John White Managing Director

John White Managing Director

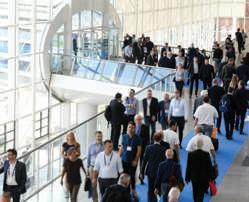

Managing Director John White welcomes events back onto our calendars.

Welcome dear reader to your latest edition of Inside Marine. There is a certain buzz and energy in the office – there is always of course because clearly my team all love their job and their boss – however I mean a little more of a buzz than normal.

One of the more popular editions for my team to work on is what we refer to as our SMM edition. An edition that is, as always, full of all sorts of company profiles, advertisements, news and views, however, a special edition that focuses on the upcoming SMM event in Hamburg.

We have been an official media partner to this prestigious event for a decade now and the only one we have missed in that time is the one that we all missed due to Covid-19 lockdowns. Therefore, I must give some of the credit for my increased staff energy to the fact that international shows, fairs, events and exhibitions seem to be firmly back on our calendars.

As many of our regular readers already know, we do enjoy being partners with some major events within the maritime industry and after the forced sabbatical due to Covid-19, I am sure that you are as happy as we are to be able to exhibit, visit or even simply read about events again.

Our editorial, sales and marketing teams are certainly glad to be in contact with the event planners, and likewise, the events teams seem overjoyed to be able to discuss media partnerships with us once more.

As an international media company specialising in business-to-business publications, we naturally must conduct much of our work over the telephone and by email,

however, the chance to meet many of you face-to-face is always a pleasure. Events of course allow us all to not only promote our products and services but also network on a more personal level. I know that the teams I often send out to these events enjoy the experience… I suspect in part due to some of the post-event restaurants and bars that some of you ‘force’ them to frequent with you!

We have been working closely with the SMM event organisers to help promote this popular event and with many of the exhibitors to help drive some traffic toward their stands. Therefore, be sure to spend some time browsing that section of the magazine if you are planning to attend this year.

Unfortunately, I cannot send a team out this year as there is simply too much to do back at headquarters with our new look websites, online company profiles, social media activity and general digital marketing plans, however, if you are lucky enough to be going, please send Hamburg our regards and we shall have to be content with the fact that at least we are there in spirit with our magazine available in the press booth there as usual. I shall sign off now and let you enjoy this edition. If you would like to take advantage of the talents of my various teams to help you promote you company or event, then I would suggest that now is as good a time as any, especially whilst they are all so excited and energised! n

Return of the living trade fair

News

36 Marine news in brief

Latest news from the marine industry

Matter of fact

42 Did you know?

Interesting and unusual marine facts from around the world

What’s new in the marine industry?

44 From simple ideas to engineering feats

The latest innovations, ideas and product launches

Special

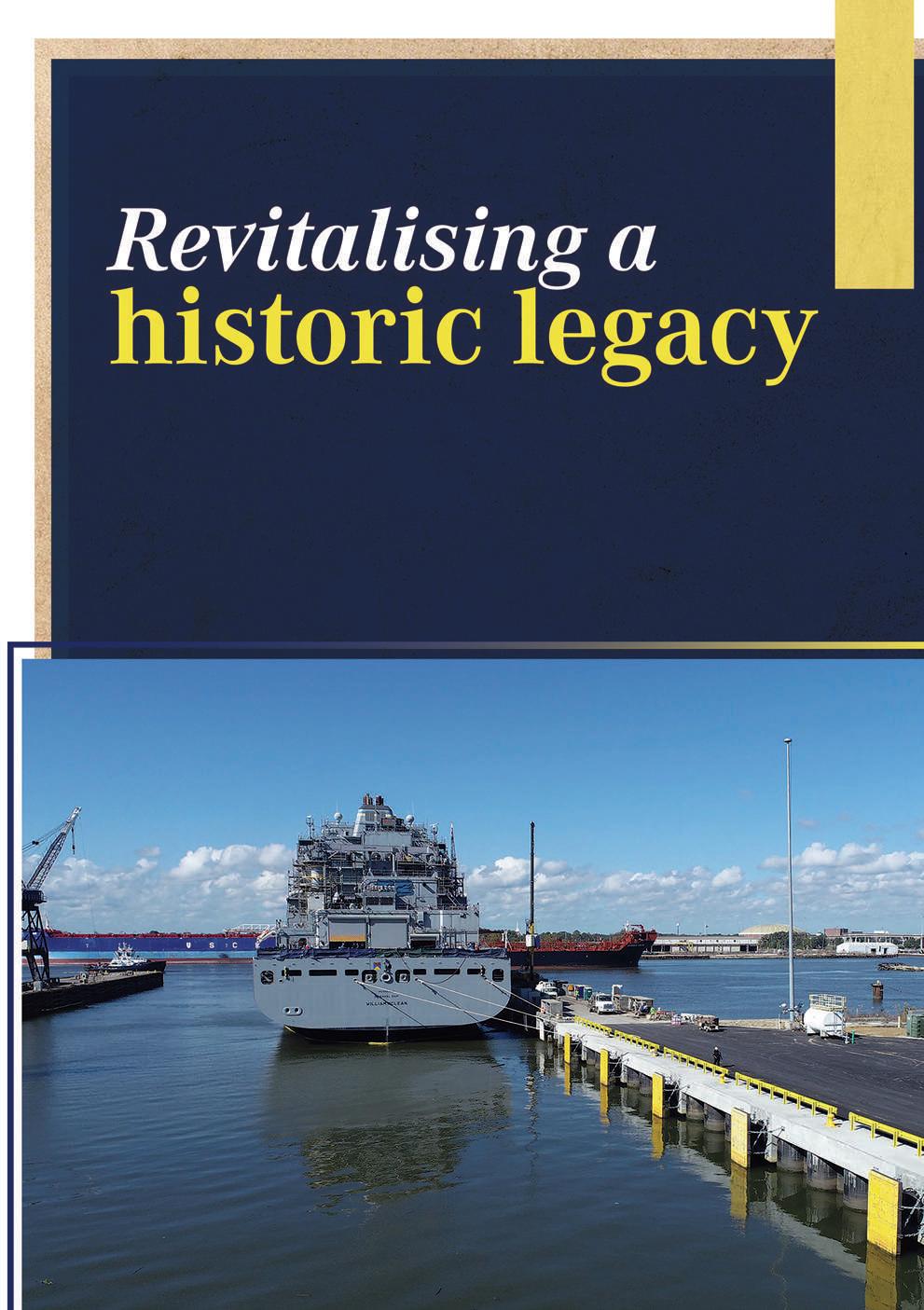

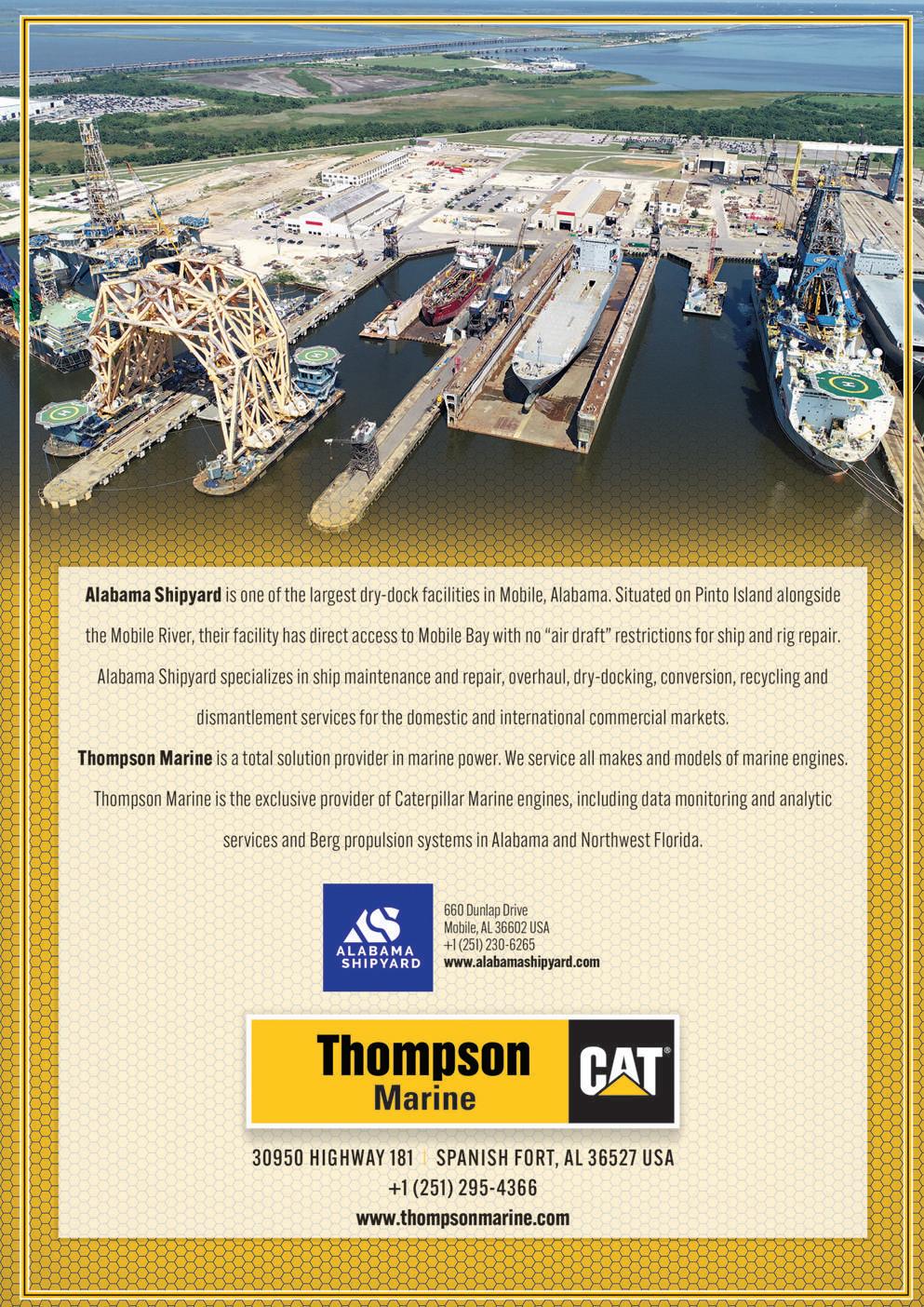

50 Revitalising a historic legacy Alabama Shipyard

Shipyards

Inside

Maersk Supply Service launces new venture company, Stillstrom, to deliver offshore vessel charging

