Operating across the decommissioning, offshore, petrochemical, refining, power generation, shipbuilding, industrial maintenance and installation market sectors, Mactech Europe has established itself as a foremost provider of highly respected portable precision machinery. As the company approaches its 30th anniversary, Richard Hagan met with Business Development Manager Lee Thornton to uncover the secret behind Mactech Europe’s ability to evolve and adapt to a market with constantly shifting demands.

the nearly three decades since it was established in 1995 by current CEO Ian Beckenham, Mactech Europe has grown from a humble two-man operation to one that is now 38 people strong and internationally recognised. While its staff count has grown considerably, so has its portfolio of products and services.

Mactech Europe provides a robust variety of portable industrial and commercial machinery, including a complete range

of tools ranging from pipe cutting to pipe penetration equipment, in both a sales and rental capacity. It services a broad swathe of sectors, but Mactech Europe’s primary trade remains the oil and gas industry.

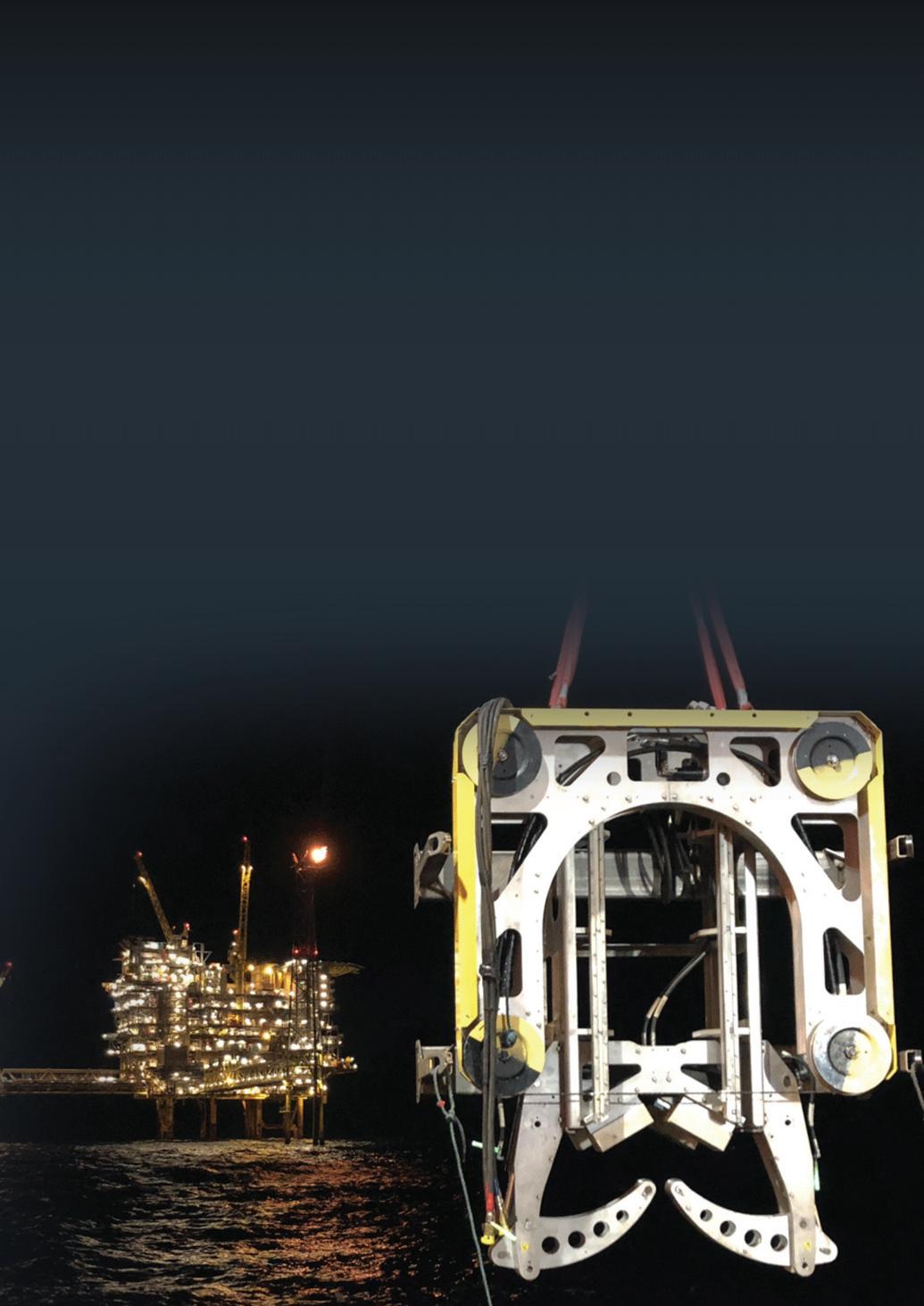

“We cater to a uniquely wide customer base; our customers range from operators through to tier one and two subsea contractors,” explained Business Development Manager Lee Thornton. We also work alongside diving and ROV companies, as well as with partners where we can offer up fully-packaged solutions to our joint

customer base. This ensures we are a commercially attractive offering lowering the commercial or transactional impact on our customers.

