TRITON AX

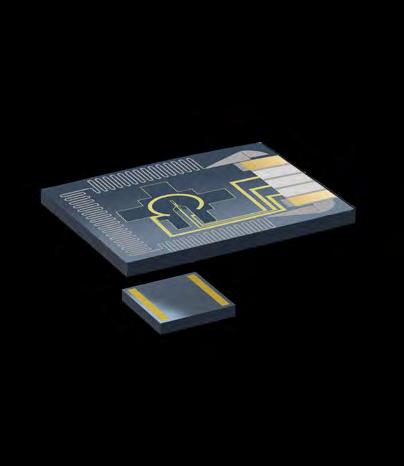

Heating & Cooling Liquid Electrochemical System for TEM

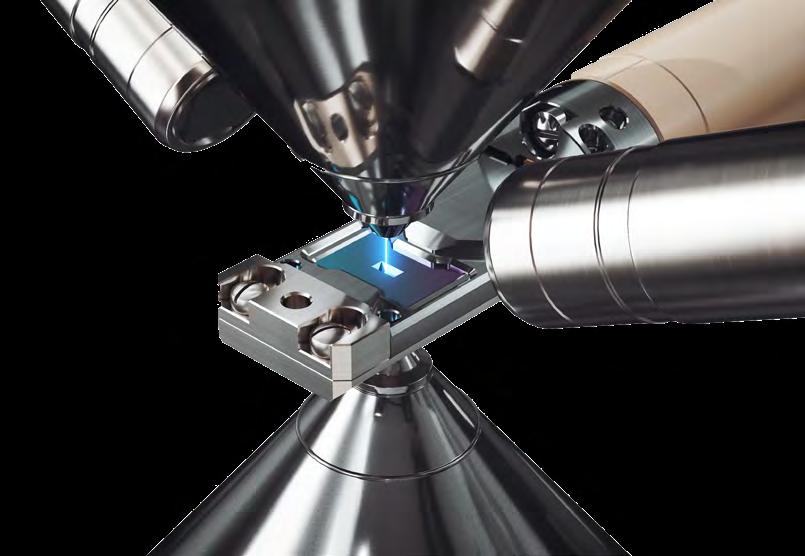

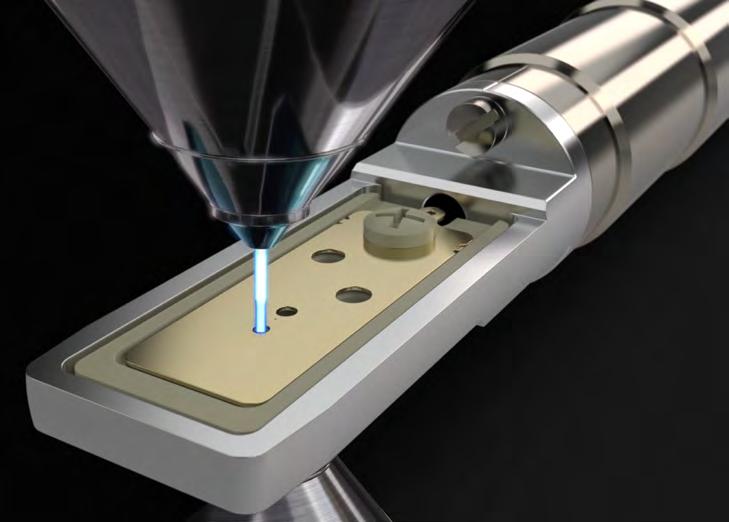

A complete solution from sample preparation to publication, Triton AX brings a new level of true operando conditions to TEM

