The all-new range of Isuzu trucks has arrived. With a sleek new cab design, more advanced safety features and a smoother, more comfortable drive, the new range will change the way we rely on our trucks. Forever. To find out more, visit your nearest Isuzu Trucks Dealer or visit isuzu.com.au

20

Australia’s road toll is the defining issue currently causing debate and calls for change in the nation’s heavy vehicle industry. Sean Mortell looks at the many factors causing a spike in road fatalities and what can be done to make freight routes safer for all

24

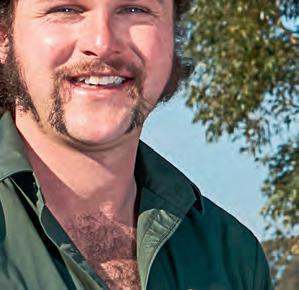

Trucking has always been a dream for James Bankes. Now, after taking a leap of faith two years ago, he’s succeeding under the banner of Bankes Haulage

30

After a recent pivot into harvest work, Luke Keams decided to concoct the perfect Mack to suit his growing list of wishes, Warren Aitken writes

38

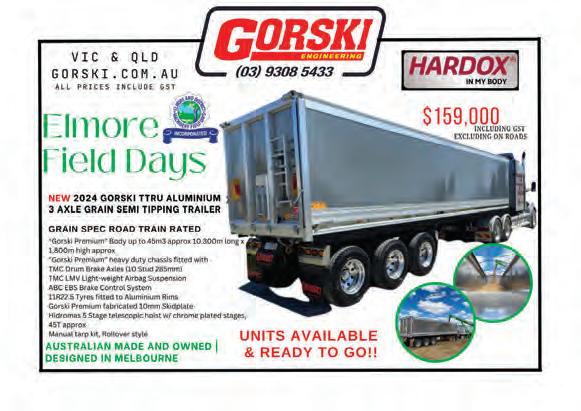

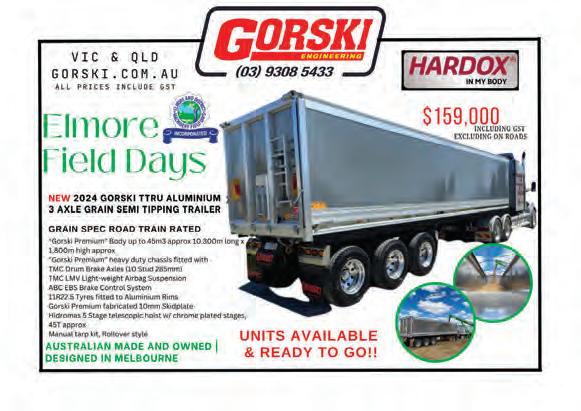

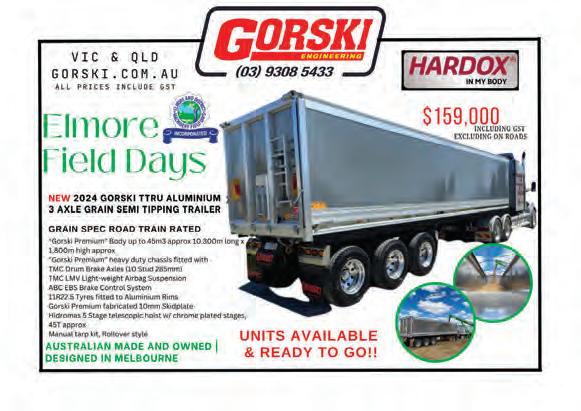

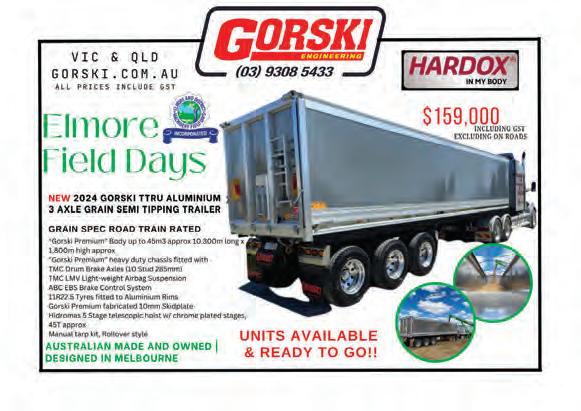

For nearly 30 years, Razor’s trailer technology has been the perfect partner for Gorski’s products. Now, technological evolution and a safety focus is allowing the Razor name to succeed on a global scale

44 DRIVING HOPE

In the midst of a family tragedy, Warren Aitken is calling on the trucking industry to contribute to a meaningful cure for a crippling disease

46

The journey that Laura Wilkinson has been on in her life has led to the launch of an exciting new WA logistics company that is taking a unique approach to project logistics

48 PETERBILT PASSION

Tiarna Condren sits down with Shane Pendergast to find out how a vintage Peterbilt made its way to Camden, NSW

50 INNDYAH THE SPARKIE

Warren Aitken found himself at Victoria’s Hallam Truck Centre in front of Inndyah Chenoveth, who may not have grown up loving trucks but is now thriving in her role within the industry

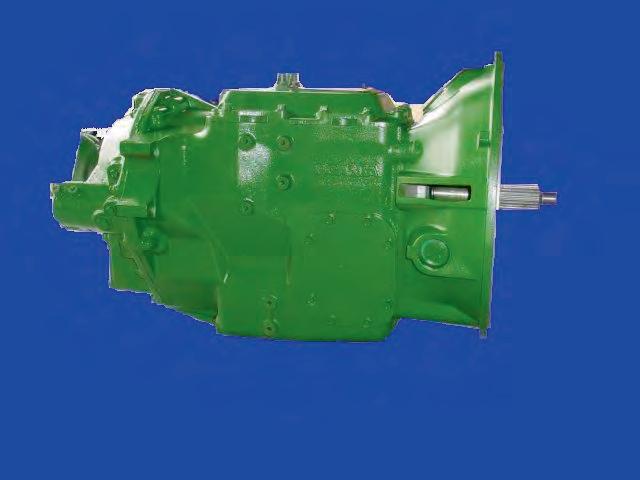

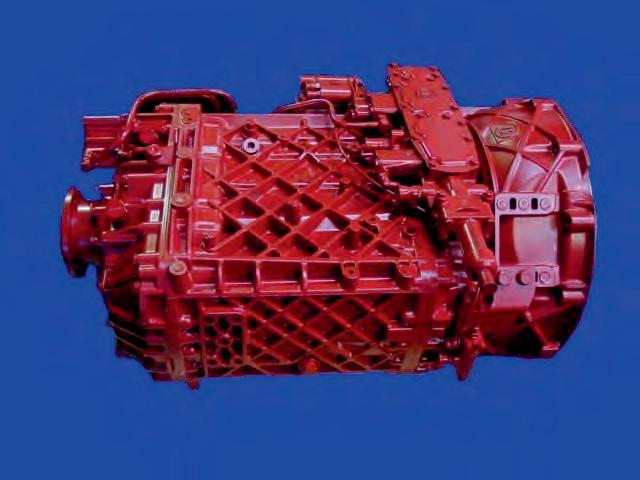

ReconditionedMercedes-BenzTransmissions. MostMakesandModelsG100,G131,GO210, G240,G280,G330available.S3. TA431566. POA

Unit 1/71 Axis Place, Larapinta, Brisbane, QLD, 4110, Australia

Ph: (07) 3276 9300 Fax: (07) 3276 9301

Email: sales@ggd.net.au davids@ggd.net.au

Ph: (07) 3276 9300 Fax: (07) 3276 9301 Email: mattc@gibbsparts.com davids@gibbsparts.com Web: www.gibbsparts.com

Web: www.gibbsparts.com

ZFEcolitepowerpacks.S40. TA952390.

Allmakesandmodelsavailable.S11. TA431615. POA

VOLVO/MACKI-SHIFT/M-DRIVE AT2512C,AT2612D&ATO3112D. S44. TA952399. POA ZFTRANSMISSIONSALLMODELS Allmakesandmodelsavailable.S10. TA431606. POA

EDITORIAL

Editor Sean Mortell

E-mail Sean.Mortell@primecreative.com.au

Phone: 0468 577 166

Journalist Tiarna Condren

E-mail Tiarna.Condren@primecreative.com.au

Contributors Warren Aitken, Frank Black, Sarah Marinovic, Rod Hannifey, Michael Kaine, Glyn Castanelli

Cartoonist John Allison

PRODUCTION

Art Director Bea Barthelson

Print IVE Print

ADVERTISING

Business Development Manager

Tosan Popo Ph 0481 260 352

E-mail Tosan.Popo@primecreative.com.au

SUBSCRIPTIONS

www.ownerdriver.com.au/subscribe

Phone +61 (0)3 9690 8766

Mon-Fri 8am-4.30pm (EST)

Email subscriptions@primecreative.com.au

Mail 379 Docklands Drive, Docklands, VIC 3008 Australia

EXECUTIVE GROUP

Chairman John Murphy

CEO Christine Clancy

Publisher Sarah Baker

Operations Manager Regina Fellner

Sales Manager – South Danny Hernandez

Now is the time for reform and change as Australia’s trucking industry is currently swaying through a world of challenges

The famous saying of ‘no news is good news’ hasn’t quite been an apt descriptor of the past month for Australia’s trucking sector. In fact, times have been incredibly tough. In the past few months alone, numerous transport companies have exited the industry. From the larger end of town like Don Watson Group and XL Express to the latest smaller and more rural operations such as Francis Transport in Corowa, it’s hard to deny that the industry is in a world of hurt.

