success

Opening the door to endless opportunities

From

“Exposure to different leadership styles gained from other industries will unlock potential in our teams and enable them to be their best.”

– Chris Godsil, Interflow

We’re Creating the Future of Water for people and communities, for generations to come

WOMEN IN INDUSTRY

in trenchless

This magazine is the official journal of the Australasian Society for Trenchless Technology (ASTT) and is distributed to members and other interested parties throughout Australia and the AsiaPacific. It is also available on subscription.

The publishers welcome editorial contributions from interested parties. However, neither the publishers nor the ASTT accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or the ASTT. Neither the publishers nor the ASTT accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media (PCM), including text and images, you are providing permission for that material to be subsequently used by PCM, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by PCM and its agents and associates or another party to whom PCM has provided permission.

CEO

John Murphy

CHIEF OPERATING OFFICER

Christine Clancy

christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock

molly.hancock@primecreative.com.au

EDITORIAL

Tim Bond tim.bond@primecreative.com.au

Gerald Lynch

gerald.lynch@primecreative.com.au

BUSINESS DEVELOPMENT

Nick Lovering nick.lovering@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGNER

Blake Storey

COPYRIGHT

Trenchless Australasia is owned by Prime Creative Media and published by John Murphy. All material in Trenchless Australasia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trenchless Australasia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008 Ph: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office

Suite 11.01, Level 11, 201 Miller St, NorthSydney, 2060

Editor’s letter

Molly Hancock

The trenchless industry is taking significant strides towards fostering inclusive and diverse environments. These exciting changes mark a pivotal moment for the sector, as it continues to break down barriers and open doors for women across all levels of the industry.

In this April edition of Trenchless Australasia, we’ve dedicated a special focus to the ongoing efforts of trenchless companies and organisations that are actively working to ensure equality in the workplace. From promoting inclusive hiring practices to creating supportive mentoring programs, there’s a growing commitment to empowering women to take on leadership roles.

This edition highlights the stories of inspiring women — those who are not only excelling in their careers but also paving the way for future leaders.

Some of these exceptional individuals have dedicated their time and expertise to mentoring women, ensuring that they have the resources and support needed to thrive in the trenchless industry. Leading the way are companies like Abergeldie, Interflow, and

Bothar Group, each of which is committed to encouraging and empowering women within the industry.

Abergeldie, for instance, has implemented strong mentoring programs and policies that support women’s career progression, while Interflow is working to ensure equal opportunities and a supportive work environment for women to thrive. Bothar Group, known for its commitment to diversity, is championing the hiring and development of women in all areas of its operations, ensuring women have access to the training and leadership opportunities needed to succeed.

As the industry continues to evolve, it’s clear that the future is not just about technology - it’s also about ensuring that diverse voices and perspectives are heard and celebrated.

Happy reading!

Molly Hancock Managing Editor molly.hancock@primecreative.com.au

Excellence in tunneling for water, wastewater and energy infrastructure.

With a focus on safety, innovation and collaborative delivery over the last 35 years, Rob Carr has achieved outstanding outcomes in water, wastewater and energy infrastructure projects in both Australia and overseas. Rob Carr is part of Soletanche Bachy a world leader in foundation and soil technologies and subsidiary of VINCI, a global player in construction across more than 100 countries. With outstanding capabilities to manage the complexities of any project, Rob Carr has the people, knowledge and experience to deliver success.

THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY

ABN 43 893 870 966

P.O. Box 2242, MALAGA

LPO WA 6944

www.astt.com.au

President: Ben Crosby

Secretary: Trevor Gosatti

Vice President: Blair Telfer

COUNCILLORS

Western Australia: Aizezi Jiang

Queensland: Ben Crosby

New South Wales: Jason Marshal

Victoria: Ash Hamer

South Australia: Shaun Melville

New Zealand: Blair Telfer

Northern Territory: Luke Woodward

Tasmania: Vacant

President’s message

TFarrugia and Andrea Edney now serving as Councillors on the ASTT board.

Their leadership reflects the growing role of women in this sector, a theme we celebrate with the upcoming Trenchless Woman of the Year Award at No-Dig Down Under 2025.

As we look ahead, there are several key events to note.

No-Dig Down Under remains a significant milestone, with a reminder for members to submit papers for the event. Additionally, we continue to promote our trenchless training courses, including horizontal directional drilling (HDD), new installation, and relining, which provide valuable skills to industry professionals.

Exciting developments are underway with International No-Dig 2026, a global gathering we anticipate with great enthusiasm.

The ASTT AGM will be held on May 19, 2025, coinciding with Oz Water in Adelaide from May 20-22, 2025.

We are also pushing forward with university initiatives, including an “Introduction to Trenchless” session where

Secretary’s corner April 2025

New members

On behalf of the ASTT, I extend a warm welcome to the following new members:

Individual Members – Australia

Scott Raynsford from Jacobs (Group) Australia

Navpreet Bajwa from CMP Consulting Group (Young Professional)

Stephen Barrett from PureService

ASTT annual general meeting

I advise that notice was given to all members that the 33rd combined council and annual general meeting (AGM) will be held in the Adelaide Room 1 of Playford MGallery Hotel, 120 North Terrace, Adelaide SA on Monday, May 19, 2025, commencing at 10am.

All financial members are welcome to attend. The meeting is scheduled in conjunction with the timing of the AWA OzWater Conference in Adelaide. Any changes to the ASTT Council will be announced at the AGM.

New ISTT website to provide benefits to ASTT Members

The ISTT has announced the “hard launch” of the new ISTT website.

The new website contains many new features for the Affiliated Societies and their members, hopefully providing many more opportunities to promote trenchless technologies around the world.

Some of the new features include:

• A database facility that assists Affiliate Societies to have their member data

included and allow members in the database to access all the features of the ISTT website.

• The database will allow a more improved search function for corporates and the goods and services they offer to industry.

• A single sign on (SSO) facility is available for the member login process.

• Each corporate member will have access to a basic corporate booth facility where the entity’s products and services can be displayed via video, brochures and WhatsApp.

• The corporate member will have the ability to “upgrade” the basic corporate booth to a higher level virtual corporate booth providing the corporate entity to promote its goods and services to a global audience. The additional features include extra video, brochures, presentations, business cards, WhatsApp and other media.

• The new website has enhanced Trenchless Technologies pages highlighting the benefits of trenchless technologies to industry.

• Enhanced pages providing past conference papers, webinars, etc are also provided where members can download material for free or visitors can purchase products.

In addition, there is links to many trenchless resource documents.

Corporate members will soon receive further information from the ASTT on how to input member data in the

database so as to encourage corporate member users to log in to their facility and update their entity’s information. This will allow members to obtain the maximum benefit of the site.

Individual members will also be able to log in and access benefits.

We hope that you enjoy the new website. I welcome your feedback on any items within the site to help to continuously improve the site over time.

Change of date for 2026 ISTT

International No-Dig New Zealand

To avoid a clash with other scheduled international events, the 2026 International No-Dig has had a revised date change, and the event will now be held from October 28—29, 2026, at the newly built New Zealand International Convention Centre in Auckland.

The International Society for Trenchless Technology’s (ISTT) annual event will be held in New Zealand in 2026 following a successful bid by the Australasian Society for Trenchless Technology (ASTT).

International No-Dig New Zealand will feature a diverse range of equipment showcases, demonstrations, and conference sessions, and highlighting the latest innovations in trenchless technology.

Save the new date in your calendar!

Trevor Gosatti ASTT Secretary

DISCOVER THE FUTURE WITH BOTHAR, A GLOBAL TRENCHLESS CONSTRUCTION EXPERT.

Ensure your project is delivered safely, sustainably, and successfully.

Bothar possesses comprehensive trenchless solutions alongside expertise in shaft construction and civil capabilities.

