INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS.

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The vehicle concepts for low-loaders are as varied as the transportation tasks. The use of air-sprung modules with rigid and steering axles is just one solution from our uniquely wide range of running gear systems for low-loaders. Challenge us!

Tari

Electronic Braking Systems (EBS) are becoming

in

e axle and suspension specialist celebrates nearly 80 years of

Central to Hendrickson’s current innovative portfolio is the

Premium Elastomer Suspension.

GORICA Group is creating a rm foothold in the Kingdom of Saudi Arabia through its passion for trailers.

“WE ARE ALSO PIONEERING ELECTRIFICATION AND SUSTAINABILITY IN THE MIDDLE EAST WITH A NEW LINE UP OF THERMO KING SOLUTIONS, SUCH AS E-COOLING UNITS AND E-POWERED SOLUTIONS THAT WE SUCCESSFULLY LAUNCHED IN JANUARY 2025.”

GORICA Chairman and founder, Ivan Fornazaric

Valk Welding enables more e cient production with innovative

An

I’m sure many readers would love to have a crystal ball to see where the future will take us. A detailed prognostication for the remainder of 2025 would come in handy for the world’s truck and trailer manufacturers, and allied industries, as they navigate their way through Q2 and beyond.

For the time being, the next best thing to a crystal ball are the market studies and research papers into the various sectors of the truck and trailer industries. e bulk of reports and studies from Q1 of 2025 have predicted a pleasing, but conservative, upward tick in industry growth across a number of sectors and geographical regions.

e Trailer Axle Global Market Report, published in January this year, revealed that the trailer axle market size will grow to $4.46 billion (€4.13 billion) in 2025 at a CAGR of 5 per cent. It predicts the global market will grow to $5.56 billion USD (€5.15 billion) in 2029, due to factors such as demand for electric and hybrid trailers, green initiatives and sustainability and integration of advanced safety features.

e ATA Freight Transportation Forecast 2024 to 2035 forecasts US trucking industry revenues to grow from an estimated $906 billion USD (€839 billion) to $1.46 trillion USD (€1.35 trillion). e European road freight sector is expected to have a 2.0 per cent uptick in 2025, while the Asia Paci c region is

estimated to contribute 52 per cent to the growth of the global road freight transport market from 2025-2029.

Navigating the plethora of industry reports and statistics can seem confusing, however the resilience and growth of the truck and trailer industries is increasingly underpinned by advances in technology and research. Forecast trends include customisation for urban mobility, integration of telematics & IoT technologies, AI machine learning, partnerships for innovation, reduced emission vehicles, modular systems and low maintenance designs to adapt to the changing markets, customer demands and regulations.

Market reports are useful reference guides for truck and trailer industries, but ultimately progress will come down to the proactive actions and strategies of the industry players in embracing innovations and technologies.

With the industry being literally on the go, I am convinced that companies operating in this sector will adopt the adage of ‘keep on trucking’, regardless of what the market reports predict. Will that result in new innovations being introduced to improve service and increase returns? Perhaps that crystal ball won’t be needed, as the in ux of new technologies continues to drive this global industry.

CEO John Murphy john.murphy@primecreative.com.au

COO

Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

EDITOR

Paul Lancaster paul.lancaster@primecreative.com.au

HEAD OF DESIGN

Blake Storey

DESIGN

Laura Drinkwater

CLIENT SUCCESS MANAGER

Isabella Fulford isabella.fulford@primecreative.com.au

COVER Image: GORICA Group

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

+61 3 9690 8766 enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Follow us on twitter @Globaltrailer

Transport and logistics company, Linfox India, has welcomed a new Country Manager.

Jaspal Singh Gandhi has accepted the leadership role and reports directly to the CEO of Linfox International Group.

“In this role, he is responsible for overseeing Linfox Logistics’ operations in India, driving growth, operational excellence, and strategic expansion,” Linfox said in a statement.

“With over 20 years of experience in supply chain and logistics, Jaspal is a results-driven leader specialising in driving profitability through business transformation.

“He has a proven track record of enhancing operational efficiency, optimising costs, and improving customer satisfaction through advanced logistics solutions, including Warehouse Management Systems (WMS), Transportation Management Systems (TMS), Load Planning, and Network Optimisation.

“Jaspal has successfully led cross-

functional teams across diverse regions, managing complex logistics projects that drive speed to market and business continuity.

“He holds a Master of Business Administration in Logistics from Lucknow University.”

Heil Trailer Asia has named Tony Pang as the company’s new Financial Controller. Effective March 2025, Pang will lead the OEM’s accounting and finance group.

Heil Trailer Asia President, Nicholas Ling, said the appointment will steer the business toward new levels of growth and success.

“With a wealth of experience in the automotive sector, Tony has a proven track record of driving significant results,” said Ling.

“He has effectively directed commercial and finance teams, streamlined financial systems and contributed to substantial growth across various organisations.

“His expertise in financial management,

system implementation and crossfunctional collaboration will make him an invaluable asset to our team.”

Heil Trailer Asia established a production facility in Bangkok, Thailand, in 1996.

This factory is reported to mirror the Heil Trailer Athens site in Tennessee, US.

At its Thai facility, Heil Trailer Asia builds aluminium and stainless-steel tankers and trailers for the Asia-Pacific region.

Heil Trailer Asia also announced the appointment of SixtyPlus Evolution Co., Ltd. (60+ Evolution) as its channel partner in Thailand.

“As a significant domestic tanker fleet operator and experienced trailer repair service provider, SixtyPlus Evolution is well-placed to provide high-level sales, aftersales, warranty, repair, REM parts, maintenance and upgrade services to Heil Trailer Asia customers in the Kingdom,” said Heil Trailer Asia.

“SixtyPlus Evolution operates a wellequipped facility in ‘Sri Racha’ Thailand, on the country’s eastern seaboard, a major trade and industrial hub.”

A state of the art, upgraded and fully integrated global manufacturing centre of trailer systems and On/Off highway systems. Expertly designed and engineered with worldwide accessibility, offering you private label and OEM manufacturing solutions.

Drawing upon decades of expertise spanning Asia, Australia, US, and in Europe, Fuwa stands as a global manufacturing powerhouse, unrivalled as the foremost network of specialists in truck and trailer components across the globe.

While DHL Group achieved substantial financial gains amid challenges in the last fiscal year, the logistics company plans to run a leaner, more efficient operation going forward.

Group revenue was up 3.0 per cent year-on-year in 2024 at €84.2 billion.

For Q4 2024, group revenue rose 6.4 per cent and operating profit (EBIT) grew 12.9 per cent.

However, EBIT was 7.2 per cent below the prior year figure at €5.9 billion (2023: €6.3 billion) but reported to be well above the pre-pandemic level of 2019 (€4.1 billion).

DHL Group CEO, Tobias Meyer, expects the global political and economic situation to remain volatile this year.

“We want to continue growing in this environment and are focusing on the measures we can control,” he said.

“We are actively increasing our efficiency and accelerating our sustainable growth ambitions with our group cost program ‘Fit for Growth.”

The ‘Fit for Growth’ program is part of DHL’s 2030 strategy which the company aims to become leaner and more efficient overall.

This will involve structural improvements to the cost base by more than €1.0 billion and includes various measures across all business units.

The full impact of ‘Fit for Growth’ is expected to be realised in FY27.

At Post & Parcel Germany, around 8,000 positions will be reduced in a ‘socially responsible’ manner.

“DHL Group is an attractive investment for shareholders,” said DHL Group Chief Financial Officer, Melanie Kreis.

“We underscore this with the dividend proposal and an extended,

topped-up share buyback program.

“We have a strong balance sheet and high financial performance.

“We expect to return to earnings growth in 2025 and are actively supporting this process with our ‘Fit for Growth’ program and targeted investments in future growth markets.”

DHL has a fourth strategic bottom line ‘Green Logistics of Choice’ to its existing ones: ‘Employer of Choice’, ‘Provider of Choice’ and ‘Investment of Choice’.

The group has anchored all components of its ESG Roadmap in the corporate strategy and is pursuing measurable goals in the areas of environmental, social and responsible corporate governance.

Logistics-related greenhouse gas emissions, for instance, are to be reduced to less than 29 million tonnes of carbon dioxide equivalents by 2030 despite considerable growth. Declining transport volumes and decarbonisation measures have helped DHL make progress with this initiative – 33.77 million tonnes of carbon-dioxide emissions for FY24 (2024 target value: maximum of 34.9 million).

Schmitz Cargobull has agreed to acquire a 48 per cent share in Polish OEM, GT Trailers.

