Denmark’s path to circular resilience

By Inside Waste

It began with an image that has become a symbol of transformation. A little boy sits alone on a toy truck in the middle of a Danish highway. The photograph was taken during the 1970’s oil crisis, when Denmark introduced car-free Sundays to conserve fuel. The country, which at the time imported more than 90 per cent of its oil, was suddenly brought to a standstill. For many Danes, those empty roads were a moment of reckoning; a realisation that energy security was not simply about access to resources but about resilience and independence.

“It was clearly, when you look back today, the turning point of how we did our energy policies in Denmark,” said Denmark’s Ambassador to Australia, Ingrid Dahl Madsen, speaking at the recent Waste Expo Australia held in Melbourne. “It taught us that energy security is not just about resources. It’s about resilience. It’s about independence.”

The oil shock of the early 1970s forced Denmark to look

inward, to rethink its reliance on external supplies, and to build a model based on innovation and collaboration. The quiet Sundays of 1973 became the starting point of a long journey towards what is now one of the world’s most advanced circular economies.

“When preparing this talk, my team asked me what I remembered from 1973,” she said. “And first, I was a little offended, because I wasn’t born until 1976. It was the impact that was significant, also for the generations that followed.

“You never left a room without turning off the lights. You never left the water running when you were doing dishes. It was just integrated in how we were and how we grew up. As kids, we all learnt about the value and the importance of saving our resources.”

From that point, Denmark began to diversify and innovate. The transition from fossil fuel dependency to renewable energy was not only a technical revolution but also a cultural one.

(Continued on page 6)

20 Waste to Energy - future directions

28 WIRA winners

46 New battery depot

What a difference good EPR makes

By Helen Millicer

A quiet but effective European revolution is catching on and spreading across the world – Extended Producer Responsibility (EPR). A robust EPR will soon materialise in Australia; now it’s a matter of when and whether we put in place the essential guardrails and work together to achieve excellence.

Over 30 years, EPR and Producer Responsibility Organisations (PROs) have evolved, introducing new measures like eco-modulation in fees incentivising improvements in design, and investing in expanded collections and recycling. Effective EPR and PROs are so valuable that EPR is becoming central to governments and industry sector strategies for circular materials and products, stronger industry sectors, local jobs, higher economic productivity, improved trade balance and lower harmful emissions.

Many of us may have seen the consequences of good EPR and PROs in our travels without noticing. From the smart design of attached caps and recyclable labels on bottles, to expanded kerbside collections and accessible, free drop-off points in stores for all types of products including electronic goods and batteries.

Origins and mandating responsibility

Germany and France first introduced EPR for packaging in early 1990s, and now every EU nation has EPR for packaging. And all have passed laws making it mandatory for producers to be responsible for the life cycle of their packaging. Others that have followed suit on mandatory packaging EPR and PROs include Norway, Ireland, Israel, Canada, Columbia, Chile and South Africa.

(Continued on page 12)

Image: Pandora Pictures/shutterstock.com

Follow the leader

Nobody likes being told what to do, even when the advice is sound. Call it ego, arrogance, hubris, or even naivety combined with ignorance, trying to change the way something is done is not something that comes easy to those in leadership roles. Which brings me to Denmark. That little Nordic country is nestled just north of Germany about two-thirds the size of Tasmania and just over one-quarter the population of Australia. What could a small country more known for its toy bricks, Vikings and Hans Christian Andersen teach a leviathan like Australia about the waste industry? Plenty.

Listening to the Danish Ambassador at Waste Expo Australia 2025 recently in Melbourne, it was easy to see why our corner of the world causes bewilderment for those trying to do business here. Why does the Danish system work so well? In a word – collaboration. There might be some quizzical thoughts going through a lot of readers heads at the brief statement. “We have lots of collaborations with both local and international partners”, I hear a lot of you saying. I’m sure you do. But where it really works in Denmark, is the collaboration between business and government. Back

Chief Executive Officer

Christine Clancy christine.clancy@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Brand Manager

Chelsea Daniel chelsea.daniel@primecreative.com.au

Designer Laura Drinkwater

Client Success Manager

Head Office

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 info@primecreative.com.au www.insidewaste.com.au

Subscriptions +61 3 9690 8766 subscriptions@primecreative.com.au

Inside Waste is available by subscription from the publisher.

SHAPE TH E FUTURE OF RECYCLING WITH ACOR

Australia’s recycling sector is a powerhouse, diverting waste and creating valuable resources, closing the loop in a circular economy. As a collective force, it contributes almost $19 billion to the economy, supporting over 94,000 jobs. The Australian Council of Recycling (ACOR) is the peak industry body for this crucial sector. We represent a diverse membership, encompassing all aspects of resource recovery, recycling, and remanufacturing. From MRFs and CDS operators, to C&D and metal recovery, to tyre, battery and textile recyclers, to glass, plastic, and paper remanufacturers, ACOR brings the entire industry together.

during the 1973 Oil Crisis Denmark’s motorways and byways were empty. Nobody could afford to run a car, but that led businesses and government to realise there needed to be a better way of doing things when it came to energy supplies. And that led to a whole slew of laws and innovations that give the country one of the best resource recovery sectors in the world – whether it be energy from waste, or bin collections. Am I optimistic that Australia can do the same? About the industry itself bringing innovation and common sense to some of these issues? Absolutely. They’ve been doing so longer than Inside Waste been a magazine. The industry isn’t the problem. As pointed out in a recent SMH piece titled Overgoverned, overtaxed and overcomplicated: How Australia was set up to fail, it highlighted how there was too much bureaucracy, too many differing laws in different states relating to the same issues, and a reign of confusion for anybody trying to navigate their way around trying to get things done. Sound familiar? Is there hope? Possibly. But it won’t be bureaucrats leading the charge.

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright Inside Waste is owned by Prime Creative Media and published by John Murphy.

All material in Inside Waste is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including

The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Waste are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Join a network of industry leaders

ACOR fosters collaboration and thought leadership among its members. Whether you’re in metal reprocessing, e-waste recovery, or plastic recycling, ACOR connects you with a network of committed enterprises working towards a common goal: a thriving circular economy.

Make your voice count

ACOR is a powerful advocate for the recycling industry, actively shaping government policy and regulations. As a member, you’ll have a direct impact on ACOR’s policy agenda, helping to shape the future of Australian recycling.

Onetrak

(Continued from the Cover)

WIND ENERGY EMERGED as a national symbol of independence, while investment in efficiency and bioenergy set the foundation for a new economic identity.

“We diversified, we innovated, we took control of our energy story,” Madsen said. “We didn’t just change our energy mix. We changed our mindset from dependence to determination, from prices to creativity.”

Today, more than 80 per cent of Denmark’s electricity comes from renewable sources, primarily wind, solar, and biomass. The country is on track to reach 100 per cent green electricity by 2027. The long-term targets are equally ambitious: a 70 per cent reduction in carbon emissions by 2030 and climate neutrality by 2050.

“Behind every percentage are citizens, companies, communities, and political leadership who turned ambition into action,” Madsen said. “And still, even when we feel proud, our resource consumption remains too high. The challenge for us now is not just to lead in producing clean energy but also by consuming less and by consuming more sustainably.”

A culture of reuse and resourcefulness

Circularity has been part of Denmark’s national mindset for decades. Denmark was the first country in the world to introduce a recycling law, in 1978, requiring at least 50 per cent of beverage packaging and paper to be recycled. This early legislation laid the groundwork for a society where waste is seen as a resource, not a burden.

