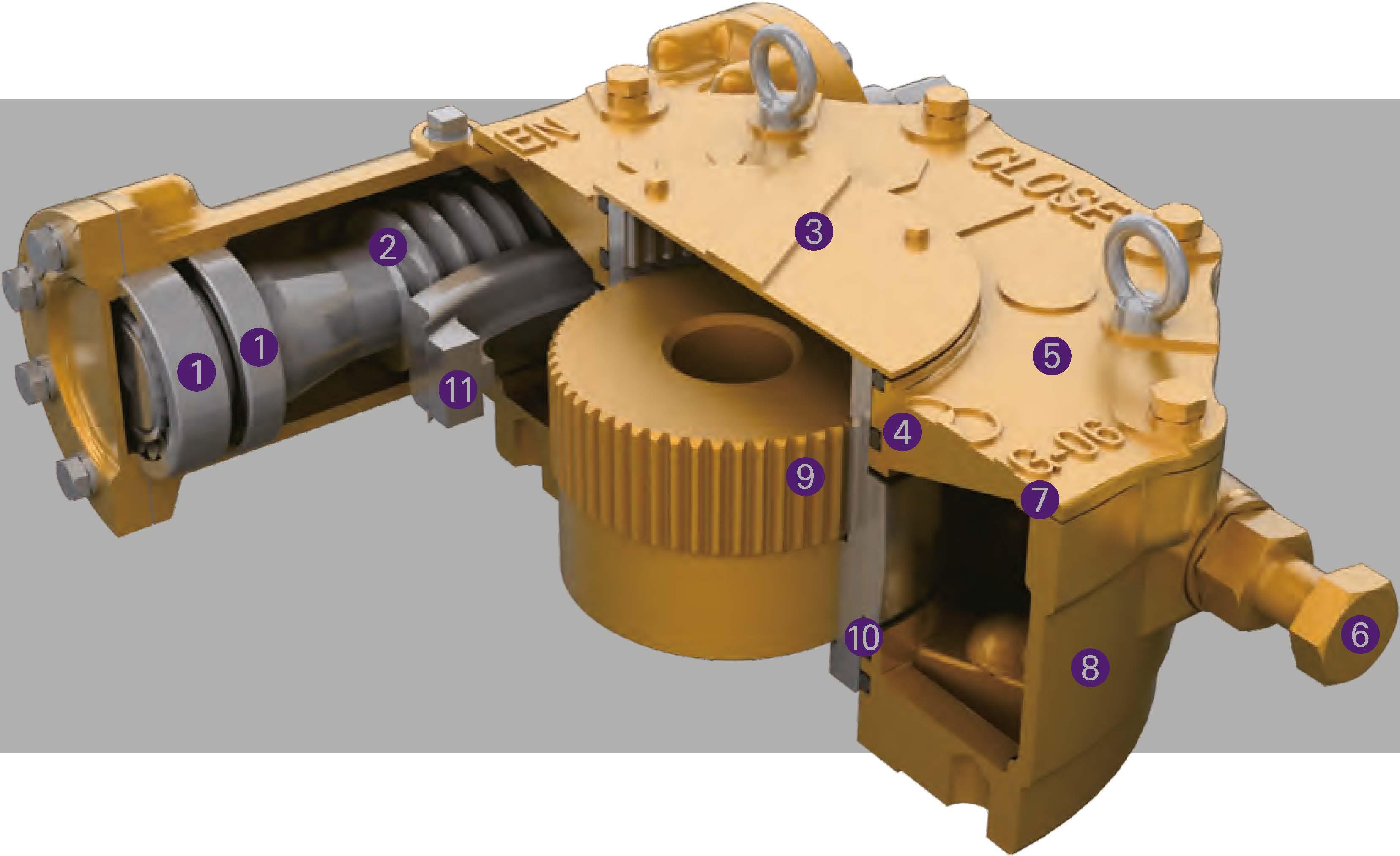

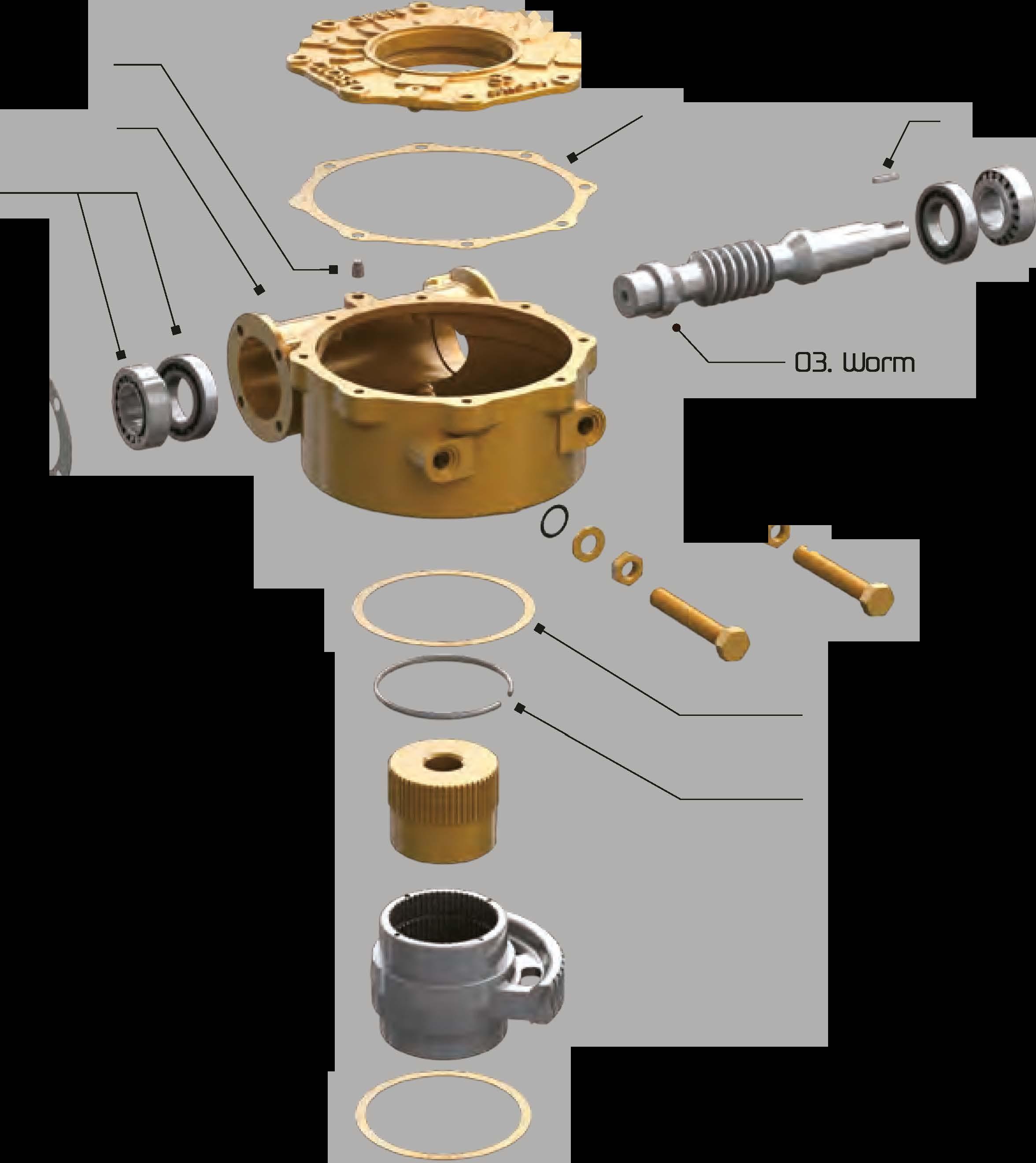

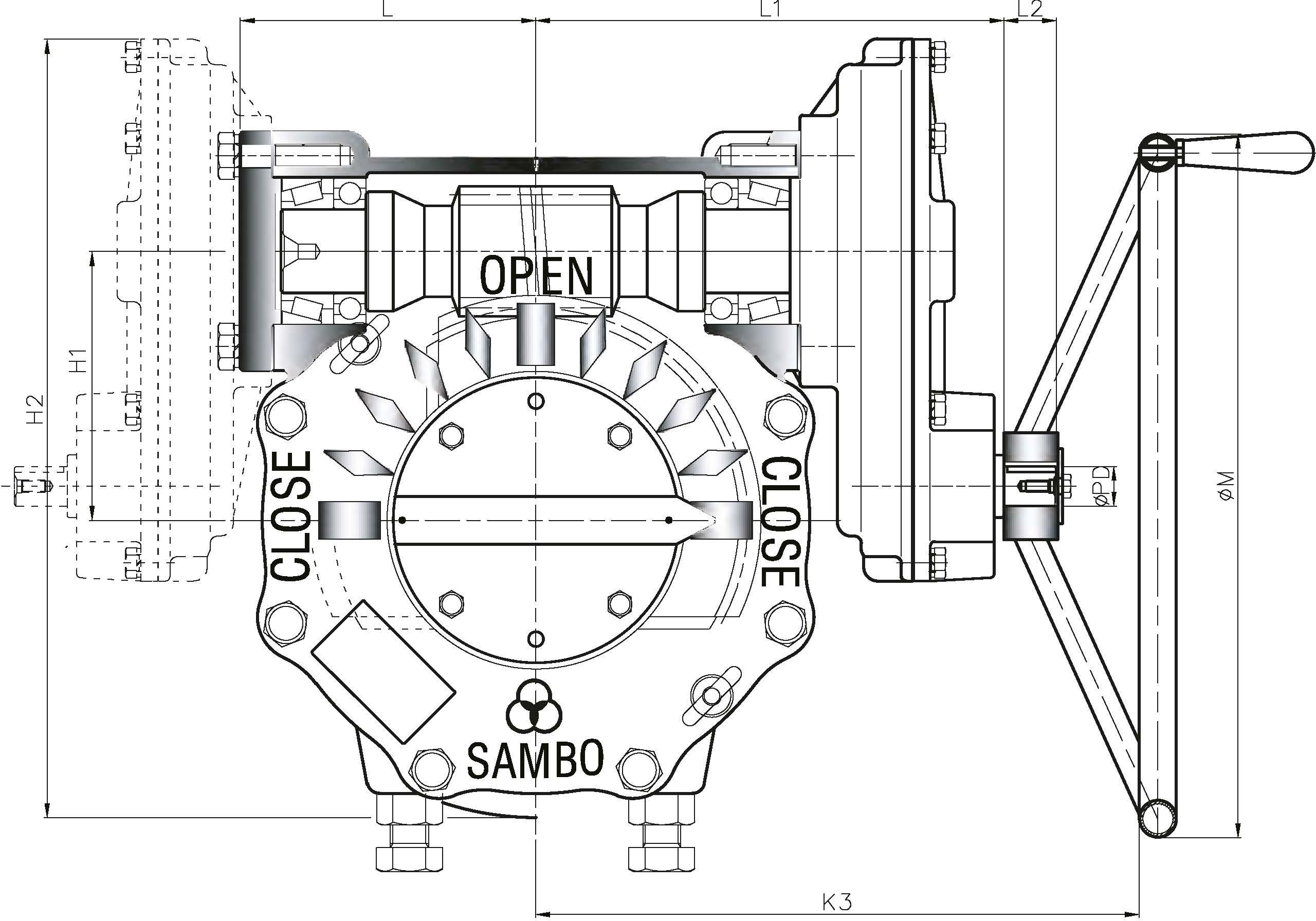

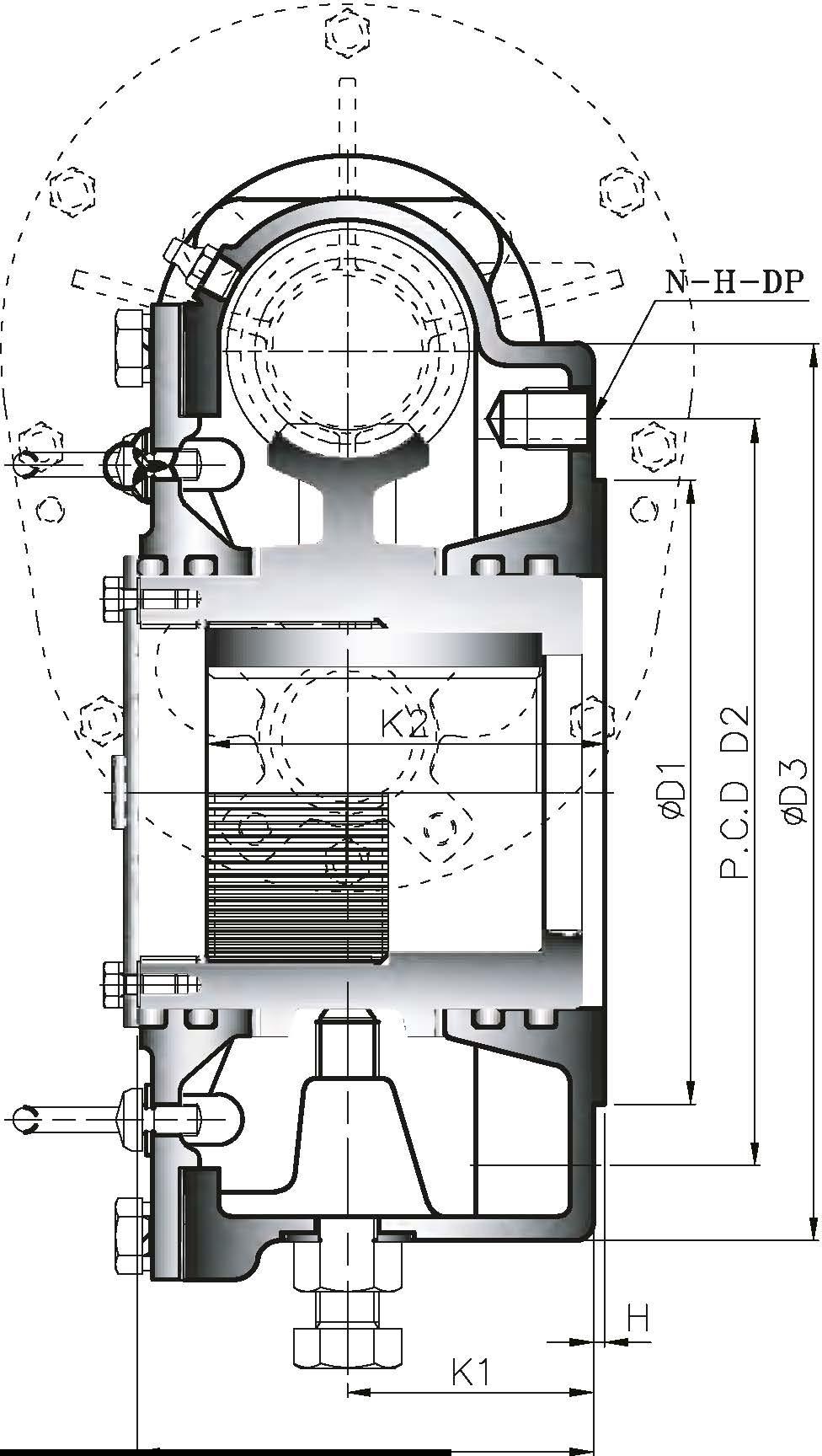

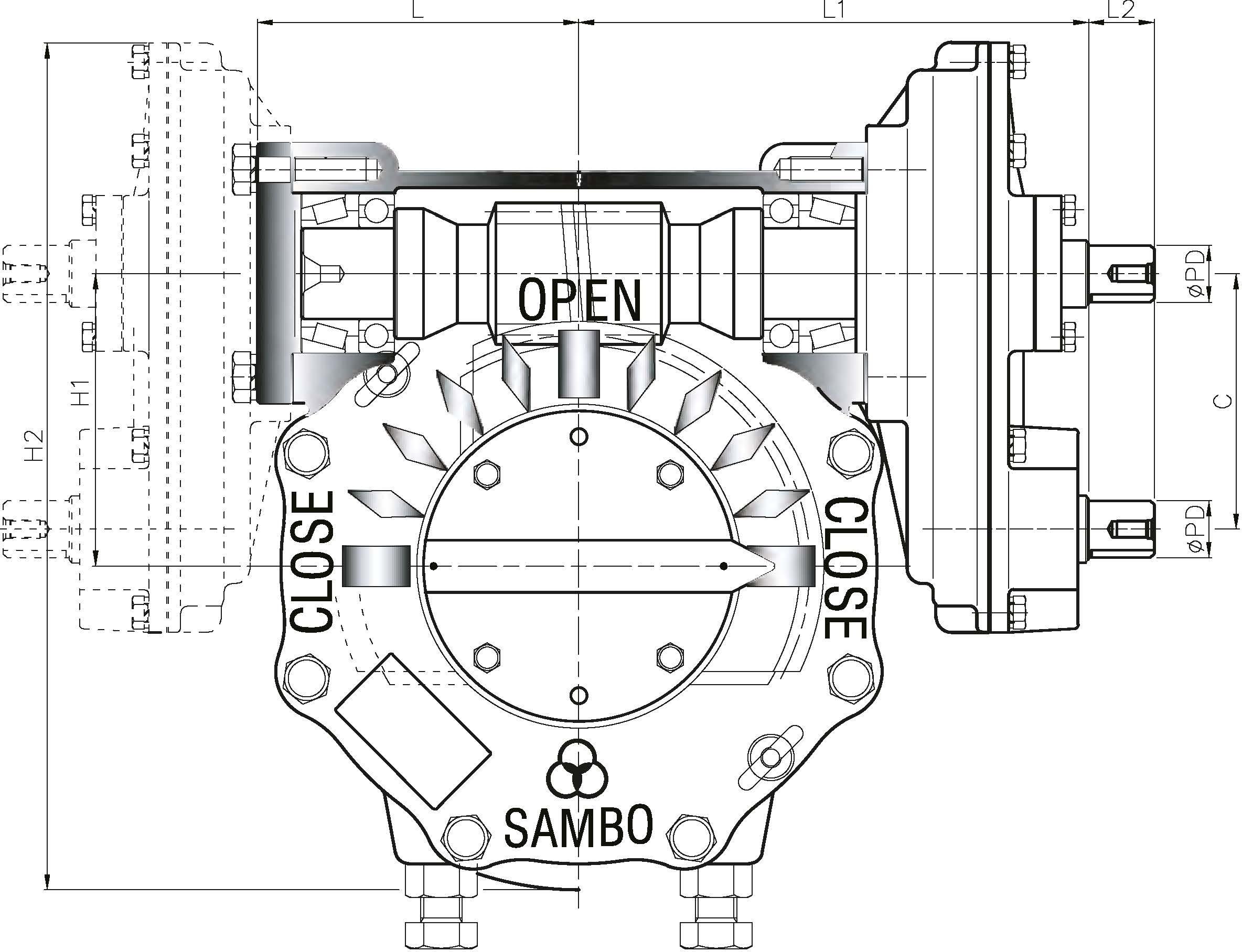

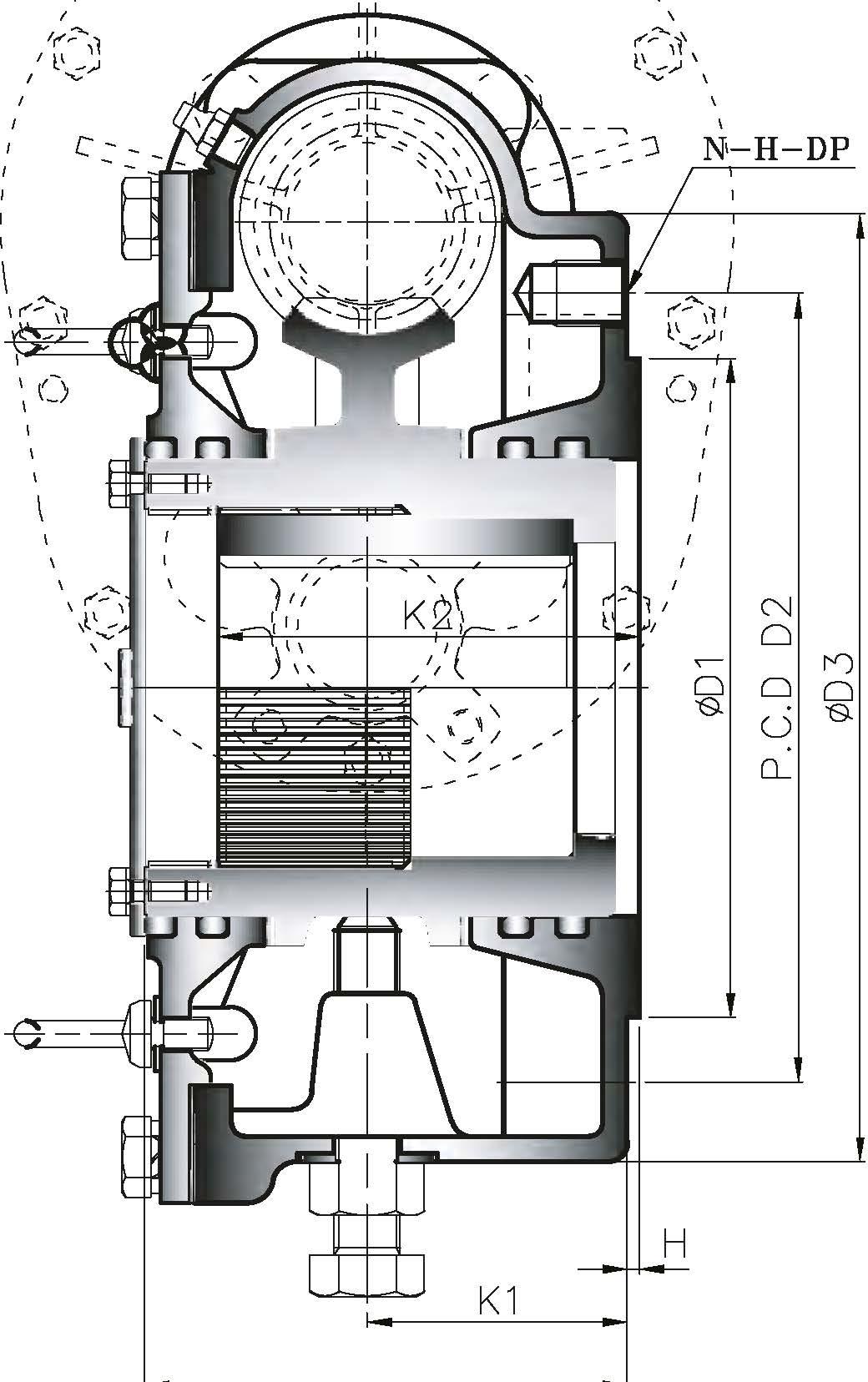

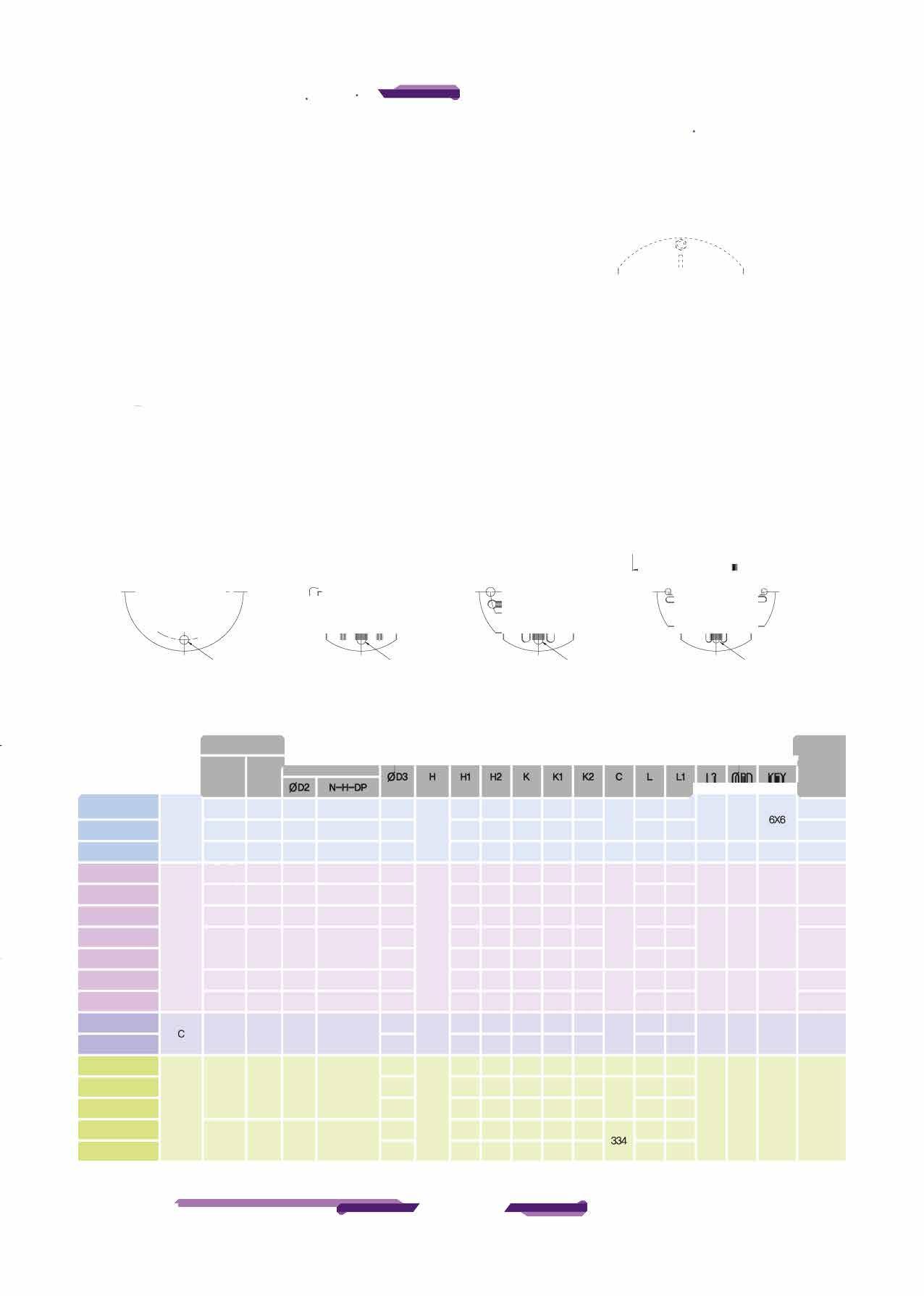

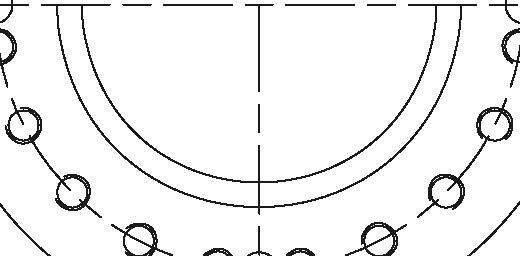

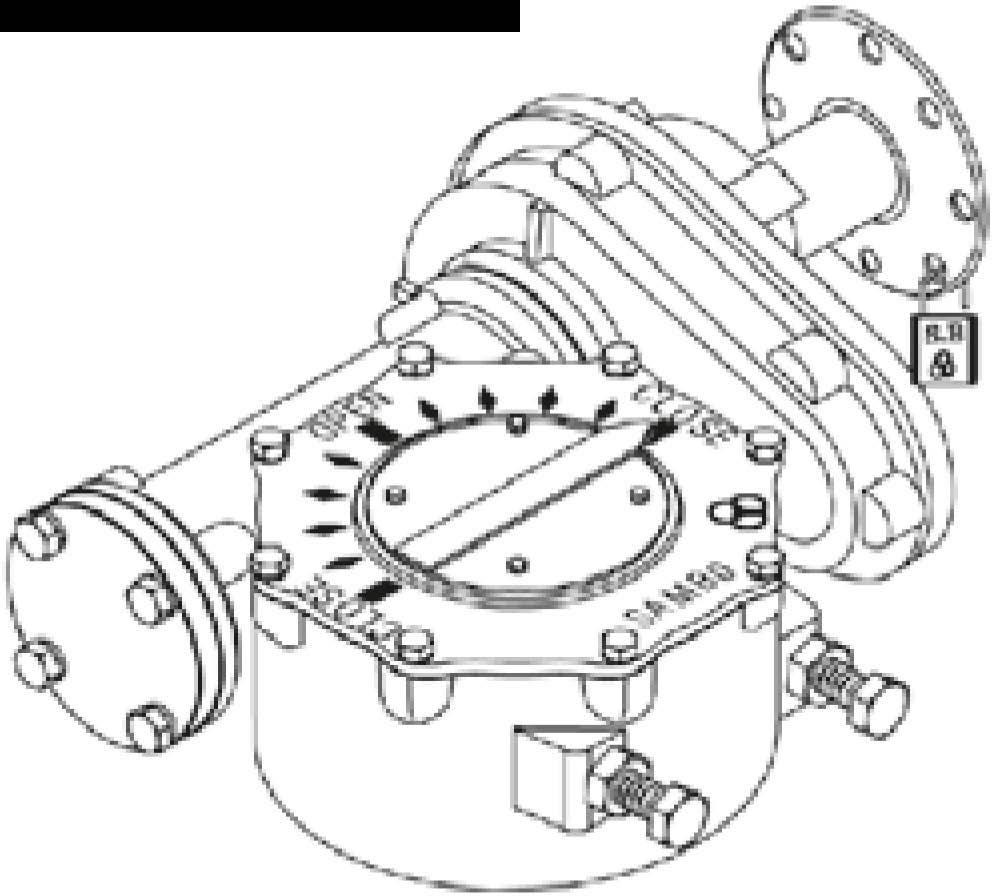

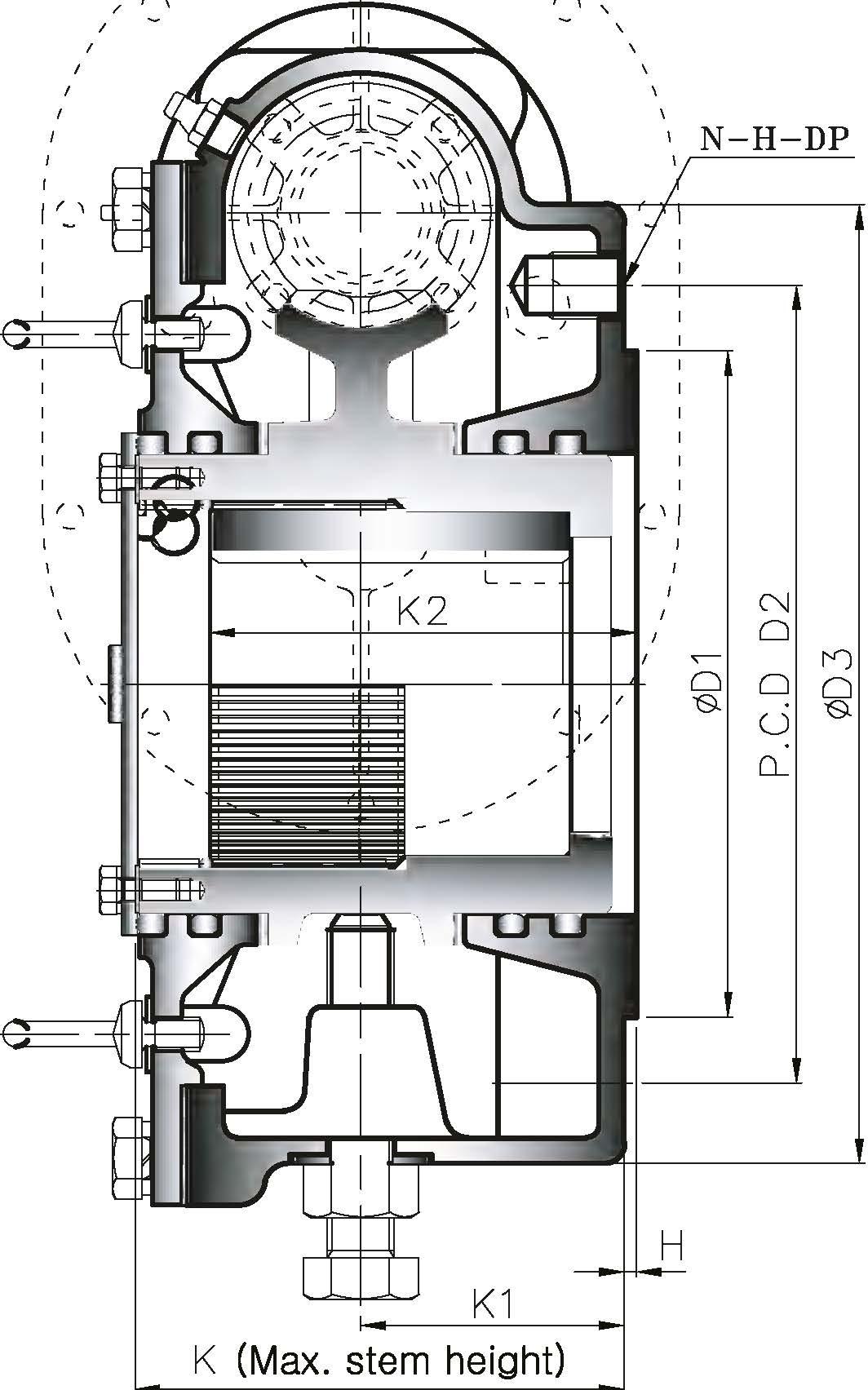

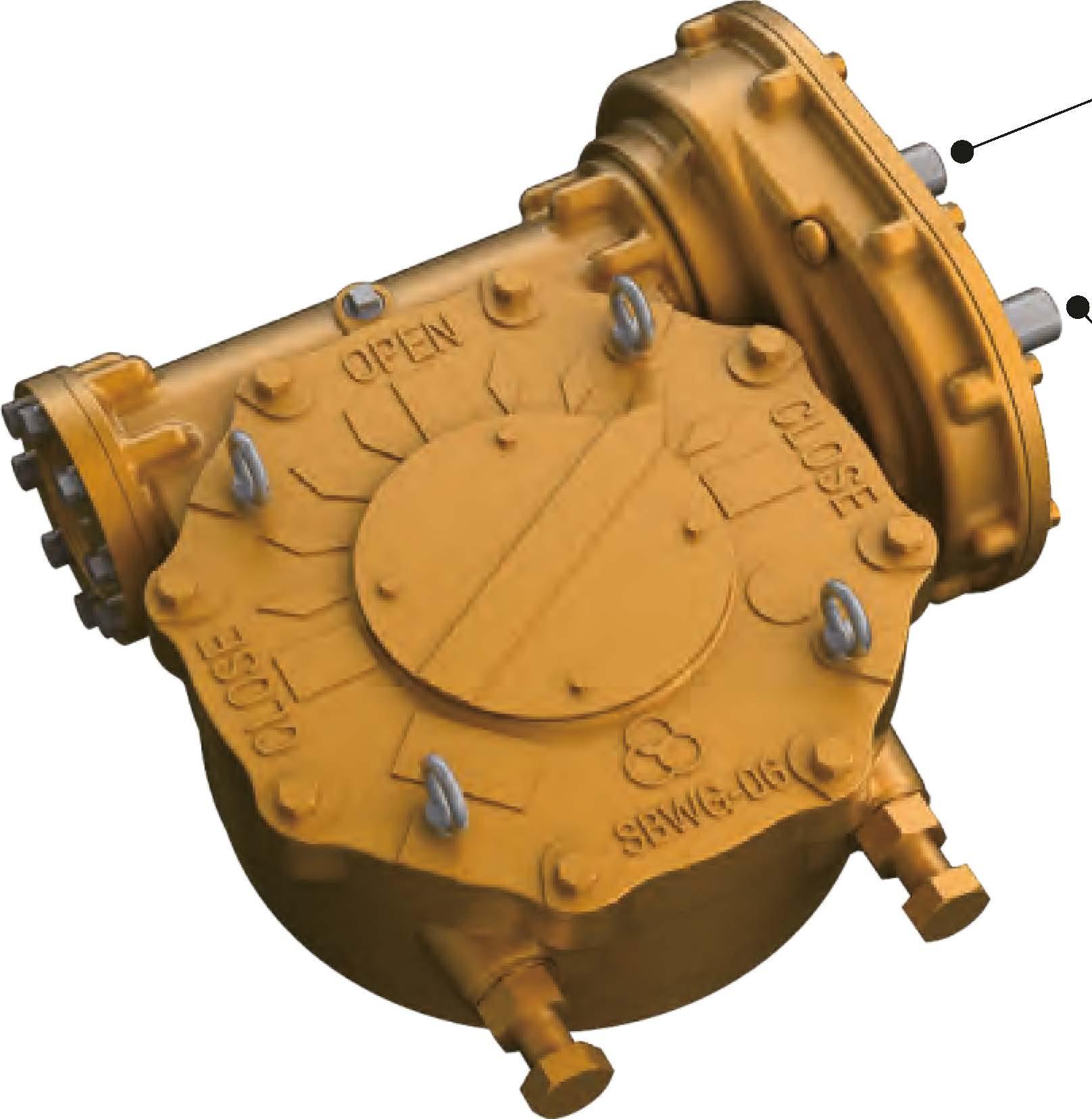

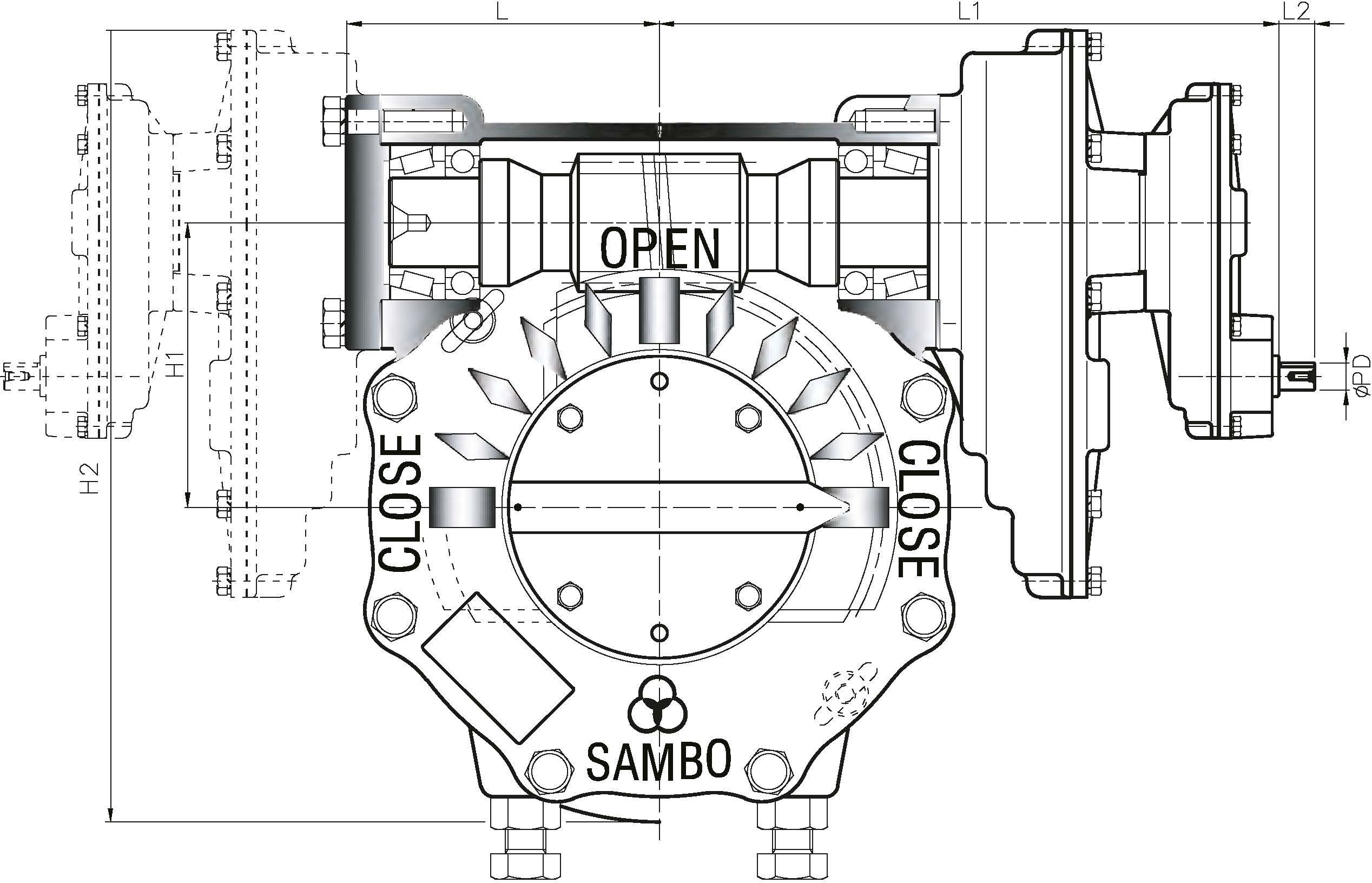

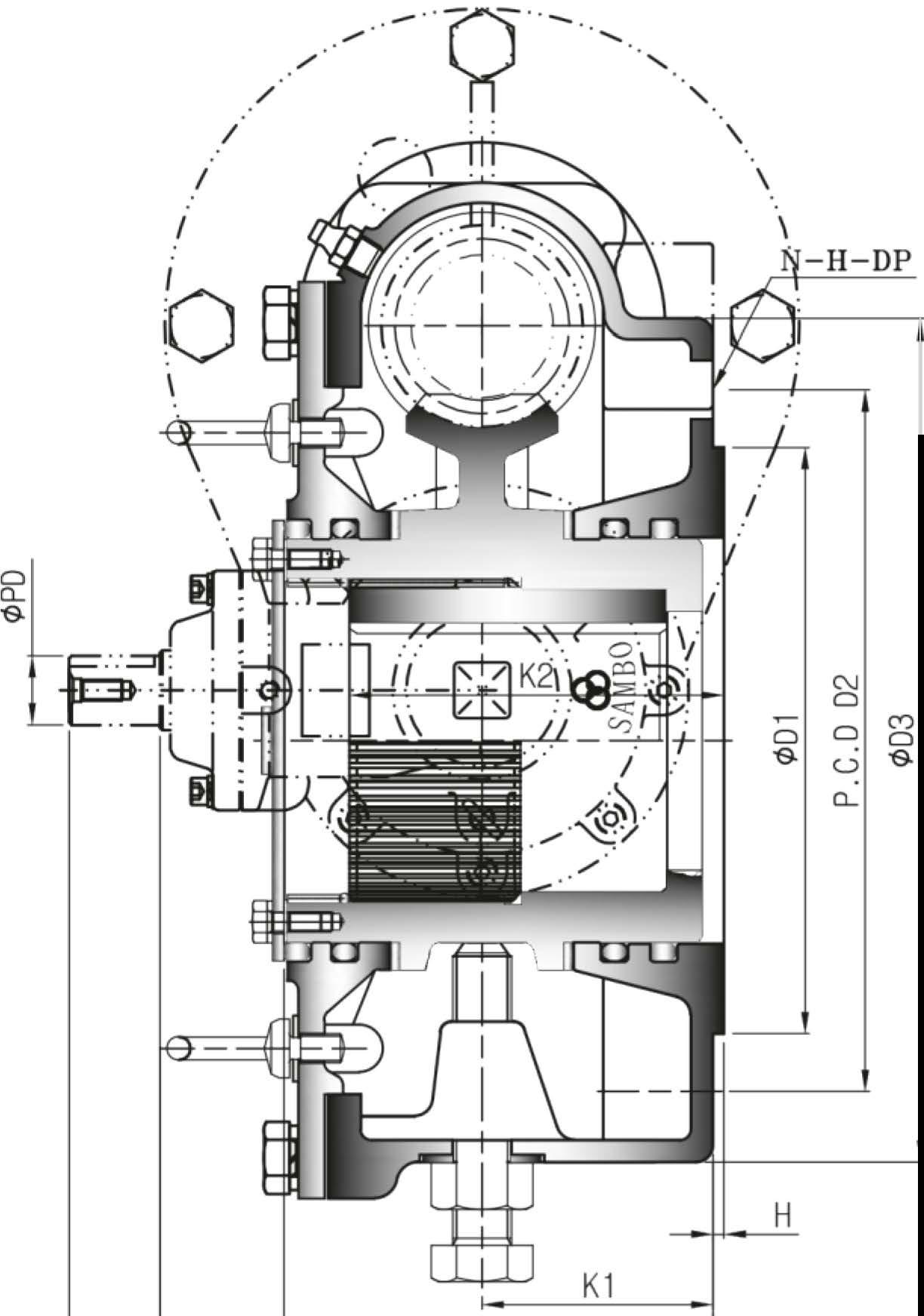

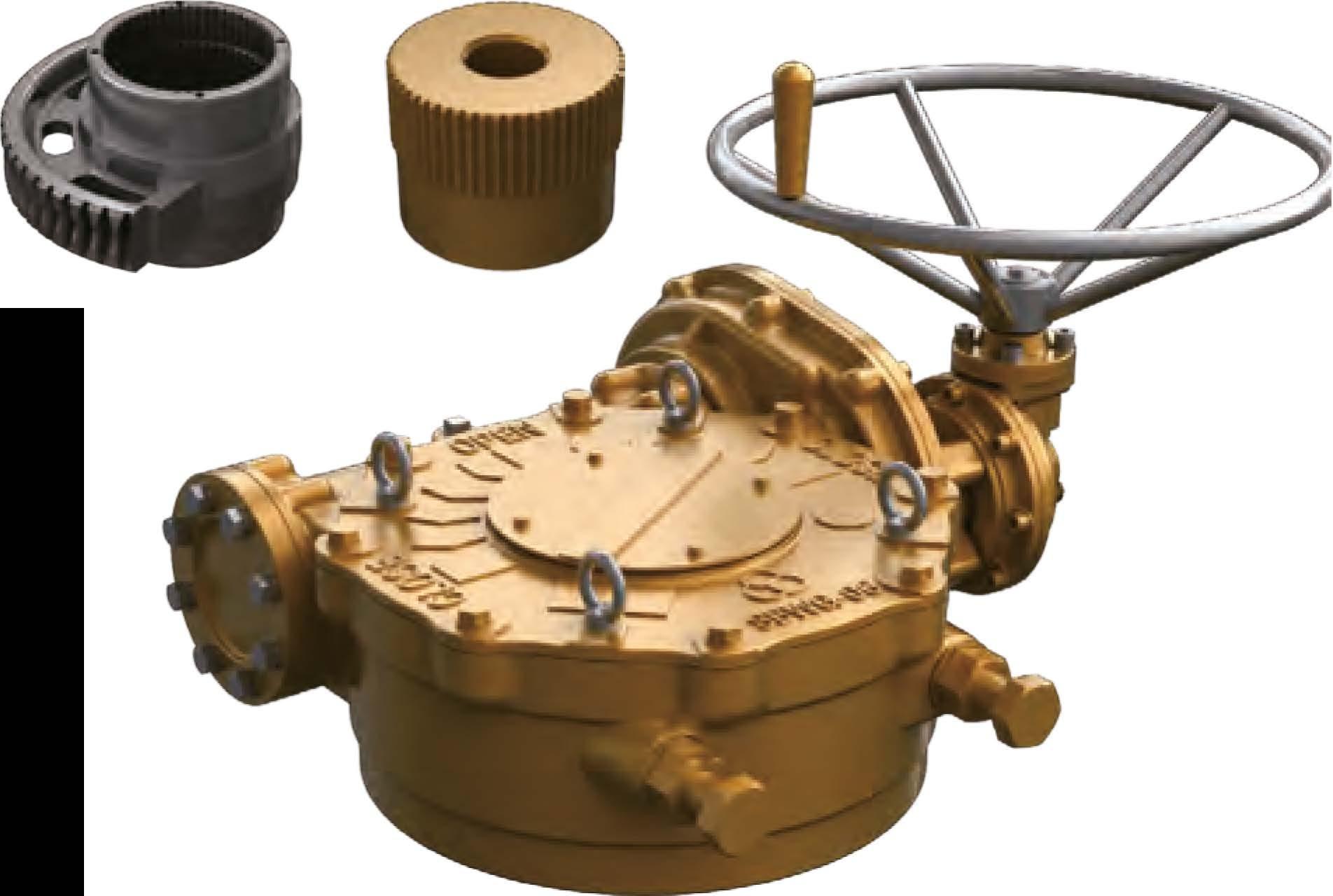

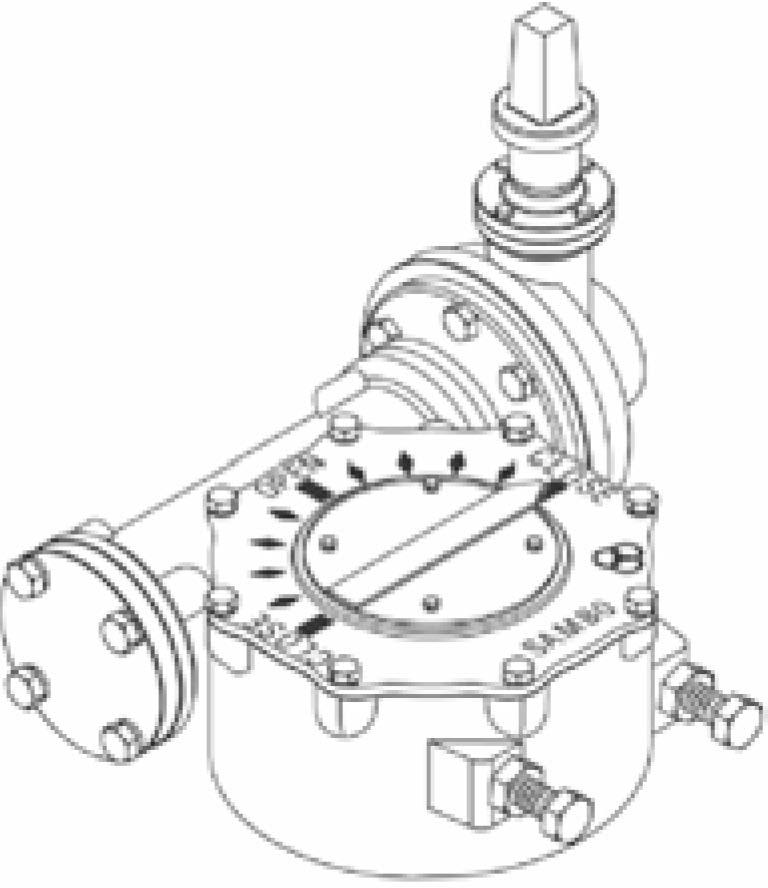

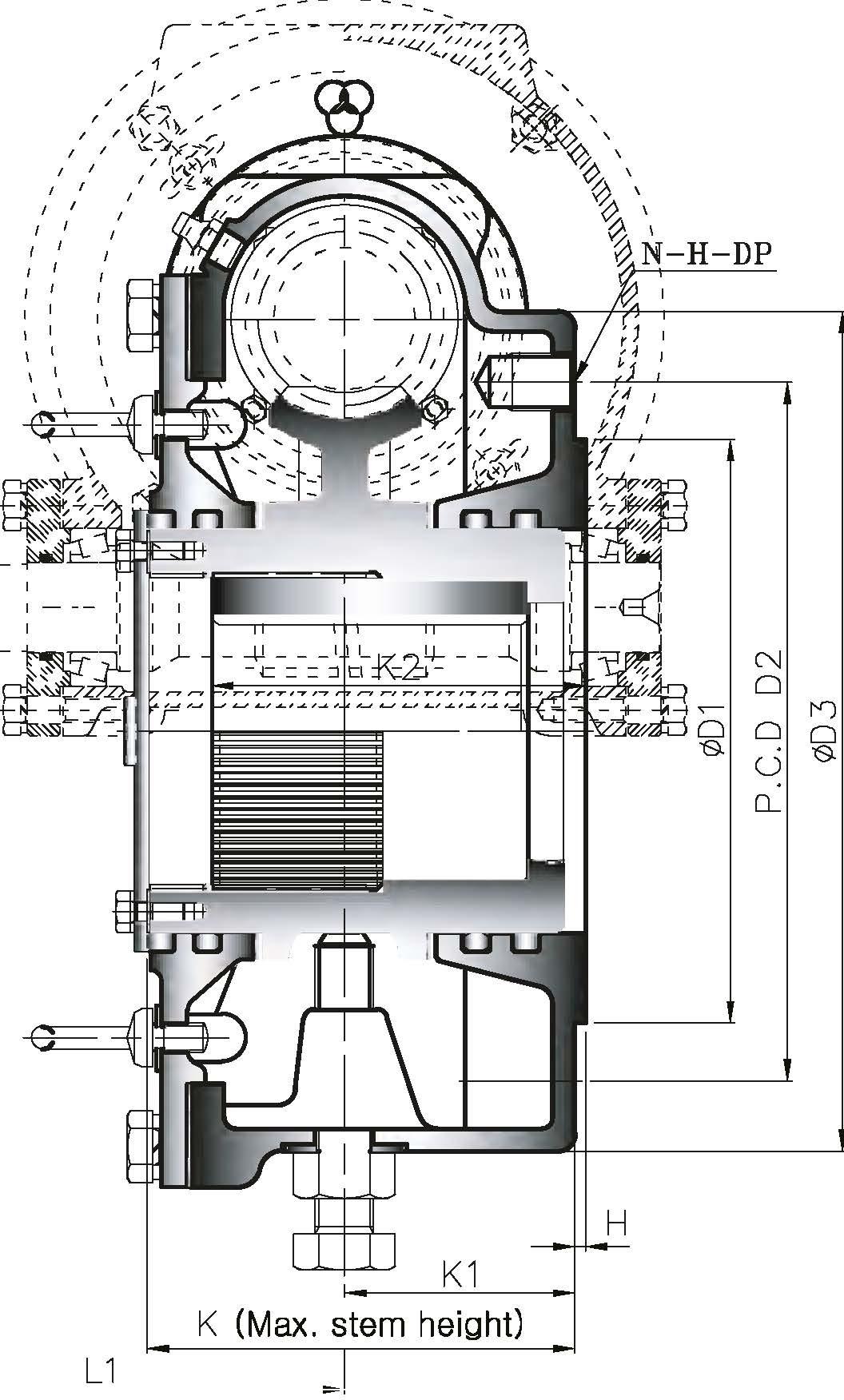

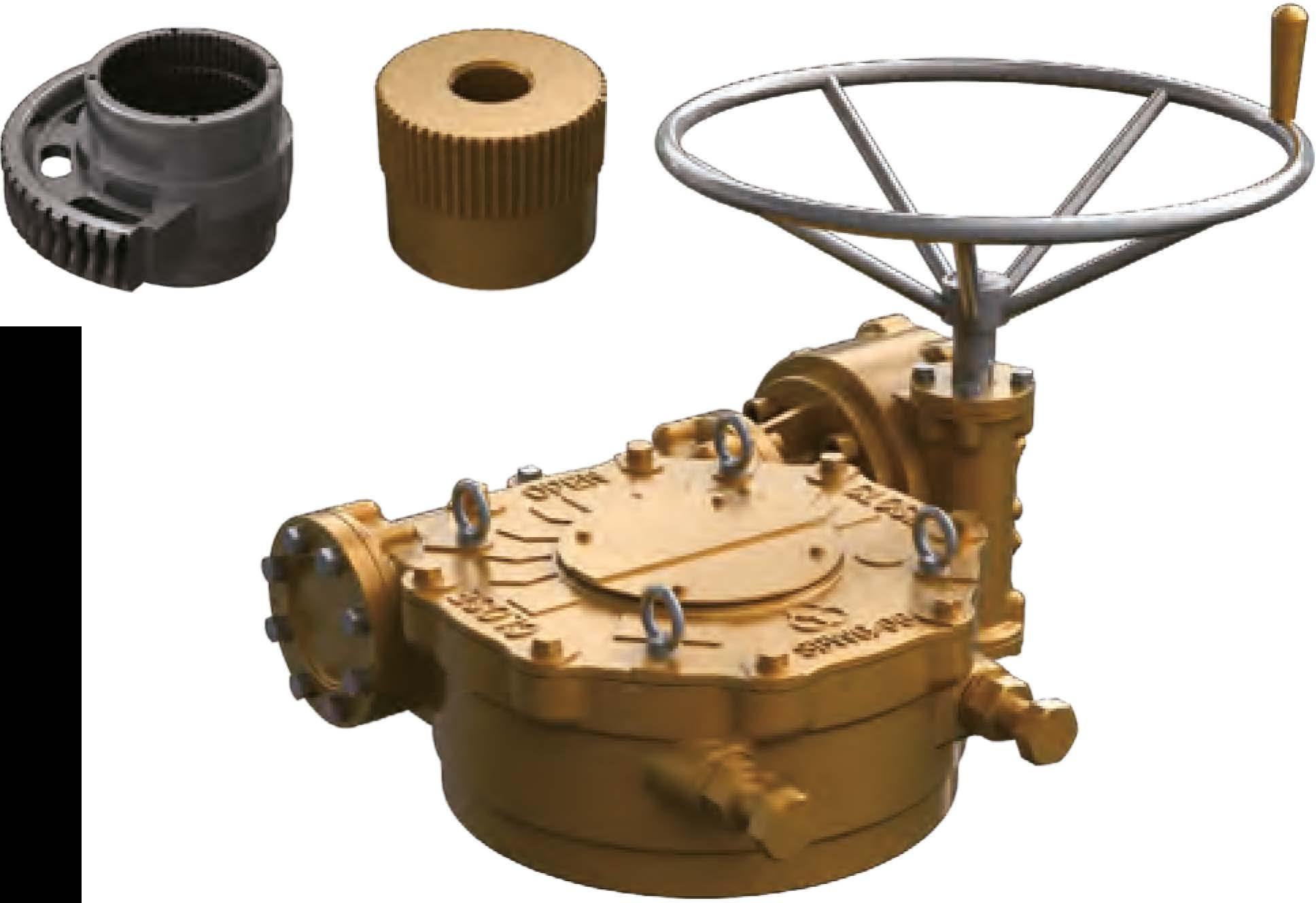

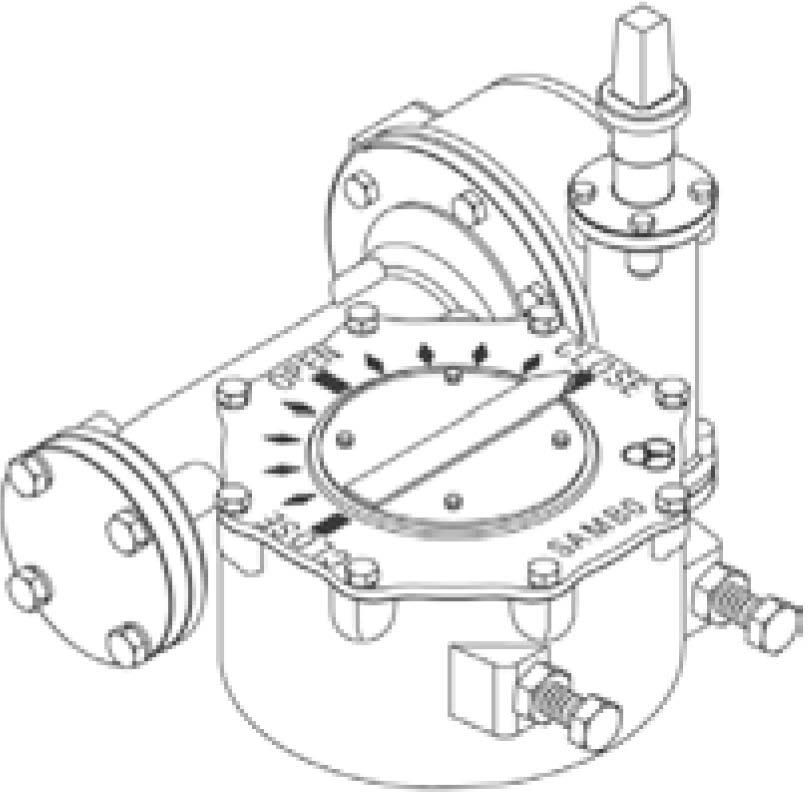

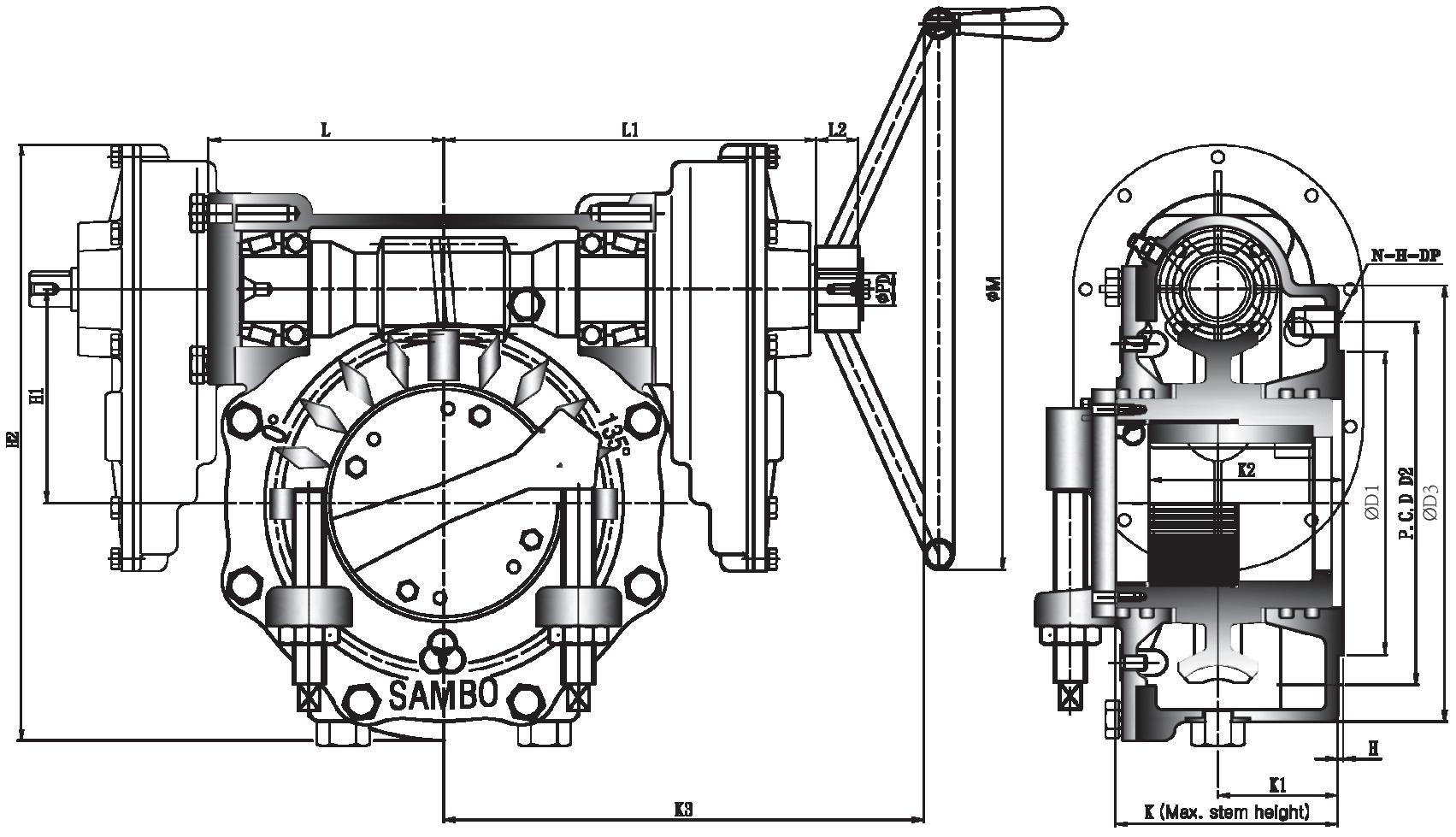

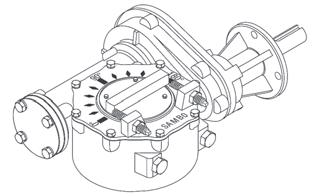

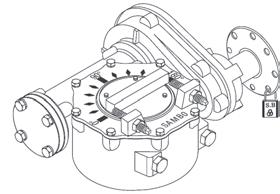

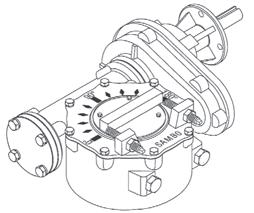

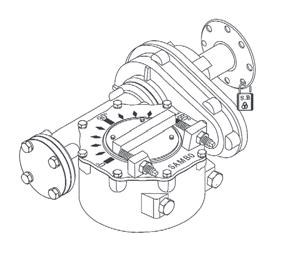

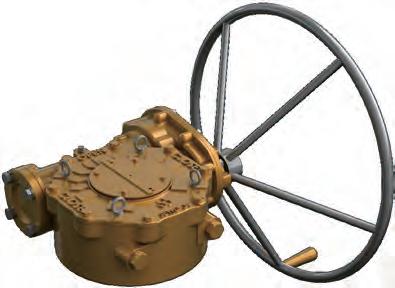

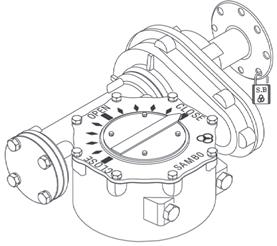

