We’re ready for the future, because we always have been

That camphor laurel (Cinnamomum camphora) may have been there for over 50 years, but that doesn’t mean it’s guaranteed to be stable after a flooding episode.

Image: TF

It’s been a tough couple of weeks.

As I’m writing this the floodwater is receding from the northern NSW rural valley which is my home. The sun is shining for the first time in what seems like ages, and people who’ve never experienced flooding would probably think everything is looking good again. So it is.

I love showing people where I live and watching their looks of disbelief. It’s very much an idyllic location. The river’s at my front door, I’m surrounded by lush pasture, and I never for a moment take for granted how lucky I am to be here. But the valley is a flood zone, and every now and then, as has just happened with Cyclone Alfred, things get a little unmanageable. The river which makes such a heartwarming view from my office window is a little less endearing when it finds its way into the house. That’s all as may be. I know that possibility is real, and over the past few decades I’ve learned to look out

for particular warning signs and to be prepared when I see them. The Bureau Of Met and the fabulous people at the SES do their best to see we’re kept informed, and these days it’s hard to understand how anyone can be caught unawares.

But another lesson I’ve learned over several flooding episodes is that the water receding and the sun shining isn’t a signal to relax.

I’ve no doubt arborists and emergency workers will have their hands full for quite some time tidying up after the cyclone. There are trees down and debris piled up everywhere.

But the circumstance I never see written about or publicised is the effect flooding has on the ground, and especially on a tree’s potential for being unable to support itself once the soil and surrounds have been saturated, softened, and sometimes removed by fast-moving torrents of floodwater. That favourite tree which has been in the backyard for generations could actually be a serious

threat to people and structures, even though it looks the same as it has done for decades.

Arborists need to be looking carefully at trees in those situations – and I’m sure they are – but home owners and members of the public need to be watchful as well. If there’s the slightest doubt, if a tree’s leaning a little, or even if it’s looking a little one-sided with foliage stripped from one side in the incredible winds, get a qualified arborist to do an assessment.

It’ll be the best investment you’ll make this year.

To all the emergency services, tree workers, arborists and volunteers who near burst their hearts (yet again) trying to help those caught up in the furore of Cyclone Alfred, a heartfelt and very sincere thank you.

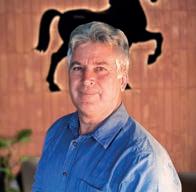

Tom Foster Editor

HUSQVARNA X-COM ACTIVE

Experience X-COM Active, a robust, high-tech communication and hearing protection headset system designed for arborists and tree care professionals –making teamwork smoother and more efficient.

• Crystal Clear sound

• Advanced noise reduction

• Excellent hearing protection

• Up to 10 team mates across 3 channels FIND OUT MORE

The Australian Arbor Age is published bimonthly by Prime Creative Media Pty Ltd.

CEO

John Murphy

COO

Christine Clancy

Head of Sales

Andrew Morrison

Editor

Tom Foster

tom.foster@primecreative.com.au

National Advertising Manager

Alex Cowdery

alex.cowdery@primecreative.com.au

Phone: 0422 657 148

Client Success Manager

Arianna Lucini

arianna.lucini@primecreative.com.au

Design

Jacqueline Buckmaster, Danielle Harris

Subscriptions

P. +61 3 9690 8766

subscriptions@primecreative.com.au

Website arborage.com.au

Copyright

The Australian Arbor Age magazine is owned by Prime Creative Media and published by John Murphy. All material in The Australian Arbor Age magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher.

The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in The Australian Arbor Age magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2025

Articles

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 11.01, 201 Miller Street North Sydney, NSW. 2060. Australia

Victorian emergency tree-removal company Granite Group recently upgraded its chipper to a Morbark 2230. It was a happy decision before the chipper even arrived

– Page 22. Image: Prime Creative Media

Whether or not California’s Pinus longaeva – understandably named ‘Methuselah’ by an adoring public – is the world’s most ancient tree is the source of some friction among academics. One lot claimed in 1957 the Great Basin bristlecone pine was 4789 years old at that time. That would’ve meant it germinated in 2833BC.

But a later attempt to verify Methuselah’s age went awry when it was found a vital core sample was missing, and in the absence of the sample the new estimate was a mere 4667 years old.

Either way, it’s a magnificent specimen which graces the arid landscape of Inyo National Forest in California at an altitude of around 3000m.

The tree’s longevity is credited to harsh weather and a lack of nutrients which slow down the decaying process.

There’s no evidence to support the assertion Methuselah may have held a treehouse in which Keith Richards and Willy Nelson rehearsed as teenagers.

Methuselah is recognised as the non-clonal tree with the greatest confirmed age in the world.

Image: zorpink/stock.adobe.com

Working Height: 14.7m + Working Outreach: 7.55m + Safe Working Load: 225kg + Minimum Weight: 1775kg

Telescopic Upper Boom

Accurate Platform Positioning

Bi-Energy Available

Optimising Utilisation

Hydraulic Outriggers

For Quick & Easy Setup

Fully Proportional Hydraulic Controls

Simple, Reliable & Easy To Maintain

Traction Drive Option

Excellent Manoeuvrability On Site

Designed & Built In UK

Local Support Team In All Areas

TO FIND OUT MORE CONTACT OUR TEAM

Call: 1300 4 NIFTY or 02 4964 9765

Email: sales@niftylift.com.au

Caterpillar Inc. is pleased to debut the Cat® FM528 GF/ LL (General Forestry/Log Loader), a forestry excavator designed for adaptability and efficiency.

Equipped with the side-entry Next Generation Certified Forestry cab, the Cat® FM528 GF/LL Forest Machine is Caterpillar’s first forest machine to offer a fixed or live heel and blade option. Its multi-configuration capabilities fill in fleet-equipment gaps and mean the machine can go to work in the woods or the millyard to help boost productivity and profitability.

Built with the Cat C4.4 173hp (129kW) engine and electrohydraulic system, the high-torque motor provides high power at low RPM while helping reduce fuel consumption and minimising downtime and maintenance costs.

“The Cat FM528 represents our commitment to understanding and

The Cat FM528 is equipped to tackle a variety of tasks with ease. Images: Caterpillar

responding to the evolving needs of the forestry industry,” said Mike Dickenson, Caterpillar’s senior product specialist for forest machines. “We are merging adaptability, operator-oriented design, and cost efficiency, empowering forestry professionals to maximise their productivity while prioritising safety.”

Whether it’s land clearing, fire clean-up, chipping, grinder loading, mulching, or processing, the Cat FM528 is equipped to tackle a variety of tasks with ease. The machine is compatible with a wide range of robust Cat forestry grapples, available in sizes from 1322mm (52") to 152mm (60").

Equipped with Triple Grouser track shoes that help provide high manoeuvrability while minimising disturbance in soft, wet-underfoot conditions, the machine also helps keep operators safe with a certified side-entry Forestry ROPS cab which includes a spacious door and an easy-to-use tilt-up armrest.

Refined visibility is integrated into the design with a large 1.25" (32mm) thick polycarbonate windshield, narrow cab pillars, large panoramic windows, and a flat engine hood, helping operators maximise engagement with their work environment.

The Cat FM528 offers a unique fixed or live heel and blade configuration, allowing operators to easily adapt to various applications like navigating steep terrain, managing heavy logs, or performing detailed sorting tasks.

With options for processor, roadbuilder, log loader, and knuckleboom loader controls, this multi-configurable machine helps crews easily transition between forestry and millyard work, increasing productivity and profitability.

Powered by the Cat C4.4 173hp (129kW) engine and an advanced

FM528 GF & FM528 LL specifications

Engine: Cat C4.4e TTA

Engine power: (ISO 14396): 129kW (173hp)

Emissions:

When you choose Cat products, services and solutions today, you’re gaining 100 years of experience and expertise “ ”

electrohydraulic system, the FM528 is designed to help lower fuel consumption while delivering superior performance. The hightorque engine operates effectively at low RPMs, minimising maintenance costs from wear and tear while maintaining precision in various job tasks. Further, the hydraulic system features cooling E-Fans with reversing capabilities to optimise engine efficiency and temperature control. Sharing common parts and

service with the Cat Next Generation excavator line, the FM528 ensures readily available components, significantly reducing downtime. Using Cat long-life fuel and hydraulic oil filters with extended and synchronised service intervals also helps lower maintenance expenses.