“There’s already a lot of good collaboration taking place within that partnership”

Denmark was the first country in the world to introduce a recycling law. Image: Alexanderstock23/shutterstock.com

For Madsen, the principles of the circular economy are deeply personal. She grew up in a small town in Denmark called Skanderborg. Each August, there was a music festival that came to the town. She said that every child in the town knew they would be earning some good money collecting beer bottles. That same system still works today. Denmark’s deposit return scheme, operated by a non-profit organisation, has a 93 per cent return rate for beverage containers and a 99.7 per cent closed-loop recycling rate. The success of this model lies in its simplicity and social acceptance, as it is not just policy but practice, woven into daily life. But Denmark still has a way to go, she said.

“I was quite surprised when I learnt recently that Denmark’s economy is only four per cent circular,” she said. “And Australia, I believe, comes out at 4.3 per cent. That was shocking when I thought about what I know about the circular economy in Denmark.”

S he explained that the low score reflects Denmark’s high consumption of virgin materials, which is around 24.5 tonnes per person annually, compared to 31 tonnes in Australia. This doesn’t

mean the remaining 96 per cent of materials are unused or wasted, she said. Denmark does a lot of sorting, and almost half of the materials in the country’s economy are utilised.

Sorting, she added, has become almost a national sport. Danes separate household waste into ten fractions: food, glass, paper, metals, textiles and more, and go to recycling stations for the rest. Only one to two per cent of household waste goes to landfill. Even its landfills are marked in such a way that the waste can be dug up again when the technology to recycle it has been developed.

Turning waste into value

Madsen described Denmark’s circular achievements as visible not only in statistics but also in the built environment itself. One of the clearest examples is Copenhagen’s waste-to-energy plant, CopenHill, which supplies electricity and heating to 150,000 households while doubling as a public recreation site. With its 80-metre ski slope, hiking trail and Europe’s highest climbing wall, it has become a symbol of how sustainability and urban life can coexist.

“Municipalities in Denmark have become so

from neighbouring countries,” she said. “Denmark imports about a million tonnes of waste from the UK and Germany to run this plant. It’s right in the middle of Copenhagen, across from where our king

Sorting has become almost a national past time. Image: Tatiana Diuvbanova/ shutterstock.com

Green garbage recycling containers in Denmark. Image: dba87/shutterstock.com

and queen live. The confidence in terms of the safety and usefulness of this is quite broadly accepted.”

Another example, she said, is Avedøre Power Station, one of Denmark’s largest plants. It runs 100 per cent on sustainable biomass, and by 2026 it will capture biogenic CO₂ for storage in Norway and for use in methanol production.

Industrial symbiosis also plays a key role. Kalundborg Symbiosis is a partnership between 17 public and private companies in Kalundborg and is driving industrial decarbonisation.

It is focused on waste resources, energy efficiency and water management. The company’s waste gets reused elsewhere, and the integrated system has achieved a carbon-neutral local energy supply.

C ircularity is not limited to infrastructure. Madsen pointed to Sydney’s Quay Quarter Tower, designed by Danish firm 3XN, as an example of Danish circular design abroad.

“It’s the world’s first upcycled skyscraper,” she

said. “From the original building, 65 per cent of the existing structure and 95 per cent of its core were retained. That resulted in embodied carbon savings of 12,000 tonnes, which is the equivalent of 35,000 flights between Sydney and Melbourne.”

Collaboration across borders

Madsen said Denmark’s progress has been built on collaboration. Public/private partnerships have driven the green transition at every level, from municipal initiatives to national strategies. In 2019, the country launched 14 climate partnerships – one for each major sector – to co-design pathways toward its 70 per cent emissions reduction target for 2030. These partnerships generated more than 400 recommendations, forming the foundation for what is now the Green Tripartite Agreement.

“In Denmark, collaboration has really led the way,” she said. “The Green Tripartite Agreement is a political agreement between the Danish government, the agriculture industry and

environmental organisations. It includes the world’s first agricultural climate tax on livestock emissions and aims to reduce nitrogen pollution, restore peatlands and promote sustainable land use.”

Collaboration, she added, doesn’t stop at the borders of Denmark. She said that Denmark and Australia have a long-standing strategic partnership that grew stronger in 2023 when Prime Ministers Mette Frederiksen and Anthony Albanese signed a new agreement focusing on climate action and the green transition.

“There’s already a lot of good collaboration taking place within that partnership,” she said. “We’ve heard about the importance of partnerships in supporting circularity. Collaboration has really been what has pushed the green transition in Denmark.

“A circular economy requires all hands on deck –government, industry, environmental organisations and all of us – to push it forward, both nationally and internationally.”

Invest in the Best Tramp Metal Protection

With more than 80 years of magnetic expertise behind them, Eriez Suspended Electromagnets offer peace of mind, knowing your processes are protected against tramp metal. Eriez. Always the Right Choice.

Protect your downstream crushers, mills, and pulverizers from damage caused by stray digger teeth, tools, and other ferrous metals.

What a difference good EPR makes

(Continued from the Cover)

FOLLOWING IMPRESSIVE RESULTS in managing packaging, EPR and PROs are now being formed for other product categories. In Belgium, for example, there are accredited PROs for electronics, batteries, oil, tyres, mattresses, PV panels and end-of-life vehicles. The French were first in forming the first PRO in 2007 for clothing/footwear/linens, proving to other nations and the European Commission that positive action can be taken to wrangle this growing product category toward a more circular future.

These priority product categories are familiar to us in Australia as almost all sit on our Minister’s Priority List for the formation of a PRO to manage a scheme. We are now ready for the next steps.

What is good EPR, and an effective PRO?

Typically, a PRO starts with industry leaders banding together to voluntarily fund the formation of a scheme in partnership with the central government. Typically, within three to four years the central government has passed legislation requiring all related producers to follow suit and take responsibility by a) either joining a scheme or b) taking back their own packaging/product and providing same level of coverage and service.

Because there is no delay, these nations avoid the ‘zombie zone’ of limping ‘half-alive’ voluntary schemes that we have in Australia that must coax producers to stay for an indefinite period with ‘best as they can muster’ services. Timely and good legislation can also prevent formation of competing for-profit schemes that race to attract members with low levies, minimal services and progress.

Timely legislation and smart regulation provide clarity for producers, enables planning, PRO contracts and investments to be formed on services and processing for quality material for markets.

Across six months in Europe earlier this year, I met many PROs from across Europe and Canada, with most covering off on packaging while others were in electronic products and textiles. It was notable that not one country has voluntary schemes. It was useful to learn how, in such countries, PROs and regulators manage the thousands of liable producers who pay the levies and pursue those comparatively few who try to dodge taking responsibility.

The difference between our voluntary and their mandatory schemes was pronounced in the budgets, capacity and internal resourcing allocations. In

Helen Millcer (right) at the Mateo Packing processing facility, Czechia, with Tadeas Hnatek (left), Head of Logistics, Mateo Packing, and Pavel Jiracek, Secondary Raw Materials Manager at EkoKom PRO. Image: Helen Millicer

Belgium’s packaging PRO, Fost Plus, ‘free riders’ are only around 15 per cent of producers, meaning 85 per cent of producers financially contribute to coordination and investments. In Australia only 15 per

cent of producers have voluntarily signed up to Soft Plastics Stewardship Australia.

Representatives of governments, PROs and industry alike politely shrugged at our voluntary approach in Australia wondering how we see this as fair, socially and environmentally responsible, economically viable or useful. They offered to help.

Brits and Germans admit mistake

At conferences, I often heard Germans and Britons say they wished they had designed their schemes as not for profit instead of for-profit schemes, and single scheme not competing PROs. They admit others got it right (like the French, Dutch, Belgians, Spaniards and Czechs). In the heady days of 1990s neo-liberalism in Germany and England, it was thought competing and for-profit schemes would deliver lower costs and greater efficiencies for producers and public.