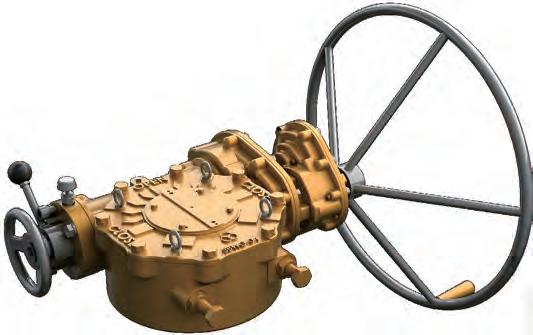

CD Tapered Roller & Ball Bearings

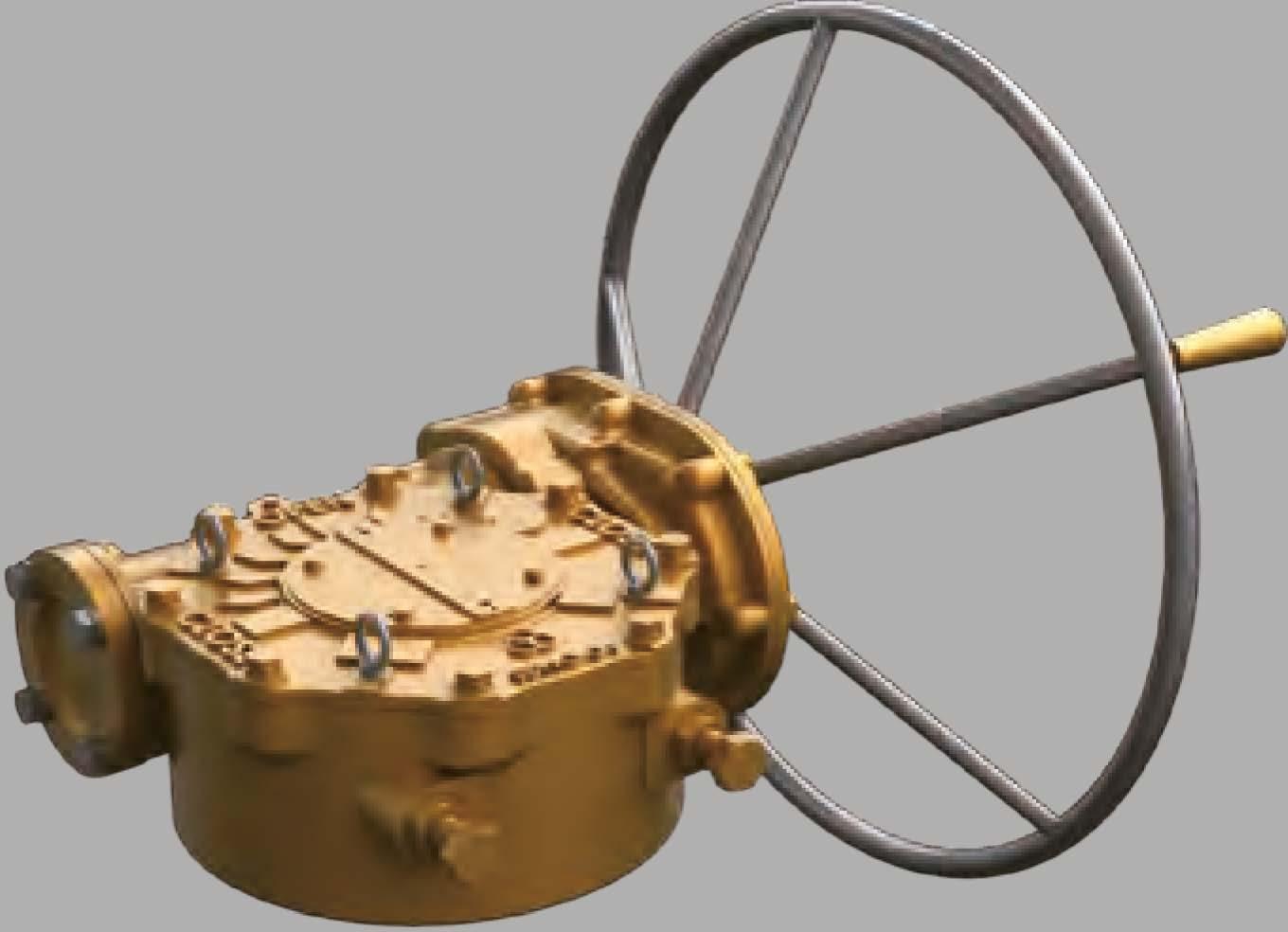

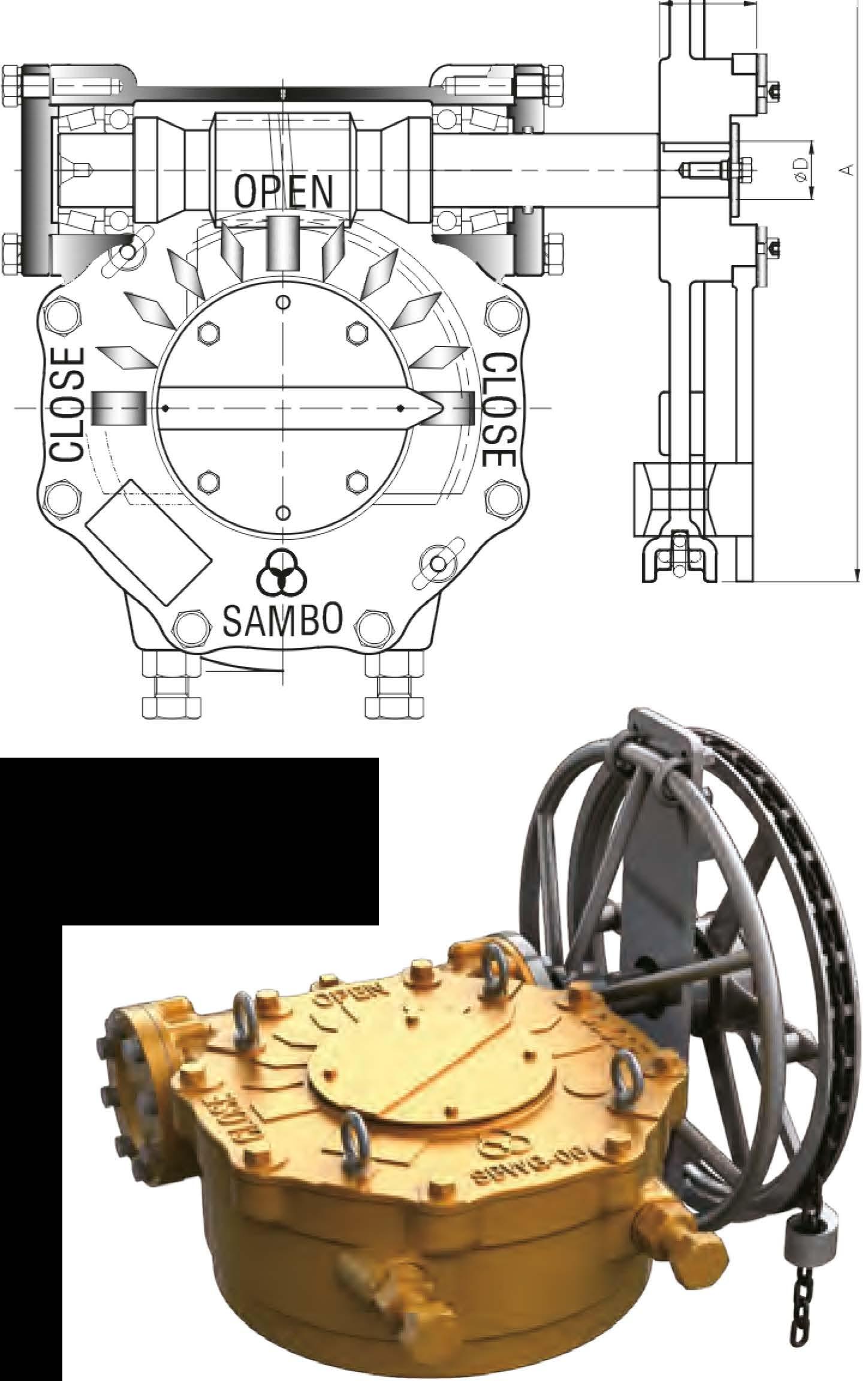

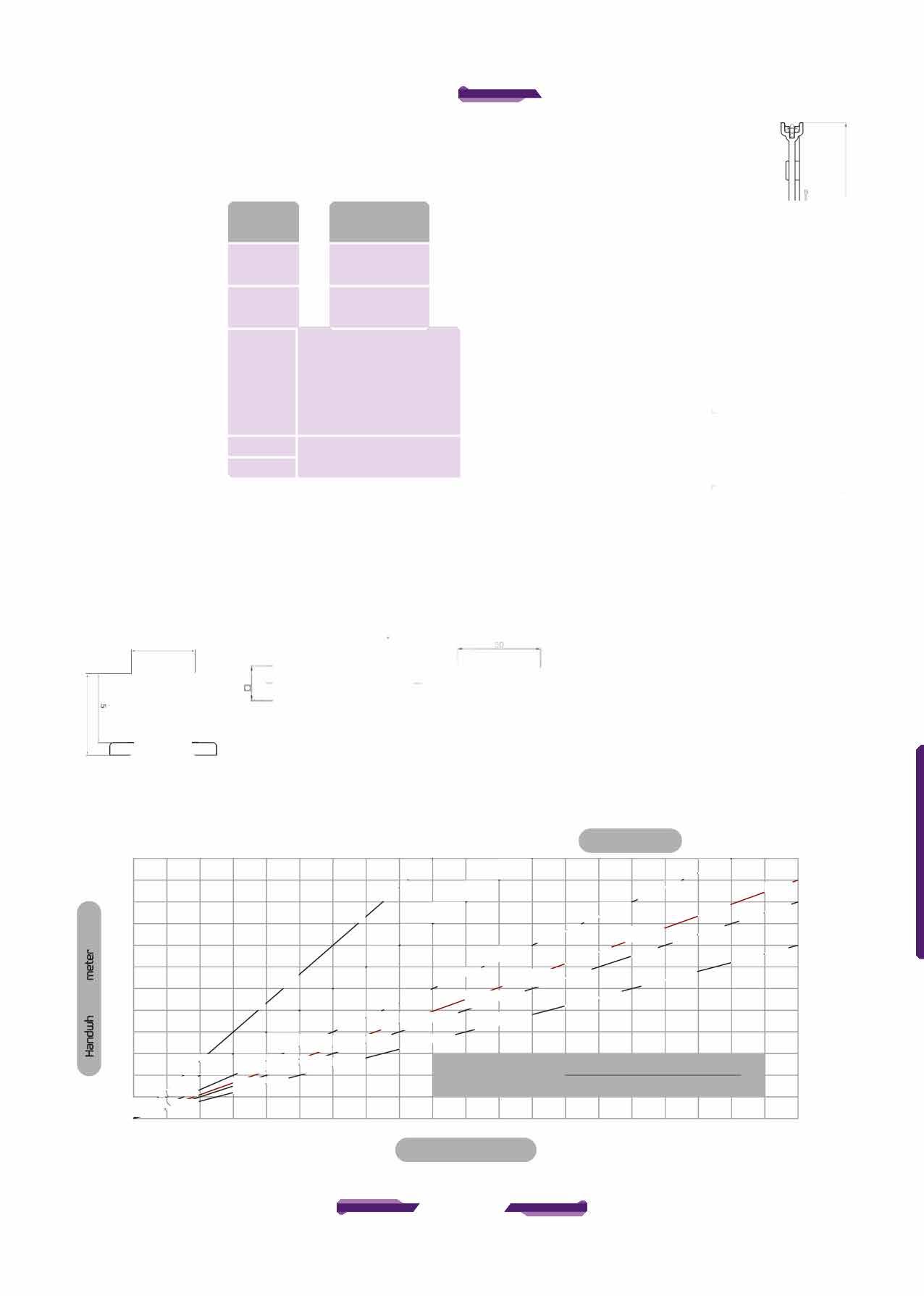

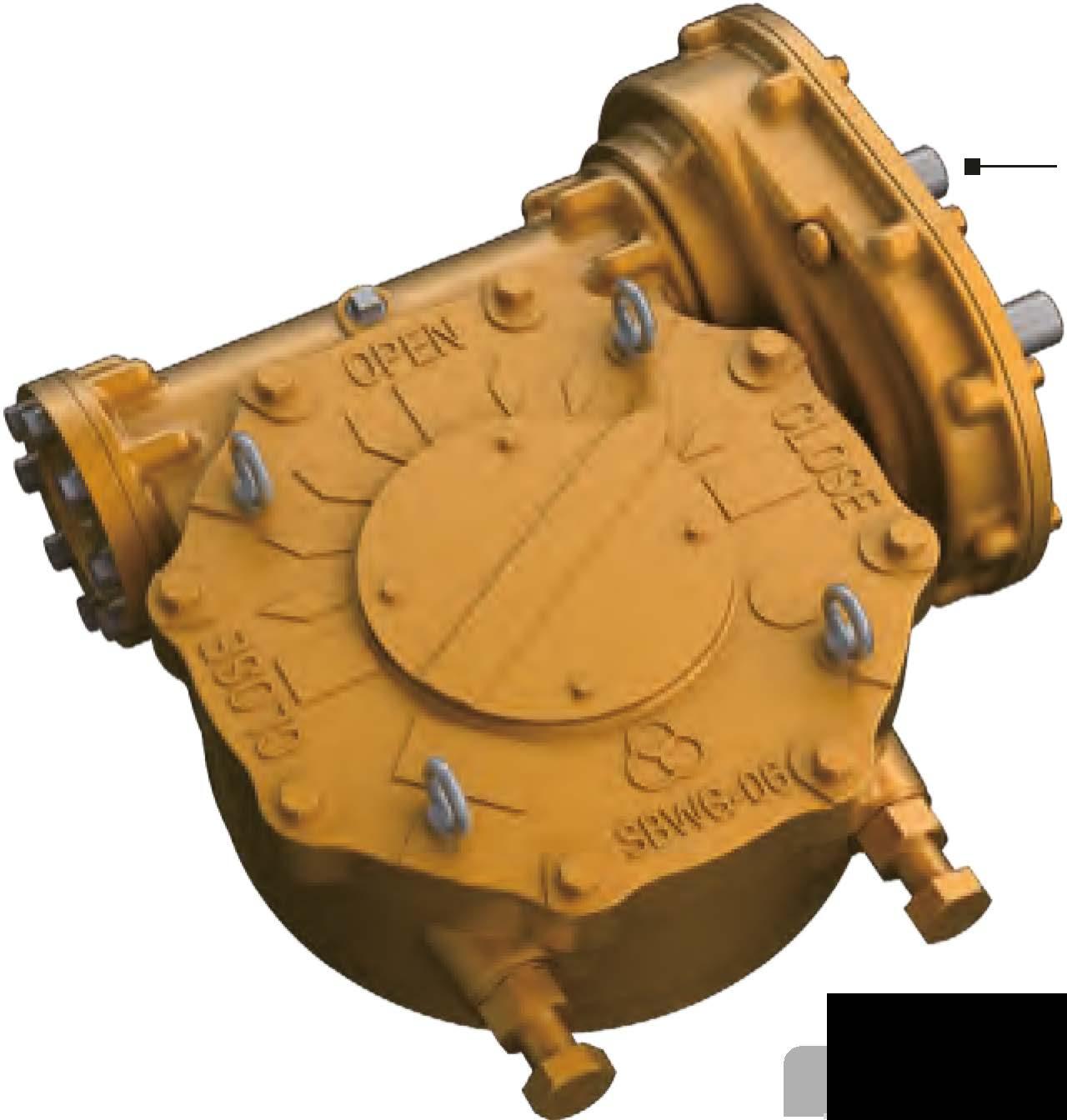

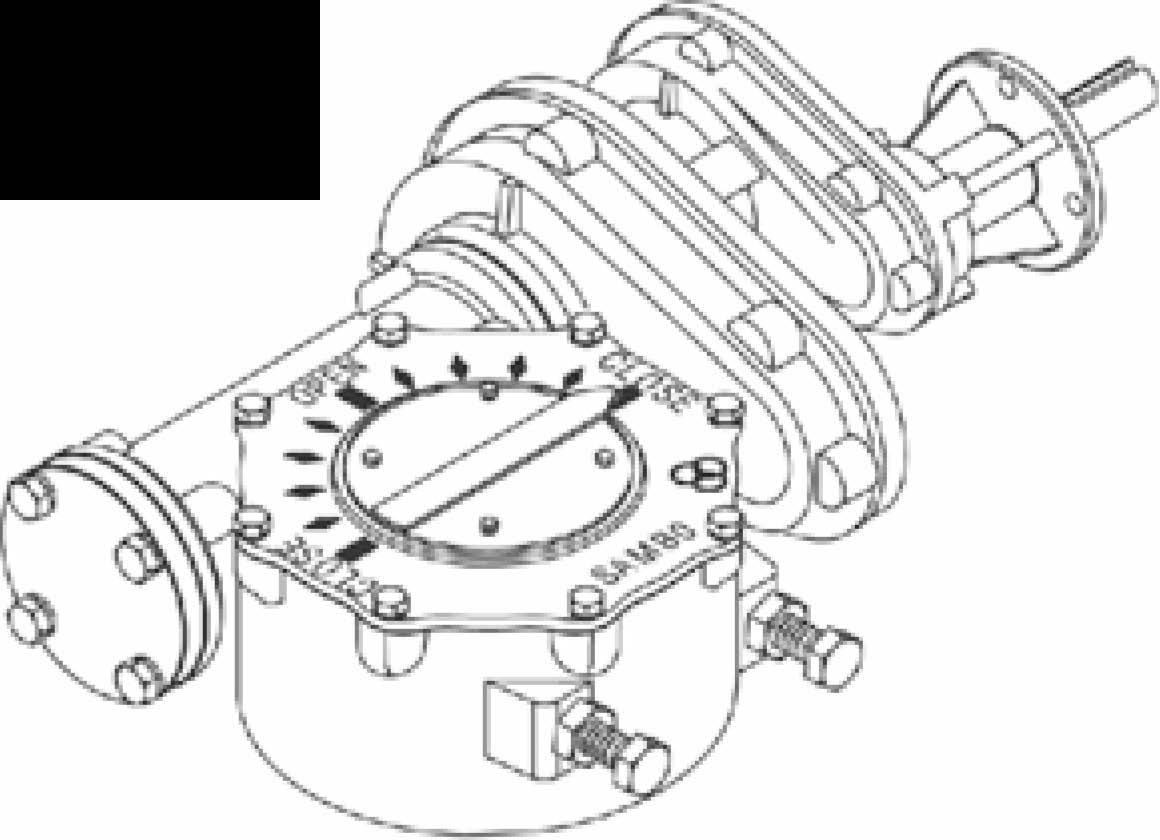

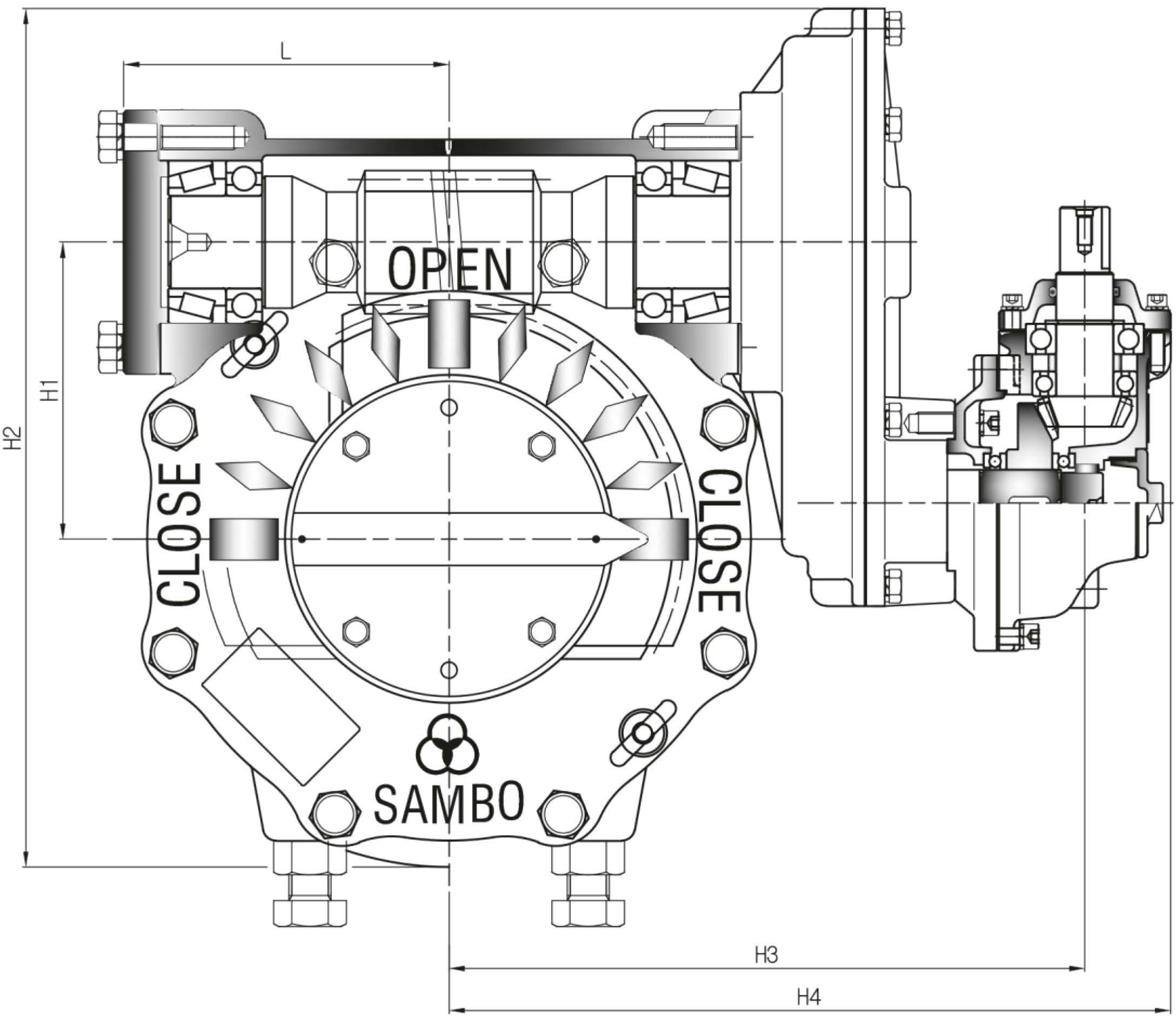

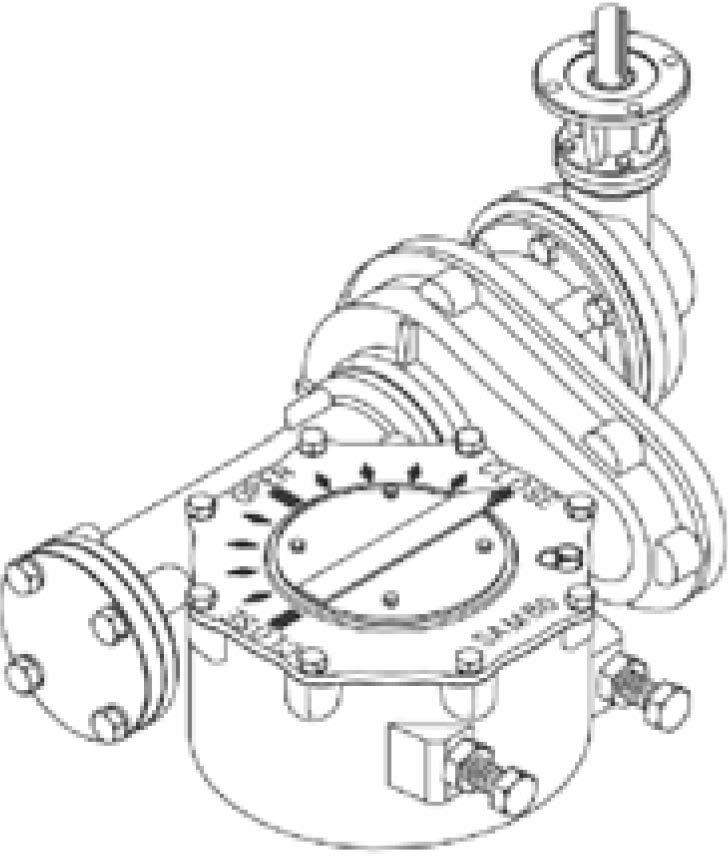

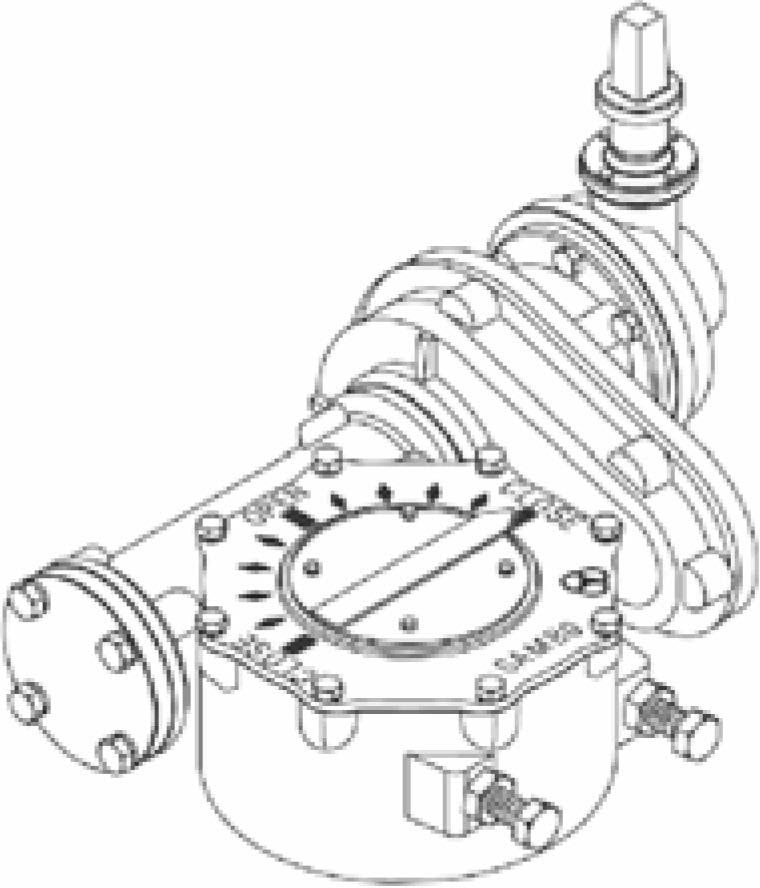

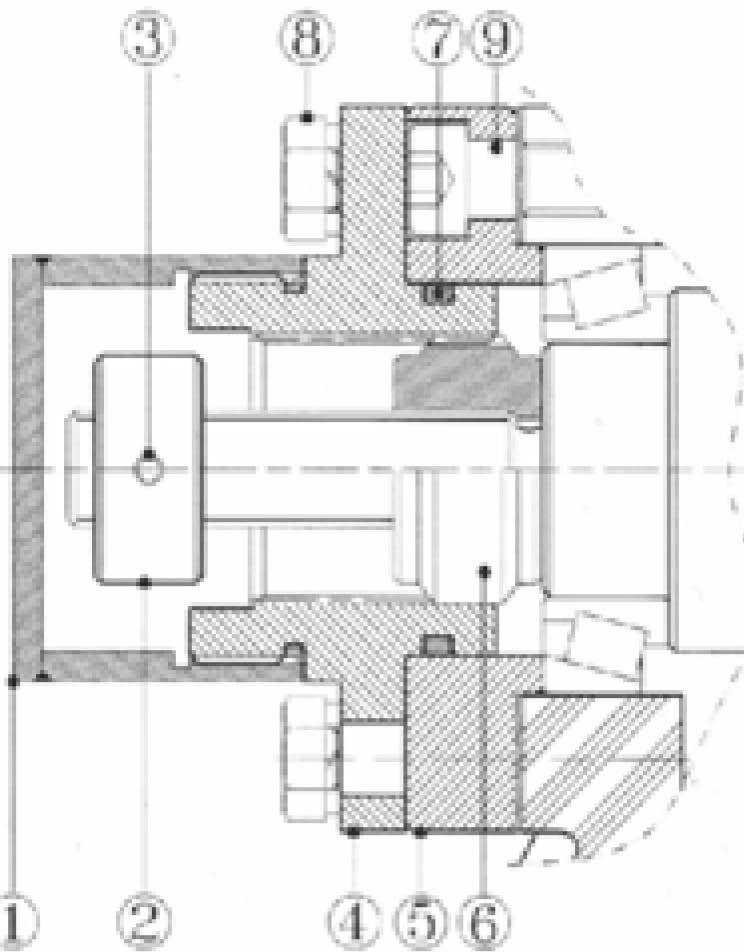

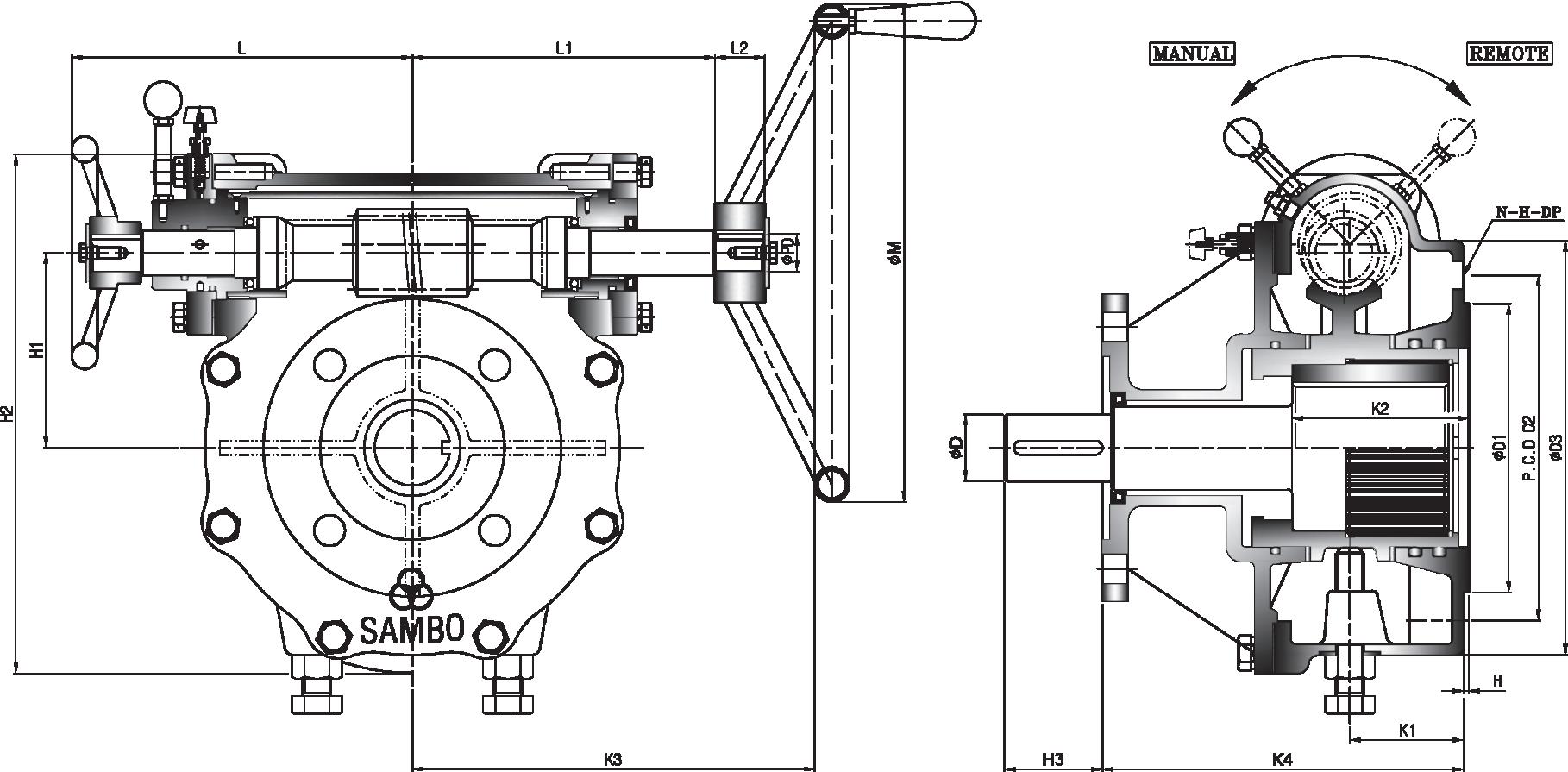

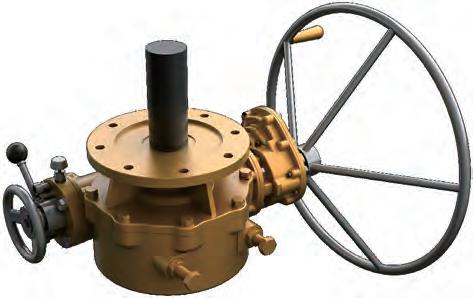

The Worm is supported on tapered roller bearings which support both the axial and radial forces generated by the gearings.They have excellent load bearing capacity.

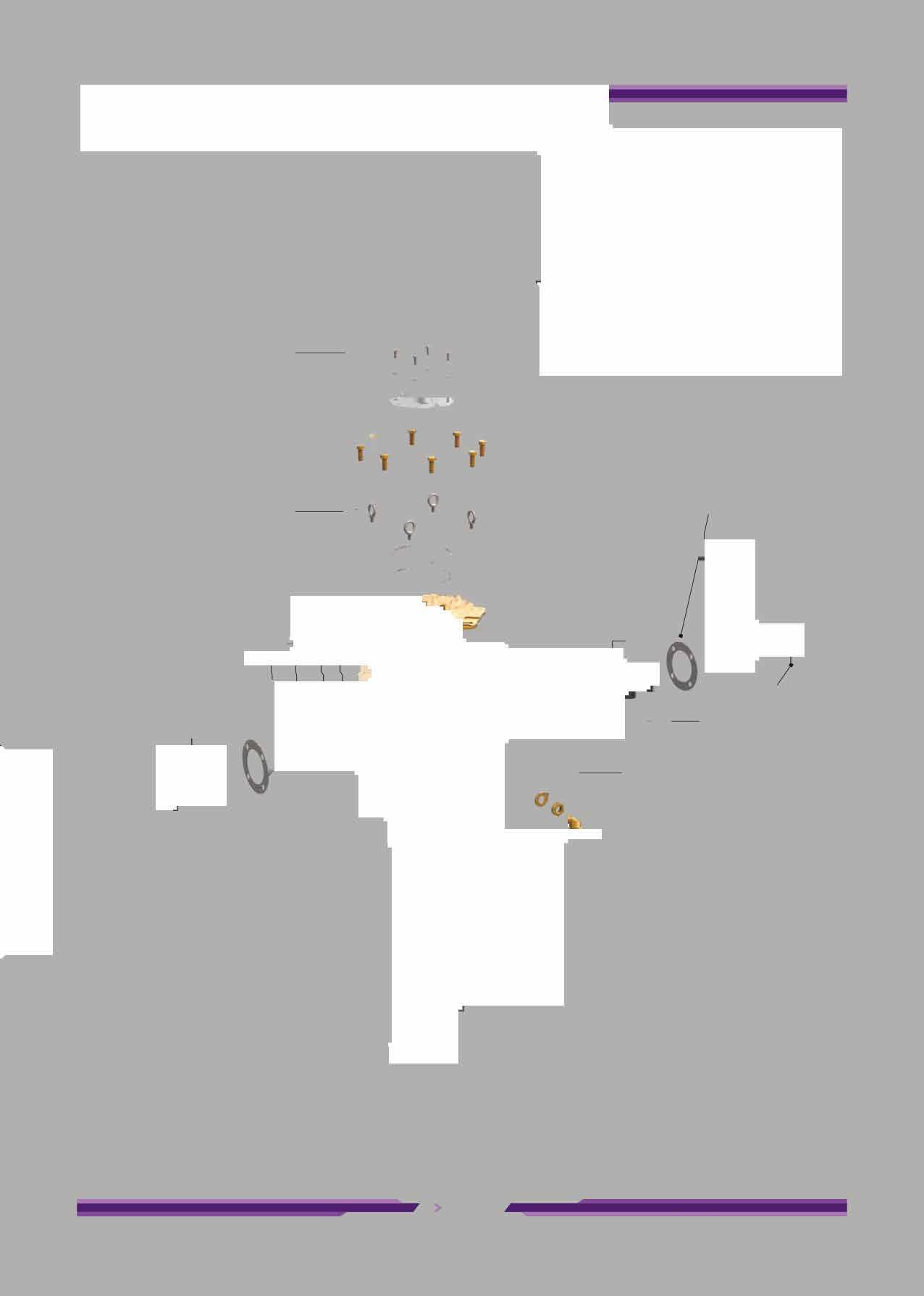

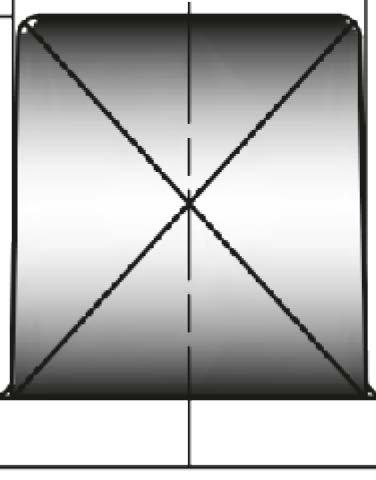

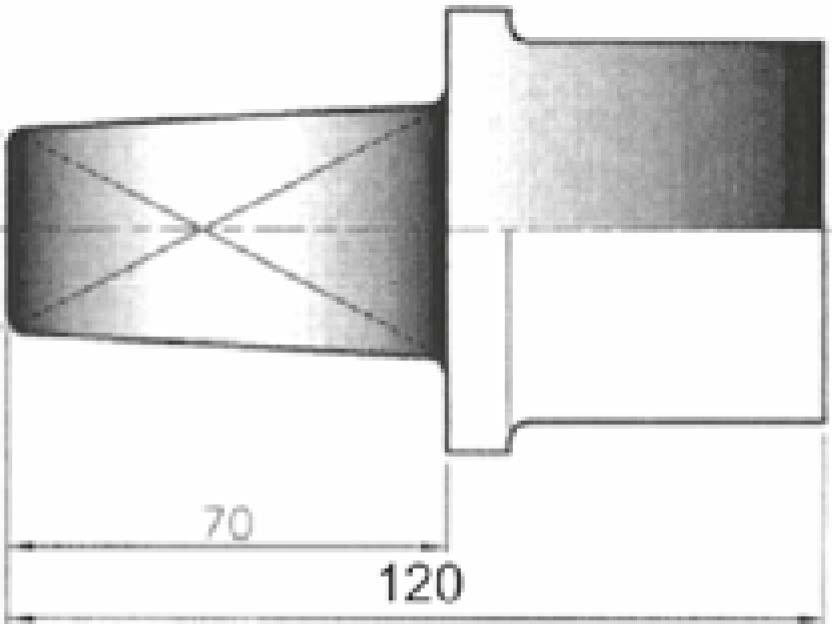

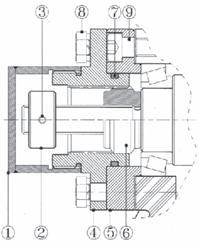

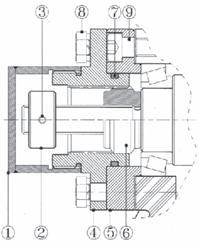

@Worm

1045 heat treated steel, with ground and polished worm threads. Precision cutting of the threads provides minimum backlash between the worm gearand worm.

