SpurGearActuators >> WormGearActuators >>>

SpurGearActuators >> WormGearActuators >>>

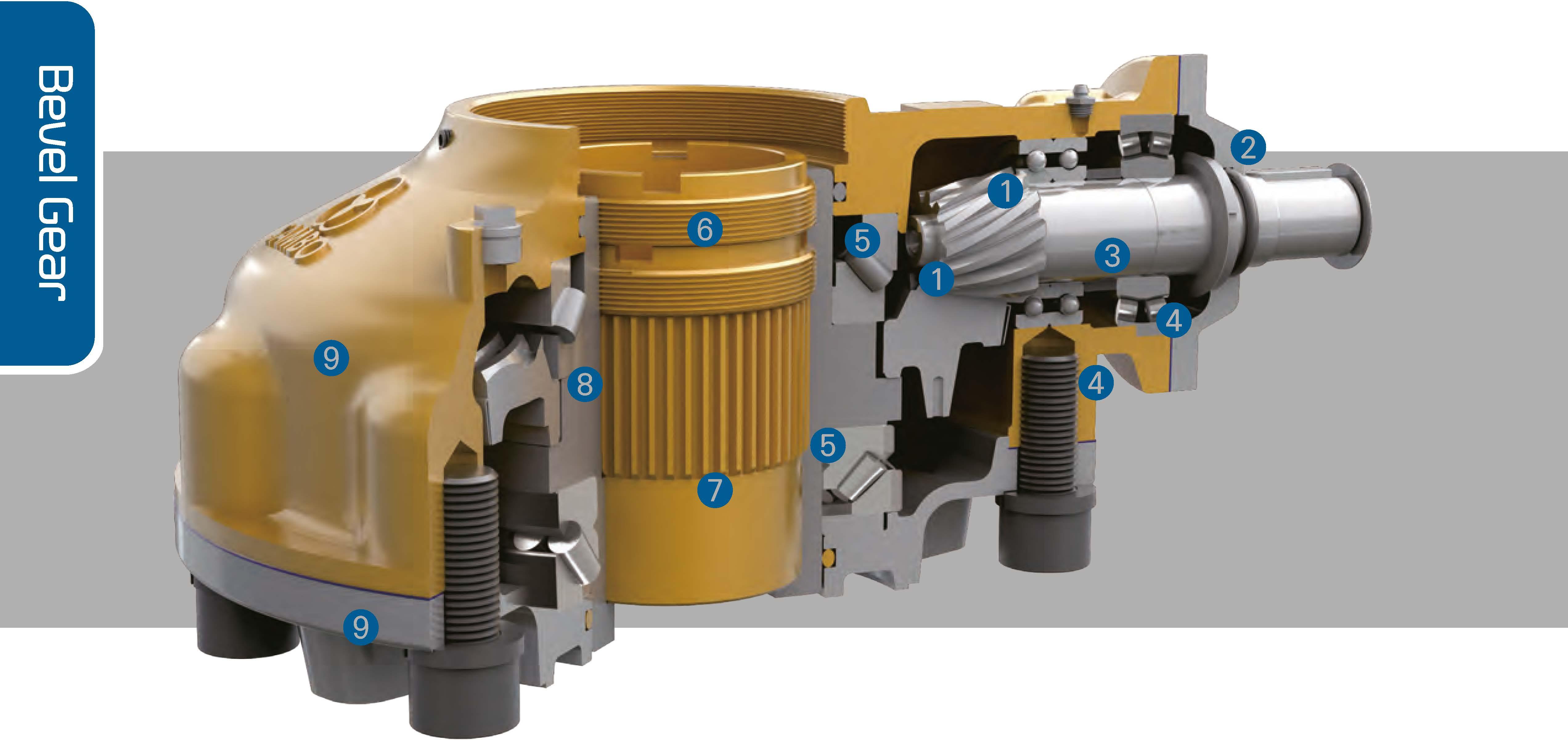

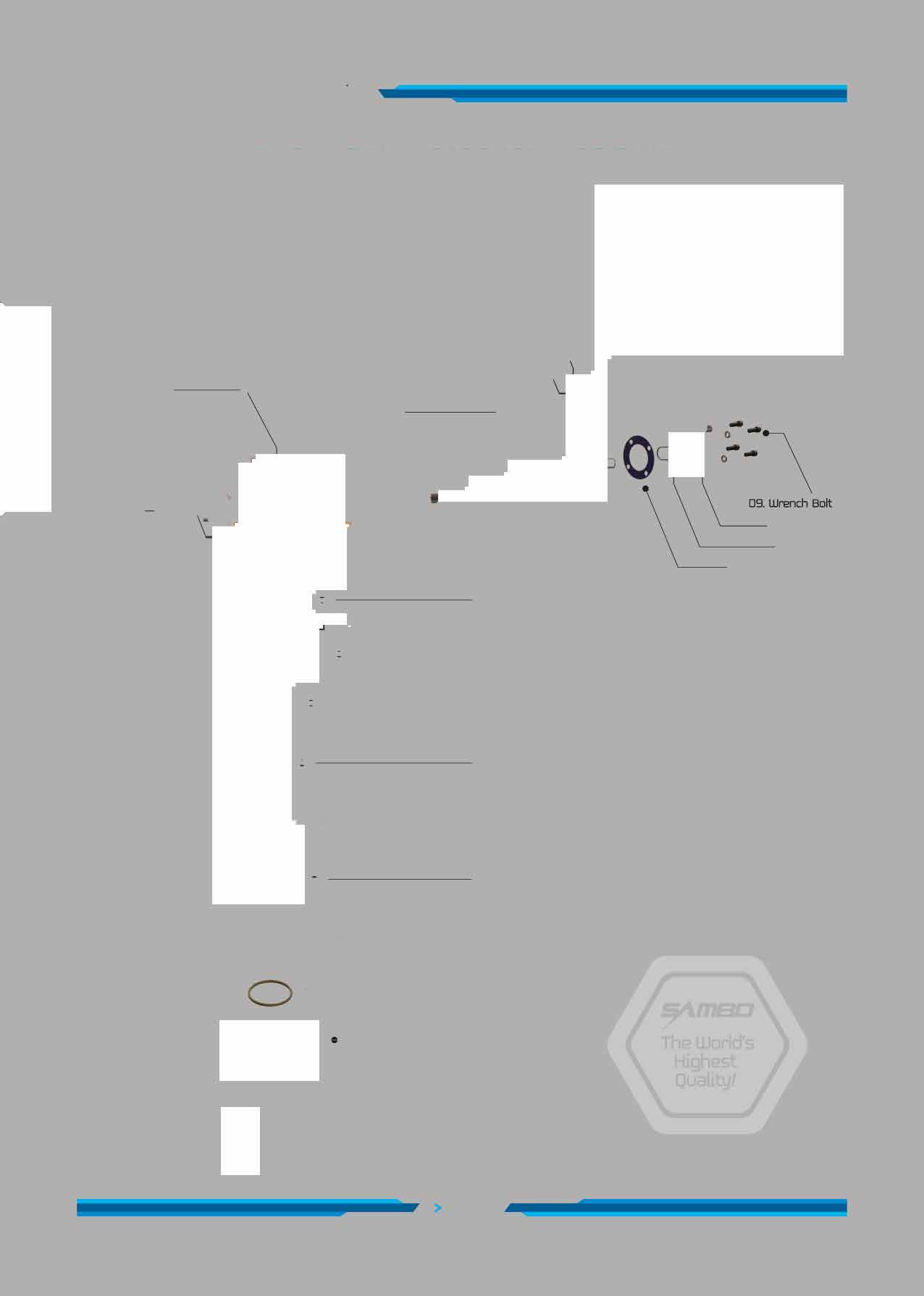

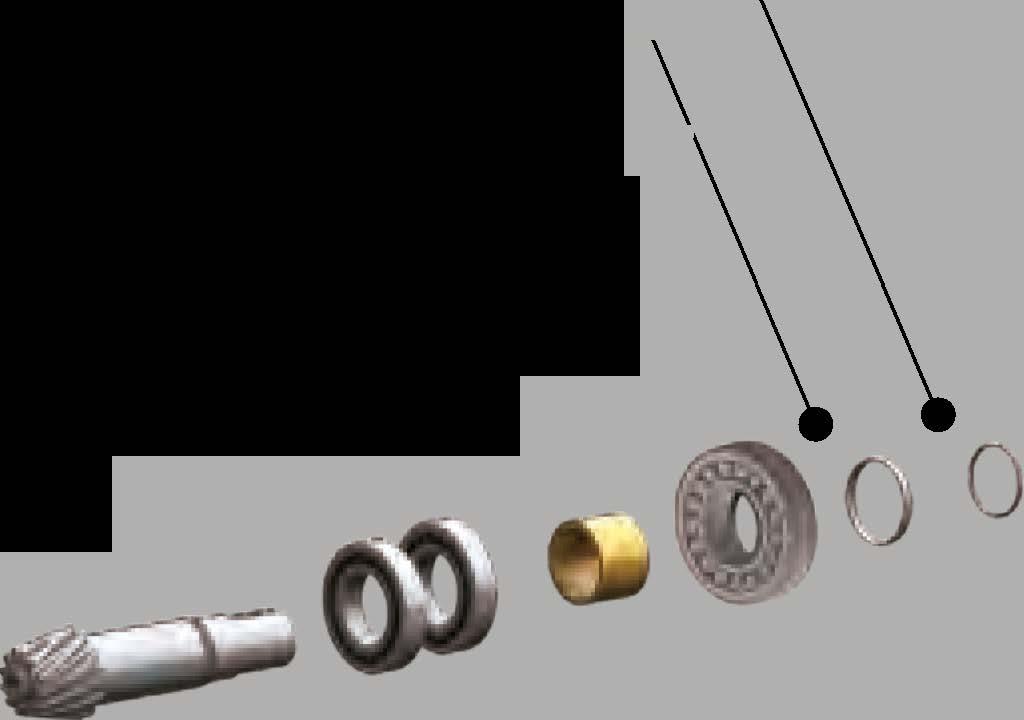

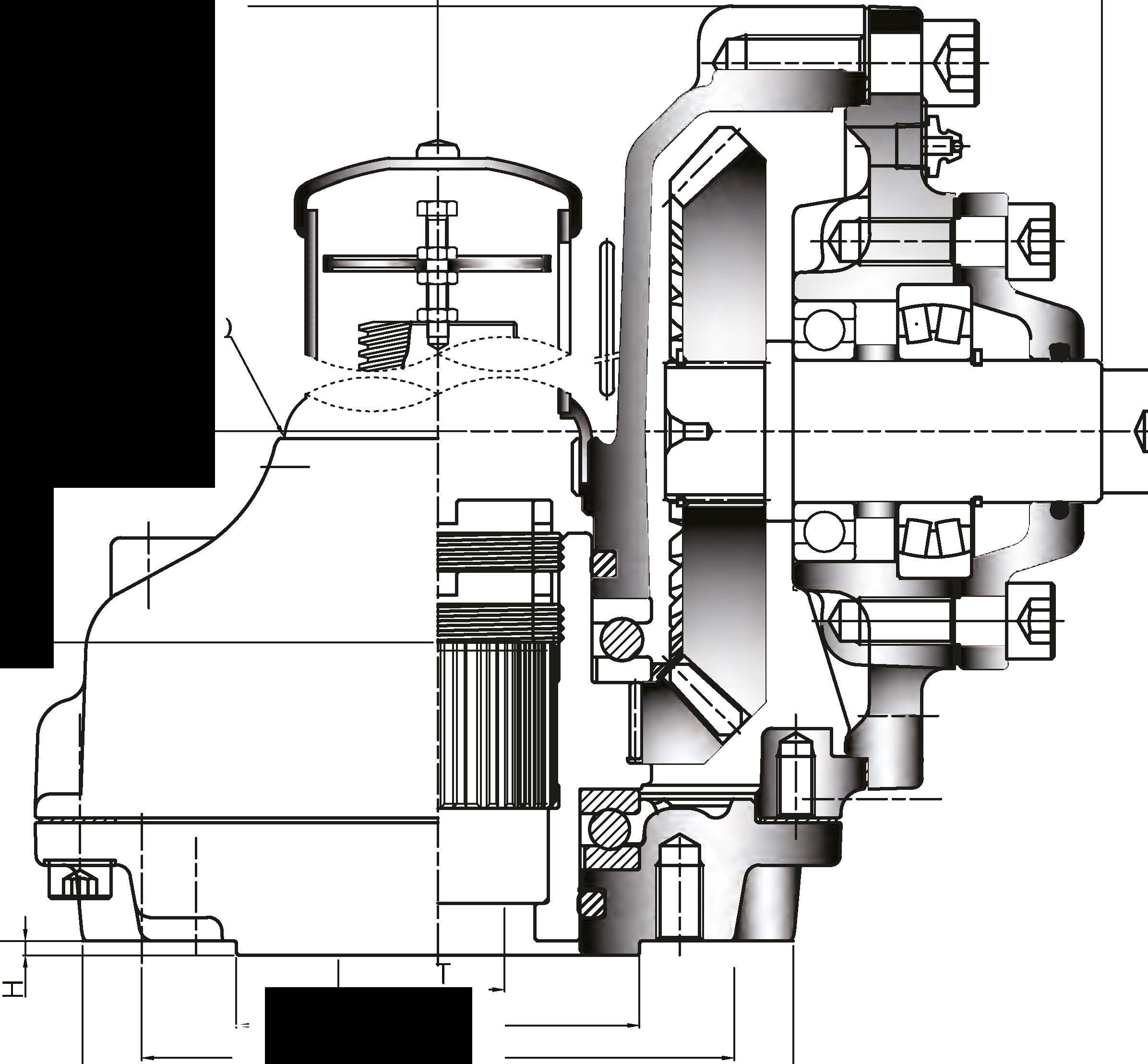

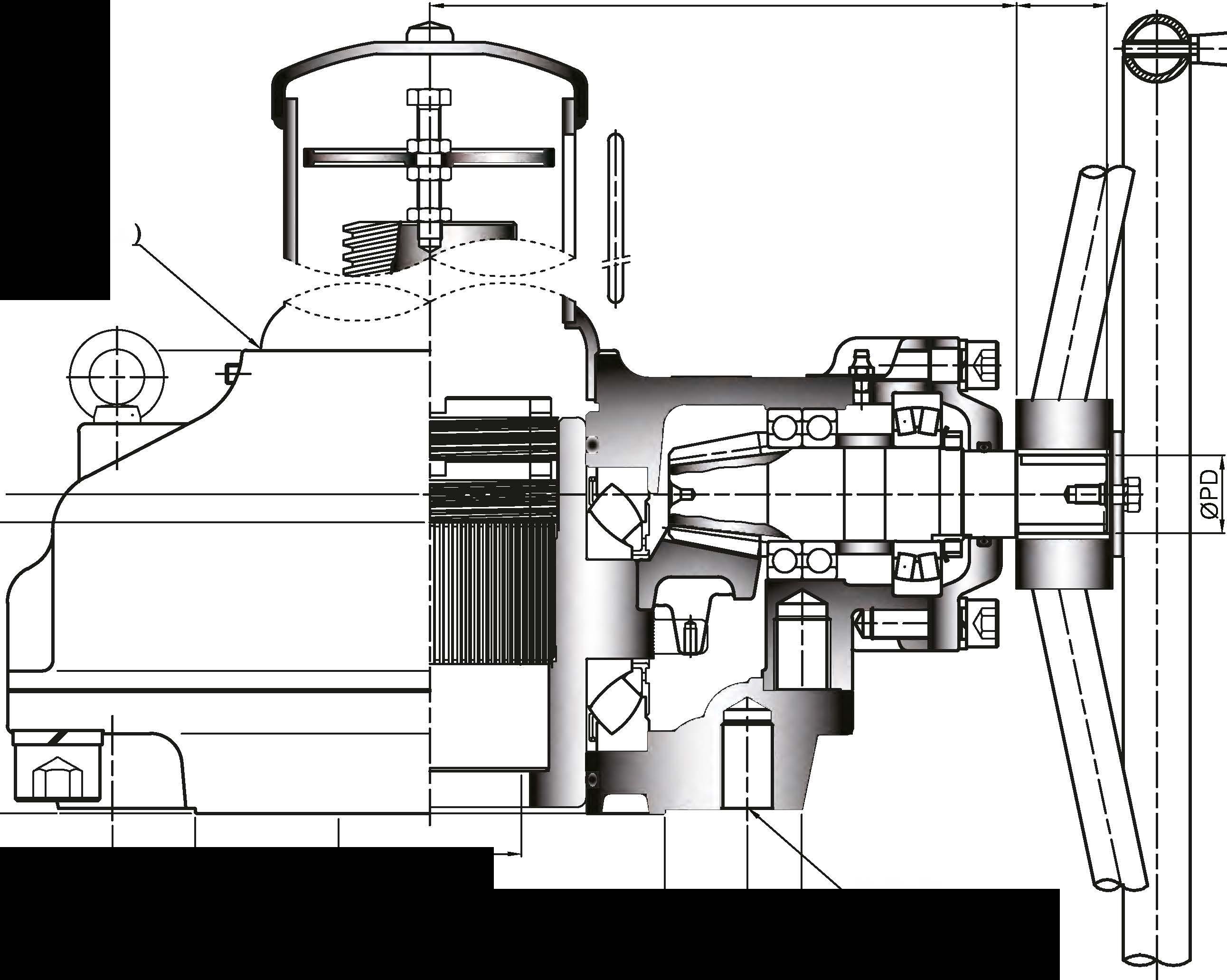

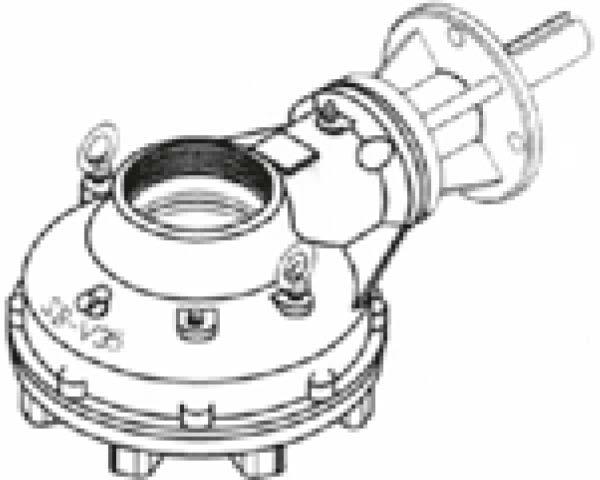

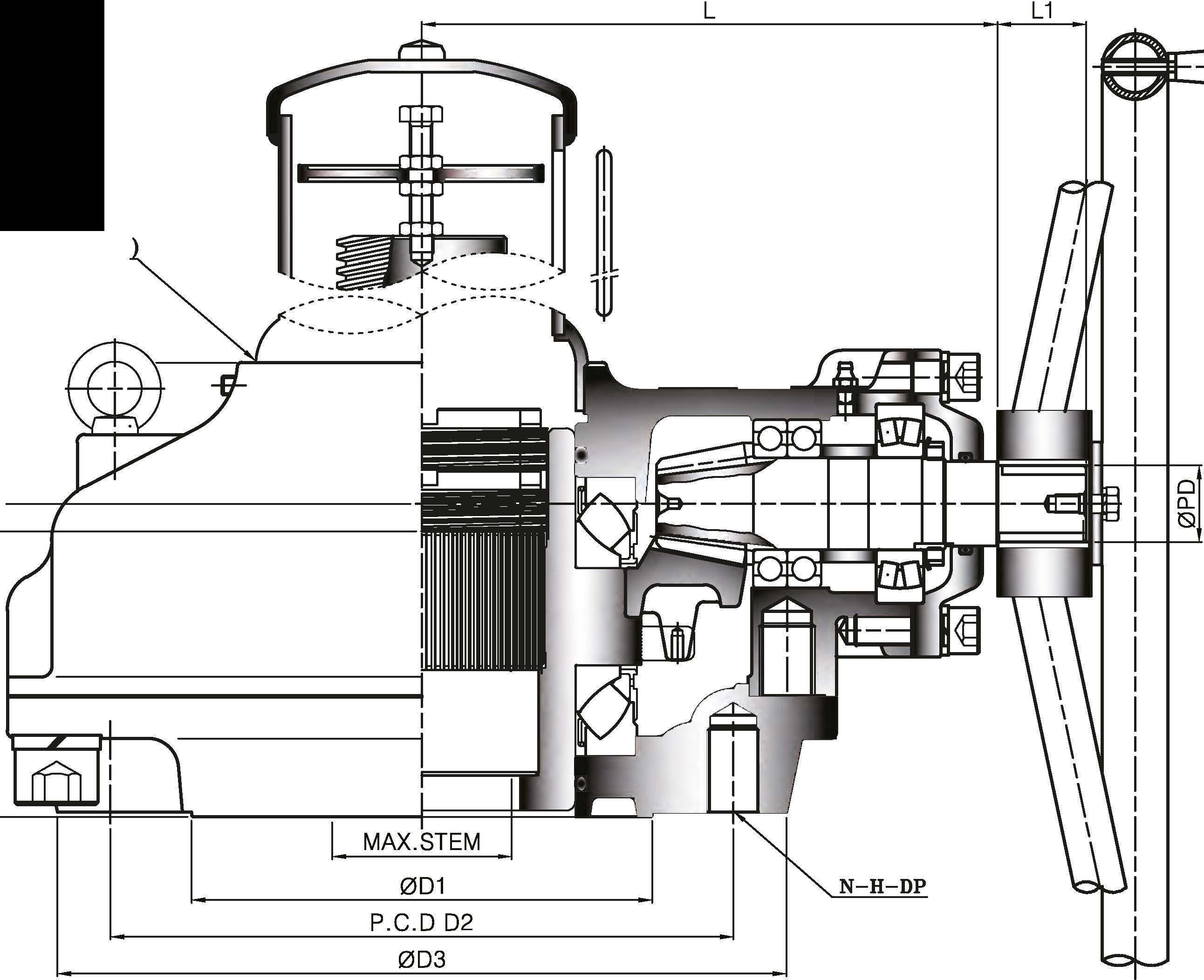

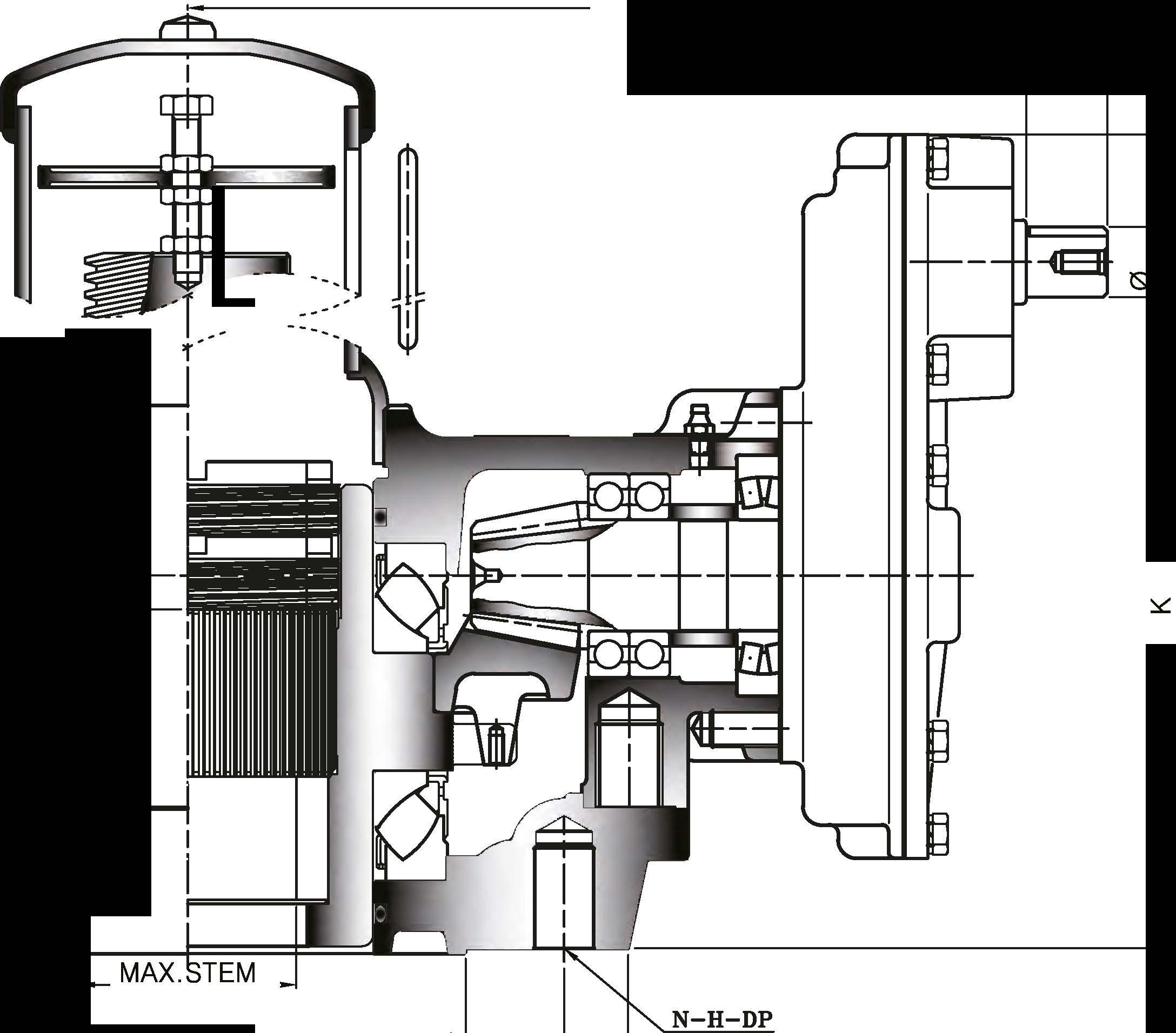

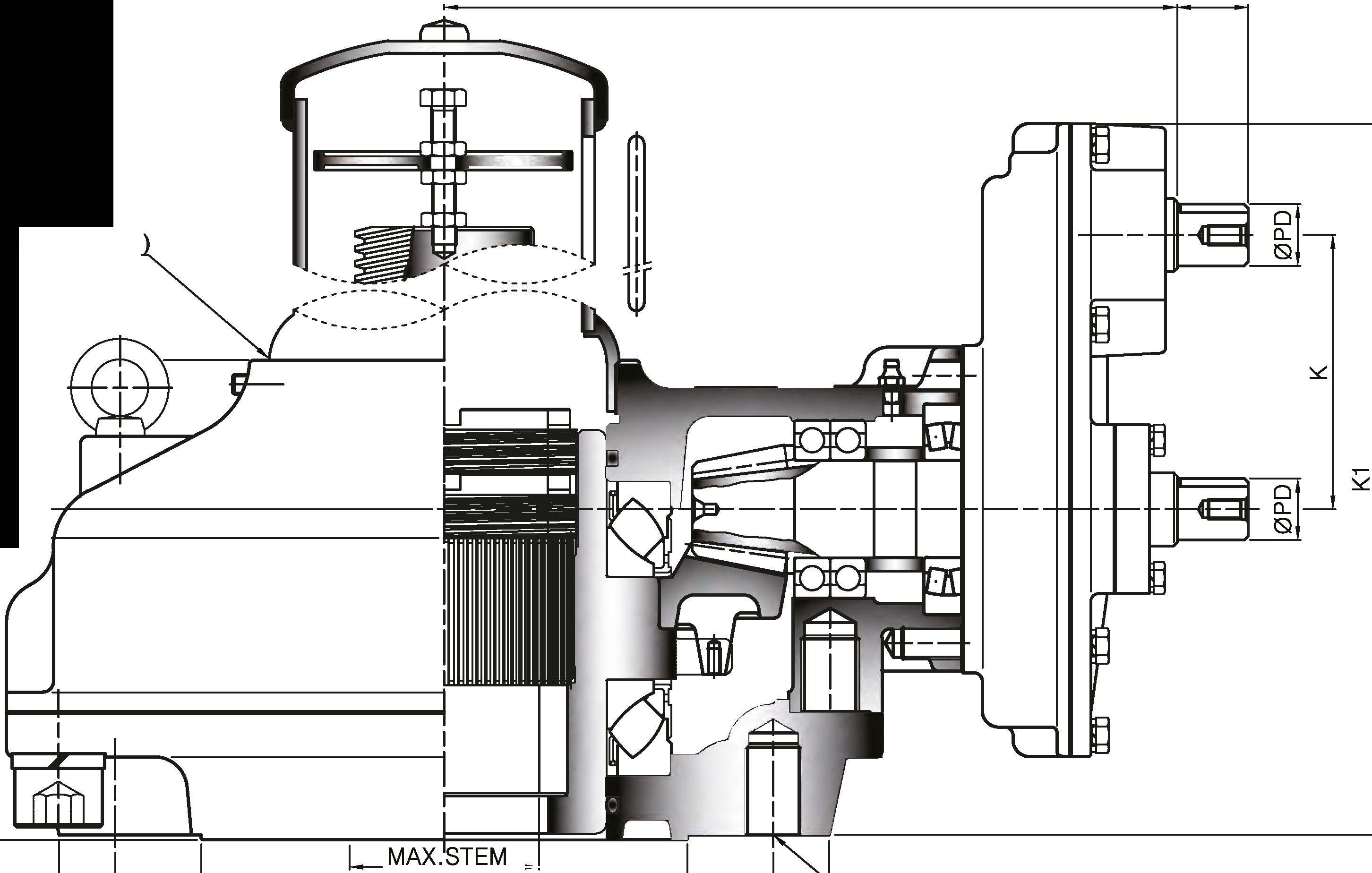

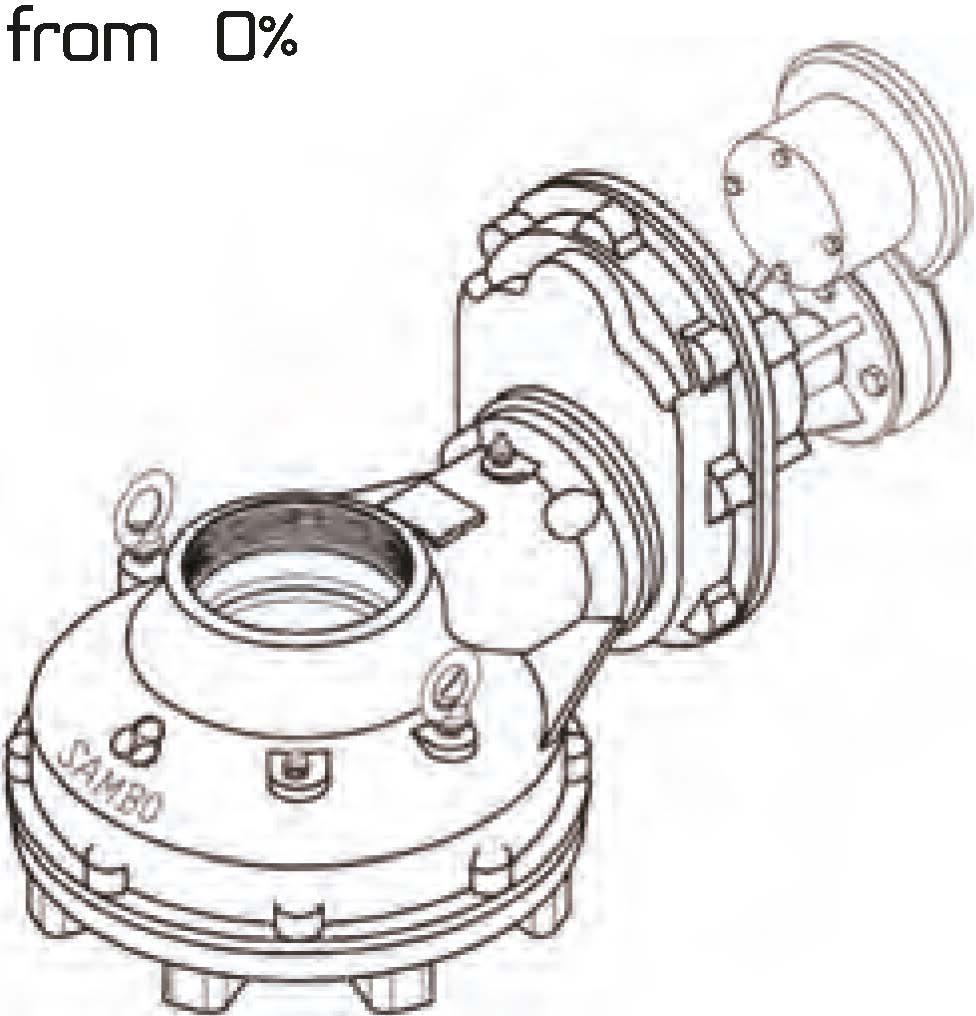

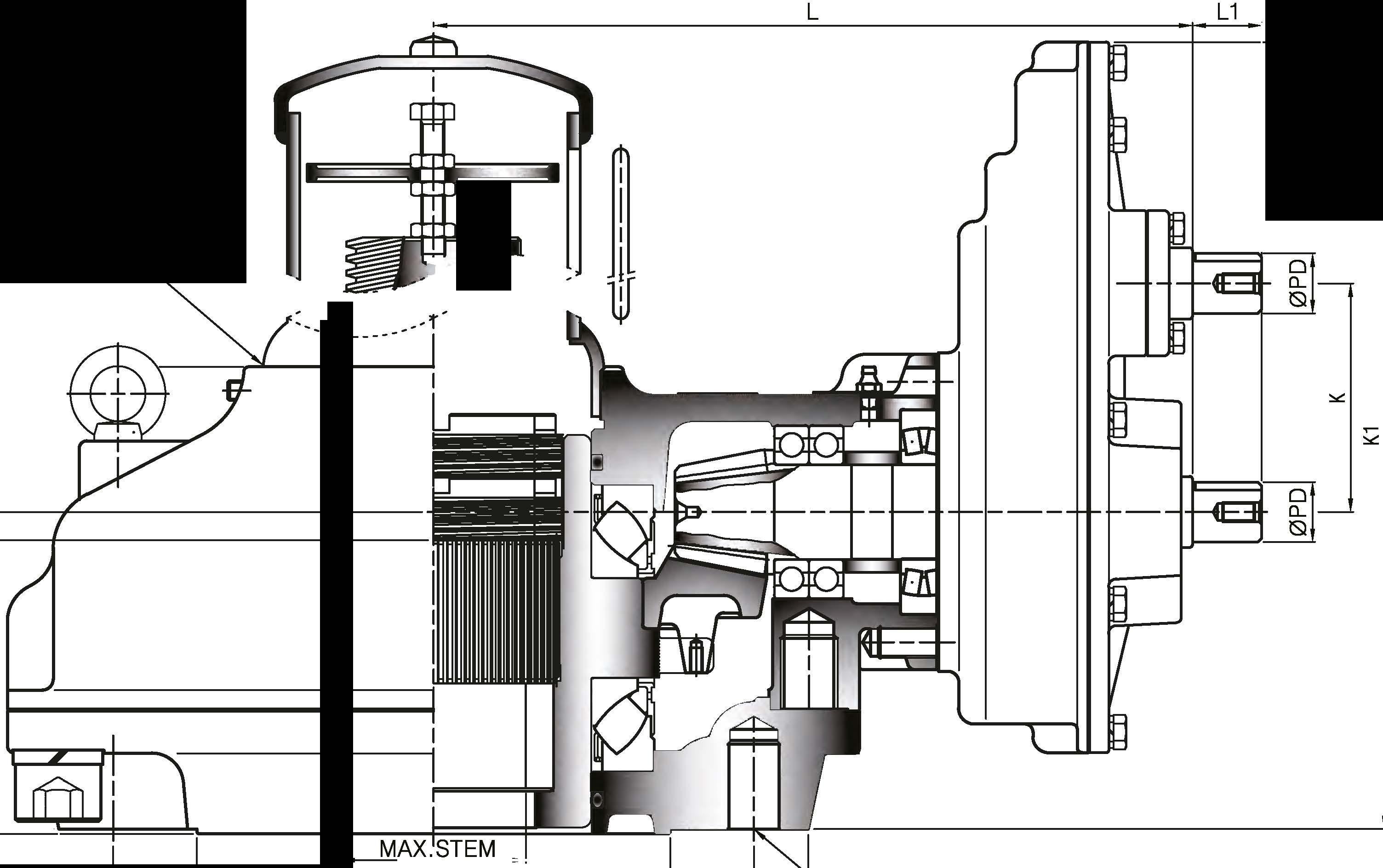

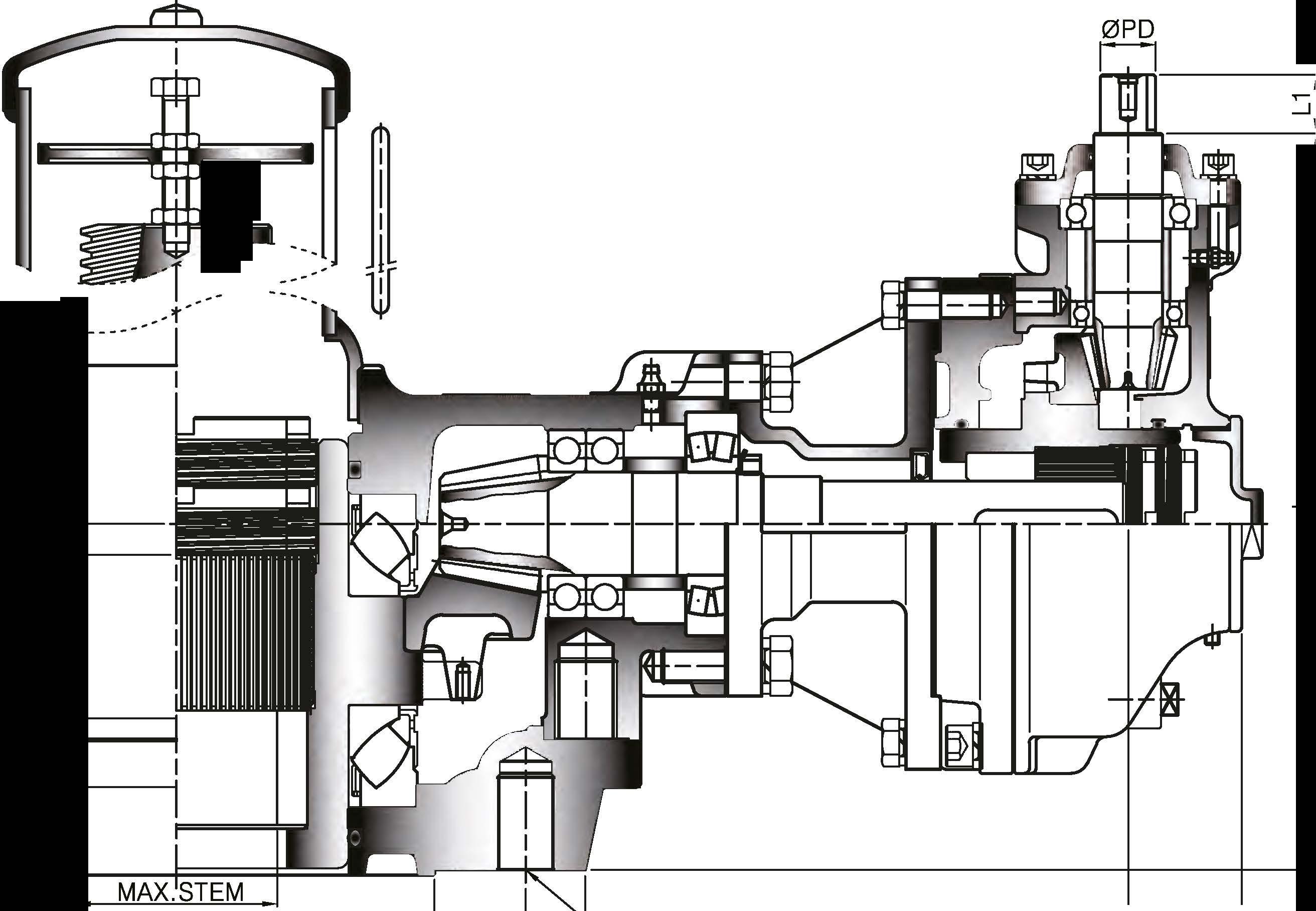

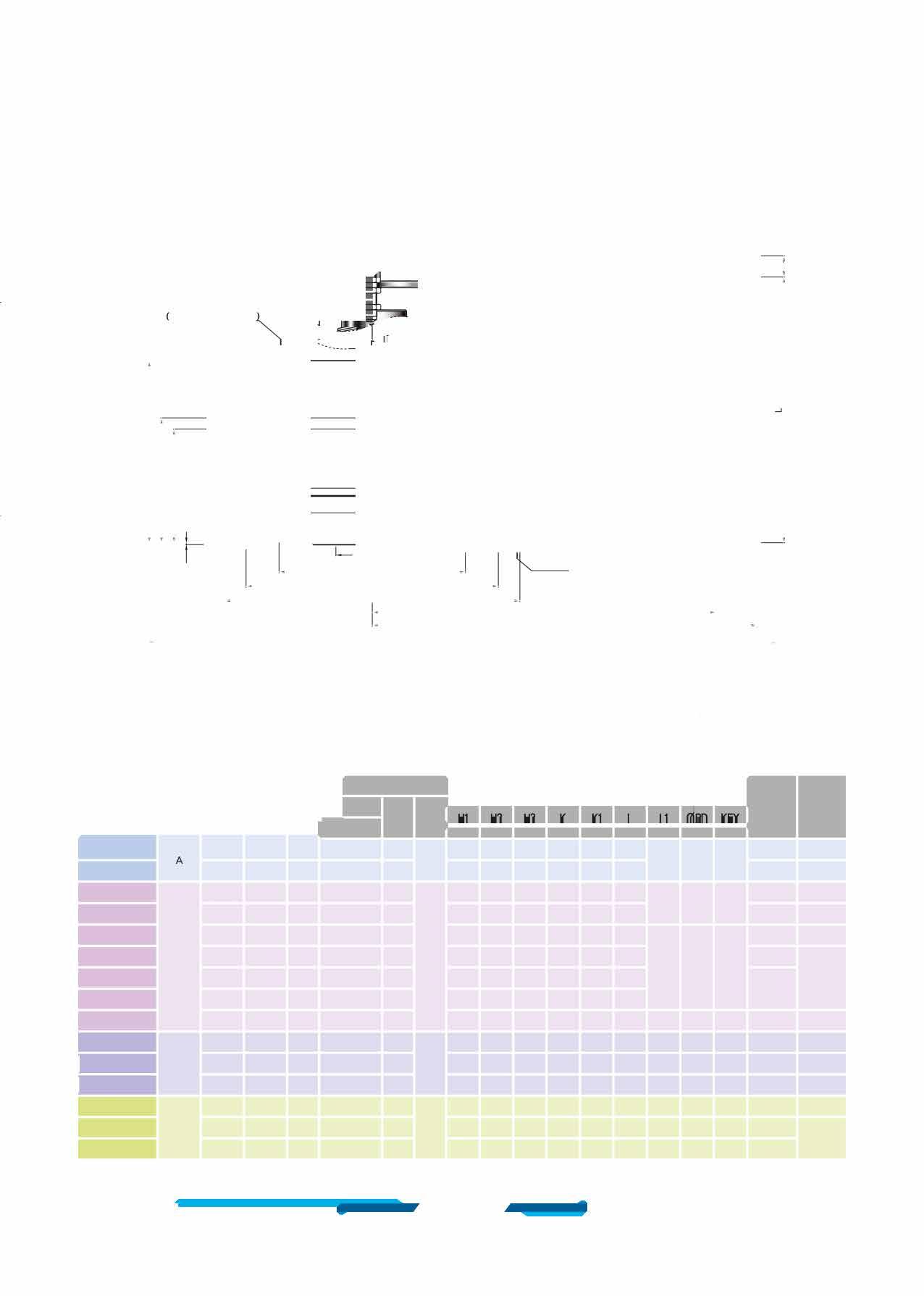

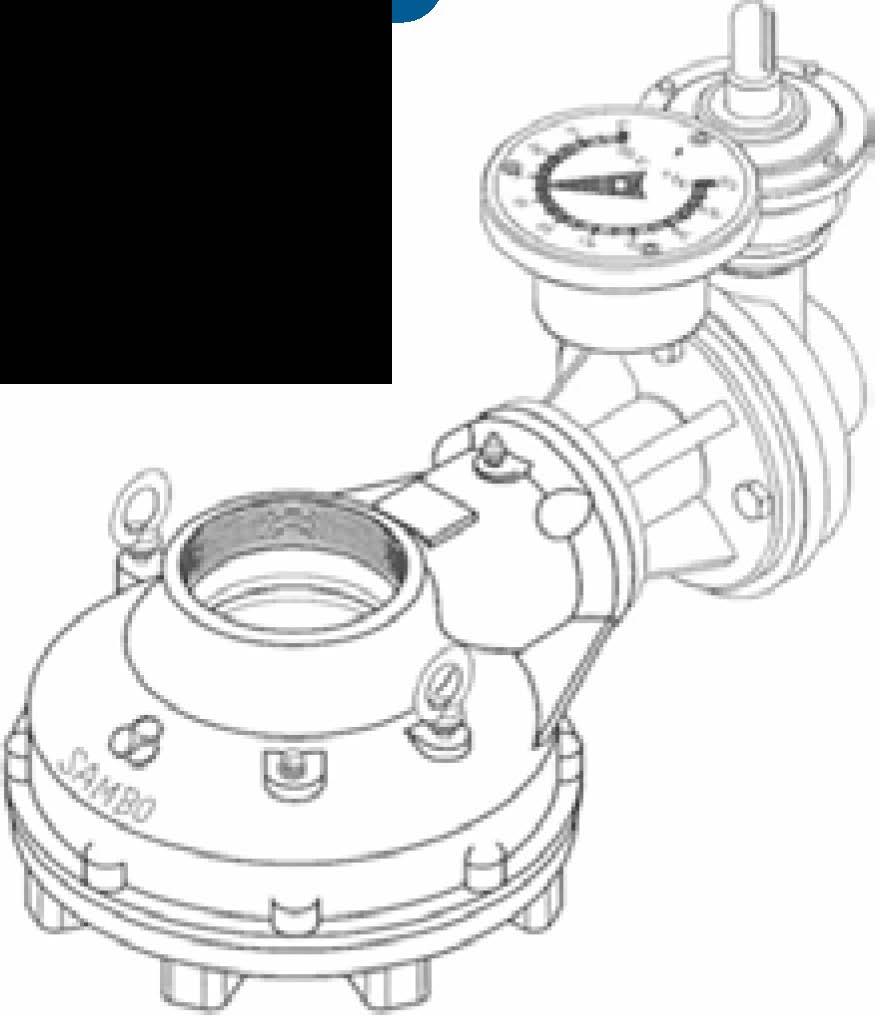

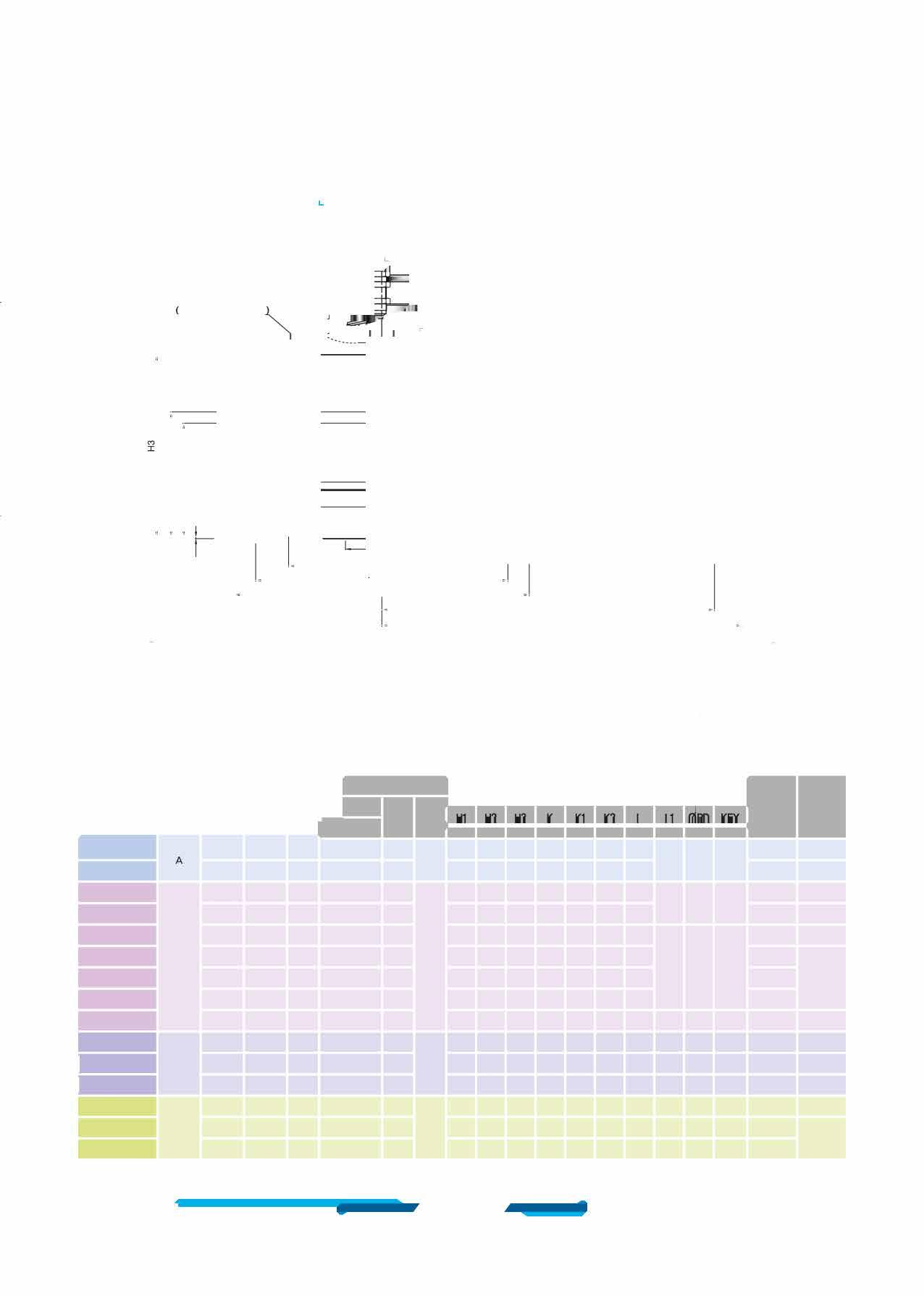

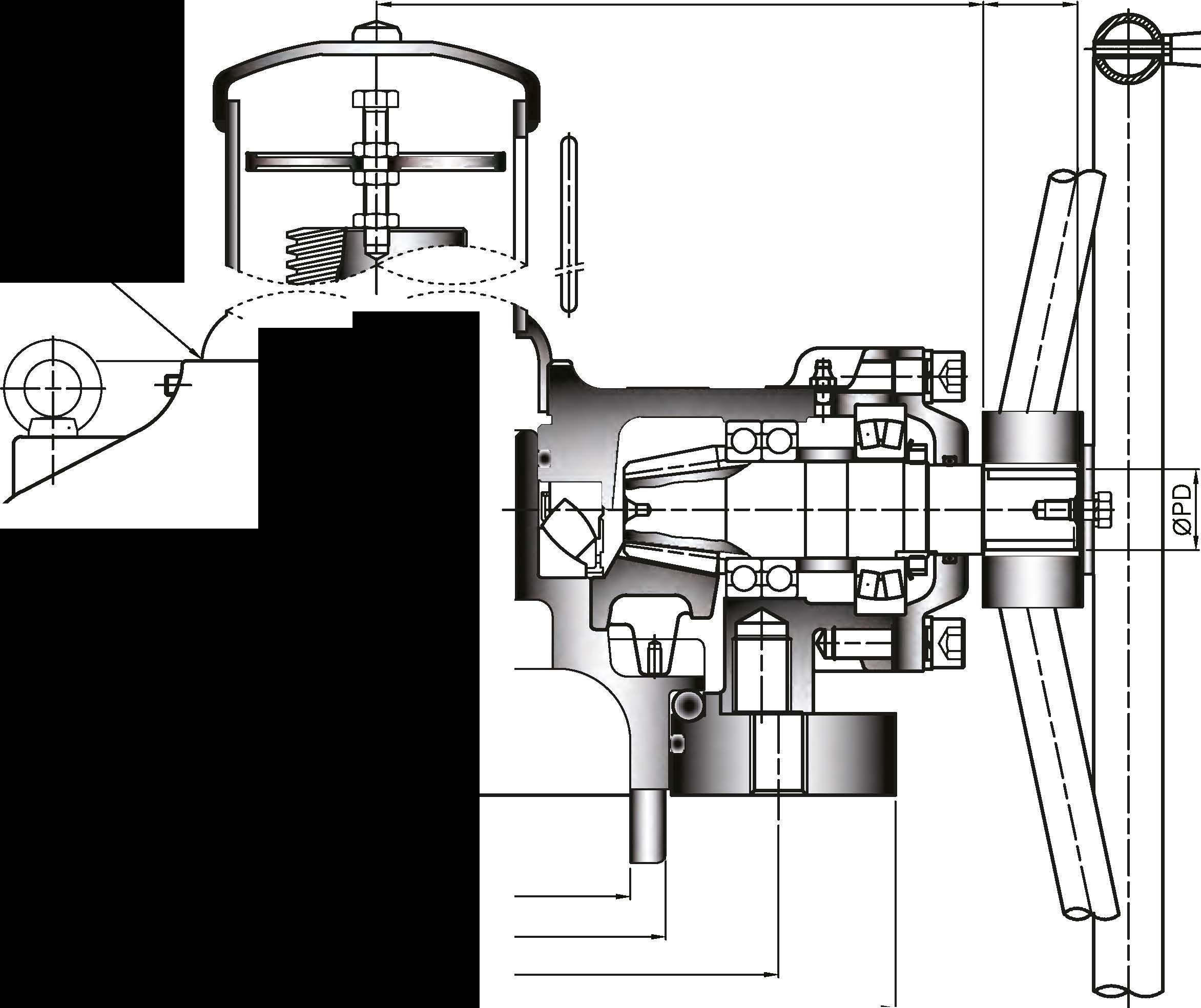

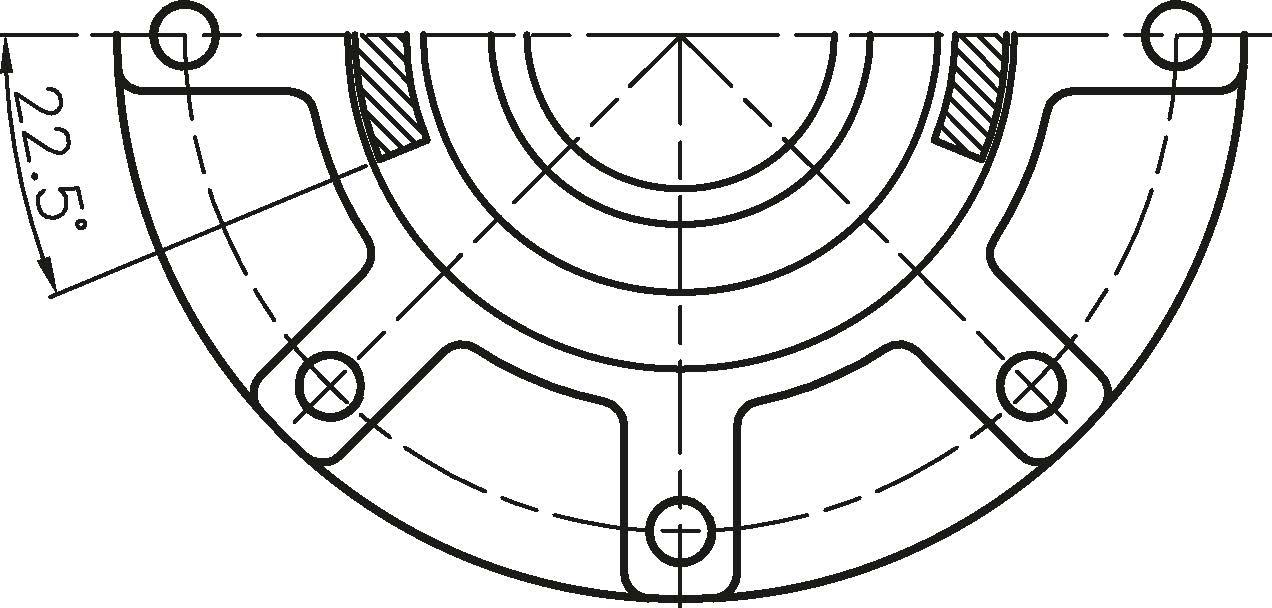

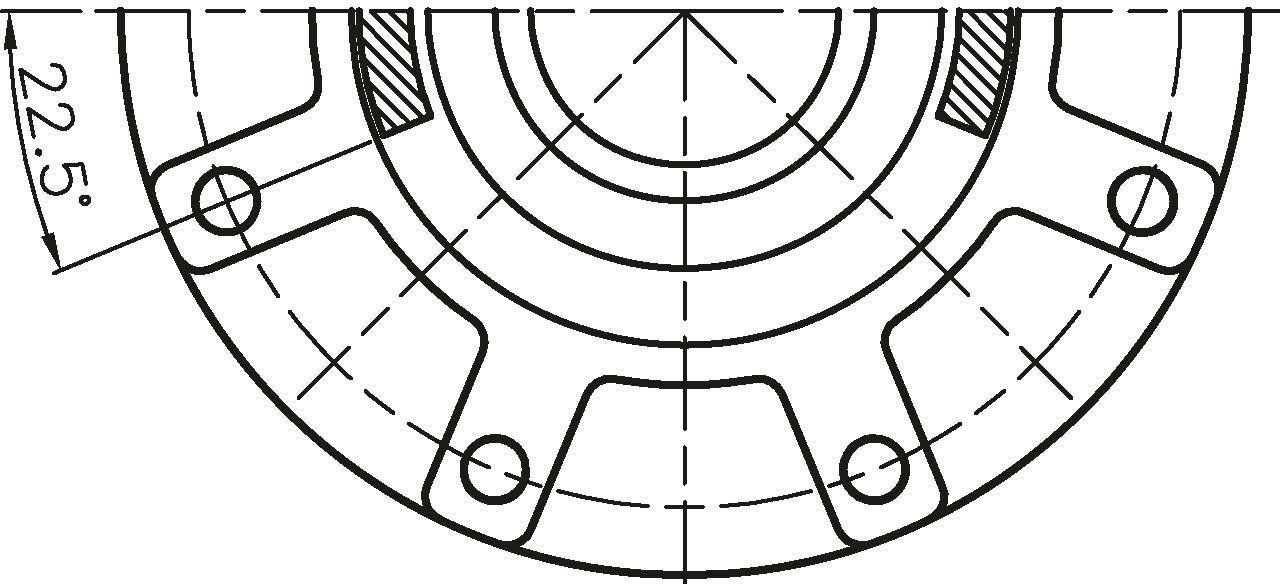

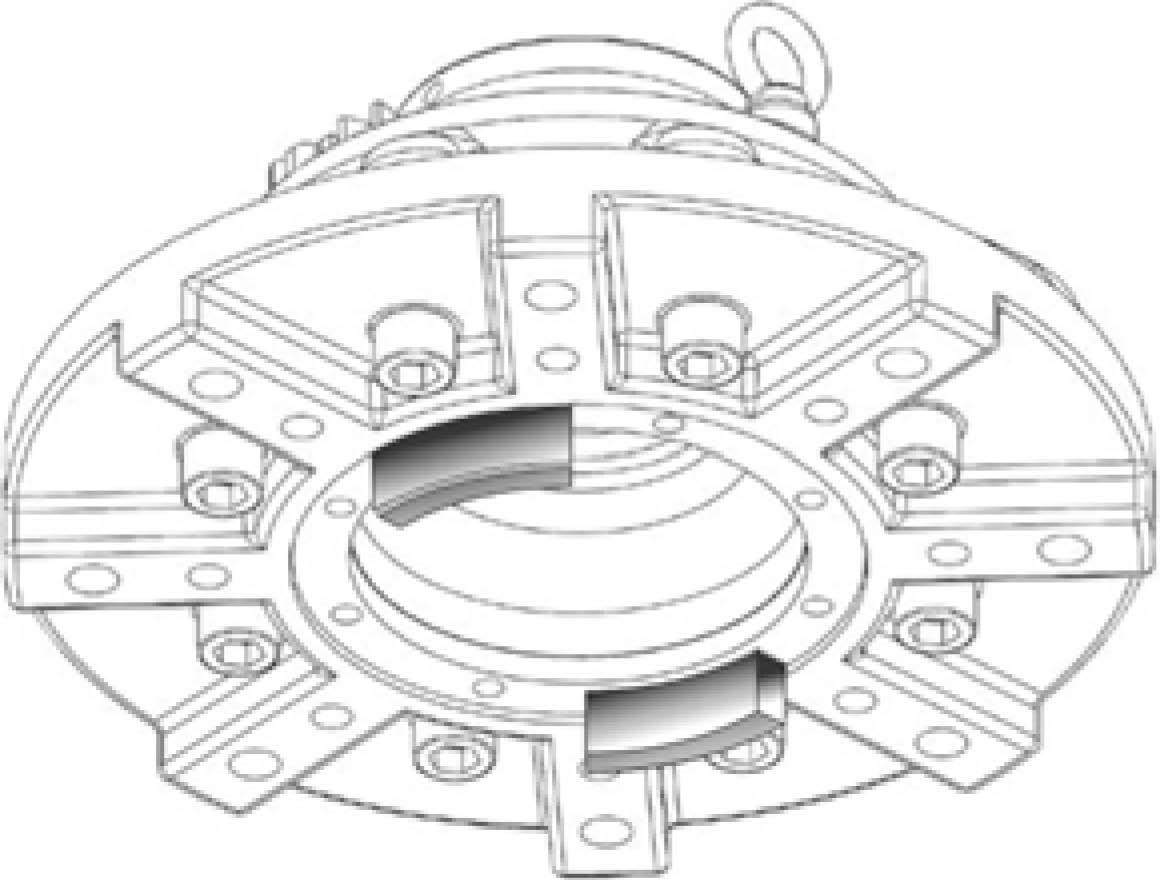

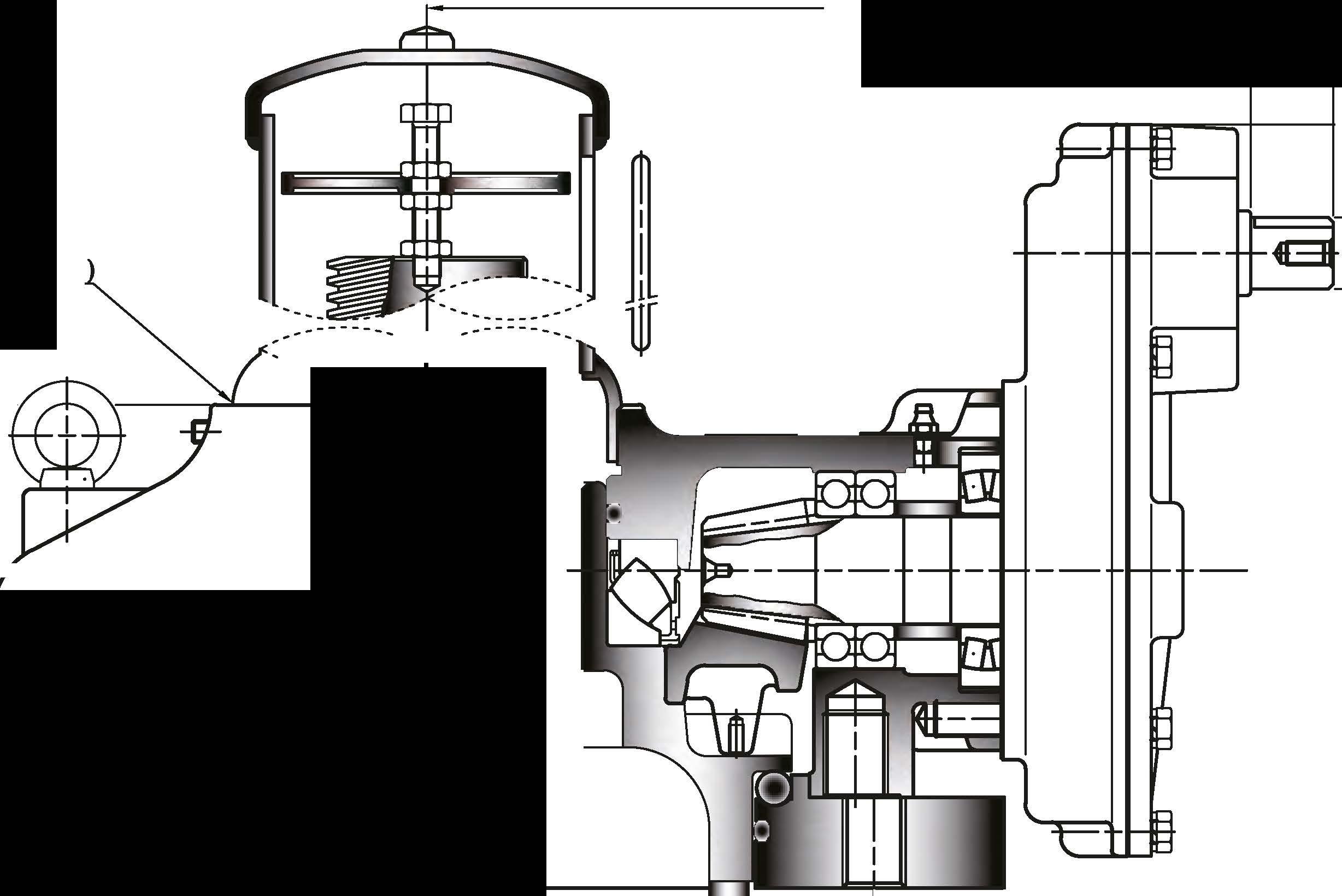