With over 30 years’ experience, Bothar is your partner for the delivery of complex infrastructure solutions.

Our Services

•Vermeer Axis Laser Guided Systems

•Auger Boring

•Direct Pipe Installations

•Shaft Construction

•Herrenknecht AVN MTBMs

•Bothar Built EPB - TBMs

•Open Face TBMs

•Tunnel Boring & Pipe Jacking

How a values-focussed approach to hiring is opening the door for women

In an industry historically dominated, but not defined by males, infrastructure company Interflow has worked hard to position itself as a leader in equity and inclusivity.

Gender equity is widely recognised as a meaningful way to foster better outcomes for workers, customers, and the community. While targets and quotas play an important role in keeping diversity on the agenda, many organisations are left wondering what they can do to attract and retain more women.

Leading pipeline infrastructure company, Inter ow, may have a solution. By building a team based not solely on technical prowess but on shared values and behaviours, they have been able to welcome a diversity of perspectives into the business.

Inclusion begins with the hiring process

Key to attracting a diverse workforce to any industry is breaking down the barriers to entry. One such barrier in the water sector is the idea that an engineering degree is indispensable for project management roles.

Inter ow is challenging this by shifting the conversation from ‘who is most quali ed for the job?’ to ‘who is best for the team, who will add to the culture and bring new ideas?’

Chris Godsil, Operations Manager at Inter ow, said that the company previously had success bringing people from the eld

into traditional engineering and project management roles.

“We took that idea and cast the net wider, outside of the engineering industry,” he explained. “We were looking for people from any industry with strong value and behaviour alignment with Inter ow, people who could communicate and build trust.

“Technical skills can be developed through training and on-the-job experience. What’s really

important to us is that behaviour alignment and transferable skills.”

ese skills and behaviours were evident in Sam Woods, who made the move from retail to become a Project Coordinator at Inter ow.

“In my previous role I was a project manager in a very di erent sector,” she said.

“I have key skills like communication, stakeholder engagement and managing timelines and budgets. ese have really helped me in my new role.”

Before taking the leap and switching industries, Woods was given the opportunity to visit a site and get a rsthand feel for what she was signing on to.

“It was actually Chris that recommended I go out on site and see what we do,” she said.

“Usually when you change role you make that decision based on what you think you know about it. So, seeing a construction site and seeing, realistically, what I’d be managing, meeting the people I’d be working with – that sealed the deal for me.”

Inter ow’s shift in focus from technical to transferable skills has been proven to encourage more women through the door. Just as important is providing clear career pathways that enable women to stay and thrive once they get there.

“One of the factors that made me interested in the role was that I could see the progression here,” Woods said.

“ at came from conversations I’d had and from looking at who was already at Inter ow and where they had come from.

“It made the risk of changing industries so much easier, knowing there was so much room to grow.”

Supporting careers, supporting lives When re ecting back, Inter ow Contracts

Administrator Teia Comelli said it was only 10 years ago she was a chef and looking for a better work-life balance.

Comelli’s search for more balance led her to a new career in the water industry.

“Eventually I found myself at Inter ow and went straight into the eld, straight into the ground and getting my hands dirty,” she said.

Over time, her changing life circumstances meant she needed a role that could adapt with her.

“My partner and I wanted to extend the family by one,” she said.

When Comelli fell pregnant, she stepped away from the eld and into an administration role.

e transition set her up for an easy return to work after being on parental leave.

“I got a phone call asking if I’d like to jump into a similar role to what I was doing before I went on leave, which was organising training for the crews,” she said.

Like Woods, Comelli had a core set of skills that could be applied to other roles.

“She had a unique insight from working in the eld,” Godsil said.

“But perhaps more importantly, Teia was aligned to the behaviours and values we look for at Inter ow. It was really important to us that we support her to stay in the business.”

Comelli was o ered a position that leveraged her skills while providing the exibility she needed at this stage of her life.

“It was perfect for me because I understood the training that was needed, the crew dynamics, and how to structure the training to reduce the impact of it on their work,” she said.

“ e role had the exibility of being able to work from home, the exibility to take my little one to doctors’ appointments. Taking it was a no-brainer.”

Benefits beyond the talent pipeline Inter ow’s simple change of approach has solved two problems; it opened the talent pool in a competitive market, and it created a pathway for women to enter the water industry. In practice, Godsil explains, the bene ts extend even further.

“Exposure to di erent leadership styles gained from other industries will unlock potential in our teams and enable them

to be their best,” he said. “At a time when our industry faces complex issues like water a ordability, water security, climate change, the more diverse our thinking, the better position we’re in to tackle them.”

Also apparent is the impact that value and behaviour-led recruiting has had on the culture at Inter ow.

“We have seen a real uplift in culture and retention,” Godsil said. “You walk around the o ce and there’s this really nice buzz because people feel they are working towards something they truly believe in. at’s pretty special.”

For more information, visit interflow.com.au

At L&D Micro Tunnelling we specialize in laser guided boring. Our Tunnel bore machines use a vacuum extraction system where all spoil is sucked into interceptor tanks for easy disposal with no mess. All our heads are hydraulically driven and guided by a high accuracy laser to achieve precision over long distances.

Women leading the way in trenchless engineering

In the trenchless industry, talent and dedication are the key ingredients to success.

Elissa Miller, Kelly McPhee, and Beth Selwyn, are three accomplished women at Abergeldie Complex Infrastructure (Abergeldie) who have demonstrated that it is the quality of their work and passion for engineering that de nes their careers.

With extensive experience in tunnelling, underground construction, and complex infrastructure projects, these women are not only excelling in their respective roles but also setting a powerful example for future generations of engineers.

eir journeys re ect a shared commitment to the work and the freedom to approach projects with autonomy and creativity as a result of Abergeldie’s strong culture.

Rather than focusing on their gender, they emphasize the importance of collaboration, strong mentorship, and creating a culture of respect and support that allows everyone to thrive.

Together, they embody the fact that success in the trenchless sector is based on skill and e ort, not gender.

Now a Construction Manager, Elissa Miller’s career is a testament to perseverance and growth.

She started her journey with Abergeldie in 2007, bringing her expertise in civil construction to a wide range of complex infrastructure projects.

From her early work on the Network Facilities Renewal Program to her more recent role as Construction Manager for a variety of projects including the noteworthy Vaucluse

Diamond Bay pump station project, Miller said she was met with a steep learning curve when she rst transitioned into the trenchless sector in 2017.

“It was challenging, but I was fortunate to work with an experienced team that supported me every step of the way,” she said.

For Miller, the key to thriving in the industry was nding a supportive environment, something she credits Abergeldie for o ering.

“Despite being the only woman in the delivery team for a long time, I never felt

that my gender held me back,” she said. “I’ve always felt respected and valued, and that sense of belonging has been a big part of my career progression.”

Miller’s advice to young women entering the industry is straightforward; “ ere are so many opportunities out there”.

“Don’t let your gender stop you from pursuing your passion. If you show you can deliver results, that’s all that matters,” she said.

“ e industry is evolving, and women have the chance to take on leadership roles and make signi cant contributions.”

Project Manager Kelly McPhee’s journey into trenchless engineering was shaped by a background in geotechnical engineering.

After years in consultancy, McPhee wanted to make a bigger impact on the ground, which led her to Abergeldie in 2016.

With a wealth of experience in tunnelling and underground construction, McPhee has successfully managed deep shaft excavations and complex tunnelling projects, such as the Maribyrnong River Main Sewer Augmentation.

However, McPhee’s journey was not without its challenges.

“Earlier on in my career, I was often overlooked or assumed to lack experience simply because I’m a woman,” she said.

“But that didn’t last long … Once I had the chance to prove myself, I earned the respect of my colleagues.”