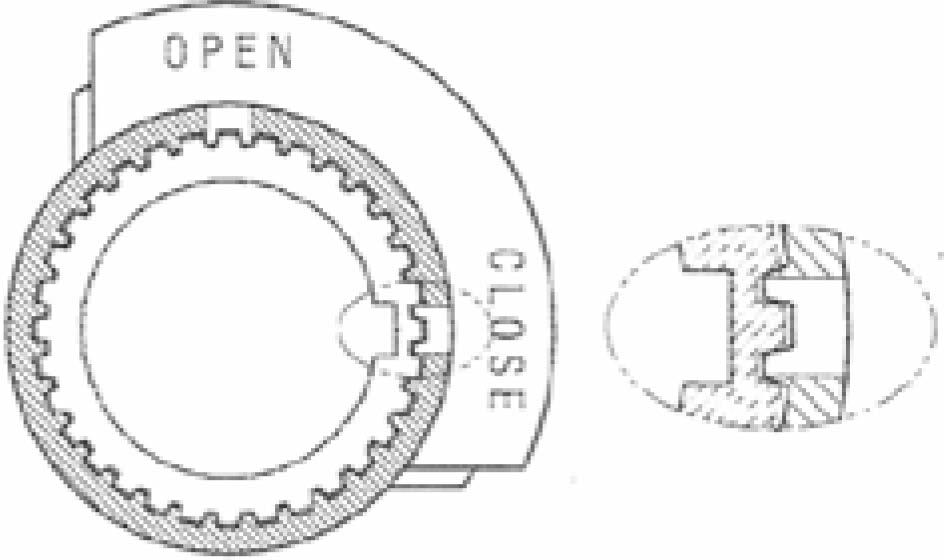

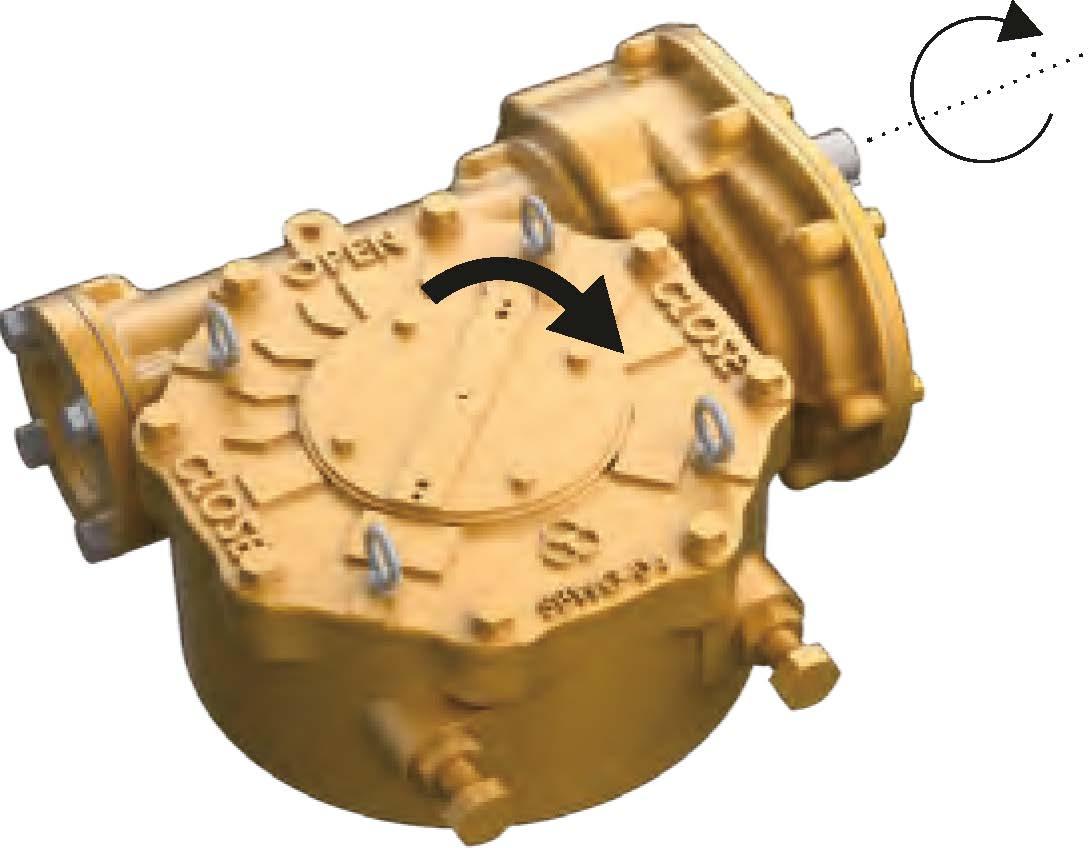

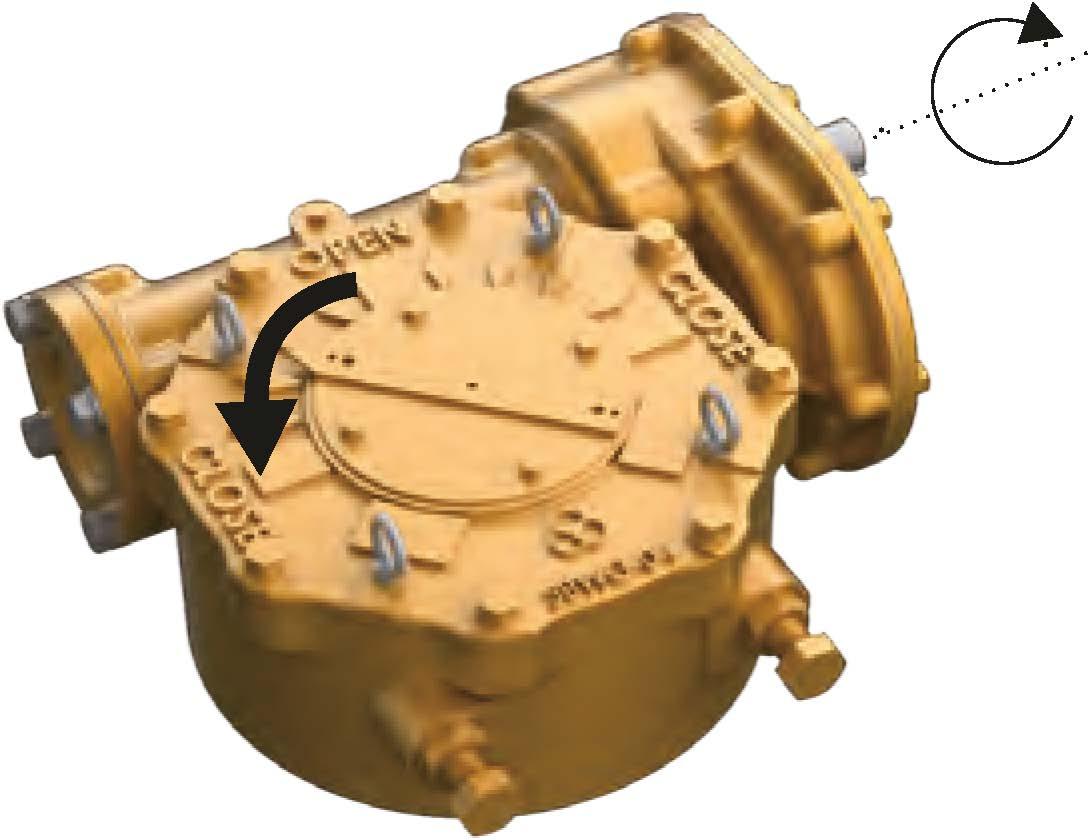

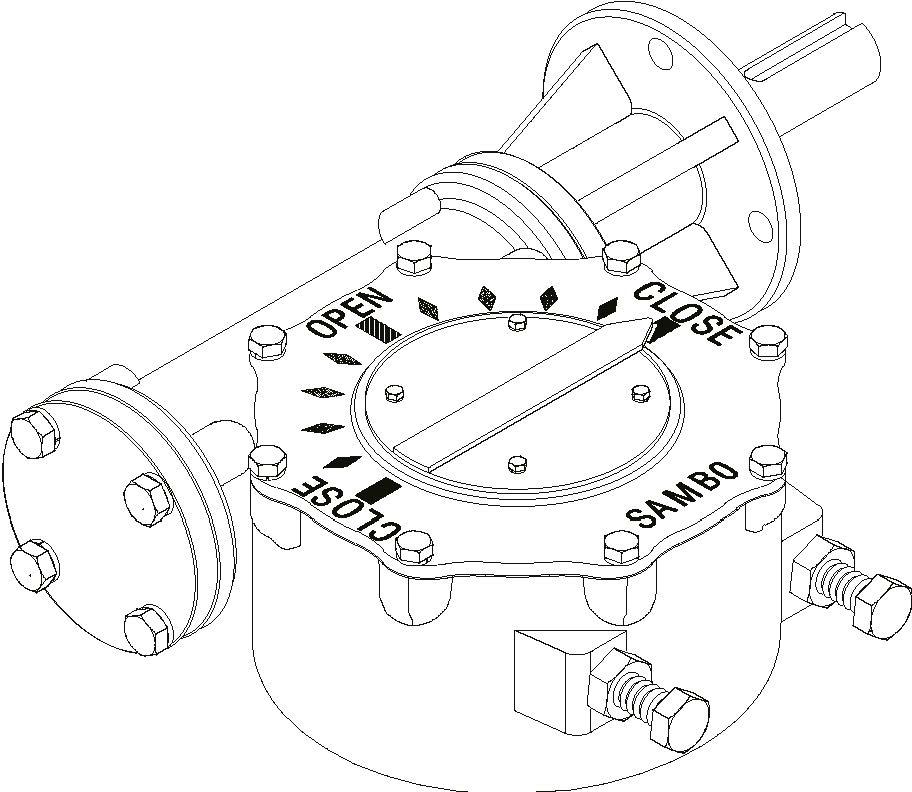

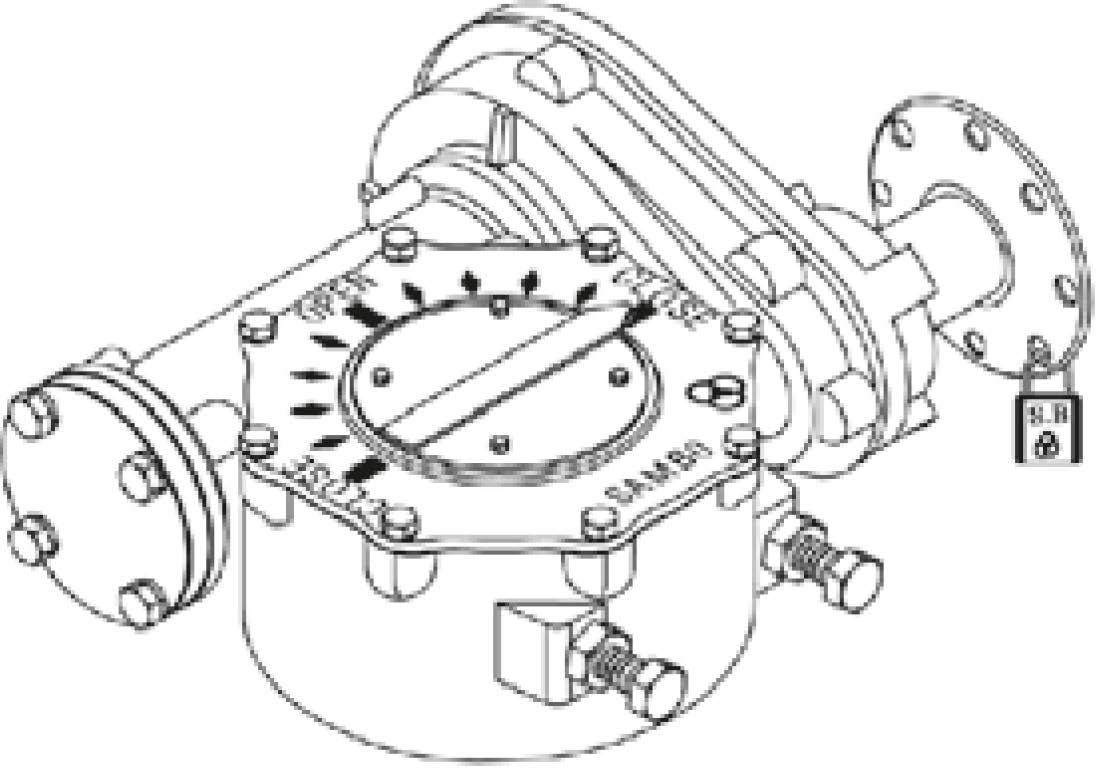

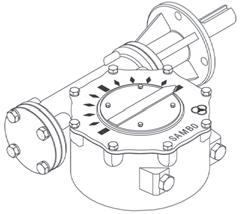

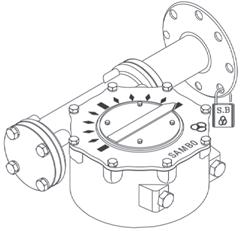

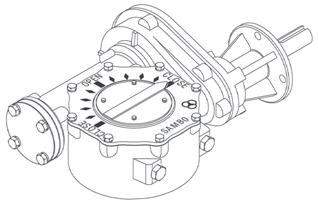

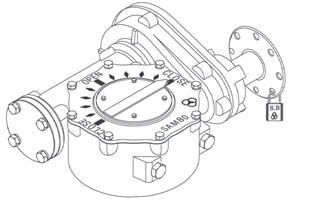

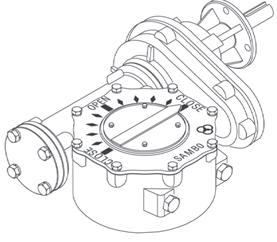

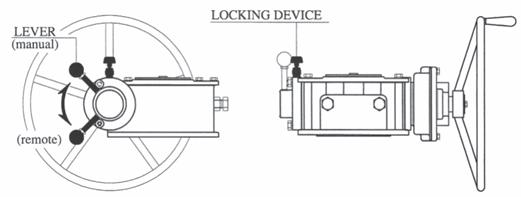

® Indicator Plate

Pointer provides positive position indication. The pointer can easily be re-positioned if required.

@ Sealing

The drive sleeve is supplied with a oil seal at the top and large cross-section a-ring at the bottom. This sealing method allows the units to be rated for submersible service to Ip57 standards.

® Cover

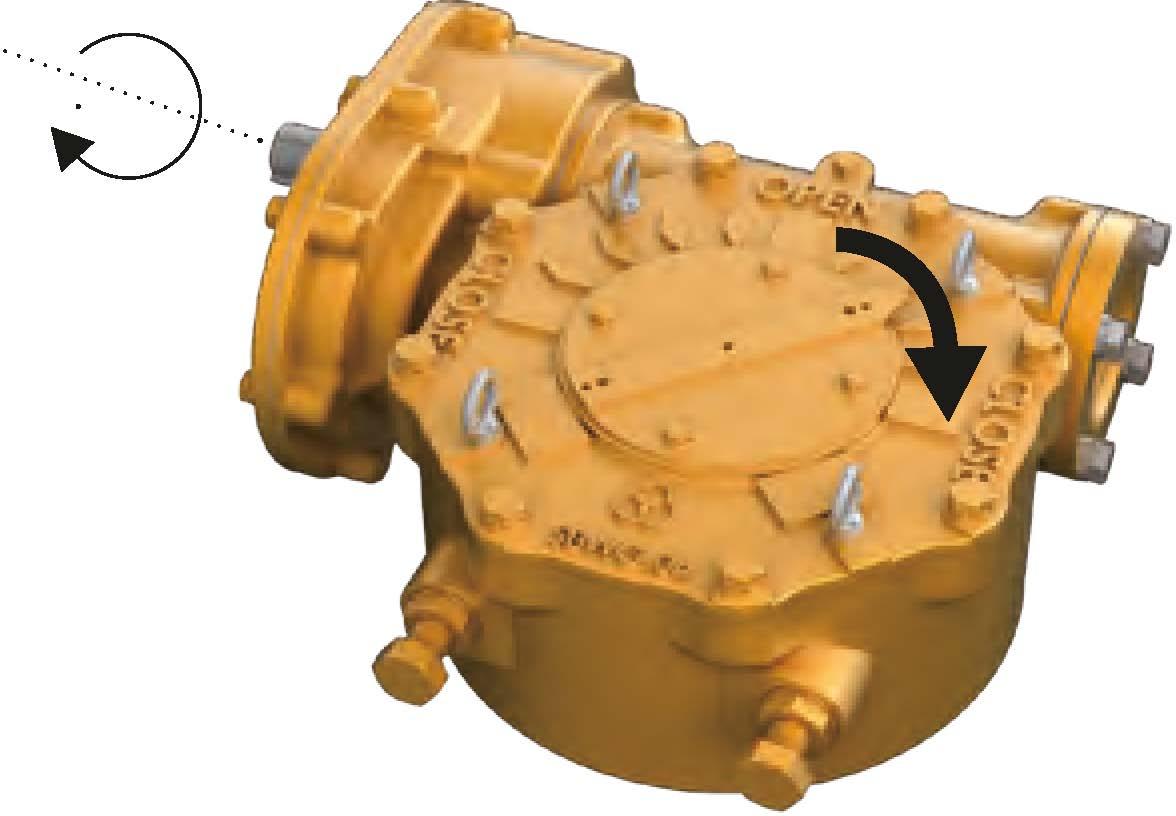

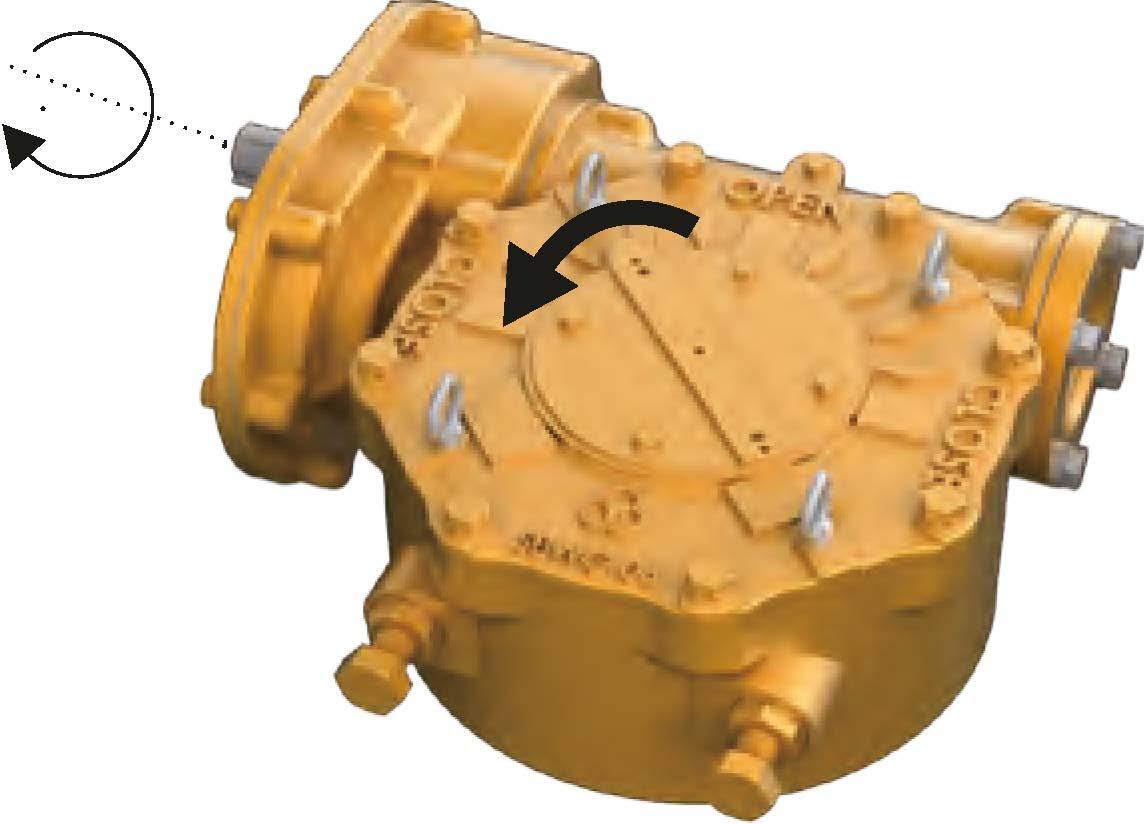

Legends, 'close-Open-Close' are cast directly on the cover.This permits operation in either direction with position indication.