64 50 years a Chilean legend ASENAV

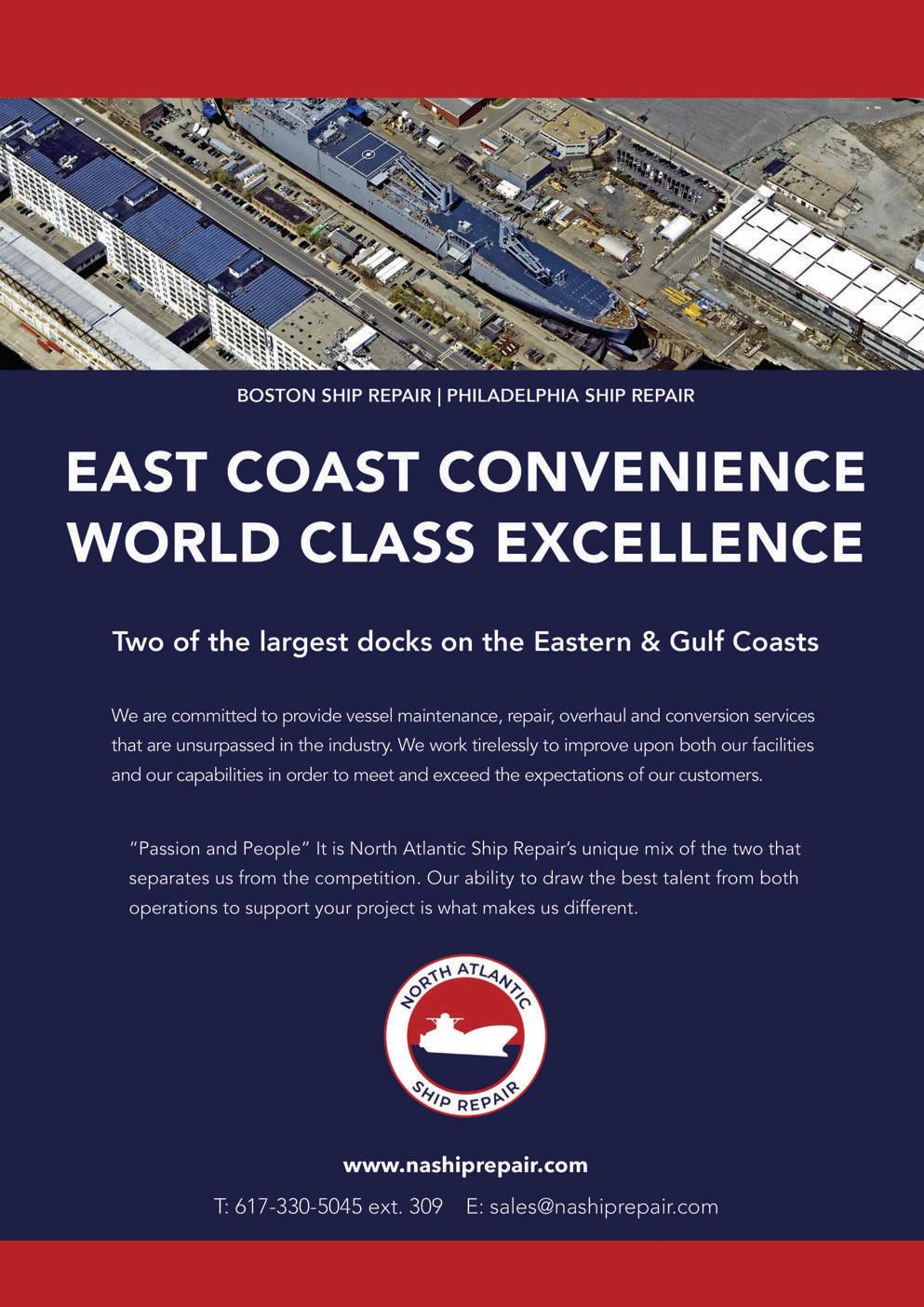

74 Fixing big ships in the northeast North Atlantic Ship Repair

82 Heading in the right direction

Couach Shipyard

88 Turkey’s largest ship exporter ARES Shipyard

92 Spanish experience and added value Aresa Shipyard

Owners, operators & managers

98 Global ship management that cares Columbia Shipmanagement

106 Crossing the sea of opportunity Baja Ferries

112 Forging ahead on all fronts BREB

118 Boutique solutions to modern shipping problems

Norstar Ship Management

124 Modern vessel operator making waves from Mexico E-NAV Offshore

130 Fuelling ambitions and industry for 50 years

Naftomar Shipping & Trading

136 Service, crystallised Crystal Pool

Equipment & services

144 The buzz for marine services

Epsco (Cyprus) Ltd

152 Deep dive into revolutionary subsea ROV tech Bisonte

158 The catalyst for green energy Permascand

166 Saving energy and fuel with smart valve control Eltorque

170 Power on sea Amco Veba Marine

174 Engineering excellence across the seven seas Hydrus Engineering

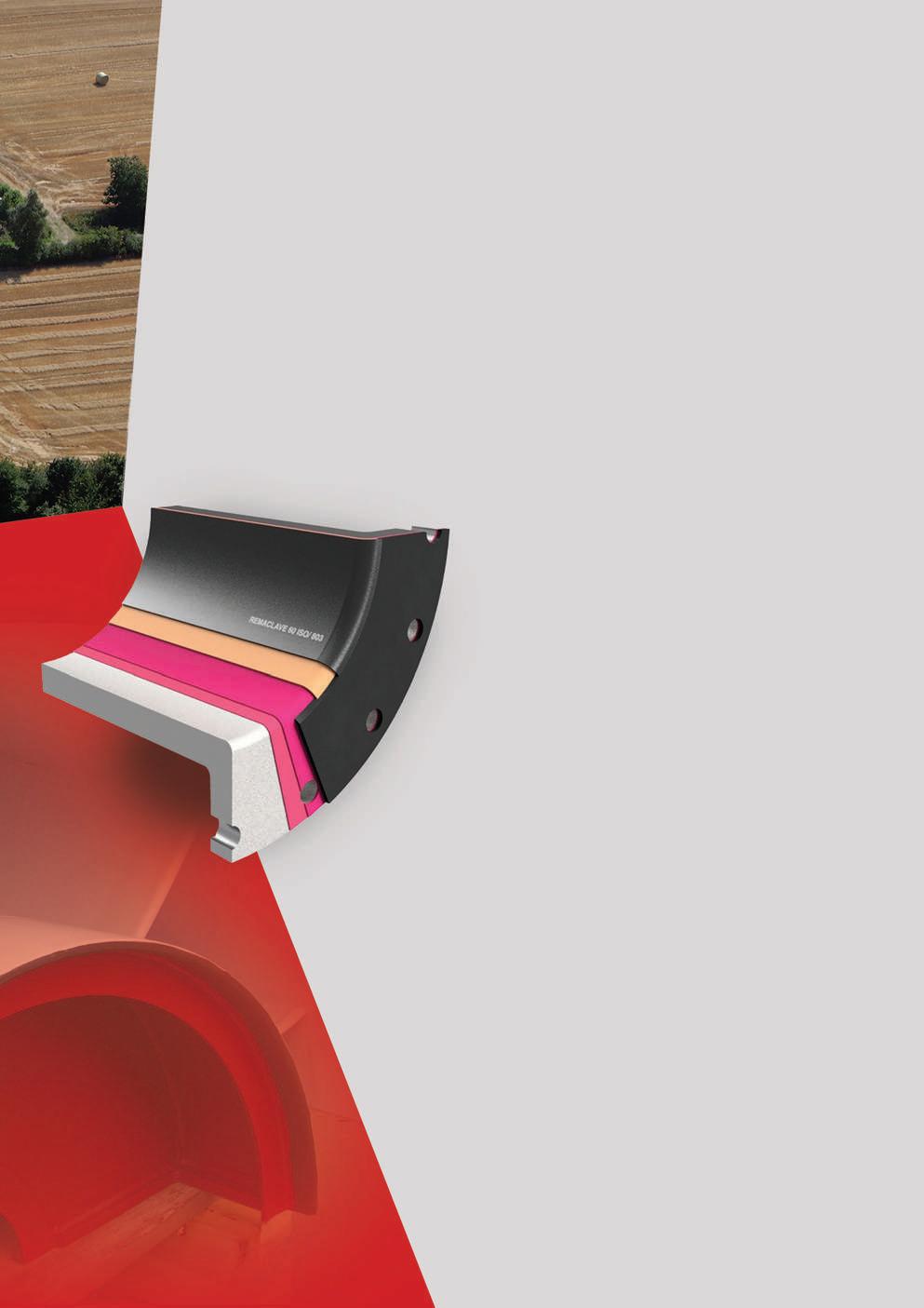

180 Combatting corrosion

Mahnke

184 Doorways to Dutch precision

Newthex

188 In search of perfection

Hydrasearch

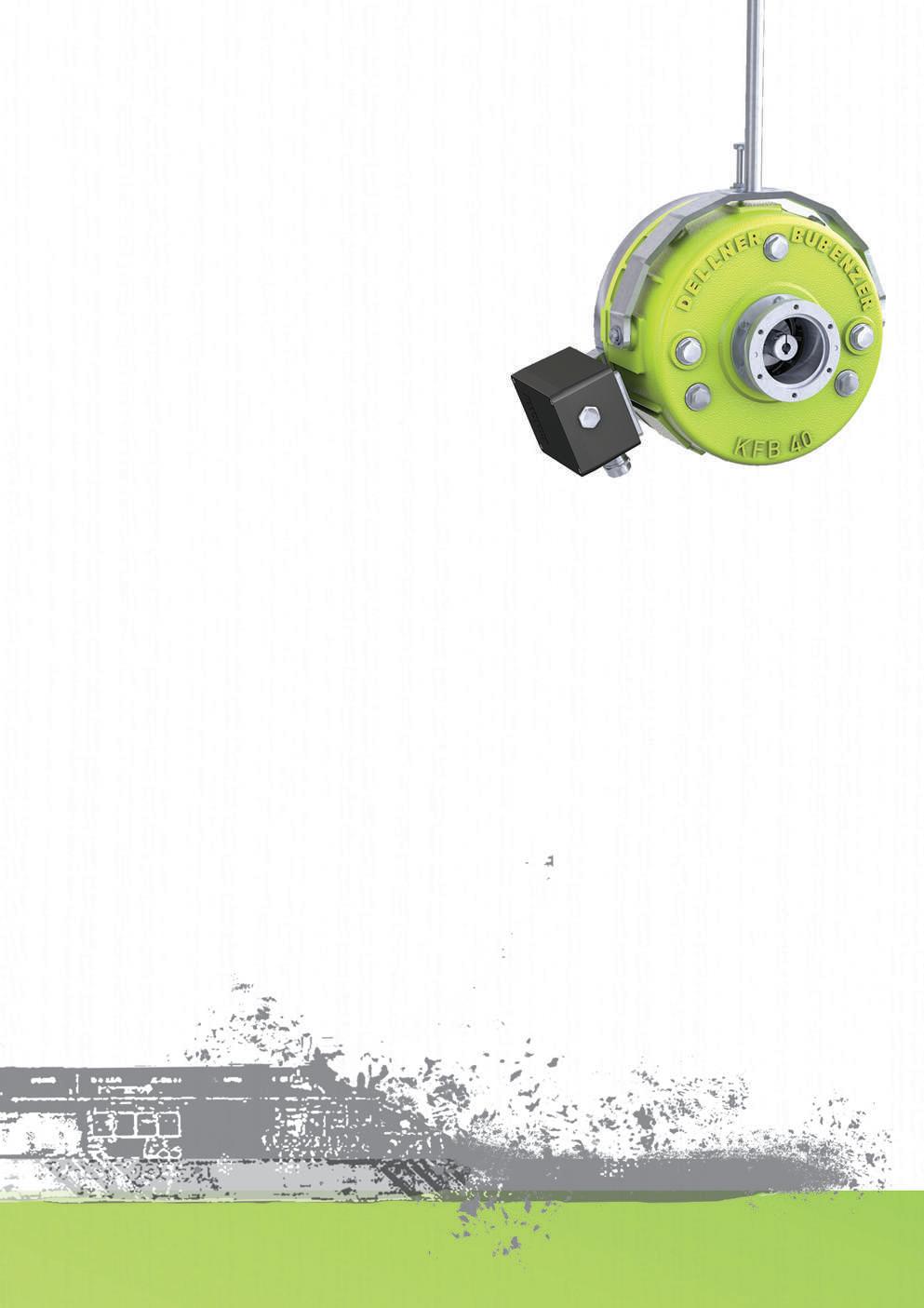

192 Braking news

DELLNER BUBENZER

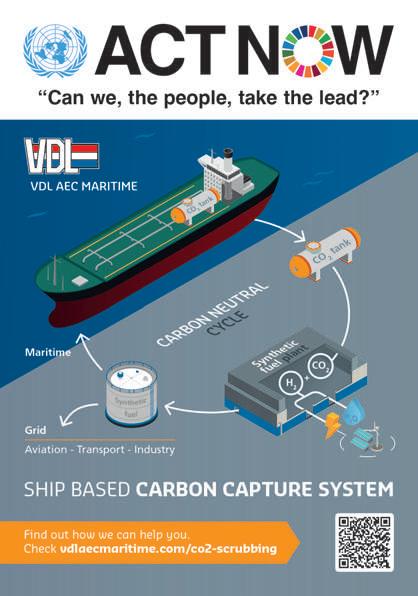

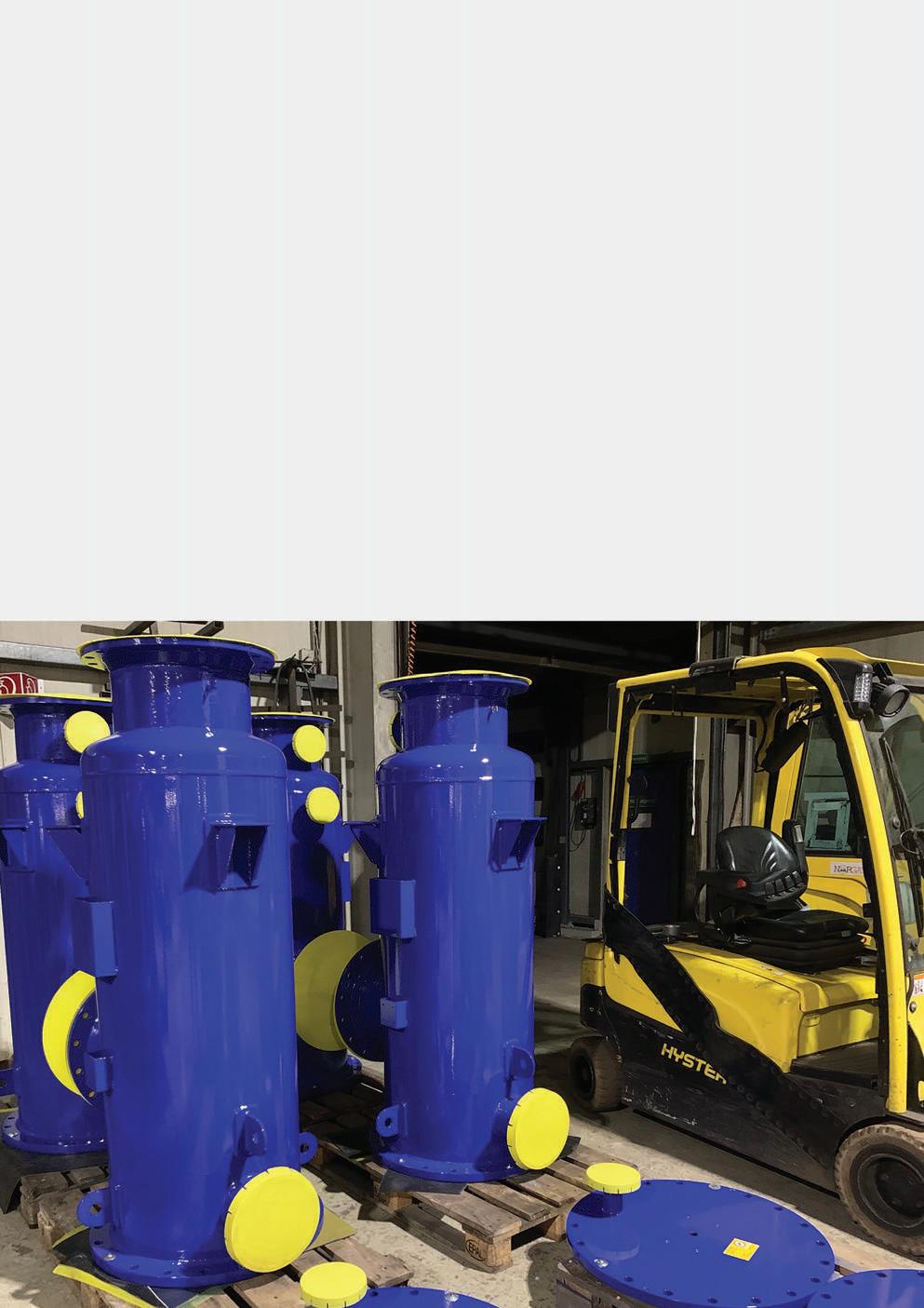

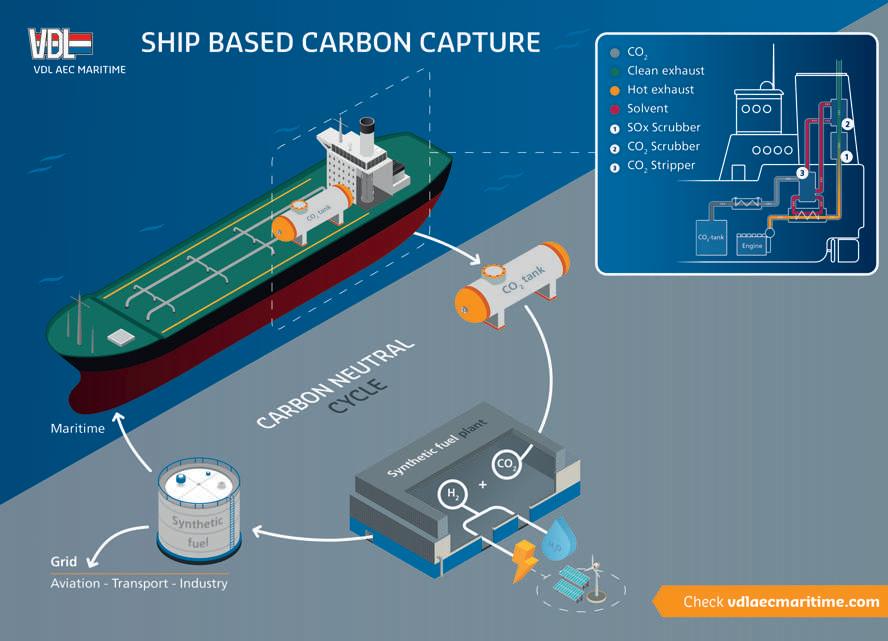

196 Taking marine’s carbon capture technology to the next level

VDL AEC Maritime

200 Keeping the maritime industry fuelled up

SEKAVIN

204 Adding value to waste management

Sepor

Water treatment

210 First every time in global water protection

