John White Managing Director

John White Managing Director

Managing Director John White on lamb chops, labels, and lentils.

Welcome dear reader, to your latest edition of Inside Food and Drink. My what a great deal has been happening both here at the head office and out there in your industries from crop through to consumption!

Our staff now work a four-day week compared to the five days we have been working for the last 12 years. In addition, our office is now almost entirely paperless and although we still print a hard copy of the magazine, the vast majority of our readers subscribe mainly to the digital edition.

The largest growth sector seen within the food and drink industry this decade, and indeed with almost all industries, is the need for us all to reduce our carbon footprint in order to make a significant dent in global carbon emissions. As such, objectives such as becoming B Corp certified, are becoming of increasing importance.

Consumers are being bombarded with information about what they should eat and drink and what stores they should visit to purchase it. In addition, complicated ecolabelling has again both helped and hampered the consumer as they strive to do the right thing. The information overload

has left many of us scratching our heads and wandering around like headless chickens (plant-based headless chickens of course) in an attempt to hunt and gather the ‘approved’ nourishment.

Many of us still consume too much and as a result are also being pushed to look at our food wastage, recycling, and consumer habits. I am confident, as with any change, that once we have all got used to it and better understand what we as individuals and businesses should, could and can do to help toward the common goal, then this current upheaval will settle down and the change will be embraced and appreciated by all. However, there is still a long way to go yet as we collectively attempt to undo centuries of conditioning.

Here at Inside Food and Drink, we have witnessed a marked increase in plant-based food stuffs and a shift, small as it is at the moment, away from a beef burger, for example, to a similarly tasting but meatfree alternative. Personally, my eating habits have changed over the years and I think I speak for many of us, when I admit to already consuming a greater quantity of fruit, vegetables, nuts, and seeds than I did some decades ago.

Another shift is within the massive area of packaging, where many businesses are adapting to alternatives from their traditional plastic of choice to fit in with recycling requirements. This is no easy task when you also need to be mindful of food protection, shelf life and the taste and smell of the product.

A reduction in running costs, more efficient machinery and manufacturing processes are also at the top of many of your ‘to-do’ lists. So, in short, there is a fair bit going on right now and we are proud to be on hand to help you promote your innovations, ability to adapt, change and improvise, and share those best practises with the rest of us. It is, or certainly should be, a team effort after all.

Therefore, without further ado, let me leave you now to enjoy the many interesting, inciteful and informative pages that follow. As I’ve touched on briefly above, I am sure you will enjoy reading the many detailed examples of what you busy little bees have been up to in order to address sustainability, right through from crop to consumption.

climate change: changing the narrative around uncomfortable truths Dr Marcus Gover, Chief Executive of WRAP, outlines the opportunities we all must consider in building a healthier planet and a fairer world for us and future generations.

industry once

eyes on London as IFE 2022 gears up for its much anticipated return

66 Solid foundation, trusted operation and commercial excellence

Athanassiou

Food service

72 Fusing culinary success in Barcelona

Ikibana

76 Italian food with a family touch

Vittoria Group

80 Providing effortless convenience to the caterer

Savona Foodservice

86 The whole story of healthy eating

Whole Foods Market

90 Warsaw’s superNova

Crowne Plaza Warsaw - The HUB Brands

96 The world of happy herbs

O’Hanlon Herbs

101 Violife could it be the best plant-based cheese alternative on the planet?

Arivia

108 Enjoy the fruits of nature’s labours

Whitworths

114 Adding Italian flair propels ingredients to next level

GCL Food Ingredients

118 Proving they are still on the rise

Antico Forno Della Romagna Group

Beverages

124 Investing in the future of Romanian wine

Jidvei

130 Toasting the best little brewhouse in the world!

Rye River Brewing Company

134 Bringing quality Greek wines to the table

Boutari Winery

142 Why Thai quality chicken is taking wing worldwide

Chaveevan Group

146 Taking stock and Moo-ving forward

Hunland

150 Quality assured fish from sea to table

Fjord Bohemia

154 Meat products, naturally

Nematekas

Alimentaria is the landmark international event for all professionals in the food, drinks and food service industry and represents an unmissable date with innovation, the latest trends and the internationalisation of the sector. Alimentaria 2022 will be strengthening the unique values that set it apart: internationalisation, innovation, gastronomy, and sector specialisation. The show will also feature a highly attractive offering based on key markets for the food industry and their consumer trends. www.alimentaria.com

Seafood Expo Global/Seafood Processing Global, to be held in Barcelona, serves industry professionals and buyers from all corners of the supply chain and world. No other resource can provide seafood buyers the sourcing opportunities and access found at Seafood Expo Global/Seafood Processing Global. At just one venue, throughout nine halls, professionals like you come face-to-face with more than 2,000 exhibiting suppliers representing 85+ countries. With nearly every type of seafood product, equipment and service at your fingertips, you are equipped to make the best purchasing decisions for your business and customers. www.seafoodexpo.com/global

At Anuga FoodTec, the industry is set to present its latest innovations and technological visions. From process technology, filling and packaging technology and food safety, to packaging materials, digitalisation and intralogistics, you can find the latest worldwide solutions for the production, packing and storage of food and beverages. Discover all of the innovations across the entire value chain. Discuss with expert peers at eye level and inform yourself in detail about the latest technologies, which will make your production more efficient. As the most important supplier trade fair worldwide, Anuga FoodTec is more than just a perfect trade fair. It is your future! www.anugafoodtec.com

Hundreds of the world’s leading candymakers debut new products at the Sweets & Snacks Expo, hosted at McCormick Place, Chicago, with exhibitors ranging from global players to up-and-coming innovators new to the confectionery industry. Find the specialty, gourmet, organic or classic candies your shoppers are searching for in one centralised location and connect directly with the people behind them. The latest innovation in chips, nuts, sweet snacks, jerky, pretzels and more can also be at the expo, with new flavours and formats galore. Don’t miss all the snack innovation and real industry connections happening each day on the show floor. www.sweetsandsnacks.com

For more than 35 years, PLMA’s annual World of Private Label International Trade Show has brought retailers together with manufacturers to help them find new products, make new contacts, and discover new ideas that will help their private label programmes succeed and grow. PLMA’s 2022 World of Private Label International Trade Show will be held at the RAI Exhibition Centre in Amsterdam. Products on display will include fresh, frozen and refrigerated foods, dry grocery, and beverages as well as non-food categories, including cosmetics, health and beauty, household and kitchen, auto aftercare, garden, and housewares & DIY. www.plmainternational.com

For over 50 years, SIAL Paris has been welcoming a melting pot of industry players to the French capital to share their savoir-faire and create the recipes of the future. Every two years, producers, importers, buyers and retailers, media specialists and independent associations of every shape and size meet at the largest exhibition venue in Paris for five-days of inspiration, debate and exchange. Whether you’re a rising start-up or a large group, a hot new product or a bluechip brand, an established chain or a groundbreaking retail model, SIAL Paris is your springboard for sustainable success. www.sialparis.com

“

Inside Food & Drink asks the experts about their personal experience in the industry

What have you discovered about your company or industry as a result of Covid-19?

We are proud of how our employees have toiled away on a daily basis against this difficult background. We have been creative to reflect the new work at home paradigm and extremely grateful to the employees for what they have done, even when the chips are down.

Cecily Gillet, Plant Manager, Banks (Barbados) Breweries

We used to think that you have to go and see the person, shake hands, have lunch, have a physical connection with the person. And we did a lot of travelling. Now we realise it’s not absolutely necessary. Covid has shown both us and our customers that we can continue doing business, we can develop our relationships perhaps even more efficiently while spending less time travelling.

It’ll change the way we do business after Covid. There’ll be less travel; fewer miles. It’s beneficial for the company as well with the lower costs and improved efficiency.

Dominique Arnault, Asia- Pacific Manager, Bayle SA

We have taken all the necessary measures to ensure production continues and, thanks to our people’s loyalty, we have continued to succeed during the pandemic.

Kolyo Atanasov, CEO, Bulmetal JSC

The whole landscape changed as consumers changed their habits and occasions of consumption. Fortunately, our categories, both tobacco and food, were, general l y speaking, positively affected.

