PRIYANK SONI

Creative Technologist

Architect, Scenographer & Digital Fabrication Specialist

Master of Advance Studies in Digital Fabrication and Architecture (MAS DFab.)

ETH Zurich ‘21

Bachelor of Architecture (B.Arch)

School of Planning and Architecture, India ‘16

Reg. Architect COA, India {CA/2016/80440}

I enjoy tackling complex spatial challenges and bringing immersive interaction concepts to life.

I firmly believe that the user experience within a space is a culmination of its form, materiality, rhythm and contextual interdependencies. By integrating my passion for computational design and expertise in digital fabrication, I skillfully analyze and actualize a dynamic dialogue, exploring diverse possibilities in a built environment.

priyankism@outlook.com

+49 17670532322

● Q2 2022.. UNIPLAN GMBH, COLOGNE (Spatial Concept Designer)

● 2020-21 GRAMAZIO KOHLER RESEARCH, ETH ZURICH (Research Assistant)

● 2017-20 ATELIER BRUECKNER, STUTTGART (Scenographer Architect)

● Q2-3 2017 OM INSTITUTE OF ARCHITECTURE, HISAR (Assistant Professor)

● 2016-17 INCUBIS CONSULTANTS, NEW DELHI (Architect & Designer)

● Q1-3 2015 TROPIC RESPONSES, BENGALURU (Architect assistant)

SKILLSET OVERVIEW

Advance Construction

Rhino 2D/3D

Sketchup

Autodesk Revit

VectorWorks /AutoCAD

Enscape

Lumion

ARCHITECTURE DIGITAL FABRICATION

SCENOGRAPHY

Spatial Experience Design

Spatial Strategy

Cinema 4D

Rhino 3D

Adobe Photoshop

Adobe Illustrator

Adobe After Effects

Corona Render

DESIGN CREATIVE CODING

Extended Reality

3D-Printing

Physics Simulation

Robotic Fabrication

Topology Optimization

Autodesk Fusion

Wood-working

Grasshopper

Unity Engine

Python

Generative A.I.

XR

Nvidia Omniverse

Computational Design

PROJECT OVERVIEW

Uniplan, Cologne

Brand strategy & Experience design Architecture

• Continental HQ, Hannover (DE)

• Vodafone Pavilion OMR 23, Hamburg (DE)

• Telekom ‘Digital X’ 23, Cologne (DE)

• OGE Pavilion GatWat23, Cologne (DE)

• Michelin Star Revelation 23, Karlsruhe (DE)

• BOBST Tech lounge, Mex (CH)

• Hyundai CES 2024, Las Vegas (US)

• Diehl Defence design strategy (DE)

Atelier Brückner, Stuttgart

Scenography & Creative conception

• Hyundai Future Mobility, Goyang (S.Korea)

• Hyundai CES 2019, Las Vegas (US)

• Museum of the Future, Dubai (UAE)

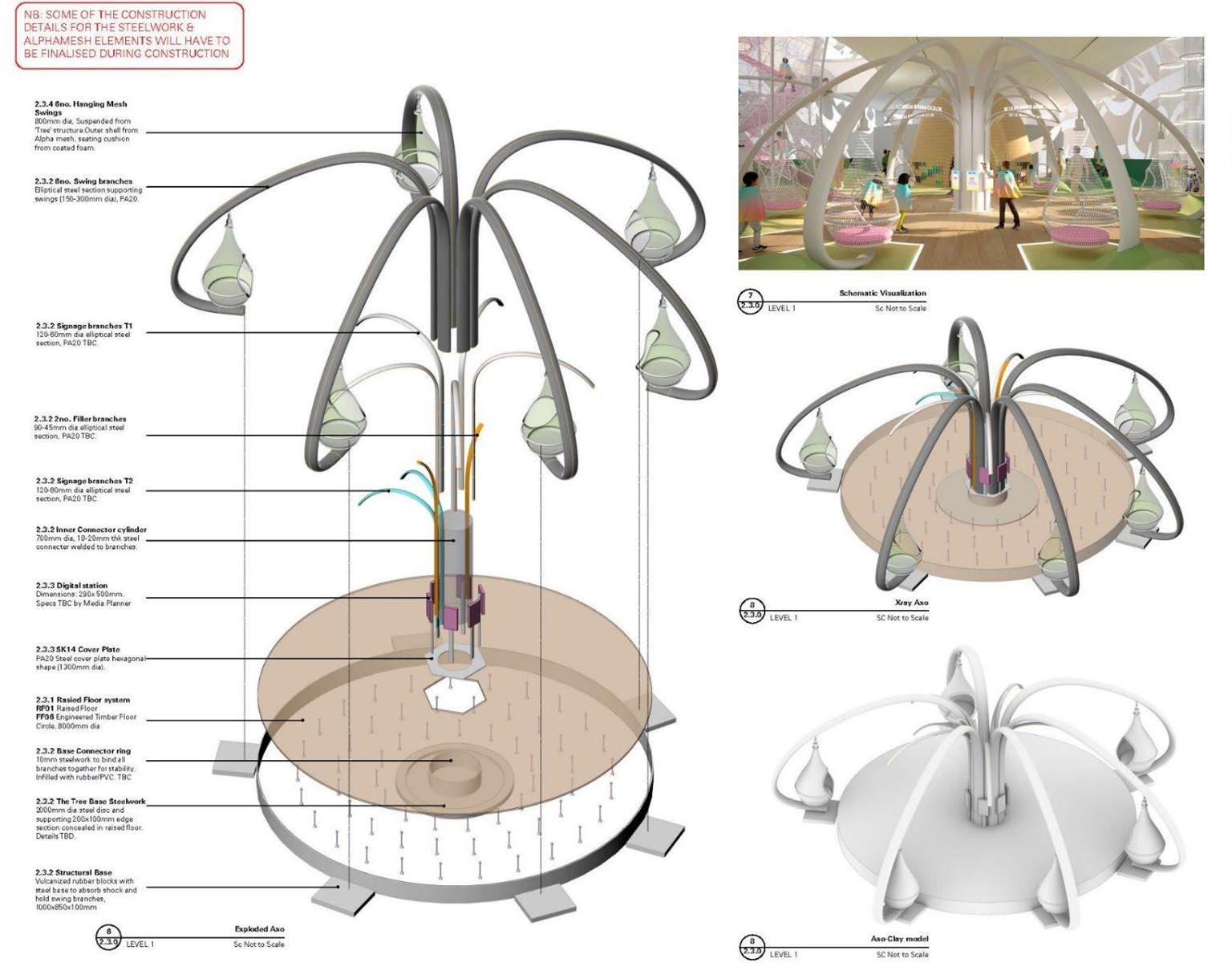

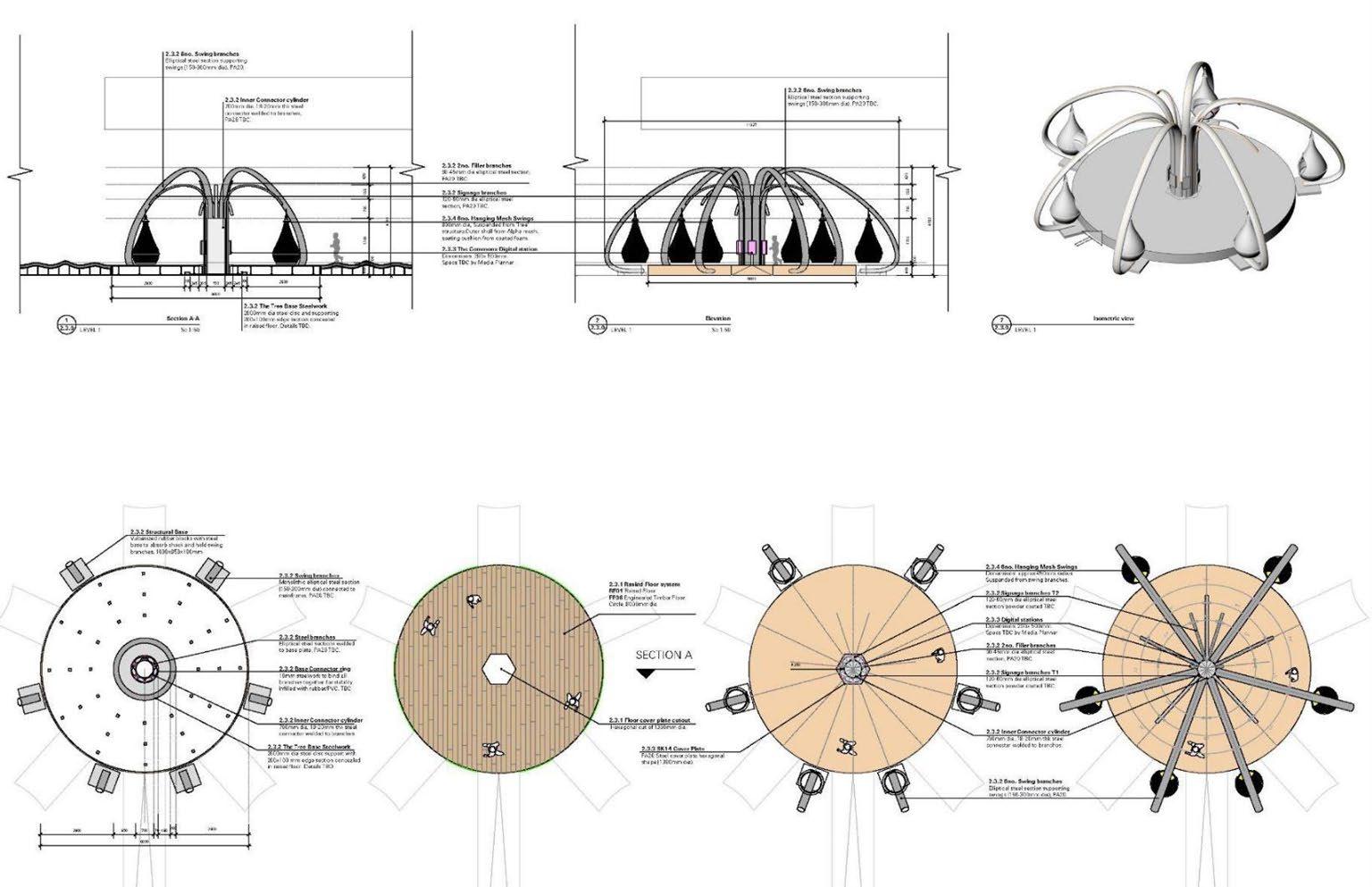

• Qatar Children Museum, Doha (Qatar)

• Lund Science Center, Lund (Sweden)

• Geberit Elements, Haldensleben (DE)

• Norsk Grafisk Museum , Stavanger (NO)

• Hyundai Motor studio N, Goyang (KR)

Exhibition design for Foyer space. Scenography & Media programming for Digital LED sculpture “Stream”.

Concept Design, Architecture, 3D prototyping & Fabrication planning for brand exhibits.

Main Stage, Interactive stage and Microsoft booth Design

Conception, Architecture & Execution planning

Ceremony Conception & Main stage design-execution

Schematic planning & exhibition design concept

Pavilion-entry Experience design “Waste to Hydrogen”

− Product presentation design pitch

Exhibition design focusing Scenography, Fabrication & 3 D prototyping of media and kinetic installations.

Concept Design and Execution planning-3D fabrication

Spatial Experience design, 3D prototyping & Fabrication of Future Heroes and Space Station H.O.P.E.

− Exhibition design and interface coordination

Exhibition concept design and Visualization

Generative Installation design and Visuals

Schematic planning & exhibition design concept

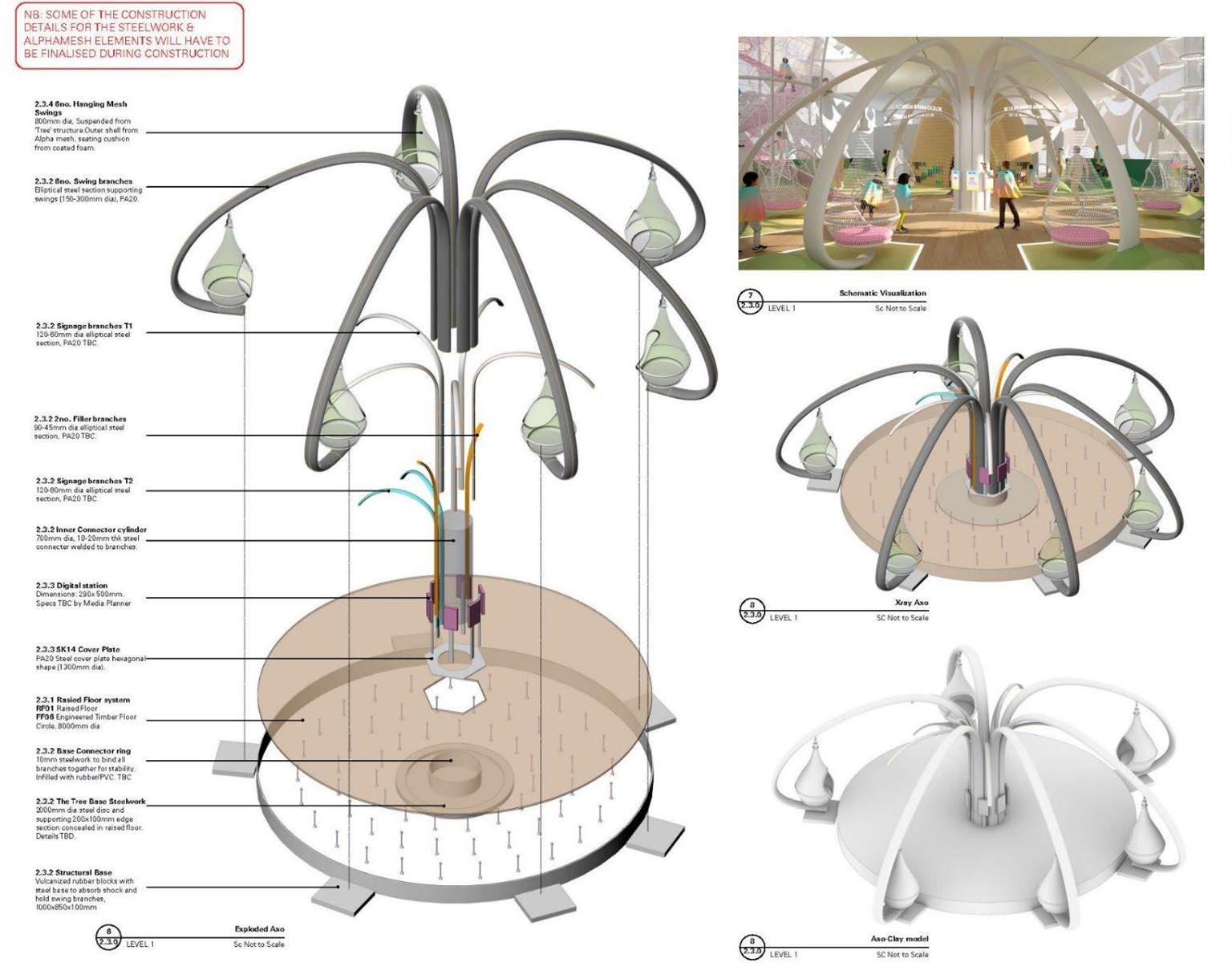

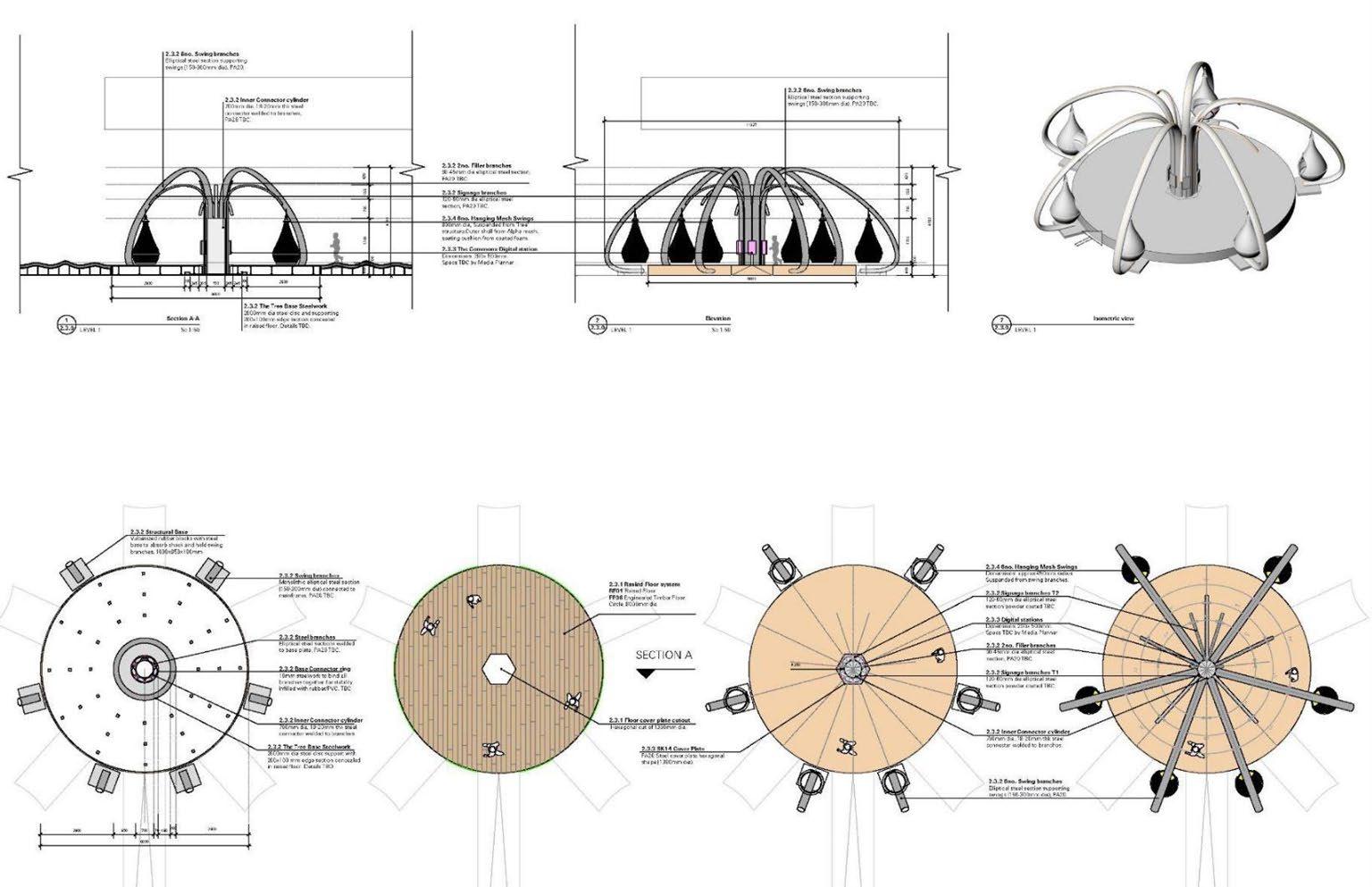

Interaction Design and fabrication drawings

Creative

Architecture Design Digital Fab.

coding

Design

Fab. Creative coding

Digital

PROJECT OVERVIEW

Gramazio Kohler Research, ETH Zürich

Research on applications of digital tools and fabrication techniques.

• Research: Kinetic Architecture with 3D Printing and Shape Memory Alloys

• Robotic 3D Printing for Composite facade design from recycled PET

• Intuitive Robotic Plastering: Human-machine collaboration for Concrete sculpturing

• Robotic Kiln glass - Coloring and Thermoforming with Contextual Data

• Research support: Data Science Enabled Acoustic Design

Miscellaneous

Fun Hobby

Published 2 Research papers with working Kinetic prototypes (EMPA + Digital Building Technologies)

Computational design, Tool path simulation and Material optimization (Gramazio Kohler Research)

Human gesture data filtering and XR interface with onsite projections (Gramazio Kohler Research)

Form Development and Physics Simulation of thermoforming process (Digital Building Technologies)

− Sound simulation data collection (Gramazio Kohler R.)

• Published Research: Design and analysis of energy-efficient bi-stable shapechanging structures based on SMA actuators (Extreme Mechanics 2023)

• Published Research: Kinetic Architecture with 3D Printing and Shape Memory Alloys (ACADIA 2022)

• Published Research: Discretization of double curved surfaces (Communications in Applied Geometry 2021)

• Published Article: "Mud vs. Concrete" (Design Details Magazine 2016)

• Certified in Advance Bamboo Construction Technology (Auroville 2015)

