LEADING

MANAGING CLIMATE RISK

The impacts of severe weather events are being mitigated through infrastructure design

UNITING INDUSTRY

A full review of one of this year’s most anticipated industry events

Setting new benchmarks in manhole construction

the way IN SAFETY

CLOSE TO OUR CUSTOMERS. For decades, HAMM oscillation has been the go-to compaction method for quality results on sensitive asphalt mixes like SMA and EME-2, especially around vibration sensitive assets like pipelines, bridge decks and buildings. Now HAMM has introduced Smart Compact Pro - another breakthrough in compaction efficiency that incorporates real-time density on the fly. Do you want to be known for producing quality pavements, quickly and with less re-work? Let Hamm help.

COVER STORY

14 Safer manholes. Smarter solutions

How Manhole Form Hire’s latest innovations are again lifting industry standards and driving new levels of safety, efficiency, and performance on worksites across Australia.

ROADS REVIEW

18 Roads Review

This month, we asked the industry’s decision-makers, ‘What fills you with optimism moving into 2026?’

TECHNOLOGY

20 Data delivering for community GBM Konect has become a fundamental tool with the location-based data collection and asset management tool ensuring the efficient delivery of essential services that residents depend on.

INNOVATION

22 Perfecting the bond

Utilising its vast global experience in polymer modified bitumen blends, Sripath has developed a brand-new product for the market, which aims to tackle a legacy industry pain-point.

25 If it ‘ain’t’ broke…

Sealants & Pavement Adhesives’ product offering has endured for decades, with t wo key product ranges forming the bedrock of the company’s growth and success in the market.

28 Decades ahead

The innovation and design of Geoquest Australia’s products are helping to minimise the impacts of weather events on infrastructure, with turn-key solutions emerging as a potential solution.

PROJECT REPORT

31 Here to stay RoadAid’s works on a major project signify the next phase of growth for the company, which is now setting its sights on interstate projects.

MACHINERY AND EQUIPMENT

34 Expanding what’s proven Specialised Roading Equipment’s first ever Australian fixed wing sprayer has made shore, aiming to offer an improved and increasingly accessible, safe and smart option for operators.

37 Constructing the future

Komatsu is navigating a shifting construction landscape by balancing innovation and training, launching new flagship machines, and advancing smart, safe, and sustainable growth across Australia and the region.

40 A safer skid steer

As construction sites continue to prioritise safety and efficiency, JCB has redefined the traditional skid steer design with innovative engineering that enhances visibility, comfort, and overall site safety.

ASSOCIATION SECTION

42 Streamlined precast delivery

The Sydney Metro Viaduct is a pivotal link in the city’s largest public transport project.

44 Remarkable transformation recognised

Municipal Works Australia’s nomination for the Most Improved Association category in the prestigious 2025 Associations Forum Awards signifies five years of extraordinary growth, reform, and renewed purpose.

46 Deeper knowledge builds better roads

A well-built road is more than just a smooth black surface – it’s a testament to engineering, teamwork, and understanding.

48 Lighting the path forward

The 20th International Conference of the Australian Flexible Pavement Association has united industry to address challenges and optimise opportunities for the sector’s betterment.

EVENTS

50 Driving Innovation, Sustaining the Planet

Roads & Infrastructure breaks down SAMI Bitumen Technologies’ recent attendance and exhibitor booth from the latest International Flexible Pavement Conference.

52 The stage is set

As preparations get underway for International No-Dig 2026, Prime Creative Media reflects on the host nation’s current trenchless landscape.

54 Turning bulk problems into big wins Bulk Expo 2026 brings Australia’s bulk handling industry together to solve problems, share solutions, and turn ideas into action.

Roads & Infrastructure provides an update on some of the contracts and tenders recently awarded or put to market across the Australian infrastructure sector. The concluding issue of Roads & Infrastructure magazine for 2025 marks

56 Nominations now open for the 2026 Endeavour Awards

N ominations are now open for the 2026 Endeavour Awards, Australia’s premier celebration of excellence and innovation in manufacturing.

CONTRACTS AND TENDERS

58 Contracts in brief

CEO

Christine Clancy

christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker

sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki

lisa.korycki@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey

ART DIRECTOR

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Loren Katie Logan lorenkatie.logan@primecreative.com.au

CLIENT SUCCESS MANAGER

Sabrina Zor sabrina.zor@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 info@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COVER IMAGE

Noble Joe Productions

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

WHAT A YEAR!

WE’VE REACHED THE END OF 2025, and what a year it’s been for the sector. Ongoing challenges from the past few years persist, but despite this, industry has achieved so much in the past 12 months.

Melbourne’s Metro and West Gate tunnels will open, the METRONET Byford Rail Extension and first permanent section of the North East Link are already open, and that’s just a small taste.

Tasmania’s largest ever infrastructure project, the $786 million Bridgewater Bridge also opened, as did the $165 million Tiger Brennan Drive Overpass in the Northern Territory. Not to mention the $1.46 billion Wilman Wadandi Highway –the largest ever road project delivered in the South West region – which is now open in Western Australia.

Major works also continue to power on for some of Australia’s largest ever infrastructure investments, including the $3.4 billion infrastructure pipeline for the Brisbane 2032 Olympic and Paralympic Games, the multi-state Inland Rail Project, as well as the River Torrens to Darlington Project in South Australia, just to name a few.

It’s great to see momentum building toward and into 2026.

For the last cover story of 2025, the Roads & Infrastructure team was fortunate to sit down with Manhole Form Hire. What started as a literal backyard operation grew into a successful business because Founder and master concreter Cliff Rae-Smith introduced a previously unheard-of level of precision, saving time and improving outcomes on worksites. Make sure to check out what is a great story, about what it takes to reach and maintain a position of preference in the sector.

Also in this edition, we provide a full recap of the recent 20th International Conference of the Australian Flexible Pavement Association, which featured a mix of presentations, networking events and keynotes, all geared towards influencing advancement and improvement within the industry.

We also hear from thought leaders in the industry, regarding their hopes and wishes for next year.

Thanks for reading and supporting the publication in 2025. From the team at Roads & Infrastructure magazine, we hope you have a great Christmas and new year’s break, and we’ll see you in 2026.

Happy reading!

Tom O’Keane

TOM O’KEANE – EDITOR

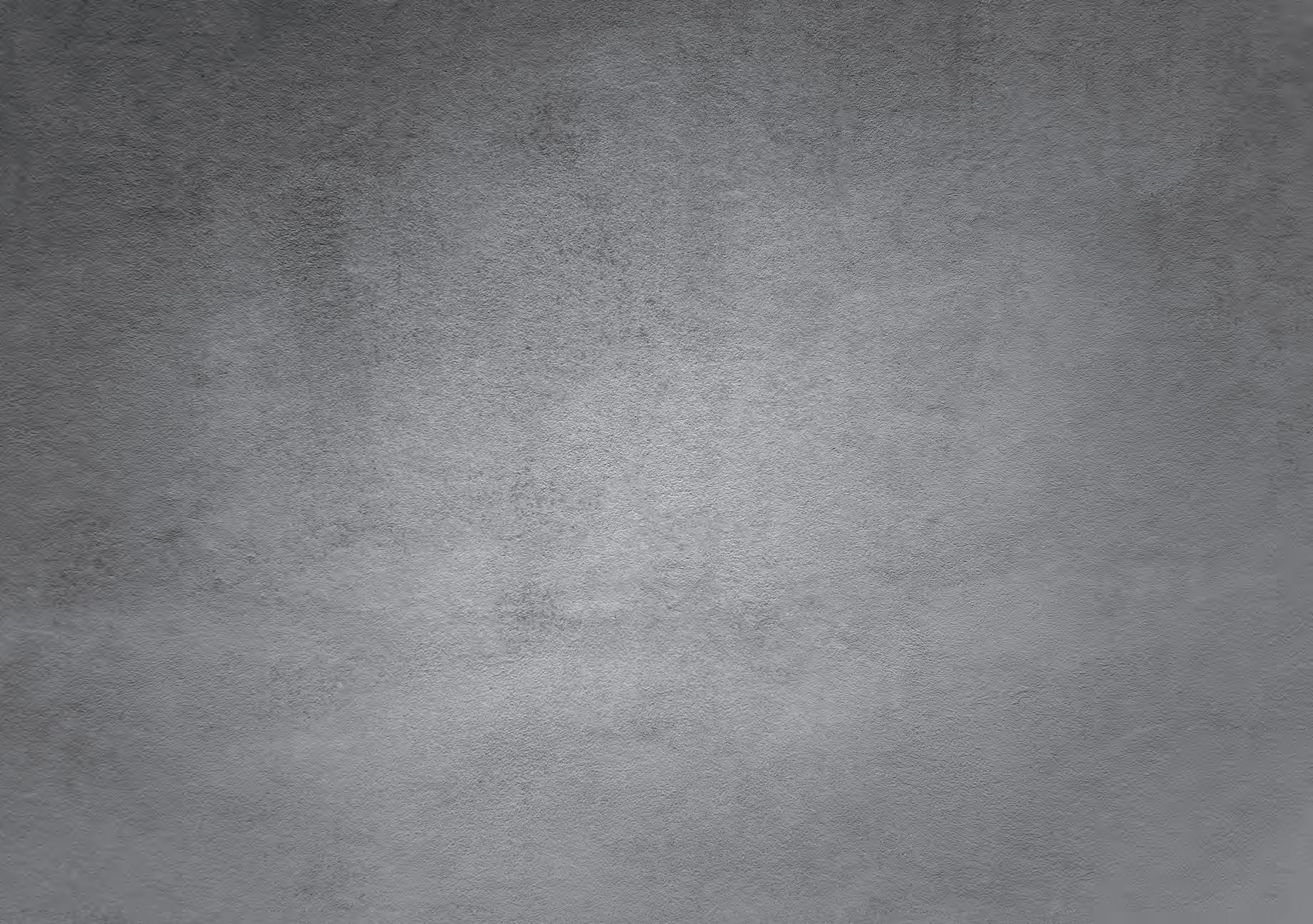

Precision Built-in: 3DMG + Payload Tech Bundle -

Komatsu’s first-fit tech bundle installed at the point of purchase –no third-party installs, no retrofit delays. Just accurate, productive earthworks from day one.