How has it got to this? There’s more to come on our end, but a combination of stagnant rates, rising costs and increasing regulation appears to be crippling operators in all sectors of transport and logistics. Our array of insightful columnists discuss the state of the industry in frank and honest terms in this month’s copy of OwnerDriver, painting the picture that time is almost out for many in the sector before more tough decisions are made.

operation. From page 24, hearing his fresh passion for all things Scania and for taking to the roads summarises the beauty of trucking.

As per usual, Warren Aitken’s contributions are a cracker, as this month his Truck of the Month is a magnificent Mack that comes courtesy of the team at Keams Transport. From page 30, the words and photos from Warren do a wonderful job of representing a beautiful truck and a wonderful trucking tale.

Through further pieces, such as his journey to raise vital awareness and funds for River’s Gift via Hope the Elephant, Warren continues to underline the caring and generous nature that makes the trucking sector so important to Australia’s DNA. He also headed to Victoria’s Hallam Truck Centre to find a particularly keen young apprentice in Inndyah on page 50 who is kicking goals and making transport her own.

To wrap up the stories for this month, another thriving operator is the newly formed X Logistics.

Owner Driver is published by

Prime Creative Media

379 Docklands Drive, Docklands Melbourne VIC 3008

Telephone: (+61) 03 9690 8766

www.primecreative.com.au

ISSN 1321-6279

OwnerDriver magazine is owned by Prime Creative Media. All material in OwnerDriver is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

Opinions expressed in OwnerDriver are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Sadly, this isn’t the only issue afflicting trucking in Australia. In a deep dive, it was an unpleasant time to uncover the rising road toll in our nation, and the involvement that heavy vehicles have in the road toll increase. The decision was made to focus on solutions, and what everyone – not just truck drivers, but motorists, pedestrians, regulators and manufacturers – can do in the bid to lower the number of people losing their lives on the road. From page 20, this industry issue is thrust into the spotlight, hopefully for the sake of change.

Despite these tough talks, there’s still plenty of good news filtering around the industry. It was a pleasure to catch up with James Bankes, a recent addition to Victoria’s owner-driver network, and discuss his initial success running his own

Led by Laura Wilkinson, who has had a unique career to date in transport and logistics, it’s always wonderful to hear of these great tales and fresh perspectives as can be read on page 46.

On the technical side, from bullbars to trailers and everything in between, our growing array of manufacturers and suppliers take you through some of the best innovations currently being made in Australia’s trucking landscape. It’s a jam-packed edition, and we hope you enjoy the read. Stay safe.

“In a deep dive, it was an unpleasant time to uncover the rising road toll in our nation, and the involvement that heavy vehicles have in the road toll increase.”

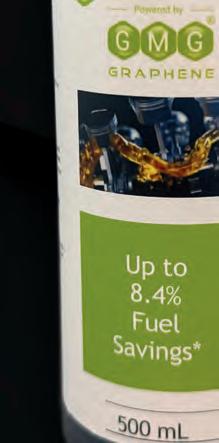

Introducing G® Lubricant, the cutting-edge graphene-based additive transforming the diesel and gasoline engine industry. Verified by the prestigious University of Queensland, this revolutionary lubricant delivers up to 8.4% fuel savings under high-load conditions, offering optimised performance and cost efficiency.

• Exceptional Fuel Savings: Achieve up to 8.4% improvement in fuel efficiency, even under demanding conditions.

• Minimal Concentration, Maximum Impact: Just 1:10,000 graphene-to-engine-oil ratio ensures safety and compatibility with any internal combustion engine and Group I,II,III and IV engine oil, not suitable for Group V oils. Suggest use in engines out of warranty.

• Proven Results: Backed by four years of advanced testing.

Graphene, a carbon wonder material known for its strength and low friction properties, enhances lubrication at a molecular level. When added to your engine oil, it reduces internal friction especially around the pistons, optimizing performance and fuel economy without compromising engine integrity.

• Eco-Friendly Solution: Reduce fuel consumption and emissions while saving money.

BE PART OF THE

Don’t get left behind in the race for efficiency. Upgrade your engine oil with G® Lubricant today and experience the graphene revolution firsthand!

Automotive enthusiasts seeking peak engine performance.

• Industrial operators aiming for sustainable energy savings.

KEY ADVANTAGES

• Significant cost savings.

• Improved Fuel Efficiency & Performance.

• Safe for all diesel and petrol engines - suggest use in engines out of warranty.

Order now and join the global movement toward smarter, greener, and more cost-effective engine solutions.

Technology, interchange and bridge upgrades are set to roll out across the country shortly, as numerous state governments have splashed cash on Australia’s roads

The New South Wales government is investing millions in its roads, aiming to improve productivity and road safety. Part of this investment will see a 28-metre-long bridge constructed along the Golden Highway, while two new fixed speed cameras are set to start operating on the Pacific Highway. Over in South Australia, contracts have been awarded to deliver $150 million upgrades of the Mount Barker and Verdun Interchanges, with major construction set to begin in late 2025.

The New South Wales government has revealed that two new fixed speed cameras are set to begin operating along the Pacific Highway.

Based north of Hornsby, the two activated cameras will be situated between Cowan and the Hawkesbury River.

Transport for NSW acting executive director of transport safety Ruth Graham says the new cameras will target speeding as part of the government’s commitment to improve safety for all road users.

“We know that increased speeds lead to an increased likelihood of a crash occurring, and higher impact speeds also lead to more severe injuries and greater chance of death,” she says.

“In the five years from 2019 to 2023, 70 crashes occurred on the Pacific Highway between Cowan and the Hawkesbury River Bridge. As a result of those crashes, sadly one person was killed and 48 people were seriously injured.”

For the first month, the new cameras will run in warning mode, with drivers and riders who are caught exceeding the speed limit by up to 30km/h being sent a warning letter. For any drivers that exceeds by more than 30km/h, they’ll be issued with a court attendance notice and will face significant speeding fines.

After the warning period ends, the cameras will enforce all offending drivers, with penalties to apply.

These fixed speed camera locations will result in major safety improvements following a 2023 review of the NSW Automated Enforcement Camera Programs. Across all fixed speed camera locations, fatalities dropped by 76 per cent, while crashes where someone was killed or injured by 56 per cent.

These figures compare the five

years after the cameras were installed to the five years before they started operating.

CONTRACTOR CHOSEN FOR $150 MILLION SA INTERCHANGE UPGRADES

The South Australian government has revealed that contracts have been awarded to deliver $150 million upgrades of the Mount Barker and Verdun Interchanges, with major construction set to begin in late 2025.

Bardavcol has been awarded the contract for the upgrade of the Mount Barker Interchange, while a joint venture between BMD and Leed will undertake the Verdun Interchange upgrade.

Bardavcol is a South Australian company with more than 45 years of experience in civil infrastructure, including on the Marion Road and Sir Donald Bradman Drive intersection upgrade currently underway.

The company previously delivered the safety upgrades on Main Road, Cherry Gardens as part of the Adelaide Hills Productivity and Road Safety Package.

BMD is an Australian engineering, construction and urban development business that has worked with the state government on projects including the South Eastern Freeway Managed Motorway between Crafers and Stirling and is delivering the upcoming River Road Junction Improvements.

Leed is a South Australian-based civil contractor founded in 2001. With over 23 years’ experience, they have previously worked on projects including the South Road Superway.

The SA government says the

interchange projects aim to improve connectivity to the South Eastern Freeway and improve the capacity of the interchanges in response to existing and projected growth for Mount Barker and the Adelaide Hills area.

The state government says upgrading the Mount Barker and Verdun interchanges on the South Eastern Freeway will improve safety and traffic flow for the thousands of motorists who travel every day between the city and Adelaide Hills communities, including Mount Barker.