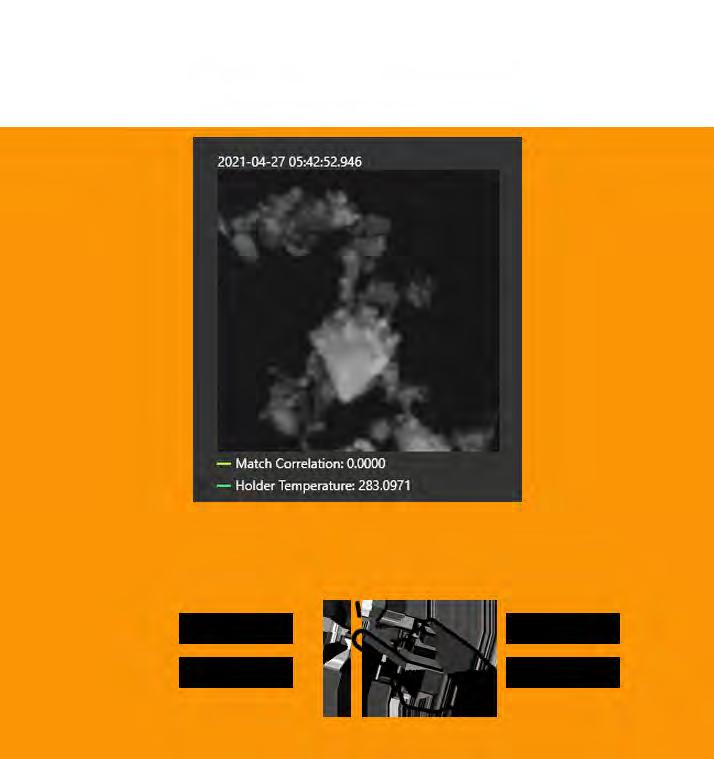

The first-of-its-kind machine vision software combined with the only thermoelectric liquid cooling system on the market enables a stable, precise, and quantitative temperature-controlled electrochemical solution for TEM that accelerates innovation.