There have been studies into the comparative differences between schemes that vary in their services and levies between countries. However, the clearest evidence of the challenges of competing for-profit schemes is that both Germany and England are passing additional laws and installing an overarching special NFP reporting entity, like a data clearing declaration centre, to receive and reconcile confidential data on quantities and obligations from for-profit producers, recyclers and schemes. There are too many blind spots, likely gaming of systems and an inability for these nations to go to the next level in circularity. I was struck by the bureaucratic complexity and duplication of the systems in these two countries and the ramifications for producers and governments,

particularly when the alternative is a single NFP PRO that delivers a beneficial service under contractual agreement and in partnership with governments.

Good governance for success

During this visit to the EU, I was keen to understand governance structures and how governments and PROs engage. There are two models for government oversight of compliance; the regulator may be within a national government department, or a separate national entity.

In Czechia and Austria, the regulator is a national government department. In Norway, Estonia, and Denmark, all PROs are overseen by the national EPA. Spain and Poland use a national Registry. In Belgium, regulation is handled by the Interregional Packaging Commission, created soon after the country’s

EPR grew out of the European environmental movement in the 1980s to make real the principle of ‘polluter pays’ for negative externalities associated with products. It was understood that g overnments and taxpayers could not continue to carry all costs and responsibility, such as managing all collections and building recycling infrastructure. Governments, communities and leading companies agreed that a levy upon products sold could be held by a Producer Responsibility Organisation (PRO) and used to f und coordination of the supply chain, particularly collections and recycling in cooperation with local councils and businesses in providing households and industry access to expanded services.

At EcoBatt, we are driving real change through our nationwide Battery Collection Service, which is designed to significantly reduce the number of batteries ending up in landfill. With over 7,000 collection units located across Australia in partnership with major retailers, we are making battery recycling more convenient and accessible than ever before.

Improper battery disposal can have serious consequences. From fires in waste trucks and landfill sites to toxic chemicals leaking into soil and waterways, the risks to our environment, wildlife and community health are far-reaching.

Recycling batteries correctly is a simple yet powerful way to protect what matters. By working together, we can create a cleaner, safer future and preserve valuable resources for generations to come.

packaging law and PRO. Its small expert team interprets policy and legislation, drafts and supervises agreements and the PRO, renews accreditation every five years, and pursues non-compliant producers.

The Commission ensures the PRO meets its Agreement obligations and requires that contracts with local authorities and service providers align with it. Like an EPA, it has a board representing Belgium’s three regional governments responsible for waste policy. Reflecting its importance and success, the Commission is now being restructured to receive responsibility for managing all other product PROs from government departments.

Given the federal structure of Australia, the number of ready schemes and evolving sophistication of their obligations and operations (eco-modulation, design assessment and supply chain contract management) Belgium’s Commission may be a good model for Australia, or it may be a role taken up by Australia’s national EPA. Australia already has examples of effective independent commissions/agencies like the ACCC, Clean Energy Regulator, for implementation of regulations and supervision of liable parties.

Next frontier – improving design of legislation, PROs and Products

Since their inception, European EPR and PROs have evolved more than their Australian counterparts. No one left me in any doubt that light-touch EPR legislation and NFP PROs, as opposed to prescribed legislation and for-profit PROs, has enabled practical government/industry collaboration on achieving progressively ambitious environmental and economic goals and plans.

While Australian schemes are either rigid or impoverished, Europe’s PROs are flexible and innovative. High-performing NFP PROs respond to evolving policies, product design, and markets,

IMPACT OF GOOD EPR AND PROS

expanding scope as approved by governments. PROs can flex their levies and uphold their responsibilities; they consistently safeguard program/supply chain solvency while serving members and the public. Having being at the coal-face, seeing the impact of China Sword in 2018-19 on Victorian councils, businesses and communities, including costly government bailouts, I know that this flexibility for PROs to manage and balance the supply chain is essential.

Notably, it was only the NFP sole-national PROs that developed and introduced eco-modulated fee structures, because they had the backing and

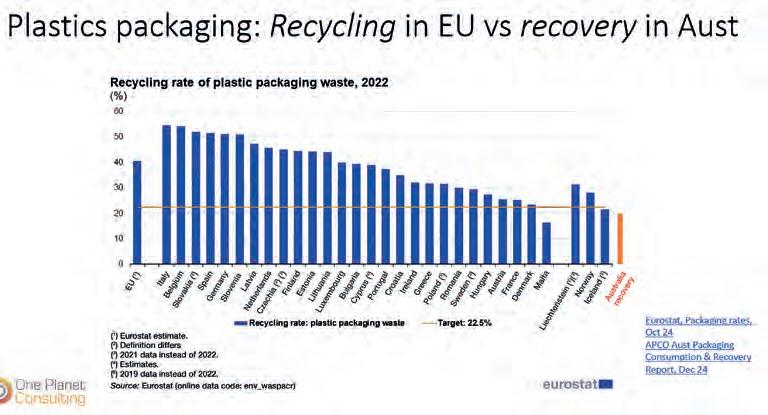

The impact of good EPR and PROs is perhaps best illustrated by this diagram on the recycling of plastic packaging. Over years, PROs in EU countries have methodically expanded collections, processing and enabled markets for recycled content. Their plastic packaging recycling rates are as high as 52 per cent, with quality secondary raw plastics sold into local and international markets. Australia, without a PRO and a regulator to manage compliance, has languished only collecting 19 per cent of plastic packaging.

flexibility of producers and governments. This has accelerated the race toward recyclable packaging in EU since 2018, and now their current focus is investing in supply chain collaboration for reusable packaging and incentivising recycled content.

Again, these innovations by NFP packaging PROs are being adopted by other product category PROs. During my stay in the Netherlands in May, the Dutch WEEE PRO CEO expressed interest in introducing eco-modulated levies to promote durable, repairable, and recyclable product design in the electronic good sector.

With such excellent EPR and PRO partnerships, governments can move decisively on key goals, and their populations gain more efficient and circular products.

Caution and encouragement

It’s important to end with a caution: advancing producer responsibility and a capable regulator in Australia will meet resistance, both from producers unwilling to pay levies and from waste operators prioritising market share over transparency or environmental outcomes.

This article sets out the roadmap for success; preparing businesses for a PRO-charged future, demonstrating benefits to new audiences, and urging governments and stakeholders to unite swiftly on reforms.

The way ahead

The path forward for Australia involves a suite of measures, from levies and bans to incentives, better carbon accounting and regulations. One of our largest underutilised levers is EPR and good PROs.

Helen Millicer, GAICD is a Churchill Fellow, CEO of One Planet Consulting and Board Director for Solving Plastic Waste CRC. She has written a report for the Australian Government on measures for eco-design of products, and advised on the formation of Soft Plastic Stewardship Australia since 2022.

Figure 1 Plastics packaging: Recycling in EU vs Recovery in Australia

From the CEO’s desk

Australia’s circular crossroads: progress, paralysis, and the power of regulation

Environment Ministers will meet for the second time this year on 7 December, following the first 2018 Meeting of Environment Ministers (MEM) in April, which was in part a response to the import restrictions driven by China’s National Sword Policy and the effects this policy has had across the Australian waste and resource recovery (WARR) industry. Key decisions derived from the April MEM

the transformation we need on their own. That’s why we need the other levers: policies that attract capital, build reprocessing plants, and create markets for remanufactured goods.