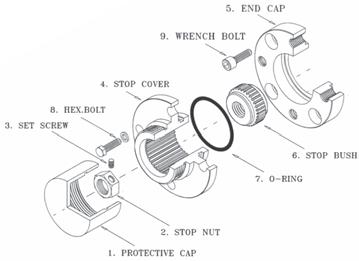

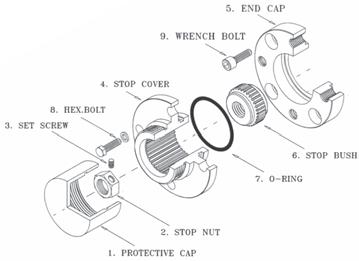

® External Adjustable Stops

The stop bolts allow for position accuracy of +/-5° . Each bolt also includes Buna-N sealing washers or prevent water intrusion

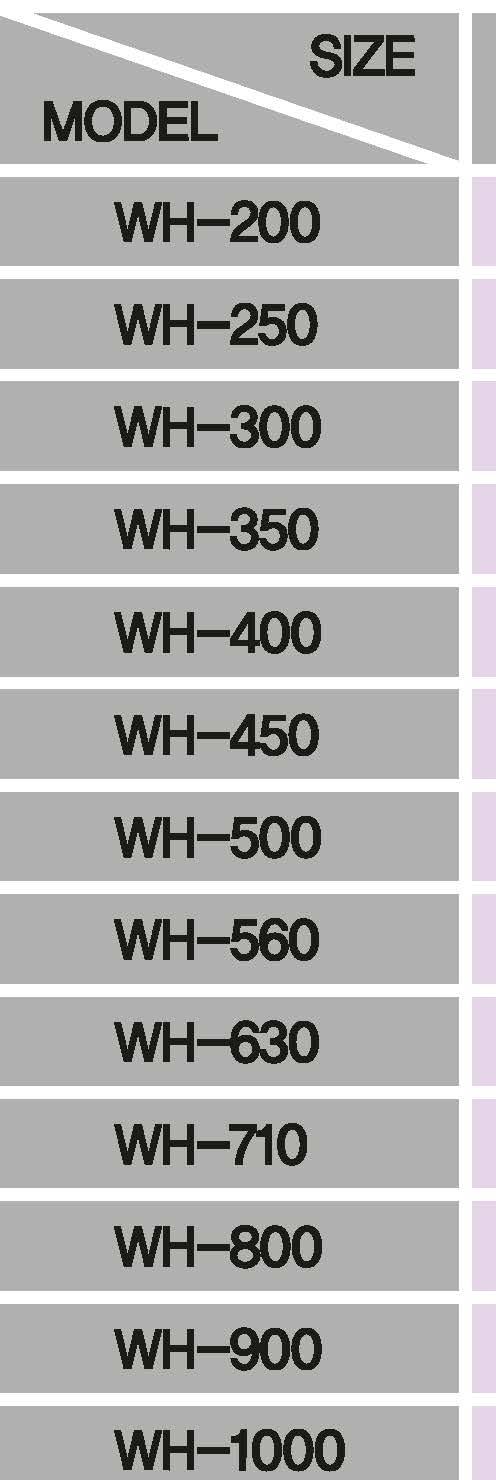

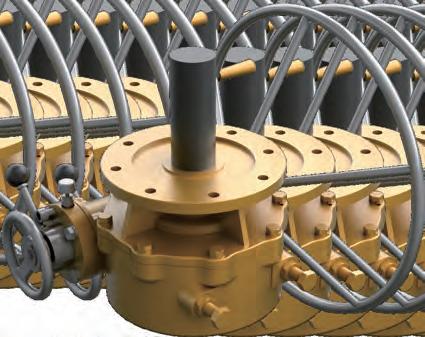

ThisseriesofWorm Gearsrangefrom36DN.m (26Dft-lbf) to970,DODN.m (710,000ft-lbf) >>

Units are available with single, double and triple reduction spur gear. other options available are : vertical input

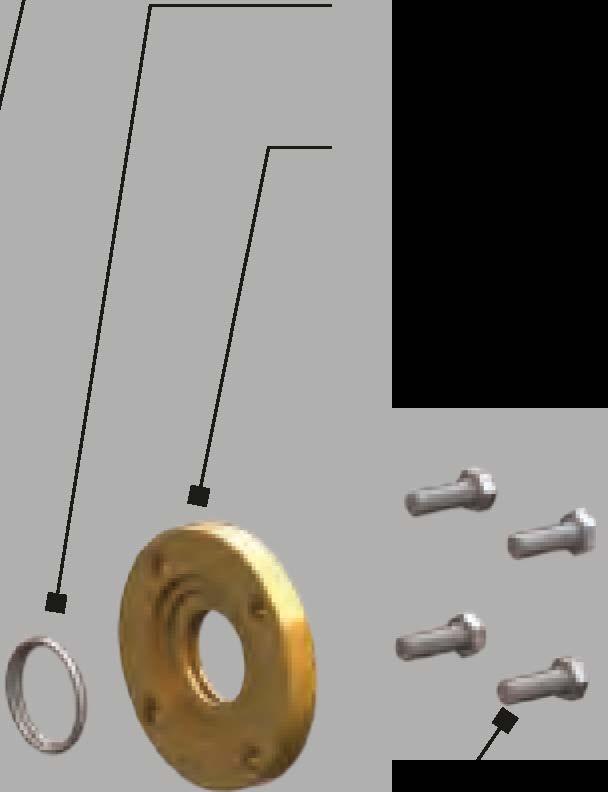

(J) Gaskets

Each end of the worm assembly is equipped with special design material(non-asbestos), which are completely water resistant.

@ Housing

All external castings are Ductile Iron. Class 65-45-12, Tensile Strength of 65,000 psi.

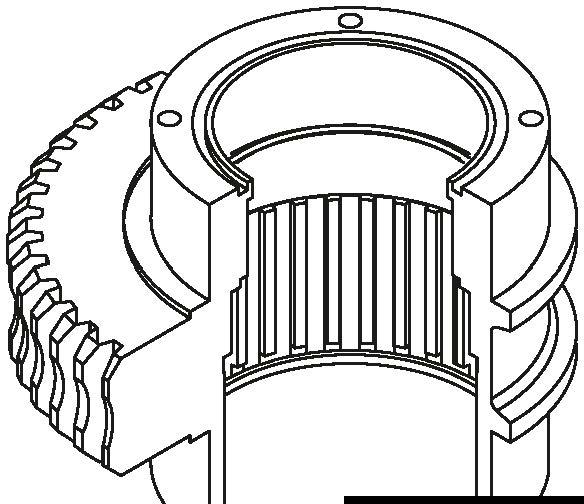

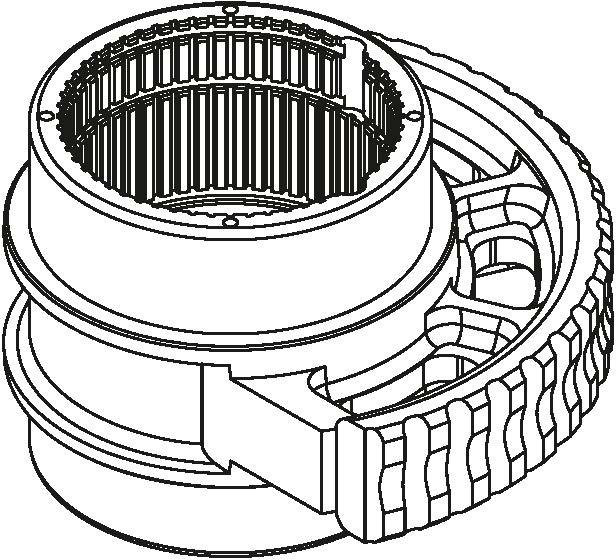

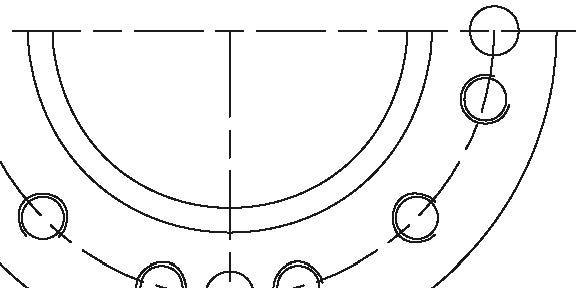

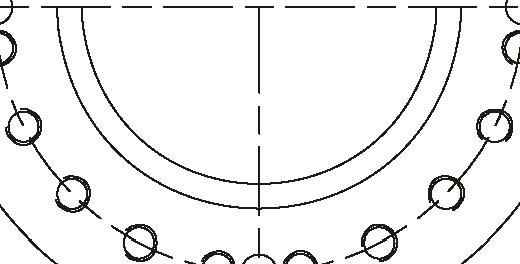

® Splined Bushings

All units furnished with removable splined bushings to permit accurate position between the gear drive and the value shaft.

@) Thrust Washer

The drive sleeve is furnished with hardened steel thrust washers above and below warm gear.

This minuimizes frictional looseness between the gear and the ductile iron castings.

@ Worm Gear

Standard material is Ductile Iron, Grade 80-55-06, Suitable most industrial applications. Option is aluminum bronze having a tensile strength of 85,000 psi Normally required for motorized applications involving modulating service and is also a requirement to meet the AWWA standards.

HorizontalInput

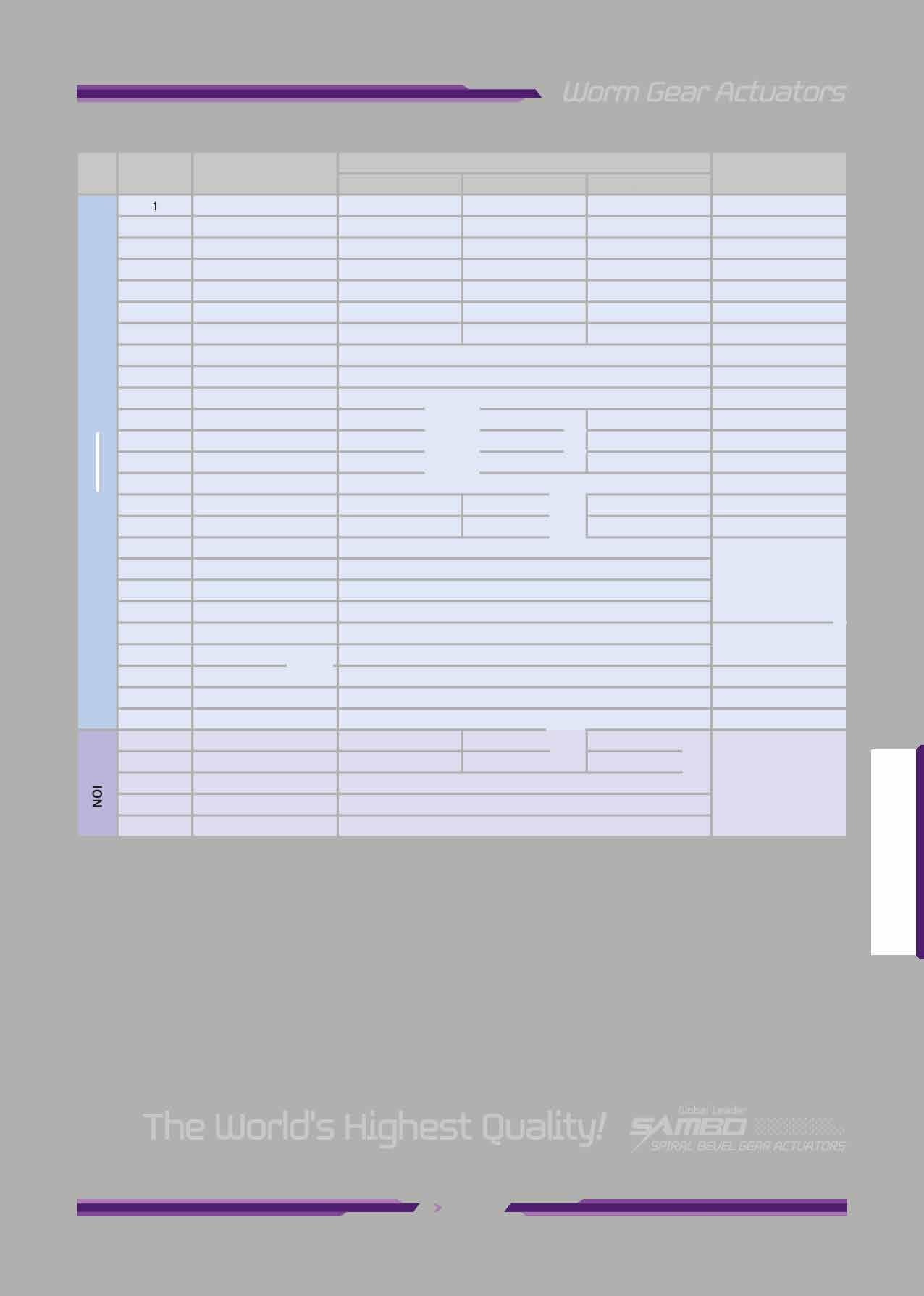

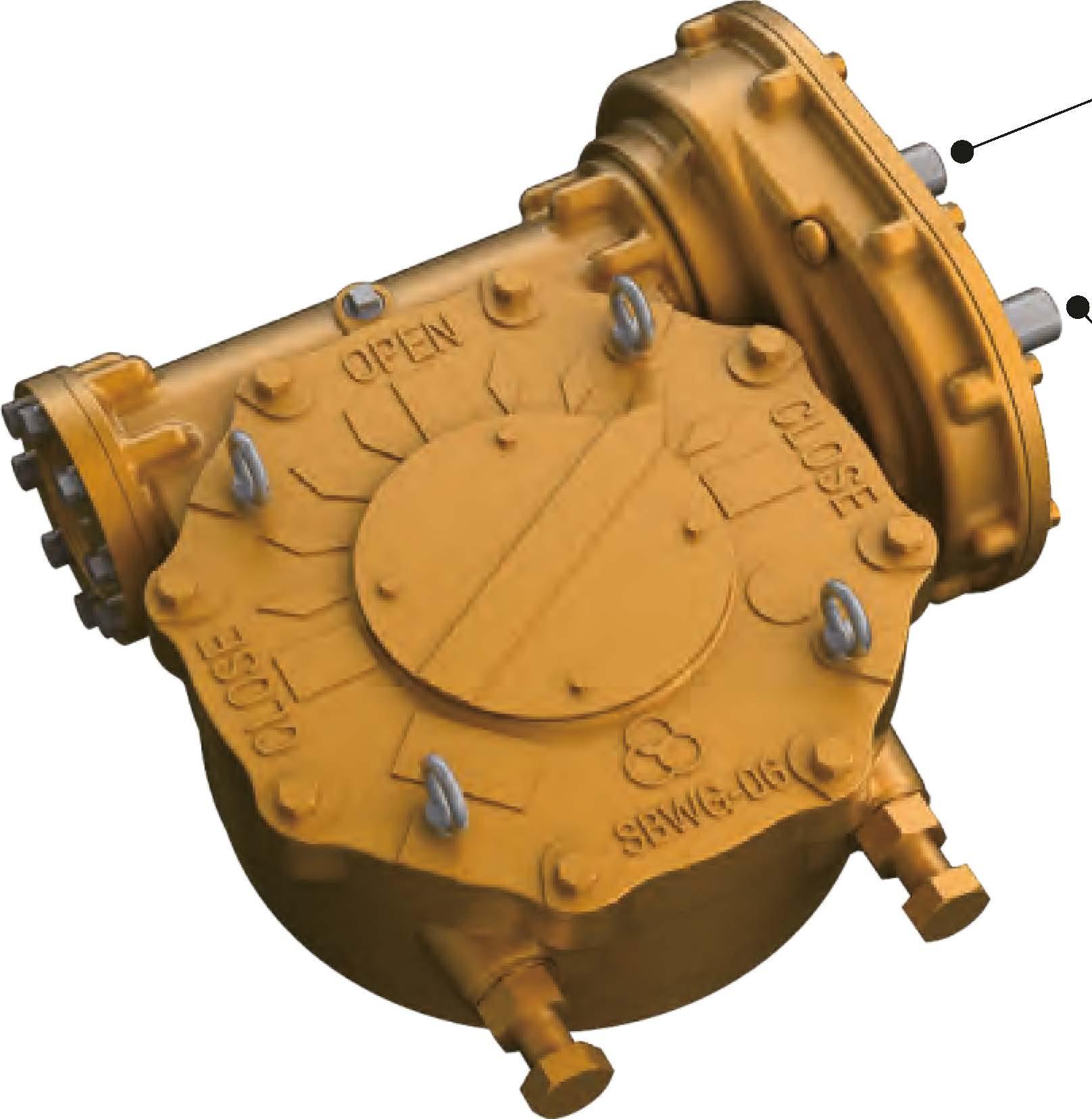

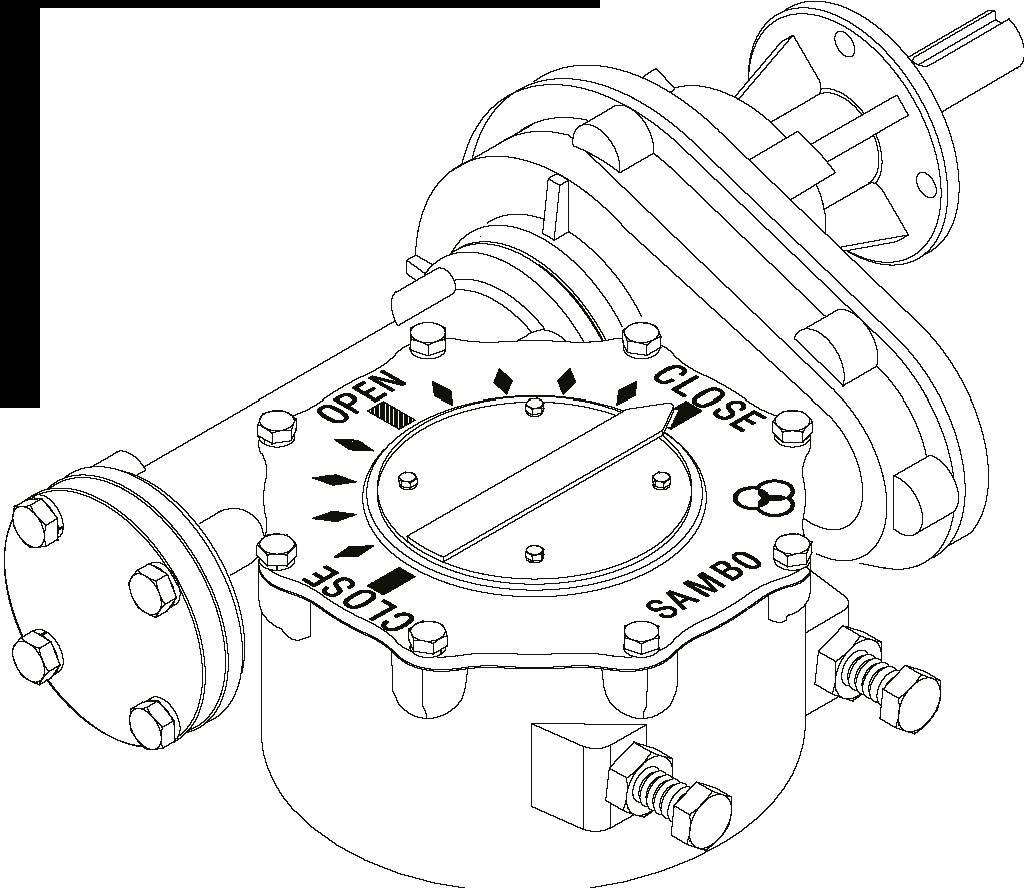

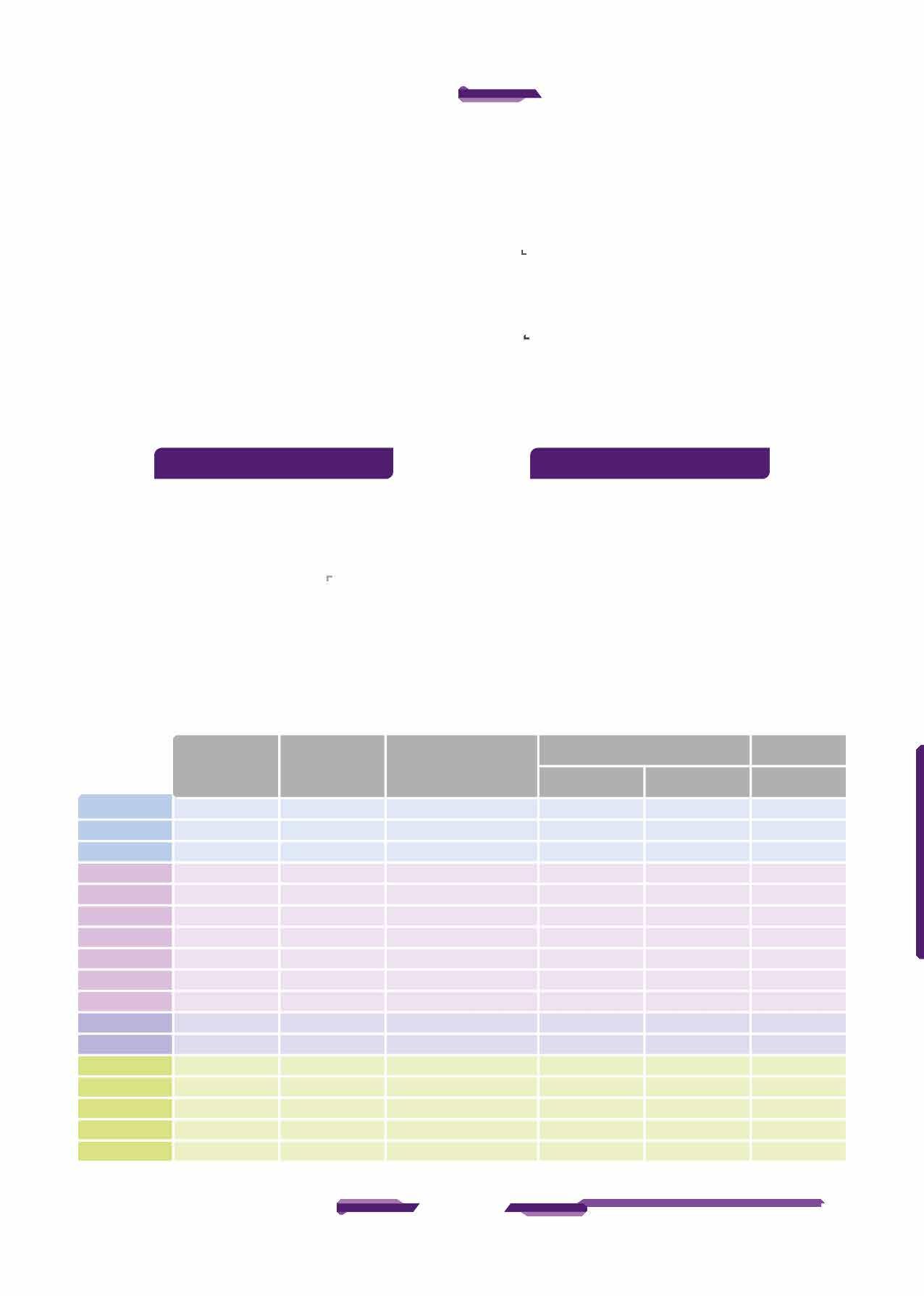

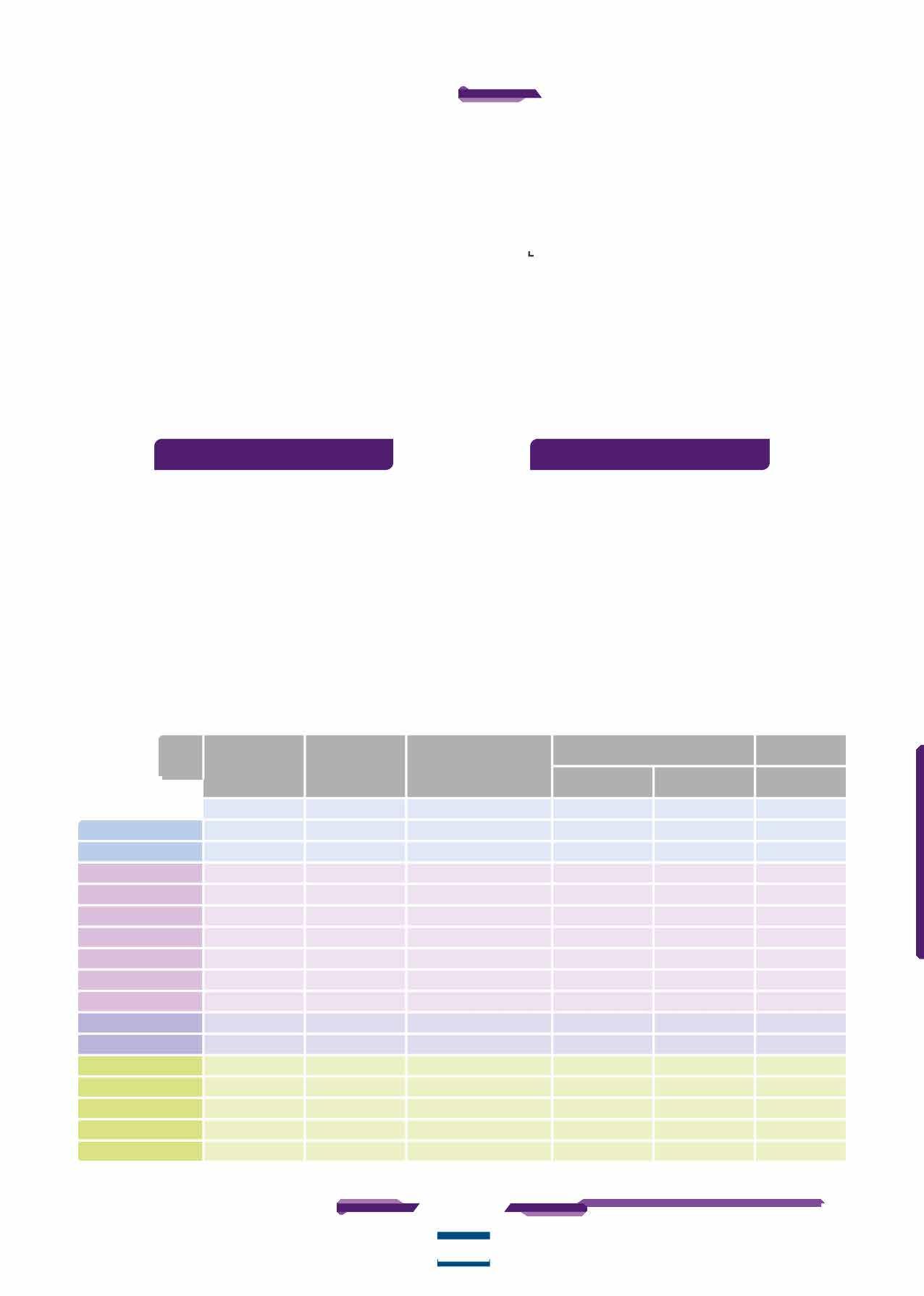

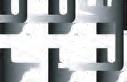

14.HEX.Bolt(P/W)

B.IndicatorPlate�

FCD-450 A536--65-45-12

FCD-450 A536--65-45-12

S45C A576-1045 NOfE.2

FCD-450 A536--65-45-12

FCD-600 A536--80-55--06 B14&-C95800(ALBC3)

FCD-450 A536-65-45-12

FCD-450 A536--65-45-12 SW2 A295-52100SCM435 A322-4135SCM435 A322-4135

S45C A576-1045

S45C A576-1045NOfE.4

VALQUA6601

PackingSeal GreaseFitting EyeBolt HandWheel Key NamePlate Washer HEX.Bolt(S/W) lvanizing lvanizing

1 All castings are Ductile Iron, FCD-450 (ASTIYI Class 55-45-12)

2. In case of option for special request, it can be worked Nickel coating, high tensile stainless.

3. Also, the material can be changed as ALBC3(Aluminium Bronze), steel(A575-1□45), A439 Gr 02[ (Austenitic ductile iron casting) and etc.

4. □-Ring Seal & Lubricant: Standard is Silicon & Buna "N", temperature range -20° [ to+12□° [ (-4° F to+248° Fl. Standard lubricant is Zenith EPSB 2, temperature Range -20· [ to+200° [ (-4° F to+392° Fl

Other option are: High Temperature Viton □-Ring Grade V75, Temperature Range -30° [ to+200° [ (-22° F to+392° Fl

Lubricant - Zenith SYN WS2 Temperature Range -30° [-400° [ (-22° F-752° Fl Low Temperature Silicon □-Ring, Temperature Range -5□° [to+ 15□° [(-75° F to 302° Fl Lubricant - Zenith SBLT5DD, Temperature Range -50° [-120° [ (-75° F-248

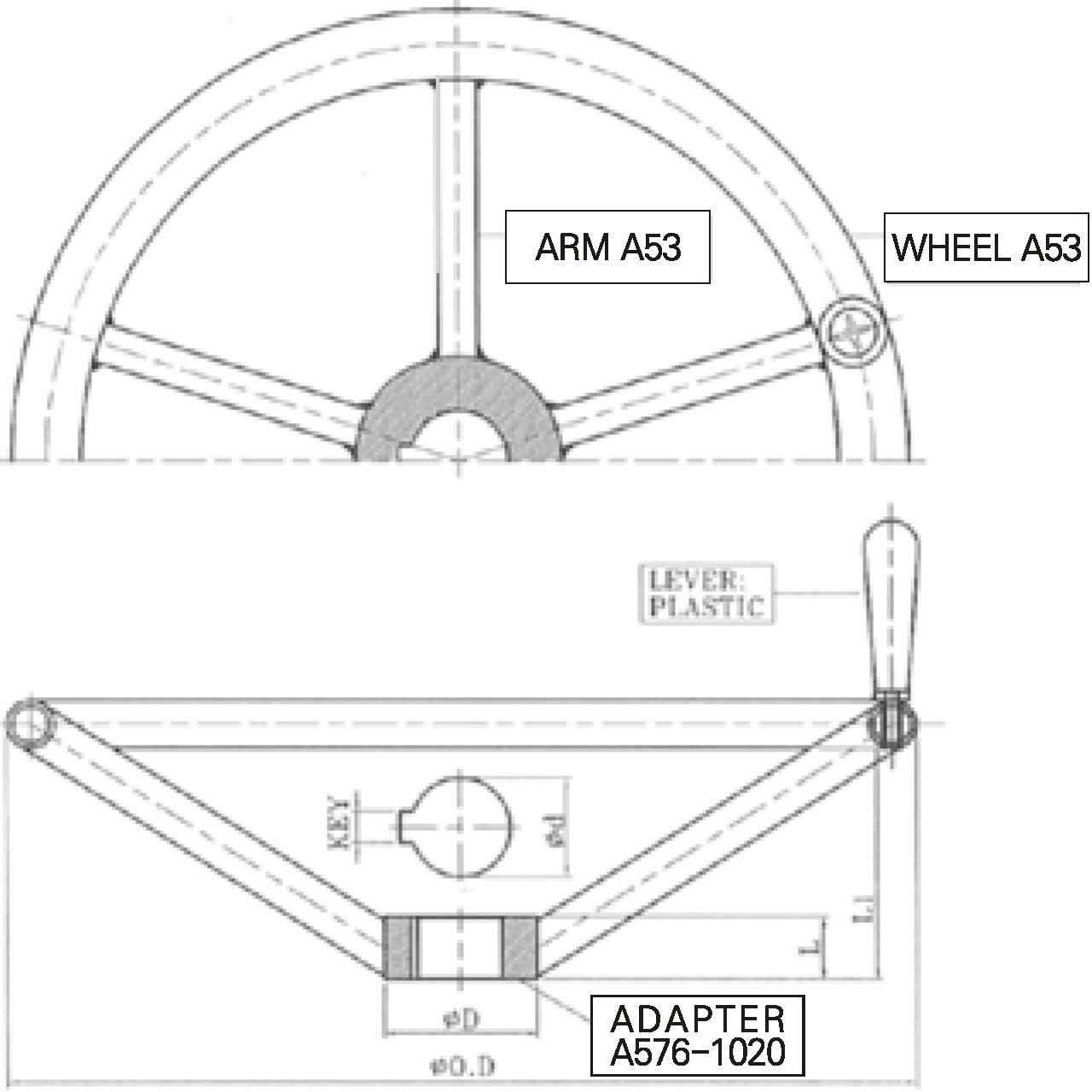

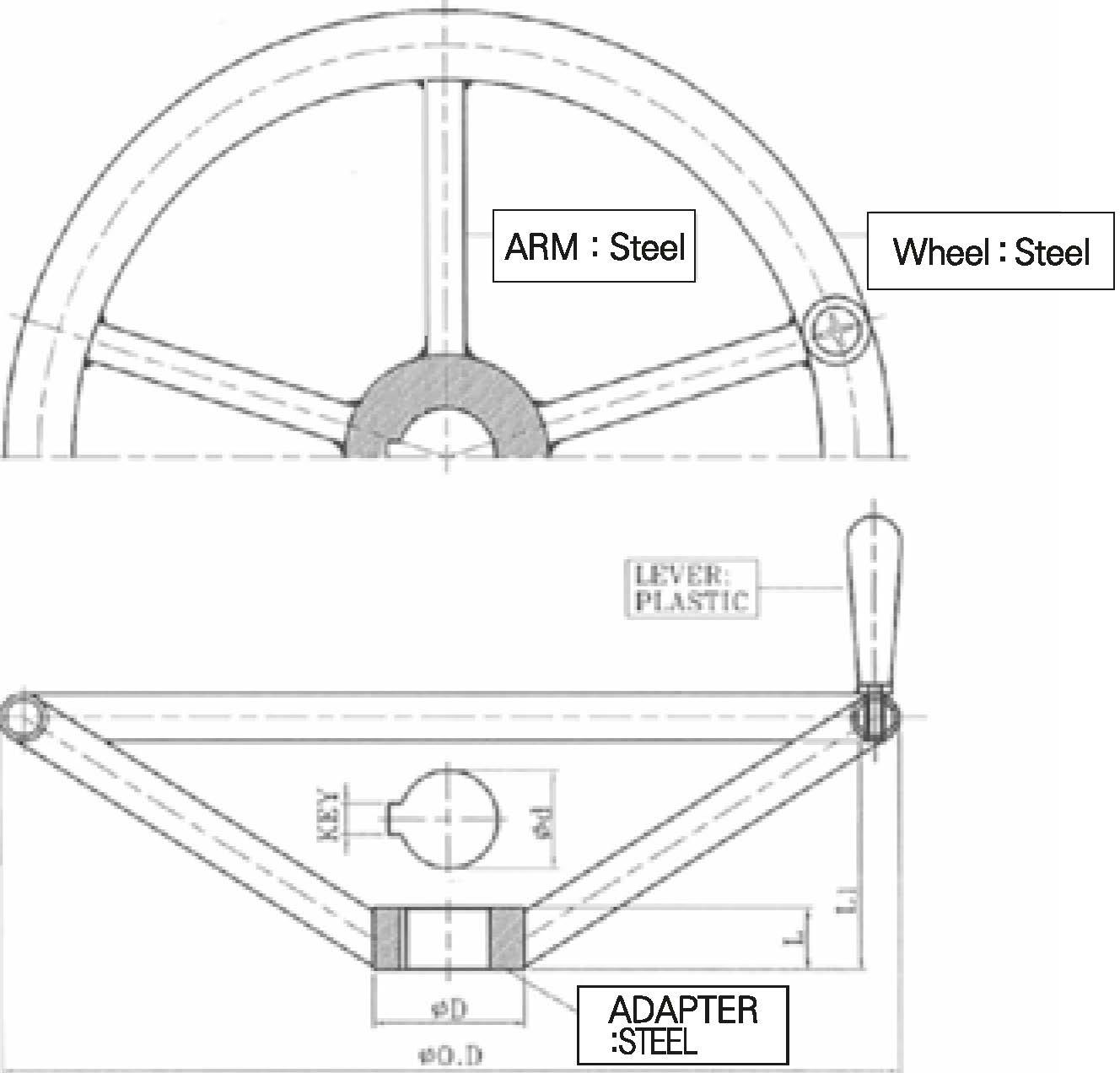

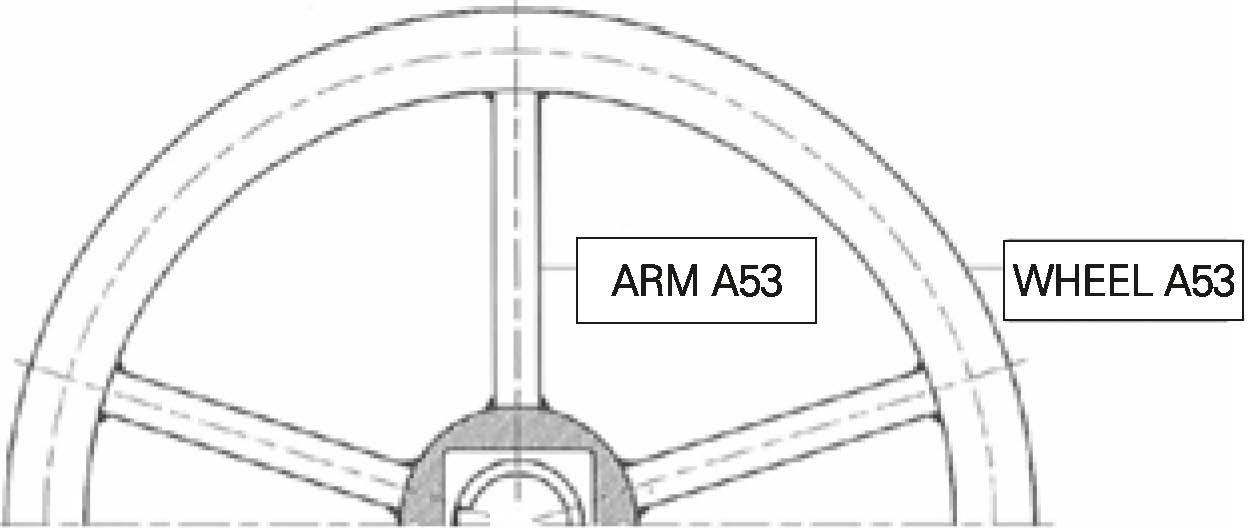

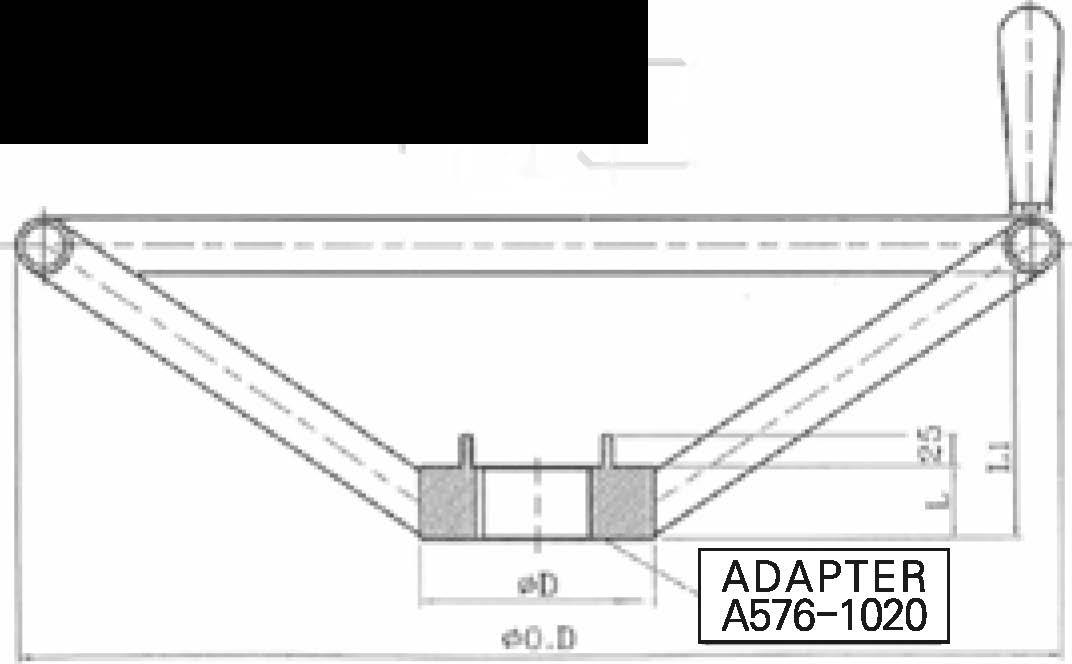

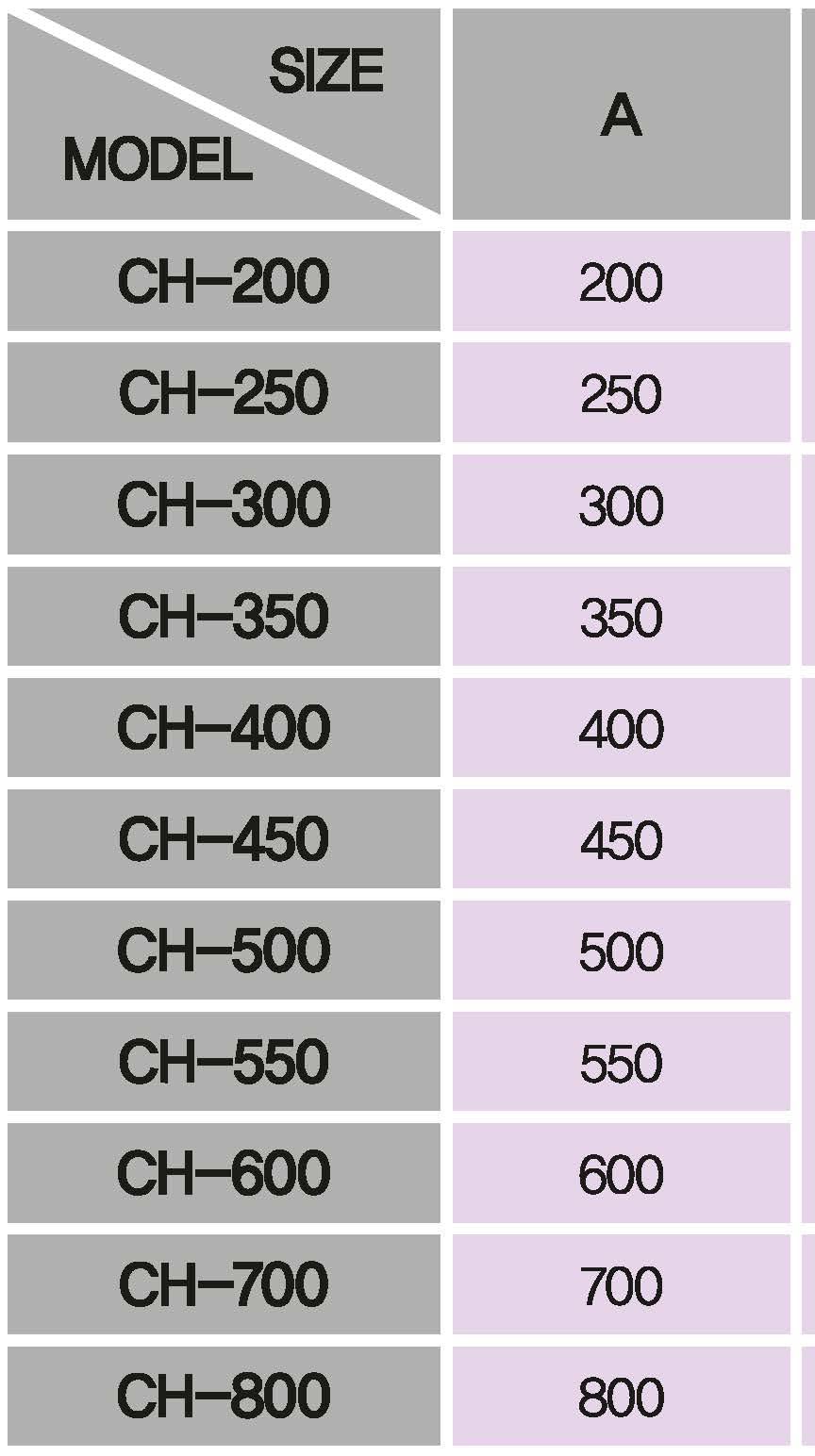

5. SAIYIBD offers a wide variety of Handwheels, Chainwheels, Input Shaft, Locking Devices and etc

5. SAIYIBD offers a wide variety of stem cover, stainless steel, Polycarbonate.

Paint: Unless specified, units are supplied with vp134 Red epoxy primer. SAIYIBD can provide finish coating upon request

