Catalytic nanoparticles are constantly changing structure throughout their lifetime which can have a profound effect on their performance. There is no question that an in-depth understanding of this structure-function relationship provides valuable insight into future catalyst design. Whether you are studying automotive catalysts or industrial catalysts, Protochips uniquely supports this research with the Atmosphere AX in-situ TEM solution. Atmosphere AX is not just an in situ TEM holder, but an entire workflow. From sample preparation to data publication, Atmosphere AX fosters relevant results that complement bulk scale analyses and drive catalyst innovation forward. To support this workflow, Protochips

focusses on a thoughtfully designed arsenal of tools that support reproducible sample preparation and fast introduction into the TEM. After preparation, the collection and analysis of data becomes critically important. Machine vision software combined with specialized analysis equipment optimize the time at the microscope. Our free data analysis software, AXON Studio, helps you easily identify trends and results in large datasets, simplifying the publication stage.

This edition of our newsletter will highlight different examples of how the Atmosphere AX system supports heterogenous catalysis research at the nanoscale!

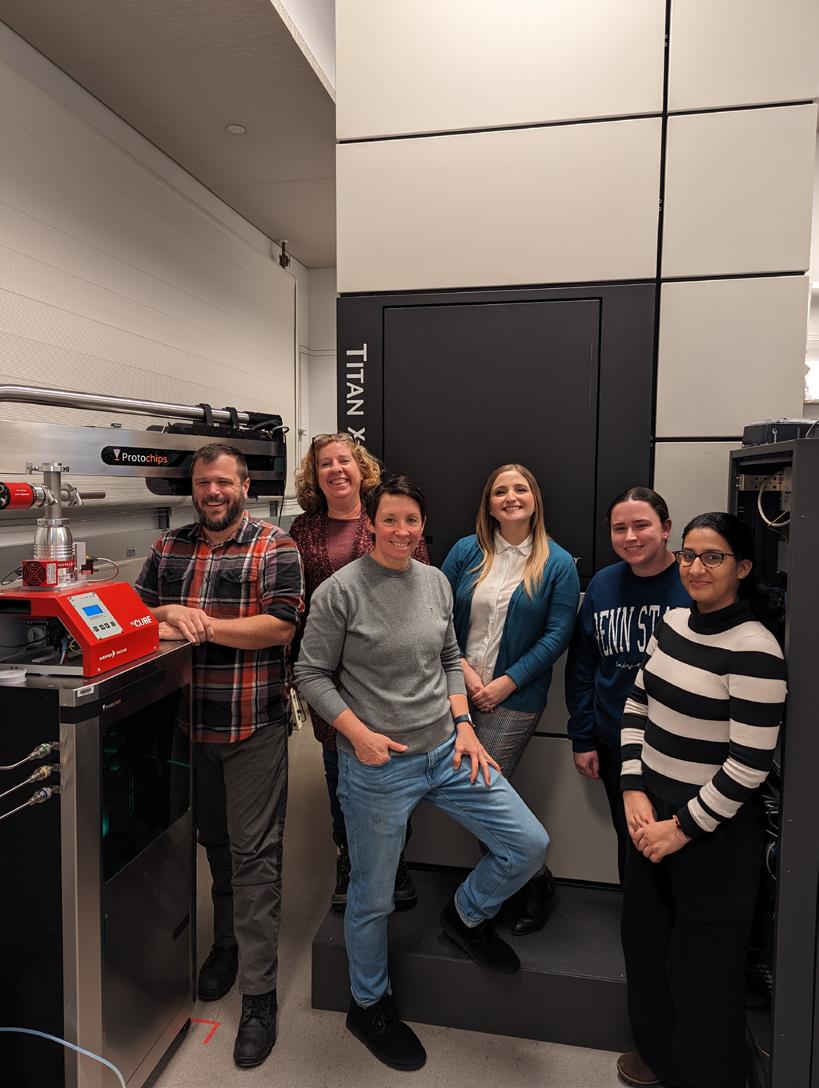

On the 20th of February Protochips’ Nynke Krans (applications) and Simon Ma (VP of Sales) visited our users in Manchester to demonstrate the operation of the Poseidon system in a Titan TFS microscope. PhD students and Postdocs from Manchester, Cambridge and UCL London came to learn from our applications specialists. We hosted a morning of great talks from both Xiangli Zhong and Simon Ma.

Xiangli Zhong gave a presentation based around the methodologies which have been developed to facilitate the preparation of electron-transparent samples from conventional bulk metals and alloys for in situ liquid/gaseous cell S/TEM experiments.She showed the development of hybrid electrochemical - Focused Ion Beam (FIB) sample preparation methods and redeposition approaches enabling successful insitu analysis using the Fusion AX and Poseidon AX systems.