ERMA FIRST

220 A solution to water scarcity

SLCE Watermakers

Ports, harbours & terminals

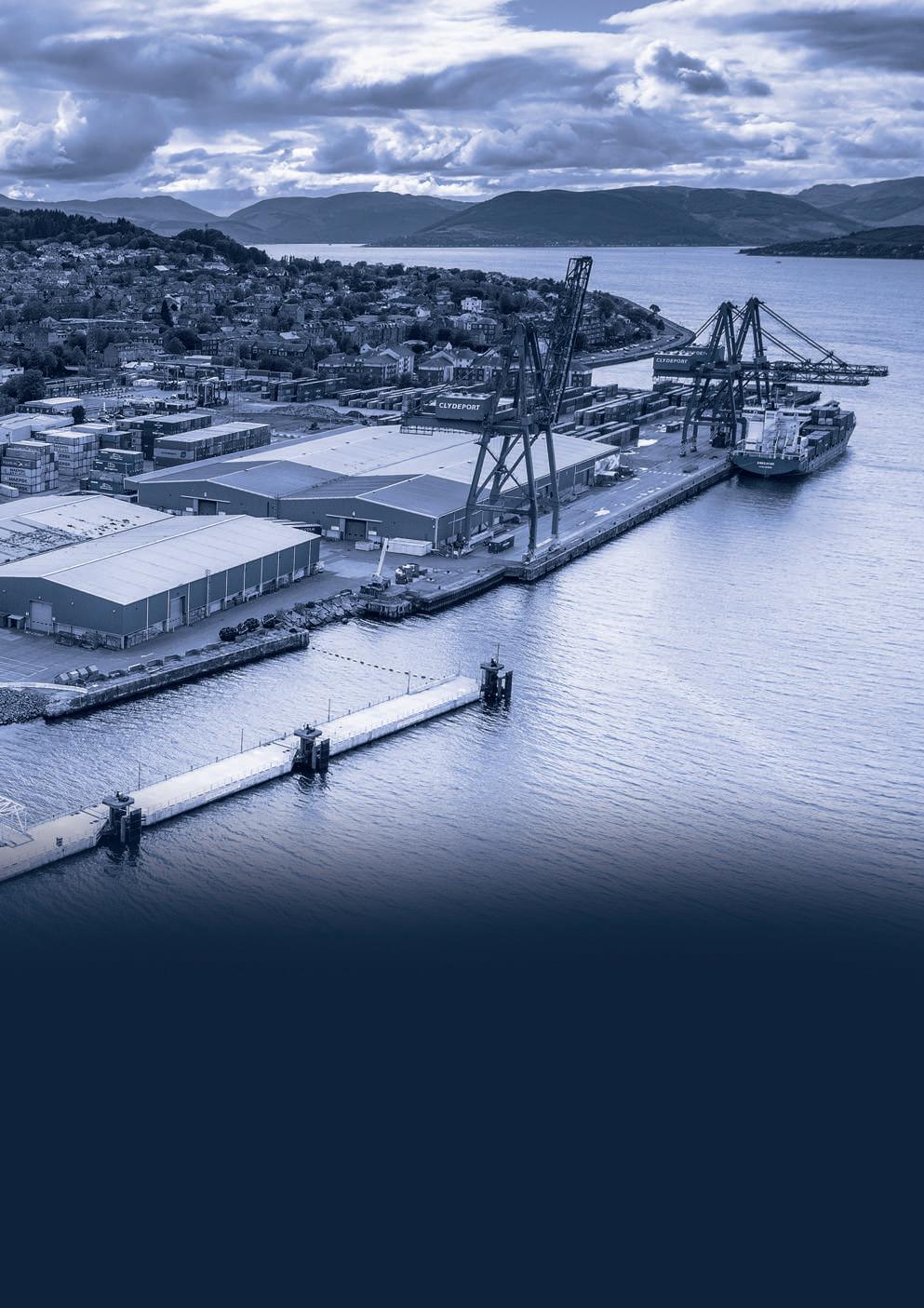

228 Award-winning excellence in port sustainability

Peel Ports

234 Mexican port set for new highs

Altamira Terminal Portuaria

Engines, motors & propulsion

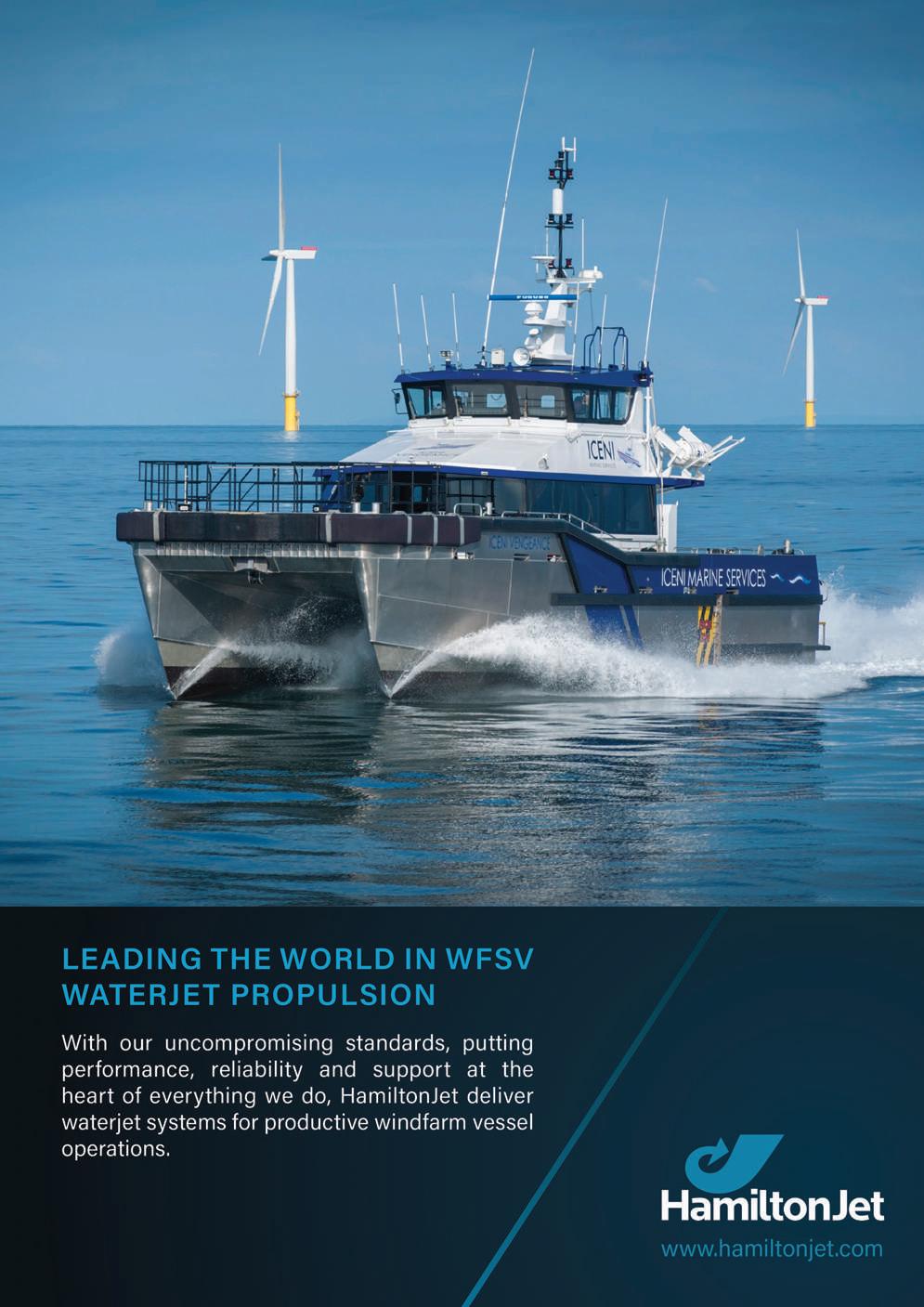

242 Propelling waterjet solutions to the next level

HamiltonJet

248 Generating growth in electronic propulsion

OSWALD Elektromotoren

252 Casting a spell on diesel machinery

Merlin Diesel Systems

Foundries & forging

258 Always one step ahead Friulforgia

266 Foundry group remains reliable performer

CMW Foundries

Electronics

272 Moving forward in marine servicing

Tefin Marine

Electronics Service Network

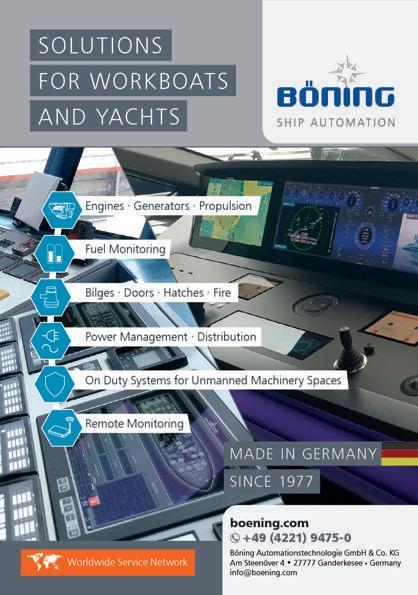

276 The beating electronic heart of maritime

Böning Automationstechnologie

Valves, bearings & piston rings

282 A change of bearing

Mikasa Corporation

286 The technology within Precision Products (UK) ltd

290 Dutch maritime heritage meets European quality

Wouter Witzel EuroValve

Digital transformation, as well as climate change and the maritime energy transition all take centre stage at the 30th SMM. With an expanded spectrum of key areas and additional presentation formats, the leading international trade fair for the maritime industry accompanies the change at close quarters. Maritime industry professionals from all parts of the world will get the complete overview of innovations from all sectors, and of course they will finally enjoy again the opportunity for live encounters on the exhibition ground as well as in the high-profile trade conferences. www.smm-hamburg.com

