THE WORLDLEADING PET

COMPRESSORS

POWERED BY INSIDE FOOD & DRINK

Originating from Liege, Belgium, Ateliers François Compressors has developed its capabilities; planting firm roots in the food and drink industry as a competent and reliable manufacturer of oil-free PET compressors. Since 2008, the company has established a strong presence within the Middle East, and General Manager of AF Compressors Middle East Gaetan Hage explained more about this journey in an exclusive interview with Inside Food & Drink. Report by Imogen Ward.

When it comes to the manufacture of oil-free PET compressors, Ateliers François Compressors is unmatched. Perfectly equipped with the knowledge and first-hand experience of the desert, the company is not afraid to adapt its products to ensure optimum efficiency within these harsher environments

“We wanted to ensure our eight and ten bar compressors had the most energy efficient design and the latest technology,” General Manager of AF Compressors Middle East Gaetan Hage said. “The redesign has been hugely successful within the Gulf Cooperation Council countries, because it has ensured our products work effectively with high

temperature resistance. This is perfect for the Gulf where humidity is high, the climate is hot, and the surroundings are very dusty.”

Branching out from Belgium

Initially set-up in 1870 to manufacture pneumatic hammers for the mining industry, AF Compressors later diversified into compressor manufacturing. Now, with a reputation for excellence (and the figures to prove it), AF Compressors currently maintains around 60% of the global PET line compressor market – and an impressive 85% within the Middle East and Africa.

“Our customers need a partner they can rely on,” Mr Hage explained. “The Gulf market is hugely competitive; it is an incredibly challenging, fast-growing market, and competition here is fierce. We have accomplished a hugely impressive l ead because we never let our customers down, and our 24/7 service solutions ensure we maintain this commitment.

“We are also probably the only compressor manufacturer present in the region that is dedicated solely to the food and beverage industry: this means we can

devote more time to ensuring our products are designed to suit this industry, rather than creating a onesize-fits-all.”

Having seen a lot of potential within the Middle East, AF Compressors decided to establish a subsidiary in Dubai, UAE, in 2008. This investment provided the company a new geographical advantage – one of many, thanks to the company’s plethora of subsidiaries situated across the globe. Now, AF Middle East is a bustling centre for sales within the MENA regions.

“AF Middle East is used as our main hub for the Gulf,” Mr Hage explained. “We have invested in distribution, service and training facilities, as well as a machine trading centre, which supervises our Turkish and Egyptian offices too. We never stop thinking about the company’s progression, and we are always on the lookout for potential

The crown jewel of compressors

One of the first air compressors developed under the AF name was the company’s ten bar design. Initially, this product was dedicated to providing cooling for the European coal mining industry but, following the emergence of the PET industry in the 1980s, AF Compressors saw an opportunity to market these compressors in a new way.

In 2008, the company made the courageous decision to redesign its eight and ten bar oil-free compressors, to offer its customers a low-pressure option. This decision was made with the Middle Eastern market in mind and was a direct response to customers’ needs within a challenging environment.

“Our customers were looking for a reliable, simple and robust compressor that was capable of working 24/7 in tough

areas of growth. That keenness to develop is part of what has led to our position as world-leaders for PET compressors.”

condi tions,” said Mr Hage. “Ever since that initial redesign, we have performed continuous product improvement to ensure our low-pressure compressors remain at the top of the market for efficiency, reliability and total cost of ownership. We also invest in new features to achieve these goals.”