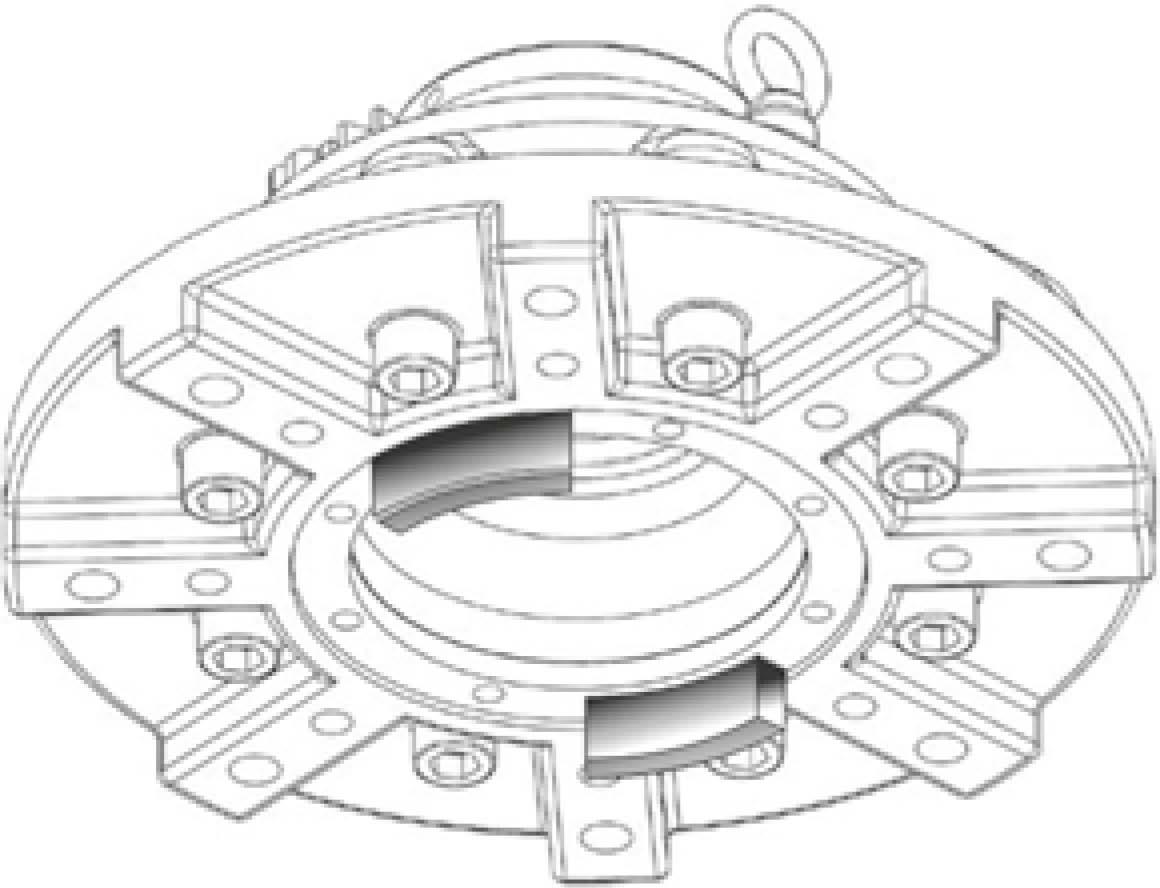

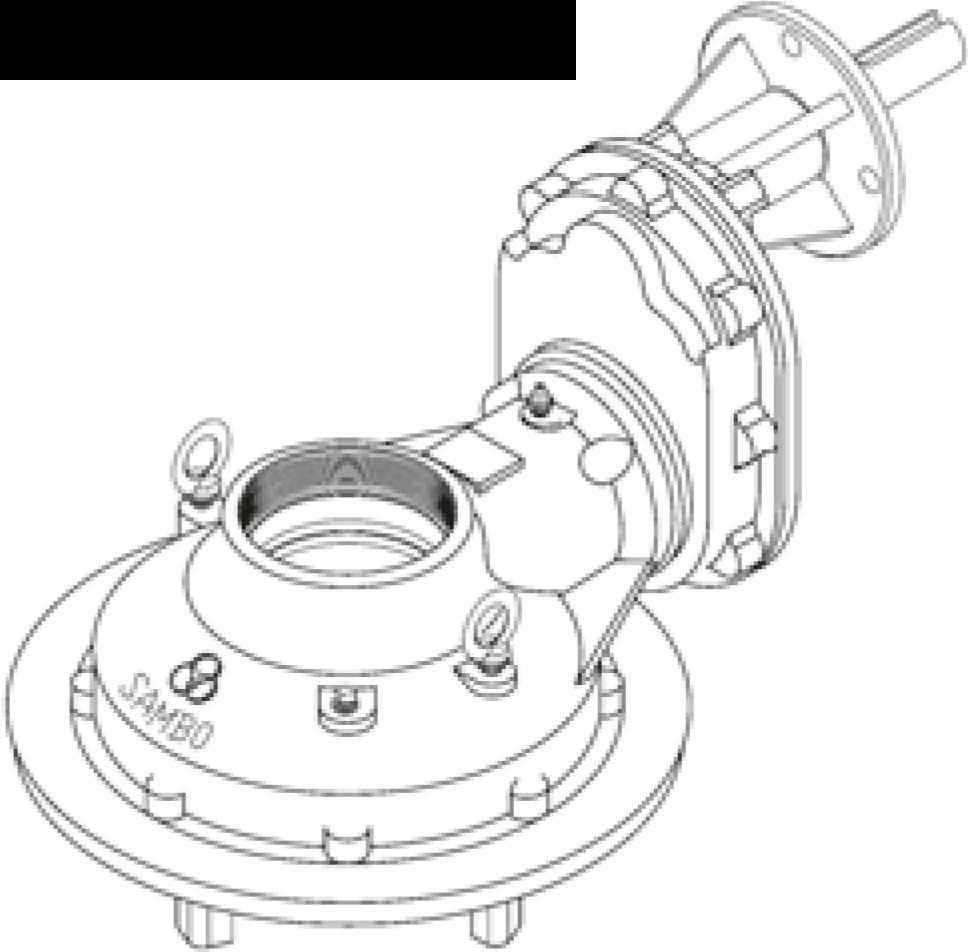

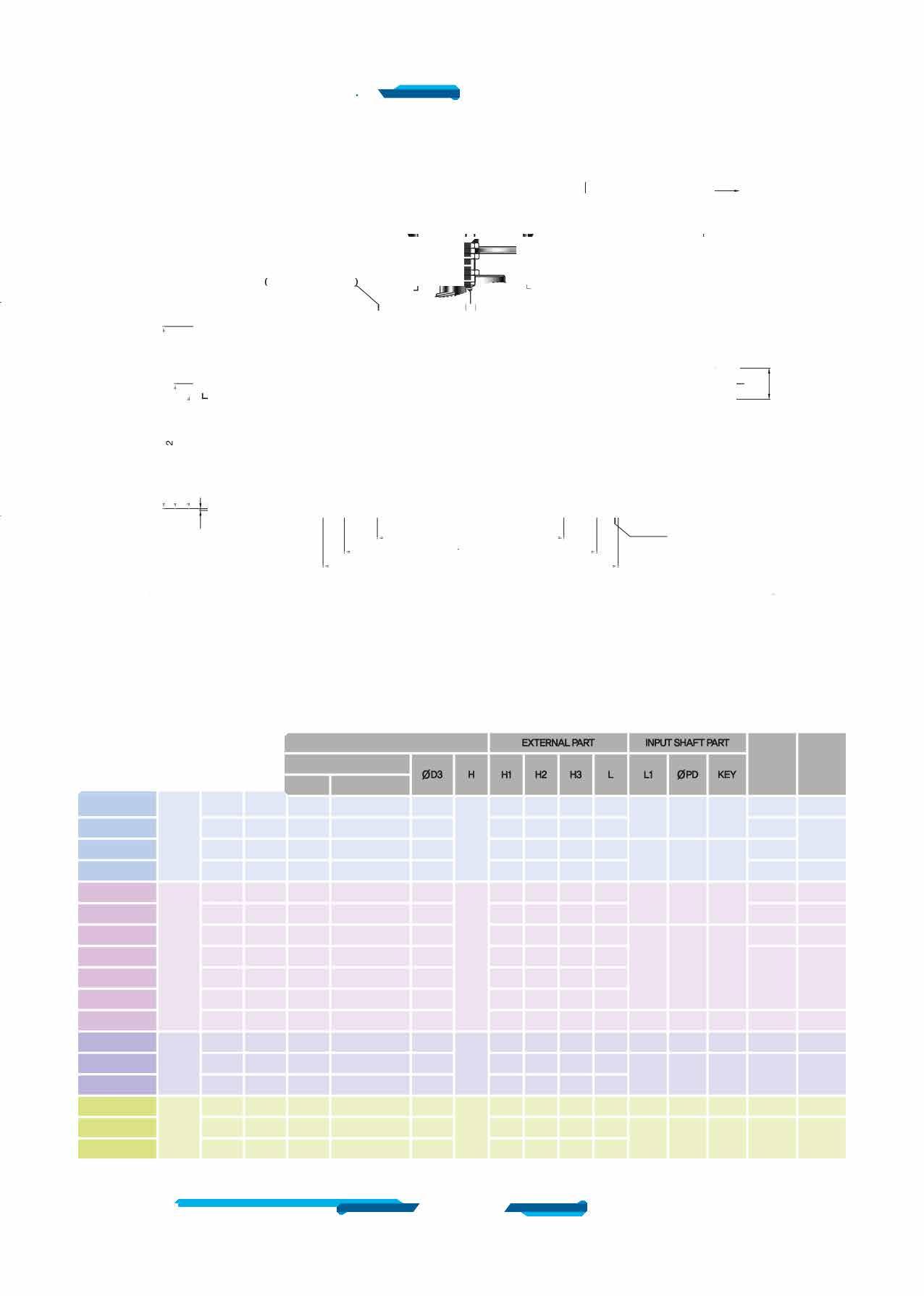

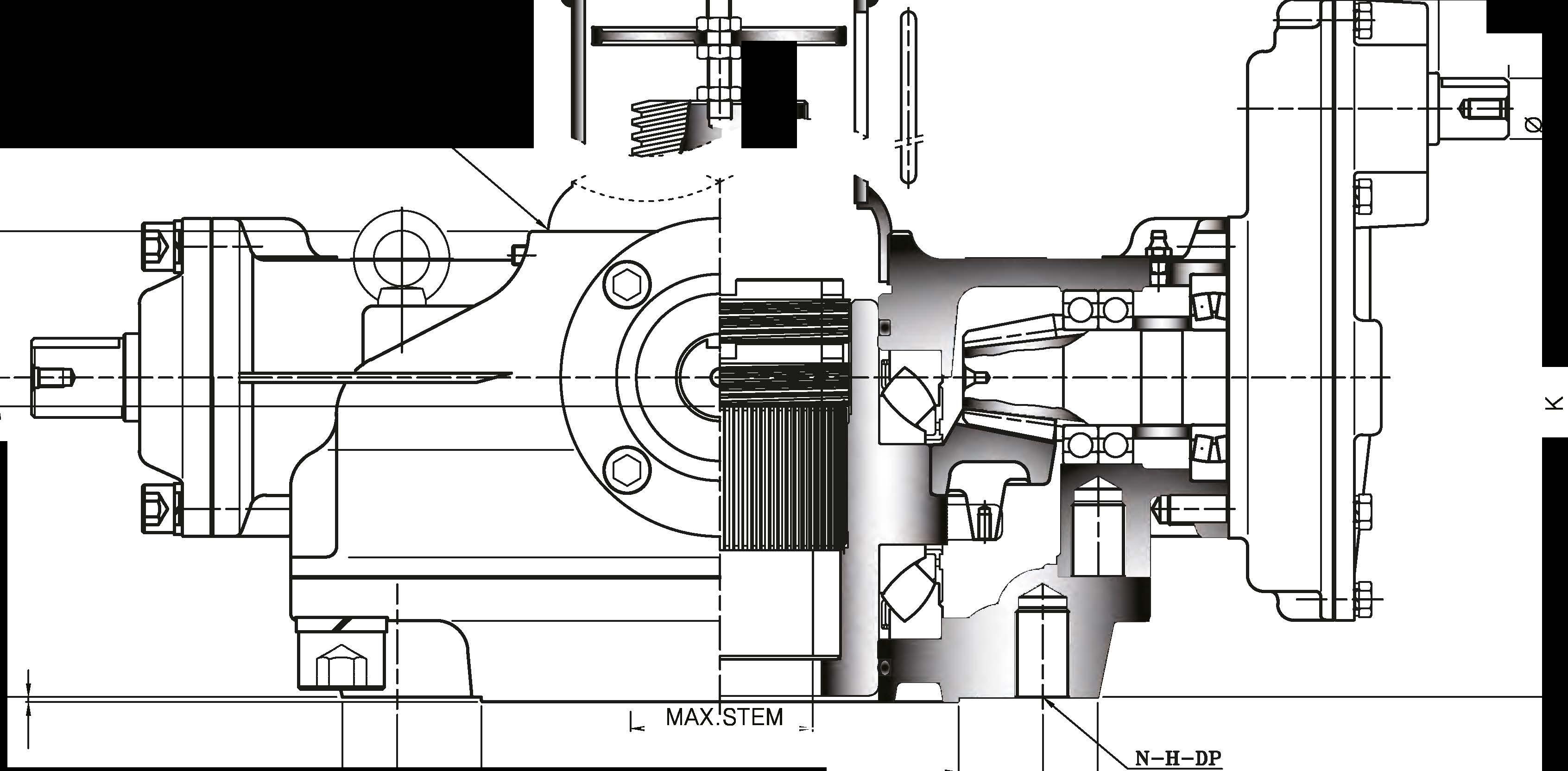

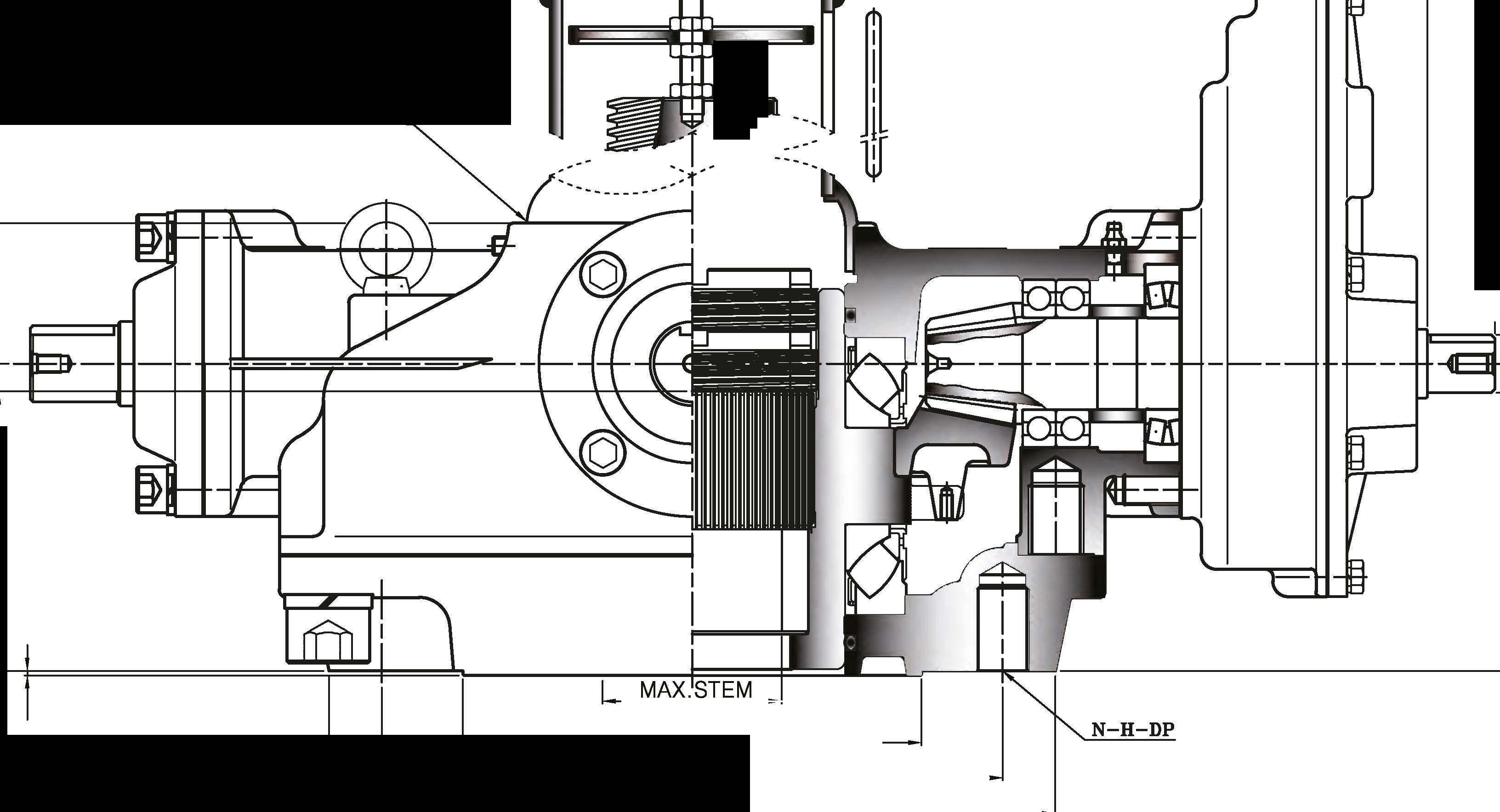

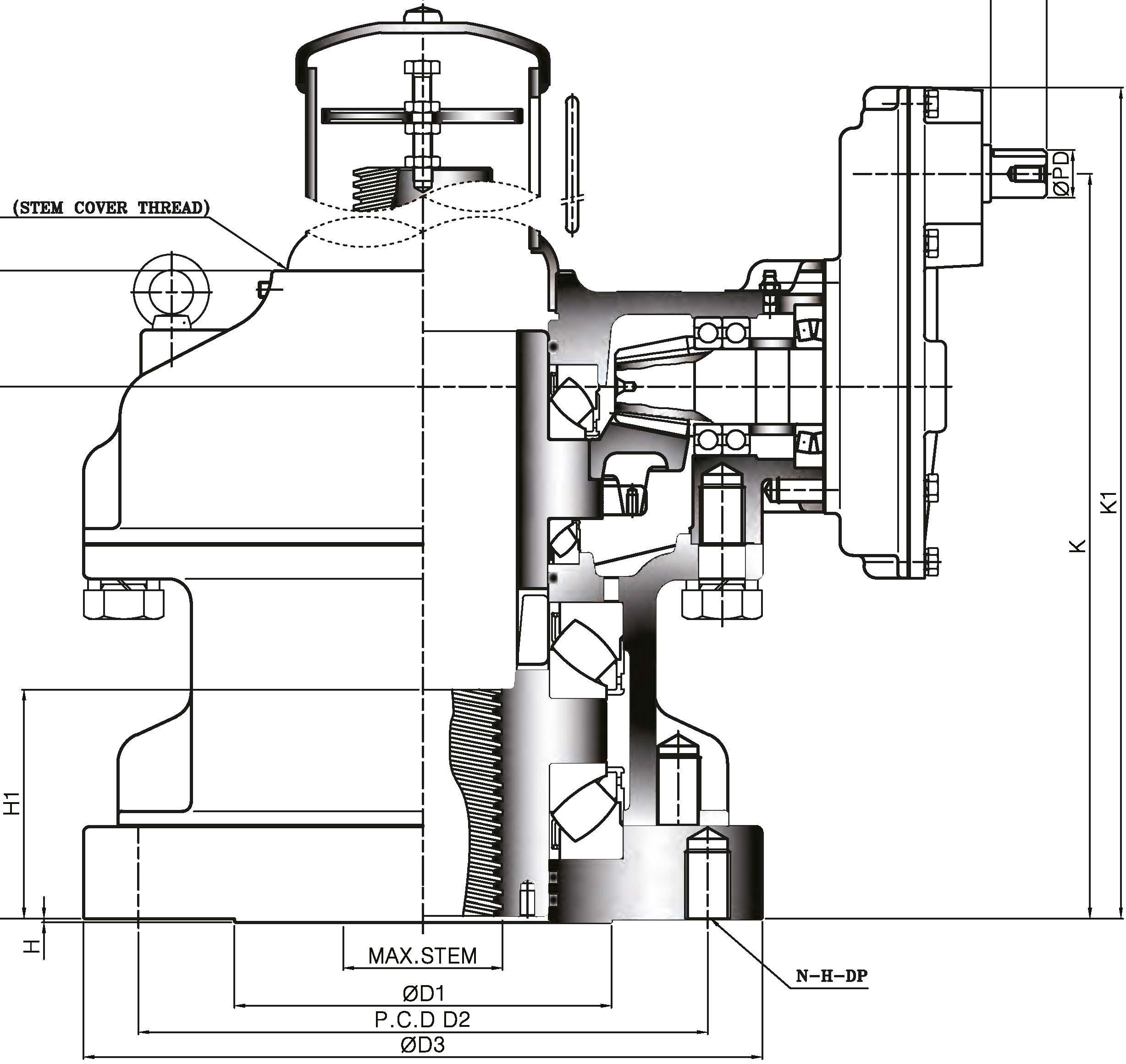

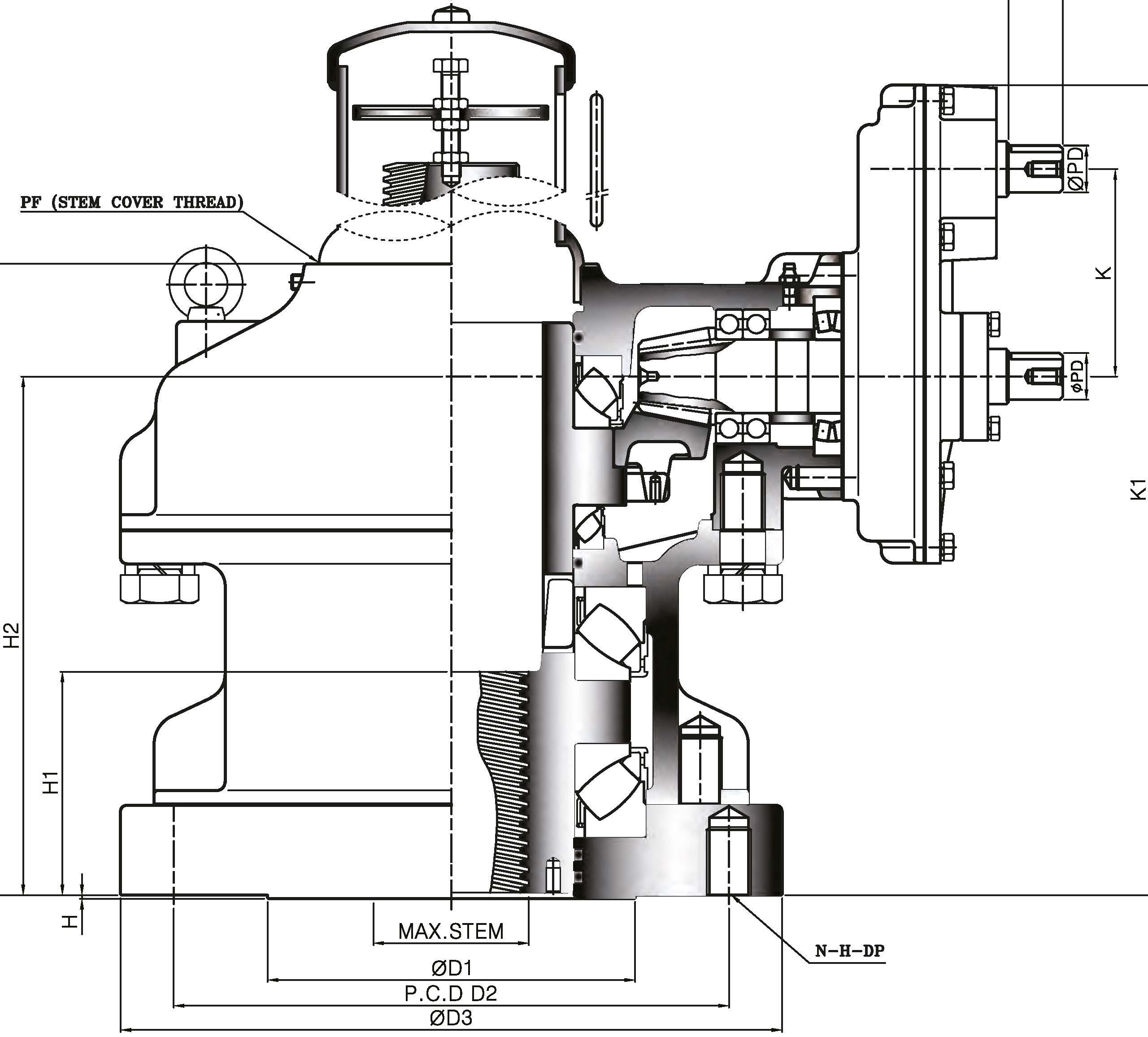

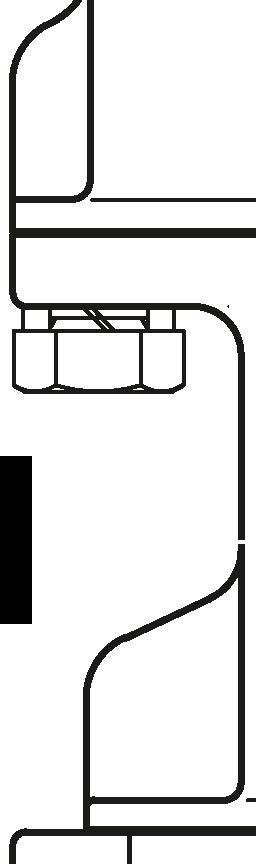

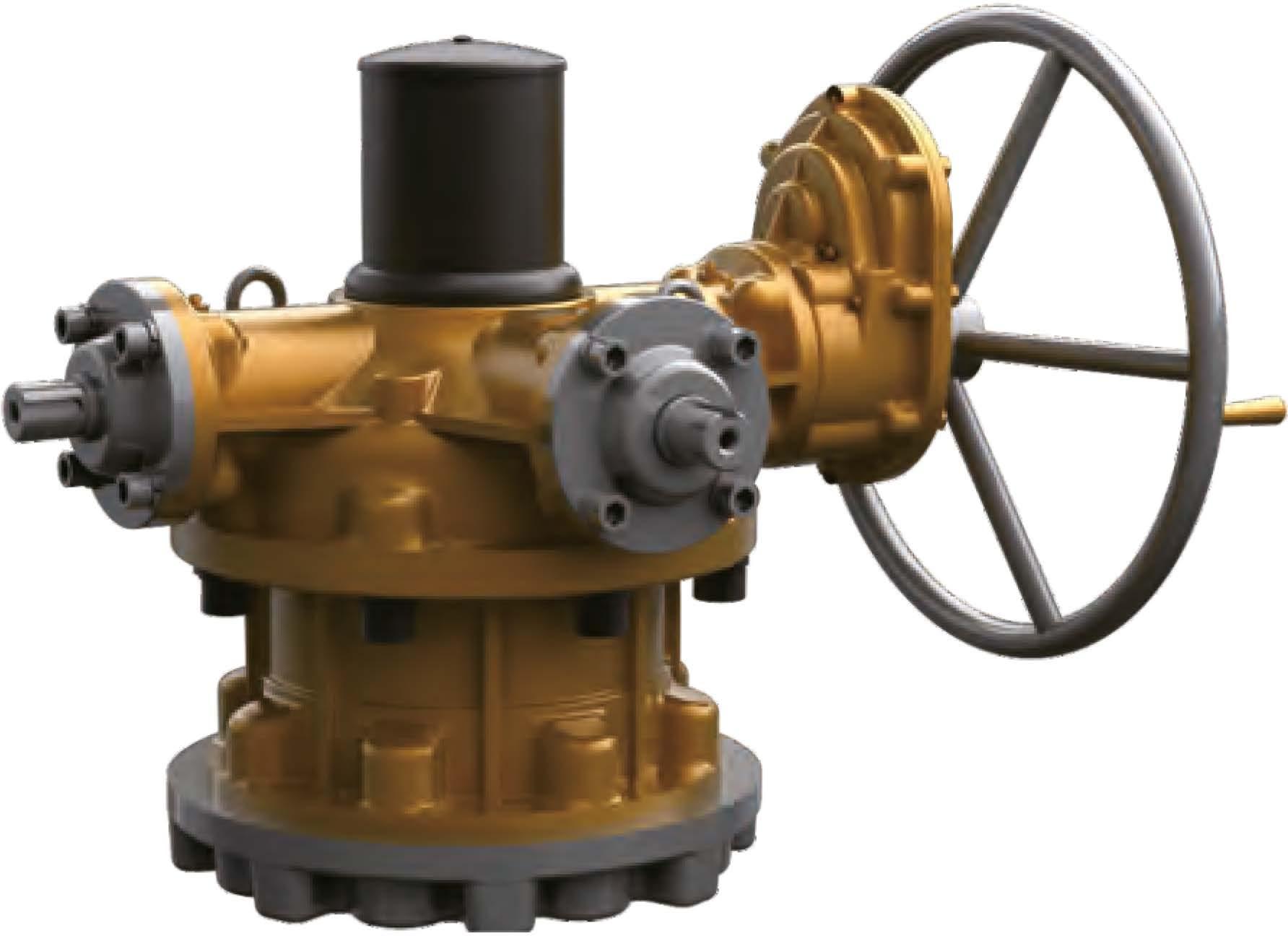

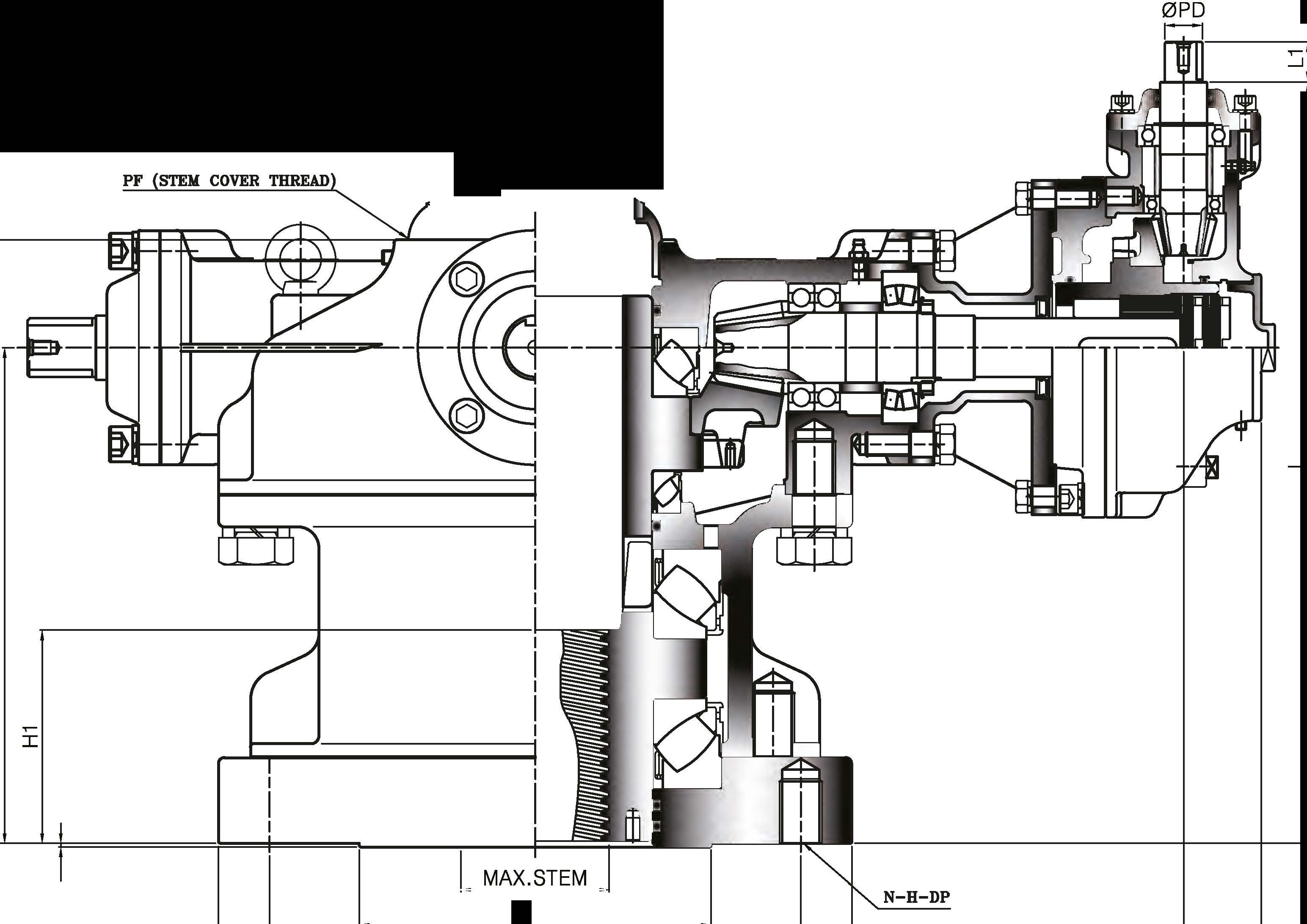

(!) Spiral Pinion and Spiral Bevel Gear

Pinion gear is 1045 heat treated steel. Bevel Gear is 1045 steel. Both gears are precision cut.

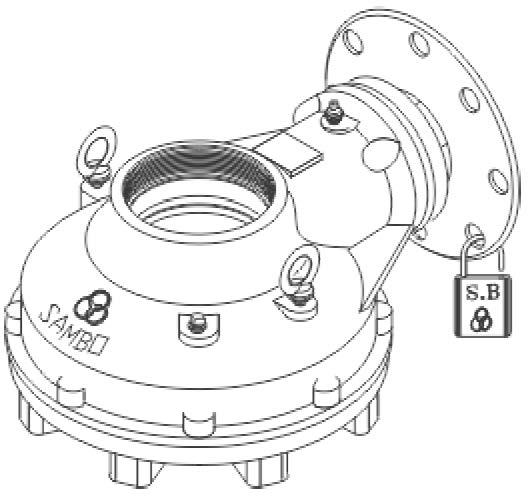

@ □-ring

Units are completely □-ring sealed, suitable for temporary submergence to meet IP67 Class.

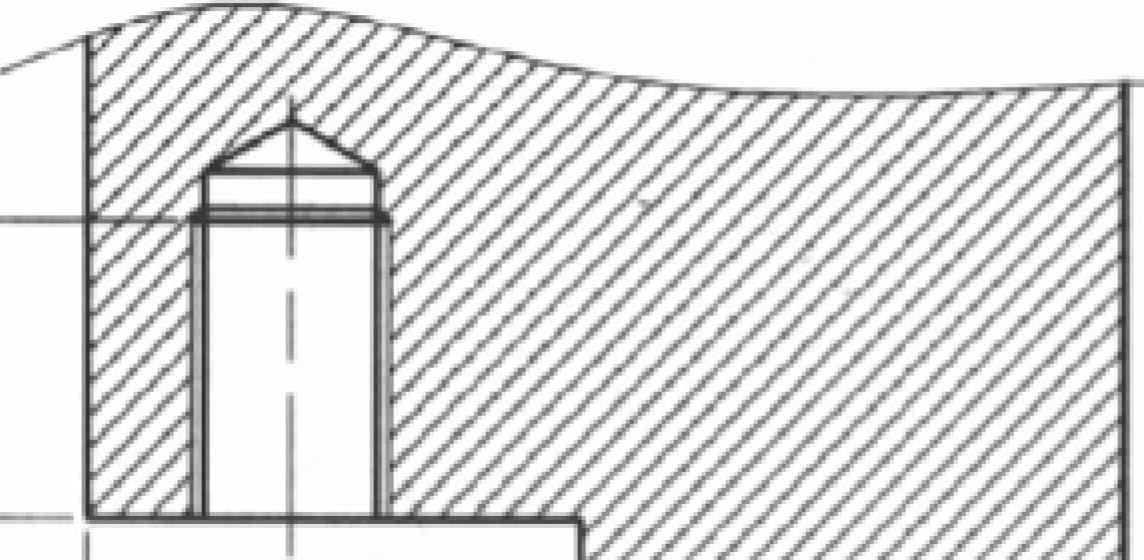

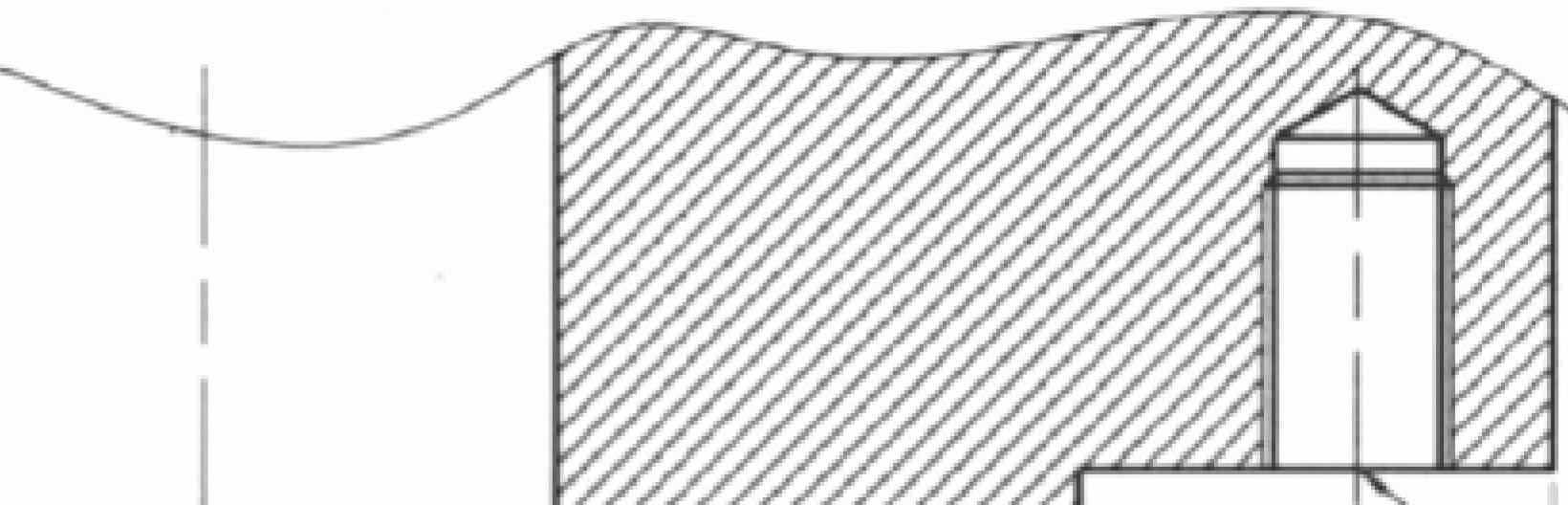

® Spherical Roller Bearing

This input Bevel pinion is fully supported on deep groove ball bearings to provide excellent radial support.