Archi. Design Digital Fab. Creative coding

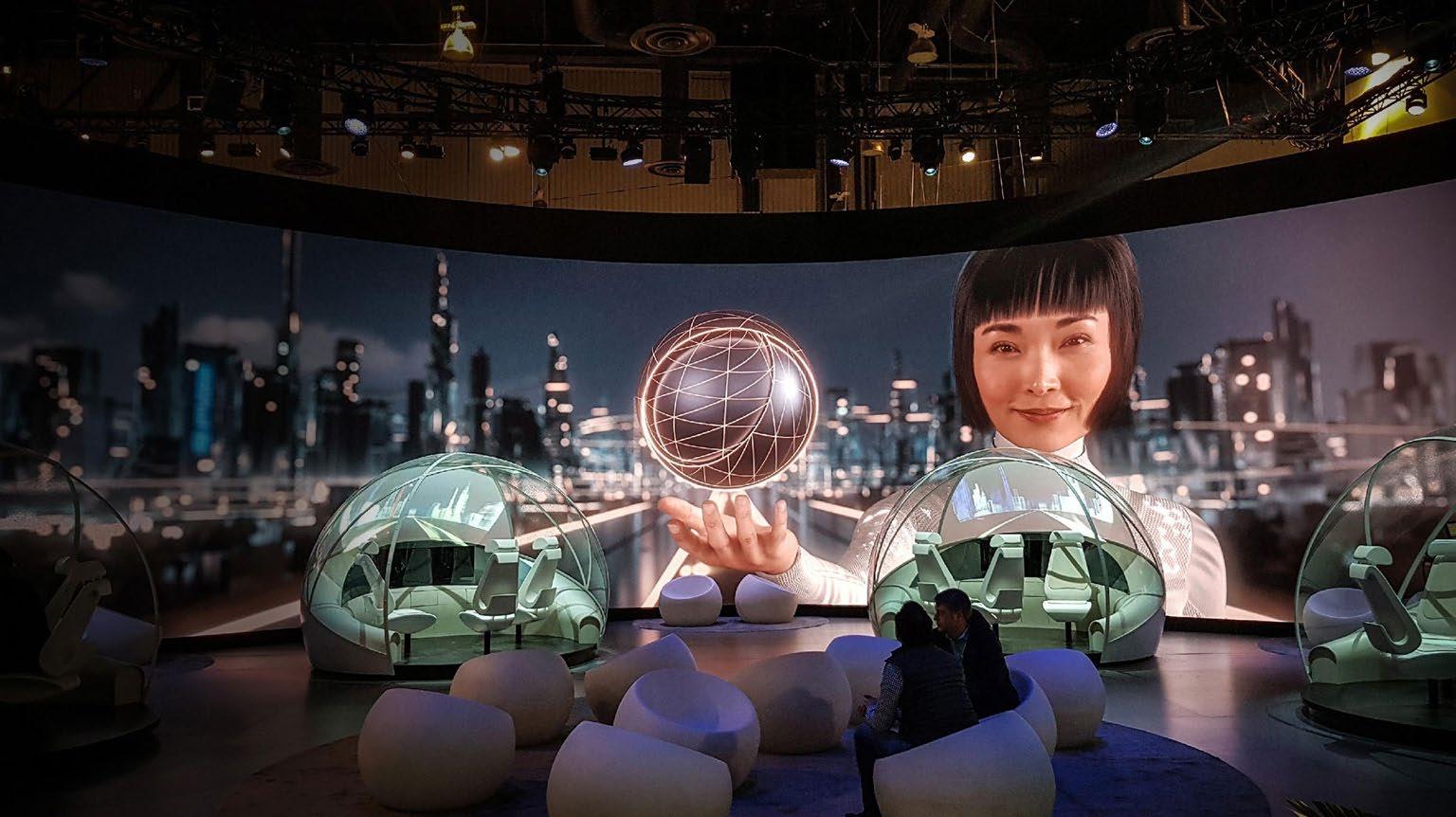

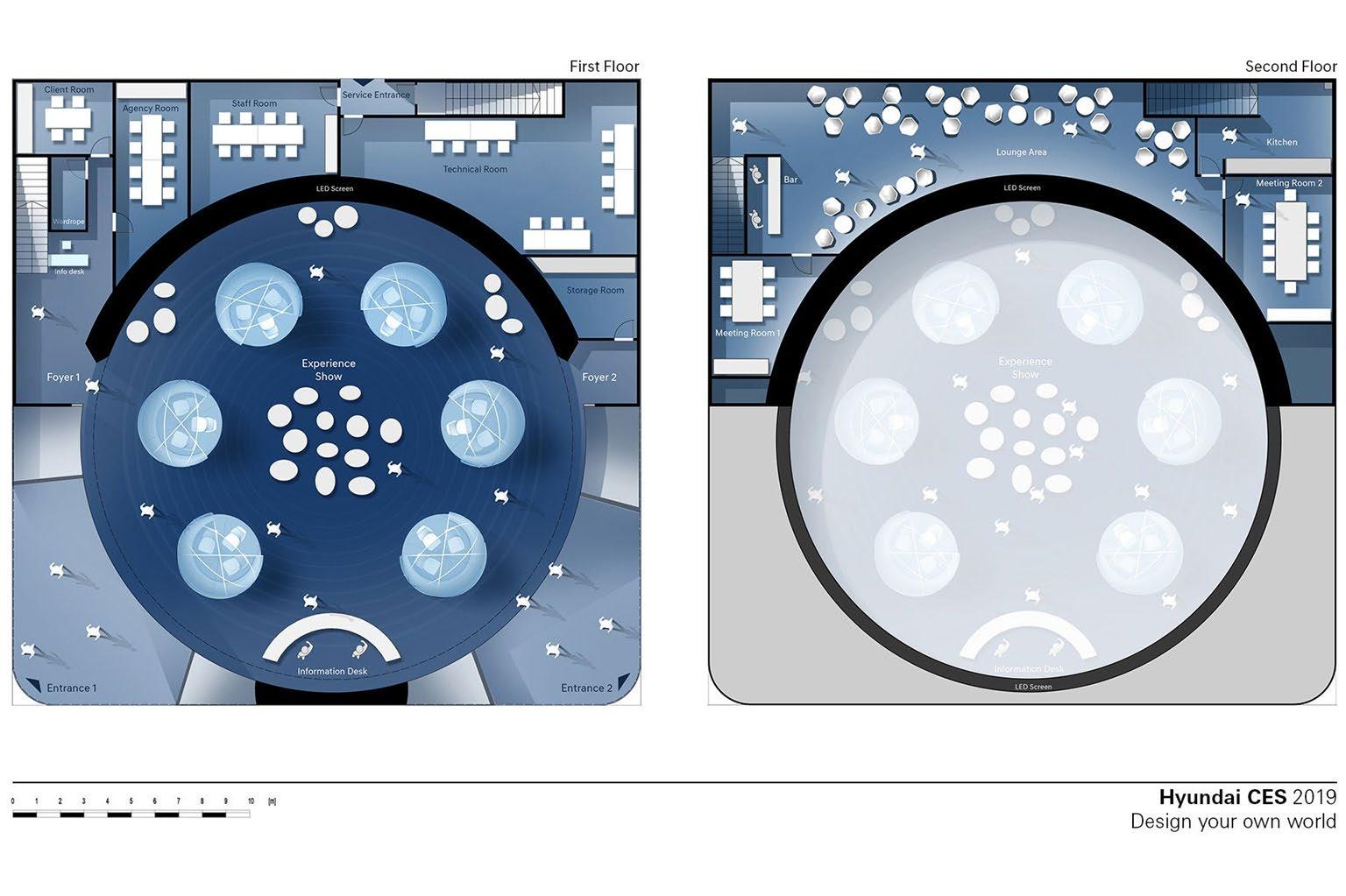

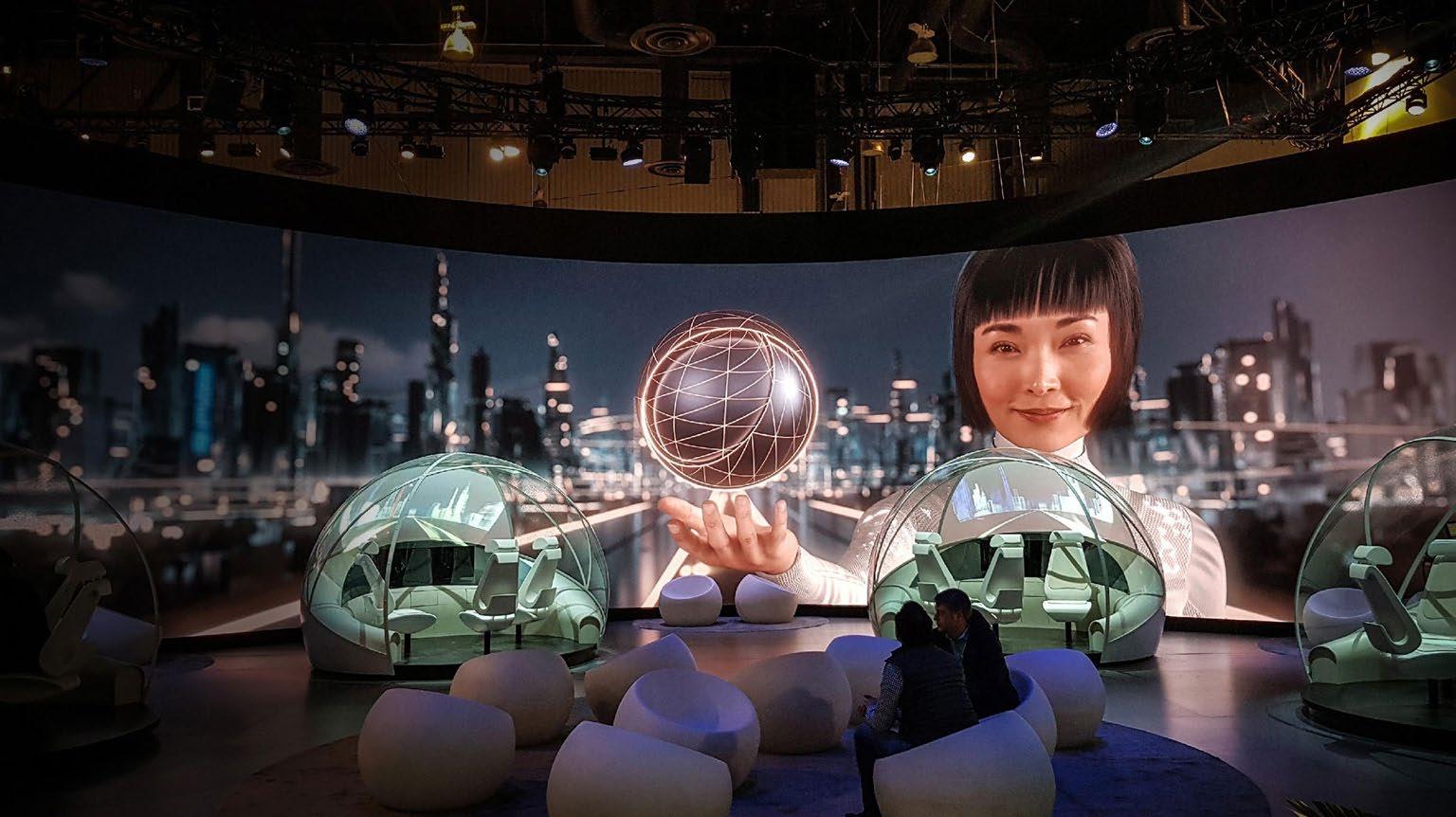

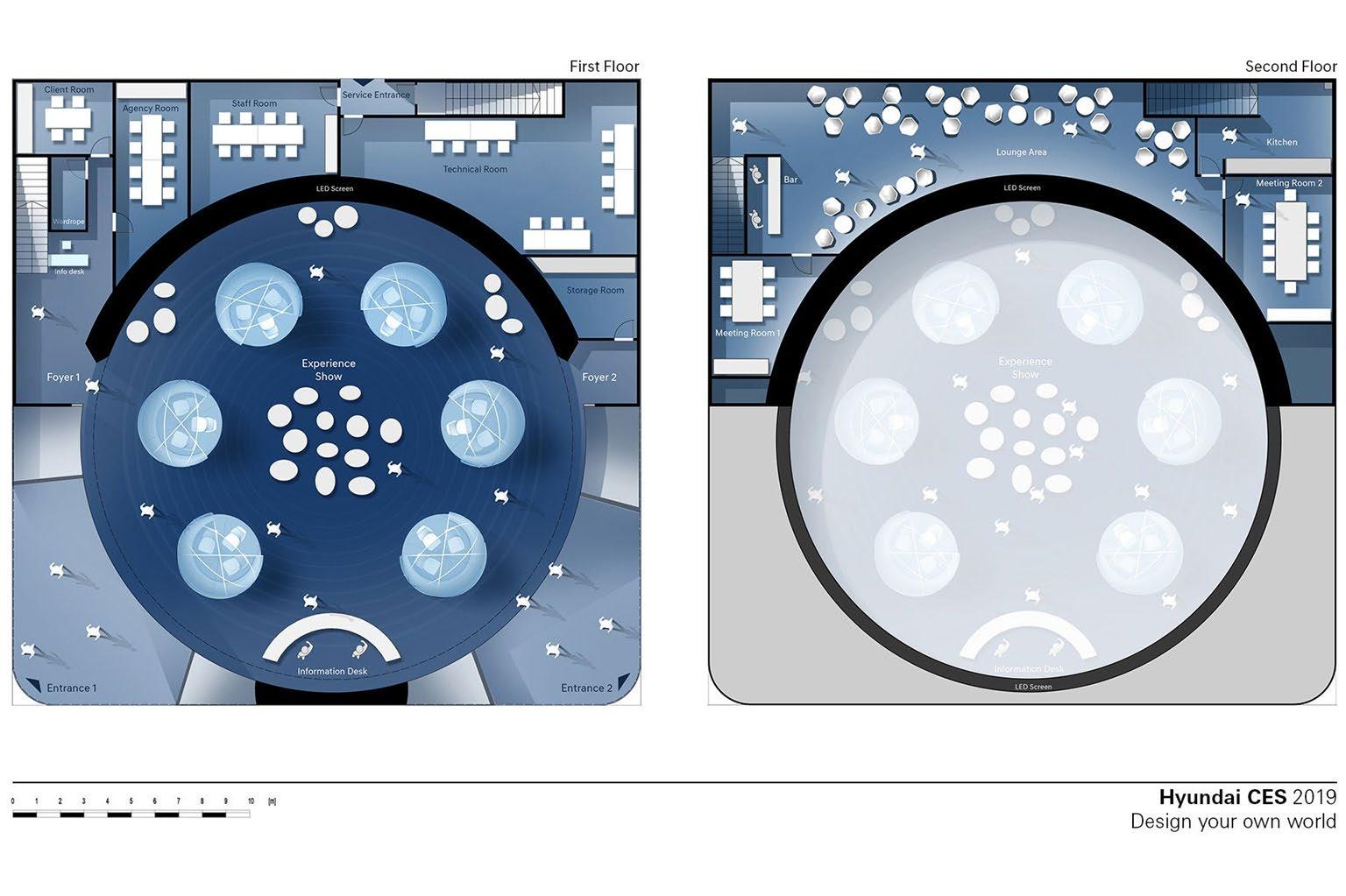

HYUNDAI PAVILION CES

2019, LAS VEGAS

‘DESIGN YOUR OWN WORLD’

@Atelier Brueckner

Mobility of the future: Hyundai presents its vision of autonomous driving at the Consumer Electronics Show (CES) in Las Vegas. Surrounded by a 360-degree screen, visitors travel to the city of the future. The vehicle’s cockpit becomes an intelligent multifunctional capsule. The spherical glass cocoon reacts to its users and changes its features as required Four sample modes are possible – from sports mode to shopping experience

Involvement :

Scenographic storyline

Schematic Planning

Fabrication & 3D prototyping of immersive Cocoons

Project Manager Communication Designer Media designer MKT Fabrication tech

Congaz

Content/Film production

Taylor Construction Contractors Hyundai Motor company Exhibition Architect Pavilion Design Realization Involvement Matrix