Our company has responded to this challenge effectivelly by adopting a new way of working, with priority number one being staff health and safety. Work from home, virtual meetings, special care for our employees, frequent weekly standardised health tests are just a few examples of this new way of working. Additionally, the company responded very fast to the changes in consumers' behaviour and preferences.

In summary, we proved to be adaptable to the new conditions and agile in capturing new trends, with empathy being a key characteristic of the management’s behavior.

Yiannis Zarkadis, Chief Commercial Officer, Athanassiou

Covid-19 has changed peoples’ behaviour, including the way they drink alcoholic beverages. It’s forced us as a company to think much more about home consumption and on education, especially teaching people how to make drinks. We’ve done online coaching, tastings and mixology education. It’s actually broadened our platform.

Steve Wilson, CEO, Cockspur Rum

“The pandemic has taught us many things we had previously failed to see or realise. It is no secret that prior to Covid, we had all become accustomed to taking people for granted and relying more heavily in technologies. But today, without doubt, we can confidently state that no computer software or automated machine can replace dedicated work from our own human resource.

We were fortunate to see our employees breaking down barriers for the benefit of the company. They worked relentlessly to ensure more clients join us and that for every sector that closed, they had found another to open. During this period of crisis, we have come closer together as a family and cherish one another more than before.

Omer Kamp, ERP employee Europe Retail Packing

“ “ “

“Our global workforce has shown true grit across the pandemic to keep operations open and ensure supermarket shelves were stocked with tomato-based products. It is an outstanding achievement that deserves recognition. Their resilience humbled me. From the line operator to the accountant – they all excelled and enabled us to continue to run our end-to-end food value chain.

João Tavares Correia: Chief Commercial Officer, Sugal Group

We rediscovered the benefits of eating at home. For that reason, lockdowns created an opportunity for us; it essentially took us back in time to a period when many of our products were used regularly in the home. Covid brought that back and I hope that demand stays this way to a certain extent.

While we expect some changes, I think the popularity of shows such as MasterChef have highlighted how much people enjoy cooking. Covid forced people to enter the kitchen and I think people found that what was previously a chore, could actually be enjoyable.

“

Martin Stilwell, CEO, HIT Group

“ “

Covid has reinforced the importance of a stable supply chain and ensuring that we always have sufficient livestock available to sell. We also learned the value of online platforms, particularly since buyers could no longer come and select livestock in person. We successfully switched to making videos and putting the whole selling process online for a period. We’ve been looking to build an online sales tool using VR and the success of this project confirmed that that tool has real potential.

Tibor Hibszki: Director of Finance & Strategy, Hunland Group

Three years ago we began a project to teach our drivers to work online using phones and laptops to send CMRs, invoices and other documents. At the time it was a huge challenge to convince the drivers of the usefulness of those tools. When Covid came along, it drastically sped that whole process up. Everybody learnt to be online virtually overnight! That was important because we transport essential items – the raw materials needed for meals – so it made us much more efficient.

Péter Hencz, Managing Director, Hunland Trans

The biggest lesson I take from the whole pandemic is that while you have to live in the moment, it is no longer the survival of the fittest; it’s the survival of the most adaptable. Those that show initiative will survive and thrive, and Macphie has been consistently doing that.

Andy Stapley, CEO, Macphie UK

Without the collective effort of the team, we wouldn’t have achieved as much as we have. They have been fantastic, highly flexible and made strenuous efforts to keep Covid-19 off site.

Tom O'Hanlon; Managing Director, O'Hanlon Herbs

We’ve rediscovered the importance of our team and the family – by that I mean the whole company, not just the Landucci family itself. During the darkest days of Covid in March 2020 and the beginning of 2021, it was such a blessing that we could still come to work and still be together. Coming here, finding all of the people in the office and in the factory, still doing their best, has been so motivational for us to keep pushing forward and to keep doing what we do in the best way that we can.

Alessandro Bonistalli, Sales and Marketing Manager, Landucci SRL

US-based Continental Grain Company has announced an investment in Agroberries, a global vertically integrated berries player based in Chile, as part of its global expansion plans.

Continental Grain’s investment is predicted to enable Agroberries to expand its production assets and global distribution capabilities, both organically and inorganically, as well as accelerate the roll-out of proprietary varietals, further strengthening the company’s year-round offering across berry categories.

As a long-term partner, Continental Grain said it will use its international network, M&A resources, and operational expertise to support Agroberries’ strategic development initiatives.

Jorge Varela, Co-Founder and CEO of Agroberries, highlighted: “I’m excited about the possibilities arising from our partnership with Continental Grain, and confident it will accelerate our global expansion plans, give our customers increased access to our novel proprietary varieties, and offer exciting professional development opportunities for our management team.”

Founded in 1996, Agroberries is a leading vertically integrated producer, marketer, and global distributor of fresh berries, catering year-round to a blue-chip customer base of leading retailers throughout the world.

With headquarters in Chile, and marketing companies in the United States and the Netherlands, the company offers a competitive and top-quality supply of both conventional and organic berries.

Agroberries is a globally recognised leader and pioneer in berry production, harvest, and packing techniques. The company owns farms and state-of-the-art packing facilities

in both hemispheres and has a strong net work of strategic alliances with trusted partners globally.

The company’s owners, directly involved as part of the management team, are deeply committed to reliability and product quality, and have developed a well-established, controlled, and diversified berry business platform.

Agroberries commercialises over 50,000 tonnes of berries per year to a blue-chip customer base primarily in North America and Europe, sourced from its landbank of more than 2,000 hectares and a diverse network of third-party growers. Agroberries’ agricultural footprint spans across five different countries, including some of the world’s most productive regions.

Carlos Poblete and Ignacio Sanz serve as Co-Heads of Latin America for Continental Grain. Carlos commented: “We have known the leadership team of Agroberries for years and believe the company is well positioned to capitalise on a wide range of growth opportunities going forward.”

Ignacio added: “We are excited to partner with Agroberries and support the next phase of the company’s global expansion. Agroberries has established itself as a highquality supplier in the markets it currently serves, and we intend to further grow the business through acquisitions that expand the company’s geographic reach.”

Continental Grain Company is a privatelyowned global investor, owner and operator of companies with more than 200

“ “

We have known the leadership team of Agroberries for years and believe the company is well positioned to capitalise on a wide range of growth opportunities going forward

years of history across the food and agribusiness spectrum.

The company says it creates longterm value by applying deep industry knowledge, capital and talent to businesses ranging from established market leaders to promising innovators; building platforms that leverage its strategic expertise in food production, processing, and distribution to source proprietary deals, working alongside trusted partners and supporting strong management teams.

Agroberries is expected to also benefit from Continental Grain’s longterm ownership mindset, concentrating on investment and operating plans that create enduring value and a sustainable, efficient and nutritional food supply chain.

The company confirmed wellness and demographic trends continue to drive strong momentum for fresh produce consumption. Given their high nutritional value, demand for fresh berries has continued to climb, making them one of the fastest growing fresh produce categories at retail stores globally. As a result, customers are seeking year-round suppliers of high-quality berries. n

Morrisons has become the first UK supermarket to switch to ‘best before’ dates only on milk, as it encourages customers to opt for the ‘sniff test’ to check. The move could potentially stop millions of pints of its own brand milk from being thrown away every year.

Morrisons has scrapped ‘use by’ dates on 90% of its own brand milk – and is encouraging customers to use a sniff test – to help to reduce food waste in the home.

‘Use by’ dates will be scrapped from Morrisons own brand British and Scottish milks, Morrisons For Farmers milks and Morrisons organic milks in store – supplied into Morrisons by Arla farmers. Morrisons South West milk and The Best Jersey milk are yet to be converted.

Morrisons will instead encourage its customers to use a simple sniff test to check if their milk is still good to consume. The milk packaging will show ‘best before’ dates to indicate to customers when they should drink it by – to get the best taste. Unlike some other fresh products, drinking milk after a ‘best before’ date is not a food safety issue.

Milk is the third most wasted food and drink product in the UK, after potatoes and bread, with around 490 million pints wasted every year. Milk also has the largest carbon footprint of these food and drink products because its production is so resource-intensive. One litre of milk can account for up to 4.5kg of CO2.

Research shows fresh milk can often last a number of days past the ‘use by’ date shown on the bottle. However UK customers are routinely throwing away milk – as they incorrectly believe the milk is unsafe to drink.