® Gaskets

The Base & end cap is sealed by a Non-asbestos Gasket to prevent any leakage and is waterproof.

® Thrust ball or Self-Aligning Thrust Roller Bearing

Provides anti-friction capacity and are high load type.

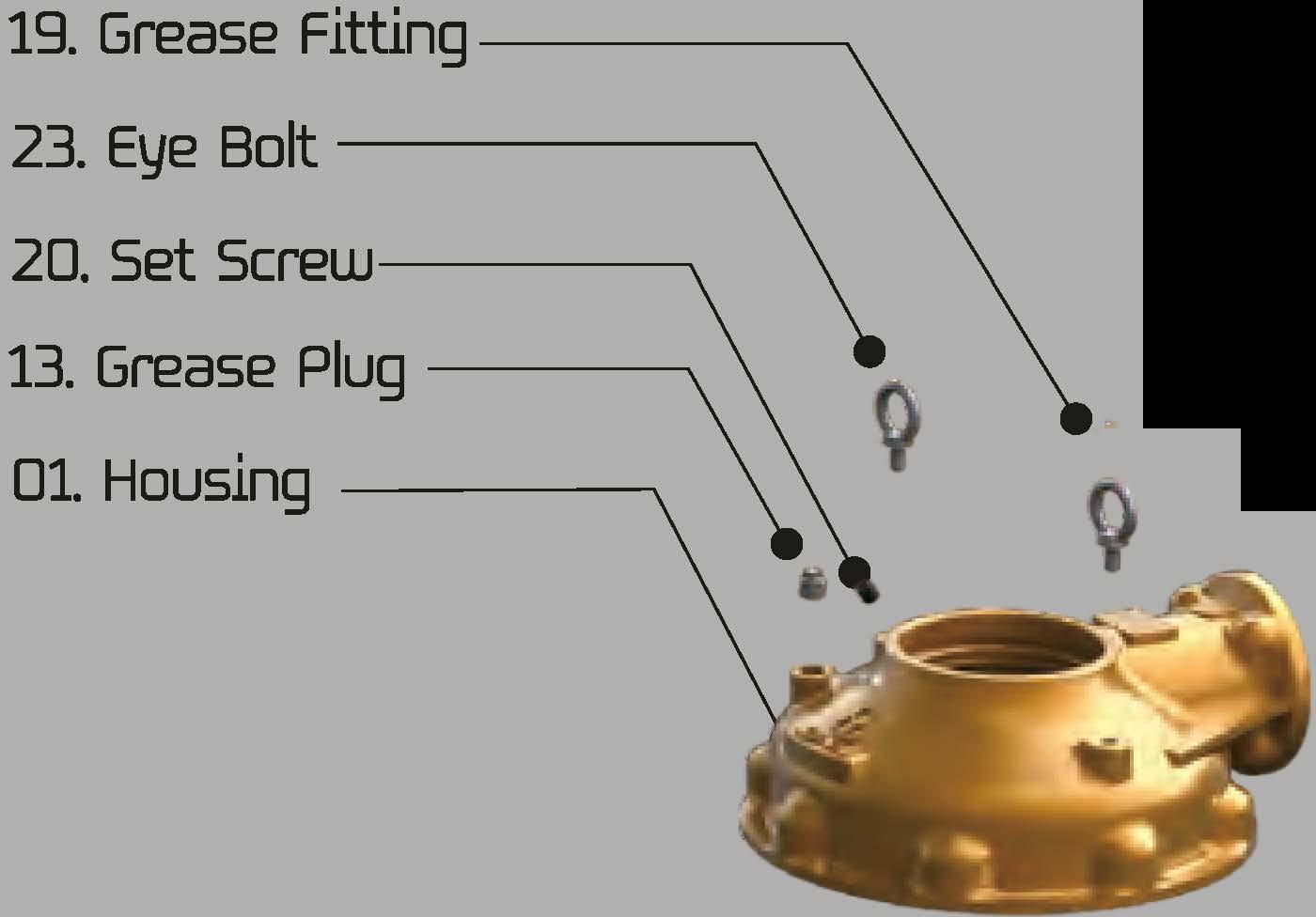

Each unit has a Alumite Grease type fitting and a grease plug for adding lubricant

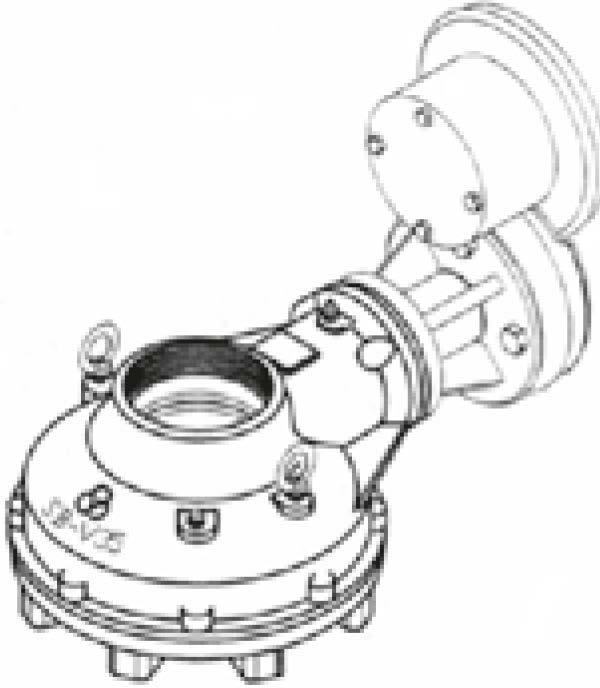

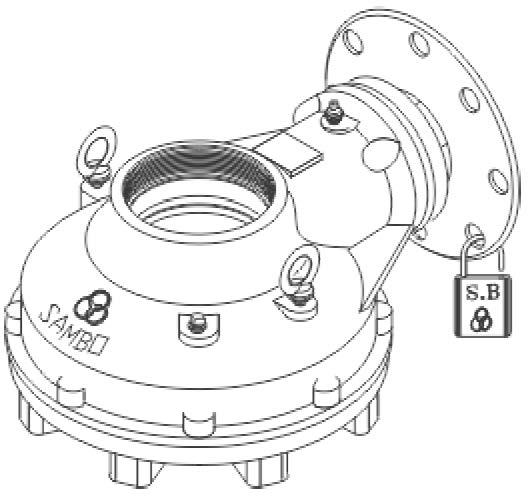

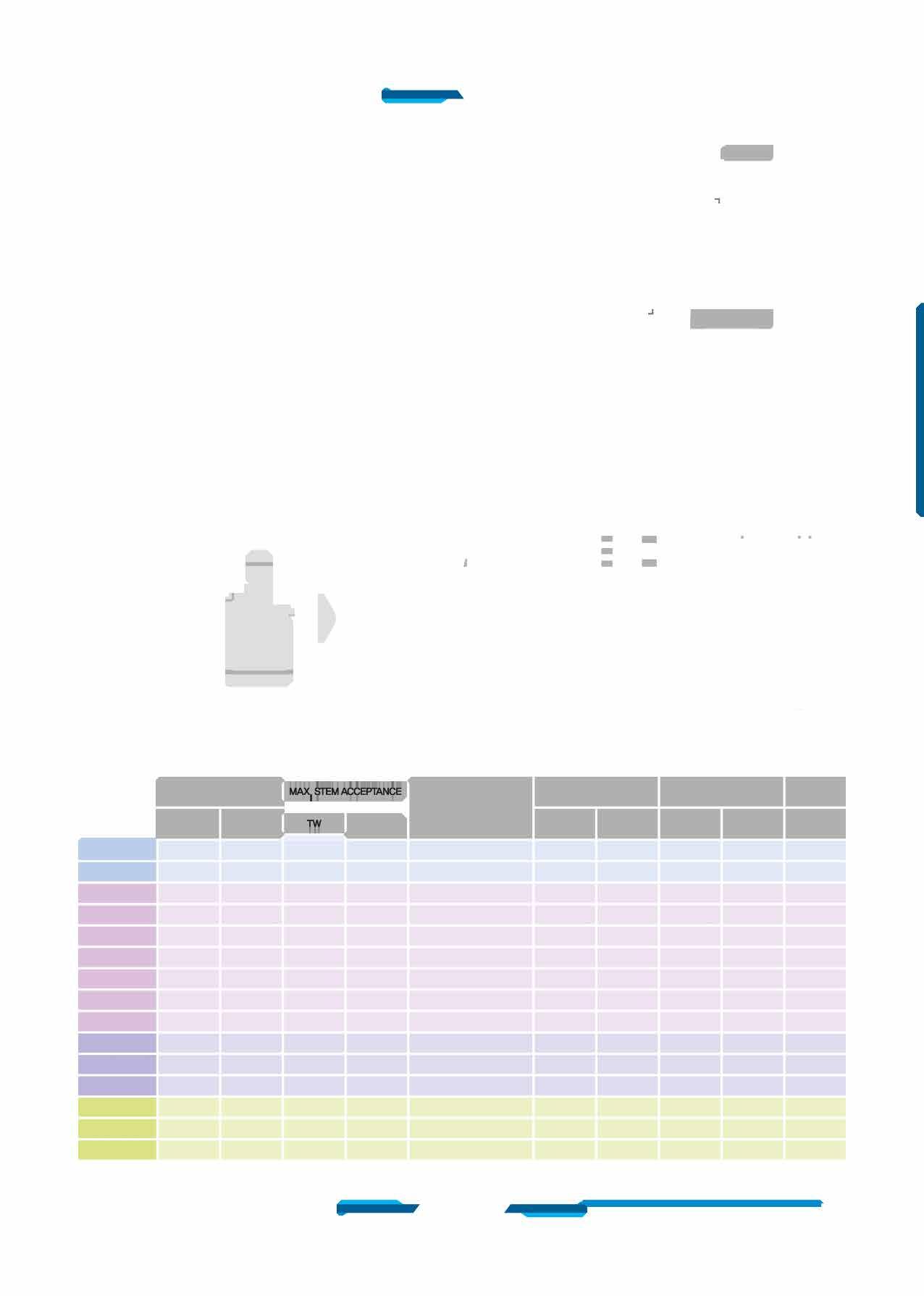

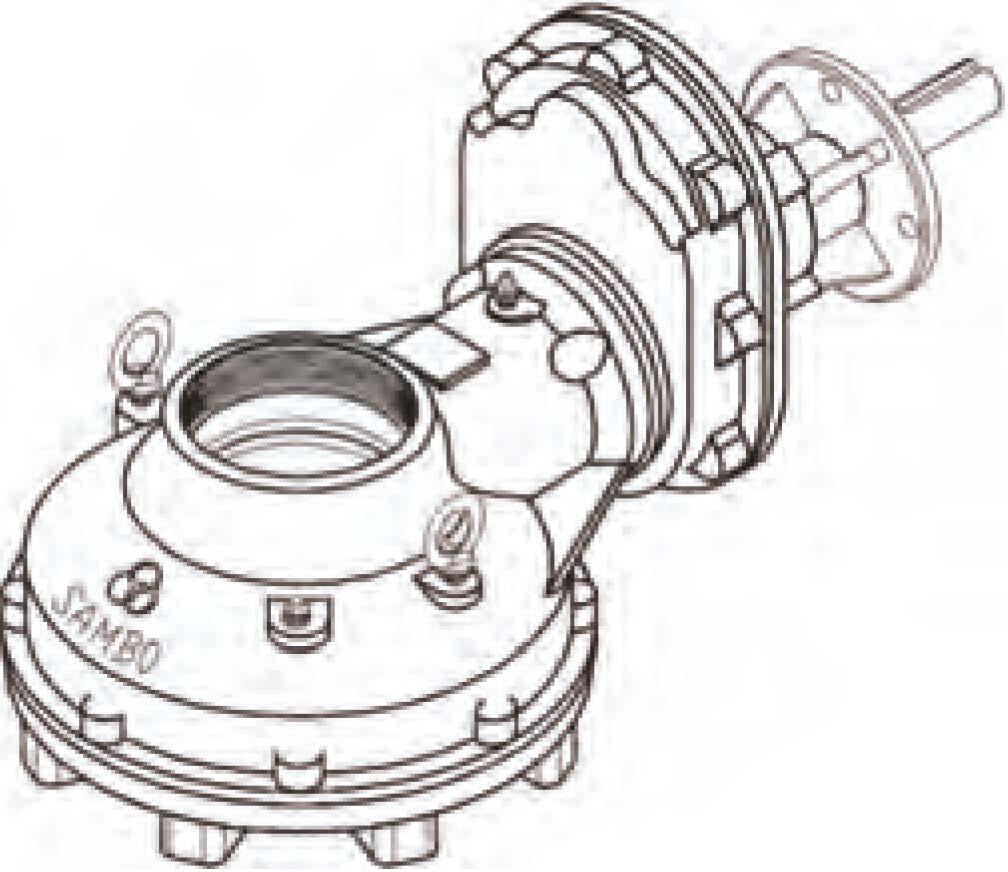

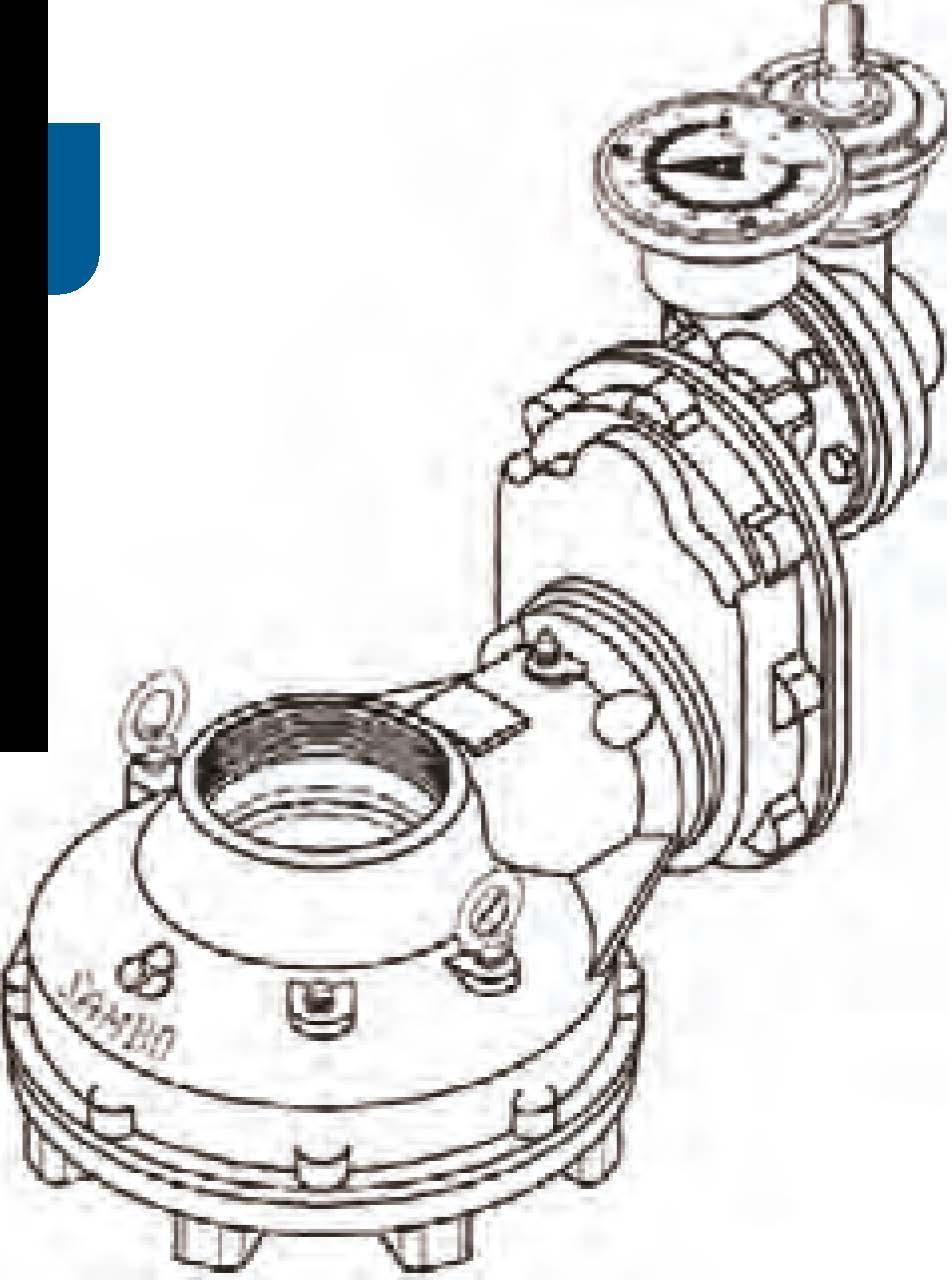

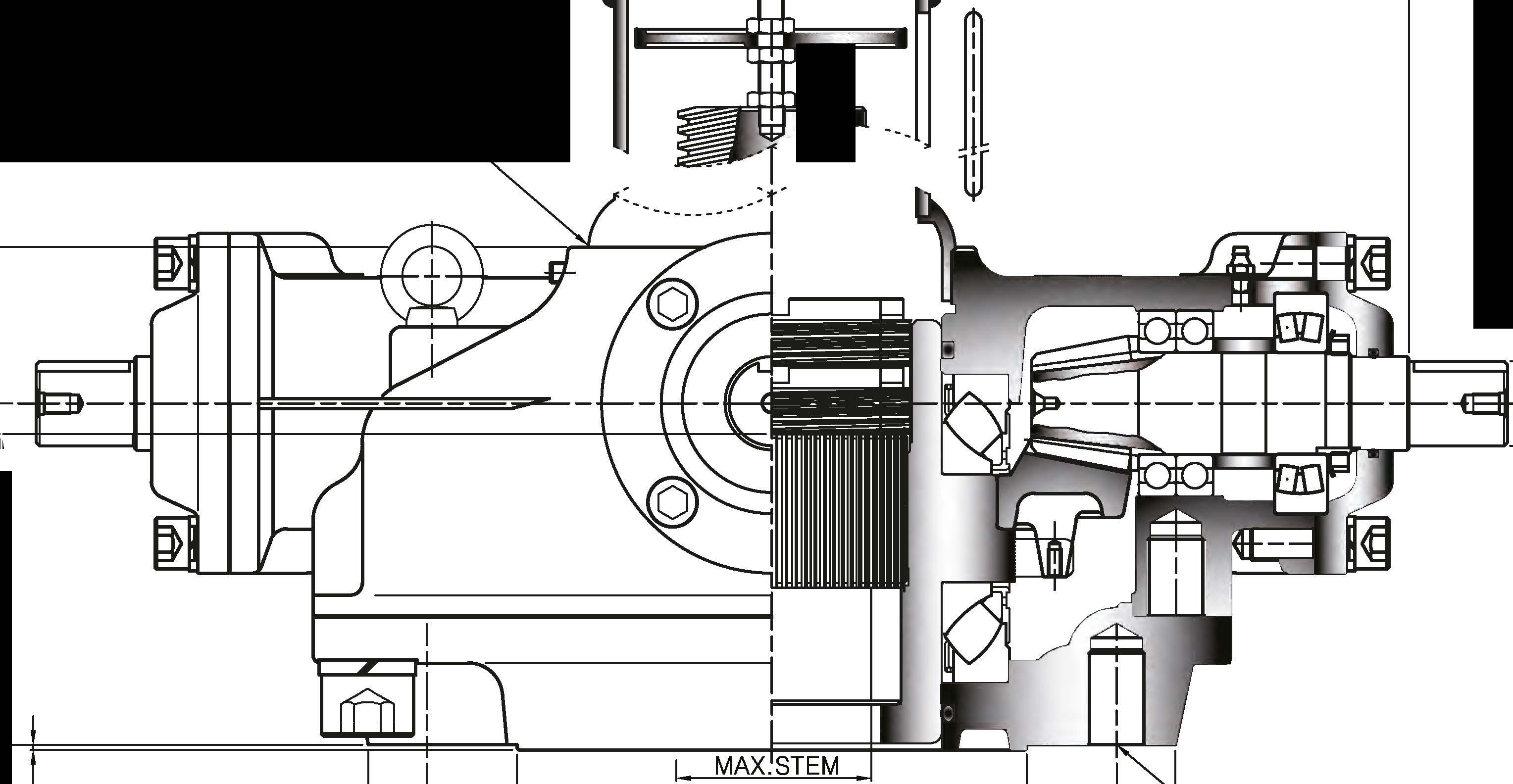

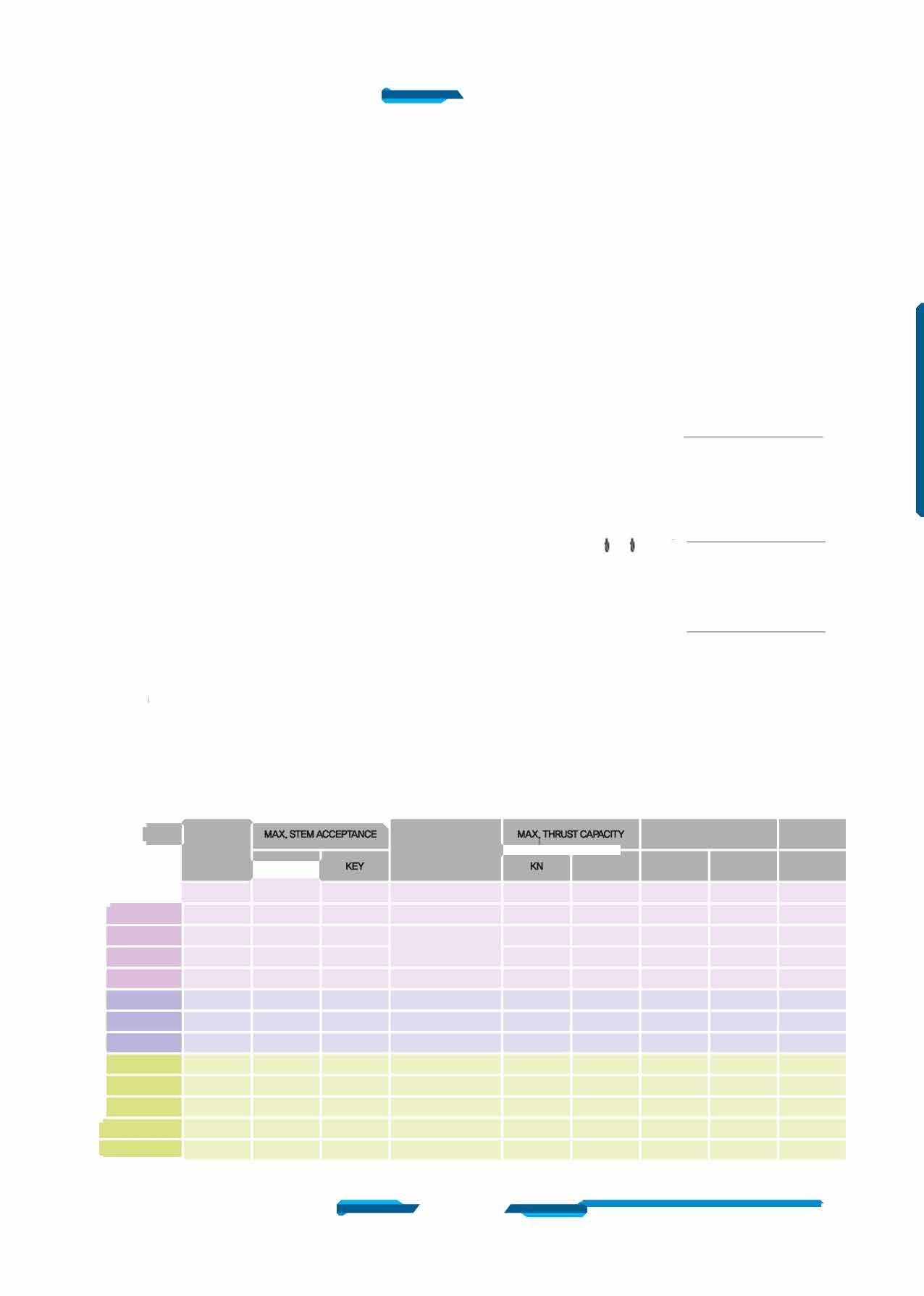

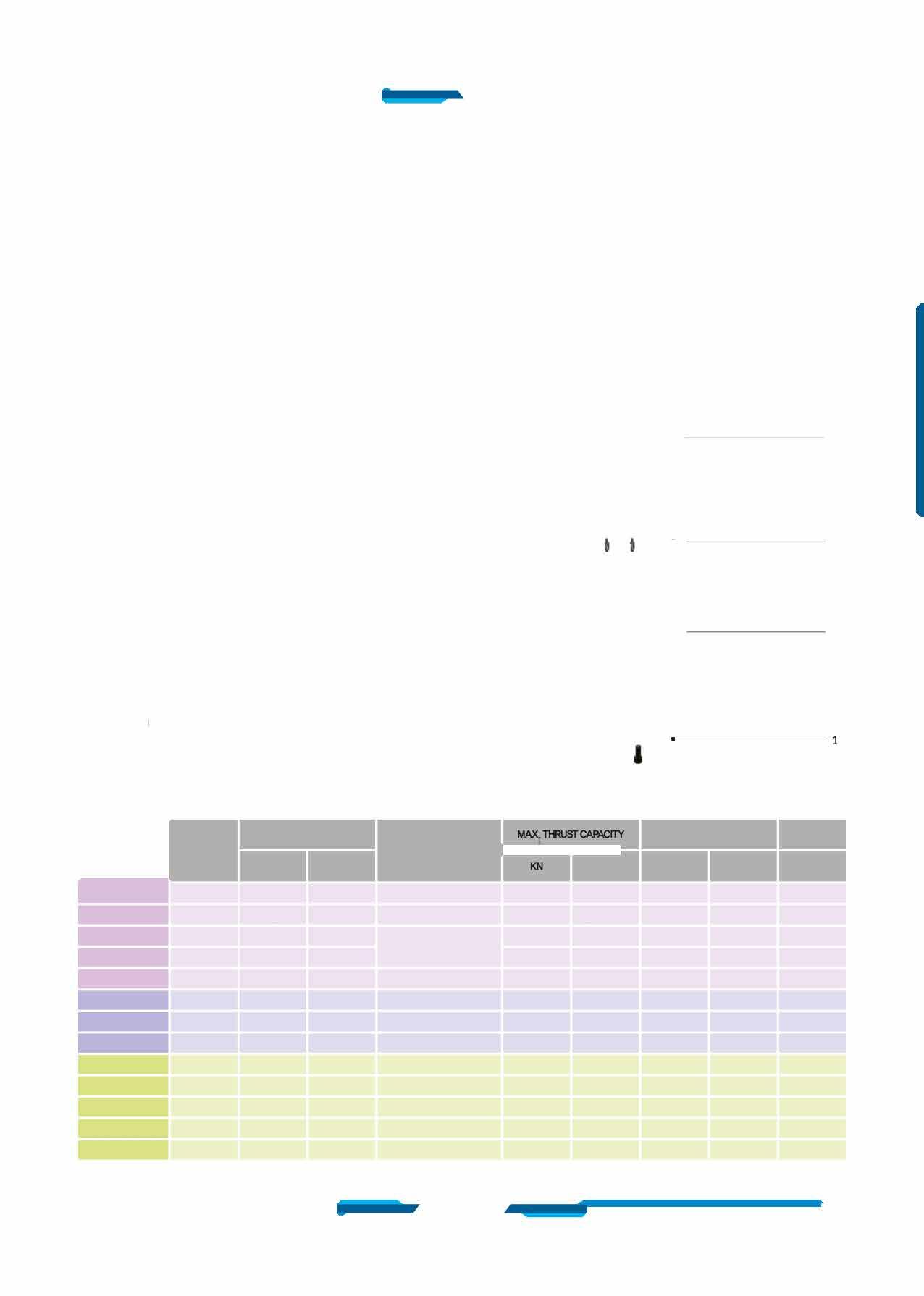

TheSB-VSeriesofSpiralBevelGearrangesupto75,DD□Nm (55,317ft-lbf}

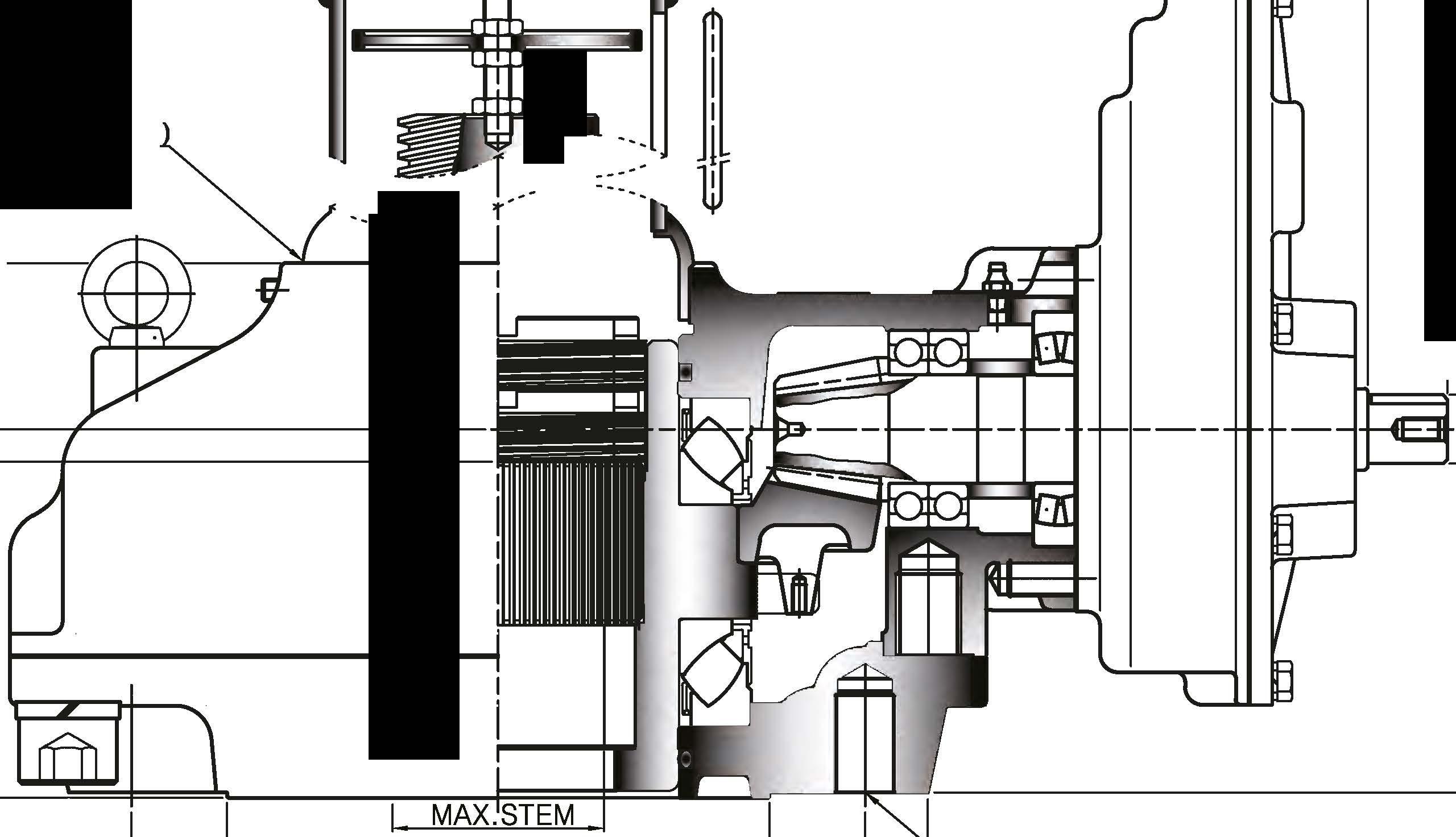

Stem capacities are up to 230mm (9.05inch).

Torque and Thrust capacities up to 7,3DDKN (2,585,300lbf}

A high Load design, type SB-VH is also available ranging up to 142,DD□Nm (1□4,734ft-lbf).

Thrust capacities up to 11,SDDKN (2,585,30Dlbf) stem capacities are up to 270mm (10.53inch).

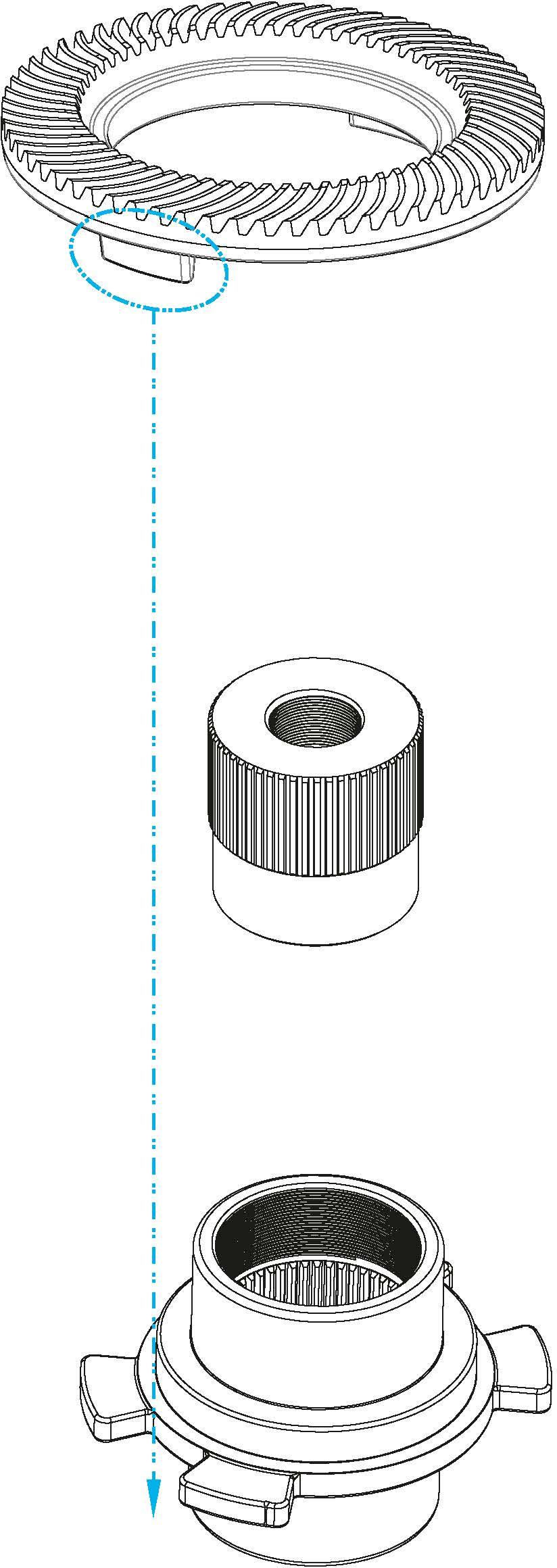

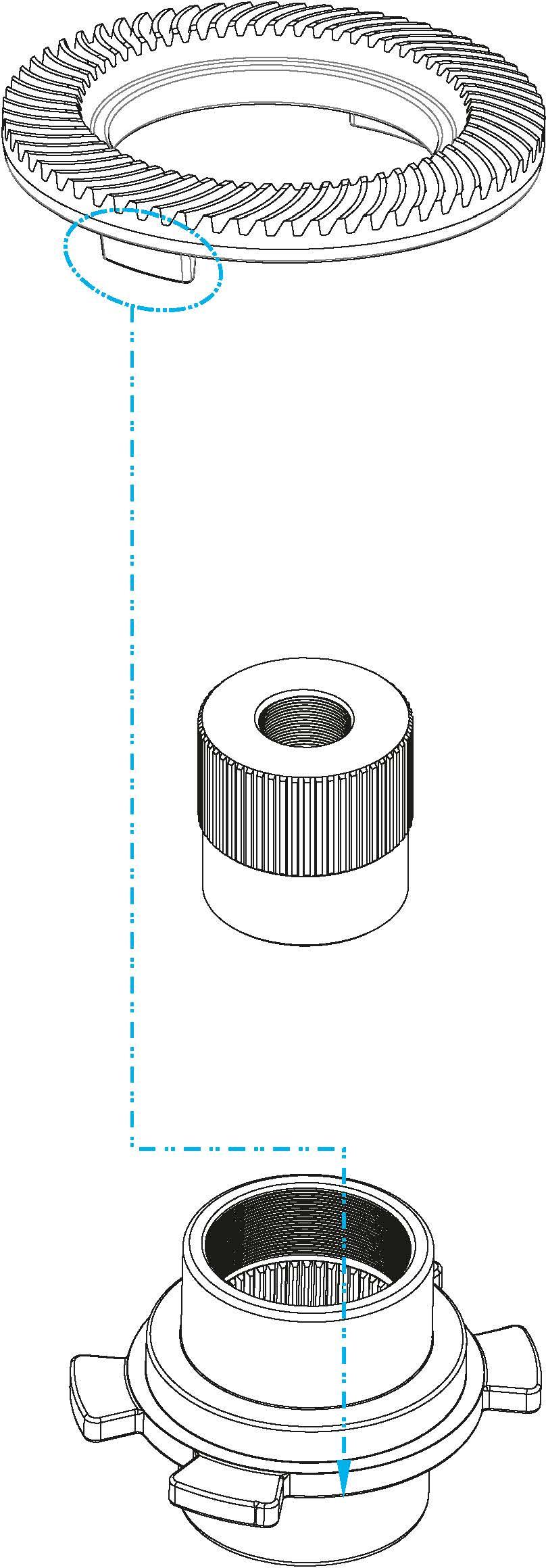

® Dual Locking Nuts

This design incorporates dual locking nuts which provide a jam Effect for positive locking. No set screw or pinning is required.

(Z) Stem Nut

A unique top Entry Replaceable stem Nut.

After long years of service can be easily replaced without removing Gear from value.

IYlaterial is high tensile brass providing both corrosion and abrasion resistance.

@ Drive Sleeve

Also Ductile Iron, Class 55-45-12. supports both axial and radial loads.

® Housing and Base

All external castings are Ductile Iron. Class 55-45-12, Tensile Strength of 55,DDD psi This provides high strength and excellent impact resistance.