•Reducing waste generation, endorsing a target of 100% of Australian packaging being recyclable, compostable or reusable by 2025, and developing

• Increasing Australia’s domestic recycling capacity.

To make Australia’s WARR system work, regulation must ensure that what comes out of the bin goes somewhere productive — and back into circulation through products, packaging, and manufacturing here at home. That means mandatory recycled content requirements to create guaranteed demand for recovered materials; design standards and stewardship obligations in order that products are built for reuse and recovery from the start; and procurement rules that make recycled content the default, not the exception.

• Exploring opportunities to advance waste-to-energy and waste-to-biofuels.

•Updating the 2009 Waste Strategy by year end, which will include circular

It is time to take stock and examine what has been achieved since these decisions were announced. Now, seven (7) months may not seem like a long time, however in that time we have seen further markets close (Malaysia, Indonesia, Vietnam) and if you are an operator under continued financial stress, seven (7) months could

years yet on the waste and resource recovery calendar – arguably the most pivotal since China’s National Sword policy jolted 2018. Ironically, much of the busyness stems not from unbridled progress, but from the constant need to stop ourselves sliding backwards.

Let’s be frank: the last term of the Federal Government left the WARR industry disappointed and frustrated. The early rhetoric was strong; promises to regulate, to expand stewardship; and to fix the broken parts of the system that leave materials stranded onshore without markets. There was talk of stewardship schemes for packaging and textiles, eco-modulation to reward better design, and national regulatory consistency to attract investment. However, by the end of the term, most of that ambition had dissolved into silence. The promised regulations never materialised. Stewardship schemes were left hanging. Investment pipelines stalled.

Following the April MEM, we have had three (3) states step in with varying degrees of financial assistance for industry (councils and operators). This should be expected considering almost all states (except Queensland and Tasmania) have access to significant waste levy income each year. On the eastern seaboard, Victoria has approximately $600 million in waste levy reserves in the Sustainability Fund and NSW raises more than $700 million per annum from the waste levy. There is certainly no lack of funds that can be reinvested into our essential industry.

remanufacturing says the same thing: clarity and consistency matter.

industry however the Queensland Government has embarked on the development of a waste management strategy underpinned by a waste disposal levy to increase recycling and recovery and create new jobs. The State will re-introduce a $70/ tonne landfill levy in March 2019. There are also strong attempts to use policy levers (levy discounts and exemptions) to incentivise the use of recycled material and make it cost competitive with virgin material. However, little has been done establish new markets and Government has not taken the lead in the procurement of recycled material. There are grants available for resource recovery operations in Queensland although no monies have been allocated to assist in 2018. This troubling as Queensland rolled out its Container Refund Scheme on 1 November, which will likely impact the cost and revenue models of the State’s MRFs – as have seen most recently in NSW.

WESTERN AUSTRALIA

Doubling material circularity by 2035 in Australia will not happen by chance. It will happen when regulation, markets, and investment work together, and when governments show the courage to make the tough calls that create certainty and unlock the capital needed to build Australia’s recycling and reprocessing capacity. There is hope on the horizon. The Recycling and Waste Reduction (RAWR) Act 2020 review presents the Federal Government’s best opportunity in years to finally put these levers to work. Done properly, it could deliver the coherent national framework we have been calling for – one that links design, stewardship, and recovery in a unified system. It could unlock the regulatory certainty the supply chain needs to invest in reprocessing, remanufacturing, and advanced recycling.

Amid federal uncertainty, some states are leading the charge. New South Wales stands out, with the first chapter of its Waste and Circular Infrastructure Plan released in October 2025, regulatory frameworks for battery-powered items underway, an expansion of the CDS, a RIS to explore stewardship for PV panels, and regulations mandating the separation of organics by 2030 (MSW and some commercial and industrial premises too!). While a review of the waste levy is still needed, it’s heartening to see multiple levers being pulled by a reforming minister. NSW shows that the circular economy is not simply a theory, it’s a practical, job-creating reality when the rules are clear and direction consistent.

Funding helps but as we know, the money goes a much longer way with Government support and leadership, as well as appropriate policy levers.

VICTORIA

And inevitably, confidence wavered. When manufacturers and investors do not see the promised follow-through, why would they commit? When government procurement and policy fail to prioritise recycled content, orders for recovered materials dry up. The result is a circular economy in name only. As industry has said many times, Australia cannot recycle its way out of this challenge with goodwill alone.

SOUTH AUSTRALIA

We need rules that reward responsibility, regulation that drives design, and markets that pull recovered materials through the system.

COMMONWEALTH

However, time is ticking. The review has been slow, opaque, and worryingly quiet. With new export restrictions taking effect in mid-2026, we cannot afford drift. Without clear direction, Australia risks losing the gains made through the Recycling Modernisation Fund and the National Waste Policy Action Plan (NWPAP), which, while imperfect, at least got federal and state governments talking about waste and materials strategies in a way we had not seen for almost a decade.

Victoria has arguably been the most active and earnest in supporting the industry post-China, with two (2) relief packages announced to support the recycling industry, valued at a total of $37 million. The Victorian Government has also gone above and beyond all others states by announcing it would take a leadership role in creating market demand for recycled products.

Government announced a $12.4 million support package comprising $2 million of additional expenditure, $5 million additional funding for a loan scheme, together with targeted funding from the Green Industries SA budget. The Government has also offered grants for recycling infrastructure.

NEW SOUTH WALES

Like every other industry, WARR needs income, investment, and a clear regulatory framework to thrive. Levies play an important role in signalling that landfilling valuable materials should not be the cheapest option and that waste material has real economic value. But levies alone are blunt tools; they often sit far from those generating the waste and are unable to deliver

At first glance, New South Wales’ eye-watering $47 million recycling support package was heralded as the spark of hope industry needed. However, on closer inspection, the bulk of this package that was funded via the Waste Less, Recycle More initiative and therefore the waste levy, was not new, making it very difficult for stakeholders, including local government, to utilise the funds as they were already committed to other activities. Some of the criteria proposed by the NSW EPA also made it challenging for industry to apply to these grants. On the plus side, efforts are being made by the NSW Government to stimulate demand for

The Western Australian Government set up a Waste Taskforce in direct response the China National Sword. As part of this announcement, the State Government urged all local councils to begin the utilisation of a three (3)-bin system - red general waste, yellow for recyclables and green for organic waste - over the coming years to reduce contamination. While this taskforce is a step in the right direction, we are yet to see any tangible results from it or any funding for industry. In October, the WA Waste Authority released its draft Waste Strategy to 2030, which comprises a comprehensive and detailed roadmap towards the State’s shared vision becoming a sustainable, low-waste, circular economy.

Sadly, that level of leadership is not uniform. In Queensland, the Local Government Association’s (LGAQ) push to abolish the so-called “bin tax” is a backwards step. Rather than building on the existing framework to grow markets and processing capacity, it risks undermining the economic and environmental foundations of the system. What’s needed is not another political soundbite, but a coordinated policy that supports recycling and remanufacturing, especially in regional Australia. Without regulation to drive design and end-market demand, we are not creating circularity; we are simply moving waste around, sometimes literally across state borders. We wait to see if the impending Queensland Waste Strategy delivers this.

Following the MEM in April, Australia now has a new Federal Environment Minister, Melissa Price, who in October reiterated to media MEM’s commitment to explore waste to energy as part of the solution to the impacts of China’s National Sword, which is troubling (EfW is not a solution to recycling). The Commonwealth also backed the Australian Recycling Label and endorsed the National Packaging Targets developed by the Australian Packaging Covenant Organisation (APCO), which has to date, failed to incorporate industry feedback in the development of these targets. To the Commonwealth’s credit, there has been significant coordination in reviewing the National Waste Policy, with the Department Environment bringing together industry players and States during the review process.