Available on all new 13–50t excavators, this game-changing bundle includes:

• 3DMG + Payload – Real-time 3D Machine Guidance + load monitoring

• Smart Construction Fleet Lite – Payload reporting from the jobsite

• Smart Construction Remote – Remote access and updates

• 12-Month Gold Support – Dedicated support

• 48-month / 8,000-hour warranty – Peace of mind built in This is genuine Komatsu technology – built, fitted and supported by Komatsu.

NATIONAL ROAD TRANSPORT TECHNOLOGY STRATEGY RELEASED

The Federal Government, on behalf of Australia’s infrastructure and transport ministers, has released the National Road Transport Technology Strategy

With the automotive industry changing with greater vehicle connectivity and automated driving technologies, the strategy will support the responsible adoption of these road transport technologies and set out a nationally consistent approach to technology deployment and adoption in the road transport sector. The strategy outlines the policy, regulatory and investment roles

of governments in supporting new road transport technologies and provides a set of nine principles to guide nationally consistent decision-making across all jurisdictions.

level of government will work on through to 2027.

This includes continuing work to develop a national regulatory framework for the safe operation of automated vehicles.

Through the strategy and action plan, the federal, state and territory governments are working together to ensure the community gets the best out of these technologies and the risks are managed.

The 2024-27 National Connected and Automated Vehicle Action Plan, which is being released alongside the strategy, sets out the national priority actions that each

WORLD-FIRST IN TUNNEL CONSTRUCTION ON SYDNEY METRO WEST

The strategy also supports the rollout of connected road infrastructure that can ‘talk’ to vehicles and other road users by developing a national Cooperative Intelligent Transport Systems (C-ITS) roadmap.

Sydney Metro West has achieved a worldfirst in tunnel construction with a Lining Erector Machine (LEM) successfully being used to line the mined service tunnels that connect to the future stabling and

maintenance facility at Clyde. The LEM is approximately 55 metres long and six metres wide and has been customdesigned to line the two 700-metre service tunnels with precast segments, which were

This strategy was endorsed through the Infrastructure and Transport Ministers’ Meeting (ITMM).

manufactured at the project’s Eastern Creek precast yard.

Traditionally, tunnels excavated by roadheaders require cast-in-situ lining. This is unlike tunnels built using tunnel boring machines (TBMs), which have the capability to both excavate and install tunnel segments to line the tunnel walls as they move.

Lining the service tunnels in the usual way would have involved assembling large formwork sections, pumping concrete from the surface, and staging multiple pours.

Instead, project engineers adapted the LEM while on the job, enabling it to complete an entire tunnel ring, built by piecing together four segments.

Weighing 310 tonnes, the LEM has installed 3438 segments and takes around 60 minutes to build a complete ring (four segments). It took two months to line the final service tunnel, which measures 762 metres in length and six metres in diameter.

Sydney Metro West has achieved a world-first in tunnel construction by using a robotic Lining Erector Machine (LEM) to line the service tunnels at Clyde. Image: stock.adobe.com/chitsanupong

The strategy will guide the rollout of new road transport technologies in Australia to help make road transport safer, more productive, sustainable and accessible. Image: stock. adobe.com/dudlajzov

TBM DELIVERY UNDERWAY FOR T2D PROJECT

The first of the Tunnel Boring Machine (TBM) components for South Australia’s biggest infrastructure project have arrived in Adelaide.

The shipment of a TBM cutterhead, delivered in five pieces, marks a milestone in the delivery of the $15.4 billion NorthSouth Corridor project.

The largest and heaviest centre section weighs around 175 tonnes, measuring nine metres in diameter.

Once assembled it is approximately 15 metres in diameter.

The components will be transported from Port Adelaide to the River Torrens to Darlington (T2D) Project Southern

Precinct in Clovelly Park. They will then be reassembled and commissioned ahead of tunnelling works starting in

REVIEW CONDUCTED INTO TUNNELLING CODE OF PRACTICE

The New South Wales Government has released an updated tunnelling code, aiming to keep workers safe from dust diseases.

Tunnelling can pose multiple risks to workers including silica dust exposure from the rock and sandstone being tunnelled through.

Prior to the review, the existing Tunnels Under Construction Code of Practice hasn’t been reviewed since 2006.

Since January 2024 to present, SafeWork NSW has conducted over 100 site inspections in tunnelling sites in the Sydney metro area.

Since 2017, there have been 516 cases of silicosis and 36 deaths due to the disease in New South Wales.

The draft updated code of practice has been developed in consultation with an industry and social partners working group, and covers many aspects of tunnel construction.

Proposed updates to the code include managing silica risks using appropriate controls, with a strong focus on the use engineering controls including adequate ventilation. As well as the inclusion of ventilation officers and certified occupational hygienists in tunnelling as best practice measures. This inclusion is consistent with recommendations from the 2024 Review of the Dust Diseases scheme.

It also highlights managing psychosocial hazards such as remote working which

is often a feature of tunnelling. As well as tunnel boring machine content to account for changing industry practice and the move away from using explosives to tunnel.

The New South Wales Government will analyse contributions and continue to consult with industry and unions before finalising the new code.

Other initiatives outlined in the code include leading the ban on engineered stone benchtops, panels and slabs containing one per cent or greater crystalline silica. This included a national ban on its importation from January 1, 2025.

The state is establishing the Silica Worker Register to monitor and track the health of

the second half of 2026. The T2D Project is jointly funded by the Federal and South Australian governments and is expected to support about 5500 jobs per year during construction.

In total, three large-scale TBMs, each more than 100 metres long, will be used to construct the twin 4.5-kilometre Southern Tunnels and twin 2.2-kilometre Northern Tunnels, as part of the $15.4 billion build.

Two TBMs will launch from the project’s Southern Precinct in Clovelly Park, while the third is set to launch from the Central North Precinct at Richmond, making the T2D Project an Australian-first of three TBMs operating at the same time.

workers undertaking high-risk processing of crystalline silica substances (CSS). It will also establish a Tunnelling Dust Safety Taskforce to help address silica-related health risks in tunnelling projects.

The Taskforce is made up of government, medical, industry and union representatives and provides expert guidance on the prevention of silica and other dust-related diseases, associated with tunnelling projects in New South Wales.

It also includes the establishment of a dedicated silica unit within SafeWork NSW which includes a Silica Compliance Team to enforce strengthened regulations, including proactive visits to sites conducting high-risk CSS processing.

The state has also committed $5 million in funding for silicosis research and a patient support program, to protect workers from dust diseases.

Above: The first TBM components arrived in Adelaide in late October. Image: stock.adobe/seanheatley

The revamped centre features a large digital screen wall, drone pilot stations for rapid incident response, more workspaces, and upgraded communication technology. Image: stock.adobe.com/ suharti

REVAMPED TRANSPORT MANAGEMENT CENTRE REOPENS

The New South Wales’ Transport Management Centre (TMC) has reopened after a $10 million revamp to boost its capability to manage traffic flow and incident response.

The TMC opened in 1999 ahead of the 2000 Sydney Olympics and managed 70 incidents a day.