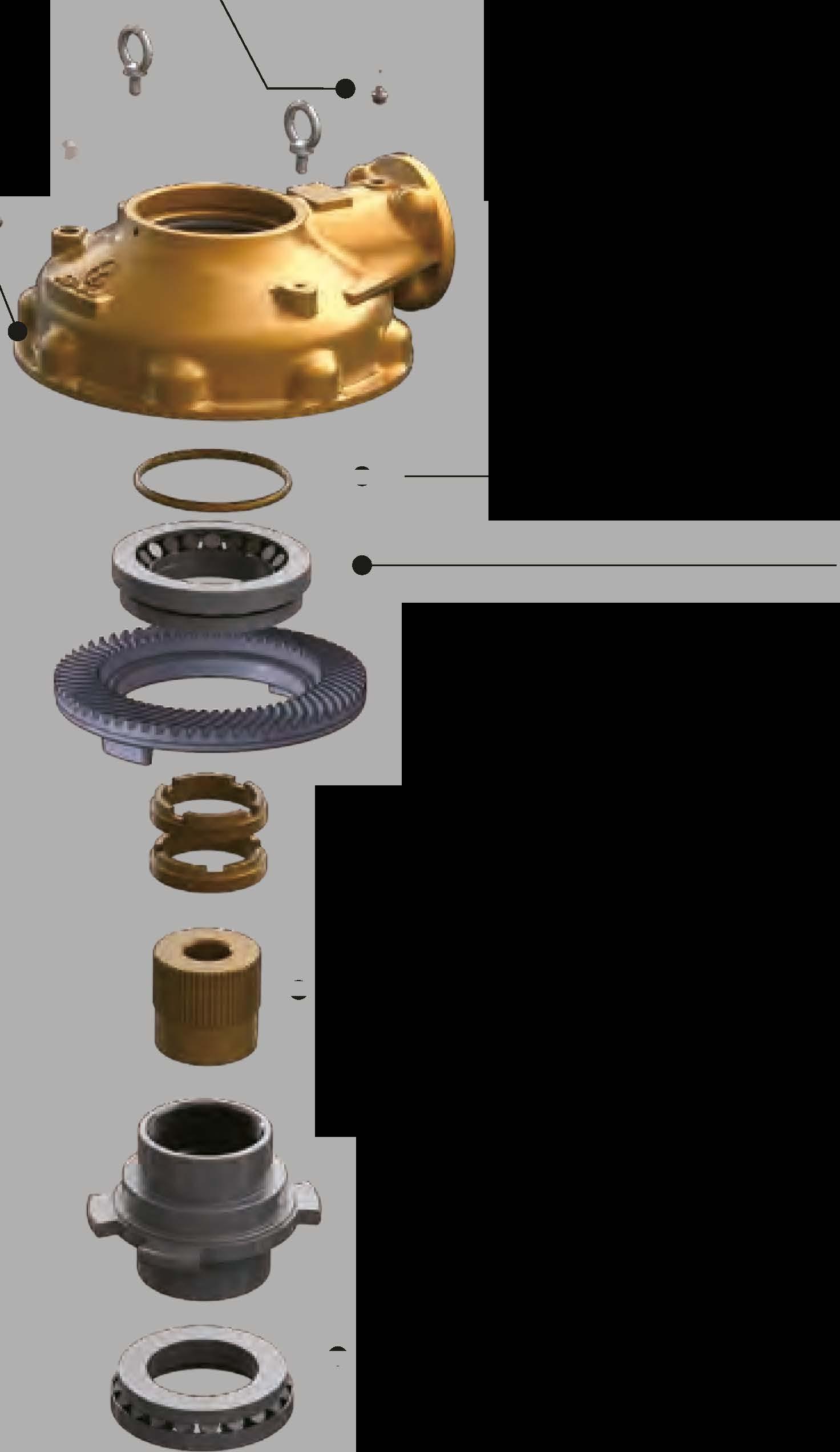

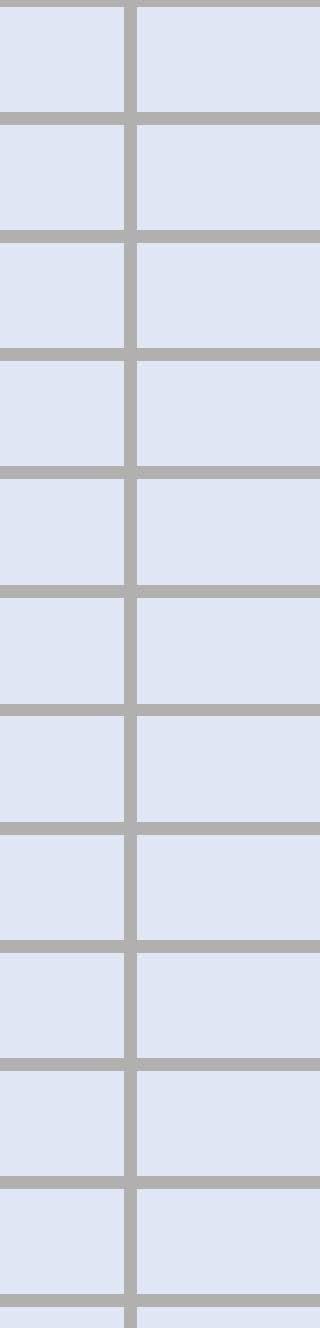

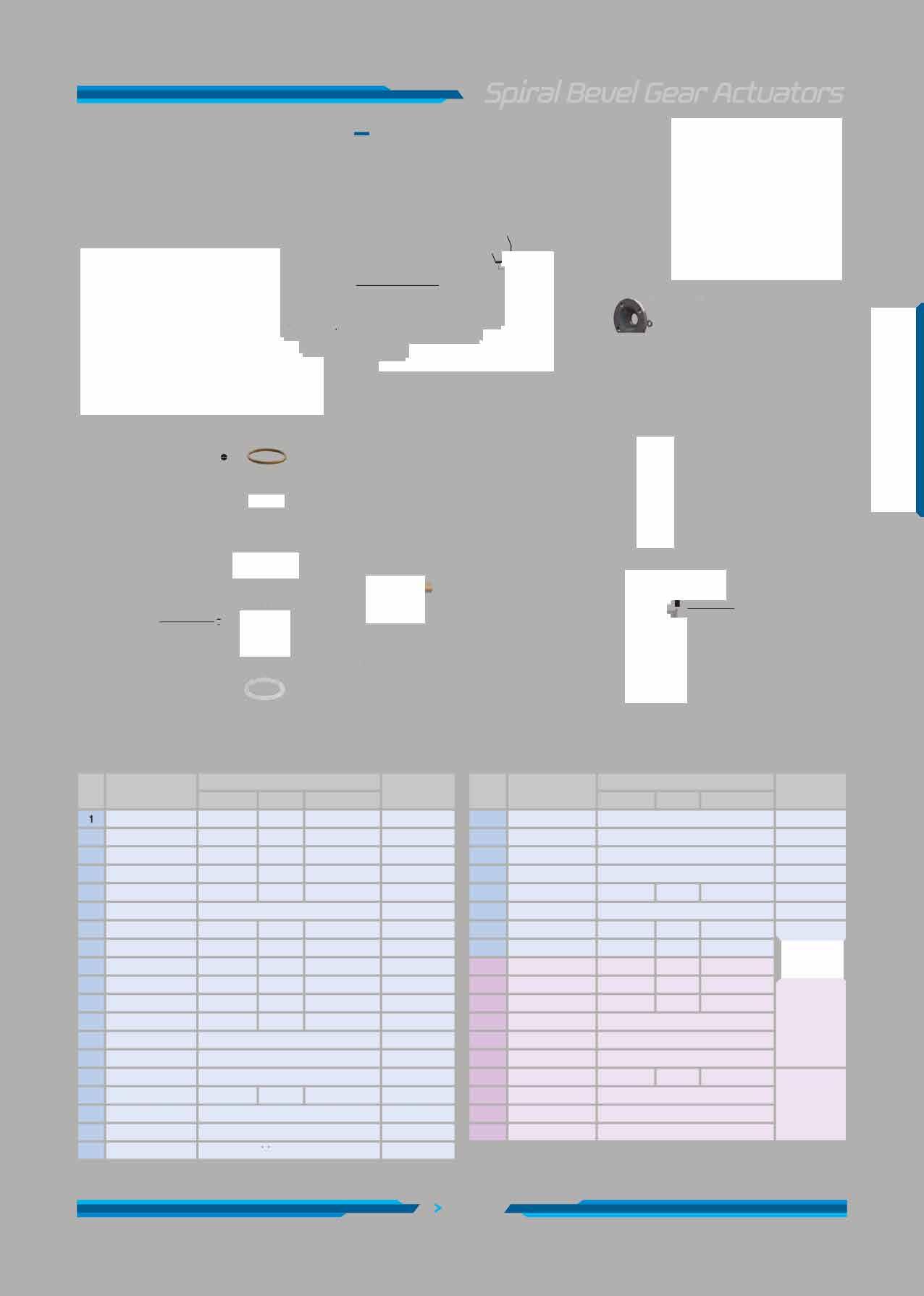

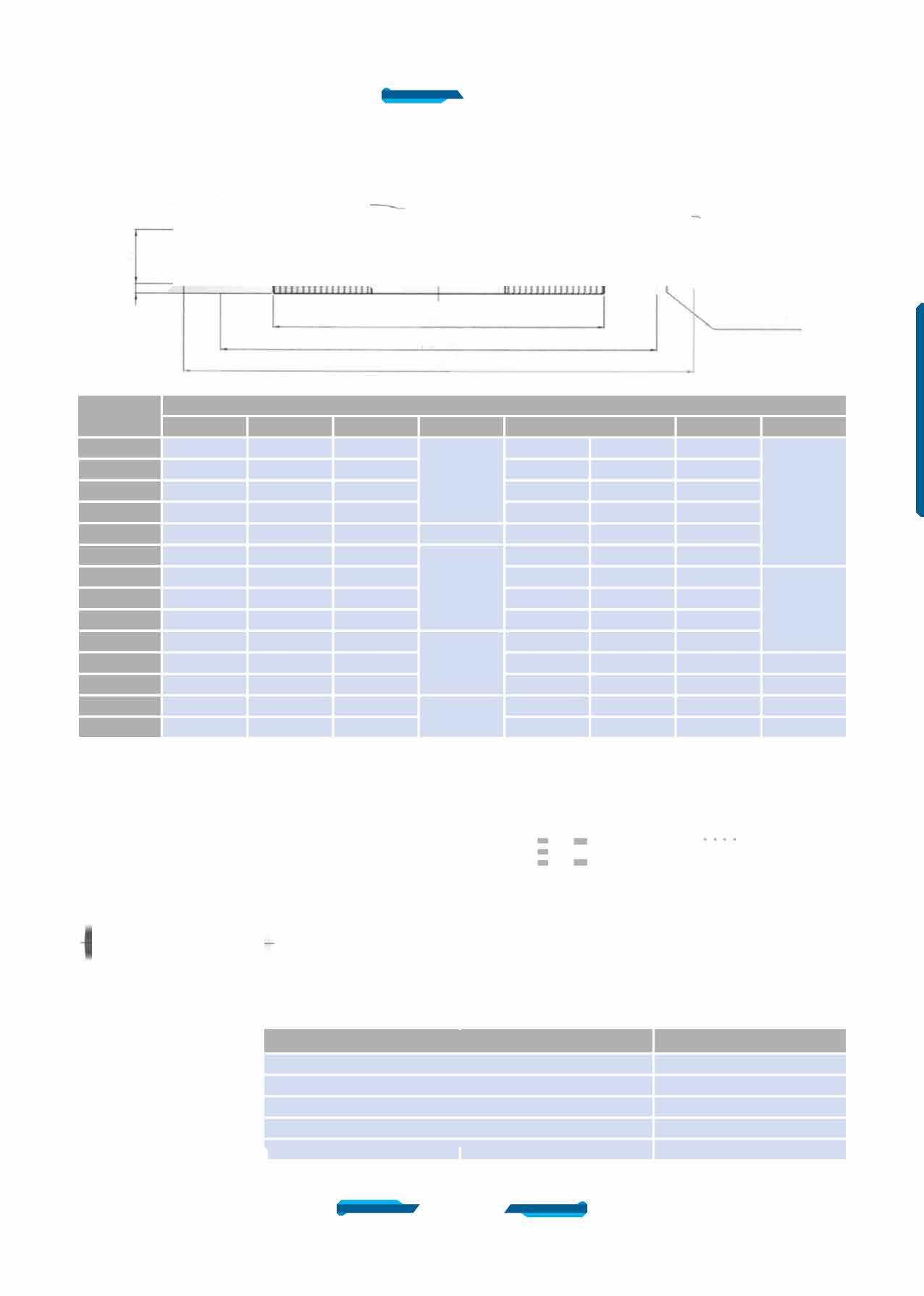

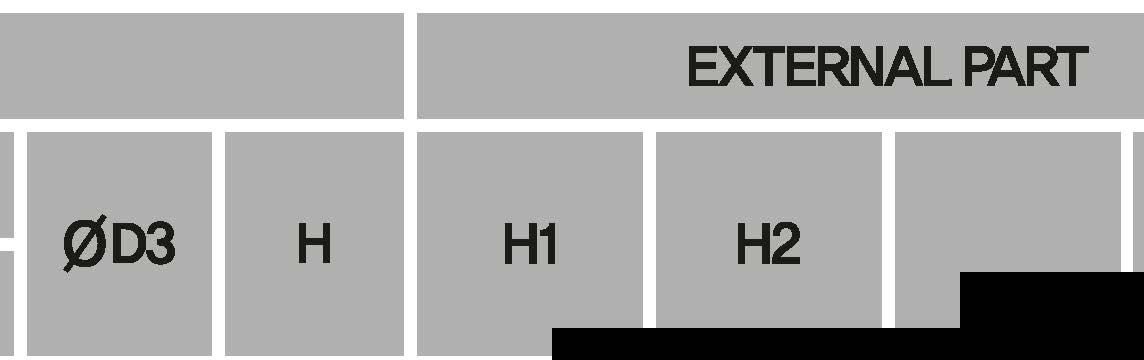

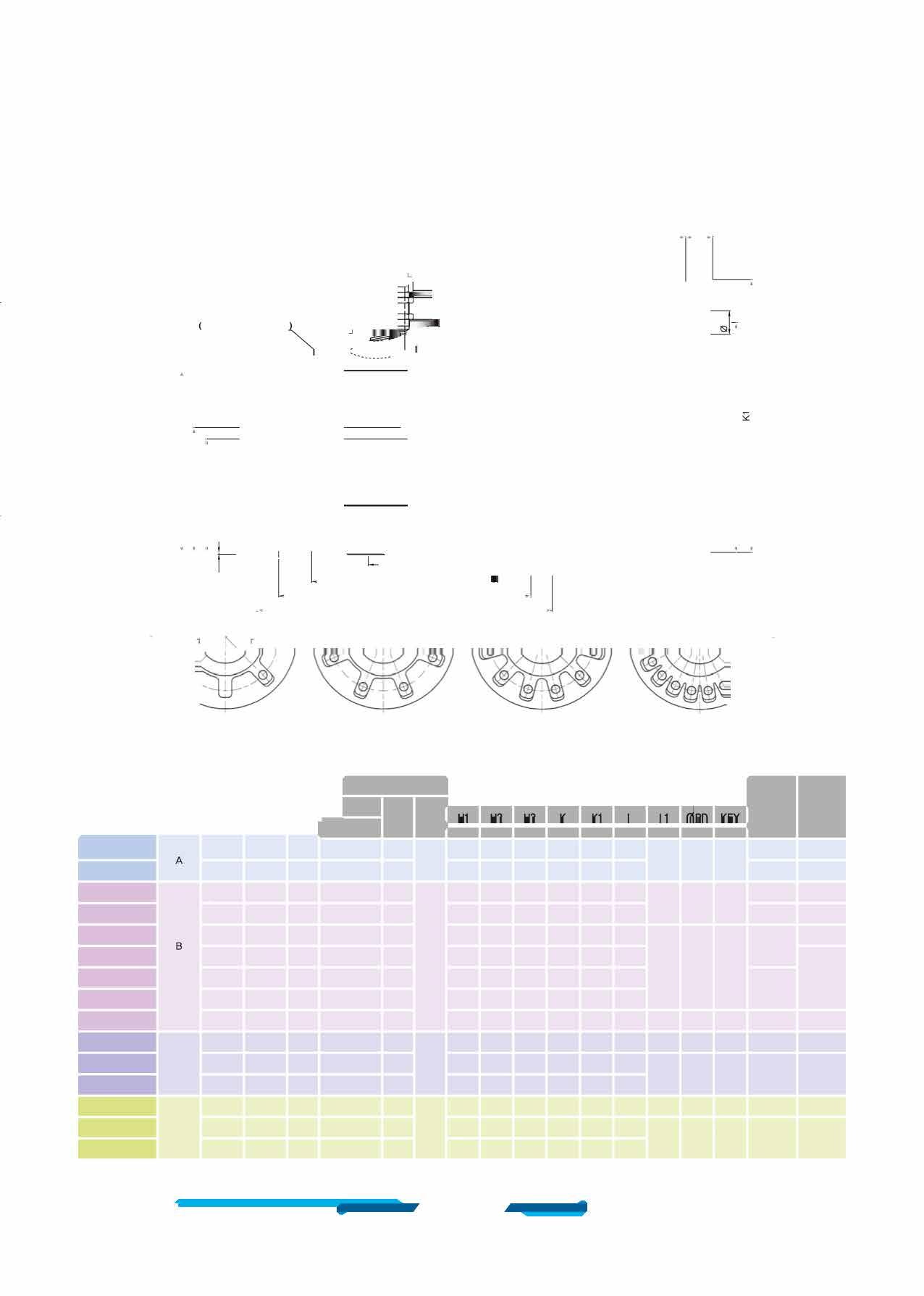

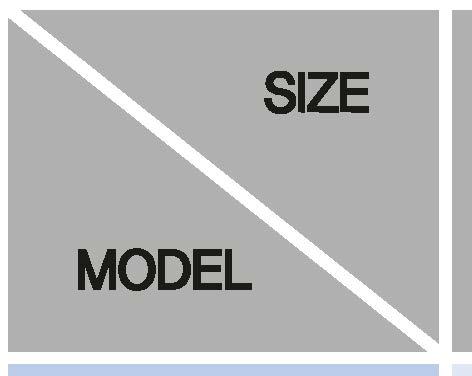

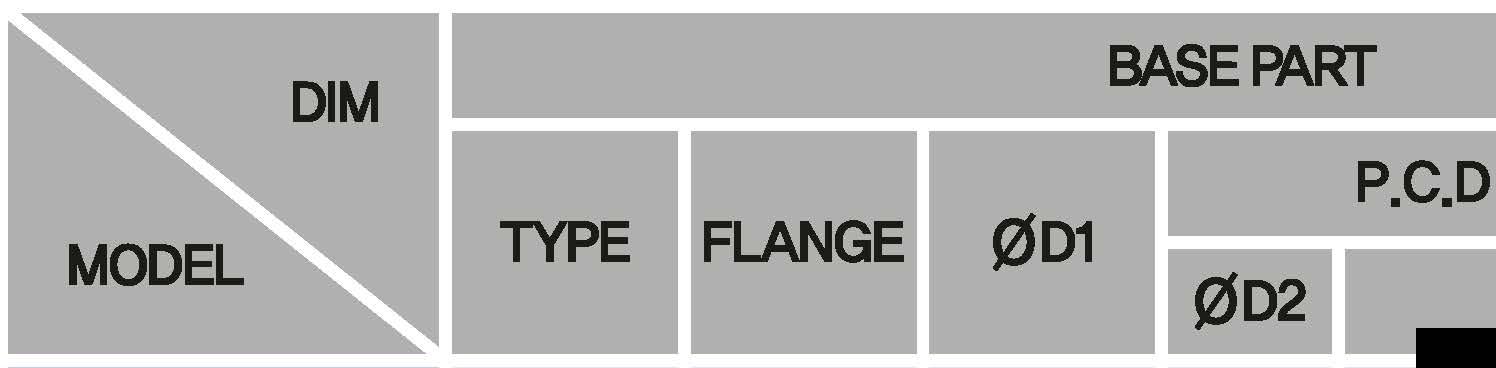

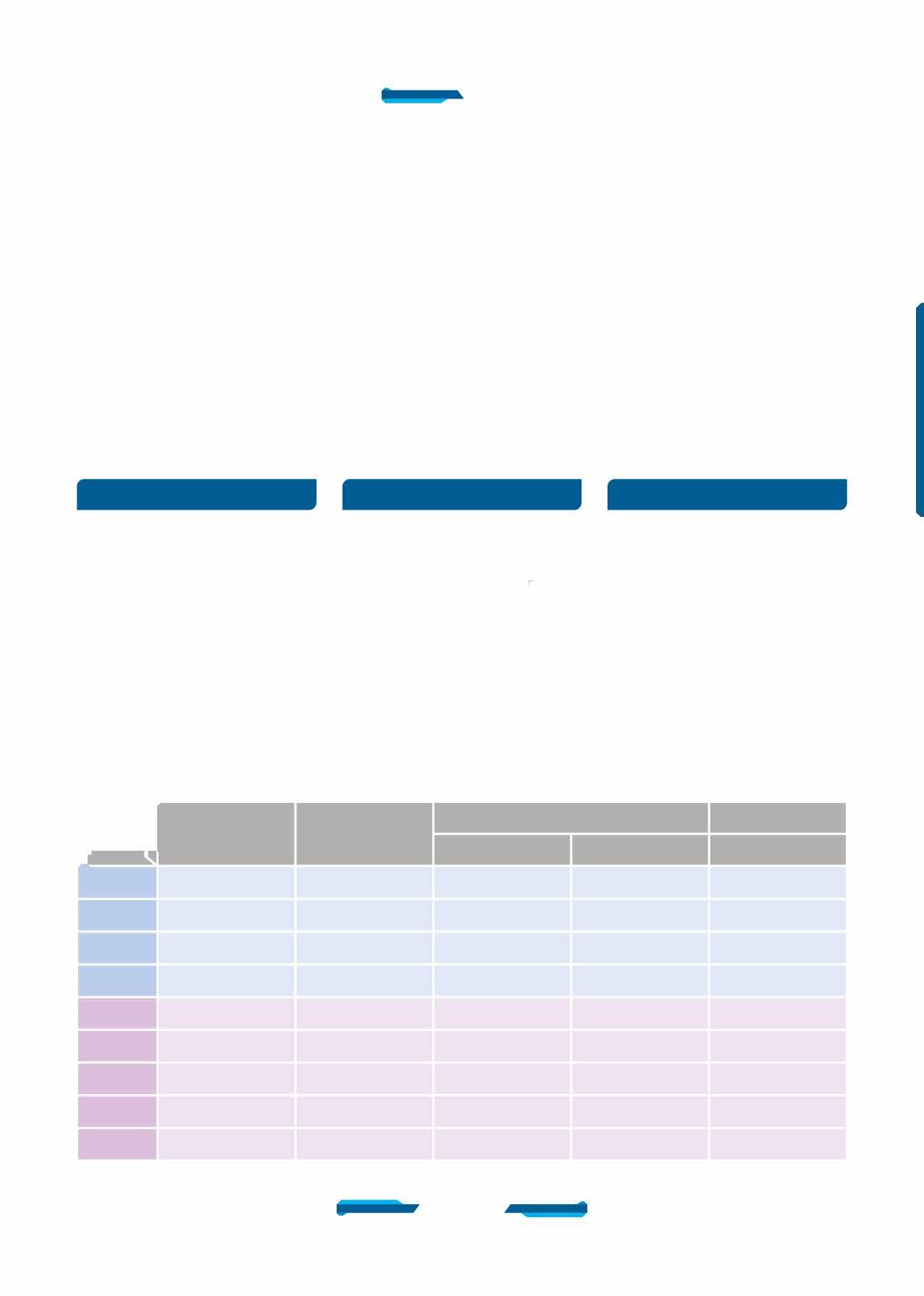

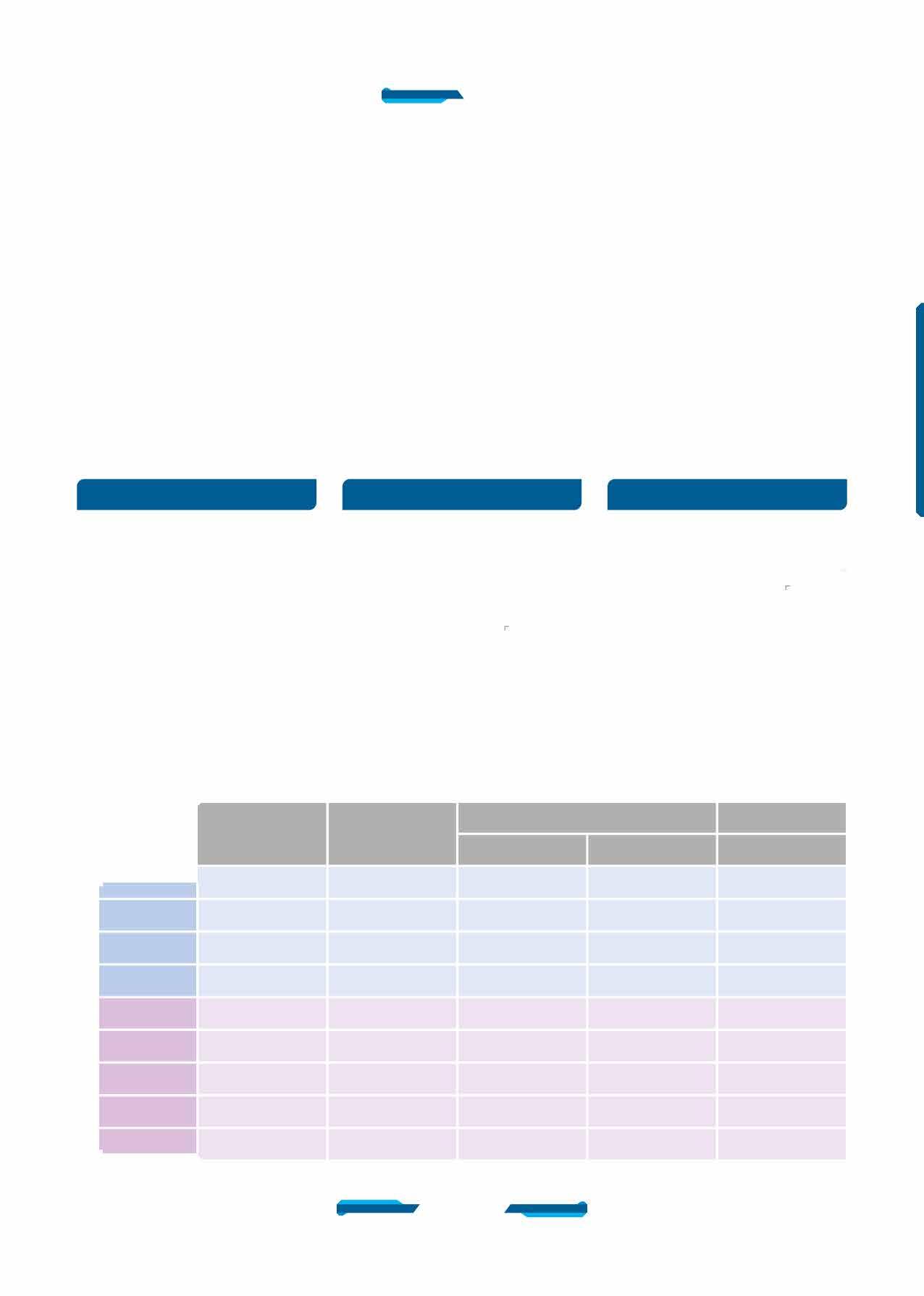

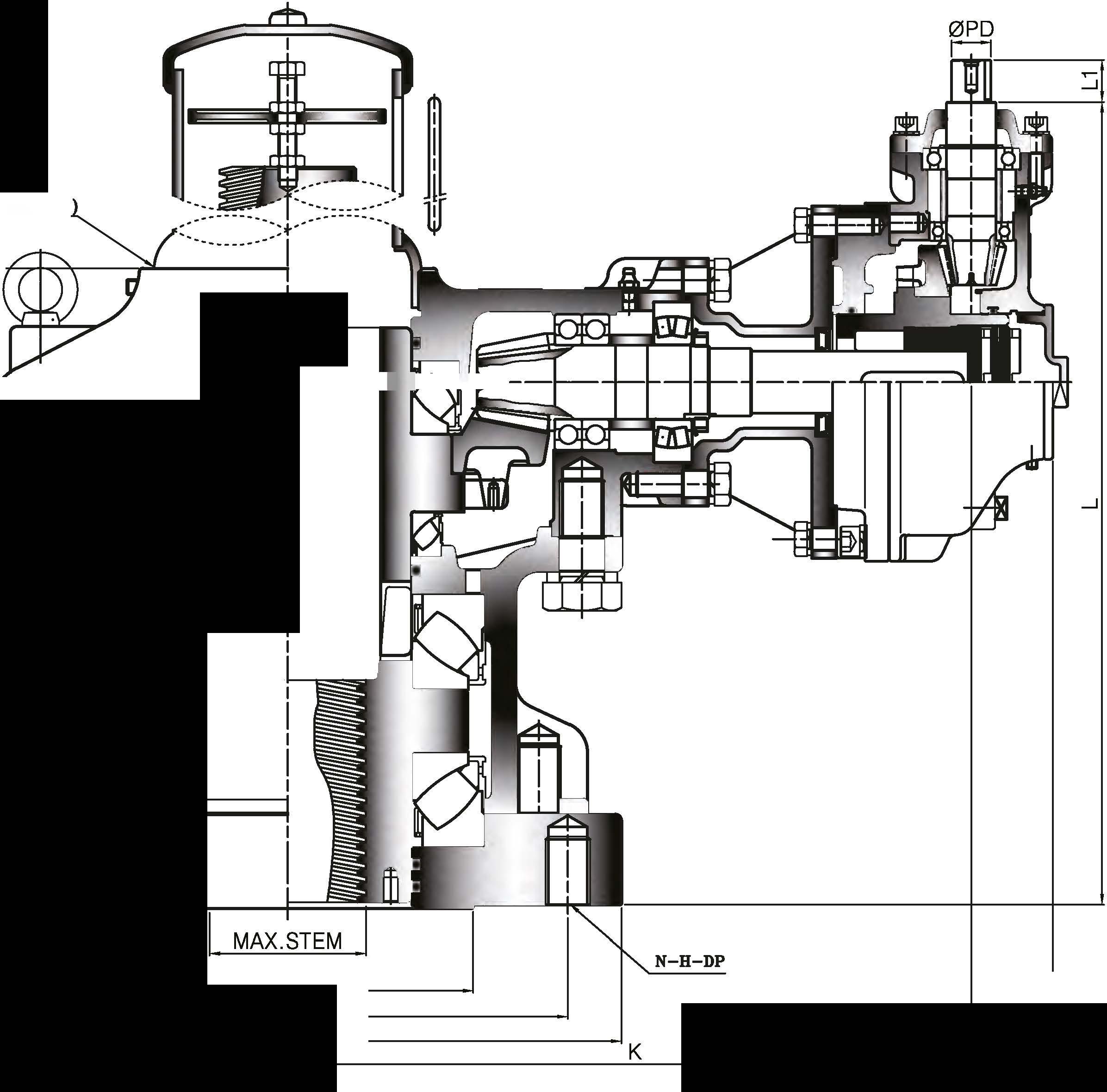

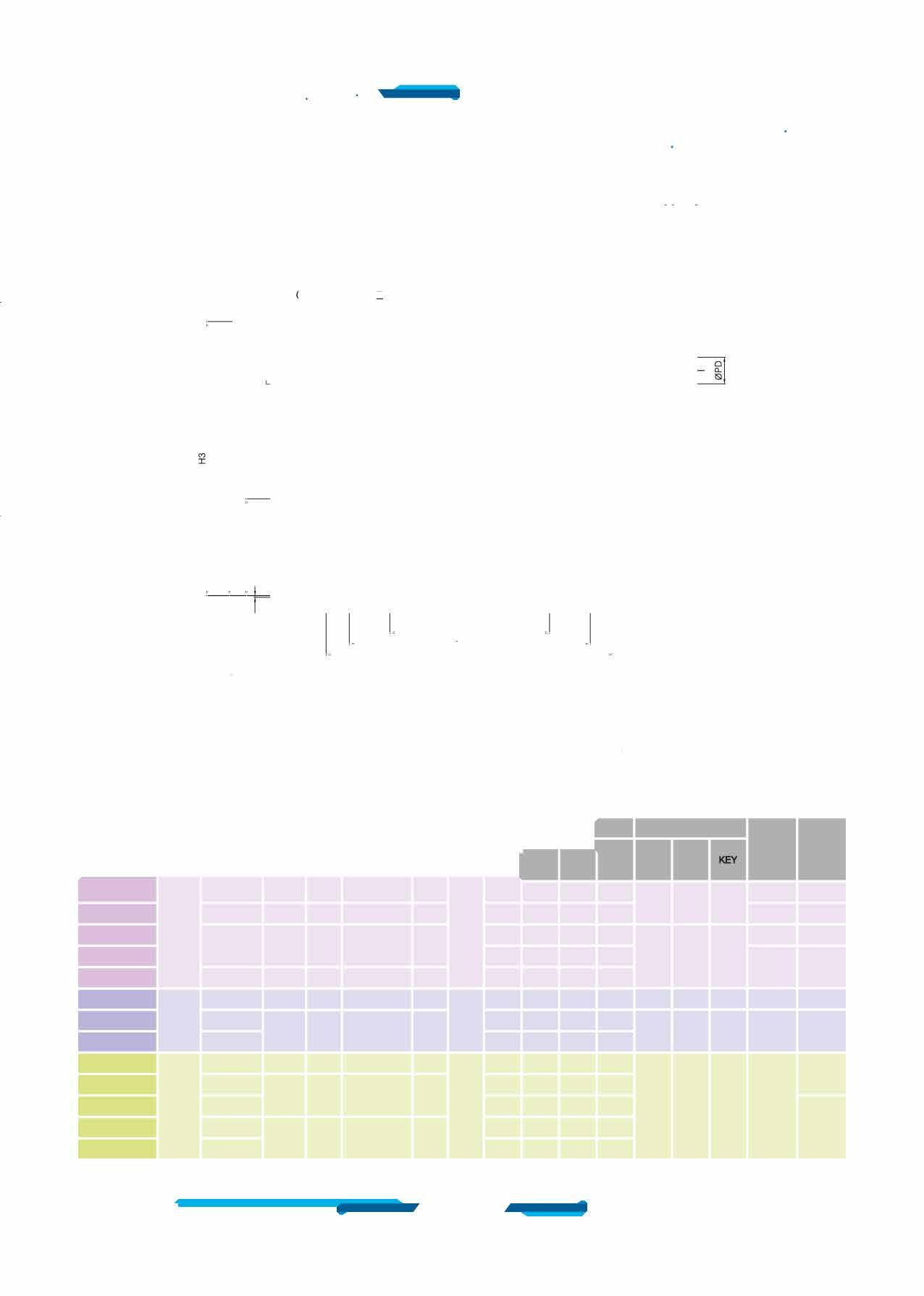

DESCRIPTION

Housing

Base

SpiralBevelGear

SpiralPinion

DriveSleeve

DualLockNuts

EndCap

WrenchBolt(S/W)

WrenchBolt(S/W)

RadialBallBearing

SphericalRollerBearing

ThrustBearing

GreasePlug

O-Ring

O-Ring

Collar

Bearing Washer

BearingNut

GreaseFitting

SetScrew

EndCapGasket

BaseGasket

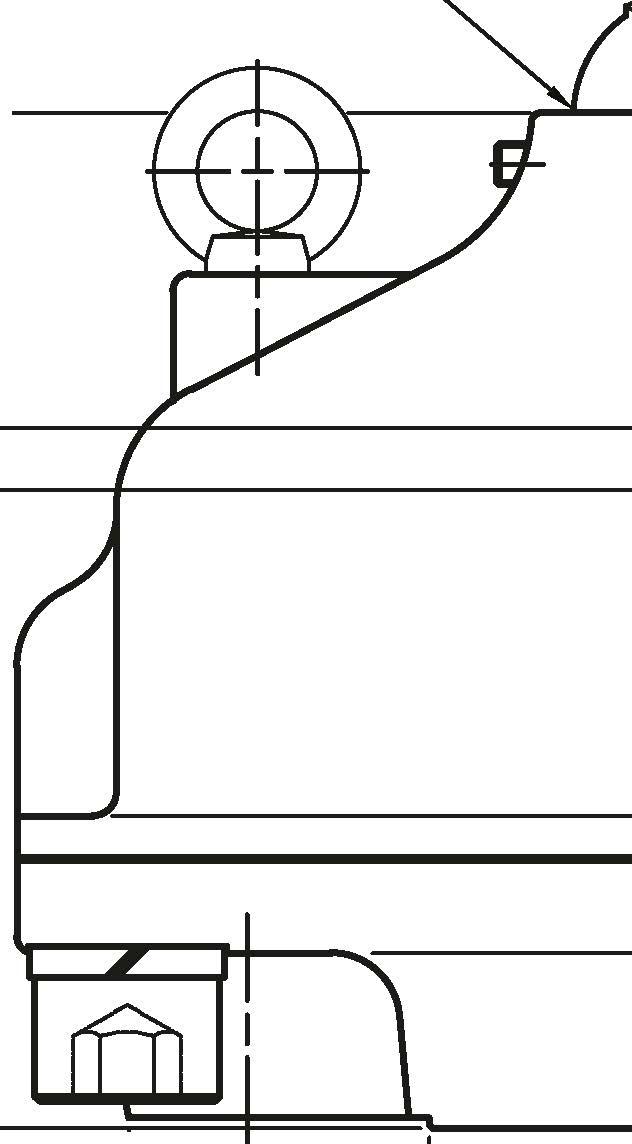

EyeBolt

OP-01. OP-02. OP-03. OP-04. OP-05. OP-06. OP-07. OP-08. OP-09.

OP-10.

StemNut

HandWheel

Key

NamePlate

Washer

HEX.Bolt(S/W)

StemCover

IndicateBolt

HEX.Nut

Indicator

MATERIAL

NAME

DuctileIron

DuctileIron

CarbonSteel

CarbonSteel

DuctileIron

CarbonSteel

DuctileIron

AlloySteel

AlloySteel

SpecialSteel

SpecialSteel

SpecialSteel

Steel+Galvanizing

Silicon

Silicon

SteelPipe

Steel

Steel

Steel+Galvanizing

StainlessSteel

Non-Asbestos

Non-Asbestos

Steel+Galvanizing

Bronze

SteelPipe �

CarbonSteel r

StainlessSteel

StainlessSteel

StainlessSteel

SteelPipe

Steel+Galvanizing

Steel+Galvanizing

Plastic

A536-65-45-12

A536-65-45-12

A576-1045

A576-1045

A536-65-45-12

A576-1045

A536-65-45-12

A322-4135

A322-4135

A295-52100

A295-52100

A295-52100 SGP ==i

1 All castings are Ductile Iron, FCD-450 (ASTIYl Class 65-45-12)

2. In case of option for special request, it can be worked Nickel coating, high tensile stainless.

3. Also, the material can be changed as ALBC3(Aluminium Bronze), steel(A576-1□45), A439 Gr □2C (Austenitic ductile iron casting), etc.

4. □-Ring Seal & Lubricant: Standard is Silicon & Buna "N", temperature range -20· C to +120° C (-4° F to +248° F).

Standard lubricant is Zenith EPSB 2, temperature Range -20' C to +200' C (-4' F to +392' F). Other option are: High Temperature Viton □-Ring Grade V75, Temperature Range -30° C to +200° C (-22· F to +392° Fl Lubricant - Zenith SYN WS2 Temperature Range -30° C-400° C (-13° F-752° F) Low Temperature Silicon □-ring, Temperature Range -6□° C to +150' C (-76' F to +302' F) Lubricant - Zenith SBLT60□, Temperature Range -60' C-120' C (-76' F-248° Fl

5. SAIYIBD offers a wide variety of Handwheels, Chainwheels, Input Shaft, Locking Devices, etc.

6. SAIYIBD offers a wide variety of stem cover, stainless steel, polycarbonate. Paint: Unless specified, units are supplied with vp134 Red epoxy primer. SAIYlBD can provide finish coating upon request Size and component specitication in this catalogue are subject to change without prior notice for quality improvement • IYlarl< has been changed and updated.

»