British registered charity WRAP (Waste & Resources Action Programme) estimates that 85 million pints of milk waste may be

a result of customers sticking to ’use by’ labels or ‘once opened use within’ guidance –when products may still be good to consume.

Ian Goode, Senior Milk Buyer at Morrisons, said: “Wasted milk means wasted effort by our farmers and unnecessary carbon being released into the atmosphere. Good quality well-kept milk has a good few days life after normal ‘use by’ dates – and we think it should be consumed not tipped down the sink.

“So we’re taking a bold step today and asking customers to decide whether their milk is still good to drink. Generations before us have always used the sniff test –and I believe we can too.”

Marcus Gover, CEO at WRAP, said: “I am delighted that Morrisons is the first UK supermarket to take this important step to help reduce household food waste – it shows real leadership and we look forward to more retailers reviewing date labels on their products and taking action.

“WRAP’s joint Best Practice with FSA and Defra is to only apply a ‘use by’ date when required for food safety reasons. Applying a ‘best before’ date to indicate quality on all

other products means people have longer to use their food. Almost 300,000 tonnes of milk is wasted from UK homes each year, worth £270 million, with the main reason being that it isn’t used in time.”

He added: “Making improvements to labelling forms an important part of WRAP’s efforts under the Courtauld Commitment 2030 to reduce household food waste. It is fantastic to see Morrisons, as a Courtauld signatory, making this change – giving people the confidence to use their judgment and consume more of the milk they buy.”

Morrisons scrapped ‘use by’ dates across some of its own-brand yogurt and hard cheese ranges in 2020.

Morrisons has committed to reducing food waste in stores by 50% by 2030. The company takes great care to order what it thinks it can sell and where products are close to their ‘use by’ or ‘best before’ date, they are offered to customers at reduced prices.

I am delighted that Morrisons is the first UK supermarket to

take this important step to help reduce household food waste

“ “

When waste does occur, Morrisons ‘Unsold Food’ programme works with a range of partners including Too Good to Go, The Bread and Butter Thing and local food banks, charities and community groups, to ensure food can be redistributed.

Where food cannot be redistributed, Morrisons uses anaerobic digestion to generate electricity, which in turn contributes to renewable energy generation across the UK.

US retail giant Walmart and Californian vertical indoor farming company Plenty Inc enter into a long-term strategic partnership with an equity investment to bring fresh, peak-flavour produce to American shoppers year-round.

Walmart has signed an agreement to invest in Plenty, an indoor vertical farming company, as part of Plenty’s $400 million Series E funding round, subject to a regulatory approval.

Walmart’s equity investment is part of a broader strategic partnership to utilise Plenty’s indoor vertical farming technology platform to deliver fresh produce to Walmart retail stores. As part of the investment, at closing, Walmart will also join Plenty’s Board of Directors.

Plenty is rewriting the rules of agriculture through its technology platform that can grow clean produce anywhere in the world, year round, with unprecedented yield and peak season quality.

The company’s proprietary approach preserves the world’s natural resources, makes nutritious produce available to all communities and creates resilience in our food systems against weather, location, pests and climate.

Plenty’s headquarters are in South San Francisco, and the company operates the largest of its kind indoor plant science research facility in Laramie, Wyoming. Plenty is currently building the world’s highest-output, vertical, indoor farm in Compton, California.

Together, Walmart and Plenty will work collaboratively to create a new, marketleading product category in vertical farming by delivering the freshness and

Plenty’s

unique farming system unlocks industry-leading crop versatility and unit economics by enabling indoor growing year round

“ “

quality that Walmart customers expect, year-round.

The long-term commercial agreement allows Walmart to source Plenty’s leafy greens for all its California stores from Plenty’s Compton farm beginning later this year. Walmart is the first large US retailer to significantly invest in vertical farming.

Charles Redfield, Chief Merchandising Officer, Walmart US, said: “At Walmart, we are focused on identifying and investing in innovative food solutions to bring our customers the freshest, highest quality foods at the best prices. We believe Plenty is a proven leader in a new era of agriculture, one that offers pesticide-free, peak-flavour produce to shoppers every day of the year.

“This partnership not only accelerates agricultural innovation, but reinforces our commitment to sustainability, by delivering a new category of fresh that is good for people and the planet.”

Plenty’s farming technology platform delivers pesticide-free produce that tastes like it was picked fresh from the garden, all year long. The company’s indoor farming architecture differs from greenhouses and

other indoor farms, combining engineering, software and sustainable crop science to grow multiple crops on one platform, at unprecedented speed.

Backed by one of the largest US patent portfolios in the industry, Plenty’s proprietary tech meaningfully improves on traditional agriculture’s use of water and land. By building farms closer to the consumer, Plenty helps reduce transportation and food waste, keeping items fresher for longer in 100% recyclable product packaging.

Vertical farming supplements traditional farming practices to help increase food supply and alleviate current challenges on the food system in a sustainable way. Walmart’s investment is the latest step in the retailer’s commitment to increase access to high-quality, fresh produce for its customers.

“Plenty’s unique farming system unlocks industry-leading crop versatility and unit economics by enabling indoor growing year round,” said Arama Kukutai, Plenty CEO.

“Our farms can be sited anywhere allowing us to put fresh fruits, greens and vegetables on shelf at all times, at speed, for maximum freshness. As a long-time market leader in retail innovation, Walmart is an ideal partner to test and scale access to our quality produce for their customers.

“This is a game-changer for the agritech industry.” n

Reporting on the latest developments from the Malaysian food and drink

Partnership will plant over one million trees under the scope of Project RELeaf.

Ramping up reforestation efforts to plant three million trees in Malaysia by 2023 via Project RELeaf, Nestlé Malaysia inked a Memorandum of Agreement with the world’s largest producer of certified sustainable palm oil, Sime Darby Plantation (SDP).

Under the agreement, over one million trees are set to be planted across 1,200 hectares of riparian zones and steep slope areas within SDP’s palm oil operation areas.

Launched in 2020 by Nestlé Malaysia, Project RELeaf aims to restore riparian and forest ecosystems across the Kinabatangan Wetlands and Merisuli Forest Restoration Areas in Sabah, as well as in forest reserves along the Central Forest Spine in Peninsular Malaysia. This is also part of Nestlé’s global efforts to fight climate change and reduce the company’s carbon footprint.

Through the partnership with SDP, Nestlé will be producing and supplying over 1 million seedlings and conducting planting activities at the sites. Planting sites will be located at selected SDP estates in both Peninsular Malaysia as well as the East Malaysia regions of Sabah and Sarawak.

Juan Aranols, Chief Executive Officer of Nestlé (Malaysia) Berhad, said:

“Safeguarding the environment is a key priority for Nestlé. This is why we have initiatives in place to help preserve and conserve the country’s natural biodiversity and these include our reforestation

efforts such as Project RELeaf, aiming to plant three million trees by 2023.

“Now, we are pleased to partner with SDP, who is also the main supplier of Nestlé Malaysia’s certified sustainable palm oil. By working together, we can help to reduce total emissions along our value chain while preserving natural ecosystems.

“This partnership will also contribute to our global pledge to achieve zero net greenhouse gas emissions by 2050,” he added.

All conservation and biodiversity activities that take place under Nestlé Malaysia’s RELeaf Project will be in accordance with the RSPO Management and Rehabilitation of Riparian Reserve Guideline 2018.

According to Mohamad Helmy Othman Basha, Group Managing Director of Sime Darby Plantation, the company is very pleased to be working again with a likeminded partner to realise its commitments of protecting and conserving biodiversity as well as contributing to combat climate change.

“Restoring forests and planting trees on a large scale are important nature-based solutions to increase carbon sinks, as part of our response to climate change. Over the last 12 years, we have planted over 1.5 million trees through various tree-planting projects, including our involvement in a previous project with Nestlé. Sime Darby Plantation is truly excited to renew our collaboration with Nestlé today with RELeaf.”

He added: “Over the next five years, we plan to double the number of trees we have planted through our treeplanting projects. And whilst we are on track to achieving our target of 40% reduction in carbon intensity by 2030, the success of our tree planting projects will be fundamental in how we lay the groundwork towards making and realising a net zero commitment.”

Project RELeaf builds on the pioneering Kinabatangan Rileaf Project, which concluded in 2020 and saw one million trees planted in Sabah. n

Dr Marcus Gover, Chief Executive of WRAP, outlines the opportunities we all must consider building a healthier planet and a fairer world for us and future generations.

