conducted the work to earn a master of science in forest biology and management from the Faculty of Agricultural, Life & Environmental Sciences.

Using the camera’s timelapse mode, Khadka monitored germination, growth and survival of lodgepole pine seedlings in a commercial tree nursery. The images were captured over six months, then analyzed using software.

The results showed that

the germination count from the GoPro in week seven of the growing cycle closely matched the final seedling count recorded in week 24, “indicating the reliability of the image-based counts,” Khadka notes.

Similarly, there was no significant difference recorded in height when 15-week-old seedlings were measured using the camera images, compared with manual measurements.

The study demonstrates how such “high-throughput” technology can help address challenges in lowtech, large-scale greenhouse operations faced with manual counting and measurements, Khadka suggests.

“Taking manual measurements is highly tedious and time-consuming, and as a result, nurseries often rely on a small sample size to estimate germination rates, which could fail to accurately represent the entire seedlot.”

As well, manually measuring the height is invasive to the tender plants, and tight bench space also makes it physically difficult, she adds.

While it would come with one-time costs to buy

the equipment and train staff, using the technology would also likely be less expensive than installing a greenhouse-wide camera system, she notes.

Using GoPro technology could give commercial greenhouses and the forest industry a jump on providing the best estimates of plant performance in the early stages of growth, says Khadka, noting that constant monitoring and tracking of the entire greenhouse is important for a

nursery working to meet the total seedling order for a forest company.

“Our results show that this technology can bring the value of big data, in terms of capturing a large volume of images that can be analyzed, to improve efficiency in low-tech nurseries.”

The research was funded through the Industrial Research Chair in Tree Improvement held by Barb R. Thomas, professor and associate dean (research) in

ALES, and supported by the Natural Sciences and Engineering Research Council of Canada, Alberta-Pacific Forest Industries Inc., ANC Timber Ltd., West Fraser Mills Ltd. (Sundre Forest Products, Hinton Wood Products, Blue Ridge Lumber and Slave Lake Veneer), the Grande Prairie and Whitecourt divisions of Canfor Ltd., and Weyerhaeuser Company (Grande Prairie and Pembina Timberlands).

Two new projects run by Skill Insight and ForestWorks are underway to support skills development in manual tree felling with a chainsaw.

They follow the 2023-24 Tree Felling Project, which reviewed and updated three units for manual tree felling.

During that project, there was strong industry support for the addition of prerequisites to the units, to ensure learners have the necessary experience before enrolling. However, this was not within the scope of that project and required additional time to investigate. Adding prerequisites to the units presents challenges in maintaining their accessibility and reaching a

consensus on the appropriate prerequisites to use.

Manual tree felling using a chainsaw is a crucial skill across arboriculture, emergency services, land management, and forestry. It is important that anyone learning these skills already possesses certain preliminary skills before undertaking training in tree felling, so they remain safe throughout their learning, assessment and future employment. For instance, learners should have chainsaw handling skills before training in basic tree felling and they should have the skills to fell a standard tree before training to fell complex trees.

Pathway to tree felling skills project

Skills Insight and ForestWorks are undertaking this project to investigate the addition of prerequisites to the tree felling units or alternative mechanisms to ensure learners who enroll in tree felling possess the necessary skills.

The team will engage with the Training Package Assurance Body and State Training Authorities to seek advice on the feasibility of prerequisites and how to best support learner safety given the highrisk of the activity and variability in delivery across training providers and industries. Consultation will also take place with employers, registered training organisations and unions from across relevant industries to understand the vari-

ous viewpoints on the issue. Out of this, we will draft recommendations and an activity plan to support skill development in tree felling while promoting safety and adherence to delivery standards. Feedback will be collected on the recommendations and activity plan to check they are in line with stakeholder needs and expectations. A report including this information will be submitted to the Department of Employment and Workforce Relations to inform future work to strengthen the tree felling units and their delivery. Further details about the project team and timeline will be available soon.