Bronze

Steel

Carbon

StainlessSteel

StainlessSteel

Steel

Steel

Steel

Plastic

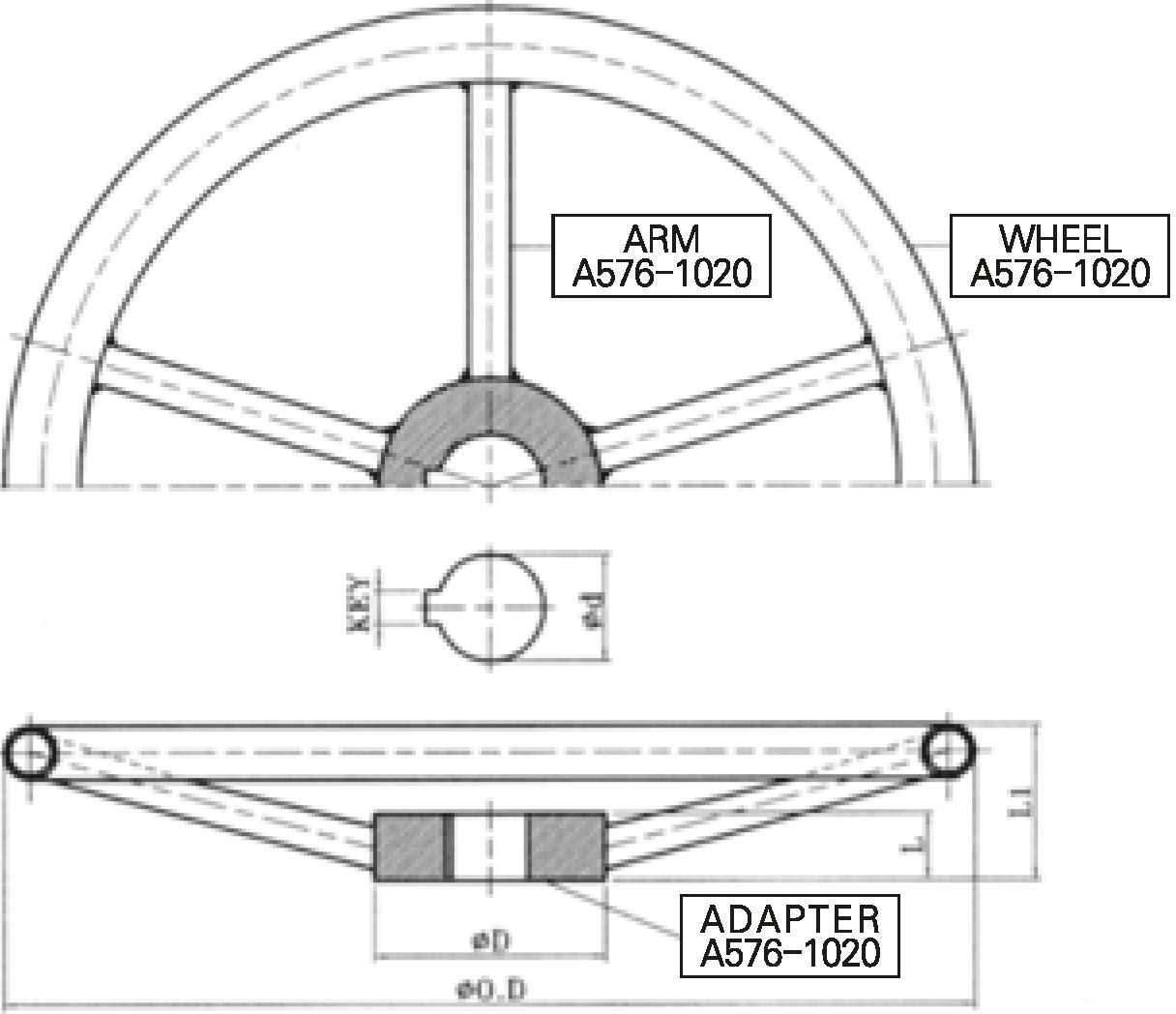

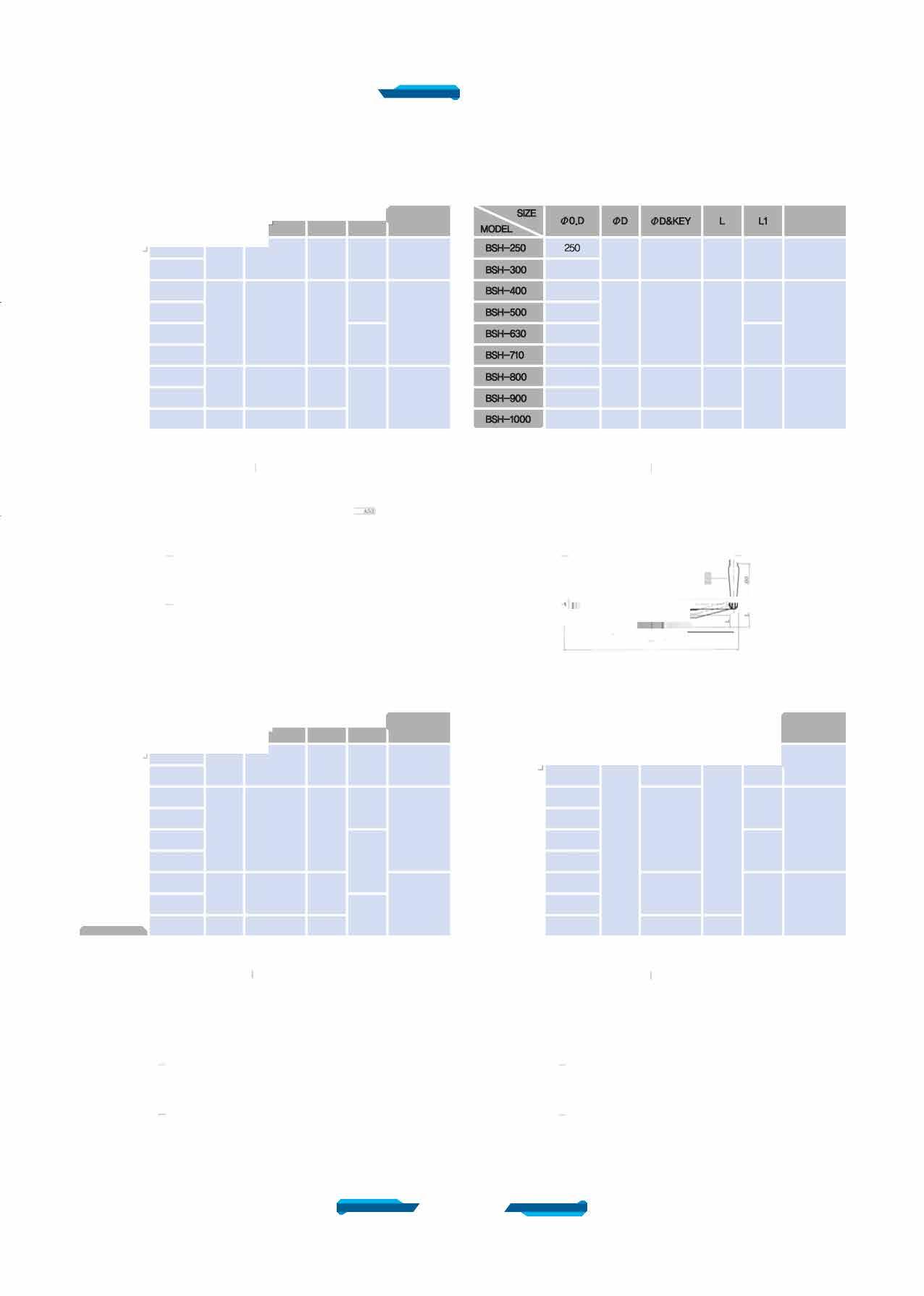

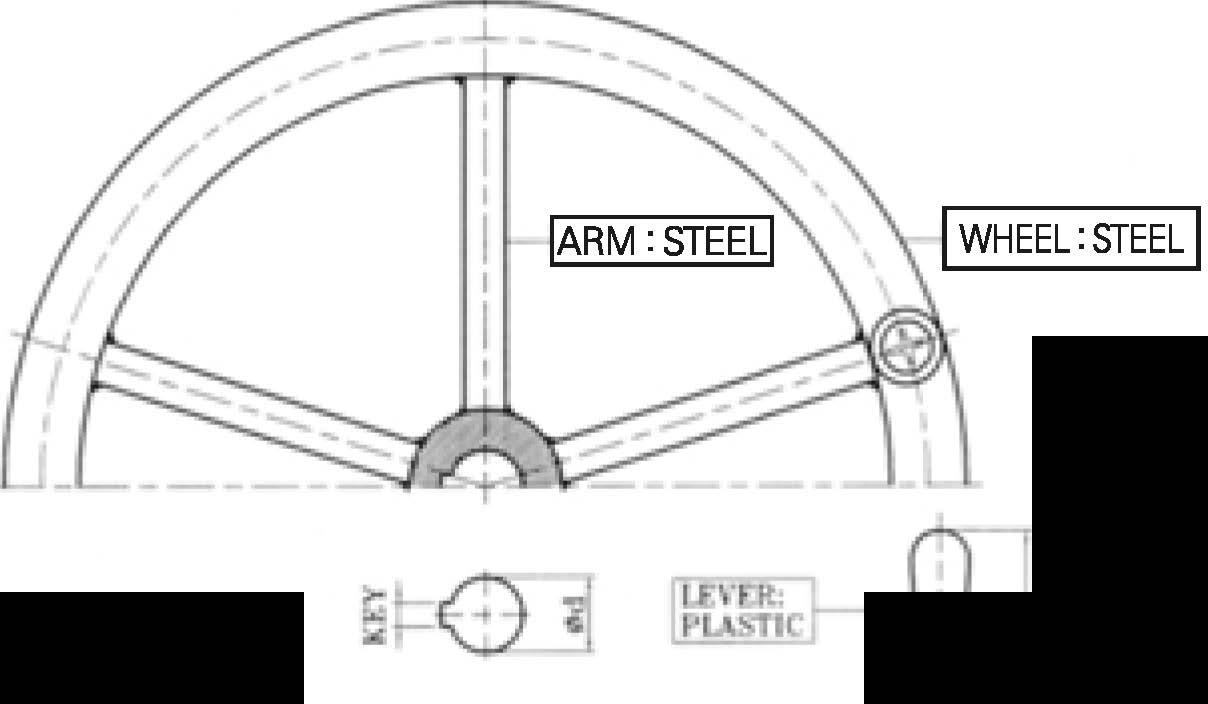

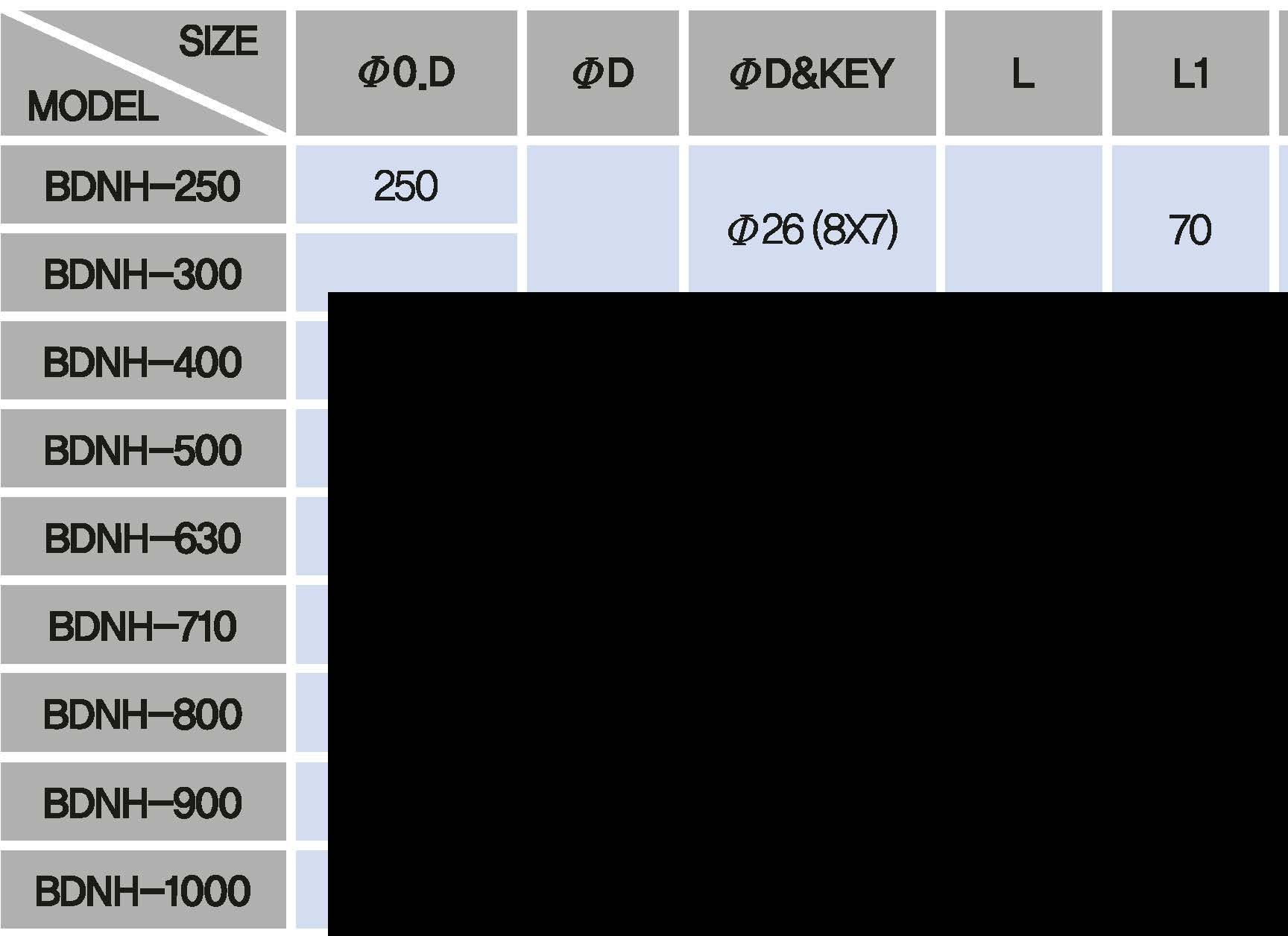

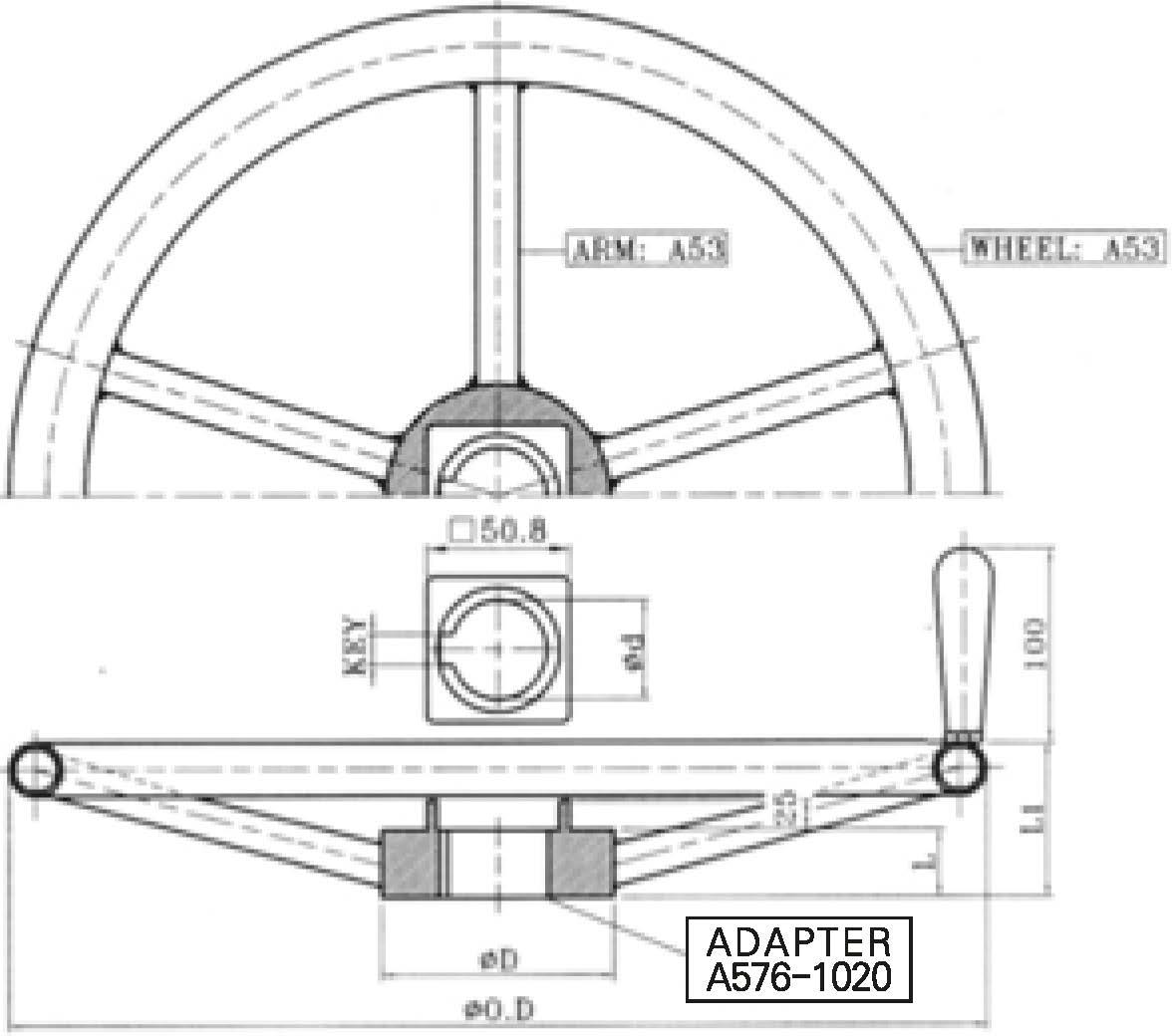

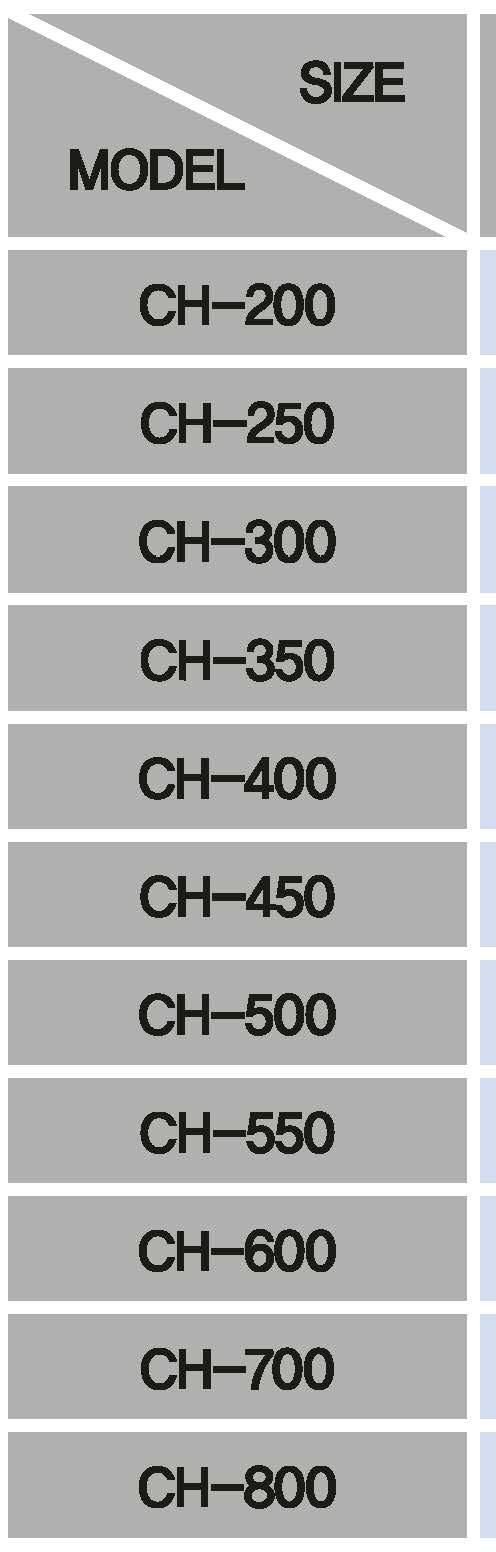

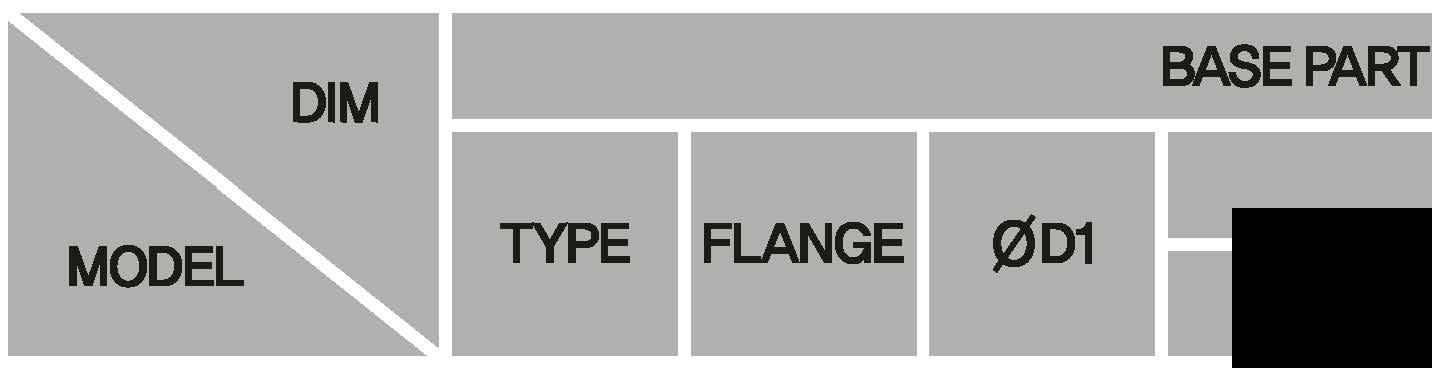

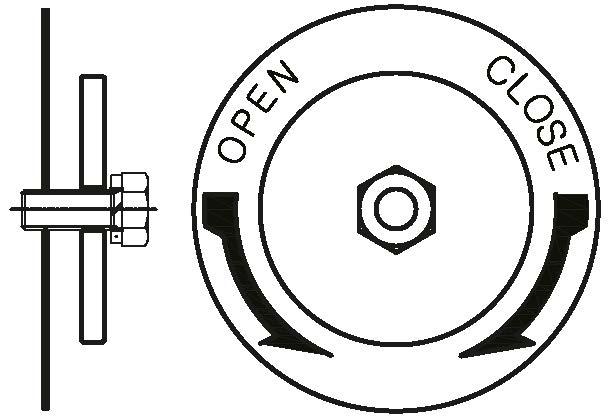

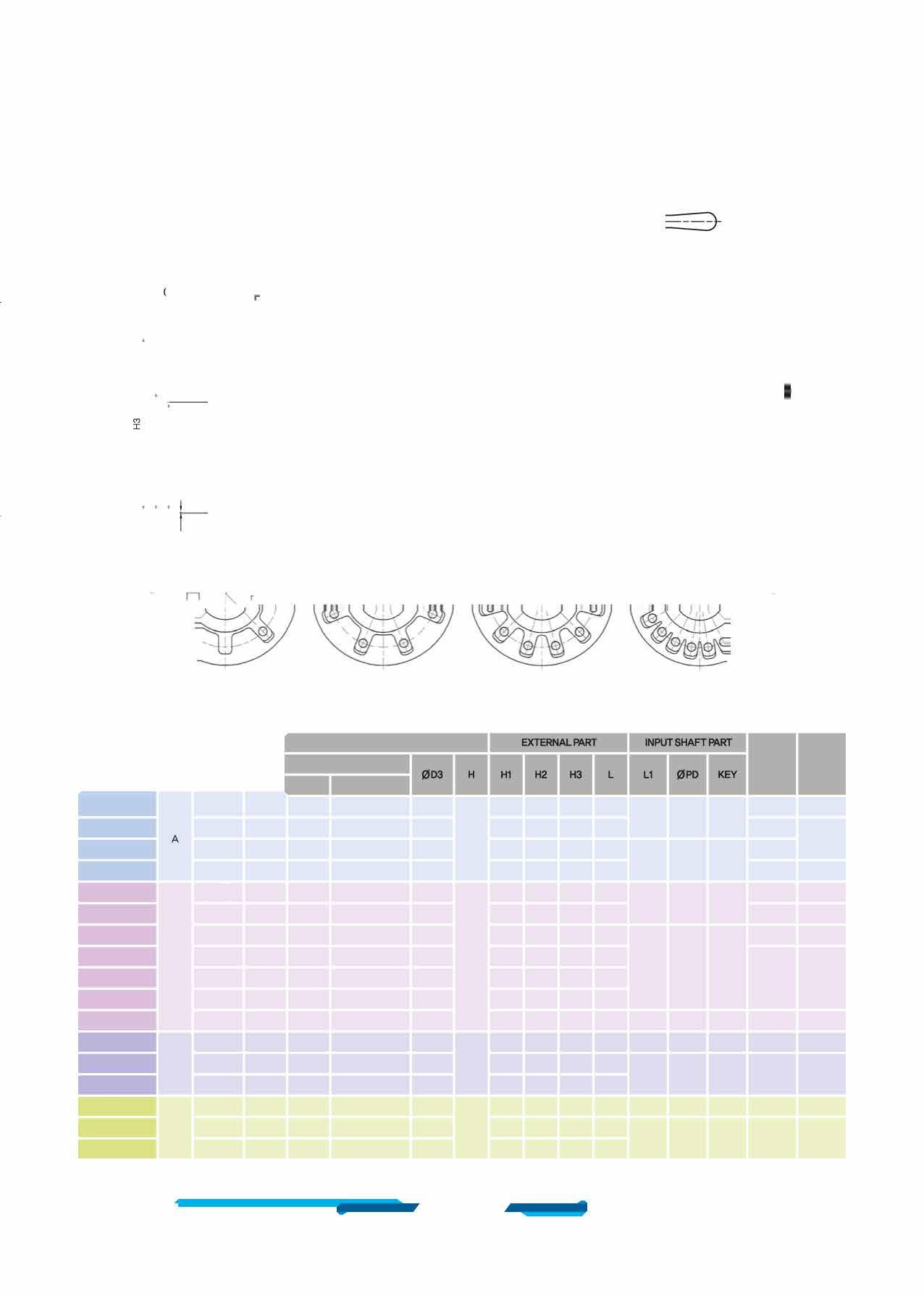

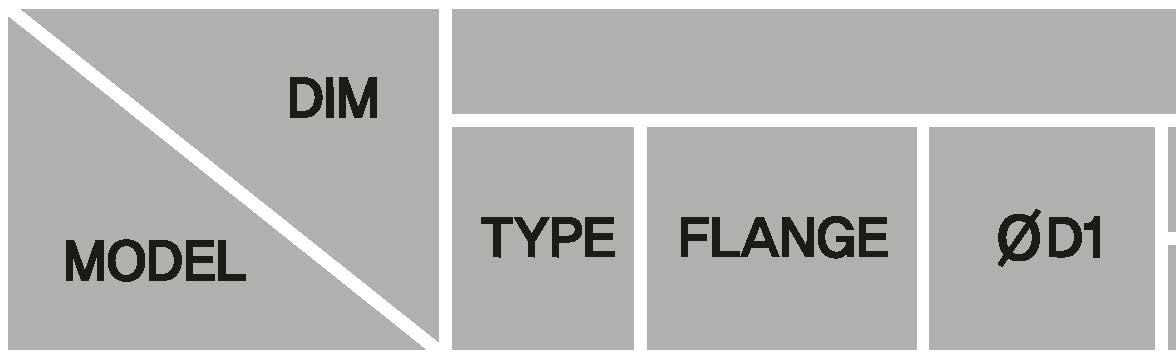

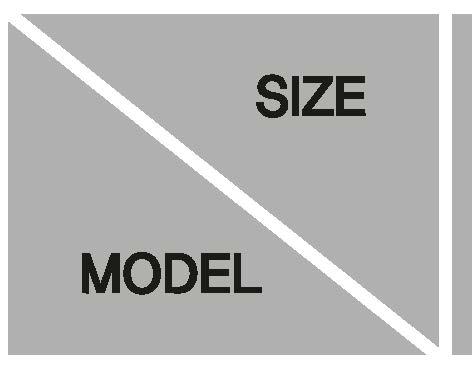

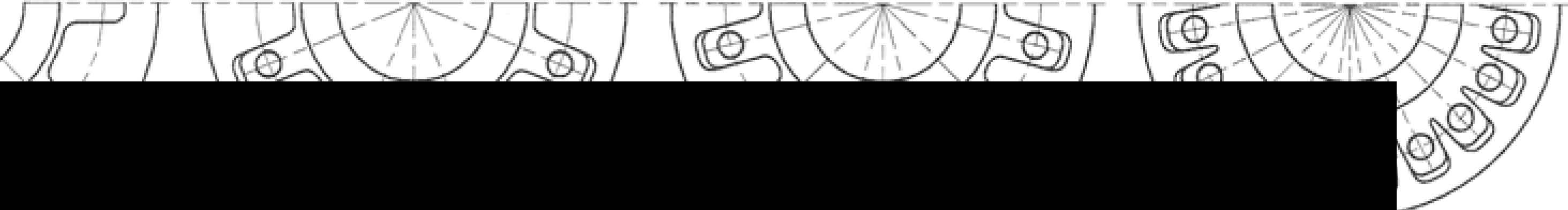

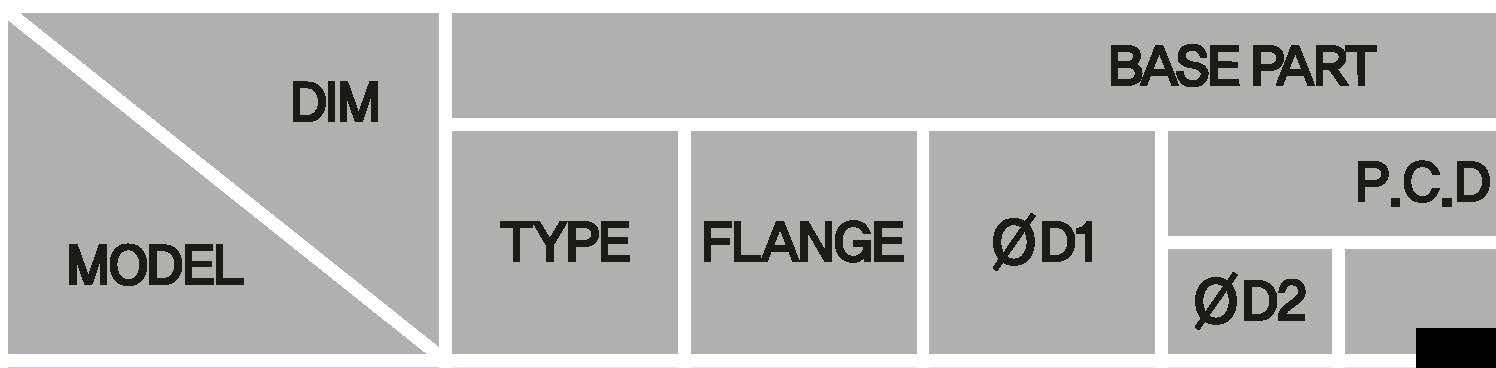

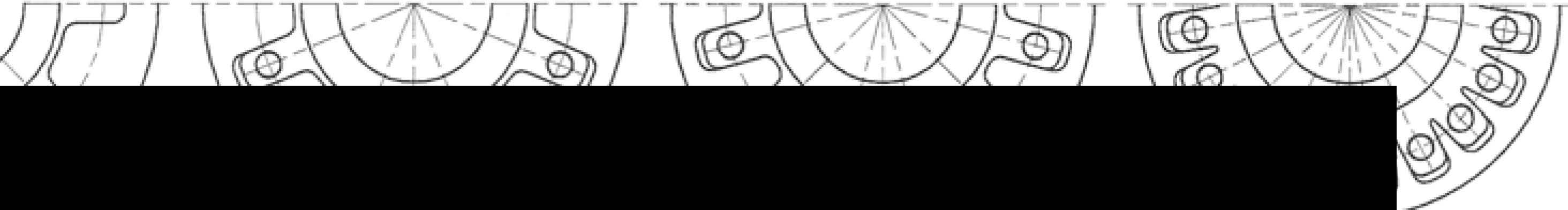

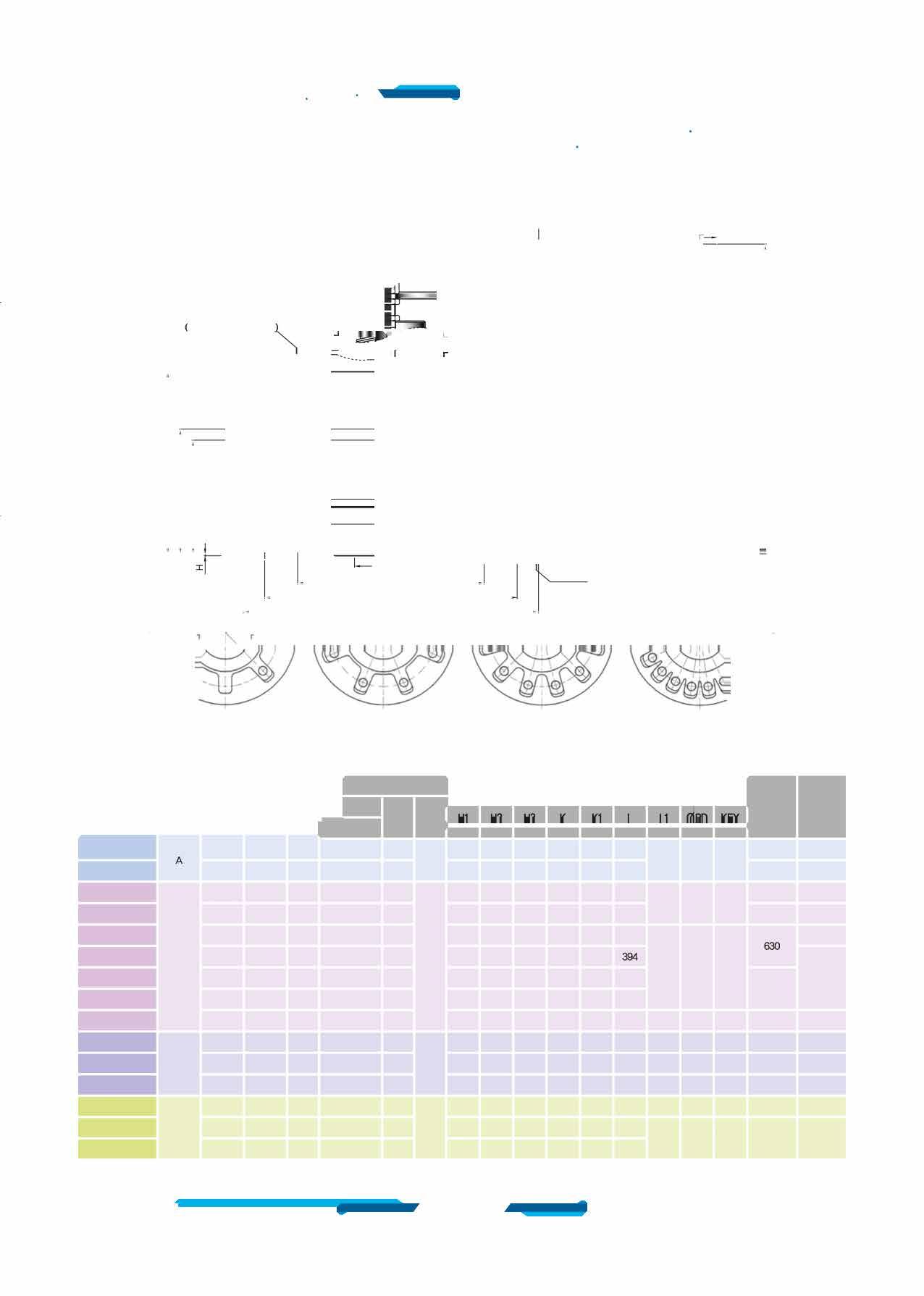

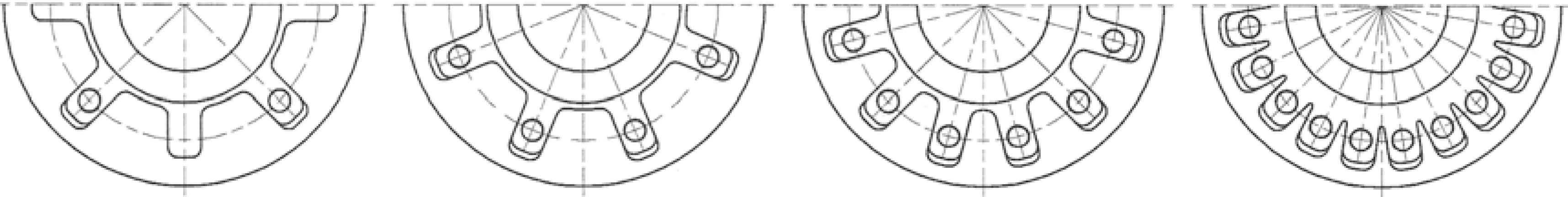

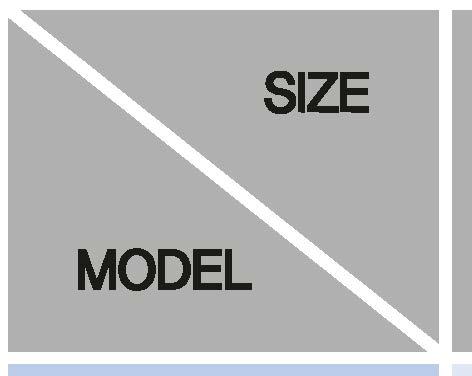

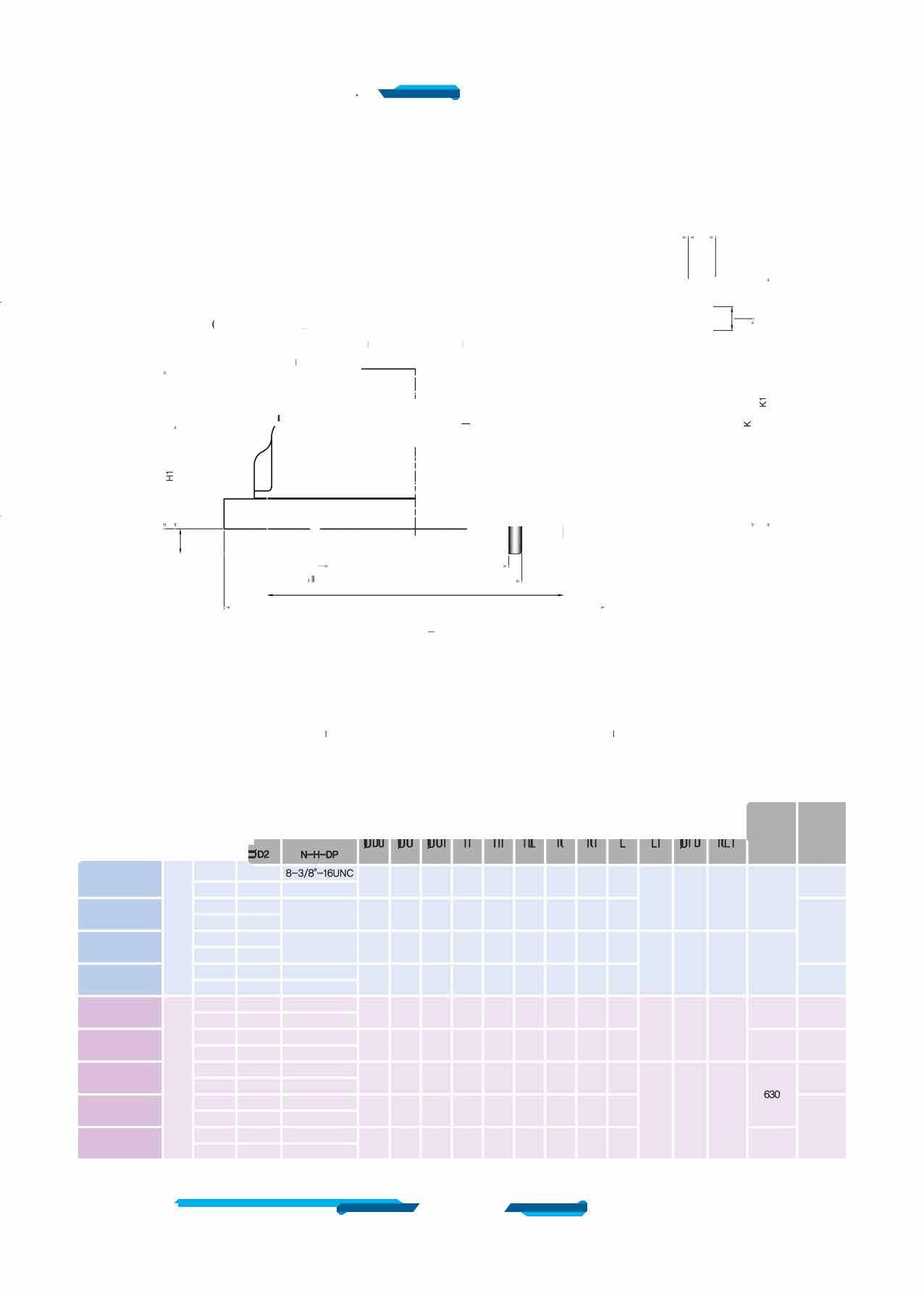

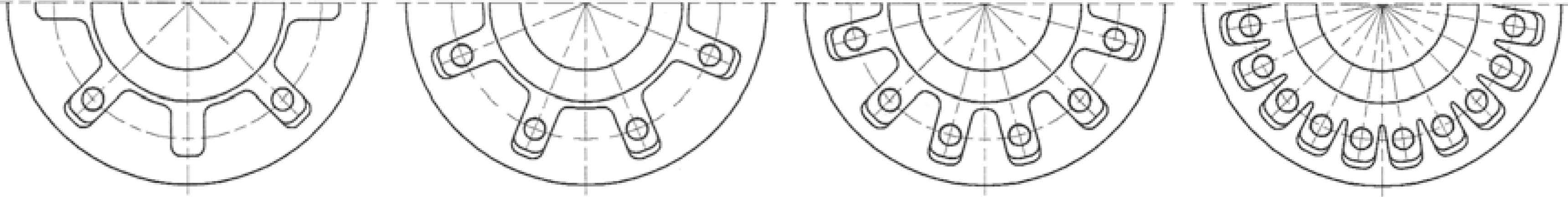

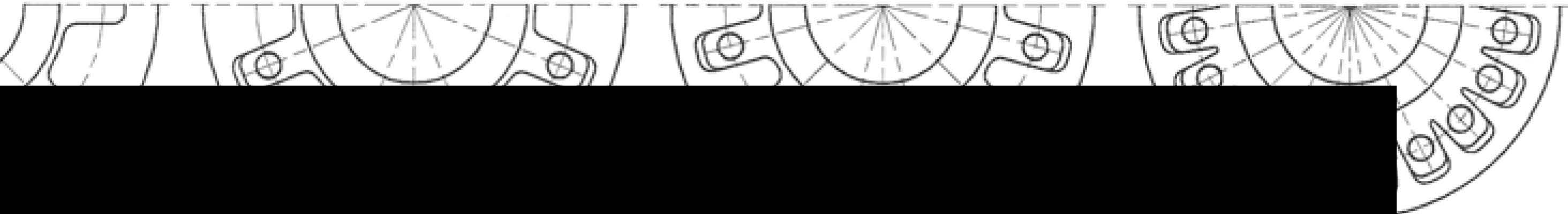

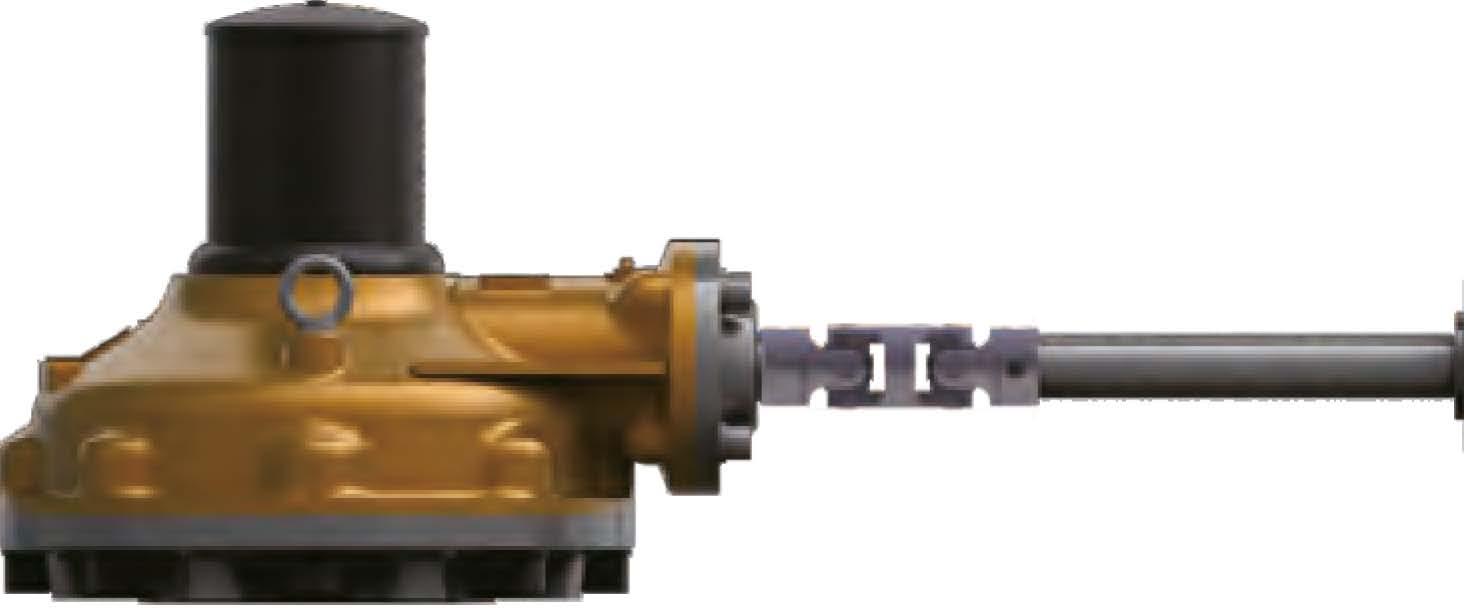

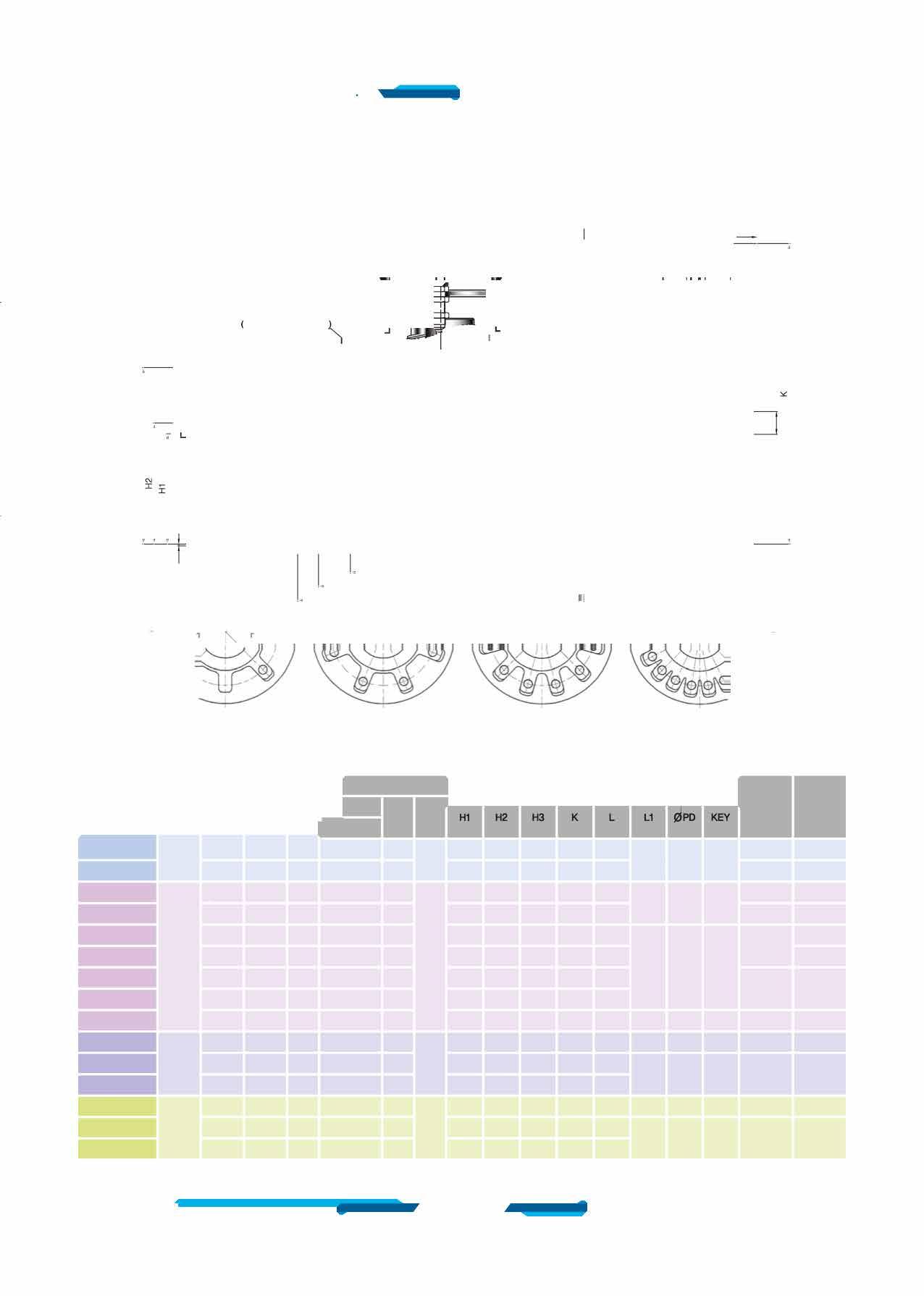

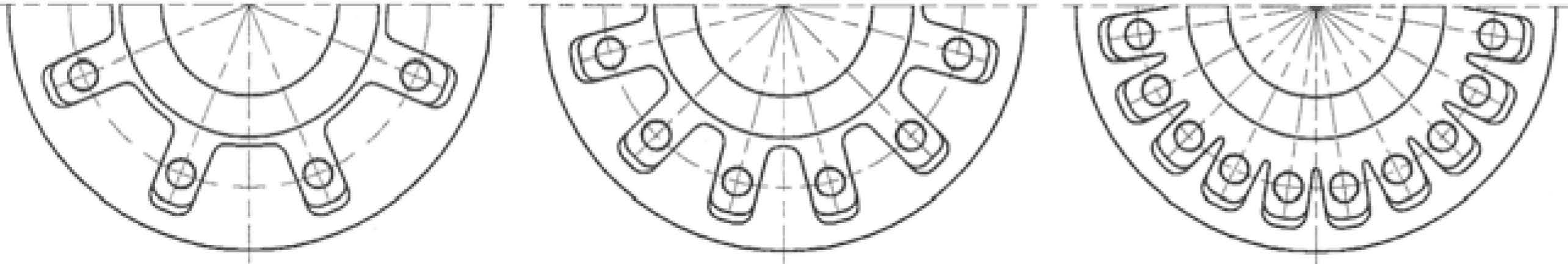

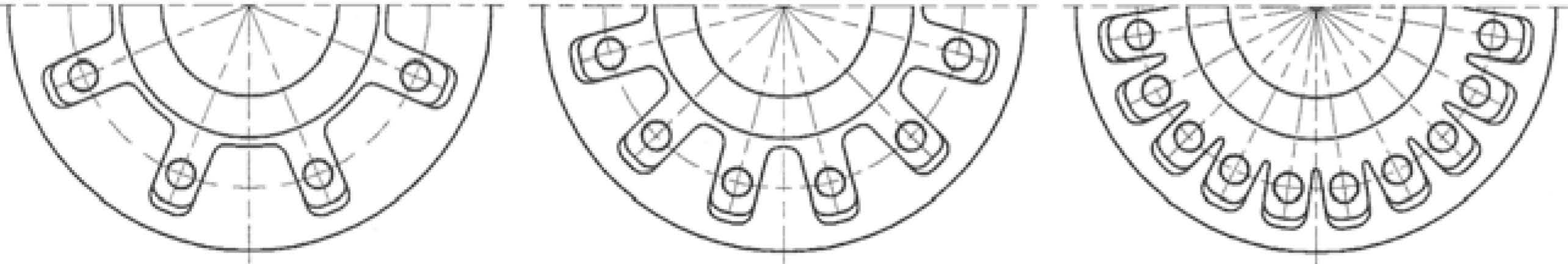

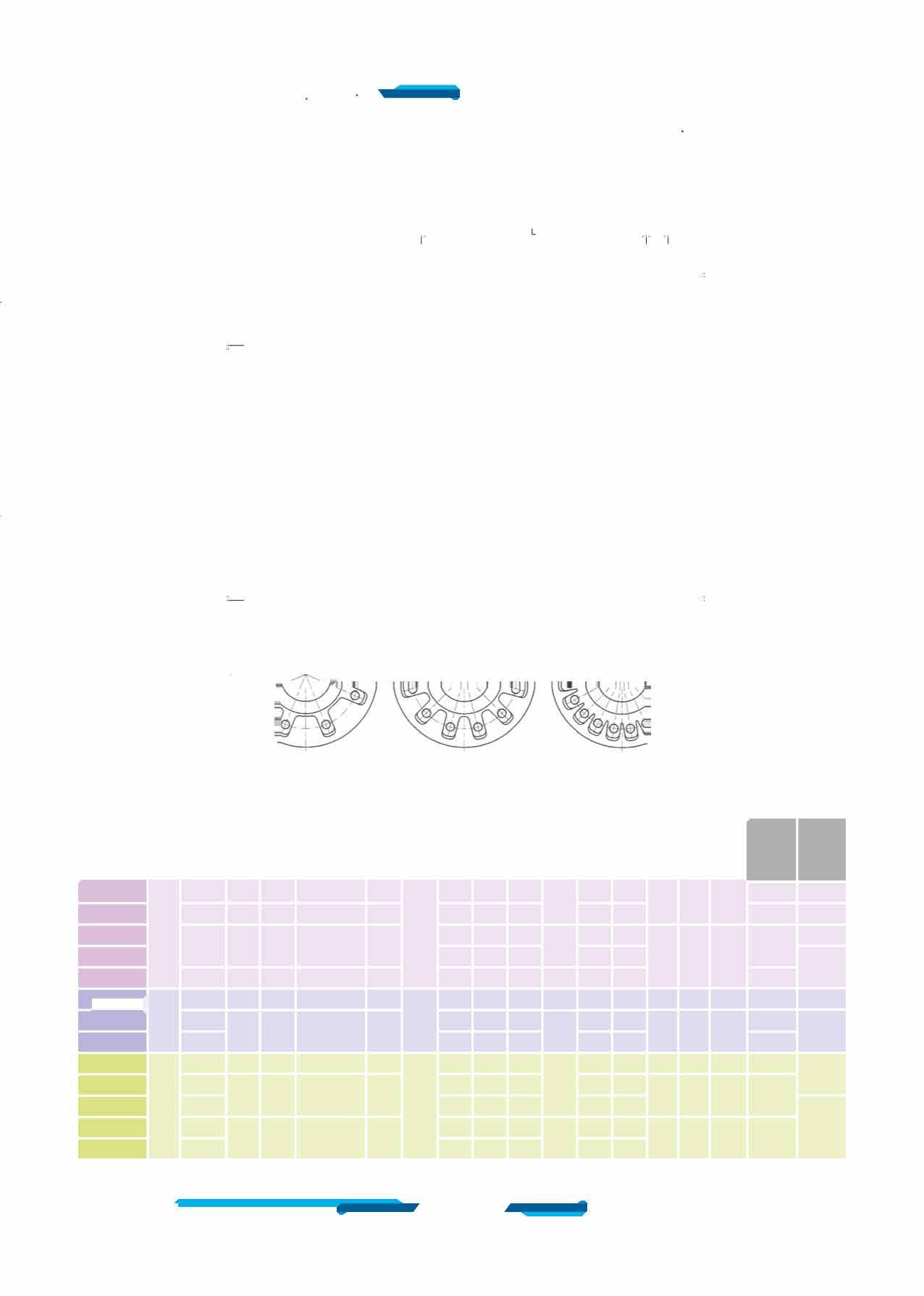

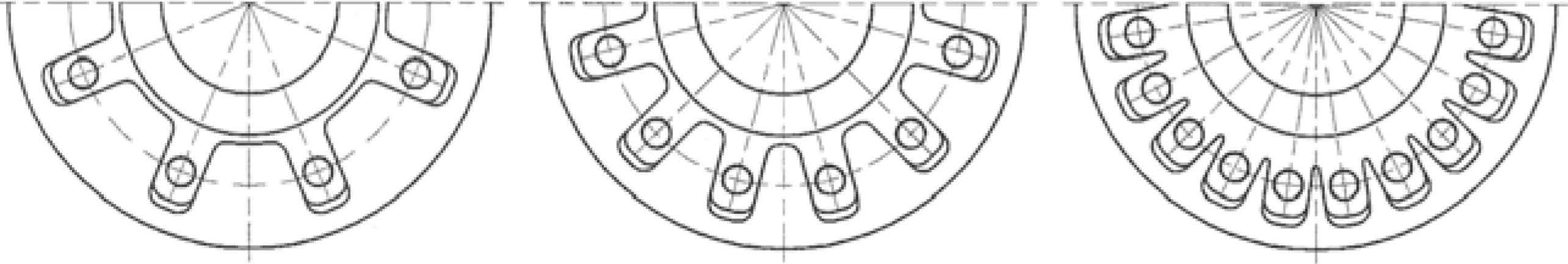

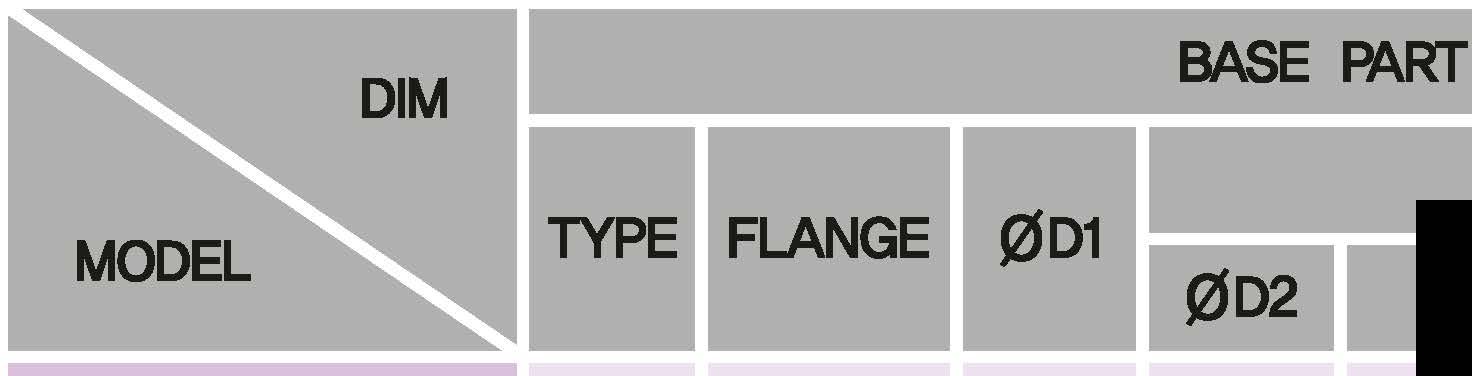

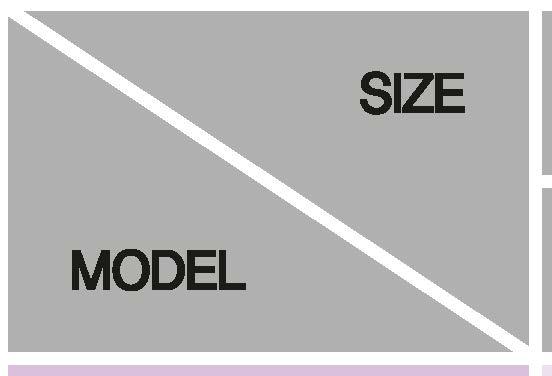

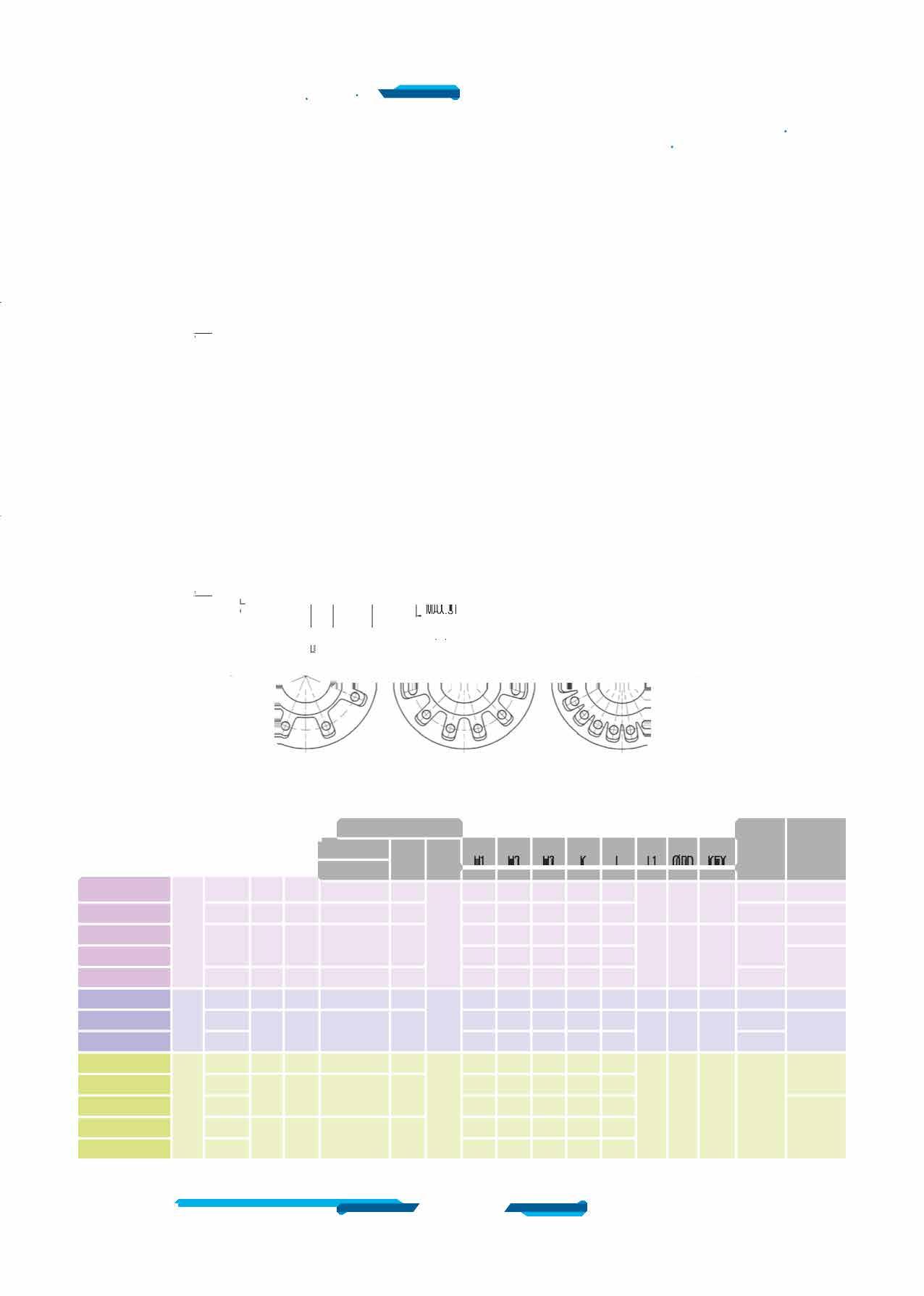

Hand Wheel Type & Chain Wheel Type

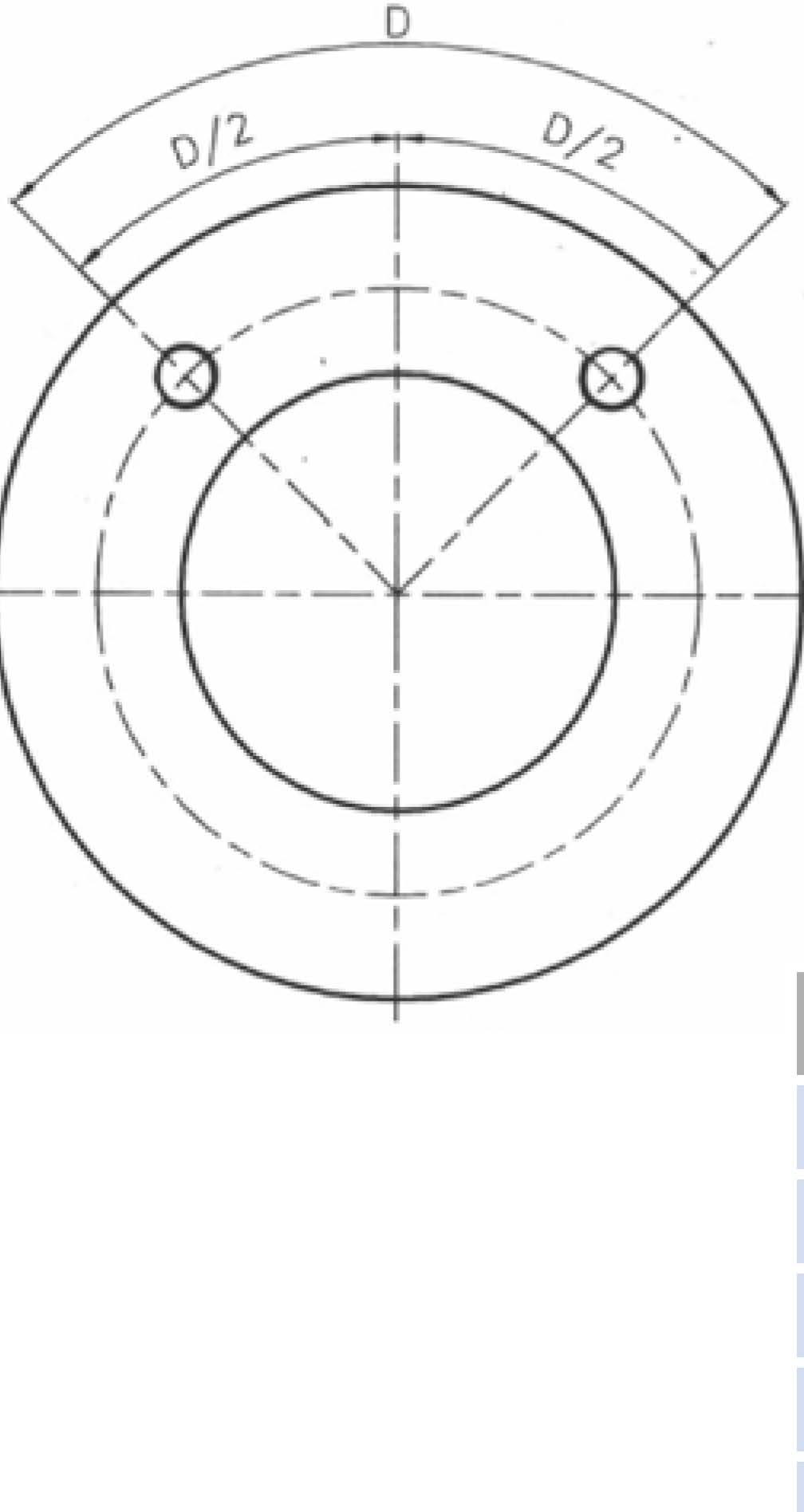

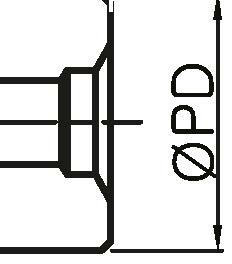

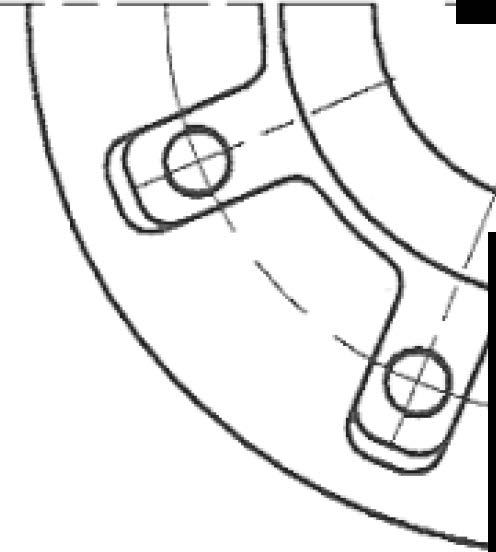

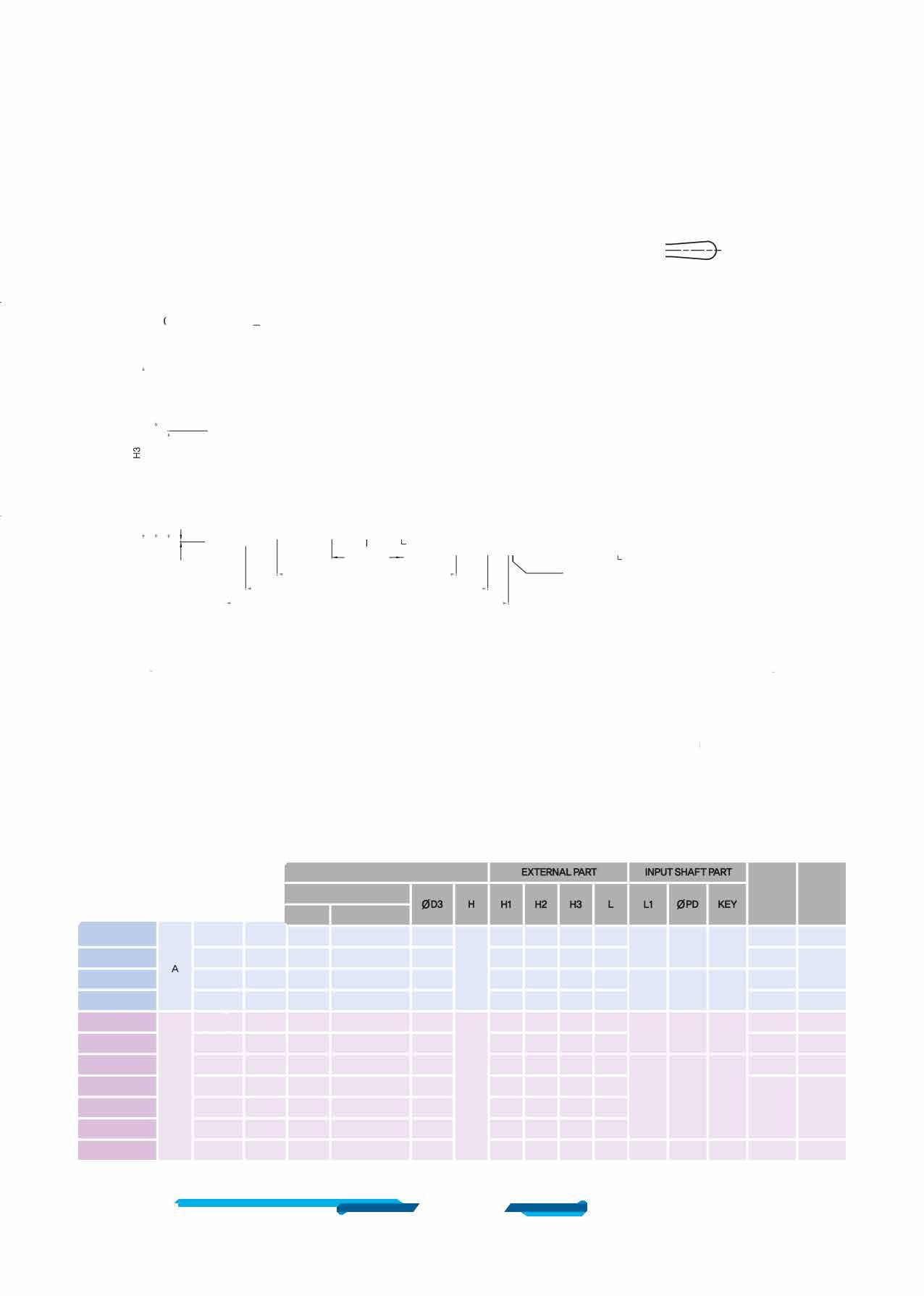

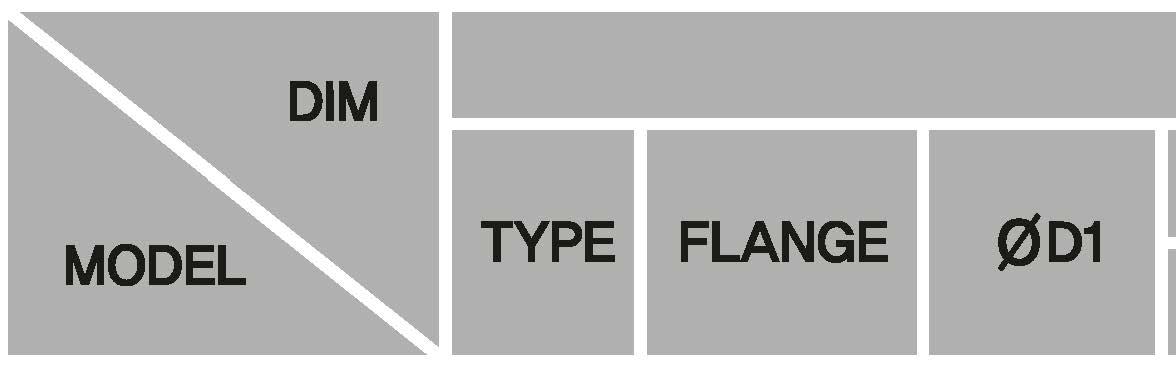

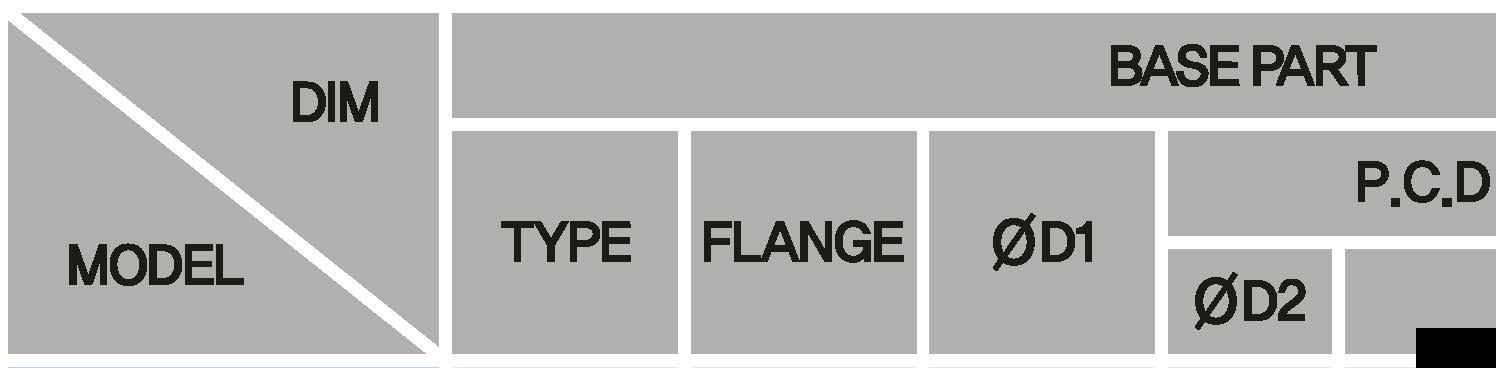

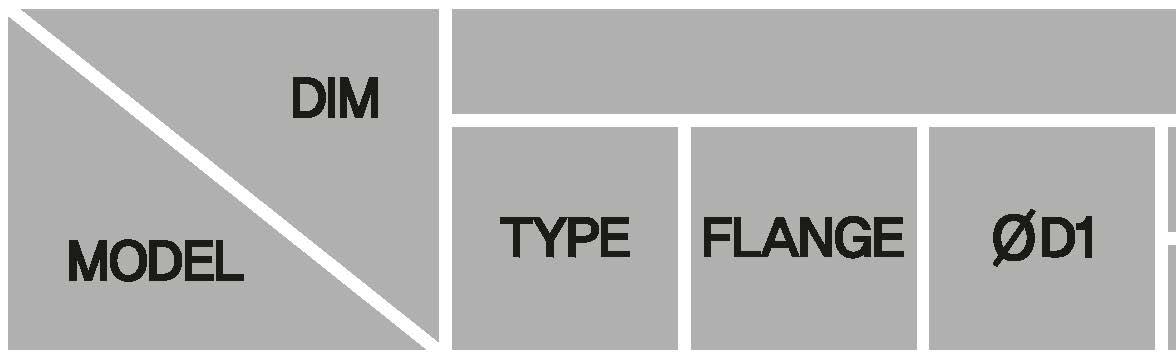

IYIDV Type & Flange Dimensions

Fix Type & Hammer Blow Type Etc.

