ENGINEERING THE FUTURE

Securely positioned in the field of mechanical engineering, Marcovil –Metalomecânica de Viseu, S.A. is a company with lots going on. Dedicating its operations to the design, manufacture and commissioning of machinery and turnkey solutions, the business works to improve the efficiency of the industry. From lifting equipment to forming technology, to the most innovative and advanced machines for waste separation and recovery of secondary raw materials, all Marcovil’s endeavours are shown the same care and attention. The company cites its ethos as ‘innovation, sustainability, reliability and efficiency.’ Board Advisor Nuno Albuquerque explained how this works to Hannah Barnett.

When Marcovil was established in 1987 at Viseu - Portugal, it was as a manufacturer of overhead cranes and elevation equipment. Board Advisor Nuno Albuquerque explained that the company continues its work in this field to the present day: “We have overhead cranes, we have mobile gantry cranes, we have jib cranes, among others. That is something that we are quite well known for and there is still a lot of demand.” There must be, because the company sold around €2 million of crane equipment in 2021 alone.

These days Marcovil is something of a four-pronged operation.

Alongside the cranes, it also produces ‘movement equipment’, as Mr Albuquerque described: “Acceleration conveyor belts, flat belt conveyor belts, sorting conveyor belts. And there is plenty of demand for it, too.”

The third strand is Marcovil’s roll bending machines. “You have a sheet of metal, and

you can bend it in whatever diameter you wish; we have machines that do that kind of work, and we can also build them,” Mr Albuquerque said.