→ Self-aligning assembly

→ Design optimized for in situ EDS in a liquid-filled cell

→ Wide chemical compatibility due to robust gasket materials

→ Maintenance does not require holder disassembly

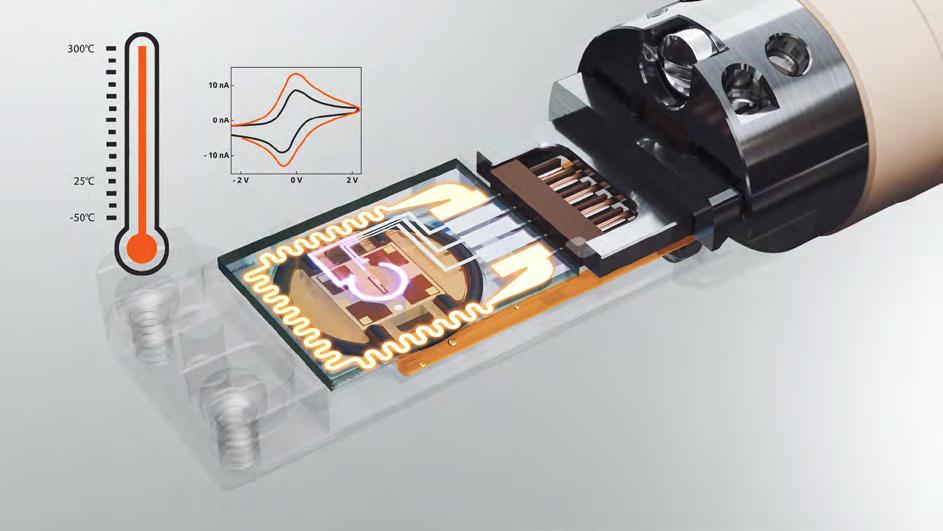

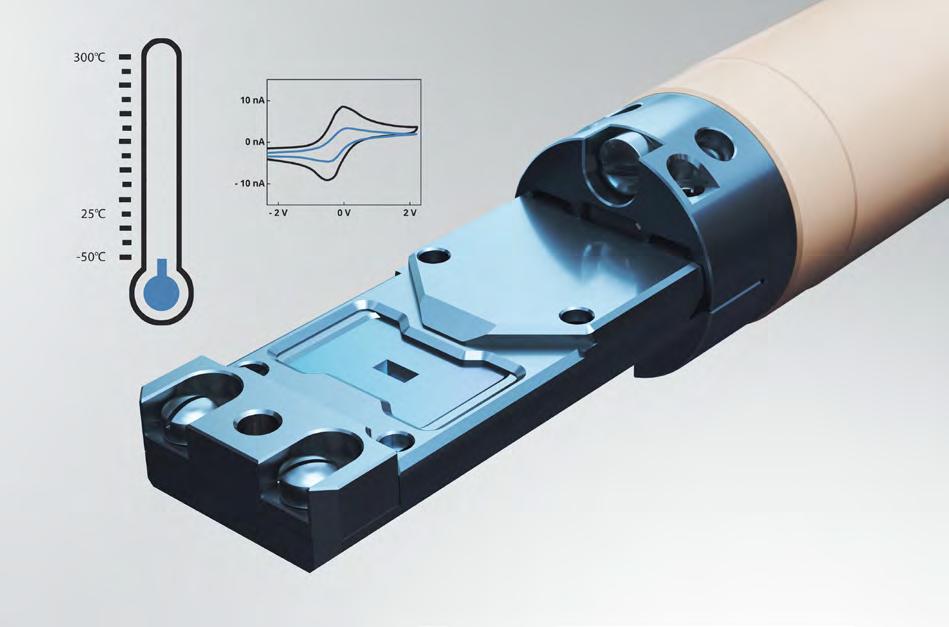

→ Temperature range of -50 °C and 300 °C

→ Unlimited, vibration-free imaging below room temperature

→ Isolated channels for heating and electrochemistry

→ Glassy carbon working electrode option

→ Standard reference electrode for comparison to bulk-scale measurements

→ Specialized E-chips available for FIB lamella from bulk materials

→ Unique designs to prevent interference from gas bubbles

→ Integration, indexing, and alignment of all electrochemical data with images

SOFTWARE PLATFORM

→ Automated drift and focus correction

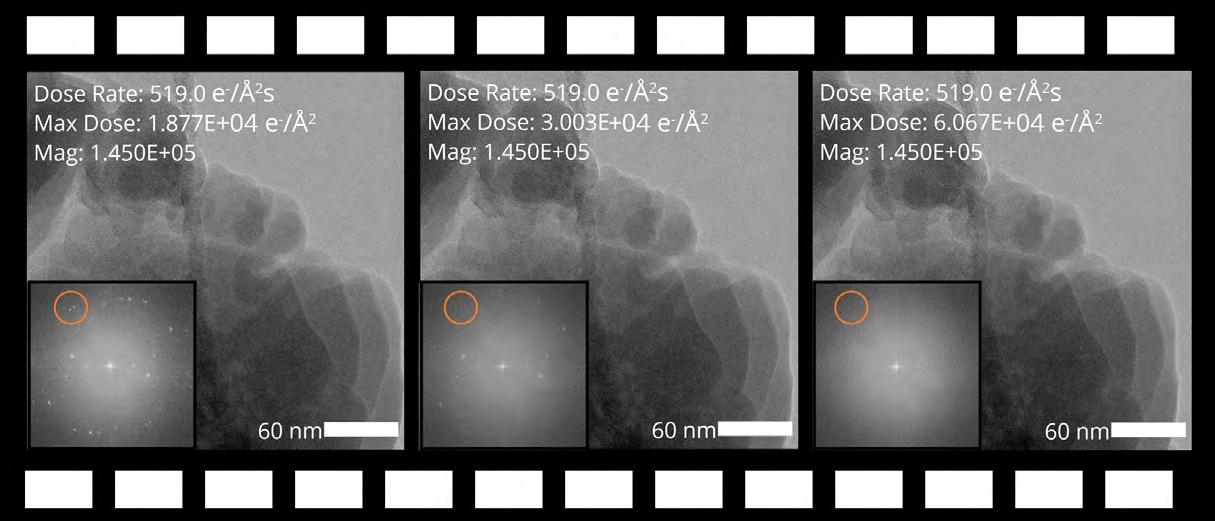

→ Real-time dose monitoring across the sample

→ Metadata indexing

→ Offline analysis software

→ Tools like the shadow mask, FIB stub, and inspection holder for quick, reproducible sample prep