Beating back climate change will be the biggest accomplishment of our lives. 2021 was the year, helped by COP26, when the world shifted up a gear in response to the emergency and 2022 looks set to be busier than ever. If we are to keep the 1.5°C target alive, then we are all going to have to face up to and turn around some uncomfortable truths, writes Dr Marcus Glover, Chief Executive of WRAP – a charity promoting and encouraging sustainable resource use through product design, waste minimisation, re-use, recycling and reprocessing of waste materials.

Many countries at COP 26 showcased big, eye-catching green technology projects with a focus on innovating our way out of the climate crisis. But this will only get us so far. We need to both invest in the new and wean ourselves off our dependency on the old. This means fundamentally changing the global systems on which we rely to produce the food we eat, create the buildings we live and work in, make the clothes we wear and manufacture the goods we need to live our lives.

There must be recognition of the need to re-invent the modern industrialised world, which can no longer be fuelled by our planet in its current form. This will be a huge undertaking, but it means we have an opportunity not only to tackle climate change, but to redress the fault lines of inequality, poor health and working conditions, exploitation that opened up as industrialisation evolved. We have the chance to build a healthier, fairer, world.

The climate crisis is felt everywhere. So, solutions have to involve thinking beyond borders, beyond agendas, beyond politics and beyond profit. It is too tempting to think territorially and get your own house in order but simply displace the problem elsewhere. This is the case for countries thinking about emissions in their own borders, but also for businesses looking to balance their own books in terms of the climate impact of their own operations, but failing to address those along their supply chains. The problem is offshored, displaced, unaccounted for, but doesn’t go away.

System change at every stage of global supply chains, tackling consumption emissions through transcending borders and business domains has to be considered alongside tackling only territorial emissions. We’ve shown it can be done through the power of partnership; underpinned by smart globally aligned policies from governments (which unlock investment) and where citizens are an essential part of the journey. This creates a joined-up, global movement for change, where everyone is working to the same goal and supporting those countries who are less able to deal with the climate emergency themselves, but whose citizens are often feeling the worst effects.

When you consider that nearly half of all greenhouse gas emissions are down to the way we produce and consume, our current model is incompatible with a 1.5 vision. Our take-make-waste culture is also using up our planet’s stock of valuable natural resources faster than it can replenish them. If we are to solve this, then we need to change the way we consume.

Every aspect of human survival is embellished by ‘stuff’. We are filling our fridges with food that we don’t eat, our wardrobes with clothes that we don’t wear and our attics with broken or outdated electronics that we don’t use. A 1.5°C world is one where we don’t waste food, we wear our clothes for more seasons, and we repair our electrical goods to keep them working. Where new goods are designed and built to be in circulation for as long as possible. And where we end the staggering amount of waste which is not only contributing to climate change, but polluting our countryside and our oceans, and damaging biodiversity.

Businesses and governments are both crucial in making this shift. They will need to support the development of new business models to support this different way of consuming. If they get it right, it will be a big opportunity rather than a threat to our way of life.

We are already seeing this shift happening, with consumers being increasingly able to rent clothes, lease cars, buy electrical goods with long warranties, and access a growing supply of remanufactured furniture. The latter in particular has huge potential. I sit on a remanufactured office chair which is high-quality, comfortable, cost half as much as the new equivalent and resulted in a fraction of the greenhouse gas emissions caused by making a new one.

New ways of consuming won’t negatively affect the quality of our lives – they will enhance it. A washing machine built to last which doesn’t break down, or is fixed if it does, is a better way of living. The calculator which still works decades after it was bought is still great to use. Not wasting food saves us up to £700 for the average family at the moment. This is a win-win world.

We need to think globally, remodelling systems and not just looking after our own backyards. But just how uncomfortable really is this? We’re not advocating a hair-shirt existence or a return to lives preindustrial revolution. A world where resources are used sustainably is a better world with multiple benefits. This truth needs to inform the narrative.

For consumers we get affordable goods that last and ease our environmental footprint (something we all want to do). What isn’t there to like about saving money by not wasting it on food we

Dr Marcus Gover, Chief Executive of WRAP, outlines the opportunities we all must consider building a healthier planet and a fairer world for us and future generations.

don’t eat or clothes we don’t wear? WRAP’s Love Food Hate Waste and Love Your Clothes campaigns are already showing the way.

For businesses, this approach unlocks innovation, opens up exciting new markets and creates the opportunity to make significant financial savings. We know that the median return on investment for reducing food loss and waste is 14:1. It also means they are also better serving their consumers – our research show that they want and expect businesses to do more to tackle climate change.

UK businesses are working together and stepping up to the plate through WRAP’s Courtauld Commitment, Textiles 2030 and The UK Plastics Pact. They are already reaping the benefits of collaboration and system change. They will be ahead of the game.

For governments, this offers a way to meet international environmental commitments, stimulate innovation and investment, build

economies, and create jobs. It will be delivering what people want too – working together to tackle climate change and making a better world. Doesn’t that sound like a recipe for getting re-elected?

So, even though the scale of change is undoubtedly daunting, that truth doesn’t need to be uncomfortable. The potential is for a life which is exciting and progressive; the chance to build a healthier planet and a fairer world for us and future generations. By embracing that opportunity, that truth can start today. n

WRAP is a sustainability NGO working across six continents with governments, businesses and citizens to tackle food waste, plastic pollution, and reduce fashion’s carbon footprint worldwide. For more information, visit: https://wrap.org.uk/

All eyes on London as IFE 2022 gears up for its much anticipated return

For more than 40 years, the mission of IFE, International Food & Drink Event, has been to help attendees build relationships and find the products that will revolutionise their business. Welcoming over 30,000 retailers, wholesalers and professionals of the food service industry, IFE is the single largest food and drinks fair in the United Kingdom.

Overseeing preparations ahead of IFE 2022 is Event Director Philippa Christer who believes the most important aspect of the show is how it gives both attendees and those who exhibit the chance to connect, which for many could be the first time they meet the people behind the brands set to line their shelves; as well as taste a huge range of products all under one roof. Jordan Yallop asked her what can be expected at the upcoming event, due to be held from 21-23 March at ExCeL London.

Philippa, for anyone new to the event, what are the main things they would experience if they were to attend IFE 2022?

Visitors attending IFE in 2022 will have the chance to experience the world’s largest gathering of UK food and drink suppliers. The show is a highly trusted and valued resource for discovering the next major trends and products, for gaining valuable insights from the UK’s leading minds in the food and drink retail on the Future Food stage, and for meeting with international food and drink businesses representing over 100 countries.

For food and drink suppliers, the event is a chance to meet with highly influential buyers from the worlds of retail and wholesale and experts in the import and export market. Businesses can take advantage of the show’s Certification Clinic, Meet the Buyer Programme and can help their products stand out from the crowd by entering the World Food Innovation Awards, which is once again being hosted at the event in partnership with FoodBev Media.

Which of these exhibiting companies or key industry personnel are you projecting will create the biggest buzz in the lead up to the show?

IFE is beloved and trusted by its audience for the variety of quality suppliers that are showcased at each edition of the event. Visitors can expect a curated selection of food and

drink suppliers, ranging from hugely respected heritage brands like Walkers Shortbread, Royal Greenland and Fentimans to newer businesses like baking subscription service BakedIn and delicious, award-winning plant-based snack supplier Plant Pops, both challenger brands which have introduced inventive and delicious new takes on classic products and services.

IFE will be co-located with IFE Manufacturing, Hotel, Restaurant & Catering (HRC), The Pub Show and The London Produce Show for the first time. Are you excited to be the industry’s largest gathering in the UK?

We’re thrilled to be partnering with all of our sister events for 2022. There’s a huge amount of crossover between the different shows and it’s a significant value add for both our suppliers and buyers as they take valuable time out of the office to join us at ExCeL London.

The launch of IFE Manufacturing is a huge value-add for visitors to IFE who have an interest in new product development, packaging, manufacturing and supply chain trends and the latest exciting ingredients available on the market.

With a legacy of over 40 years in the food and drink sector, IFE certainly has experience with monitoring trends. With the challenging events of the last couple of years altering the way buyers and producers operate, what have you brought to IFE 2022 to cater to these changes?