The current Mount Barker Interchange is subject to significant traffic congestion and queuing, with 43 crashes reported between 2019 and 2023.

It will be upgraded to include a new three-lane bridge across the South Eastern Freeway for northbound traffic, the conversion of the existing bridge to accommodate three lanes of southbound traffic and a new shared use path, plus improved ramp capacity and new traffic signals to improve safety.

The project will also include pavement rehabilitation and safety upgrades such as smart lighting.

The existing Verdun Interchange will be upgraded to a full interchange, allowing access to and from the South Eastern Freeway in both directions to improve connectivity and traffic flow.

It will feature an eastbound entry ramp towards Mount Barker, and a new westbound exit ramp, which will cross under the existing westbound entry ramp and connect with a new roundabout at Mount Barker Road adjacent to Silver Road.

The upgrade also includes pavement rehabilitation and upgrades to traffic barriers on the existing Adelaide-bound entry ramp and bridge pier protection on Mount Barker Road.

The total project cost to upgrade the Mount Barker and Verdun interchanges is $150 million, with the Australian government committing $120 million and the state government contributing $30 million.

Major construction on the interchanges is expected to begin in late 2025 and be completed by late 2027.

The New South Wales government has revealed that early work is now underway to build a new bridge along the Golden Highway.

The 28-metre-long bridge will be built around five metres above the current road level, which is high enough to withstand a one in 100-year flood.

Based over Mudies Creek between Belford and Mount Thorley, the new single-span bridge is part of the $133 million Golden Highway program that is jointly funded by the Australian and NSW governments.

Transport for NSW regional director north Anna Zycki says the new bridge will help improve productivity and road safety.

“The Golden Highway is a critical link between the New England and Castlereagh Highways, servicing key mining and agricultural activities,” Zycki says.

“This is a vital upgrade to an important regional artery used by 7,000 vehicles every day.

“The existing culvert over Mudies Creek and its approaches are subject to flooding in a one in five-year event, so improving access at this point will deliver significant benefits to local residents and businesses, as well visitors and freight operators.

“The project will also provide a boost to the local economy, with around 135 jobs to be created during construction.”

The work will include realigning a one-kilometre section of the road to the south of its current location to allow for the new creek crossing.

Contractor Acciona will deliver the project, with the new bridge expected to be open to traffic in mid-2027.

The regulator says a “concerning” number of fatigue offences were registered as part of its latest safety operation

The National Heavy Vehicle Regulator (NHVR) has revealed the findings from its latest major safety operation conducted during Easter.

Operation Omega II was a week-long safety initiative that targeted fatigue during the Easter period, with the NHVR intercepting 2,985 heavy vehicles during the blitz.

NHVR chief operating officer

Paul Salvati says operations like Omega II are crucial to protecting lives on Australia’s roads, especially during high-risk holiday periods.

“Fatigue continues to pose one of the most serious safety risks in the heavy vehicle industry and is a known contributor to road trauma – it only takes a momentary lapse in concentration for lives to be lost or forever changed,” he says.

“That’s why NHVR Safety and Compliance Officers (SCOs) conducted 426 intercepts each day during Operation Omega II, ensuring drivers both understood how to manage their fatigue and were compliant with the law.

“Of the 2,985 intercepts conducted throughout the week-long safety operation, 131 were found to be non-compliant with fatigue requirements in some way.

“To put it simply, that’s 131 instances where we could have seen potential tragedy occur

on our roads, had our SCOs not intervened.”

Salvati says the NHVR issues 172 fatigue-related offences during the operation, with 46 classified as either critical fatigue breaches or breaches due to drivers making false and misleading entries in their work diary to hide a fatigue offence.

“This is a concerning figure and shows an increase in the number of breaches of this severity

in comparison to the previous Operation Omega, which ran in the lead up to Christmas,” he says.

“This year, there have been 60 fatal crashes involving a heavy vehicle across Australia, which is not only tragic, but preventable.

“The results of Operation Omega II should serve as a wake-up call for those doing the wrong thing by intentionally driving while fatigued.”

While he says the fatigue

The Brisbane-based company with more than 35 years of experience in the local industry has called in administrators

On June 27, FTI Consulting was appointed as the voluntary administrators of the XL Express Group to begin an “urgent assessment” of the viability of the company that has more than 35 years of experience in the industry.

The Queensland-based business first started operating in 1990 and forged a national road transport logistics network. It was announced as the co-major partner for the Brisbane Lions AFL side for the 2020 and 2021 seasons.

The administration notice says XL Express Operations is impacted alongside 15 other associated entities under the XL Express banner.

There is currently no reasoning

provided to what has led to the administration move for XL Express, with FTI Consulting confirming that contingency plans are now being put in place.

“The administrators will investigate the financial position of the companies and provide a report to creditors in due course,” FTI Consulting says in a statement.

“Where services are unable to be fulfilled, arrangements are being made for customers to collect their goods held in XL Express Group distribution centres.”

The first meeting of creditors was scheduled to be held before July 9, where further information was to be confirmed.

figures are “alarming”, Salvati says the positive outcome from the operation was seeing many operators implement appropriate measures to prioritise rest and alertness for drivers.

He says SCOs also delivered 407 education sessions centred on fatigue and work diaries, totalling almost 97 hours.

“The fantastic takeaway is how many professional drivers and companies understand that no freight task is worth more than a human life and we commend them for putting safety first,” he says.

“When drivers are impacted by fatigue, they’re at risk of impaired judgment, slowed reaction times and an increased chance of being involved in a catastrophic collision.

“Throughout Operation Omega II, SCOs took the time to engage with drivers, providing education and raising awareness about the serious risks of driving tired, with the aim of encouraging voluntary compliance with the law.

“An additional 253 education sessions were provided to drivers on other Heavy Vehicle National Law requirements, such as vehicle standards, loading and mass.”

During the operation, a number of additional compliance issues were also identified, with mechanical non-compliance proving to be the primary area of concern.

A

lot can change in 90 years.

However, some things never change, like UD Trucks’ commitment to challenging the status quo.

It’s a commitment to tradition while continuously seeking to innovate. It’s a commitment to going that extra mile when no one else will, but most of all it’s a commitment to customer success.

Here’s to ninety more years.

From the moment the first UD truck was conceived in 1935 to now, UD Trucks has been driven by a passionate curiosity to make the world a better place.

Going the Extra Mile

PACCAR Parts has announced a “significant step” towards improving heavy vehicle road safety in Australia through a new Kenworth retrofit project to meet a recent Australian Design Rule (ADR).

PACCAR Parts will provide a solution for Autonomous Emergency Braking (AEB) that brings earlier model Kenworth trucks into line with the standards.

The new ADRs are aimed at improving heavy vehicle safety for heavy goods vehicles that came into effect in February. This includes ADR 97/00 that mandates the fitment of AEB for most heavy goods vehicles over 3.5 tonnes GVM.

Knorr-Bremse technical and account manager Brett Medlin says this crucial technology seeks to minimise the severity of in-lane frontal collisions, particularly in monotonous highway driving conditions.

While most new locally built trucks, including Kenworths, will come with the new safety systems installed as a default, Medlin says it’s important for drivers to know how the technology works.

“Bendix Fusion is an Advanced Driver Assistance System, designed to enhance vehicle control and safety across diverse driving conditions. The technology is already fitted as standard on most new Kenworth models, ensuring compliance with ADR 97/00,” Medlin says.

PACCAR has been an early adopter of AEB technology, including adding Bendix Fusion technology since the locally manufactured T610 model was launched in 2016. This system combines radar, camera technology and the Bendix Electronic Stability Program to provide comprehensive collision mitigation and enhanced braking capabilities.

“The collision mitigation system PACCAR uses on its locally manufactured Kenworth trucks is the fully featured version of Bendix Fusion that includes Enhanced Autonomous Emergency Braking, Enhanced Stationary Vehicle Braking, Multi-lane Autonomous Emergency Braking, and Highway Departure Warning and Braking,” Medlin says.

“Nose-to-tail collisions is the second-most common accident involving trucks after rollovers. In scenarios like a car cutting off a truck, or moving out from a lane of stationary traffic in front of the

“Bendix Fusion is an Advanced Driver Assistance System, designed to enhance vehicle control and safety across diverse driving conditions.”

truck, the Bendix Fusion braking system applies the brakes in a much faster way than a driver can react.”

Medlin says AEB is also relevant for compatible older vehicles, with PACCAR Parts now allowing its customers the chance to upgrade certain older Kenworth trucks that are compatible with the latest Bendix Fusion system.

“Most Kenworth trucks that have an electronic stability program on it could have the electronic brake controller upgraded with the Bendix Fusion system. So long as you’ve got the right level of electronics and valves on the truck, you can retrofit it,” Medlin says.