→ Extensive E-chip catalogue: range of spacers for different samples and narrow window widths to control bulging

Enable the study of nanoscale structural changes that affect bulk-scale function at extreme temperatures

Observe the correlation between structure, morphology, and chemical composition with changes in robustness, activity, lifetime, and other functional properties of materials over time and in a relevant environment.

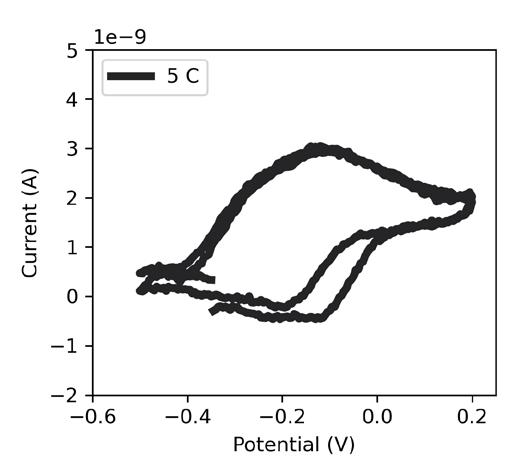

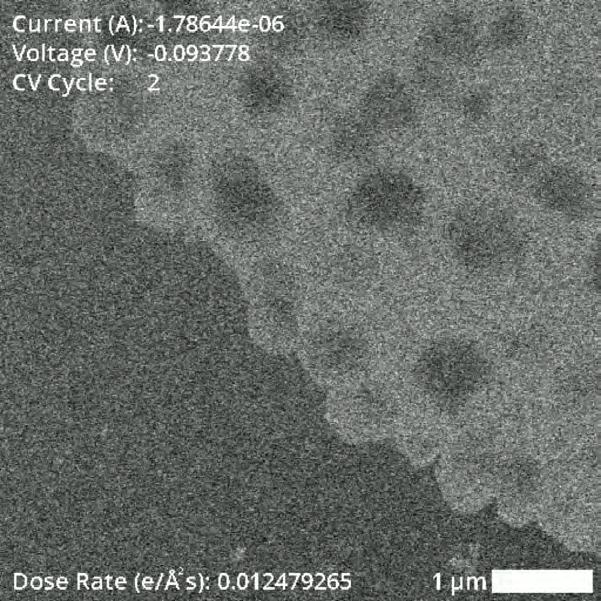

STEM micrograph and cyclic voltammogram of Pt working electrode with copper plating layer at 5 °C. Copper sulfate electrolyte (50 mM) in sulfuric acid (0.1 M) flowing at 10 uL/ hr. Dendrite morphology, kinetics, and current measurements differ significantly (smaller, slower, and lower, respectively) from those at higher temperatures (right). Dose was tracked using the AXON Dose software.