McPhee’s experiences with Abergeldie have been positive, citing the company’s family-

like culture and the exibility it o ers to its employees.

“When I returned to Brisbane after having my baby, Abergeldie was extremely accommodating,” she said.

“ ey allowed me to work a exible schedule and from home, which helped me balance my new role as a mother with my professional responsibilities as a project manager.”

For McPhee, being a woman in the trenchless industry has never been a disadvantage.

“I’ve always felt like just an engineer, if you’re passionate about your work and dedicated to delivering results, that’s what people see,” she said.

Beth Selwyn’s path in the trenchless sector began with an undergraduate position with Transport for London.

Her early experiences in tunnelling projects, such as the Northern Line Extension and ames Tideway, gave her a solid foundation in the industry.

Seeking new challenges, Selwyn moved to New Zealand to work on the Central Interceptor project, which brought her to Abergeldie.

Her journey continued with a move to Australia, where she now works on complex tunnelling projects in Sydney as a Senior Project Engineer. Selwyn feels that being a woman has opened doors for her in the industry.

“In fact, it’s often been a strength,” she said.

“I focus on doing my job well and building strong relationships with my colleagues. As a result, I have been able to progress my career at each company that I have been a part of.”

One of the things Selwyn appreciates most about working at Abergeldie is the company’s supportive culture which empowers its employees to thrive.

“ e senior managers are approachable and give you the autonomy to manage your projects as you see t, they trust you to make the right decisions, provided you can back them up with a strong rationale.”

Selwyn’s experience highlights the importance of mentorship and the supportive networks that are important for women in engineering.

“ ey’ve shown me the ropes and encouraged me to push myself, which has allowed me to grow in my career.”

Miller, McPhee, and Selwyn’s experiences show that in the trenchless industry, it’s not about gender – it’s about skill, dedication, and the willingness to take on challenges.

Mark Whelan, Abergeldie’s Executive General Manager of Infrastructure, is con dent that Abergeldie’s future in tunnelling and underground work is promising.

“ e future of tunnelling and underground looks bright at Abergeldie, thanks to our skilled and diverse team, including leaders like Elissa, Kelly, and Beth,” he said.

The world’s most compact hot

“ is year, with the launch of our new graduate program, we’re excited to develop the next generation of professionals who will help us to deliver the complex infrastructure needed to build better communities.”

Minitap’s patented technology provides a portable, robust and safe hot tapping solution for large offtake hot tapping in confined space environments

• Advanced cutter designs

• Comprehensive training program

• Local service & support

• Designed and manufactured in Australia

From behind the scenes to leading projects: Bothar’s trailblazers

Trenchless Australasia speaks with three excellent and hard-working women from Bothar Boring.

Bothar Boring leverages decades of experience, a robust safety culture, and an extensive eet of specialised equipment, to deliver complex trenchless solutions around the world. e company’s ability to execute intricate projects in demanding environments has earned it a solid reputation in the realm of subsurface engineering and infrastructure development.

And just as Bothar Boring backs the trenchless industry, it in turn is backed by its team of hard-working employees. Trenchless Australasia had the pleasure of speaking with three of these team members.

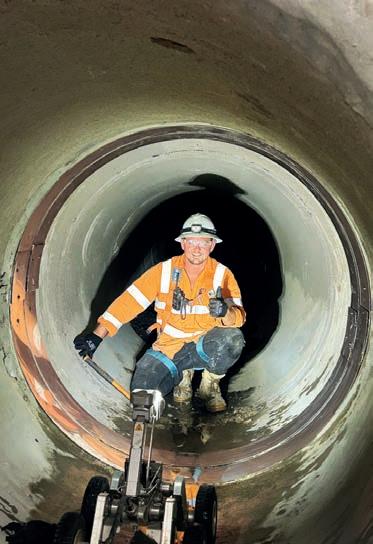

Con ned Space Spotter Vanessa Rashleigh spends her working days on the frontline of Bothar’s Queensland operations. Ten months ago, Rashleigh plucked up the courage to make a career change from hospitality to trenchless construction, a move she calls ‘the best decision of her working career’.

With a slew of site safety quali cations to her name, Rashleigh’s role covers everything from onsite procurement to con ned space spotting and everything in between.

Her positivity and hard-working nature quickly made Rashleigh an invaluable member of the Bothar team. And for her, those feelings are mutual.

“I love being part of a great team who all work together with good ethics and respect for one another,” she said.

“Bothar Boring is very easy and approachable to work for – I’m proud to call the company my ‘working away family’.

“I’m proud of myself for moving out of my comfort zone in the middle stage of my working career and trying something new.

“To other women who might want to enter the trenchless industry I would say give it a try and don’t look back – you’ll love it.”

In Melbourne, Bothar Boring is gearing up for a pipeline of major projects and has recently hired a number of new professionals. One of those is Achini Attanayake, a Site Engineer.

Responsible for overseeing construction projects and ensuring there is minimal interruption to work ow, her role carries a lot of responsibility, but Attanayake is up for the challenge.

“As a site engineer, I enjoy being out on site and witnessing the works occurring in action,” she said.

Attanayake said the best thing about working at Bothar is the team of great people.

“It is refreshing to work in a more intimate work setting,” she said.

“ is has led to stronger and more authentic relationships with coworkers.”

Attanayake shared some words of advice for other women considering a career in the trenchless.

“Unfortunately, there are still gender disparities in our industry in terms of culture, leadership and wage,” she said.

“However, things are slowly getting better and as women, we can continue to combat this by continuously standing up for ourselves even when it feels di cult and solitary to do so.”

While trenchless projects are impressive to behold, much of the work happens before anyone sets foot on site. is is something that Bothar Contracts Administrator Alexandra Lambie knows only too well.

Working within the commercial team, Lambie manages the contract and cost side of Victorian projects, from pre-construction all the way through to completion of the delivery stage.

She was drawn to the role by an interest in the intricacies of contracts.

“I have always had a keen interest in contracts themselves; as every project is di erent, you need to understand the clauses and the commercial triggers of each contract when a job is awarded,” she said.

While Lambie has always worked in the civil infrastructure space, working at Bothar was her rst introduction to the trenchless environment.

“At Bothar, I have had many opportunities to get involved in di erent aspects of the project lifecycle,” she said.

“Management always wants you to learn and expand within your career, which has been exciting process for me. It’s allowed me to explore lots of di erent aspects during the delivery phase of a project which I’ve never had the chance to do before.

“As Bothar has a lot of exciting work starting, I’m excited to get out on site more and see the tunnelling work happen.”

Lambie encourages any women considering a career in trenchless construction to take the leap and get involved.

“ ere is a wide range of roles within the sector, and you’ll be able to nd something that suits you,” she said.

“ ere is space for everyone in construction, especially women.”

For more information, visit botharboring.com.au

Ready to build the future

Ready Group is backing the NSW trenchless industry with a range of critical services like non-destructive digging and liquid waste management.

Even the largest infrastructure projects are dependent upon the e ective execution of many di erent ancillary works. In an economy where regulation is strict and manpower and material is costly, asset owners want to ensure that every link in this chain of services is rock solid.

And that’s why the NSW trenchless industry turns to Ready Group. With a deep suite of services and an appetite for growth, Ready Group has been supporting trenchless projects

with a careful and experienced hand since 2011. Originally started as a small familyowned business under the name Readyvac, the business has charted an impressive course of growth throughout its lifespan. In 2023, Readyvac acquired Non-Destructive Excavations Australia (NDEA), further solidifying its position in the non-destructive digging (NDD) industry.