Following the ten-month project, the Eveleigh facility has the capacity to handle upwards of 700 incidents by coordinating rapid response across roads, the transport network, using traffic lights, a network of cameras, variable message

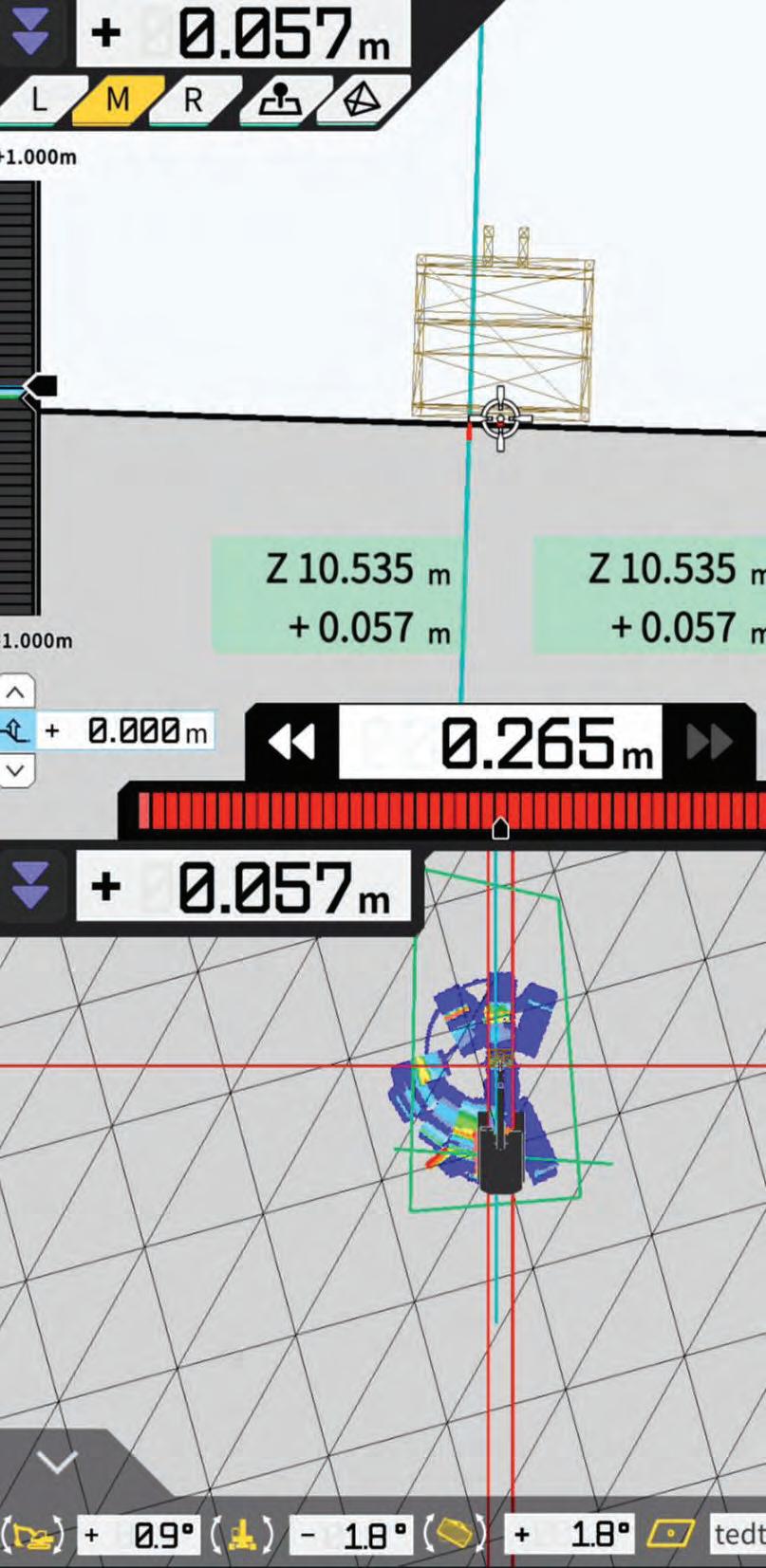

DESIGNS RELEASED FOR TASMAN BRIDGE PATHWAY UPGRADES

New designs have been released for upgrades to the Tasman Bridge’s pathways in Tasmania.

The upgrades are part of the Federal and Tasmanian governments’ $130 million shared commitment to the Tasman Bridge Upgrade project, which aims to make journeys safer for people who walk and ride across the bridge.

The upgrades will include higher barriers on both pathways, added width at handlebar and waist height, addition of safety handrails, improved

signs, traffic response crews and tow trucks. It also coordinates replacement services and major events transport.

The new TMC includes a 23-metre-long digital screen wall streaming live feeds from across the state, allowing the TMC team to display more content, including live CCTV feeds, network data and analytics and other content.

Drone pilot stations with beyondvisual-line-of-sight capability allow crews to direct an immediate response to major incidents in any part of the state. The upgrades also included a 55

per cent increase in workspaces in the main operations room, ensuring there is sufficient space for 24/7 operations. It also included upgraded communications technology for faster public and media updates, and improved lighting, amenities and facilities.

An expanded control room will allow for the recruitment of new team members to add to its current 123 on-site staff, ahead of the opening of Western Sydney International Airport in 2026. A further 320 staff are based across the state.

sight lines, three new passing bays for safer overtaking on each pathway, and improved pathway connections. The designs were developed following

Upgrades include installing three-metre-high waterside barriers and raising roadside barriers to 1.2 metres. Image: stock.adobe.com/tktktk

consultation with key stakeholders and based on extensive technical assessments. They’re now also available for viewing.

ReLIXER® - A Bio-Oil Based Asphalt Rejuvenator

PGXpand® - A Bitumen-Friendly Polymeric-Additive

PHALANX® - Environmentally Friendly Warm Mix Additive

ButaPhalt® - An Innovative Crosslinking Additive

- A Bio-Oil

Bitumen

Contact our Sripath Asia-Pac team at ravi@sripathapc.com or 1800 191 799 Learn more about our products at sripath.com

WALKING AND CYCLING BRIDGE OPENS AS PART OF WEST GATE TUNNEL PROJECT

A new dedicated walking and cycling bridge is now open along Dynon Road, as part of the West Gate Tunnel Project in Victoria.

The new bridge has been designed to provide a safer and more accessible way to travel between the Moonee Ponds Creek Trail, across the rail yards, into the North Melbourne Station precinct and onto the city.

Spanning 440 metres across the rail yards near North Melbourne Station,

the new bridge separates bike riders and pedestrians from vehicles.

At three metres wide, the bridge accommodates a range of active transport – including walkers, runners, bike riders as well as mobility scooters, wheelchairs and prams.

The new path gives bike riders from the west two direct routes into the city. One via the Footscray Road path, offering direct access to Docklands and central Melbourne’s broader cycling network,

and another via Dynon Road, providing a link to North Melbourne, Carlton, and nearby suburbs.

The bridge also provides a safer and more convenient alternative to crossing busy arterial roads, giving people a protected route between North Melbourne and the Moonee Ponds Creek Trail and will connect with the recently opened green bridge across Footscray Road and Waterfront Way and the future veloway.

$200 MILLION ROAD MAINTENANCE BLITZ ACROSS GREATER SYDNEY

The New South Wales Government has fast-tracked $200 million to deliver pothole and road maintenance across some of Sydney’s busiest corridors.

With more than 5100 potholes already repaired across Sydney’s roads this past August and September, the new funding aims to further improve the safety, reliability, and resilience of the network by ensuring faster repairs, fewer potholes, and reduced vehicle damage.

Work under the program will be prioritised based on traffic volumes, the location and severity of the pothole, and the road’s importance for freight, bus services, and emergency access.

In 2024, 1.57 million hours of maintenance work were completed across Sydney’s roads, resulting in 10,879 potholes repaired, nearly one million square metres of road resurfaced and 344,000 linear metres of new line markings installed.

This bridge provides a safer, more direct connection for pedestrians and cyclists between the city, the Moonee Ponds Creek Trail, and suburbs in the west. Image: Victorian Government

SMARTER SOLUTIONS SAFER MANHOLES.

ROADS & INFRASTRUCTURE LEARNS HOW MANHOLE FORM HIRE’S LATEST INNOVATIONS ARE ONCE AGAIN LIF TING INDUSTRY STANDARDS AND DRIVING NEW LEVELS OF SAFETY, EFFICIENCY, AND PERFORMANCE ON WORKSITES ACROSS AUSTRALIA.

Since its beginnings in 1994, Manhole Form Hire has built a reputation as a trusted name in civil construction, delivering certified and patented in-situ forms known for their reliability and strength.

The company was founded by master concreter Cliff Rae-Smith, whose ingenuity in building his own manhole forms in his backyard sparked an industry shift. Rae-Smith’s early designs allowed chambers to be cast in-situ, with precision that was previously unheard of, saving time and improving outcomes on work sites across Queensland.

Today, Manhole Form Hire operates out of Brisbane, Sydney, Melbourne, and the Sunshine Coast – a remarkable expansion from its early days as a small Queensland operation. The company’s steady growth reflects not only increasing demand for its trusted systems but also a reputation built on precision, safety, and reliability.

“It’s been incredible to see how far we’ve come,” says Managing Director, Barry Kuster.

“Demand has continued to grow year after year, and expanding into these regions allows us to better support contractors working further afield. We’re proud to now offer the same trusted service and reliability to projects across a much broader footprint.

DRIVEN BY INNOVATION AND SAFETY

“From the very start, we’ve looked at how to make the process easier for crews on the ground,” says Kuster. “We’re not just supplying gear; we’re creating solutions that make jobs safer and more efficient.”

That mindset has led to a string of innovations that are now industry benchmarks. The latest include improvements to Manhole Form Hire’s patented scaffold system, designed to make working at height during pours safer and more efficient. The full scaffold is quick to assemble, straightforward to use, and makes working at height simple and secure.

After listening to customer feedback, the team developed a half-scaffold, ideal for sites with limited space or where a shoring box is in place. Customers asked, and Manhole Form

Left: The new stair system provides safe, stable access to scaffolding and in-situ forms.

Every form is meticulously cleaned and treated to ensure it’s delivered to site in optimal condition, ready for the next pour.

Hire delivered a solution that keeps the same safety assurances while fitting into tighter conditions.