The phrase “necessity is the mother of invention” has never rang truer than in the last two years. As much as it has become an unpopular buzzword, both our suppliers and buyers were forced to pivot and adapt their offering to survive.

On the retail side, big brands arguably had the initial advantage, as having an online shop and a delivery offering became vitally important. But smaller, independent retailers were quick to meet this challenge and consumers were eager to discover new products and support local businesses.

From a supplier side, we’ve seen an explosion of exciting new products entering the market, both from established brands and from a large number of first-time owners of food and drink businesses, bringing long-held dreams to life. It’s a hugely exciting time for the industry and we’ve heard first-hand from the retailers and wholesalers that come to the event saying they can’t wait to discover and taste these new products at IFE in 2022.

All eyes on London as IFE 2022 gears up for its much anticipated return

We’re supporting our audience through this period of uncertainty by facilitating further innovation, whether that’s through new show areas to help buyers find the product types suited to their changing needs, new networking spaces to enable those all-important face-to-face business connections or fresh new approaches to common challenges from the industry leaders in our seminar programme.

So with these changes in mind, what would you consider to be the newest trends to look out for 2022?

There continues to be rapid growth in the world of meat alternatives, with a huge number of vegan and plant-based options launching across a wide range of product types, from bacon, scotch eggs to caviar. Alongside this, lab-grown or ‘motherless’ meat is certainly on the horizon as an interesting trend to follow.

Innovations aren’t limited to the lab, with many in the new product development space exploring more creative uses for mushrooms, sugar alternatives and underexplored food solutions such as seaweed, kelp and samphire.

Health and wellness is another key trend, particularly with a consumer desire for less processed foods, preferring instead options with limited, natural ingredients.

From the retail side, sustainability is the name of the game, with free refills steadily growing in popularity across food and drink prod-

ucts. Notably ASDA has recently partnered with Craft on Draft to launch a refillable beer service. Ocado also signalled their commitment to working with sustainability-focused brands by launching a dedicated B Corp aisle in early 2021.

Covid-19 completely devastated the trade show industry. At this stage of the pandemic, what actions has IFE taken to ensure guests who physically visit the March event will remain safe?

As events, trade shows are a highly controlled environment, and events have been running securely in the UK and abroad as tried and tested measures have been put in place. The Association of Event Organisers, our official association body, has been collaborating with organisers around the world to ensure a valuable, straightforward and enjoyable experience for trade show attendees and suppliers. We have spent the past two years planning for a wide range of possibilities for the live events and will implement the most appropriate as the show approaches, in line with government guidelines.

And what particular areas of the food supplier and buyer markets have you seen grow over these recent events?

As I mentioned previously, a key area of growth is vegan and plantbased products, with alternative meat products in particular growing

21-23 March 2022

rapidly as a product category. According to research by Kantar, from the year 2016 to 2020, the meat-free and plant-based dairy categories doubled in size and are now worth just under £600 million each. We've engaged insightful speakers such as Matthew Glover, founder of Veganuary and Vegan Fried Chicken, and a Veg Capital investor, to discuss how this trend is set to evolve in 2022 and beyond on our Future Food Stage.

In this increasingly crowded marketplace, there has been a huge amount of innovation and new product development, which will be showcased in our all-new Vegan & Plant-Based Section, in partnership with the Vegan Society.

From big name brands in the sector such as The Meatless Farm, Beyond Meat and The Vegetarian Butcher to up-and-coming small businesses like Plant Alternative, this section will represent the full spectrum of businesses in this area.

On the buyer side, food and drink retailers have had to adapt fast to the emergence of speedy grocery businesses such as Getir, Gorillas, Zapp and Weezy, which have grown rapidly and made use of “dark stores” to service consumers.

The focus now is longevity and we’ve been following the recent partnership between Gorillas and Tesco to offer sub-10-minute deliveries with interest. We’ll be examining how to meet these demanding consumer needs more closely on the Future Food Stage at IFE 2022.

Sustainability has been one of the other hottest topics in recent years, do you think this will be a prominent feature of IFE 2022?

Sustainability continues to top the agenda for every industry, and food and drink is no exception. We’ve seen huge growth in the number of B Corp certified businesses and the environmental impact of products is

being increasingly measured and quantified, plus retailers and wholesalers are consistently factoring this into their sourcing decisions.

Any new products entering the market are expected to have thought through their supply chain, packaging and ingredient sourcing with sustainability in mind, meanwhile larger, more established brands are taking significant steps to change their processes, offset their emissions and fund NPD and innovation in sustainable packaging and manufacturing.

For retailers, wholesalers and suppliers, food waste is a key issue, with many partnering with charities like City Harvest (one of our key show partners) and Too Good To Go to find a second home for products reaching the end of their shelf life and working to reduce the impact and volume of food waste at every stage of the manufacturing process. IFE 2022’s seminar programme will have a major focus on sustainability and how environmentally focused processes can be implemented at every level of a business.

And the final question, what is the main message you would like to share to the readers of Inside Food & Drink about this upcoming event?

IFE 2022 will be the industry’s first chance in over three years to gather together and meet face to face. Anyone who’s anyone in the world of food and drink will either be on the stage, on a stand or on the show floor.

Don’t miss this opportunity to meet with over 1,500 suppliers, meet and learn from your peers, gain invaluable insights into the trends of tomorrow and ready your business for the next stage of its evolution. For food and drink professionals serious about success, IFE is a must-attend.

A look into the most exciting spiced rums to try in 2022

Spiced rums have been gaining in popularity constantly over the years. This trend is projected to continue well into 2022 and beyond. But with this ever-expanding market, just which of the myriad of rums should you try? Well, whether you are propping up the bar at your local, dusting off the cocktail shaker in your kitchen, or sitting on a beach sipping a cocktail, we here at Inside Food and Drink have got you covered. Here is a round up of our choices for rums to give a try this year. We’ve done the hard work so you don’t have to. Here’s our ‘rumdown’ of the ones to watch.

2

(37.5% ABV – 70cl)

launched in 2020, Bush Rum Co is marketed as the world’s first sustainable rum. This particular offering takes flavours of Caribbean Rum Shacks and brings them to life. Guyanese rum is mixed with a secret blend of spices to create a spiced rum full of flavour bursting with sweet ginger, soft vanilla, toffee and warming spice. So smooth you can sip it on its own or mix it with cola or ginger beer. Perfect in fruity cocktails such as a Pina Colada and a pineapple rum punch.

Jordan – Editorial Assistant: “Finely balanced and so smooth you’d be forgiven for forgetting that you are drinking alcohol. I enjoyed this one neat over ice and it goes down very easily.”

www.bushrum.co.uk

(42% ABV – 70cl)

Just a year since launch, Welsh craft-rum brand, Devil’s Bridge, has wowed judges, journalists and customers alike for its complex flavour, smooth finish and striking matt-red bottle. From a purposebuilt distillery in Carmarthen, the company collaborates with local artisan producers to discover the perfect food pairings to infuse into their rum. The base rum is a blend from the Caribbean’s most renowned distilleries. In Wales the base is infused with Bara Brith and distilled in a copper pot still with fruits and spices for sweetness, Shirgar Carmarthanshire butter for smoothness and Glengettie black tea for an unusually dry finish. Devil’s Bridge is an outstanding rum that can be enjoyed on its own over ice, served long with a mixer or as a first class kick in any cocktail.

i F D &

Gavin – Head of Support: “Smooth, spicy, lightly fruity and very strong! It is certainly a drink to really take your time with and enjoy every sip.

www.devilsbridgerum.com

Richard – Sales Director:

(40% ABV – 70cl)

A recently revitalised historic label, Wing Walker Rum is a premium rum from the Caribbean coasts of Venezuela and The Dominican Republic, distilled in copper pot stills and aged in vintage oak barrels for three years. It is then shipped to London where expert mixologists at Innovatus blend it with citrus, vanilla and caramel. An exceptionally smooth and silky rum which when ice is added, the flavours open and the incredible character bursts into life, bringing the warmth of the Caribbean to your glass. You’ll be walking on air with this one.

Ian – Art Director: A strong but smooth rum, you can definitely appreciate the notes of orange peel. While full of flavour this rum really takes off when mixed into a traditional Cuba Libre. This tastes great on its own, and I also enjoyed it mixed with pineapple juice.”