Over the past century Caterpillar has grown with its customers to help build a better, more sustainable world.

That’s why Caterpillar continues to support forestry customers with five models, including the FM528 GF and FM528 LL machines, plus a range of work tools that deliver dependability, versatility and efficiency to every fleet. When you choose Cat products, services and solutions today, you’re gaining 100 years of experience and expertise.

For more information about the FM528, contact a Cat dealer or visit cat.com.

Versatile, efficient, and reliable lifting equipment for arborists and tree-care professionals.

The newest addition to the renowned Leguan line of all-terrain spider lifts offers exceptional performance, speed, and ease of use.

The Leguan 265 Spider Lift boasts a maximum working height of 26.5 metres, a side reach of up to 13.6 metres, and a lift capacity of 250kg, making it one of the most powerful and capable lifts in its class. Whether working on a towering eucalyptus or clearing high branches, the Leguan 265 offers unparalleled access for tasks requiring vertical and horizontal reach.

Designed with the unique needs of tree-care professionals in mind, the Leguan 265 excels in rough terrain. Its rugged track system provides exceptional ground clearance and gradeability of up to 45%, ensuring it

can reach places other lifts can’t. A low centre of gravity and powerful diesel engine ensure stability and reliability, even on challenging job sites, and for operations in remote or tough-to-access locations, the Leguan 265 is the tool for the job.

Time is money, and the Leguan 265 doesn’t waste either. As the fastest 27-metre spider lift in the world, the Leguan 265 features a rapid setup time of just one minute and 35 seconds to fully extend the booms to maximum working height. This exceptional speed enables tree-care professionals to complete jobs more quickly, increasing productivity and profitability across the board. With its intuitive joystick controls, the

Leguan 265 is incredibly user-friendly, allowing operators to focus on their work rather than navigating complex equipment. The machine’s automatic levelling and precise proportionaloutreach monitoring ensure a safe and efficient work process, minimising human error and maximising safety.

The Leguan 265 is engineered to perform in all seasons, with features that make it ideal for tree-care professionals working year-round, regardless of the weather. The platform’s shielded booms and chassis protect vital components from sawdust, water, and other debris, ensuring reliable performance even in wet conditions. Its robust construction, combined with excellent paint quality

and corrosion resistance, ensures longevity and maintains the machine’s high resale value.

Why choose the Leguan 265?

Features include:

• Exceptional stability, ground clearance, and gradeability for rough and uneven terrains

• User-friendly intuitive joystick controls and automated functions for easy operation, with minimal training required

• Quick setup and operation speeds

• Durability, and being ideal for yearround use, even in harsh conditions, and

• Proportional-outreach monitoring and automatic safety features to prevent errors.

With its cutting-edge features, impressive performance, and exceptional ease of use, the Leguan 265 Spider Lift is set to become the go-to lift for Australia’s arbor and tree-care sectors. Whether tackling difficult terrain or reaching impressive heights, the Leguan 265 offers everything needed to complete tree work safely and efficiently.

As the official Australian distributor of Leguan Spider Lifts, Monitor is pleased to offer the Leguan 265.

With a commitment to providing topquality products and excellent customer service, Monitor ensures an investment in Leguan equipment is supported by expert advice and after-sales care.

If you’re ready to take tree-care operations to the next level with the Leguan 265 Spider Lift, contact Monitor for more information on pricing, features, and availability. Call 1800 025 024 or visit monitor.net.au.

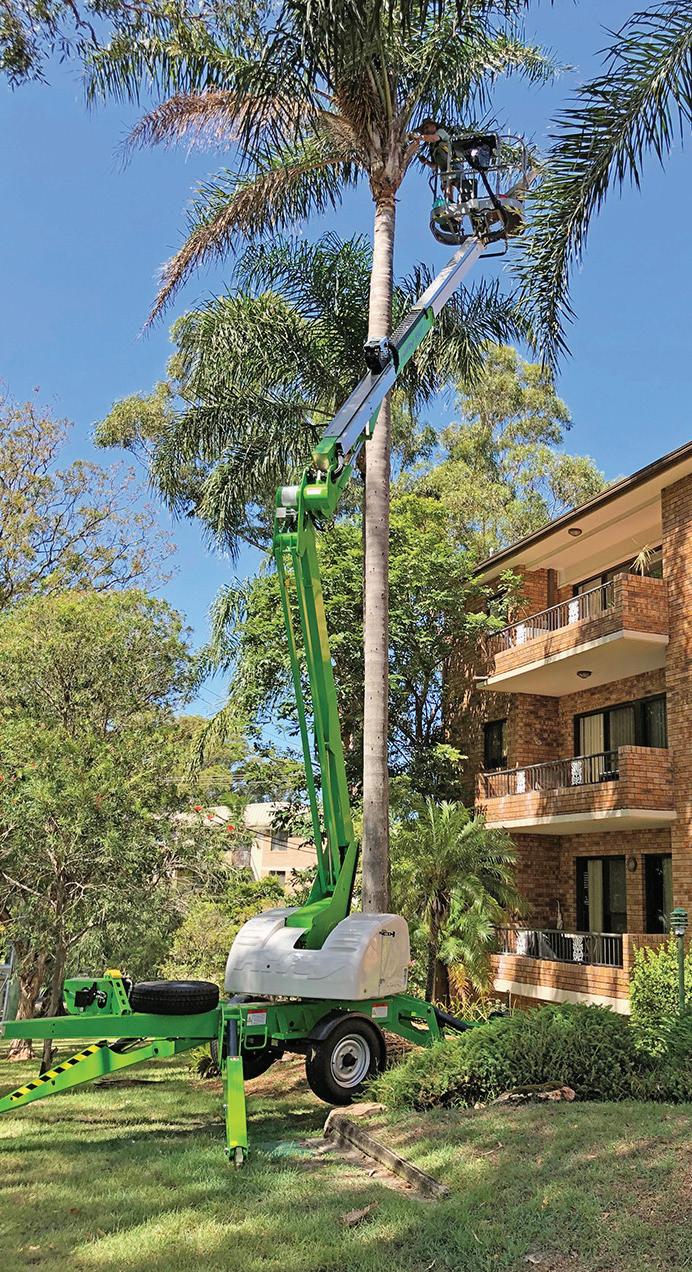

Niftylift’s Self Drive and TrackDrive MEWPs provide an ideal solution for arborists looking to work smarter, safer, and faster. Image: Niftylift

Why Australian arborists are turning to mobile elevating work platforms (MEWPs) for tree pruning and clearing.

Tree work in Australia is uniquely challenging. Whether maintaining urban landscapes, large estates, or managing trees in rugged bushland, arborists need equipment that is safe, efficient, and built to handle Australia’s terrain and climate.

For years, traditional rope climbing has been a primary method for accessing tree canopies. However, safety regulations and industry best practices now strongly encourage the use of MEWPs wherever possible to reduce fall risks, operator fatigue, and inefficiencies.

Niftylift’s Self Drive and TrackDrive MEWPs provide an ideal solution for arborists looking to work smarter, safer, and faster. Designed for Australian conditions, these machines help treecare professionals reach difficult areas, reduce strain, and substantially improve overall site safety.

Working at height is one of the biggest risks arborists face. While tree climbing remains a necessary skill, using an MEWP reduces the time spent in harnesses, minimising fatigue and the risk of falls.

MEWPs also provide a stable platform for arborists to work from, ensuring better balance and controlled movements. Niftylift’s Self Drive and TrackDrive models feature secure outriggers, proportional controls, and safety interlocks, helping operators work with confidence.

Also, MEWP rescue operations are quicker and safer compared to aerial rescues using ropes, and Australian arborists often work in extreme temperatures. Prolonged exposure can lead to heat stress, dehydration, and loss of focus. MEWPs reduce climbing effort, allowing arborists to focus on

precision cutting and pruning rather than exhausting rope work. Less physical exertion means operators can work longer and complete jobs faster without the need for extended rest periods.

The diverse Australian landscape requires machines suited for different ground conditions. Soft grass, steep slopes, and uneven terrain all demand specialist access solutions.