The two companies intend to unite their expertise in designing and building superstructures on rigid chassis, including tarpaulin, boxes and refrigerated solutions.

The transaction is subject to approval by the relevant competition authorities.

“Schmitz Cargobull and GT Trailers are both family businesses, with a reputation for reliability and longevity

in the industry,” said Schmitz Cargobull CEO, Andreas Schmitz.

“Not surprisingly, because both companies offer galvanised chassis and bodies with anodised aluminium.

“By merging our innovation efforts and collaborating in sales we expect to increase the market share in the segment of high-volume combinations.

“At Schmitz Cargobull, we firmly believe that cooperation and strategic partnerships are key drivers of innovation and growth.”

Agata Duliniec, CEO of GT Trailers, said: “With our strong commitment to quality and sustainability, GT Trailers has become a trusted name in the transport industry. The cooperation with Schmitz Cargobull will position us for continued success in the years ahead. Through this partnership we pave the way for innovation in products, services and market development.”

Austrian logistics company, Gebrüder Weiss, is expanding its services in Poland.

Since the beginning of 2025, Gebrüder Weiss has been offering national and international partial and full truck loads as well as additional warehousing and logistics solutions including order picking.

The new services complement Gebrüder Weiss’ existing logistics, air and sea freight services on offer since 2020. As a result, the team is growing to 70 employees.

“Our goal is to offer companies in Poland with a first-class and comprehensive range of logistics services,” said Gebrüder Weiss Area Manager Slovakia and Poland, René Stranz.

“By combining different modes of transport, our customers will be able to react even more flexibly to market

requirements and make their supply chains more efficient in the future.”

Today, Gebrüder Weiss in Poland has branches in Krakow, Wroclaw, Gdynia and Warsaw. Its customers reportedly come mainly from the high-tech, automotive, consumer goods and e-commerce industries.

In addition to transport, the logistics provider also handles the storage and order picking of pharmaceuticals that require special refrigeration.

“Depending on how the economy develops, further locations are also possible,” said Gebrüder Weiss Country Manager Poland Land & Logistics, Maciej Szczyglowski. “For example, in Wroclaw or Katowice, where we can imagine new logistics terminals for goods handling.”

Refrigerated transport specialist, McCulla Ireland, has reviewed its latest

electric Schmitz Cargobull trailer.

The fridge has no combustion engine, according to the fleet, and is powered by an electric battery in conjunction with a generator in the middle axle which has three settings from eco setting through to max retardation.

“We have been running trials on this trailer on all work types and on runs right across Ireland and Great Britain,” McCulla Ireland said in a statement.

“To date, we are very impressed with this zero emission fridge supplied to us by our long term fridge trailer supplier.

“At McCulla we are continually innovating on way to make our already green fleet, even greener.”

McCulla Ireland, established in 1969, provides ambient, chilled and frozen logistics and storage solutions.

It is now a second generation familyowned business with three facilities based in Lisburn, Dublin and Mallusk.

Transport and logistics company, Aramex, has reported strong financial results due to higher shipment volumes and further gains in market share.

Revenue for Q4 2024 was 1.7 billion AED (approx. €442.3 million), 11 per cent up year-on-year.

Full year revenue was 6.3 billion AED which is also up 11 per cent (approx. €1.6 billion).

Aramex is reported to be benefitting from emerging nearshoring trends as businesses streamline supply chains by positioning inventory closer to key markets.

“Aramex has a clear competitive

advantage to cater to this trend, thanks to its integrated solutions,” said Aramex CEO, Othman Aljeda.

“We have gained significant volumes from several businesses that we have helped nearshore their stock in our key markets.

“Domestic volumes were up 11 per cent, international express volumes were up 20 per cent and our contract logistics business is operating near full capacity.

“What this means is that we are seeing more demand for local deliveries through our domestic express solutions, and a shift from long-haul cross border to shorter and intra-regional cross border activity through our international express product

and trucking business.

“Our margin profile has adapted accordingly, while the business continues to grow at healthy levels in absolute terms.

“Gross profitability for our consolidated international and domestic express product was up 8.0 per cent. Our contract logistics product also grew gross profitability by 8 per cent year-on-year, while freight forwarding was resilient with a 4.0 per cent decline in gross profitability due to increasing competition and industry pricing pressure as well as cost inflation.”

This year the business is focused on growth, scaling, maintaining operational discipline and driving innovation.

Canadian transport and logistics company, TFI International, aims to relocate to the US.

This follows ‘solid’ year-on-year performance amid ongoing challenging conditions according to TFI International Chairman, President and CEO, Alain Bédard.

“We generated more than $260 million of net cash from operating activities and over $200 million of free cash flow, bringing our full-year free cash flow to more than $750 million for a third year in a row,” he said.

“We reinforced our firm financial footing by reducing debt and executed targeted bolt-on acquisitions during and subsequent to the quarter, as well as additional share repurchases following the October renewal of our normal course issuer bid.

“We were also pleased to declare a 13 per cent increase to our quarterly dividend in December.

“Looking ahead into 2025, the skilled men and women of TFI International are intensely focused on continued strong execution in our mission to generate robust free cash flow and make strategic investments, especially during periods of reduced freight volumes, all while returning meaningful capital to shareholders and building long-term value.”

Total revenue for 2024 was $8.4 billion USD (2023: 7.52 billion USD). Revenue before fuel surcharge of $7.30 billion USD compared to $6.42 billion USD the prior year. The increase is primarily due to the acquisition of Daseke and is partially offset by decreases from existing operations due to weaker market demand.

US-based OEM, Pitts Trailers, has congratulated Brandon ‘B’ Wisenall – who has served as a Territory Sales Manager since April 2024 – on earning his Master’s in Business Administration.

B’s commitment to professional growth aligns with Pitts Trailers’ core values of excellence and continuous development. His dedication to sales leadership and industry expertise continues to drive success for Pitts Trailers and its customers.

“We’re incredibly proud of B for achieving this milestone,” said Pitts Trailers President, JP Pierson. “His drive and professionalism set a great example for our team.”

Pitts Trailers has been in business since 1976 and touts itself as the world’s largest and only complete line forestry trailer manufacturer offering logging trailers, hydraulic elevating load carrier trailers, open and closed top chip vans and moving floor vans.

The trailer builder also produces hydraulic removable neck lowboys,

fixed neck lowboys, hydraulic folding tail lowboys and construction grade tag-along lowboys.

Hyundai Translead has reinforced its commitment to delivering high quality transportation solutions following its partnership with Fleet Trailer & Equipment (FTE) in January.

FTE, headquartered in Brookside, Alabama, and founded in 2022, will serve as a full-service and aftermarket parts provider for Hyundai Translead.

“We are very excited to partner with FTE and welcome them to our dealer network,” said Hyundai Translead Senior Channel Development Partner, Allison Seol.

“FTE’s reputation for excellence and its strategic location in Alabama make them an ideal addition to our channel. We look forward to working together to serve the needs of our customers in the area.”

The partnership between Hyundai Translead and FTE reflects a shared dedication to addressing the changing needs of the market and delivering innovative solutions that prioritise customer satisfaction.

“We are excited and grateful for the opportunity to represent Hyundai Translead, and look forward to a strong, long-standing relationship,” said FTE CEO, Pres Overby.

“Hyundai has a proven record of building high quality trailers backed by exceptional service.

“FTE has a dedicated, experienced dealer team, state-of-the-art facilities and a solid, customer focused process. Together, this partnership will be strong and tough to beat.”

Brazil-based OEM, Randoncorp, announced its acquisition of AXN Heavy Duty in January.

This follows the company’s internationalisation strategy to expand its auto parts portfolio presence in developed economies.

For the past 16 years, AXN has distributed axle and suspension systems for semitrailers in the US.

“AXN arrives to contribute to one of the company’s focuses in offering increasingly innovative solutions to the market,” said Randoncorp EVP International, Anderson Pontalti.

Randoncorp CEO, Sérgio L. Carvalho, said:

“We continue to expand our international presence in resilient markets, bringing the group’s expertise in developing complete mobility solutions.

“The acquisition of AXN is a successful step to strengthen the operations of our companies in the North American market, this time through auto parts for the OEM semi-trailer segment.”

Hamburg-based transport and logistics company, Hoyer Group, has acquired Chilean company Inter-Tank.

This strategic acquisition, according to

Hoyer Group CEO Björn Schniederkötter, will strengthen Hoyer’s market position in Chile, its global network as well as its capabilities in the liquid bulk and flexitank logistics sector.