DuctileIron

CarbonSteelS45C A57&-1045

DuctileIron FCD-450 A536--65--45-12

DuctileIron FCD--600A536--80--55-06B148-al5800(ALBC3)

DuctileIron FCD-450 A536-65-45-12

DuctileIron FCD-450 A536-65-45-12

Steel+EP

Steel

Steel

SpecialSteel SW2 A295-52100

AlloySteel SCM435 A.322-4135

AlloySteel SCM435 A.322-4135

StainlessSteel

CarbonSteelS45C A57&-1045

CarbonSteelS45C A57&-1045

PackingSeal

GreaseFitting 25 EyeBolt

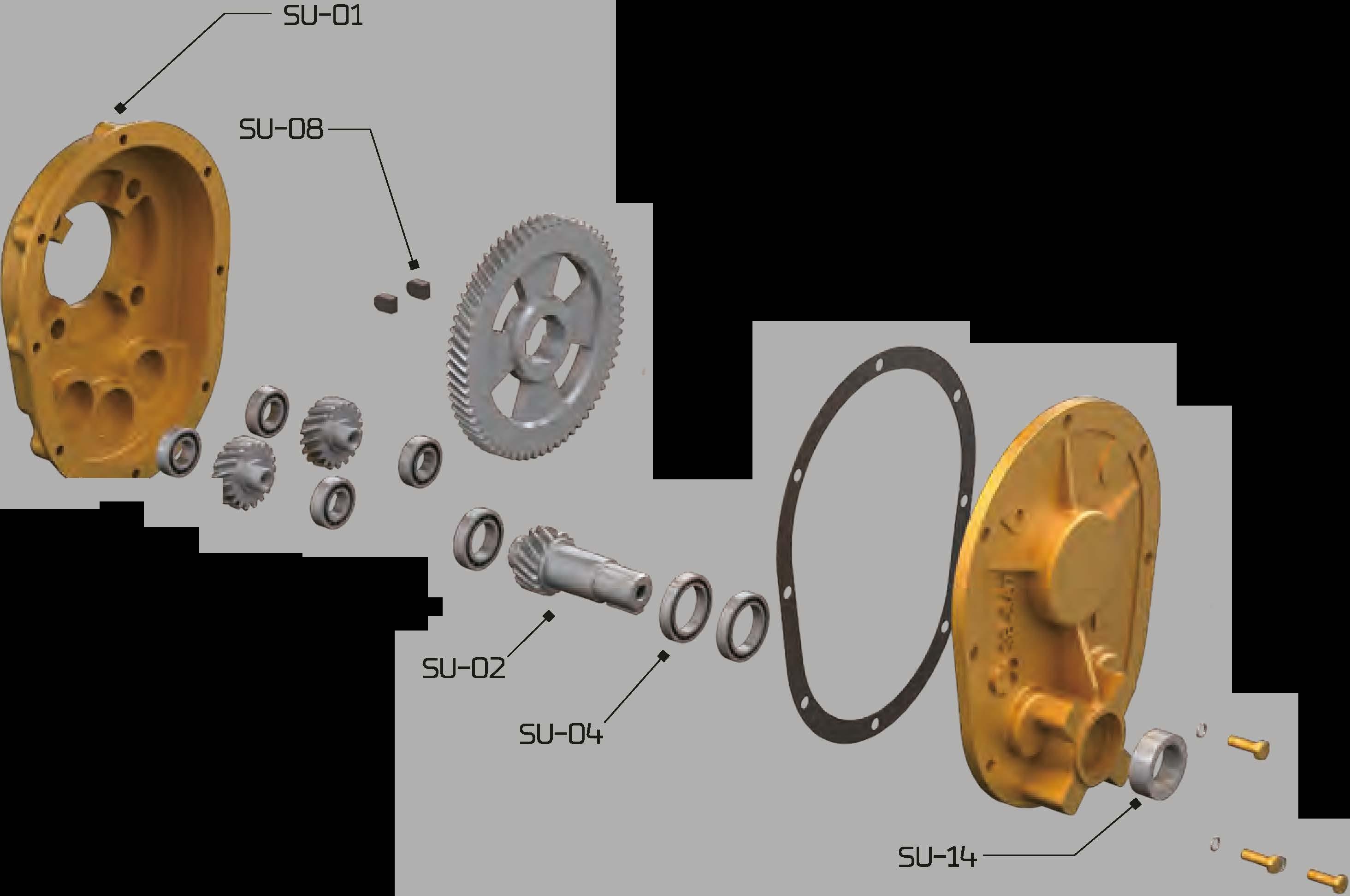

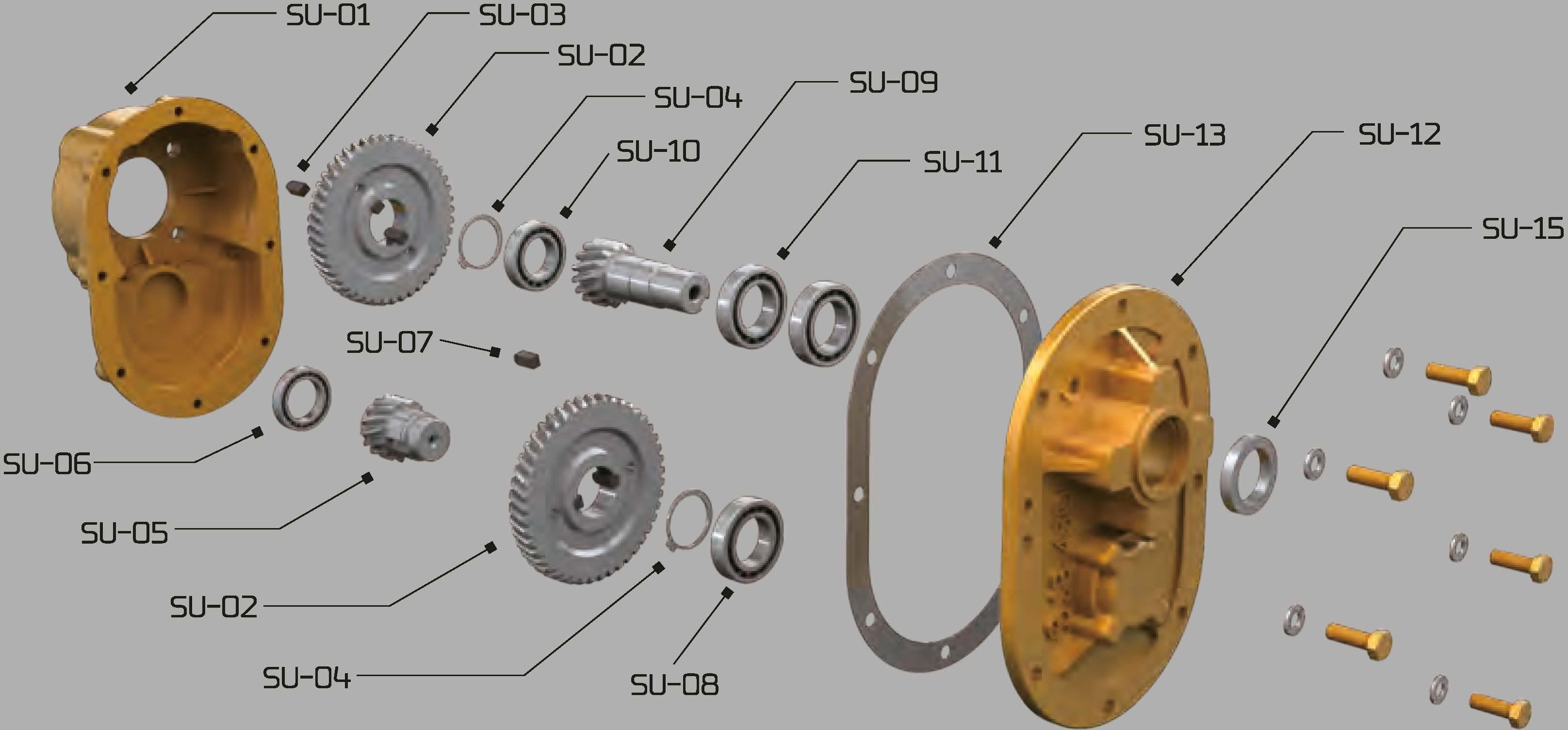

SlHJ1 SupportHousing

SlHJ2 HelicalPinion

SlHJ3 RadialBallB/R

SlH)4 RadialBallB/R

SlHJ5 IdleGear

Sl l6 RadialBallB/R

SlHJ7 HelicalGear

SlJ--08 Key{1R)

Sl J9 SnapRing

SU-10 RadialBallB/R

SU-11 SupportCover

SU-12 &-CoverGasket

SU-13 HEX.Bolt(S/W)

SU-14 Oil-Seal

OP--01 HandWheel

OP--02 Key{1R)

OP--03 NamePlate

OP-04 Washer

OP--05 HEX.Bolt(S/W)

Silicon

Steel+Galvanizing

Steel+Galvanizing

DuctileIron FCD-450

CarbonSteelS45C

SpecialSteelSW2

SpecialSteelSW2

CarbonSteelS45C

SpeciialSteelSW2

CarbonSteelS45C

CarbonSteelS45C

CarbonSteelS45C

SpecialSteelSW2

DuctileIron FCD-450

Nonasbestos

AlloySteel SCM435

BunaN NBR

SteelPipe SGP

CarbonSteelS45C

StainlessSteel

StainlessSteel

StainlessSteel

A536--65--45--12

A57&-1045

A295-52100

A295-52100

A57&-1045

A295-52100

A57&-1045

A57&-1045

A57&-1045

A295-52100

A536--65--45--12

A.322-4135

A53

A57&-1045

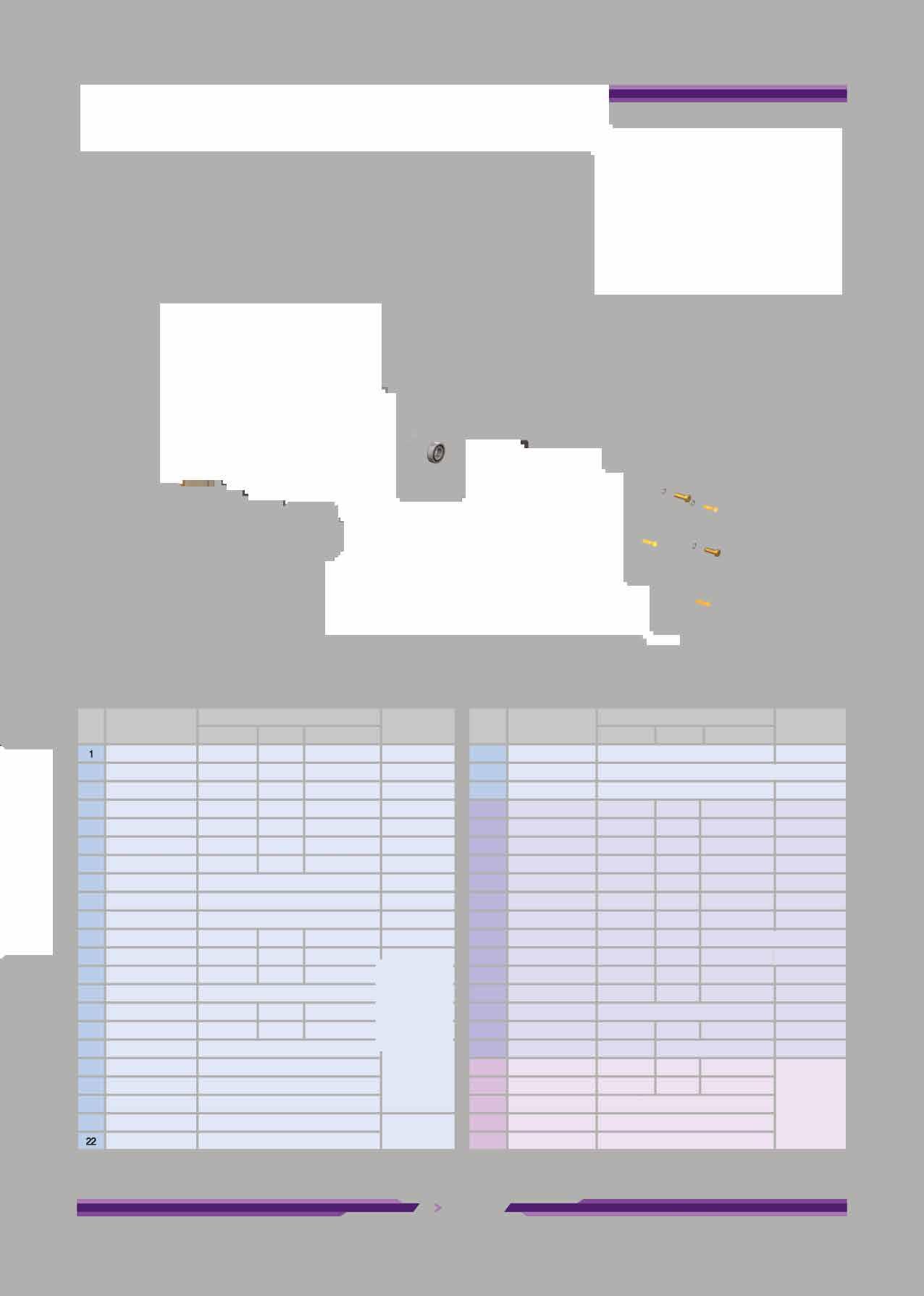

DuctileIron FCD-450 A536----65----45-12

NO DESCRIPTION

23 PackingSeal

NAME M,lij"ERIAL JIS ASTM

Silicon

REMARK

DuctileIron FCD-450 A536----65----45-12 CarbonSteel S45C A57&-1045 Ductile

24 GreaseFitting

25 EyeBolt

A536----65----45-12

DuctileIron FCD-600A536-80-55-06B1<18-C95800(ALBC)

DuctileIron FCD-450A536----65----45-12

DuctileIron FCD-450A536----65----45-12

S45C S45C Non-Asbestos Non-Asbestos A295-52100 A322-4135 A322-4135 A57&-1045 A57&-1045

NOfE.3

VAL.QUA6601

SlHl1 SupportHousing

SlHl2 HelicalGear

SlHl3 Key{1R)

SlH)4 SnapRing

SlHl5 IdleGear

Sl l6 RadialBallB/R

SlHl7 Key(1R)

SlJ--08 RadialBallB/R

SlH)9 HelicalPinion

SU-10 RadialBallB/R

SU-11 RadialBallB/R

SU-12 SupportCover

SU--13 &-CoverGasket

SU--14 HEX.Bolt(S/W)

SU--15 Oil-Seal

OP--01 HandWheel

OP--02 Key{1R)

OP--03 NamePlate

OP-04 Washer

OP--05 HEX.Bolt(S/W)