Niftylift Self Drive MEWP key models for estates, parks and urban tree care include the SD170 and SD210 4x4x4. The SD210 4x4x4 offers features like turf tyres to protect grass on golf courses, parks, and residential properties, and four-wheel steering which enhances manoeuvrability, allowing operators to access trees in tight spaces.

Four-wheel drive also ensures reliable access, even on irregular ground.

For slopes and soft ground Niftylift’s TrackDrive MEWPs – like the TD120T, TD120TN, and TD150T – offer superior traction on steep slopes, making them ideal for rugged terrain and embankments. The tracks improve stability on soft or loose ground and are well suited to bushland and off-road applications.

The compact dimensions of the TD range also enable access to tight or confined areas.

Arborists working on high-volume commercial contracts or emergency storm clearances need to get jobs done quickly and safely. MEWPs significantly reduce setup time compared to rope climbing, and that means less downtime and faster job completion.

Less fatigue means higher productivity – operators can complete more pruning or removals per day – and using MEWPs reduces the likelihood of injuries, leading to fewer insurance claims and work disruptions.

Tree work in protected areas and residential zones often requires low emissions and minimal ground disturbance. Niftylift’s Self Drive and TrackDrive MEWPs are powered by efficient diesel engines that meet Euro Stage V (Tier 4 Final) emissions standards, ensuring compliance with modern environmental regulations.

The SD170 is available with battery or bi-energy power (battery and diesel), offering a quieter, loweremission alternative for sensitive environments, and low-weight designs help minimise ground impact, reducing the risk of damage to parks, golf courses, and landscaped areas.

With Australian arborists facing greater safety expectations, environmental considerations and pressure for efficiency, the shift towards MEWPs as a primary tree-access solution is inevitable.

Niftylift’s Self Drive and TrackDrive models provide the reach, terrain adaptability, and operator comfort needed for modern tree work. Whether working on a large estate, a city park, or a rugged bush property, Niftylift MEWPs offer a smarter, safer, and more efficient alternative to traditional tree-climbing methods.

For Australian arborists looking to improve efficiency and safety, Niftylift provides the ideal solution.

To learn more contact Niftylift Australia to discuss which MEWP suits your tree-work needs. Phone (02) 4964 9765, or log on to niftylift.com.au.

Keeping an Elevating Work Platform (EWP) in top condition isn’t just about operational efficiency. It’s also about keeping people safe. When it comes to health and safety, the trusted Brisbane Altequip team of servicing experts is on your side.

With multiple years of experience across all the major EWP brands, Altequip can be relied upon to keep equipment performing at its best. Personnel will be safer thanks to Altequip’s expertise, experience, and compliance with all Australian standards.

Altequip also understands the importance of streamlining the servicing process for owners and operators. There’s a completely paperless system whereby all service documentation is emailed directly to the customer. All EWP service and repair records are on file without the worry of keeping track of paperwork.

Altequip has a service reminder program in place which includes email

and SMS notifications when an EWP is due for a service. The equipment stays safe and compliant, without the hassle of manually tracking schedules.

Altequip has been operating in the EWP Brisbane and Queensland sector for over a decade. The company understands the nature of the industry, but most importantly, it understands the machines themselves. The qualified Altequip technicians have experience in maintaining and repairing equipment from the entire range of EWP manufacturers.

With regular maintenance and servicing, owners and operators can avoid costly breakdowns and ensure

maximum uptime throughout the year. If a problem does occur, Altequip technicians are skilled in diagnosing the issue and promptly applying a fix. Machinery is back up and running in the shortest possible time.

Having an EWP break down and put a stop to work for the day is a huge frustration.

While regular servicing helps minimise the chance of this happening, breakdowns do occur and they need to be handled in the best way possible. Altequip offers emergency repairs for EWPs, and aims to get them back up and running fast to minimise downtime. While assistance depends on the

owner’s schedule, Altequip will do its best to prioritise an emergency EWP repair.

Hire companies and owners of large fleets of elevating work platforms can take advantage of Altequip’s fleetservicing offering. Working around the owner’s schedule, Altequip technicians are able to do on-site servicing at a depot for multiple pieces of equipment. Keeping gear in top condition will ensure it can be hired out with confidence, avoiding conflict with customers and allowing for

seamless operations and relations.

The dedicated Altequip team promises innovative solutions and a strong commitment to customer satisfaction with every EWP service. Thanks to extensive knowledge and experience, and the latest industry technology, Altequip can keep elevating work platforms in peak condition. Minimal downtime and maximum productivity are the result.

To learn more of Altequip servicing and products, visit altequip.au/ewpservicing/.

A few key services from Altequip include:

• 90-day inspections – detect potential issues before they snowball

• Annual in-depth assessments –ensure optimum operations and full compliance with safety regulations

• Repairs and breakdowns – minimise downtime and get back in action as quickly as possible (subject to time and availability Ts and Cs).

The Altequip team can work on everything from small scissor lifts to large truck-mounted travel towers.

Victorian emergency tree-removal company Granite Group recently upgraded its chipper to a Morbark 2230. It was a happy decision before the chipper even arrived.

Granite Group has three main strands to its business: Earth and construction; Tree works; and Environmental, and cites its aim as ‘to be a unified force in environmental solutions, construction expertise, and arboriculture…a one-stop destination for a wide array of services from ecofriendly environmental management to top-tier construction projects and comprehensive tree care.’

The Tree works section of the business deals with:

• Stump grinding

• Complete tree removal

• Large-scale chipping

• Tree reports, and

• Milling

The Australian Arbor Age caught up with Director Jon Rogash at the National Golf Club at Long Island in Frankston. Granite Earth was rehabilitating the course, doing the tree removal and land clearing for the new fairways. Thousands of cubic metres of material were being removed.

The machine chosen for processing the foliage was a recently purchased Morbark 2230 Wood Chipper, and as Rogash outlined to The Australian Arbor Age magazine, upgrading from the previous chipper hadn’t been a difficult decision.

The Morbark was being fed by a 15-tonne excavator with a rotating grapple saw, and from what we could

The Morbark breaks up large logwood with ease.

see, the 2230 was doing the job – quickly and efficiently.

“We upgraded from a smaller machine,” said Rogash. “When we looked at the Morbark 2230, it had 365 horsepower, and in my eyes it was just the straight out brute horsepower.

“It was no brainer.”

“I got talking to Monitor Business Development Manager Stuart Samson about this machine, and the more I inspected it, the more I liked it.

“I decided to pull the trigger on it.”

While it was the grunt of the Morbark which caught Jon’s watchful eye in the

first place, the safety offered by the remote control on the 2230 has been major bonus.

“We run a strict machine-feed only,” explained Jon. “It eliminates any risk of people being caught in foliage or things like that. We run it straight off the machine with the remote and nobody’s in harm’s way.”

The angle on the chute eliminates blockage, and the higher drum speed forces the material through quicker “ ”

Matching the Morbark with Granite Earth’s other machinery has also shown some big productivity improvements.

“When we team up some of the other equipment with this machine, we can break down big logwood, and it doesn’t struggle pulling it through. It’s got the horsepower to pick up the drum speed,” explained Rogash. “Also, the angle on the chute eliminates blockage, and the higher drum speed forces the material through quicker.”

It was clear Jon had been giving the Morbark a thorough workout and knew his way around the 2230.

“The top infeed roller is a very aggressive style which grabs the foliage and logwood and forces it through without any drama, and without having to use the lift-and-crush.”

Jon’s satisfaction with the Morbark carried over to his high opinion of supplier, Monitor.

“It’s been really good,” he said. “Whenever there’s been an issue – which has been very rarely – it’s been fixed straight away, and parts are readily available for the Cummins engine throughout Australia.”

While Granite Earth is a firm fan of both Monitor and the Morbark 2230, and further business between the two companies is likely, there’s work to be done first.

“We’re not going to upsize our fleet for now,” said Jon thoughtfully, “but in two years we’ll look at upgrading to a newer model and it’s a no brainer: we’ll be staying with Morbark.”

When you choose the BVR Brush Chippers from Morbark, LLC, you’re not just investing in a machine — you’re investing in decades of innovation, quality, and craftsmanship. These chippers are designed to stand the test of time and make your toughest jobs easier and more profitable.

Don’t settle for less. Choose the chipping power of the BVR Brush Chippers and experience the difference that Morbark’s legendary performance can bring to your business.