Lounge area at upper floor

View of the central space

Lounge area at upper floor

View of the central space

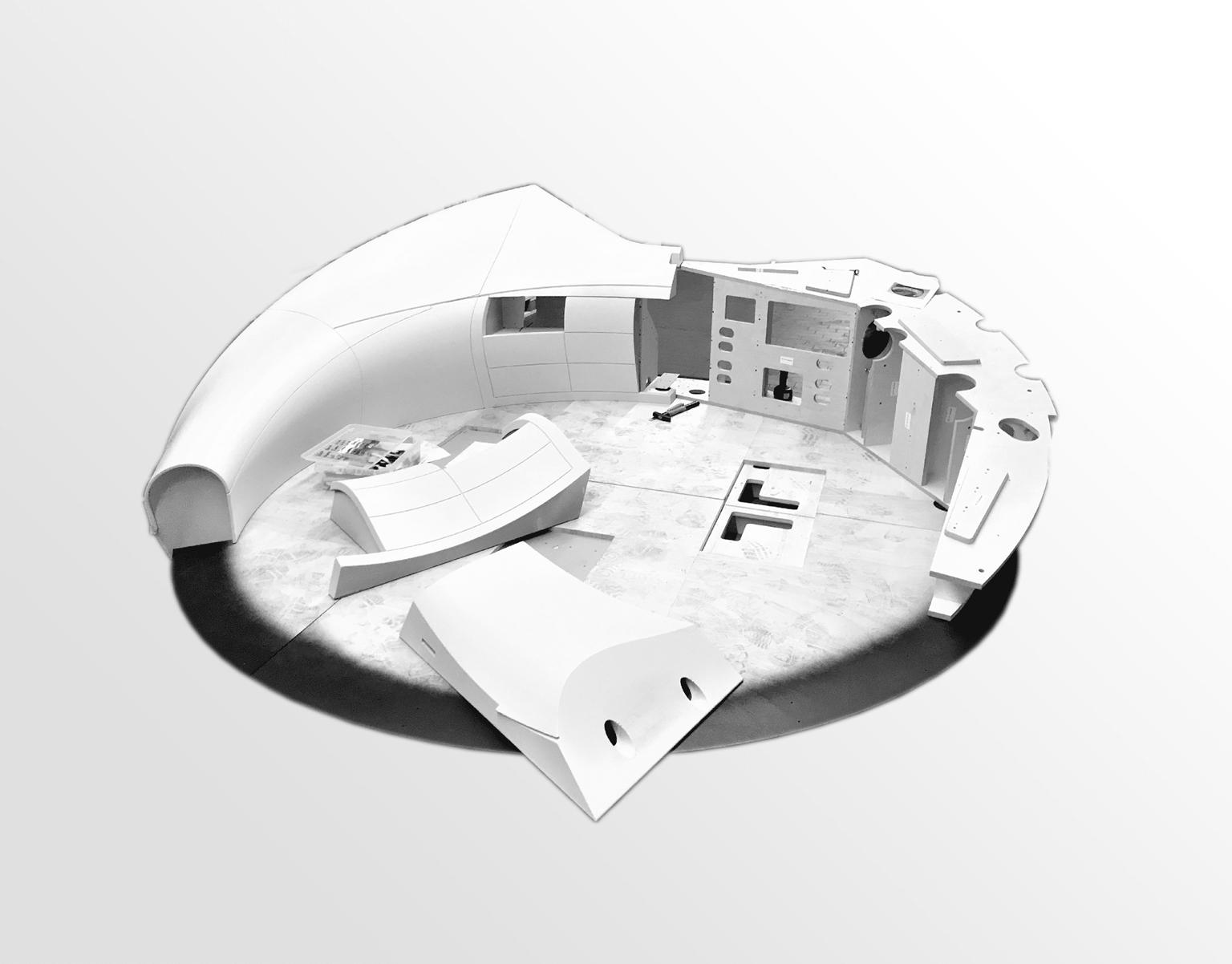

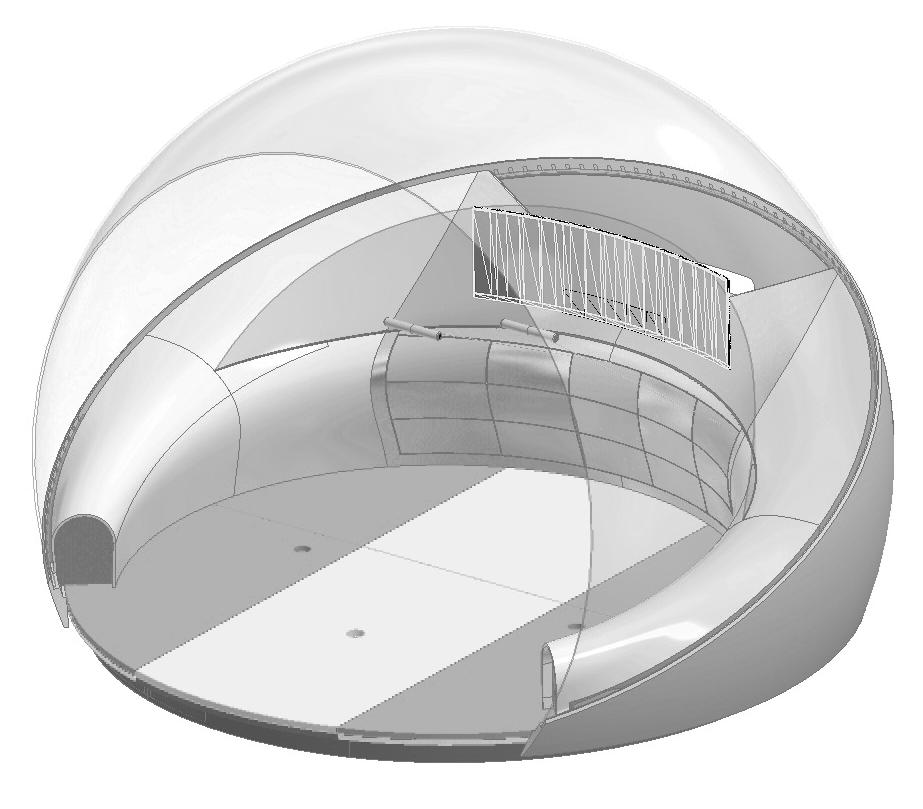

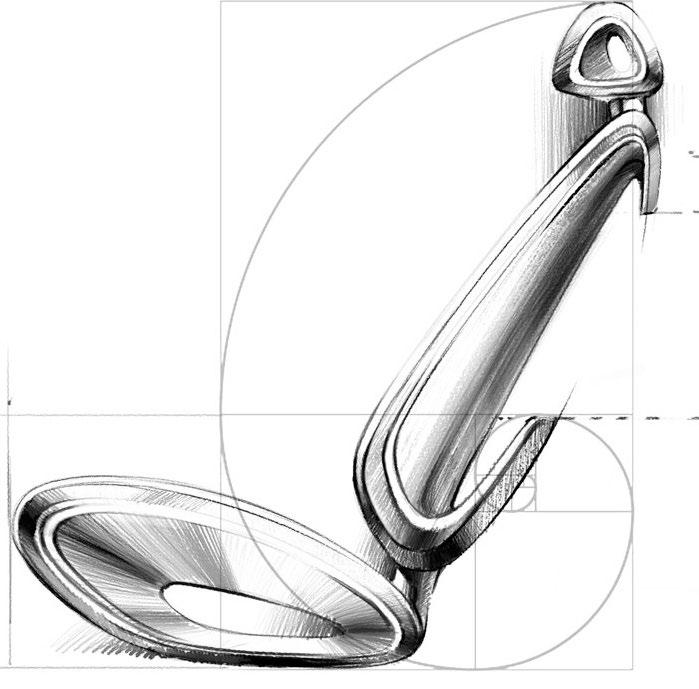

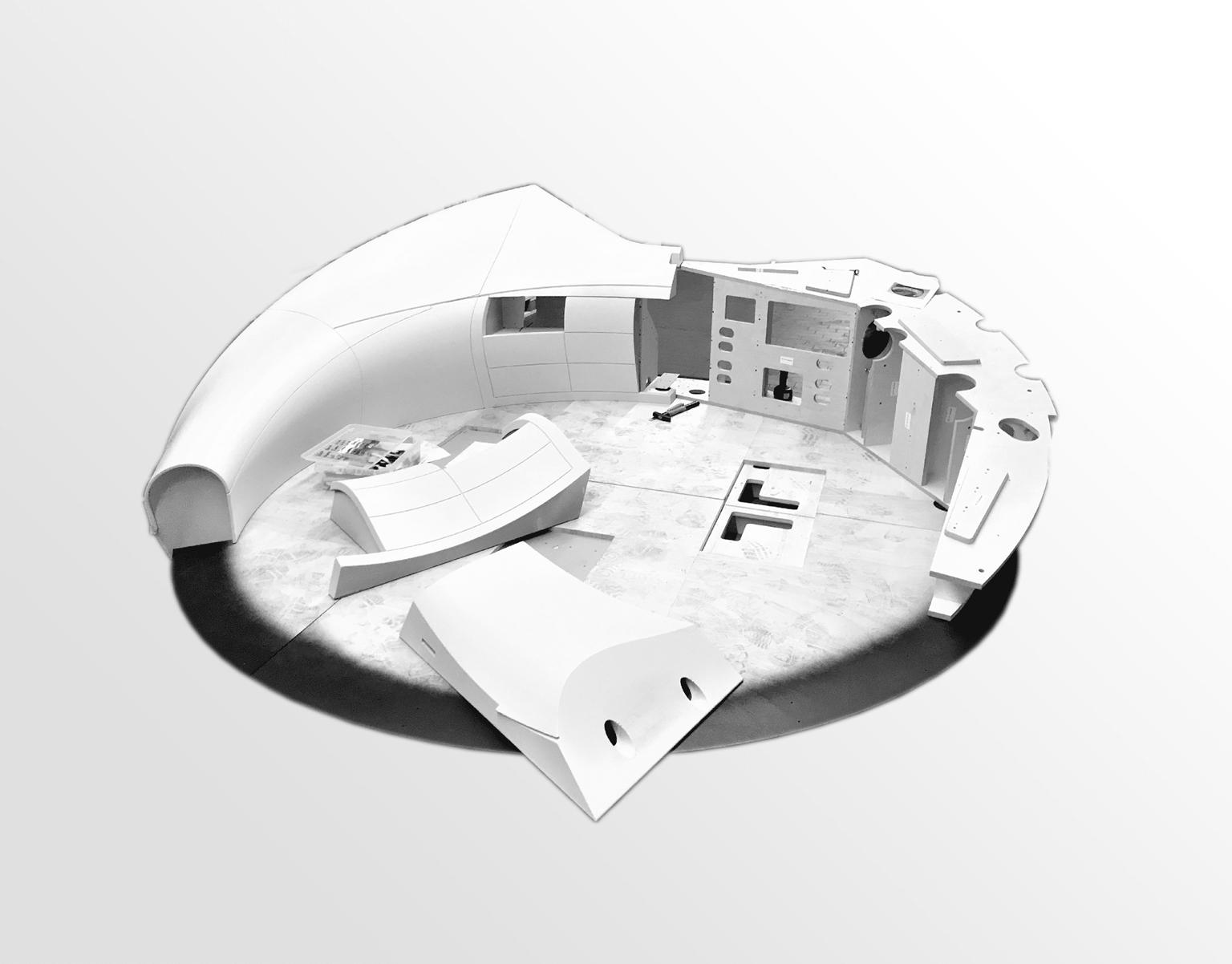

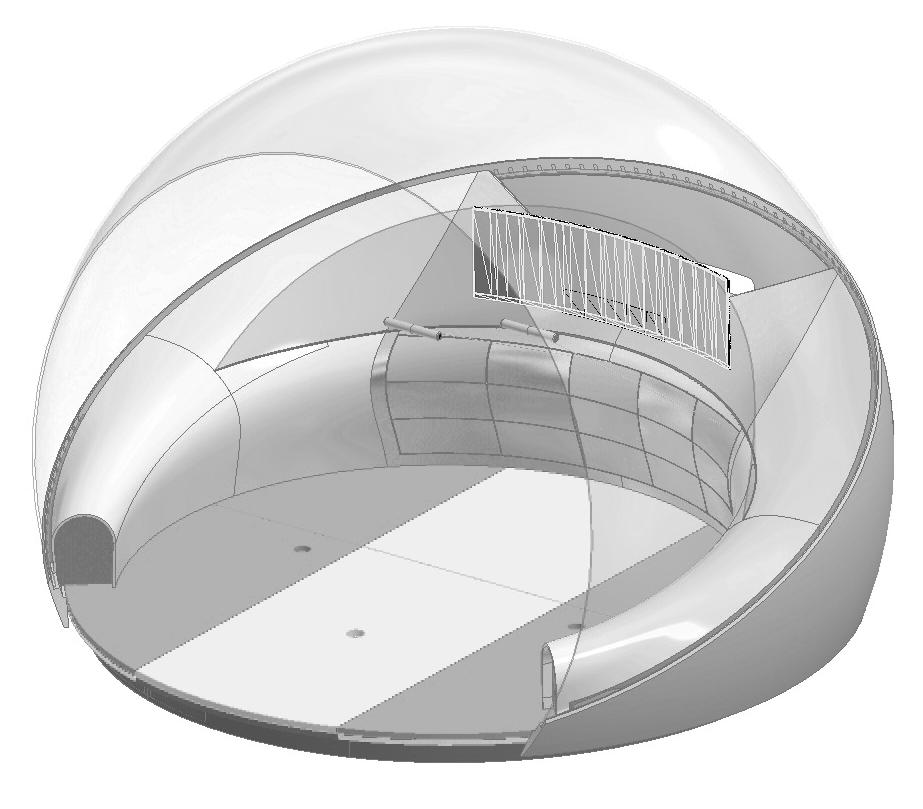

COCOON DESIGN & FABRICATION

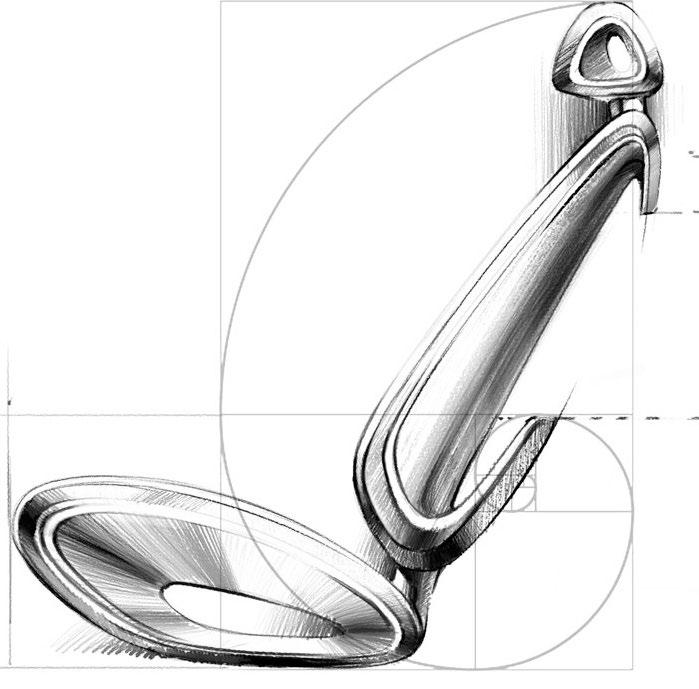

"Hyper-Connectivity" as the key feature to be portrayed here through futuristic mobility cocoons. Each cocoon were to hold 3 people inside and take them on a virtual journey to the future.

For the fabrication, Intensive digital prototyping and simulations were done to design an immersive experience. It was finally 3D printed in parts and assembled in Las Vegas CES 2019.

Console for interaction and control

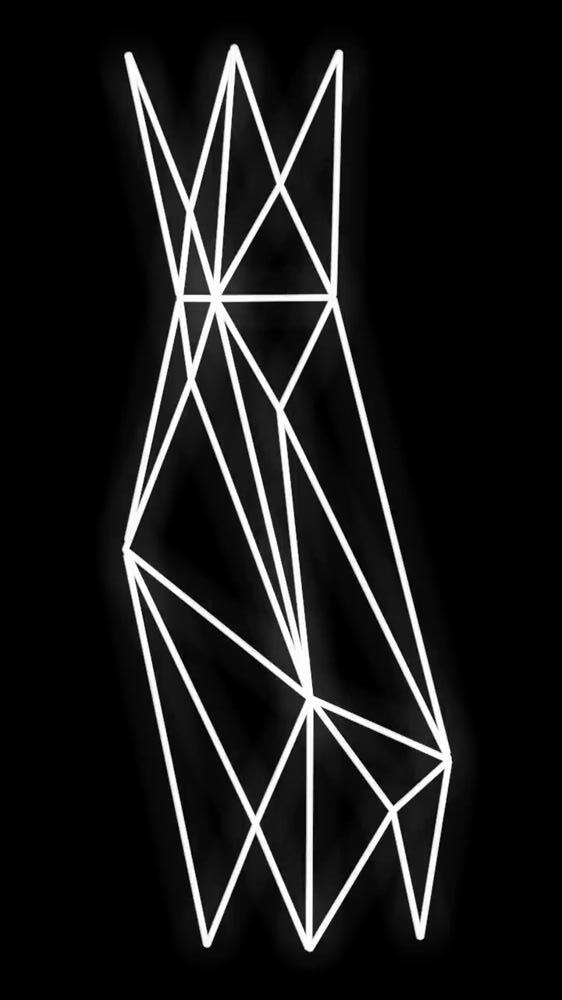

Initial Concept sketch

Acrylic spherical shell ø3000mm

Metal + timber covered base

3D fabrication model of Cocoon

Acrylic spherical shell ø3000mm

Metal + timber covered base

3D fabrication model of Cocoon

Framework built-up Assembly at CES 2019,

The chair being innovatively used by my friends

3d printed Thermoplastic Dashboard

Las Vegas

Latex Cussioning

Acrylic sheet outer shell

Chair fabrication model

HDF support framing

3D printed parts of Cocoon interiors

CONTINENTAL HQ , HANNOVER

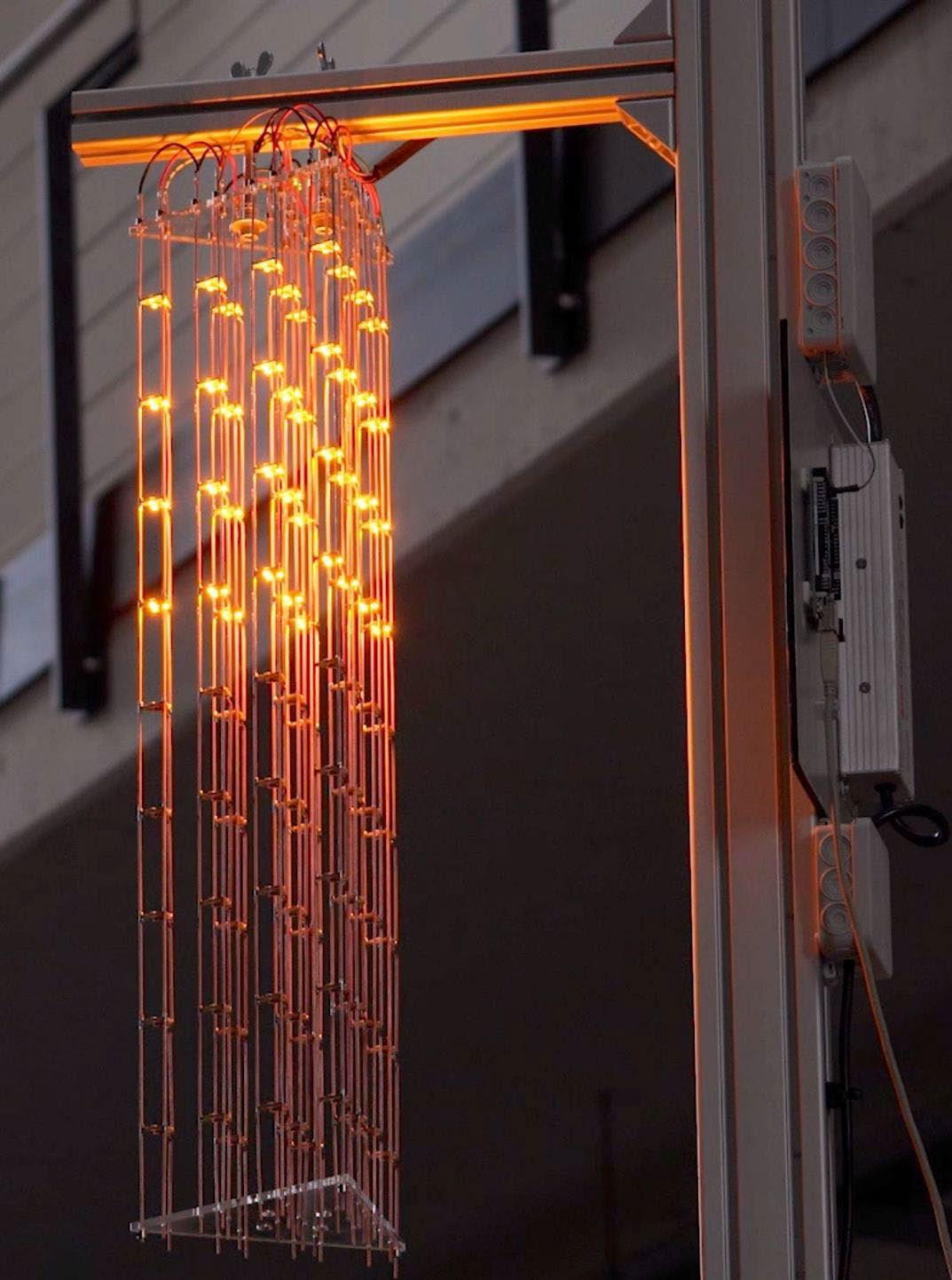

‘STREAM: The Empowering Source

@Uniplan

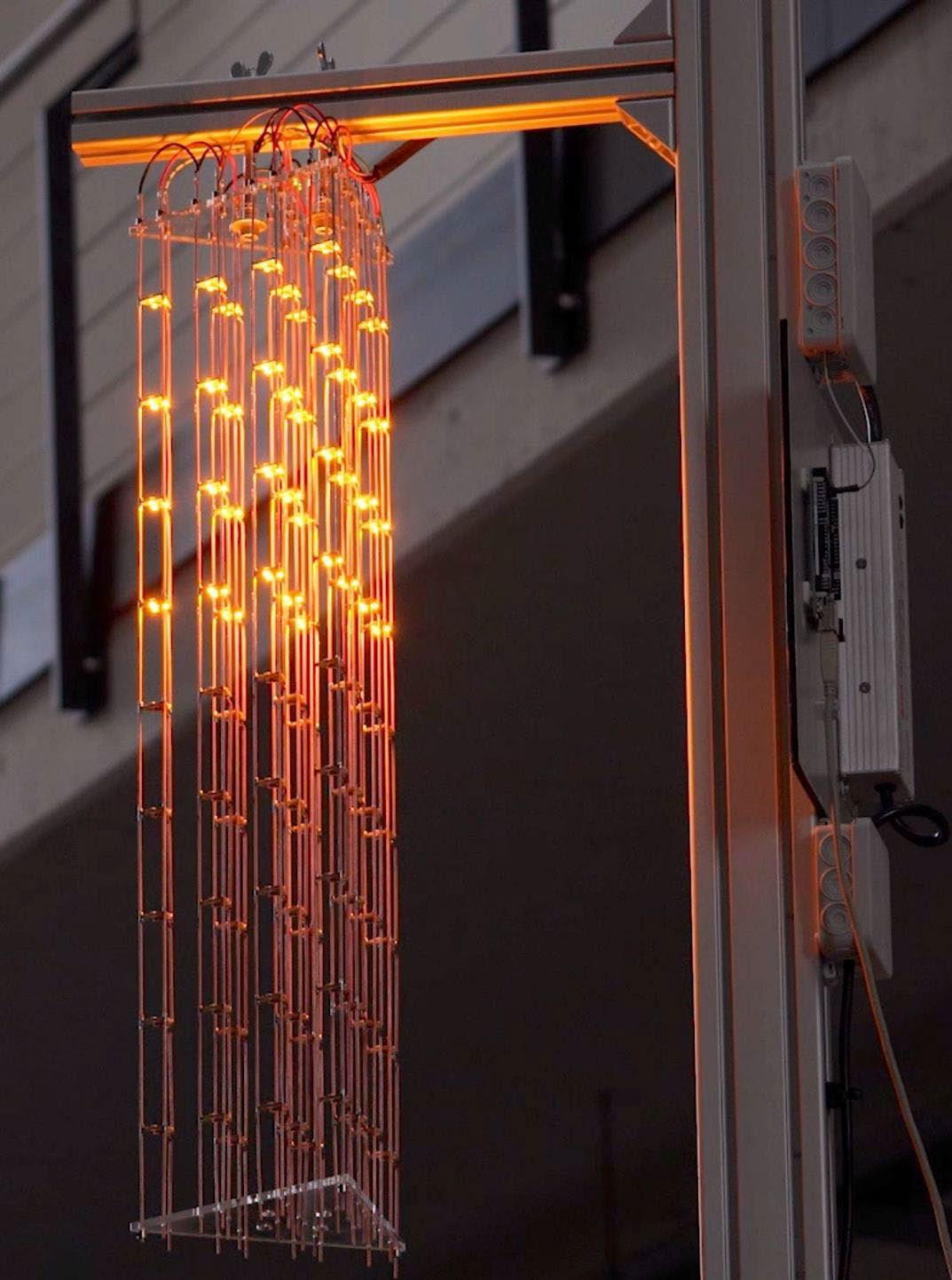

The challenge was to stage the tagline from Continental: Future in Motion – The vision, drive, values, behavior, and standards in one concentrated and emotional expression.

Thus, Foyer space acted as the showcase for the cuttingedge technology and innovation. ‘Stream’ is the flagbearer is the empowering source to the people and spirit of the company. It interacts, empowers and reflect the progress through movement

Involvement :

Foyer area Scenography

Exhibition design and execution

Interaction Design and sensorics

Content Programming for LED sculpture “Stream”

CONTINENTAL AG

ExhibitionRealization Design & Planning

Architect

Creative Technologist

Concept Designer

Project Manager

Digital Technician Media

LED Sculpture

MKT

Technical Fabrication

11

Involvement Matrix

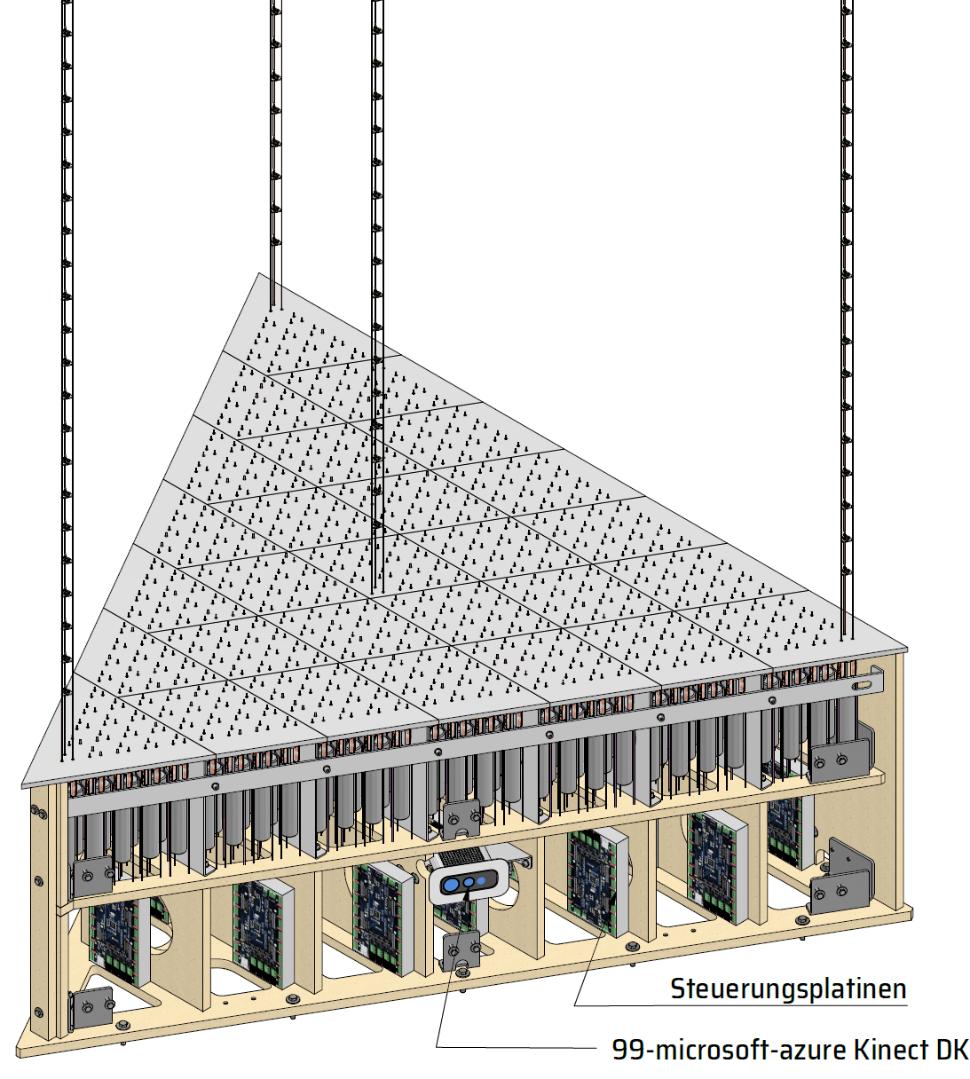

FACTS AT A GLANCE

Dimensions: 10m x 1.5x 1.5m

LEDs: ≈ 370,000

Pixels/PCBs: ≈ 61,000

Max Energy/ hr : 42,6 KW

General usage/Day: 300 KWH (Enough for 1600 KM in an electric car)