With an expanded customer base under its belt, the business embraced a bold new

identity, rebranding as Ready Group to re ect its evolution and future ambitions. Fast forward to 2025 and Ready Group boasts the largest eet of VTI (Vac Truck Industries) vehicles in Australia and has garnered a reputation in the industry as an e cient and dependable contractor.

e business’ core capabilities include vacuum excavation, liquid waste management, jetting and drain cleaning and civil services. With the recent expansion to include in-house street sweepers and water carts, the company now o ers a more comprehensive range of services to meet client needs.

When it comes to vacuum excavation, Ready Group can provide NDD, limited access excavation, site dewatering and 24/7 emergency response for e cient wet and dry material removal.

“Our vacuum trucks deliver safe, precise excavation using advanced water blasting and vacuum techniques,” Ready Group Managing Director Matthew Spaninks told Trenchless Australasia.

“With a versatile eet ranging from 6000–10,000L units, we have the right truck for every job, from tight urban spaces to largescale excavation projects.”

e company’s expansive eet of vacuum trucks feature powerful suction systems, high-volume tanks and exible hoses designed for optimal reach and e ciency. is ensures seamless excavation and waste transport, keeping construction and infrastructure

projects running smoothly. Sourcing its vacuum trucks from a single reputable source like VTI means that Ready Group understands its equipment through and through.

“Having a close relationship with VTI means that we can deliver consistent and high-quality performance for our clients,” Spaninks said.

“ is eliminates uncertainties associated with using machines from multiple manufacturers. We understand the high standard of work our vacuum trucks can deliver, know how to best apply them, and have the capability to service the eet in-house.

“All of this translates to greater e ciency for our clients.”

Operating out of a constantly developing area like Sydney, Ready Group is no stranger to working with Tier 1 and 2 contractors – often repeat customers – on major infrastructure projects.

In fact, the company is currently providing a range of services in support of a nationally signi cant tunnel project in Sydney.

“Our scope of work primarily involves NDD and waste management. We clean out large ltration systems which collect waste, and also help to clear excess water and waste out of the tunnel as it is being constructed,” Spaninks said.

“We also provide street sweeping

impact on the community.

“As we look to the future, we are committed to embracing new technologies and integrating them into our operations to enhance our service o ering.

“By continuously pursuing opportunities for diversi cation and expansion, we ensure we stay ahead of industry needs.”

And while the suite of services is broad, it’s the business’ willingness to go the extra mile that keeps customers coming back.

“Our operations team is really good at shu ing the deck to make sure we always show up for our customers, even on very short notice,” Spaninks said.

“We’ve proven over the years that we don’t let our clients down – that we’re reliable.

“So now when we say we’re going to do something, our clients know that they can trust us to deliver every time.”

For more information, visit readygroup.au

Withlocalmanufacturing,product qualityandreliabilityofsupplyare ensured.SmartLockreallyisthe smartchoiceforAustralian contractorsandassetowners.

SMART LOCK the GOLD standard in Point Repair.

Betting on a sure thing

Vacuum Truck Supplies’ most powerful vacuum truck NDD models have just touched down in Australia.

With more than 30 years of experience and over 1000 vacuum trucks built to date, Vacuum Truck Supplies (VTS) has been a long-time supporter of the Australian trenchless industry.

e company’s DiggerVac and DrainVac trucks, traditionally o ered in a mobile 6x4 con guration, deliver reliable non-destructive digging (NDD) and drain cleaning to projects across the country.

And now, the much anticipated 8x4 models have touched down on Australian soil.

e upscaled DiggerVac9000 boasts a 9000L waste capacity and a 4000L water capacity, perfect for large scale or remote projects where payload is critical. Featuring a Jurop 6000m3 per hour Helix blower vacuum pump, and an UDOR NDD pump that puts out 17L per minute at 300-BAR, the DiggerVac9000 means serious business.

Also new to the market is the DrainVac8000, VTS’ heavy-duty solution to both drain cleaning and hydro excavation. is model has a waste capacity of 8000L and a water capacity of 4000L, which supports a Pratisolli drain cleaning system capable of putting out 346L per minute at 170-BAR. e truck also features a 4000 m3 per hour liquid ring vacuum pump, and the same UDOR NDD pump that produces 17L per minute at 300-BAR.

In fewer words, these trucks are well equipped to handle even the most rugged NDD, liquid waste, and hard waste projects.

“We’re very excited to bring these

larger 8x4 models to market, which will complement the smaller range and allow our customers to tackle jobs both big and small,” VTS Managing Director Rod Glue told Trenchless Australasia.

Despite the impressive capabilities of these machines, each was designed with the intent to maximise operational life and serviceability.

Just like their previous 6x4 iterations, the DiggerVac and DrainVac are built with stainless steel waste, water and tipping tanks, full opening rear doors, and a non-computer control system.

is nal feature is critical to the design, and means the vehicles rely on mechanical and hydraulic engineering standards that have been proven for decades.

“Our trucks feature no computers at all for hassle-free operation and maintenance,” Glue said.

“ ey’ve been designed to withstand the harshest Australian conditions – without any unwieldy European manufacturing in uences – and are built to be abused.”

e trucks were delivered in partnership with manufacturer Aryan Pumps and Enviro Solutions, which has been building NDD solutions for more than a decade and has delivered hundreds of trucks all over the world.

All of this translates to a proven and dependable product with inherent simplicity in diagnostics, repair and maintenance.

VTS will be showcasing these new trucks at the upcoming Brisbane Truck Show, held in May.

“VTS has been attending the Brisbane Truck Show for a while now, and this year we’re excited to showcase our new range,” Glue said.

“If you want to see them in person and learn more, come to the show and pay us a visit.”

Pro Line supplies UV-CIPP liner from DN100 – DN2400 and is suitable for the following host pipes:

• Gravity

• Pressure

• Potable Water

CONTACT US TODAY

by actively partnering with local community groups and creating employment opportunities that support the growth and sustainability of the communities we serve. By partnering with community groups and Aboriginal businesses, we not only deliver innovative pipeline solutions but also help build a stronger, more resilient future for generations to come.

Partner with Pro Line for unmatched support across every stage of your UV-CIPP projects. Please feel free to send an email to info@pro-line.com.au

A safer future with robotics

KOR Equipment Solutions is backing Australian-first robotics to make industrial cleaning and excavation both safer and more efficient.

The use of robotics to enhance industrial vacuum recovery and ultra-high pressure water blasting has been in practise for decades in Europe, but only now has a company brought the method down under.

After conducting its own extensive research procedures, KOR is now the exclusive distributor in Australia and New Zealand of Gerotto remotely operated vehicles (ROV’s) and Falch’s robotic water jetting equipment.

e Gerotto range includes the Lombrico S, a hydraulic, remotely operated robot speci cally designed for vacuuming any type of material found in high-risk con ned spaces such as inside re neries, steel plants, tank terminals, biogas plants, and industrial plants.

e Falch range includes the Surface Rob 250 that is a high-pressure universal water jetting robot, the Frame Rob 250 that is a fully automatic water jetting unit, and the Multi Worker 250 that is a semi-automated water jetting unit.

What really sets Falch apart from others is its commitment to continuous pump development, having an extensive accessory range, and the investment made in robotic solutions which ensures superior machine performance, improved safety, and environmental responsibility.

KOR’s Head of Product and Commercial, Tim McGregor said it is surprising the products weren’t introduced sooner, as the

robotics equipment provides new ways to solve the issues of safety, time constraints, and sta ng.

“Traditional methods typically involve having multiple people operating hands on at the source of the material,” he said.

“Whether they’re vacuum loading or highpressure water jetting or ultra-high pressure water jetting, they’re e ectively required to put themselves in harm’s way.

“For the rst time in our industry, these robotics give the opportunity to remove the operator out of harm’s way. Instead of an operator needing to hold onto a vacuum hose which is very labor intensive, very di cult, and when in a very high-risk environment can be quite dangerous, it allows them to be removed up to 100m away.

