pumpindustry

The pumps that drive oil and gas

you should ask when purchasing a control valve Ten questions

Sydney Water invests in infrastructure

Make pumps great again

Our industry survey highlights what needs to be done

ISSUE 18

SUMMER 2017

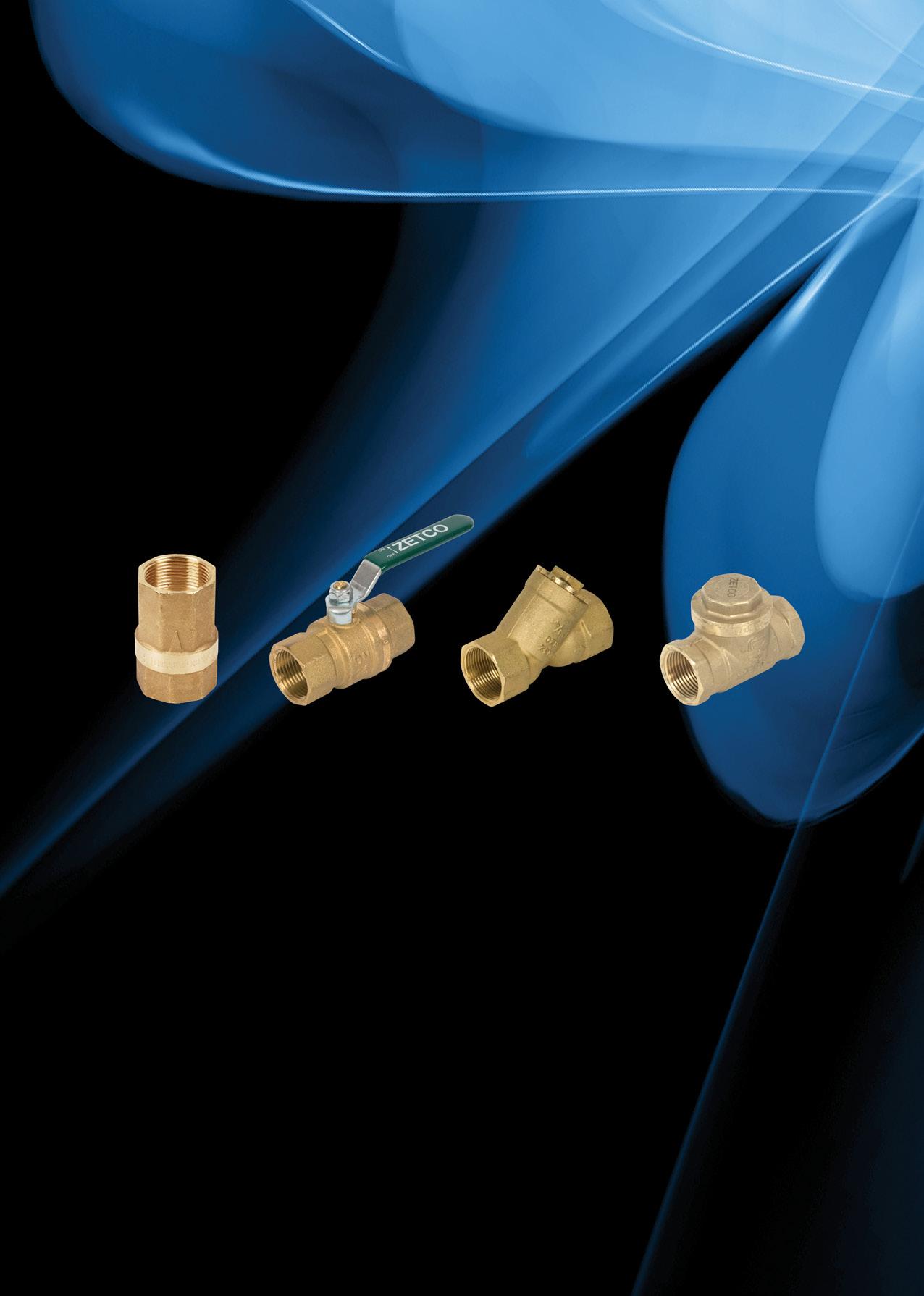

When it comes to WaterMarked valves, Zetco specialises in WaterMarked manual isolation valves including ball, gate, globe, check valves and Y strainers in DZR brass, bronze and stainless steel. Zetco has you covered Phone 1300 659 639 Email enquiries@zetco.com.au www.zetco.com.au IAPMO WM-000110 AS 5830.1

Pump Industry Australia Incorporated

PO Box 55, Stuarts Point

NSW 2441 Australia

Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

Dave Alexander – President KSB

John Inkster – Vice President Brown Brothers Engineers

Kevin Wilson – Treasurer/Secretary Executive Officer

Keith Sanders – Councillor Executive Officer – Marketing & Statistics Life Member

Alan Rowan – Councillor Executive Officer Publications & Training Life Member

Ken Kugler Executive Officer – Standards Life Member

Ron Astall - Councillor United Pumps Australia

Ashley White – Councillor Davey Pumps

Peter Passalacqua – Councillor Grundfos

David Brooks – Councillor Flowserve FSD

Jamie Dixon – Councillor White International

President’s welcome

Firstly, a big thank you for nominating and electing me as PIA President for 2017. I’ve always valued the informative market insights gained from my connections through the PIA, and I look forward to giving back to the association during my time as President.

Outgoing President Ron Astall has left big shoes to fill. Thankfully, we will continue to share his insights and experience as he stays on as a councillor for the PIA.

Working alongside my fellow councillors, we hope to foster more engagement and opportunities to network for members of the pumping equipment industry in 2017.

We’d like to encourage the best of the best to consider careers in the pumping industry, and support them through training as we welcome them into the fold.

The PIA is here to help and support our members, and will look for your feedback in improving our services. Please feel free to contact myself or any of the council members with your suggestions and ideas.

It’s encouraging to see commodity prices increasing, including thermal coal and iron ore. I hope this increase is sustainable and will result in investment in infrastructure and new projects. The end goal for us is to fill demands for new pumping equipment and service requirements.

In 2017, the PIA will be focusing on providing training seminars that will benefit our members, and we will continue our normal meetings which are held across the country.

I will be encouraging our members to attend these meetings and training seminars. It is important to all members that we have a strong PIA association to act on our behalf.

Yours in pumping,

Dave Alexander President, Pump Industry Australia

1 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 PUMP INDUSTRY

by Monkey Media Enterprises

by Monkey Media Enterprises

WEditor’s welcome

elcome to the first edition of Pump Industry for 2017. We’ve started off the year with our in-depth State of the Industry survey to see what worked and what didn’t work for pump companies in 2016, and find out how industry professionals are feeling going into 2017.

While our survey found 2016 to be a mixed bag for most pump companies, respondents have a much more positive outlook for 2017, with around 70 per cent feeling confident for what this year will bring.

Ron has been the PIA President since just after we launched the first ever issue of Pump Industry magazine in 2012 and we have greatly enjoyed working with him over the years. His encouragement, advice and practical support as our unofficial technical adviser has been a huge help in getting this magazine off the ground in its early years.

ABN: 36 426 734 954

PO Box 1763

Preston South VIC 3072

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au

info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Publisher and Editor: Chris Bland

Managing Editor: Laura Harvey

Associate Editor: Jessica Dickers

Contributing Editor: Michelle Goldsmith

Journalist: Lauren Cella

Journalist: Jesse Tyler

Marketing Director: Amanda Kennedy

Marketing Associate: Mathew Walker

Marketing Consultant: Aaron White

Marketing Consultant: Steven Golding

Production and Customer Service:

Titian Bartlau

Senior Designer: Alejandro Molano

Designer: Jacqueline Buckmaster

The survey also found the water, wastewater, and irrigation sectors were key areas of opportunity for pump companies, with respondents expecting these areas to continue to grow.

The full analysis of your responses and an insight into industry trends and areas for growth can be found in our feature ‘New opportunities drive optimistic outlook’.

The new year also brings change to Pump Industry Australia with the departure of President Ron Astall and the appointment of Dave Alexander to the role.

This magazine is published by Monkey Media in cooperation with the Pump

not necessarily the views of either the publisher or the PIA. Neither

advertisers.

All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions

providing content to the publisher, you authorise the publisher

with other content in any of its publications and in any format at the publisher's

While we will miss working with Ron in this capacity, we’re glad he is staying on board as a PIA councillor and will also continue to provide his much valued technical advice and contributions to this magazine.

We are excited to welcome Dave Alexander to the position. Dave has many great ideas for the PIA moving forward, including a focus on growing the membership and networking opportunities, and we look forward to continuing the collaborative relationship between Pump Industry and the PIA.

Chris Bland Publisher and Editor

Cover image highlights our State of the Industry feature - read the article on page 32.