Building on this success, the scaffold arms have been redesigned to allow secure clearance for stairs supplied by Safe Smart Access. Manhole Form Hire has recently added these stairs to its hire fleet, providing a safer and more stable alternative to ladders. Designed with integrated lifting points, the stairs can be positioned with an excavator, eliminating manual handling and improving onsite efficiency.

This upgrade enhances accessibility and ensures crews can work securely and

productively. Fully certified to Australian Standards and engineered for real-world site conditions, it reflects Manhole Form Hire’s ongoing commitment to smarter, safer, and more practical designs.

At the core of Manhole Form Hire’s operations are its certified inner and outer drums, offered in the largest range of sizes in the industry. Inner drums span from 900 millimetres (mm) to five metres (m), while outer drums range from 1150mm to 5.7m. This versatility

allows contractors to complete projects to exact specifications, whether they’re dealing with smaller pits or large-scale chambers with thicker walls.

Kuster explains, “We know every project is different. By offering such a wide range, we give contractors flexibility. They can complete their work

“WE’RE NOT JUST SUPPLYING GEAR; WE’RE CREATING SOLUTIONS THAT MAKE JOBS SAFER AND MORE EFFICIENT.”

Designed for confined sites, the half-scaffold improves mobility and safety, with the backdrop form ensuring a clean pipe exit at the base.

without compromise, knowing we can supply the right forms for the job.”

Manhole Form Hire has also refined the tools that make the process smoother. Pour boards, for example, were developed to allow concrete to be poured directly from an agitator truck while keeping the inner shaft free from excess material. This not only reduces waste but also helps crews achieve a neater, safer, and faster pour.

The company’s heavy-duty boxes are another standout innovation. Designed for large square or rectangular boxes, the panels can be configured into L-shapes or T-shapes simply by reversing the corners.

Kuster explains that they’re “easy to assemble, adaptable, and perfect for custom requirements.”

Manhole Form Hire’s heavy duty panels were the first of their kind in

Above: Damaged forms are carefully repaired and refinished in-house, maintaining the reliability and performance that customers depend on.

Heavy-duty panels and corners easily configure into L-shapes for flexibility on-site.

the industry and remain unmatched for flexibility and ease of use. The panels range from 150mm to 2100mm and can be configured to suit customers’ exact needs.

Another safety advancement is the introduction of patented lifting lugs, designed to enhance the structural integrity of each form. These make the handling of heavy components far simpler, allowing crews to move them with confidence and efficiency while maintaining strict safety standards.

Together, these innovations form a complete system that has transformed how manholes are poured on site. Crews can now work faster, with less physical strain, fewer hazards, and more predictable results.

“Safety has always been at the heart of what we do,” Kuster says. “If we can reduce risk for the crew while also saving them time, then we’ve achieved what we set out to do.”

SUPPORT THAT DELIVERS

For Manhole Form Hire, innovation doesn’t end with the equipment itself.

The company prides itself on offering comprehensive support to every customer, from helping select the right forms for a job to answering questions about assembly and setup.

“Our gear is straightforward to use, but sometimes customers like the reassurance of having us pop out to site and walk them through it,” Kuster explains. “It’s that extra bit of support that gives crews confidence and keeps jobs running smoothly.”

This customer-first mindset has cemented strong relationships with

contractors across the country. It has also contributed to the company’s reputation as a trusted partner rather than just a supplier.

Kuster emphasises that this approach comes from the company’s roots.

“Cliff built this business on reliability. If he said he’d deliver, he delivered. That’s something we’ve kept front and centre to this day,” he says.

The legacy of Cliff Rae-Smith continues to shape the company’s direction. His eye for detail and passion for innovation still inspire the team, while Kuster’s own leadership has added new layers of inventiveness and efficiency.

Having joined the company in 2002, Kuster has been instrumental in driving quality control, developing new patents, and overseeing the national expansion. His ability to solve problems quickly has earned him the respect of colleagues and customers alike.

Under his stewardship, Manhole Form Hire has become not only a provider of forms but also a driver of industry standards.

Each new piece of equipment introduced is carefully considered, tested, and certified before being released to the market.

This focus on quality has allowed the company to stay ahead, even in a competitive environment. While others may attempt to replicate

Manhole Form Hire’s elongated drum demonstrates on-site versatility, the freedom only in-situ construction can provide.

their designs, Manhole Form Hire continues to lead through originality and reliability.

Looking to the future, Kuster sees plenty of opportunities for further innovation.

”We’ll keep investing in smarter, safer equipment,” he says. “The industry is evolving, and our goal is to make sure crews always have access to the best solutions available.”

For contractors, this means more than just efficiency, it’s the assurance that every pour will be backed by equipment that has been designed with safety and practicality in mind.

It also means knowing that behind every piece of equipment is a team committed to support, service, and continuous improvement.

That combination of innovation, certification, and customer service has made Manhole Form Hire a leader in its field, a position it has held for over three decades. From a backyard vision to a nationwide operation,

the company has never lost sight of its founding values. Precision. Reliability. Innovation.

And with each new system developed, each form delivered, and each chamber poured, those values

continue to shape the future of civil construction.“We’ve got some exciting new complementary products in development, innovations the industry hasn’t seen before. Watch this space,” Kuster says.

Engineered solutions are setting the benchmark for manhole construction across Australia.

ROADS REVIEW

THIS MONTH, WE ASKED THE INDUSTRY’S DECISION-MAKERS, ‘WHAT FILLS YOU WITH OPTIMISM MOVING INTO 2026?’

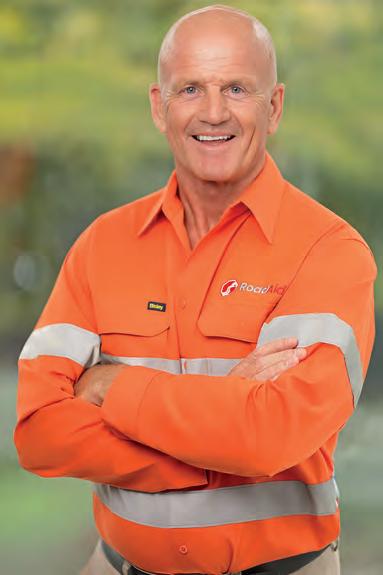

DAVID LIGHTFOOT, QLD DELIVERY COORDINATOR – ROADAID

What gives me optimism heading into 2026 is the change in our industry culture. There is a growing appreciation for the people who keep our infrastructure running, and more emphasis on building strong, capable teams. I am encouraged to see real conversations about career development, wellbeing, and creating workplaces where everyone feels valued. At RoadAid, we have a team that takes pride in what they do and genuinely care about each other’s safety and success. That sense of unity and purpose across the industry gives me confidence that we are moving in the right direction.

Image: RoadAid

MATTHEW BERENI, CHIEF EXECUTIVE OFFICER – TRAFFIC MANAGEMENT ASSOCIATION OF AUSTRALIA

What fills me with optimism moving into 2026 is the momentum across our industry. We’re seeing collaboration at unprecedented levels between government, industry, and technology partners, all focused on improving safety, sustainability, and workforce capability. The shift toward innovation in traffic management, through smart infrastructure, data-driven decision-making, and stronger national standards, means we’re not just managing roads, we’re shaping safer communities. The energy, passion, and professionalism I see in our members every day make me confident that together we’ll keep driving positive change for Australia’s road users and workers.

Image: Traffic Management Association of Australia

CADELL TAYE, CHIEF EXECUTIVE OFFICER – NATIONAL PRECAST CONCRETE ASSOCIATION OF AUSTRALIA

Moving into 2026, I’m optimistic about the growing recognition of precast as a smarter, safer, and more sustainable way to build. Advances in digital design, automation, and AI are transforming how we plan, produce, and deliver precast elements, improving efficiency and quality while reducing waste. The industry’s increasing focus on lowcarbon concrete, circular materials, and factory-controlled, production aligns perfectly with Australia’s sustainability goals. I’m encouraged by stronger collaboration across the supply chain and greater investment in skills and innovation. With these shifts, precast is positioned not just as an alternative construction method, but as a leader in shaping a safer, greener built environment.

Image: National Precast Concrete Association of Australia

KRISHNA SRINIVASAN, PRESIDENT – SRIPATH TECHNOLOGIES

As we move into 2026, I’m filled with optimism about the momentum across our industry. We’re seeing unprecedented innovation in asphalt technologies with solutions that enhance performance while also advancing global sustainability goals. At Sripath, this progress inspires us daily. Our product portfolio is expanding, and our collaborations worldwide are driving measurable impact. In the past five years, Sripath Asia-Pac has made great strides in Australia and New Zealand, forming valuable partnerships across the asphalt industry. As we prepare to celebrate Sripath Technologies’ 20th anniversary next year, I’m proud of how far we’ve come and energised by the opportunities ahead to build more high-performing, sustainable roads.

Image: Sripath Technologies

HORROCKS, DIRECTOR MEMBERSHIP, COMMUNICATIONS AND STAKEHOLDER ENGAGEMENT – AUSTRALIAN FLEXIBLE PAVEMENT ASSOCIATION

Starting in this role at AfPA, I’ve had the chance to meet members from across Australia and every corner of the industry. What’s struck me most is how open people are; sharing ideas, challenges, and a genuine drive to improve how we build and maintain roads. There’s real energy right now, conversations are shifting from ‘why’ to ‘how’ and whether it’s safety, sustainability, standards, or skills, the industry is innovating solutions and getting on with it, and AfPA’s role is to back that momentum, and I’m excited to play my part.