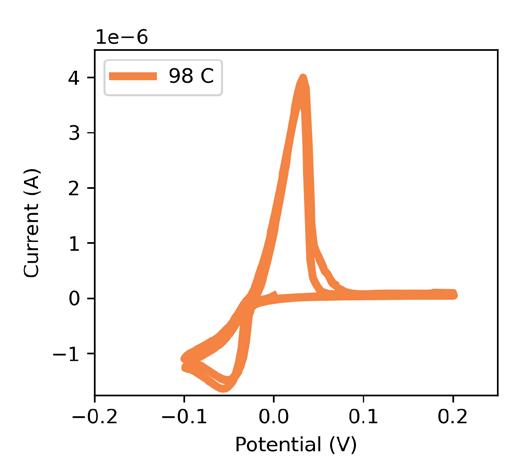

STEM micrograph and cyclic voltammogram of Pt working electrode with copper plating layer at 98 °C. Copper sulfate electrolyte (50 mM) in sulfuric acid (0.1 M) flowing at 10 uL/ hr. Dendrite morphology, kinetics, and current measurements differ significantly (larger, faster, and higher, respectively) from those at lower temperatures (left). Dose was tracked using the AXON Dose software.

Perform quantitative electrochemical analyses at temperatures ranging from –50 °C to 300 °C

Precisely set the temperature through the entire range using a combination of thermoelectric cooling and Protochips’ patented full-cell heating technology. Enjoy unlimited, vibration-free imaging time as there is no liquid nitrogen to refill.

With the addition of cooling, the study of electron beam sensitive materials now becomes more manageable.

Isolated channels for heating and electrochemistry prevent interference from crosstalk, enabling quantitative, accurate electrical measurements while heating or cooling.

Miniaturize standard electrochemical experiments using common materials for results that are more easily compared to bulk-scale data

Utilize any standard reference electrode that makes sense for the experiment, such as silver/silver chloride or saturated calomel, for maximum signal stability and a more straightforward comparison to bulk experiments.

Glassy carbon is offered as a standard working electrode material which is not only inert, but allows for a wider viewing area of the reaction than a metal electrode due to electron beam transparency

A novel deposition method for these NixB electrocatalysts is tested, depositing them onto an electron-beam transparent glassy carbon working electrode, and then cycled.

Flow management E-chips are an easy and reliable way to manage bubbles, whether intentionally or unintentionally generated, and ensure enough electrolyte is around the electrodes for maximum signal to noise.

Cyclic voltammetry curves obtained while scanning at low voltages. The normal H2 formed at -1.23 V is mitigated by the specialized E-chips. The selected flow rate was 1200 μL/h

View gas-generating reactions such as the reduction of CO2 without the risk of drying the viewing area or interrupting the electrical signal.

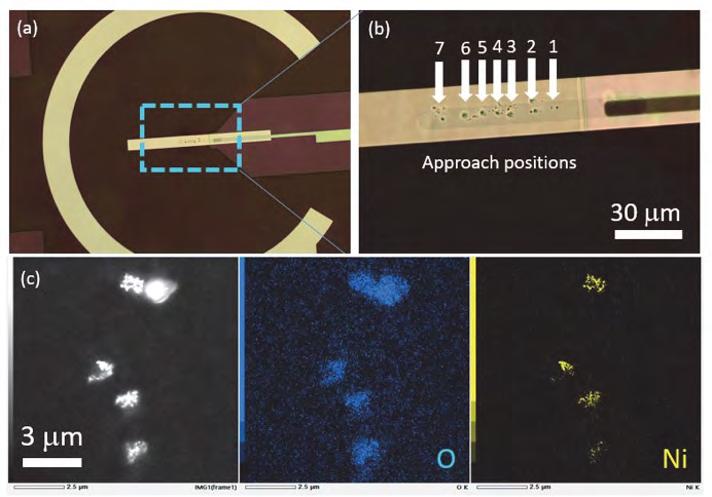

Analyze chemical composition of samples with maximized x-ray collection for accurate EDS analysis in a liquid-filled cell

Active electrodes are always located on the top chip of the cell to enable in situ x-ray analysis with EDS and high resolution STEM imaging, even in a liquid-filled cell. There is no need to empty the cell in order to perform EDS.