Published

Industry Australia Inc. (PIA). The views contained herein are

the publisher nor the PIA takes responsibility for any claims made by

must comply with the publisher’s editorial policy which follows. By

reproduce that content either in its original form, or edited, or combined

discretion.

ISSUE 18 The pumps that drive oil and gas Sydney Water invests in infrastructure you should ask when purchasing a control valve Ten questions Our industry survey highlights what needs to be done Make pumps great again

1 April 2016 - 30 September 2016

to

pumpindustry

4,153

Three times longer life for pump components significantly lowers production costs.

High fluid velocity means wear, erosion and corrosion at high impact points like pump impellers, valve seats and stems, and bends and elbows in pipe work systems. A worn component means inefficiency and delays. We work with both pump OEMs and end-users to produce cost-efficient long-wearing solutions to high wear components. Our unique surface engineering technologies - developed to increase resistance to wear and corrosion – optimise component and system performance so they work better, last longer and cost you less.

Contact

Production equipment and components surfaceengineered by Laserbond® will operate in-situ for longer and perform more efficiently. An extended operating life increases the cycle time for regular maintenance and decreases maintenance costs.

Pump impellors, pump shafts, housings and seal areas are returned to original specification with laser cladding and machining. LaserBond® surface engineering improves and maintains operating efficiency, improves the overall process, and cuts production loss.

Find out more at laserbond.com.au/fluid_handling

LaserBond now and our Tech Team (experienced engineers) will recommend a cost-saving

longer

solution. LaserBond Limited | www.laserbond.com.au Sydney | Adelaide | Freecall 1 300 527 372 International +612 4631 4500 | Fax +612 4631 4555 Email info@laserbond.com.au Quality 9001, Environment 14001, Health & Safety 4801 14587 A4

3 x

wear-life

LaserBond®

significantly extend your

operating lifespan by reducing wear to its components from abrasive and corrosive fluids.

surface engineering technologies can

pump’s

takes legal action over “flushable” wipes

pump station

pumps ready for flood protection

explores first

water supply

for

snaking and leaking from irrigation hoses....................12

sludge pump choking

Industry Innovation Award

Concertor trial a success for

municipality....................

drought proofing Australia the possible dream?

STATE OF THE INDUSTRY

OIL AND GAS

ENERGY EFFICIENCY

4 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au MARKETING Marketing 101 for pump companies: how to get your business noticed ........................ 20

State of the Industry in 2017: New opportunities drive optimistic outlook ........ 32

The pumps that drive oil and gas ........................... 40 Do you have a spare pump in case of failure? 44

Sydney Town Hall powers up with trigeneration ................................................... 46 TECHNICAL Interaction of components in piping systems ......................................................... 62 NEWS ACCC

............................ 6 Wastewater

upgrade wins

8 Launceston

9 Queensland

solar-pumping

........ 10 New

industry .............................. 11 Eliminating

PIA NEWS Solving

problems 14 Shaping

...... 16 PIA

.... 18 INDUSTRY NEWS Flygt

Swedish

22 Is

26 A new innovation in solar pumping 28 Providing a complete pumping solution ......................................... 30 CONTENTS

award

partnership

HVAC

the industry’s future

5 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 pumpindustry SYDNEY WATER Major investment in new Sydney Water infrastructure .......................................................... 52 VALVES Ten questions you should ask when purchasing a control valve ............................................................ 56 TRAINING Become a master of pump systems ....................... 60 PUMP PIONEERS Keith Sanders ........................................................... 64 PUMP HANDBOOK Thinking positive: the characteristics of positive displacement pumps ................................ 68 REGULARS President’s welcome ................... 1 Editor’s welcome 2 Pump school .............................. 59 Pump Standards Part 2 Ask an Expert Progressive cavity pumps in the oil and gas industry ........................ 50 Editorial schedule ...................... 72 Advertisers’ index ..................... 72

ACCC takes legal action OVER “FLUSHABLE” WIPES

The Australian Competition and Consumer Commission (ACCC) is taking several companies to court for allegedly making false and misleading claims that their wet wipes were “flushable”.

The ACCC has instituted proceedings in the Federal Court against Kimberly-Clark Australia and separately against Pental.

“Flushable” wet wipes that are entering sewer systems are causing serious damage to pumping infrastructure as pumps are unable to break down the wipes, causing blockages.

The ACCC alleges that, by labelling these products as “flushable”, consumers were led to believe that the products had similar

characteristics to toilet paper, would break up or disintegrate in a timeframe and manner similar to toilet paper, and were suitable to be flushed down the toilet, when this was not the case.

ACCC Chairman, Rod Sims, said, “The ACCC alleges that the impression given by the representations which Kimberly-Clark and Pental each made about these products was that they were suitable to be flushed down

6 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au NEWS FOR INFORMATION VISIT WWW.PENTAIR.COM.AU PRESSURE SYSTEMS AUTOJET SERIES - MULTIMAX 120 PERFECT FOR THE HOUSE PERFECT FOR THE GARDEN ® NEW!

household toilets in Australia, when this was not the case.

“These products did not, for example, disintegrate like toilet paper when flushed. Australian water authorities face significant problems when non-suitable products are flushed down the toilet as they contribute to blockages in household and municipal sewerage systems.”

In both proceedings, the ACCC is seeking declarations, pecuniary penalties, injunctions, corrective notices, compliance program orders and costs.

Sydney Water’s Peter Hadfield said Sydney Water supports the ACCC’s milestone announcement.

“Sydney Water has been a leader on this issue for the past 18 months through our ‘keep wipes out of the pipes’ education program and we have strongly advocated that only the three P’s should be flushed down the toilet - pee, poo and (toilet) paper,” Mr Hadfield said.

Water Services Association of Australia (WSAA), Executive Director, Adam Lovell, said WSAA and its members from Australia and New Zealand have been joined by over 300 water utilities and partner organisations around the globe in a joint international statement raising awareness of the issues

associated with products labelled ‘flushable’.

“The international statement also outlines that only the three P’s should be flushed,” Mr Lovell said.

“It also calls for clearer labelling and covers the key requirements for any future standard for ‘flushable’ products’.”

Queensland Urban Utilities has also welcomed the decision of the ACCC to take court action, citing it as a positive step towards solving a big problem for sewer pipes as they can cause blockages to the network and household pipes, leaving homeowners with expensive plumbing bills.

Queensland Urban Utilities spokesperson Michelle Cull said, “Wet wipes, including those labelled ‘flushable’, don’t disintegrate quickly like toilet paper and can lead to costly blockages in our network.

“We spend around $1.5 million every year clearing blockages from our sewers. We also remove around 20 million wet wipes from our sewage treatment plants annually, which laid end-to-end would stretch from Brisbane to Bali.

“Labelling can be confusing for shoppers, so we welcome the ACCC’s decision and will be following the matter with interest.”

FLEXIBORE FLEXIBORE

www.pumpindustry.com.au NEWS FLEXIBLE RISING MAIN 22 Industry Place Bayswater VIC 3153 Australia Phone: +61 3 9720 1100 Email: sales@crusaderhose.com.au www.crusaderhose.com.au

Flexibore reduces head loss, improves flow rate and eliminates iron bacteria build-up due to swelling under pressure. SWELLING ELIMINATES BUILD-UP

Wastewater pump station upgrade wins award

A$7.7 million upgrade of the largest wastewater pump station in the City of Logan, Queensland, has been recognised at the 2016 Institute of Public Works Engineering Australia Queensland (IPWEAQ) Excellence Awards.

The Alfred Street pump station, located at Slacks Creek, has operated since 1984, taking wastewater from residential and commercial properties to the Loganholme Wastewater Treatment Plant for processing.

Logan City Council Roads and Water Infrastructure Committee Chairman, Phil Pidgeon, said the pump station was a “quiet achiever” in the city’s infrastructure assets.

“Treating sewage is an essential community service, but it usually goes unnoticed by the community because it operates so efficiently,” Mr Pidgeon said.

“Because we’ve completed this upgrade, we have reduced the risk of

overflows to waterways or the urban environment.

“We have increased capacity and improved efficiency to prepare for the significant population growth we are expecting in the next few years.”

Mr Pidgeon said the council’s Logan Water Infrastructure Alliance had saved $1 million during the project by reusing existing pump station components.

“The project was delivered by 270 mostly local workers in 22,500 working hours, and approximately 95 per cent of the major construction and supply contracts were completed by SouthEast Queensland companies,” Mr Pidgeon said.

“All of this led to the project winning the top accolade for water projects between $5 million and $10 million

at the IPWEAQ awards – testament of the expertise we see in the Logan Water Infrastructure Alliance.

“On behalf of Logan City Council, I’m thrilled to say that we are continuing to lead the way in delivering quality infrastructure for our residents and I’m excited to see that work recognised by our industry peers.”

8 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au NEWS

Launceston pumps

READY FOR FLOOD PROTECTION

TasWater has completed upgrades and maintenance works on stormwater pumps at the Margaret Street Pump Station near Kings Park in Launceston.