“Instead of having the potential risk of injury, lower productivity and operator fatigue, the robot can work 24/7, preventing operator fatigue and operational issues, and allowing remote use of equipment for longer periods of time, with typically less people needed on the site.”

While the bene ts are clear to see, robotics have previously not been explored as an option for industrial vacuum recovery, which to McGregor, given the climates in Australia, is puzzling.

“A shutdown project may take up to 15 people into dangerous hot and remote environments … so to be able to go from this

number, to less than half with the use of a Gerotto robot, makes it signi cantly easier,” McGregor said.

“In Europe, the robot that we have for vacuum loading and high-pressure water jetting has been the standard for operation for decades, but until now they have not been adopted in Australia.

“We are showcasing this industry change for the rst time as it allows operators to be out of high-risk environments that, until now, has never been known to be achievable. is is mainly because this type of equipment has never existed in our region and even if people have known about it, they haven’t properly understood. So up until now it has just been too di cult for the industry to adopt.”

He said a shift in the workforce, where younger generations appear less likely to work in high-risk environments, led KOR sourcing safer work methods with robotic solutions which will assist growing industry appeal.

McGregor said the early adopters have been more than satis ed to what is a major change in their operations.

“Everyone’s been extremely receptive, whether it’s been through demonstrations in Australia and New Zealand or when a number of prospective customers come with us to visit the manufacturers in Europe” he said.

“ e response has been a light bulb moment for people when they rst understand the capability and equipment and the safety it can provide, and particularly around removing the need for mass labor on certain projects, because not only can it make it safer, but it can also simplify management by as it reduces the amount of operators.

“Customers who have purchased the equipment have very quickly seen the bene ts operationally and talking with us about future purchases for additional work … But it is confronting for some customers to understand how their business can transition from operators holding equipment in high-risk environments, to removing themselves and operating outside that high-risk environment therefore conducting projects in a safer way, but in a di erent operational format with not having someone right at the source.”

For more information, visit KOR.com.au

EXPERTS IN TUNNEL PLANNING &

Setting the standard in vacuum excavation

Vacuum excavation is the modern solution to a long-standing challenge, using high-pressure water or air to break up soil and safely reveal underground infrastructure, such as gas, water, electricity, and communication lines, without causing damage.

Today, most contractors know how critical vacuum excavation is, especially since the ground beneath footpaths and roads is a web of vital services powering households and businesses.

For contractors, choosing the right vacuum excavation machine is no small task. It can be the di erence between winning a contract and losing it to a competitor. e stakes are high, but Vermeer Australia makes it easy.

What sets Vermeer apart?

Gone are the days when contractors had months to source equipment. Projects start fast, and downtime is costly. at’s why Vermeer Australia has trucks tted with vacuum excavation machines ready to roll. From 2000L to 7600L machines, with a range of power capabilities, the company has got projects covered.

With 13 dealerships across Australia, Vermeer Australia is ready to support operations no matter where the project is. Its experienced sales managers work with clients to understand needs, ensuring they get the machine that maximises e ciency, minimises downtime, and boosts your pro tability.

Built to perform, designed to last Vermeer’s vacuum excavation machines are built with the industry’s best components:

• Engines from trusted brands like John Deere, Kubota, and Yanmar ensure reliability and power

• Root blowers, known for their e ciency and durability, feature a dual oil bath system for both gears and bearings. Unlike others that rely on grease on one side (an easy oversight leading to costly failures), our blowers are designed to keep you running smoothly

Smart boom design for maximum productivity

Operator fatigue from handling heavy, mudlled hoses can slow down your crew, and blockages in traditional booms can lead to hours of downtime.

Vermeer’s telescopic booms solve these challenges:

• e hose widens in diameter along its length, starting at 5 inches and extending to 8 inches. Blockages, when they occur, are almost always in the narrower section. Unlike other vacuum excavators that use the same diameter for the whole length of the hose

• Using the remote control, operators can lower the boom to chest height and clear blockages in seconds - no need to leave the site or lose valuable time

• With 270 degrees of rotation, Vermeer booms provide unparalleled reach and manoeuvrability

Vermeer vacuum excavation machines are built with unmatched features that give

users a competitive edge. e reverse ow technology allows users to clear blockages in seconds with the simple ip of a lever, saving valuable time and reducing downtime throughout the year, which boosts both pro ts and client satisfaction. Additionally, the patented Cam-Over locking rear door keeps the spoil tank securely sealed, preventing messy leaks during transport and ensuring a clean and e cient operation.

Vermeer machines also come equipped with advanced operator features designed for ease and safety. User-friendly controls, in-tank cleanout systems, and safety components enhance the overall experience, while the precise water pump PSI-to-litre ratios and integrated weight scales ensure your truck stays within legal limits. ese thoughtful innovations make Vermeer the top choice for reliable and e cient vacuum excavation.

Your partner in success

For over 20 years, Vermeer Australia has been delivering innovative vacuum excavation solutions tailored to the needs of Australian contractors.

Whether you need a compact trailermounted unit or a powerful truck-mounted Mega Vac, the company have the perfect machine for your business.

For more information, visit vermeeraustralia. com.au or contact 1300 VERMEER

The Pezzimenti name has been synonymous with pipeline construction since 1957 when G. Pezzimenti and Sons began contracting to the Melbourne Metropolitan Board of Works.

Since then, Pezzimenti Trenchless has established itself as a leader in the trenchless industry, using the Pezzimentideveloped laser-guided microtunnelling system to install gravity sewers, water mains, stormwater, gas and electrical conduits ranging in diameters from 325 to 1850mm.

Working with all leading sewer and water contractors and all major water boards throughout Victoria and South Australia.

Impreg adds coaching to premium lining products

Impreg is backing its high-quality lining products with coaching and service support.

Since landing in Australia and New Zealand, Impreg has exponentially grown its reach in the regional trenchless industry.

Impreg is one of the world’s leading manufacturers of cured-in-place-pipe (CIPP) liner systems for UV-curing.

e company’s agship GL16 liner was developed for all common pipes from DN 150 to 2000 for sustainable and e cient trenchless rehabilitation.

Impreg liners boast over 100 years of design life, high quality UV resins, easy installation, and extreme durability even under tough conditions. Liners can even be designed to t irregular pipe shapes, like ovoid or liner diameters that transition from one diameter to another in one section.

After an initial consultation to understand the project, Impreg is able to o er a design solution in a matter of days, backed by a distribution centre near Sydney, NSW, and another in Auckland, New Zealand.

And while it’s premium-quality products have certainly helped forge the company’s stellar reputation, there’s much more to the picture.

If you ask Impreg Australia and New Zealand Country Manager Colin Murphy the key to the company’s success in Australasia, he’ll tell you it’s partly to do with the deep connections it forms with its customers and industry partners.

Understanding the complexities of trenchless projects, Impreg backs its customers with nation-wide training and support. If a client is new to UV lining, requires training through an in-person workshop, or is in need of an additional hand onsite, the company is able to go the extra mile to ensure the e ective use of its products on a project.

Murphy, along with Impreg Technical Consultant Jamie Patrick, have been working closely together visiting clients across Australia where they have been involved in many technical discussions, site visits, liner installation assistance and pre-tender meetings.

Most recently, the duo headed to Queensland’s Gold Coast to provide UV installation training to the Nu ow Australasia team alongside ProKASRO Mechatronik.

Training began at Nu ow headquarters over a three-day period and then moved over to New Zealand to provide the same service to Nu ow partners.

e Impreg team carried out theory-based training with videos, slides and then some practical hands-on learning.

Following this the team also made an onsite installation to cement the knowledge.

“Impreg can o er tailored training and technical advice to all our clients both existing and new anywhere in Australia and New Zealand,” Murphy said.

“ is type of high calibre training coming from an experienced technical consultant is unique in our region.