Max Brightness: 6000 Nits

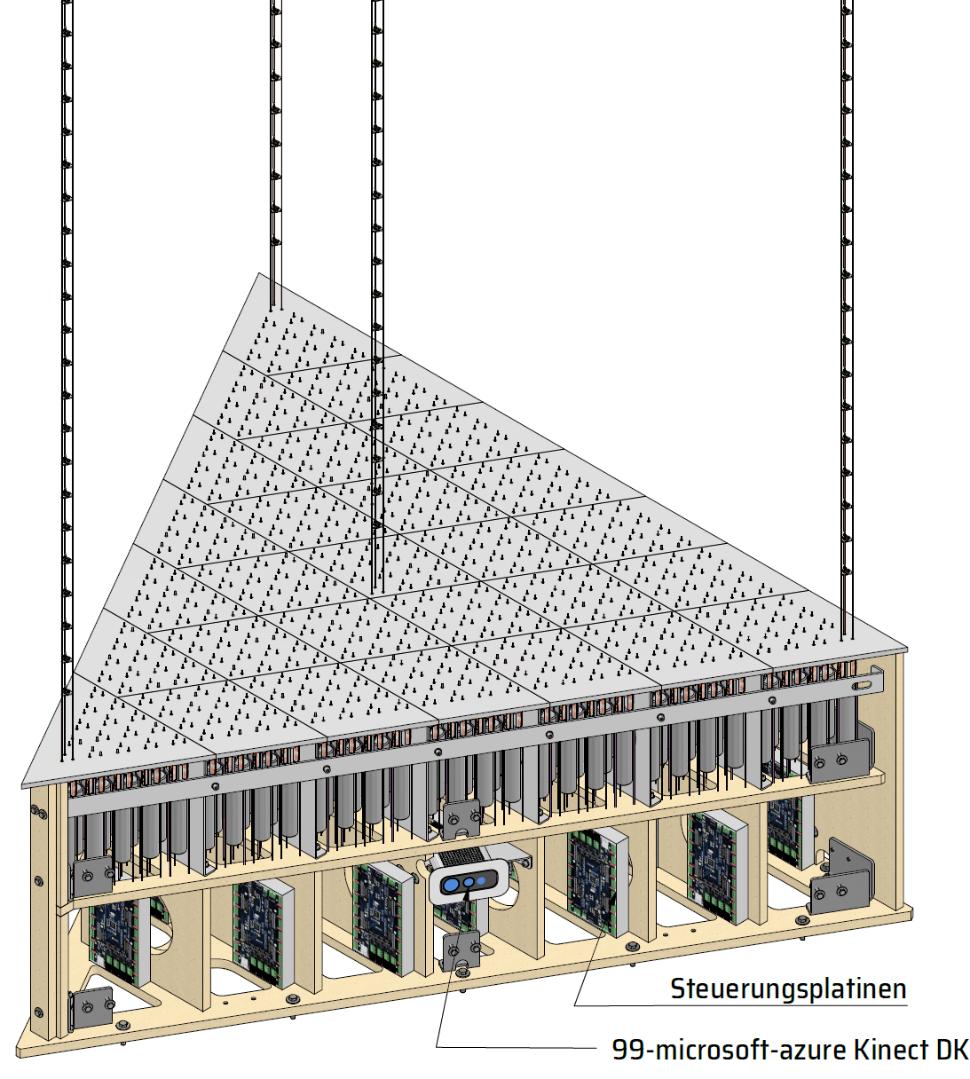

Hardware Apparatus: 496x micro controllers

28x micro computer modules

1x Render Server

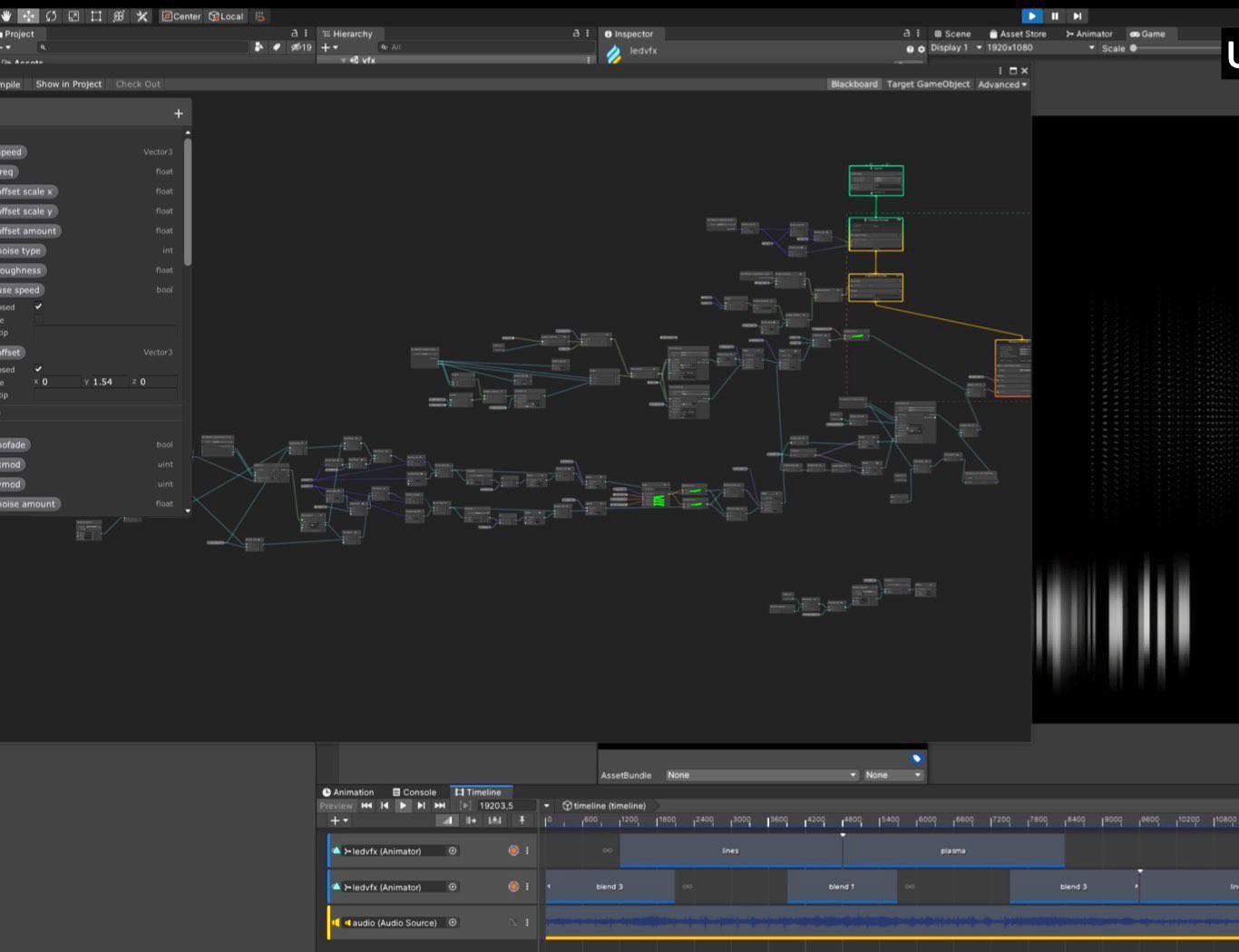

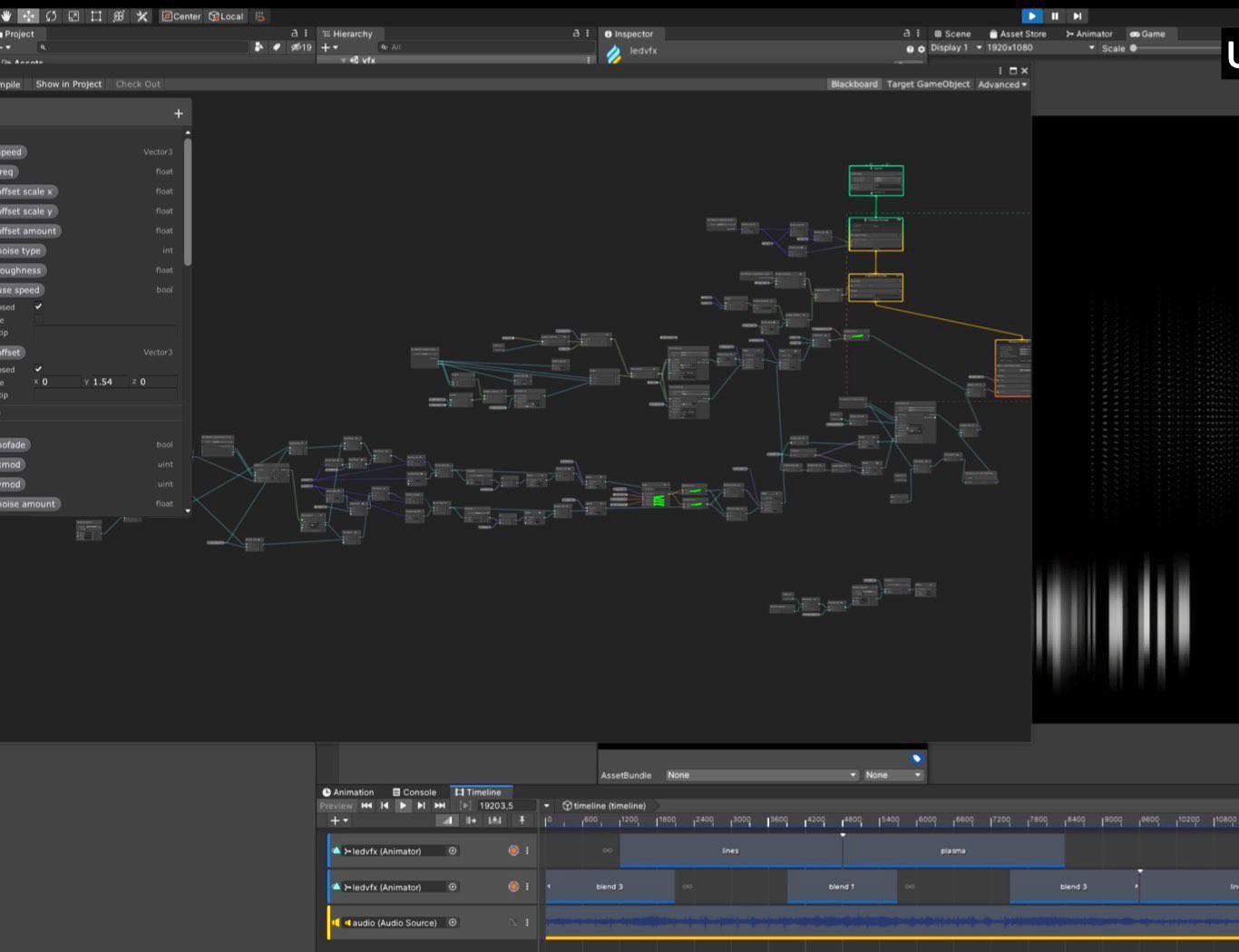

Software Apparatus: Unity Game engine

ARTNET connect

Custom IP protocols

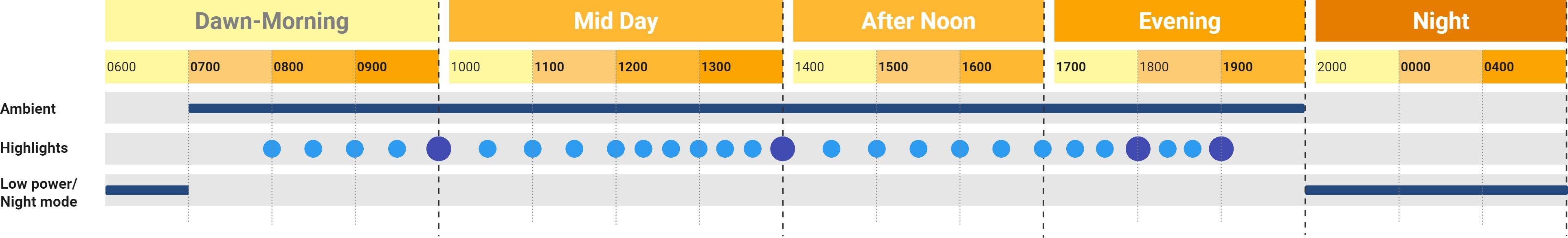

SCENOGRAPHY

The ‘Stream’ being the empowering source, not just has to be a sculpture that mesmerizes its surroundings, but it also must act with a personality, one like an Organism, a Spirit.

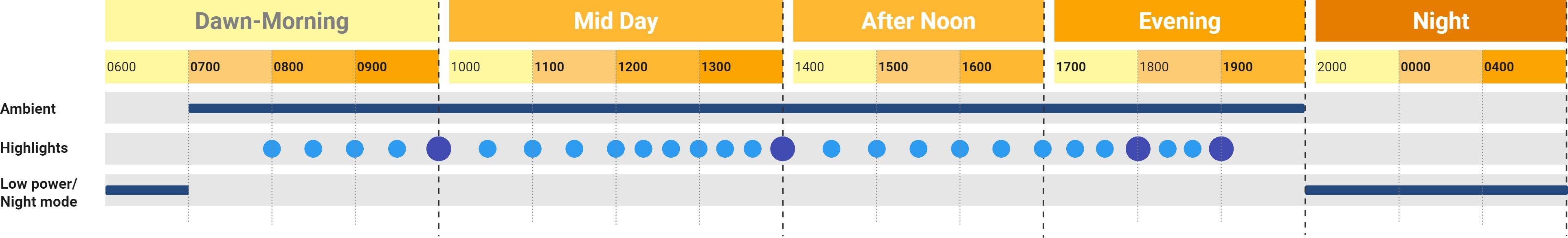

Thus, the scenography needed it to behave differently throughout the day. Starting with a calm awakening to empower itself from the coming visitors and later becoming a charged spirit to radiate the joyful aura by the evening. At night, it again calmed down to a resting state like an organism

Calmness

Empower

Reflect

Rest

Calmness

Empower

Reflect

Rest

INSIGHTS

• Modularization in 28 clusters for better reparability and troubleshooting

• LED PCBs were digitally fabricated in China but all the manual assembly, copper soldering and testing was done in Germany.

• Per wire strengthening with 2kg weights under the base.

• Game Engine VFX system used for creative coding and simulation of a digital twin.

• VFX graph to produce 60 FPS data feed for 61000 PCBs leading to 3.7 million commands each second.

Assembly design-Microcontrollers and Casing Pre-Final assembly at MKT HQ Final Assembly and testing on site with 75% brightness

Test Setup with 540 LEDs

Unity VFX graph and timeline UI

Wire stabilizing weights

RESULTS

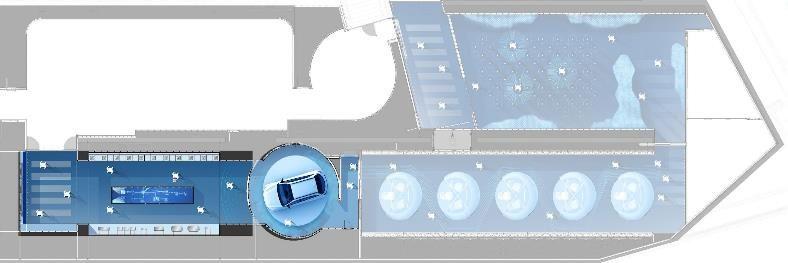

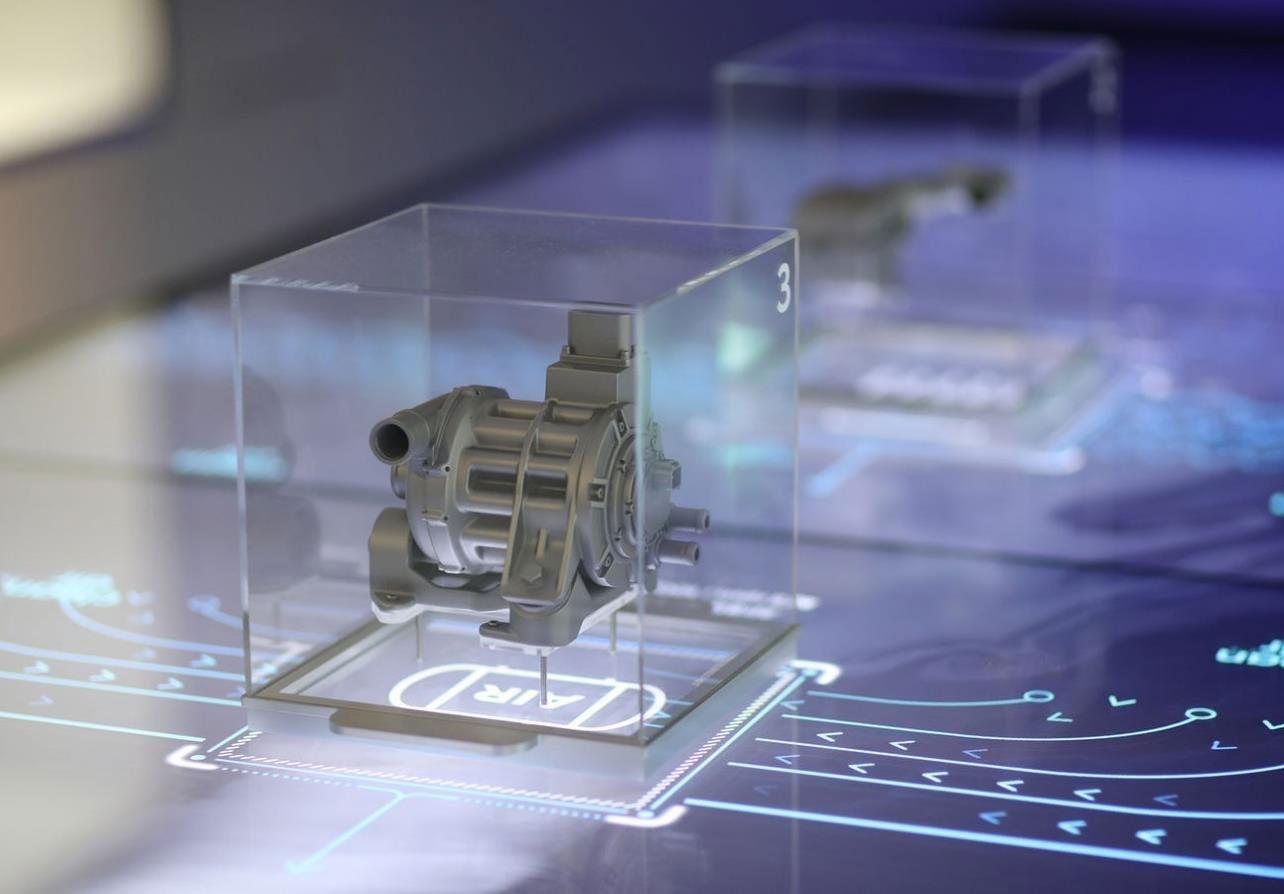

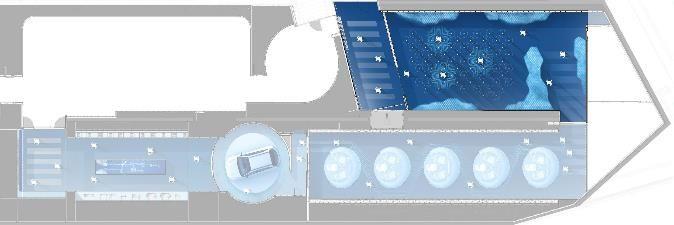

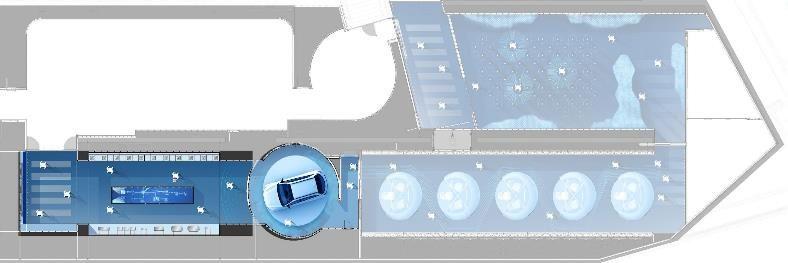

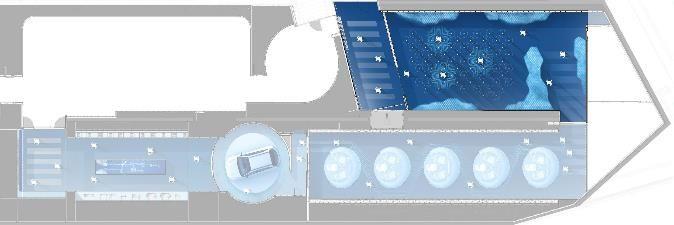

HYUNDAI FUTURE MOBILITY EXPERIENCE, GOYANG

(Motorstudio)

@Atelier Brueckner

Insight into Hyundai’s vision of future driving: The permanent exhibition “Hyundai Future Mobility” takes a look at the current challenges facing humanity in the field of mobility.

Visitors learn about possible solutions and deal with alternative drive technologies, for example. The conclusion and highlight of the exhibition is a darkened room with 73 luminous pendulums hanging from the ceiling. With the help of sensors, they recognize the movements of visitors and avoid them. This is how new paths are created.

Involvement :

Scenography and Schematic planning User experience design

Fabrication & 3D prototyping mechanical parts

Storytelling and content development

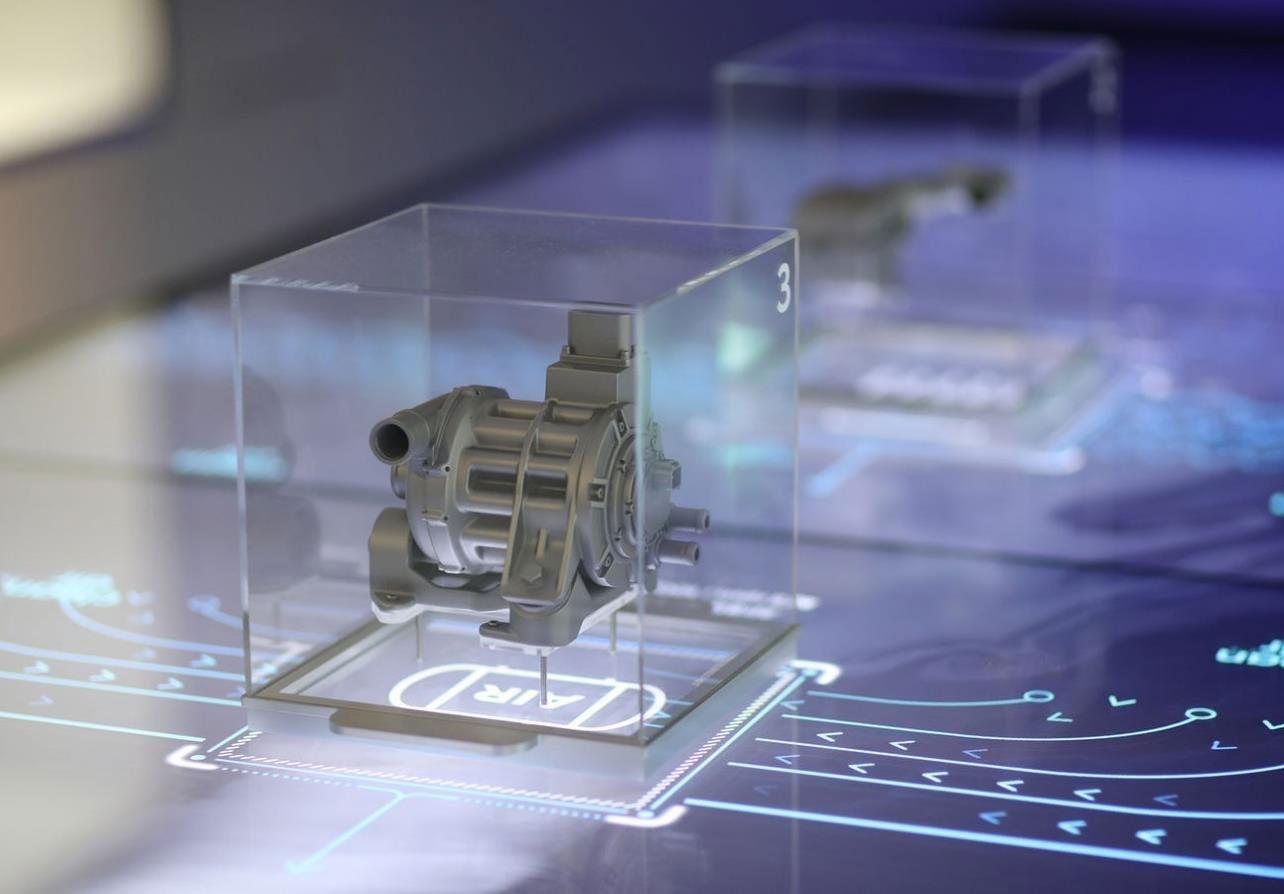

"Lab" experience allows visitors to assemble a miniature hydrogen fuel cell with 3d printed parts on an interactive media table Interactive elements in showcase

3D printed Interactive element on media table

Project Manag er Communication Designer Media designer Formnext 3D printing TransSolar Smoke tech Congaz Content/Film production EasyWith 3DP & Fabrication Hyundai Motor company Exhibition Architect FUEL CELL LAB