Glen Rowlands, TasWater’s Department Manager, Urban Treatment Plants, said, “The major flood event in June this year demonstrated the effectiveness of the Launceston flood protection system of which the Margaret Street Pump Station is one of a number of key facilities in Launceston’s combined system, which provides

sewerage and stormwater services to the city as well as protection from flooding during periods of heavy rain.”

The pumps can remove massive volumes of stormwater from the system during high rainfall events, transferring it over the levee system into the river, even against the flow of a high tide.

Mr Rowlands said if the pumps did not operate as designed, stormwater would collect behind the levee system and cause flooding in and around the city centre.

“When all of the pumps are operating

the station is capable of discharging almost 10,000 litres of stormwater each second into the river.”

The Margaret Street pump station is one the largest of its type in Australia and at the time of construction in 1990, was reportedly the largest in the southern hemisphere.

The maintenance work will ensure the pumps remain in good working order and have an optimal asset life.

“All the pumps have been lifted to the surface and have undergone an inspection and performance check by specialist service agents,” Mr Rowlands said.

“The pumps have proven to be in excellent condition and should provide many more years of reliable service.”

Installed by the Launceston City Council, the pump station is now part of TasWater’s infrastructure, who will also carry out ongoing operations and maintenance of the pump station.

9 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 NEWS

PlatycatSnatcher is distributed through Australia’s foremost certifier and distributor of lifting equipment, All Lifting P/L. CALL 1300 666 733 www.alllifting.com.au THE P LATYCAT S NATCHER IS A NEW AND SAFER WAY TO LIFT Australian safe lifting invention designed to deliver: • enhanced workplace safety • simplicity of use • significant cost-savings www.platycatsnatcher.com.au TO FIND OUT MORE GO TO:

Queensland explores first solar-pumping water supply

and it will soon progress to a concept design.

Mount Isa Water Board Chief Executive, Stephen Farrelly, said the pre-feasibility study undertaken in June 2016 found that the project is expected to be viable and would generate a net cost saving for customers.

“The project is still in its infancy and, as is appropriate for such a substantial investment, it will need to progress through a series of approvals before a final investment decision can be made,” Mr Farrelly said.

“We can see that if successful, it will have great benefits to our customers and the community.”

The Mount Isa Water Board is progressing a study to bring reduced-cost solar pumping from Lake Julius in Queensland’s Gulf Country region, in what would be the state’s first solar powered water supply.

Queensland Minister for Biofuels, Energy and Water Supply, Mark Bailey, said the innovative project could see renewable energy being used to increase water supply security, while reducing operational costs.

“This project has the potential to reduce the substantial cost of pumping water from Lake Julius to Mount Isa’s water treatment plant, some 70km away,” Mr Bailey said.

A pre-feasibility study has been completed for the project,

Mount Isa Mayor, Joyce McCulloch, said the study aligned with the council’s plans for exploring renewable energy projects for the future of Mount Isa.

“This project could bring so many benefits to Mount Isa,” Ms McCulloch said.

“There is the obvious water security and reduced costs of pumping from Lake Julius, but it would also mean greater year-round recreation access for Lake Moondarra if the region can use water from Julius for a similar cost.

“North West Queensland and Mount Isa have been identified as having one of the highest amounts of solar radiation per square metre, so it makes perfect sense for solar projects to be pursued.”

10 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au NEWS Welling & Crossley Diesel Fire Control Panels are Fully Compliant with Australian Standard AS 2941-2013 3 stage Battery Charger - Standard Ref. # 9.4.14 Jacket Heater Failure Indicator - Standard Ref. # 9.4.7 Battery Charge & Temperature Monitoring - Standard Ref. # 9.4.14 GO CHECK YOURS NOW! Don’t risk it with a non-compliant panel 59 Export Drv Brooklyn VIC 3012 Email: sales@wellcross.com.au Are the Fire Panels that you supply FULLY AS 2941-2013 C ompliant? The ones we’ve seen that are not, don’t have:

“The inspectors are coming”

New partnership for the HVAC industry

The Australian Institute of Refrigeration, Air Conditioning and Heating (AIRAH) has signed a collaborative agreement to promote and enhance energy efficiency practices and services in the HVAC&R industry to end users.

AIRAH and the New South Wales Office of Environment and Heritage (OEH) will work together to promote a better understanding of HVAC&R energy efficiency.

AIRAH CEO, Tony Gleeson, said, “AIRAH and OEH have long held a strong collaborative relationship.

“The agreement solidifies the parties’ commitment to enhance the skills, knowledge and opportunities for HVAC&R service providers to assist NSW businesses.

“It will also support both organisations’ current and future programs, schemes and related initiatives. AIRAH is committed to conducting cross-promotion activities, communications, and to deliver other appropriate support to OEH’s relevant activities.”

As per the agreement, some initial areas of focus will be the commercial refrigeration sector, HVAC optimisation, energy efficiency training courses, PRIME, the New South Wales Energy Savings Scheme, NABERS, and other industry events.

AIRAH Executive Manager, Government Relations and Technical Services, Phil Wilkinson, said he is looking forward to working collaboratively with OEH to explore a range of potential projects.

“There are several exciting developments already in the pipeline,” Mr Wilkinson said.

“We will assist in a national delivery of co-branded OEH energy efficiency training courses, and work to develop commercial refrigeration information material, such as an optimisation guide and fact sheets. A cool room/freezer room benchmarking tool is also on the cards.

“Also, off the back of the successful co-branded, jointly developed HVAC Optimisation Guide, we’re looking to further advance strategies to enhance the market’s capacity to deliver energy-efficient HVAC services.”

AIRAH will deliver co-branded versions of the OEH’s Energy-efficient commercial refrigeration, Introduction to HVAC and Advanced HVAC training courses in all Australian states and territories, excluding New South Wales.

Both parties will promote selected initiatives to its members, program participants, and newsletter recipients through their various communication channels.

THE NEXT GENERATION OF SOLARPAK

11 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 NEWS

Eliminating snaking and leaking from irrigation hoses

An Australian cane grower has found a solution to eliminate snaking and puncture tears in irrigation hoses, making the process of irrigating his crops faster and easier.

Norman Anderson, a cane grower in Queensland’s Childers region, operates 21 travelling irrigators and four centre pivots as part of his business. Mr Anderson often faces tough farming conditions which means finding an irrigation hose that can withstand extreme weather and possible punctures, without being too bulky, is a difficult task.

However, advancements in technology and products have allowed Mr Anderson to find an irrigation hose

that has minimum pressure loss and maximum hydraulic efficiency.

“Technology keeps bringing on improvements with machinery, use of machinery and reductions in labour. Even hoses for the travelling irrigators are so much better,” Mr Anderson said.

“We’ve been trialling Angus’ latest hose, Flowmaster, and their advanced manufacturing technique has more or less eliminated the old problems of snaking, wearing and puncturing we have associated with hoses.

“Overall, it is working smarter, not harder or longer. Easy to say, many don’t do it.”

Angus Flexible Pipelines’ irrigation hose, Flowmaster, is a flexible layflat drag hose for all types of irrigation applications that boasts a long service life, easy deployment and retrieval, and a 10-year warranty.

One of the main difficulties irrigators like Mr Anderson find with hoses is the balance between durability and ease of use. Often, tough long-lasting hoses are either not practical to use or don’t coil back easily.

The Flowmaster irrigation hose comprises a circular woven hightenacity polyester reinforcement covered in a tough elastomeric

polyurethane cover and lining, designed to fit a wide range of coupling types.

The polyurethane cover is resistant to abrasion, cutting, ozone, UV, weathering and microbiological attack, allowing it to last for a long period of time with minimal maintenance.

While its construction makes it durable, the Flowmaster is also steamed to size which minimises snaking and ensures the hose coils back easily. The Flowmaster has a maximum swell of only six per cent which maintains pressure and eliminates hose contraction, and its ‘fine weave’ one-piece construction maximises reeler capacity.

The Flowmaster is available in standard lengths of 200m, and up to 400m, and is suitable for both travelling irrigators and linear irrigation systems.

Mr Anderson has been trialling Angus Flexible Pipelines’ irrigation hoses for six years and says he finds it lightweight, easy to deploy continuous lengths without the hose twisting, and that it fits well on a standard reel.

“This latest hose is the one. I’ve trialled and tested it for over six years and bought several more. No leaks, and a generous 10-year warranty,” Mr Anderson said.

12 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au NEWS | PARTNER SOLUTIONS

ANGUS FLEXIBLE PIPELINES PROVIDES INNOVATIVE LAYFLAT HOSE SOLUTIONS FOR MINE

AND A WIDE RANGE OF FLUID TRANSFER

Wellmaster is the Industry Standard Flexible Rising Main for all types of ground water extraction and well-monitoring operations.