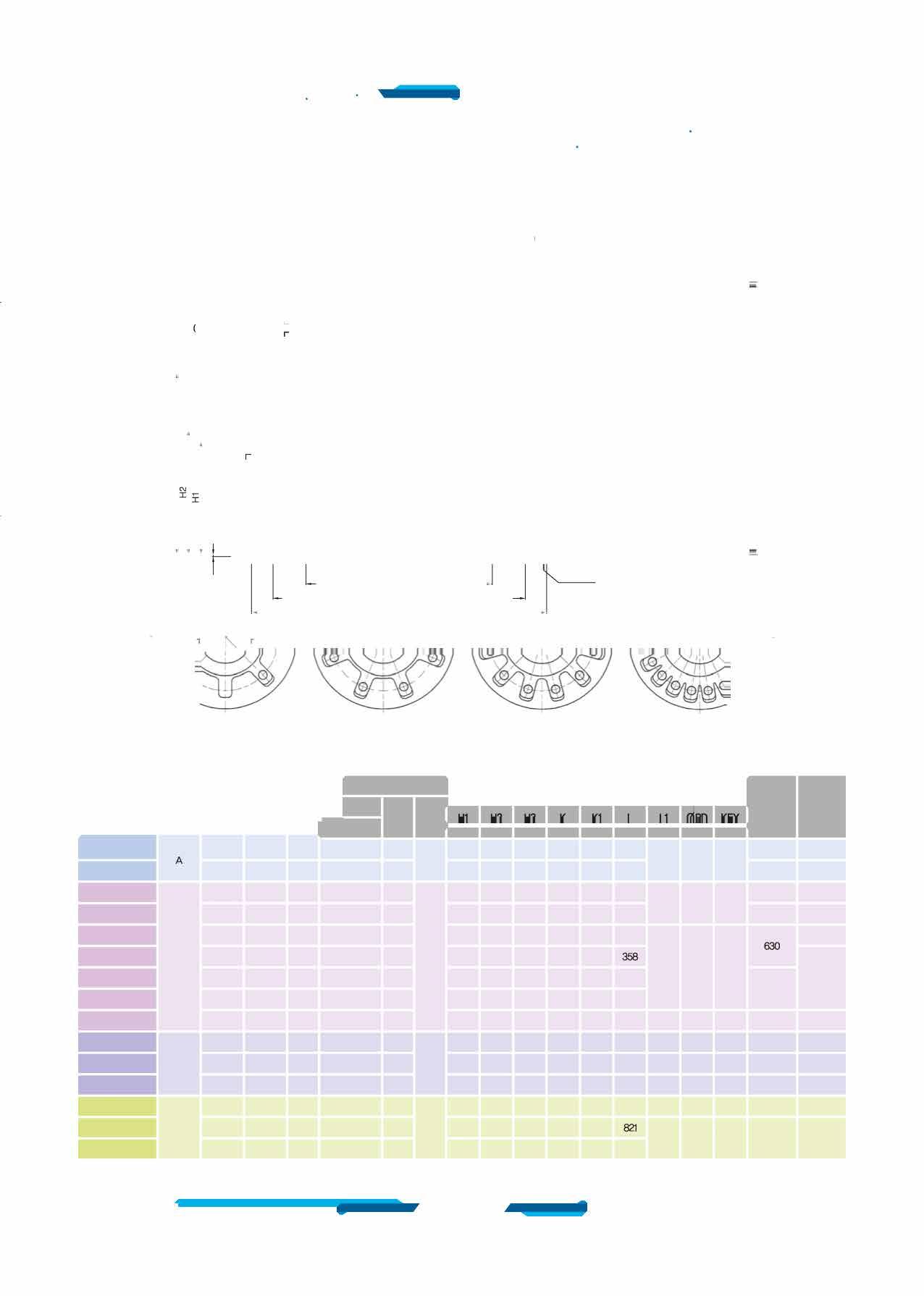

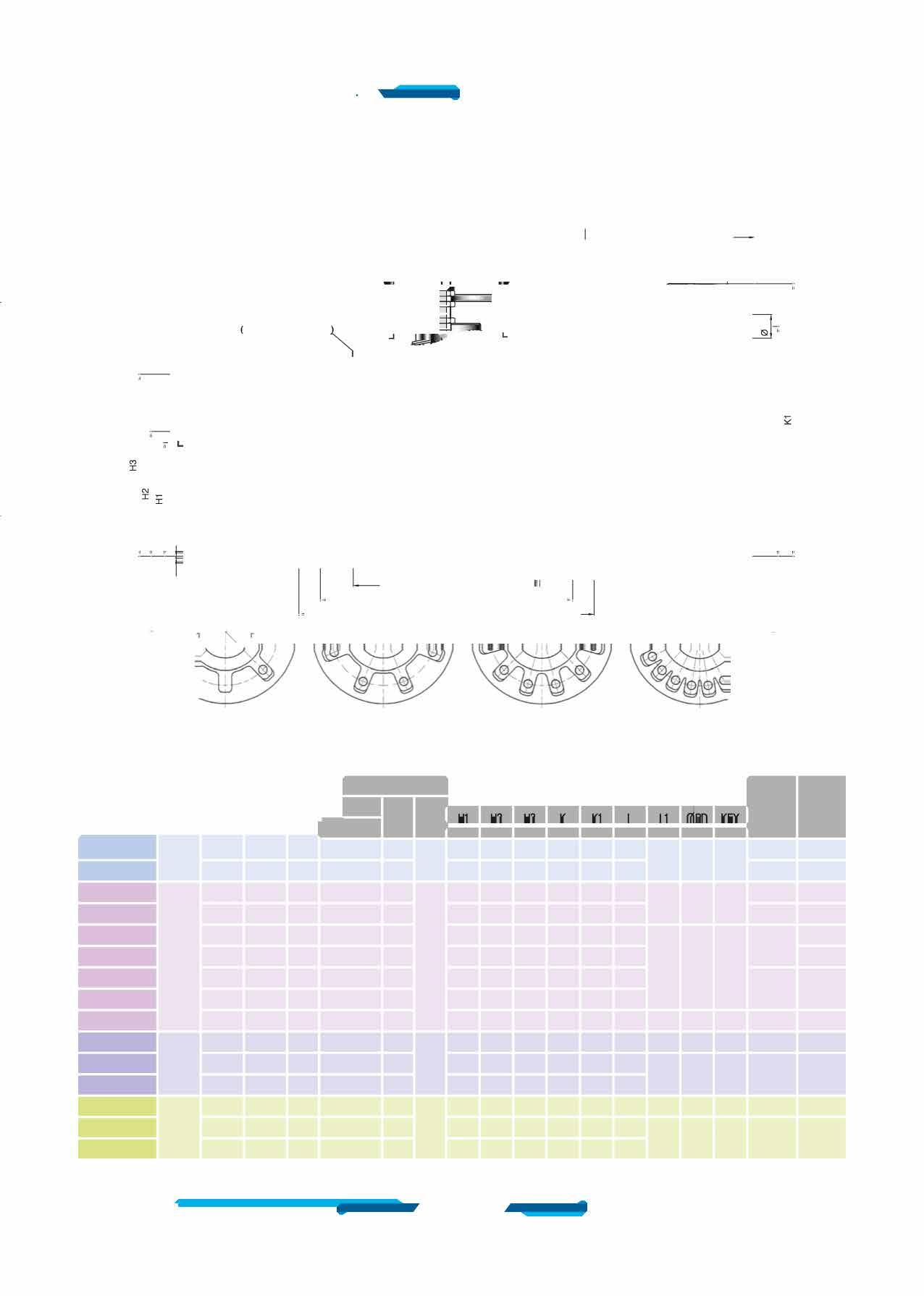

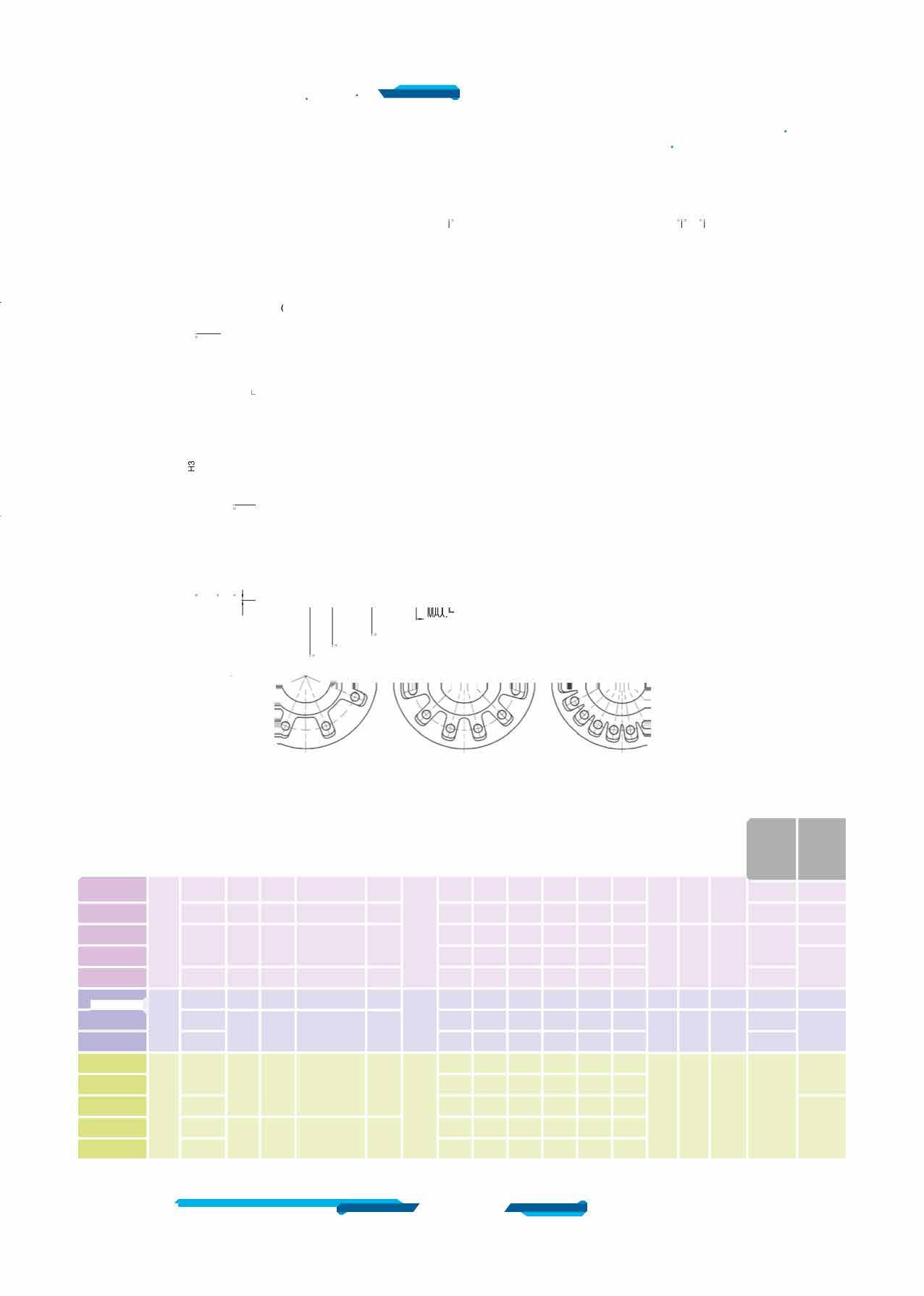

Standard Type A - Thrust & Torque

Horizontal Input

Standard Type A - Thrust & Torque

Horizontal Input

Standard Type A - Thrust & Torque

Horizontal Input

Standard Type A - Thrust & Torque

Horizontal Input with Single Reduction Gear Attachment

Standard Type A - Thrust & Torque (Twin Shaft)

Horizontal Input with Single Reduction Gear Attachment

Standard Type A - Thrust & Torque

Horizontal Input with Double Reduction Gear Attachment

Standard Type A - Thrust & Torque (Twin Shaft)

Horizontal Input with Double Reduction Gear Attachment

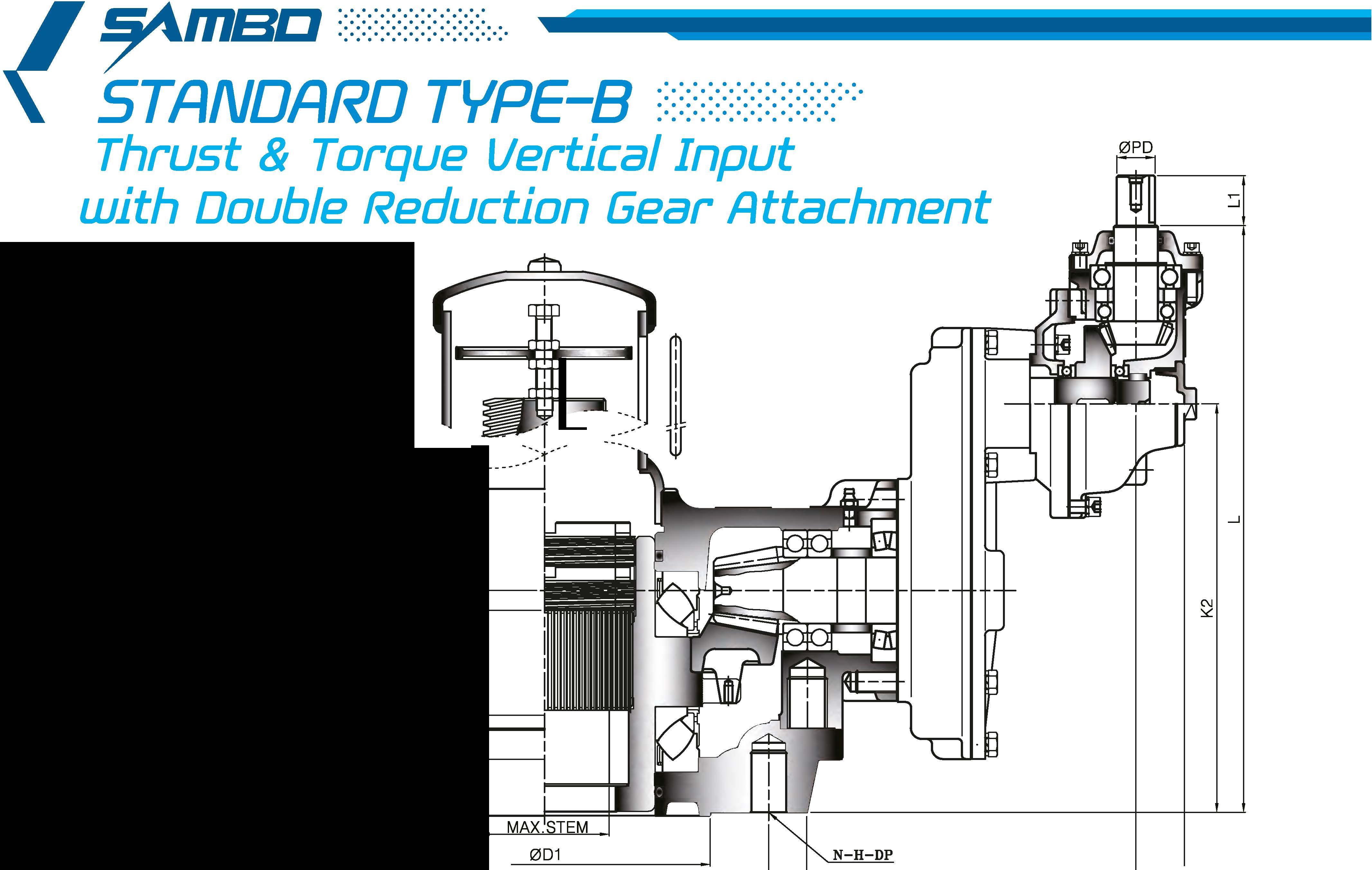

Standard Type B - Thrust & Torque

Horizontal Input with Single Reduction Gear Attachment

Standard Type B - Thrust & Torque

Horizontal Input with Double Reduction Gear Attachment

Standard Type C - Torque only Lug Drive

Horizontal Input

Standard Type C - Torque only Lug Drive

Horizontal Input with Single Reduction Gear Attachment

Standard Type D - IYlultiple Input Shaft - Thrust & Torque

Horizontal Input

Standard Type D - IYlultiple Input Shaft - Thrust & Torque

Horizontal Input with Single Reduction Gear Attachment

�ndard Type D - IYlultiple Input Shaft - Thrust & Torque /fiorizontal Input with Double Reduction Gear Attachment

Standard Type E - High Load Thrust & Torque

Horizontal Input

Stan"dard Type E - High Load Thrust & Torque

Horizontal Input with Single Reduction Gear Attachment

Standard Type E - High Load Thrust & Torque (Twin Shaft)

Horizontal Input with Single Reduction Gear Attachment /

Standard Type E - High Load Thrust & Torque

Horizontal Input with Double Reduction Gear Attachment

Standard Type E - High Load Thrust & Torque (Twin Shaft)

Horizontal Input with Double Reduction Gear Attachment

Standard Type E - High Load Thrust & Torque

Vertical Input with Single Reduction Gear Attachment

Standard Type F - IYlultiple Input Shaft: High Load Thrust & Torque

Horizontal Input /

Standard Type F - IYlultiple Input Shaft: High Load Thrust & Torque

/Horizontal Input with Single Reduction Gear Attachment

Standard Type F - IYlultiple Input Shaft: High Load Thrust & Torque

Horizontal Input with Double Reduction Gear Attachment

Standard Type F - IYlultiple Input Shaft: High Load Thrust & Torque

Vertical Input with Single Reduction Gear Attachment

�izean«□mponentspeciticationinthiscataloguearesubjecttochangewi�priornoticeforqualityimprovement.

•IYlarkhas enchangedandupdated. /

•

•

Ifthere is no

from

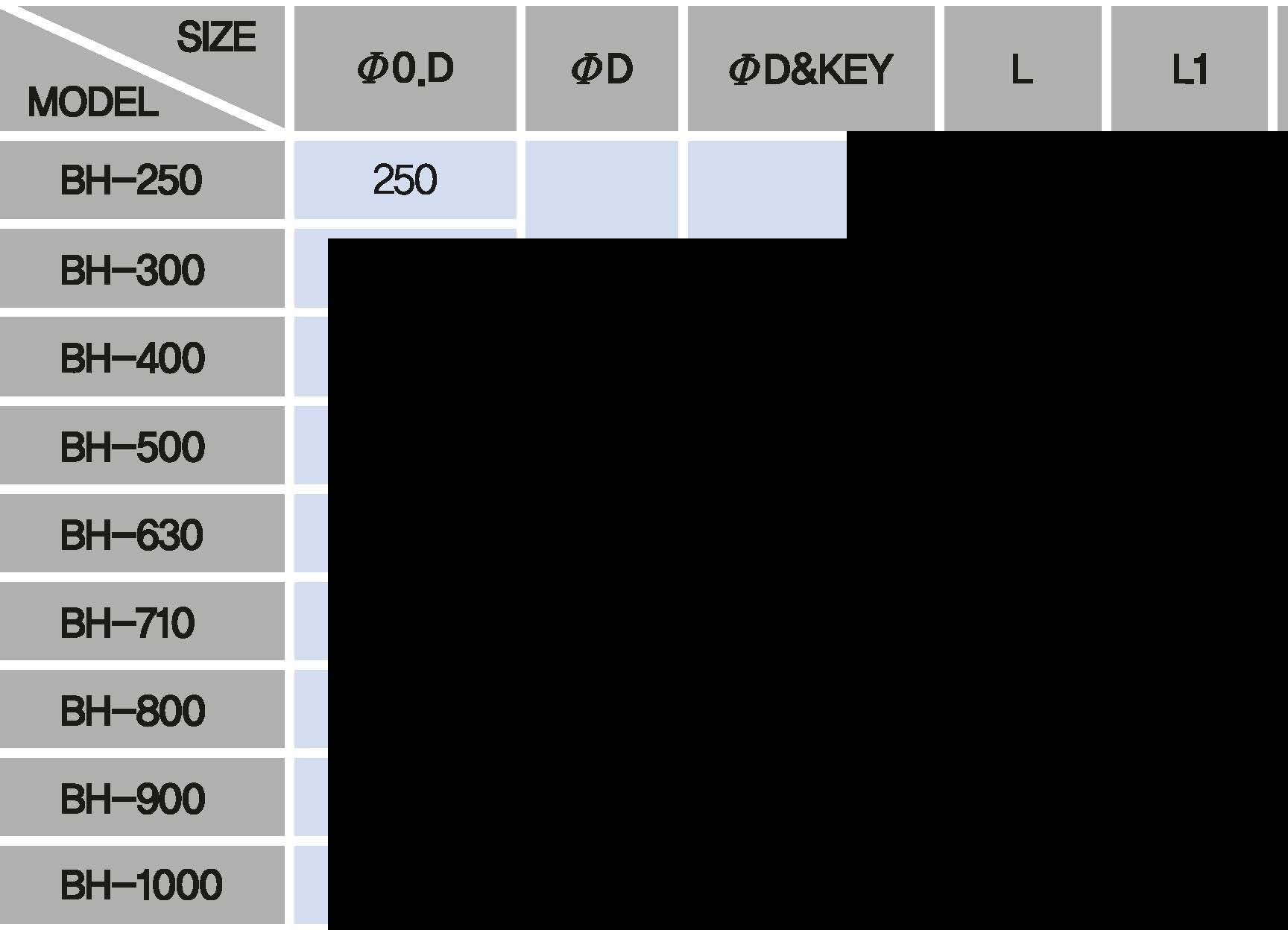

Allmaterialof round barhandwheelare made by

• IYlark has been changed and updated.

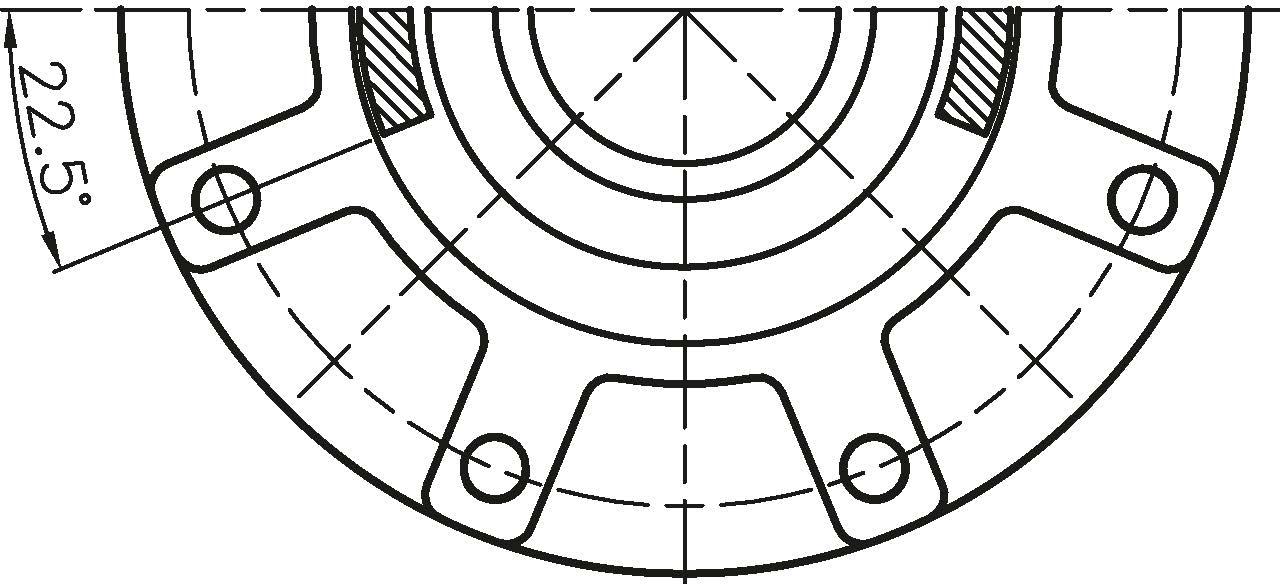

(!)50(16X10)

This Handwheel is the type using alr impact wrench and it can be made properly according to customer' s request

Chainwheel has 2 types

• First, hammer type which isjoined with handwheel.

• Second, gear type which is adhered to gear directly.

• material : sprocket rim (FCD4S□l, guide arm (AS76-104S), chain (steel+zn)

Global Leader

Stlrdardlype

SUpportType

FlangeType Fa,gelype

a>30(10XB)

a>35(10X8)

d)40(12XB)

d)45(14X9)

70 6 90 8 110 10

(1)55(16X10)

(1)65(18X11)

(1)65(18X11)

a>80(22X14)

a>90(25X14)