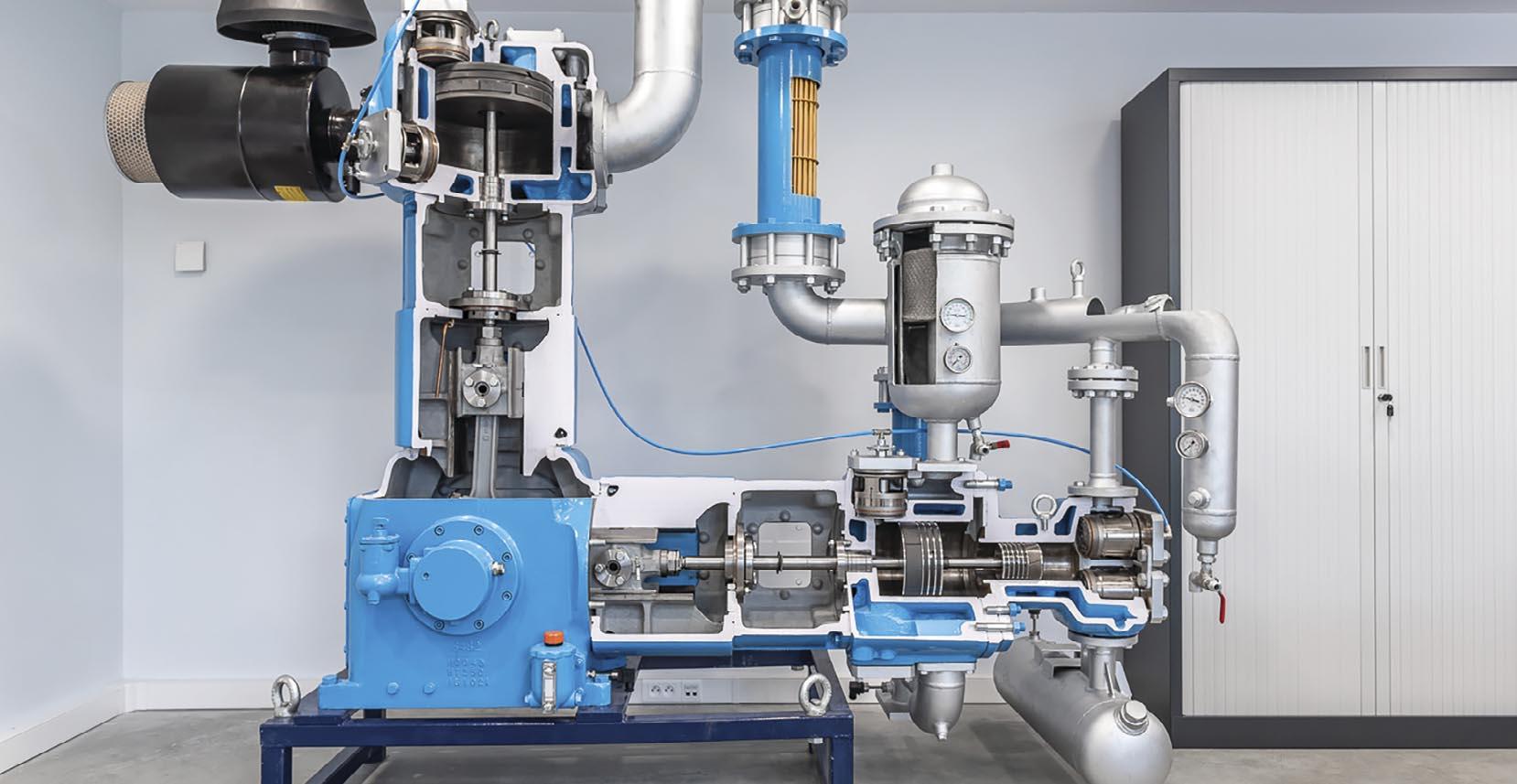

Designed with efficiency in mind, the eight and ten bar oil-free compressors have a low idle consumption of 10% and incorporate the company’s iconic ‘L’ shaped piston cylinders, designed for reliability and longevity.

“Our compressors are incredibly reliable; so much so, that they often surpass our customers’ expectations,” Mr Hage said . “Machines that we installed 20 to 40 years ago are still running today, and that’s because they are incredibly reliable, and they stand the test of time.”

Efficiency within simplicity

A simple design is one of the company’s well-known secrets when it comes to the manufacture of its compressors. “Our

customers are very much focused on the simplicity,” Mr Hage said. “They want a machine that is reliable, but also easy to repair; and designing a product that is too complex does not benefit anyone. When new customers come and view our products and see them in action, they become convinced that they are the solution for them, b ecause they realise how simple and efficient compressors can be.”

In line with this, the company was eager to market a new slogan to the international market. Based around the company’s designs, this slogan highlights the products’ efficiency within simplicity. “Compressing air is quite a simple process, but designing a compressor in a way that also reflects that simplicity is quite something,” Mr Hage said.

The company is planning to take its new slogan to the Gulfood Manufacturing exhibition in November. A hugely popular event dedicated to the food and drink industry, GM allows innovators from across the globe to gather in one place and learn about the latest advancements from the industry.

AF Compressors has been a loyal attendee of the event since the first trade show back in 2014, and strongly believes in its ability to connect companies. “AF Middle East has never missed an opportunity to attend Gulfood Manufacturing,” Mr Hage explained. “Every year, we attend with a greater presence, because we believe it to be the main hub for the Middle Eastern, African and subcontinental countries to meet. It’s an excellent opportunity for us, because everybody attends, from our customers to our competition.

“With minimal visa restrictions, the even t is easy to access from all over, and Dubai is always such a welcoming city, with so many opportunities for people to explore. That really encourages visitors to attend.”

Discussing this year’s show, Mr Hage said: “We have great expectations for the 2023 show; we have doubled the size of our booths, and we are bringing Sales Managers from many different regions as we anticipate the attendance of customers from all over the world. Our visitors will also have high expectations for us, and we don’t want them to be disappointed. They will want to see what is new, and how they can improve their machines.

“Every exhibition has resulted in a high return for us, and we expect this year to be no different,” he concluded. “We look forward to showing our customers what we can do from Hall 1, booth B1-18 at this year’s Gulfood Manufacturing show.”