Fuel cell Lab with 3d printed media exhibits

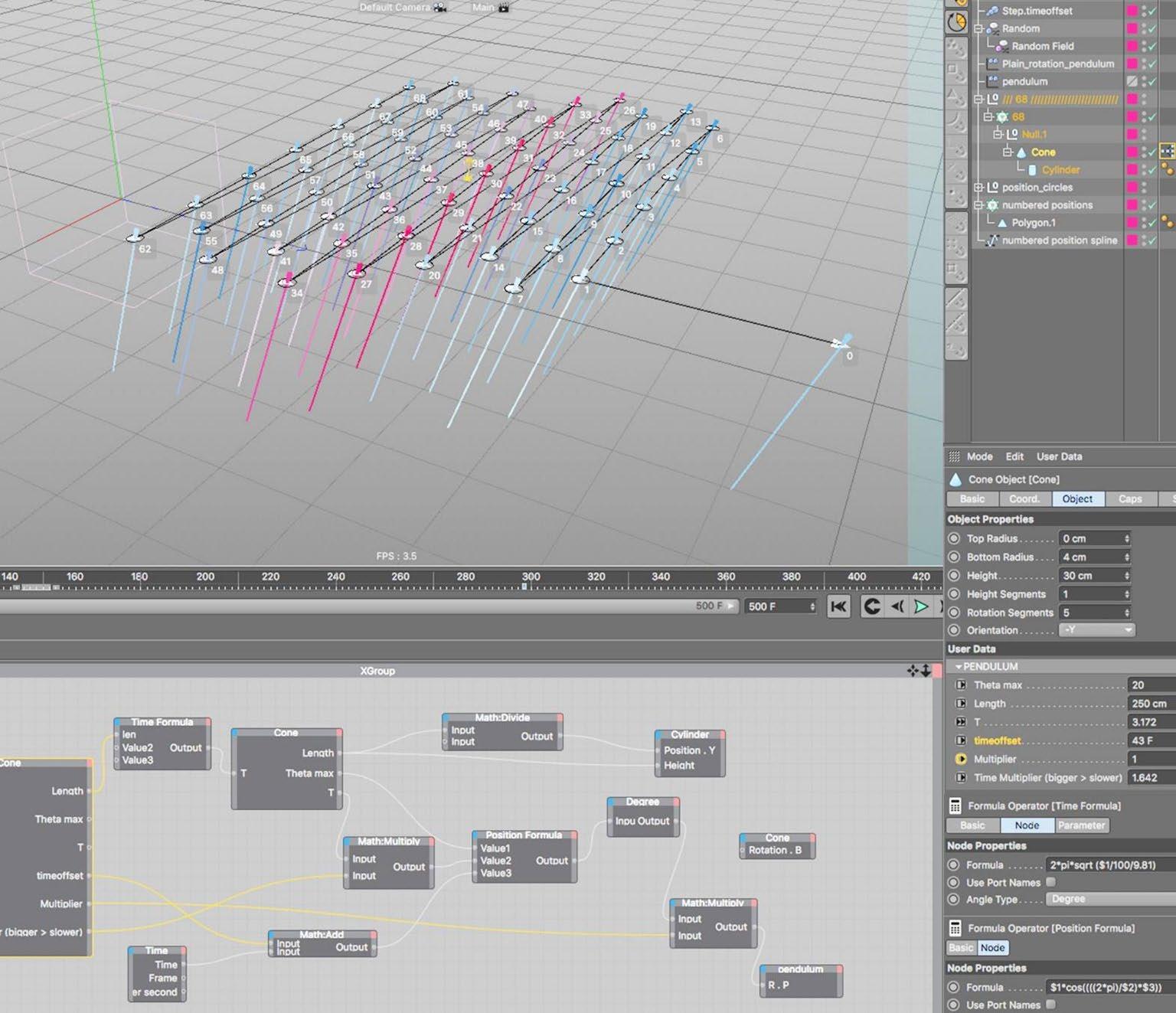

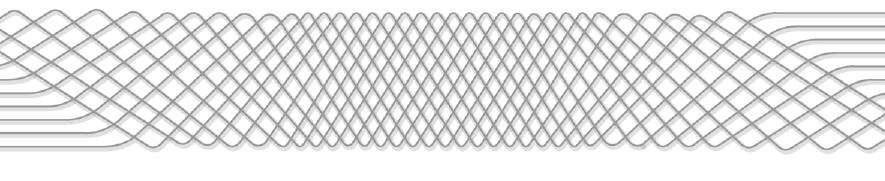

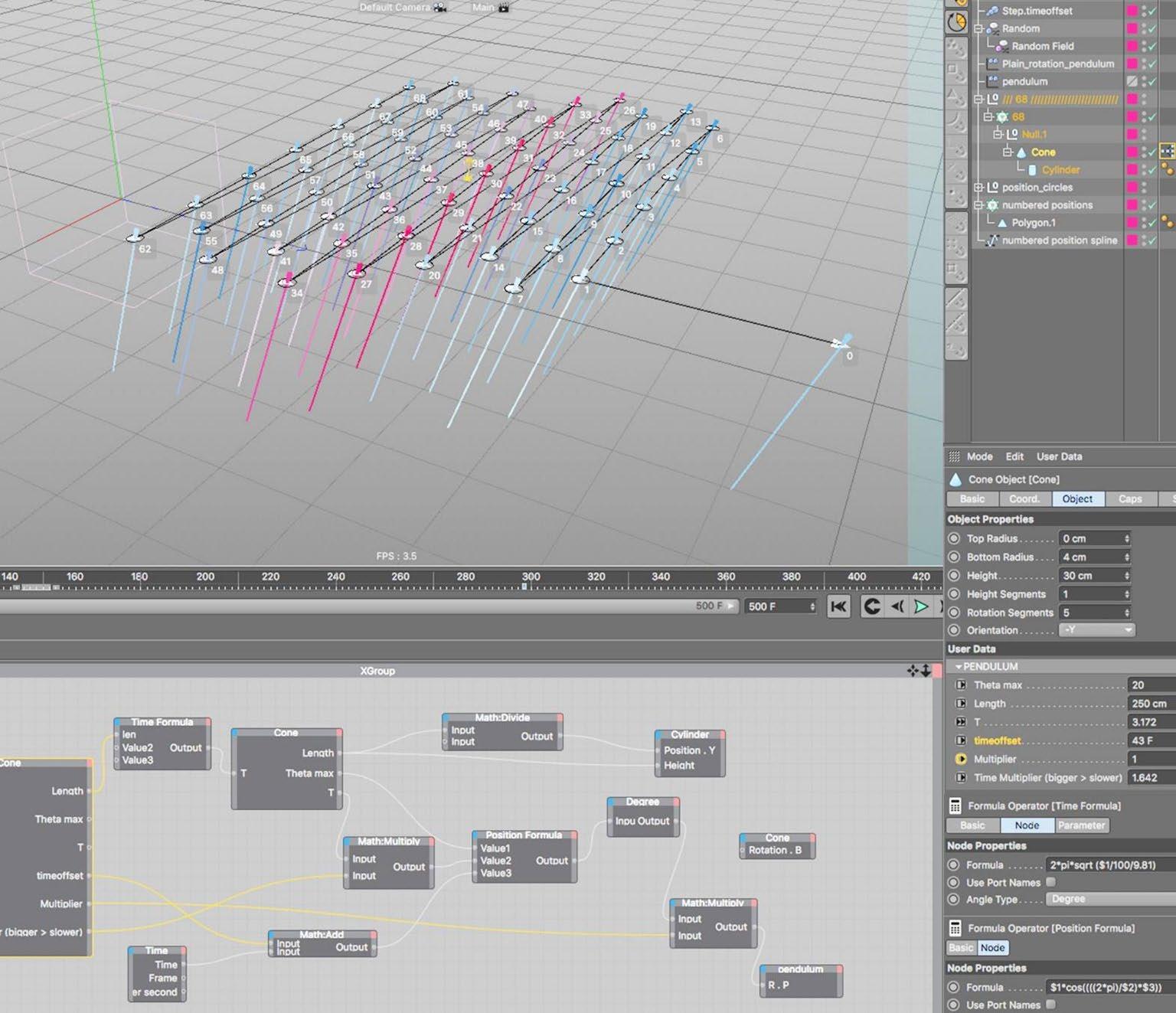

KINETIC SMART FIELD EXHIBITION

Smart Field Experience showcases the collaborative awareness and connectivity of the Hyundai future mobility vision.

Oscillating pendulums are portrayed as a manifestation of Future Mobility. Visitors pass through this field of light sticks to experience connectedness and responsiveness of upcoming transporters. The space has Lidar motion mapping to detect the presence allowing the pendulums to avoid contact with the visitors and collectively make a way to walk through them Digital simulations were programmed before prototyping with 1:1 working models in Korea.

Pe Realized Project in Goyang

Motion assembly prototype

Omnidirectional socket

Working prototype assembly

Bi-directional Motorbox Embedded LiDAR Trackers Safety framing to calibrate motion Diffuser Light tube Processing unit connection

Prototype I

Exhibition planning

Procedural programming to simulate the movements

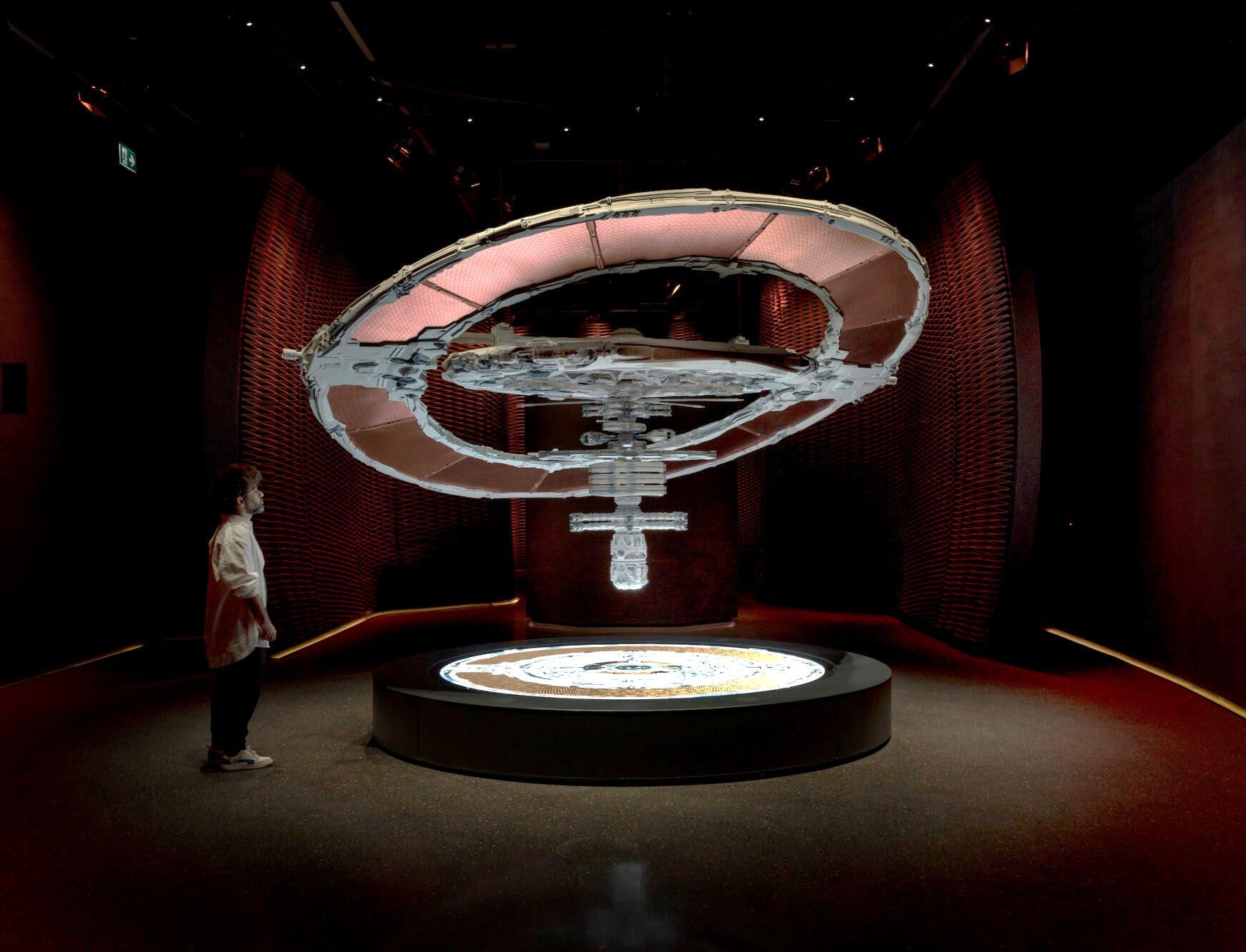

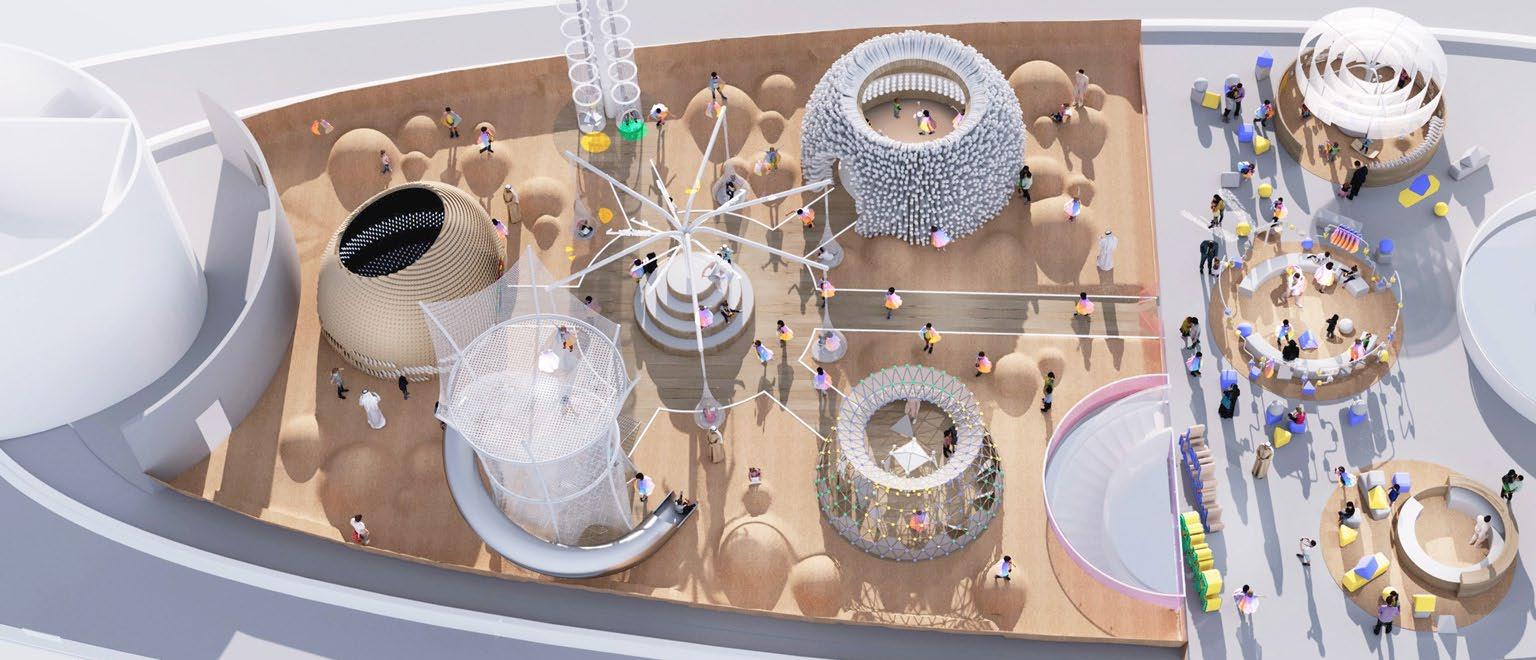

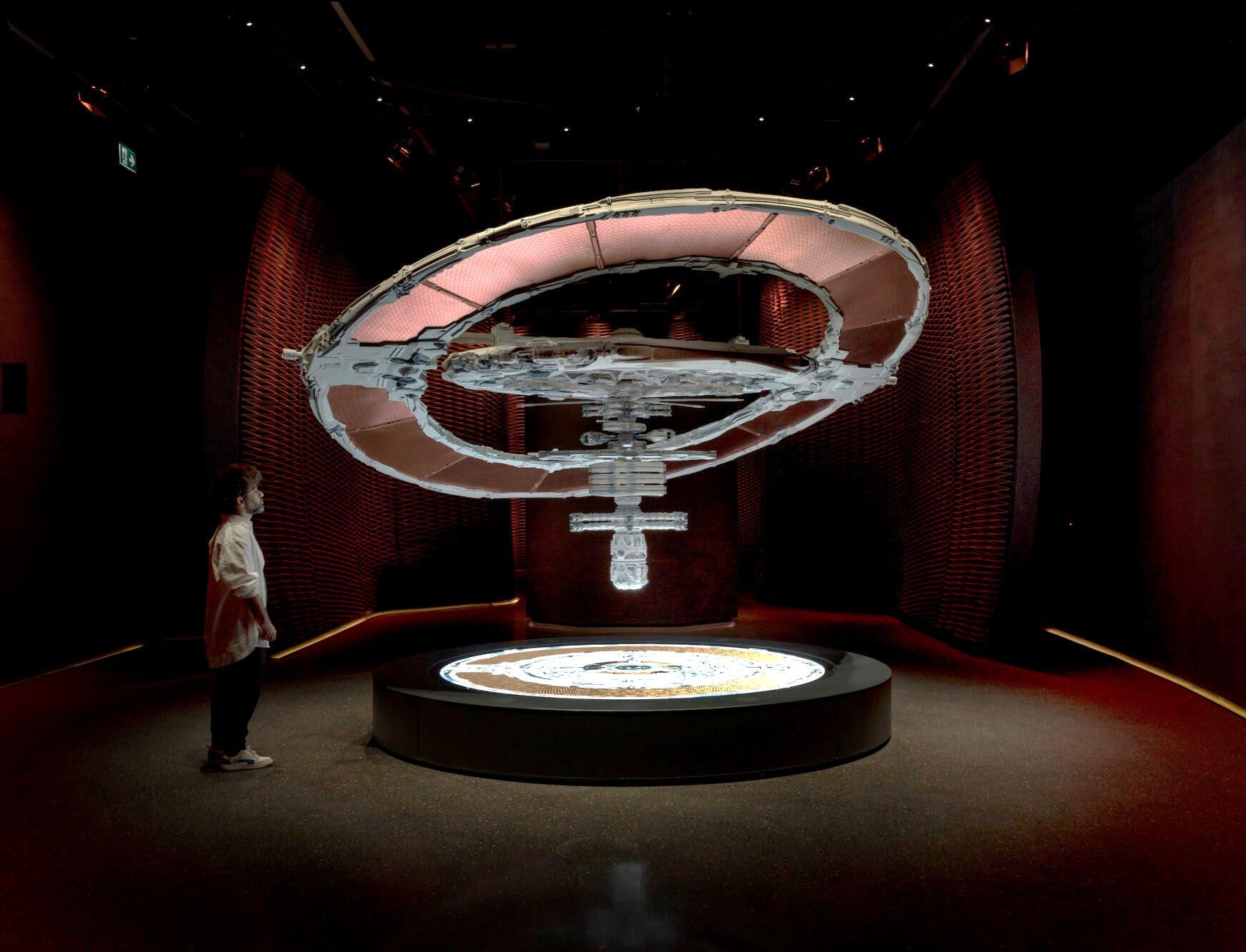

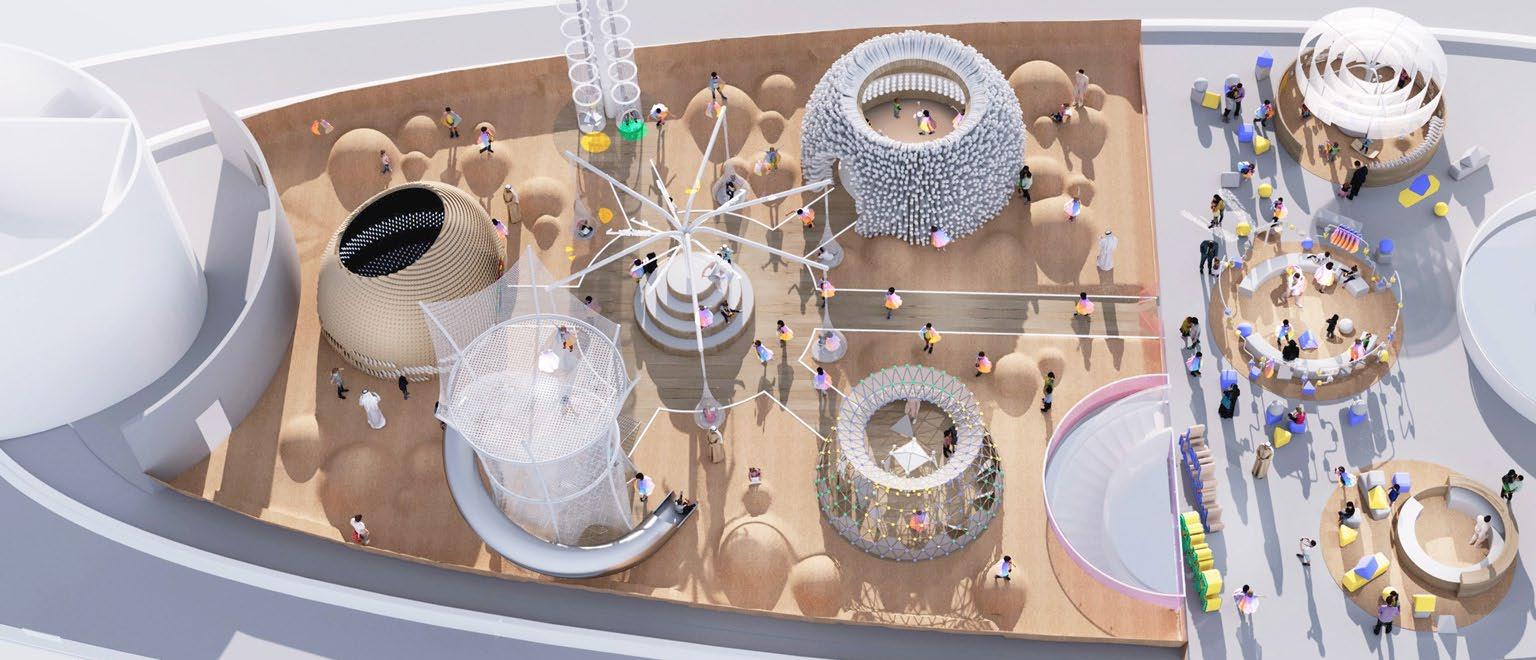

MUSEUM OF THE FUTURE, DUBAI

(Dubai Future Foundation)

@Atelier Brueckner + Killa Design

The Museum of the Future is envisioned to be a permanent home for the world’s greatest innovations and works to stimulate and incubate imaginative solutions to the challenges of future cities. The creative content for the Museum is spread out on 7 floors over an area of approximately 12,500 m2 and offers immersive experiences.

Involvement:

LEVEL 5 / Orbital Space Station - Computationally Designing the incubation space and shuttle experience. Arrival space to match futuristic Space theme

LEVEL 1 / Future Heroes - Generative design exploration of exuberant landscape to thematize surprise and playfulness.