“AEBS not only improves the safety of these vehicles, but a lot of tenders including government, construction and grocery projects specify the level of technology that must be on the truck, including the fitment of AEBS.

“PACCAR customers who are considering retrofitting the Bendix Fusion system to their vehicles should speak to their PACCAR Parts dealer. The dealer will coordinate with PACCAR’s technical team and Knorr-Bremse’s technical support team to ensure the chassis number is compatible and guide the implementation of the retrofit safety system.”

The growing Melbourne transport company has now received eight Kenworth models in the past nine months

Australian transport company Pace Australia Logistics has added to its fleet recently, taking delivery of two new Kenworth trucks.

The Melbourne-based operator has received two K220 2.3 metre cabs into its fleet to complete fridge van work. This latest delivery means Pace has

added eight Kenworth models to its business in the past nine months.

“The owner, Akash Bharti, has been working closely with our salesman Nick Gesovski to continue to put quality trucks into their fleet,” Kenworth DAF Melbourne says in a social media post.

Manheim Industrial Australia has been selected as auction partner by national freight company Don Watson Transport, taking responsibility for selling the company’s large fleet of trucks and trailers

Don Watson Transport, one of the country’s leading refrigerated logistics operations and a 77-year-old family-owned business, made the difficult decision to close its operations earlier in June this year.

The fleet to be sold via Manheim Industrial auctions comprises 130 well-maintained heavy trucks and 170 trailers, plus a further 10 rigids. The assets will have their decals removed and repainted white.

These trucks and trailers are located across several sites including Derrimut in Victoria, Weatherill Park in New South Wales and Hemmant in Queensland.

“When we took the incredibly tough decision to close the business due to market conditions, our top priority was ensuring all staff received their entitlements,” Don Watson Group CEO Lyndon Watson says.

“An orderly and effective process to divest our fleet was an important piece. Manheim’s tailored approach, deep understanding of transport assets, process for asset preparation and commitment to understanding our

requirements were key in them being selected as the preferred partner.”

As a leading industrial equipment auctioneer with physical locations across Australia, Manheim is well-placed to handle this large, high-profile and multi-location truck and trailer sale.

Among Don Watson Transport’s priorities are ensuring orderly sales

of its assets. Manheim understands the company’s commitment to taking care of its people and determination to preserve the goodwill accumulated over decades.

Having won the contract, Manheim will begin to prepare the trucks and trailers for sale – including the rectifications – and prepare for a steady sale-off backed by extensive

The National Heavy Vehicle Regulator (NHVR) has released its 2024 Heavy Vehicle Industry Safety Survey, with there being a massive change in how drivers are operating within the local transport landscape.

The main change is seen in whether drivers own and run their own vehicles or choose to be employed by a business. In the 2022 survey, 70 per cent of drivers ran their own vehicles while 20 per cent were employees by a business and nine per cent sub-contract.

NHVR industry survey reveals major shift

The latest survey has revealed a major shift in the size of transport companies and the set-up of how drivers are running trucks

In the 2024 edition, which surveyed 8,883 members of the transport industry, now only 29 per cent own and drive their own vehicle while 65 per cent are employed by a business –a shift of 45 per cent. The 2024 survey says only six per cent of drivers now sub-contract for a business.

When it comes to where these drivers are based, there’s been a shift away from Victoria, with the number of drivers being based in Victoria dropping from 50 per cent in 2022 to 32 per cent in 2024. In its place, there’s

been rises in NSW (up from 20 per cent to 27), Queensland (up from 15 to 19 per cent), South Australia (up from seven to nine per cent), WA (one per cent to four) and the Northern Territory (from 0.1 per cent to 0.4).

There are also less and less operations running just the sole truck while the number of major operators has grown. One-truck operations has decreased in popularity from 15 per cent in 2022 to seven per cent in 2024.

In its place, the number of businesses with 200 or more vehicles

marketing and awareness campaigns.

Manheim is confident that these trucks and trailers will find new homes during the process, noting the sterling reputation Don Watson Transport has earned across the sector when it comes to maintaining its vehicles.

“We are honoured to have been appointed as the exclusive remarketing partner for Don Watson Transport,” Manheim Australia head of advisory Aiden Hsu says.

“This mandate reflects the strength of our advisory capability, national footprint and proven expertise in managing high value, multi jurisdiction, complex fleet divestments.”

Manheim head of transport sales

Chris Williams says: “After decades of Don Watson Transport delivering excellence in the industry, Manheim is privileged to be given the responsibility of selling down the fleet.

“The fleet itself, as would be known widely in the industry, consists of a huge range of prime movers including Kenworth K200s, K200 King Cabs, T409s, T609s, T610s, T909s, Mack Superliners, Scanias and more.

“With extensive service history, engine rebuilds and new crate motors in many of the trucks, they are ready to go to work. Additionally, the refrigerated trailers are made up primarily of FTE, Lucar and Vawdrey that will be a great addition to any company’s fleet.”

in the fleet have risen from six per cent in 2022 to 14 per cent in 2024.

This is reflected in the business size trends by people – now, 12 per cent of respondents in the industry have only the one person, while the number of operators with two to 10 people having fallen from 61 per cent in 2022 to 30 per cent in 2024.

On the other end, the number of businesses with 500 people or more have risen from three per cent to nine per cent in the latest iteration of the survey.

When it comes to what primary industry sectors these companies work in, there’s been a swing in buses, construction and landscape, general freight and primary production/ farming.

The number of bus companies participating in the industry survey has risen by 14 per cent to 16 per cent in 2024, while construction and landscape product businesses have fallen from 18 per cent in 2022 to 12 per cent in 2024.

General freight companies have risen by two per cent to 22 per cent in 2024, while primary production and farming groups have fallen to 13 per cent in 2024, down seven per cent from the last survey.

With over 150,000 parts across 30 product groups, SAMPA delivers one of the most comprehensive selections of commercial vehicle components in the industry. Our extensive range includes suspension systems, drivetrain components, fifth wheel assemblies, air springs, landing gears, and much more – all engineered to meet the highest industry standards for durability and reliability.

Want to know more or find the right part for your fleet? Simply contact your local SAMPA sales manager, we are here to help.

Just 14 months after breaking ground on the site, the milestone Scania branch in WA is now officially open to local operators

Scania Australia has announced a milestone moment in its local presence, doubling its Western Australian footprint with the opening of a brand new, purpose-built branch in Hope Valley.

Situated within the City of Kwinana, south of Perth, the 19,000sqm sales and service site is located at 6 Armstrong Road.

It includes a stand-alone 3,500sqm regional warehouse that will supply WA Scania on-road customers and off-road mining and resources clients while also assisting the existing Kewdale site with the implementation of Scania’s industry leading autonomous and EV mining truck solutions.

The site is the 10th that Scania uniquely owns and operates for its sales and service locations around Australian capital cities, with customers also being supported via a network of more than 60 authorised independent dealers across truck, bus, marine and industrial engine applications.

Hope Valley has been designed to accommodate future BEV vehicle needs, with sufficient capacity in the electrical supply for fast-charging and underground preparation for the installation of charging infrastructure. The site will also include a climate controlled clean room for repairs to battery cells when required.

“Hope Valley is our second company-owned sales and service location in the Perth region, and it is well situated close to the developing Kwinana outer harbour port facility, and supported by upgraded road infrastructure,” Scania WA, SA and the NT dealer director Michael Berti says.

“Demand for Scania products has been increasing significantly in the west over the past decade, and we were very much in need of additional service and parts facilities to maintain our customers’ uptime, and that of our projected conquests over the medium term.

“We opened a new dedicated parts distribution warehouse in Welshpool only around four years ago, but such has been the growth of the Scania business in Western Australia, this facility has already surpassed all expectations, and this in part prompted us to further expand our parts capacity at Hope Valley. We have effectively doubled our available warehousing floorspace, and the storage height available, to handle current demand and support future developments in both ICE and BEV product ranges.”

Scania Australia managing director Manfred Streit broke ground on the project site alongside Berti in March last year, with the new warehouse and sales and service branch being handed over to the company by developers in May 2025, just 14 months later.

“This new addition to the Scania network of company-owned workshops and parts warehouses is a logical step for us to maintain high levels of customer uptime and to further encourage the uptake

of repair and maintenance contracts, assisted by Scania’s ever-growing array of vehicle productivity and efficiency programmes,” Streit says.

“Scania is a global industry leader in connected services, which allows us to monitor very accurately how vehicles are performing and provide timely scheduled servicing which prevents unplanned downtime, underpinning customer profitability potential.