Unlock Powerful Performance with the BVR Line of Wood Chippers from Morbark.

When you choose a BVR Wood Chippers, you’re not just investing in a machine — you’re investing in decades of innovation, quality, and craftsmanship. These chippers are designed to stand the test of time and make your toughest jobs easier and more profitable. Don’t settle for less. Choose the chipping power of BVR Wood Chippers and experience the difference that Morbark’s legendary performance can bring to your business. To find a Dealer in your neck of the woods, go to https://dealers.morbark.com.

Monitor Industries - Australia

Ph: +61 1800 025 024 www.monitor.net.au

Stevens Group - New Zealand

Ph: +64 09 275 0443

www.stevensgroup.co.nz

To learn more about the complete line of BVR Wood Chippers, scan the QR Code with your mobile camera

The SC48TX’s low ground pressure and narrow footprint gives access to difficult jobsites.

Images: Vermeer Australia

The Vermeer SC48TX is a compact, highly mobile machine designed to navigate tight spaces and efficiently remove stumps of all sizes.

The latest addition to Vermeer’s hard-working stump grinder lineup, the SC48TX, is compact in size to manoeuvre through tight jobsites, but its robust cutting capabilities mean it’s ready for even the toughest jobs.

For more information on Vermeer’s extensive line-up of professional tree-care and arbor equipment, visit vermeeraustralia.com.au.

Here’s a few highlights of the SC48TX…

The beltless directdrive system of the SC48TX ensures maximum power “ ”

The beltless direct-drive system of the SC48TX ensures maximum power is delivered from the engine to the cutter wheel through a pair of gearboxes connected by a driveshaft. Maintenance costs are minimal thanks to the beltless design.

The SC48TX stump cutter was built to help efficiently grind stumps of all sizes. It has a 48hp (36kW) CAT diesel engine for optimum fuel economy, durability and performance, and is backed by proven worldwide service and support, including three-year coverage.

The optional full-function remote control allows operating the stump cutter without being at the operator’s station, giving jobsite flexibility.

An optional backfill blade efficiently moves chips around the jobsite, reducing the need to manually relocate the chips. The blade has a rounded lower edge to minimise turf damage.

When jobsites or approaches are tight, The SC48TX can retract to only 35" (89cm), and then extend the tracks to 49" (124.5cm). The low-disturbance tracks provide optimum traction and stability in tough conditions – reducing job prep and leaving minimal clean up.

Exclusive stump-cutting technology maximises time at the stump – features like the Vermeer cutting system, SmartSweep™ control system, and the operator presence system.

Morbark’s Whole Tree Chippers and Eeger Beever range stand out as ideal choices for Australia’s demanding environments.

Australia’s diverse landscapes present arborists with myriad challenges that demand robust, reliable equipment capable of handling rugged terrain and diverse vegetation. From the dense rainforests of Queensland to the arid outback of Western Australia, arborists require machinery that can adapt to varying conditions while ensuring efficient and safe operations.

One of the standout features of Morbark equipment is its adaptability to Australia’s varied terrain. Whether it’s tackling thick underbrush in the Northern Territory or processing timber in the forests of Tasmania, Morbark Eeger Beever brush chippers and whole-tree chippers excel in manoeuvrability and performance.

Harsh weather conditions, including extreme heat and occasional cyclones, are commonplace across Australia. Morbark equipment is engineered to withstand these challenges with durable construction and robust components. Designed for longevity and minimal downtime, Morbark machinery ensures arborists can maintain productivity even in adverse weather, crucial for meeting deadlines and client expectations in Australia’s competitive arboriculture industry. Chippers

Equipped with powerful engines and advanced hydraulic systems, these machines effortlessly handle the challenges of uneven ground and steep slopes, ensuring arborists can operate effectively in any environment.

Australia’s unique flora, including native eucalyptus trees and dense shrubbery, requires specialised equipment for effective vegetation management. Morbark horizontal and tub grinders and whole-tree drum and disc chippers are designed to efficiently process a wide range of materials, from large tree trunks to stumps to slash, converting them into valuable mulch or wood

chips. This capability not only aids in maintaining environmental balance, but also supports sustainable landmanagement practices essential for preserving Australia’s natural habitats.

Safety is paramount in arboriculture, and Morbark prioritises operator safety with ergonomic designs and intuitive controls. Features such as enhanced visibility, emergency shut-off systems and noise-reducing technology contribute to a safer working environment, reducing the risk of accidents and enhancing overall operational efficiency.

Supporting Australia’s arborists

Morbark brush chippers, horizontal and tub grinders and whole-tree chippers are not just tools, but indispensable partners for arborists and forestry professionals in Australia. Their ability to adapt to diverse terrain, efficiency in vegetation management, durability in

harsh conditions, and focus on safety and comfort make them the preferred choice for professionals across the continent.

As Australia’s landscapes continue to evolve, Morbark remains committed to supporting arborists and forestry professionals with innovative solutions that uphold performance, reliability, and sustainability in every operation.

Learn more about whole-tree chippers at morbark.com.au and Eeger Beever brush chippers at monitor.net.au.

Hansa’s commitment to excellence.

In today’s demanding arboriculture landscape, professionals require tools that not only perform under extreme conditions but also reflect a commitment to environmental responsibility. The team at Hansa approach product design and manufacturing to ensure every piece of equipment excels in the field while being designed with sustainability in mind.

The Hansa journey begins behind the scenes, where innovation drives the development process through direct collaboration with arborists. Rather than relying solely on conventional production methods, the engineers and designers work closely with field experts to identify everyday challenges. This real-world feedback plays a crucial role in shaping Hansa’s design philosophy. Every ergonomic adjustment, safety enhancement, and operational improvement is tailored to meet the rigorous demands of modern arboriculture. This collaborative process ensures the equipment is truly built for arborists, delivering tangible benefits such as reduced downtime and increased efficiency on the job.

Simultaneously, Hansa redefines

sustainable manufacturing practices. With a state-of-the-art production facility incorporating energy-saving processes and waste-reduction measures that significantly lower its carbon footprint, Hansa continually explores innovative ways to minimise waste and optimise resource efficiency throughout daily operations. This commitment to sustainability benefits the environment and enhances the durability and reliability of the products, ensuring every machine produced by Hansa remains as robust as it is responsibly made.

The impact of these combined efforts is evident in the real-world performance of Hansa chippers. Whether it is advanced chippers or other robust equipment, each product results from a dual commitment to cutting-edge design and sustainable production. Arborists across Australia experience firsthand how these innovations improve productivity, reduce maintenance challenges, and create a safer, more reliable working environment. Ultimately, Hansa equipment stands as

Every ergonomic adjustment, safety enhancement, and operational improvement is tailored for modern

a testament to what is possible when industry expertise meets responsible innovation.

Looking ahead, Hansa remains dedicated to pushing the boundaries of what equipment can achieve. it continues to invest in research and development initiatives that enhance performance and improve sustainable practices. By doing so, the team at Hansa is confident the future of arboriculture will be defined by a balanced approach – one where groundbreaking technology and environmental stewardship work together to support the hardworking professionals who care for our trees. At Hansa, the commitment to innovation and sustainability is not just a promise – it’s a reality. It translates into equipment built for arborists, designed to perform under the most challenging conditions while protecting the planet for future generations.

To see more of Hansa’s equipment and commitment to sustainability, log on to hansaproducts.com/au/.

The Australian Arbor Age has written several times about the impressive build quality of Piranha Chippers. But even though the company is still in its early stages, it’s already headlong into development and planning for the future.

When Piranha Chippers unveiled its BT300, The Australian Arbor Age was quietly impressed.

Powered by the 4HK1 Isuzu turbodiesel engine which produces a classleading 197hp, the BT300 runs a 650mm diameter cutter drum which weighs 400kg, and there’s a 380mm X 500mm (15" X 20") direct opening into the cutterdrum housing – there are no step downs.

It’s obviously a serious 15" capacity chipper with plenty of horsepower, and a state-of-the-art electronically controlled common-rail direct-injection diesel motor offers amazing fuel economy and runs at very low volume.

The dual horizontal infeed wheels give plenty of pulling power, and with the advantage of a hydraulic winch which quickly folds out of the way when it’s not needed, trees and branches are dealt with using minimal physical effort from the operators.