This year it will be 55 years since forest machine entrepreneur Einari Vidgren founded a forest machine factory in Vieremä, Finland.

The anniversary year started on a high note as the 21,000th Ponsse forest machine was manufactured and delivered on February 6, 2025, to Scheff Logging & Trucking Inc. from Minnesota, USA.

Scheff Logging & Trucking Inc. is a family business established in 1977.

Jhace Pearson, the company’s representative, came over to the Ponsse factory with his best friend Matthew Vosika to receive the new Ponsse Buffalo.

Scheff Logging considers it vital that Ponsse’s entire personnel are committed to excellent service.

Scheff has grown into a three-generation harvest-

ing and transport company and employs more than 40 professionals.

Throughout its history, the Finnish family-owned company has focused on the development and production of cut-to-length forest machines and the provision of maintenance services for them.

While all forest machines are still manufactured in Vieremä, Ponsse is at home in forests around the world, as the company currently operates in the logging sites of almost 40 countries.

“Since the earliest days, Ponsse’s driving force has been the belief that only the best people, in cooperation with customers and stakeholders, can develop and manufacture the best forest machines in the world,” says Jarmo Vidgren, Chair of Ponsse’s Board of Directors.

“Still today, forest ma-

chines are developed and manufactured in the same way by more than 2000 Ponsse employees.

“As a result of long-term cooperation, Ponsse has grown over the years to become the world’s leading manufacturer of

cut-to-length forest machines,” he said. “In honour of the anniversary, we are going on a worldwide tour to meet our customers and stakeholders.”

Ponsse is celebrating the milestone by inviting customers, stakeholders

and Ponsse people to join the anniversary tour. The anniversary tour started from Finland on March 18 and will continue around the world during the year. Welcome to the events: https://events.ponsse. com/

Our service and support team are on hand to keep your operation running at peak efficiency.

Three foresters have started in specialist roles within Forestry Corporation after completing a two-year graduate training program.

Staff members Lydia Kearns, based at Wauchope, Jack Power at Batemans Bay and Justin Yip at Tumut started with Forestry under the 2022/23 graduate intake.

Over the course of the past two years, they have completed ‘on-the-job training’ undertaking a series of work rotations across different Forestry divisions.

Graduating as foresters, they have now started in roles within their chosen fields of forest science.

Graduating as foresters, they have now started in roles within their chosen fields of forest science.

“It’s a position where I deal with many sides of the business, assisting teams who work across Tourism Partnerships, Roading and Production, Cultural Herit-

age and Ecology in a role that combines a good mix of time in the office with trips out into the field,” Lydia said.

Originally from the Blue Mountains, Lydia started with Forestry Corporation after graduating from the University of Sydney with a Bachelor of Science and Bachelor of Advanced Studies Majoring in Environmental Science, Ecology and Evolutionary Biology.

“I really appreciated the opportunity to join Forestry as a graduate here in Wauchope. It was a great starting point where I got to learn the whole perspective of Forestry both as a science and as an industry,”

Lydia said.

“The program is a good gateway for anyone wanting to get involved in this style of work, particularly university students who might not necessarily know what silviculture involves.

“Highlights in the job for

me have been helping to provide ecology plans and working in the field with ecologists on their wildlife monitoring and trapping programs.

“I have also enjoyed the experience of becoming an accredited firefighter working on wildfires and hazard reduction burns to protect state forests and native wildlife from bushfires.”

Justin Yip is now working with the Softwood Division’s Forest Resources Team on plantation and tree improvement programs.

Originally from Sydney, Justin started with Forestry Corporation after graduating from Charles Sturt University with a Bachelor of Environmental Science and Management degree, specialising in Parks, Recreation and Heritage.

“During the two-year program in Tumut, I rotated through Silviculture, Harvest and Roading, Forestry Resources and Fire and

Stewardship. During this time, I was given the opportunity to gain an insight into the inner workings of each division,” Justin said.

“What I appreciated most about this program was the opportunity to work with a range of talented people in different areas of the business,” he said.