“By increasing the capacity for regular maintenance in our own workshops, our customers will have access to the most advanced in-service vehicle management available.

“We know mining customers demand and depend on predictable uptime. This is underscored by the huge cost of unplanned downtime. We have configured our service scheduling and parts supplies to take account of this.

“For on-road customers, the uptime issue is no less important, and given WA’s geographic position establishing a larger parts warehouse and additional service capacity south of Perth is a necessary development for Scania, underpins business growth and continued customer success using our products.”

The new Scania workshop comprises three work-bays and a maintenance pit, as well as a full complement of vehicle testing equipment including shakers and rollers for assessing suspension, braking and steering components.

The site is located close to major routes for easy accessibility, especially by larger WA-style combinations, with the maintenance pit designed to accept extra-long multi-trailer vehicles without decoupling. Large crossovers and hardstands will provide ease of access for vehicles up to 36.5m in length, such as B-triples.

Additionally, trailers and trailer equipment can be serviced on site along with vocational rigids (such as construction and jetvac trucks, as well as fire appliances), making life easier for customers by offering a one-stop-shop service destination.

“The new location is well positioned to support many of our customers in the busy City of Kwinana port area, providing a more convenient location for servicing and parts supply,” the newly appointed Hope Valley branch manager Michael Phipps says.

“We have assembled a team of enthusiastic technicians and parts specialists from within Scania WA as well as from the broader industry, and we are confident that this team will deliver maximum uptime for our customers, one of Scania’s core values.

“Scania Hope Valley will have plenty to offer truck drivers, with a comfortable lounge area and a number of resting locations ideal for catching some sleep while having their vehicle serviced or repaired.

The workshop will operate from Monday to Friday from 7.30am to 5pm.”

The new warehouse replaces the Welshpool site and in addition to the additional floorspace now boasts an improved and optimised operational flow.

“It’s a more open site, so we can process and handle higher volumes into the future,” Scania national parts manager Matthew Pol says.

“We can now do more and do it better, with a staff of four and a supervisor. Previously, we could only process one container at a time, but now the footprint allows two or three containers to be processed, so we can get more volume through the building. We will be holding more product lines, to cope with the depth and expansion of our growing truck, bus and engines product, and for our time-critical mining customers.

“In the new building we have probably five to 10 years of growth capability, not only because of the expanded floorspace but we’ve also volumetrically doubled our height. The bulk racking has gone from four metres to eight metres tall.”

Scania Australia now operates 10 company-owned sales and service branches, with three in Victoria, two each in New South Wales, Queensland and Western Australia, and one in South Australia, with additional dedicated sales representation in Tasmania.

Transport and logistics giant Lindsay Australia has announced one of its directors has retired, naming his replacement

Director Matthew Stubbs has retired from Lindsay Australia on June 27, with CEO Clay McDonald thanking him for his time spent at the transport company.

“The board of Lindsay Australia Limited wishes to thank Mr Stubbs for his leadership, guidance and contribution which has supported the business since his appointment in 2021,” McDonald says in an ASX update.

“In particular, his expertise and experience in supporting the company in the formulation of its growth strategy over the period of his service.”

The board has announced that Rodney Boys will assume the role of chair of the audit and risk committee, replacing Stubbs.

The proudly South Australian logistics company says the win is more than “just contracts” as it prepares a custom-built depot for urgent freight response

South Australian logistics operator Energy LogistiX (ELX) has announced a “defining milestone” as it celebrates being awarded a logistics contract to support BHP’s Copper South Australia operations.

In the wake of Aurizon being awarded part of the contract to deliver rail freight services to and from BHP’s copper mines in the state, ELX has now received the logistics contracts to complete road

freight operations.

The contracts will see ELX provide same-day, critical freight movements via PBS road train combinations using its Fleet Smart system as well as a custom-built OSR depot in Adelaide that is fully SAP-integrated.

The contracts will also see ELX provide 24/7 urgent freight response

to BHP Copper SA sites nationwide.

As a proudly run SA business, EXL managing director Shaun Williamson says this moment reflects what its people, suppliers and supporters have built over the years.

“We’re not here to be the biggest; we’re here to redefine what’s possible by empowering vital industries and our regions, and shaping a stronger future for South Australia,” Williamson says.

“It’s more than freight. It’s a partnership that moves critical materials and moves our state forward – through jobs, capability and trust.”

Williamson says the contract is about creating more local jobs, using Australian-made equipment and reinvesting into the state economy through a 95 per cent local spend commitment.

“These aren’t just contracts; they’re a shared step forward in a journey we’ve built with purpose and pride,” Williamson says.

“We’ve always believed that doing things the right way, with care, pride and purpose, would take us far. Now we get to prove that alongside one of the most respected companies in the world.”

As global copper demands surge, Williamson says SA is in a “prime position” to meet it, with ELX playing a supporting role.

The verdict is in and the ACCC has given DP World Australia the green light to complete a major acquisition within Australia’s container transport market

The ACCC has announced that it won’t oppose DP World Australia’s proposed acquisition of transport operator Silk Logistics.

Following an extensive investigation, including considering detailed responses to its statement of issues, the ACCC has concluded that the acquisition would “not likely result in a substantial lessening of competition”.

It means DP World Australia, who operates container stevedores at the ports of Botany, Melbourne, Brisbane and Fremantle, is free to acquire the transport company.

Silk is a national container logistics provider around the country, hauling import and export containers using trucks to and from ports where DP World Australia operates.

During the process, the ACCC says it considered the integration of DP World Australia’s container terminals with Silk’s national container transport and warehousing business, as well as the potential impact it would have on container transport service providers in the supply chain.

The review focused on whether DP World would have the ability and incentive to engage in “discriminatory conduct” against Silk’s container transport rivals by raising their costs of lowering the quality of access to DP World’s Australian terminals.

The analysis indicated that DP World Australia is “unlikely” to engage in forms of discriminatory conduct that would lead to material operational delays and disruptions at DP World’s terminals.

The ACCC says a reduction in DP World Australia’s ability to efficiently process containers at

its terminals would risk DP World Australia losing shipping lines in other terminals, damaging its own business.

“Although DP World Australia may be able to engage in subtle

forms of discrimination without adversely affecting its primary function as a container terminal, such conduct is unlikely to reach a level so as to substantially lessen competition,” ACCC commissioner

Australian freight giant Toll Group has announced its new leader, with the operator revealing its latest executive chairman who started at the new financial year

Thomas Knudsen has assumed the role, effective from July 1, taking on the role in an interim capacity.

He replaces Alan Beacham, who departed the role of group managing director earlier this year.

Knudsen brings more than three decades of experience in global logistics and leadership across Asia, Europe, the Middle East and the Americas to the role.

He joined Toll in 2018 as president of Global Forwarding before serving as managing director from 2020 to 2022. He most recently was a non-executive chairman from 2022 to 2025.

He has played a significant role in strengthening Toll’s global operations over the years, including navigating the business through the challenges of the COVID-19 pandemic and driving key innovation and efficiency initiatives.

As executive chairman, Knudsen will provide executive oversight while continuing to work closely with the Toll

Dr Philip Williams says. “DP World Australia would continue to face competition from a range of established and prospective container transport providers.”

Board and executive leadership team to ensure continuity of operations and a sharp focus on business performance.

“Toll has a proud history and a strong future. I’m honoured to step into this role at a pivotal time and continue working alongside a talented leadership team committed to delivering for our customers, people and partners,” he says.

“My focus will be on stability, execution and momentum as we transition into our next chapter.”

In addition to his extensive experience

with Toll, Knudsen currently advises several private equity and investment firms, bringing strong commercial insight and a global perspective on capital strategy and business transformation. While originally from Denmark, Knudsen has been based in Singapore since 2010. He holds an Executive Master of Management in Supply Chain from IE Business School in Madrid, and has completed executive programs at Harvard Business School, INSEAD, and Cranfield School of Management.

International telematics provider

Geotab has revealed the leading factors that are causing a rising number of distracted driving fatal crashes around the world.

Geotab’s latest report has revealed distracted driving caused more than 3,000 fatal crashes in 2023, with the problem only getting worse.

Using insights from more than four million connected vehicles using Geotab, the company has identified the leading causes for these incidents.

The first factor is unclear phone rules, while cab clutter and eating and driver fatigue also among the top causes.

No real-time alerts and inconsistent coaching are the other main factors.

Geotab says distracted driving can be broken down into three types – manual (taking your hands off the wheel), visual (eyes off the road) and cognitive (thinking about something else while driving).

Distracted driving can include drowsy driving, driving under the influence of alcohol, drugs or medication, eating or drinking or using your phone in the vehicle.