A hydraulic auto-engage clutch, hydraulic discharge-chute swivel and the hydraulic tailgate raise-andlower functions were the icing on the operational ease-of-use cake.

Details

While all that was impressive enough, we were also struck by how much thought had gone into access and time

saving on servicing and maintenance.

Service intervals on the Isuzu 4HK1 are 500 hours, which marks the Piranha as a professional-grade machine. Piranha was also quick to point out that with so many arbor and forestry companies running Isuzu trucks and commercial vehicles, the stockholdings of essential engine parts and spares can be greatly reduced.

As far as access goes, all filters and service points are within easy reach when the front door of the engine compartment is opened, and a remote oil drain hose makes draining the sump quick, easy, and, most of all, not messy. An access door at the top of the engine cover makes replacing the oil a breeze, and a work light mounted inside the engine bay ensures the maintenance and servicing is very low-stress.

Another big plus on the Piranha BT300

Piranha as a company isn’t sitting on its hands and congratulating itself. It’s still trying to improve “ ”

is the access to the chipper knives via the side walkway ramp. With the chipper housing hood open the top part of the cutter drum is nicely exposed, making changing the knives extremely easy and, above all, safe.

With a machine as new and impressive as the Piranha BT300, we were a little surprised when we rang Piranha Chippers boss man, Nathan Sangster, to ask how things were going, and he

told us he was out in the field with the BT300 doing some development with a discharge chute modification.

“When we built the original machine we had a fixed-height discharge chute,” he explained as the Isuzu purred away quietly in the background. “The chute could swivel 360 degrees, but the height was fixed. The end has a deflector for shooting the woodchip down to the ground if needed, but we found it couldn’t shoot up into the taller arbor trucks. They were too high. It wouldn’t

The aim is to make the BT300 work better and make it easier and simpler for everyone “

”

reach up into the back of bigger trucks.”

We could see that wouldn’t be ideal, especially when the BT300 obviously had the power to throw the discharge a good distance.

“We’ve now developed a heightadjustable discharge chute. It can be lifted up and it’ll send the material up and all the way to the front of the big Kenworth tippers if needed,” said Nathan, clearly pleased with the development.

It’s a testament to the Australianmade Piranha BT300 that while it’s undoubtedly a well-designed and tough, professional machine, Piranha as a company isn’t sitting on its hands and congratulating itself. It’s still trying to improve.

Apparently the testing and fine tuning of the new chute had taken a fair slice of Nathan’s time.

“We’ve spent weeks!” he told The Australian Arbor Age.

“Weeks and weeks this testing has been going on for.

“Even this week we’ve done three days out in the field testing this, tuning that, going back and cutting off some more steel, welding some more on in a different place…

“The aim is to make the BT300 work better and make it easier and simpler for everyone.”

It’s a noble aim, and we tip our hard hats in Piranha’s direction.

It’s the way really great machinery evolves.

Thanks to a new partnership with UK company Klou, attachment specialist Forest Centre offers a broader range of solutions for excavators – especially grapples.

Reymund Kell, Director at Forest Centre in Tumut, NSW, is a very knowledgeable bloke when it comes to heavy machinery and its specific uses. He’s always enthusiastic whenever he’s speaking to The Australian Arbor Age, and he seems especially keen on the details behind choosing the right grapple or grapple saw for a contractor’s needs.

Lately Rey’s been directing his attention to the smaller excavators and skid steers often encountered on a tree-work site, and when we caught up with him recently we weren’t all that surprised to learn Forest Centre had added another arrow to the quiver.

“As we’re working more frequently with arborists,” enthused Rey, “we’ll be concentrating on the excavator grapples manufactured by Klou.”

‘Klou?’ we wondered. ‘Wasn’t that company started by Cutters?’

Cutters, Klou’s parent company, kicked off in the UK in 1999 as distributors of landscape and forestry equipment in South Africa. Originally, Cutters provided garden and arborist equipment sales and servicing across the UK’s south. But by 2010 Cutters had expanded into the manufacture of hydraulic attachments.

In 2014, the decision was made to concentrate solely on the attachment side of the business under the brand name of Klou – which rhymes with ‘plough’, by the way.

Since then Klou has grown into a global business which supplies customers in the Americas, Australasia, Africa and across Europe with highquality hydraulic attachments manufactured in Dorset, UK.

The company’s catchcry is ‘brutally effective’, and in the world of excavator attachments, it’s probably a good one.

Klou’s KXG-10 is built tough for the professional operator and optimised for the popular two-tonne to five-tonne class of excavators, both with and without rotation.

The attachment is designed and built to handle almost anything, including:

• Timber

• Bra sh Stone and concrete

Klou claims the KGX-10, being made of Hardox® and Strenx®, is ‘practically indestructible’. It says the grapple can work fast thanks to optimised geometry, can rip out fences, roots

The KGX-10 is backed by a three-year warranty, which says a lot for Klou’s faith in its equipment.

New model on the way Rey Kell was understandably rapt to have Forest Centre offering machinery of such high quality, but he was just as excited at the pending release of a new Klou grapple for five-tonne to eighttonne machines.

“Our primary focus remains with purpose-built tree- and timber-handling attachments for larger machines,” he explained, ‘though it’ll be great to offer some complementary solutions for the smaller excavators many arb businesses run, too.”

The first KXG-10s were yet to arrive at Forest Centre as we wrote this, but they’re not far away. Keep an eye on forestcentre. com.au for updates on availability and for first-class tree-handling machinery

Merlo’s flagship rotating telehandler can operate on a huge range of terrain – everything from factory loading yards to uneven forestry sites – and use a big variety of attachments.

When it comes to versatility in forestry operations, Merlo’s 50.26Plus rotating telehandler is tough to beat. From construction jobs with high access points to tree-service jobs that require a telehandler with a grapple saw or a telescopic tree pruner, the Merlo Roto 50.26Plus can do it all.

Tackle just about anything

The strength of the Merlo lies in its wide range of attachments.

While the list of available attachments is a long one – including, but not limited to, buckets, hooks, platforms and a

When it comes to versatility in forestry operations, Merlo’s 50.26Plus rotating telehandler is tough to beat. Images: EEA

range of specialty equipment – the standout in the forestry and arbor fields is definitely the machine’s performance with grapple saws like the GMT035 and GMT050.

The Merlo Roto 50.26Plus can be configured with aerial work platforms complying with EN280 standard, further underlining the machine’s versatility.

Functional and comfortable

Ergonomics were as big a consideration for Merlo in the design of the 50.26Plus as was the machine’s durability and functionality.

Access to the air-conditioned cab is simple, thanks to a door which can be opened 180º and a large handrail to make ingress and egress safe and easy.

The air-conditioning unit itself is built to automotive standards, cutting warmup and cool-down time in half, and the inlet vent is on the side of the cab, away from potential sources of dust and dirt. Inside the cab are eight vents, helping to ensure operator comfort.

Alongside comfort, but an asset for performance, is the grouping of information and the controls of the various systems and devices for

Ergonomics were as big a consideration for Merlo in the design of the 50.26Plus as was the machine’s durability and functionality.

optimum ergonomics, and the reverse shuttle on the steering wheel is also available on the joystick.

The 50.26Plus has a metal structure above the glass roof on the outside of the cab to comply fully with FOPS Level II standard, the most stringent certification level in protecting the operator from falling objects, and in order to remain fully compliant with regulations in frontal tipping prevention, the machine is equipped with features developed specifically to keep the operator safe from frontal tipping, without sacrificing performance, particularly boom speed and lifting capacity.

A 170HP FTP Iveco Cummins engine provides plenty of power for both working and travelling with the Merlo, and to operate the many available attachments. The original Merlo mounting layout was designed to give panoramic visibility and ensure maximum accessibility to components.

Coupled with excellent braking capacity when the accelerator pedal is

released, high torque to the wheels is guaranteed during material handling and transfers, as well as millimetre precision of movements when positioning the load.

For arborists and those involved in treecare work, the primary point of interest in the 50.26Plus will be its performance with a grapple saw, and there are few people who know more about that subject than Rey Kell at Tumut’s Forest Centre

If you’re looking for a grapple, Rey’s your man. We asked him about the Merlo and his thoughts on the attachment best suited to the telehandler for tree work.