“ is program not only bene ts our clients, but also the UV industry as a whole by keeping the installations across the country at a high standard.”

Patrick echoed this sentiment, adding that they have received great feedback from all who attended the training.

“Look forward to working closely on all upcoming projects with of our clients,” he said.

“We hope to educate our clients on key ‘do’s and don’ts’ to ensure that we get the best installation every time.” Murphy and Patrick will continue to o er a variety of support to the trenchless industry, setting a new standard in UV CIPP customer service in Australasia.

For more information, visit impreg-australia.com

Expertise that delivers

We are a leading tunnelling and underground specialist with broad expertise in delivering complex infrastructure projects across a variety of sectors. With a fleet of tunnel boring machines to cater for any ground condition, experience in various methods of mined excavations and world-leading blind boring capabilities, we ensure your project is delivered on time, on budget, and with great results.

To learn more visit our website abergeldie.com

Pro Line plays pivotal role in groundbreaking Middle Eastern pipeline rehab

Pro Line has been instrumental in currently the largest ever pipeline rehabilitation project in the Middle East through its supply of UV-CIPP liners.

In a monumental achievement for both Pro Line and the UV-cured-in-place-pipe (UV-CIPP) industry, the company has successfully partnered with a local installation contractor for the largest UV-CIPP projects in the Middle East.

e project, which spanned over 1.2km of DN1100 to DN1900 presented a unique set of challenges, but Pro Line’s innovative solutions and expertise ultimately helped lead to the successful delivery.

As a testament to its partnership approach, Pro Line strategically partnered with the local installation contractor for supply of UV-CIPP liner as well as experienced on-site technicians.

e UV-CIPP liners supplied by Pro Line were designed to ensure a full structural relining of the host pipe as well as to meet the rigorous demands of the Middle East’s extreme environmental conditions.

e project’s success was heavily reliant on the precision of the liners, as well as the expertise of Pro Line’s team, ensuring that the large-diameter pipes were rehabilitated in a timely and e cient manner, minimising disruption to the surrounding areas and extending their life by a further 100 years.

As part of Pro Lines’ support to the local installation contractor, the team worked collaboratively with them around planning, delivery methodology and project management support.

Further to this, Pro Line also supplied three highly skilled on-site technicians for the training of local contractors and delivery crew

to ensure the successful delivery of the project.

e UV relining project was undertaken in one of the most challenging environments in the Middle East, with ambient temperatures regularly exceeding 40 degrees Celsius.

ese high temperatures presented a signi cant challenge, as the work environment can become gruelling for workers and technicians, as well as for the materials involved in the relining process.

e extreme heat posed risks to the integrity of the liner and could have potentially hindered the installation process if not carefully managed.

Moreover, the liners required for the project were considerably large and heavy, particularly when dealing with pipes ranging up to DN1900.

Handling and transporting these liners in such extreme conditions demanded a high level

of logistics coordination, careful planning, and precise execution.

e weight of the liners, combined with the hot temperatures, could have led to di culties in handling, positioning, and curing them correctly.

Pro Line’s UV-CIPP liner, however, proved to be a critical asset in addressing this challenge.

e UV curing process, which allows for rapid hardening of the resin within the liners, played a pivotal role in speeding up the overall project timeline.

e ability to deliver and cure the liners quickly allowed the project to stay on schedule, even under the pressure of tight deadlines.

Pro Line’s team of skilled technicians provided invaluable expertise throughout the project.

From overseeing the logistics of liner supply to ensuring correct installation techniques, Pro Line’s technicians played a vital role in ensuring that the liners were installed to the highest standards.

e technician’s experience and training allowed them to work seamlessly with local teams, solving any issues that arose and ensuring the project was completed on time and within budget.

Technical support is a key pillar of the Pro Line business and an area the business works closely with all clients across all projects.

e use of Pro Line’s UV-CIPP system not only ensured the timely rehabilitation of 1.2Kkm of large-diameter pipes but also helped extend the lifespan of these critical infrastructure components by a further 100 years, o ering long-term solutions for the region’s aging pipeline network.

As a result, Pro Line’s UV-CIPP liners provided a durable, cost-e ective, and e cient method for pipeline rehabilitation, reducing the need for expensive and disruptive excavation work.

By overcoming extreme environmental conditions, tight timelines, and complex logistical challenges, Pro Line has solidi ed its position as a leader in the UV-CIPP sector, demonstrating its commitment to providing innovative and high-quality solutions.

For more information, contact info@pro-line.com.au

Renoline powers ahead with innovation in pipeline renewal

Renoline is redefining pipeline rehabilitation with cutting-edge technology, securing major contracts and pushing the boundaries of efficiency in trenchless repair.

As a trusted family-owned and operated business, Renoline brings extensive industry experience, re ning its expertise in e cient, precise, and minimally disruptive cleaning and renewal methods for compromised drainage systems.

With over 35 years of experience, Director Rick Johnstone leads with a focus on innovation, continuously enhancing the company’s capabilities and service o erings to better support customers and reduce operational disruptions.

is dedication to progress has driven the

company to adopt cutting-edge technology, ensuring they remain at the forefront of trenchless pipe repair solutions.

A commitment to investing in the right equipment has enabled Renoline to e ciently carry out residential and commercial renewal work across Brisbane, regional Queensland, and beyond.

In 2024, the company took a signi cant step forward with the acquisition of the state-of-theart Cosmic System from Cosmic Engineering. is modular system has enhanced Renoline’s ability to conduct high-precision mainlines and

lateral inspections, perform robotic cutting, and install UV-cured tophat seals and shortform patches in sewer and stormwater pipes.

“Since entering the Australian and New Zealand markets through local supplier Pipe Core, the Cosmic System has proven to be a high-performance, dependable, and long-term solution, particularly valued by local councils, water authorities, and asset owners looking for modern, cost-e ective maintenance options,” Jason Marshall, CEO at Pipe Core said.

One of the standout projects using this technology has been Renoline’s ongoing

contract in Moreton Bay, where the team has averaged forty tophat installations per week as part of an extensive pipeline rehabilitation program.

“Our client has been highly impressed with this UV technology, which has led to additional secured work for our team. e e ciency and precision of the system allow us to deliver high-quality results while minimising disruption to surrounding communities,” Johnstone said.

While one crew remains dedicated to the Moreton Bay program of works, another team was temporarily stationed at Murwillumbah High School in the Northern Rivers of New South Wales, assisting Hutchinson Builders with the relining phase of their school upgrade. is project showcased some of Renoline’s newest, high-performance equipment.

Operating within a tight timeframe, the crew successfully relined 45m of DN150 pipes using a Renssi RID-800XL Inversion Drum, the I.S.T. VIOLIGHT system – cutting-edge UV technology for the trenchless pipeline renewal, and the Hächler Climbolino E, an advanced electric milling robot from Germanmanufacturer Hächler GmbH – capable of tackling pipes from DN60-DN300.

“ e most challenging aspect of the project was navigating ve 90-degree bends along the pipeline, requiring expert execution to ensure a awless installation,” Johnstone said.

“Despite the relining taking place during school holidays, it was crucial to remain on schedule to avoid disrupting Hutchinson Builders’ overall timeline.”

e job was completed in just three days, following thorough cleaning, UV lining, precision cutting with the Climbolino E, and a nal CCTV inspection using the Scanprobe X40, an advanced drainage inspection camera system designed for optimal control and surveying around tight bends.

As part of its continuous drive toward sustainability and e ciency, Renoline has further expanded its capabilities with the purchase of the rst ROM bv e-Cube, a 100 per cent battery-powered sewer cleaning jetter. is innovative piece of equipment has already been deployed at Castlemaine Brewery,

home of the XXXX beer brand, showcasing its ability to deliver powerful cleaning performance with zero emissions.