Paco Koudstaal, Regional Director Latin America of the Hoyer Group, added: ”We are excited to integrate Inter-Tank’s expertise and welcome over 30 new colleagues with extensive experience in Chile’s wine and oil markets.”

Philip Fell, Commercial Manager of InterTank, also commented on the partnership: ”Being a part of the global network of the Hoyer Group will create additional valueadded for our customers.”

Durban-headquartered OEM, Serco Industries, has designed and manufactured a walking floor trailer for a waste removal company. This walking floor trailer, a first for Serco, features a unique upper structure, built using high-strength composite facings with a reinforced core. This provides a light weight, high strength yet cost-effective alternative to the traditionally imported aluminium extrusions used in similar trailers.

The 15.4m trailer, Serco said,

is loaded through an open-top design and secured with a rollover tarpaulin to ensure safe and contained transportation.

“The new walking floor trailer is a part of our diversification strategy, allowing us to broaden our product range and bring innovative solutions to a wider market,” said Serco CEO, Clinton Holcroft.

“By engineering smarter, costeffective alternatives, we continue to support our customers with the most efficient and high-quality transport solutions available.”

Serco specialises in the design and manufacturing of insulated and dry freight truck bodies and trailers.

These trailers, according to Serco, are relied upon by Southern Africa’s leading transporters and long-distance hauliers to carry everything – safely and hygienically – from ice cream and day-old chickens to beef and bread.

In addition to its Durban head office, Serco also has branches in Johannesburg, Cape Town and Gqeberha.

Following positive momentum in financial performance, New Zealand company, MOVE Logistics Group, has promoted its interim CEO.

Paul Millward has been named CEO of MOVE, effective 28 February 2025.

“In the past six months as interim CEO, Paul has demonstrated his passion for MOVE alongside strong leadership and is making good progress on the transformation program and the shift to a high performance culture,” said MOVE Chair, Julia Raue.

“His appointment reflects the

Board’s confidence in his ability to lead the organisation in achieving transformational change and delivering value to stakeholders, as demonstrated by a significantly improved 1H25 result.”

For the six months ended 31 December 2024, total income was $150.7 million NZD (approx. €83 million) – down 5.0 per cent compared to 1H24 but ahead of 2H24.

“MOVE is an iconic New Zealand business and I’m privileged to be stepping into the CEO role on a permanent basis,” said Millward.

“While there is still work to be done,

we are making good progress.

“I’m looking forward to leading MOVE through its next phase and unlocking sustainable value in our business for our team, our customers and our shareholders.”

info@versus-omega.com www.facebook.com/versusomega www.versus-omega.com

THE KINGDOM OF SAUDI ARABIA IS THE LARGEST NATION IN THE MIDDLE EAST WITH A GDP OF ABOUT €977.495 BILLION AND THE GORICA GROUP IS CREATING A FIRM FOOTHOLD IN THIS DESERT NATION THROUGH ITS PASSION FOR TRAILERS.

Dubai-based GORICA Group’s approach to its trailer operations can be seen to mirror that of the UAE’s successful initiative when dealing with other nations. e oil-rich nation has cleverly used its reputation as a trading hub at the crossroads of society to forge lasting and rewarding partnerships and ventures with a myriad of countries to exponentially grow the small Middle East nation.

roughout the course of its operations GORICA has reached out companies in various companies, seeking to utilise their respective expertise in a range of allied industries – from Oil and Gas, general cargo trailers, dry bulk semi-trailers, road tankers semi-trailers, concrete mixers, refuse collectors, to semi-trailer tipper bodies.

e company that started almost four decades a er the formation of the UAE, has taken a leaf from its host’s playbook, and is reaping the rewards of a forward-thinking approach to business growth, through strong and lasting partnerships and collaborations.

e UAE is renowned for its approach to business and commerce – do it with complete focus and with passion. GORICA has taken the same approach to its burgeoning business operations – do it with a passion for trailers and innovation.

e latest stage of development for the Dubai-based company has seen it combine its approach to innovation with another market leader – in the Kingdom of Saudi Arabia (Saudi Arabia).

GORICA’s leveraging of cutting-edge technology, coupled with industry expertise, and a commitment to quality, has seen it provide tailored solutions for operational e ciency, enhanced value, and long-term success of its partners across cold chain logistics of perishable goods. Hence, its market presence has grown to where GORICA Industrial KSA was appointed in November 2024 as o cial authorized dealer for ermo King’s operations in Saudi Arabia. ermo King is a world-leading manufacturer of cooling units for the transportation industry. e appointment comes a er the GORICA Group signed an OEM strategic partnership agreement in 2023, for GORICA leading refrigerated semi-trailers/bodies, THERMO KING cooling units and PALFINGER tail li s to be supplied across the Middle East Africa (MEA) region, as a fully integrated end-to-end solution.

For GORICA Chairman and founder, Ivan Fornazaric, the agreement with ermo King KSA is another piece in the company’s vision to further expand and grow as leading MENA developer and manufacturer of a complete range of trailers, tankers and more.

“ is close partnership means a lot for both partners, as innovation and market leaders. Together, we o er fully integrated solutions for perishable goods transportation as turnkey solutions,” he said.

“ is is a special recognition for the GORICA Group allowing also horizontal market penetration and for ermo King it means additional market share growth in Saudi Arabia and the ability to tap into new market segments where GORICA is strongly present, including Pharma and institutional clients, such as the UN, UNICEF, the Red Cross and the defence sector.”

GORICA’s General Manager of Sales and Marketing, Domen Bockor said: “It’s a positive, disruptive strategy of traditional, legacy channels as markets have evolved from sell-buy process to solution-based sales, focusing on total cost of ownership.”

As an authorised ermo King dealer, GORICA will provide the following services to its partners and clients:

• Supply of the new ermo King cooling unit, including mounting and commissioning for all

the refrigerated bodies, refrigerated semi-trailers and special application temperature-controlled bodies/trailer.

• Full warranty support and repairs, as per ermo King’s international warranty policy

• A er sales service

• Genuine spare parts supply

• Client/operator training

• All connectivity and telematics for ermo King solutions

• Fleet maintenance contracts

Bockor said the partnership with Thermo King is creating a ‘winning formula’, comprising “the integration of products and services, such as connectivity services, extended warranty programs and maintenance agreement bundled in single client package”.

Fornazaric said GORICA was leading the eld with its approach to innovation in refrigerated transport.

“We are also pioneering electri cation and sustainability in the Middle East with a new line up of ermo King solutions, such as e-cooling units and e-powered solutions that we successfully launched in January 2025,” said Fornazaric.

GORICA’s expanding presence in Saudi Arabia has meant it now has a greater foothold in the Middle East market, with Fornazaric noting its refrigerated semi-trailers market share in the GCC countries, including Saudi Arabia, is now between 65-70 per cent of all newly sold refrigerated semi-trailers, excluding second-hand imports from the EU.

“GORICA’s market share is predominately driven by our technical speci cations with GRP skin single piece, seamless insulated panels with no joints, and our ve-lip gasketing system. e combination with ermo King’s cooling unit makes a natural choice focused not only on CapEx, but also OpEx with the lowest total cost of ownership in the industry. In addition, our award-winning a er sales support is a key element in the growing market share,” said Fornazaric.

e collaboration between the GORICA Group and ermo King has been a symbiotic meeting of minds, harnessing innovation in refrigerated transport to meet communities’ needs for fresh, safe and lasting products, such as food and medicines.

Domen Bockor said it was both companies’ recognition of these needs, coupled with growing sustainability requirements, that has proven to be a winning combination.

“ e demands on the sustainability of transport are increasing and with rising costs of diesel

and fuel, even in the Middle East along with strong transportation sustainability initiatives in Saudi Arabia, the demand for innovative green solutions is fuelling demand,” said Bockor said.

“ is requires pioneers, like GORICA to be the rst in the MEA region to develop innovative solutions. It is another proof that teamwork and partnership approaches in our industry are the key to success.”