“When it comes to grapple-saw equipment for tree-care tasks, we are often asked ‘which one is the best?’” he told us in his usual direct and competent fashion. “Though the jobs couldn’t be more different, we like to draw a comparison to earthmoving – as you most likely wouldn’t carry out all of your work with just one bucket or work tool.

“With grapple saws there are various different solutions and, as a buyer, it’s nice to know some freedom of

choice extends to their application on telehandlers too.

“On Merlo Roto machines two different plug-and-play grapple-saw solutions are available, each tailored to different working needs. These come with Merlospecific ZM2 attachment hitch pickup, hoses and electrical connection.

“When a high degree of flexibility is required for approaching cuts from different angles and working within the canopy – like having a climber in the tree – the GMT Equipment felling grapple saws, GMT035 and GMT050 with Total Tree Control are an unbeatable combination.

On the other hand, if the work ahead will more often require larger cutting and heavier lifting capacity, perhaps with a larger drop zone or processing area to work with, the CS750 Smart grapple saw from Westtech Woodcracker may be the best fit.

“For the ultimate in capability, you can of course have both attachments for Merlo Roto 50.26Plus machine and utilise each as your project needs change.”

There are a few alternatives there, but one thing is constant: The Merlo 50.26Plus.

Regularly check drum speed, shift pressure, and balance to ensure smooth operation.

Vital for land clearing, vegetation management and utility maintenance, the effectiveness of mulching equipment depends on its proper operation and upkeep. To help get the most out of their attachments, the experts at Diamond Mowers have compiled some essential tips for optimising performance and extending equipment lifespan.

Mulching equipment plays a crucial role in land clearing, vegetation management, and utility maintenance. Whether tackling dense undergrowth or clearing storm debris, having the right tools can make all the difference. To help landowners and mulching pros get the most out of their equipment – whether they’re using depth-control or open-drum configurations – the experts at Diamond Mowers offer the following tips for maximising the performance and lifespan of mulching attachments.

To keep drum mulchers operating at peak performance, routine maintenance is essential. Skid steer and excavator operators can prevent costly downtime and maximise efficiency by:

• Caring for mulching teeth. Among

the hardest-working components of a drum mulcher, teeth may need to be replaced throughout the year, depending on operating conditions. Since they endure constant wear from processing vegetation and engaging with the ground, regular

Founded in 2000, Diamond Mowers is a leading manufacturer of mowing, mulching, and brushcutting equipment for the skid-steer and excavator markets. The company’s products include boom mowers, rotary mowers, flail mowers, and forestry mulchers for municipalities, contractors, and landowners, as well as attachments for small-scale and large-scale brush clearing operations.

inspection and maintenance are crucial. Four-point hardenedsteel teeth can be removed, sharpened, or rotated directly on the attachment to maintain efficiency and productivity. Twin Chisel® Planer Teeth are even easier to maintain since they can be sharpened while still mounted to the drum. Twin Maul® Carbide Teeth require no maintenance and simply need replacement when worn or damaged

• Inspecting hoses, couplers, and connections for signs of wear or damage before each use. Loose fittings should be tightened and worn components replaced to prevent downtime and ensure optimal performance, and

• Cleaning the drum and checking for debris buildup or damage after every use. Regular cleaning prevents clogging and reduces unnecessary strain on the equipment, extending its lifespan.

Maximising the performance of a drum mulcher isn’t just about maintenance – proper operation is just as important.

• Optimise hydraulic flow: ensure the carrier’s hydraulic flow matches the drum’s specifications to achieve

Teeth may need to be replaced throughout the year, depending on operating conditions.

Reduce strain on the mulcher and improve results by making multiple passes through dense vegetation.

working with dense undergrowth should focus on steady, controlled operation “ ”

maximum cutting power and efficiency

• Tune the drum for optimal performance: regularly check drum speed, shift pressure, and balance to ensure smooth operation. Adjust settings to match material conditions, preventing excessive vibration and promoting even cutting.

• Use strategic cutting techniques: reduce strain on the mulcher and improve results by making multiple passes through dense vegetation. Excavator-drum-mulcher operators can take advantage of their machine’s extended reach for precise mulching in hard-to-access areas such as steep slopes, pond edges, or roadside ditches.

• Prevent overloading: avoid forcing the drum into materials beyond its cutting capacity. Skid-steer operators working with dense undergrowth should focus on steady, controlled operation to maintain consistent productivity and prevent unnecessary wear.

Routine maintenance and proper operation not only extend the lifespan of mulching equipment, but maximise performance and productivity, ensuring consistent results. By selecting the right drum mulcher for an application and maintaining equipment, operators can confidently tackle the toughest jobs.

Visit colbrookindustries.com.au to learn more.

The Queensland Arboricultural Association (QAA) continues its great work.

ISA has announced significant updates to the Tree Risk Assessment Qualification (TRAQ) program, set to launch in late 2025. Images: QAA

Abig thank you to all who attended the February Meet & Mingle. It’s fantastic to see this event gaining momentum, bringing together industry professionals in a relaxed and engaging setting. If you missed it, don’t worry – the next Meet & Mingle is set for April.

Stay tuned to QAA’s social-media channels and website for updates. If you’re interested in getting involved, reach out —the QAA would love to hear from you.

QAA is committed to helping businesses and arborists align for long-term success. The association actively promotes initiatives to connect professionals with the right teams and opportunities within the industry. If you’re interested in learning more or getting involved, get in touch by phoning (07) 3821 1488, emailing office@qaa.net. au, or through the website.

ISA TRAQ program changes are coming in 2025.

ISA has announced significant updates to the Tree Risk Assessment Qualification (TRAQ) program, set to launch in late 2025.

Key changes will include:

• New training and exams – a revised program with updated training materials and examinations will roll out in Q3/Q4 2025

• Extended certification validity – TRAQ certification will now last seven years instead of five, and

• End of TRAQ renewal – the current renewal option will be phased out once the new program is live. What does this mean for you?

A few things, but mainly:

• Current TRAQ holders will remain certified until their credential expires,

• TRAQs renewed before November 2025 will have their certification extended under the existing system (five-year validity), and

• Those who want the seven-year credential will need to wait for the new program’s release.

Check your certification status via the ISA Directory to ensure you’re up to date.

The Quantified Tree Risk Assessment (QTRA) workshop is back on May 22 and May 23.

There are only a few seats left, so secure yours now before they’re gone. To register, contact QTRA directly.

Join QAA members for an exclusive Single Rope Technique (SRT) workshop at Tamborine Showgrounds on Saturday, April 05, led by the world’s number-one climber, Barton Allen-Hall.

Learn advanced SRT skills from the best in the field.

Following the workshop, don’t miss the Masters Invitational on Sunday, April 06. It’s set to be a thrilling competition showcasing top-tier climbing talent. For more details and registration, visit qaa.net.au.

Stay updated on events, workshops, and initiatives by following QAA on social media or at qaa.net.au.

ArbWest recommends engaging with a professionally trained arborist for advice on wildlife interaction with trees. Image: Michelle/stock.adobe.com

The

Arboricultural Association of Western Australia (Arb West)

shares some thoughts on managing trees and wildlife.

Arborists have a passion not only for trees, but also the wildlife they support.

In arboriculture it’s a fine balance between managing trees and maintaining natural habitat, food sources and a healthy ecology to support local fauna. The work of treecare professionals impacts not just trees, but also the wildlife that relies on those trees, and, in turn, the clients’ properties.

It’s important to ensure advice is the most up-to-date a trained, certified arborist can give, to ensure services don’t inadvertently cause issues for the homeowners.

Here are ArbWest’s three key points to consider while maintaining trees to ensure a harmonic balance with nature.

1. Tree Planting: nut-bearing and fruit-bearing trees

While species like figs and apple trees are beautiful and beneficial, they can

attract rodents and other critters if not strategically placed. When arborists provide professional advice on tree selection, they consider the location of fruit-bearing trees and advise planting away from buildings and structures.

For established trees, maintenance pruning is advised, such as formative pruning, clearing old fruit and removing dead wood. This will not only help keep pests away but assist in the new season’s growth and overall structural form of the tree.