The show features everything the leisure marine industry has to offer. Ranging from paddleboards to superyachts, and all the products and services you need to enjoy life in, on or around the water – you’ll find it at the show. Show favourites, new exhibitors and exciting attractions make sure there’s a lot to see and do: From kayaks to catamarans, SUPs to superyachts, there’s a boat for everyone.

www.southamptonboatshow.com

Breakbulk Americas is the event for all those involved in the project cargo and breakbulk industry. Focused on companies and projects from Canada down to the tip of Argentina and the Caribbean, this is the place to expand your operations in one of the most promising regions of the world. In addition to meeting more than 200 exhibitors, you’ll find a full conference agenda featuring industry leaders, including shippers, global project forwarders, leading carriers, and more. You will hear perspectives and lessons learned from major project participants, information that you won’t find anywhere else. www.americas.breakbulk.com

The Monaco Yacht Show is world-renowned for the exceptional quality of its superyachts and their impressive length: among the +100 units on display, +40 new models are unveiled as world premieres each year. The fleet has an average length of 50m and mega yachts exceeding 100m. The show has become an emblematic event for private visitors who come to discover an outstanding concentration of superyachts available for purchase or charter and to meet the industry experts in the festive and glamorous atmosphere of the Principality of Monaco. www.monacoyachtshow.com

The METSTRADE Show is the world’s largest trade exhibition of marine equipment, materials and systems. Labelled as the only truly international B2B exhibition for the marine leisure industry, METSTRADE has served as a platform for innovation, market developments and networking since launching in 1988. In addition to the overall leisure marine industry, METSTRADE caters for three specialist sectors, namely superyachts, marinas and yards and construction materials through three specialised pavilions, each offering a smaller self-contained show within the larger METSTRADE Show context. www.metstrade.com

After two years of industry change, port technology advancement and digital acceleration, TOC Asia will connect the port and container supply chain community across the APAC region. Hear from change-makers within the global container supply chain and discover the latest innovations within terminal operations. Alongside a first-class conference, visitors will also benefit from a global port technology exhibition and the return of TOC’s famous social programme. TOC Asia will enable you to identify and leverage the key market opportunities that are waiting for you. Visit TOC Asia for solutions, powerful learning and the long overdue networking that only face-to-face events can bring. www.tocevents-asia.com

CF Industries becomes the latest big name to sign up to the centre, set up in 2020 to identify, demonstrate and mature viable operational zero carbon solutions and their transition pathways.

The Copenhagen-based Mærsk McKinney Møller Center for Zero Carbon Shipping has announced that CF Industries will become its latest Strategic Partner, committing to a long-term strategic collaboration and contribution to the development of zero carbon technologies and solutions for the maritime industry.

As one of the world’s leading ammonia producers, CF Industries brings decades of experience in safe production, storage, transport, and trade of ammonia and is supporting global decarbonisation by producing nearly 2 million tons of low-carbon ammonia production capacity by 2024. This includes installing a 20MW electrolyzer to enable the production of green ammonia at its Donaldsonville Complex in Louisiana. All are critical aspects when looking to unlock ammonia as a fuel pathway, enabling the transition of the maritime industry.

In welcoming CF Industries to the Center, CEO Bo Cerup-Simonsen said: “As a US based producer, CF Industries brings additionality to the centre’s established partner portfolio from both a geographical and a value chain perspective. This will significantly compliment and strengthen our ability to work, collaborate, and create impact on enabling robust low-emission ammonia fuel pathways, addressing safety topics on handling and operation of ammonia, and creating robust engagement on regulatory topics.

“CF Industries has a strong sustainability agenda and will play a prominent role in transforming the ammonia industry. The company is well positioned to pave the way forward for low emission fuel production.”

With 100,000 ships consuming around 300 million tons of fuel annually, global shipping accounts for around 3% of global carbon emissions, a share that is likely to increase as other industries tackle climate emissions in the coming decades.

Achieving the long-term target of decarbonisation requires new fuel types and a systemic change within the industry. Shipping is a globally regulated industry, which provides an opportunity to secure broad-based industry adoption of new technology and fuels.

To accelerate the development of viable technologies, a coordinated effort within applied research is needed across the entire supply chain. Industry leaders play a critical role in ensuring that laboratory research is successfully matured to scalable solutions matching the needs of industry. At the same time, new legislation will be required to enable the transition towards decarbonization.

The Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping is a not-for-profit, independent research and development centre working across the energy and shipping sectors with industry, academia, and authorities. With its partners, the objectives of the centre include exploring viable decarbonisation pathways, facilitating the development and implementation of new energy technologies; building confidence in new concepts and their supply chains; and accelerating the transition by defining and maturing viable strategic pathways to the required systemic change.

The centre, based in Copenhagen but works with partners globally, was founded in 2020 with a start-up donation of DKK 400 million (approximately €54 million) from the A.P. Moller Foundation.

CF Industries joins a list of Corporate Partners at the centre that already includes Alfa Laval, American Bureau of Shipping, A.P. Moller - Maersk, bp, Cargill, CF Industries, DP World, Hapag-Lloyd, MAN Energy Solutions, Mitsubishi Heavy Industries, Mitsui, NORDEN, NYK Line, Seaspan Corporation, Siemens Energy, Stolt Tankers, Sumitomo Corporation, Swire Group, Topsoe, TotalEnergies and V.Group.

CF Industries is on a path to decarbonise its ammonia production network – the world’s largest – to enable green and blue hydrogen and nitrogen products for energy, fertilizer, emissions abatement and other industrial activities. The company has nine manufacturing complexes in the United States, Canada, and the United Kingdom, an unparalleled storage, transportation and distribution network in North America, and global logistics capabilities.

Tony Will, President and CEO of CF Industries said: “As the world transitions to low carbon alternative energy sources in order to realise net zero carbon emissions, collaboration across industries is critical to accelerate the development of achievable solutions.

“We believe ammonia has an important role to play in the world’s transition to clean energy and is a particularly promising approach for the maritime industry.”

French ferry operator Brittany Ferries has signed a long-term agreement with Titan LNG for the supply of LNG and Liquified Bio Methane (LBM) to two new LNG-fuelled hybrid Ro-Pax vessels that Brittany Ferries will operate between England and France from 2025.

Brittany Ferries’ two 194.7m, 1,400passenger LNG-hybrid ships will join the fleet in 2024 and 2025, replacing two of the longest-serving vessels, Bretagne (1989) and Normandie (1992). They will follow two new LNGfuelled ships, Salamanca, which entered service in March this year, and Santoña which will arrive on fleet in 2023.

The new ferries will serve established routes connecting Portsmouth with St Malo, and Portsmouth with Ouistreham. Titan aims to supply fuel to both vessels during usual cargo operations alongside (SIMOPS) to avoid delays to sailing schedules.

The hybrid vessels will have a large battery hybrid power system of 10 MWh for propulsion and manoeuvring in port and an 8 MW electric shore connection that will allow charging in port, when infrastructure allows. As well as significantly cutting emissions, hybrid propulsion promises less noise and a smoother ride for passengers.

“Ships like Salamanca, Santoña and our forthcoming hybrid ships are cleaner today

and greener tomorrow,” added Frederic Pouget, Operations and Ports Director Brittany Ferries.

“Thanks to LNG, they promise an immediate and significant reduction in air quality emissions and a small reduction in GHG emissions. They are greener tomorrow because they are capable of running on fuels like LBM first and later future fuels like Hydrogen Derived Liquid Methane. These have the potential to slash well-to-wake GHG emissions. Our new vessels will therefore automatically become greener when these fuels arrive and there is great potential for expanding the development of the LBM value chain with Titan LNG.”

As a leading independent supplier of LNG, Titan LNG is the frontrunner in economic and clean (bio)LNG supply to the marine and industrial sector in Europe.

Titan LNG believes LNG is the best transport fuel and essential in the energy transition during the coming decades.

In creating the infrastructure for further decarbonisation via (bio)LNG and synthetic LNG, carbon-neutral solutions can be achieved.

With headquarters in the AmsterdamRotterdam-Antwerp area, Titan LNG and its partners believe LNG should be easily

accessible to all. Through building a global supply network, Titan LNG offers complete natural gas solutions: LNG bunkering, LNG transport and supply, LNG storage tank and vaporizer rental, including maintenance and service.

LNG distinguishes itself from oil-based fuels, as a cleaner, economical and safe fuel. It is abundantly available and has been used for over 50 years. With LNG becoming the fuel of choice for travel to Mars, Titan LNG believes the fuel will also enable clean transport on earth.

Régine Portocarero, Titan LNG’s Business Development Manager, said: “We look forward to our journey forward with Brittany Ferries and these innovative ships. We believe strong partnerships are essential for the maritime industry to successfully decarbonise. Furthermore, thanks to the unique farmer-shareholder ownership structure that underpins Brittany Ferries, we see great potential in available stocks for local LBM production.”

This partnership marks the significant expansion of Titan’s operations in the English Channel which will enhance the availability of LNG, LBM, and in the longer run hydrogen-derived LNG in the region. Titan will bring additional barge capacity to meet this demand. There are plans for a Krios series vessel to serve Brittany Ferries and to regularly transit between relevant ports. n

The 117,000 sqft manufacturing addition will house the latest state-of-the-art computerised and robotic steel processing equipment to handle all of the current and future demands of the US Navy and the US Coast Guard.

American shipbuilder Austal USA has celebrated the opening of the company’s state-of-the-art steel facility. The addition of steel shipbuilding capability compliments the company’s well-established aluminium shipbuilding expertise.

This $100 million investment is expected to create jobs and spur economic growth throughout the region.

“We are so excited to see our plans to add steel to our capabilities come to fruition,” said Austal USA President Rusty Murdaugh. “The addition of steel capability is a game changer as it opens up our capability to support the US Navy, US Coast Guard and other customers with high-quality ships. We appreciate the confidence the Department of Defense and the Department of the Navy have shown in us with the award of the DPA grant to get this project started and look forward to repaying that confidence with our future performance delivering high-quality steel ships.”

The 117,000 sqft manufacturing addition will house the latest state-of-the-art computerised and robotic steel processing equipment to handle all of the

current and future demands of the U.S. Navy and the US Coast Guard. A 60,000 square foot stock yard will be utilised for handling the raw steel and a 19,500sqft paint facility will provide the ability to paint and blast simultaneously in two separate cells, or both cells can be combined providing the ability to paint super-modules.

“Austal USA will operate our steel production line using the same lean manufacturing principles that we’ve refined over the last 15 years building LCS and EPFs for the Navy,” continued Mr Murdaugh. “That process has resulted in Austal’s reputation for delivering quality ships on time and on budget ship after ship. We will bring that same reliable production capability to steel ship construction.”

tain, protect, and expand critical domestic shipbuilding and maintenance capacity. Austal USA matched these funds and invested an additional $50 million into the completion of the steel facility.

The opening of the new steel facility follows the recent news that Austal USA was awarded a $230.5 million contract for the detail design and construction of EPF 16, the Navy’s newest EPF ship.

EPFs have demonstrated their operational capability to conduct a variety of missions to include humanitarian assistance, disaster relief, maritime security, surveillance, command and control, and counter narcotic missions around the globe.

“ “

Our reputation for delivering quality is a direct reflection of the commitment and dedication of our talented shipbuilders and suppliers

Austal has delivered 15 Littoral Combat Ships (LCS) and 12 Expeditionary Fast Transports (EPF) to the Navy while another seven total aluminium Navy ships are under construction. The company is also under contract to build two Navajo-class Towing, Salvage, and Rescue Ships (T-ATS); these will be the first steel ships constructed in the new facility.

Financing for the new steel production line was provided in part by a Defense Production Act (DPA) Title III Agreement between the US Department of Defense, in support of the US Navy shipbuilding industrial base, and Austal USA. The agreement, valued at $50 million, was announced in June 2020 and was part of the national response to Covid-19 to main -

“Like the previously delivered EPFs, EPF 16 will benefit from the serial production of this program, resulting not only in a worldclass ship but also providing assurance to the US Navy that capability will be delivered on budget and on schedule,” said Mr Murdaugh. “Our reputation for delivering quality is a direct reflection of the commitment and dedication of our talented shipbuilders and suppliers.”

EPF 16 will be the third ship constructed in the Flight II configuration. Flight II ships will enhance the original capabilities of the Spearhead class through incorporation of reconfigurable spaces for operating rooms and postsurgical recovery efforts.

Construction efforts on EPF 16 are expected to commence later this year with delivery projected for 2025. n

The new Carnival Grand Bahama cruise port destination, expected to open in late 2024, is being developed on the south side of the island and will continue to serve as a gateway to Grand Bahama while also offering guests a uniquely Bahamian experience with many exciting features and amenities, along with business opportunities for the residents of Grand Bahama.

With a strong showing of validation of the cruise industry’s return and optimism, and reflecting a long-standing partnership between Carnival Cruise Line and The Bahamas, Carnival, in cooperation with the Grand Bahama Port Authority and the Government of The Bahamas, recently held a groundbreaking ceremony for its new cruise port destination on Grand Bahama Island.