Image: AfPA

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2026, please get in touch with Editor, Tom O’Keane: tom.okeane@primecreative.com.au

SRE’s telescopic bitumen sprayers or our newly developed 8m fixed wing bitumen sprayers are available for late 2026 delivery.

Fully compliant with all Australian regulations our sprayers meet all Austroads performance requirements for bitumen sprayers and are ready to go straight to work.

FOR COMMUNITY DATA DELIVERING

GBM KONECT HAS BECOME A FUNDAMENTAL TOOL FOR MELBOURNE’S BANYULE CITY COUNCIL, WITH THE LOCATION-BASED DATA COLLECTION AND ASSET MAINTENANCE TOOL ENSURING THE EFFICIENT DELIVERY OF ESSENTIAL SERVICES THAT RESIDENTS DEPEND ON.

Located in Melbourne’s north-eastern suburbs, the City of Banyule oversees the delivery of community services for a population greater than 130,000.

Spanning 21 suburbs, the area is known for its parklands, as well as its key industries in construction, education, and health care.

Some years ago – to better support its delivery of community services – Banyule City Council began using GBM Mobile – a previous iteration of GBM’s offering, helping to increase the safety, efficiency and delivery speed of council responsibilities. It was primarily used for data collection, tree management and proactive RMP (Road Management Plan) inspections

It was this journey that would eventually lead the council to connect with locationbased data collection application GBM Konect – a relationship that has blossomed ever since.

Banyule City Council transitioned to GBM Konect shortly after its release, with the initial and enhanced capabilities, such as real-time collaboration among multiple field operators, easier data management, and the ability to tailor use to its needs, a major attraction.

Scott Nutt, Spatial and Property Systems Analyst – Banyule City Council says this migration allowed the council to move from a manual desktop-based data download/ upload process to a modern, field-friendly, real-time solution.

“Konect opened us up to a wider world, given the fact that it’s not plug in and download-driven, like other platforms were at the time,” he says.

“We’ve used the platform ever since to manage our RMP inspections, as well as maintenance works on our footpaths, roads and a whole lot more.”

In fact, Konect’s use has now spread to council’s operations and parks depots, covering roles such as street sweepers, gardeners, mowing crews, drain cleaners, as well as those involved in parks and sports field maintenance.

Nutt attributes this to the flexibility and adaptability provided by the platform.

“The beauty of Konect is its tailor-ability. You can make it as simple, or as complex as you need,” he says.

Council can tailor forms, workflows, data views, and even visual styles to the specific needs of different roles and departments, all without requiring coding or technical expertise.

Nutt says this capability is a fundamental requirement, with the nature of council operations involving a multitude of external parties and contractors.

Tasks, defects, and data entries are automatically routed to the appropriate crews or contractors based on set rules, minimising administrative intervention.

“Whether they’re external, or it’s a Council department, once the workflow is set there is no need for them to deal with me. They’ll enter the platform with their own log-in, only see the fields that they need to see, then they can complete the necessary fields to record the required data,” Nutt says.

“For road and footpath defects, our evidence base is always solid, because we’ve got before and after pictures for each job. All of this in just three fields: changing the job status, adding a photo, then selecting which person or contractor did the job. It’s all seamless.”

Nutt adds that Konect’s customisation has also enabled an improved transition for computer-averse staff.

“It’s all just tap the screen. With Konect, we can tailor the view to show only what that particular person needs to see, which removes any confusion,” he says. “Even for those who aren’t as computer-embracing as office workers have taken to it, no problem.

“If someone’s got red-green colour

Banyule City Council oversees municipal services for more than 20 suburbs.

blindness for example, we could make the interface black and white and stylise the data a particular way for a particular user.

“One of the many strengths of GBM Konect is that you don’t need to engage with them once you’ve learned the system. If you’ve done that, then the tools are at your disposal. You don’t need to know code. You don’t have to be a computer head. The interface is very simple.”

IN THE FIELD

Just one example of the council’s use of Konect has been its management of potholes and footpath defects.

As part of its delivery of services, council gets external contractors to conduct comprehensive inspections across the road and footpath network, recording issues such as potholes, displacements, line marking problems, sign issues, and pit lid issues directly into Konect. Tasks, defects, and data entries are also automatically routed to the appropriate crews or contractors based on set rules, speeding up response time.

Konect integrates with corporate Geographic Information Systems (GIS), ensuring all teams and stakeholders access upto-date and consistent information.

“Konect’s inherent spatial capabilities make data collection easier. For example, from an operator point of view, they don’t have to know what road section they’re on when they’re collecting the data, because it’s spatially enabled it can automatically add that data to the record being collected,” Nutt says. When a pothole is recorded, the defect is instantly routed to the asphalt crew’s dashboard in Konect. The crews check their dashboards daily for new work, and as repairs are completed, those issues disappear from their map in real time.

Multiple operators can work simultaneously in the field on the same data set, allowing updates and information to be shared instantly, eliminating any potential for duplication and ensuring everyone is working with the latest available data.

Nutt says this “single source of truth” has equally been as effective as part of council’s environmental monitoring responsibilities, an important responsibility that forms part of the effective planning and delivery of community infrastructure.

Council’s environmental team uses Konect, paired with a Trimble device, to track endangered Eltham Copper Butterfly larvae with sub-metre accuracy in parks. The team can pinpoint larvae clusters with high

Banyule

positive or negative impacts of tree planting or other remedial works on the butterfly population. Nutt adds that the ability to adapt management efforts based on realtime, spatially accurate information has been a huge help in reporting, planning, and justifying

you build what you want’. We’ve given our people the power to create and edit data in a controlled fashion and, as a software administrator, being able to do all of that with little to no coding experience makes it an even more powerful tool,” he says.

Image:

GBM

Konect

GBM Konect now plays a key role in the delivery of maintenance and upkeep, under the council’s road management plan.

City Council’s transition and adoption of GBM Konect was straightforward, thanks to the versatility and accessibility of the platform.

Image:

Banyule City Council

PERFECTING THE BOND

UTILISING ITS VAST GLOBAL EXPERIENCE IN POLYMER MODIFIED BITUMEN (PMB) BLENDS, SRIPATH HAS DEVELOPED A BRAND-NEW PRODUCT FOR THE MARKET, WHICH AIMS TO TACKLE A LEGACY INDUSTRY PAIN-POINT.

Polymer modified bitumen (PMB) has played an essential role in ensuring the robustness, performance, and longevity of transport infrastructure across the country.

That being said, PMB hasn’t done this alone. Several additives and methods, used in conjunction with the application of PMB, have helped to further future-proof major intersections, urban roads, and bus lanes. All of which are subjected to heavy traffic, straining and fatiguing pavement surfaces which can result in them rutting, ravelling or suffering other failures.

Crosslinking is just one method that’s been used to strengthen the bond between polymers and bitumen during the PMB production process to enhance durability, elasticity, and resistance to rutting.

Crosslinking bonds polymer chains with bitumen to form a connected network. These bonds, created between polymer and bitumen molecules, have proven to be essential in extending pavement life and delivering performance.

Traditionally, sulfur has been used as a crosslinking agent. But sulfur has its drawbacks, says Deepak Madan, Chief Operating Officer –Sripath Technologies.

Crosslinking agents can vary greatly in chemistry, reactivity, and dosage requirements, but the vast majority contain sulfur powder, a component that can prove to be counter-intuitive due to dustiness, handling difficulties, poor PMB thermal stability, and the release of hazardous H₂S (hydrogen sulfide) emissions.

For these reasons, Sripath created a new product designed to overcome these issues by improving PMB performance, increasing efficiency, reducing emissions, and offering safer handling.

Above, L to R: ButaPhalt is one of Sripath’s newest and most innovative additives; The unique formulation of ButaPhalt greatly increases crosslinking connectivity, as well as production efficiency.

THE BIRTH OF BUTAPHALT®

In May 2025, Sripath Technologies acquired ButaPhalt Products and the related Buta Business.

crosslinking reaction more effective. It ties up the sulfur very quickly in the reaction, that way it’s not hanging around to create high levels of H₂S.”

Part of this portfolio was the ButaPhalt patent, an innovative crosslinking additive specifically engineered to improve performance by allowing sulfur to more effectively crosslink with the polymer during the production of PMB.

Madan says it’s important to note that Sripath’s ButaPhalt does not exclude sulfur. Instead, it’s a formulation that greatly improves upon productivity and provides better thermal stability compared to traditional crosslinkers.

He says ButaPhalt expands on proven methodology, while improving the downfalls of conventional products.

“We went out there to look for different additives that could be part of this formulation. We reached out to different sectors and industries to see what knowledge existed, and how we could bring that into this technology,” he says.

“In addition to sulfur, we’ve added other ingredients that actually make the

“As an additional benefit, you can get a much higher performance for a PMB, as well as increased productivity. All of this can help contribute to lower operating costs.”

Ravi Rajagopalan, General Manager –Sripath Asia-Pac, adds that ButaPhalt also improves productivity and provides better PMB thermal stability compared to traditional crosslinkers.