Simon Ma gave an overview of how Protochips tries to fill in the gaps to in situ electron microscopy using a workflow solution. He talked about how the system can be used for a number of applications and gave examples from published battery, corrosion and electrochemistry studies.

The afternoon session included a tour of the labs and a live demonstration of the electrochemical formation of silver dendrites from a AgNO3 solution. In this experiment, we used cyclic voltammetry to grow and dissolve the silver while imaging at the microscope! Then, we went to enjoy some drinks and snacks with poster presentations and some handson experience with the system.

Thank you again Matthew Lindley and Sarah Haigh for hosting us at your institute!

PIK Instruments, our esteemed distributor located in Piaseczno, is well known for supplying market-leading scientific instrumentation for microscopy, metallurgy and technical cleanliness to research institutions across Poland. This company was founded in 2010 and has been working with Protochips for over 5 years. Within PIK Instruments, Lukasz Remez can be seen in the photo above, second from the right, has been representing Protochips since 2019.

PIK

https://pik-instruments.pl/en/

PIK Instruments is a growing company that distributes laboratory equipment from well over 25 manufacturers within the field of microscopy, ranging from SEM/TEM, to atomic force microscopy to sample preparation tools. Additionally, PIK Instruments offers solutions for metallography and digital microscopy.

As the owner of Micro-Shop the first online shop in Poland (https://micro-shop.pl/?lang=en) to offer accessories for electron microscopy, PIK instruments meets the expectations of our customers by facilitating a simple and smooth ordering process.

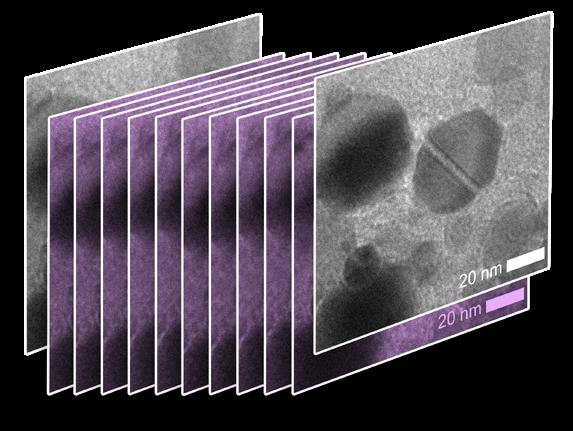

A catalyst materials’ stability is fundamental to its performance and successful commercial adoption. Especially core-shell structures have demonstrated improved stability, encapsulating the catalytically active sites within the core in a porous protective layer. The strong metal support interaction (SMSI) phenomena between a catalyst particle and its support material can play a critical role in the formation of stabilizing core-shell structures during cycling.

Researchers at The Hong Kong Polytechnic University and University of Oxford have developed a generalizable, onestep approach for encapsulating transition metal catalyst particles via thermally induced SMSI. Using Protochips’ in-situ gas-TEM system, Atmosphere AX, they were able

to visualize and characterize the encapsulation mechanism in real-time under operando conditions. They were able to identify promising, morphologically stable candidates that exhibited significant improvements in long-term performance.

Click on the image below to view the Flash Talk on YouTube

In her flash talk, Dr. Charlotte Vogt delves into structure insensitive reactions, shedding light on the underlying mechanisms through a study on silica-supported Ni metal nanoparticles. Supported nanoparticle catalysts, like those examined in this study, play a crucial role in various industries. Dr. Vogt highlights the common size-dependent activity relationship observed in catalytic reactions, where smaller particles typically exhibit greater activity (structure sensitive reactions), while conversion in structure-insensitive reactions remains constant regardless of nanoparticle size. Through in-situ observations using the Atmosphere system, she reveals how ethene hydrogenation triggers lattice expansion and particle distortion, ultimately exposing active sites and leading to the observed structure-insensitive behavior.

https://www.nature.com/articles/s41467-021-27474-3

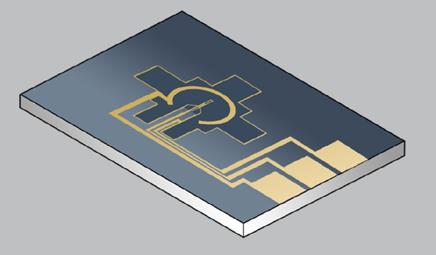

In this webinar, Dr. Unocic focuses on an operando closed-cell gas reaction (CCGR) studies performed using (scanning) transmission electron microscopy (STEM) to capture dynamic morphological changes in various material systems (catalysts and structural materials). For these experiments, we used Protochips Atmosphere holder that utilizes microelectromechanical systems (MEMS)-based heating microchips (E-chips). Examples of the experiments performed in dry and wet air will be discussed with integrated residual gas analyzer (RGA) system to provide a further validation of gas exposure conditions during reactions. Several sample preparation methods will be also described for various material form factors.