“As we celebrate our 50-year partnership with The Bahamas, today’s groundbreaking on our incredible new Grand Bahama destination represents an opportunity to collaborate with the government and people of Grand Bahama – to contribute to the local economy through job and business opportunities, meaningfully engage with local communities, and further expand our experience offerings for our guests who will have a breathtaking new port of call to enjoy,” said Carnival Cruise Line President Christine Duffy.

“Our sincere thanks to the government of The Bahamas and The Grand Bahama Port Authority for their continued support as we begin construction. Our guests already love The Bahamas, and we are certain this new project will give them even more reason to want to visit.”

The Grand Bahama Port Authority Acting Chairman, Sarah St George, commented: “The new Carnival cruise port destination will have a monumental impact on our

island’s economy, including a panoply of new business opportunities, a huge surge in tourist visitors, as well as increased activities for established businesses. It is transformational in the true sense of the word.

“We are immensely grateful to Carnival for choosing Freeport and Grand Bahama for this flagship project. Today, we mark this incredible achievement made possible by the efforts of Carnival with The Grand Bahama Port Authority, Port Group Limited, the Grand Bahama Development Company and Freeport Harbour Company, and the Government of The Bahamas. A project of this magnitude is only possible through genuine collaboration. Grand Bahamians have withstood life-changing challenges, particularly in recent years. Despite these, Carnival never wavered in their commitment to building their next cruise port in Freeport. We are very proud to have played our part to the best of our ability towards making this a reality.”

The cruise port development includes a pier able to accommodate up to two Excelclass ships simultaneously welcoming guests to a stunning white-sand beach The Bahamas are known for. Guests will be able to explore and enjoy Grand Bahama by way of sea, via a dedicated shore excursion dock, or by land, via the dedicated ground transportation hub. The cruise port itself will also feature an area designated as a nature reserve and an interior pool feature, along with many Bahamianoperated retail, food and beverage options for guests to enjoy.

“This development signals opportunities for creatives, vendors, and small and medium sized businesses, and represents our commitment to collaboration with local and international partners for the betterment of our island,” said The Honourable Ginger Moxey, Minister for Grand Bahama.

The cruise pier will allow Grand Bahama to welcome guests from Carnival’s larger ships, such as the 5,282-passenger Mardi Gras, which debuted in 2021 as the line’s largest and most innovative ship and North America’s first cruise ship powered by Liquefied Natural Gas (LNG), and Carnival Celebration, sister ship to Mardi Gras, which will begin sailing from Miami later this year.

Deputy Prime Minister and Minister for Tourism, Investment and Aviation, The Honourable I. Chester Cooper, added: “The cruise port is an integral part of our plan to restore Grand Bahama to economic viability. Carnival will play a critical role in stimulating our economy and shining a light on Grand Bahama as a rejuvenated and premier destination in our country and the region. We believe the excitement of what is happening on Grand Bahama will be contagious.”

Additional details on the design, features and the name of the cruise port destination will be revealed over the coming months. n

Inside Marine takes a look at a number of

Owner: Havila Voyages

Builder: Tersan Shipyard, Turkey

Vessel Type: Passenger (cruise) ship

Length: 124m

Info: Havila Capella is a plug-in hybrid ship with the world’s largest battery packs designed for passenger ships. The battery pack weighs 86 tonnes and has a capacity of 6.1 megawatt hours. The batteries on board the modern ship allows her to sail for four hours without noise and emissions, meaning she can sail quietly and sustainably through world heritage fjords and pristine surroundings along the Norwegian coastline. The ship is built to run on biogas, but is also prepared to run on hydrogen or ammonia and is therefore a ship built for the future.

Owner: Celebrity Cruises

Builder: Chantiers de l’Atlantique

Vessel Type: Cruise ship

Length: 327m

Info: Designed to give guests endless opportunities to disconnect from the world – while simultaneously reconnecting with the world that surrounds them – Celebrity Beyond goes further than imagined possible for a cruise ship, creating a new world of wonder and approachable luxury. With forward-thinking design by the world’s leading architects and interior designers, culinary excellence from Michelin starred chefs, world renowned wellbeing partners, exquisite art, luxury brand retailers and Celebrity’s uniquely intuitive service, Celebrity Beyond shatters every preconceived notion of the cruising experience. A floating boutique hotel, Celebrity Beyond exemplifies newluxury travel and its future at sea.

Owner: DEME Group

Builder: CSBC Corporation, Taiwan

Vessel Type: Offshore installation vessel

Length: 216.5m

Info: This revolutionary offshore installation vessel is designed to handle the next generation of multimegawatt turbines, jackets and components. It has an unrivalled combination of load capacity, impressive lifting heights and green technology. Owned by CDWE, a joint venture between CSBC, the largest shipbuilder in Taiwan, and DEME Offshore, Green Jade is the first floating, DP3 offshore installation vessel to be built in Taiwan. With a 4,000-tonne crane capacity, this pioneering vessel will enable CDWE and its customers to transport multiple jackets and foundation components for the new giant wind turbines in a single shipment, making it extremely cost effective.

Owner: Terntank Rederi AS

Builder: China Merchants Jinling Shipyard, Yangzhou

Vessel Type: Tanker

Length: 147m

Info: TERN FORS is a 15,000 DWT vessel with a cargo capacity of 16,500 cbm in 14 epoxy coated tanks. The pioneering new vessel design is derived from the product carriers of Ternsund-type. Together with the design partner Kongsberg Maritime, Terntank has taken a step further, combining LBG/LNG-powered engines with the Hybrid Solution® – a combination between battery pack, shore power connection and a DC-Link system. By combining the optimised hull and rudder design with dual fuel capability, TERN FORS will reduce fuel and energy consumption resulting in extensively low CO2, sulphur oxide, nitrogen oxide and particle emissions.

Owner: Royal Caribbean Group

Builder: Chantiers de l’Atlantique

Vessel Type: Cruise ship

Length: 362m

Info: Wonder of the Seas was completed in 2022 in the Chantiers de l'Atlantique shipyard in SaintNazaire, France, the fifth in Royal Caribbean’s Oasis class of cruise ships. Across Wonder’s eight unique neighbourhoods – a Royal Caribbean first – variety and innovation come to life in a line-up of unparalleled thrills, more than 20 restaurants, bars and lounges, and show-stopping entertainment. Wonder of the Seas has a gross tonnage of 236,857 across 18 decks. This ship accommodates 5,734 passengers at double occupancy up to a maximum capacity of 6,988 passengers, as well as a 2,300 crew.

Owner: East by West Ferries

Builder: Wellington Electric Boat Building Company

Vessel Type: Electric ferry Length: 19m

Info: The southern hemisphere’s first fully electric, carbon fibre commuter ferry has successfully completed its inaugural round trip. Ika Rere, Mãori for flying fish, has joined the East by West fleet operating the New Zealand ferry company’s Wellington to Eastbourne route. The 19m long, 135 passengercarrying fast cat is also the first vessel delivered by the Wellington Electric Boat Building Company, a joint venture between the ferry operator and established boatbuilder Fraser Foote. The ferry is very quiet at 19 knots and silent at 10 knots. It is faster and uses less energy than was first anticipated.

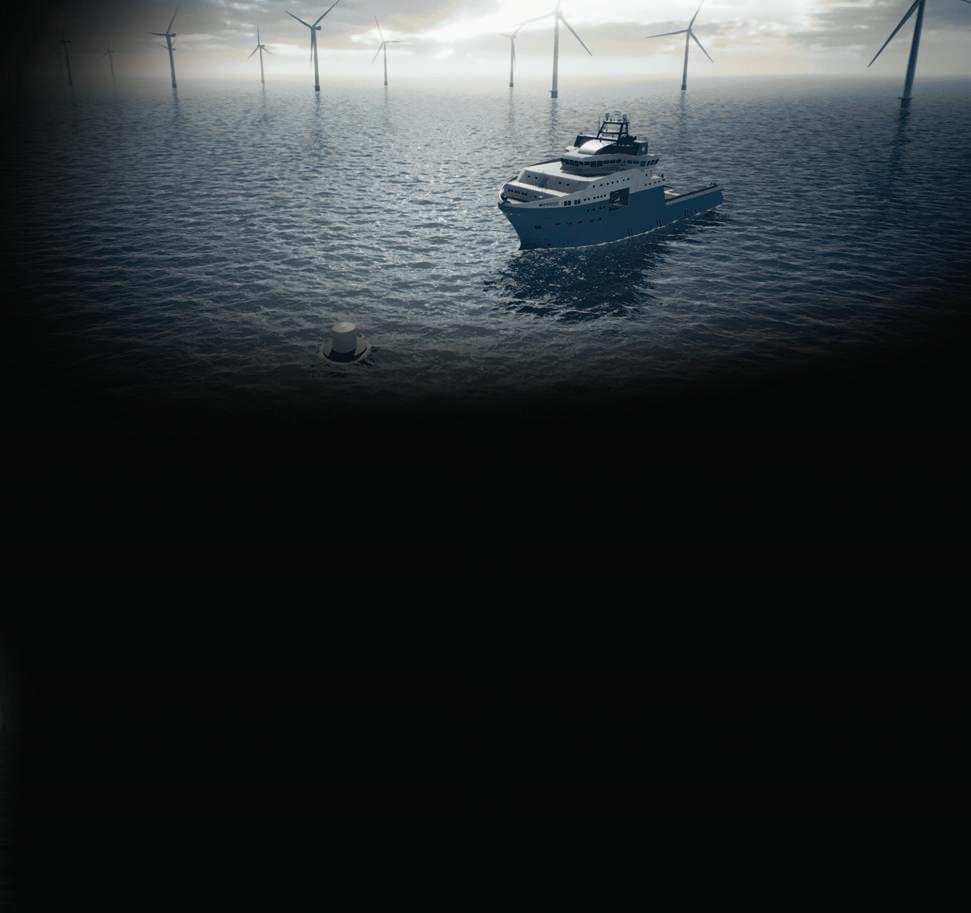

Offshore vessel-charging venture Stillstrom launched to support the decarbonisation of the maritime industry

launches new venture company, Stillstrom, to deliver

Maersk Supply Service, a part of AP Moller-Maersk, is launching its offshore vessel-charging venture, Stillstrom, to support the decarbonisation of the maritime industry by eliminating idle emissions. Together with Ørsted, Stillstrom will demonstrate the world’s first full-scale offshore charging station for vessels at an offshore wind farm, scheduled for installation later this year.

Maersk Supply Service’s pioneering new company will deliver offshore electric charging solutions to vessels at ports, hubs and offshore energy operations. “Stillstrom”, meaning “quiet power” in Danish, is an early-stage technology spin-out, whose full-scale product launch will be the first-to-market in offshore charging, enabling idle vessels to power from clean electricity.

Offshore charging for idle vessels is critical to facilitating the decarbonisation of the maritime industry, since it allows

vessel owners to replace fossil fuels with electricity while being safely moored to the charging buoy.

The first full-scale charging buoy will, as previously announced, will be demonstrated with offshore leader Ørsted in Q3 2022. The power buoy will supply overnight power to one of Ørsted’s Service Operations Vessels (SOV), thereby supporting Ørsted’s target of climate-neutral operations in 2025. Ørsted will be responsible for the grid integration of the charging buoy.

Making intellectual property publicly available Ørsted intends to make publicly available any intellectual property generated during the design of the buoy’s integration into the offshore wind asset, to maximise the potential uptake of this carbon-reducing innovation across the offshore wind sector.

The charging buoy itself is large enough to charge an SOV-sized battery- or hybridelectric vessel. The same solution will be scaled and adapted to supply power to larger vessels, enabling vessels of all sizes

to turn off their engines when lying idle. By substituting fossil-based fuels with green electricity, virtually all emissions and noise pollution are eliminated while the buoy is in use.

“Stillstrom is part of our commitment to solving the energy challenges of tomorrow,” said Steen Karstensen, CEO of Maersk Supply Service. “By investing in this ocean cleantech space at an early stage, we can help lead the green transition of the maritime industry. Stillstrom has been developed within Maersk Supply Service and the timing is right to create a venture that will be focused on delivering offshore charging solutions.”

Sebastian Klasterer Toft, Venture Programme Manager at Maersk Supply Service, added: “Our vision at Stillstrom is to enable maritime decarbonisation, by providing the infrastructure that will allow vessels to charge from clean energy when idle offshore. The mission is to remove 5.5 million tonnes of CO2 within five years of commercial rollout, additionally eliminating partic ulate matter, NOx, and Sox.”

Stillstrom is fully owned by Maersk Supply Service and has received funding support from the Danish Maritime Fund and EUDP.

Maersk Supply Service is a leading provider of marine services and project solutions for offshore energy sectors.

With a large fleet of anchor handling and subsea support vessels, the company specialises in towing, mooring, and installing floating units, and is expanding into renewable industries such as floating wind and ocean cleaning.

Maersk Supply Service, as a subsidiary of AP Møller-Mærsk, employs around 1,100 offshore and 220 onshore staff. Headquartered in Lyngby, Denmark, the company has a global presence in Angola, Australia, Brazil, Canada, Equatorial Guinea, Ghana, Mexico, Norway, the Philippines, and the UK. n

Excitement builds as September’s return of SMM is just over the horizon

6-9 Sept 2022 - Hamburg

TUR N of the living trade fair

SMM Hamburg returns in 2022 from 6th to the 9th of September. Business Unit Director Maritime and Technology Fairs & Exhibitions at Hamburg Messe und Congress, Claus Ulrich Selbach, chatted with Phil Nicholls about the forthcoming fair.