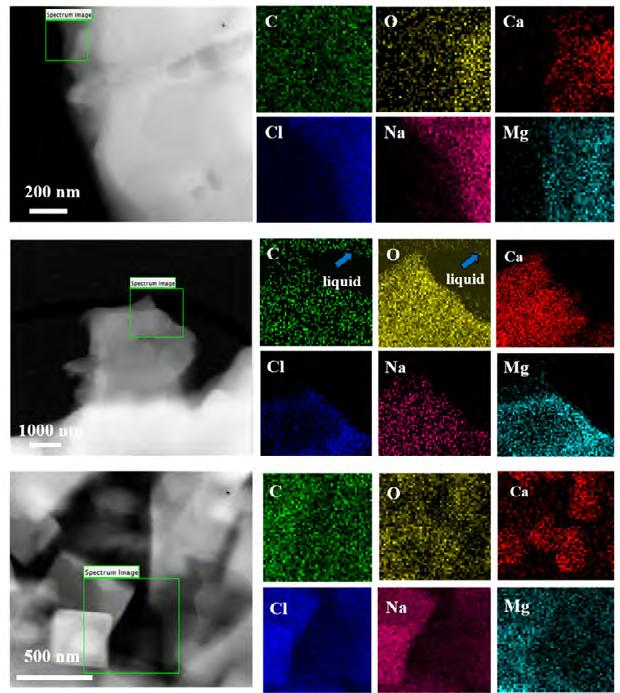

Research on the synthesis of core-shell nanostructures while simultaneously imaging the compositional distribution. EDS and STEM images were captured in a liquid-filled cell

(Right) CaCO3 nanoparticles investigated as a model rock system to show the interaction between calcite, oil, and brine at the interface. Dodecane was added to a low saline-water mixture and measured with EDS to visualize the liquid interface. The broad chemical compatibility of P-rex gaskets makes it possible to investigate a large variety of liquids.

Accurate semi-automated beam current and area calibration with proprietary Faraday cup holder

Once calibrated, the AXON Dose software tracks electron exposure even as the sample moves. Electron exposure can be illustrated using colorful dose maps for quick visual understanding of accumulated dose

Thoughtfully designed arsenal of tools that support reproducible sample preparation and fast introduction into the TEM

Workflows to fit your sample

Drop-cast, sputtered & powder samples

Flow, Static and Microwell Configurations

Pre-experiment ex situ

Electrochemistry and Heating

The inspection holder enables screening of sample deposition onto the E-chips, as well as high-resolution pre- and postexperiment analysis of the sample to complement in situ results.

Post-experiment ex situ

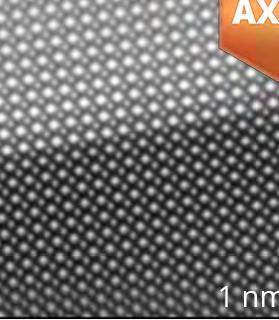

4D-STEM provides critical information about a material’s structure, and when coupled with in situ observations, changes in morphology can be coupled to structural changes. In this example, the morphological evolution of copper nanoparticles is observed during electrochemical cycling. 4D-STEM and selected area diffraction were obtained using controlled bubble formation to enhance resolution in the cell. These results showed that the Cu2O nanograins consisted of several crystallographic domains, which can give insights about the structural factors that are of importance during C2+ product formation.

Coupling diffraction with in situ electrochemical cycling can reveal changes in structural composition during catalyst operation. In this research, researchers are following the evolution of Pd to PdHx during cyclic voltammetry. The Pd particles underwent morphological changes when applying various potentials in a CO2 saturated 0.1 M KHCO3 electrolyte. To confirm the visual changes, Protochips’ glassy carbon working electrode was combined with selected area diffraction. Ultimately, researchers combined these results to draw conclusions about the catalyst’s performance during operation