If you’ve logged into the Protochips’ Success Community since the beginning of the year, you’ve likely noticed some big improvements. Each system now has an easy-tonavigate support page with articles that guide you through each step of the workflow. Here you’ll find comprehensive articles that cover system setup, holder loading, sample preparation, software guides and much more.

This month, we’re excited to introduce a new section of the Success Community: In-Situ TEM Studies. This page hosts a variety of educational resources, from webinar series and customer Flash Talks, to curated bibliographies. We’ll be adding to this page regularly and intend for it to serve as a starting point for anyone interested in learning more about in situ TEM techniques.

The In-Situ TEM Studies page and its content is accessible to anyone with a Protochips’ Success Community account. It’s free to signup for an account, and we encourage you to share it with colleagues, students, and anyone else who is interested in learning more about cutting-edge in-situ TEM research!

Have you recently updated your AXON? Find the newest version here!

ELECTROCHEMISTRY IN THE TEM

Topic: A Webinar Series With Applications Examples for Batteries, Corrosion and Catalysis

Click here to watch!

SAMPLE PREPARATION IN IN SITU TEM

Topic: A Webinar Series on Tips and Tricks How to Prepare Samples for In Situ Microscopy, Including FIB Preparation

Click here to watch!

GO WITH THE FLOW

Topic: A Webinar Series Including Simulations and Experiments Using Protochips’ New Flow Management E-chips.

Click here to watch!

CLOSING THE PRESSURE GAP: CLOSED-CELL ENVIRONMENTAL TEM

Topic: A Webinar Series With Applications in Gas-Solid Phase Studies of Catalysts and High Temperature Materials

Click here to watch!

Over the past several years, the use of in situ gas phase electron microscopy to study the behavior of catalysts in real time under relevant atmospheric conditions has increased significantly. Since catalyst performance is based on atomic and nanoscale properties, observing changes of nanoscale phenomena can help researchers understand the causes for large scale changes in material stability, activity, or selectivity. However, observing nanoparticle behavior without understanding the gas composition leaves a large knowledge gap in the lifecycle of catalysts.

The integration of residual gas analyzer (RGA) technology into the Protochips’ Atmosphere AX system fills this knowledge gap and enables you to study catalyst structure as it relates to its function. The main challenges with integrating a mass spectrometer are:

• Vibrations – RGAs require rough pumps to support their vacuum environment which causes a loss in spatial resolution from vibration.

• Response time – quick response times support easier alignment of TEM images and RGA data and prevents peak broadening, however moving it closer to the TEM affects the resolution.

Protochips has taken these two main challenges into account with the design of our integrated RGA, making it the first RGA designed specifically to be used alongside a TEM:

• Image at high resolution while the RGA is operation – the unique design of the Atmosphere AX’s manifold system has allowed the integration of the RGA into the vacuum design and enables operation of the RGA with the need of a noisy roughing pump.

• Maximized response times – the integration of the system allowed mounting on the Atmosphere AX’s boom and gets it as close as 0.5 m from the TEM without affecting imaging resolution. Initial response times are as fast as 3 seconds or better, maximizing signal to noise for these nanoscale reactions.

For example, one study looked into the behavior of catalysts that can convert syngas (CO/H2) into olefins and paraffins for fuel production. The authors used cobalt/ platinum catalysts at industrially relevant temperatures and pressures (430 °C, and 105 Pa) and combined this with RGA analysis. This resulted in insights into the relative performance and lifetime of cobalt/platinum catalysts.

By combining high-resolution TEM with RGA data, researchers gain crucial insights into catalyst performance, enabling accurate interpretation of active-state behavior. The Atmosphere AX system was designed to support your research by giving you the best opportunity to obtain structural information that can be aligned with the gas product information for a complete understanding of your catalyst’s performance.

