FOR BETTER LOGISTICS

Movella offers versatile transport solutions for the concrete element industry. Translifters, U-loaders and load platforms improve efficiency.

transport trestle system

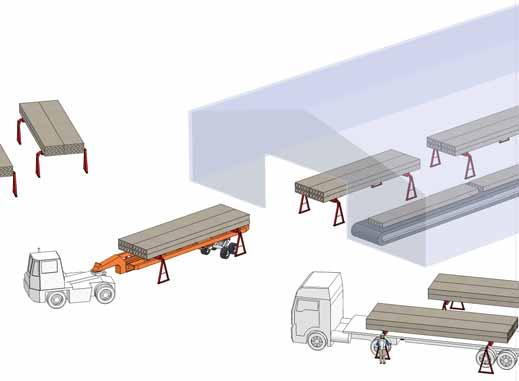

Hollow core slabs from production to the customer with as little handling possible. No cranes in the warehouse area, no handling damages, minimum man power.

Translifter eliminates transport and warehousing problems

Movella translifter eliminates transport and warehousing problems in concrete element factory. Self loading translifter picks up the load, transports it out and leaves on the warehouse area without any help from cranes. Movella translifter is specially suited for long products such as hollow core and TT-slabs, beams and poles and wall elements, stair cases and even re-bars. One translifter takes care of all transports in concrete element factory.

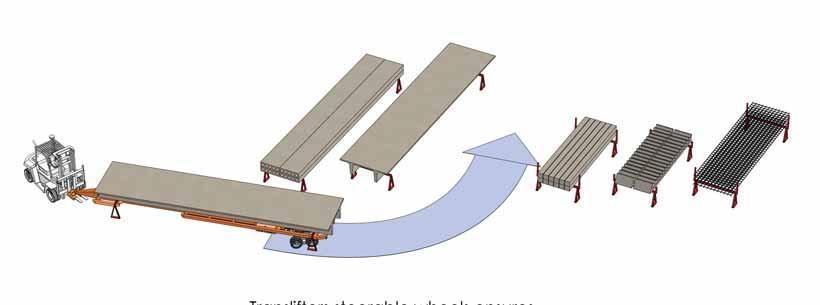

Movella U-loader solves the warehousing problems in the wall element production and minimizes handling of the elements. Movella U-loader is like the inloaders which are commonly used in

the road transports but Movella U-loader is designed for internal logistics: it is safe, easy to use and technically robust. Movella U-loader is compatible to standard cargo flats of inloaders. U-loader can be operated by a terminal tractor or a big forklift truck.

A-cassette is both working platform in production and transport platform between production stages and the warehouse. This reduces handling of the elements and improves efficiency. Working with A-cassette is safe as it is equipped with proper stairs and safety rails.

Translifter

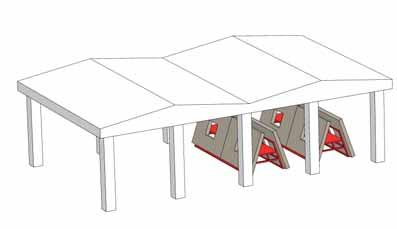

Wall elements are loaded on cargo flats to shipping ready loads.

Wall elements are loaded on cargo flats to shipping ready loads.

NT25 22 – 354 – 2521007001050F, W, T

NT25H 25 – 356 – 2521009501750F, W, T

NT40 30 – 506 – 3522706701000F, W, T

NT60 40 – 657 – 3526009501300T