Steel+Galvanizing

Steel+Galvanizing

DuctileIron FCD-450

CarbonSteel S45C

CarbonSteel S45C

CarbonSteel S45C

CarbonSteel S45C

SpecialSteel SUJ2

CarbonSteel S45C

SpecialSteel SUJ2

CarbonSteel S45C

SpecialSteel SUJ2

SpecialSteel SUJ2

DuctileIron Nonasbestos

Stainless FCD-450 SCM435

BunaN SteelPipe

CarbonSteel

StainlessSteel

StainlessSteel

StainlessSteel NBR SGP S45C

A536--65--45--12

A57&-1045

A57&-1045

A57&-1045

A57&-1045

A295-52100

A57&-1045

A295-52100

A57&-1045

A295-52100

A295-52100

A536--65--45--12

A322-4135

A53

A57&-1045

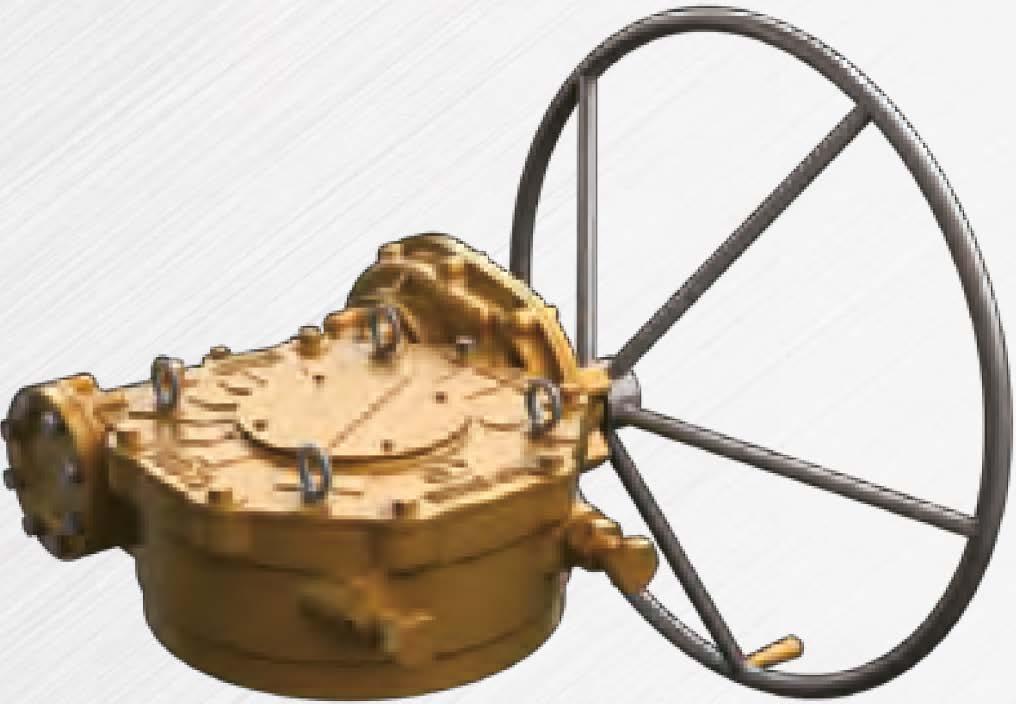

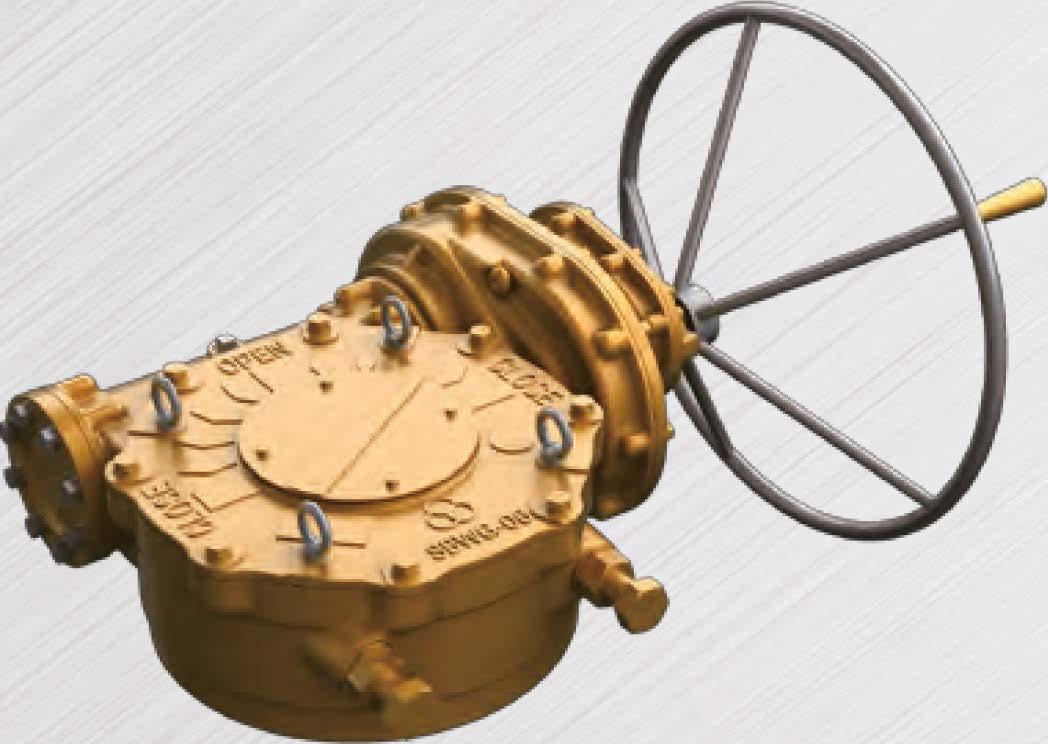

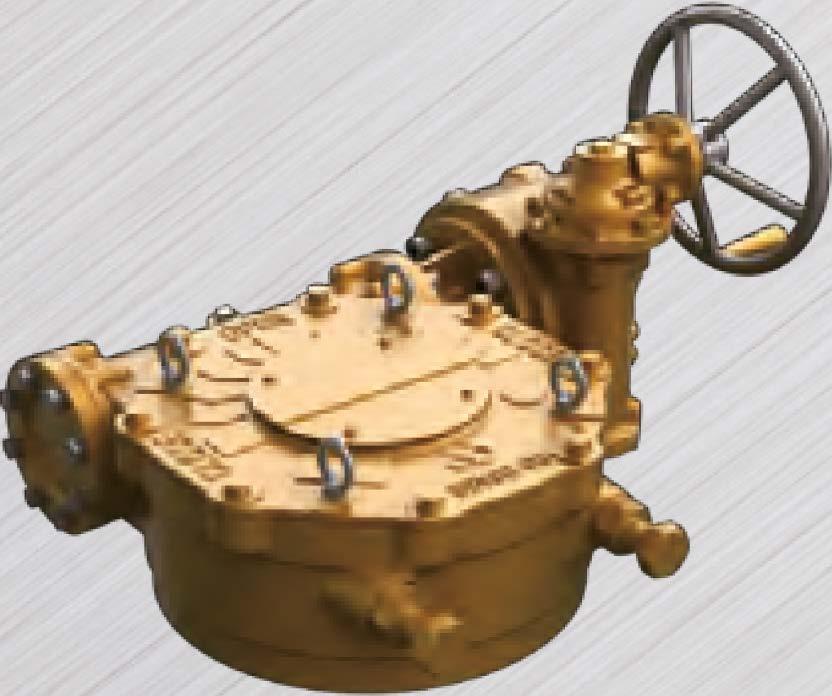

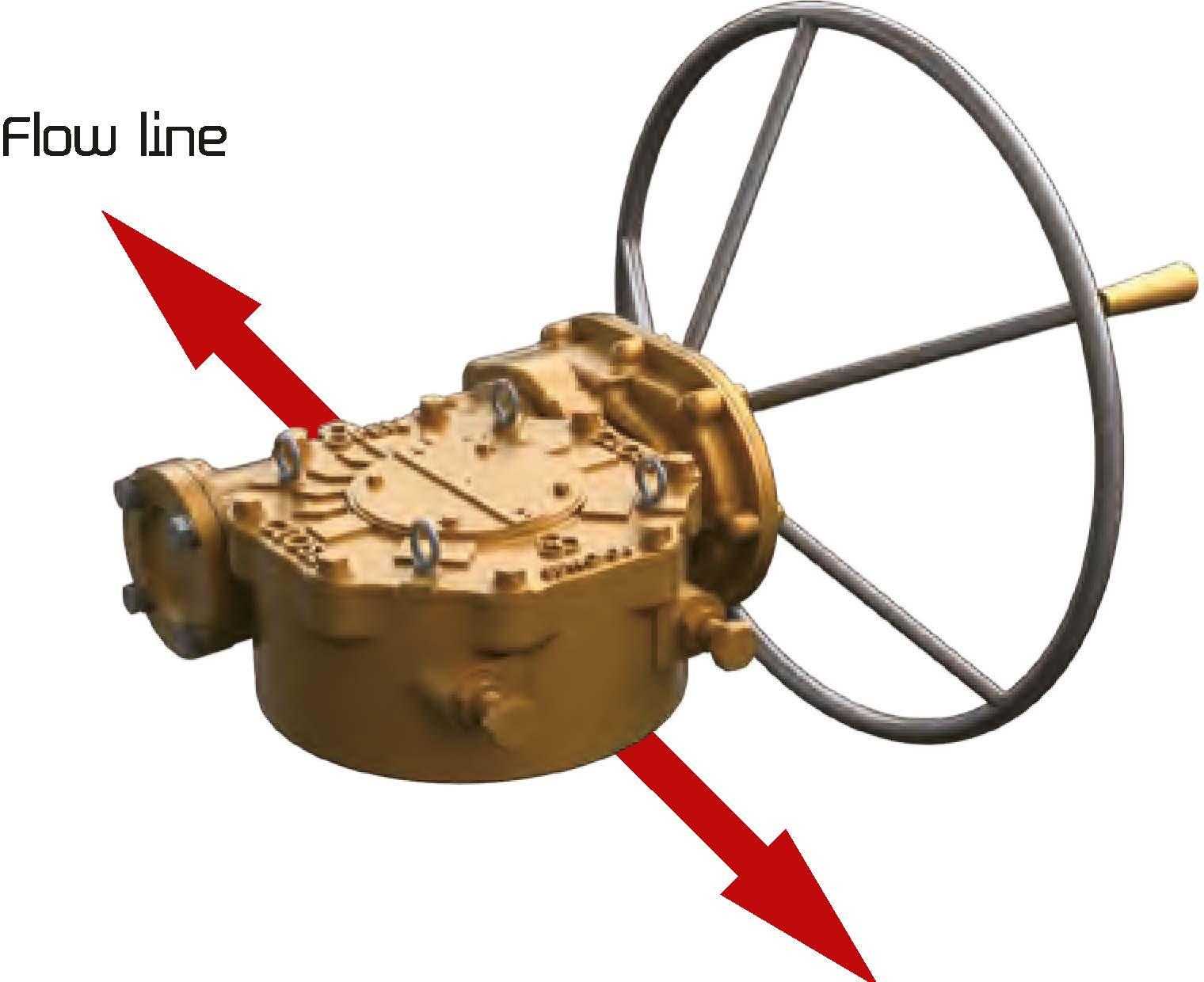

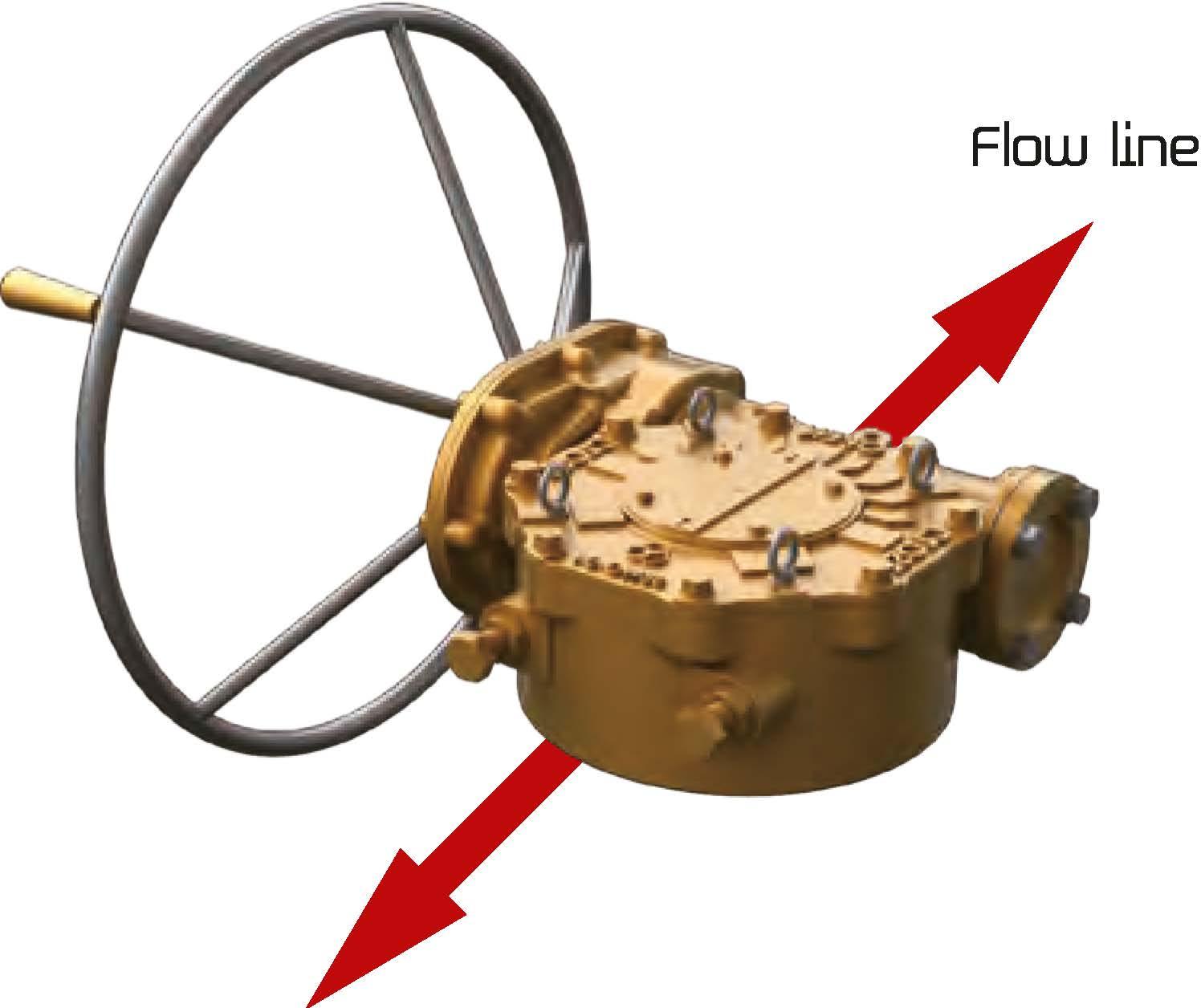

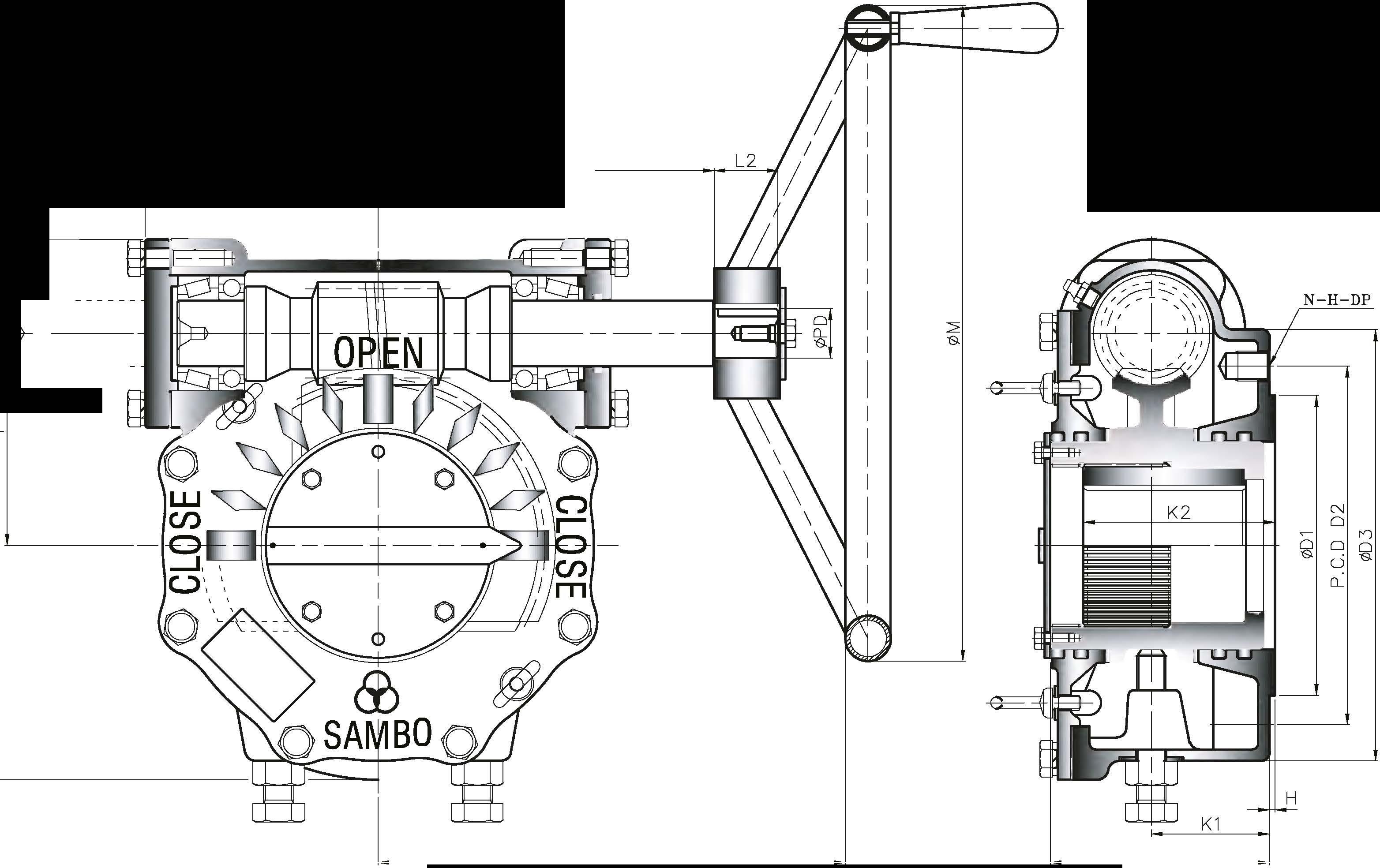

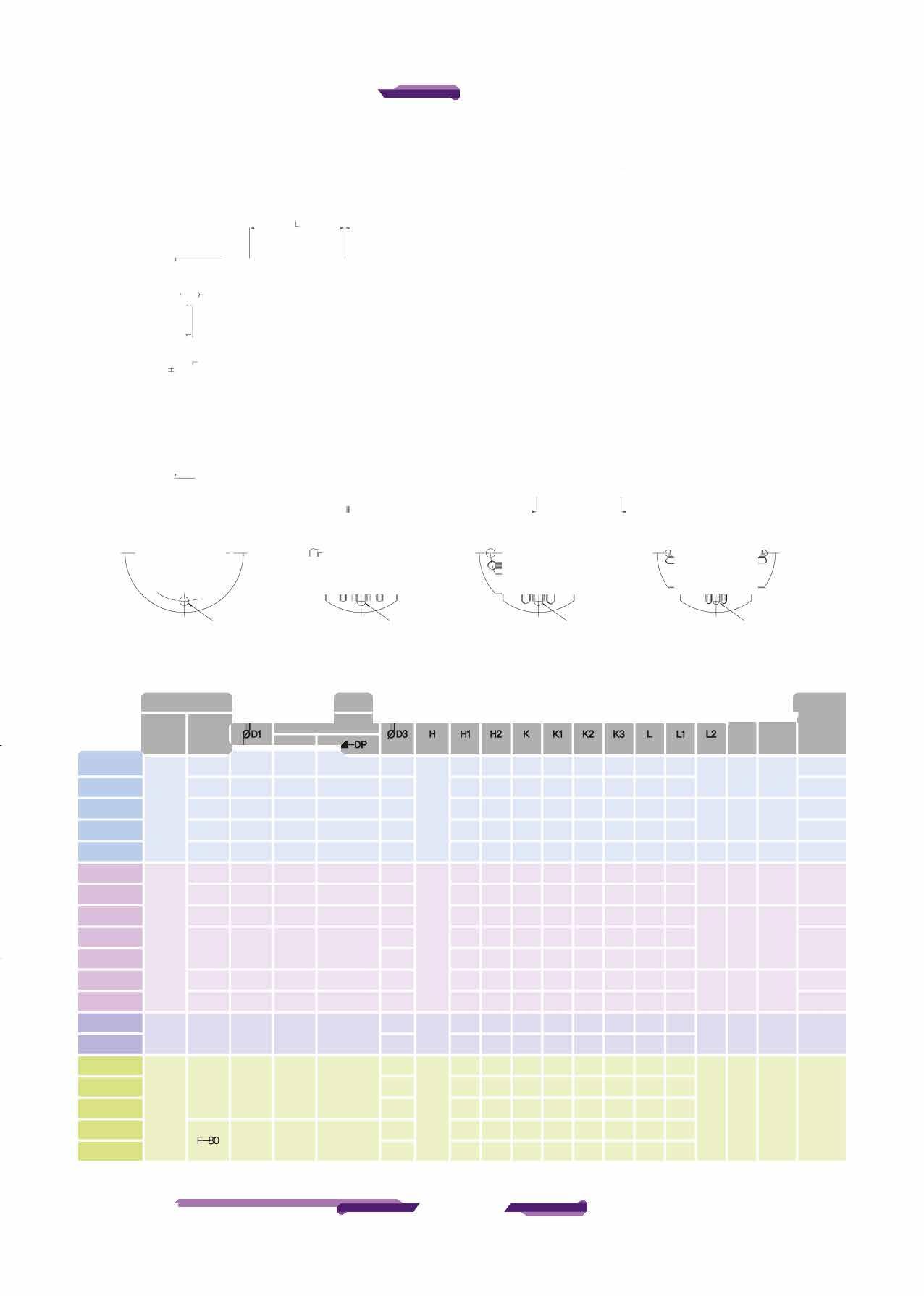

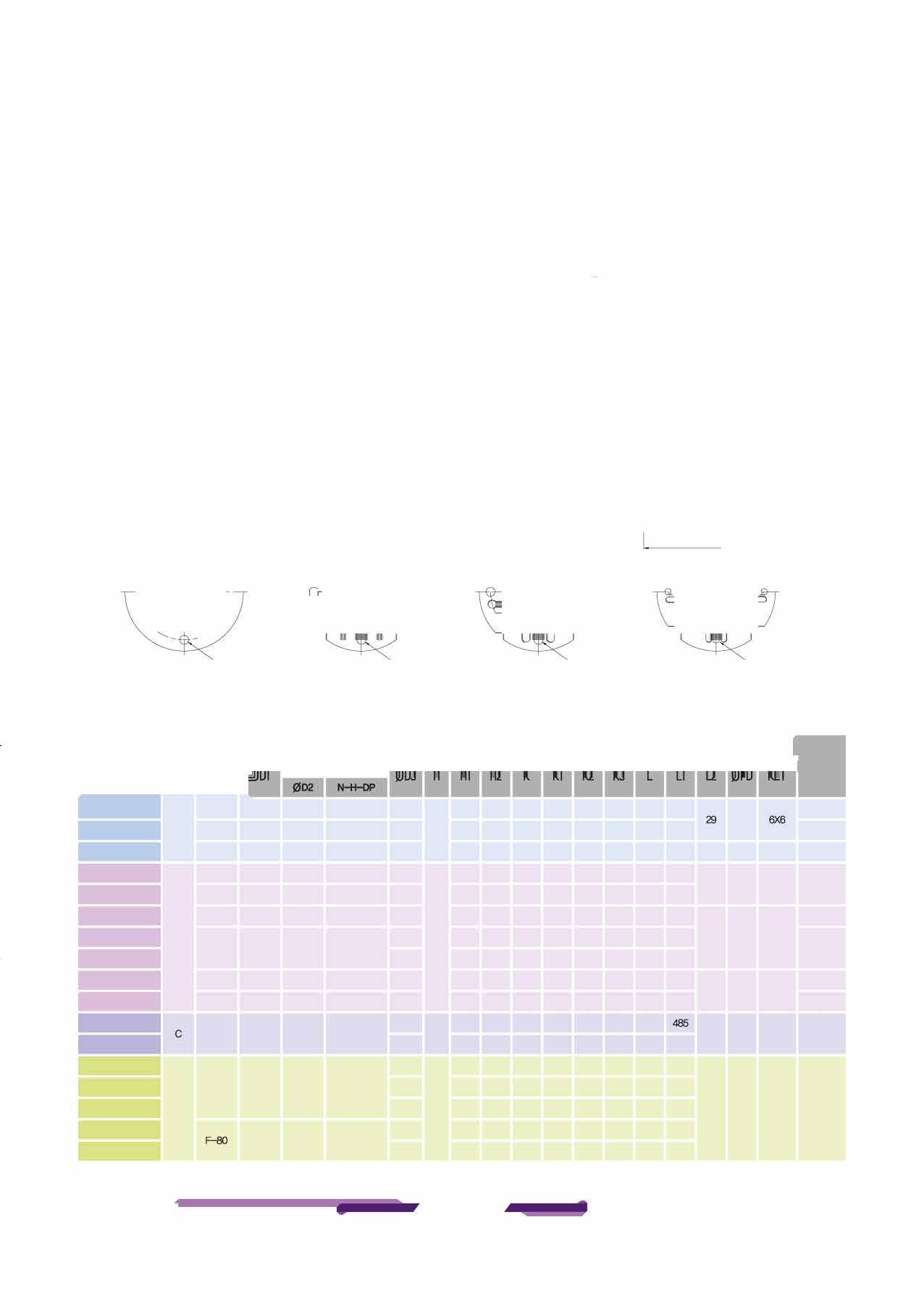

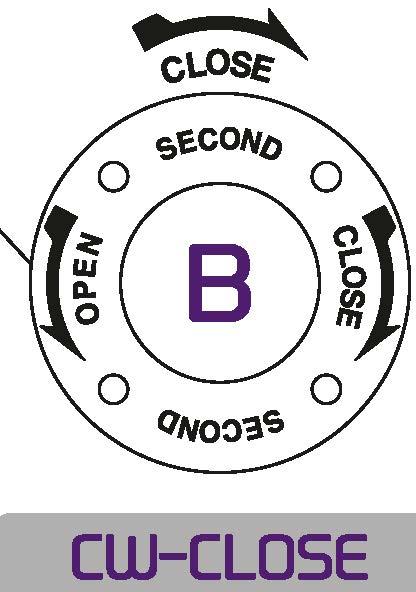

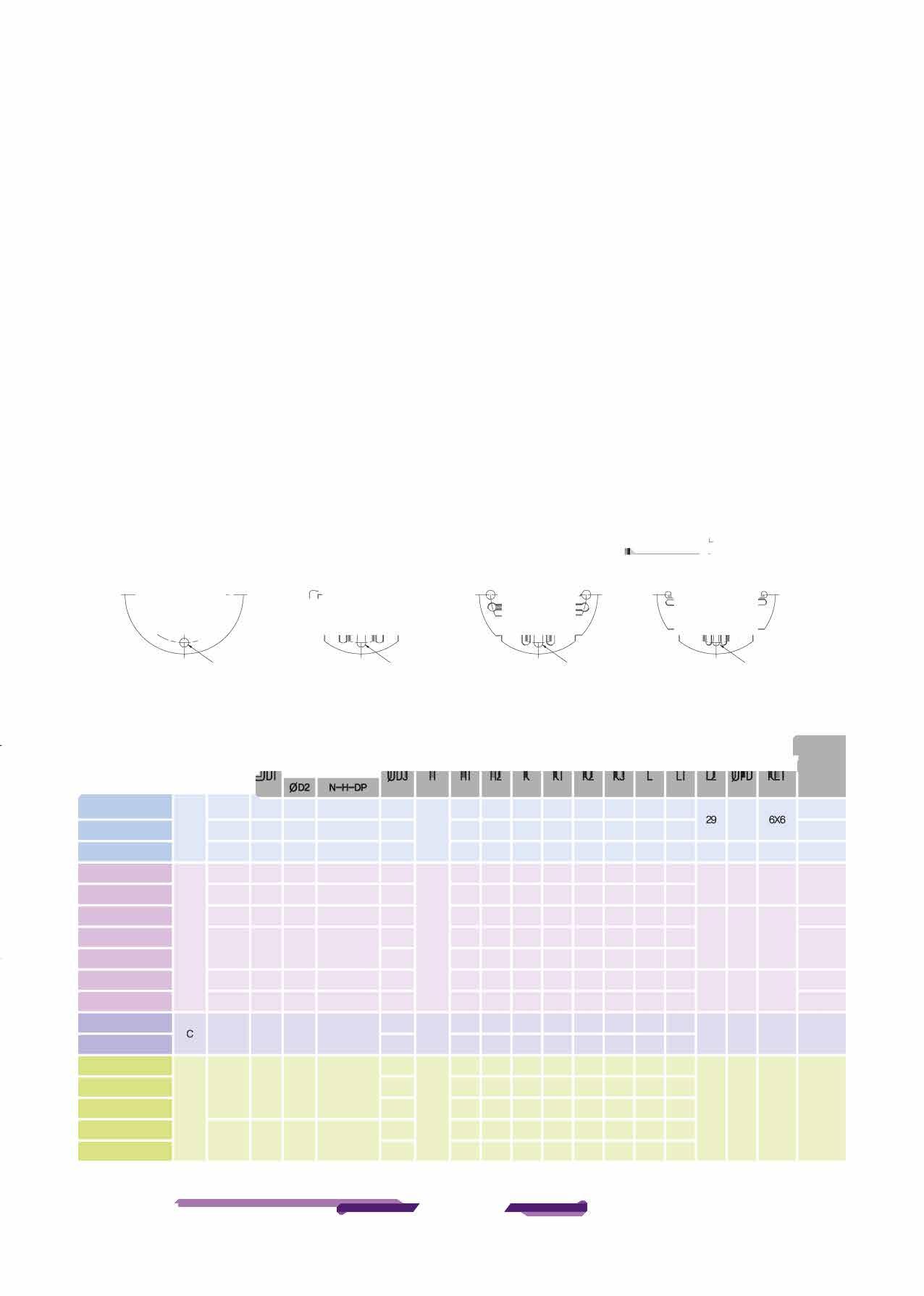

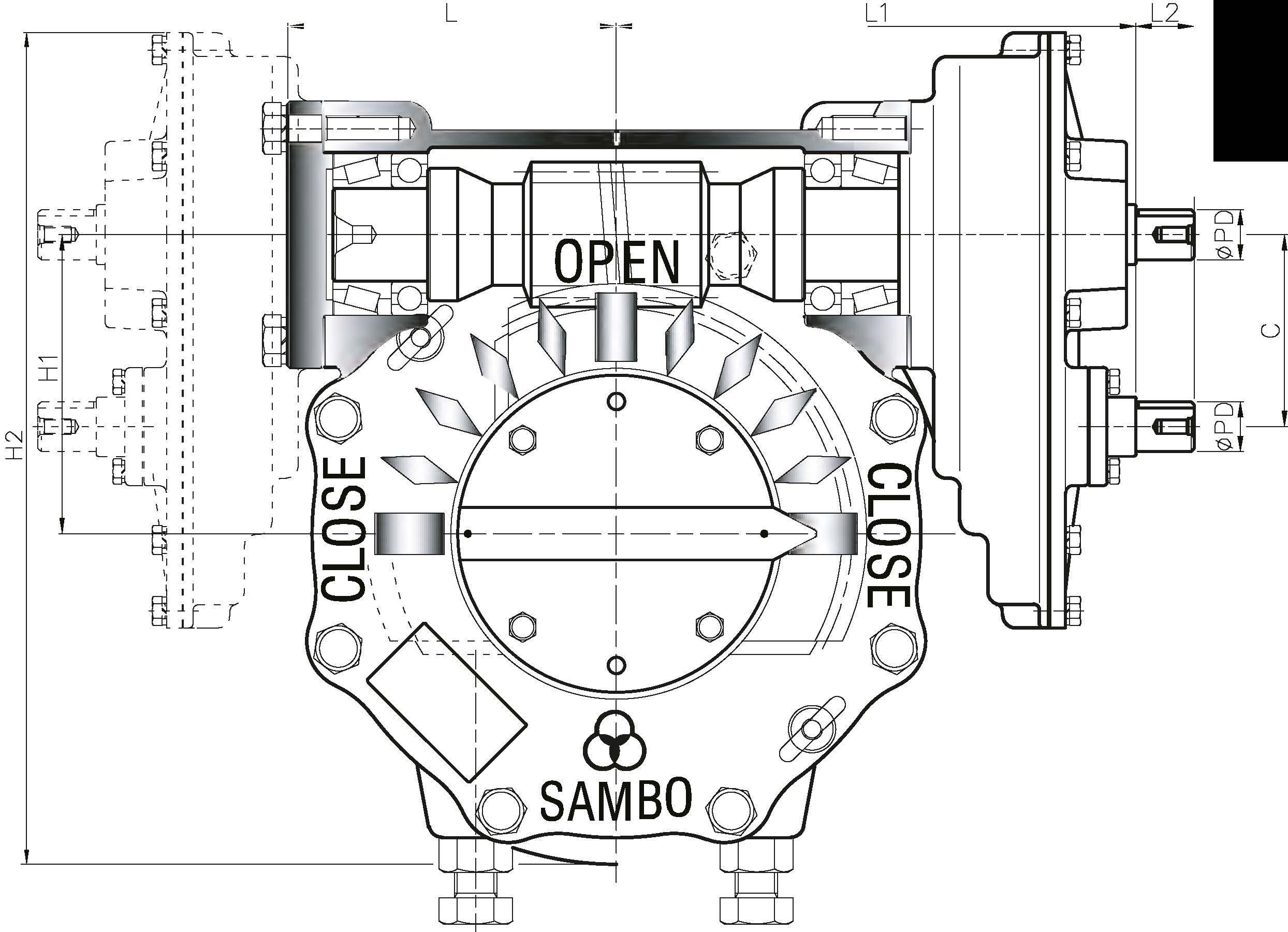

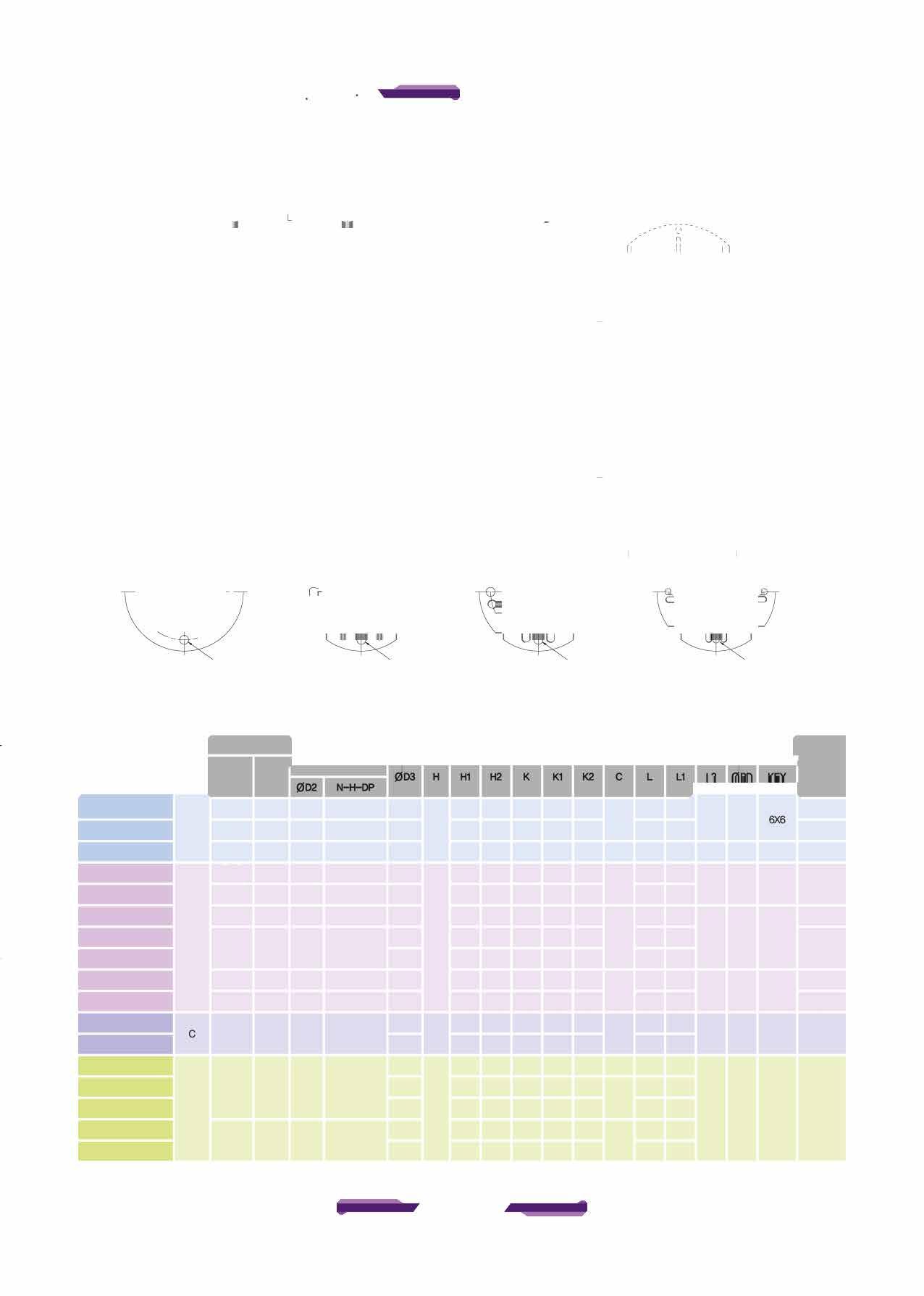

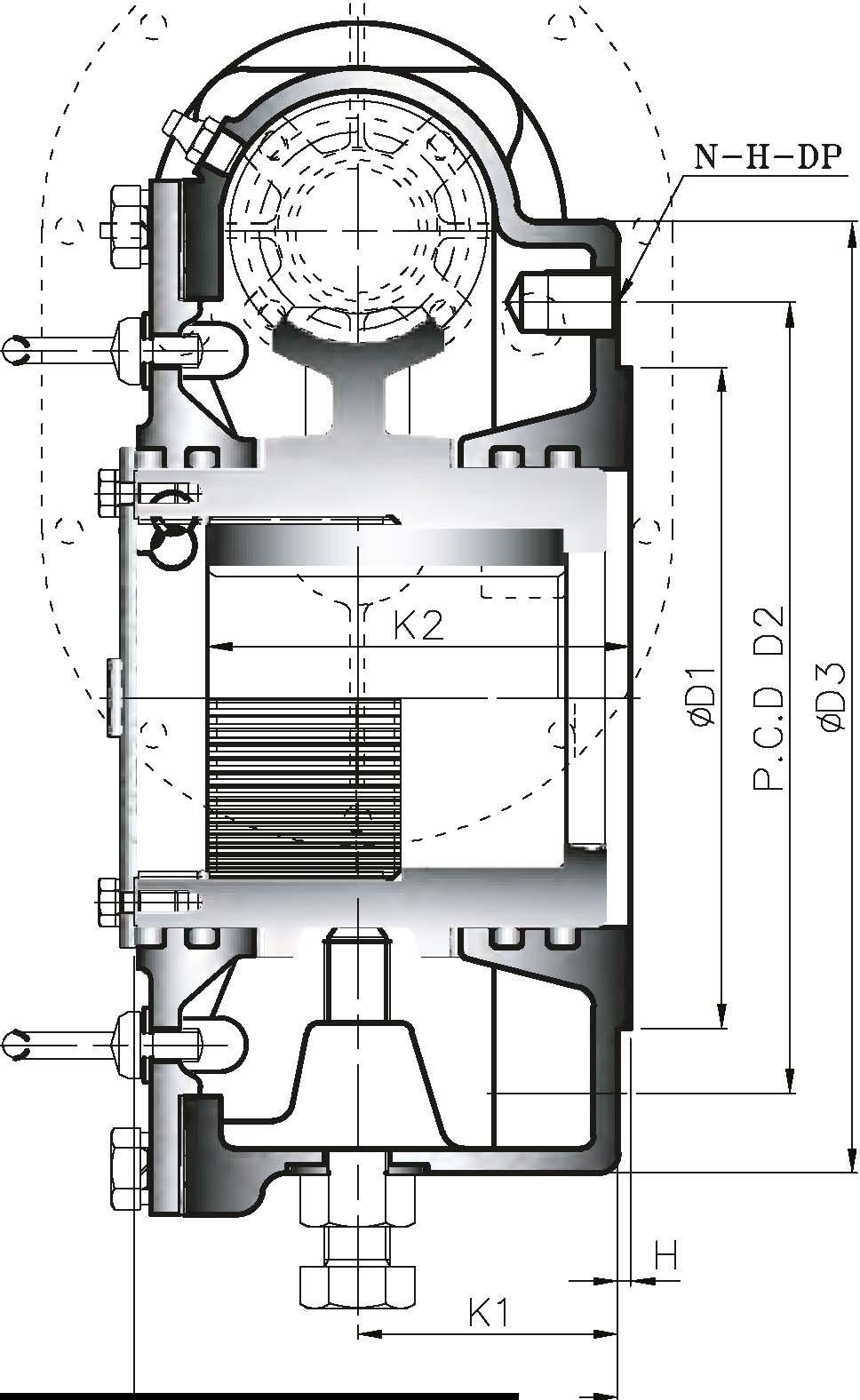

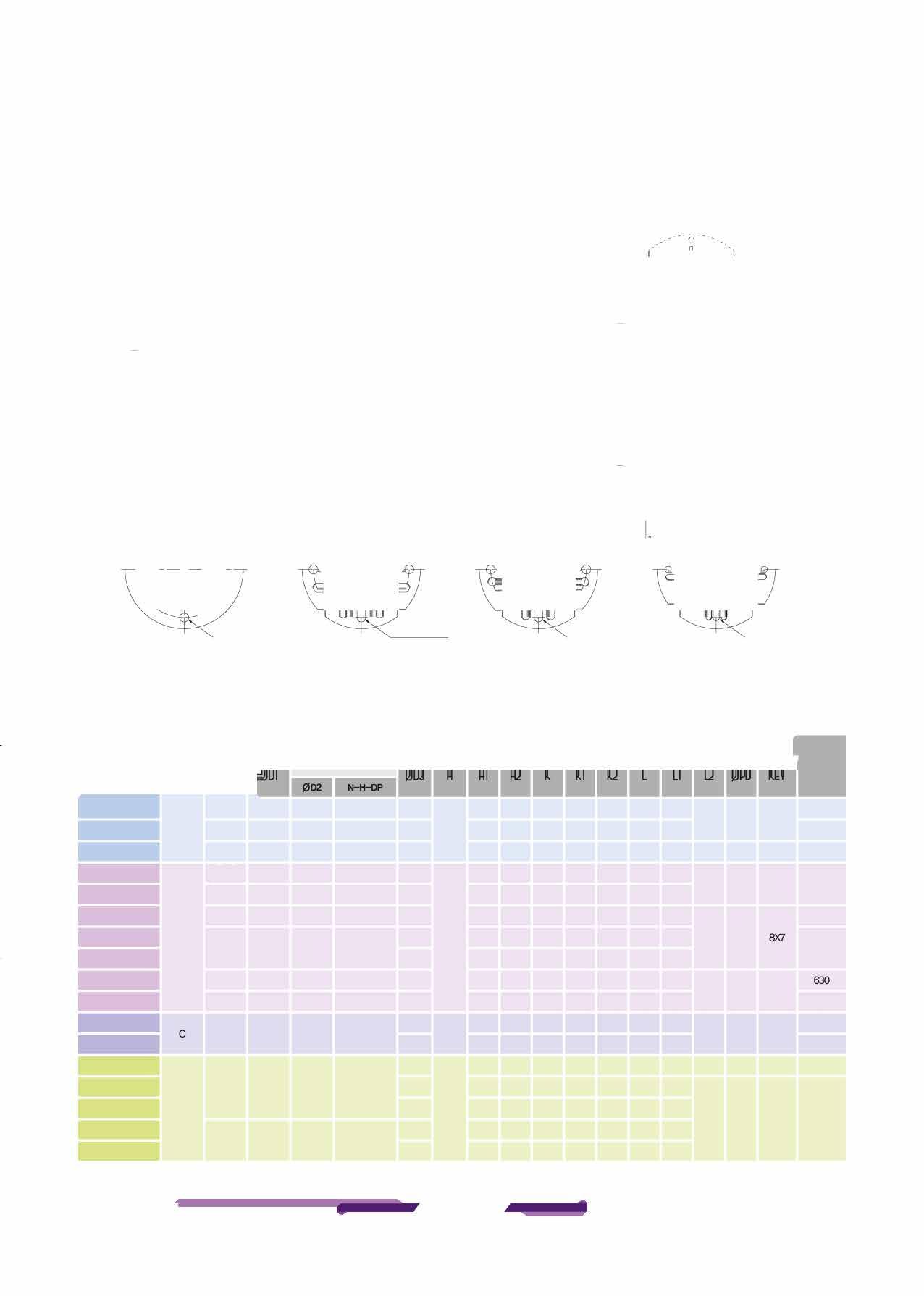

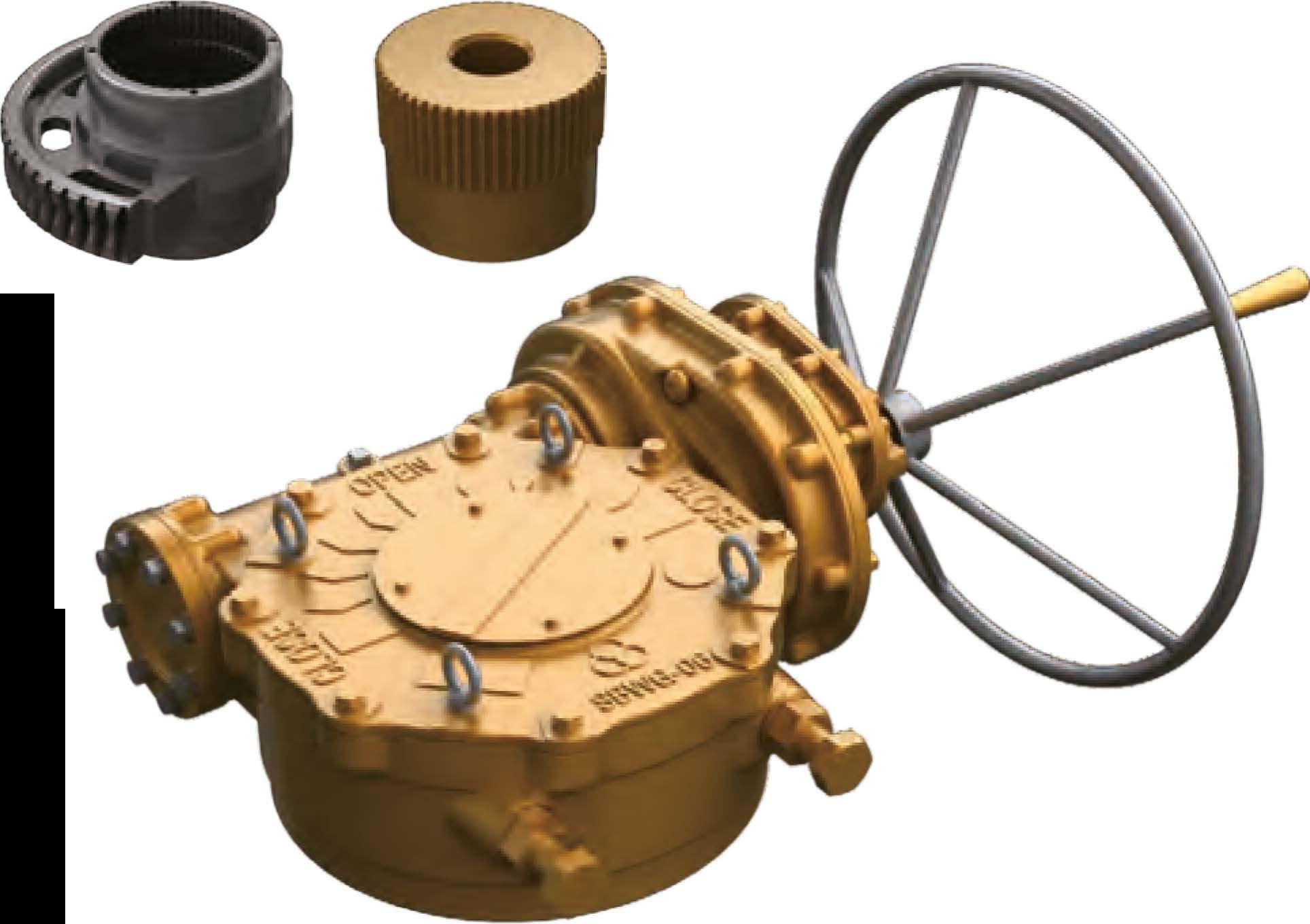

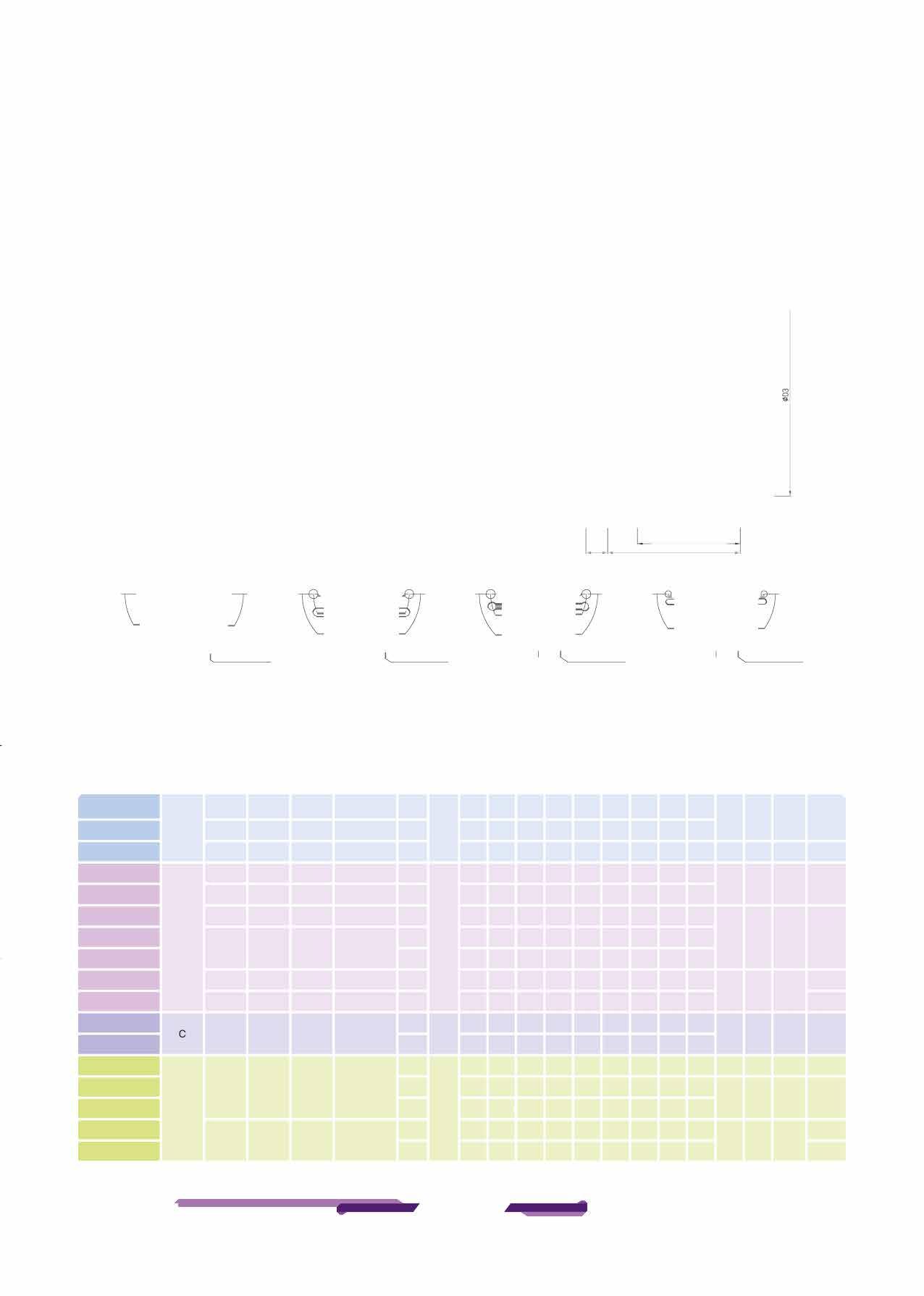

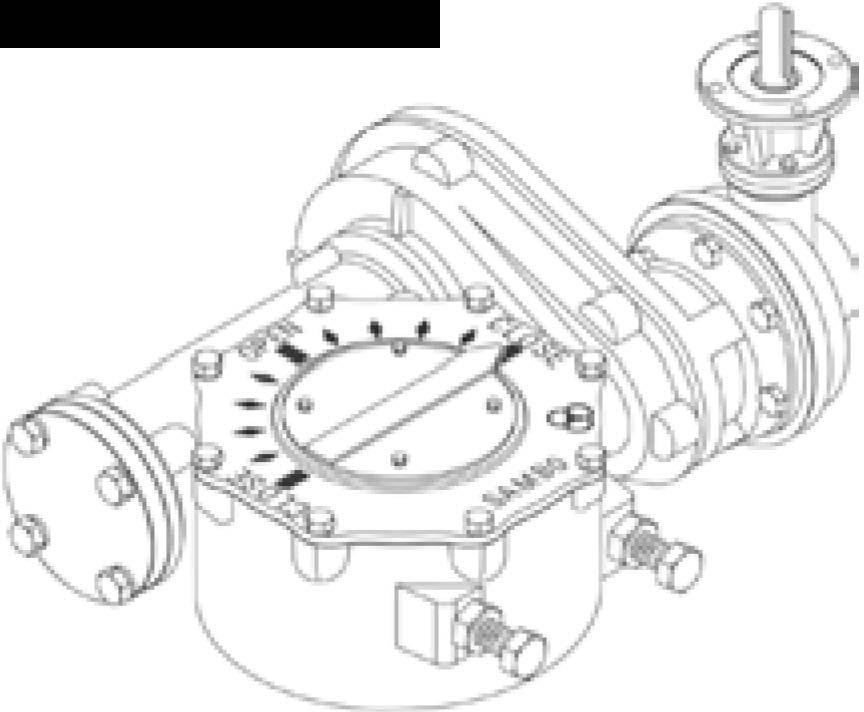

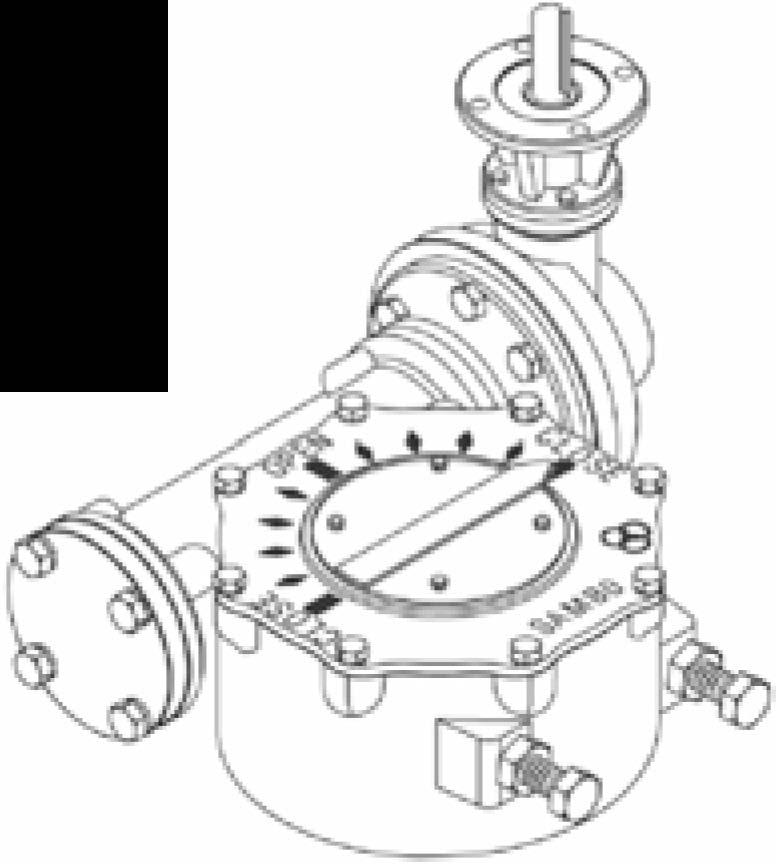

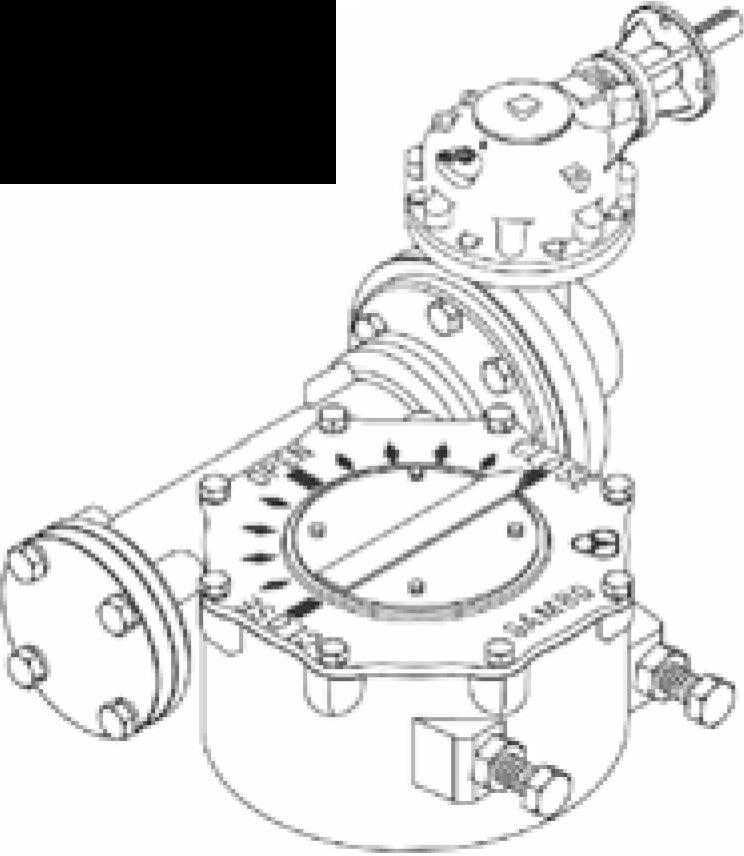

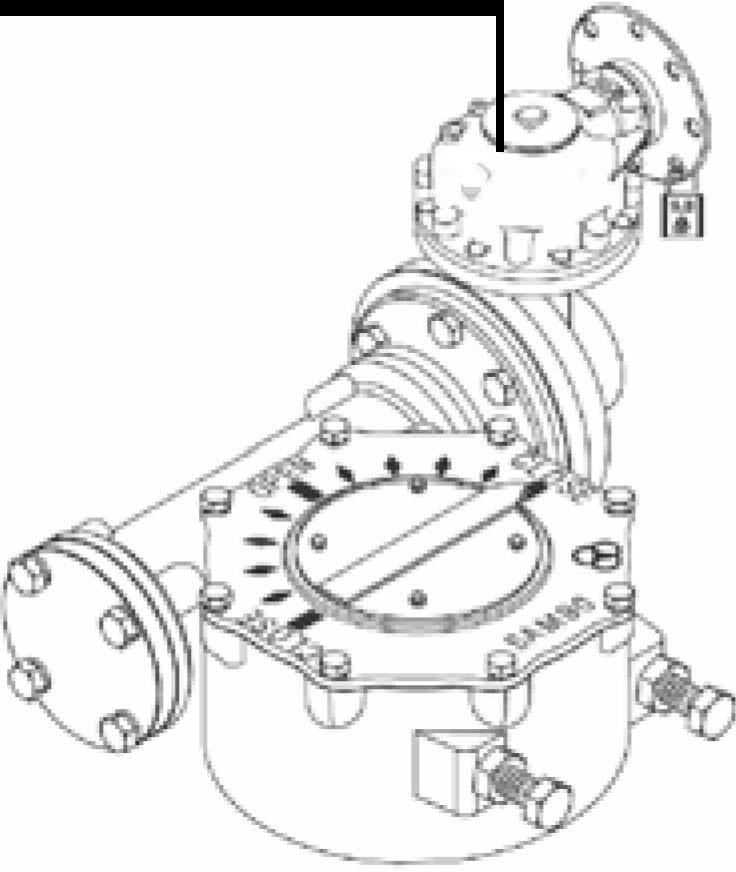

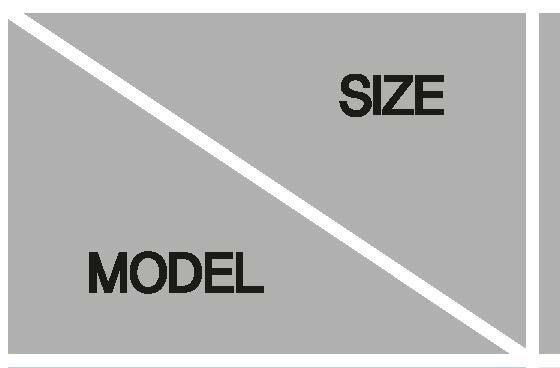

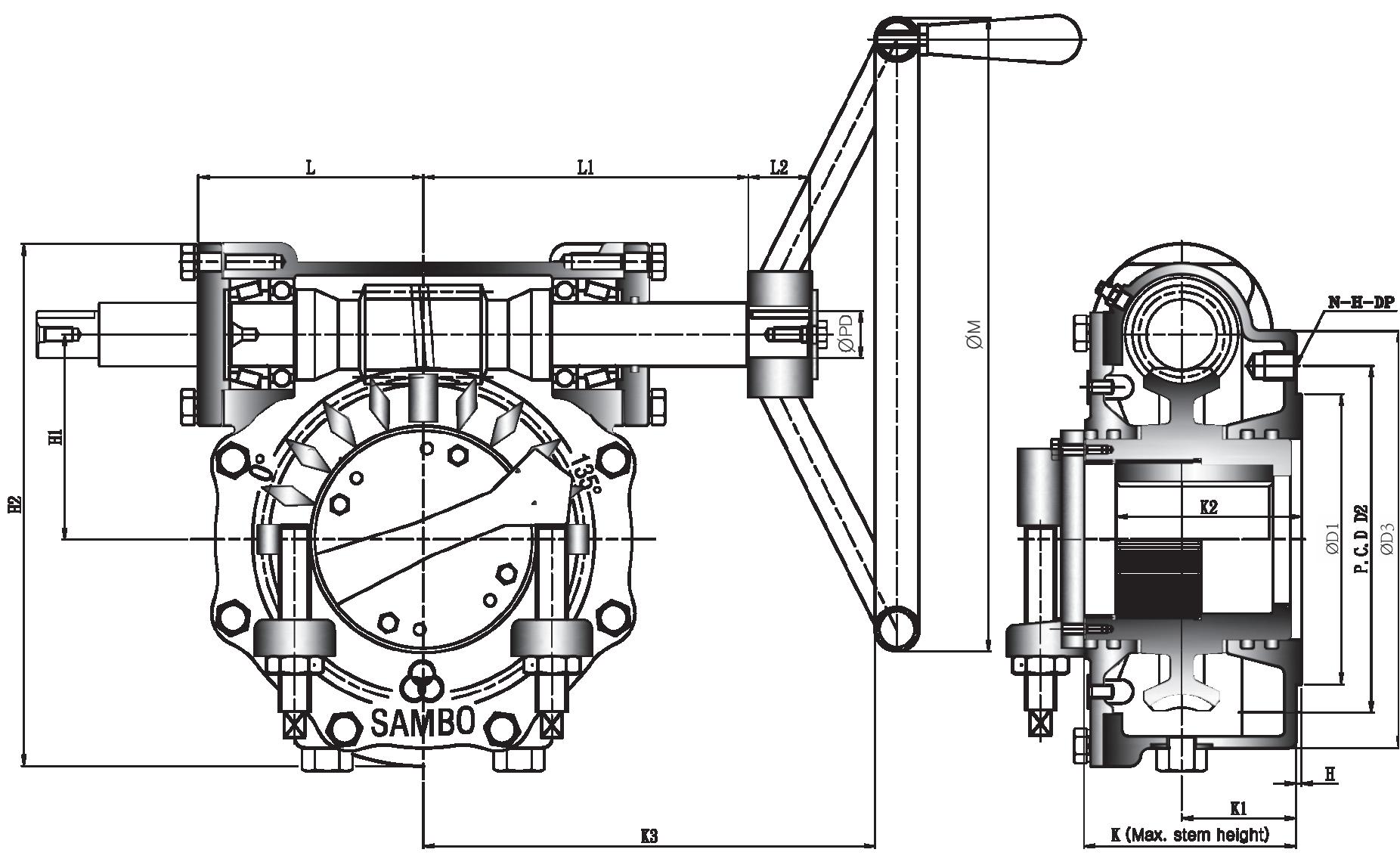

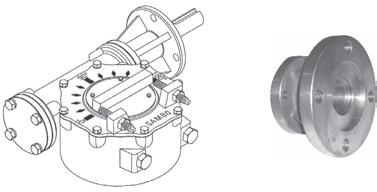

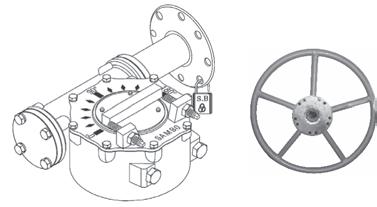

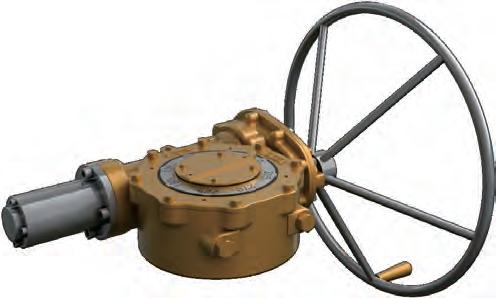

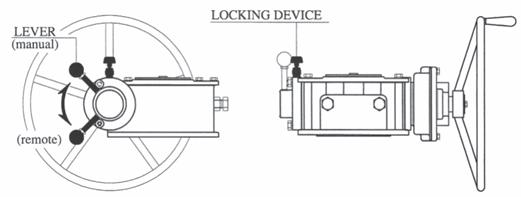

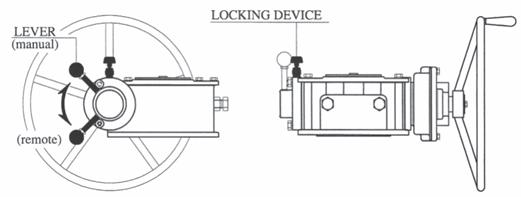

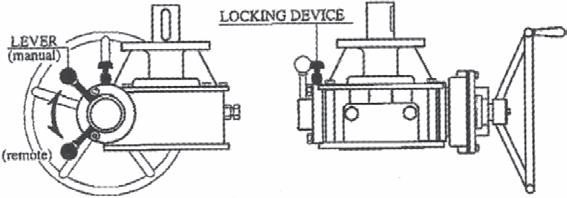

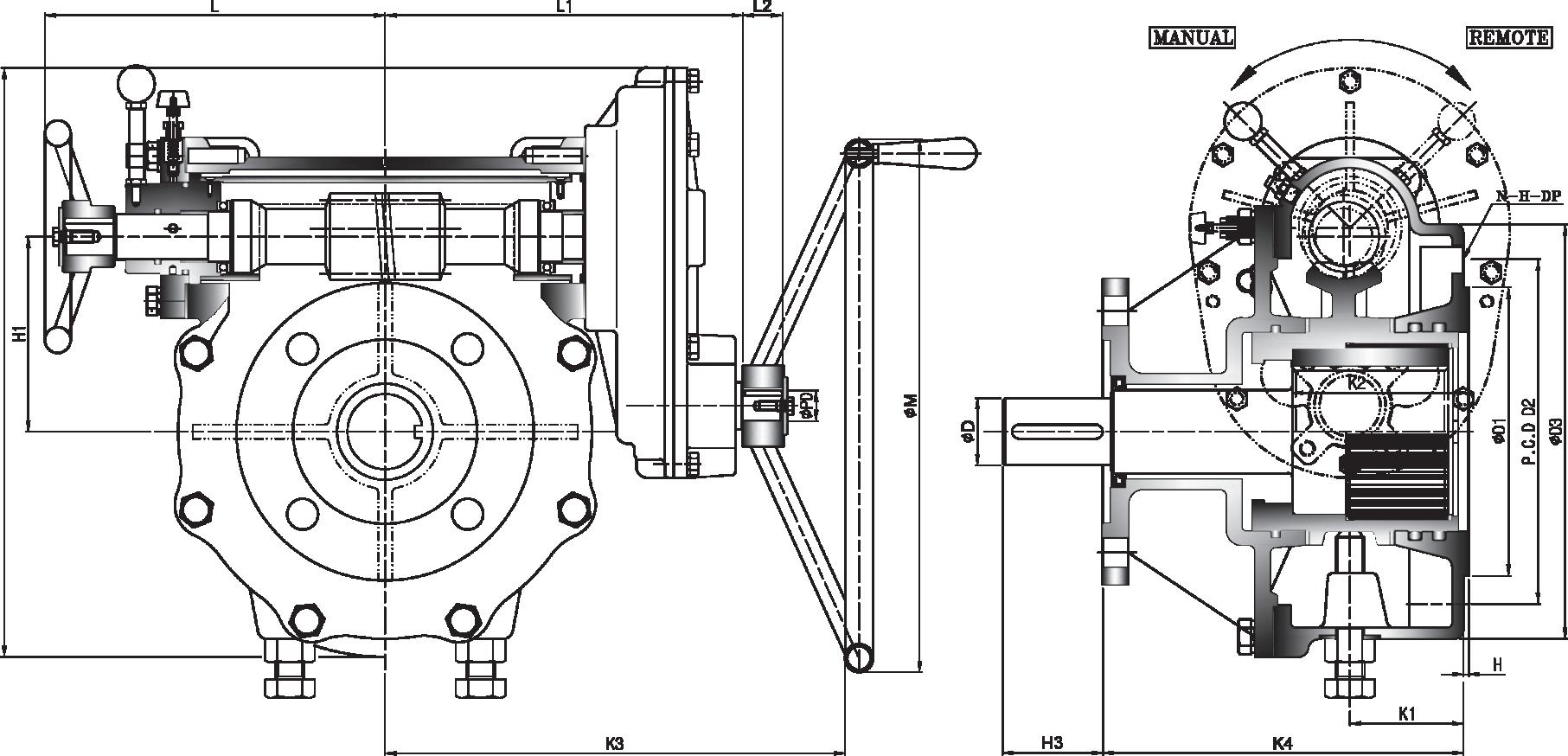

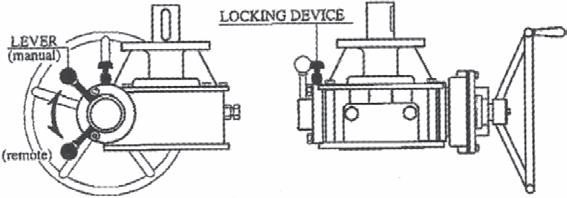

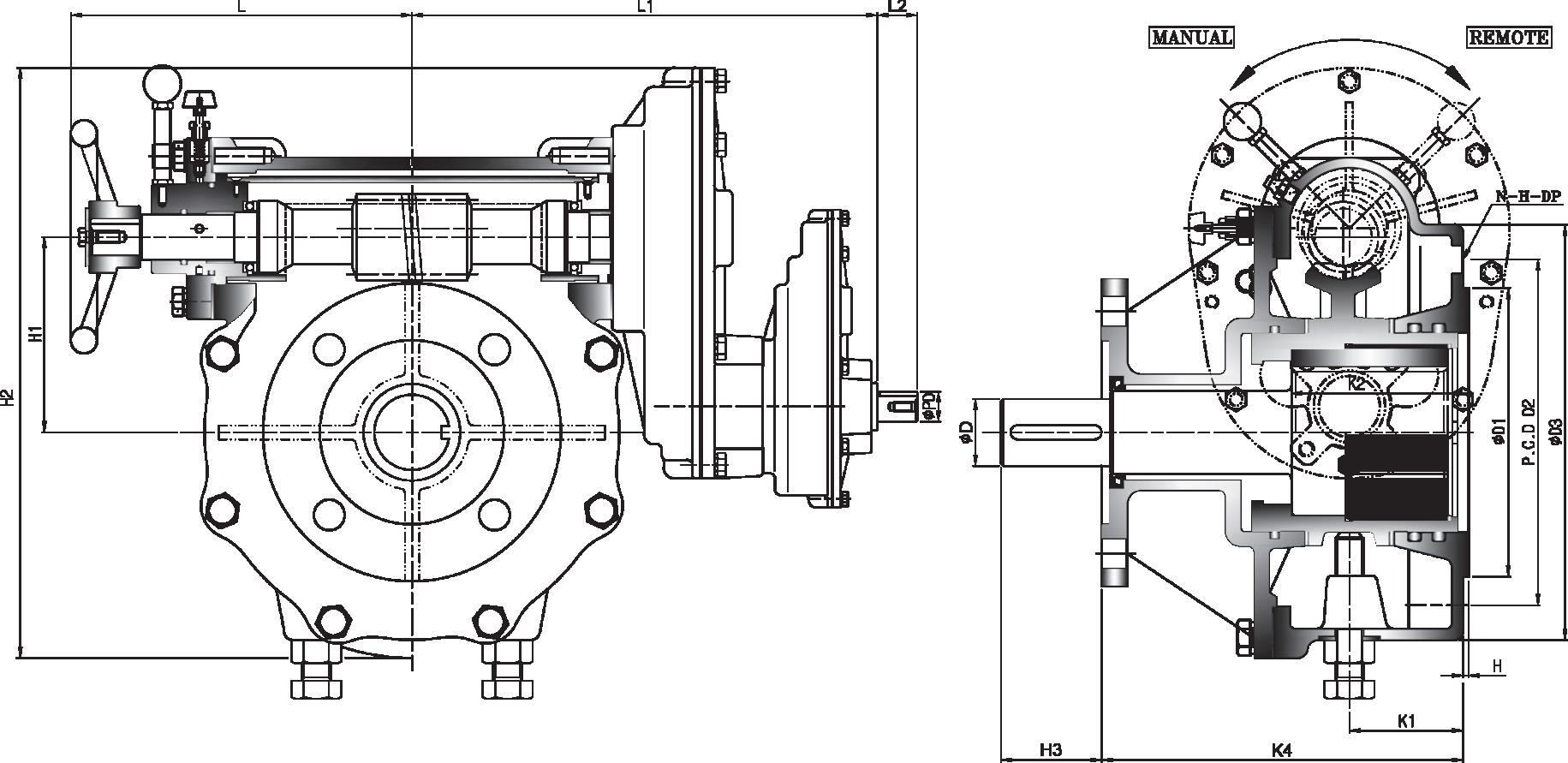

Hand WheelType & Chain Wheel Type

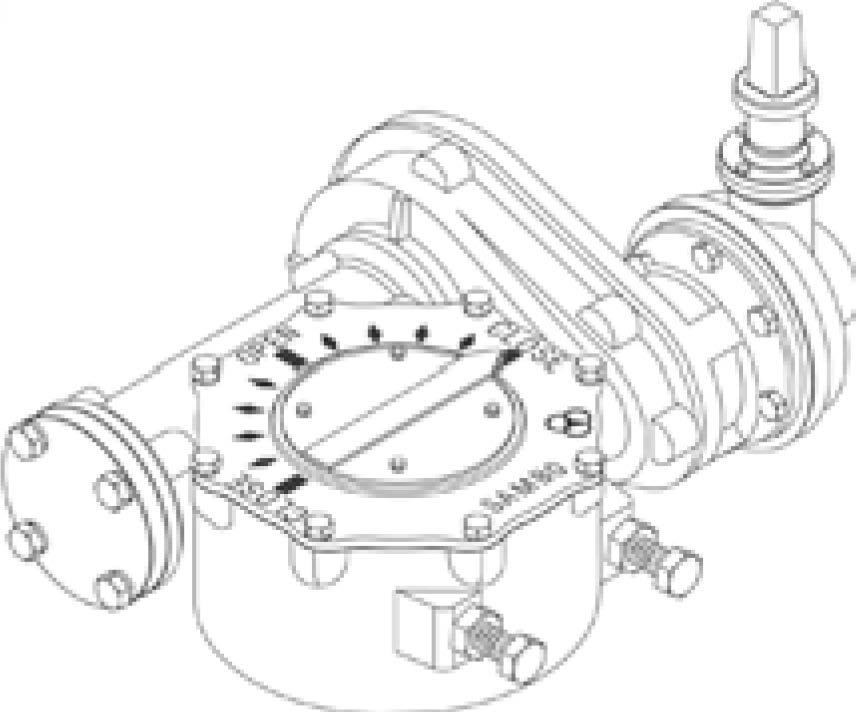

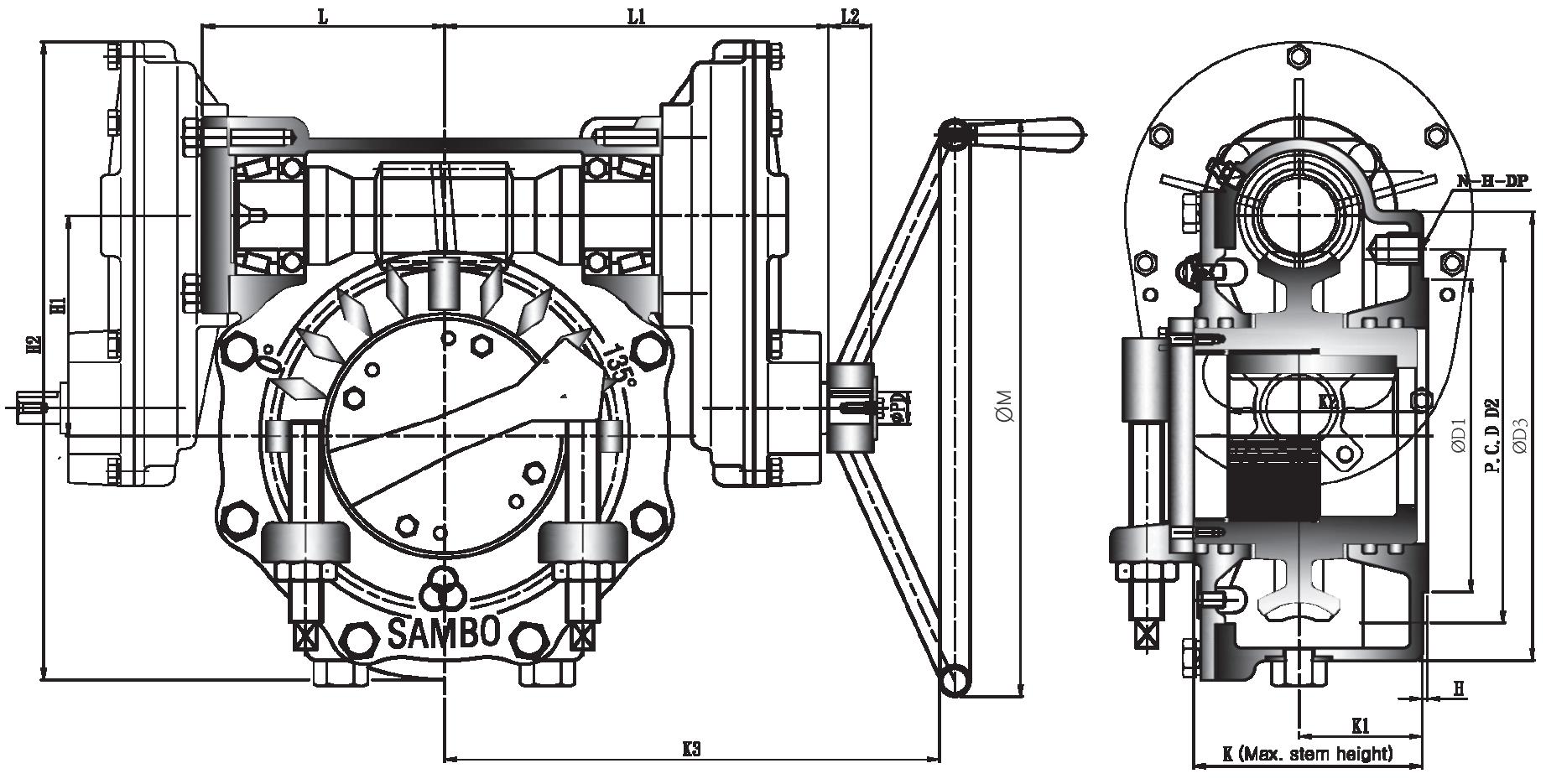

Bush Insert & Setscrew /Twin Shaft Gear Actuator Type

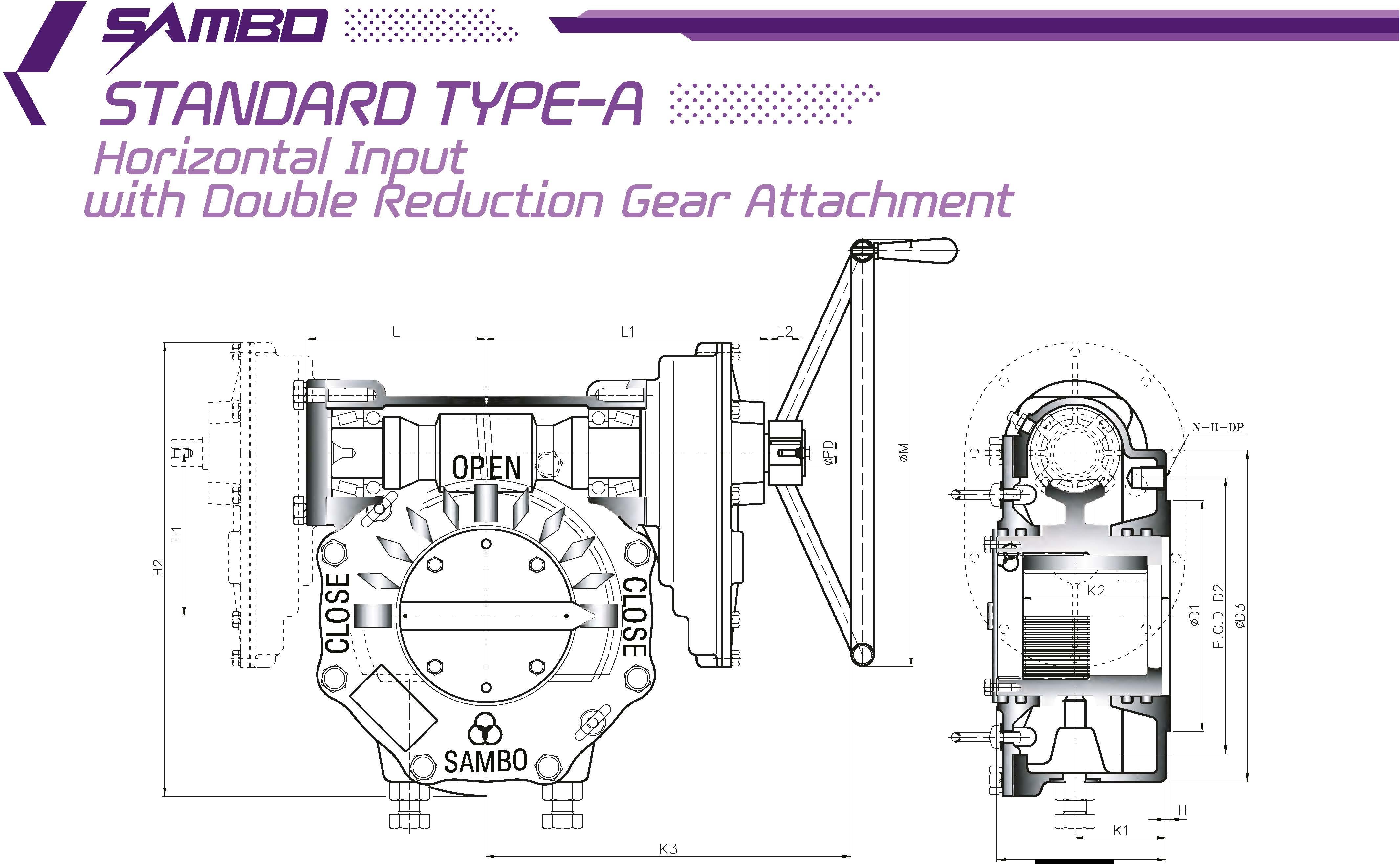

StandardTypeA

Horizontal Input

StandardTypeA

Horizontal Input with Single Reduction Gear Attachment StandardTypeA-TwinShaft

Horizontal Input with Single Reduction Gear Attachment

StandardType A

Horizontal Input with Double Reduction Gear Attachment StandardTypeA-TwinShaft

Horizontal Input with Double Reduction Gear Attachment

StandardTypeA

Horizontal Input with Triple Reduction Gear Attachment

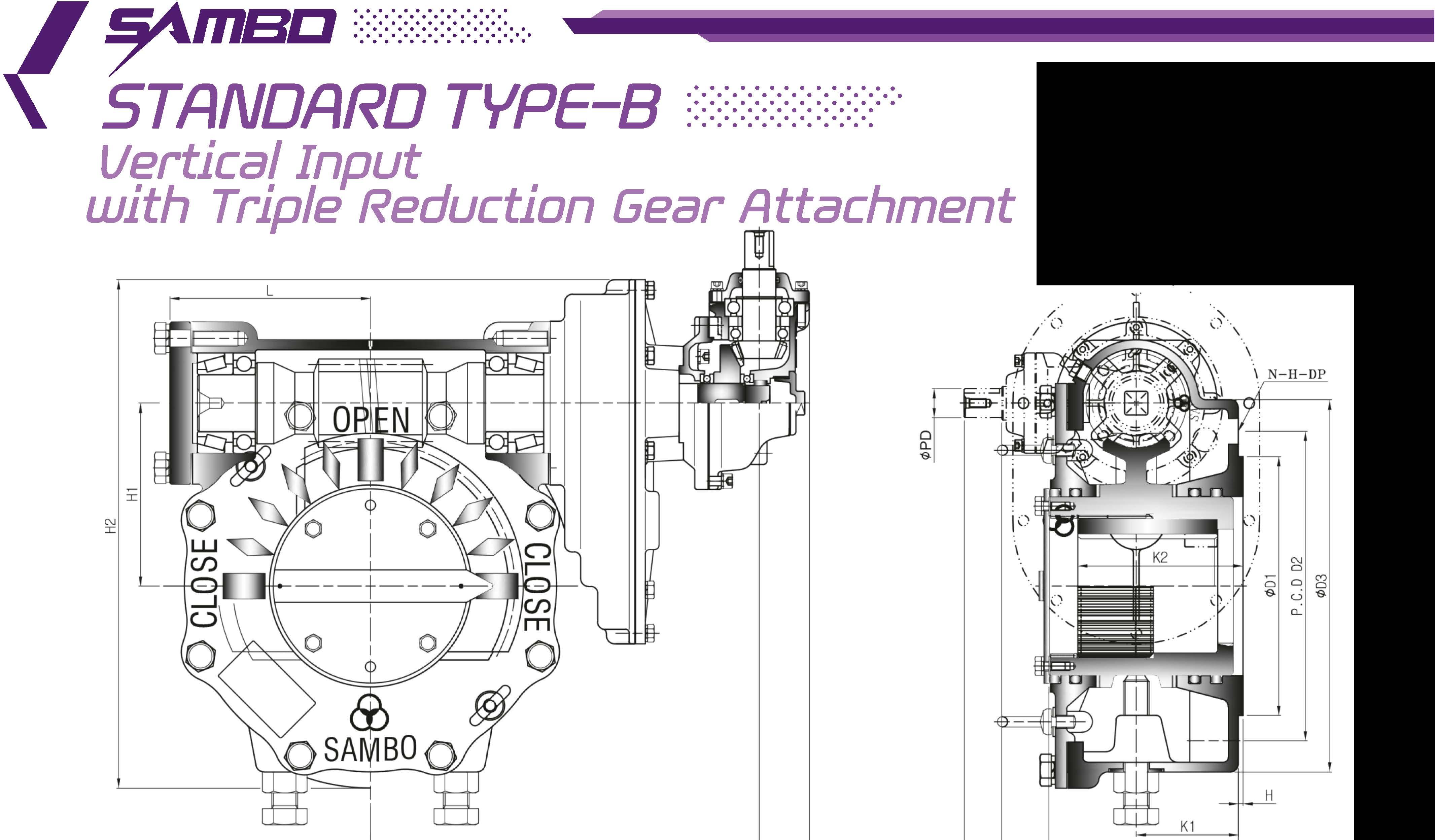

StandardType B

Vertical Input with Double Reduction Gear Attachment

StandardType B

Vertical Input with Triple Reduction Gear Attachment

StandardType B

Vertical Input with Single Reduction Gear Attachment

StandardType C

Horizontal Input with Double Reduction Gear Attachment

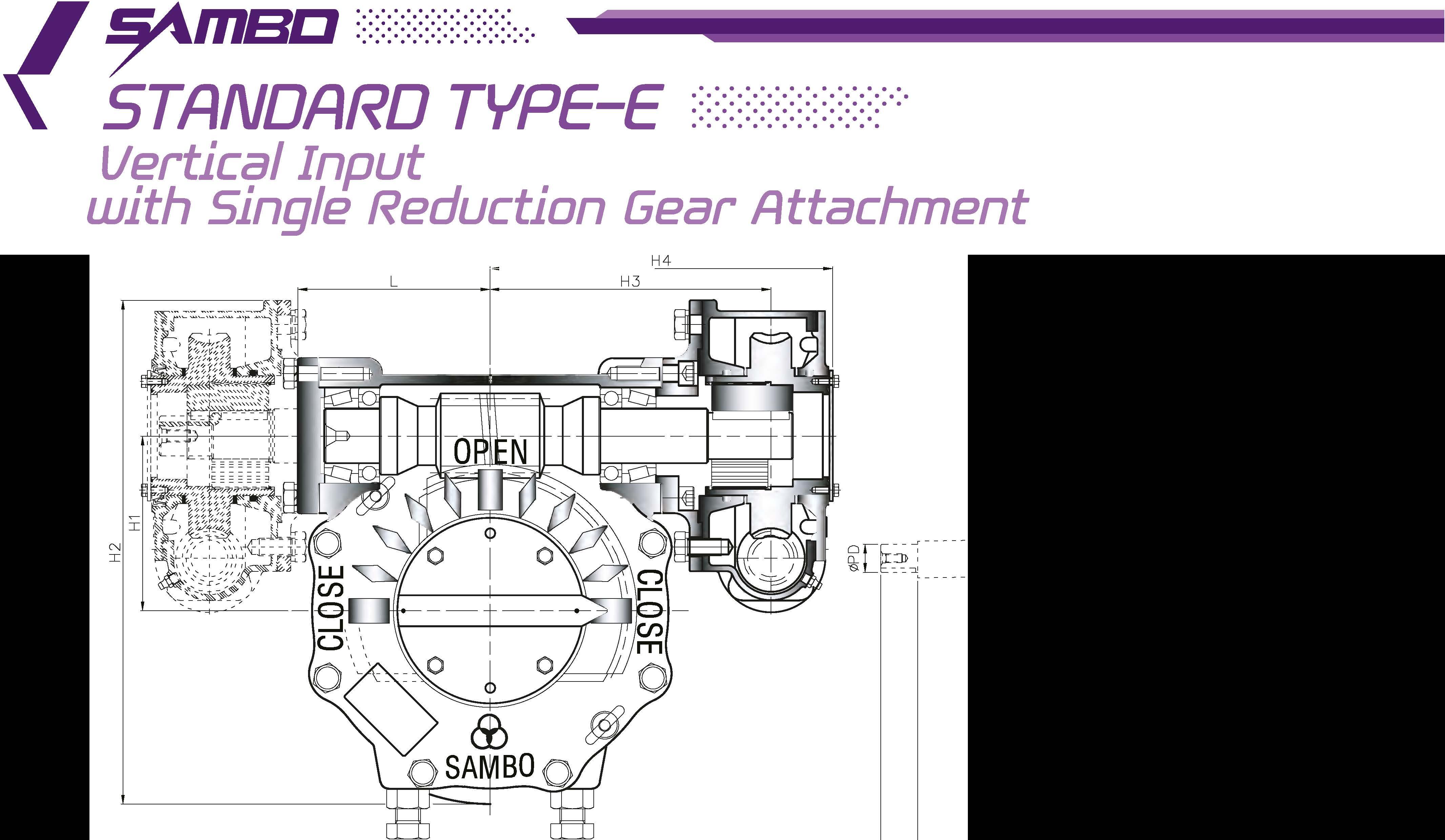

StandardType E

Vertical Input with Single Reduction Gear Attachment

StandardType E

Vertical Input with Double Reduction Gear Attachment

PartTum135°

Horizontal Input

PartTum135•