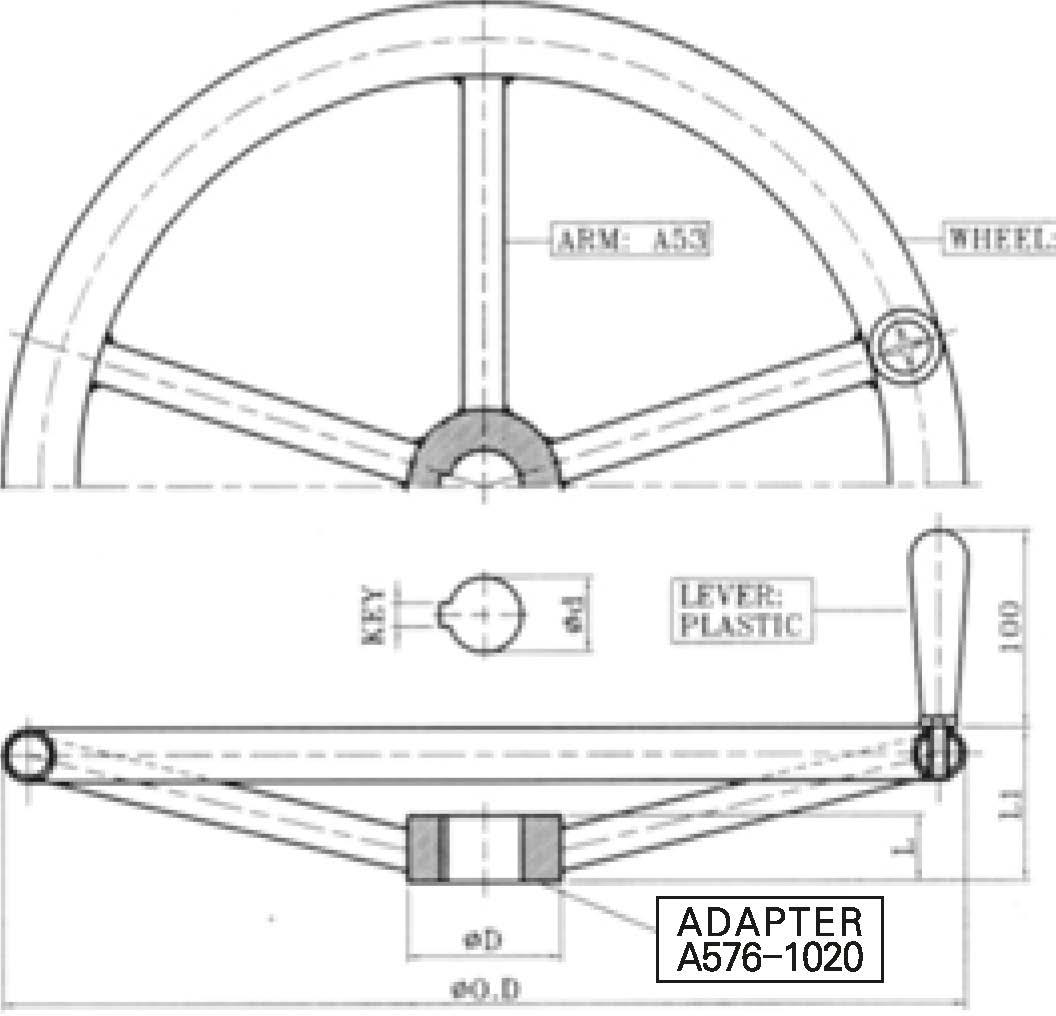

StlrdardType

FlangeType

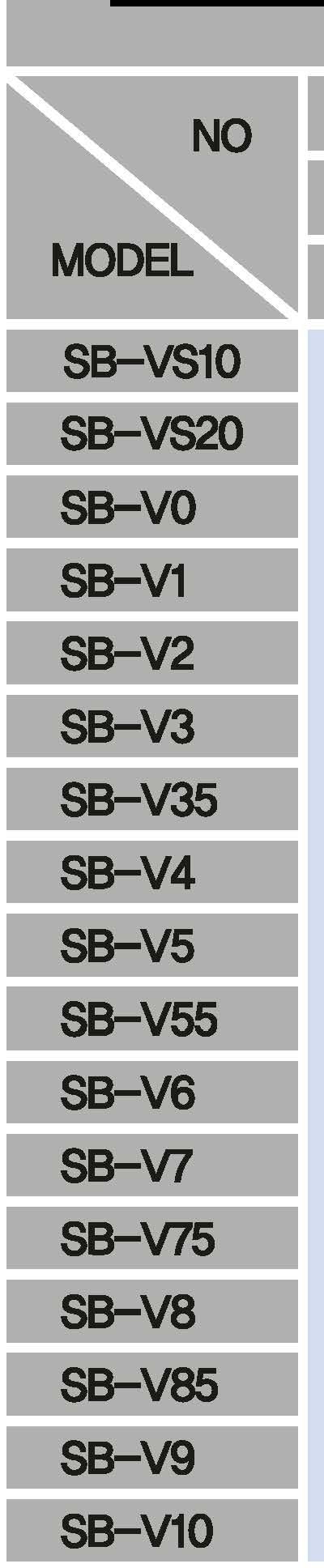

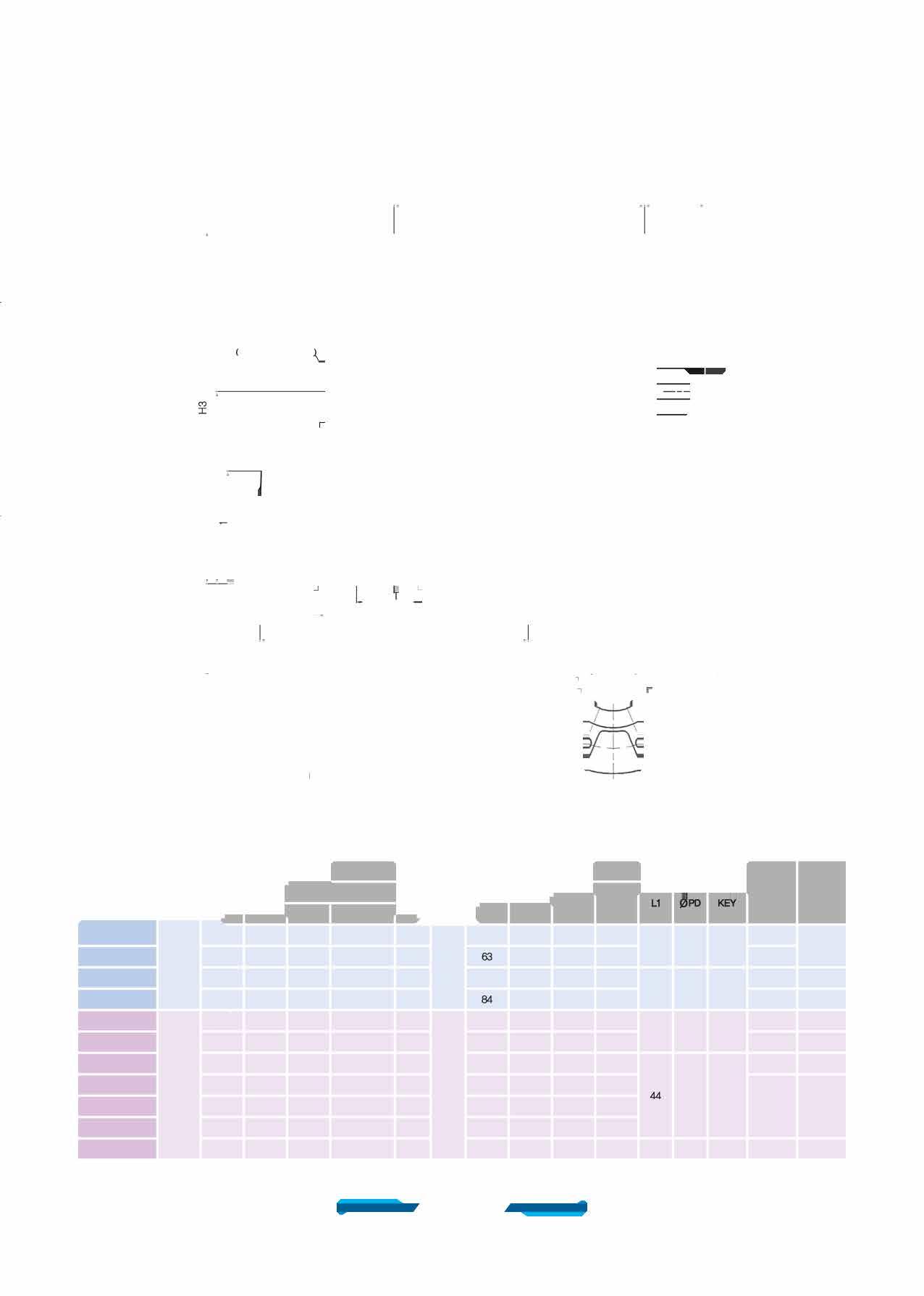

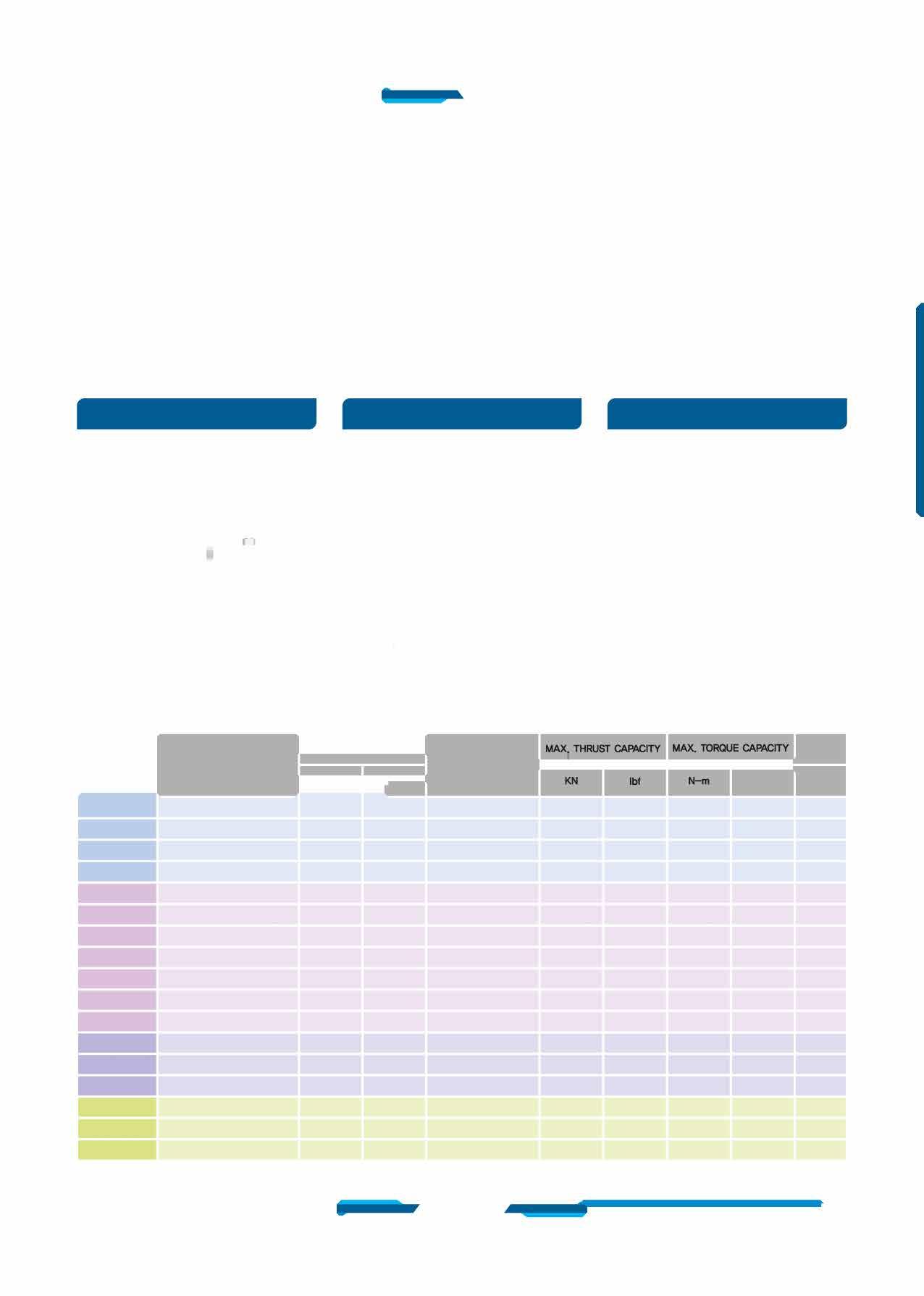

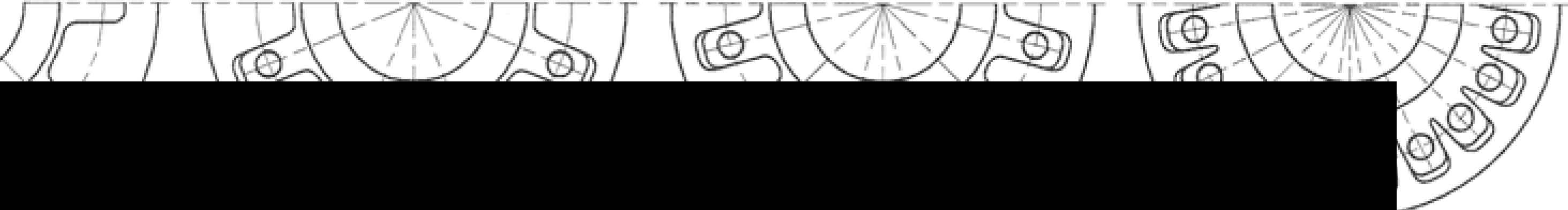

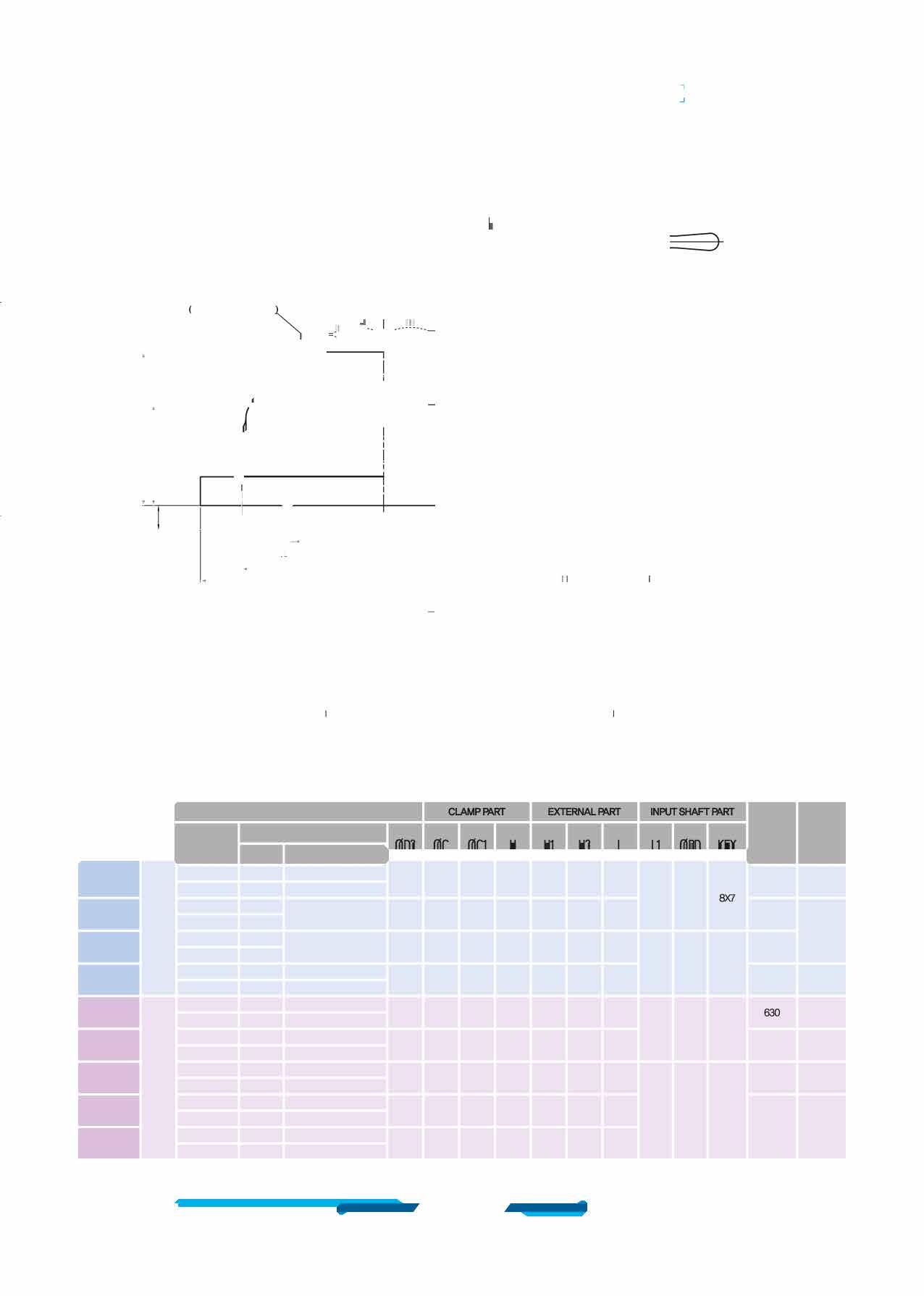

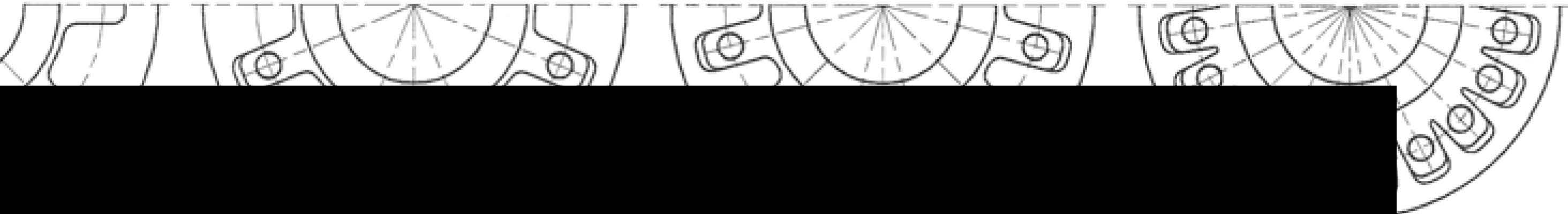

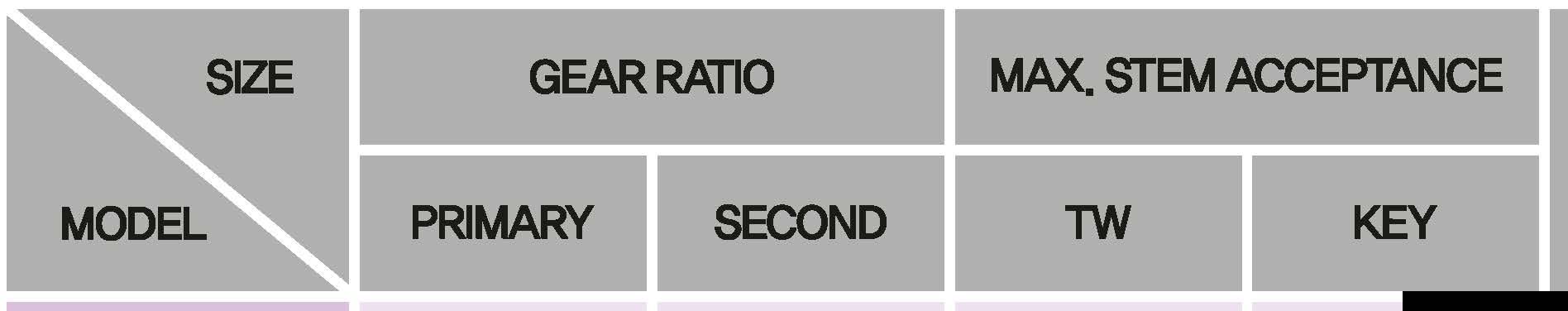

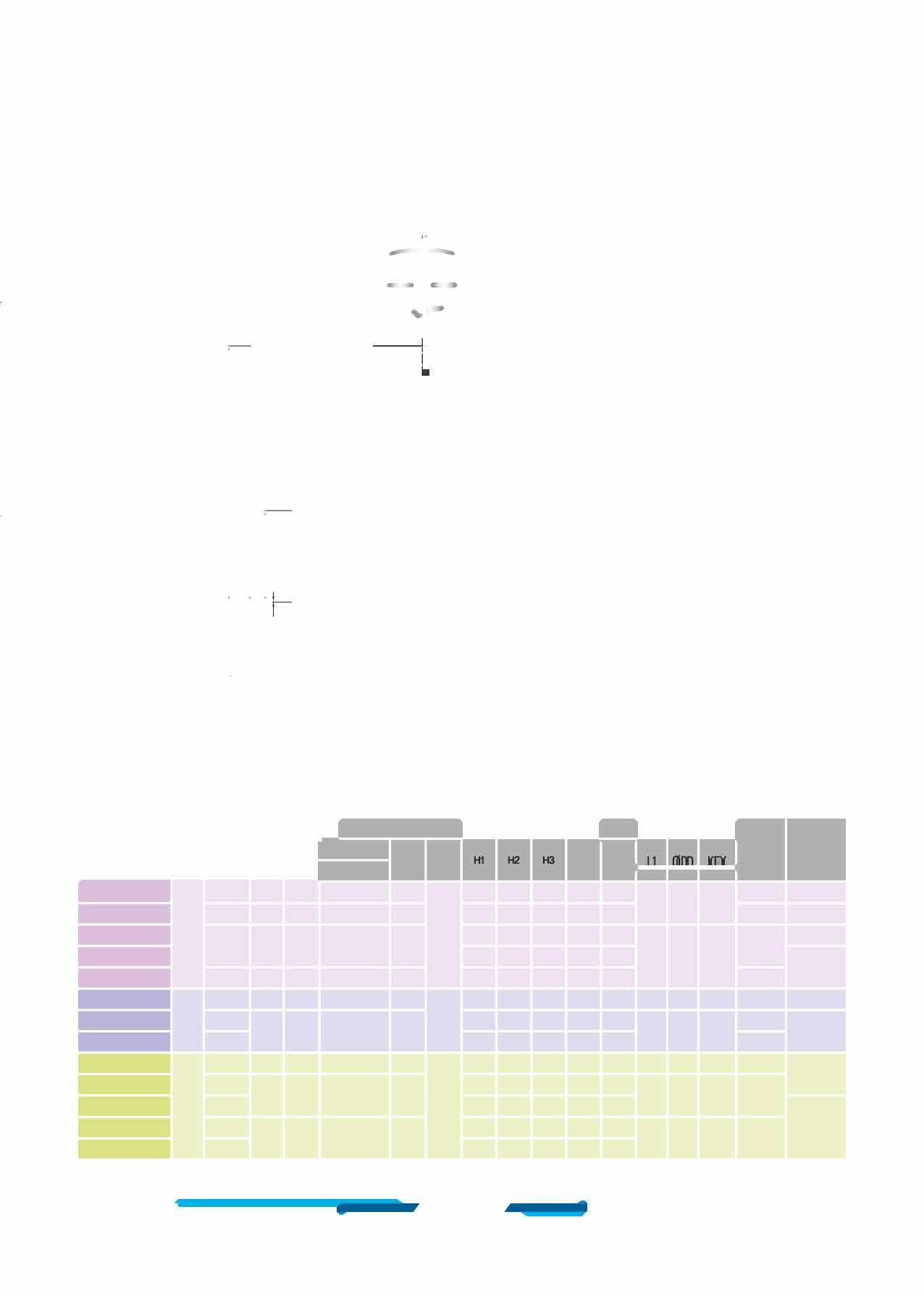

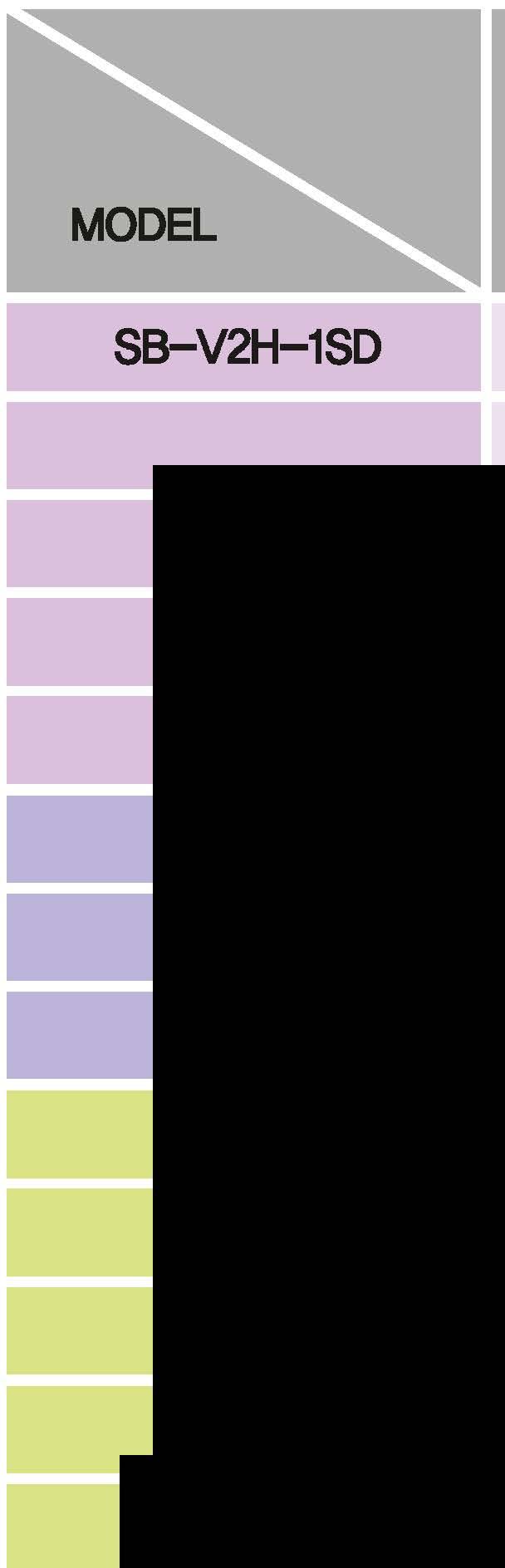

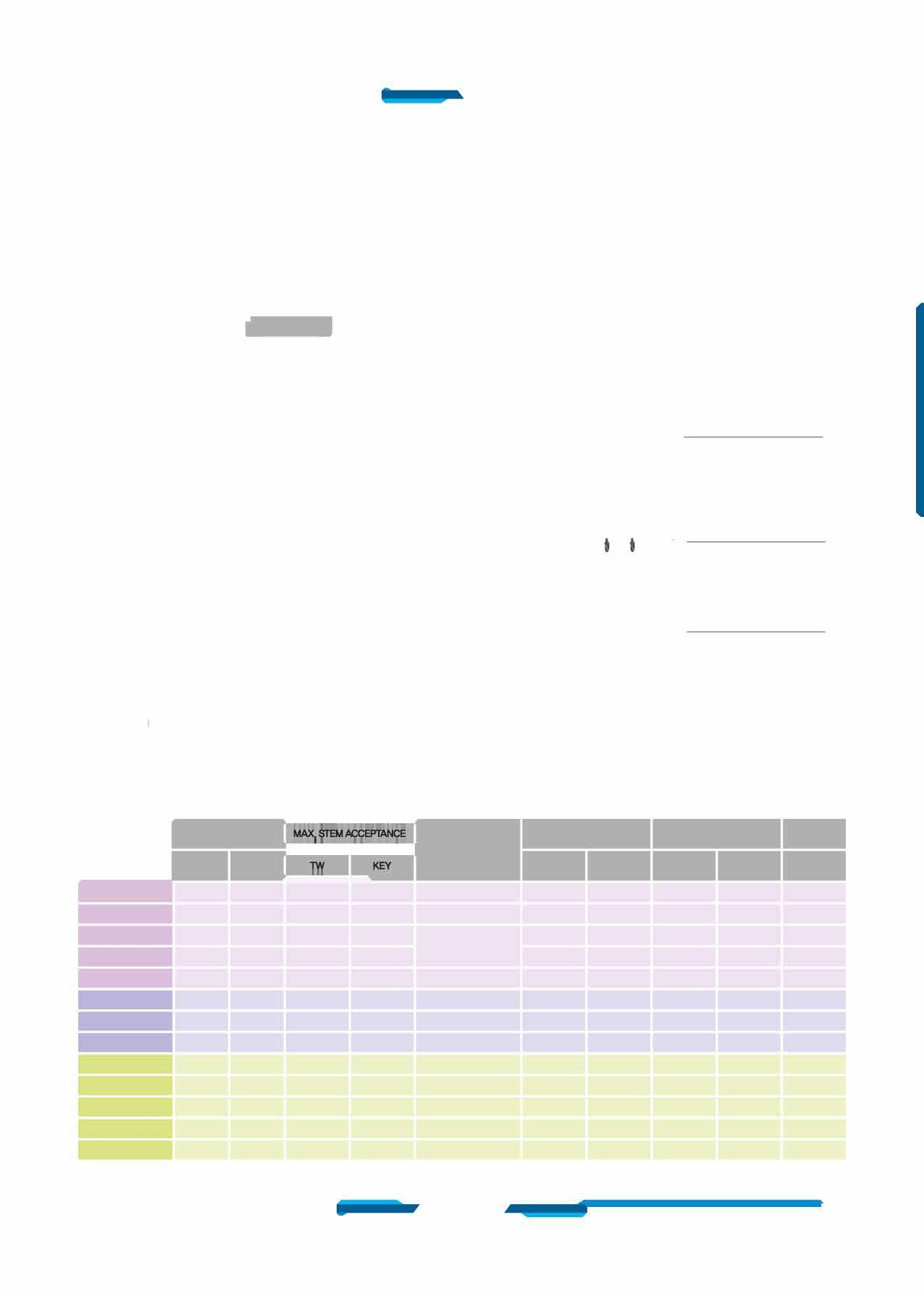

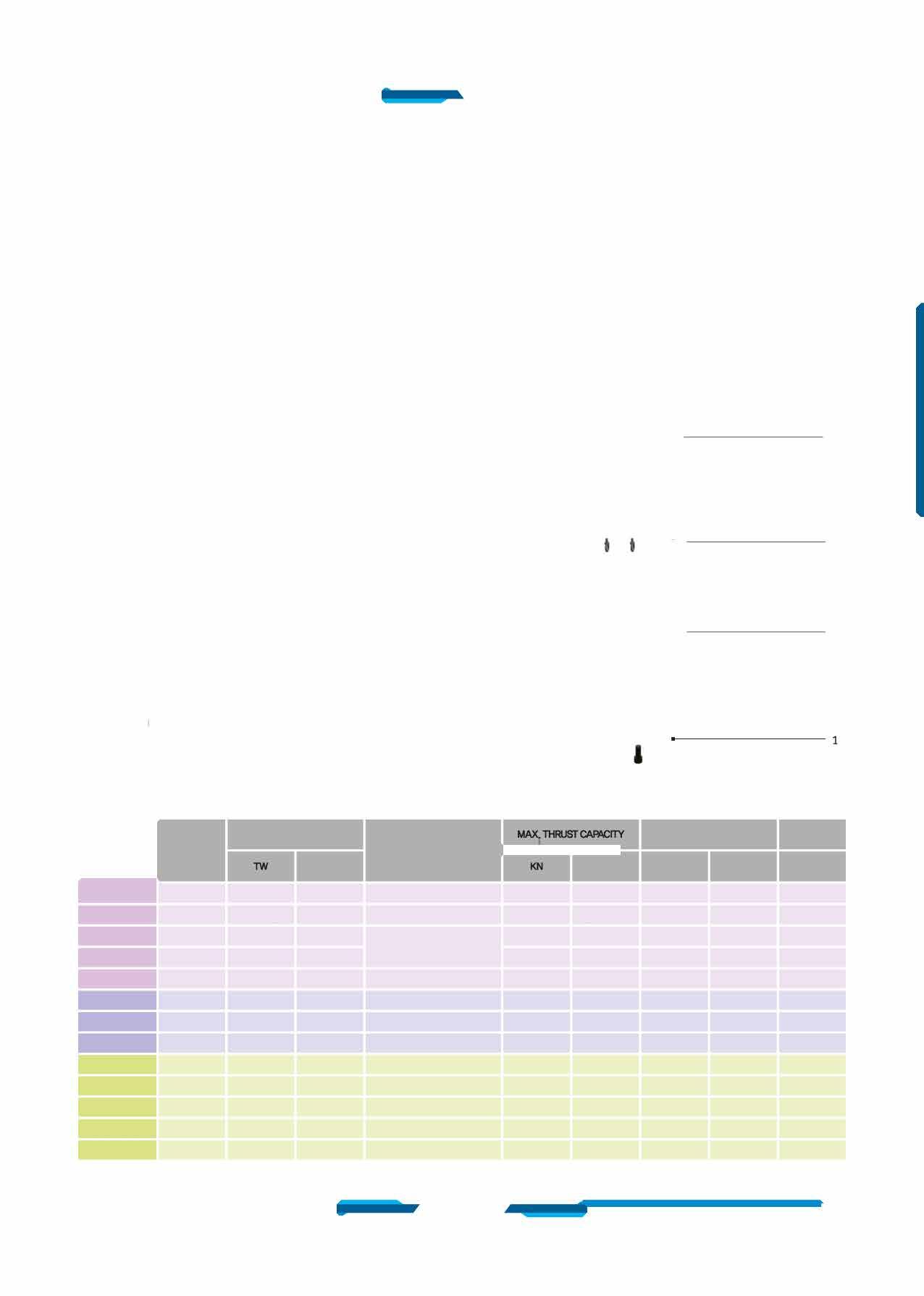

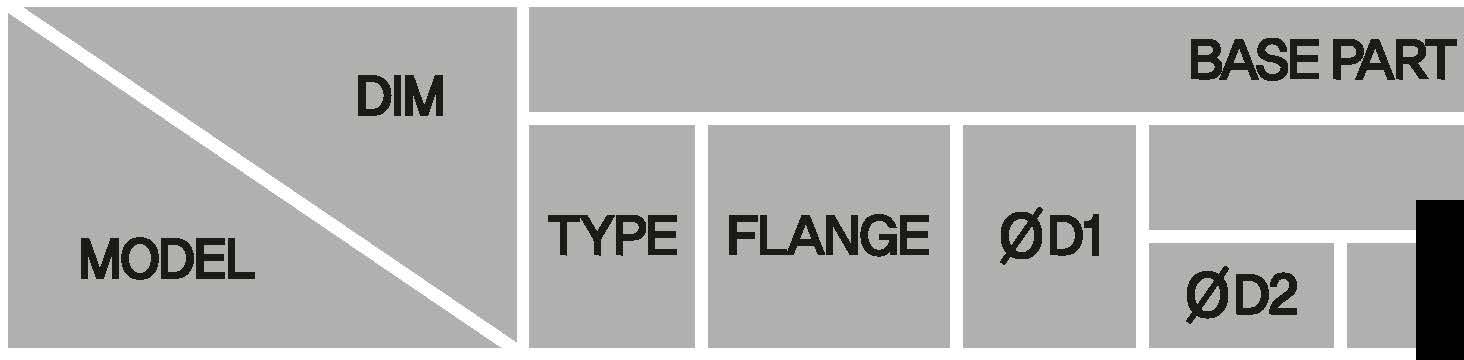

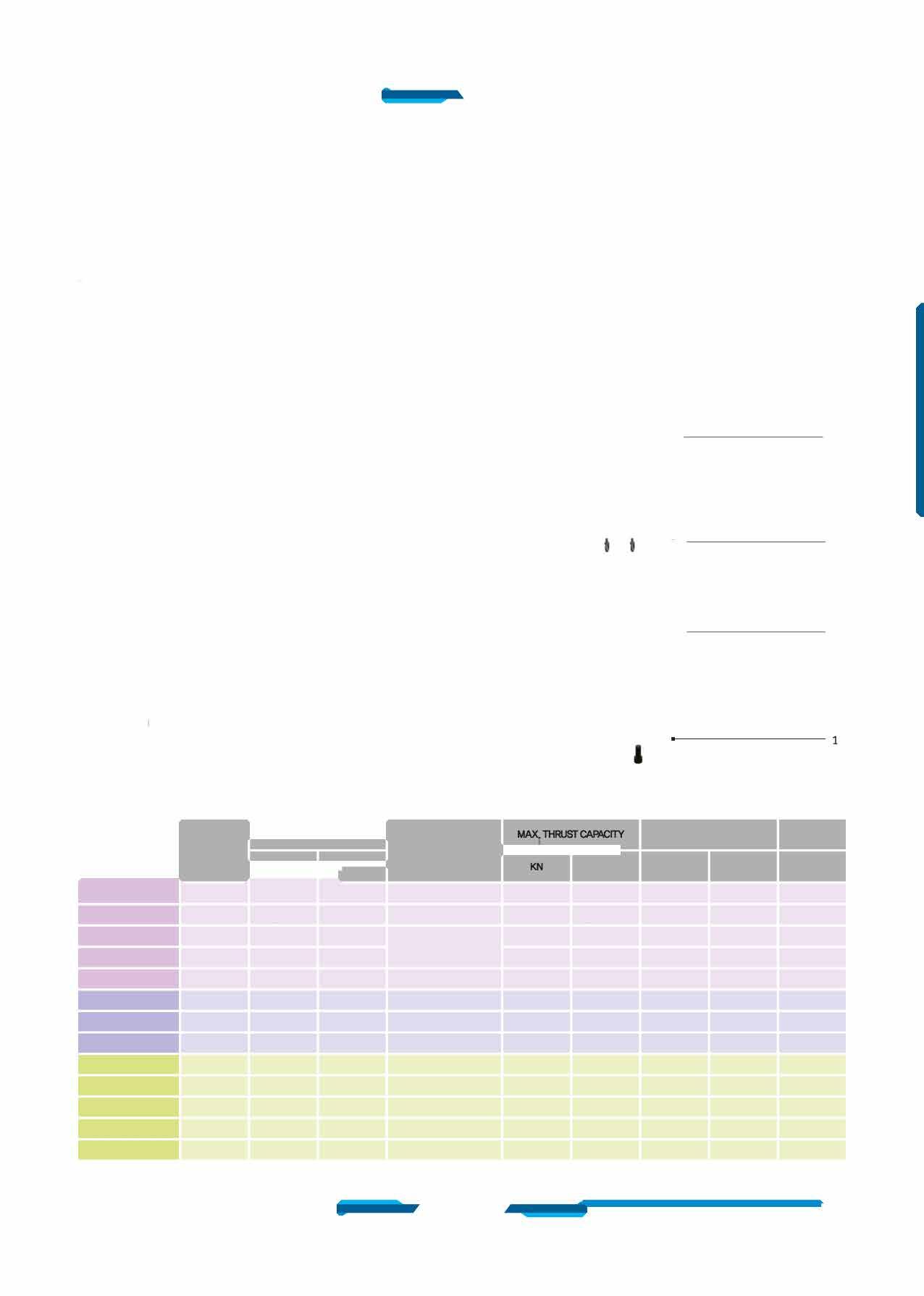

SB-V2-1S,1SD

SB-V3-1S,1SD

SB-V35-1S,1SD

SB-V4-1S,1SD

SB-VS-1S,1SD

SB-V55-1S,1SD 70 6 90

SB-V6-1S,1SD

SB-V7-1S,1SD

SB-V75-1S,1SD

SB-V8-1S,1SD

SB-V85-1S,1SD

SB-V9-1S,1SD

SB-V10-1S,1SD

Max_d)D&Key

a>30(10XB)

a>30(10XB)

a>35(10XB)

a>40(12X8) 8

a>45(14X9)

SUpportType

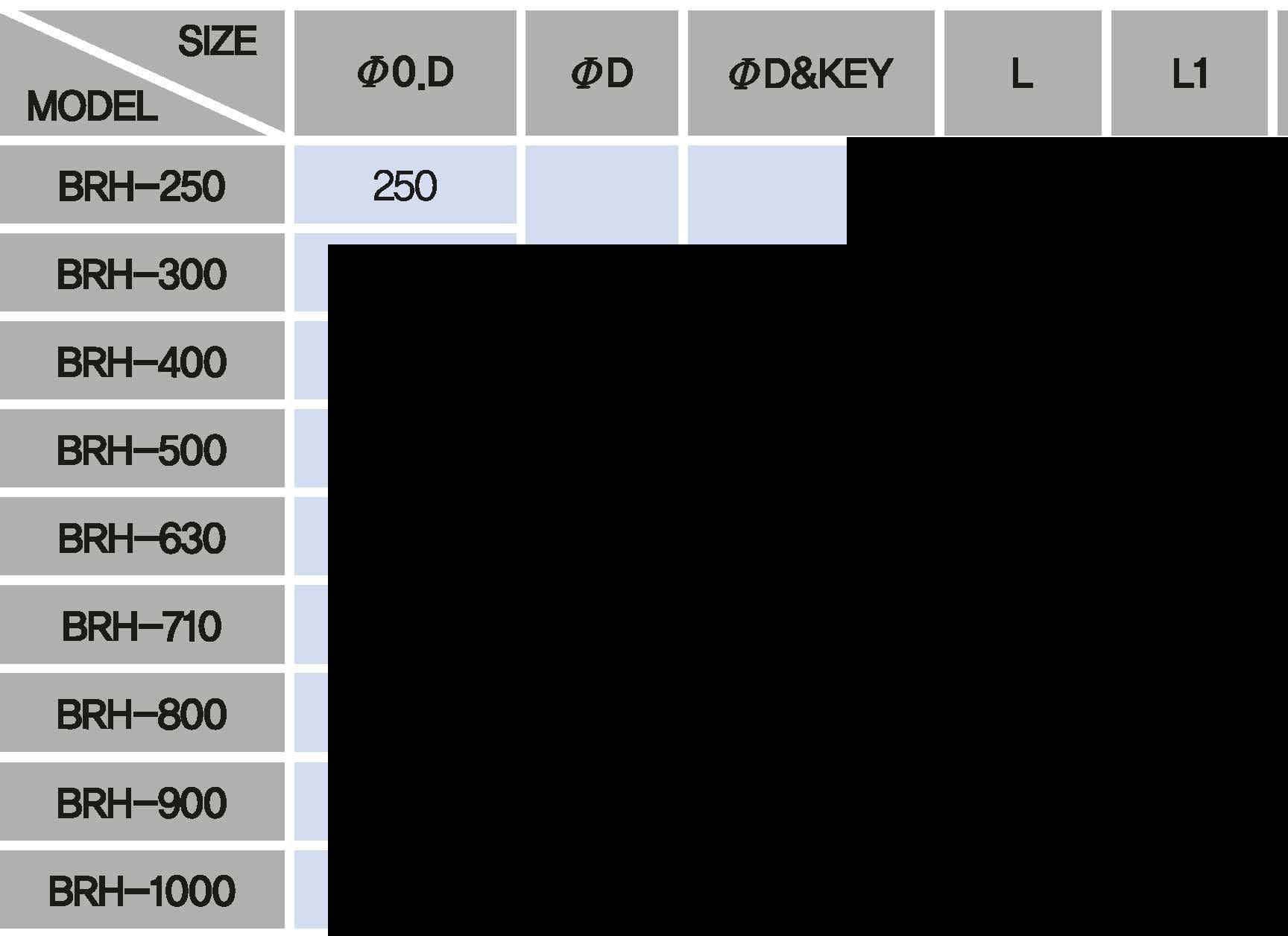

(1)'20(6X6)

(l)25(8X7)

a>35(10XB)

d)45(14X9) 70 6 90 8 110 10 70 6 90

(1)55(16X10)

(1)70(18X11)

(1)90(25X14)

(1)120(32X18)

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement. • IYlark has been changed and updated.

(1)55(16X10)

a>70(18X11)

Max_d)D&Key

a>25(8X7)

a>30(10XB)

a>35(10XB)

8 a>45(14X9)

(l)55(16X10)

a>70(18X11)

(1)70(18X11)

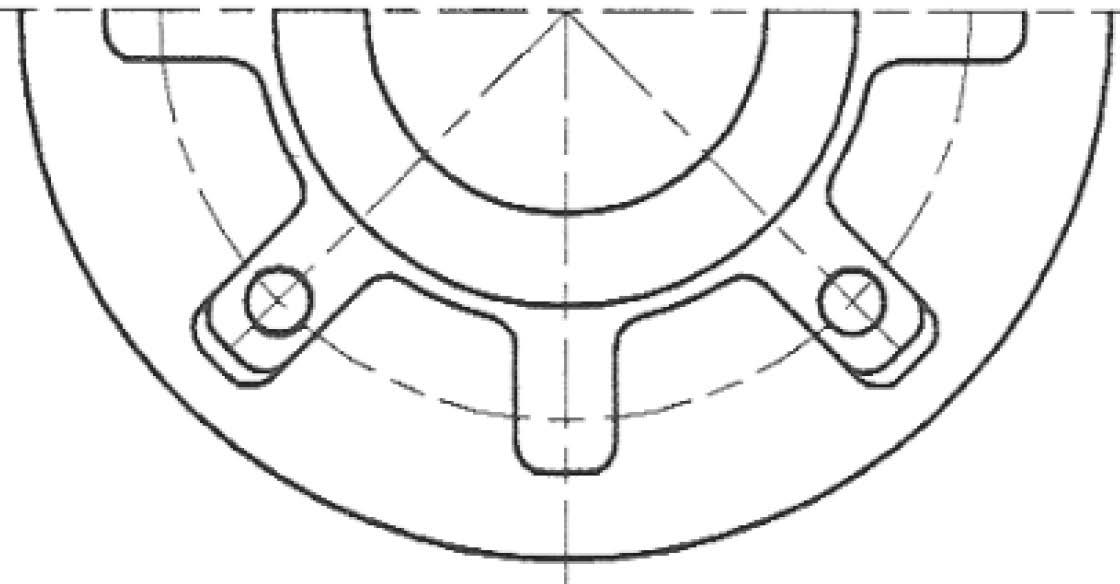

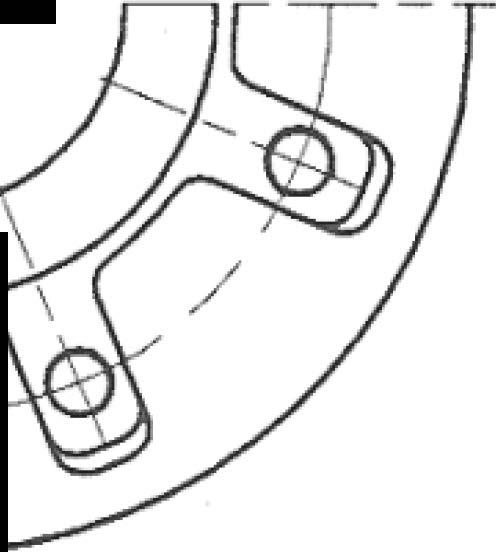

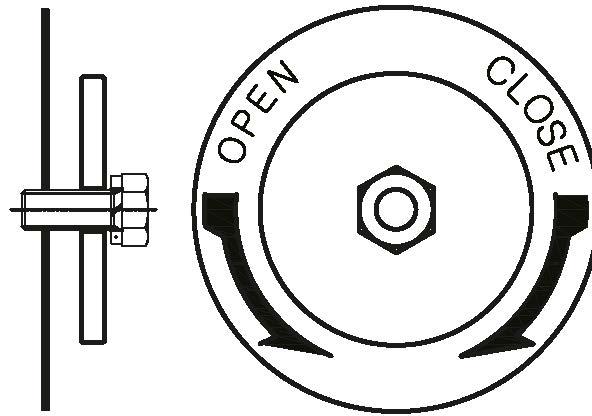

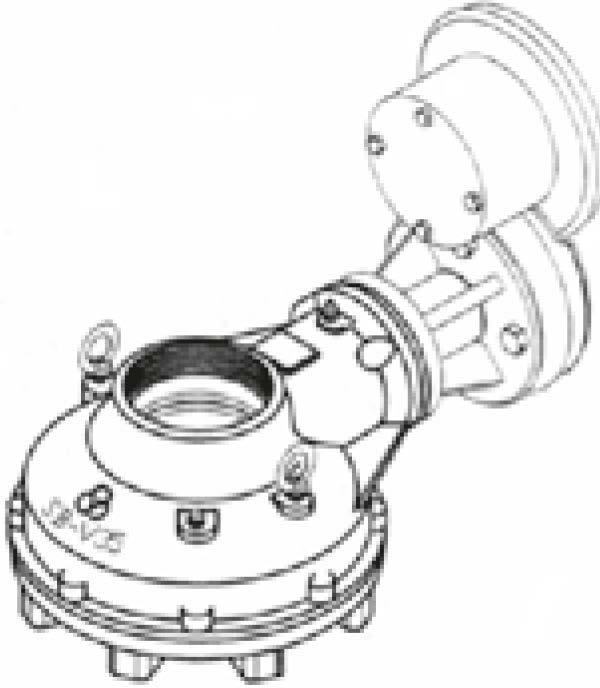

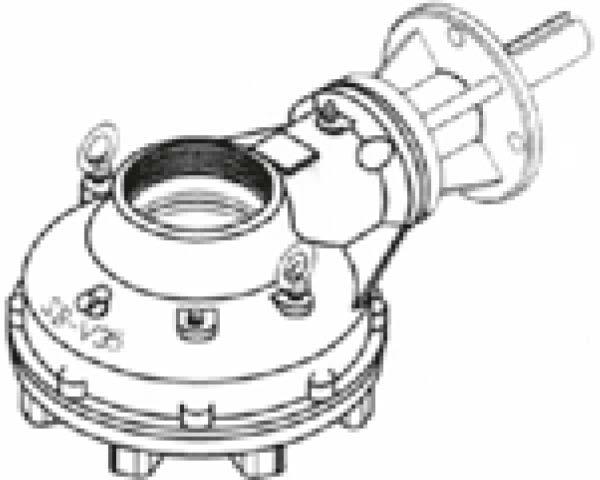

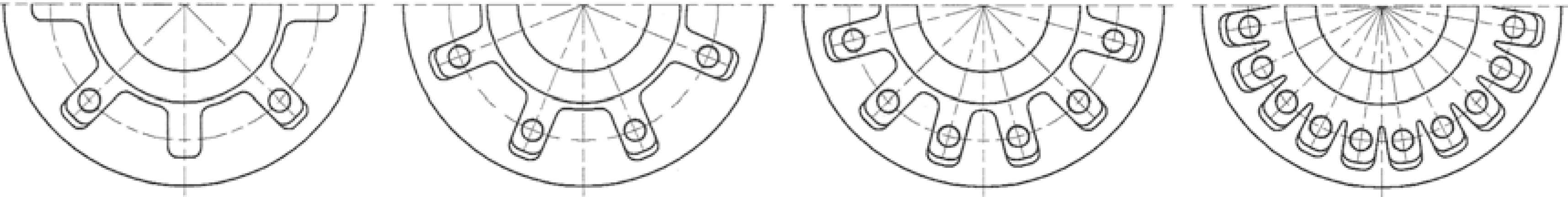

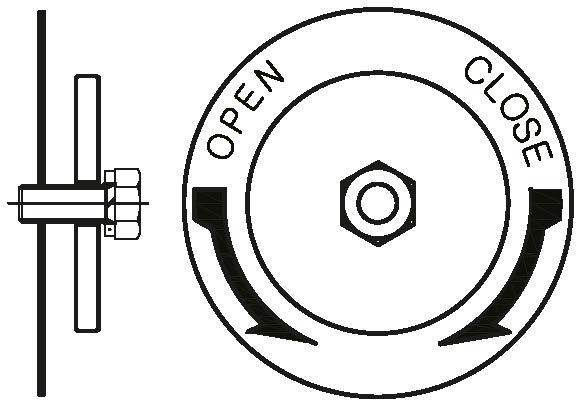

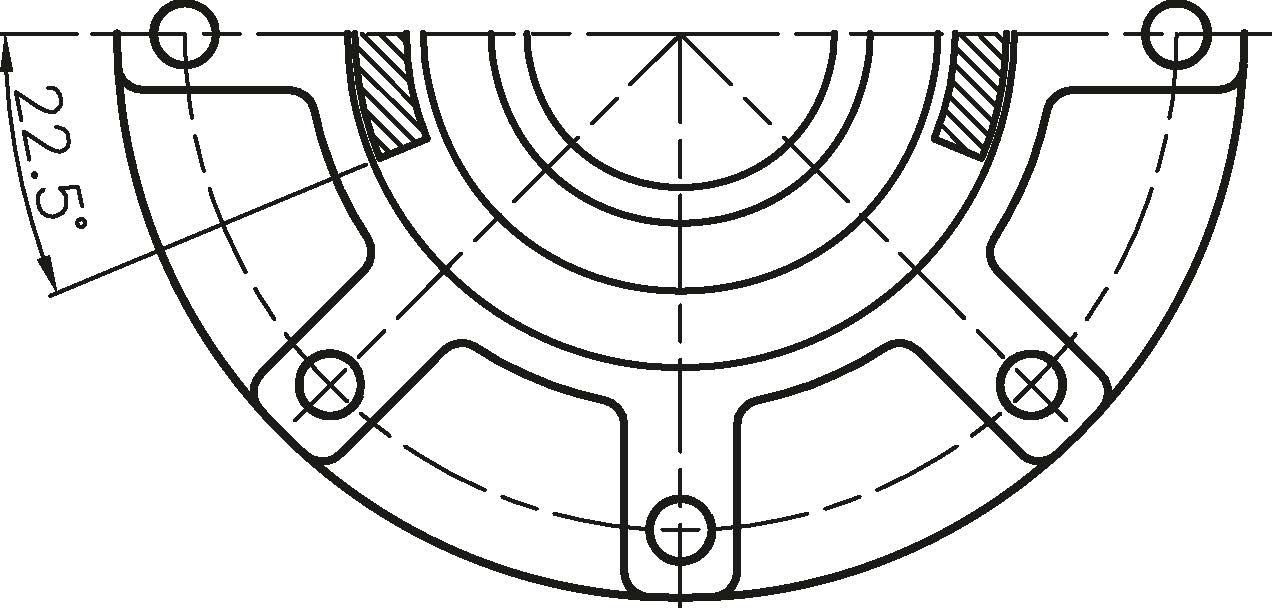

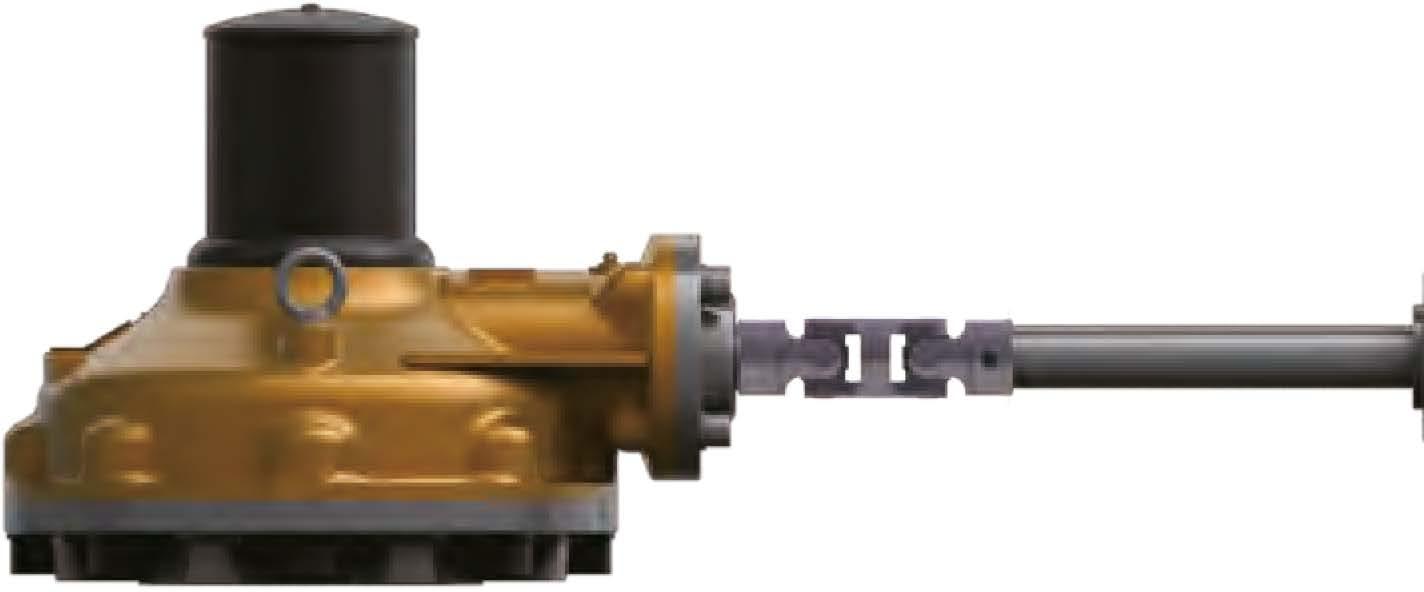

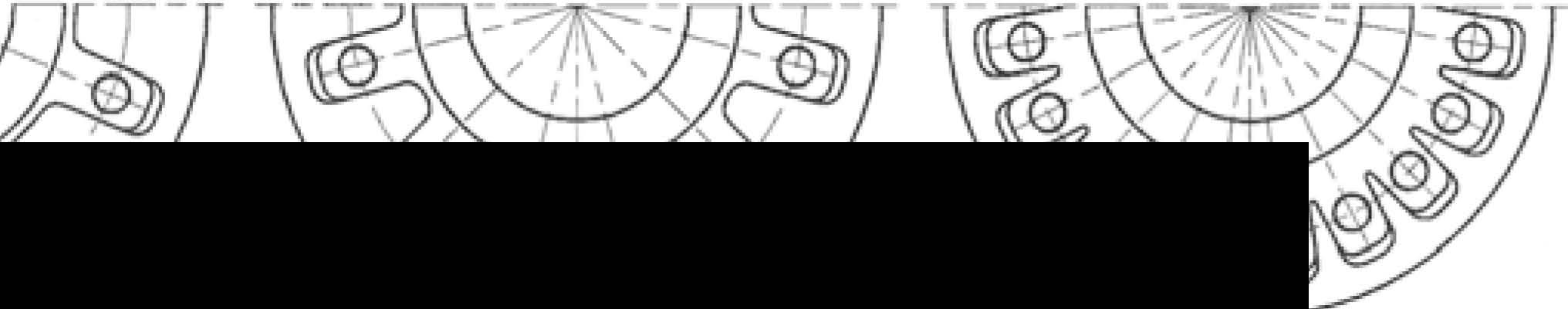

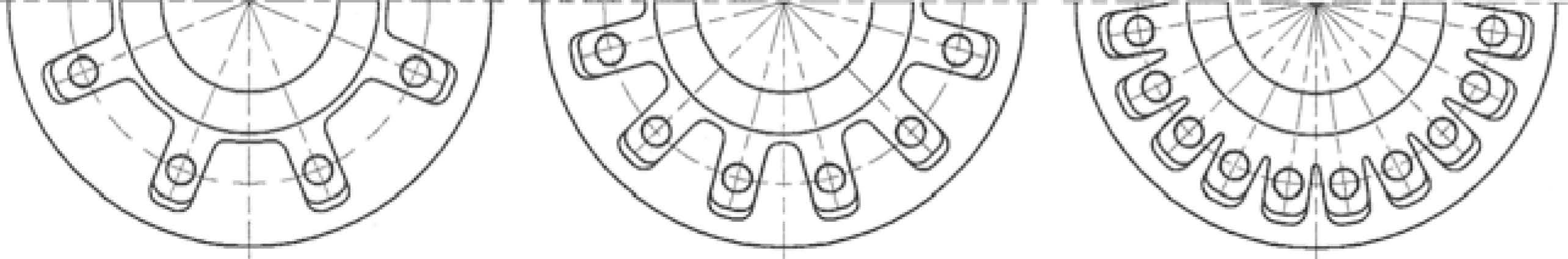

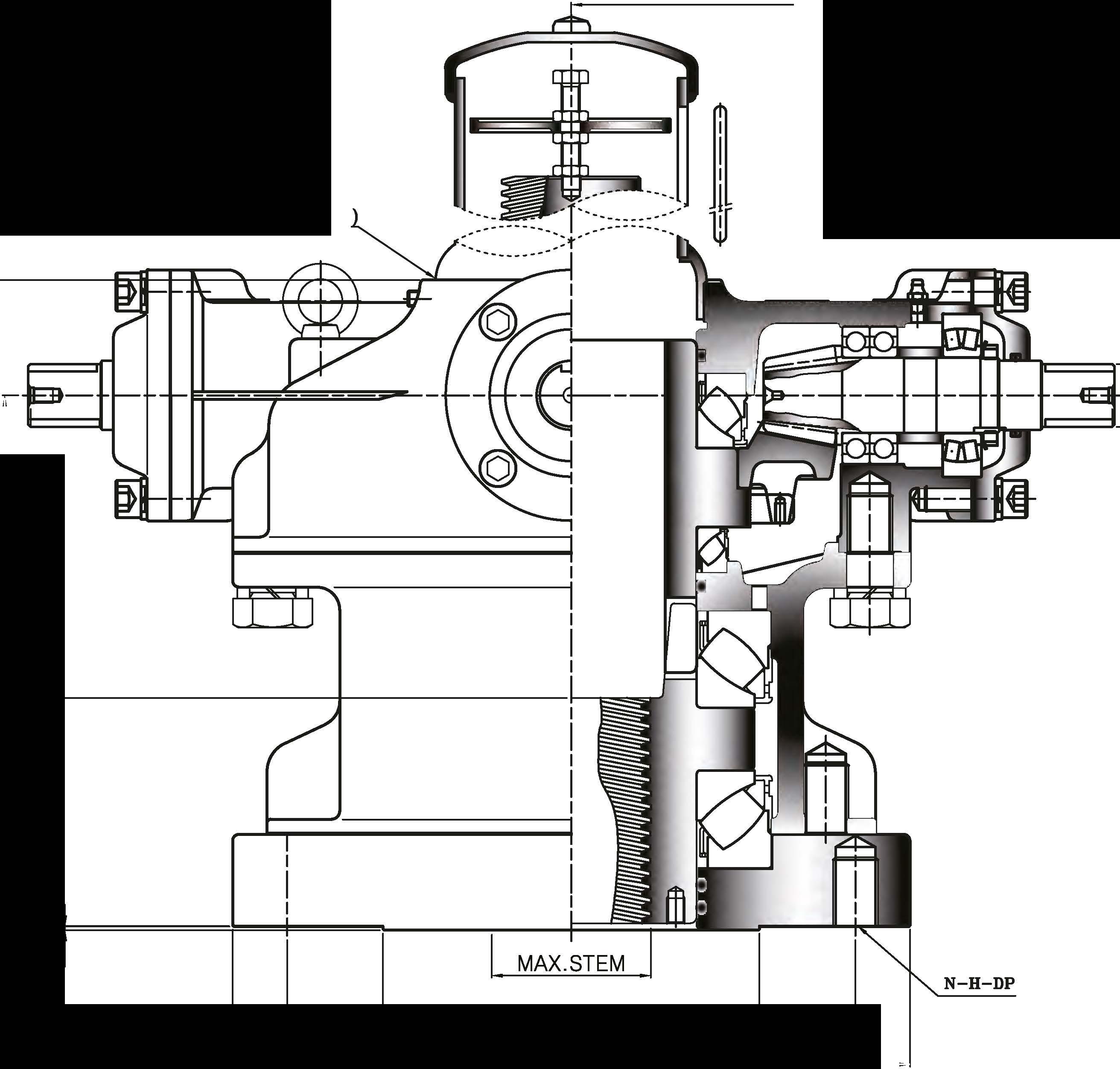

BevelGearshavetheab.ilitytabe assembledwith'tost-/Ylotion-[Hammerblow]"or with"No-Lost/Ylotion"outputdriuearrangement IYI•0•V TYPE / DUAL TYPE

HANDLE TYPE

SPIRAL BEVEL GEAR

Fix Type (IYI • 0 • V/Dual} >>> No-Lost IYlotion

This type eliminates the gap in the lug drive between the Spiral Bevel Gear and Drive Sleeve. It is the preferred method for Electric Actuators having positioning control capability.

BEVEL GEAR

Hammer Blow Type (Handle) >>> Lost IYlotion

This type eliminates the gap in the lug drive between the Spiral Bevel Gear and Drive Sleeve enabling a momentary impact. It is the preferred method for all IYlanual operation and for Electric Actuators of Wedge Gates and Globe Valves.

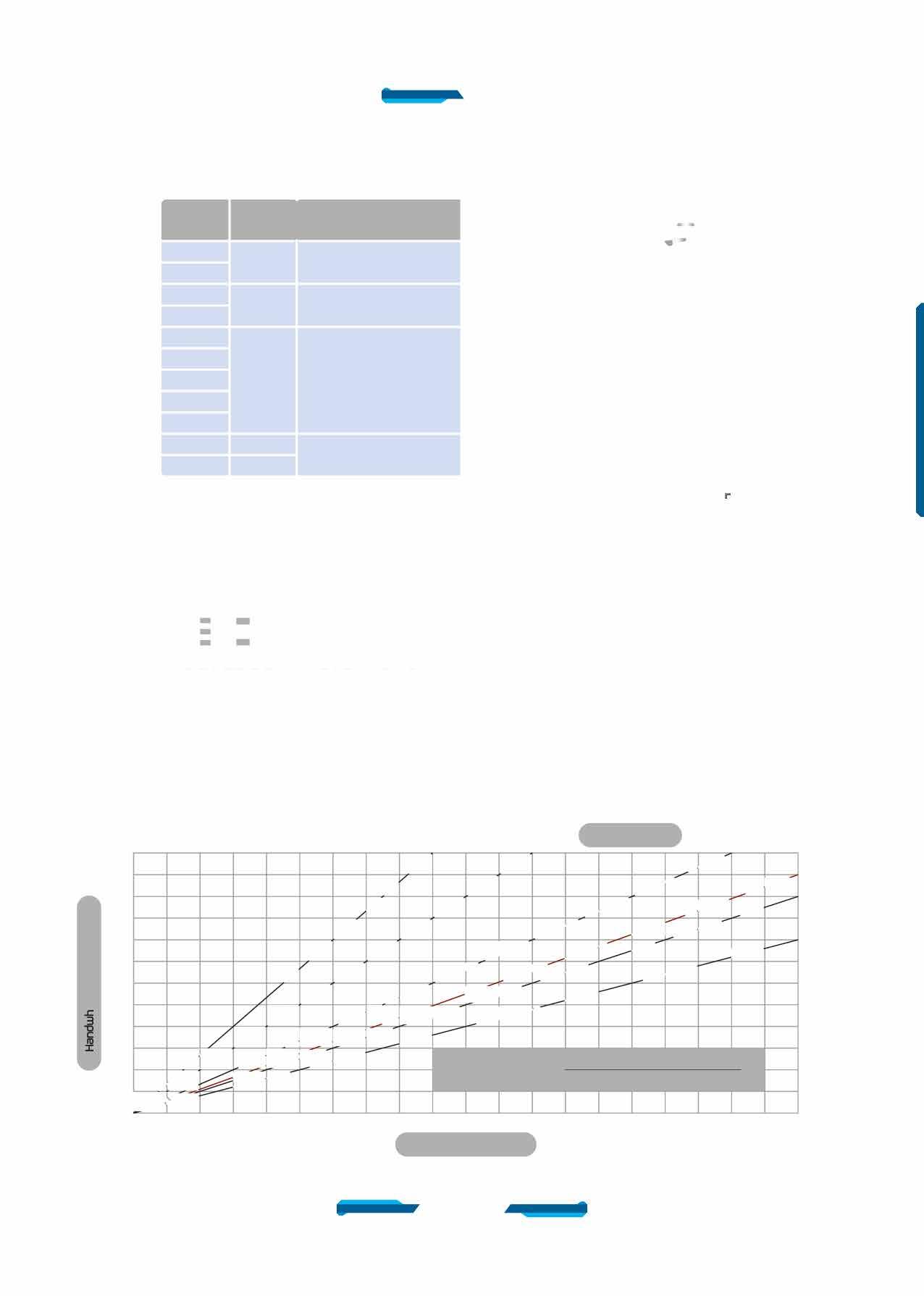

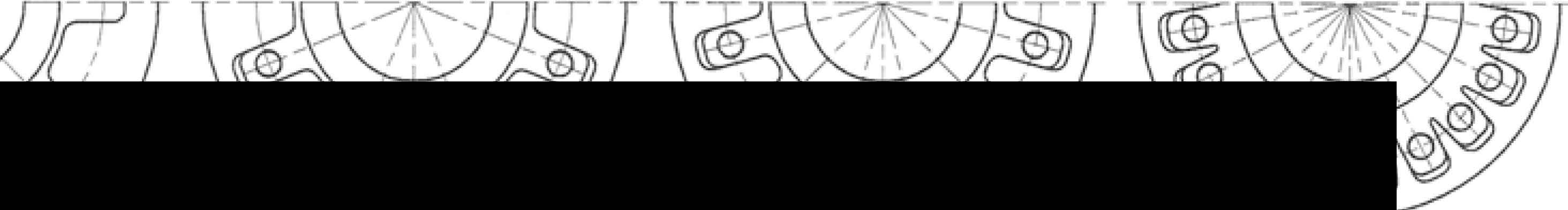

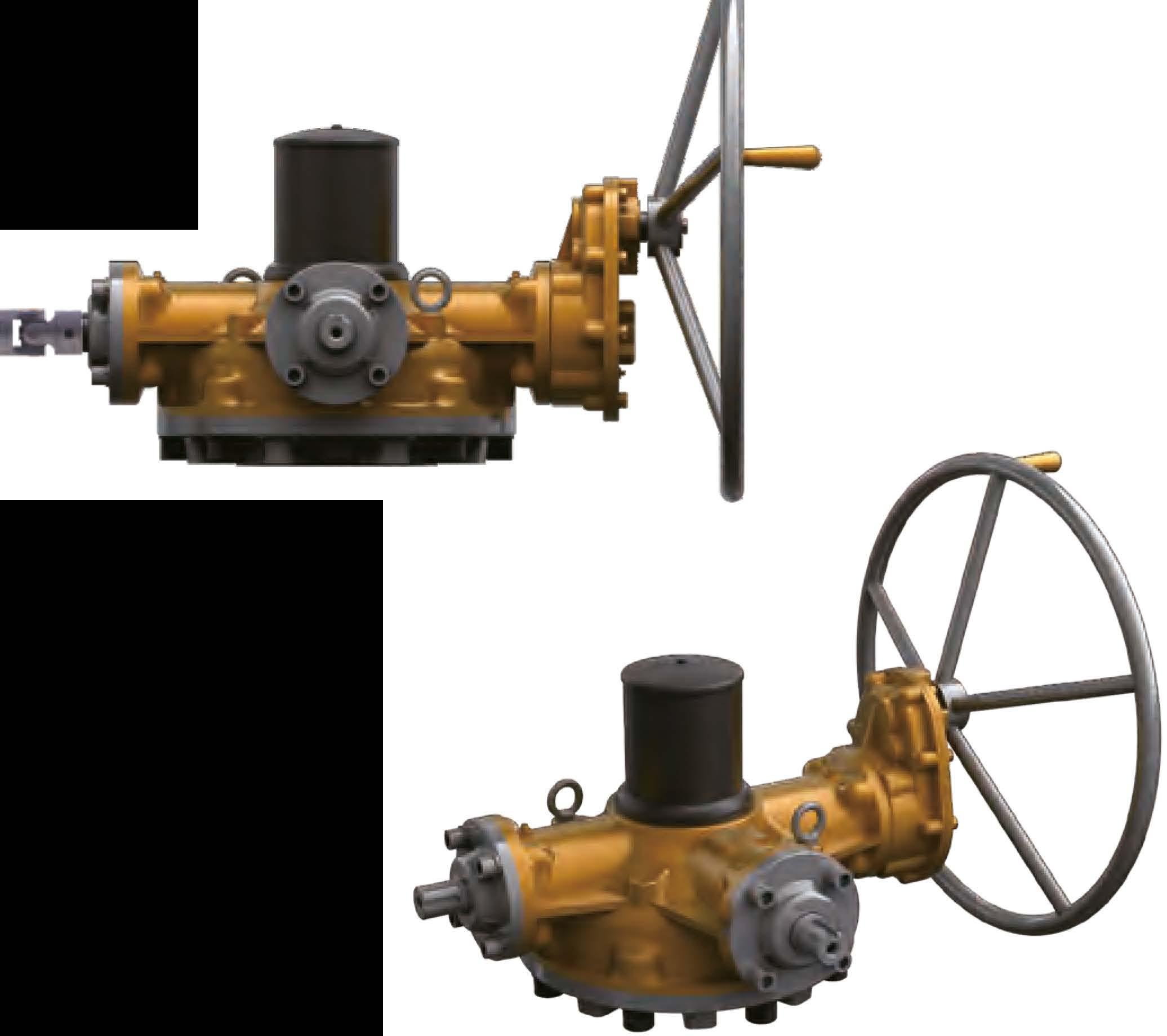

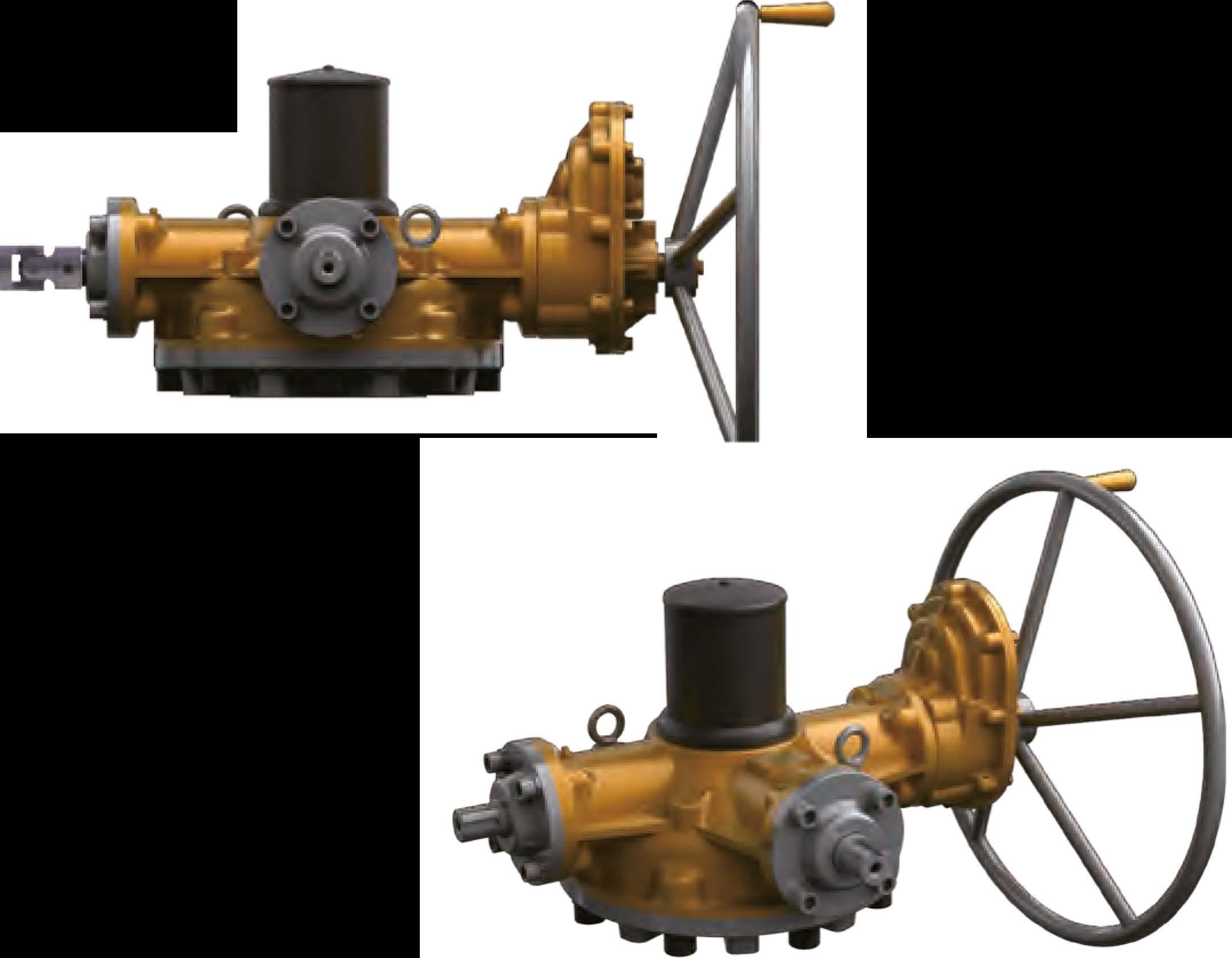

There are two input shafts in the below support box type. One shaft is for high speed and the other shaft is for low speed.