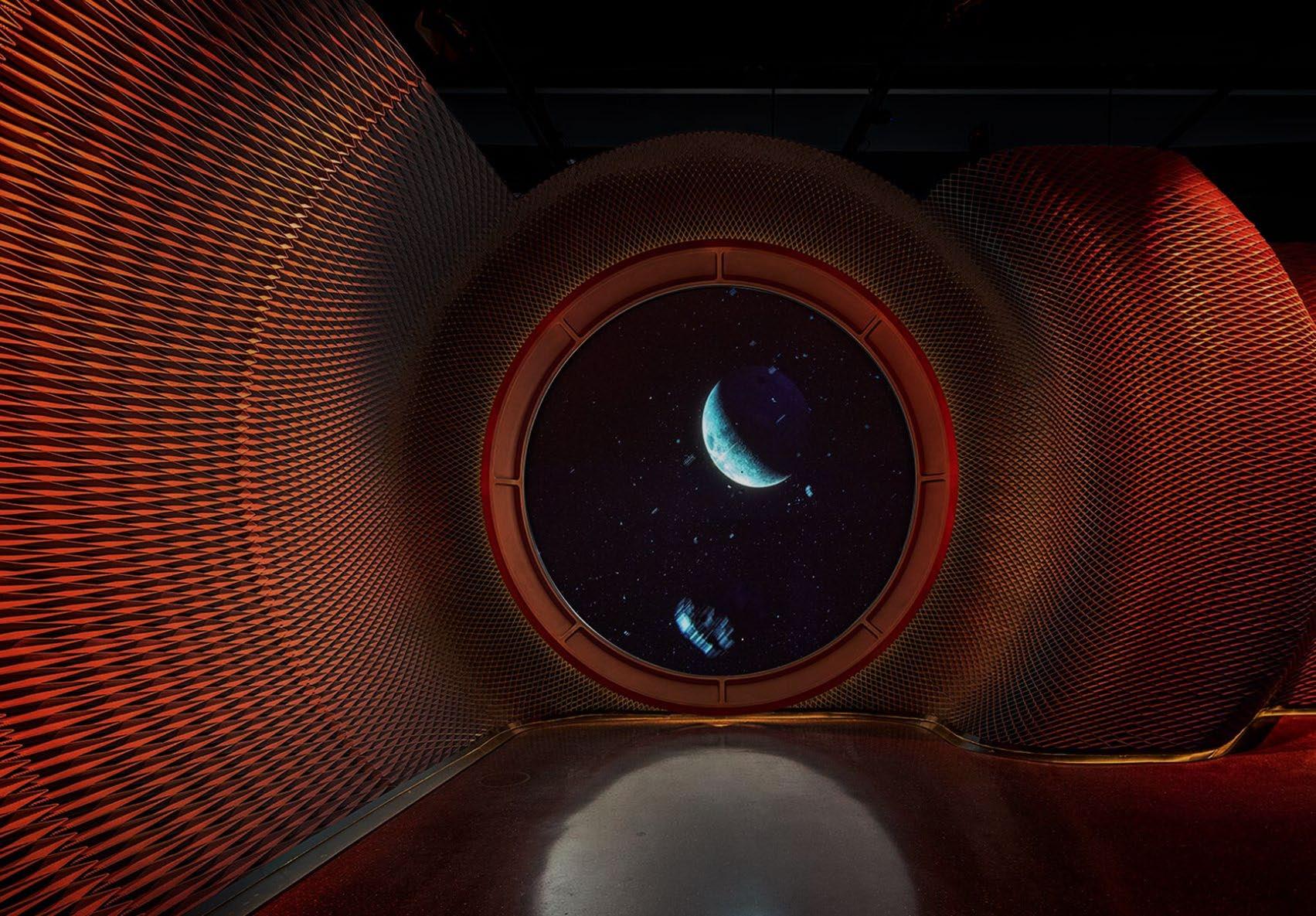

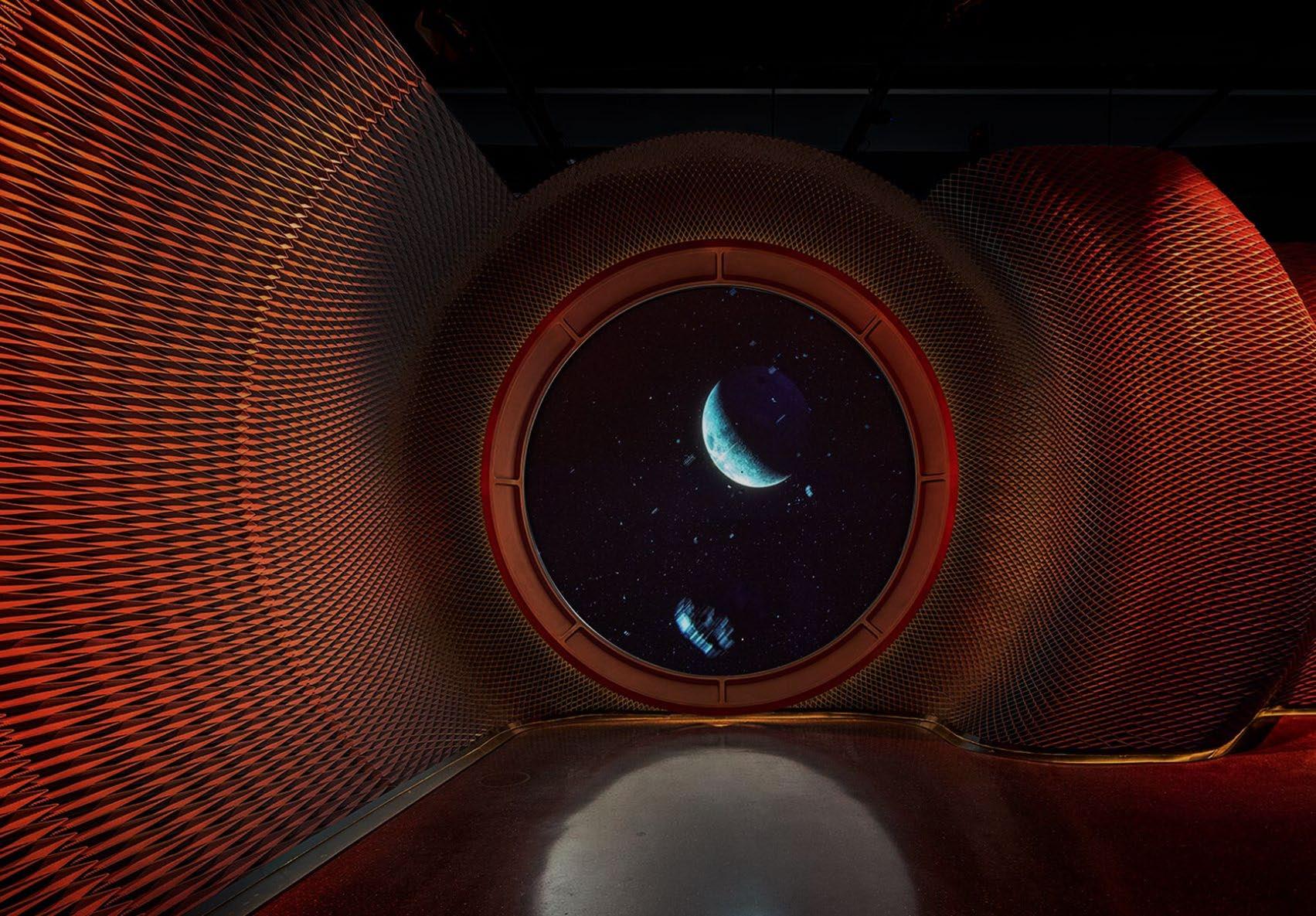

LEVEL 5: Orbital Space Station H.O.P.E

Orbital Space Station H.O.P.E. is an ambitious inception from NASA and Dubai future foundation. It is going to be the intermediate point of approach for Mars' human settlements.

Computationally Designing the incubation space and shuttle experience. Arrival space to match futuristic Space theme

DESIGN-FAB. STRATEGY

To simulate the space station Aura, Level 5 has been encased in this hyper-futuristic theme.

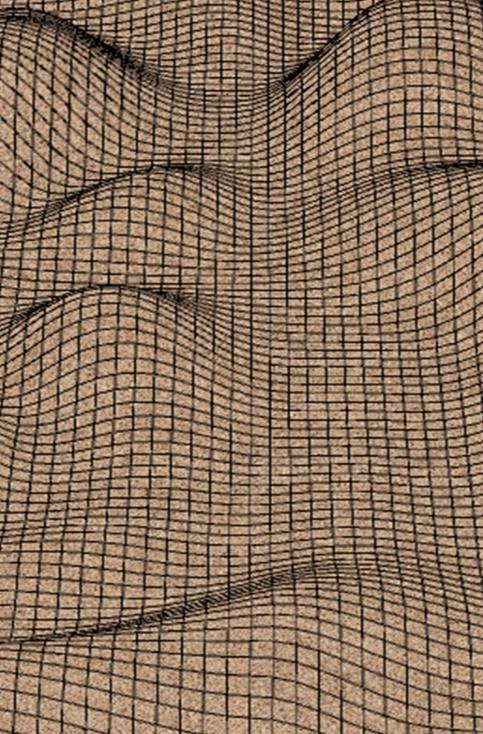

Exhibition floor is thus presented as a unifying gesture that gives an understanding of the Outer space. The idea was to test simple recyclable materials with future technologies to simulate the prerequisites of inter-planetary human settlements.

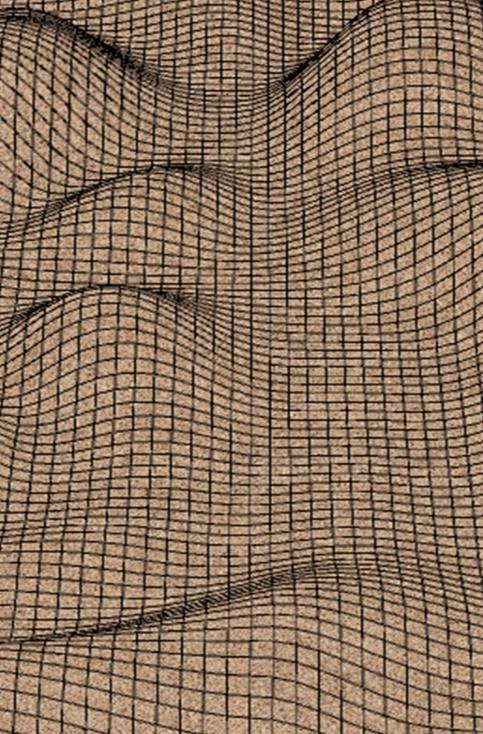

It required test of various geometric patterns by digital production process to find the best possible pattern for undulating geometry and light opacity. Further 3D Printed samples were tested for feasibility and overall look and feel in the space

Inspiration Material Implementation by Aectual

Opaque

Overview Zone covered in custom weaves

Variating wall patterns at OSS deck overlooking earth

Tested Prototypes of Layered 3D printed pattern for internal partitions paneling

Transitions Weaved structure windows Transitions Weaved structure windows

Layered 3D printed structure, for internal partitions/neutral backgrounds

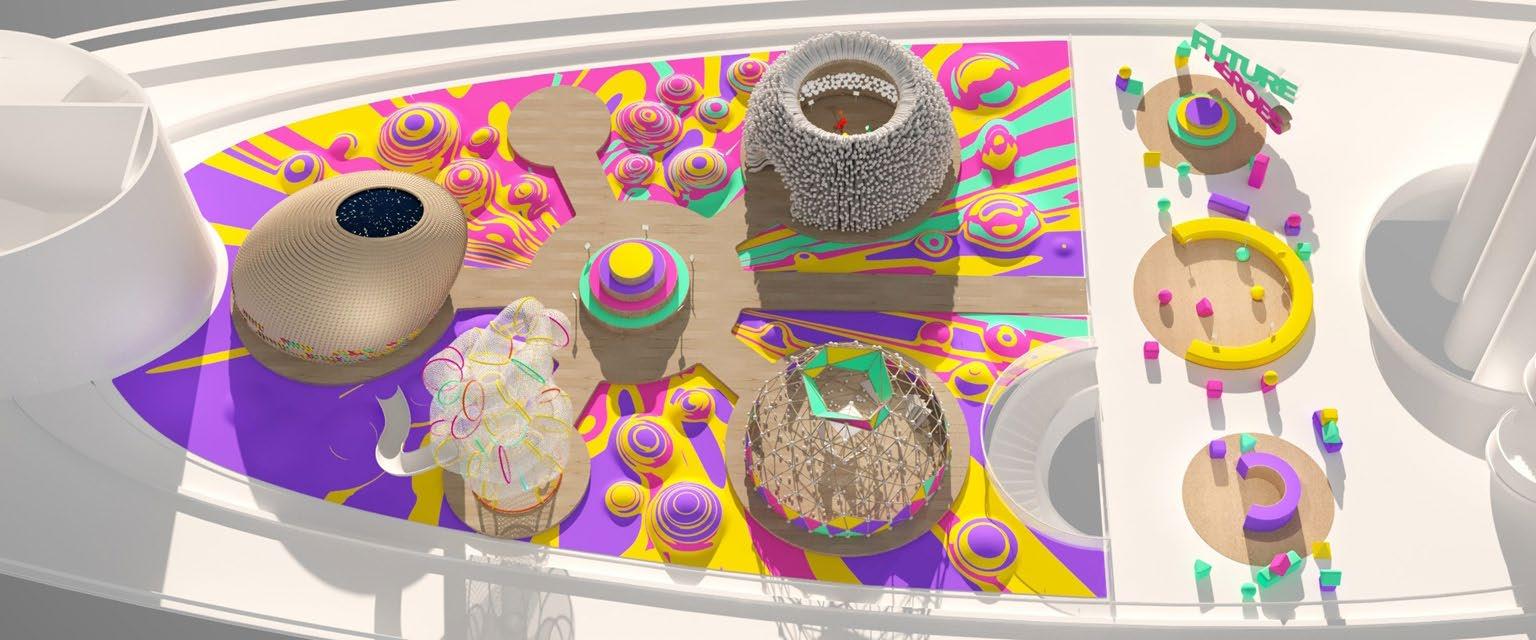

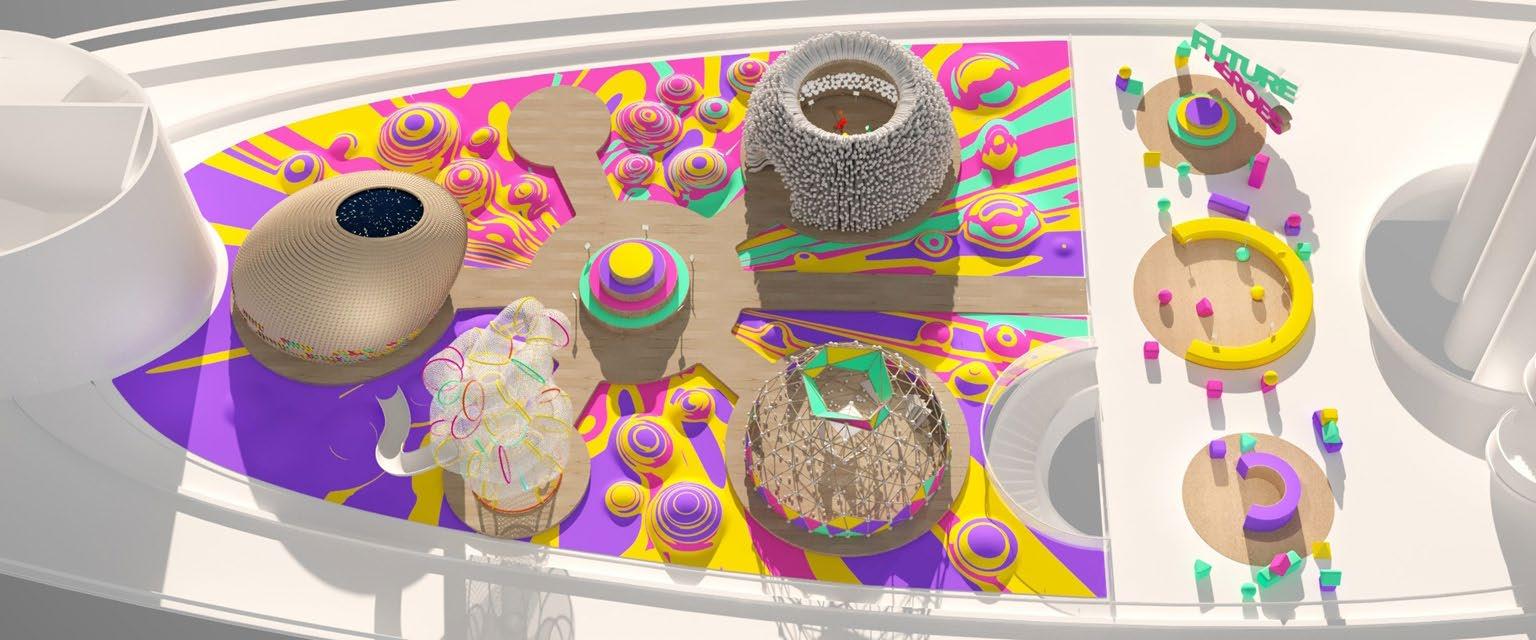

LEVEL 1 / Future Heroes

Generative design exploration of exuberant landscape to thematize surprise and playfulness for children

Fabrication-coordination of Special surfaces and metal structure

Project Manager Buro Happold Construction Communication Designer MKT Technical Fabrication Kompan Playground Experts Dubai Future Foundation Exhibition Architect ExhibitionRealizationArchitecture Design - Fabrication Involvement Matrix

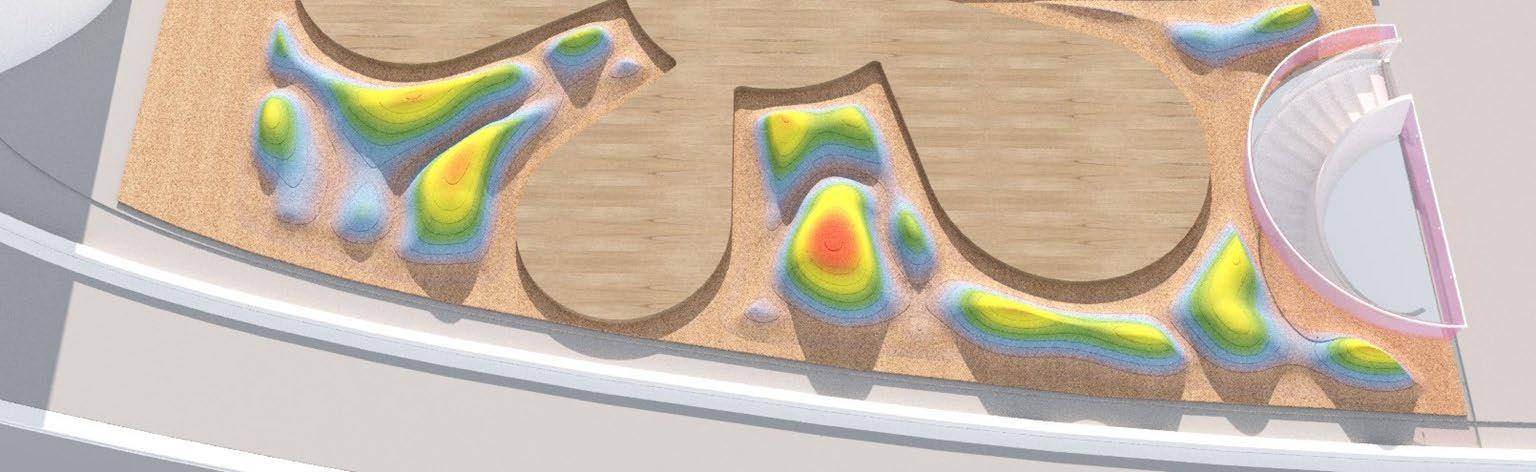

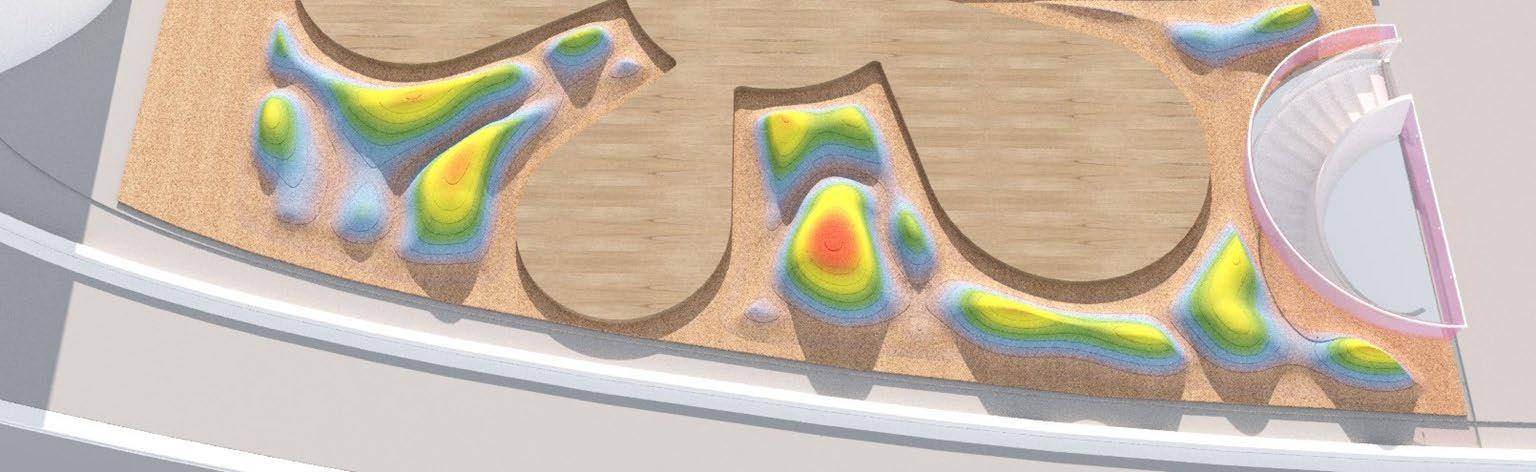

LEVEL 1. FUTURE HEROES PLAYSCAPE

The Floor of the Children a.k.a Future Heroes is a space where children unleash their Imaginations to design and build future skills. It is a proactive space emerging out of fictional or otherworldly landscapes.

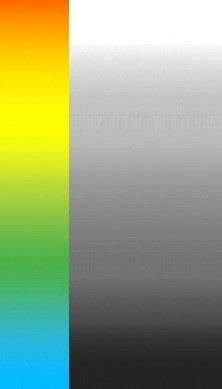

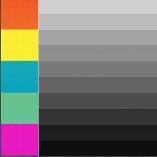

The objective was to explore the right design aspects like Dynamism, Safety, Zeal- Surprises and Material Feasibility To achieve these goal pour-in rubber flooring was shaped procedurally, a shader-based geometry effector approach was tested in different combinations layered with color mapping