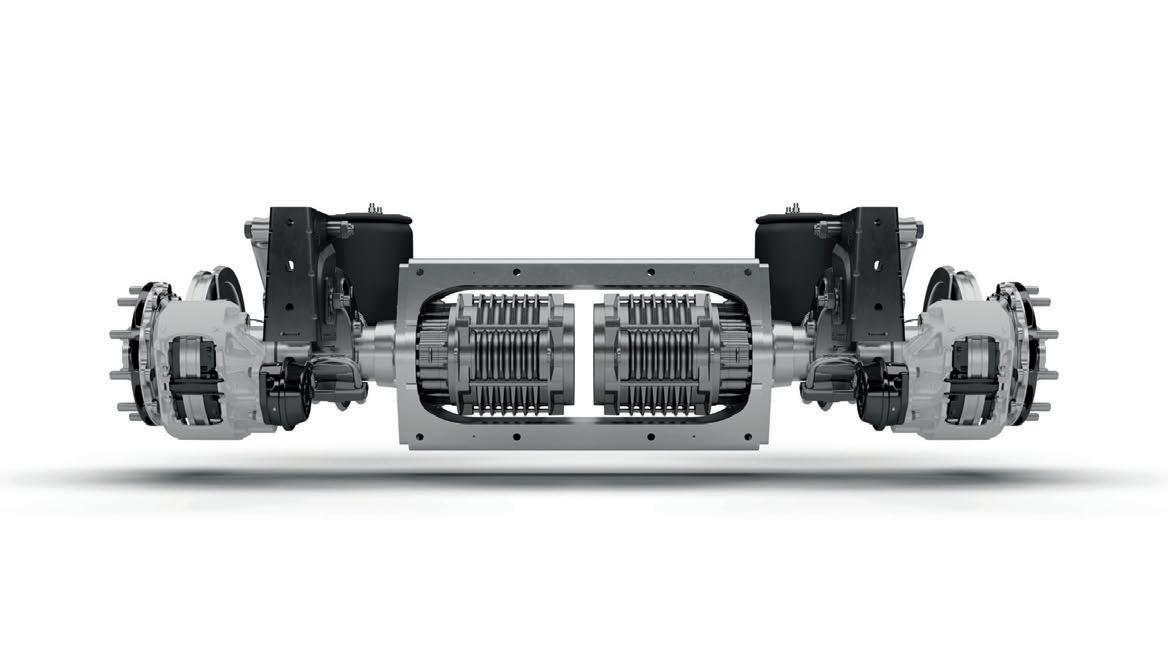

is productive partnership has already bore fruit, with the launch of the MEA region’s rst e-powered refrigerated semi-trailer, developed in conjunction with BPW axles, and which has been sold to Almarai, the largest dairy manufacturer in the MEA region and one of world’s largest.

In a huge win for the Saudi-based dairy giant with interests across the GCC, the new production saw the innovative BPW axles and ermo King’s cooling unit/battery pack solution installed on a GORICA refrigerated semi-trailer, bringing sustainability to a new level by eliminating the use of fossil fuels to run the cooling system, thereby producing energy with zero consumption of diesel.

At the forefront of the design and development process, which took GORICA’s design and engineering teams almost a year to complete with the ermo King and BPW engineering/ product teams, was to create a trailer that would operate e ectively in the Middle East’s harsh weather conditions. Collaboratively, the teams were able to overcome any obstacles, driven by GORICA’s ‘passion for trailers’.

Additional paramount factors for a viable solution were sustainability, with reduction and/or elimination of fossil fuel to run the cooling system, the reduction of CO2 emissions and the ROI for all stakeholders.

e nished product saw the combination of the new e-powered axles and a complete 34kW battery pack integrated into the 16 metre-long, GORICA trailer chassis. e trailer itself broke new ground in that it was almost three metres longer than standard trailers in Europe.

Bockor described the three-way venture as a “natural choice to combine heads of all three partners and bring the solution that market was calling for”.

“We truly believe that sustainability, in order to be accepted by the market, must be commercially viable and not only as a marketing tool,” said Bockor.

“This is crucial in all GORICA Group innovations and development. All this has been also achieved without any impact on payload due to innovative chassis design despite there is additional 34kW double battery pack and extra generators on drive axles.”

For the GORICA trailers, e-power is used in a new axle module developed by BPW which converts wheel rotation into energy and temporarily stores it in a backup battery before feeding it into the system, as needed. is enables a carbon-neutral, quiet supply of power to the ermo King refrigeration units for temperature-controlled transport.

Two generators are used to provide double the power and reliability, while intelligent energy management ensures that the ermo King cooling system always has access to sufficient battery reserves – even on long journeys or in tra c jams. Recuperation (i.e. braking) also recovers lost energy and feeds it back into the system and, crucially, a major bonus of the new e-power system is it does not carry current until it is inputted by the inverter. Moreover, the two generators only supply the amount of energy that is really needed at any given time.

One of the most signi cant bene ts of the new system is the saving of up to 4,000-litre fuel and 10 tonne of CO2 per annum, per trailer. Other key features of the new E-powered trailer include the following:

• Reliable, independent power supply for fully electric or hybrid refrigeration units

• Self-charging on the road –no logistics operational changes

• Intelligent energy management and e cient operation

• 3-4 years’ ROI

• Two axle generators for double power

• More (failure) safety redundant system

• Generators for long life out of the automation area

• Equal torque on both wheels (equal wear)

• No di erential meaning more e ciency and higher e ectiveness

• Safe disconnection in critical driving situations (e.g. EBS)

• Four operating modes for optimum adaptation to the respective driving situation

• Generator power adapted to demands and the driving situation, avoiding additional consumption as much as possible

• Full-autonomous supply

• No additional maintenance intervals

• Hybrid or full-electric refrigeration units

• Battery autonomy (8 hours)

• Real-time monitoring for status information, geofence and fault diagnosis via ermo King tracking system

• Future proof investment and competitive TCO

With GORICA’s e-powered trailer in operation since February 2025, the scores on its performance have already been extremely impressive.

Feedback from eld tests and the rst year of commercialization has been that end-customers of the trailers have had their expectations met, reporting great ease of installation and use at the unit level, as well as ease of use at the eet manager level for tracking and organisation of delivery journeys.

Strong performance with refrigeration and energy usage, coupled with quiet operation and reliability,

were also reported. While the ease, or lack, of maintenance scored highly with the system’s end-operators.

“We are thrilled with the performance and the results. Basically, not a single litre of diesel was consumed to power the ermo King Advancer A500 cooling unit that is used on GORICA 16 metre-long refrigerated semi-trailer,” said Fornazaric.

Its latest foray into Saudi Arabia may be seen as a game-changer for the refrigerated transport industry, but for GORICA the need for constantly innovating and evolving never stops, as the increased development and expansion of the GCC region continues to drive new technologies in the transport industry that are focused on sustainability.

As with the growth of nations like Saudi Arabia, the UAE and Oman in the region, GORICA’s own growth appears to be going to greater heights.

“ roughout the years as a leading developer and manufacturer of transport solutions in the MEA & GCC regions, the GORICA Group has launched several innovations in the commercial vehicle transport industry,” said Fornazaric. “We have already new projects in the development pipeline now, more than even focused on electri cation, telematics and hydrogen in cooperation with our OEM European partners.”

www.goricagroup.com

SMOOTH SAILING AHEAD OR NAVIGATING BUMPY ROADS? WHAT YOU NEED TO KNOW ABOUT AMERICA’S ROAD TRANSPORT AND LOGISTICS NETWORKS IN LIGHT OF TARIFFS AND TRUMP’S HISTORIC ACTIONS.

Semi-trailer trucks on the Nevada Highway. Image: CK/stock.adobe.com

The US’s transportation sector – primarily its road and logistics industries – has long been at the forefront of America’s economic prosperity. e nation has long been proud of its trucking industry that keeps Americans moving, connected, fed, clothed, healthy, entertained and employed. However, it is an industry that is facing an uncertain future due to a number of factors, as well as the spectre of tari s being implemented by the current Federal Administration against Canada, China and Mexico.

America has long relied on its transport industry to connect people with goods and services across its vast land. In the early 1800s, the National Road was the rst highway built entirely with federal funds, opening up the Midwest for settlement and commerce. is led to greater westward movement of people and goods, thus expanding the United States to what it is today.

e US road network and transportation services have long driven the growth and expansion of the country – connected by an interwoven network of roads, highways and railways. ey facilitate the rapid movement of people and goods from coast to coast. is has resulted in increased urbanisation, economic growth, industrialisation, and connectivity between communities, towns and cities. e result is that today, the US road freight industry is responsible for moving over 70 per cent of all domestic freight.

A ourishing transportation sector is therefore vitally critical to the nation’s economy. Not only does it connect homes, workplaces and communities, it connects manufacturers with supplies and consumers with essential goods and products.

A er taking a huge hit during the Covid-19 pandemic, the transportation and allied industries employed more than 16 million people across the US in 2023, which accounted for about 10 per cent of the US workforce. In addition, in 2023, transportation services contributed approximately $2.5 trillion to the US gross domestic product.

