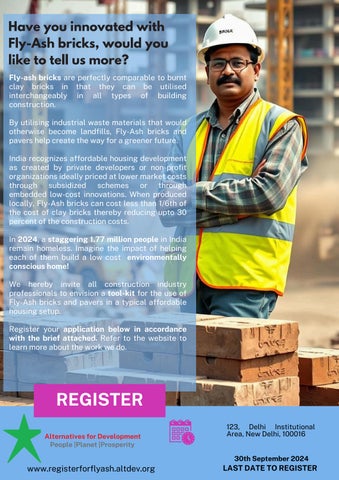

Have you innovated with Fly-Ash bricks, would you like to tell us more?

Fly-ash bricks are perfectly comparable to burnt clay bricks in that they can be utilised interchangeably in all types of building construction

By utilising industrial waste materials that would otherwise become landfills, Fly-Ash bricks and pavers help create the way for a greener future.

India recognizes affordable housing development as created by private developers or non-profit organizations ideally priced at lower market costs through subsidized schemes or through embedded low-cost innovations. When produced locally, Fly-Ash bricks can cost less than 1/6th of the cost of clay bricks thereby reducing upto 30 percent of the construction costs.

In 2024, a staggering 1.77 million people in India remain homeless. Imagine the impact of helping each of them build a low cost environmentally conscious home!

We hereby invite all construction industry professionals to envision a tool-kit for the use of Fly-Ash bricks and pavers in a typical affordable housing setup.

Register your application below in accordance with the brief attached. Refer to the website to learn more about the work we do.

Why Fly- Ash Brick ?

72 percent of India’s power plants are coal based and produce 40 million tons of fly ash annually. Clay is typically entrapped during the formation of coal.

When coal is burnt, the incombustible clay particles are left behind as ash. In today’s energy efficient pulverised-coal technology, the ground clay escapes along with other flue gases that are collecting as ash in a bag filter or in electro-static precipitators.This gives rise to the name 'fly ash'.

India has a long industrial tradition of coal plants since pre-independence. A vast majority of them continue to power the country’s development.

Did you know ?

Coal dust has historically been collected as a waste product from homes and industry. During the nineteenth century, coal ash was taken by 'scavengers' and delivered to local brick works, where the ash would be mixed with clay to make ungraded bricks.

By utilising industrial waste materials that would otherwise be used to fill landfills, Fly-Ash bricks help pave the way for a greener future.