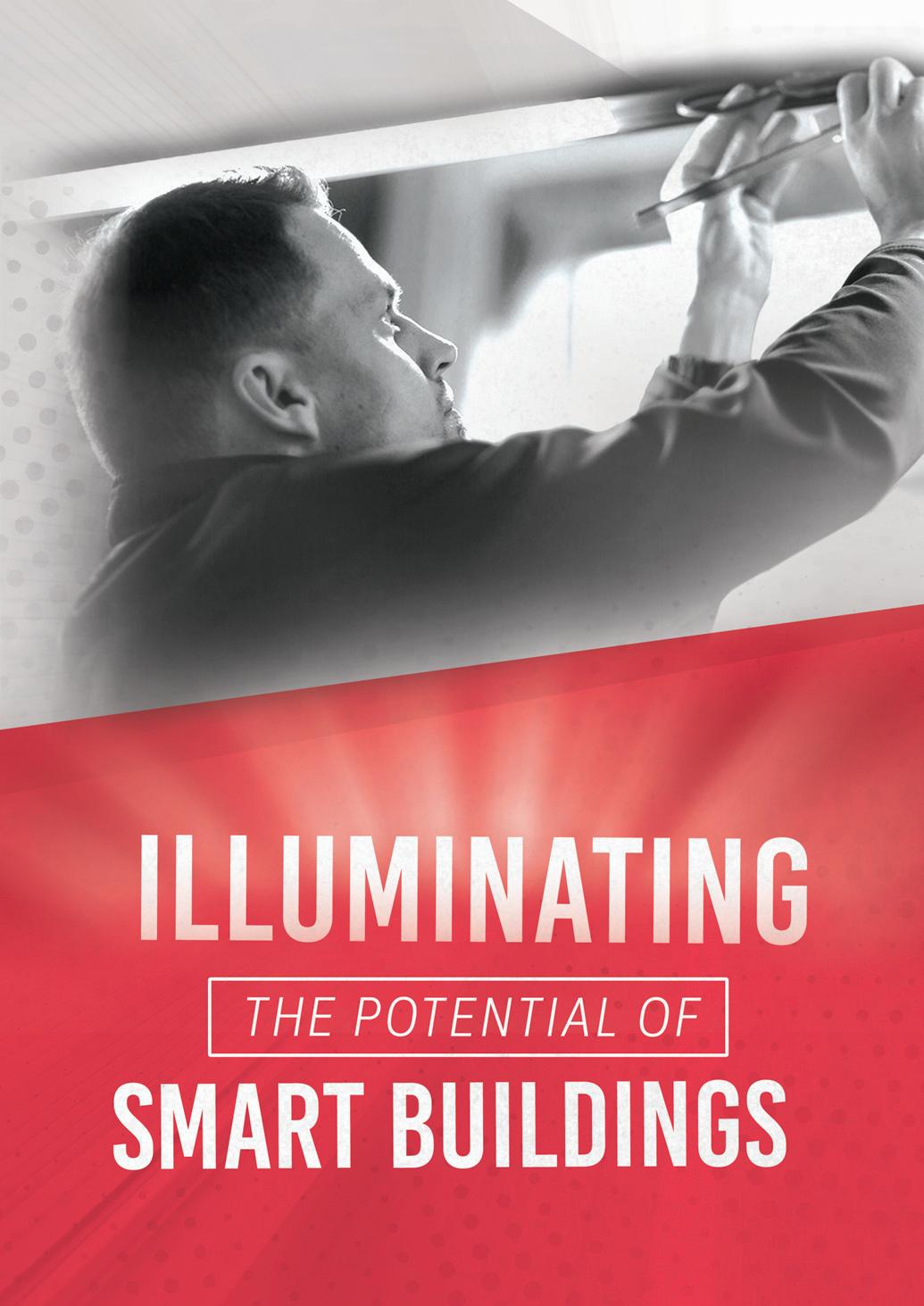

Prolojik engineers energy-efficient, data-rich, responsive, adaptable, inspiring places in which to work, live and innovate. The company’s open protocol lighting systems allow users complete control over their lit environment. Founder & CTO Asela Rodrigo explained more to Hannah Barnett.

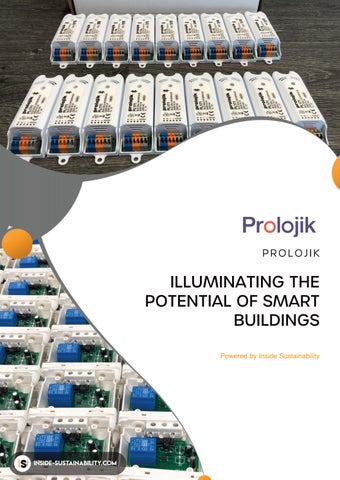

Since Prolojik was founded in 2002, it has delivered lighting control systems to over 2,000 buildings. The company takes on construction and refurbishment projects in the commercial, educational, scientific and public sectors , and has delivered over 200,000 smart sensors into the marketplace.

Prolojik prides itself on developing a bespoke approach for each client, seeking tailored solutions rather than a cookie-cutter response.

“We are an outcome-based business,” said Asela Rodrigo, Founder & CTO. “We’re not a massive corporate organisation. We work to a solution that the client wants to see. And equally, we’ve got a unique breadth of products and services that’s

unlike any of our competition. It means we’ve got a great playbook to refer to, and we can build tailor-made solutions from a set of tried and tested ones.”

How it works

Prolojik has developed sophisticated smart sensors that can do anything from turning lights off when they are not needed to regulating ambient light, as well as measuring temperature and relative humidity.