OVER 90,000 installations worldwide

Flexible Rising Main

Wellmaster Approvals:

Reg 31 UK

NSF 61 USA/Canada

DVGW W270

DM174 Italy

Institut d’Hygiene

AFNOR

AS 4020 Australia/NZ

9/67 Depot Street BANYO Qld 4014 M: 0497 799 098 Ph: 07 3256 7624 Angus Flexible Pipelines Australia Pty Ltd

DEWATERING

Germany

Switzerland

France

Solving sludge pump choking problems

Lismore City Council was having chronic problems with their digester pump choking at their South Lismore Sewage Treatment Plant, until an innovative new solids management system was introduced at the plant.

According to plant employees

Matt Potter and Brad Hampson, the pump would choke on a daily basis during its job of turning over the digester. They were using a Gorman-Rupp T3A3S-B self-priming sewage pump, but the sheer number of rags made it very difficult for even this excellent solids handling pump to pass all the rags, all the time.

Over the years, they tried different

wear plates (even from different companies), but the best they could achieve was to limit choking to once or twice per week by installing one of Gorman-Rupp’s self-cleaning wear plates.

The council was then told of Gorman-Rupp’s new Eradicator Solids Management System and wanted to try it. The Eradicator™ system features an aggressive self-cleaning wear plate incorporating a number of notches and grooves, as well as a patent-pending lacerating tooth that helps break up stringy materials (such as rags), scrape them off the impeller vanes and pass them through the pump – all without impacting performance or interrupting service. A special cover plate with the system also includes a patented lightweight inspection cover that can easily be removed, if necessary, to inspect pump internals.

The Eradicator system is available on all Gorman-Rupp Super T Series pump models, so the range can achieve flows from five litres per second (LPS)

through to 150 LPS and deliver heads to 40m, all while working on suction lifts to 7.6m. Because they are self-priming pumps, the pumps can be located at ground level, giving operators easy and safe access to the pumps for monitoring and/or service, unlike submersible pumps which require cranes and several operators to access. Wet well lids also stay closed with self-priming pumps so that operators are not exposed to falling into the wet well when anything needs to be done with the pumps. Clearance adjustments, oil changes, and general inspections only take minutes, which adds up to massive savings in time over the life of the pump.

As the new system is available as an upgrade kit for existing Super T, Lismore City Council installed one of these into their existing Gorman-Rupp T3. The pump then ran for three months without a single choke. In the same period, they would have expected to have between 12 and 24 chokes. Matt, Brad and their colleagues at the council are very pleased with the result.

14 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au PIA MEMBER NEWS | PARTNER SOLUTIONS

Sludge

Transfer

Call now for low finance rates & your nearest dealer AUSTRALIA WIDE 1300 582 582 kubota.com.au Power, performance and reliability with larger four-cylinder engines

pump applications

applications Agricultural irrigation Engine power packs are fully assembled with world class components Support of a national dealer network for Service and Spare Parts requirements Always Reliable - Kubota DIESEL ENGINES

pump

Shaping the industry’s future

Last November, the PIA council and members met for the association’s 13th annual general meeting and dinner. Attendees discussed the extensive training and liaison activities undertaken by the PIA in 2016, and discussed potential pump opportunities in China.

The PIA was happy to report the continuing success of its Installation and Commissioning training course, which was held twice during 2016 at Link Pumps in Sydney in February and September.

The course is continually being updated and improved, with the council currently exploring the possibility of running the course in Perth if suitable facilities for the practical “hands on” demonstrations can be organised.

The PIA also discussed its continuing liaison with industry organisations and government departments to promote cooperation between industries.

During his President’s speech Ron Astall reported that a fire pump installation checklist produced by PIA life member Ken Kugler has been adopted by the Fire Protection Association Australia as an official document.

The checklist will be included in the next revision of AS 2941 as an appendix.

The council reported it is continuing to work with the Department of Environment and Energy on Emissions Reduction Fund initiatives and is putting together the Industrial Equipment Upgrade proposal for pumping equipment.

The council also awarded the PIA Industry Innovation Award 2016 to Pentair for its SX Solids Pneumatic Air

Operated Vacuum Pump.

To find out more about the award, see page 18.

At the end of the AGM, attendees also enjoyed a presentation by special guest speaker Harry Katunar, Queensland and New South Wales Sales Manager at Pentair, who discussed his experience doing business in China while working at KSB.

He discussed the differences and similarities in the industry between the countries, as well as the opportunities that China could provide the Australian market.

The presentation provided great insight for those wanting to break into the Chinese market.

16 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au PIA NEWS

Outgoing President Ron Astall passes the baton to new President Dave Alexander.

James Blannin and Ken Kugler.

Scott Donoghue, Peter Passalacqua and Craig Frank.

PIA WELCOMES NEW COUNCIL MEMBERS

At the PIA’s general meeting last November elections were conducted for the positions of President, Vice-President and councillors. Outgoing President Ron Astall was thanked for the work he had done for the PIA as its leader over the past four years, and it was noted that he will continue his work with the association as an elected councillor.

The outgoing councillors were also thanked for their work over the past year and David Alexander, Managing Director of KSB Australia, was elected as the new PIA President.

Mr Alexander has worked for KSB Australia for 21 years and held the position of Managing Director for the past nine years.

John Inkster, CEO of Brown Brothers Engineering, joined Mr Alexander on the council as the re-elected Vice-President. Earlier in the evening, a motion to amend the PIA constitution was passed to increase the council to eight members, with at least six being accredited representatives with full association membership.

Mr Alexander, Mr Inkster and Mr Astall are joined by Alan Rowan, Keith Sanders, Peter Passalacqua, Ashley White, and David Brooks who were elected as councillors during the meeting, with Jamie Dixon appointed at a later date.

Congratulations to Mr Alexander and all the new and re-elected members of the council.

17 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 PIA NEWS

Rhys Laughton and Derek Price.

The PIA Council for 2017.

Kevin Wilson and Alan Rowan.

Aaron White and Carl Gilbert.

PIA Industry Innovation Award

In 2016 the PIA launched the Industry Innovation Award, which recognises and encourages new products and techniques the Australian industry will need to foster in the coming years to remain a powerhouse in the global pump industry.

In developing the Industry Innovation Award, the PIA noted that the future prosperity of the Australian pump industry will be heavily dependent on the ability of PIA members to introduce innovation that meets the needs of Australian and regional pump users.

The climate, geography and resource development potential in the Asia Pacific will continue to present challenges for innovation to meet the environmental and economic circumstances of the region. The PIA believes that Australian businesses are ideally placed to capitalise on this potential, the aim of the Industry Innovation Award is to encourage businesses towards impressive achievements in this arena.

In calling for applications for the 2016 award, the PIA asked applicants to demonstrate the contribution their design team had made to the industry with their new pump, pumping system or similar pump related project.

Applicants were advised that initiatives that save energy or minimise environmental impact through innovative design or system development would be well regarded in the judging process.

2016 award

The winner of the inaugural PIA Industry Innovation Award was announced last November at the association’s annual dinner.

The award for 2016 went to Pentair Southern Cross for their SX700 –E-Vac In Line Vacuum Units. These pumps provide increased efficiencies and reduced completion times, all while meeting the increased safety requirements of working within a confined space.

In early 2016, a demonstration of the abilities of these pump units was conducted at Malaysia Marine and Heavy Engineering (MMHE), with very impressive results – the chosen SX pumps delivered up to 30m vertical discharge.

Following this demonstration, Pentair Southern Cross was awarded a contract with ZAR Lynx Malaysia on a product for Floating Production Storage and Offloading (FPSO) tank sludge removal and cleaning.

An ongoing issue that FPSO owners and operators experience is that the vessels need to be in dry dock for the tank sludge removal and cleaning for a number of days; resulting in high costs. Often a hole had to be cut into the vessel for cleaning which then needed to be repaired.

ZAR Lynx and Pentair Southern Cross worked together to develop the SX700 series specifically for this application. The compact unit can be carried by an operator, allowing for the possibility of tank sludge removal and cleaning to occur while the vessel is afloat, reducing dry dock costs and reducing the down time for the FPSO – a significant benefit to vessel owners and operators.

For further information please contact Southern Cross on 131 PUMP.

18 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au PIA NEWS

Jon Mans from Pentair accepts the PIA Innovation Award from President Dave Alexander.

Ef

Reconditioning

Restor e Clear ances

Re- Engineering

P f T ti erfor mance Testing.