While it appears that the NWPAP has been placed on the backburner, the reality is that we already have a forum capable of driving real change across Australia: the Heads of EPA (HEPA). In many ways, this group does not need to wait for Canberra given the majority of regulation occurs at the state level. HEPA can and should be making a tangible difference by aligning standards across jurisdictions and addressing long-standing regulatory gaps that block investment.

AHEAD OF MEM 2

So… will 2026 become the defining year for Australia’s circular economy? Hopefully if we get clear air after the reforms to the Environment Protection and Biodiversity Conservation Act 1999, the Federal Government must follow through with regulatory action. We already have the levers, the industry capability, and the public support. To truly shift the dial, Australia must deliver a strong RAWR Act review with enforceable stewardship and design obligations; mandate recycled content and eco-design standards to drive demand; empower HEPA to deliver national regulatory consistency; and support investment in remanufacturing, not just collection and sorting.

The updated Policy will now go before Environment Ministers on 7 December. Commonwealth can play a key role – one that goes beyond the development of National Waste Policy. WMAA is supportive of the Federal Government maximising the levers it has, including taxation and importation powers, to maintain a strong, sustainable waste and resource recovery industry.

Take organics, for instance. Australia has a national target to halve organics to landfill by 2030, yet we still lack consistent national standards for testing, sampling, or contamination limits. These inconsistencies add risk, delay investment, and stifle progress. The same applies to emerging contaminants like PFAS, where coordinated national guidance remains elusive. HEPA could show genuine leadership by setting nationally consistent standards that reduce uncertainty and support investment. Every investor in recycling and

There may be movement across Australia, with some states doing better than others, but the consensus is, progress is still taking way too long. It is evident that there are funds available in almost all States to assist with developing secondary manufacturing infrastructure, however the only way that this will really happen if there is government leadership around mandating recycled content in Australia now, not later.

If we want jobs, investment, and materials that stay in circulation, we need a policy ecosystem that values both sides of the equation – recovery and reuse, supply and demand, collection and creation. Australia doesn’t lack ambition. What we lack is regulatory courage. We already know what works: clear standards, enforceable schemes, strong procurement, and stable markets. The countries that lead in circularity don’t rely on voluntary measures or good intentions, they regulate for success.

The circular economy is not a slogan. It’s a system. And systems need structure.

Let’s stop circling the same conversations and start building the framework that will keep materials, and our industry, in motion.

Voluntary schemes like the Used Packaging NEPM, under which APCO is auspiced, are not working. We have 1.6million tonnes of packaging waste in Australia, which needs to be used as an input back into packaging. Barriers to using recycled content in civil infrastructure must be identified and removed, and Government must lead in this field and prefer and purchase recycled material. A tax on virgin material should also be imposed as it is overseas. MEM must show strong leadership on issue. Ministers have, since April, dealt directly with operators and councils that are under stress and we have a chance to create jobs and investment in Australia

development increase

$70/ policy material done to procurement operations

This is November, we response to Government for coming direction, October, comprises vision of Minister, explore Sword, has Packaging (APCO), development significant Department of review

The the maximising strong, than that secondary happen is Australia auspiced, which content lead material this that Australia

MegaTrans is Australia’s largest logistics conference and exhibition, uniting industry leaders and cutting-edge technology to drive a smarter, more sustainable supply chain. Be

Towards a cleaner waste to energy future

ASHLEIGH JONES , Director of Regulation and Oversight at Recycling Victoria, recently spoke at the Waste Expo Australia held in Melbourne, about the state’s progress and future direction under its waste to energy scheme. Addressing delegates, she reflected on the transformation that had taken place over the past year. When she last presented, the cap licensing process had not even begun. Now, the first round of licences has been issued, marking a milestone in Victoria’s journey towards a circular economy.

Part of her team’s responsibilities includes leading the cap licensing process, overseeing service standards for household waste and recycling, and managing the broader regulation and operations functions within Recycling Victoria. Jones said it was encouraging to see how far the program had advanced, even though there was still a long journey ahead.

“It is incredible to think that when I last stood here, we were still preparing to launch the cap licensing process,” she said. “A year later, we’ve issued our first licences, and the scheme is now operational. That represents a real step forward in how we manage residual waste in Victoria.”

The role of waste to energy in a circular economy

Jones explained that waste to energy occupies a critical place within Victoria’s transition to a circular economy. Its purpose, she said, is to extract the last possible value from resources that would otherwise be sent to landfill. This complements the state’s other circular economy initiatives, which focus on waste reduction, reuse and recycling.

“In a circular economy, our goal is to use materials as efficiently as possible and to reduce the overall material footprint,” she said. “We want to make sure we’re reusing, repairing and recycling wherever we can. Waste to energy is about what happens to that

small portion of waste that can’t be recovered any other way.”

Jones said the process not only creates energy but also recovers valuable materials such as aggregates and metals. By capturing these and avoiding landfill, waste to energy provides environmental benefits and supports a cleaner, more resource-efficient system.

She described the technology as proven, with strong regulatory oversight and less off-site impacts such as odour when compared to landfills. The need for such facilities, she said, was becoming increasingly urgent. Victoria’s landfills are running out of capacity, and constraints are expected to appear from the mid-2030s. Without investment in the process, the state would need to plan for new landfill capacity far sooner than desired.

“Waste to energy sits right at the end of the waste hierarchy,” Jones said. “It ensures we’re making full use of materials before final disposal, and it helps us manage residual waste in a responsible and efficient way.”

Planning for future capacity

Turning to projections, Jones discussed the findings from the Victorian Recycling Infrastructure Plan, launched at the previous Waste Expo. The plan assessed the state’s waste infrastructure needs and future demand. She said Victoria currently has around 150 million square metres of available landfill airspace with planning and EPA approvals in place. Although this might sound extensive, it is a limited and finite resource that will be depleted over time.

By 2053, Victoria is expected to generate around nine million tonnes of residual waste each year. This estimate takes into account population growth and the expected impact of reforms designed to reduce and recover more waste. Based on this analysis, landfill throughput capacity is likely to begin running

out in the mid-2030s. Jones explained that as existing landfills reach capacity and begin to close, waste will need to be diverted either to other landfills or to alternative facilities such as waste to energy plants.

She noted that reforms to recycling will certainly help, but they alone will not solve the problem.

“We can’t afford to wait,” she said. “The lead time on these projects is long, and we need facilities ready before our existing landfills reach capacity.”

A regulated and transparent scheme

Jones explained that the waste to energy scheme was created under the Circular Economy Act to ensure that the technology plays its proper role in Victoria’s circular economy. The scheme is designed to prevent waste to energy investment from undermining recycling and recovery efforts, while still reducing pressure on landfills. It also supports the state’s broader goal of diverting 80 per cent of waste from landfill.

The scheme operates by setting a cap on the amount and type of waste that can be treated through thermal processes each year. This cap is managed through a competitive licensing process, ensuring the market remains diverse, fair and transparent. Initially, the cap was set at two million tonnes. After a public consultation and a regulatory impact assessment, it was increased to 2.5 million tonnes in July, allowing Recycling Victoria to allocate licences.

Jones said this figure was based on long-term waste forecasts and represented a balance between diverting sufficient waste from landfill and avoiding over-investment in waste to energy. The increase also reflected the Victorian Government’s support for sustainable infrastructure investment. To process waste within that 2.5-million-tonne limit, proponents are required to obtain a cap licence from Recycling Victoria.

Waste to energy technology has strong government oversight.