“We consider our lighting network like a vine that goes through the infrastructure of a building,” explained Mr Rodrigo. “A standard building management system has lights everywhere that people go, and a network to those lights. We’re leveraging that network to get

MERCURY SAFETY AND SECURITY

Mercury is proud to be one of Prolojik’s main suppliers for the last 15 years, manufacturing lighting control and management systems.

We work to IPC-A-610 and offer comprehensive turnkey electronics manufacturing solutions, including fast turnaround, prototyping, PCB assembly, cable assembly and finished products to the UK’s leading companies

more insight about how the building works, and then allowing people to make smart decisions about energy usage, footfall and similar.”

As a result, Prolojik is confident about its environmental credentials, and has reduced electricity use by 10MGW per year across its projects; the equivalent to 2.2 million tonnes of CO2.

A recent school build project used light in highly efficient levels, around 4W per square metre. The next step involves trialling a system whereby different staff members carry lanyards as digital keys for variable outcomes.

“It’s a reactive system,” Mr Rodrigo explained. “So, if you’re a teacher, it recognises that, and the lights will stay

o n for as long as the lesson takes. But for a cleaner, the lights only come on at 50 per cent and then go off as soon as they leave the room. For a security guard, the lights will only go on in the corridor, and are inhibited in other areas.”

The company also offers state-ofthe-art sensors and thermal imaging cameras that can tell if room space is being used efficiently.

“Lighting is just the starting point,” said Mr Rodrigo. “During Covid, the most important thing was building sanitisation. Clients wanted to know how to clean buildings more efficiently. If they knew how many people had been in a meeting room, they would know when to go back in and clean again.”

Making Mission M

Prolojik’s Mission:

“We offer digital solutions that enable three steps: sensing, understanding and response. They are applicable anywhere, from a railway tunnel to an office block, or a pharmaceutical laboratory. In essence, we offer different solutions to fit different applications.” Asela

Every aspect of Prolojik’s business is focused on maintaining best practice in relation to sustainability. This ethos is reflected in Mission M, the company’s strategy of continuous improvement.

The strategy is divided into five pillars: Minimise, Material, Miles, Make, Migrate and Maintain.

Minimise means using the most compact and efficient technologies possible. On the material side, one achievement involved the replacement of rack servers with solid-state NUC, reducing carbon emissions by 86%.

Rodrigo, Prolojik Founder & CTOThe company is keen to cut down miles travelled wherever possible, too. “We manufacture our equipment within 100 miles of our offices and all our partners are within that radius,” said Mr Rodrigo. “We don’t import stuff or make products in China.

“This means we can be confident about the pedigree and the ancestry of the kit that’s gone into a project. And it’s not just electronics, it’s the metal work and plastics, it means that we’ve got complete visibility of our supply chain.”

Migrate involves taking the entire lifecycle of a product into account, via Prolojik’s Hermit Crab Initiative. This turnkey approach to upgrade embraces the recycle, return and recommission of client equipment. “Like a hermit crab, which moves from shell to shell,” Mr Rodrigo added.

In practice, the Hermit Crab Initiative means if a customer needs new electronics, but the metalwork remains in good order, Prolojik will collect the product in an e-vehicle, replace the electronics and send it back to be reinstalled.

“We just did a project where we reduced CO2 emissions by two and a half thousand tonnes, thanks to reusing the metal work,” Mr Rodrigo explained. “In the old days, it would have been scrapped and gone to landfill.

“And we work with recycling companies to take all of the rare earth minerals in the stock we get back, returning them to the

chain of production. Mining is about 80 times less efficient than taking a mineral from something that already exists. We’re looking at technologies that eliminate the need for mining and we want to recycle and reuse wherever possible.”

Smart projects

Prolojik takes on around 200 projects each year, but a milestone development comes “every two or three years,” according to Mr Rodrigo.

These include a contract at the iconic Lloyd’s of London building, where the company developed a completely bespoke network over a decade ago. Another innovative achievement was the Arm Holdings in Cambridge, where Prolojik used a Power over Ethernet system to great effect.

“We took three tonnes of CO2 out of the building by using that system,” said Mr Rodrigo. “Basically, using data cables for the lighting and getting rid of mains cables

throughout the building. And that has yielded power savings and also a massive carbon footprint reduction in the delivery of the building.”

A huge recent landmark project was KGX1, Google’s new headquarters in Central London.

“On KGX1, we went wireless and developed a system for the lighting to communicate via Bluetooth,” said Mr Rodrigo. “For a reasonably small business, based in High Wycombe, we have a really broad reach.”

A bright future

Prolojik values the strong relationships it has built with its suppliers, some stretching back as far as 20 years.

“We engage closely with them,” said Mr Rodrigo. “We know the MDs and the guys that operate on the shop floor. So, it’s about that connectedness, because they have a stake in what they build for us too. We keep the supply chain very close, and

if things do go wrong, then we are nearby and can deal with it.”

This integrated approach works especially well thanks to Prolojik’s own turnkey set-up and the range of its inhouse capabilities.

“The beauty of our businesses is that we’re completely self-contained,” Mr Rodrigo concluded. “We have all the intellectual property from design conceptualisation, software and hardware, all the way through to delivery. We could start with a blank sheet of paper and deliver a finished system within our four walls. And having that talent around the table is great.

“Personally, I love technology and how it can be applied to make a difference. There’s a huge buzz when someone tells me a problem and I go away to sketch something with the team. I am driven by finding a way to make something better, more practical and, most of all, more efficient.” n