SHADER based on grayscales

PLAIN

POINT EFFECTOR only for Z direction

EFFECTED GEOMETRY lighter regions rise in Z direction

Wave shader + Linear rainbow color mapping

COLOR MAPPING color associated to grayscale GEOMETRY

Boundary

Hump

Command

+ Custom contour shader

Generative bump shader

+

FINAL DESIGN

Custom contour shader

Linear

band color mapping

height of 1100 mm

range 3001000mm in height

center structurally attached to the landscape

with slide ending at flat landscape zone 1m offset from stairwell for safety

made by shader overlapping

Climber

Seating

+

Custom contour shader

Turbulent color mapping

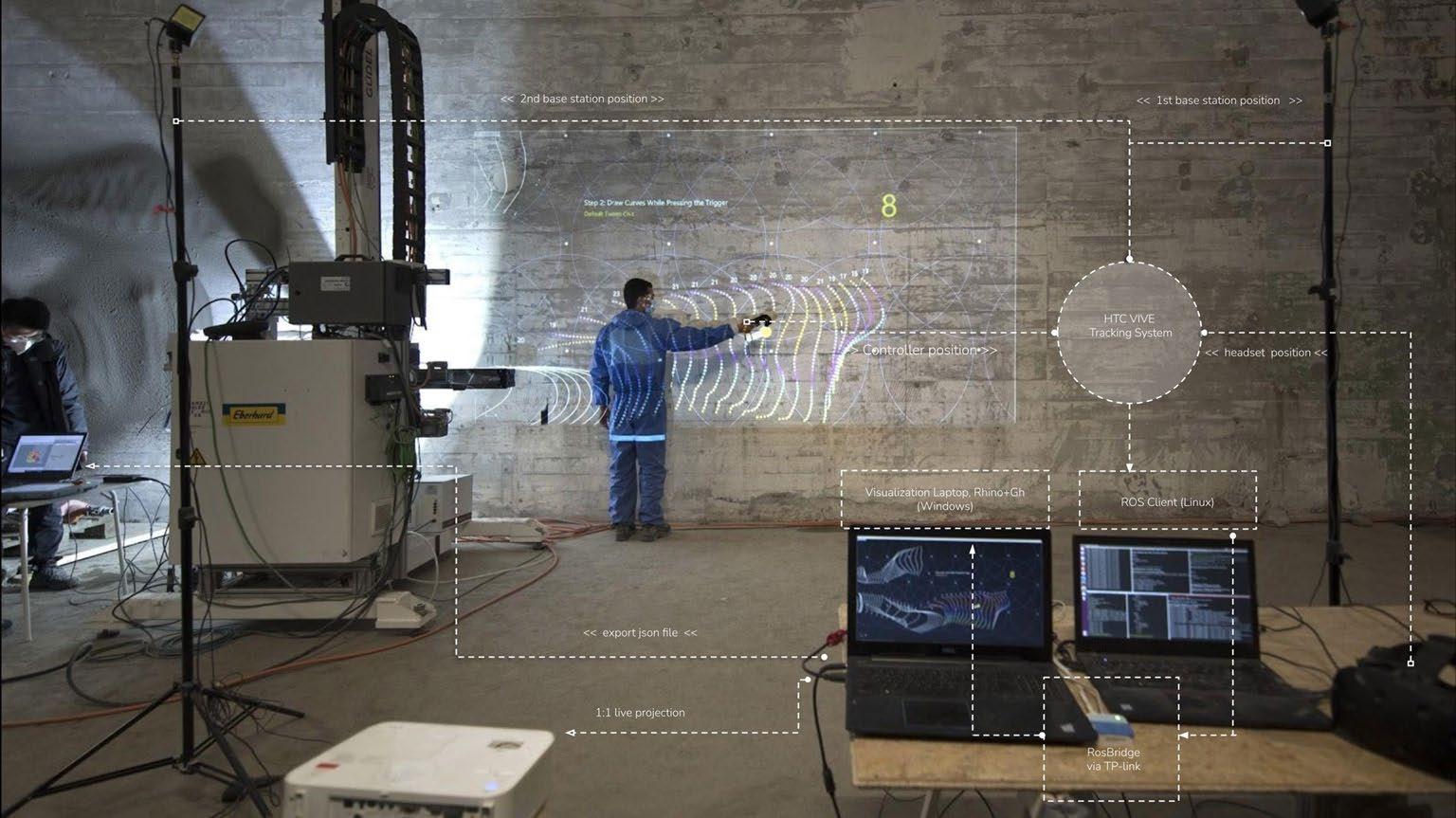

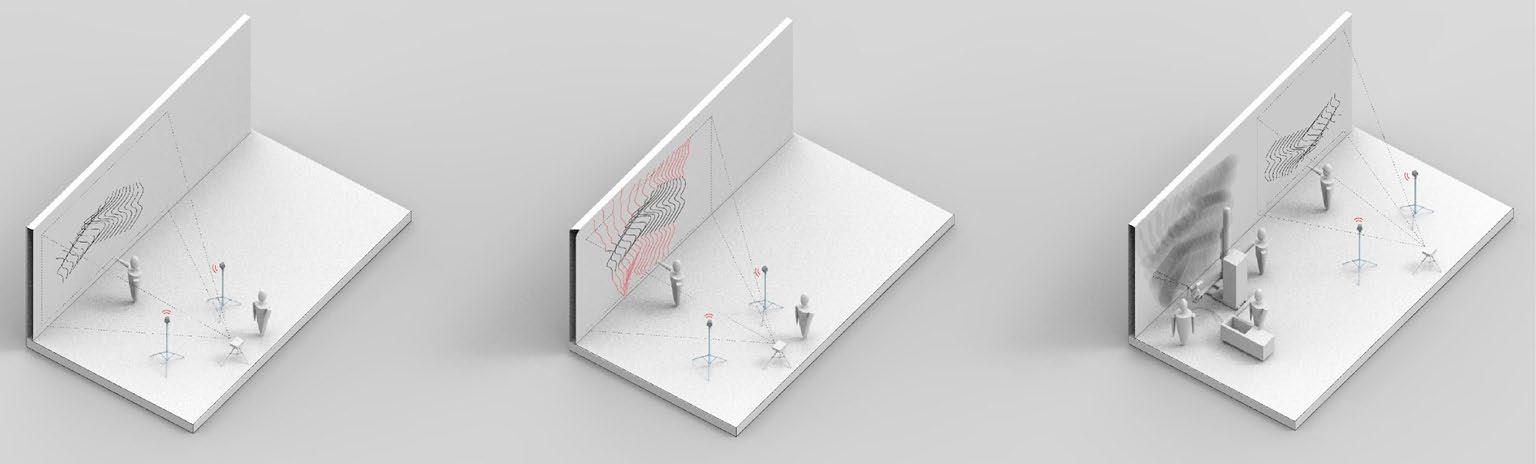

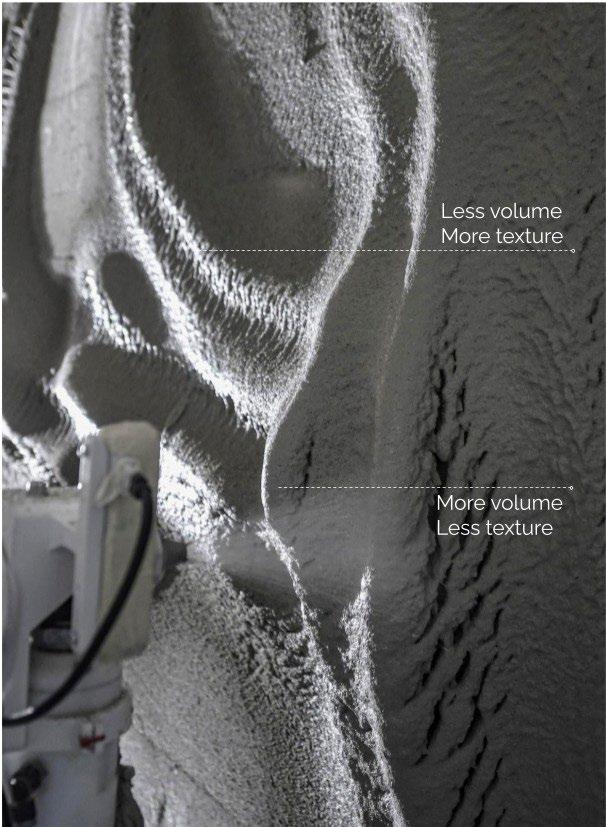

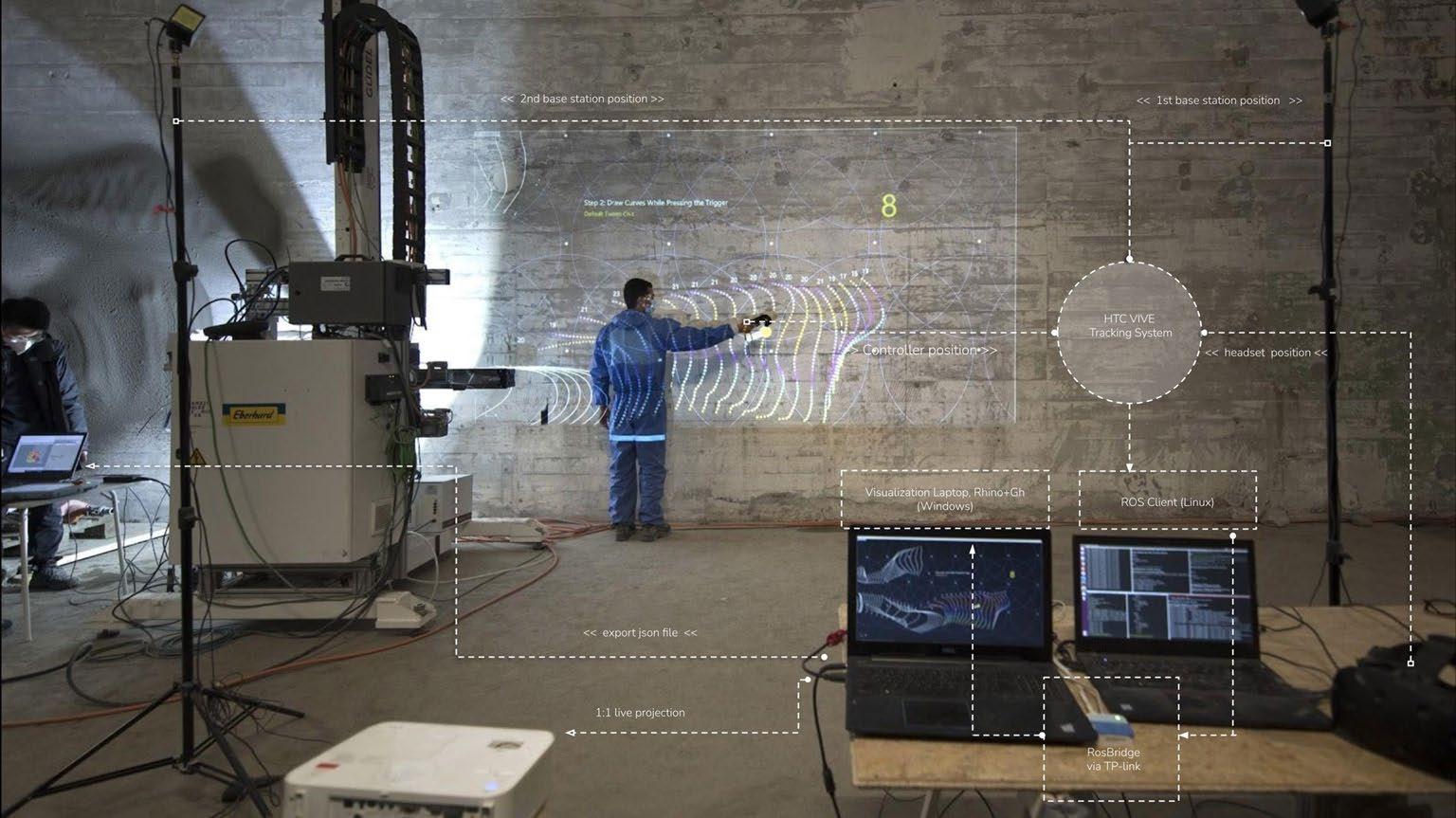

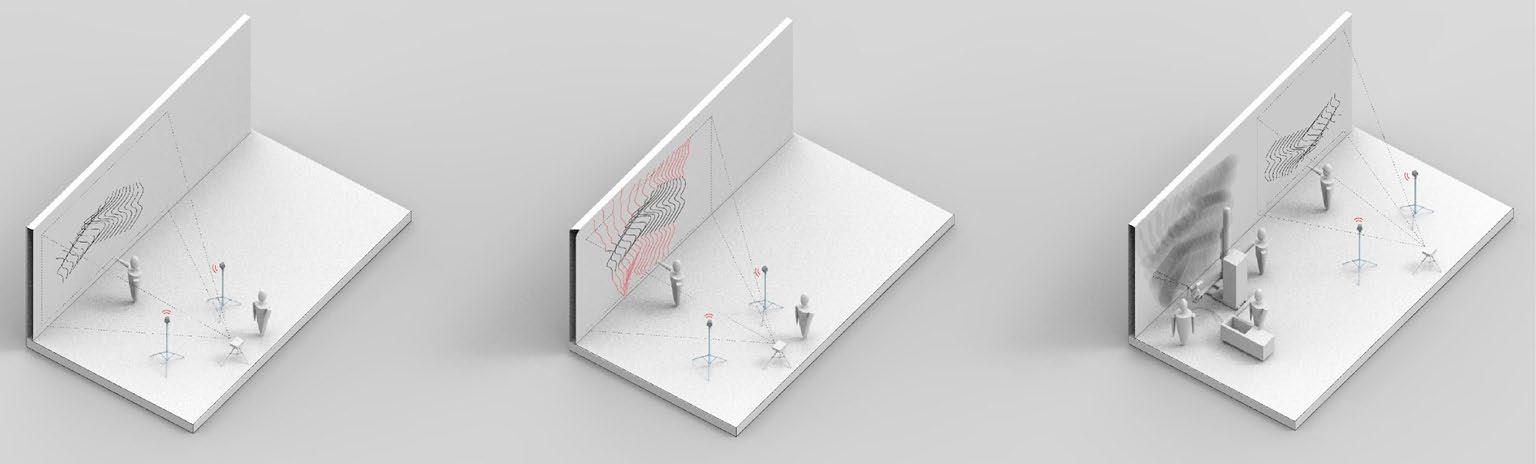

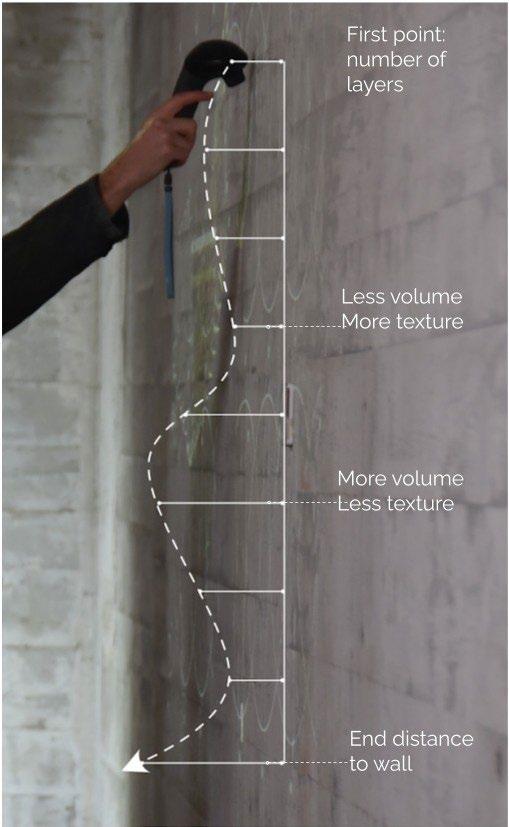

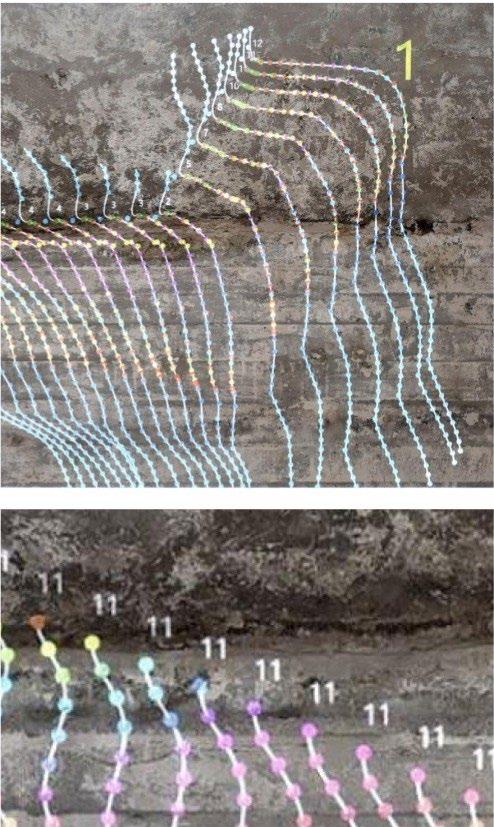

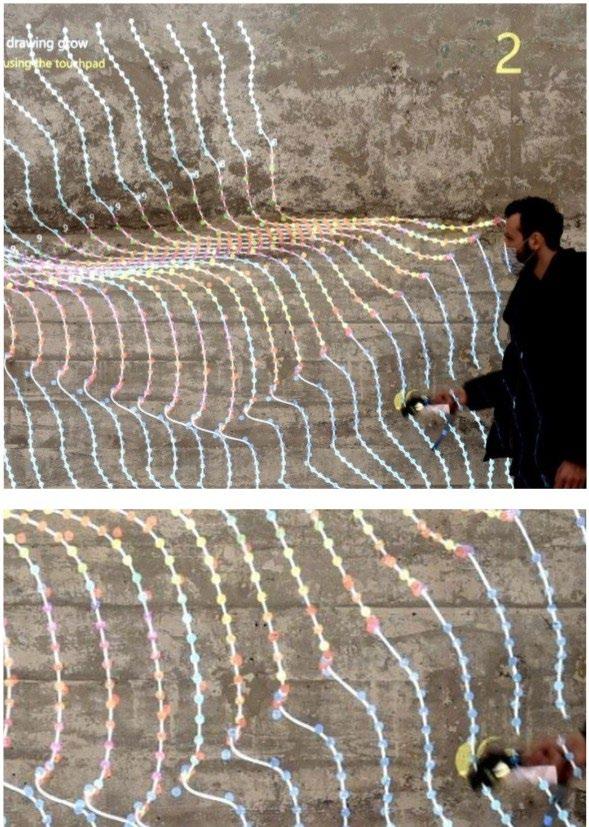

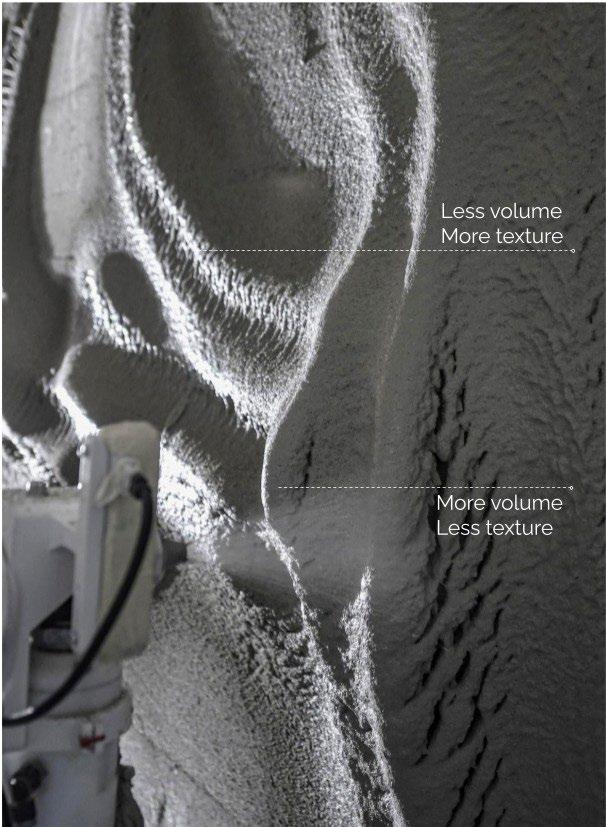

INTUITIVE ROBOTIC PLASTERING

( Human-machine Collaboration )

@Gramazio Kohler Research

This 11-week project explores the potential of novel digital fabrication processes to implement a full-scale construction project The topic combines two PhD research projects on Robotic Plaster Spraying and Human-Machine Collaboration to propose new design and fabrication methodologies under the name of Intuitive Robotic Plastering.

Tools used:

UR 10 robotic arm, HTC Vive, Projection mapping, Grasshopper, ROS, COMPAS framework, Siemens Dual axis, Anybotics ANYmal, Intel Realsense D435

Involvement:

•Amorphous material fabrication strategies

•On-site Interaction design - XR Communication

•Hand gesture capturing and filtering strategies

•Digital process chronology

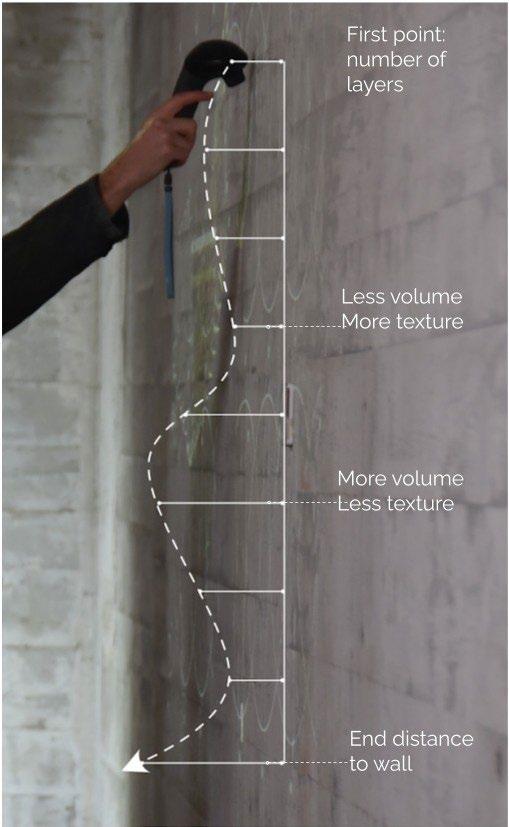

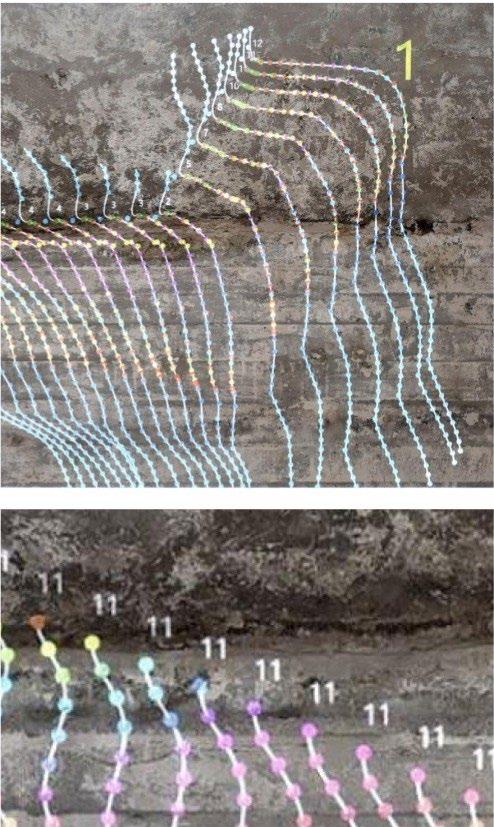

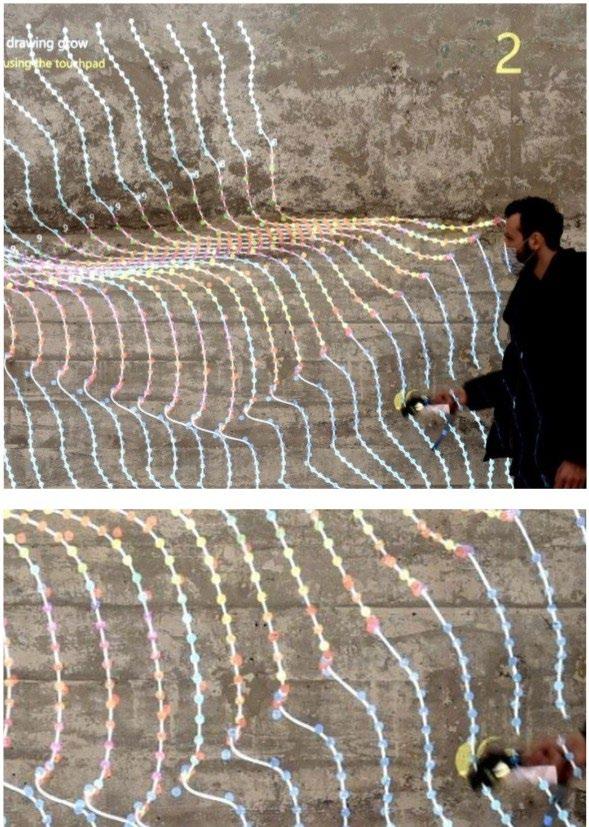

Projection mapping based XR (ExtendedReality) makes an on-site experience. HTC Vive heads-on display feed was projected on the working area to direct the artist with audio instructions to let them achieve intended results. Design

Recording gestures according to the site constraints with HTC vive link

Translating intentions to extend styles for toolpath design

Spraying and recording the next segment learning on the previous

Hand drawing embedded information

Design intention fabricated

Hand drawing embedded information

Design intention fabricated

details and examples of recordings on site

The results show the design and construction of an interior space through an adaptive thin layer printing process with an interactive design procedure.