As fruit ripens, don’t forget to harvest the fruit so it can be enjoyed. If left on the tree, pests can become present, and owners may consider removing the trees as their preferred option.

Kelvin Ussher, ArbWest President warned: “If an owner allows this to persist, they may require the services of a pest exterminator, who may advise to have the tree removed. Awareness and education of these potential issues via a trained

arborist can often negate or remove these infestations, with forward planning and maintenance being the key.”

Consider open areas for fruit-bearing trees. The added light and airflow often enhance the amount of fruit produced as well as minimising rodent issues. Also, avoid planting them near high-traffic zones like driveways or pathways where they can create slip hazards – or beside retaining walls and fencing where the root systems may cause structural issues long term.

Annual or biannual inspections of trees by a qualified professional arborist is advisable. Not only do the trees receive a health check, but the advice incorporates the overall maintenance and health of green spaces to maintain safe distances from property and infrastructure before it becomes a costly issue.

Trees provide food and shelter for animals; they also provide travel routes. Branches that overhang, or touch, roofs act as access points for local fauna.

“When trees are giving the local wildlife easy access to the roof, rodent problems are almost guaranteed,” Kelvin Ussher said. “This is particularly true if the trees are of the nut- or fruitproducing variety.

“The benefits of using trained arborists in maintaining trees around a property ensures an abundance of fruit, infrastructure kept clear of rodents and bushfire concerns, plus it addresses the structural and formative form of the tree for potential storm-damage prevention.”

3. Handle tree stumps wisely

Tree stumps, while beneficial for some wildlife, can also attract pests such as rodents, snakes and white ants. These pests often find stumps to be ideal for nesting and breeding, especially within urban areas.

A trained arborist will advise the best method of stump removal as it often depends on factors like the size of the stump, its location, the risks involved and how these can be mitigated.

Unfortunately, there aren’t many hard-and-fast rules regarding the best way to remove stumps. Depending on the situation, consider stump grinding which can remove most of the tree base. Chemical treatments should only be considered as a last resort due to the implications to both native fauna and resident pets.

ArbWest recommends anyone with a potential issue to engage with a professionally trained arborist for the right advice on wildlife interaction with their trees and all maintenance requirements. This will help avoid costly future issues while also fostering the preservation of trees and maintaining a harmonious environment for local fauna to inhabit.

Visit arbwest.com.au and search the ‘Find a Contractor’ section for a professional arborist servicing your area.

Image: Paul/stock.adobe.com

Depending on the situation, consider stump grinding which can remove most of the tree base.

Image: Waldis/stock.adobe.com

The TTIA’s Brian Beecroft offers some important points to consider when dealing with an underperforming employee.

Irecall once reading a decision issued by the Fair Work Commission specifically suggesting that when an employment relationship had broken down, employers should consider the option of demotion rather than outright termination as a preferable alternative disciplinary measure. It instantly raised the issue of whether an employer demoting an underperforming employee runs the risk of an unfair dismissal under the Fair Work Act, and whether the associated issues relating to procedural fairness still apply.

‘Significant’ reduction?

In some circumstances management may feel the offer of demotion to

a position is more suitable to an employee’s skills and experience when they have failed to prove their competence in another role. While their duties and responsibilities would change, there is often a lower remuneration attached to the demoted position. Therefore, the key issue is, does the employer have the right to demote the employee for reasons of unsatisfactory performance?

While demotion, in this circumstance, may be viewed by the employer as preferable to the dismissal of an employee, there are a number of implications of which an employer should be aware when considering the demotion of an employee. The Fair Work Act (s386(c)), in explaining the

Brian Beecroft TTIA CEO

meaning of dismissal for the purpose of unfair dismissal, states a person has not been dismissed if the person was demoted in employment, but

the demotion does not involve a ‘significant reduction in the person’s remuneration or duties’, and the person remains employed with the employer that effected the demotion.

What amount represents a ‘significant’ reduction in remuneration or duties can be difficult to assess, and would be determined on the individual circumstances of each case. It can also be a factor whether the employee will consent to the demotion.

Demotion generally involves the termination of the employee’s existing contract of employment and the offer of a new contract. This is because the terms of the new contract are usually significantly different in at least one important aspect (job status, work duties, responsibilities,

There are a number of implications of which an employer should be aware when considering the demotion of an employee. Image: Roy Pedersen/ stock.adobe.com

If a demotion turns into a claim for unfair dismissal, the employer will need to prove he or she acted with procedural fairness “ ”

Employers should consider the option of demotion rather than outright termination. Image: Oulaphone/stock.adobe.com

remuneration, career prospects and so forth). Because termination of the contract is involved, it raises the possibility the employee has actually been dismissed rather than demoted. The employment contract could be repudiated when an employee is demoted without their consent, and suffers a significant reduction in duties or remuneration. The employer must also be careful in avoiding any hint of duress or influence in the employee’s decision to accept a demotion. Because demotion and dismissal are alternate options, TTIA members should follow the same procedures leading up to the decision to either demote or dismiss. These are likely to include objective performance reviews and discussions, performance counselling, warnings, opportunities to improve, training, and similar circumstances. If a demotion turns into a claim for unfair dismissal, the employer will need to prove he or she acted with procedural fairness before making its decision, and whether there was a valid reason.

A demotion which involves a significant reduction in the employee’s remuneration or duties may be deemed by the Fair Work Commission as unfair dismissal unless permitted under the contract of employment, or applicable modern award or enterprise agreement.

TTIA is proud of offering members the peace of mind of knowing they have access to the association’s inhouse lawyer and legal department. This service is unique in the timberproducts industry.

The TTIA won’t refer you to a third party for legal assistance.

With this in mind, members should consult the TTIA for legal advice in any circumstance involving demotion issues, whether performance-related or for other reasons like redundancy or restructuring, to avoid potential costly litigation.

Contact the TTIA on (02) 9264 0011, or by email ttia@ttia.asn.au, for advice on this issue.

TCAA

regular Jim McArdle underlines the

importance of networking among people and groups with similar goals and interests.

Collegiality is a broad term used to describe the elastic bond of communication between arborists in a similar group, body or blog space. The definition of collegiality I like best comes from the Oxford Dictionary and reads: ‘As a noun, collegiality means cooperative interaction among peers. As an adjective, collegiality indicates the way a group of colleagues take collective responsibility for their work together with minimal supervision from above’.

The energy of collegiality is in the process.

Most of us can relate to collective responsibility or people who work pleasantly together for a time. It sounds like a dream, and I’m sure we’ve all started on the ground and felt we weren’t initially really part of the team.

But those who join an association will meet people with similar aspirations and ideals, and the collegiality is there right from the start.

Communication is a huge factor in collegiality.

Not all experienced, bona fide arborists are good at sharing their thoughts and ideas. Sometimes, with the best of intentions, thoughts and principles can be shared far more easily when discussed in a group – especially with diagrams and images – as opposed to in a mentor-to-mentee discussion. An association meets regularly and the interaction with an executive team can Those who join an association will find collegiality from the outset. Image: Chanyapat/stock.adobe.com

‘turbo’ discussions and resolutions and help clarify explanations and enquiries.

Advantageous

Networking, advertising, utilising similar risk tools and creating a blog or email trail often encourages peers to form a collegiate group, and groups of that kind are very beneficial to the people and ideas they represent.

Writing and communicating – or representing and teaching – are ways in which an arborist can increase their experience in arboristry. The written word is perhaps the best medium, and certain documents should be scoured for news, technological examples or a new way of progressing.

Discussions which increase cooperation are often the basis on which industry collegiality is founded. Put this together with interested colleagues from forestry, council Tree Preservation Order officers, environmental lawyers and barristers – people with aligned interests – and a thinktank may emerge with a new position on arboristry practices and principles that have been debated or discussed.

Sometimes, with the best of intentions, thoughts and principles can be shared far more easily when discussed in a group “ ”

A relevant example is the Code of Practice that has been worked on since 2006. With years of involvement I’m sure Dan McArdle – one of two arborists on the board – has finally seen the light on this new, soon-to-be released document. Assembling this material was an epic collegial exercise and the whole arboriculture industry will benefit.