Designed for urban environments, the ROM e-Cube operates with a cleaning pressure of 150 bar and a water capacity of 50 l/min while producing minimal noise pollution. Its lightweight design integrates seamlessly into light delivery vans, making it a versatile and practical solution for both commercial and residential applications.

Renoline’s ability to adapt, innovate, and embrace cutting-edge technology has

positioned it as a leader in trenchless pipeline renewal. Strategic investment in advanced equipment has not only improved operational e ciency but also reinforced the company’s reputation for delivering consistent, highquality solutions.

By staying ahead of market demands and maintaining a strong focus on customer service and long-term partnerships, Renoline continues to set itself apart with an approach that prioritises both innovation and reliability.

MARKSMAN HDD GUIDANCE SYSTEM.

CUT THRU THE

NOISE.

The Subsite® Marksman HDD Guidance System provides superior performance in high-interference environments with the industry’s widest range of frequencies in a single beacon. Easy to use with your choice of user interface, the Marksman View features intuitive graphics and clear data, and with a simple single toggle control you’re more productive from day one.

Continuous cross-section measurement in ovoid pipes

IBAK discusses the successful execution of a sewer rehabilitation project, where its inspection equipment played a critical role.

The City of Dortmund, Germany, with nearly 600,000 residents, operates a sewer network spanning 1996km. As part of modernisation e orts, the Dortmund Sewage Department commissioned VOGEL Ingenieure GmbH to rehabilitate combined wastewater sewers built between 1882 and 1920. is includes 24 brick-built sewer sections with ovoid cross-sections measuring 600/900, 700/1050, and 900/1350, totalling over 1230m. To ensure the success of rehabilitation, accurate cross-section measurements were necessary.

e historic construction methods presented unique challenges, such as curved layouts and inaccessible lateral in ows. Many of the a ected sewers run beneath high-tra c areas, requiring careful planning and tra crelated permits.

To obtain high-quality data, sections were temporarily taken out of service, cleaned with high-pressure jetting, and inspected optically. Existing TV inspection data (2006–2014), digital site plans, and manhole measurements supplemented the study. VOGEL Ingenieure

GmbH managed coordination to ensure smooth execution and work ow.

Traditional manhole-based measurements and pointwise assessments in larger sewers were insu cient, as cross-section variations of a few centimetres remained undetected. ese gradual changes impact liner dimensioning, which requires precise internal size data to ensure durability over a 50-year lifespan. Optical inspections alone do not reveal subtle variations, necessitating continuous crosssection measurement.

The

IBAK solution

e IBAK ORPHEUS 2 pan-and-rotate camera with integrated lasers enabled comprehensive cross-section measurement during standard optical inspections. e laser scan took place as the camera returned from the target manhole to the starting point, traveling at a steady speed of 5–7cm per second. e rugged IBAK T 86 tractor ensured stability in sections with fractures and bends. e laser system seamlessly integrated into the inspection process,

eliminating extra setup time. Switching from inspection to laser scan mode automatically deactivated standard lighting and activated laser measurement. As the camera reversed and rotated, it generated a spiral of laser points, capturing the entire pipe cross-section. e density of the spiral depended on reversing speed—slower speeds yielded more precise measurements. e system calculated the pipe centre from measured values, allowing exibility in camera alignment.

Data analysis with IKAS evolution so ware

Planning engineers analysed the captured laser points using IKAS evolution software. A reference curve of expected dimensions helped validate results, with software tools allowing direct video cross-referencing. Engineers could identify anomalies such as deposits, residual water, and structural defects.

To improve measurement accuracy, irrelevant data (such as water accumulation or deposits) was masked and replaced with ideal values. Expert post-processing ensured accurate

liner dimensioning, as small errors could signi cantly impact liner t and performance. For instance, an uncorrected circumference measurement of 2513mm was adjusted to 2609mm (a 3.8 per cent correction), preventing miscalculations that could a ect rehabilitation planning.

Analysis revealed that all reviewed pipes had larger circumferences and heights than asset records indicated. In seven of 24 cases, circumference variations within sections exceeded seven per cent. One section exhibited a 12.5 per cent di erence between its maximum and minimum circumferences, emphasising the need for precise measurements when selecting liners.

For instance, a section recorded as 600/900 showed a 17.02 per cent larger circumference than expected, prompting a reassessment to 700/1050. Another section’s minimum circumference exceeded its recorded value by 13.11 per cent, indicating an intermediate size. Even seemingly minor deviations required expert analysis to ensure liners could stretch adequately without exceeding material limits.

Correct liner sizing prevents issues such as incomplete adhesion, excessive annular gaps, and overstressing. Without proper adjustments, liners may not conform properly or could su er premature failure.

IKAS evolution software presented results in clear, structured reports integrated with video data.

is allowed the Dortmund Sewage Department to make informed rehabilitation decisions based on precise crosssection measurements.

What comes next?

Proper sewer cleaning before laser scanning is crucial to minimise measurement disruptions. e continuous, laser-supported measurement method with the IBAK ORPHEUS 2 provided signi cantly more accurate cross-section data than traditional optical inspections. is data plays a key role in selecting and sizing liners to match actual pipe dimensions, preventing installation failures and extending service life.

By incorporating continuous cross-section measurements during planning, delays and

costly modi cations can be avoided. e data also aids in optimising liner procurement, ensuring appropriate stretch capacity and durability.

VOGEL Ingenieure GmbH is now preparing implementation plans and tender documents, with additional studies such as ground investigations and static calculations underway. e project aims to launch tenders in summer 2020, with rehabilitation work beginning in 2021. is project underscores the importance of precise sewer assessments for successful infrastructure rehabilitation, demonstrating the value of advanced measurement technologies in municipal planning.

A reliable partner in HDD excellence

AJ Civils Australia is a leader in the horizonal directional drilling industry, focused on providing top-tier services in civil works.

Aspecialist in HDD, open cut works, and utility installations for major clients, AJ Civil Australia’s work spans telecommunications, water, sewer, and power upgrades, among other infrastructure projects.

Tanya Bowen, a key gure at AJ Civils and wife of founder Tony Johnston, emphasised the company’s people- rst approach.

“It’s about the team and the people who make it all happen. We have had many great employees over the years who have been integral to our success, and we couldn’t do it without them” she said.

As part of its commitment to staying at the forefront of the horizonal directional drilling (HDD) industry, AJ Civils relies on high-quality equipment, particularly from TRACTO, a trusted partner in its operations.

Over the years, the company has accumulated a signi cant eet of TRACTO drills, one of the largest across Australia and New Zealand.

Bowen said TRACTO’s products are ideal for the projects the company takes on.

“ e advanced control systems provide high accuracy and e ciency, which is critical

for bore planning. e machines are userfriendly and designed with ergonomics in mind, which is great for operator comfort,” she said.

Another key bene t is the integration of bore data, which can be monitored remotely in real-time.

Bowen highlighted how TRACTO’s commitment to creating low-emission engines aligns with their values, adding, “the German engineering is designed with fuel e ciency and environmental impact in mind, which is important to our clients as well”.

One of the standout features of TRACTO, according to Bowen, is the company’s customer service.

“ ey o er training with each machine purchase and have fantastic technicians to solve any issues. ere are times when machines need support, and TRACTO’s team is very responsive and understands our high expectations for minimal downtime,” she said.

AJ Civils has worked on several impressive projects using TRACTO drills.

Recent projects include: a challenging

350mm diameter bore under a freeway in Berwick; installing a 20-way bore for Telstra in Box Hill; a 255m four-way bore under the Maribyrnong River; and a 460m bore in Longwarry, navigating rocky and hilly terrain.

“Every bore presents a unique challenge, and we have the right machinery and skilled sta to get the job done,” Bowen said.