Services available include:

• Inspection and trouble-shooting

• Case build up and re-machining

• Aillitfid bi Axial split case facing and reboring

• Axial thrust balancing

• Shaft and bearing API 610 upgrades

• Mechanical Seal upgrades to API 682

• Bearing housing & back cover retrofit

• Lube system upgrades

• Composite Wear Parts

• Tighter clearances

• Hydraulic Re-Rating

• Ridtti Rapid prototyping

• Driver upgrades (MEPS compliance)

• Baseplateadaptors and rebuilding

• Custom Spare Parts

• Rotating Element balancing

• ASME & AS1210 qualified Welding

• Hydrostatic Testing

• Performance Testing

• FFT Vibration analysis

Re-Manufactur e and Re-Design Ser vice For ALL types of Centrifugal Pumps

Repair,

ovement

ficiency Impr

A.B.N. 37 006 317 979 EMAIL unitedpumps@unitedpumps.com.au http://www.unitedpumps.com.au/ 31 WESTERN AVENUE SUNSHINE, VICTORIA 3020 P.O. BOX 348, SUNSHINE, VICTORIA 3020 •PHONE +613 9312 6566 •FAX +613 9312 6371

Marketing 101 for pump companies: how to get your business noticed

With hundreds of local and international businesses vying for a customer’s attention, pump companies need to know how they can stand out from the crowd. The marketing landscape has changed enormously in the past decade with SEO, social media, and content marketing all becoming key elements of any marketing strategy. The team at Monkey Media have evolved at the same time, and in this edition we give you a peek into how our marketing agency operates to help take pump companies’ marketing to the next level.

Australian pump companies need to be across a diverse range of industries, including water and wastewater, oil and gas, HVAC, dewatering, food and beverage, and chemicals, among other sectors. Due to the sheer number of companies in the market, the internet can be a pump company’s best friend, but only if they know how to use it to their advantage.

We’ve analysed how pump end users find the products they are looking for online and found that when someone is searching for a pump they won’t go directly to a company’s website, but will Google how to fix a specific problem and find a pump that can help. With this in mind, the best way to get noticed by pump users is to actively provide an answer to their questions or a solution to their problems.

How to get started?

Businesses talk about things like SEO, EDMs and adwords but when it comes to using these techniques for their company, they are often unsure where to start. Most pump companies don’t have the time to dedicate to understanding this area properly or don’t have the resources to employ one person to work solely in marketing.

Monkey Media often works with companies who are only just beginning to market their business and helps to demystify how these marketing strategies can be implemented. Our team also stays up-to-date on all the news and trends in the pump industry to make sure our clients always know what is going on.

To start, we help pump companies develop a clear strategy outlining exactly what they want their marketing to achieve (promoting a service, product, being viewed a certain way) and then we help deliver this by developing high quality articles.

Some companies spend a large amount of time creating well thought-out marketing plans but never actually implementing them, making any strategy useless. While it’s essential to know what you want to achieve, without tangible outcomes it won’t be successful.

Our outcomes are the articles created, which can be targeted to a specific market or be used to reinforce a message. While any company can write a few paragraphs telling everyone how great their product is, the difference with Monkey Media is that a team of journalists and editors are creating content that shows your business in a positive light while still providing the reader with useful and sought-after information.

These stories are sent directly to the inbox of customers and can be tracked, so pump companies can see how many people are reading them, and who, which creates hot sales

leads. The key here is to have good information – it shouldn’t just be about you, it should be useful information for your reader.

If customers receive regular online newsletters filled with articles they find helpful or interesting they are more likely to have your company front-of-mind the next time they need to buy the products or services you offer.

Writing informative and useful articles

Firstly, we work with the business to decide what areas they want to focus on, which is then clearly laid out in a one to two page ‘marketing focus’ document. This document then becomes a guide for our journalists to refer back to, ensuring each article relates back to a core focus.

Once the focus is decided, we develop a list of topics and write the articles. This can include interviewing staff or writing technical and issues-based articles. The process is easy because the company can decide what level of input they want, while retaining overall approval.

The articles produced for pump companies can include technical information; tips for selecting, installing, or maintaining a pump; how to fix or prevent specific pump problems; how to reduce costs or fuel; how to increase efficiencies; case studies of clients using pumps; or the benefits of specific products or services offered. We also create a bank of less time-sensitive story ideas while keeping tabs on what is happening in the industry.

20 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au

MARKETING

Marketing Associate Mathew Walker and Associate Editor Jessica Dickers discussing the details of a pump company’s marketing focus to ensure upcoming articles maintain the company’s core messages.

Looking at the big picture

Our marketing process isn’t as simple as writing standalone stories and sending them off – it’s more holistic. We check-in regularly to see if current procedures are still working or if anything needs to move in a different direction.

As we’re also a publishing agency with our own magazines, namely Pump Industry, there are also opportunities to use this relationship to get stories published in the magazines and on our websites. We can also manage external publications so stories can be seen by different markets or industries, or use our publishing and industry contacts to enhance the visibility of stories.

All of our experienced writers and editors have a strong knowledge of the pump industry and write content for Pump Industry magazine. We know what pump users want to read and can create technical articles that are interesting to read without sacrificing the technical information. Pump companies can be confident they have a trusted expert on board rather than a marketing generalist.

Well written articles are at the core of all the content we create but we can also create other types of content for pump companies as part of a strong marketing strategy, including:

• LinkedIn shareable graphics/updates on various social media platforms

• A variety of design work, thanks to our in-house design team

• Creating, managing or upgrading pump company websites and web hosting platforms

• Sourcing images from our extensive database It all comes down to content

There’s no use having a great product or service if no one knows about it, so having a strong online marketing strategy is vital in making sure your company is the one pump users go to. As consumers, no one likes to be bombarded with in-your-face promotional materials spamming their inboxes, which is why providing content that is useful and informative is key.

For example, if a pump company is providing information on a technique that will save pump users money or that will increase system efficiency, this is helpful content that people will want to read because it can directly impact their pump applications.

Or if a pump user is experiencing a specific problem, goes online to find a solution and finds an article explaining how your pumps can help solve that problem, they are more likely to contact you.

This high quality content allows pump companies to be seen by pump users as experts in their field, and as a company that can provide the solutions (and products) they need.

If your pump company could benefit from online marketing, contact Chris Bland or Mathew Walker at Monkey Media on (03) 9988 4950 for a confidential discussion about your needs.

Top five tips to get started

1. Be clear on what your message is and who your target audience is

2. Focus on content that will be useful to your customers

3. Make sure your website and social media profiles are up-to-date

4. Consider a newsletter/EDM to keep your business front-of-mind for customers

5. Track and record all leads

21 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18

MARKETING

The Monkey Media team deciding on the content and layout for a client’s newsletter.

Managing Editor Laura Harvey and Senior Designer Alejandro Molano repurposing a client article that proved popular on LinkedIn into Pump Industry magazine.

Flygt Concertor trial

A SUCCESS FOR SWEDISH MUNICIPALITY

Operators of a municipal wastewater pumping station in the rural town of Lomma on Sweden’s south-western coast agreed to install and trial a revolutionary new wastewater pumping system in an effort to solve clogging issues at the pump station.

As well as delivering clogfree pumping, Xylem’s Flygt Concertor, a state-of-the-art pumping system with integrated intelligence, significantly reduced energy consumption at the wastewater pumping station.

The operators were so impressed that they decided to purchase and permanently install the new system at the facility.

Efficiency challenges

Lomma Municipality is located in the Skåne region of southern Sweden. It serves over 23,000 inhabitants in three main districts, including several villages and neighbouring communities. The municipality’s Civil Administration Unit is working intensively to expand and improve its services as its population has steadily grown over the last five years.

It is in this context that operators of the Borgeby Treatment Plant agreed to trial Concertor, Flygt’s new wastewater pumping system, in one of their pump stations. The main challenges were to improve plant efficiency and reduce instances of pump clogging, which typically required maintenance staff to intervene once a month.

Delivering clog-free pumping and significantly reducing energy consumption

In June 2015, Flygt Concertor was installed at Flädie Lundavägen pumping station and the system’s performance was closely monitored over a period of six months. This showed that the newly installed system delivered a significant reduction in energy consumption. In addition to the energy savings, maintenance costs decreased by €1,300 annually.

Anders Sjöstrand, Manager at Borgeby Treatment Plant said, “Since installing Flygt Concertor we have seen a significant drop in our energy bill. Furthermore, maintenance call-outs have also been reduced to zero as the overall performance at the station has been greatly improved.

“We were so impressed with the system that we decided to replace our current system and install this new solution permanently at Flädie Lundavägen.”

Furthermore, the benefits of acquiring a system that is so flexible is that, in addition to the immediate positive impact of the trouble-free pumping and energy savings, operators can, for example, plan a significant

reduction in their pump stock, reducing the variety of pumps needed to cover all of their applications.

Lomma Municipality is aware of the inventory savings made possible with Flygt Concertor.

“By having Concertor with three outlet dimensions, we can drastically reduce our inventory as we won’t need so many varieties of pumps and impellers. We’re confident that this can deliver savings for us, and we are looking forward to seeing how it will work in the future,” concluded Sjöstrand.