“There’s tremendous opportunity across Australia and the Asia-Pacific region for a new generation of crosslinkers. Producers here are looking for solutions that move beyond the limitations of traditional sulfur systems, such as materials that can improve PMB stability, streamline production, and boost productivity without compromising performance,” he says.

“ButaPhalt delivers on all three, giving producers the flexibility they need to meet regional demands and evolving performance standards.”

This is in addition to glaring safety and sustainability benefits. By reducing the concentration, emission and “nasty odour” of H₂S, ButaPhalt provides reduced environmental, health, and safety impacts across the board.

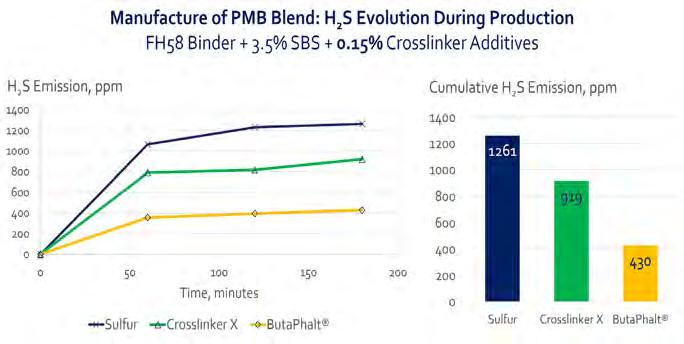

Such performance capabilities were recently put to the test. H₂S emissions were measured during the production of PMB using FH58 binder plus 3.5 per cent SBS (styrene-butadiene-styrene) and 0.15 per cent crosslinking additives.

When sulfur was used as the crosslinker, H₂S levels rose sharply within the first 50 minutes and reached a cumulative emission of approximately 1261 ppm (parts per million). In contrast, a conventional crosslinker generated moderately lower emissions (≈ 919 ppm).

ButaPhalt stood above the rest, demonstrating a substantial reduction in total cumulative H₂S emissions, limited to about 430 ppm.

Such trials validate ButaPhalt’s ability to minimise hydrogen sulfide release during PMB manufacture, helping to improve workplace safety and environmental performance compared to traditional sulfur-based systems.

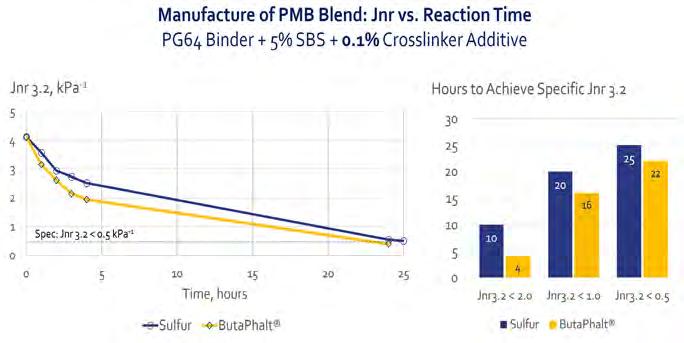

Additional trials have also compared the reaction kinetics of PMB blends prepared with sulfur and ButaPhalt as crosslinking agents.

Using PG64 binder with five per cent SBS and 0.1 per cent crosslinker additive, the parameter Jnr 3.2 (kPa-¹), an indicator of resistance to permanent deformation at high temperatures and traffic loads, was monitored over 25 hours.

ButaPhalt modified blend reached the target Jnr specification (Jnr 3.2 ≤ 0.5 kPa-¹) more rapidly than the sulfurbased systems.

ButaPhalt demonstrated faster reaction completion and improved productivity, pointing towards its enhanced PMB reaction kinetics, allowing reduced processing time and potentially lower manufacturing costs.

Jill McConaghie, Marketing Specialist –Sripath Technologies, says the product is one of many innovations, that – since leaving Sripath’s doors – have helped to establish a new standard across industry.

“At Sripath, our mission has always been to tackle the evolving challenges of the asphalt industry with practical, science-driven solutions,” she says. “ButaPhalt exemplifies this approach,

Assessments have verified the elastic recovery and performance of ButaPhalt.

A visualisation detailing BituPhalt’s H₂S emissions during production, compared to conventional crosslinking methodologies.

“AT SRIPATH, OUR MISSION HAS ALWAYS BEEN TO TACKLE THE EVOLVING CHALLENGES OF THE ASPHALT INDUSTRY WITH PRACTICAL, SCIENCE-DRIVEN SOLUTIONS.”

helping to enhance pavement performance while supporting more efficient, safer production. It’s a key part of how we are blending innovation and sustainability to help contractors, suppliers, and communities meet their goals.”

McConaghie further explained the traction ButaPhalt is experiencing, saying, “ButaPhalt was recently designated as one of the ‘Top 15 Products of 2025’ by AsphaltPro Magazine, a USAbased publication.”

Despite launching under the Sripath’s banner in September 2025, ButaPhalt’s track record can be traced back nearly two decades, having been used by PMB manufacturers in North America since 2007.

Dennis Krivohlavek, Business Development Specialist – Sripath Technologies, believes ButaPhalt will become a preferred crosslinking agent for decades to come.

“As polymer modified bitumen formulations continue to evolve, producers face growing challenges balancing performance, safety, and sustainability,” he says.

“ButaPhalt was developed to meet those challenges by offering reliable crosslinking performance while simplifying production and reducing H₂S emissions.”

“ We believe this technology will help our customers achieve higher performance and greater efficiency for their PMB blends.”

Images:

Sripath

• Reinforced backfill applications

• Soil-structure interaction

• Precast concrete solutions

• Geosynthetics

• Environmental hazard protection

www.geoquest-group.com.au

IF IT ‘AIN’T’ BROKE…

SEALANTS & PAVEMENT ADHESIVES’ PRODUCT OFFERING HAS ENDURED FOR DECADES, WITH TWO KEY PRODUCT RANGES FORMING THE BEDROCK OF THE COMPANY’S GROWTH AND SUCCESS IN THE MARKET. ROADS & INFRASTRUCTURE TAKES A PEEK BEHIND THE CURTAIN TO LEARN MORE.

Sealants & Pavement Adhesives was built on the principal that customers deserve to have all their requirements satisfied from a single location.

A national distribution agreement with Crafco has enabled the company to supply both the sealant, as well as compatible equipment, meaning customers can rely on and benefit from a single solutions provider.

Sales Manager Kevin De-Simone believes supplying both the sealant and the application machine grants customers much more than just peace of mind. This approach has built trust between Sealants & Pavement Adhesives and the industry,

leading to the company’s solutions being deployed by both new and longstanding customers – some for more than two decades.

This trust is further strengthened by the partnership between Crafco and Sealants & Pavement Adhesives.

The Super Shot range of crack sealing machinery is a shining example. Having been in production and use since 1996, the Super Shot 60 and Super Shot 125 represent some of Crafco’s oldest offerings and they are still going strong.

“It just goes to show how reliable they are,” De-Simone says. “Despite being some of Crafco’s oldest types of machines, they’re still the primary option in this

space. I know for a fact that one of the earliest models from the 2000s is still in use in Australia.”

The Super Shot 60 (230-litre tank) and the Super Shot 125 (500-litre tank) series of crack sealing machinery have become well known for their safety, reliability and ease of use.

The former is thanks to its design. The Super Shot range features a nonpressurised system, reducing the risks of pipe blowouts and other hazards. Splash risk is further mitigated, with material required to be loaded through a hatch that halts the agitator.

“On the wand itself, these units also have a safety lock. That way, when it’s

Images:

Sealants & Pavement Adhesives

Sealants & Pavement Adhesives product range has remained consistent, a testament to the trust and support between the company and supplier Crafco.

“A ‘PUMP ON DEMAND’ FEATURE – A RARITY AMONG UNITS SUCH AS THIS – MEANS THE PUMP ONLY OPERATES WHEN THE TRIGGER IS PRESSED, REDUCING WEAR, ENERGY USE, AND POTENTIAL FOR BLOCKAGES.”

not being used, the trigger is unable to be activated on accident, therefore also removing the risk of material flowing out unintentionally,” De-Simone says.

When it comes to operation, De-Simone adds that an innovative control system helps to increase accessibility, accuracy and efficiency for operators of all experience levels.

“It’s all operated from one control box,” De-Simone says. “Once you set your preferences, you’re good to go. You don’t need to have someone standing over you to make sure it’s still configured.”

A “pump on demand” feature – a rarity among units such as this – means the pump only operates when the trigger is pressed, reducing wear, energy use, and potential for blockages. The fully electric hose and wand also keep material hot throughout delivery, further cutting down on blockages and maintenance needs.

Automatic temperature adjustments and burner control further simplify operations.

The Super Shot range can also be used for other applications such as applying road markers and adhesives. Each unit

has also been designed to cater for skid mounts, meaning they can be mounted to different types of trailers or trucks to fit user needs.

BEST OF BOTH

Sealants & Pavement Adhesives’ ability to provide both the sealant and compatible machinery continues to be a source of pride for De-Simone. As does supplying the best sealants currently available.

While Crafco offers a wide variety of sealant options, one in particular has emerged as a national favourite.

“Crafco makes about 20 different types of sealant. The Polyflex Type Three Crack Sealant is the one that we’ve chosen, based on its performance and suitability for Australian conditions,” De-Simone says.