As AJ Civils looks towards the future, the company is con dent in its ability to meet the demands of an ever-evolving industry.

Its dedication to quality, customer service, and continual improvement sets it apart, making them one of the standout players in the HDD sector.

For Bowen and Johnston, the journey is far from over.

“We’ve built a solid relationship with TRACTO over the years, and we look forward to continuing our successful partnership,” Bowen said.

With a strong foundation, a growing eet, and a highly skilled team, the future of AJ Civils is undoubtedly bright.

For more information, visit tracto.com/au

ROVION HD THE FUTURE OF SEWER INSPECTION

Full HD Video Capability: Capture more detail and ensure accurate inspections.

Steerable 6-Wheel Drive: Overcome obstacles and navigate complex pipelines with ease.

Modular System: Easily configurable for various pipe sizes and inspection challenges.

Reliable Design: Built to endure harsh conditions and reduce downtime.

Contact SECA today to learn how the ROVION HD can revolutionise your sewer inspections.

All Terrain Directional Drill now in good supply

With the frustration of stock delivery delays now firmly in the rear-view mirror, Ditch Witch CEA is boasting a strong supply of Ditch Witch AT32 All Terrain Directional Drill’s.

Contractors, local councils, and water authorities around Australia often grapple with the challenge of trenchless tunnelling in any terrain.

In many urban settings throughout Australia, contractors and local councils not only need to deal with busy environments but the di culty of managing noise. In rural settings, getting to the site can create a unique set of circumstances.

e AT32 enhances utility contractors’ productivity while drilling through hard rock. e newly designed mid-size drill replaces the AT30. ey provide better power and easier system operation for increased operator e ciency and pro tability.

Designed with more power, stability, and advanced electronics, the AT32 features a 155-horsepower Cummins Diesel engine. It combines seamlessly with 32,000lb of thrust and pullback and has increased rotational torque by 50 per cent over the previous AT30. ese features combine to ensure that AT32 has the power for e cient installations in any soil condition.

Ditch Witch HDD Global Product Marketing Manager Je Davis said the AT32 lls a gap in the market of mid-size HDD tools, “bringing full-size power to the job site without the full-size footprint”.

“ e result is an accessible, compact, and versatile machine that boosts productivity on various rural and urban job sites,” he said.

e unit features a new rod loading system that allows operators to carry 137m of AT drill pipe on board. is is 30 per cent more than the AT30. Drillers can manually insert additional sticks of pipe when running low.

A higher-powered uid pump helps contractors get the most out of their machine by providing 40 per cent more uid ow to help operators stay productive on longer bores with larger diameters. It also improves e ciency with less wear and tear on downhole tooling.

A heavy-duty anchor system holds the operational position for more precise control in all soil conditions. e latest version in the all-terrain evolution also features 4200lb (5694 Nm) of rotational torque to release new performance levels.

“ e new look AT32 replaces the outgoing AT30 model, o ering signi cantly more power and e ciency advancements in a similar footprint,” Ditch Witch CEA Brand Leader Scott O’Hare said.

“ e AT32 shares a common platform with existing next-generation models in the Ditch Witch line-up with features such as a new climate-controlled quiet cabin, increased power, thrust and torque, more onboard pipe, and a higher ow uid pump.

“CEA also o ers local HDD guidance and utility locator servicing for their Subsite Electronics products. In addition, CEA also provides operator training via their Virtual Reality Simulator, based on these new HDD models. ese are all important factors in the aftersales support in the drilling market.”

e AT32 follows the same modern design evolution as other latest Ditch Witch directional drills to enhance operator comfortability and ease of operator use and now comes standard with multi-mode joysticks (like all new generation Ditch Witch drills), allowing operators to select between single and dual stick operation.

e consistent design also makes it easy for current customers to step into the machine and become familiar with its controls, features, and operator platform, which boosts uptime.

e two 7-inch LED screens support a focused approach to drilling. At the same time, the Subsite Marksman + HDD Tracker has been designed for interference mitigation and avoidance, beacon performance, and ease of use.

Better tracking results lead to better bores, providing improved performance at deeper depths.

e Marksman HDD Guidance System performs well in high-interference environments with a large range of frequencies in a single beacon. e tracker weighs 3.2kg and has a battery life of up to 16 hours. It also comes with on-screen menus, graphics, and an integrated GPS.

“ e AT32 is standard with an in-built screen for the Subsite Marksman +: the most advanced tracker in the Subsite Electronics line up. It also provides access to all the Subsite technology to minimise risks to owners and increase their e ciency and pro tability,”

O’Hare said.

“ e new user interface is user friendly, o ering the choice of di erent views, which will make it suitable for both new and existing Subsite customers.”

Ditch Witch CEA has a comprehensive lineup of directional drills, HDD tooling, vacuum excavators, trenchers, vibratory ploughs and more available on the market. With impetus on power, the Ditch Witch range is curated to withstand extreme use.

Construction Equipment Australia (CEA) supplies equipment to many industries, from construction to agriculture and waste management. All machines are developed for their grunt, versatility, and ergonomics, backed by more than 70 years of expertise.

Ditch Witch CEA has AT32 units available for order.

For more information, call 1300 788 757

Thinking outside the box

Tailor-made solution for an unusual box culvert at Penrith water recycling plant.

The rehabilitation of aging infrastructure presents unique challenges, often requiring innovative solutions to extend asset life while minimising disruption. is was precisely the case at the Penrith water recycling plant in New South Wales, where high water levels in the oxidation ponds caused the culvert structure to become pressurised, leading to surcharges. ese surcharges, combined with the deteriorating condition of the culvert, posed a risk to the surrounding environment and were also causing damage to the aboveground infrastructure. e culvert was a precast reinforced concrete box structure set on a reinforced concrete base, with internal dimensions measuring 1800mm in width and 900mm in height.

What initially seemed like a straightforward relining project quickly revealed itself to be a far more complex challenge.

A 30m section of the culvert presented an unexpected anomaly: a non-standard shape where the structure tapered down to approximately 50 per cent of its original height before expanding back to full capacity. Traditionally, a complex section like this would have been dug up and replaced – but this is a costly, disruptive and time-consuming process. Calculations showed that applying the twin Rotaloc methodology to this section of culvert would have resulted in a hydraulic capacity that was lower than acceptable; and stainless steel sleeving was also considered but ruled out earlier because of the associated cost and the weight of each section.

Faced with these challenges, Inter ow turned to Channeline for a solution that would deliver durability, precision, and e ciency. Channeline’s bespoke glass reinforced plastic (GRP) lining system provided the perfect answer to this complex problem. Unlike conventional relining methods, Channeline’s liners are individually designed and handcrafted to ensure a precise t within existing structures – regardless of shape, size, or dimensional variations. is unique manufacturing approach proved to be invaluable in addressing the Penrith culvert’s irregular geometry.

The Channeline advantage e unique advantage of Channeline is its ability to accommodate complex shapes and non-standard dimensions, thanks to the

company’s bespoke design and manufacturing processes. is was particularly crucial for the Penrith culvert, which was not only non-circular (box) shaped, but also had a signi cant change in internal diameter over the a ected section.

ere is really no theoretical limit to the shapes and sizes that Channeline liners can come in. For this project, a transition liner was created to facilitate a seamless shift between the changing diameter. is seamless shift decreases turbulence within the pipeline, and continues to ensure optimal set up, crosssectional area, and ow e ectiveness.

A successful installation

e rehabilitation process began with a trial installation using a timber template to verify the liner’s t within the culvert’s unique shape. is preliminary step con rmed that the bespoke Channeline solution would t

seamlessly inside the structure. en, with precision manufacturing complete, the custom liner was delivered and installed. Person-entry into this section of culvert wasn’t permitted, so each segment was winched into place, then sealed.