4 i F D &

“A sweet sipping rum, to be enjoyed slowly. Strong flavoursome honey notes, coupled with an undertone of orange.”

www.honeybellrum.com

(40% ABV – 70cl)

Harnessing the sweetness of English blossom honey and balancing it with bittersweet orange is central to creating the unique flavour of this spiced rum. The company’s incredibly meticulous distillation process is complemented by the selection of handpicked botanicals that infuse to create a unique and complex flavour profile. English blossom honey, orange and vanilla pods with emergent notes of cacao and assam tea combine for a spiced rum aimed at changing the narrative of what a spiced rum can be. This smooth rum is most certainly for sipping but could also be used as an exceptional cocktail base.

A look into the most exciting spiced rums to try in 2022

(60% ABV – 70cl)

Two Drifters is a rare British distillery making rum from scratch, rather than importing the base spirit from overseas. Distilled in Devon in the world’s first carbon negative distillery, its creators identified the Overproof market was growing in line with the ever popular flavoured rum market. Overproof Spiced Pineapple Rum is Two Drifters’ latest addition to their line-up. Flavours of rich and fruity rum with irresistible notes of ripe pineapple, salted caramel and crème brule are designed to make the best rum and coke you’ve ever tasted.

Jordan – Editorial Assistant: “The strongest on this list but don’t let that fool you, it is a smooth and clean drink. While I thoroughly enjoyed it with cola, I can certainly see this being at home in a finely crafted cocktail.”

www.twodriftersrum.com

(37.5% ABV – 70cl)

Creating premium botanical spirits with natural ingredients foraged from the Wyre Forest and surrounding land, WildJac carefully hand pick, select and blend the finest botanicals to ensure the most amazing drinking experience for consumers. WildJac’s Honey Spiced Rum is barrel aged and infused with Worcestershire Honey and English Coriander. A smooth feel on the mouth, a honey spice aroma leads to ginger and orange with a satisfying vanilla finish. Spicy coriander, nutmeg and a hint of oak underpin this full bodied rum. It is perfect served over ice or works equally well with your favourite mixer. The rum is also made from sustainably sourced sugar cane plantations grown in the sub-tropical climate and fields of Nicarayua, Costa Rica and Honduras

i F D & John – Managing Director: “Big spice blast, yet not too sweet. Really natural honey taste without an overpowering sweetness.”

(38% ABV – 70cl)

Located near the centre of Amsterdam, Spirited Union is an independent pioneering rum company creating a new flavour driven category for rum. One of Spirited Union’s most exciting innovations is Queen Pineapple & Spice – a rum that celebrates the sweet taste of Queen Victoria pineapples. These mini pineapples have a fragrant golden orange skin and bright yellow flesh. They are sweeter and more aromatic than more commonly found pineapples, resulting in a delicious rich aroma and complex fruity notes. The natural sweetness of pineapple is balanced by infusing the rum with cassia wood and aromatic cinnamon, creating a well-rounded taste.

Daniel – Editorial Manager: “The fresh smell and taste of pineapple was unmistakeable. I thoroughly enjoyed drinking it with a non-sugary mixer as the rum itself is sweet enough!”

www.spirited-union.com

(40% ABV - 70cl)

Daniel – Editorial Manager: The cocoa really comes through when drinking this neat. Whilst I enjoyed it over ice, I think it would be just as delicious added to a hot chocolate or cappuccino on a cold winter’s night.” 8

Cockspur is a hugely popular rum in the Caribbean. The company’s spiced offering is inspired by the ancient gods and history of voodoo. Said to be the god of tricks and deception, the story goes that Balla was trapped by ritual sacrifice within a bottle of rum. A sensational concoction of charred molasses, infusions of local Caribbean spices with a touch of heat for a mysteriously intriguing experience, this is an excellent cocktail base but is perfect as a rum and coke – a must for any rum bar. Release your spirit within, enter the darkness.

i F D & www.ballarum.com

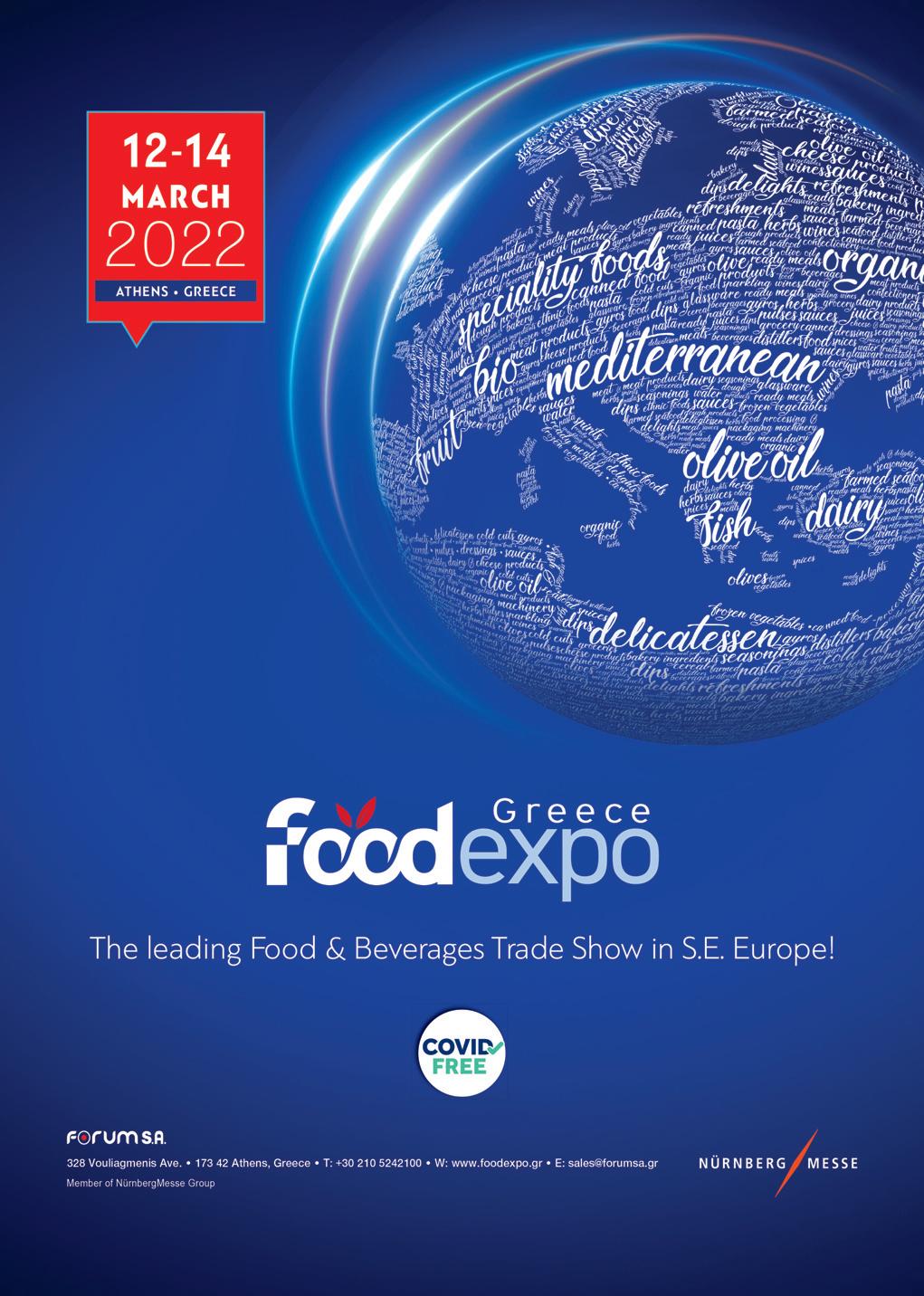

Getting ready to experience the tastes and smells of FOOD EXPO 2022

With events now back up and running following a Covid hiatus, what better place to get back into the swing of things than at FOOD EXPO 2022 – Greece’s largest food and beverage event, and one of southeast Europe’s most influential?

Thanasis Panagoulias, CEO of event organiser FORUM SA (which is a member of NürnbergMesse Group), spoke to Daniel Barnes about the excitement of getting back to physical trade shows and its ambitions to maintain and expand its impressive position and reputation in the upcoming years.