Realized project photos

Details

Realized project photos

Details

of information translated to Layered plaster

Fabrication tool setup

RESULTS

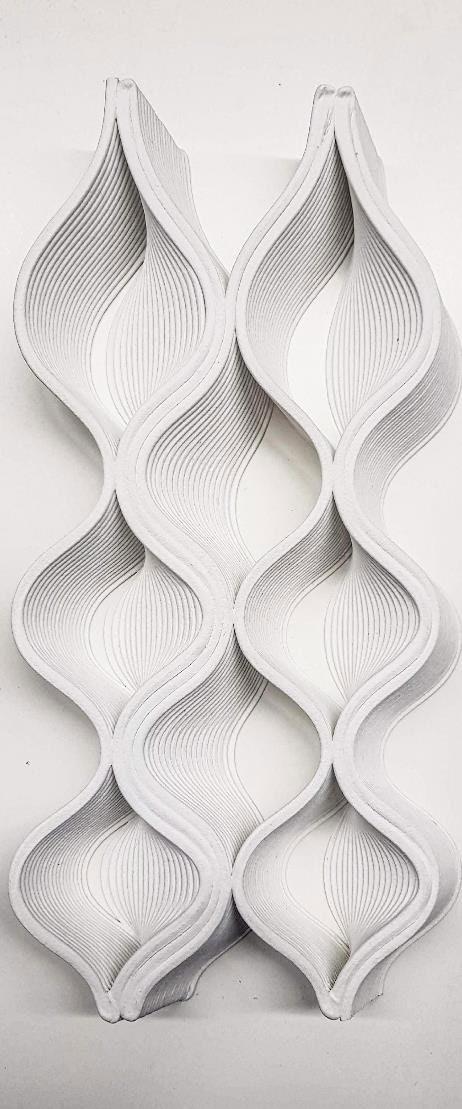

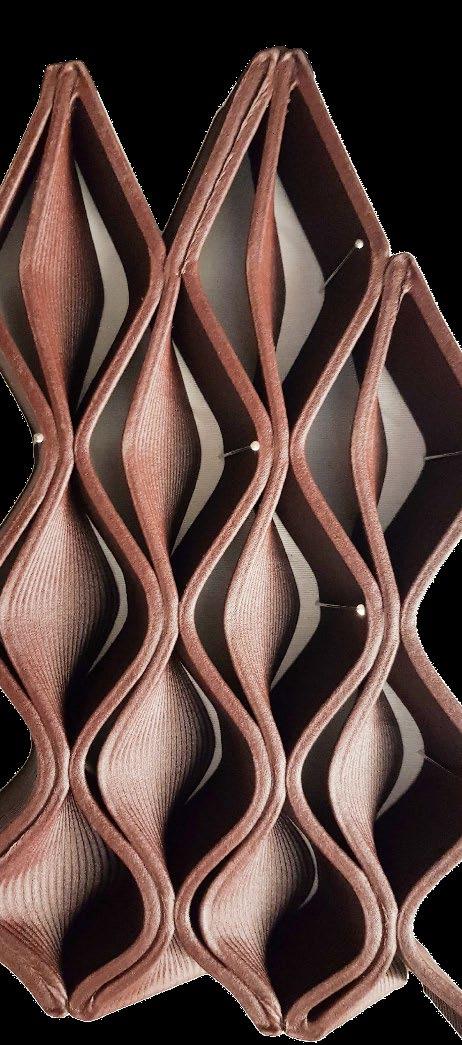

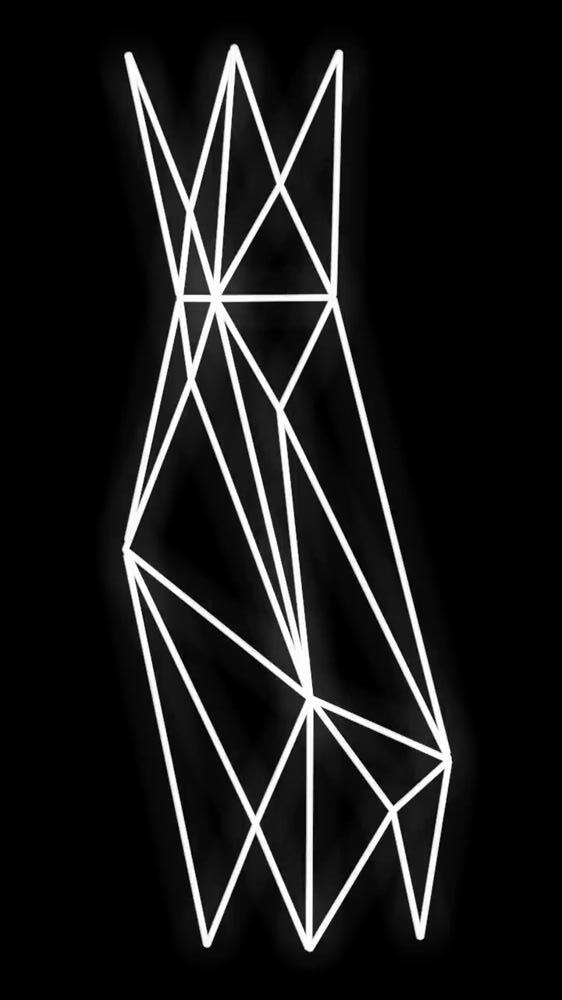

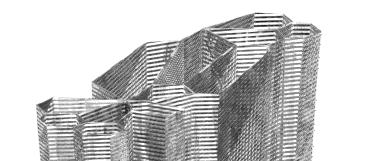

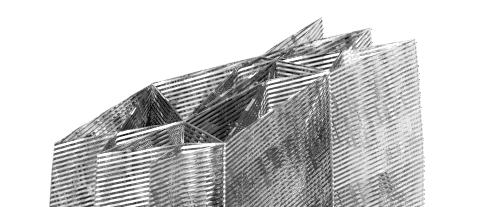

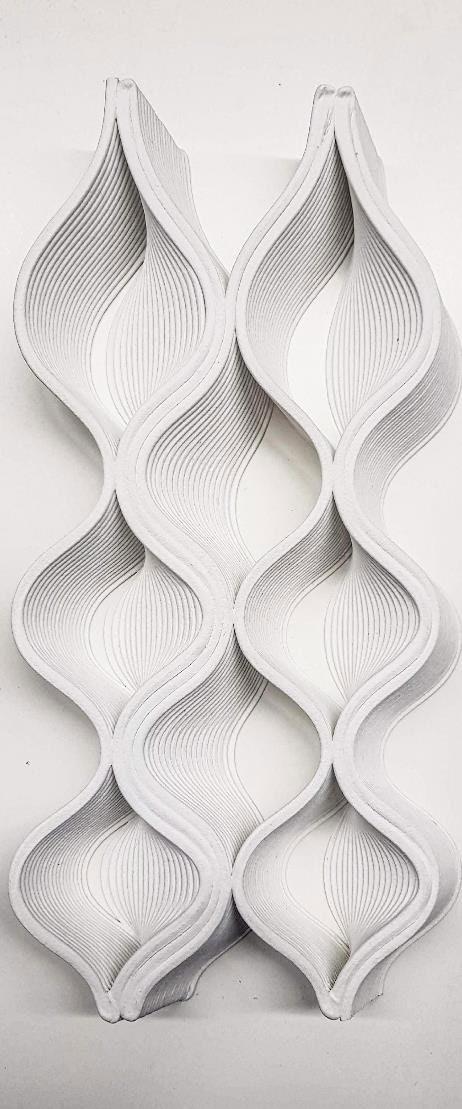

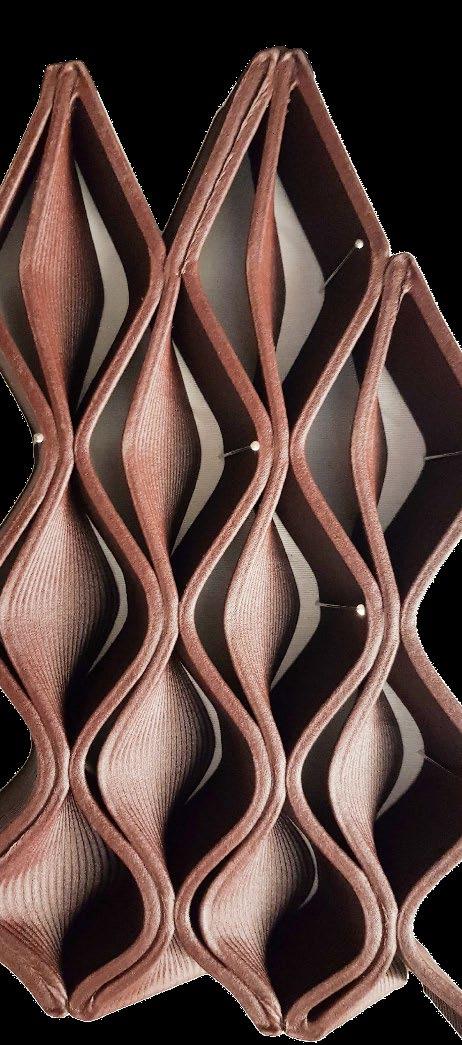

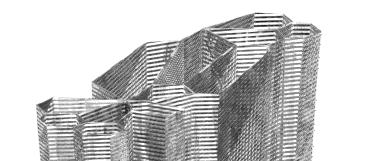

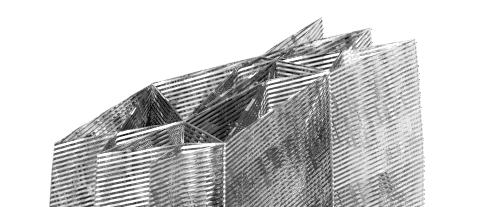

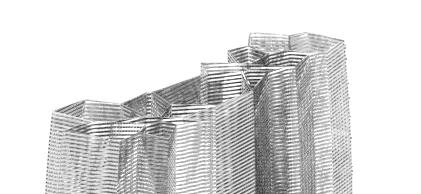

3DP COMPOSITE FACADE

@Digital Building Technologies

Guillaume Jami, Priyank Soni

The aim is to create a façade system that is versatile enough to fit the needs of a contemporary building such as structural strength, Ventilation, Insulation, Light and services carriage. A system that is modular and can be adjusted to optimize itself based on its context. A true definition ‘Composite Façade’.

Involvement:

Robotic toolpath design

End effector Design

3DP strategies

Tools used: - UR 5 robotic arm

- 3D printing end-effector - Arduino - Rhino - Grasshopper - Boid plugin - Compas Slicer - Cinema 4D simulations - Keyshot rendering

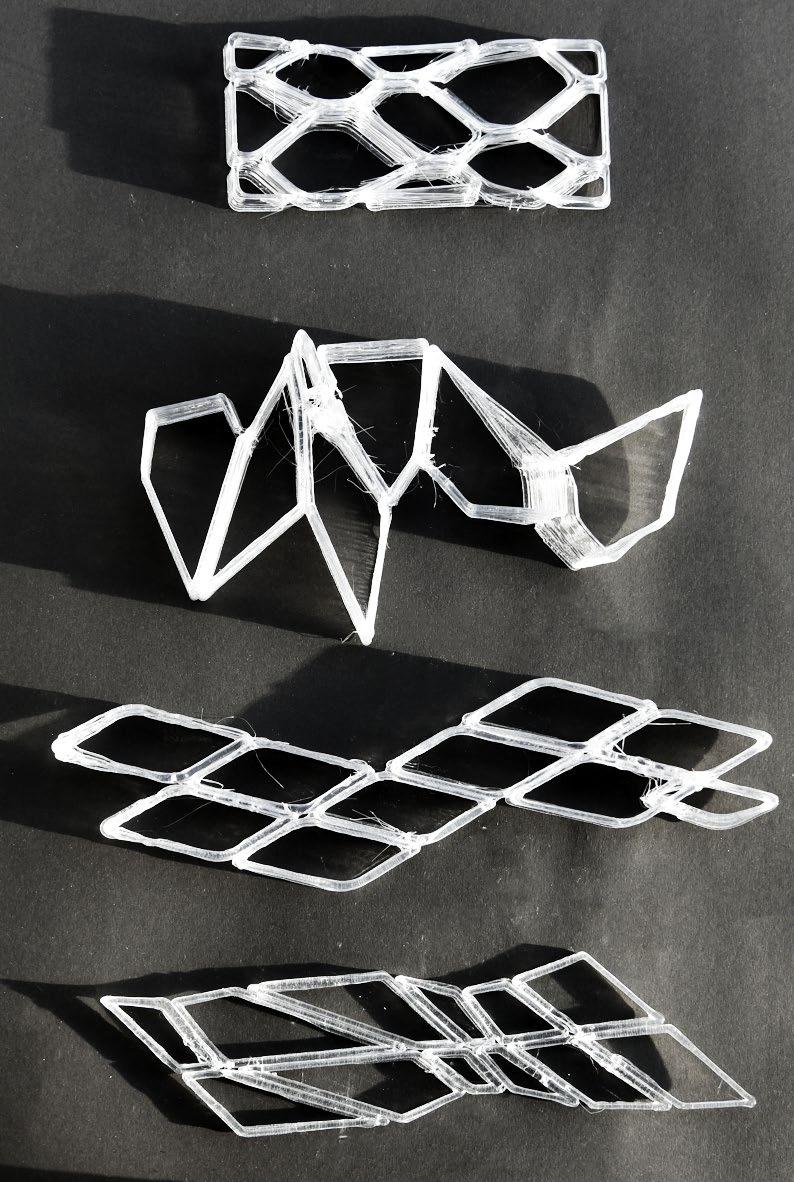

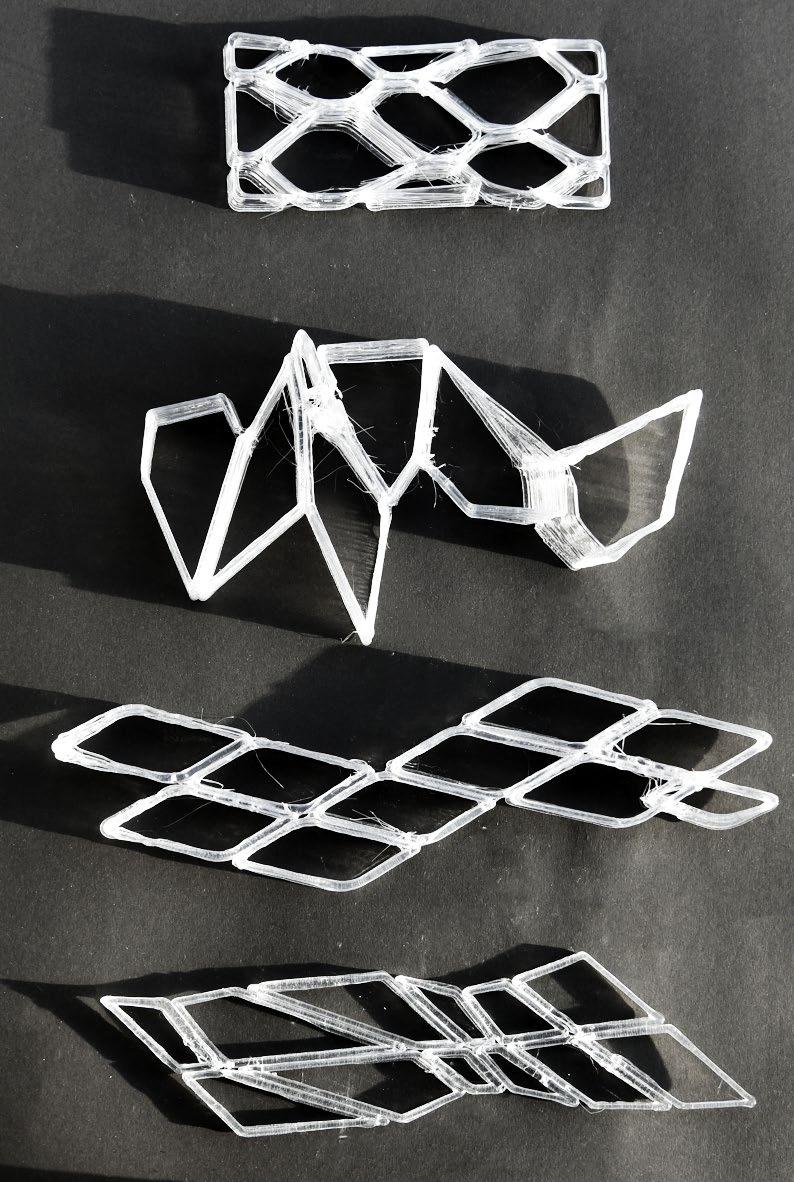

METHODOLOGY OF PATTERN RESEARCH

Pentagonal cells

Hexagonal cells

Triangular cells

Rhomboid

Pentagonal cells

Hexagonal cells

Triangular cells

Rhomboid

cells Quad cellsPhysical Results

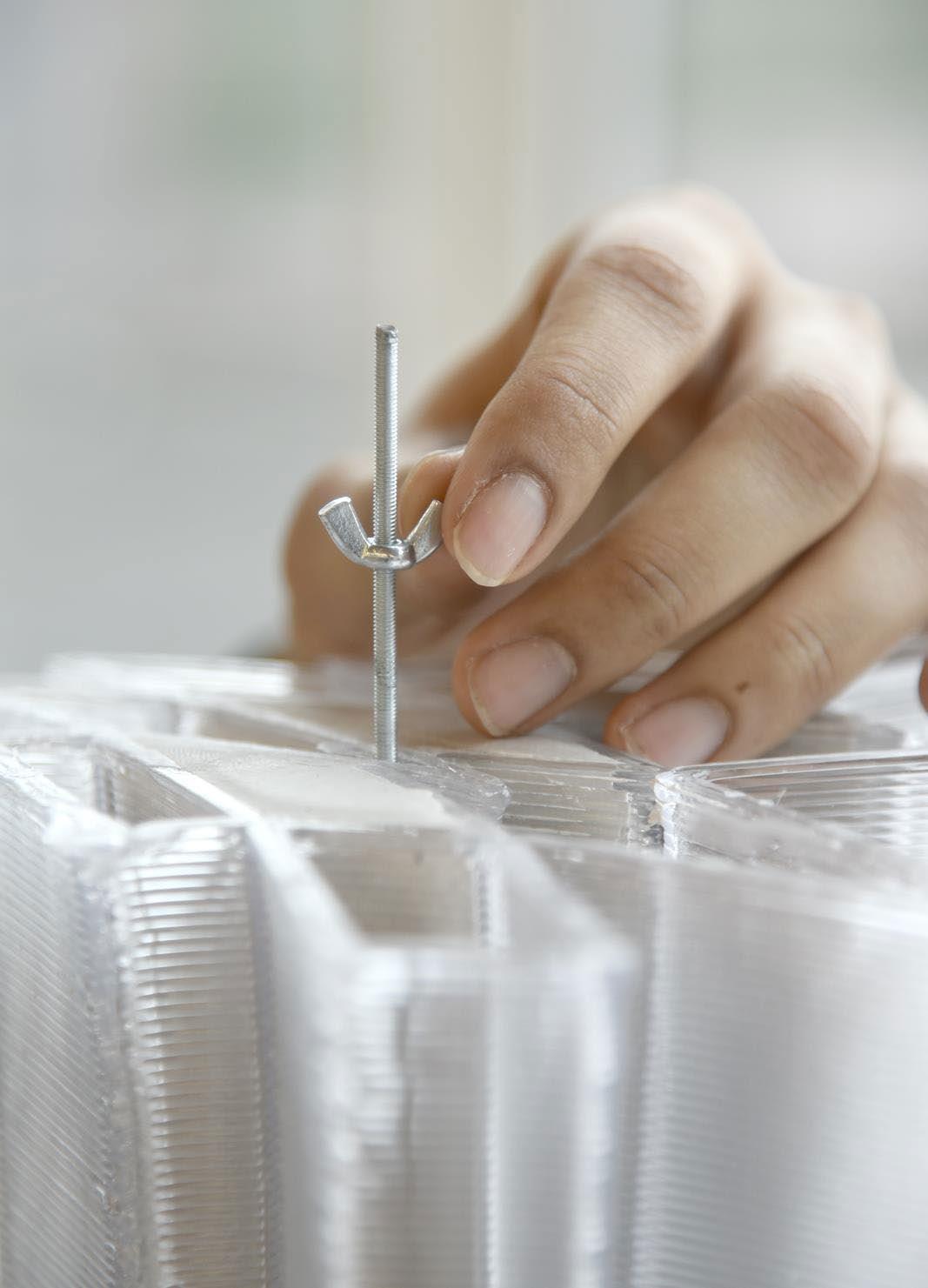

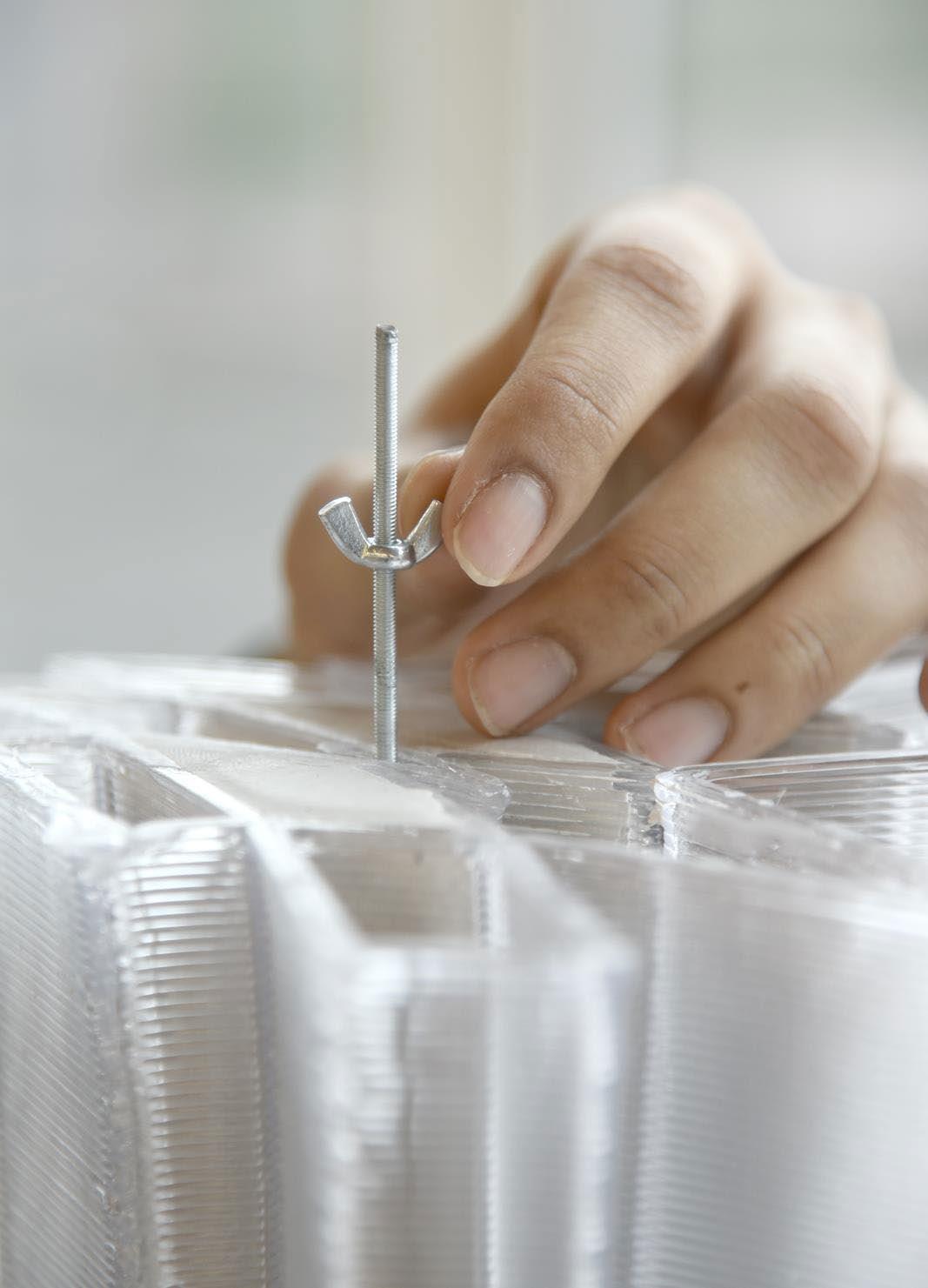

ASSEMBLY MECHANISM

Structural and junction details

Assembly

Post-tensioning

External junction Concrete

Reinforcement channel

Reinforcement 3mm

Prototype upper part

Prototype lower part

Post-tensioning

Structural and junction details

Assembly

Post-tensioning

External junction Concrete

Reinforcement channel

Reinforcement 3mm

Prototype upper part

Prototype lower part

Post-tensioning

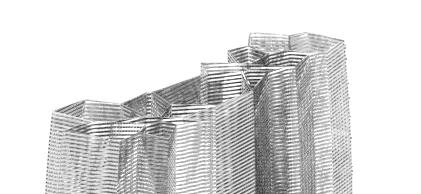

FORM EXPLORATION PROTOTYPES

Architectural projection

Final Patented Prototype module

Architectural projection

Final Patented Prototype module

Lounge area at upper floor

View of the central space

Lounge area at upper floor

View of the central space

Acrylic spherical shell ø3000mm

Metal + timber covered base

3D fabrication model of Cocoon

Acrylic spherical shell ø3000mm

Metal + timber covered base

3D fabrication model of Cocoon

Calmness

Empower

Reflect

Rest

Calmness

Empower

Reflect

Rest

Hand drawing embedded information

Design intention fabricated

Hand drawing embedded information

Design intention fabricated

Realized project photos

Details

Realized project photos

Details

Pentagonal cells

Hexagonal cells

Triangular cells

Rhomboid

Pentagonal cells

Hexagonal cells

Triangular cells

Rhomboid

Structural and junction details

Assembly

Post-tensioning

External junction Concrete

Reinforcement channel

Reinforcement 3mm

Prototype upper part

Prototype lower part

Post-tensioning

Structural and junction details

Assembly

Post-tensioning

External junction Concrete

Reinforcement channel

Reinforcement 3mm

Prototype upper part

Prototype lower part

Post-tensioning

Architectural projection

Final Patented Prototype module

Architectural projection

Final Patented Prototype module