One of Concertor’s unique features is its flexibility. Not only does this new system adjust pump performance based on actual flow requirements, making selection easier and guaranteeing optimal performance under variable flow, but it is also scalable, which means that it is possible for operators to add new functionality without losing their initial investment. This makes it suitable for challenges in many different sectors, being able to improve the efficiency of stations with different characteristics.

Flygt Concertor will be available in New Zealand from early 2017.

22 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au

INDUSTRY NEWS | PARTNER SOLUTIONS

INTEGRATED NEW PUMPING

CONCERTOR™ INTELLIGENCE

SYSTEM WITH

WORLD’S FIRST WASTEWATER PUMPING SYSTEM WITH INTEGRATED INTELLIGENCE

This revolutionary system delivers optimal performance while reducing your total cost of ownership. It also offers unparalleled flexibility and simplicity on a whole new level. You might even say it thinks for itself. We invite you to enter a new era in wastewater pumping with Flygt Concertor.

See Flygt Concertor for yourself at the New South Wales Water Industry Operators Conference & Exhibition in Canberra, 29th & 30th March 2017.

One powerful solution. Unlimited possibilities.

www.xylem.com/pumping

Pump Genius WEG

PUMP INTELLIGENCE TO YOUR SYSTEM

The Pump Genius is a customizable feature of WEG drives that enables your standard VSD to become dedicated for pumping systems. It ensures accurate pressure / flow control throughout the processing cycle, starting with raw water and its usage, ending on wastewater treatment.

With an easy-to-use programming wizard, Pump Genius helps you to minimize downtime and maximize energy savings Everything you need is available through selecting one of the three options that best fits to your application.

Submersible pumps Desalination plants Water distribution Wastewater plants Irrigation systems simplex multipump multiplex

simplex

The Simplex software adds ideal features to the VSD for single pump control.

g Pipe Charging Mode

g Sleep & Wake-Up Modes

g Dry Pump Protection

g Broken Pipe or Leakage Detection

g Pump Cavitation Monitoring

multipump

Multipump is the best choice when a pumping system needs to be integrated with a costeffective solution. It enables one single VSD to control up to 5 pumps via DOL, soft-starter or other starting methods.

multiplex

Multiplex software is the most complete solution to accurately control flow and pressure with high reliability.

The VSDs control, monitor and manage the entire system on their own. There is no need for additional PLC, HMI or any external devices thus installation costs can be optimized.

Is drought proofing Australia the possible dream?

by Warwick Lorenz, Managing Director, Australian Pump Industries

Afew years ago I picked up a book at a second hand book shop called Australia Replanned Thumbing through it I noted that it was written in 1944 and published in January 1945. What drew me to the book was a fold-out map of Australia that showed an inland sea in the north east of South Australia, with rivers draining into it fed from the north east sectors of Northern Queensland.

The book was written by a gentleman writing under the name of Veritas. Veritas was a pseudonym for a journalist called Luscombe who also, as I recall as a kid, was writing for The Truth newspaper in Sydney.

The book is a call to arms, warning Australians that they need to get with it and do something with this wonderful huge country of ours. Here’s the key points he makes:

Our opportunities

Luscombe points out that in 1944, the war is effectively over and that we need to start thinking about what to do with our country. He draws a parallel with the United States, a country of three million square miles and a population of 130 million.

Australia, he points out, is 2.9 million square miles with a population of seven million. Of that seven million, approximately one million were in uniform or working 100 per cent in the war effort. Luscombe also points out that in the years of the Second World War we tripled the productivity of the country, which leads to the obvious question – what next?

The dead heart

Luscombe, who of course was writing long before climate change, refers to the central regions of Australia as the “dead heart” of the country. He points out that this was once fertile land covered with dense and luxurious vegetation, evidenced by the fossilised remains found in the Diamantina and Lake Eyre districts.

Creating a vast live heart

It should be pointed out that Luscombe wrote at a time when horsedrawn graders were not that uncommon and crawler dozers used cable controls to raise and lower tractor blades.

In spite of that, he dared to dream that the parched and arid dead heart of Australia could be brought to life.

The vision was an inland sea of approximately 50,000 square miles. This sea would be fed by northern and north eastern rivers, and the flood waters

26 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au

INDUSTRY NEWS

diverted back across the Dividing Range to flow along the dry central river beds to the inland sea.

Examining the scheme

In 1944, almost 90 per cent of the total land area of Australia was put to very little use. Those huge areas of land, mainly arid, barren and useless, needed water security.

The question we have to ask ourselves is, are we ready to carry out projects like that in Australia? Ion Idriess, one of the great Australian writers of the 20th Century, used the slogan ‘Water is Life’ in a number of his books.

In Luscombe’s plan, an inland sea would be created and connected to the Great Southern Ocean by a canal from the head of the Spencer Gulf via Lake Torrens. The canal would be up to half a mile wide with a depth of around 25 feet! The bed of Lake Torrens might be excavated, and locks and pumping stations would be required in order to provide a shipping passage similar to the Panama Canal.

Luscombe, of course, is writing at a time when the greatest civil engineering feats the world had seen were considered to be the Panama and Suez Canals.

He must have been conscious of the Hoover Dam, draining approximately 1,000 square miles across seven states and capturing up to 740 billion cubic feet of water from the Colorado River each year.

When you consider the fact that the Hoover was built in around four to five years, with the primitive equipment and methods of the time, Luscombe’s plan, or something like it, seems absolutely achievable.

However, whether the drought proofing of the country, or large sections of it, can be achieved with an inland sea is questionable in today’s world with our 70 years of additional knowledge. What is beyond dispute is

the fact that water storage and water security are essential for the progress of our agricultural industries and to foster population growth in the years to come. Why bother?

In a world where Australians appear to enjoy higher wages than just about anybody else on the planet, we are sitting on the biggest piece of unused real estate in the world. It is also possibly the greatest opportunity to provide food resources for a growing world population. It seems there’s plenty of good reasons to provide farms and cities with water security.

From a political perspective, governments of either persuasion are and will be faced with financial challenges that must be addressed. The country clearly can’t rely purely on commodity prices to maintain our lifestyle, create employment or sustain our welfare programs. In other words, something has got to give.

Imagine a drought proof Australia where we brought life back to country towns, provided farmers with water security, built processing plants to value add raw product, and at the same time, provide the Greens with an environmental wonderland.

Going back to Luscombe’s dream, he envisioned forests throughout the centre of Australia – all in a time before we had to worry about greenhouse gases.

Is there a market for what we produce?

When Luscombe wrote his book in 1944, the global population was three billion. Now we are seven billion and heading for ten, so it is highly likely there will be a market for top quality food and agricultural produce for at least the next thousand years.

The Prime Minister preaches jobs and growth. Well here’s a package that will deliver both. I’ve discussed this idea with civil contractors, farmers, irrigation specialists, water well drillers and a whole wide range of folk to test the water. What I get in return is astonishment that somebody had thought on this scale 70years ago. I get excitement at the possibility of a vision that would change the country forever. I get 100 per cent unqualified support of the vision.

Of course the question everybody asks is, “Who is going to do it?”

Gina Rinehart would do it! Barnaby Joyce would do it! Most of the people I talk to in the pump industry would certainly not only support it but would

be happy to be deeply involved. Would it rebirth our pump manufacturing industry? Maybe it would.

Think about these statistics:

1. China had the same sized economy as Australia in 1990

2. Twenty-six years later, their economy is 16 times ours and they are number two in the world

3. They have 1.3 billion people, we have 24 million people. We produce approximately 60 million people’s worth of food per year (my rough calculation) and they produce 1.3 billion. In other words, they produce 22 times more food than we do but from about the same landmass

Let’s assume we drought proof Australia and can produce five times more food than we do at the moment (i.e. $300 billion worth).

That’s bigger than the iron ore business. Not only that, but it’s a much bigger employer and there are loads of benefits that we will get from employment, not the least of which is lower taxes for the rest of us.

Let’s go

Luscombe prefaced his book with the comment that if he was wrong in his ideas, he would welcome correction.

He also stated three principles that appear to be just as relevant today as they were in 1944. Here they are:

1. Think clearly, without prejudice

2. Think fearlessly, with regard for nothing but the truth

3. Think big, with the knowledge of the almost limitless possibilities of technology

As a simple pump man, I welcome the comments of my peers. Copies of Luscombe’s map are freely available from Australian Pump Industries and may serve to inspire some of the readers of this magazine. Bring it on!

27 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 INDUSTRY NEWS

Warwick Lorenz.

The original scheme for drought proofing Australia.