“For fleet operators, distracted driving isn’t just a safety concern — it’s a serious business risk. It can lead to injuries, vehicle damage, rising insurance costs and costly delays. Preventing it helps protect your team and keep operations running smoothly,” Geotab says.

“To address distracted driving in your fleet, you’ll need to understand how widespread the

issue is and what the latest data shows.”

Recent road crash statistics around the world shows that distraction-related collisions caused 3,275 deaths and another 324,819 injuries in 2023, with five per cent of all drivers involved in fatal traffic conditions in 2023 being

reported as distracted at the time of the collision.

Geotab also says distracted driving violations grew by 48 per cent in the first six months from 2023 to 2024, with Gen Z and Millennials aged 16 to 45 accounting for 72 per cent of all distracted driving violations.

Australia’s road toll is the defining issue currently causing debate and calls for change in the nation’s heavy vehicle industry. Sean Mortell looks at the many factors causing a spike in road fatalities and what can be done to make freight routes safer for all

It’s the call no operator, family member or friend wants to hear. Being woken up in the early hours of the morning. The phone buzzing and the sense of dread taking away all breath from the body and placing it in a chokehold tighter than a wrestler’s headlock. The loss of a person on the roads is a cruel twist of fate that no one deserves to experience. Unfortunately, this moment is happening too much in Australia as the road toll continues to increase. The confirmation that 1,301 lives were lost on Australian roads in 2024 set a 12-year high and has been enough to raise the alarm for many in the heavy vehicle industry.

According to ANCAP crash data, light trucks

are involved in approximately 15 per cent of all fatal collisions recorded on Australian roads in 2024. Light trucks only constitute less than three per cent of all Australian registered vehicles.

Considering the workplace of heavy vehicles are on Australian roads, the call to improve road safety and lower the road toll is particularly vital and emotion charged.

The sweeping issue of lowering Australia’s road toll is one that is keeping many in the transport industry awake at night.

“Fatalities are on the increase across all road users – we’re now losing more than 1,300 lives in Australia each year,” National Road Transport Association (NatRoad) CEO Warren Clark told OwnerDriver.

“This represents a huge and completely unacceptable failure in public policy.”

While heavy vehicle crashes on our roads already have a seismic impact on employers, colleagues and fellow members within the transport industry, ANCAP’s data suggests the effect is also rippling across other motorists on the road. Its latest statistics say more than 75 per cent of serious crashes on Australian roads in 2024 involving light trucks have resulted in fatalities or serious injuries to other road users outside of the truck.

So what is the cause of these worrying trends in the nation’s road toll data? And, most importantly, what can be done by both the industry and governments to curb this rise before more lives are lost?

The complex nature of this serious issue is that there is no single reason or solution. Instead, a variety of causes and ideas are being thrown around to keep drivers more focused and vehicles and roads safer to use each and every day. ANCAP’s data suggests this isn’t working.

“Unfortunately, the trend in the heavy vehicle industry matches that of all other road users,” Clark says.

“Human factors, like inattention and distraction, are still a major factor in road crashes. In addition, too many smaller vehicle drivers are not aware of how to drive around heavy vehicles. More needs to be done to ensure the public is better educated on safe driving around trucks.”

The latter point is shared by others in the transport industry, including Glyn Castanelli, who is the president of the National Road Freighter’s Association (NRFA). While the overall national road toll has risen by 4.8 per cent, the latest March 2025 Heavy Vehicle Road Deaths Report paints a slightly different picture – there’s been a slight reduction in fatalities involving heavy vehicles.

However, Castanelli says this must be contextualised due to the damage heavy vehicle crashes can cause. His take is that the training of other motorists is key to safer trips in and around heavy vehicles that are trying to complete their daily work.

“The biggest factor contributing to these tragic outcomes is the lack of real-world training and awareness among light vehicle drivers,” he told OwnerDriver

“Most Australians simply don’t understand how to drive around trucks. They cut in front, hover in blind spots and misjudge stopping distances. The NRFA supports industry-led campaigns to bridge this knowledge gap through initiatives like the Steering the Future Trailer and the National Heavy Vehicle Regulator’s (NHVR) We All Need Space campaign.”

However, both Clark and Castanelli admit the industry first needs to look inwards before solely blaming light vehicle drivers for the soaring road toll. A pivotal way of ensuring more and more Australian truck drivers operate safely behind the wheel is training.

Castanelli says training is “absolutely foundational”, leading to him supporting the

“Too many smaller vehicle drivers are not aware of how to drive around heavy vehicles. More needs to be done to ensure the public are better educated on safe driving around trucks.”

“We have crumbling shoulders, narrow lanes, potholes, outdated bridges, lack of overtaking lanes, poorly designed infrastructure and a shortage of appropriate rest facilities, especially in capital cities.”

Chartered Institute of Logistics and Transport Australia’s (CILT-A) Driver Supervisor Assessment Program that recently received Heavy Vehicle Safety Initiative funding.

“This is a potential game-changer for our industry, especially for small fleets who can’t afford expensive training programs but still want to do the right thing,” he says.

“A licence test alone doesn’t prepare someone for night driving, wet conditions, tight loading docks, fatigue management or the pressure of tight delivery windows. Real-world driver training and supervised experience could save more lives than any compliance form ever will.”

Castanelli says the current mindset of allowing too many drivers to be employed without being job-ready is incredibly dangerous and is playing a pivotal role in the nation’s current road toll issue.

From Clark’s perspective, training is essential. While NatRoad has consistently called for legislative improvements to tighten safety in the industry, Clark says simple and effective driver training is just as important to make the sector’s culture a safer one.

“Safer drivers mean safer roads – we urgently need reform to our licensing and training systems to increase the number of appropriately trained drivers and ensure all heavy vehicle drivers are equipped for the realities of Australian roads and vehicles,” he says.

“The review of the national heavy vehicle driver competency framework is an important step but it’s moving far too slowly. It’s vital that implementation becomes a priority.”

Road quality conundrums

It’s part of Clark’s comments above that raise the next issue in Australia’s rising road toll – the decaying quality of the nation’s key arterials and freight routes is providing another safety factor

that truck drivers must tackle each and every day.

Clark says governments around Australia need to invest more in improving the quality of roads and heavy vehicle rest areas to keep roads safer for all. While landmark funding is becoming more common in recent months, especially relating to the Queensland and federal government’s milestone $9 billion upgrade to the Bruce Highway that is now underway, Clark says this needs to become the norm if Australia’s road toll is to drop.

“Building safer roads is fundamental to reducing fatal and serious crashes,” he says.

“The fact is, every time you improve a road’s safety rating by one star, you roughly halve the risk of death or serious injury. Despite this, governments are not transparent about the safety ratings of our national road network and do not use the star rating scale to determine funding.

“The recent federal government commitment to upgrade the Bruce Highway to a minimum 3-star standard is a welcome exception and should be the model for funding in the future.

“The provision of truck rest areas is also vital to improving road safety and helping drivers to manage their fatigue. Research shows more regularly spaced rest areas lead to better road safety outcomes.

“While we’ve seen encouraging progress over the past three years, thanks to additional federal funding and strong input from industry stakeholders, we’re still facing significant gaps in the quality and quantity of rest areas across the network. There’s much more work to be done.”

Castanelli says Australia’s road network, particularly in regional and freight-heavy corridors, is in “a poor state” and requires fixing. His plan urges the federal government to prioritise freight route upgrades, particularly in rural and regional areas, fix known black spots and dangerous intersections and build modern rest areas to allow for safer fatigue management.

“We have crumbling shoulders, narrow lanes, potholes, outdated bridges, lack of overtaking lanes, poorly designed infrastructure and a shortage of appropriate rest facilities, especially in capital cities,” he says.

“These aren’t just frustrating — they’re deadly, especially for heavy vehicles that rely on predictable road conditions to operate safely.”

Enforcement mantra

A common response from truck drivers in recent times has been the approach to heavy vehicle law enforcement in Australia. Whether it be state police or the likes of the NHVR, the approach taken to ensuring drivers abide by safety laws has led to a wider discussion on enforcement principles.

On Castanelli’s side, he wants regulators to prioritise data-led enforcement, encourage the use of technology and proactive safety systems and listen to grassroot operators who know where the real problems are.

“Regulators need to shift their focus from roadside enforcement to investigating the influence from within the contract chain,” he says.

“Economic customers need to be held accountable for their decisions to engage a risktaking operator. We need an enforcement culture that rewards good behaviour, not just punishes non-compliance.”

Clark also supports this notion of better complementing non-compliance enforcement with a renewed focus on rewarding operators around Australia who are driving safely.

“Enforcement should be risk-based and targeted at genuine safety, not paperwork errors or technicalities that have no bearing on crash outcomes,” Clark says.