Justin said he gained a wealth of professional satisfaction working on significant State Forest projects.

“During my rotation with Fire and Stewardship, I was privileged to be involved with the Bago State Forest Nature-Based Tourism Enhancement project, which is important because it represents the community’s ongoing recovery following the 2019-20 Black Summer Bushfires,” Justin said.

“I played a part helping with the installation of infrastructure at the new iteration of the Sugar Pines and upgrade to the Lochinvar Rest Area.

“I particularly enjoyed my involvement with these projects as open space management was one of the subjects I enjoyed most during my studies.

“Throughout the program I was completely supported by each team. I felt my work was meaningful and contributed positively to the business with opportunities to develop professionally. I also formed positive working relationships with colleagues and contractors,” he said.

For decades, Forestry Corporation has offered pathways to university graduates, who have completed studies in the fields of forestry, agriculture, environmental science and natural resources.

All Forestry Corporation staff train and serve as forest firefighters providing fire protection and land management across two million hectares of state forests in NSW.

P&T Lonergan Pty Ltd is a family-owned logging business based in Tumbarumba, NSW.

Founded by Peter and Theresa Lonergan, the business operates as a close-knit team.

Peter, with 30 years of experience in the logging industry, oversees field operations, while Theresa manages the office/field administration and operating a forwarder when required.

The company began its haulage operations in 2005 and expanded into harvesting in 2007 with Hume Forests Ltd, Tumbarumba, where they ran a hot log operation for five years.

Leveraging their expertise, they expanded further with a Forest Corporation NSW Tumut harvesting contract from 2012 to 2021.

This was followed by HVP harvesting contracts in the Ballarat and Northeast forest areas from 2014 to 2017.

In the aftermath of the devastating 2019/2020 fires, the company located its operations to Forest Corporation NSW Bathurst in late

2021 for a short-term rollover contract.

In November 2024, P&T Lonergan successfully secured a new Clear Fall contract and a five-year T1 contract with ACT Forests, which began in February 2025.

As a true family business, all members of the Lonergan family are involved in the operation.

Callum operates a harvester in the Bathurst/ Oberon region, Ben runs a clear-fall harvester, and Zoe, who recently joined

the team, operates the wheeled harvester in the ACT.

While they are all skilled operators, they also serve as supervisors on their respective jobs.

The family’s long-term plan is for their children to take over the business when Peter and Theresa retire.

The relationship between Komatsu Forest and P & T Lonergan dates back to 2009 when Peter first participated in one of Komatsu Forest Sales representative

Nigel Howard’s contractor motorbike rides in Tasmania.

Nigel, who handles the Lonergan’s region, successfully sold Peter a new Komatsu 895 in April 2015 for the HVP contract in Ballarat.

In 2017, Peter and Theresa joined Komatsu Forest’s customer tour to Elmia Wood in Jönköping, Sweden, with a slight detour to attend the Isle of Man Classic motorbike race.

For their two new ACT contracts, the Lonergans required four new machines; a large harvester and forwarder for the clear-fell operations, and a medium-sized harvester and forwarder for the first thinnings.

Like every major purchase decision in today’s market it was a highly competitive process to win Theresa and Peter’s business.

Komatsu Forest was successful in gaining the forwarder business based on a good industry reputation and their products provided the right mix of capacity for both contracts.

T he 895 Speed Shift for clear-felling is perfect for handling large amounts of wood

“The Komatsu 875 is an excellent forwarder for thinning operations,” Peter said.

“Its smaller size provides better flotation across the ground, particularly in wetter areas during winter.

“The 895 Speed Shift for clear-felling is perfect for handling large amounts of wood,” he said.

“The Comfort Ride, Speed Shift, and Smart Crane features make the machine a pleasure to operate, ensuring our operators feel more refreshed at the end of the day.”

The Lonergans have experienced the many changes in the industry over the last 25-30 years which has been challenging but rewarding, especially establishing the family team.