However, despite it being a powerhouse for America’s continued economic stability, the transport and logistic sectors are facing an uncertain future. According to a November 2024 article by the Manhattan Institute the US’s transportation system is at the ‘crossroads’ and facing a challenging and possibly precarious future, including “rapid changes in technology, values, culture, demographics, … transportation funding shortfalls and a backlog of needs for aging infrastructure.”

e latter of these has seen a plethora of accidents and delays caused by failing road and rail infrastructure, including the 2023 train derailment in East Palestine, Ohio, the Baltimore Bridge collapse and more. Such disasters have a deleterious impact on the nation’s ability to transport goods and services across America.

Added to these issues are the vexing topics of chronic shortages of quali ed drivers in an industry where they are being driven away due to uctuations in fuel prices, high operating costs, long hours and reduced returns. Coupled with this are cost of living issues and reduced consumer con dence, where the cost of eggs has been a topic of debate and anger domestically in what many see as a symptom of the global cost of living crisis confronting many governments. ese venerable industries are also facing challenges related to global supply chains, such as port congestions, as well as tougher safety and environmental regulations and the growing focus on reducing greenhouse gas emissions from vehicles, coupled with an increased push for the adoption of electric trucks and alternative fuels.

According to the US Environmental Protection Agency (EPA), “climate change can disrupt

transportation networks, stress infrastructure, and pose safety risks to people.” It cites the rise in sea levels, changes in precipitation, extreme weather conditions, and heat uctuations as major threats to the e cacy of transportation and logistics systems.

e Manhattan Institute added that, in addition to the concerns related to labour shortages, aging infrastructure, climate change, economic conditions, America’s transportation sector is also having to come to grips with issues of “electri cation, automation, and application of arti cial intelligence.”

e report also stated: “Technology has enabled significant changes in transportation, such as rapid increases in work-from-home participation, e-commerce utilisation, and technology-enabled services and business models (for example, everything from ride-hailing and e-bikes to computer-enabled logistics, payment, and scheduling capabilities for person and freight transport).”

e rapid rise of online shopping, increased demand for rapid deliveries, as well as the automation of freight handling in organisations, such as Amazon, have placed further strain on the trucking and transport industries.

But it hasn’t been all bad news for the transportation industry, with the National Retail Federation showing monthly inbound cargo for 2024

outperforming the 2023 volumes, with levels over two million Twenty-foot Equivalent Units (TEUs) anticipated for a sustained period. In addition, the US Bureau of Labor Statistics showed the in ation rate as of June 2024 was 2.97 per cent, similar to June 2023, but much lower than the June 2022 peak of 9.06 per cent.

Road transport industry stakeholders also have reason to feel buoyant, with the announcement on March 12, 2025, by the EPA that it is undertaking 31 historic actions, which includes reconsideration of electric vehicle mandates and truck emissions standards, in an e ort to save the American economy trillions of dollars in regulatory and compliance expenses.

As part of its reviews of current practices, the EPA will review the ‘Clean Trucks Plan’, which includes the 2022 Heavy-Duty Nitrous Oxide (NOx) rule. at rule, created under the Biden Administration, will reportedly result in making goods delivered by trucks, such as food and household items, more expensive.

Lee Zeldin, EPA Administrator, said the ra of plans was part of the Trump Administration’s ‘Power the Great American Comeback’, to “to drive down cost of living for American families, unleash American energy, bring auto jobs back to the US and more.”

American Trucking Associations President, Chris

Spear, has praised the Trump Administration for the plan to reopen the Phase 3 Greenhouse Gas emissions standards (GHG3), as well as the review of the federal NOx standard.

“GHG3 in its current form is unachievable given the state of battery-electric technology and the sheer lack of charging infrastructure,” said Spear.

“ is rule has been an albatross for the trucking industry, threatening to reduce equipment availability, increase costs for businesses and consumers, and cause major supply chain disruptions.”

Spear said the trucking industry is keen to see a revival of a working partnership with the EPA that will improve emission standards and boost the transport sector.

“Cra ing a new national rule will prevent states like California from attempting to make an end run around the administration, creating a patchwork of impossible mandates that would jeopardise our economy,” he said.

Spear said the proposed changes to the GHG3 by the EPA, would result in 60 trucks today emitting the same amount as one truck manufactured in 1988.

e Truckload Carriers Association (TCA) has also welcomed the EPA’s review of the GHG emissions standards for heavy-duty vehicles and a goal for “practical and achievable emissions standards”.

“As a founding member of the Clean Freight Coalition, TCA has worked diligently to ensure that federal emissions policies re ect real-world operational and economic considerations,” it said in a statement.

e current action by the EPA comes a er the previous Agency announced, in March 2024, its “Greenhouse Gas Emissions Standards for Heavy-Duty Vehicles – Phase 3,” that set higher standards to reduce greenhouse gas emissions from heavy-duty (HD) vehicles beginning in model year (MY) 2027. Opponents to these stronger standards have argued that increased emissions reduction requirements for nitrogen oxide would result in substantial and exorbitant costs to a new Class 8 tractor.

e Trump-era EPA has won industry praise for the extensive reviews, which will also look at Greenhouse Gas Emissions Standards for Heavy-Duty Vehicles, as well as a reconsideration of light-duty, medium-duty and heavy-duty vehicle regulations that were the foundation

for the Biden-Harris electric vehicle mandate. It is estimated that the EPA review could save $700 billion in regulatory and compliance costs that otherwise would have led to higher consumer prices on goods transported by trucks. As a result, the proposed changes are being billed by the current EPA as the “greatest and most consequential deregulation in the history of the United States.”

“ATA looks forward to working with the Trump Administration to develop realistic, technology-neutral federal emissions standards that will bene t our environment, preserve and create jobs and set our industry and supply chain up for success,” said Spear.

Despite the EPA’s welcomed action and reviews with respect to Greenhouse Gas Emissions Standards, there is a dark cloud looming over the future prosperity of the transportation and logistics industries in the form of the US Government announcing 25% tari s on imports of many goods from Canada and Mexico, including cars, trucks, steel and timber, and which are to take e ect from 2 April 2025.

Combined with the immediate retaliatory actions of Canada and Mexico, the tari s’ impact on the trucking industry could be signi cant, with the potential to depress near-term truck volumes and, over time, reshape commercial vehicle manufacturing.

Despite Canada and Mexico retaliating with similar tari s on US goods, industry experts view the American tari s as highly impactful on the Medium Heavy Commercial Vehicle (MHCV) industry, particularly trucks and buses in the gross vehicle weight (GVW) Classes 4-8, or above 14,000 pounds. e tari s could undo the work of USMCA trade agreement, which saw the share of commercial trucks imported from Canada and Mexico accounting for almost 33 per cent of new-vehicle demand in the US. Moreover, more than 40% of the heavier Class 8 trucks sold in the US are imported from Canada and Mexico.

In addition to those sanctions, in February 2025, the US O ce of the United States Trade Representative (USTR) published its proposed actions under Section 301 of the Trade Act of 1974 (Section 301) to address the harm it saw being incurred by the US due to China’s seeking to dominate the maritime, logistics and shipbuilding sectors.

e USTR proposes to impose signi cant port fees on Chinese maritime transport operators and operators with current eets of Chinese-built vessels and requirements for the increased use of US vessels to carry US goods in coastwise and international transport from US ports.

e USTR has proposed the following fees and restrictions on services:

Chinese transport operators will be charged: up to $1 million USD per vessel entrance to a US port; or up to $1,000 USD per net tonne of the vessel’s capacity per vessel, per vessel entry to a US port.

Transport operators with eets comprised of Chinese-built vessels will be charged: up to $1.5 million USD per vessel entrance to a US port; or based on the percentage of Chinese-built vessels in an operator’s eet; or an ‘additional fee’ of up to $1 million USD per vessel entrance to a US port if the number of Chinese-built vessels in the operator’s eet is equal to or greater than 25 per cent

e potential of high port fees on Chinese vessels entering US ports could lead to increased costs for importers and exporters, supply chain disruptions, together with possible retaliatory measures from China. If implemented this could a ect global trade ows and impact businesses that rely on sea transportation.

e USTR is inviting comments from the public on the proposed Section 301 actions, intending to hold a public hearing on 24 March 2025 at the International Trade Commission. is comes a er the US Chassis Manufacturers Coalition recently led petitions alleging traded imports of chassis from Mexico, ailand and Vietnam threaten the American chassis industry.

e petitions claim that producers in Mexico and ailand receive an unfair bene t from numerous countervailable subsidies, which, depending on the country, may include tax exemptions and/or incentives, duty exemptions, preferential lending, grant programs, state-level investment programs and other support.