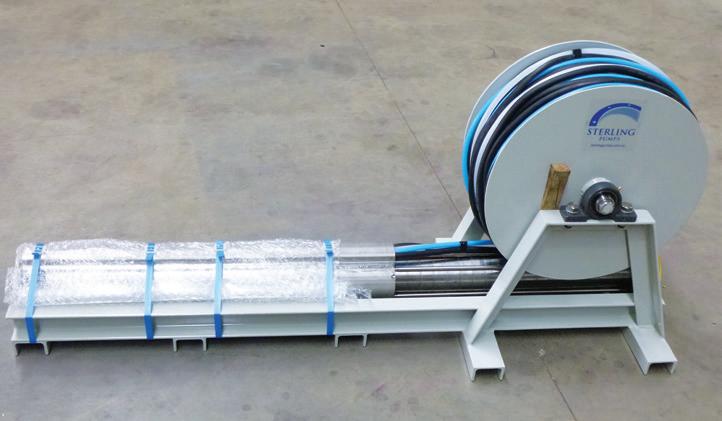

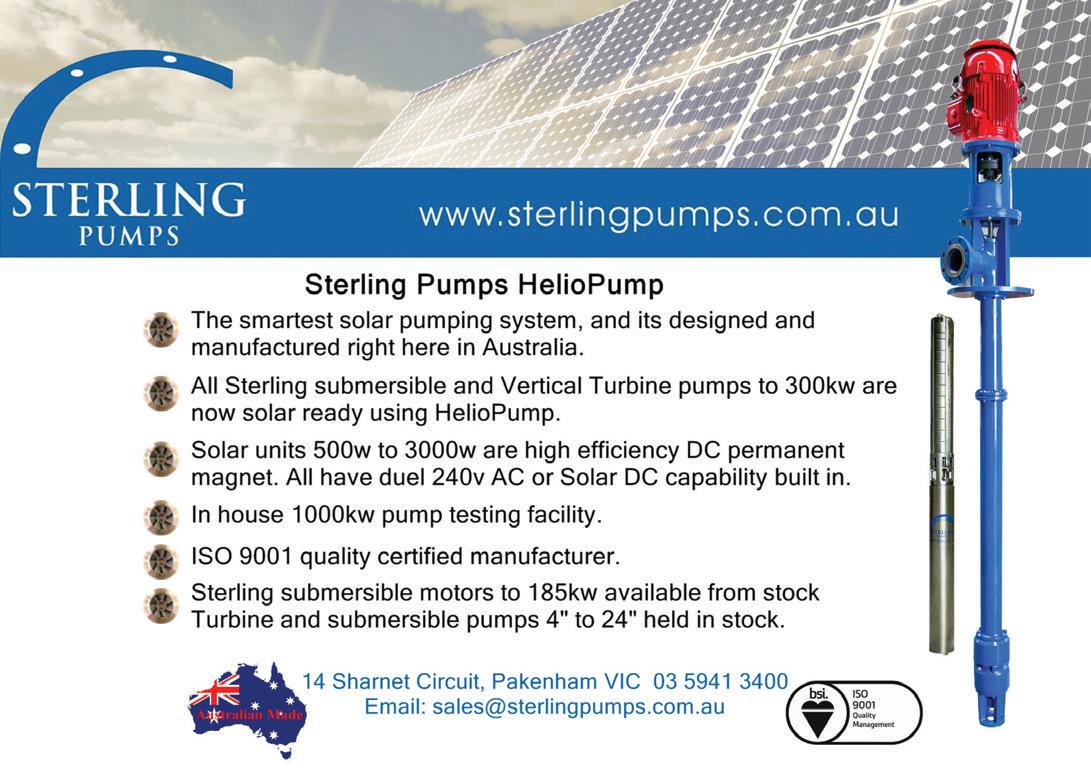

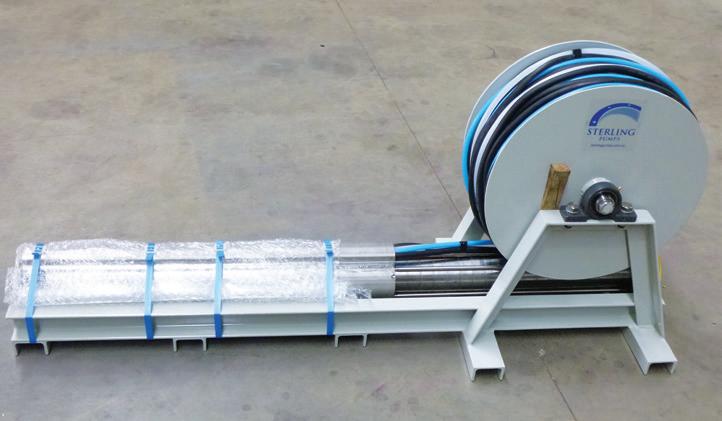

A new innovation in S OLAR PUMPING

Shakti helical rotor pumps are high quality products designed for drinking water supply and smaller irrigation applications. DC powered helical rotor pumps have been designed specifically to pump water efficiently using solar power. The helical rotor pump is simple, efficient and reliable, pumping water with very low levels of solar power.

The motor has been developed specifically for the helical pump and is designed according to the permanent magnet principle with controller. The motor speed range is 500-3,600rpm, depending on power input and load. Each system consists of a pump, motor and a controller. This modular concept keeps all electronics above ground providing, simple servicing.

Benefits of the Shakti helical pump:

• Designed for use in remote and harsh conditions

• Smart modular design for simple and cost effective servicing and repair

• Water filled motors for reliability and to avoid oil contamination

• Fast and simple installation

• Cost effective spare parts philosophy

• Very strong ROI against diesel powered pumping

• Helical pump to closely match high head and low flow application and optimise efficiency

Features:

• Water temperature specific variants to provide the most efficient outputs, with a permanent magnet motor (PM motor) featuring a higher efficiency within the power range compared to a conventional asynchronous motor

• Stainless steel components

• Magnet motors, designed for solar, with over 85 per cent efficiency even low power

This form of water pumping has become increasingly popular throughout the world. As a widely adopted solar energy technology, the usage has increased dramatically over the past 20 years. Even though a solar water pump motor is used for smaller operations, the benefits are huge.

The key to success is using a high quality solar water pump motor created by a company with years of experience in the business.

The development of such affordable, inexhaustible and clean solar energy technologies will have huge long-term benefits. It will increase countries’ energy security through reliance on an indigenous, inexhaustible and mostly importindependent resource, enhance sustainability, reduce pollution, lower the costs of mitigating climate change, and keep fossil fuel prices lower than otherwise.

28 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au

INDUSTRY NEWS | PARTNER SOLUTIONS

Providing a complete pumping solution

Global leaders in pump control ComAp introduce their plug-and-play solution for the pumping market, making installation easy.

C> Complete solution with plugand-play in a polycarbonate or mild-steel panel

> Simple, intuitive controls mean you always know how your pump is performing

> Easy speed control of mechanical or electronic engines

> Remote monitoring and alarms from your smart phone or tablet

> Quickly disable failed sensors to ensure continued water supply to stock or crops

omAp has just released a new solution featuring the InteliDrive IPC in either a polycarbonate or mild steel panel, providing significant benefits to the operator.

The solution is easy to install, use, fault-find and repair.

The polycarbonate panel features an IP67 rating, suitable for mounting outside in all weather conditions, and the mild steel panel features an IP44 rating, making it ideal for mounting in a shed or lean-to.

Both the mild steel and polycarbonate solution come standard with a resettable fuse to protect the controller, while also having space for an emergency stop button should it be required.

Deutsch connectors are included in both the polycarbonate and mild steel solution for easy installation, incorporating the same pin configuration, so that if the application changes, the solution can change to match.

The irrigation pump controller at the heart of the solution allows for control, monitoring and protection for both mechanical and electronic diesel/gas engines in one unit. With automatic, manual or remote start/stop of the engine and automatic SMS on alarm, an increase in automation and efficiency can be expected in process and operation of the application.

With only the highest quality materials used, the solution is dependable, durable and supported by ComAp’s strong local sales and engineering team. ComAp services a range of industries, including mining, oil and gas, commercial and agriculture.

Specialising in electrical engineering services, including design, installation, commissioning, technical support and consulting, ComAp has a range of products and services to suit your needs.

30 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au INDUSTRY NEWS | PARTNER SOLUTIONS comap.com.au/products/drive We’ll help you grow That’s smart

control

THE NEXT GENERATION OF THERMAL OIL PUMP HAS ARRIVED NKX-Design <350oC Thermal oils Volute casing, interchangeable with most common DIN/EN pumps Efficient Impeller design Drain plug SiC-sleeve bearing set Large ball bearing for extended service Cooling fan Std low temperature mechanical seal Cooling fins Patented cooling and self-venting system for personnel and environmental safety To see the pump in action, go to https://www.youtube.com/watch?v=VL6S2-k92sU FOR DISTRIBUTION ENQUIRIES, CONTACT SALES@RPS-GROUP.NET OR +61 (03) 9763 3221 www.rps-group.net RPS Group made in Germany Why repair when you should UPGRADE!