Digital transformation within the marine industry will be a big focus of this year’s event. What were the factors behind choosing this as a key area? How do you ensure that your topics reflect the current demand of the industry?

As the leading maritime trade fair, we have an extensive and multi-faceted industry network across the globe which allows us to follow the market dynamics closely. We constantly talk to our partners, exhibitors, and visitors about their needs, interests, and expectations for SMM.

One key issue is the digital transformation in the maritime industry. This is nothing new and has been a fixed component of SMM for years now. This year, we will take a closer look at all the digital innovations and solutions which can help the shipping industry become greener in the next couple of years.

SMM 2022 promises to drive the maritime energy transition. Can you share how the event’s Transition Stages will facilitate this process?

Our new Transition Stages will be the perfect meeting places for all the industry experts who want to drive the transition of the maritime industry.

In addition to our conferences, and in parallel on three stages at the exhibition area, stage partners and exhibitors will present innovative concepts and solutions on central topics of SMM 2022.

The Green Transition Stage in Hall A4 presents alternative propulsion and environmental technologies to reduce emissions, The Digital Transition Stage in Hall B6 features digitalisation in the maritime industry, and The Marine Interiors Stage in Hall B5 focuses on interior design, equipment, and technology for passenger ships.

Excitement builds as September’s return of SMM is just over the horizon

6-9 Sept 2022 - Hamburg

Another new feature for 2022 is the Start-up Route. What can you tell us about this aspect of the event? How popular is this area in terms of number of exhibitors booked and sectors represented?

As the name itself says, the Start-up Route guides visitors to entrepreneurs in the maritime industry which present their smart and innovative concepts at one of the Start-ups@SMM joint stand areas. There will be a special icon identifying the Start-up Route as well as the participating companies in the online exhibitor directory, the visitor guide, and the app.

So far, the feedback to the new Start-up Route has been great. Whilst I can’t give you exact details yet, you can be sure that there will be lots of interesting start-ups to discover.

2022 marks the 30th SMM. How are you celebrating this milestone?

We will celebrate the 30th edition of SMM together with our international friends and partners in various online and offline events. Let us surprise you!

What visitor and exhibitor numbers are you targeting this year? Is there any room to grow, especially in terms of number of exhibitors?

We are expecting 2,000 exhibitors and 40,000 visitors from more than 100 nations. Due to the pandemic, there is no room to grow this year. But I’m sure there will be in 2024.

Honestly speaking, we are quite happy with what we have got already – especially in times of the pandemic where it won’t be

possible to welcome all markets, such as from China. But we are hoping to increase the number of industry players from across the maritime supply chain that can make it to Hamburg this year.

With so many global exhibitions available to companies, why do you feel that SMM is so successful in attracting the world’s biggest companies? What benefits do these companies get from exhibiting at SMM?

There is just nothing that compares to SMM. Here you can meet all your business partners, customers, and friends from all over the world at one place within a short time span of four days. It saves so many trips and phone or video calls. It is the personal interaction that exhibitors and visitors are longing for most these days. SMM will be the first opportunity in 2022 to meet again in a very international atmosphere.

We will reflect the whole supply chain of the maritime industry –in both the 11 exhibition halls and our highly-ranked conference programme. In addition, there will be many possibilities to chat in a relaxed atmosphere or to even take a break in our beautiful park directly next to our halls or in our daily ‘wine o’clock’ social events.

Besides the fact that we will offer all of the industries’ solutions, innovations and inspiration, it is important to us that our exhibitors and visitors will have a good time at SMM. There will be several networking events so that each and every one can make the most of their participation. Especially in times like these where everything seems to be in constant change, where there are so many conflicts and crises in the world, we would like to make a small contribution by focusing not only on business but also on interpersonal exchange.

Excitement

as September’s return of SMM is just over the

Please can you tell me more about your conference programme – who do you have lined up to speak and what topics are high on the agenda?

There are so many great speakers and topics that I can’t sum it up in just a few words. All the details can be found on our website. To put it in a nutshell, all five conferences cover topics that are high on the industry agenda.

The Maritime Future Summit (5 September) focuses on the ‘Next Phase of the Digital Transformation’, especially on smart alliances and evolving multidisciplinary solutions. Gmec – the global maritime environmental congress (7 September) - addresses the shipping industry’s part in tackling the growing climate crisis. MS &D, the international conference on maritime security and defence (8-9 September), will discuss the industry‘s and navies’ security transition – from future military and non-military threats to artificial intel ligence for global as well as regional maritime security.

MS&D’s title this year is: Secure your position: Protecting the seven seas. Experts will discuss how navies and the maritime industry can prepare for security issues such as future military and non-military threats or technological developments of manned and unmanned platforms as parts of the Fourth Industrial Revolution (4IR).

The Offshore Dialogue (8 September) will discuss innovative maritime technologies for monitoring climate change processes in the oceans as well as opportunities offered by digitalisation to achieve our climate targets. Finally, the motto of the TradeWinds Shipowners Forum (6 September) is “Phoenix rise – Rebound prospects for containers and shipyards.”

What do you consider to be the main industry challenges for 2022 and the upcoming years? How far do events such as SMM go in helping companies overcome such difficulties?

Of course, I do not have as much expertise as all the stakeholders who will present at SMM, but it’s clear that it will take many innovations, discussions, and negotiations to fulfil the industry's own set goal to achieve net-zero emissions by 2050. All sectors agree on the fact that everything must be done to make shipping greener, to slow down climate change, with alternative energy sources or propulsion solutions.

But the energy transition costs the industry a lot of money, and it takes a lot of expertise and concrete product solutions. Now, the demand in the industry, as in other industries, exceeds what the market can offer. So that might be one of the main challenges

in 2022 and the coming years. I’m sure your readers will find some of the many ideas and answers to this huge challenge at SMM in September.

For those who may be new to the event this year, and may be visiting Hamburg for the first time this September, what advice would you give? What can they expect from their trip to Hamburg and SMM?

Hamburg is always worth a trip. There is so much to discover in our beautiful city. The good thing is that SMM takes place in the heart of Hamburg – all the places worth visiting are just a few minutes away. I advise your readers to have a closer look at our homepage for more information: https: //www.smm-hamburg.com/en/infos/travel/hamburg.

Is there anything not covered by the above questions that you would like to share with our readers?

Thank you so much for all your questions, Phil. I think we spoke about everything that will be key at SMM. On a personal note, let me express how much I am looking forward to meeting all the friends of SMM in Hamburg from 6-9 September. Let’s cross our fingers that everything can take place as currently planned! n

APMTerminals Mobile has signed an agreement with the Alabama State Port Authority to add 32 acres to the current 134 acre container terminal yard to keep pace with future demand, creating one million TEU throughput capacity that is approved to handle 14,000 TEU ships. This represents the third expansion in the last six years as importers expand their volumes to meet regional consumer demand and tap into rail service to the Midwest US market.

The $104 million terminal expansion will begin later this year. The first 19 acres are expected to be completed in 2023 and the remaining 13 acres by early 2025. As part of the expansion, APM Terminals will purchase two, new super post-panamax ship-to-shore gantry cranes and related support equipment (such as trucks, landing chassis/container carriers) for crane operations which will complement the current four gantry cranes.

In 2020, the berth was expanded to allow two x 8,000 TEU vessels alongside. The US Army Corps of Engineers is currently dredging the Mobile Harbor channel to reach 50 feet by late 2024.

APM Terminals Mobile now ranks as the second largest US Gulf port of container imports. April 2022 container volumes through the port showed a 39.7% increase over April 2021 volumes. The port’s intermodal container transfer facility posted 112.6% growth during the same period. Refrigerated cargo also maintained its double-digit growth, posting a 57.9% gain over the same period.

“Supply chain leaders are looking to expand their routing options in 2022 to add more flexibility and fulfillment speed to serve consumer demand. We’re working with customers to deliver high port productivity, more port space and more inland logistics connectivity to address the market demand,” said Brian Harold, Managing Director of APM Terminals Mobile.

Sealand – A Maersk Company has added a new service called the Bonita Express with the inaugural call at APM Terminals Mobile on May 18th. The new, direct all-water service links Mobile to the key Central American ports of Puerto Cortes in Honduras and Santo Tomas de Castilla in Guatemala (with connectivity to multiple inland locations including to/from Nicaragua and El Salvador).

Turkish shipbuilder Cemre Shipyard will build the world’s first service operation vessel that can operate on green fuels for ESVAGT, the Danish provider of emergency rescue and response vessels.

The design of the vessel has been developed by the Norwegian design company HAV Design in cooperation with ESVAGT, and the vessel will be the third turnkey project Cemre has built for ESVAGT.

According to a statement by Cemre Shipyard, “This pioneering project will change the path of the offshore wind service and support the market to reach carbon neutral and environmentally friendly solutions.”

The SOV will be powered by batteries and dual fuel and pure methanol engines, capable of sailing on renewable e-methanol, produced from wind energy and biogenic carbon, which will lead to a yearly emission reduction of approximately 4,500 tonnes of CO2. These systems will provide carbon neutral power for the vessel’s propulsion, positioning, and main operations.

This 93m long vessel will provide accommodations for 124 persons and will be built according to DNV classification rules sailing under the Danish flag. The SOV will serve the world’s largest offshore wind farm, Hornsea 2 located off the UK’s Yorkshire coast in the North Sea.

This new state-of-the-art ESVAGT SOV is expected to provide high comfort standards to the crew and technicians on board in addition to space for recreational activities including fitness facilities, games rooms, cinemas, and individual accommodation.

The vessel will provide a highly efficient workspace together with safe transfer of the technicians at the wind farm via a motion-compensated gangway and transfer boats as well as a crane to lift heavy spare parts. The SOV will also be equipped with a helicopter deck for fast and easy access and transfer from shore.

“This success marks another milestone for Cemre, and having the confidence sourced from the former challenging ‘firsts’ we believe Cemre Shipyard will present this green-committed and futuristic vessel to the sector successfully when completed,” said Burak Mursalolu, Head of Business Development at Cemre Shipyard.

Satellite communications company Inmarsat has made its marketleading maritime broadband service, Fleet Xpress, available to shipyards. Installed during new building, Fleet Xpress for Shipyards eliminates time-consuming and costly installation works in port, offering owners a pre-fitted very small aperture terminal (VSAT) solution included in the initial cost of the vessel.

“Fleet Xpress for Shipyards is a game-changer for shipbuilders and owners alike, streamlining installation, providing remote connectivity from vessel launch and enabling optimal integration between integral onboard systems,” said Ben Palmer, President, Inmarsat Maritime.

“We are delighted to collaborate on the shipyard offering with JRC and Intellian, two of our value-added manufacturers and trusted partners.”

Inmarsat’s newly-launched service enables delivery of Fleet Xpress capability to the shipyard during vessel construction. All terminals, cables, and below deck units are installed as a Fleet Xpress line-fit service, allowing the yard to deliver a one-stop solution to the owner that improves safety and offers fast and reliable connectivity from the first voyage.

“Working with Inmarsat to deliver Fleet Xpress for Shipyards allows us to strengthen our relationship with yards as a technology partner for smart vessels,” said Eric Sung, CEO, Intellian. “As one

of the world’s top shipbuilders, we’re delighted that Hyundai Heavy Industries is among the first to recognise the value of this line-fit solution – we’re seeing significant interest from yards across all markets.”

For shipyards, Inmarsat said early installation of Fleet Xpress will enhance responsiveness to growing customer demand for highspeed communications and provide remote vessel monitoring and maintenance capabilities upon delivery. Furthermore, by using data to counter improper claims and ensure preventive operations, shipyards can minimise warranty costs.

With the vessel featuring state-of-the-art VSAT equipment at launch, owners and managers are assured that their bandwidth needs are fully integrated and sea-trialled at the point of handover, while the crew has access to fast, ultra-reliable connectivity as soon as they step onboard. In addition, Fleet Xpress allows the implementation of a range of digital services and automation onboard the vessel that further delivers advantages for ship performance and crew well-being.

“Fleet Xpress for Shipyards gives shipbuilders the competitive edge of being able to pre-install Inmarsat’s industry-leading Fleet Xpress service,” said Mr Palmer. “Early interest in the solution has been strong. With the first implementations executed, we already have several more projects in the pipeline.”

The world’s first autonomous commercial ship voyage in congested waters, powered by Orca AI, in partnership with the Designing the Future of Full Autonomous Ships (DFFAS) and The Nippon Foundation, has been successfully completed after 40 hours of navigation, with full autonomy being activated 99% of the journey’s time.

The trial was performed by cargo ship Suzaku, a 749 Gross ton vessel chosen for the project by the DFFAS consortium, comprising 30 Japanese companies and led by NYK group company – Japan Marine Science Inc (JMS) and MTI Co Ltd.