While the US transportation and logistics industries are certainly at the crossroads of their future growth and sustainability due to the array of factors, the industries are by no means being given the nal rites. ere will always be a need for transport services across America – the expansive nation that is devoted to mobility and all associated industries and services. As the Manhattan Institute study found:

“Mobility has long motivated both public and private investments in transportation facilities and services.”

e future of transport in the US will require a uni ed, all-of-stakeholder, bipartisan plan of action to ensure that the industries weather the current storm and move forward, ensuring the future and viability of industries that have been the backbone of America’s growth and prosperity for the past 150 years.

www.globaltrailermag.com

THE BURGEONING SUITE OF THE JOST PRODUCT PORTFOLIO, INCLUDING ROCKINGER, TRIDEC AND HYVA, IS TAILOR-MADE TO MEET THE DEMANDS OF SPECIALISED, HEAVY HAULAGE TRANSPORT NEEDS.

The transportation of massive, substantial and large parts and equipment, such as turbine blades, bridge elements, machinery or prefabricated modules, does not pose an unsolvable issue to JOST. Even faced with di cult road conditions, there is a solution at hand with JOST products, relying on high-quality, precision products under its JOST, ROCKINGER, TRIDEC and Hyva brands.

e ROCKINGER brand comprises the core components of towing hitches (including manual hitches), traverse and towing eyes, hitch support, drawbar eyes and drawbars for transporters and trucks. ROCKINGER products are also used in agricultural applications and equip agricultural vehicles from hitches to three-point linkages. e TRIDEC brand o ers steering systems and axle suspensions for trailers.

JOST’s 2025 acquisition, Hyva complements JOST’s portfolio with its globally recognised transport solutions for commercial vehicles. Hyva products are used worldwide across a range of sectors, including on-highway transport and o -highway agriculture, construction, mining, and environmental services. Hyva provides a range of products from tipping solutions, container handling, loader cranes and truck and trailer needs. It is the world’s leading producer of front-end tipping cylinders and o ers a full range of underbody and double-acting cylinders, truck and trailer components, container li ing systems (hook loaders and skip loaders),

waste handling solutions, and truck-mounted cranes. JOST’s Quicke brand specialises in agricultural front loaders and equipment and extends to also include products for the mining, construction and forestry machinery industries.

In the heavy haulage transport sector, JOST’s stable of brands o er the following specialised solutions:

JOST provides a range of components for high and maximum load conditions, such as the heavyduty h wheel coupling JSK50 made of cast steel. is is designed to be used for the highest loads, with imposed loads up to 50 tonnes. en there is the JSK52 – JOST’s super heavy-duty h wheel coupling for use with imposed loads up to

74 tonnes. It is particularly suitable for the mining industry. Both the JSK50 and JSK52 h wheels are speci cally designed to easily handle di cult and challenging transport conditions, using the robust JOST King pins with a diameter of 3 1/2”.

JOST has also created its JSK38CX, speci cally for rugged conditions in the Brazilian and Australian markets. e 90mm heavy-duty cast h wheel o ers unmatched strength for heavy-duty applications and with its 2-point sensor technology, truck drivers will bene t from enhanced safety and reliability. Additionally, pneumatic operation provides greater comfort when uncoupling and coupling, reduces manual e ort and increases e ciency.

Another solution for specialised transport is JOST’s Modul CH heavy-duty landing gear. Advantages of the Modul CH include maximum resistance to bending due to its outer reinforcement and reinforced inner tube; heavy-duty bearing for better shock resistance; and increased static test load (66 tonnes). It also has a full-length back plate for high mounting variability and is also available with two-side operation and special crank.

JOST’s modular systems provide a great variety of tailor-made solutions and adaptation of JOST leadings axles to the individual use case. For example, load-supporting axles for all 6x2 and 8x4 vehicles can be handed-over customer-speci c and are also available with an arched axle tube as a leading axle, particularly with short wheelbases.

JOST’s rst product – the ball bearing turntable – produced with great success in 1952 at its NeuIsenberg factory has also been modi ed and adapted for use in the heavy transport eld. Today, using hi-tech technology, the double-row ball bearing

turntable is extremely robust, strong and durable. e extra-large support balls transmit the axial loads over a wide area directly onto the vertical bar of the ring parts. Horizontal forces, in pull or push direction, as well as the moment load resulting from braking and centrifugal forces, are supported by the interplay of the two ball rows. A specialised e-coating on the turntable ensures outstanding corrosion protection.

e ROCKINGER RO56E – a heavy-duty towing hitch for regular special transport applications up to 500 tonnes – has shown that heaviness is not an issue when transporting large equipment, particularly as it is suitable for all types of special transport trailers. e RO56E’s hinged hitch head allows towing eye swivel angles, ranging between -58° and +35°, as well as with poor terrain. However, if more towing power is needed to meet the highest demands in the special transport, ROCKINGER o ers the RO58 - the world’s only automatic towing hitch with a trailer load of 1,000 tonnes. With 300 kg net weight, the RO58 is robust, but designed to be highly user-friendly with its ease of operation with a hand lever. e automatic towing hitch is approved for use in road tra c. Additionally, as counter pieces for the RO56E and RO58, ROCKINGER o ers matching heavy-duty towing eyes.

Properly engineered mechanical, hydraulic or electronic steering systems, as well as wheel and axle suspensions, are needed when building specialised vehicles for speci c applications. is is where TRIDEC excels, developing and manufacturing bespoke steering and axle solutions for clients’ transport challenges.

TRIDEC’s hydraulic steering systems are primarily installed in specialised transport vehicles and vehicles of exceptional length or width. Due to the signi cant dimensions of these vehicles, installing a steering system is o en necessary to satisfy legal requirements. Hydraulic steering is exceptionally well suited for extendable trailers, as there is no mechanical linkage between the h wheel and the axle. Optional manual steering by wireless remote control further contributes to the vehicle’s manoeuvrability.

One of its innovations in this sector is the TRIDEC Tritronic Trailer Management System, which supplements the hydraulic TRIDEC steering and suspension systems. Tritronic o ers unique functionality, ease of operation and safety in special transport applications. e highperformance remote control for operating various trailer functions includes manual steering, automatic tracking, automatic ride height control, ramp control, gooseneck control, hydraulic landing gear, warning lights and much more.

Another innovative solution, particularly for low loaders, is the TRIDEC swivel axle suspension TP-O Low. With suspension travel of 600 mm, the TP-O Low o ers the lowest ride height with 12 tonnes per axle line, combined with a greater steering angle than any other suspension solution.

Hyva o ers a wide range of tipping solutions tailored to meet diverse heavy haulage needs. Its selection of front-end and underbody cylinders, available with wet kit options, is designed to provide reliability, safety, and e ciency, even in demanding conditions. As part of Hyva’s commitment to supporting the mining industry, it also includes a comprehensive range of mining cylinders, such as the Alpha UHD-PRO front-end cylinders and twin USE underbody cylinders, built for heavy-duty applications with load capacities of up to 160 tons. Additionally, Hyva has introduced its latest hydraulic suspension cylinder, developed speci cally for hydro-pneumatic suspensions on wide-body mining dumpers.

www.jost-world.com

SOUTH AFRICA AND BPW ARE DRIVING THE SUSTAINABLE COLD CHAIN REVOLUTION WITH THE EPOWER GENERATOR AXLE.

BPW’s fruitful, 63-year association with South Africa continues at pace with its latest venture that sees innovation once again go hand in hand with tradition to reap rewards.

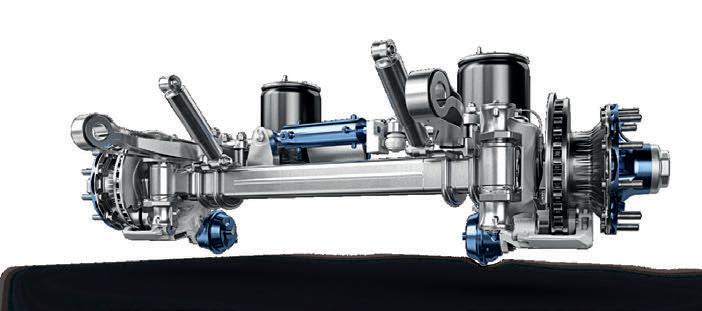

e year 1962 marked BPW’s rst foreign venture outside Germany – to South Africa. is was followed by BPW establishing its own development and production facilities in 1990, complemented by its extensive service network to countries across the whole of southern Africa.

In alignment with the diverse geography of southern Africa, BPW’s range of sturdy solutions was equally diverse and customized to be ‘ t for purpose’, depending on the particular industry.