“We need to stop penalising drivers over minor, non-safety issues and focus on what

actually causes harm on the roads.”

Outside of this, Castanelli says the current state of the industry is also providing reasons that lead to truckies driving without a rigid focus on safety. Whether it be the economic pressures of falling rates, a lack of a minimum standard of entry to operate or an inconsistent adherence to the law, particularly around Chain of Responsibility requirements, he says this all combines with the previous factors to concoct a “volatile operating environment”.

The modern age of technology is just another factor that Clark can name that has led to an industry playing a central role to the rising national road toll.

“The NTARC’s Major Incident Investigation Report 2024 showed a 27 per cent increase in overall incidents from 2022 to 2023, with humanfactor-related crashes rising by 42 per cent in just one year,” he says.

“Drivers need to be effectively trained to drive to the conditions and avoid distractions.”

The problems have been made clear, the numerous issues have been aired. But this is only part of the road toll conundrum. From here, what can members of Australia’s transport industry do to make their workplaces safer?

In the short-term, Castanelli wants the National Heavy Vehicle Driver Competency Framework implemented in a coordinated way to limit crossborder differences between licensing systems. He also says practical training, apprenticeships and mentoring programs should be funded, particularly for small businesses, while an accelerated investment in critical freight infrastructure is key.

In the long term, he wants truck driver apprenticeships to receive wider industry support, while fair payment and contract terms should be embedded in the supply chain to reduce deadly pressures being placed on operators. Throw in the implementation of compulsory accreditation and safety management

systems alongside industry-led safety innovations and Castanelli believes real change can be made.

“Technology also has a key role to play, but it’s only as good as the people and systems behind it,” he says.

“Tools that help include fatigue monitoring systems, electronic work diaries, vehicle telematics and dashcams and AI-based collision alerts. However, without training and support, technology alone won’t fix the human factor.”

As it currently stands, Clark can’t see the industry meeting the National Road Safety Strategy of reducing fatalities and serious injuries by 2030 unless it “dramatically shifts course”. With fatalities increasing, he wants governments to do more to revise current road safety policies.

“More must be done to fund safe, high-quality roads and to deliver adequate rest areas,” he says.

“It is past time for governments to deliver on independent safety road crash investigations and ensure safety lessons are learnt. Without learning from these tragedies, we’ll never make meaningful progress.”

On the technology side, Clark points out that Safer Freight Vehicles reforms mandate several safety technologies, but these only apply to 2.55m heavy vehicles. Instead of restricting these rules, he wants helpful technology to be made the norm across the entire industry.

“Safety technology, such as devices for indirect vision, lane departure warnings, blind spot monitors and emergency braking systems, should be mandatory on all new heavy vehicles, not just those 2.55 metres wide,” he says.

The final word goes to Castanelli, who provides a timely reminder for the industry. He says that now is the time to push for change before more lives are lost on Australian roads and the heavy vehicle industry is faced with more harrowing calls that permanently alter lives for the worse.

“The transport industry is filled with hardworking, capable people doing their best under extreme pressure, but expecting professionalism without providing professional training is a recipe for disaster,” he says.

“We are seeing good businesses close with dignity and others fall into insolvency from trying to stay compliant while getting paid peanuts.

“We can’t paper over the cracks anymore. If the government wants a safer industry, it’s time to listen to the operators on the ground and back practical, achievable reform. The NRFA is ready to work with anyone committed to that cause.”

Trucking has always been a dream for James Bankes. Now, after taking a leap of faith two years ago, he’s succeeding under the banner of Bankes Haulage

It was two years ago and James Bankes faced a crossroads moment in his life. Up until then, the passionate truckie had always dreamed of owning and operating his own truck, working for himself around the nation. To date, his career had involved a wide range of driving jobs for a variety of employees.

Based in Victoria’s Gippsland region, a lack of work meant he was sat at home, angry. Instead of stewing over a boss who was stuffing him around, James made a decision that he would never regret.

“I was working as a casual driver when I first moved down to Gippsland, but they had a truck break down and they stopped giving me work,” he told OwnerDriver.

“I decided he could have his job and I would do something I always wanted to do – start my own business.”

It was this call that led to the foundations of Bankes Haulage. Two years on, James is now excelling behind the wheel of a unique truck and living the owner-driver

dream. That doesn’t mean his journey to this point has been smooth sailing.

James has wanted to work behind the wheel of a truck for as long as he can remember. His first memory of trucks was heading to the supermarket as a kid with his Mum and running off. Where did he end up, you ask? The loading dock out back, talking to a truck driver about his vehicle and the engine.

“I’ve been fascinated in trucks since I was a little kid,” he says. “Which is funny, because neither of my parents have been in the industry. I just really loved trucks and always wanted to get into the industry.”

His passion turned into a career at age 15 when he started washing trucks at Hilders Transport in Rowville, Victoria. From there, he began a school-based apprenticeship for a couple of years at Altona before progressing to forklift driving in Dandenong.

From there, his experience continued to amass and he began gaining his qualifications, starting with his

Images: Scania Australia

medium rigid licence. This gave him the opportunity to drive trucks for the first time in Hallam, hopping behind the wheel of a Fuso.

“I loved it and looked after it very well, I added some bling and kept it tidy,” he says.

“After about 12 months of working there, I got my heavy rigid and heavy combination licences, as well as my dangerous goods tickets.”

A 1993 International single-axle ACCO was next on the list for James as he began doing fuel tanker work.

A variety of trucks were to follow as James went from Koo Wee Rup to working for transport giant Linfox, running semi-trailers for the best part of five years for Woolworths.

However, the beauty of the Australian transport industry is the many mentors that guide younger drivers through the challenges of trucking each and every day. James’ mentor is Kevin Nesci at Nesci Transport. After starting work with him at the age of 23, James gained an important industry friend for life before returning to his array of jobs at major transport companies.

It all culminated in 2023 when James found himself in Gippsland and without work. His longstanding dream of wanting to buy and run his own truck and control his own work came to mind. Like many great operators, James took a leap of faith.

“That was when I started Bankes Haulage – I always wanted to do it and I thought that if I didn’t do it at that time, then I would never do it,” he says.

“At the time I also had my eye on a black Scania tray truck for the best part of six months and the price was slowly dropping, so I thought it was the perfect way to start. It wasn’t the riskiest investment, but I had some embroidered shirts, business cards and flyers made and off I went.”

The origins of Bankes Haulage are modest – James began his solo journey by knocking on doors for a couple of months in Gippsland’s industrial areas, looking for work. It was a slow approach, but it paid off when he landed a couple of gigs through the old-school method of shaking hands and putting himself out there.

After a solid start, a change in his personal life gave Bankes Haulage the opportunity to grow in a different area of Victoria.

“It was becoming more and more evident that the solo gig wouldn’t be a long-term proposition while I was in Gippsland,” James says.

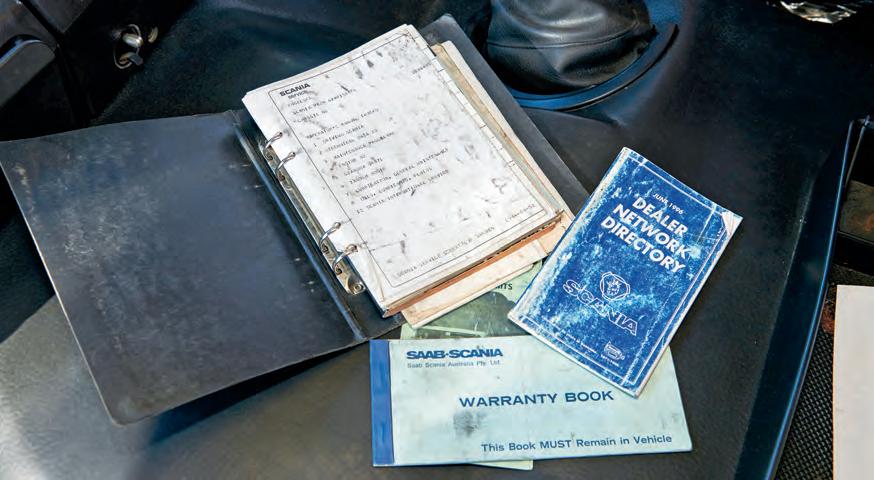

“At the time I also had my eye on a black Scania tray truck for the best part of six months and the price was slowly dropping, so I thought it was the perfect way to start. It wasn’t the riskiest investment, but I had some embroidered shirts, business cards and flyers made and off I went.”

“I have always been passionate about Scania. I had a collection of Saab cars as well, because of the Saab-Scania affiliation. I’ve just got a real passion for the brand and the design.”