Image: John Corry/shutterstock.com

She said Recycling Victoria’s role under the Circular Economy Act encompasses three main areas: licensing, oversight and strategic planning. Her team licenses both existing operators and new projects that have received cap allocations. It also provides ongoing oversight of licence holders, ensuring compliance with licence conditions and verifying that facilities process only the permitted types and quantities of waste.

Jones explained that Recycling Victoria works closely with regulatory partners such as the Environment Protection Authority and planning authorities. These agencies continue to assess projects for human health, environmental protection and local planning considerations. Recycling Victoria’s oversight therefore complements rather than replaces other regulators’ roles, ensuring the sector operates transparently and in the best interests of the state.

Building a sustainable and accountable industry

Recycling Victoria has now completed both stages of the licensing process. The first covered existing operators with EPA or planning approvals before November 2021. Jones noted that one such facility is already operating, and is processing paper and cardboard to improve energy efficiency and manage contaminants. The second phase was the competitive cap licensing process, open to both new and existing operators.

She described the assessment as rigorous and detailed. The licences issued reflect a balance between proven technologies and more innovative projects,

licensed facility demonstrated that it would achieve a net reduction in greenhouse gas emissions compared with landfill and fossil fuel alternatives over the life of the facility.

Jones said the projects collectively represent about $8 billion in infrastructure investment and are expected to recover around $50 million of materials each year that would otherwise be lost to landfill. They will also create an estimated 2,500 construction jobs and 650 ongoing roles.

“For most proponents, the journey is only

are central to Victoria’s long-term sustainability.”

She concluded by noting that Recycling Victoria’s oversight will continue as projects progress. Licence holders must meet milestones and operational deadlines, and her team will engage with industry, government and communities to ensure the successful establishment of facilities. Timely delivery of waste to energy infrastructure, she said, is critical to achieving Victoria’s circular economy ambitions and to ensuring a sustainable waste management system for decades to come.

Designing finance to enable circular transition

FINANCE PLAYS A CRUCIAL ROLE in enabling the transition to a circular economy, but so does thoughtful design. At a recent seminar, a panel explored how well-conceived projects and initiatives can gain support from financial institutions by prioritising sustainability. Even the most innovative designs require funding, robust business models, and economic incentives to achieve scale.

The discussion began with Dr Simran Talwar, programme lead for resource stewardship and research director at the University of Technology Sydney. She argued that the path to circularity cannot be added at the end of a process but must be present from the beginning.

“If you want a product to be reused, if you want it to be dismantled or recycled, you have to think about that in the first sketches,” she said.

Talwar stressed the significance of repairability, the use of non-hazardous materials, and designing for disassembly as building blocks of a system that can adapt to the challenges of limited resources. The framing of design as a discipline that anticipates change, rather than reacts to it, created a foundation for the conversation. Talwar pointed out that businesses that ignore these principles face higher risks in the long term. The costs of waste disposal, the liabilities of hazardous substances, and the challenges of customer demand for greener products all accumulate when design is shortsighted.

David Simmons, executive director of sustainable finance at ANZ Bank, followed by emphasising the scale of his institution’s commitment.

“We’ve set ourselves the goal of funding $100 billion worth of social and environmental activities by 2030, and we’re already at $60 billion,” he said.

His comment underlined the appetite in finance for projects that align with sustainability but also revealed that banks are selective. According

to Simmons, strong design principles that make products and systems durable and adaptable increase investor confidence.

Jo-ann Kellock, chief executive officer of the Design Institute of Australia, placed the conversation in the context of the challenges faced by smaller players. She believes that for small businesses the ideas are there, but the finance is not. Too often the language of design doesn’t match the language of banking. Her comment illustrated the barrier between creative thinking and financial assessment.

Kellock noted that banks often look for certainty in terms of revenue streams and return on investment, while designers talk about creativity, innovation, and user experience. Without translation between these worlds, many projects stall. She stressed the need for design institutes to help bridge that gap by showing how circular design is not only environmentally sound but also economically rational.

Talwar returned to the theme by highlighting how investors look for predictability – something that design can provide if implemented correctly.

“If a product is built to be repaired, its useful life is longer. That means less risk for investors,” she said.

Her point illustrated the intersection of design and finance: when design extends a product’s life, financial models benefit from reduced exposure to sudden obsolescence.

The ANZ Bank has set itself the goal of funding $100 billion worth of social and environmental activities by 2030. Image: ArDanMe/Shutterstock

Industry schemes to drive systemic change

Danielle Kent, general manager for industry transformation at Seamless, Australia’s national clothing stewardship scheme, offered an example of how these ideas translate into practical action. She described the clothing stewardship scheme introduced by her organisation.

“Every garment is levied at four cents, but if it is eco-designed, the levy drops to three cents,” she explained. “This structure creates a direct incentive for manufacturers to consider sustainability at the design stage.”

Kent expanded on how the levy accumulates across the industry to create a pool of resources that can be invested in recycling infrastructure, education, and industry reform. She argued that the scheme is an example of how small changes, when scaled, can lead to transformation. By attaching a financial signal to design decisions, the scheme pushes businesses towards circularity without relying on voluntary goodwill alone. Simmons agreed that this type of scheme is appealing to financiers.

“When you can show us a predictable revenue stream linked to sustainability, that is something we want to back,” he said.

His endorsement made clear that finance is ready to support initiatives that combine strong design, collective industry action, and reliable economic models.

Kent also spoke about the consumer perspective. She noted that the levy builds awareness among shoppers, who begin to see sustainability not as an optional premium but as an integrated part of the cost of clothing. She felt that the industry should start normalising sustainable choices, explaining that when eco-design is rewarded, it reshapes the market baseline.

Policy frameworks and government direction

The conversation turned to the role of policy and regulation. Simmons drew attention to the Australian Government’s sustainable finance roadmap and how being clear on expectations was important to getting the necessary outcome.

“Policy clarity is vital. Without it, investors fall back into short-term decisions,” he said. “For banks and large institutions, knowing that government policy is aligned with sustainability goals reduces uncertainty and encourages long-term commitments.”

Talwar urged that design must be a central part of policy, not an afterthought. She stated that if regulation only focuses on finance and ignores design, Australia will miss the point. Circularity starts with design. She reinforced the idea that rules and incentives should not only direct money but also guide how products and systems are conceived in the first place.

Kellock added that for small- and medium-sized businesses, interpreting new policies is particularly difficult. A large company has sustainability staff to track regulation, smaller firms do not. They need guidance that is practical and clear, she said. Her comment reflected the reality that unless policy is translated into accessible frameworks, many enterprises will be left behind.

Kent highlighted the way stewardship schemes can

“We are no longer only looking at credit risk. We have to assess climate risk, sustainability risk, and reputational risk.”

complement government action. By standardising industry practice, such schemes create a bridge between regulatory expectations and business operations. She emphasised that collaboration across sectors is essential.

“No single business can make circularity viable. It needs alignment between government, finance, and industry,” she said.

Risk, transparency and reporting obligations

Risk management formed another major theme. Simmons described how financial institutions are changing the way they assess businesses.

“We are no longer only looking at credit risk,” he said. “We have to assess climate risk, sustainability risk, and reputational risk.”

This evolution requires businesses to present clearer data on how they manage sustainability challenges. Without such transparency, financing becomes much harder to secure.

Talwar pointed out that many of these risks are shaped by design decisions. She stated if hazardous materials are chosen, a company must be aware of the regulatory risk associated with those materials. If they design without thinking about disassembly, they carry disposal risk. She believes that design is risk management. Her comment positioned designers as not just creative professionals but as key actors in safeguarding financial stability.