Other amazing left-of-field arboristry ideas which emerged from sharing and broad thinking include:

• The professor from UTS-NSW technology who utilised trees and green spaces on roofs as a step into the future. It was fascinating to see how arboriculture and design overlapped, and issues like soil depth, soil fertility, exposure and other variances on a tall-building rooftop interacted to affect tree growth and stability;

• Avatar, the blockbuster film by James Cameron, entirely based its scenery on fluorescent creatures and plants;

• A crowdsourcing team raised $440k in one day from backers all around the world for a chance of fluorescent seed progeny (biogenetics). According to the journal Scientific American, this brilliant idea has rolled around in science since 1924;

• Utilising plants like hemp in construction and fashion;

• Research and development of fastgrowing cultivars to produce timber within four to five years link sample plots studied around Sydney;

• Katie Holten, an aloof evolutionary

biologist, noted Leonardo da Vinci’s mathematical observation, ‘Branches of a tree at every stage and at any height, when put together, were equal to the trunk below them’. There is tree maths in Tree Protection Zone calculations and SRZ formulae, climate data to interpret like tables of BOM weather patterns, and it’s surprising the amount of maths relating to wind force as Breloer & Matthecks showed in The Body Language Of Trees: A Handbook For Failure in 1994;

• Maths for ratings, estimating weights and specifying weights may be absolute, but sometimes an engineer has less knowledge than the incumbent arborist when it comes to weights of tree species. Bracing and estimating weights from crane use, and from questioning an expert crane driver if the weight is bearable or reaching capacity of a load, can sometimes be a justifiable alternative, and the collegiality can have very real and serious benefits;

• The rapid transport of exotic pests and diseases is a key issue. Identifying risks to our urban forest biosecurity

There are many good arborists in the field who enjoy being collegial but rarely have time because of their crackingly busy schedule “ ”

requires vigilance. Pests need to be identified and communicated to agencies and the general public informed when something is going wrong in our forests – like pine nematode eradication with no active vector in Melbourne, and myrtle rust affecting trees in the Daintree and causing extinction events in some species. Agonis flexuosa is susceptible

and perfect for development of this disease. Being collegial we can ‘resist’ the new Asian Longicorn beetle, the Mulberry Longicorn beetle and the Japanese Pine Sawyer beetle. Those are three pests we don’t want in our country, but which have found entry to Australia. Serious issues like these need vigilance or we’ll lose large tracts of forest;

• AQF level 5 arboristry is collegial in utilising researchers, including climate consultants and ecologists (bio-credits), and we’re pressed into collegiality because we need other experts to support or challenge us to a new position.

Several peak bodies in Australia use a qualification process to promote learning in arboriculture. So many points need to be done or completed to keep membership.

This idea of accreditation is perhaps outdated, but at least it keeps achievements transparent to the executive. I’m of an opinion that real learning comes from understanding and communicating in a variety of

It was fascinating to see how arboriculture and design overlapped in the design of rooftop gardens. Image: sorasat/stock.adobe.com

forms, whether podcasts, essays, commentary, photos or another medium to a mentee or mentor.

What about the utilising of AI in our literature? Or the question of new tariff costs on our equipment from the United States?

There are many issues where I urge arborists to skill up with a cooperative and be resourceful. NSW tree climbers have done it, and so have a multitude of interest groups on Meta, Instagram or other social interfaces.

There are basic questions of privacy of resources when sharing, and certainly phoning a colleague and requesting permission to source their works, or seeking their consent for a peer review, is as collegial as it gets. TCAA member Arbor Pride has released gardening newsletters of a high professional standard, and sharing these with members and the public at its own cost has ensured the company is held in high regard. It also confirms its place in arboristry.

Using this process TCAA has contacted many experts and always

found the relationship rounded down to mentor-and-mentee, or one of common industry bonds trying to build decorum. TCAA sourced Jeremy Barrell’s ULE and changed it to TULE with relationship to timeframes. We asked Andrew Morton for his blessing on Retention Values. We also met with the minister and are still trying to get apprenticeships and traineeships for the industry and other industry-related processes.

There are many good arborists in the field who enjoy being collegial but rarely have time because of their crackingly busy schedule.

Why don’t we have students learn arboristry in schools? There are so many good collegial principles that can extend from our field. NATSPEC has a great student prize of $8000 in a national student competition to promote collegiality.

The TCAA will was represented at the Arboriculture Australia 2025 conference and sought to be collegial with other state heads to bring about the licensing of arborists and partnerships.

Why don’t we have students learn arboristry in schools? “ ”

Utilising plants like hemp in construction and fashion came about thanks to sharing and broad thinking. Image: Heng Heng - AI Stock/stock.adobe.com

When

the job calls for non-destructive excavation, Sydney’s Synertree is ready to comply…thanks to AirSpade.

All arborists love trees. That seems fairly self-evident.

But arboricultural consulting company Synertree, based in Rosebery, NSW, takes that ethos to a very high level. The company’s website even claims Synertree is ‘Nature’s collaborative experts, specialising in human and tree synergy’.

It’s a big call, but a call director and AQF-5 consulting arborist Mathew Phillips is proud to make.

With a deep-rooted passion for trees and a strong commitment to environmental preservation, Mathew and Synertree are dedicated to delivering professional, reliable, and sustainable services tailored to individual requirements.

Clever ‘Syner… Synert…”

The Australian Arbor Age’s normally eloquent editor stumbled around the unusual name.

“It’s ‘Synertree’, explained Mathew patiently. “As in ‘synergy’ and ‘tree’.”

The company motto ‘We represent the trees’ clicked into focus and we realised the name was very clever.

Almost as clever as the company’s embracing AirSpade.

“I’m using the AirSpade 2000,” said Mathew, clearly happy to discuss the equipment. “I’m in consultation with Knight Pneumatics to possibly trial the AirVac, and it’s something we’ll look at purchasing.”

Mathew and Synertree offer a big range of consulting services in and around Sydney, and the AirSpade plays a significant part in the company’s operations.

While the AirSpade is a versatile piece of equipment, Mathew is finding an increasing demand for the gear is coming from councils and LGAs.

“Everything ranges from nondestructive root exploration,” he explained. “I would say that’s our primary use of the AirSpade. We do that for everyone from government to private residents.

“It’s mostly for development applications or where trees are impacting infrastructure.”

Aside from that type of reporting and consulting, Synertree has the AirSpade showing its value in various applications.

“We use it for transplanting small trees,” mused Mathew. “Again, mostly within development applications where we identify trees that can be transplanted, or they’re identified for transplanting by architects or landscape architects. We come in and AirSpade around the tree, work out what roots could be pruned – if any, or if we have to – and then we lift the tree and carefully transplant it.

“Most councils, tree officers, and landscape officers in and around Sydney are now demanding non-destructive root exploration, and a lot of the time they’re specifying AirSpade.”

AirSpade’s proprietary supersonic nozzle turns compressed air into a high-speed, laser-like jet that dislodges soil. It’ll easily and gently remove soil around tree roots for better nutrient absorption and growth, and it can dig through soil, clay, and other materials with precision and control, breaking up compacted earth and improving drainage.

Powered by an air compressor, excavation with the AirSpade offers several advantages over conventional tools such as picks, shovels, and backhoes. It’s two to three times faster than hand excavation and causes less worker fatigue. There are no sharp metal edges, so AirSpade is harmless to buried, solid objects such as utility lines, telecommunication cables, hazardous-

waste containers, military ordnance, and, of course, tree roots.

But there’s another big advantage.

“It’s very easy to use,” Mathew explained in a matter-of-fact tone.

“You have to learn how to operate it to get the best results, but we mostly stick with the 105cfm straight nozzle. There’s also a curved nozzle which allows for angled displacement. When you use that setup it takes a little muscle work from the operator to control, but with the straight nozzle it’s excellent.”

Selection of the nozzle depends on the job.

Mathew explained: “Overall it depends on the use, the site, and the level of deposition.

“The AirSpade can displace a lot of soil and it can create a lot of dust, so, depending where you are, you may want to blow it straight into the hole and then move it out the end of the trench with a shovel, or displace it fully and replace the soil.

“Normally we start at the structural root zone or the proposed cut location. Let’s say someone wanted to put in a building and wanted to cut for a slab. We get the builder to outline where the cut was proposed, then, first up, we dig a trench down to the local government’s specified level – normally around 800mm – and we try and find any roots.