In just half a dozen iterations, FOOD EXPO has become Greece’s largest international food and beverage trade show. How has this been achieved in such a relatively short space of time?

It is true that it only took seven years since FOOD EXPO’s very first iteration to consolidate its reputation as the largest international food and beverage trade show ever organised in Greece and the most significant of its kind in southeast Europe.

The reasons are numerous. First, the food and beverage sector is one of the most dynamic fields of the Greek economy, and FOOD EXPO offers the opportunity to Greek businesses – and mainly production businesses – to strengthen their position in the Greek market.

Secondly, there is a high demand from international food traders for quality Greek and Mediterranean products and specialty foods and FOOD EXPO – through the well-organised Hosted Buyer program – gives the opportunity to the sector’s small and medium enterprises, to meet buyers from foreign target markets. Lastly, with targeted marketing strategies we have managed to build a strong brand name in Greece and abroad.

12-14 March 2022

Covid-19 completely decimated the trade show industry throughout the past two years. What actions has FOOD EXPO taken to ensure guests who physically visit the March event will remain safe?

FOOD EXPO will take place under all the safety protocols that the Greek Government has issued. More specifically, entrance will be allowed only to visitors with a Green Pass, the use of masks will be obligatory to all spaces of the exhibition centre, all attendants need to keep at least 1.5m distance between them and detergents are going to be placed everywhere along the exhibition centre. Finally, specialised medical staff will be at the exhibition centre during all days of the trade show.

FOOD EXPO is promising to overcome the issues of the current situation thanks to also offering a digital attendance with FOOD EXPO Digital. Please can you tell us more about this?

Adapting to the circumstances and the restrictions created by the pandemic, we decided in 2021 to hold a digital edition of the FOOD EXPO trade show. The success of the first FOOD EXPO Digital created the need to establish the digital exhibition as an additional service of the physical exhibition in the coming years. So, in 2022, in parallel with the physical exhibition (March 12-14), the digital platform will operate again.

Through the custom-made platform, which will be open to Greek and international food traders during the physical trade show, the exhibitors will have the opportunity to create a personalised profile of their business, where their products and services are showcased with photos and videos. They will also be able to hold pre-arranged one-on-one meetings via chat or video call with Greek and international buyers that will not attend the trade show in person and network with them.

At the same time, through the digital platform, Greek and international food traders will be given the chance to go through the exhibitors’ profiles, as well as get to know an extensive range of products and services that meet their needs and close important commercial deals with the exhibitors.

What exhibition and visitors’ numbers are you aiming to reach for FOOD EXPO 2022, and how does this differ to previous years?

The food and beverage sector in 2020 showed great resilience towards the unprecedented and difficult conditions caused by the pandemic, with Greek exports gaining ground and creating conditions for their further penetration into international markets.

In 2020, exports increased, compared to 2019, by 3.2%. In addition, recent events confirm that the market still needs physical exhibitions since they are the most important forums for the development of

Getting ready to experience the tastes and smells of FOOD EXPO 2022

trade contacts and cannot be substituted by any other form of actions and activities.

According to these facts, FOOD EXPO 2022 is expected to attract 1,350 exhibitors, 30,000 visitors and 900 Hosted Buyers. The numbers are quite the same as the 2019 event.

What particular areas of the food supplier and buyer markets have grown over recent events?

Due to the nature of the show and its Mediterranean identity, dairy and cheese products as well as olive oil and olives will always play a significant role to the fields of interest of the trade show. Also,

through the last editions of the show there has been a huge interest in fresh fruit and vegetables as well as bio and health products.

For anyone new to the event, what are the main things they would experience if they were to attend FOOD EXPO 2022?

Visitors at FOOD EXPO 2022 will have the chance to discover under one roof the leading suppliers and food and beverage producers and reconnect with them after almost two years of absence of physical exhibitions.

They will also be able to attend B2B meetings with Greek and international exhibitors, evaluate competing solutions across every product category and make business deals.

In addition, visitors can explore a huge range of products and services all gathered in one place, saving time and money. They can discover traditional, local and modern Greek and Mediterranean food and drinks and give their business a competitive edge.

Attending FOOD EXPO 2022 means visitors will stay up-to-date with the latest trends and innovations in the sector, through seminars, workshops and events.

What items are new for 2022?

FOOD EXPO covers the needs of the Greek market, while at the same time fully responds to the export orientation of Greek manufacturing enterprises in the sector. At the same time, it brings together thousands of professionals from organised retail, wholesale, food and beverage industry, hotels and mass catering.

Which exhibiting companies or key industry personnel are creating the biggest buzz in the lead up to the show?

12-14 March 2022

The biggest buzz is being created by the unique Hosted Buyer Program’s participants which belong to a number of key categories, including: supermarkets and hypermarkets, food servers, food and wine importers, wholesalers, distributors, brokers and delicatessen stores.

From your professional experience, what do you consider to be the greatest challenges associated with organising an event such as this?

Despite the great internationalisation of the exhibition, we need to maintain its Mediterranean character and promote it as the top annual meeting point of business professionals of the food and beverage industry.

Finally, what is the main message you would like to promote to the readers of Inside Food & Drink?

FOOD EXPO, the largest food and beverage trade show in southeast Europe and one of the most significant of its kind internationally, is staging a strong comeback between 12-14 March 2022, in a covid free environment at the Metropolitan Expo exhibition centre!

Featuring 1,350 exhibitors from Greece and the rest of the world and 3,500 key food traders, FOOD EXPO 2022 is consolidating its leading position in the wider region while further strengthening its international reach. n

Afish processing business in the north of Scotland has received an eight-figure funding package from HSBC UK, backed by UK Export Finance (UKEF), as it sets its sights on new international markets.

Peterhead-based Denholm Seafoods, which champions Scotland’s high quality, sustainable seafood, will use the additional finance to support its ambitious overseas growth plans.

The pelagic fish business, which processes herring and mackerel caught from sustainable fisheries, is looking to expand in European and Asian markets as it promotes the quality of its Scottish origin fish.

The funding package was backed by a £15 million General Export Facility (GEF) backed by UKEF, the government’s export credit agency. The scheme, which was launched last December, has already provided over £120 million for businesses across the UK. It has made the UK government’s support more accessible, allowing Denholm and HSBC UK to take a longer-term view and underpins the management team’s growth aspirations.

Allan Stephen, Director at Denholm Seafoods, said: “Our growth plans are ambitious and, by utilising this funding, we’re excited to enter new markets and grow in existing ones. It is the quality of our product, coupled with this additional funding that will afford us this opportunity.

“As we invest in the future of Denholm Seafoods, we intend to progress the sustainability of our operations, by reducing our environmental impact as we drive the growth of our business forward.”

Denholm Seafoods processes pelagic fish caught from sustainable fisheries by its local fishing partners in the rich waters of the North East Atlantic. Its wide range of high quality pelagic fish products include mackerel, herring and herring roe, which are delivered fresh or frozen to customers in the UK and worldwide. Denholm Seafoods is part of the Denholm Group.

Mike Freer MP, Minister for Exports, said: “Scottish seafood is renowned around the world for its quality and focus on sustainability – and I’m delighted that UKEF is helping Denholm grow and sell more to the world.”

Denholm Seafoods currently exports 80% of its product while the remaining 20% supplies major retailers in the UK market.

Denholm Seafoods is part of the Denholm Group which operates in four sectors: shipping, logistics, seafoods and industrial services. The group was originally founded as a ship agent and factor by James Denholm in 1866, who was joined in the business by his brother John in 1869. Today, the fifth generation family business is still owned by John’s descendants and employs over 1,000 people.

Molson Coors Beverage Company has expanded its exclusive agreement with The Coca-Cola Company to develop and commercialise a brand of full-flavour alcohol beverages inspired by the US juice brand, Simply®.

“Over the past two years, we’ve seen success by shaking up existing categories with new brands that have clear, compelling points of difference, like Coca-Cola's Topo Chico® Hard Seltzer, Vizzy Hard Seltzer and ZOA Energy Drink,” said Michelle St. Jacques, Molson Coors’ Chief Marketing Officer. “Now, we have a huge opportunity to leverage the power of Simply® – a brand known for real juice and big flavour – to disrupt the full-flavour alcohol segment in a way that’s never been done before.”