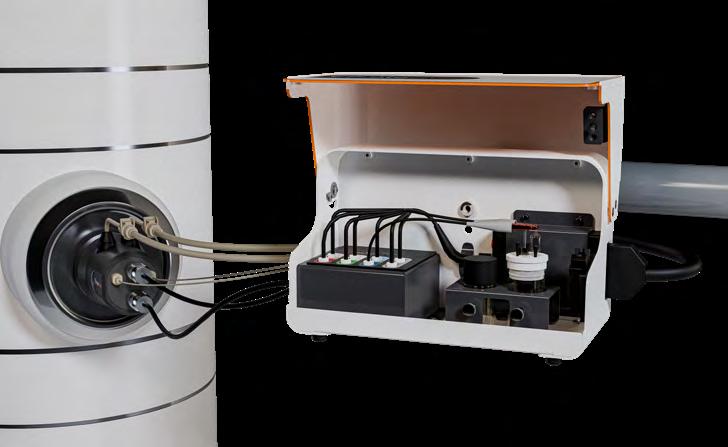

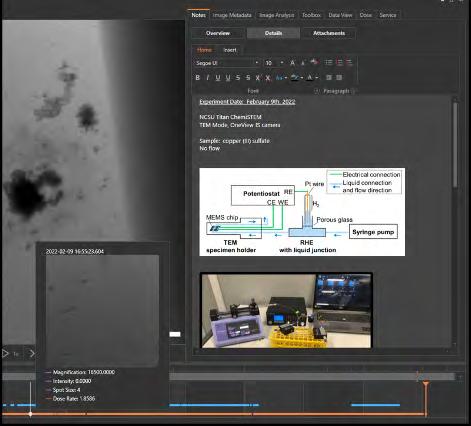

AXON is a machine vision software platform with modular expansion for the TEM. AXON enables data collection and communication with the TEM and imaging systems, electron dose management, and large data set processing for reports and publication both inside and outside of the lab.

AXON provides a solution to help science return to a high level of rigor and reproducibility, and greatly enhances the productivity of scientific communication and collaborations.

Obtain high resolution images much easier through machine vision stabilization technology | AXON SYNCHRONICITY

Live, 4-level drift correction technology continuously recenters and aligns the image throughout an experiment, even at high magnifications

Rough sample stage movements

Smaller piezo corrections Beam shifts for smaller drifts

More consistent, high-quality results for users of all experience levels

Digital correction is always on

Visualize and navigate large amounts of data quickly and create reports

Include “session metadata” like notes, publications, and photos related to experimental preparation

Filters and fast data scrubbing allow a quick review of very large image stacks to focus on the most important areas

All metadata aligned with images in real-time…

A simple copy/paste function builds reports in seconds, eliminating the need for complicated export processes and reformatting of data

Identify trends and results much more easily in large data sets and across different instruments

Enhance collaboration by making experimental results easier to share, publish and reproduce

Studio is freely available to the community allowing data and metadata to be shared with anyone, greatly enhancing collaboration

All session and experimental history recorded, making correlation and reproduction of results far more accurate and quantitative, even between different instruments

All data continuously synchronized and indexed making it easy to sort, filter and analyze very large data sets

Conforms to the FAIR Principles Initiative – making data more Findable, Accessible, Interoperable and Reusable

Temperature Range -50 °C to 300 °C

Temperature Accuracy ≤ 4% of ∆ between room temperature and setpoint temperature

Temperature Resolution Measure 0.01 °C Control 0.01 °C

Cooling Time

Cooling Mechanism

Room temperature to 0 °C 5 minutes

Room temperature to -50 °C 20 minutes

Thermoelectric device (Peltier)

Imaging Time (at Temperature) Heated Unlimited

Resolution 2 ± 1 nm or better

Ultimate Drift (AXON off) < 0.1 nm/min

Ultimate Drift (AXON on) 0 nm/min

Electrical Crosstalk < 10 mV ∆ between OCP at RT and OCP at 50 °C, DI Water

Electrochemical Stability

< 5 mV ∆ OCP at 25 °C, DI Water

Electrode Materials RE* Ag/AgCl, Pt (pseudo-RE on E-chip)