Horizontal Input with Single Reduction Gear Attachment

PartTum135•

Horizontal Input with Double Reduction Gear Attachment

PartTum l8D0

Horizontal Input

PartTum l8D0 _,,Horizontal Inp�t with Single Reduction Gear Attachment /PartTum180

Horizontal Input with Double Reduction Gear Attachment

PartTum-45°,90

Horizontal Input

0eclutch Gear-45

,90

,135

,180

l'klrizontal Input with Single Reduction Gear Attachment

Declutch Gear-45°,90

Horizontal Input with Double Reduction Gear Attachment

MultiTurn360•

Horizontal Input

MultiTurn360•

Horizontal Input with Single Reduction Gear Attachment

MultiTurn360•

Horizontal Input with Double Reduction Gear Attachment

Declutch Gear

Horizontal Input

Declutch Gear

Horizontal Input with Single Reduction Gear Attachment

Declutch Gear /

Horizontal Input with Triple Reduction Gear Attachment

Declutch Gear- Pneumatic Actuators

HorizontalInput

Declutch Gear- Pneumatic Actuators

Horizontal Input with Single Reduction Gear Attachment

Declutch Gear- Pneumatic Actuators

If

As

This Handwheel is the type using air impact wrench and if can be made properly according to customer' s request

Size and component specitication in this catalogue are subject to change without prior notice for

• IYlark has been changed and updated

WORM Standard >>>

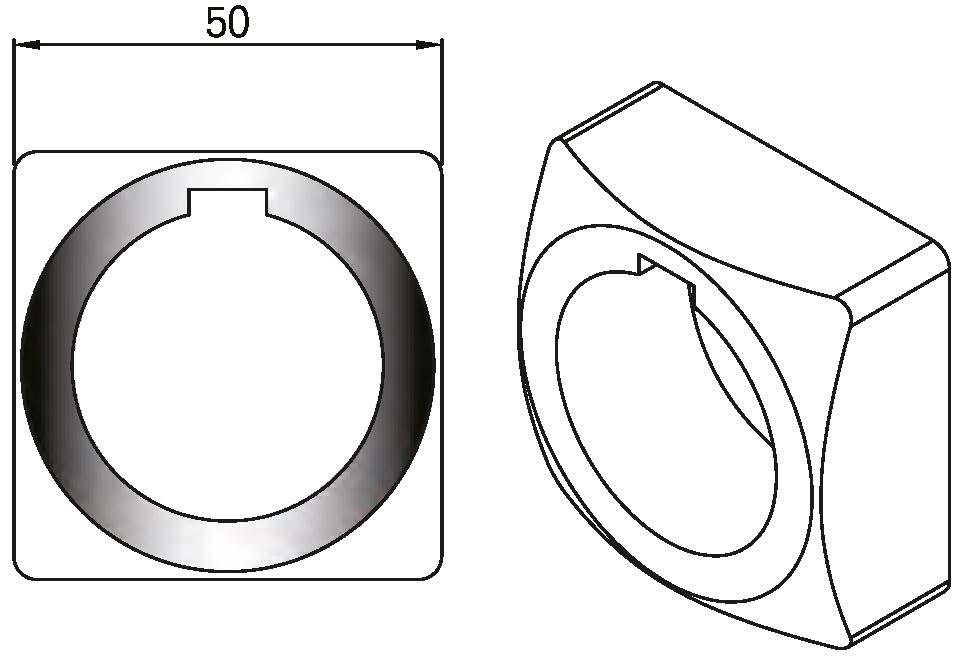

Chainwheel has 2 types

• First, hammer type which is joined with handwheel.

• Second, gear type which is adhered to gear directly.

• material : sprocket rim (Fc□-450), guide arm (Fc□-450), chain (steel+zn)

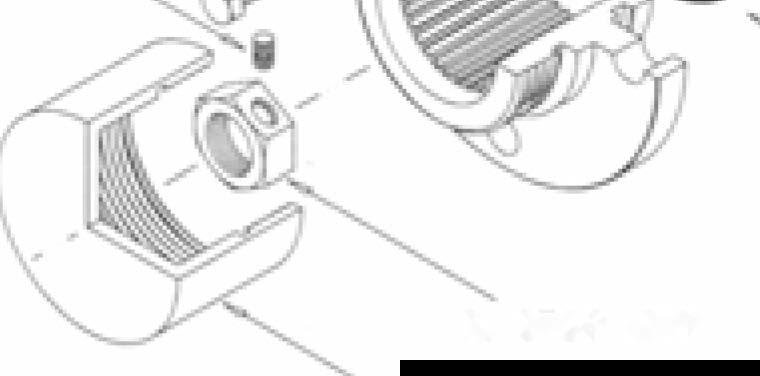

Square Adapter >>>

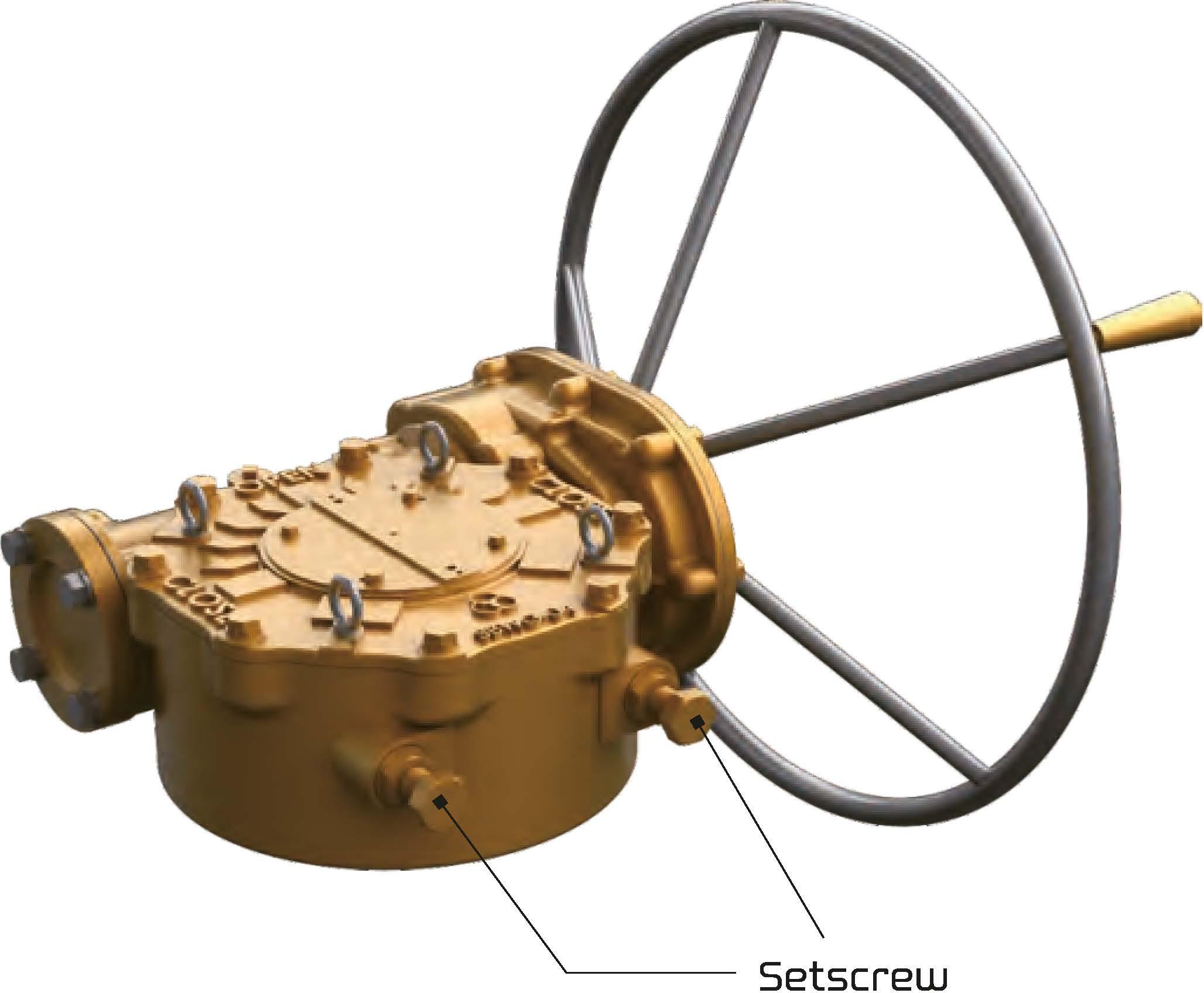

1. Secure setting for the valve and actuator correctly. 2. After finish setting. finally use to adjust the setscrews of worm gearbox.

WARNING

• SAIYIBD worm gearboxes are not set at exactly 90 degree.

• After complete valve and actuator, accurately adjust and use setscrews.

• Incorrect setting of setscrews may cause damage and user is responsible for this.

•Ifitdoesnotmatch,thepositionmaynotbe

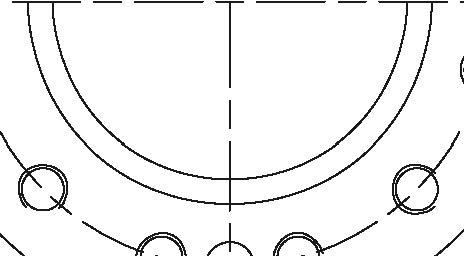

Assembly

1. Turn gear box to see bottom side.

2. Insert bush correctly into the worm gear. Insert bush into grooves of worm gear. (IYlatch groove and bushing key in a straight line.) There is 2 grooves at bottom of worm gear. One groove is for open and the other is for close.

3. Fix spring.

CAUTION

• In case of bushing insert, match groove of worm gear and bushing key correctly.

• This groove is marked the position of Caution "close" or "open".

• If it does not match, the position may not be proper.

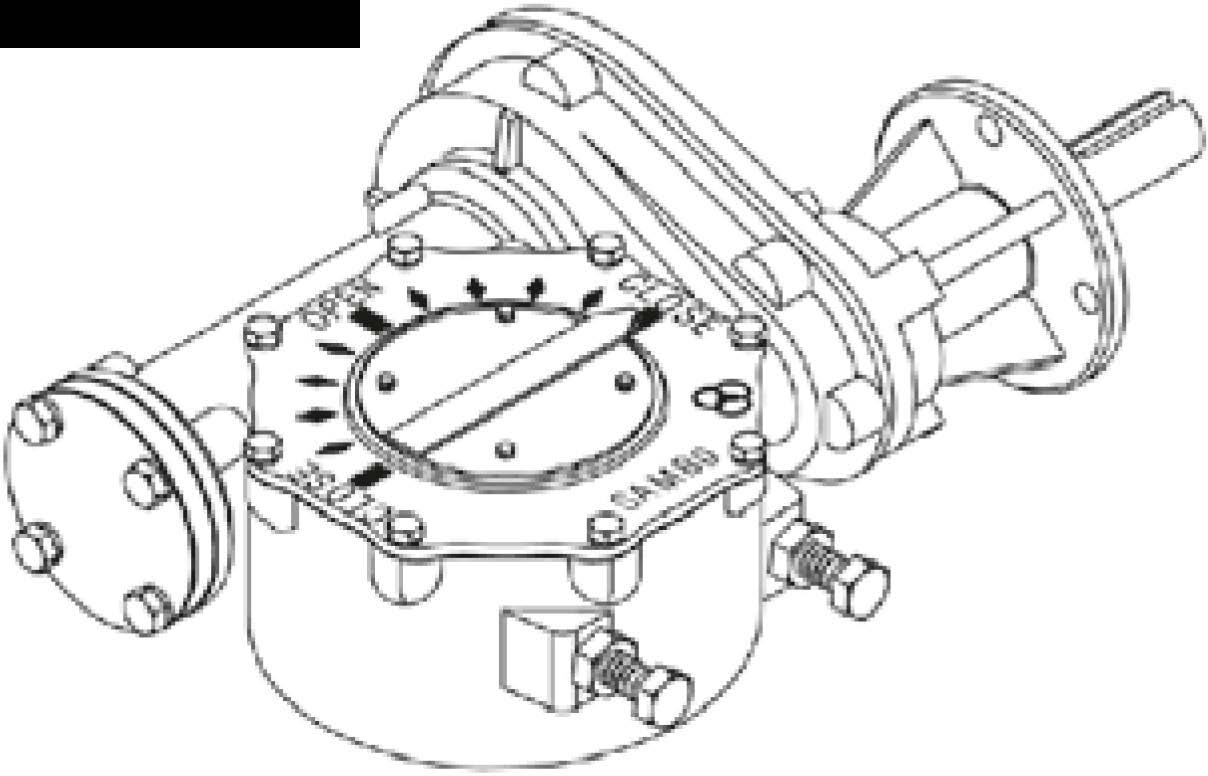

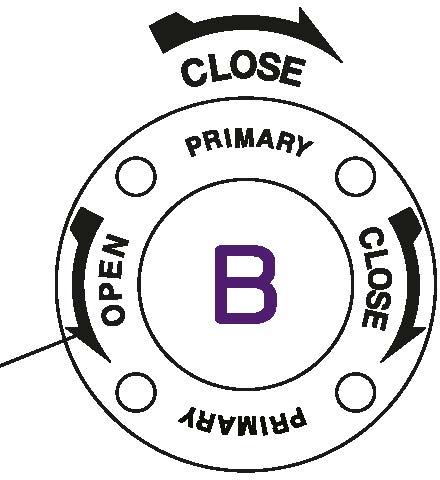

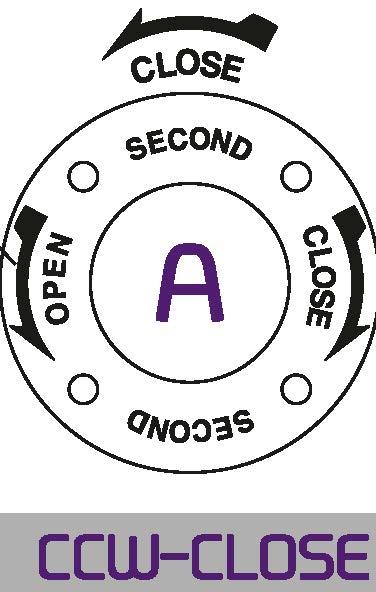

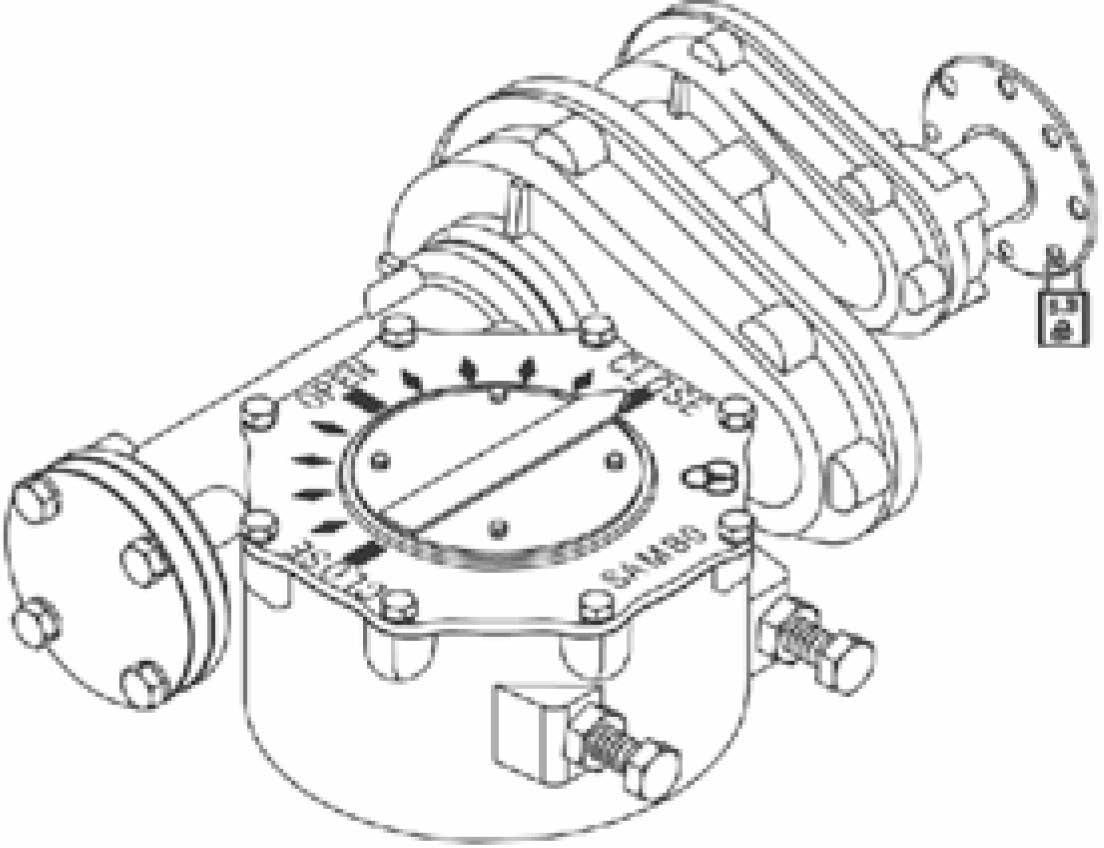

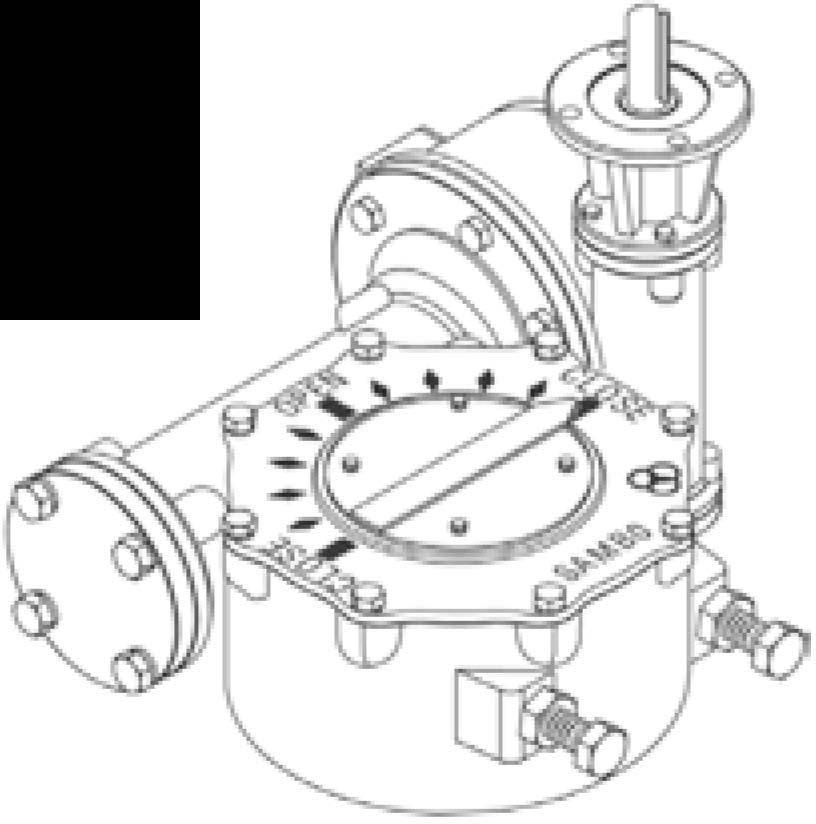

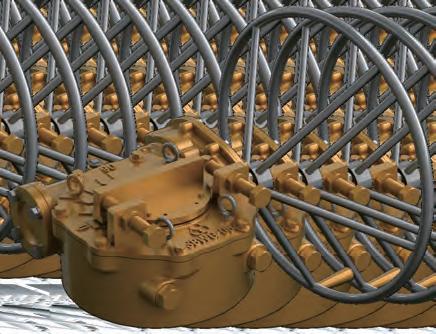

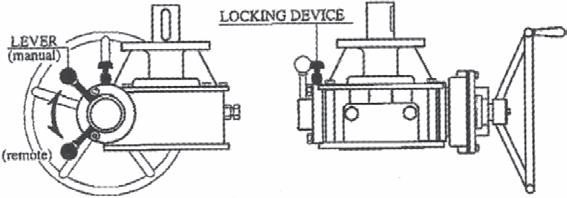

There are two input shafts in the below support actuator type. One Shaft is for high speed and the other shaft is for low speed.

