ARANOW 1 Inside Marine INTERNATIONAL, INNOVATIVE PACKAGING SOLUTIONS powered by Inside Food & Drink insidefoodanddrink.com

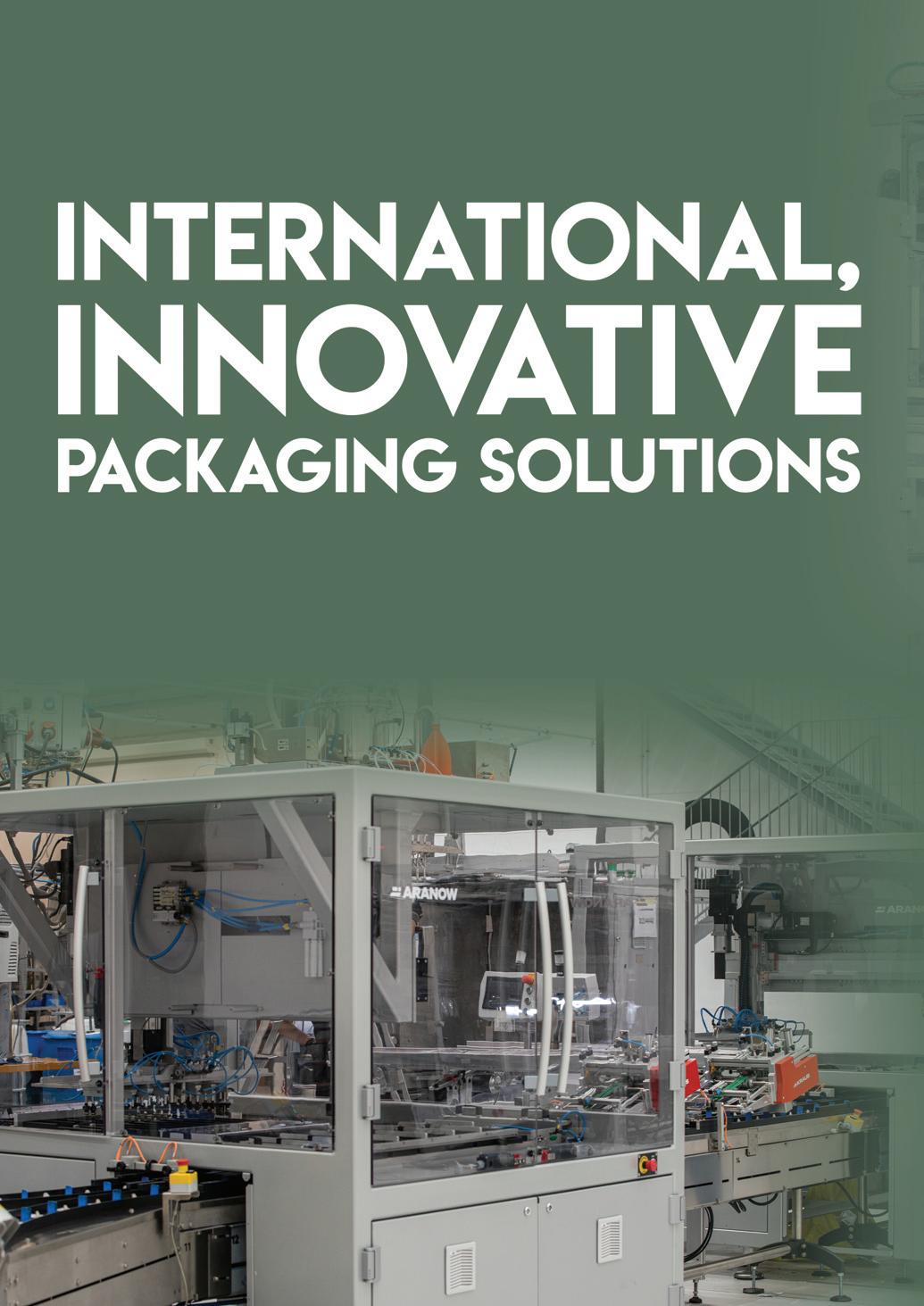

Aranow specialises in primary packaging solutions for food, pharmaceutical, cosmetic and dairy products. The company offers customised solutions and cutting-edge machinery, boasting an extensive catalogue of equipment for packaging any type of product: solid, granulated, powder, viscous or liquid.

90 Inside food & drink

ARANOW I PROFILE

Chief Commercial Officer Paco Gibert explained more to Hannah Barnett.