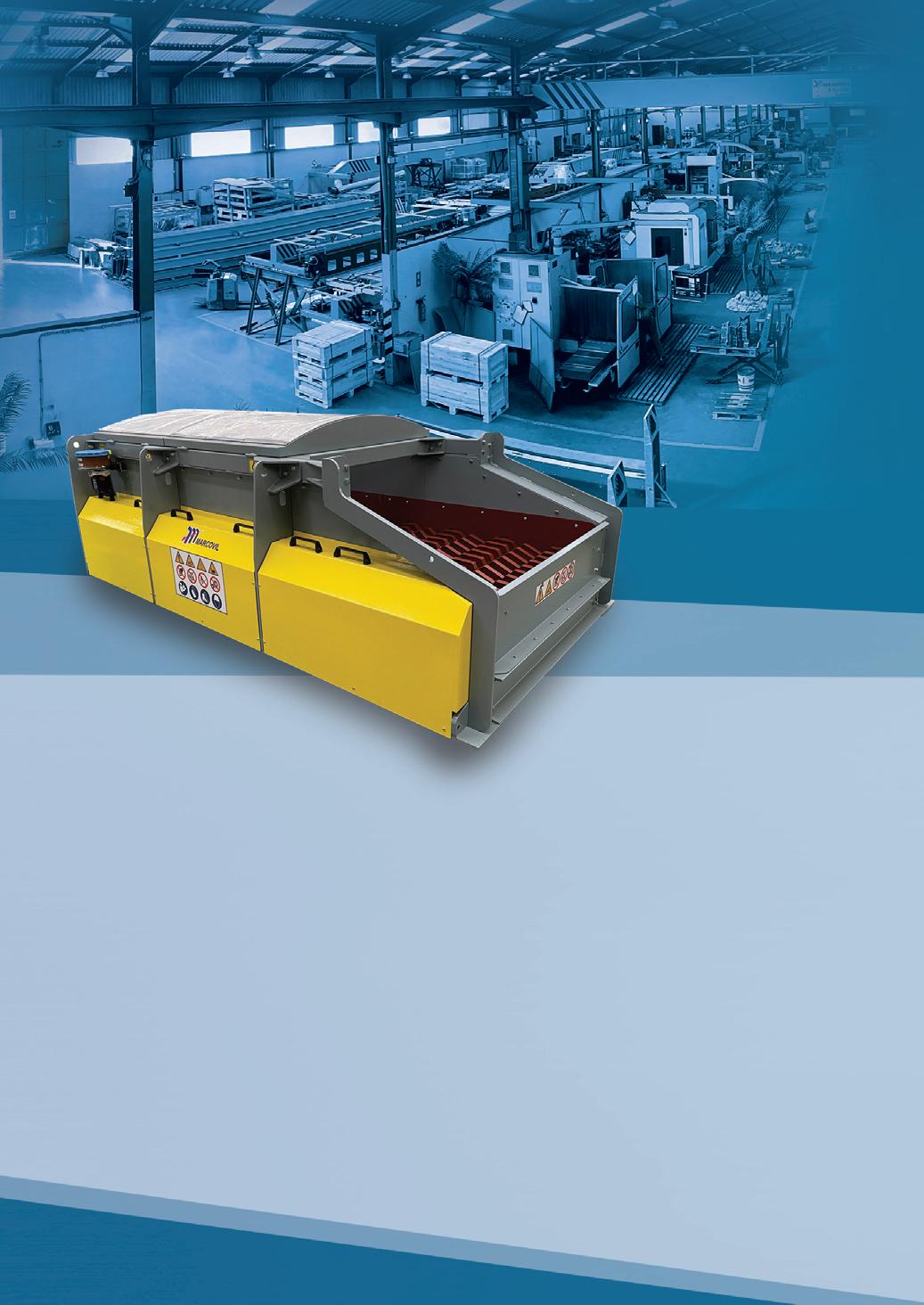

The final part of the operation falls within the recycling arena. “We produce individual equipment, but also turnkey solutions, like complete lines to recycle plastic,” explained Mr Albuquerque.

Marcovil’s plastic separation machines are designed to separate plastic e-waste by type and colour so that they can be recycled as a raw material. On average 44.7 million tonnes of e-waste are generated per year, while the potential value of plastic raw material in e-waste is a staggering €15 billion per year. It is clearly both environmentally and economically prudent for the company to capitalise on this.

Alongside the plastic e-waste operation is the fridge compressor, which is a machine designed to recycle the compressors of small, non-industrial fridges.

“We have come up with a machine (patent pending) that can read the different geometries of the compressors, and then make the cut automatically in the compressor,” Mr Albuquerque said. “This will then open the body and you can separate the copper from the plastic. The copper is a highly valuable material.”

Environmental innovation is a significant aspect of what the company does, and it is paying dividends: “We have invested quite a lot in the I&T department. We have spent a lot of time in that area – a good example is the recycling compressor cutting machine. And I can tell you that right now we have various orders for these machines in Europe.”

Around 65% of Marcovil’s core business now comes from its environmental products. The company has an ongoing project in Europe to build three recycling plants.

Mr Albuquerque explained how the company works closely with each customer to create a bespoke recycling system suitable for their specific needs.

“The client tells us about the tonnage per hour that they want, based on their input and output, and it is up to us to come up with a solution,” he said. “After that, we discuss the layout, we discuss the implementation area, and then we start working on the machine and its components. We produce most of the equipment internally. Overall, it's our responsibility to make sure that the line will work properly, and we will achieve the goals the client wants.”

The company, Mr Albuquerque said, is fastidious in its attention to the highquality of the products it produces. This is one of the key features that sets Marcovil apart from competitors.

“Even though it's a little bit more expensive, it's important that the equipment has the right thickness and robustness,” he e xplained. “That is a key feature for us. We prefer to have concrete solutions and good, thick, strong stainless steel. We firmly believe that those kinds of materials will improve not only the efficiency but also the life expectancy of the product. That’s one of our signature moves. We prefer to spend a little bit more money on things like stainless steel, rather than using other materials that are not as robust.”

It is not just around Europe that the Portugal-based business operates. It has an impressive international reach. “We have had partners in the five continents

since 2000. We dispatch equipment for Australia, Africa, Asia, Europe and America, both South America and Central America.”

It is the concept of a global operation that is intrinsic to Marcovil’s ethos. The company positions itself as part of the ‘circular economy’, the economic system of closed loops in which raw materials, components and products lose their value as little as possible, with the emphasis placed on renewable energy sources.

Mr Albuquerque explained what the circular economy means to Marcovil

specifically: “We don't just want to extract, use and dispose; we also want to produce, use and recycle. We are trying to be part of a global network where we can retain valuable raw materials, reduce the risk of losing our supply of primary raw materials; where we can preserve the environment, reduce carbon emissions and reduce waste disposal.”

The company lives up to its promises: installation of solar panels at its site in January 2022 allowed Marcovil to be on the front foot when it came to the later challenges of the year.

“Obviously, solar panel systems allow us to save on our energy consumption from the grid,” Mr Albuquerque said. “But they also work as a kind of insurance against an increase in energy prices, as well as reducing the ecological footprint. We have 490 solar-power modules with a total of 184,000 kWp. We can also sell the energy. It's a win-win situation for everyone involved and it’s an investment that came at the right time, given the latest spike in the electricity prices since the Russia-Ukraine conflict.”

Marcovil estimate that it has produced 5,000 machines and

turnkey solutions since 1987. This is not hard to believe for a company that not only sets objectives like ‘innovation, sustainability, reliability and efficiency’, but also effectively puts them into action. n