As a result, BPW supplies axles for the gigantic tipper trailers used in the African mining industry, while also providing high-tech innovations, such as ‘ePower’ for emission-free refrigeration logistics.

BPW has now launched an ‘ePower’ generator axle in Africa to help drive the sustainable cold chain revolution that is gaining rapid momentum in growing countries, such as South Africa. With its strategic presence in the South African market, BPW is steadfastly aligned to incorporating innovation and technology with its most recent market solution.

e ‘ePower’ electric generator axle, which is an integral part of ermo King’s AxlePower system, is an example of the company’s commitment to anchoring technological advances in operational reality.

The ‘ePower’ electric generator axle, which is an integral part of Thermo King’s AxlePower system, is an example of the company’s commitment to anchoring technological advances in operational reality.

By harnessing energy from braking and driving, in order to power emissionfree cooling units, BPW addresses both environmental concerns and practical operational needs.

The success of ‘ePower’ in rigorous real-world testing – including a 20-week continuous cooling period powered by energy generated during normal operations – speaks to its viability for harvesting energy for sustainable refrigeration.

Harnessing energy from a vehicles’ continual braking and driving to power emission-free cooling units, BPW addresses both environmental concerns and practical operational needs.

e success of ‘ePower’ in rigorous real-world testing – including a 20-week continuous cooling period powered by energy generated during normal operations – speaks to its viability for harvesting energy for sustainable refrigeration.

In South Africa, it’s not just world-class nature, wildlife, gastronomy and appealing lifestyle that are attracting visitors and commercial operators. Now, the tech scene is booming and an increasing number of start-ups and freelancers from Europe are heading south relocating their businesses to the Cape of Good Hope over the winter months.

South Africa’s appeal is also evident in people’s everyday shopping needs, with premium supermarket chain Woolworths, affectionately known as “Woolies”, enjoying success in Africa, Australia and New Zealand, due to its premium quality grocery and merchandise o erings, ranging from food to fashion and cosmetics.

It also enjoys a strong presence in South Africa, where the country’s burgeoning middle class’s buying power has resulted in a 9.1 percent increase in food sales, due to grocery chains adopting high quality and sustainability goals.

e supermarket giant is setting global standards in fresh food logistics and sustainability, as evidenced by its pioneering use of AxlePower Technology from ermo King and BPW.

Woolworths has wholeheartedly embraced this innovative technology, using it to ensure its products maintain a rigorous high standard. It is able to ensure its “Ripe&Ready” food label, which o ers highly perishable fruits such as gs, papayas and avocados, is kept at the perfect moment of ripeness. O en sourced from small contract farms in remote areas, this is a logistical tour de force in a country the size of Germany, France and Italy.

Its approach to food quality has ensured Woolworths is at the head of the game. Since early 2024, Woolworths was the rst international retail chain to use ermo King and BPW’s electric freight refrigeration solution, AxlePower.

e solution is used in conjunction with the logistics partner DP World, a multinational logistics company headquartered in Dubai, combining global know-how with local expertise.

DP World and Woolworths sent the refrigerated

trailer equipped with AxlePower straight into regular operation on the route between Johannesburg and Cape Town, some 1,400 kilometres across the Karoo Desert. e transported goods have to withstand temperatures exceeding 40 degrees Celsius in summer and below freezing in winter.

Coupled with the extreme temperatures are the notorious potholes in the greater Johannesburg area and the unpaved washboard roads o motorways that also demand maximum resilience.

Managing Director of BPW Axles in South Africa, Susan Pretorius, said: “Our ePower has proven itself as the heart of the overall AxlePower system, even under the most challenging driving conditions. If ePower can withstand Africa, then the rest of the world is a walk in the park.”

e electric transport refrigeration not only saves 27 tonnes of CO2 per vehicle annually but also reduces noise and exhaust fumes. “It’s a blessing for residents near supermarkets and restaurants, as well as for the drivers,” said Pretorius.

BPW’s ePower system also ensures protection against fuel the , a problem which is also becoming more acute in Europe.

Susan Pretorius added that top logistic specialists and vehicle manufacturers were now embracing BPW’s AxlePower system.

“In South Africa, logistics specialists and trailer manufacturers are open to innovation as long as they are cost-e ective, robust and reliable,” said Pretorius.

“ ermo King and BPW’s excellent reputation has created the necessary trust in the new technology – and the solution has now become a real success.”

e advances in technology from BPW Axles and its partners is great news for the cold logistics industry, consumers and producers. It comes at a time when the global cold chain market is expected to under a signi cant expansion in the coming years.

Market reports have forecast that the global cold logistics industry is expected to grow to be worth an estimated $372 billion USD (€344 billion) by 2029, which equates to a compound annual growth rate (CAGR) of 10.9 per cent.

e multiple reasons for the boom in this industry include the need for fresh consumable foods products, such as dairy, fruit and vegetables in communities, including the growing African and Middle Eastern nations which face harsh weather conditions.

ere is also the culture of ‘eating at home’, due to the global nancial issues, which has seen families eating at home and pursuing a farm-to-table fresh food diet. e globalized food supply chains, and the rise of e-commerce has seen consumers increasingly want to gain easy access to fresh produce.

Hence, the cold logistics industry is able to accommodate those demands. Coupled with technological advances in the transportation of goods by industry stakeholders like BPW, ermo King and DP World, there has been an exponential growth in this burgeoning sector.

e new ePower system will be showcased at the BPW stand (Hall A6, Stand 310) at Transport Logistic in Munich from 2-5 June.

www.bpw.de

Woolworths has invested in BPW’s e-axle technology. Image: Woolworths.

4.0 PLATFORM FROM HALDEX ARE LIKELY TO PLAY AN INCREASINGLY CRUCIAL ROLE IN THE FUTURE OF TRANSPORTATION.

It is a fact of life that technology, and technological advances, drive the world of transport. is is clearly evident in truck and trailer braking systems, particularly Electronic Braking Systems (EBS).

As a starting point, basic trailer brake systems with ABS (anti-lock braking system) consist of coupling heads, a relay emergency valve and a load-sensing device. e load-sensing device measures the load on the trailer and adjusts the brake force accordingly.

Conversely, the EBS integrates the load sensing into the electronic control unit. EBS is brake by wire, so the brake signal is set by an electrical brake pedal rather than pneumatics. Additionally, EBS for truck trailers rely on many components working together with so warebased control, all of which must stay up to date with a changing landscape of regulations.

In this constantly evolving eld, it appears one specialist is ahead of the curve.

Seeing EBS as the ‘heart’ of modern trailer braking systems, Haldex, part of the SAFHolland Group, is working to improve the e ciency and safety of EBS, contemporaneously aligning with new UN regulations for the industry. Consequently, it has undertaken a review of its braking systems and components and come up with some innovative ways to simplify the design and installation of EBS for trailer manufacturers.

e result is its new, modular system – the EB+ 4.0, which enables trailer manufacturers to exibly and e ciently react to current and future challenges in the commercial vehicles industry. It consists of three main modules – the electronic control unit (ECU), solenoid valves, and pressure modulators, all connected to a manifold base. As is common with ‘ t for purpose’ modular systems, for more advanced functions, including EBS, additional modular components can be added, such as a pressure protection valve, pneumatic auxiliary module, mobiliser, and a spring brake control module.

e EB+ 4.0 platform, which has been described by Alexander Kraus, senior commercial product manager at Haldex, as ‘future-proof’, incorporates several modules, allowing for the use of di erent types of ABS and EBS in both 12 and 24-volt systems. Its modular design facilitates a straightforward upgrade from ABS to EBS, as the piping, cabling, and mounting

positions remain the same, negating any additional changes to the wiring or installation points.

e EB+ 4.0 has already demonstrated its practical advantages, in that trailer manufacturers bene t from the simple processes needed to expand the system. Additional modules, such as a pressure protection valve, pneumatic auxiliary module, mobiliser, and a spring brake-control module can be easily added on.

Additionally, the new platform complies with the current legal requirements, particularly in Europe, where the new Regulation No. 141 for tyre pressure monitoring systems (TPMS) has been binding for trailers since July 2024. Older ABS generations were no longer able to meet these requirements, whereas EB+ 4.0 comes with the TPMS gateway capability already integrated.

e modular approach also extends to the so ware, keeping pace with the constantly evolving so ware

eld. ere is basic so ware for EBS, with additional application layers that can be added for controlling auxiliaries and connecting other devices such as tire pressure monitoring systems (TPMS).