The main thing that distinguishes Aranow from its competitors is the company’s specialisation in stick pack and flat sachet machinery to offer flexible packaging solutions. Responding to the needs of each sector, and often complemented with secondary packaging machinery, Aranow offers optimal results with complete lines.

“We are one of the few suppliers in the world that specialises exclusively in the design, manufacture and development of vertical, multilane packaging machinery,” said Paco Gibert, Chief Commercial Officer. “This has enabled Aranow to develop truly unique and innovative solutions.”

The company specialises in single dose packaging, the advantages of which are numerous. “There is the usability factor,” said Mr Gibert. “The customer can take a single portion with them anywhere.

The other advantage is that in developing countries, end users do not always have the economic means to buy the complete box of a certain product, so, they can buy just what they need. Also, with single dose packaging, we can reuse a lot more of the plastics, compared to blister packaging and so on.”

Expansion and growth

Aranow was founded in 2003, in the heart of the Barcelona Packaging Valley in Catalonia. The company was established with the mission to create single-serve packaging for the most demanding sectors, whilst upholding the strictest safety protocols.

Aranow sold its first machine, a stick pack, to the South African market. The second it exported to Morocco and the third to Mexico. ‘We were

Inside food & drink 91

ARANOW I PROFILE

born with international DNA,’ states the company website.

And the global footprint has extended to the present day. Aranow still exports 90% of its solutions and maintains an especially strong presence in Southeast Asia and South America.

Complementing this worldwide dominance, Aranow also shows signs of healthy growth, doubling its turnover in the last five years. The company expanded into new facilities in 2021, after finally outgrowing its original location. This has proved a shrewd move, increasing production capacity by a massive 80%.

“Before we moved, we were buying factories next to ours and trying to attach one to the other in order to fulfil our production demand,” explained Mr Gibert. “But we reached a point where our original factory

was not able to meet the demand that we were experiencing. Now, we can not only provide more machines to the market, but also improve the way that we make them by implementing the Aranow Production System inspired by lean manufacturing. This allows us to follow the appropriate quality and traceability standards together with a verification department using the best precision instruments.”

Alongside increased efficiency, the new HQ is also a hub of innovation. It includes some electrical and software simulation laboratories and state-ofthe-art product test rooms, equipped with temperature and humidity controls. These clean rooms allow all products to be tested in a controlled environment, helping the design teams meet bespoke customer specifications.

92 Inside food & drink

Innovation in Switzerland

Another significant investment into the cutting-edge came in 2022, with the establishment of an Innovation Centre in Neuchâtel, Switzerland, and the accompanying formation of Aranow Swiss, a sales office for central european countries.

The location is no accident. In recent decades, Switzerland has developed into one of the world’s most prominent hubs of industry innovation. The country has become an exceptional research ecosystem, recognised worldwide, especially for pharmaceutical packaging.

Through local partners like CSEM, Microcity and EPFL Innovation Park, Aranow Swiss focuses on innovation in equipment, production processes and business units. This includes research into advanced production techniques and smart technologies such as artificial intelligence to improve productivity.

“The purpose of the Innovation Centre is to work with recycled plastic films, to pursue

industry 4.0 and to have that flexibility in our machines to design personalised solutions for specific customer demands,” said Mr Gibert. “So, thanks to the centre, we are adding more value to our technology all the time.”