During the trial, the vessel automatically performed 107 collision avoidance manoeuvres on the outbound voyage alone, with the program director at the consortium suggesting that the system avoided a total of 400 to 500 ships. The voyage, which started from Tokyo Bay – one of the most congested routes in the world – sailed towards the port of Tsumatsusaka in the Ise Bay.

Powered by AI and deep learning technologies, Orca AI’s safety navigation system was set up on the vessel to act as a ‘human watchkeeper’ and provide real-time detection, tracking, classification and range estimation on 18 onboard cameras, totalling a 360° day and night.

Orca AI’s algorithms were trained on data collected over a year from Suzaku to identify targets in the complex Japanese shorelines environment. The information from the cameras reflected to the fleet operations centre in Tokyo – hundreds of kilometres away.

Yarden Gross, co-founder and CEO of Orca AI, said, “We are honoured to collaborate with the DFFAS consortium led by NYK group to drive automation and autonomous capabilities in commercial ships in some of the most congested waters in the world. The world’s first commercial autonomous voyage is a significant milestone in this journey and we expect to see big shipping companies implementing advanced AI and computer vision technologies to materialise the autonomous shipping vision.”

Dr Hideyuki ANDO from NYK group company – MTI.Co, Ltd added: “With the great majority of Japan’s international trade relying on shipping, it’s been imperative for us to find technological solutions that can make shipping safer.

“We thank Orca AI for helping us find the ultimate computer vision solution to enhance situational awareness on ships, despite the obstacles the global pandemic has presented. Their successful delivery of the entire project, thousands of kilometres away from Japan and with complex hardware and software being shipped and remotely updated regularly, is a prime example of the potential technology has to transform the industry.”

Headquartered in Israel and founded in 2018, Orca AI provides an intelligent safety platform for the shipping industry to increase safety, efficiency and sustainability. Founded by two experienced naval technology experts, Yarden Gross and Dor Raviv, Orca AI’s technology helps ships get an accurate, real-time view of the environment by combining new sensors with existing onboard systems to aid crews in making more informed navigation decisions, improving safety in crowded waterways.

SAAM

Towage continues to fortify its fleet. Its latest acquisition is a new tug, the SAAM James Point, that arrived in Vancouver, Canada after completing its loading operation onto the cargo ship BBC Moonstone in Halong Bay, Vietnam.

SAAM Towage Technical Manager Pablo Cáceres commented: “This state-of-the-art Damen tug has technology that reduces environmental impact and is highly manoeuvrable thanks to its size, innovative hull design, manoeuvre winch settings and installed capacity, making it a true contribution to our operations in Canada.”

The new Damen 2312 tug is named after respected Musqueam Point Family Patriarch, James Point. Born shortly after confederation, he was a fisherman, who worked the Fraser River, and up and down the coast. He was a well know lacrosse player in his youth.

“The Point Family feel that honouring great leaders/servants of the Musqueam people, such as James Point, is a very respectful way for SAAM Towage to recognise Musqueam, to acknowledge our historical presence in the waters of our territory, including the Lower Mainland/Southwest corner of British Columbia, and to celebrate our successful business relationship with SAAM Towage,” stated Director of Business Development of the Musqueam Capital Corp, Jay Mearns.

Featuring an innovative Damen ASD2312 design, this tug was acquired from the Dutch company Damen and built at its Song Cam shipyards in Vietnam. Measuring 23 meters long and 12 meters in beam, it boasts 70-bollard pull capacity, Kongsberg

azimuth thrusters and two CAT 3512C IMO Tier III main engines, which enable it to operate in emissions control areas (ECA).

“SAAM Towage is excited to add this innovative design to our Vancouver fleet. The characteristics of this tug design will complement the various berth configurations in Vancouver Harbour. We look forward to putting the tug to work with our local crews to enhance the marine safety system in Southern British Columbia,” said Vice President Operations and Indigenous Relations Officer of SAAM Towage, Mark Bingham.

venture headed by shipping giant Hapag-Lloyd is building a new terminal in the port of Damietta, Egypt.

“With the new terminal Hapag-Lloyd will significantly improve its transshipment operation in the East Mediterranean market as well as access to the local Egyptian trade,” said Rolf Habben Jansen, CEO of Hapag-Lloyd.

The joint venture, called Damietta Alliance Container Terminal SAE, consists of three core shareholders: Hapag-Lloyd Damietta GmbH (39%), Eurogate Damietta GmbH (29.5%) and Contship Damietta Srl (29.5%). Two other partners, Middle East Logistics & Consultants Group and Ship & CREW Egypt SAE, will each hold 1%.

The new Terminal 2 at the port of Damietta is expected to start operations by 2024. It will have a final total operational capacity of 3.3 million TEU and serve as Hapag-Lloyd’s dedicated strategic transshipment hub in the East Mediterranean.

Thomas H Eckelmann, Chairman of the EUROGATE Group Management Board, stated: “With the Terminal 2 being operational

in 2024, Hapag-Lloyd and its partners will be able to use a state-ofthe-art terminal with sufficient capacity, high productivity and a dense feeder network.”

Cecilia Eckelmann-Battistello, Chairman of the Board of Contship Italia, added: “We feel privileged and are extremely grateful for the support of the Egyptian government. The concession to operate the facility is granted to the joint venture for 30 years. This gives us and our respective customers a long-term perspective in the port of Damietta.”

The Egyptian Minister of Transport, Lieutenant-General Eng. Kamel Al-Wazir, commented: “This is a very encouraging, well planned partnership of international and Egyptian private sector in order to position Egypt as a global hub for logistics and trade. In this first phase we will establish the port of Damietta as an integrated logistics hub for containers, which will then be followed by the establishment of logistic corridors reaching to different manufacturing areas in Egypt by railway network.”

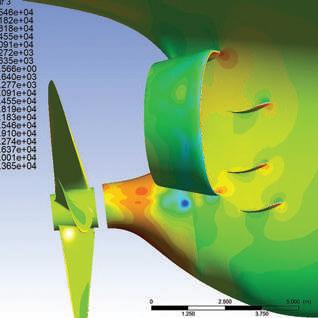

Kongsberg Maritime (KM) has signed a new technology contract of around €28 million with Chinese shipbuilder COSCO Shipping (Qidong) Offshore for an F-class, foundation installation vessel. The vessel will have greater lifting capacity than previous vessels and will be delivered to Danish service provider Cadeler in 2025.

The agreement will see KM supply a comprehensive technology package for the F-class jack-up which will be able to transport up to six XL monopiles (weighing 2,300-2,600mt each) per round-trip, substantially improving efficiency over current vessels.

The F-class vessel also features a unique convertible design, allowing a simple refit process to convert its role from a foundation installation vessel to a wind turbine installation vessel (WTIV).

This is the third contract KM has received for Cadeler installation vessels with KM’s Integrated Solution being crucial to the delivery and operation of all three vessels, which are destined to be among the largest of their type and capable of transporting and installing multiple sets of next- and future-generation wind turbines, and their foundations.

This well-proven suite of solutions combines KM’s optimised thruster package, electrical solution and dynamic positioning functionalities to maintain operability in all conditions and includes multiple digital tools to improve sustainability and reliability.

“Our vessels are designed to meet both the current and future needs of the offshore industry,” said Mikkel Gleerup, CEO at Cadeler. “So as the world needs more efficient offshore windfarms to help meet sustainability goals this requires larger turbines and larger, more efficient vessels to install them. Kongsberg’s innovative technology solutions are a key enabler in this.”

“This is a very smart vessel with a very bright future in the rapidly evolving offshore wind market,” added Egil Haugsdal, President, Kongsberg Maritime. “The bespoke solutions we have devised for the wind turbine installation vessels and this newly announced foundation installation vessel indicate how much thought and effort we devote to facilitating and encouraging sustainable marine operations.”

Cadeler is currently in discussions concerning a XL Monopile foundation installation contract in the North Sea, which will commence with this state-of-the-art F-class vessel.

The World Shipping Council (WSC) continues its work for a safe , secure and sustainable industry, and is excited to welcome a new member in Swire Shipping.

Headquartered in Singapore, Swire Shipping is a leading provider of specialist customer solutions for a wide range of cargo and aims to provide a full suite of land and ocean solutions. Swire Shipping celebrates its 150th anniversary in 2022, and for much of its modern history it has been actively involved in liner shipping in the Asia Pacific region.

“We are very pleased to welcome Swire Shipping to WSC. Expanding our membership broadens our perspective when repre -

senting the liner sector and we look forward to participation from Swire Shipping representatives in our councils and working groups,” said John Butler, President and CEO of the WSC.

Jeremy Sutton is Chief Operating Officer of Swire Shipping, and has been elected as a representative to the WSC Board, effective immediately.

“We are delighted to join the World Shipping Council and to share our knowledge and experience especially in the areas of safety, security and sustainability. We also look forward to learning from our peers and by so doing, contribute to building a vibrant, safe and sustainable industry for years to come,” said Mr Sutton.

On 17 March 1907, the White Star Line steamship SS Suevic ran aground on the Maenheere Reef off Lizard Point in Cornwall. Despite the fog and violent gale, five RNLI lifeboats sped to the rescue and subsequently set the record for most lives saved in a single operation – 456 passengers and crew over the course of 16 hours. After three weeks on the rocks, the wrecked SS Suevic was dynamited into two pieces. The reclaimed two-thirds of the stern was taken to Southampton, where a new bow was added. Suevic served in the First World War before being sold to a Norwegian whaling company and renamed Skytteren. The sea claimed her again in 1942 when escaping Sweden, she was scuttled to avoid capture by the German navy.

HMHS Britannic, Titanic’s younger sister, suffered a similar, short-lived life at sea. Entering service as a hospital ship in December 1915, less than a year later, on 21st November 1916, she struck a mine in the Aegean Sea and sank, becoming the largest single shipping loss of the First World War.

The first Transatlantic cable was built by Cyrus West Field from 1854 to 1858. It only functioned for three weeks before excessive voltage destroyed the cable.

The first true bell buoy was invented in 1852 by Lieutenant Brown of the US Treasury Lighthouse Establishment.

Every problem is a gift we would not grow without problems “ “ – Anthony Robbins –

The world water speed record was set by Australian Ken Warby in a jet-powered wooden speed boat, with an official speed of 275.97 knots (511.09 km/h, or 317.58 mph).

Construction of the 100ft superyacht HISTORY

SUPREME by Stuart Hughes required about 100,000kg of gold and platinum. The yacht features gold-plated hull and anchor, plus a meteoric stone wall accented with genuine T-Rex bone.

Europe’s mostimported fruit is the banana, 950,000 tonnes in 2018, while the USA’s first choice is the avocado, 1.2 million tonnes in 2021.

China’s Yangtze River is not only the longest river in Asia at 6,300 km, but it is also the world’s busiest river, carrying 2.93 billion tonnes of cargo in 2019.

About half the shipping containers imported into the UK will sail away empty. Thus, the UK’s largest export by volume is fresh air.

What’s new in the marine industry?

From simple ideas to engineering feats

Trelleborg’s marine and infrastructure operation launches SafePilot CAT PRO. The latest addition to its SafePilot range utilises state-of-the-art software and smart technology to help pilots and ports optimise safety, efficiency and sustainability in day-to-day operations. The completely independent portable pilot unit is designed for use in demanding applications requiring the highest positioning and speed accuracy. An extended battery life of 30 hours and ultra-fast wireless charging provides minimal loss of time between operations. SafePilot CAT PRO is configurable in four different operational modes to suit all types of vessel maneuvers with interchangeable units.

Armach Robotics, a spin-off company from marine software pioneer Greensea, has unveiled its first post-prototype Hull Service Robot (HSR). The HSR is a disruptive technology in hull cleaning, being man-portable at under 66lbs (30kgs) and around 34 inches (86cm) long. The HSR is a streamlined vehicle, capable of operating in fast water currents and on lower friction coatings, built around state-ofthe-art miniaturised navigation sensors providing rock-solid vehicle control. Armach’s ‘Robot-as-a-Service’ solution offers shipowners a constantly clean hull and following each cleaning operation provides an accurate georeferenced hull condition survey.

After successfully introducing real-time monitoring for its reefer container fleet in 2019 with the IoT product Hapag-Lloyd LIVE, the company will begin installing newly developed devices to all standard containers of its three million TEU fleet. Hapag-Lloyd LIVE will become available for its standard container customers during 2023. The devices will transmit real-time data from each container, making the supply chain more transparent by delivering GPS location data and monitor any sudden shocks to the container. The monitoring device integrates the latest energy-harvesting technology and low-power consumption techniques to ensure ultra-long lifetimes with high-frequency data sending.

Kalmar, part of Cargotec, has received an order for Kalmar SmartPort process automation solutions from Terminal Graneles del Norte SA (TGN) for their greenfield container terminal being built in Mejillones Bay at the heart of Chile’s mining region. TGN’s new port will feature an automated rail-mounted gantry crane system enhanced with Kalmar SmartPort solutions to improve the efficiency of the terminal. TGN will benefit from three Kalmar SmartPort packages to improve efficiency, security and productivity: SmartMap, SmartTrucks and SmartLane. The SmartPort products will be fully integrated with the gate operating system and Navis N4 terminal operating system.