Kellock acknowledged that for many designers and small enterprises, the growing complexity of reporting is overwhelming.

“We hear from members who simply don’t have the resources to meet elaborate reporting requirements,” she said. “We need simplified mechanisms that will allow broader participation in sustainable finance without imposing disproportionate burdens on smaller businesses.”

Kent explained that stewardship schemes can relieve some of this pressure. By pooling responsibility across an industry, reporting can be standardised and simplified. She said that collective approaches make accountability possible. Without them, transparency

becomes another barrier to entry. Her argument showed how collaboration not only generates funds but also eases compliance, creating a more level playing field.

Building viable circular business models

As the discussion drew towards its conclusion, attention turned to what is ultimately required for circular models to succeed. Simmons was clear: “Finance is ready to support these models, but the business case must be strong. Sustainability alone is not enough. We need to see profitability and resilience.” His words emphasised that while there is appetite for change, investors demand evidence of long-term stability.

Talwar argued that design leadership is non-negotiable. “Only when design leads can we achieve outcomes that finance wants to support,” she said. She reiterated that circularity has to be built into the DNA of products and systems, not added as an afterthought. Kellock reflected on the importance of communication.

“Designers must be able to tell financiers why their work matters in economic term,” she said. “If we only talk about creativity and not about cost and durability, projects will be overlooked.”

Her point emphasised that dialogue between disciplines is essential for progress.

Kent closed the session with a call for collaboration.

“No one sector can achieve this alone,”she said. “Circularity needs the combined effort of design, finance, policy, and industry.”

She pointed again to the clothing stewardship scheme as a practical model, demonstrating how collective action can reshape an industry.

The discussion showed that finance and design, often seen as separate worlds, are in fact interdependent. When aligned, they can transform the way businesses operate and accelerate the transition to a circular economy. The challenge is not only to secure funding but also to ensure that design principles, policy frameworks, and business models all point in the same direction. Only then can circularity move from aspiration to reality.

Sydney landfill crisis in pictures

By Mike Ritchie

SYDNEY LANDFILLS ARE FILLING very fast. We are heading for not just a problem but a real disposal crisis. Just imagine the state of the economy and public health if we could not collect and dispose of household and commercial waste. Hopefully you are getting pictures of Naples during the strikes in your heads –piles of rubbish, rats and other vermin, public health outbreaks and social discord.

The NSW EPA has predicted that all putrescible landfills (which take wet waste including food) will be full by 2036 and inert landfills (taking dry waste) by 2028 i.e. much sooner.

I put together these image collections using MRA’s own photos and images from Google Earth.

Putrescible landfills

Woodlawn and Lucas Heights are the key, large putrescible landfills servicing Sydney. The Woodlawn landfill near Goulburn is operated by Veolia. It takes one million tonnes per year of mainly putrescible (wet) waste. It is pretty obvious that Woodlawn only has 5 or so years left in it. Lucas Heights landfill in Sutherland Sydney is operated by Cleanaway. It takes about 1.2 million tonnes per year. Again, mainly putrescible waste. Industry has been calling for years for action to preserve this valuable landfill space but government(s) of both persuasions, have been very slow to act.

Images on right - Lucas Heights landfill 2013-2017. All images: Google Earth/MRA Consulting Group

Woodlawn Landfill 2004

Woodlawn Landfill (this image) 2018 and 2024 (below).

Woodlawn Landfill 2011

Inert Landfills

Our inert landfills are filling even faster. The Genesis landfill in Eastern Creek Sydney, operated by Bingo takes about one million tonnes per year of inert waste including contaminated soils and construction waste that cannot be recycled.

There are a handful of other smaller inert landfills, but they are all filling quickly and some will close in the next few years. These include:

• W anless at Clifton Rd Western Sydney.

• B reen at Kurnell.

• V eolia at Kemps Creek.

• K imbriki at the Northern Beaches.

It is astounding that a city as sophisticated as Sydney is so vulnerable to economic disruption as a result of decisions, or lack of decisions, with respect to waste. It is irresponsible.

The government has announced four energy from waste precincts but only two have live planning applications.

Neither are approved and both have significant community opposition.

Even if both were approved tomorrow, they would take about five years to build and w ould account for only 0.8 million tonnes/year between them.

We have a big problem, and government needs to stop dawdling. It has current reviews into the landfill levy, planning approvals for waste, the energy from waste policy, the definitions of waste, the national waste targets and the kerbside recycling system. None have been published or finalised.

The key measures which government must enact tomorrow, include:

1. H igher real landfill levies to drive materials to recycling rather than landfill.

2. H ypothecated (guaranteed and allocated) expenditure of those levy funds to recycling infrastructure.

3. S peedier approvals of recycling facilities.

4. B ans to landfill or mandated recycling. On this point I need to congratulate NSW Minster for the Environment Penny Sharpe on mandating commercial and residential food collection by 2026 and 2030 respectively.

5. S tronger Product Stewardship making manufacturers responsible for the take-back of their products. Again, plaudits for the NSW battery stewardship proposals and Container Deposits. But it is not enough.

These initiatives work but we are running out of time.

We will have a shortfall of at least 1-2 million tonnes/year by about 2030. Note that it takes 4-8 years to get waste infrastructure such as l andfills and energy from waste plants approved in NSW. NSW Premier Chris Minns and Minister Sharpe need our political support to get it done. Urgently.

Mike Ritchie is the managing director of MRA Consulting Group, as well as a former Sessional Commissioner for the New South Wales Land and Environment Court.

Images right: Genesis Landfill from 2013-2017.

Changing minds while shaping sustainable procurement

AT A TIME WHEN LOCAL GOVERNMENTS are being asked to lead the transition to low-carbon, circular systems, the challenge of behaviour change has become central to how sustainable procurement is carried out. During a panel discussion at a recent resource recovery event, three experts shared their views on what drives – and hinders – progress. The participants were Esther Landells, senior policy officer at Local Government NSW; James McGregor, director of consulting firm Blue Tribe; and Lara Barclay, managing director of Adaptation Environmental Support.

Landells began by acknowledging the depth of the challenge noting that trying to change behaviours is hard work. She said that councils face barriers beyond goodwill such as limited resources, conflicting priorities, and deeply ingrained habits across procurement systems. There are a lot of competing demands.

“It’s not that people don’t want to do the right thing, it’s that they often don’t have the time, the knowledge, or the incentive to change the way they’ve always done things,” she said.

Within local government, Landells explained, procurement is as much about risk management as it is about sustainability. Officers are expected to meet compliance, budget, and political expectations all at once. She believes that risk aversion is a big part of the equation. People are worried about making

That sense of risk can stall progress even when sustainable options exist. Councils may want to buy recycled materials or low-carbon products, but fear of untested suppliers, or the perception of higher costs, can hold them back. Telling someone they must change for the sake of it will carry little or no weight, she said. Councils and other bodies involved in the waste and resource recovery industry need to understand why people behave the way they do and support them through it, or give them levers to want to change.

Understanding the science behind decisions

McGregor picked up on that theme by arguing that behaviour change must be treated as a science, not a slogan. He thinks governments and other agencies tend to believe if they give people information, they’ll make better decisions. That’s not how human beings work, he said. His background in behavioural economics has shown him that people rarely act rationally, even when they know what’s right. Instead, he said, decisions need to be based on social norms, emotional cues, and what we see other people doing. In other words, telling procurement teams to buy recycled content isn’t enough, they need to see evidence that others are already doing it successfully. Social proof is a powerful tool, he said. If you can show that another council is buying those products and

as saying ‘well done’ – these are concrete rewards that reinforce behaviour,” he said. “We can’t assume logic will win. We must make sustainable behaviour the easier, more rewarding, more normal choice.”