This summer, Molson Coors will start by launching the Simply Spiked Lemonade™ variety pack, inspired by some of Simply®’s best-selling non-alcoholic products, including Strawberry Lemonade, Watermelon Lemonade, Blueberry Lemonade and, of course, Signature Lemonade.

As The Coca-Cola Company’s second-largest US brand for net revenue after Coca-Cola, Simply® is a $1 billion+ and growing brand.

“The Coca-Cola Company and Molson Coors have a thriving relationship in North America. The proof is in the success of Topo Chico Hard Seltzer’s national expansion and the introduction of Topo Chico Ranch Water Hard Seltzer,” said Dan White, Chief of New Revenue Streams, Coca-Cola North America Operating Unit.

“With this momentum, we are excited to expand our relationship with products inspired by another one of our most valuable brands: Simply®. We believe people will be excited to try this delicious beverage when it arrives on shelves later this year.”

Simply Spiked Lemonade will be sold in slim-can 12 packs as a variety pack, and 24oz standalone cans of select flavours.

Simply Spiked Lemonade and the national expansion of Topo Chico Hard Seltzer mark the latest initiatives to aggressively grow Molson Coors’ above premium portfolio as part of the company’s revitalisation plan.

Molson Coors Beverage Company will produce, distribute and market Simply Spiked Lemonade as part of an agreement with The Coca-Cola Company.

Glanbia Ireland, Ireland’s largest dairy processor, has launched an €18 million annual Sustainability Action Payment as part of a three-year programme to assist the company’s 5,000 milk suppliers in reducing their carbon footprint, enhancing water quality and biodiversity and improving air quality and soil health in line with Glanbia Ireland’s sustainability strategy, Living Proof.

As part of this initiative, dairy suppliers will receive 0.5 cent per litre (cpl) (including VAT) through delivering specific sustainability actions. This will equate to almost €3,000 in 2022 for the average supplier. Across the lifetime of this three-year programme, over €54 million in total will be made available to family farms as they continue to adopt a range of actions.

The measures are closely aligned with the climate action measures identified in Teagasc’s emissions reduction Marginal Abatement Cost Curve (MACC) climate plan.

Glanbia Co-op Chairman John Murphy said: “Irish farmers are renowned for producing high quality dairy products with world leading natural credentials. Our farmers are proud of their family farms and want to protect them for the next generation.

“We all have a role to play in climate action, water and biodiversity protection and air quality enhancement. It is important that our family farms are assisted as they continue to enhance the environmental and economic sustainability of their farms.

“This initiative is designed to reward suppliers for adopting a series of measures identified as key to delivering on our comprehensive sustainability strategy, Living Proof. As part of this initiative, there is a strong framework of measures for farmers to implement with verifiable proof-points.”

As part of Living Proof, Glanbia Ireland, along with its family farms, has pledged to deliver a 30% reduction in greenhouse gas

(GHG) emissions associated with each litre of milk produced by 2030 and has signed up to the internationally-recognised ScienceBased Targets initiative (SBTi). All of Glanbia Ireland’s dairy suppliers are accredited to the Bord Bia Sustainable Dairy Assurance Scheme (SDAS).

The Sustainability Action Payment will be made to all suppliers that deliver any seven sustainability actions from a total of 16 options.

These include: reducing carbon emissions by utilising multispecies swards and clover; measuring grass growth: improving the herd Economic Breeding Index (EBI) to deliver lower GHG emissions; milk recording and opting for FarmGen renewable energy generation.

Other options include: improving air quality through use of Low Emissions Slurry Spreading (LESS) equipment and the use of Protected Urea; supporting biodiversity by planting additional native trees and increasing hedgerows; protecting soil health and water quality through nutrient management planning; delivering ASSAP water quality improvement plans and water protection measures; supporting animal health and welfare by herd disease screening; improving udder health and participating in the innovative Twenty20 Beef Club.

Glanbia Ireland Chief Executive Jim Bergin said: “We believe that by working together, through support and education, we can continue to adopt changes in practices that deliver real environmental impact.

“As an organisation, we are firmly committed to working with our farmers to implement proven technologies and practices that will benefit the environmental performance of our suppliers’ family farms, as set out in our Living Proof strategy. We will continue to actively seek out leading edge technologies to further support our family farms in their endeavours.”

The latest news from across the global food and drink sector

Global taste and nutrition company Kerry Group has announced two major biotechnology acquisitions. In lateFebruary, the company reached agreement to acquire leading German biotechnology company c-LEcta. This follows the acqui sition of Mexican-based enzyme manufacturer Enmex in December 2021.

c-LEcta is a leading biotechnology innovation company specialising in precision fermentation, optimised bio-processing and bio-transformation for the creation of high-value targeted enzymes and ingredients. Based in Leipzig and employing over 100 people, c-LEcta has established itself as a leading innovator in disruptive new sciences for the pharmaceutical market, with a strong pipeline of functional bioactives across food, beverage and other consumer markets.

This strategically compelling combination will accelerate Kerry’s innovation capabilities in enzyme engineering, fermentation and bio-process development. Kerry’s broad market reach across food and pharma markets, combined with its deep enzyme applications expertise and integrated ingredient technology design, will enable and accelerate the growth potential of c-LEcta’s strong portfolio and technology capabilities.

Dr Marc Struhalla, founder and CEO of c-LEcta, commented: “We are very happy to join Kerry Group and their global presence in the food and pharmaceutical sectors gives us access to additional markets. At the same time, their expertise in ingredient technologies and applications is a perfect fit as we continue to drive our growth potential in the future. We will continue to collaborate with our existing industry partners and will of

course continue to produce and distribute our products for our valued customers.”

This acquisition will further support Kerry’s commitment to invest in the development of innovative sustainable technologies, which the company said will be at the heart of future sustainable food and health systems.

Commenting on the agreement with c-LEcta, Dr Albert McQuaid, Chief Science and Technology Officer of Kerry, said: “The food and pharmaceutical industries are on the cusp of a new wave of innovation where new developments in biotechnology, synthetic biology and precision fermentation are radically transforming these sectors.

“Our broad market reach across food and pharma markets, combined with our deep enzyme applications expertise and integrated ingredient technology design, will enable and accelerate the growth potential of c-LEcta’s strong portfolio and technology capabilities while also supporting us in the creation of tastier, more sustainable and healthier products.”

Enmex is a well-established enzyme manufacturer based in Mexico, supplying multiple bio-process solutions for food, beverage and animal nutrition markets. With a long history of partnering with global customers, Enmex has a complementary enzyme portfolio and a strong manufacturing infrastructure, which will extend Kerry’s fermentation and enzyme manufacturing capabilities into Latin America.

Kerry is the world’s leading taste and nutrition partner for the food, beverage and pharmaceutical markets, with its broad range of ingredient solutions reaching over one billion consumers around the world.

OneOrder, the new logistics company aimed at solving Egyptian restaurants’ supply chain inefficiencies, has announced its launch and successful completion of a $1 million fundraising campaign.

The fundraise was led by A15, the leading MENA venture capital firm, and renowned as one of the most prominent backers of early-stage start-ups in the region.

OneOrder is the first company of its kind in Egypt; a logistics company addressing the major inefficiencies faced by Egypt’s restaurants when sourcing supplies. It is the creation of leading Egyptian restaurateur Tamer Amer, the founder of Fuego Sushi and Longhorn Texas BBQ – two of Egypt’s most successful restaurant chains.

OneOrder is creating a platform to address the significant structural problem faced by Egyptian restaurants – interacting on a regular basis with a number of small, fragmented suppliers and vendors from whom they source their meat, vegetables and equipment.

According to Mr Amer, this suboptimal supply chain structure causes inconsistent and non-transparent pricing, unreliable quality which, in turn, gets passed onto restaurant customers, and irregular delivery timing, with supplies often late, limiting restaurants’ daily menu offerings.

OneOrder’s platform means Egyptian restaurants can buy all their needs from one application, with reliable quality, prices and timing.

“We are delighted to announce our launch and fundraise, and I thank A15 for their outstanding support,” said Mr Amer. “Given Egypt’s flourishing restaurant industry and the challenges it faces caused by a fragmented supply chain, OneOrder offers a much needed technology-enabled solution at the perfect time. My experience in the food and beverage industry means I know what restaurant owners need; it is a reliable, timely supply of quality goods, at a consistent price – without the stress of managing various suppliers on a daily basis.