Recently Pump Industry undertook its fourth annual State of the Industry survey. The survey’s results provide insights into current trends in the industry, areas for growth and opportunity, what has or hasn’t been working for companies over the last year, and the industry’s outlook for the year ahead.

NEW OPPORTUNITIES DRI State of the In

32 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au

STATE OF THE INDUSTRY

What

is your company's outlook for 2017?

What is your company's outlook for 2016?

DON' T KNOW

Our survey results suggest that 2016 was a mixed bag for the pump industry. While some companies reported exceeding their expectations for the year by various degrees, and a good number of others performed as expected, many still fell short due to a range of factors, including restricted government project expenditure, reduced market confidence, increased competition from imports, lower oil prices, economic downturn and political uncertainty.

However, while 2016 undoubtedly had its challenges, the majority of survey respondents were positive about what 2017 might bring.

70.4 per cent of respondents thought their company’s outlook for 2017 was positive, while 21.1 per cent had neutral expectations for the year. Only 5.6 per cent of respondents had a negative outlook

for 2017, while 2.8 per cent were unsure what to expect. These results are shown in Figure 1.

These results signify greater confidence and a more positive general mood within the pump industry than last year, when around equal numbers of respondents expected to perform better (45 per cent) or the same (44 per cent) than during the previous year, and eight per cent expected to perform worse (Figure 2).

This increased optimism was also reflected in responses to the question of whether respondents expected their company’s 2017 performance to exceed that of 2016. As shown in Figure 3, 77.4 per cent of respondents answered in the positive, while 16.9 per cent didn’t expect better performance, and 5.6 per cent weren’t sure.

Comparing the results of the first two questions

dustry in 2017

33 www.pumpindustry.com.au pump industry | Summer 2017 | Issue 18 STATE OF THE INDUSTRY VE OPTIMISTIC OUTLOOK

NEGATIVE NEUTRAL POSITIVE

DON' T KNOW

2.8% 70.4% 21.2% 5.6%

Figure 1. What is your company’s outlook for 2017?

NEGATIVE NEUTRAL

POSITIVE

3% 45% 44% 8%

Figure 2. What is your company’s outlook for 2016?

Note the increased positivity in 2017.

of this year’s survey suggests that some respondents expected their company’s performance to improve in 2017, but still did not consider the year’s outlook to be positive overall.

Possible explanations for this include that some respondents considered an increase in performance as a neutral result, perhaps because the expected improvement was not huge, or that, for some companies, the expected 2017 improvement was required to make up for a slower 2016, but wouldn’t necessarily result in burgeoning growth.

Similar to last year, our respondents were more confident about their own company’s outlook than about the outlook for the industry in general. 41 per cent of respondents expected 2017 to be a positive year for the industry,

30.5 per cent had neutral expectations, while 12.6 per cent thought the industry as a whole was in for a bad year. 15.8 per cent were unsure about what 2017 would bring.

These expectations are considerably more favourable than results for 2016, as shown in Figure 4.

Performance by vertical

Key to understanding the current state of the pump industry is to examine which particular verticals performed the best and worst for businesses during 2016, and to identify how key sectors are expected to fare in 2017. We asked our respondents how the volume of work across key verticals had changed for their businesses during 2016, and how they expected them to change in 2017.

Figure 5 illustrates the actual reported performance of various verticals for our respondents during 2016, compared to their expected 2016 performance at this time last year, and their anticipated performance in 2017.

The rundown on 2016

According to our respondents, the best performing verticals in 2016 were water and wastewater, and irrigation. On the other hand, the vertical that performed the worst overall was mining, with the greatest number of respondents reporting a slight or significant decrease in the volume of work in that industry.

Overall, a greater range of verticals experienced increases in volume of work than in 2015, and fewer verticals exhibited overall decreases in work volume.

These results fall relatively close to the expectations for 2016 expressed in last year’s survey results, suggesting that our respondents have their fingers

on the pulse of the industry.

What’s in store for 2017?

Once again, our respondents considered the water and wastewater industry to be the biggest boom area. Most respondents thought the volume of work in this area would increase during 2017, and no respondents thought it would decrease at all. Significantly more work was also expected in irrigation.

In contrast to last year, a greater percentage of respondents seemed to consider the sharp decline in the mining, and oil and gas industries to be coming to an end, with most respondents expecting the work volumes in these verticals to increase slightly or remain stable.

Factors affecting the industry

Our respondents cited a variety of key factors that had impacted upon their performance, for better or worse, throughout 2016. Our respondents’ thoughts are summarised in Figure 6, which showcases the factors that have had a negative impact on the industry against the factors that have had a positive impact on the industry; and Figure 7, which summarises the overall impact various factors have had on the industry.

Asking our respondents to identify the industry trend or external factor that had the single biggest impact on their businesses in 2016 unearthed a number of recurring themes.

An increase in agricultural and irrigation projects was a positive for some respondents. “The agricultural industry is experiencing a boom at the moment and there are still government grants available for private irrigation infrastructure upgrades,” said one respondent.

However, other respondents said that, in their experience, higher rainfall had reduced irrigation requirements, which had affected their business negatively.

This reflected a general trend in responses where some respondents cited an increase in greenlit projects as having positively affected their business, while others, perhaps operating in other states or industries, considered project spending to have dropped off, affecting their businesses negatively.

Increases in electricity prices were also mentioned by a number of respondents, with companies that managed to take advantage of the increased demand for energy efficient or solar-powered pumping products reaping rewards as a result.

“The rising cost of power is forcing

34 pump industry | Summer 2017 | Issue 18 www.pumpindustry.com.au

STATE OF THE INDUSTRY DON'T KNOW NO YES Do you expect your company to 5.6% 77.5% 16.9%

better

perform

in 2017 than 2016?

Figure 4. Industry outlook in 2017 versus industry outlook in 2016.

2016 2017 Industry outlook in 2017 versus industry outlook in 2016. 0 10 20 30 40 50 DON'T KNOW NEUTRAL NEGATIVE POSITIVE

Figure 3. Do you expect your company to perform better in 2017 than 2016?

larger agricultural producers to upgrade pumping plants to more efficient units,” said one respondent, while another cited solar pumps as the “next big thing”.

Changes in the HVAC industry had caused real problems for a number of respondents, who expressed serious concerns about the quality of product being specified throughout the industry.

“The HVAC industry is declining in quality with builders/plumbing contractors changing specifications and putting in the cheapest rubbish available,” said one respondent. “Fire services has also gone the same way and these jobs have decreased significantly in value and quality.”

Similar sentiments were expressed in other responses. “In the building services industry, D&C (design and construct) jobs have meant a lower standard in engineering and quality of product supplied, driving prices down,” said another respondent.

Competition from cheaper imports, especially from Asia, also had negative impacts on a number of companies.

Some respondents cited the downturn in mining as having the biggest negative influence on their business in 2016. However, others managed to make this trend a positive by capitalising on the mining industry’s “heavy focus on cost reductions and operational improvements”.

Low commodity prices were a negative for some respondents, however a number said they expected them to improve during the next year.

Other factors that had affected our respondents included the value of the Australian dollar, unemployment, and reduced focus on staff training. Weather conditions were also listed as a big influence on performance during 2016 by many respondents. Other respondents had received benefits from making the most of marketing opportunities.

Looking forward into 2017, we asked our respondents about a range of economic trends and whether they thought they would have a positive or negative impact on the Australian pump industry.

Trends that the majority of our respondents expected to have a positive impact on the industry included the agricultural industry, and major projects being approved or underway.

Opinions were more divided over other trends, such as the value of the Australian dollar, global oil prices, interest rates, the performance of the mining industry, and commodity prices.

Increasedsignificantly Decreasedsignificantly Increasedsomewhat Decreasedsomewhat Stayed thesame

MiningOil&Gas

Pulp&PaperPlastics&Rubber PowerGenerationBuildingServices/HVACFood&beverageWater&wastewaterIrrigation Chemicals&PharmaceuticalsManufacturing

Figure 5. Performance by vertical. Note the difference between expected performance in 2016 and the actual reported performance; as well as the significant expected increase across a range of verticals in 2017.

Influential factors on the Australian pump industry in 2016 – negative to positive.

Figure 6. Influential factors on the Australian pump industry in 2016 – negative to positive.

The end of the mining downturn?

In response to last year’s survey, many of our respondents said that they had been hit hard by the collapse in commodity prices and subsequent downturn in the mining industry during 2015.

This year, we asked whether they thought we had reached the end of the mining downturn.

Opinions were divided on this topic, ranging from, “Yes, there are signs that commodity prices are improving,” to “Yes, but it will remain flat for some time before any recovery,” to “No – American imports from China being restricted will have a detrimental affect on our raw products,” or “No, due to government disincentives and the cost of power”.

However overall, a slightly greater

number of respondents thought that the bottom of the downturn had been reached than didn’t.

The impact of ChAFTA