Specifically selected and formulated for Australian climates and a wide range of road temperatures, the Polyflex Type Three Crack Sealant features an asphaltbased composition, suitable for use on both asphalt and concrete surfaces.

One of the standout qualities of this offering is the meltable packaging, which

disperses within one to two seconds of contact with the hot sealant, with no adverse effect on product quality.

Thanks to this unique packaging, blocks can be thrown directly into the melter, saving time and simplifying the process. It also helps to reduce potential impacts on the environment, with only the pallet and shrink wrap needing disposal – a far cry from boxed products.

“The sealant is made for the Super Shot range, and the machines are made for the sealant,” De-Simone says. “Customers can come to us and receive the best of both, all from the one place.”

Support is also offered, with each of Sealants & Pavement Adhesives’ machines featuring a detailed operating manual, including a comprehensive troubleshooting guide for resolving most issues.

If a problem cannot be solved locally, help is provided through direct contact with Crafco, De-Simone says.

“We always find a way to get a solution, either through me or Crafco directly working with the customer.”

The Super Shot is a premier crack sealing machinery range that’s capable of completing jobs of varying scale and conditions.

ASPHALT PAVING ESSENTIALS WORKSHOP

up-to 18 CPD hours

February 2026

Melbourne

High-quality asphalt pavements require technical ex pertise, precise planning, and expert onsite management.

From compaction and joint construction to mix handling and paving sequence planning, every step ensures smooth, durable roads.

REGISTER NOW: FEBRUARY 2026 | MELBOURNE

DECADES AHEAD

THE INNOVATION AND DESIGN OF GEOQUEST AUSTRALIA’S PRODUCTS ARE HELPING TO BUILD RESILIENCE AND MINIMISE THE IMPACTS OF GEO RISKS AND WEATHER EVENTS ON INFRASTRUCTURE, WITH TURN-KEY SOLUTIONS EMERGING AS A POTENTIAL SOLUTION.

Rising sea levels, increased rainfall intensity and duration, extreme fire weather and extreme heat events are just some of the everyday realities of the world’s changing climate.

Of growing concern is the potential impact that such weather events will pose to public and private infrastructure. Intensifying rainfall, flooding, and landslide activity are placing unprecedented pressure on these structures, from road and rail corridors, to embankments, bridges, and retaining structures.

Geoquest Australia is just one of few companies at the forefront of strengthening and increasing resiliency in critical

infrastructure. Its expertise in integrating geotechnical engineering design and components has seen it influence some of the most complex and at-risk infrastructure structures globally.

The company also has a rich history in Australia, emerging as a key thought leader in climate preparedness.

As Riccardo Musella, Managing Director explains, Geoquest Australia has lent its hand to support the local industry’s bid to mitigate climate risk and manage uncertainty.

“The native flexibility of our systems, as well as our ability to provide holistic design capabilities, gives us the opportunity to address issues that cannot be addressed on a stock-standard basis,” he says.

“Sometimes, these systems need to be

Above: Geoquest Australia is employing sustainable production practices, helping to reduce its impact, while also minimising the impact of weather events on infrastructure.

ArmaLynk is an ultra-high performance PET geogrid, which ensures reliable ground reinforcement in challenging site conditions.

looked at in more detail and be customised and contextualised on a project-toproject basis.”

RESILIENCE IN DESIGN

Geoquest Australia’s product range and services vary across foundation performance, drainage, erosion control, and structural integrity across road, rail, and mining infrastructure.

Drawing on more than 60 years of global expertise, Geoquest provides fully integrated geotechnical and structural systems that build resilience into every layer of civil and transport infrastructure.

Whether stabilising soft soils and embankments, reducing erosion, flood, and rockfall risks, or delivering MSE (Mechanically Stabilised Earth) retaining walls, tunnels, overpasses, bridge abutments, and optimised drainage, Geoquest’s connected solutions ensure long-term performance and protection of vital assets.

Rockfall protection and slope stabilisation remain among the most visible elements of climate resilience, and a key aspect of Geoquest’s capability.

“These systems from part of what we call the environmental product line, which includes three key categories – rockfall protection, erosion control and water management,” Musella says.

In Erosion control, Geoquest Australia designs and supports implementation of systems like revetments and drainage solutions aimed at managing water flow, protecting against flooding, and minimising soil loss.

Rockfall and landslide prevention comprises mesh systems and other solutions that prevent or stabilise landslides, particularly in areas prone to heavy rainfall or water events.

The aforementioned MSE retaining walls are yet another key offering within Geoquest Australia’s range.

“Something that’s inherent in these systems is the flexibility of the structure and design of the mechanically stabilised earth walls. There’s two reasons for that,” Musella says.

“The first is the segmental nature of our walls, that allows movement between the panels, compared to conventional designs that are more rigid and therefore prone to cracking if there’s ground movement.

“The second factor is that we employ soil reinforcement, which is particularly efficient and effective under movement and stress.”

Rockfall protection systems are just one design that can help to mitigate geohazard risks.

Geoquest’s MSE wall solutions have demonstrated strong real-world performance in New Zealand and Japan, showing resilience even after significant earthquakes.

FULLY INTERCONNECTED

Beyond unpredictable ground conditions, supply chain disruptions and delivery risks are now central considerations for major projects.

That’s why Geoquest Australia provides a fully integrated, turn-key approach which combines design, manufacture, supply, and installation.

It’s this approach that’s emerged as one of the most effective ways to mitigate geo and climate risk and manage uncertainty, particularly for projects of large scale.

Musella says end-to-end project capability has also become a defining factor in both cost control and resilience outcomes.

“Fragmentation in project delivery can add risk, both technical and commercial. Our model at Geoquest allows clients to engage one partner from concept through to delivery, ensuring design intent is preserved, logistics are streamlined, and site challenges are addressed and managed holistically

in real time,” he says.

This integrated approach ensures that engineering responses adapt comprehensively to on-site conditions, a critical advantage in geotechnically complex or weather-sensitive environments.

“It’s not a case of us looking at the problem, handing over the product and saying ‘use it’. We get to the bottom of the issue, ‘what’s the challenge? What’s the best design’. Then we can customise the solution to fit that problem,” Musella says.

This oversight, granted by manufacturing and designing in-house, also enables Geoquest Australia to implement sustainable materials and methods during production.

“Material innovation and lifecycle performance are central to resilience,” Musella says. “By optimising material use and designing for durability, we help reduce embodied carbon while extending asset life, a direct contribution to sustainability and cost efficiency.”

“Resilience isn’t just about building stronger. It’s about designing smarter, integrating systems, reducing interfaces with turn-key solutions, and using innovation to deliver safety, durability, and value under increasingly uncertain conditions.”

Images: Geoquest Australia

CAPABILITIES SHOWCASE

A GO TO RESOURCE FOR FINDING CONTRACTORS

ALL CONTRACTORS ARE INVITED TO LIST THEIR BUSINESS. SCAN THE QR CODE TO LIST YOUR BUSINESS FOR FREE

HERE TO STAY

ROADAID’S WORK ON CRITICAL INFRASTRUCTURE MARKS THE NEXT PHASE OF GROWTH FOR THE COMPANY, WHICH IS NOW SETTING ITS SIGHTS ON INTERSTATE PROJECTS. ROADS & INFRASTRUCTURE LEARNS WHAT SETS ROADAID’S MAINTENANCE AND LABOUR HIRE SERVICES APART.

Through its proactive approach and a commitment to nurturing positive on-site culture, RoadAid has built a reputation for quality, trust, and a vision for continued growth into new markets across Australia.

The company’s recent work on a tunnel in Melbourne – one of the state’s most significant transport infrastructure projects –is a standout example.

RoadAid supported a major infrastructure provider with works to replace low-voltage cables on the project.

To minimise impacts on traffic and the local community, works were conducted in a live tunnel environment, with one lane remaining open to traffic. This required flexible crew sizes, with the works being conducted over the course of about eight months.

Safety was the highest priority, requiring an experienced and coordinated maintenance partner capable of maintaining constant oversight and safe worksite parameters.

It was these requirements that led the contractor to RoadAid, as Director Chris Couldrey explains.

“After our Queensland team supported our client on a project and delivered the works safely, without incident, and beyond expectations, our details were shared with the Project Team in Melbourne. They recognised that we provide a reliable and professional service,” Couldrey says.

“Having worked on this asset for over a decade, I was in a unique position to support the project delivery and help answer some

of the more technical questions. We’ve got strong expertise, we know the assets, we know how to transit and operate very well. It’s just a smooth process, essentially.”

RoadAid provides project support and skilled labour for major infrastructure projects, with a particular focus on environments like live tunnels and roadways where safety and flexibility are essential.

Its services include supplying EWP (Elevated Work Platform) operators and spotters, Confined Space Spotters, general and skilled labourers, and crews for tasks such as cable upgrades, maintenance works, and other support roles.

A fundamental aspect of its service is safety.

Shannon Tutin, People and Culture Manager – RoadAid explains that safety isn’t just a benefit of service, it’s a factor that’s embedded within the company’s DNA.

“Safety is the core of our operations. Everything we do relies on the safety and wellbeing of our team and those working alongside us,” she says.

“We empower our team to speak up when it comes to safety. We ensure they’re comfortable, confident, and competent with all the plant and infrastructure they’ll be using or spotting.