In his view, leadership is also crucial. He believes people look to leaders for cues about what matters. When senior managers visibly support sustainable procurement and acknowledge its successes, that signal ripples through the organisation. He said that culture changes when people see what gets praised and what gets funded.

Building engagement through access and trust

Barclay brought the discussion to life with an example from the community level. Her organisation, Adaptation Environmental Support runs the Recycle Mate program, which is designed to reduce contamination in household recycling and improve resource recovery. The program rests on five pillars: awareness, access, knowledge, support, and trust.

“Awareness is about helping people understand why it matters,” Barclay said. “Access is ensuring they can actually do it — that the infrastructure and systems are in place for all household waste streams. Knowledge means providing the right information at the right time, while support and trust come from consistent engagement, feedback and

She emphasised that rebuilding trust is especially important in communities that have seen mixed messages or system failures in the past. If people have been told for years that recycling is going to landfill, it takes time to rebuild their confidence, she stated. Her approach combines education with visible proof of results; showing residents where their recyclables go and how they are used. Her mantra is that transparency builds belief and belief drives behaviour.

The program’s success, Barclay said, comes from meeting people where they are rather than expecting instant change.

“We tailor our communication to different audiences – households, schools, businesses –because each group has different motivations,” she said. “You can’t talk to everyone the same way.”

From intent to action

As the panel reflected on what unites these experiences, a shared message emerged: behaviour change is not a single event but a process. Landells said that while policy frameworks set direction, real progress happens when systems, leadership, and culture align. She believes it’s about embedding sustainability into everyday decisions, something that doesn’t happen overnight. She argued that councils need to be realistic about capacity.

“We’re often asked to do more with less,” she said. “Collaboration becomes essential. Partnerships between councils, suppliers, and state agencies can pool resources and share learning. We don’t all have to reinvent the wheel.”

McGregor agreed, adding that collaboration also amplifies social proof. He believes that when councils work together, it changes the story. It shows this isn’t a fringe idea, it’s mainstream. He encouraged local governments to highlight their successes publicly and make case studies visible. The more examples that are highlights of what works, the faster the shift will spread.

When senior managers visibly support sustainable procurement and acknowledge its successes, that signal ripples through the organisation.”

For Barclay, the key is to stay focused on the human side of systems change.

“Procurement, recycling, resource recovery, they all come down to people,” she said. “If we can design programs that respect how people think and feel, we can make sustainability part of normal behaviour.”

Barclay also warned against seeing behaviour change as purely educational. Information alone doesn’t transform habits, she said. Conditions need to be created for people to act differently. Barriers need to be removed to encourage progress, make it easy, and celebrate progress. Her experience with community engagement showed that small wins often lead to larger ones.

Leadership, learning and lasting impact By the close of the session, the panel’s focus had shifted from theory to leadership. Landells spoke about the political realities of local government. She pointed out that elected officials have different priorities. It is up to industry to bring them along the journey by showing how sustainability aligns with community values and financial responsibility. When councillors see environmental procurement as good governance, not just good ethics, they are more likely to support it.

McGregor returned to the importance of framing.

“We should stop talking about sustainability as a cost,” he said. “Frame it as value; risk reduction, innovation, long-term savings. If we keep saying it’s expensive, people will believe it’s expensive. If we show it’s smart, they’ll believe that instead.”

Barclay added that leadership is not confined to formal titles. She said that everyone has

influence, w hether they’re a procurement officer or a community educator, those in the industry can model the behaviour they want to see. She described leadership as “contagious” – when one person acts with conviction, it encourages others to follow.

The discussion closed on a note of cautious optimism. Landells said she had seen a growing appetite within councils to align procurement with environmental goals.

“There’s a real desire to get this right,” she said. “We just need to support people with the tools, the data, and the permission to try new things.”

McGregor agreed. “Behaviour change isn’t mysterious,” he said. “It’s predictable. If we apply what we know about human psychology, we can design systems that make sustainable choices feel like the default.”

Barclay added the final word: “Change happens when people feel capable, connected and trust the system. If we can build those things, the rest follows.”

Across their different perspectives, Landells, McGregor and Barclay painted a coherent picture of what it takes to shift behaviour in sustainable procurement. The barriers are real with limited resources, risk aversion, and political pressures at the fore, but they are not insurmountable. Behavioural science, tailored engagement, and visible leadership can turn intention into action.

The conversation ended where it began: on the human element. Systems, policies and procurement frameworks matter, but change only takes root when people believe it can. As Barclay put it, “trust drives behaviour”.

Innovations headline awards night

THE WINNERS OF THE 2025 Waste Innovation and Recycling Awards (WIRA) were announced at a gala event held at the Melbourne Arts Centre. Innovators and go-getters came together to celebrate the resource recovery/waste industry’s highachievers. Congratulations to all the finalists and winners.

Winners:

Operational Excellence:

Tomra Cleanaway

TOMRA Cleanaway, led by CEO James Dorney, operates container deposit schemes across NSW, Victoria, and Tasmania. Since 2017, the team has returned over 14.6 billion containers, reducing litter and avoiding an estimated 1.5 million tonnes of CO₂. Recognised as a 2025 AFR Sustainability Leader, TOMRA Cleanaway uses advanced sorting technology, digital innovation, and community partnerships to transform recycling, with more than 1,000 collection points and nearly $86 million raised for charities.

Community Engagement Award

Sponsored by VISY

Surf Coast Council – Be a Good Sort campaign

Be a Good Sort: Know Your Bins initiative featuring a four-part video series that shows the journey of recycling, FOGO, glass, and general waste from home bins to their final destinations. The series highlights advanced sorting technology and the importance of correct bin use at home. By educating the community, the program reduces landfill waste, protects the environment, and keeps resources in use, contributing to Surf Coast Shire’s 71 per cent landfill diversion rate and promoting sustainable waste management practices.

TOMRA Cleanaway won for Operational Excellence.

Surf Coast Council won Best Community Engagement.

Young Professional of the Year

Sponsored by REMONDIS Australia

Dr Linda Mitchell – Tyre Stewardship Australia

Dr Linda Mitchell is the Science, Research and Innovation manager at Tyre Stewardship Australia and a nationally respected advocate for circular economy leadership. With a PhD in chemistry and a Westpac Future Leaders Scholarship under her belt, Mitchell is known for her ability to translate complex environmental science into practical, scalable solutions. Her work has reshaped national approaches to carbon accounting, product stewardship, and procurement standards, while amplifying the voice of science in public and policy discourse. She is a passionate communicator, mentor and role model — making technical pathways more accessible to women in STEM and the broader resource recovery sector.

Outstanding WARR Project: Regional Award Contained Waste Solutions and Gunnedah Shire Council

The Gunnedah Waste Management Facility in north-western New South Wales transformed its operations by implementing an LBin Waste Transfer Station. Previously, the public deposited waste directly at the landfill, creating safety and compliance challenges. Traditional waste transfer systems proved costly and underperformed in key areas. The LBin solution addressed these issues effectively, delivering safe, compliant operations.

The team from Contained Waste Solutions -Tobias (l) and Elliott Lacey (absent Jason Lacey).

The TSA’s Dr Linda Mitchell (l).

Resource recovery, sorted.

REMONDIS Australia helps 24,000 commercial, industrial and government customers meet their waste reduction, recycling and circular economy ambitions.

Our Integrated and Managed Services division is Australia’s largest environmental managed services provider, partnering with our peers to deliver innovative solutions for large organisations, national product stewardship schemes and major infrastructure projects.