Technology group Wärtsilä launches the 46TS-DF multi-fuel engine focused on efficiency, environmental performance, and fuel flexibility, signalling a new era of medium-speed marine engines. The Wärtsilä 46TS-DF has a two-stage turbocharging delivering high levels of efficiency and power density across a wide operational range for vessels. This level of efficiency reduces fuel consumption and lowers emissions, while being easily retrofittable for future carbon-neutral and carbon-free fuels as they become widely available. The dual-fuel Wärtsilä 46TSDF engine can run LNG, which dramatically reduces air pollutants as well as offering a viable platform for further decarbonisation using bio- or synthetic methane in the future.

Original

Naval architect firm C-Job has designed a brand-new liquid hydrogen tanker that it says will revolutionise the renewable energy market. The concept, developed in partnership with LH2 Europe, is a critical element in a sustainable liquid hydrogen supply chain. LH2 Europe will use the abundant renewable electricity in Scotland to produce green hydrogen, then market it in Germany. When completed, the 141m liquid hydrogen tanker will be powered by hydrogen fuel cells and carry three liquid hydrogen storage tanks with a total capacity of 37,500 cbm. The ship is expected to be commissioned six months before the first delivery of hydrogen in 2027.

Send us your innovation

We welcome all your latest innovations and product releases. If you wish for us to share these with our readers please send them to us today. Send your innovation

ABP cuts its carbon footprint further with two electric cranes at the Port of Ipswich

Associated British Ports (ABP), will further reduce carbon emissions, as two of the very first fully mains-electric powered hydraulic cranes arrive at the Port of Ipswich. These cranes are amongst the first of their kind in the UK and are the latest in a series of bold investments in sustainable measures from ABP, which have contributed to a 36% decrease in greenhouse gas emissions since 2014.

The cranes, Mantsinen model 95ER, have been configured around specific workings of the operations at the Port of Ipswich to optimise efficiencies and further reduce energy consumption. It is estimated that these two electric cranes will save up to 5,275 tonnes of CO2 over their lifetime.

ABP has partnered with provider, Cooper Specialised Handling in this pioneering agreement to invest in these multi-million-pound, state-of-the-art cranes that can be powered by the solar energy generated at the port itself. The two cranes will be able to manage a range of material received in the East Anglian port, which handles over 2 million tonnes of cargo each year and is the UK’s leading grain export port.

Paul Ager, Divisional Port Manager said: “ABP is really committed to reducing the greenhouse gas emissions arising from port activity. This £4 million investment at the port is the latest development in ABP’s carbon reduction goals tailored to its operations. The transition to electric machines will not only improve ABP’s cargo handling service to its customers but will also feed into ABP’s wider policy to reduce CO2 emissions all the way down to zero.”

For more information, visit: www.abports.co.uk

seven seas, five oceans, one voice

alabama shipyard i M

Storied US dockyard Alabama Shipyard has a proud history of shipbuilding and maintenance dating back over 100 years. Today, Alabama Shipyard continues to fulfil a critical – even strategic – role in the country’s naval fabrication and maintenance capabilities. The company’s management team updated Inside Marine about Alabama Shipyard’s plans, both current and imminent, to keep this veteran shipyard relevant for the coming decades. Report by Richard Hagan.

Just 18 miles inland from the Gulf of Mexico, in Mobile, Alabama, lies the aptly named Alabama Shipyard. Located on Pinto Island on a 45-foot deep channel, the yard has a proud history that dates back to 1916. During the Second World War, Alabama Shipyard made a formidable name for itself with its production of the famous Liberty Ships, at one stage launching them at an almost unbelievable rate of one new ship every week. B y the end of the war, Alabama Shipyard had been solely responsible for the production of 600 ships.

“The company has depths of history associated with it,” emphasised CEO Greg Wagner. “It has a history of helping not only the country but also the world. The Liberty Ships that were produced here, had a huge role in helping the allies win the war in the Atlantic.”

Of course, that was many, many decades ago; and in order to ensure the yard continues to thrive into the next several decades, Alabama Shipyard has assembled a dynamic management team that is laser-focused on updating and continuing the yard’s legacy in the coming decades and beyond.

In 2021, Alabama Shipyard completed the first phase of a multimillion dollar infrastructure renovation and upgrade project.

COO Lee Stokes described the work done on its largest pier: “The

project involved $8 million-worth of work revitalising and rebuilding the pier.

“In early 2022 we began CapEx work on the second of our large piers that hosts our drydock. We’re investing a lot of money back into the company here for the future and it’s all going very well,” he said. Mr Wagner echoed Mr Stokes’ comments: “We’re putting a lot of resources into the facility. It’s older and has been here for a long time. So we’re upgrading electrical cabling and installing compressors for each pier. Overall, all of the raw infrastructure is here, but we’re modernising the yard to have 21st century capabilities.”

“We’re also continuing to steady-up our plans to see what the best drydock solution for our vessels is,” added Mr Stokes. “It’ll remain an open item until we get that settled. We understand that we need more drydock capacity, but we’re being careful about establishing what size dock we need and where we’ll put it. We really want to make sure that we make the right decision.”

In the meantime, the company continues to rely on its gargantuan drydock, also named Alabama. Built in Japan and delivered to the US in the 1980s before being sold to Alabama Shipyard later that same decade, the drydock is one of the largest floating drydocks in the US. With an overall length of 240m and a width of around 50m,

“The project also ties us back to the Second World War, with this facility helping and supporting everything that was happening in the world. So it’s a huge point of pride for us having it here” is very important to us”

its 46,400 tonne capacity is able to comfortably accommodate up to Capesize vessels.

The Alabama’s heavy lifting is handled by its two 35 tonne wingwall cranes while the company’s highly skilled workforce of over 250 take care of all required work in the drydock.

Outside of the drydock facility, Alabama Shipyard has an 800 tonne US-flagged crane barge that is being integrated into its operations.

And finally, the company is actively pursuing ship recycling projects. This is an area that is seeing increasing growth as ship owners, under increasing public and regulatory pressure, eschew foreign shipbreakers in favour of local operations having all of the required safety and environmental measures.

In 2019, the US Navy initiated an environmental assessment to evaluate three new locations to include in its existing waste disposal sites; Alabama Shipyard is one of the three. Approval will allow the company to carry out dismantling of ex-nuclearpowered vessels for the US Navy.

“The yard is being studied by the relevant organisations and the decision is expected to be announced towards the end of 2022,” revealed Mr Wagner.

Meanwhile, Alabama Shipyard is participating in a very large, high-profile project to recycle a massive but unusual barge.

The US Navy’s Surface Ship Support Barge, or SSSB, is a 268foot long barge that the US Navy operated from 1964 to 2016. Its

role was to refuel nuclear vessels spent nuclear fuel pool. The project is valued at $129 million and has been underway at Alabama Shipyard since June 2021.

“Having the barge here is a big point for us,” said Mr Wagner “We’re proud that we’re undertaking the project safely and efficiently.”

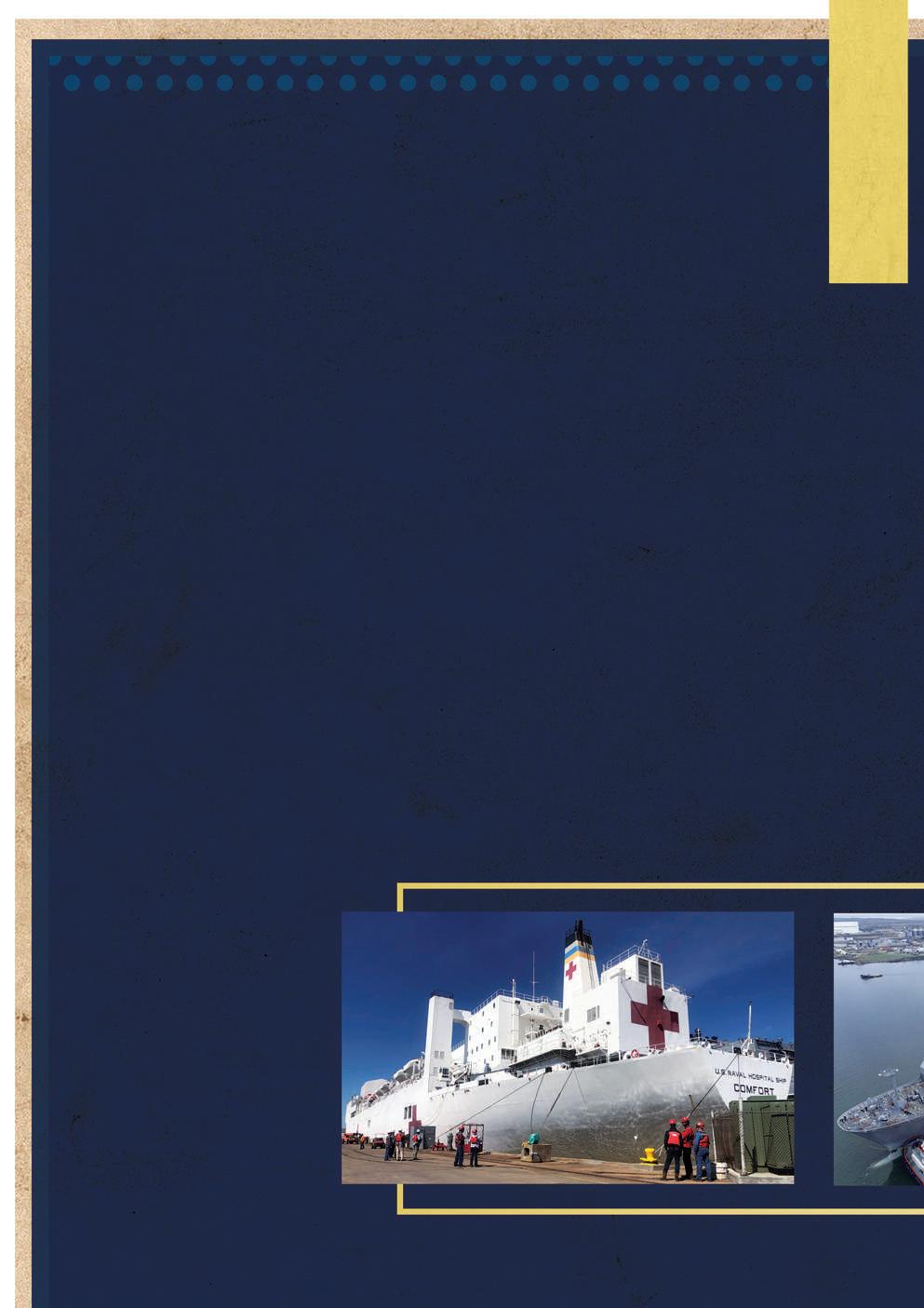

In March 2022, Mobile celebrated the arrival of the US Navy’s iconic, world-renowned hospital ship USNS Comfort. Alabama Shipyard proudly won the historic $25 million drydocking and overhauling contract – the first of its kind won by the yard in 30 years. The contract is due for completion at the end of July 2022.

“It’s a big project with a big scope,” said Mr Wagner. “We’re proud to have it here, working on it and getting it ready for its next mission.

“Comfort is an important piece of equipment for the world as it supports humanitarian efforts globally,” he continued. “The project also ties us back to the Second World War with this facility helping and supporting everything that was happening in the world. So it’s a huge point of pride for us, and having it here is very important to us.”

Alabama Shipyard is particularly proud of the man agement team it has assembled to take the company forward into its bright new future.

Mr Wagner, of course, heads up the team and noted that he is proud to have returned to the yard after having left for other opportunities just after its purchase from former owner BAE Systems Southeast Shipyards.

“I was here in 2018 when we first purchased the yard, so rejoining the team as CEO in early 2022 has been a big milestone

in my career and I’m beyond excited to be back,” he admitted. “We then built up the team systematically, but a big highlight was the arrival of Lee and his team.”

“Greg recruited me to come over,” added Mr Stokes. “But he wouldn’t answer my call. I had to hunt him down!” interjected Mr Wagner. “I thought it was a prank call!,” said Mr Stokes, laughing. “But it all worked out great. Greg rounds out the executive team perfectly. His energy radiates daily.

Of course, executive management is only one part of the picture. Equally important is the company’s workforce carrying out the increasingly demanding and complex projects arriving at Alabama Shipyard.

“We started with eight staff in 2018 and we’re now at 250,” detailed Business Development Manager Nikole Lee. “That number excludes subcontractors as well as OEMs and technical teams. Depending on the workload, we can surge to upwards of 700 employees quickly.”

To keep its growing staff compl ement happy, Alabama Shipyard is adamant about maintaining a healthy and happy working environment.

“We work hard at being a company that values our staff,” said Ms Lee. “We ensure that they’re safe at work and getting home to their fam ilies every day. Folks want to feel valued and appreci ated, that they’re part of a family. We really try to drive that kind of environment.”

Mr Stokes agreed. “Here, you feel welcome. We try to invest in our people and even build a reputation within the community

that this is a great place to work; that you can have a long career here.”

In closing, Mr Wagner discussed his outlook for the future: “We’re very bullish for the next 12 months,” he stated emphatically. “Outside of current geopolitical tensions, we’ve got a globally strong economy. We’re situated on one of the deepest ports

in the world and there are no air height restrictions. Globally, that’s huge.