Provides maximum mechanical advantage for seating and unseating of valves.

Allow for less turns after valve has been unseating. Input/OutputShaftRotationOptions>>>

Right Hand Input

Size and component specitication in this catalogue are subject to change without prior notice for

• IYlark has been changed and updated.

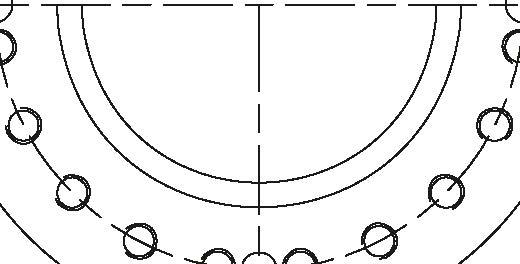

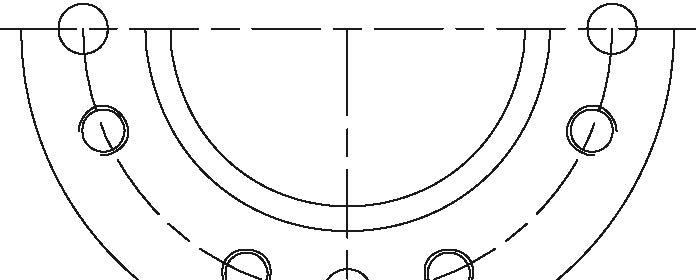

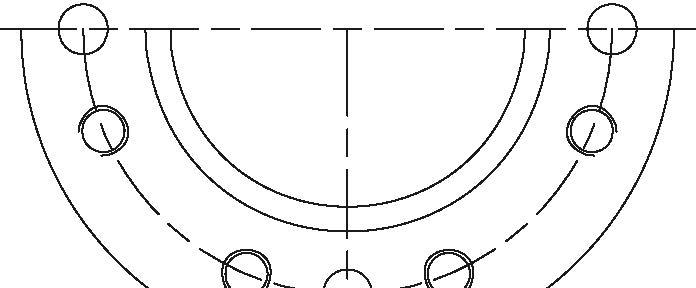

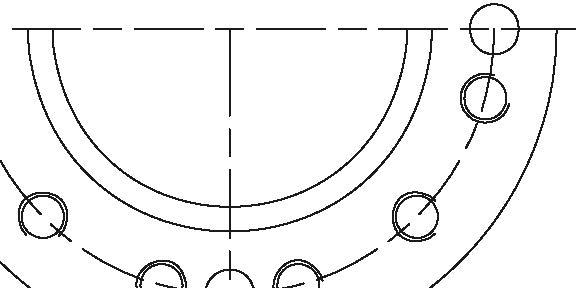

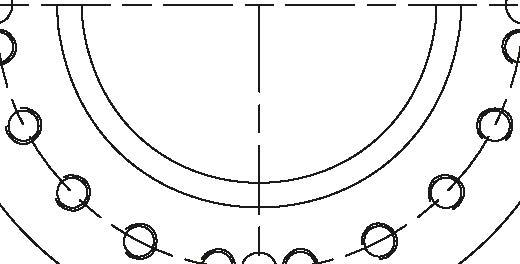

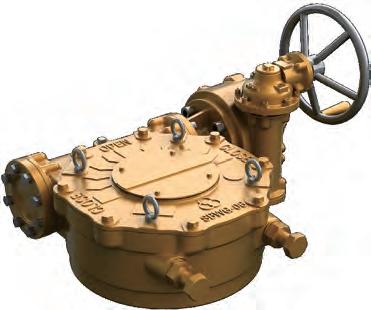

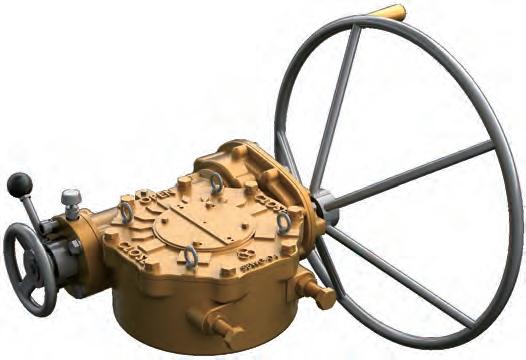

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Splines permit accurate alignment of valve stem key.

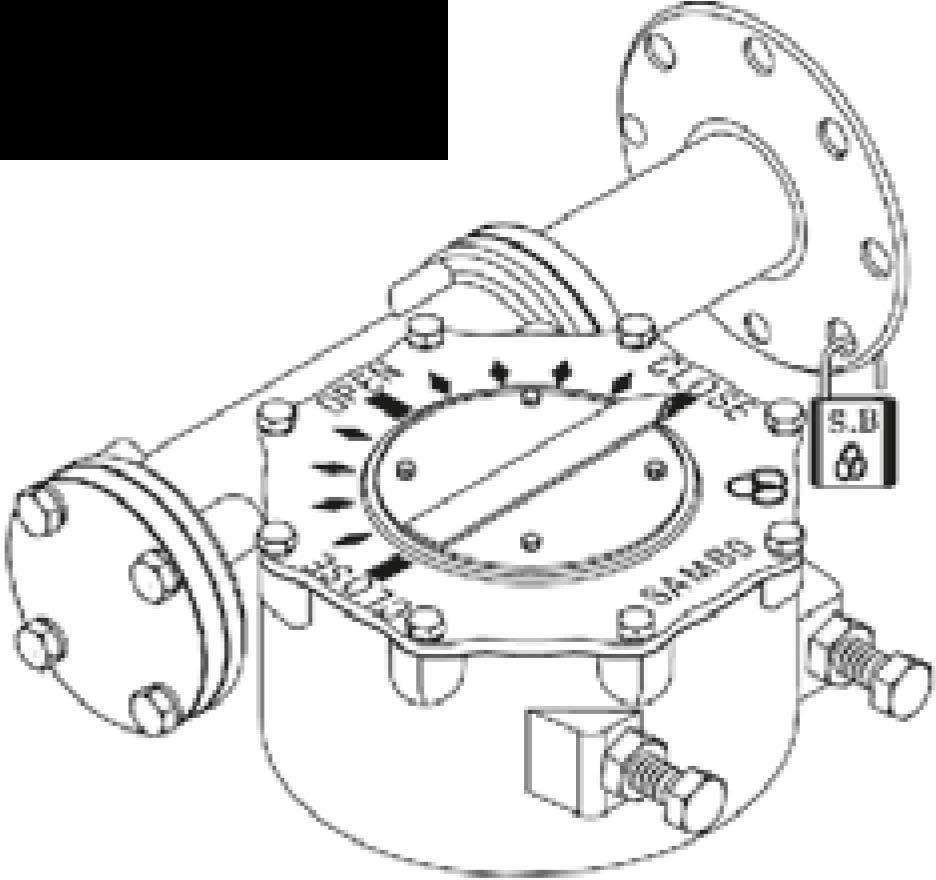

Input can be equipped with a Handwheel locking device for IYlanually operatedunits.

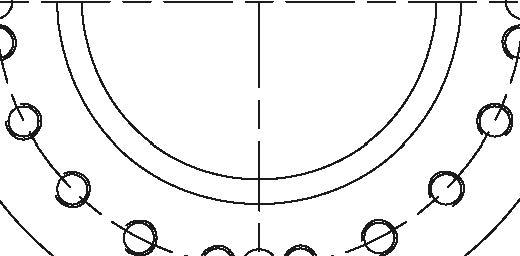

SBWG-35 52:1 80(22X14) F-16,(F-20),F-25

* SBWG--05 60:1 115(32X18) (F-20), F-25,F-30

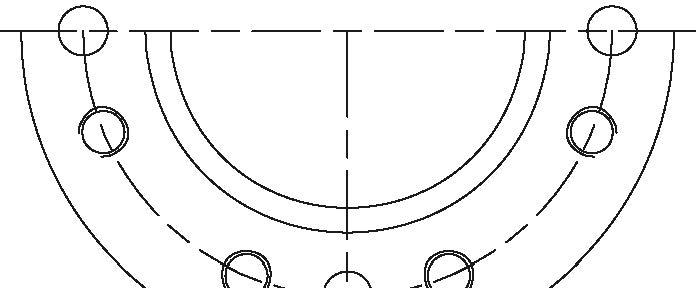

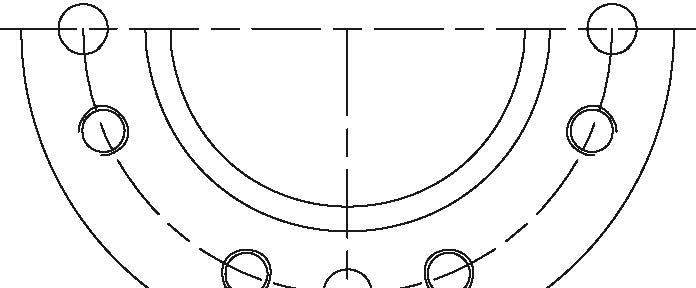

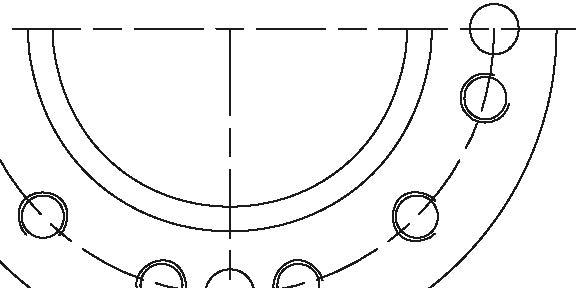

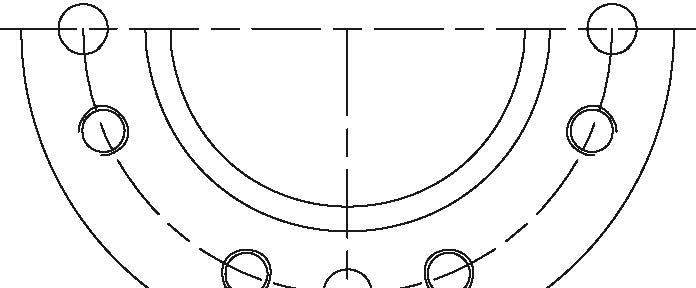

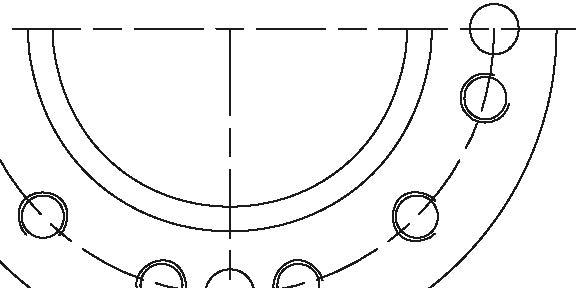

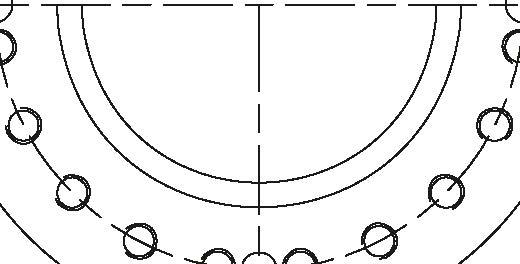

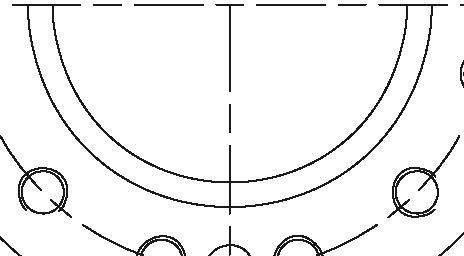

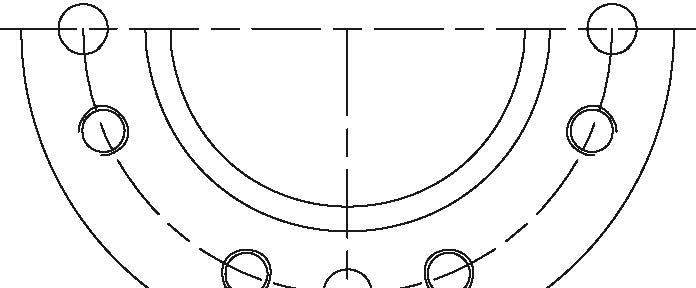

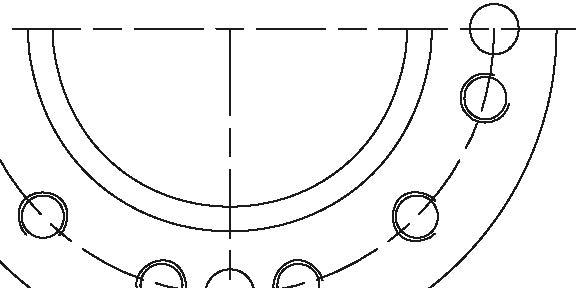

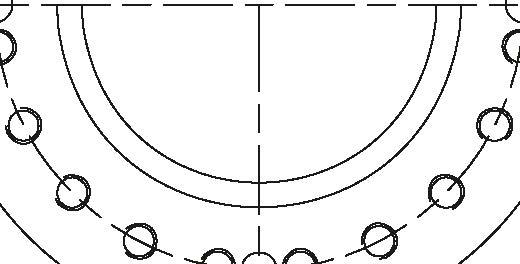

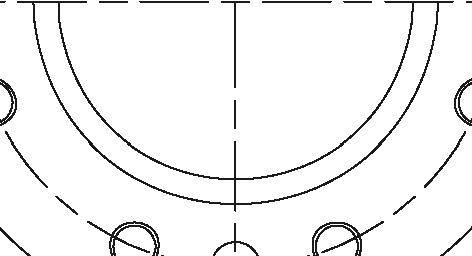

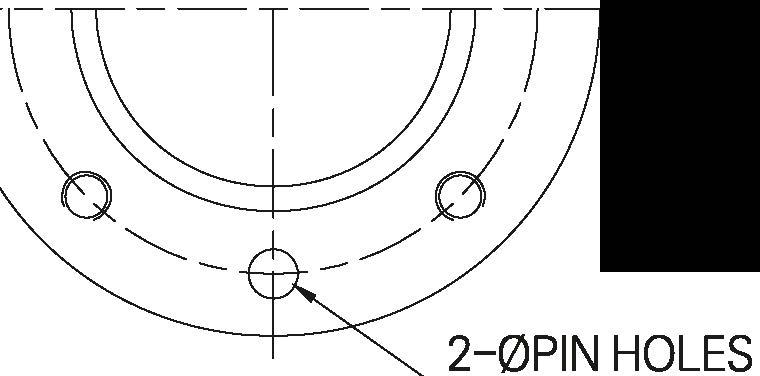

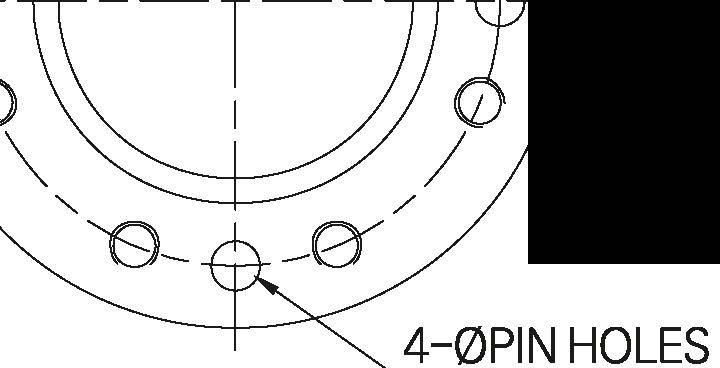

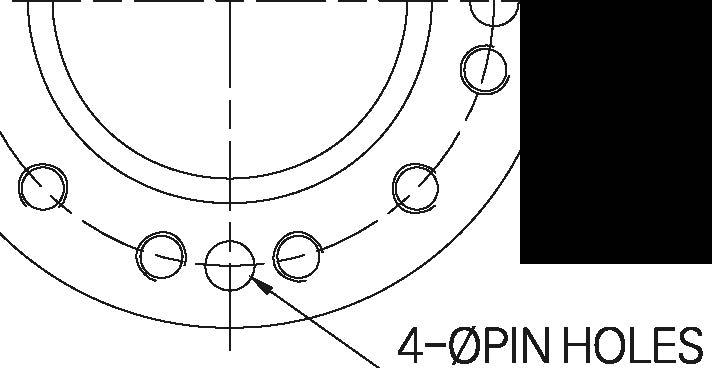

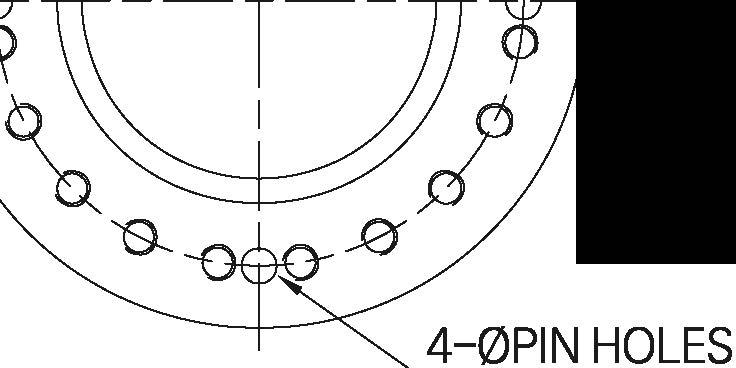

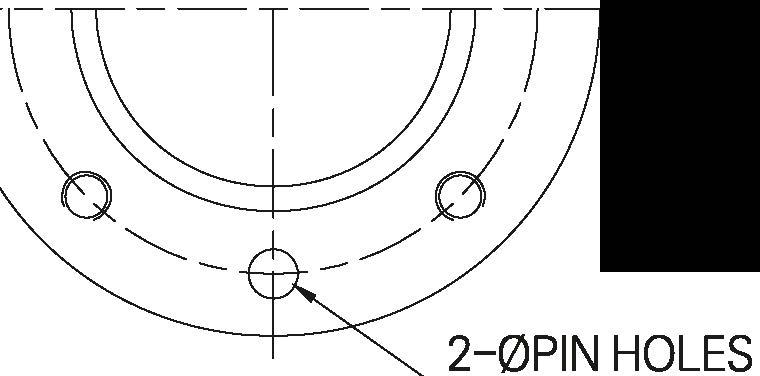

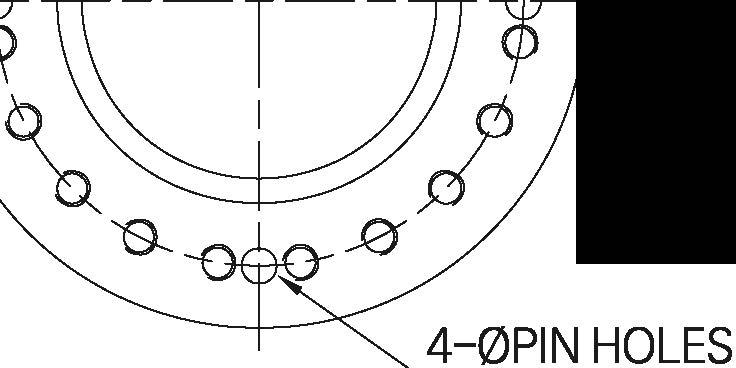

•Pin hole size is same as tap out diameter 1�T--/ I / 'a 0 / 2-(l)PIN HOLES

S&MHJ0-1S F-12 85

SBW<HJHS A F-14 100

SBW<Hl2-1S F-16 130

SBW<Hl3-1S F-16 160 (F-20)

SBWG-35-1S F-25 200

SBWG--04-1S F-25 200

*

SBW<HJS--1S B F-30 230

SBWG-55-1S

SBW<Hl6-1S F-35 260

SBW<Hl7-1S F-40 300

SBWG-75-1S F--48 370

SBWG--08-1S �1S

SBWG-10-1S F-60 470

SBWG-11-1S D

*

*

Size and component specitication in this catalogue are subject to change without prior notice for

improvement. • IYlark has been changed and updated.

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

•Pin hole size is same as tap out diameter 1�T--/ I / 'a 0 /

SBWG-00-15T F-12 85

SBWG-OHST A F-14 100

SBWG-02--15T F-16 130

SBWG-03-15T F-16 160 (F-20)

SBWG-35-15T F-25 200

SBWG-Q4-15T F-25 200

*

SBWG---05-15T B F-30 230

SBWG-55-15T

SBWG-06-15T F-35 260

SBWG-07-15T F---40 300

SBWG-75-15T F-48 370

SBWG-08-15T

SBWG-09-15T

SBWG-10-15T F--60

SBWG-11-15T D

*SIMG-12--15T F--80

*SIMG-13-15T

Size and component specitication in this catalogue are subject to change without prior notice for

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

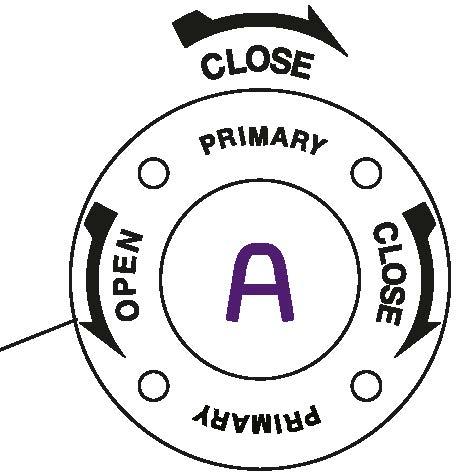

CW-CLOSE Bushing Type Splines permit accurate alignment of valve stem key.

A. Primary Input Shaft (High Speed Input Shaft) Allow for less turns after valve has been unseating.

B. Second Input Shaft (Low Speed Input Shaft) Provides maximum mechanical advantage for seating and unseating of valves.

Pin hole size is same as tap out diameter

SBWCHXl-1SD F-12 85

SBWCHlHSD A F-14 100

SBWCHl2-1SD F-16 130

SBWCHl3-1SD F-16 160 (F-20)

SBWG-35-1SD F-25 200

SBWG---04-1SD F-25 200

*SBWCHl5-1SD B F-30 230

SBWG--55-1SD

SBWCHl6-1SD F-35 260

SBWCHl7-1SD F---40 300

SBWG-75-1SD F-48 370

SBWCHl8---1SD

SBWCHl9-1SD

SBWG-10-1SD F--60 470

SBWG-1HSD D *SBWG-12-1SD

Size and component specitication in this catalogue are subject to change without prior notice for

• IYlark has been changed and updated.

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

SBWG-35--1SD 333.7:1 80(22X14) F-16,(F-20),F-25

SBWG--04-1SD 504:1 95(25X14) F-16,(F-20) F-25 10400 7671 *SBWG--05-1SD 540:1 115(32X18) (F-20), F-25,F-30 15900 11727

SBWG-55-1SD 558:1 125(32X18) F-25,F-30 23500 17333

SBWG--06-1SD 1024:1 140(36X20) F-25, F-30,F-35 32800 24192

SBWG-07-1SD 1088:1 180(45X25) F-30,F-35, F--40 51100 37689

SBWG-75-1SD 1650:1 210(50X28) F-35,F--40, F-48 81500 60111

SBWG--08-1SD

•Pin hole size is same as tap out diameter

1�T--/ I / 'a 0 / 2-(l)PIN HOLES TYPE -A

FLANGE 0D1

SBW(H)()-1SDT F-12 85

SBW<H>HSDT A F-14 100

SBW<Hl2-1SDT F-16 130

SBW<Hl3-1SDT F-16 160 (F-20)

SBWG-35-1SDT F-25 200

SBWG---04-1SDT F-25 200

*�"ISJT B F-30 230

SBWG-55-1SDT

S8'MHJ6-1SDT F-35 260

SBW<Hl7-1SDT F-40 300

SBWG-75-1SDT F-48 370

SBWG--08-1SDT

SBWCHl9-1SDT

SBWG-10-1SDT F-60 470

SBWG-1HSDT D

*SIMG-12-1SIJr F--00 670

*SIMG-13-"ISJT

Size and component specitication in this catalogue are subject to change without prior notice for

• IYlark has been changed and updated.

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

CW-CLOSE Bushing Type Splines permit accurate alignment of valve stem key.

A. Primary Input Shaft (High Speed Input Shaft) Allow for less turns after valve has been unseating.

B. Second Input Shaft (Low Speed Input Shaft) Provides maximum mechanical advantage for seating and unseating of valves.

• Pin hole size is same as tap out diameter 1�T - -/ I / o d / 2-IZlPIN HOLES

SEMG-00-2SD F-12 85

SEMG-01-2SD A F-14 100

SB,\G-02-2S[) F-16 130

$Y,G-()3-2S[) F-16 160 {F-20)

SIMG-35-2SD F-25 200

SEMG-04-2SD F-25 200

•SEW3-05-2SD B F-30 230

S:MG-55-2SD

S:MG--06-2SD F-35 260

SEMG-07-2SD F--40 300

SIMG-75-2SD F-48 370

SBMHll-2SD

SJ,\G-00-2S[)

SIMG-10-2SD F-60 470

SIMG-11-2SD D

•SIMG-12-2SD

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

*SB\',G-05-ZSD 1368:1 115(32X18) (F-20), F-25,F-30 15900 11727

SBWG-55-280 1413.6:1 125(32X18) F-25,F-30 23500 17333

SBW<Hl6-2SD 3072:1 140(36X20) F-25, F-30,F-35 32800 24192

SBWG-07-280

•Pin hole size is same as tap out diameter

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement. • IYlark has been changed and updated.

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

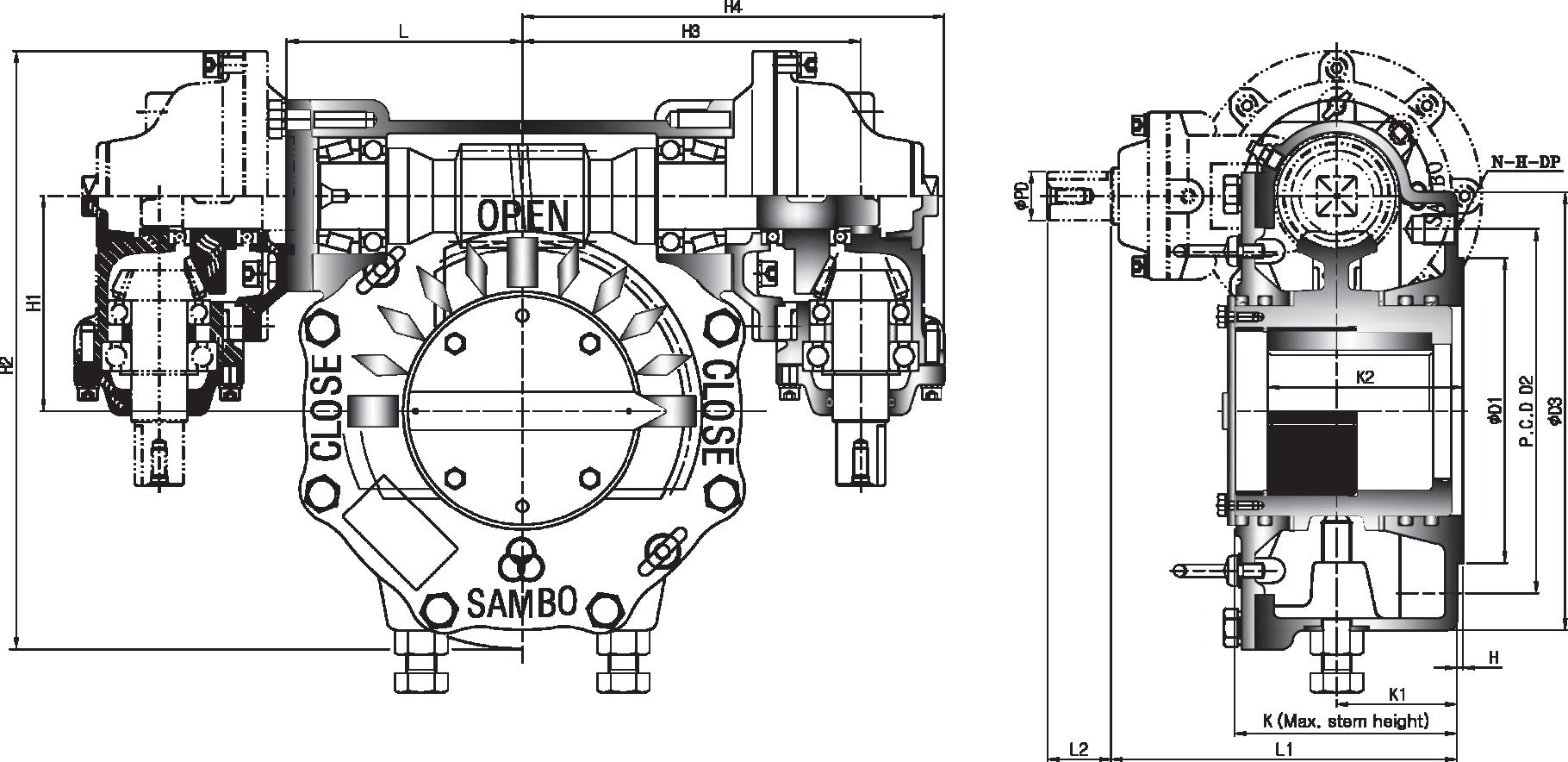

H3 H4

•Pin hole size is same as tap out diameter

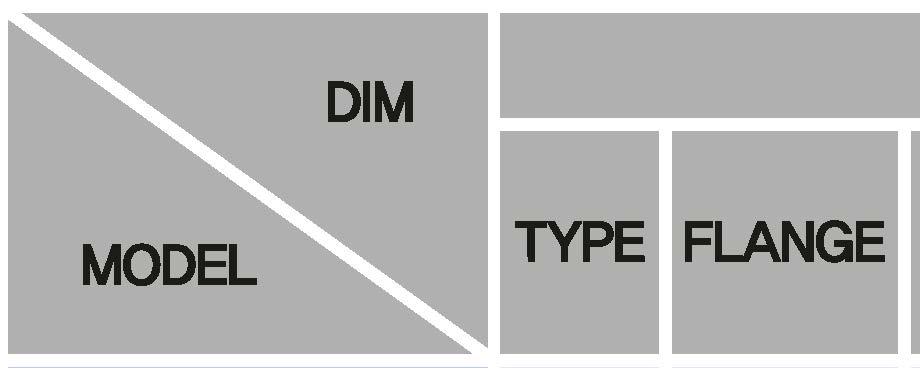

SBWG--00-1SD28 F-12 85 125 4-M12-18 165

SBWG--01-1SD28 A F-14 100 140 4-M1&-24 190 2

SBWG--02-1SD28 F-16 130 165 4-M20-30 220

SBWG--03-1SD2B F-16 160 205 &-M1&-24 250 (F-20)

SBWG-35-1SD28 F-25 200 254 &-M1&-24 300

SBWG--04-1SD28 F-25 200 254 &-M1&-24 300

•SBWG--05-1SD2B B 350 3 F-30 230 298 8-M20--30

SBWG-55-1SD2B 350

SBWG--06-1SD28 F-35 260 356 &-M30---45 415

SBWG--07-1SD28 F-40 300 406 &-M3&-55 475

SBWG-75-1SD2B 560 F-48 370 483 12-M36---55 5

SBWG--08-1SD2B

SBWG--09-1SD28

SBWG-10-1SD28 F--60 470 603 20-M3&-55 800

SBWG-11-1SD2B D 900 5

•SBWG-12-1SD28 1000 F--60 670 813 20-M42--63

•SBWG-13-1SD28

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement. • IYlark has been changed and updated.

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

SBWG-35-1SD2B 667:1 80(22X14) F-16,(F-20),F-25 6100 4499

SBWG--04-1SD28 1260:1 95(25X14) F-16,(F-20),F-25 10400 7671

•SBWG--05-1SD28 1350:1 115(32X18) (F-20),F-25,F-30 15900 11727

SBWG-55-1SD2B 1395:1 125(32X18) F-25,F-30 23500 17333

SBWG--06-1SD28 3072:1 140(36X20) F-25, F-30,F-35 32800 24192

SBWG--07-1SD28 3264:1 180(45X25) F--30,F-35,F--40 51100 37689

SBWG-75-1SD28 6600:1 210(50X28) F--35,F--40, F--48 81500 60111

6600:1

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

•SBW<HlS--28 180:1 115(32X18) (F-20), F-25,F-30 15900 11727

SBWG-55-28 186:1 125(32X18) F-25,F-30

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

SBWG-55-280 465:1 125(32X18) F-25,F-30

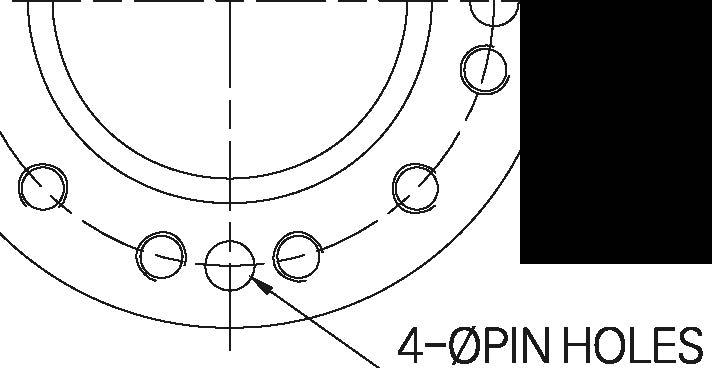

•Pin hole size is same as tap out diameter 1�T--/ I / a 0 /

2-0PIN HOLES TYPE-A

f!BNG-00-3/J F-12 85

S91',G-{)1-3N A F-14 100

f!BNG---Cfe-3N F-16 130

SBl,G-{)3-3/J F-16 160 (F--20)

SB,\G----35---3/J F--25 200

S91'.G---04-3N F--25 200

•SBWG---05-3W B F-30 230

'.:BNG----$-3N

f!BNG---00-3N F-35 260

fBNG---<Tl-3N F-40 300

SB,\G---7fr-3N C F---48 370

SB/,G---00--'1N

'i!BNG---00---3N

SB,\G-10-3N F--60 470

SB,\G-11-3/J D

•SB,\G--12-3N F-80 670 •SB,\G-13-3/J

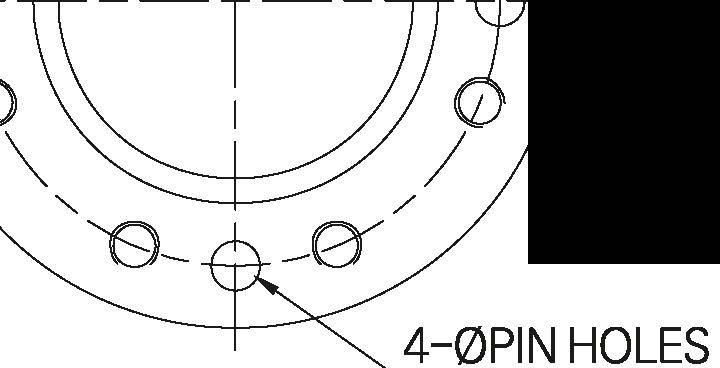

4-0PINHOLES

Size and component specitication in this catalogue are subject to change without prior notice for

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

Splines permit accurate alignment of valve stem key.

Worm Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

SBWG--04-3W 2688:1 95(25X14) F-16,(F-20) F-25 10400 7671

•SBWG--05-3W 2880:1 115(32X18) (F-20), F-25,F-30 15900 11727

SBWG-55-3W 3224:1 125(32X18) F-25,F-30 23500 17333

SBWCHl6-3W 3328:1 140(36X20) F-25, F-30,F-35 32800 24192

SBW<Hl7-3W 3536:1 180(45X25) F-30,F-35, F--40 51100 37689

f!BNG-75-3W 3696:1 210(50X28) F-35,F--40, F-48 81500 60111

SBWG-08-3W

• All mounting bases conform to ISO 5210/1 standards.

• All castings are ductile iron, Class 65-45-12 excellent strength and impact resistance.

• Worm gear material is available in two option.

- Ductile iron.Class 80-55-06

- Aluminum bronze, B148-[95800

• Worm is 1045 heat treated Carbon steel.

• Removable splined bushing to permit accurate positioning between gear drive and valve stem.

• Options include hand wheels, chain and etc.

• If worm gear actuators are supplied on a value, the end stops are already set.

• In case end stops need to be adjusted set end position OPEN first, if the exact end position of the value can not be seen through a position marking at the value shaft, the setting may have to be done with the value removed.

Splines permit accurate alignment of valve stem key.

• Remove all bolts@ at stop cover@

• Turn value manually to end position OPEN.

• In case stop cover.@ do not correspond to the threads of the housing. Take off the stop covers.@ and place it in the required positon.

• Fit bolts@ withe washers and fasten them euently.

• Finally, protective cap<D remove, turn stop nut� to adjust end position CLOSE.

Contact your local CDC sales representatives:

Serving OH, MI, W.PA, WV, E.KY, VA

143 S.Thomas Rd. Tallmadge, OH 44278

Tel: 330-253-4800

Email: sales@portersvilleprd.com

7707 Cole Lane Midland MI 48642

Tel: 586-764-4336

Email: sales@portersvilleprd.com

www.portersvilleprd.com

2680 New Butler Rd. New Castle, PA 16101

Tel: 724-368-8725

Email: sales@portersvilleprd.com

700 Southlake Blvd. North Chesterfield VA 23236

Tel: 804-593-2384

Email: sales@portersvilleprd.com

1500 E. Burnett St. Signal Hill, CA 90755

Tel: 562-424-8108

Email: Sales@BV-BM.com

www.bv-bm.com

403 Technology Dr South Point, OH 45680

Tel: 740-377-0012

Email: sales@portersvilleprd.com

3800 Fruitvale Avenue Bakersfield, 93308

Tel: 661-589-6801

Email: Sales@BV-BM.com

3195 Park Road, Benicia, CA 94510

Tel: 707-590-6688

Email: Sales@BV-BM.com