“At the same time, my relationship broke down and I moved back to my home in Grantville.”

James took the same approach of door knocking and hand shaking to the Bass Coast Shire, near Phillip Island. It paid off in spades.

“Being closer to Melbourne, I thought I had a better shot at succeeding in Grantville,” he says.

“I could’ve sold my trucks at that point and headed back to the good jobs I’d done before, but I wanted to at least find out if I could try and succeed.

“I went around Dandenong and Pakenham, dropping off business cards and flyers and speaking to people. I was lucky to bump into Brad Gourley, who runs Gourley Enterprises in Pakenham, when he needed a tow operator.”

The timing was exceptional, and James had his big break in the owner-driver game. He now currently successfully works for himself, paying his own way and staying very busy behind the wheel. He only operates as a tow operator, but now his success has allowed him to add another vehicle to his fleet.

The origin of Bankes Haulage saw James use a 1985 Scania P112M rigid with a tray in a distinctive black wrap. However, when clients told him they wanted him to use a prime mover to pull trailers, he bought a 2001 R124L 4-Series to cart precast concrete panels and steel.

Now, as he plans to downsize and condense his fleet, this current model is leading the way in his recent success.

“Moving forward, I’ll swap a rigid to a trailer to tow behind the prime mover so I can do a bit of anything,” he says.

This takes us to the other part of James’ love for trucks in his collection of older Scanias that he has been building for some time. As a kid, he remembers having Scania posters on the wall and collecting the brochures. While he started working in a variety of trucks when he entered the industry, at age 21 he bought his first Scania in a 1977 LKT111 as part of a restoration project.

From there, a 1978 LKT141 was acquired and quickly changed from a parts truck to a restoration project yet again. With Scania also dominating Bankes Haulage’s small fleet, the European brand is a key focus for the passionate truckie.

“I’m currently in negotiations to swap out some of the older trucks, to condense the fleet of old historic trucks, and I’m on the lookout for a T143 V8,” James says, confessing to being very keen on Scania V8s.

“I remember when the 730 V8 came out. I went down to Scania Dandenong to have a look at it. I have always been passionate about Scania. I had a collection of Saab cars as well, because of the Saab-Scania affiliation. I’ve just got a real passion for the brand and the design.”

James’ current 4-Series Scania has done around 1.8 million kms and is still running at 24 years of age. He says it drives like a modern truck, remaining quiet and comfortable as well as fuel efficient.

“I do most of the maintenance myself, and anything larger, I give to Kev in Leongatha,” he says.

“I’ve been doing a little bit of work for Kev for a few years, and his mechanics, Tim and his son Hayden, will do anything that I can’t tackle. They’re really gifted mechanics.

“In fact, I started working for Kevin after I saw an article about him in the Scania magazine, about 10 years ago. I remember reading that and seeing the photos of the beautiful silver trucks. I just thought ‘I’ve got to go and have a drive of them’. I did in fact end up driving their R620 V8s and their 730s.”

To this day, James still has his Scania 4-Series posters. With Kev as a constant mentor at his back, the truck nut is continuing to enjoy his owner-driver lifestyle. For those wanting to follow in his footsteps, he says research, education and financial pillars are critical to not falling at the first hurdles.

“Mum and Dad have been a great help and very supportive,” he says.

“I’d tell people who want to go out on their own to do research, do some more and then do some more again.

“I went out pretty half-cocked and made an emotional decision. I was lucky I had savings to start and didn’t have to borrow money. I’d advise people to do the maths beforehand and ensure it’s worthwhile and what you want to do.”

While the owner-driver life isn’t for

everyone, James has made it his own in the past couple of years. Backed by a love for trucks (particularly Scanias), a strong industry network and a belief in himself, he’s a shining example in tough times for operators that success can still be found in trucking solo.

“My best advice is if you want to do this, don’t listen to anyone who tells you that it’s impossible,” he says.

“I remember a lot of older drivers who got out of the game telling me not to, but I knew I was always going to do it, and I’m so glad that I did.

“If you can learn how to run a business, have good support from friends and family and have good mentors like I’ve had with Kev and Brad, you can succeed in the industry for many years.”

We’ve known for a long time that road transport is in dire need of reform.

It’s why the whole industry has come together to campaign for and win laws that will let us start making road transport better.

Road transport is more united than it’s ever been – but that doesn’t mean there are no opponents. Wealthy clients like Amazon and Aldi, and the employer groups representing them, always put up the same tired arguments. The one that comes up again and again is that increasing standards for drivers and transport operators will harm productivity.

But new research has shown that the opposite is the case. A report by transport not-for-profit TEACHO has revealed transport operators suffer as one of the lowest profit segments in the economy. What’s more, though road transport languishes with profits two-thirds less than the national average, the clients it provides services to have much higher profits.

This is despite road transport providing billions to the economy. Of course, this will not be surprising to anyone who’s working in road transport. As decades of research have shown, these low profits have huge flow-on effects for the drivers and operators carrying out the work in this industry. The new study demonstrates that large client profits are built by increasingly shifting work to cheaper, more dangerous operations.

The number of single contractors doing work is increasing, and increasing exponentially – and there’s nothing wrong with that in principle – but the problem is, it’s increasing in the wrong areas – like Amazon Flex, where there are absolutely no standards.

When the gig economy first came to our shores, the alarm bells were already ringing. We recognised as an industry that, with standards already going sharply downhill, we’d be left with nothing if something wasn’t done.

The combination of transport clients putting a deadly squeeze on contracts, and the lack of standards in the gig economy, has had devastating human and economic consequences – for not just the industry, but the whole Australian community.

As it turns out, the squeeze on transport operators and drivers, meaning drivers have to work increasingly longer hours, severely reduces productivity in the industry. The more hours a driver

works, the more productivity declines.

And the lower the wages, the less incentive there is for people to stay in the industry – again increasing the workload for those who are left, and further reducing productivity.

Unpaid queueing is the same story –not only does it disadvantage drivers and operators, there are efficiencies lost because of a lack of incentive to improve waiting times. As well as productivity loss, razor-thin profit margins have dire safety implications.

Transport operators and drivers forced to cut corners to make ends meet. We know how desperate the situation is. We are nearing 100 people killed in truck crashes in Australia just this year, 30 of them truck drivers. Over 600 transportrelated businesses have become insolvent in the last financial year.

With deadly pressures on our roads and businesses going broke left, right and centre, it’s clear how drastically we need decent standards in this sector to save lives and improve productivity. The Aldis and Amazons of the world will argue the opposite – that we should have fewer standards. But we’ve seen what the research shows. And the people in this industry have lived experience of that.

Of the long hours, the pressures to meet deadlines, the choice between vital truck maintenance or putting food on the table.

By the time you are reading this, a transport roundtable focused on productivity will have taken place.

The federal government, since it has been in power, has sat down and listened to several delegations of the road

is the

of the Transport Workers Union of Australia. Contact Michael at: NSW Transport Workers Union, Transport House, 188-390 Sussex Street, Sydney, NSW 2000. twu@twu.com.au

transport industry. That includes drivers, transport operators, large and small employers, industry associations and academics.

We now have applications in progress to put in place standards like maximum 30-day payment terms, rights for food delivery workers and a decent floor in the last mile sector to stop the race to the bottom.

What we will continue to make clear –as an entire industry – to the government is that these applications under the new system are well on their way to making significant change in road transport. Lifting standards in road transport will increase productivity. We have new research to prove it. But much more importantly, it will improve safety in the deadliest industry in this country.

We cannot continue to keep seeing this low profit squeeze from the top of road transport supply chains, with drivers and operators bearing the deadly pressure to work long hours, as well as low wages causing skills drain and critical shortages in the industry. This transport industry roundtable is another chance for us to keep making the case that we need decent standards. This is much more powerful as a united front and backed by research that shows low profits and long hours are a barrier to productivity.

It’s research that’s back by all corners of road transport – from clients like Coles to transport businesses like Toll and Linfox and by ARTIO, NatRoad and the NRFA. It was undertaken by internationally renowned academics Dr David Peetz from Griffith University and Professor Michael Belzer from Wayne State University after being commissioned by TEACHO.

With automatic rights now in place against unfair contract deactivations, and consultation on standards applications close to complete, we’re well on our way to seeing change in road transport. We’re not stopping there.

Next year the TWU has aligned over 200 Enterprise Agreements to expire right across transport, in road and in aviation. We need to see transport clients funding decent standards to see real gains in productivity, driver retention, safety and health outcomes. And whether they’re on board or not, we’ll do it in every possible way we can.

After a recent pivot into harvest work, Luke Keams decided to concoct the perfect Mack to suit his growing list of wishes, Warren Aitken writes