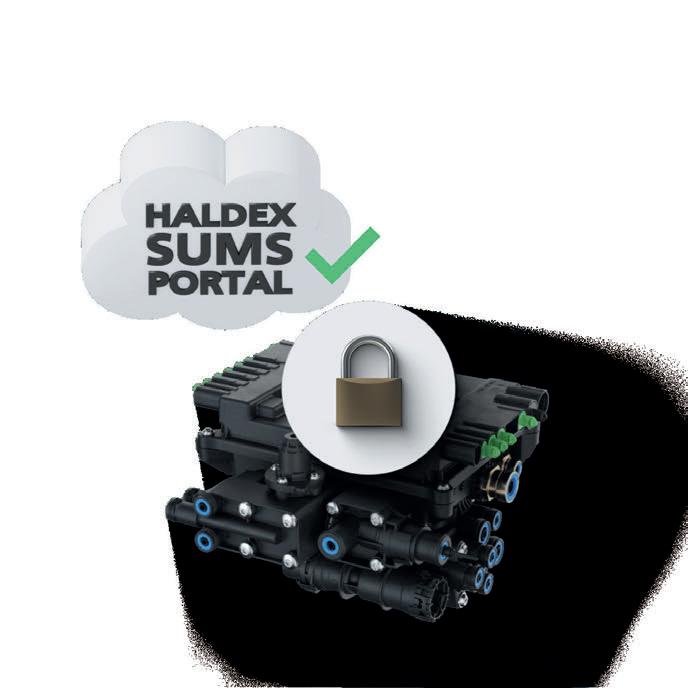

Software is evolving not only to provide new functionality, but also to meet new regulations aimed at improving vehicle safety. Recently the United Nations introduced UN R156, a new regulation aligned with EU 2018/858 that makes the implementation of a So ware Update Management System (SUMS) for category O vehicles mandatory.

e UN regulation includes the necessity to record and secure all so ware updates that impact Type Approvals, such as ECU so ware updates, braking pressure setups, and VIN number changes. This measure aims to prevent unauthorised modi cations that could compromise vehicle safety or regulatory compliance.

As part of its so ware development, Haldex has implemented a SUMS portal which will provide manufacturers with all the necessary control and evidence of so ware updates applied to their trailers to comply with UN R156.

e suite of Haldex hardware and so ware products designed to be integrated into trucking braking systems, making vehicle control systems even more advanced include so docking for automated assistance when backing up trailers, TPMS 2.0 for

real-time tire pressure monitoring, and the info centre for displaying critical vehicle information to the user. Other integrable products include the CAN Hub for e cient data sharing between EBS systems, TEM+ for emergency and park braking capabilities, COLAS+ for manual trailer height adjustments, and ILAS-EP for automatic li axle control within the air suspension system.

e exible and adaptable so ware solution of the EB+ 4.0 platform enables fast and uncomplicated so ware updates for easy implementation of regulatory changes and the latest safety standards. According to Alexander Kraus of Haldex: “ e success of the EB+ 4.0 platform impressively con rms our modular approach. e easy implementation of expansions and adaptations ensures that trailer manufacturers are optimally prepared for current and future challenges. Our customers particularly appreciate the cost e ciency, exibility and future-proof concept o ered by this system.”

By combining modular hardware design with adaptable so ware and integrated auxiliary systems, Haldex is not only meeting current needs but also proactively preparing for future developments in the industry and future technology trends. As regulations tighten and the demand for smarter, safer, and more e cient vehicles grows, systems like the EB+ 4.0 platform are likely to play an increasingly crucial role in the future of transportation.

With the exible and future-proof modular EB+ 4.0 platform, Haldex is positioning itself as a pioneer and reliable partner of the commercial vehicles industry, supporting manufacturers and users to meet the highest safety standards, while ensuring cost e ciency.

In the current landscape where safety and e ciency are of paramount importance to the truck and trailer industry, technology advances, such as the EB+ 4.0 and its modular so ware systems, must be at the forefront of considerations and actions for all industry stakeholders. It is greatly pleasing to see the work by Haldex with its EBS system being wholeheartedly adopted, which, in turn, will drive further technological advances and e ciencies across the industry.

www.safholland.com www.haldex.com

AS IT EAGERLY ANTICIPATES ITS EIGHTH DECADE OF AXLE AND SUSPENSION MANUFACTURE, THIS ALMOST-OCTOGENARIAN IS CERTAINLY NOT RESTING ON ITS LAURELS. IN FACT, SAE-SMB IS WELL AND TRULY READY TO GRASP THE FUTURE.

From its genesis in 1947, when three mechanical engineering technicians combined their specialised talents, SAE (now SAE-SMB) has been a pioneer in the production of high-quality truck axles and suspensions, for loads ranging from 5.5-tonne to 20 tonnes, combining tradition and innovation to meet the evolving needs of the transportation industry.

In renowned engineering fashion, SAE-SMB has combined its commitment to providing solution-driven results with cutting-edge research and innovations, to forge a future-resilient business that boasts a global reach and resilient, collaborative partnerships.

While it looks to the future across Europe, Asia and South America, SAE-SMB has not forgotten its combined past – the roots upon which this enterprise was built.

SAE, or Société Ardennaise d’Essieux, grew rapidly in a post-war world due to its founders’ knowledge and determination. As a result, SAE became a leader in the production of industrial axles in the French and European markets, renowned for its product quality and reliability.

It was particularly known for its specialised axles and “turnkey” mechanical and pneumatic systems, gaining the attention of manufacturers of special trailers, low loaders, tankers, dump and forestry trailers.

SMB was a child of the booming 1970s and grew to be the exclusive supplier of axles and suspensions for all trailers under the General Trailers group (Fruehauf, Benalu, Trailor and Titan).

Pragmatism shone through when SAE’s founders realised the value of forging industry partnerships to grow the business and meet growing demand for their products. is led to the 2007 merger of the two competing companies, resulting in the new-

look entity gaining a rm foothold in the highly competitive European markets. In a few short years, the ADR Group, the world’s leading agricultural axles, purchased SAE-SMB in 2013, which saw an injection of more than €8 million.

e spirit of growth was rmly part of the SAESMB psyche, with the prospects of untapped, new markets beckoned. With its subsidiaries in India, Middle East, China and Brazil, SAE-SMB is able to produce and sell its products worldwide.

e spirit of allied-industry partnership continues at pace for SAE-SMB, with its recent foray into air suspension systems with Dutch manufacturer VDL Weweler, itself starting operations in 1924.

VDL Weweler are experts in the development and production of air suspension systems, axle-li s systems and parabolic springs. At the 2024 IAA Transport Expo the companies introduced the MBS OMEGA, a new modular solution and the latest revolutionary range of air suspensions for the future, in combination with SAE-SMB’s AIRMAX axles.

is partnership now sees SAE-SMB’s clients being provided with a complete solution – its 9-tonne axle seamlessly equipped with the MBS suspension.

e combination of SAE-SMB’s AIRMAX axles and VDL Weweler’s MBS OMEGA air suspension results in what is seen as one of the lightest combination of axles and pneumatic suspension for general purpose trailers. e combined e ect is a reduction of at least 100 kilograms in trailer weight compared to traditional solutions.

is weight reduction of the trailers enables transporters to increase the carrying capacity of their eets without any investment, reducing the cost of fuel and CO2 emission per transported tonne of goods by at least two per cent. e body of the rigid axles, produced from one unique piece of forged seamless tube, allows a high carrying capacity with minimum weight.

Lightweight and simple, the VDL Weweler MBS OMEGA air suspension adapts the attitude of the vehicle to the load and the route. It guarantees stability in cornering, maximum grip and e ective braking, and its modularity makes it compatible with all trailers.

e partnership of these products results in lightweight, rigid and resistant SAE-SMB AIRMAX axles with high tensile steel structure, oversized bearings and a lubrication system. e combination therefore ensures optimum working conditions in all environmental conditions with simple maintenance.

e ultimate result of this partnership is that the SAE-SMB AIRMAX axles and VDL Weweler MBS OMEGA air suspension, being lightweight, high-quality and easy to operate, are one of the lightest combination for general purpose trailers, reducing the CO2 emission by at least two per cent, compared to similar solutions on the market. In addition, trailer manoeuvrability is improved by the steering axle, and the easy maintenance of both axles and suspension, coupled with long-range warranty of components, reduces maintenance costs. In addition to forging lasting industry partnerships, SAE-SMB has undertaken an ambitious program of investment in research and development, resulting in innovative and high-quality products. e company is now looking forward to showcasing its innovations and products at the Solutrans exhibition, to be held at Lyon, France from 18-22 November 2025.