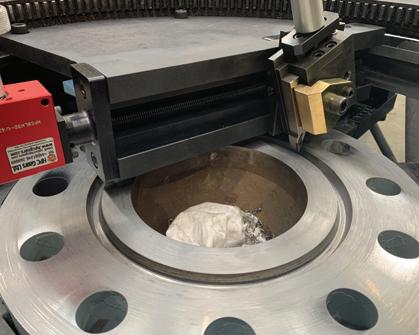

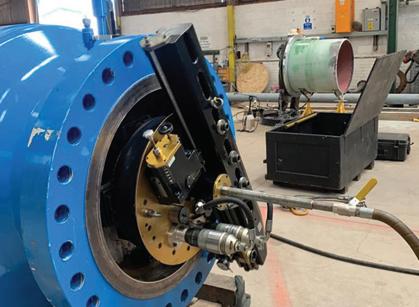

Mactech Europe is especially well known for its diamond wire saw cutters. Available to cut 4½ to 120-inch pipe and structures with larger capacity designs ready to go to build stage, Mactech Europe’s diamond wire saw cutters cater for subsea and topside cutting for a variety of materials and projects. Customers are able to choose from a range of cutters including articulating saws, cut-off saws, inline saws and even an ROV-specific saw.

Its diamond wire saws are far from being Mactech Europe’s only cutting solutions: “We also offer a lot of bespoke cutting capabilities which are less well-known but pretty incredible,” said Mr Thornton. “For example, we have a drill and pin solution that clamps on to the structure, drills through, and allows for the pin insert to enable safe operation and recovery to the top side. This solution is mainly utilised in offshore caisson cut and recovery operations.” The drill and pin/diamond wire saw combi tool is also perfect for multi-string cutting operations – ensuring the integrity of the product is kept throughout the operations.

Mr Thornton explained that, in addition to its off-the-shelf sales and rentals, Mactech Europe has enjoyed strong growth in its bespoke equipment offerings: “Bespoke and specialised equipment is the

We work closely with customers to develop specialised solutions and consequently, we’re seeing a lot more engineering requirements as part of that. They’re often up-engineered solutions.”

Mactech Europe also offers various complementary services to the industry, which the company is keen to promote. Amongst others, it offers decommissioning, in-situ machining and bolting services. Its customers can additionally access heat exchanger plugging, hydrostatic testing, engineering, equipment refurbishment and equipment training services.

“There are no problems that our teams can’t find solutions to,” said Mr Thornton.

Mactech Europe employs approximately 40 people across three facilities, including its head office in Congleton, near Manchester in the UK, one in the Netherlands and one in Aberdeen. The Dutch facility is the company’s newest one and is a particular highlight due to its specific growth potential.

“Opening our Aberdeen facility, however, was a big milestone for us, because prior to that, all of our work in the North Sea fields had to be managed and delivered from our Congleton facility,” Mr Thornton revealed. “This new facility has allowed us to reach and service the oil and gas market more substantially.”

Going forward, Mactech Europe has firm plans to expand into the Middle Eastern market. Having established its reputation for excellent service in the region, Mactech Europe enjoys repeat orders from customers in the Middle East. The company expects that a local office and presence will allow it to further bolster its service delivery and client relationships, whilst also reducing its carbon footprint through an overall reduction in travel and shipping from the UK.

Given the region’s size and pedigree, the Middle Eastern market has also proven to be a strong source of decommissioning work for Mactech Europe.

“While the on-site machining side of the business is a constant and generates the most regular revenue for the business, decommissioning projects tend to deliver more profitable streams with higher revenues,” Mr Thornton continued. “We see a lot of repeat work from our customer

base across the globe. It’s a testament to our teams – they’re experts in their fields.”

Since many decommissioning projects are highly complex, Mactech Europe is routinely called upon to provide engineering services to solve difficult on-site challenges. “For example, there can be space constraints, or difficult loads that must be lifted,” said Mr Thornton.

He recalled a recent decommissioning project in which Mactech Europe had to assist with solutions for multiple such challenges: “Working with the client, we had to develop a bespoke, very unique cutting methodology with double cuts of over 3.5 metres in diameter. In addition to that, it was a zoned area requiring ATEX (explosive atmosphere risk)-rated modular saws that had been highly modified to suit the irregular structures we had to cut.

“Due to the hazardous area, we had to ensure that there was no spark potential and that the heat was kept down: this required monitoring the temperature of the wires, ensuring that there was a constant flow of water for cooling to prevent any potential for sparks, and also that the speed of the wire was kept below 12 metres per second to minimise spark potential. It was a fascinating but challenging project.”

Mactech Europe’s ability to develop and successfully deploy these bespoke solutions ultimately saved the customer over 200 man-hours of operational time offshore, and for both the client and Mactech Europe, the project was a resounding success.

In the meantime, Mactech Europe is busily attending multiple trade shows and industry events. A particular highlight in its

events calendar is Offshore Europe, held in Aberdeen in September 2023. Mactech Europe will have multiple physical assets on display, alongside a large team drawn from all of its offices, and they look forward to meeting you there, or at one of the other industry events.