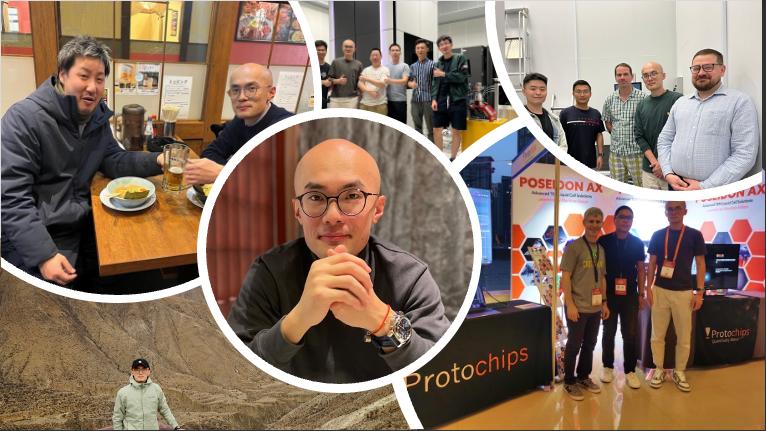

Tenet has had an impressive journey at Protochips! His determination, commitment to customer success, and his technical expertise have played a pivotal role in training our newest users and supporting our most established partners in Asia and around the world. Tenet’s passion, technical aptitude, and his fine attention to detail have elevated our global service standards and established him as a trusted ambassador of our brand. When Tenet is not working, he is out enjoying music, basketball, and the great outdoors with his family and friends.

Tenet has been an exceptional addition to the service team –both from the perspective of the customers he interacts with as well as his colleagues at Protochips. Cheers to Tenet! Your hard work and passion do not go unnoticed, and Protochips is grateful to have you on the team!

• Thinner-spacer electrochemistry E-chip that give you the ultimate flexibility to determine the liquid layer thickness.

• Going down to 100 nm, you can find the best balance between liquid layer thickness for your sample and optimizing the electrical signal.

• Both to be ordered in Pt and GC working electrode

Higgins Lab, ChemEng McMaster University

Conducting in situ LP-TEM experiments under liquid cell conditions is extremely challenging and prone to sample damage. With AXON Dose, I can individually monitor and adjust the optimal dose rates on a per pixel basis, enhancing the efficiency of my experiments in ways previously unattainable.

Small E-chips have deep channels to improve control over flow and bubbles

RALEIGH, NORTH CAROLINA, USA PROTOCHIPS HQ, SERVICE

SOUTH CAROLINA, USA APPLICATIONS

SAN FRANCISCO, CALIFORNIA, USA SALES

AUSTIN, TEXAS, USA SALES

EMEA UTRECHT, NETHERLANDS APPLICATIONS

BERLIN, GERMANY SERVICE

LONDON, ENGLAND SALES

ASIA

SHANGHAI, CHINA SERVICE

TOKYO, JAPAN APPLICATIONS

CLICK HERE TO FIND OUR DISTRIBUTORS ON THE WEBSITE

PICO 2024

April 21 - 25, 2024

Vaalsbroek, Netherlands

We are happy to once again come to the Netherlands with PICO 2024! This time our CEO David Nackashi will be here to answer any questions you have regarding our workflow for in situ electron microscopy.

Japanese Society of Microscopy

June 3 - 5, 2024

Makuhari Messe, Chiba, Japan

IAMNano

June 26 - 29, 2024

Gothenburg, Sweden

18th ICC (booth #5B)

July 14 - 19, 2024

Lyon, France

EMC Poland

June 9 - 12, 2024

Zakopany, Poland

M&M (booth #562)

July 28 - August 1, 2024

Cleveland, Ohio, USA

I have been working at Protochips for 6 years as a product manager and recently acquired the marketing team. My background is in chemistry and I previously worked as a forensic chemist for the US government. I love hiking, especially in the mountains despite being scared of heights!

I started working at Protochips in 2021 and have enjoyed every moment so far. My background is in catalysis, liquid cell TEM and I expand my knowledge by talking to users in the field. I love learning new and weird things, that’s why I do pole dancing, cooking and playing with my pet rats on the weekends!

I started working at Protochips in early 2023 and have loved every minute of it ever since. I earned a doctoral degree in Cell Biology from UNC-Chapel Hill, after working in the biotech industry. I enjoy traveling, reading, and trying new cuisines but visiting my family in Saint Lucia will always be at the top of my list!

I have been at Protochips almost 15 years after completing my PhD with Dr. Niels de Jonge. I have had a front row seat to growth and development of both the field and Protochips as a company. I enjoy collecting vintage dolls and crafting miniature clothing and accessories.

I have been at Protochips for one year and was hired due to my extensive TEM knowledge. I got my PhD in materials science after working a job that had nothing to do with microscopy. In my free time, I enjoy the outdoors, particularly bouldering, I’ve even brought the marketing team to the rock wall gym once or twice!