For Komatsu Forest it has been a great result in re-establishing a customer connection with the Lonergan family and look forward to strengthening the connections in the future.

Nigel mentioned that maybe the family will give Peter a leave of absence to join his next motorbike tour.

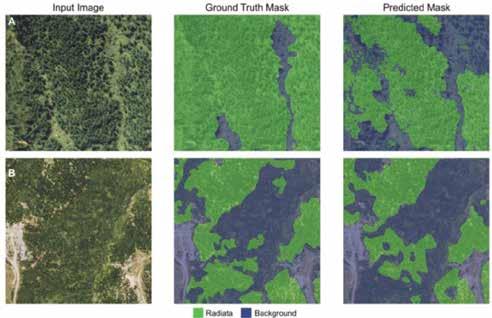

New Zealand and Flinders University experts have deployed artificial intelligence and 3D laser scanning to accurately map planted pine (radiata) forests for most of NZ’s North Island.

The results, which distinguish planted large estates, small woodlots and newly established stands as young as three years old, showcase a new way of using remote sensing with other technology to reveal forest growth and update growth information.

This approach is just as relevant for Australia, where radiata pine is also widely grown, says Dr Grant Pearse, Senior Lecturer in Remote Sensing and Geographic Information Systems (GIS) at Flinders University. “In New Zealand, where radiata pine plantations dominate the forestry sector, the current national forest description lacks spatially explicit information and struggles to capture data on small-scale forests,” says Dr Pearse, from the College of Science and Engineering at Flinders University in Adelaide, South

Australia.

“We combined deep learning-based forest mapping using high-resolution aerial imagery with regional airborne laser scanning data to map all planted forest and estimate key attributes.”

The spatially explicit forest description provides wall-to-wall information on forest extent, age, and volume for all sizes of forest.

This facilitates stratification by key variables for wood supply forecasting, harvest planning, and infrastruc-

ture investment decisions – applications equally valuable for other forestry industries.

The research, with New Zealand timber industry researchers from Rotorua, Christchurch and Auckland, was carried out on planted forests in the Gisborne region, which has

publicly available aerial imagery and airborne laser scanning data.

This region is particularly significant as it was severely impacted by Cyclone Gabrielle in early 2023, which caused widespread landslides and forest debris flows.

For such vulnerable ter-

rain, knowing exactly where forests are located in the landscape, their age and condition is key to managing the risks of harvesting operations on the region’s steep slopes.

The forest map derived from artificial intelligence can be viewed at: www.forestinsights.nz

The newest member of Kesla’s forestry trailer range, the KESLA 165 trailer with a net payload capacity of 16 tons, has been granted EU167/2013 type approval.

This type of approval is a requirement in EU countries for the trailer to be registered for road use. With the type approval, the trailer’s maximum speed for road traffic is 30 km/h.

This type approval continues Kesla’s history of type approvals for its forestry trailer models. For the KESLA 165 trailer, the approval has been expanded to include, in addition to pneumatic brakes, dual-circuit hydraulic brakes and 710/40-22.5 inch tires.

“Type approval for road use is essential in the EU, especially in Central Euro-

pean and Baltic markets,”

Aappo Hyttinen, Product Manager for Kesla’s Tractor Equipment, said.

“It’s great that for the 165 trailer, we managed to extend the approval to cover dual-circuit hydraulic brakes and 710/40-22.5 inch tires.

“The 165 trailer now offers brake options with dual-circuit pneumatic and hydraulic systems, providing great flexibility when it comes to tractor selection.

“Kesla is the only manufacturer of 16-ton net payload trailers on the market with 167/2013 type approval,” he said.

Finnish Kesla launched a new generation box-framed KESLA 165 forest trailer at the Agricultural Machinery Trade Fair in Helsinki, Finland, last year.

Kesla 165 marks the beginning of a new era in tractor-drawn forestry trailers with its robot-welded boxframe-type structure and technical features earlier known from purpose-built forwarders.