New designs

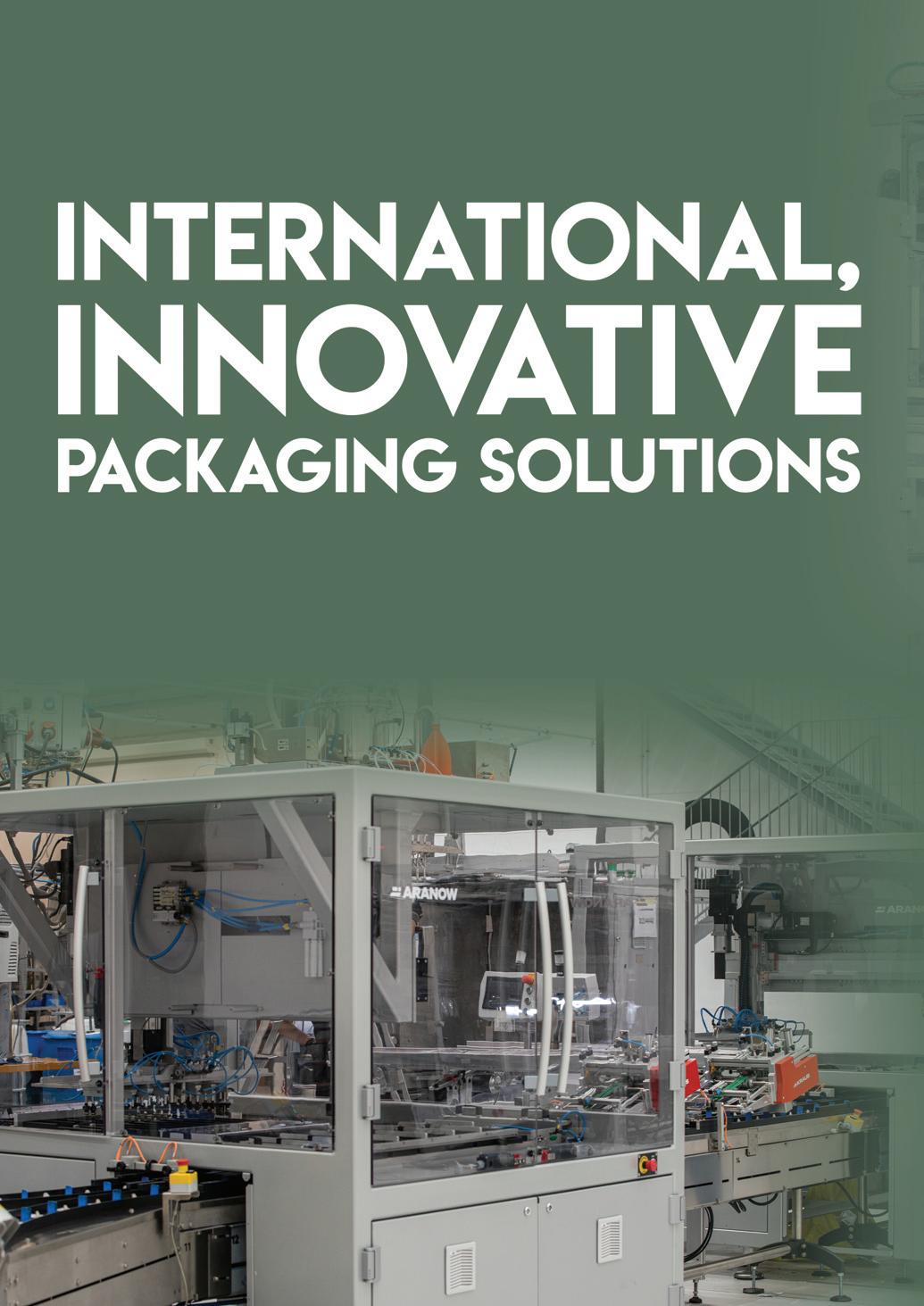

Innovation runs through the core of Aranow. The company recently attended Interpack 2023 to showcase some of its

Inside food & drink 93

most exciting designs. This included two multi-track machines with different production volumes, as well as a complete line that integrates secondary packaging. Visitors were able to discover first-hand the ease of access and low maintenance of the components.

As Mr Gibert emphasised, it is listening to views of customers that ignites the company’s innovative spark: “We developed these solutions after receiving feedback from the market. Customers were looking for flexibility in machinery. So, we have developed a unique solution that allows the customer to change the format or the dimension of the packaging sachet in less than five minutes.

“We have developed solutions for the transferring system from our packages to secondary packaging machines. That was

also created after receiving feedback from our customers: and we have some smaller innovations for smaller solutions. For example, the way we cut the film, or the way can we put nitrogen in the stick packs. It all helps the customer have a more efficient machine in the end.”

For specialists in primary packaging, a robust long-term relationship with secondary packaging suppliers is vital; as it is, for Aranow; maintaining the level of quality the company has made its name with. That is why all its secondary suppliers have

ARANOW I PROFILE 94 Inside food & drink

a contract devised by Aranow’s technical department which ensures the equipment of potential partners meet the same highquality level.

Looking ahead

Though the future looks bright for such a successful and innovative company, there are, of course, challenges too: mainly, in the need to reduce, and eventually completely stop the application of single-use plastic.

“ That’s why we are investing in the Swiss Innovation Centre,” reflected Mr Gibert. “ It has given us somewhere to partner with different plastic film suppliers. This means looking into different formulas of recyclable films; compost films – generally films with a smaller environmental impact.”

On the whole, the outlook is positive for the company and for the CCO himself. He concluded: “Aranow will continue to develop new solutions tailored to the needs of the contemporary consumer, investing in research and innovation as we have been doing for 20 years.” n www.aranow.com

Inside food & drink 95