“We ensure safety is spoken about daily and we are always conducting 360 degree reviews to see where we might be able to improve.”

A number of guiding principles shape every decision and behaviour on site. Thorough risk assessments are conducted, the ground and

Images: RoadAid

Recent works on a major project have emplified RoadAid’s ability to cater for large scale infrastructure works.

work environment are continually monitored, and if hazards arise, such as dust or changes in conditions, team members reposition themselves to maintain safety.

Recruitment also plays a part. Every team member is selected not only for their skills but for their safety mindset and cultural fit. Each is trained never to turn their back to traffic, and unsafe conditions are immediately called out and reported, reflecting RoadAid’s strong safety culture and alignment with client expectations.

“Looking back on the work that was completed within the Tunnel, it’s clear that we were able to create a team of like-minded team members who all had a focus on safety that never wavered,” Tutin says.

“We were able to create a team of workers, not just 8-10 individual people doing a task, but a RoadAid team who became a positive extension of the brand that we were aiding, as well as the project.

“ Their pains became our pains, and their wins became our wins. This quantified our ability to seamlessly join a project and other teams to be task focused and motivated.”

It’s Couldrey’s belief that – apart from safety – reliability has become a shining quality that’s leading to RoadAid becoming a preferred provider.

“Our clients can call and say, ‘we need 10 people tomorrow,’ and we make it happen,” he says.

“Within the hour, we can come back with a full list of names, qualifications, and everything needed for permits and access requirements. That reliability is what our clients know us for.”

“We pull everything together, all the key details, permits, and contacts, so nothing’s left to chance,” he says. “And when it’s a major project, we go further by developing a tailored project plan that maps out the scope of works, key contacts, emergency procedures, and site maps. It means our team walks onsite fully prepared, and our clients know from day one that we’re there to make their project a success.”

This approach, combined with a shared sense of purpose, has seen RoadAid continue to grow steadily, positioning itself for larger and more complex opportunities.

“RoadAid is at a wonderful stage of its journey,” Tutin says.

“Over the past few years, we’ve built our name through word of mouth, strengthened our culture, and stayed true to our vision of safety for all. Now that we’ve established a solid foundation, we’re ready to take on those bigger projects.”

Beyond its project delivery, RoadAid’s leadership is focused on shaping the broader industry culture.

The company has become a corporate member of several professional associations, including NAWIC, and has introduced an internal Employee Assistance Program (EAP)

Safety is always front of mind for RoadAid’s crews, with it being a key tenet of the organisation.

Every second counts in those situations and effective training can make the difference in preventing or minimising secondary incidents.”

“Every second counts in such situations, and effective training can make the difference in preventing or minimising secondary incidents.”

September 2026

EXHIBIT IN 2026. BE SEEN. BE HEARD. BE CHOSEN.

EXPANDING WHAT’S PROVEN

SPECIALISED ROADING EQUIPMENT’S (SRE) FIRST EVER AUSTRALIAN FIXED WING SPRAYER HAS MADE SHORE, AIMING TO OFFER AN IMPROVED AND INCREASINGLY ACCESSIBLE, SAFE AND SMART OPTION FOR OPERATORS.

Specialised Roading Equipment’s (SRE) history is rich with innovation and creativity. Founded by a spraying operator who became disenchanted by the lack of variety available at the time, SRE has emerged as a pioneer in the design and delivery of bitumen sprayer equipment.

That’s why it came as no surprise that the company’s newest innovation was heavily inspired by industry consultation and response.

“It came about initially from some discussions with a couple of customers, who were frustrated around the lead times and lack of response in the Australian market,” says Mark Wansbrough, Managing Director – Specialised Roading Equipment. “They asked if we would consider doing

a fixed wing sprayer for Australia. At the time, we were more focused on our telescopic sprayer solution. Ultimately, we took a step back and saw that there was an opportunity to help out those customers – whether due to preference or their projects – where a fixed wing was the preferred option.”

“We needed to be able to give our customers a choice between telescopic or fixed wing, depending on their operational needs.”

SRE’s telescopic sprayer is still one of the company’s primary spraying solutions, being the preferred iteration for jobs in SRE’s homeland of New Zealand.

Upon hearing industry feedback and identifying the opportunity in the Australian market, SRE set out to develop

an Australian fixed wing sprayer that could deliver on several key criteria.

One of the prevalent factors was the possibility of such equipment being used on extended deployments, in some of the harshest conditions that Australia has to offer. Chris Kaelin, Business Development Manager – SRE explains.

“The telescopic sprayer has its place and offers some very real advantages, but there are situations where you’d need to send a sprayer up north for at least a month at a time,” he says.

“That’s why we wanted to create a simple machine that can go out and complete those long runs, when you don’t need the telescopic functionality, but instead need to be able to spray the whole width of a road in one hit.”

As such, durability, ease-of-maintenance and strong support were non-negotiables.

Another, Wansbrough adds, was “smarts”.

“When we’ve visited our Australian customers’ depots, they might have three sprayers that are all from the same supplier. All three would’ve been purchased over the course of 25 years, and there’d be literally no innovation and barely any changes,” he says.

“We’ve looked at what works best and what doesn’t, to deliver on smarts that relate to accessibility, operation and safety.”

SRE’s also implemented technologies and features that have proven to be popular within its telescopic sprayer iterations.

Pumps, pneumatics, and the spray bar have been made simpler and safer to access from ground level, removing the need for confined space permits while also making maintenance easier. They’re

For the first time ever, SRE has delivered a fixed wing sprayer designed directly for the Australian market.

just a few changes that have been directly informed by feedback from users of the telescopic sprayer.

“It’s now really easy to access the pneumatics to change your pressures and whatnot, also to complete your servicing,” Kaelin says.

Actions that previously required the operator to be at the back of the sprayer, a hot and potentially dangerous area of the machine, can now be done from within the cab. There are also automated heating controls, a standard feature in New Zealand that’s been brought across to the Australian model.

Four-inch pipework allows for higher flow rates, while operators also have the chance to pick from full manual, or individually controlled pneumatic valves.

Existing SRE customers can also benefit from their knowledge of sprayer components, with the chassis, tanks and hydraulic systems all remaining the same across the telescopic and fixed wing range. Not only does this make maintenance and seeking spare parts easier, for SRE it also accounts for faster production and assembly.

with additional orders and expressions of interest already tabled for 2026.

Such interest, on top of existing orders for SRE’s popular telescopic models across both Australia and New Zealand will be the beneficiary of the company’s new production and assembly site.

In fact, it’s taken just 11 months to go from concept to delivery. A major achievement, considering average wait times for spraying equipment surpass the one-year mark.

With a spray width of up to eight metres, 12,000 or 14,000 litre tank options, as well as full Austroads compliancy, SRE’s first Fixed Wing Sprayer has been delivered to a long-term customer in Western Australia,

“We’ve created a modular production process, that’s been aided by using the same chassis, tanks, pumps and more. As we get more orders, we’ll be able to assemble much quicker. It doesn’t matter if it’s telescopic or fixed wing, we’ll be able to react to what the market wants,” Kaelin says.

“To give a better example of that, a month ago, we had both a six-metre telescopic

“WE NEEDED TO BE ABLE TO GIVE OUR CUSTOMERS A CHOICE BETWEEN TELESCOPIC OR FIXED WING, DEPENDING ON THEIR OPERATIONAL NEEDS.”

and a fixed wing sprayer shipped on the same date, on the same boat for Australia, with one going to Brisbane, and the other to Perth.

“We had the two units sitting side by side for most of their build. The new site that we have now really gives the ability to work on both as they get pushed through the line.”

When reflecting on what has been a year of significant growth for SRE, Wansbrough says the move to a new facility has really set up the business for the future.

“It’s also been fantastic to see [Kaelin] and his team put a massive amount of work in to get our first fixed wing to Australia.

“To be going from just a conversation to delivery within 11 months is incredible. It’s yet another sign of the momentum that’s been made in a market that’s responding really well to us.”

Chris Kaelin, Business Development Manager – SRE has been a key figure in the development of the brand new Australian fixed wing sprayer.

Australian customers now have access to both fixed and telescopic spray variants, both of which are highly suited to domestic conditions and projects.

The global stage for trenchless innovation

New Zealand International Convention Centre, Auckland 28 – 29 October 2026

EXHIBIT NOW

Komatsu’s Smart Construction ecosystem allows people to visualise their job sites and use equipment more productively.

THE FUTURE CONSTRUCTING

OVER THE PAST YEAR, KOMATSU HAS NAVIGATED A SHIFTING CONSTRUCTION LANDSCAPE BY BALANCING INNOVATION AND TRAINING, LAUNCHING NEW FLAGSHIP MACHINES, AND ADVANCING SMART, SAFE, AND SUSTAINABLE GROWTH ACROSS AUSTRALIA AND THE REGION.

After several years of bustling activity in the construction industry, the Australian sector is entering a new phase, one marked by recalibration, technological maturity, and measured optimism.

For Komatsu, one of the industry’s key machinery suppliers, the current environment represents a challenge and an opportunity.

David Small, Executive General Manager of Komatsu, says the business has come off the peaks of the past three to four years, which were COVID and stimulus inspired.

“The market is definitely down, but it’s down from probably the highest point I’ve seen in 20 years. If you look back historically, we’re still in a very good market,” he says.