Provides maximum mechanical advantage for seating and unseating of valves.

Allow for less turns after valve has been unseating.

The below input shaft type is used to require Gear Actuators which is operated by 2 spindles. As option, there are motorized type, dial type and manual type.

Stem cover for valve can be offered as AS3, SUS3O4, polycarbonate and etc. Stem cover and indicator sets can be made by several different types. The length of stem cover will be changed as per customer' s request.

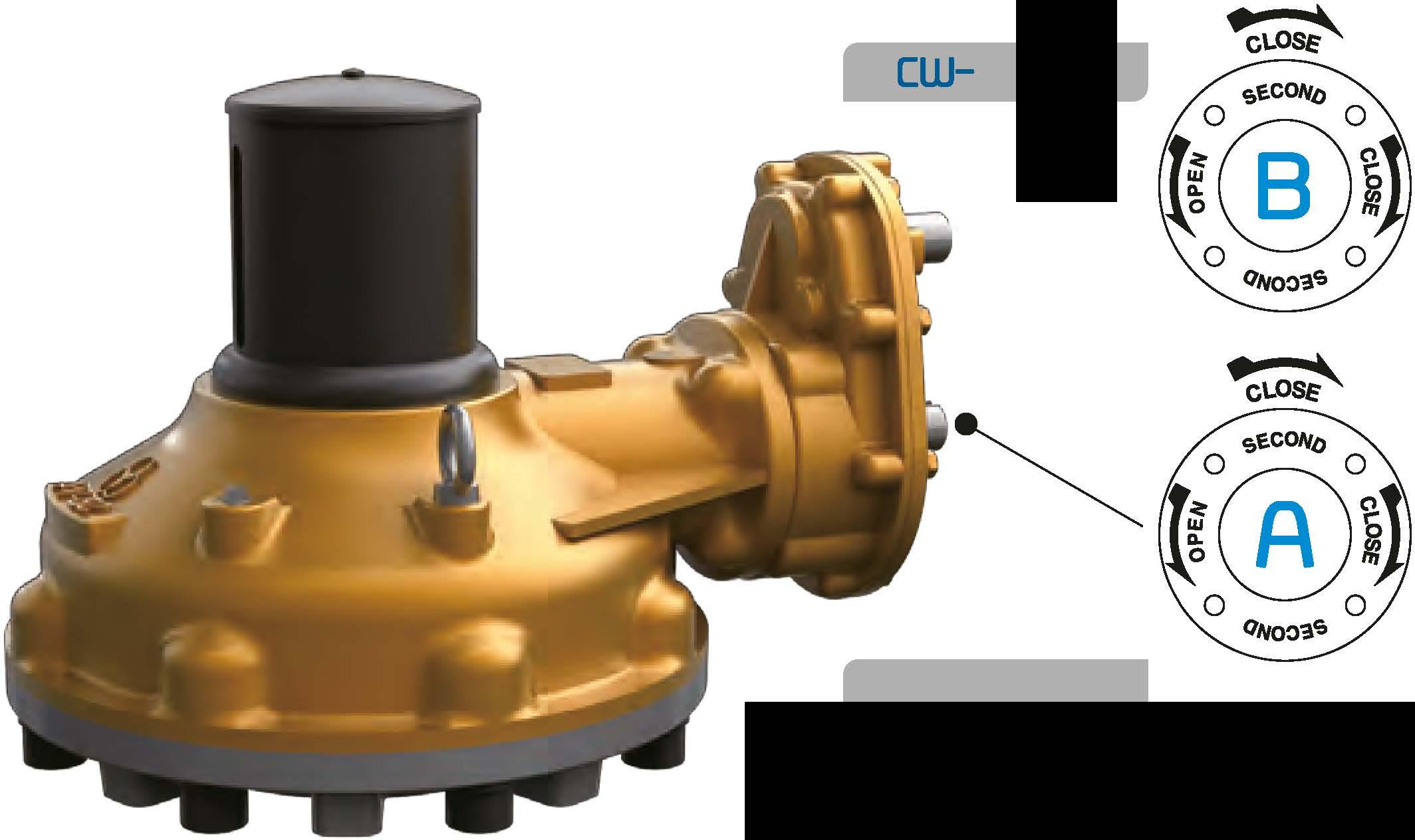

Samba' s standard input shaft rotation is based on a clockwise input resulting in a clockwise output (Clockwise In = Clockwise Out). The reverse rotation can be operated. As per customer' s request, it can be made by such types as buried, submersible, marine, radiation and high & low temperature service and etc. Also, Gear ratio and specification of flange can be changed.

SB-MT-V4

SB-MT-V5

SB-MT-V55

SB-MT-V6

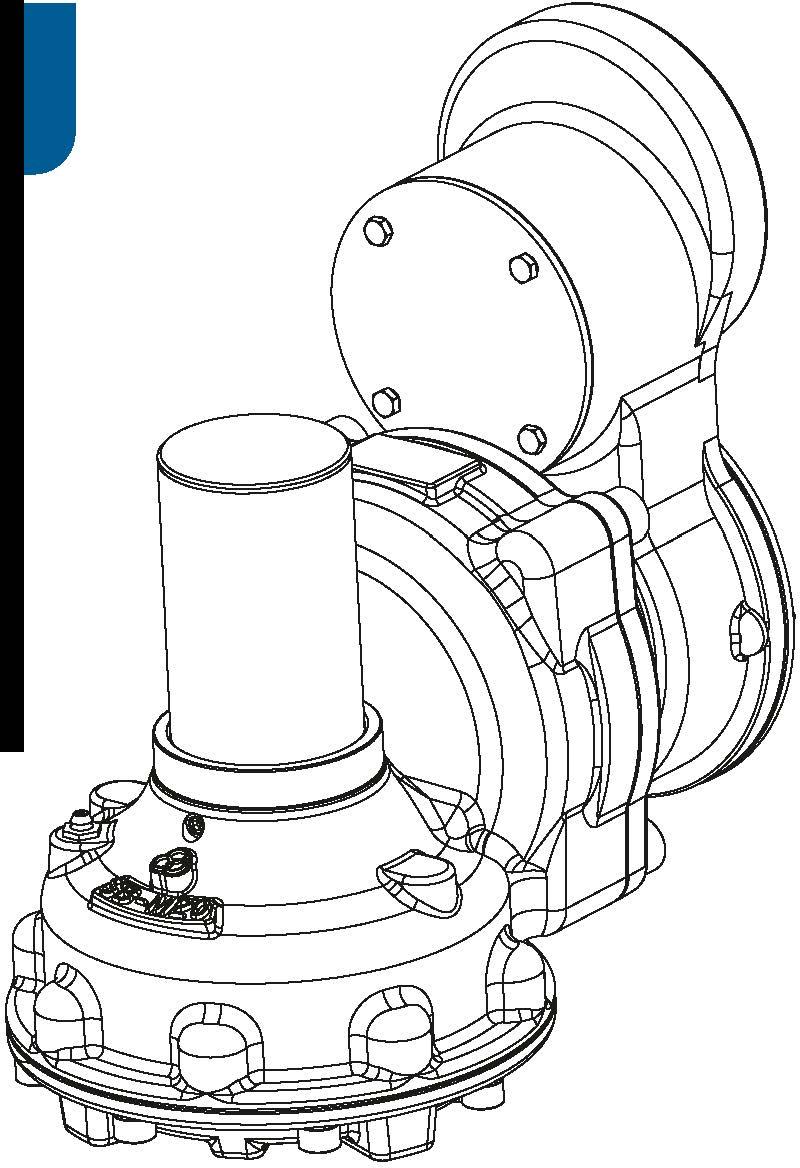

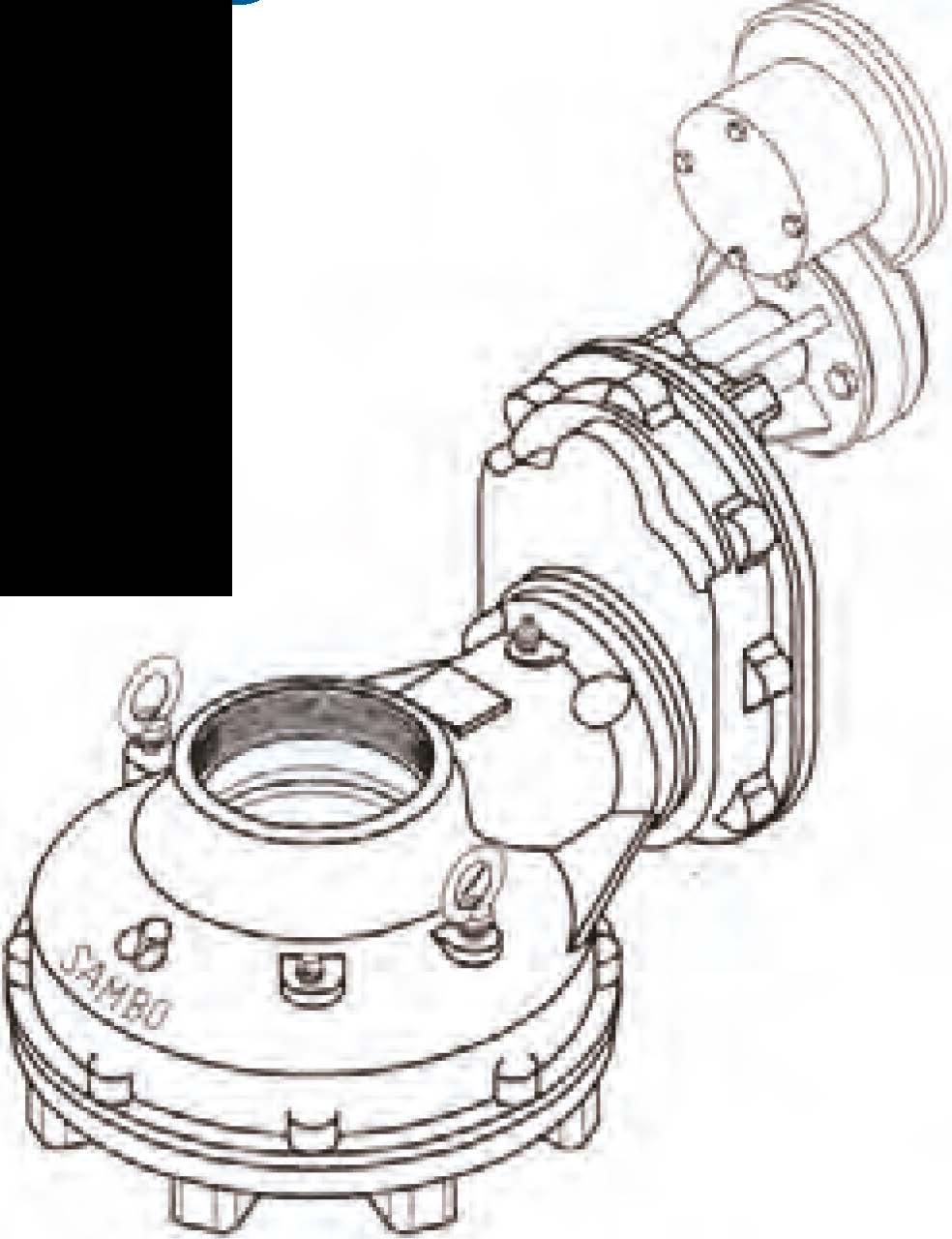

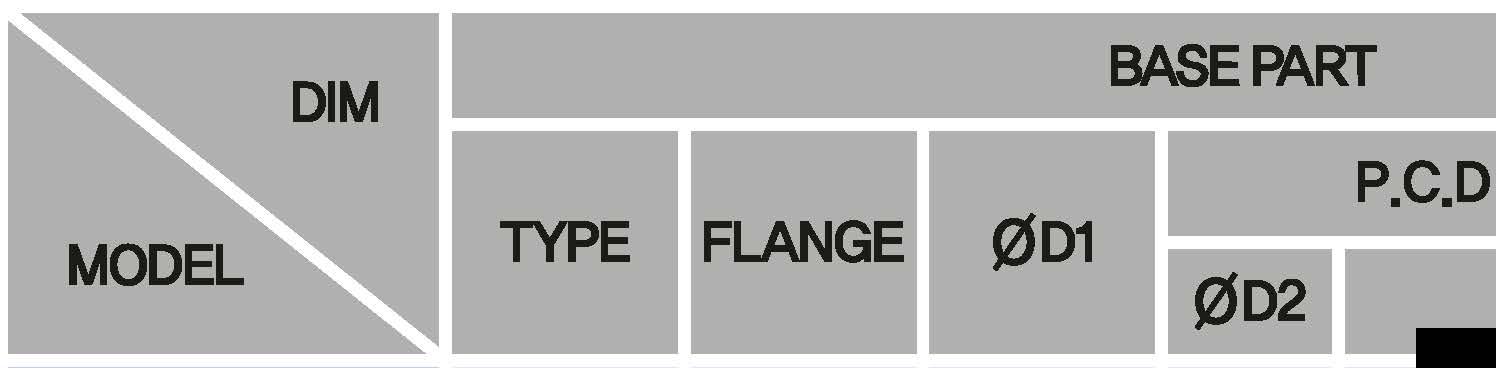

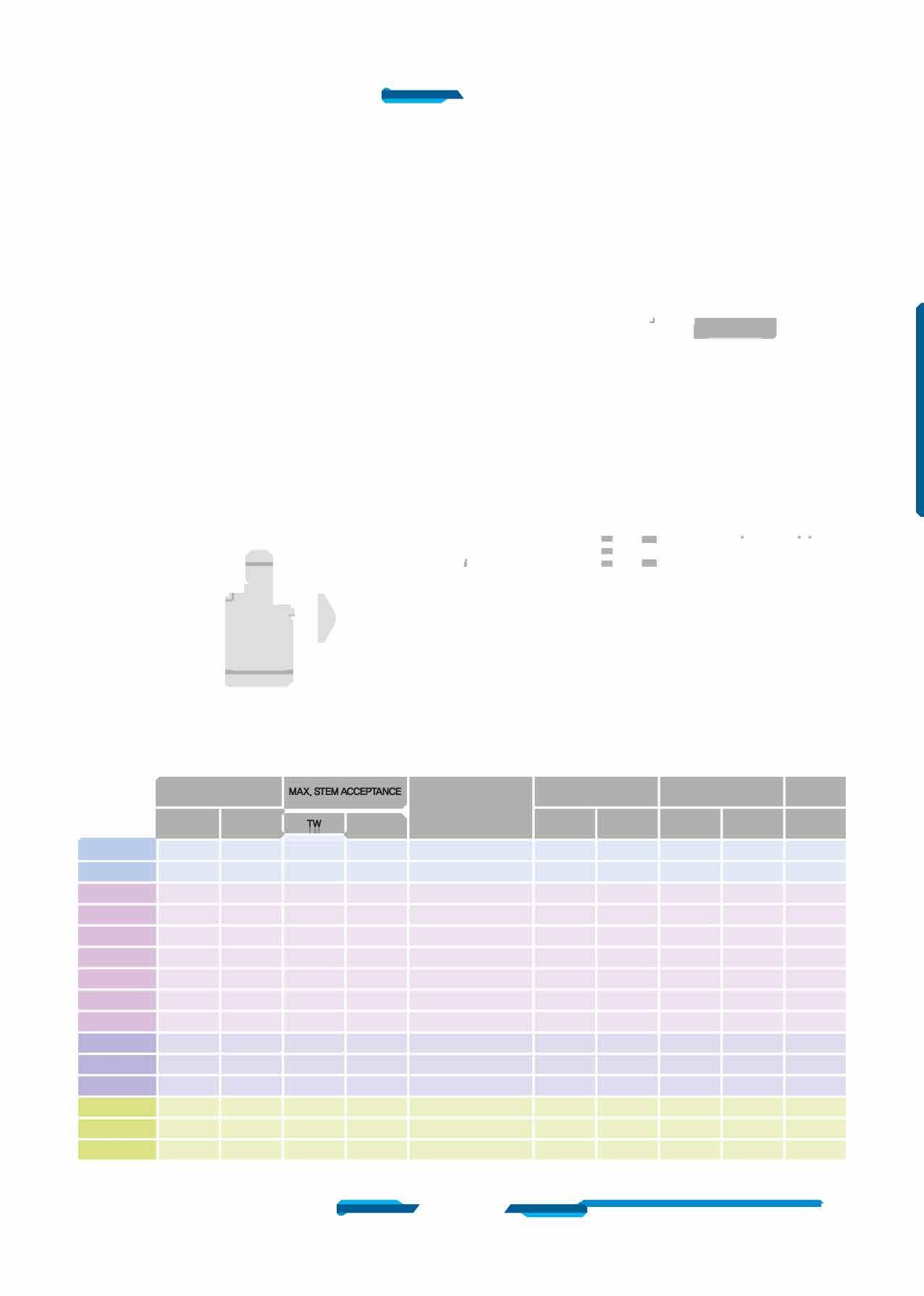

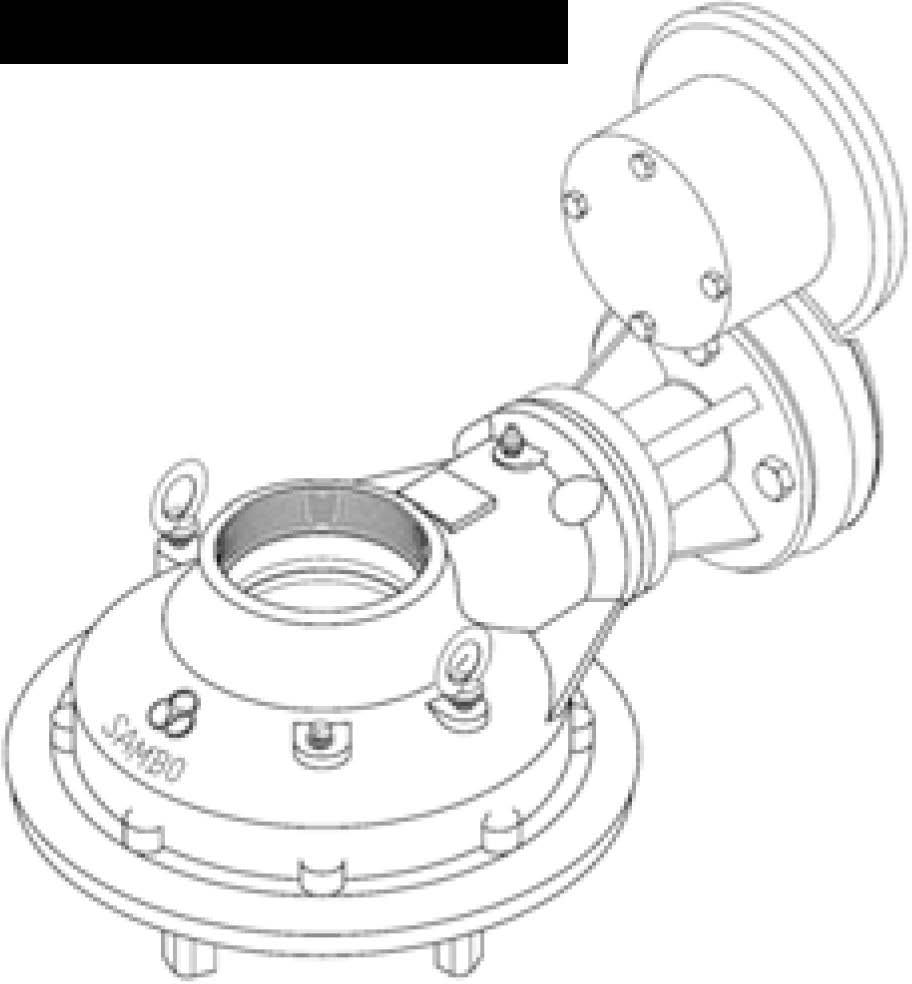

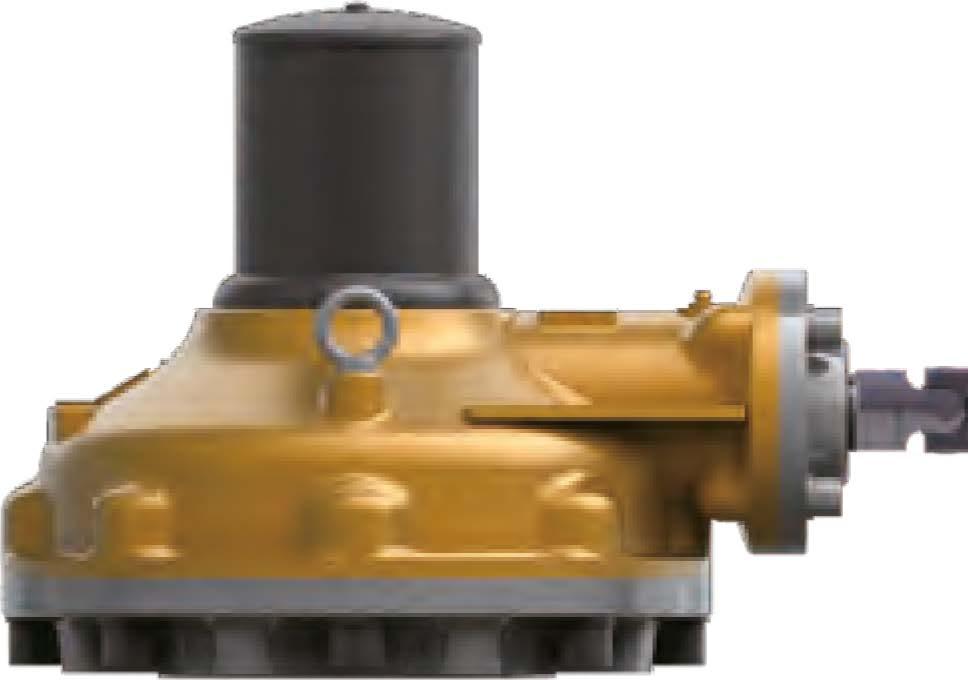

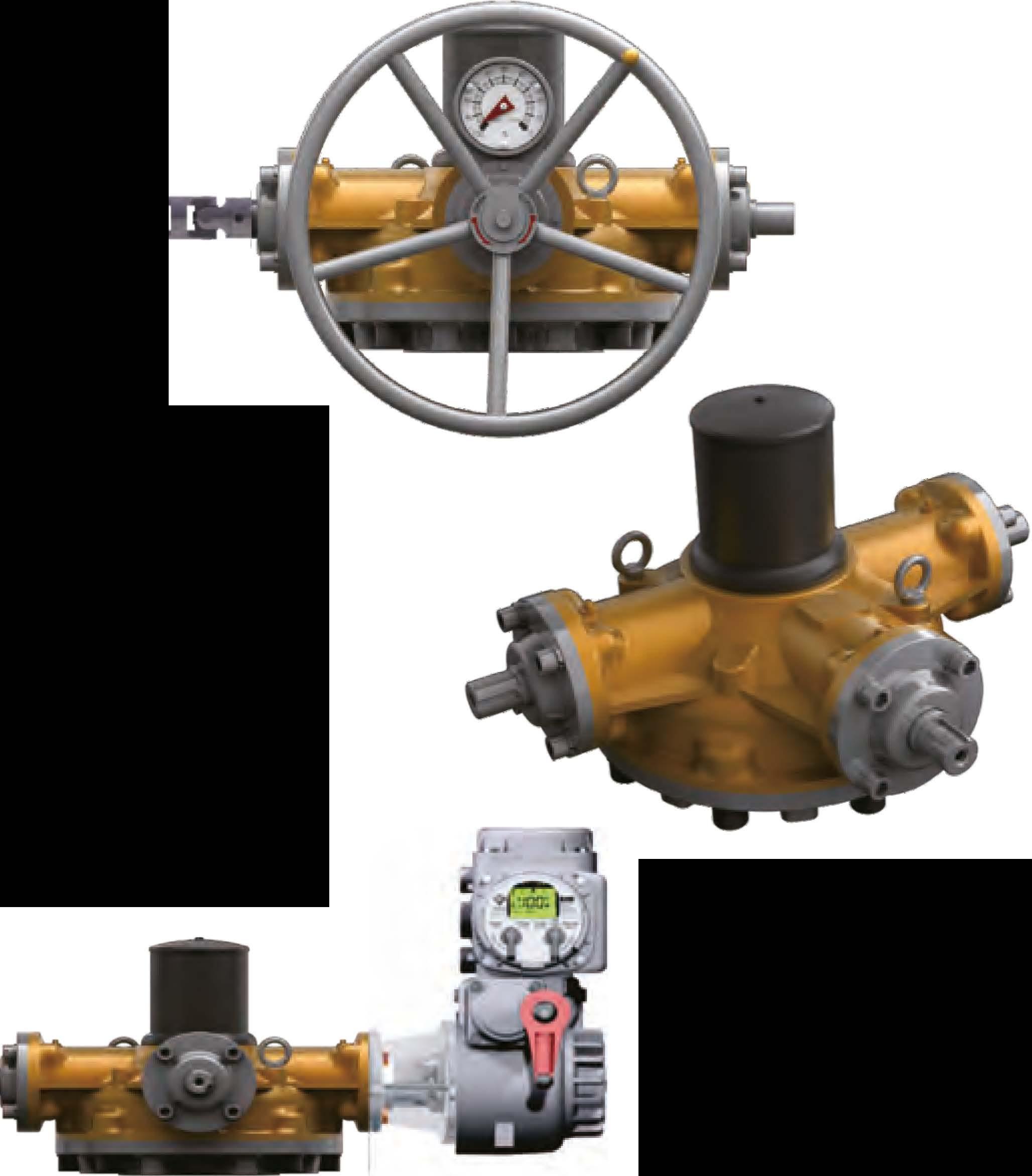

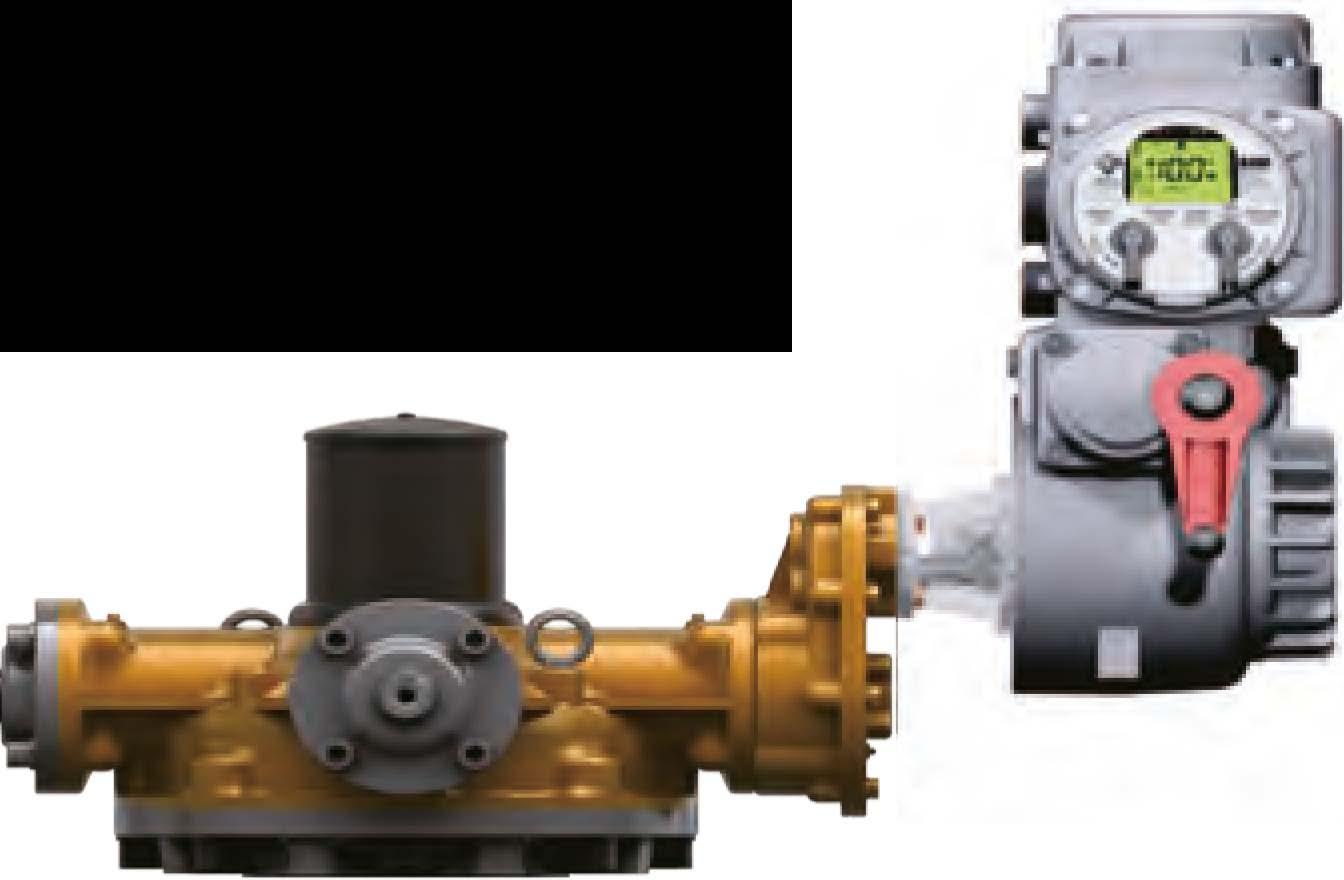

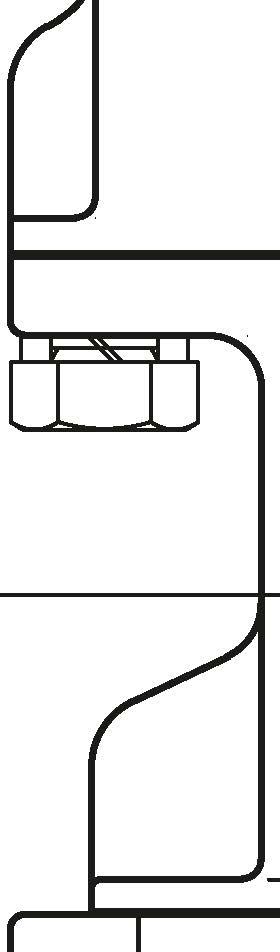

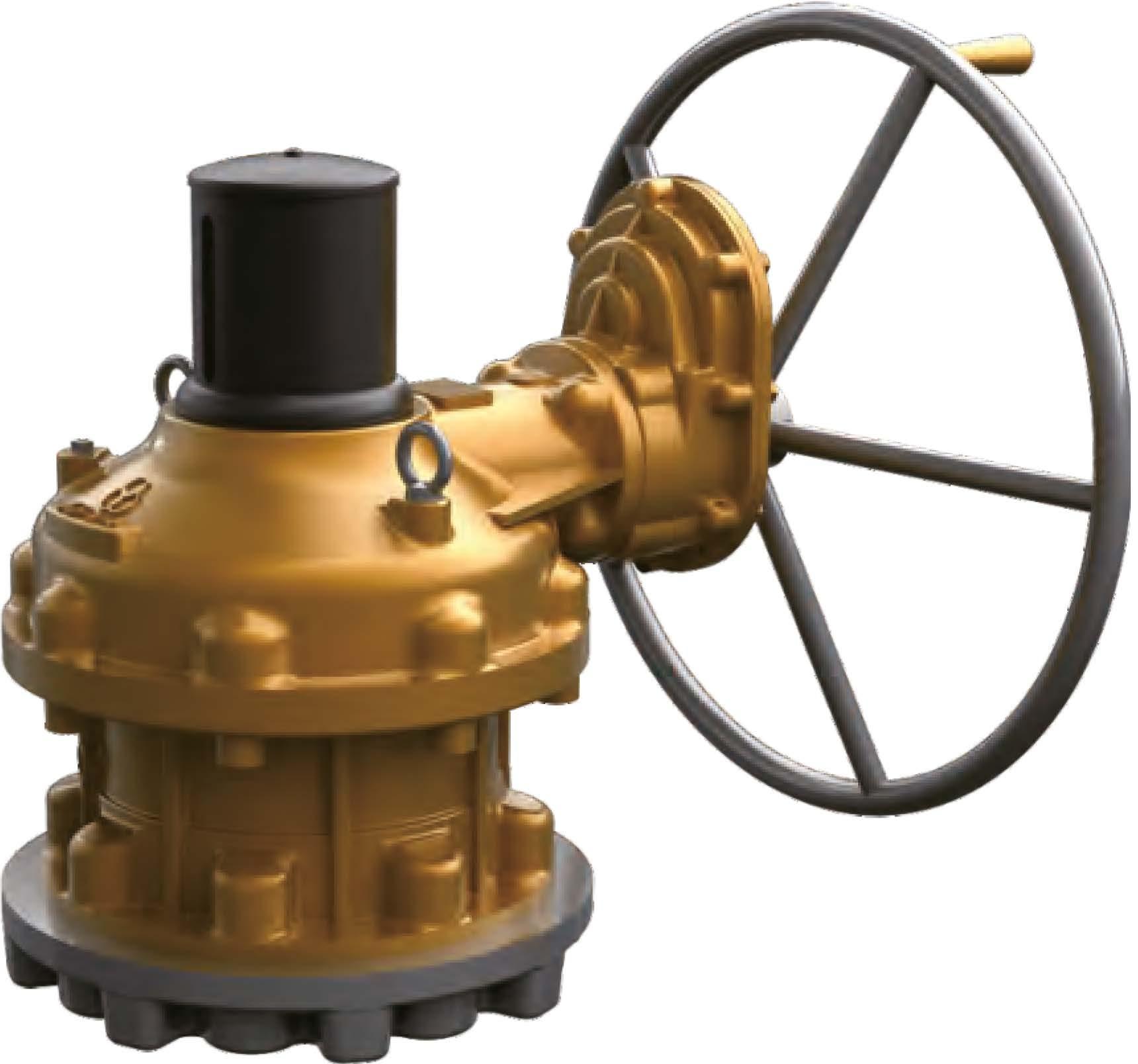

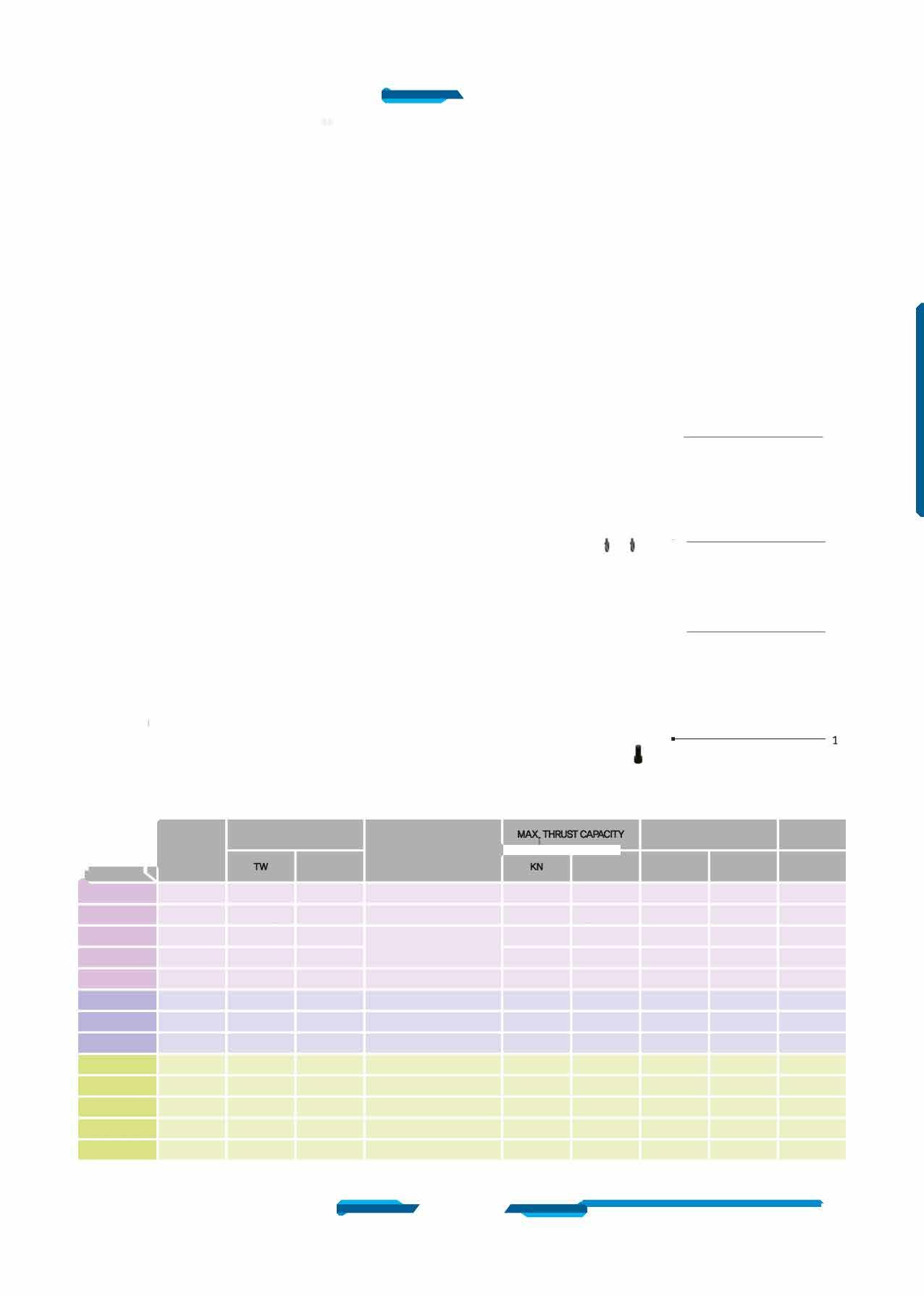

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (dose) to 100% (open).

.eader

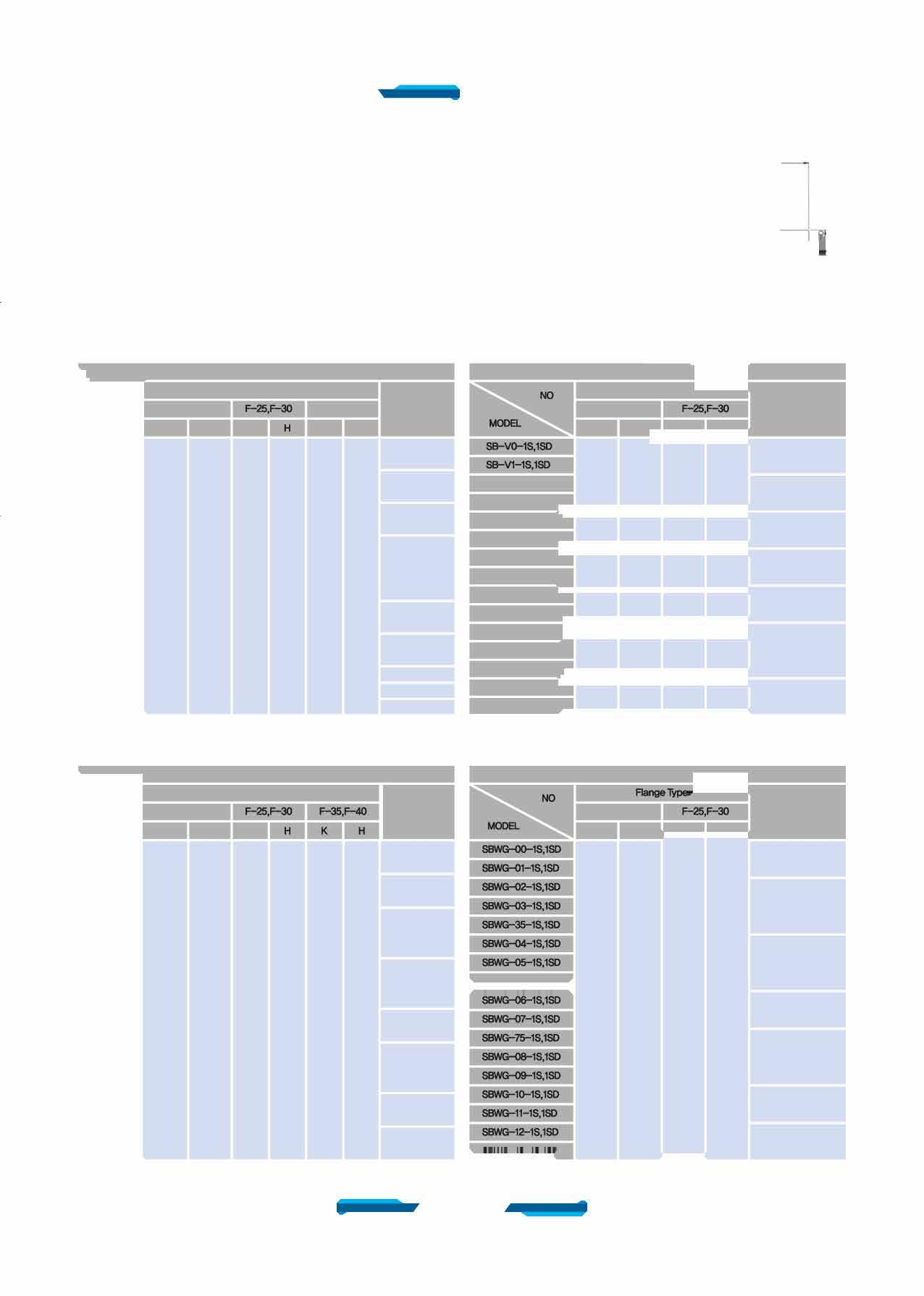

Bevel Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

*SB-SP-VS20 F-12 85

•SB-SP-VO F-14 100

•SB-SP-V1 F-16 130

•SB-SP-V2 F-16 140 (F-20)

•SB-SP-V3 F-25

•SB-SP-V35 F-30

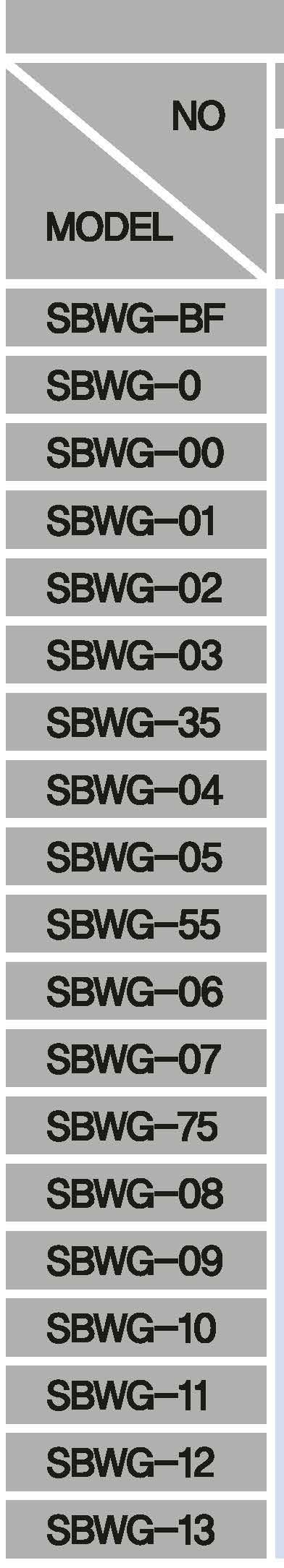

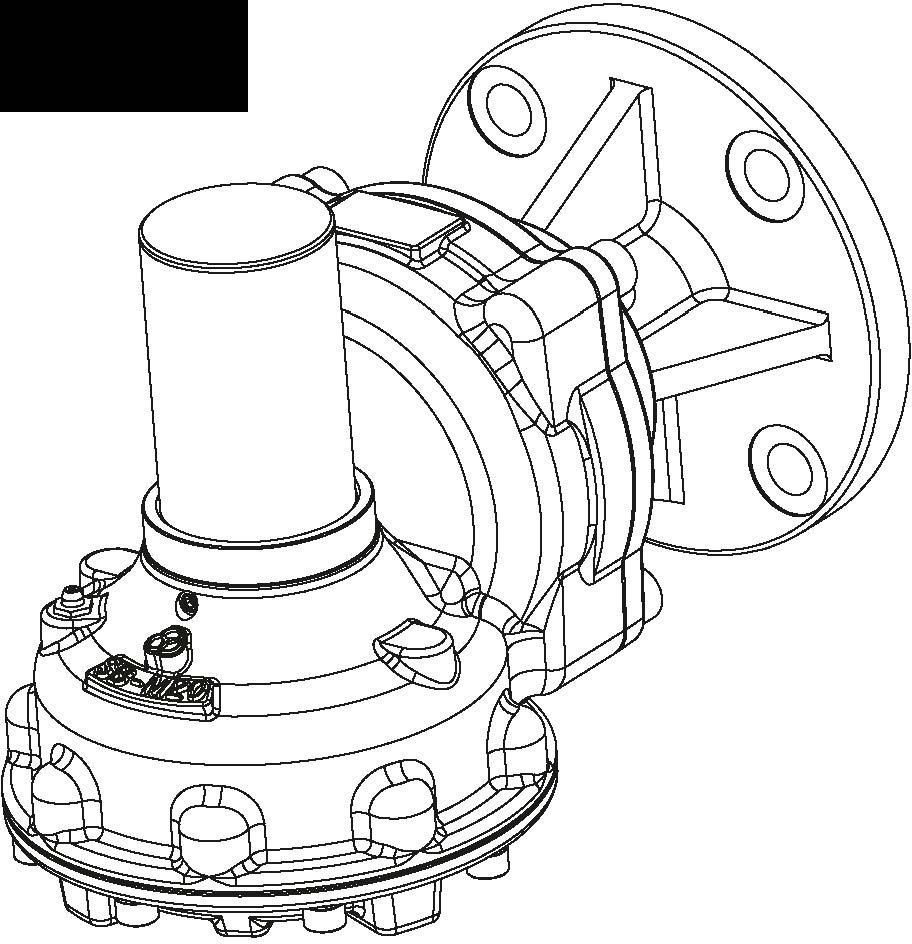

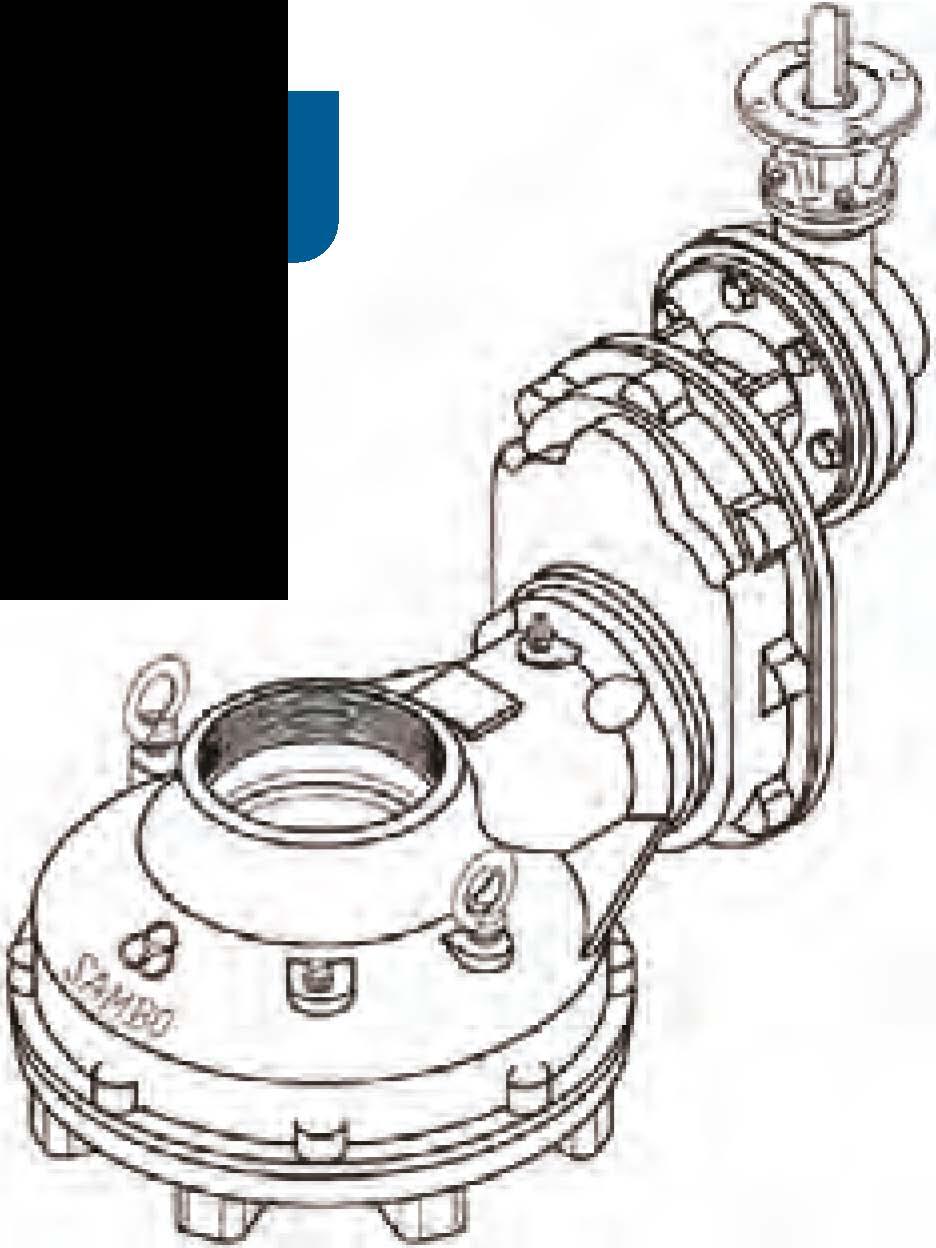

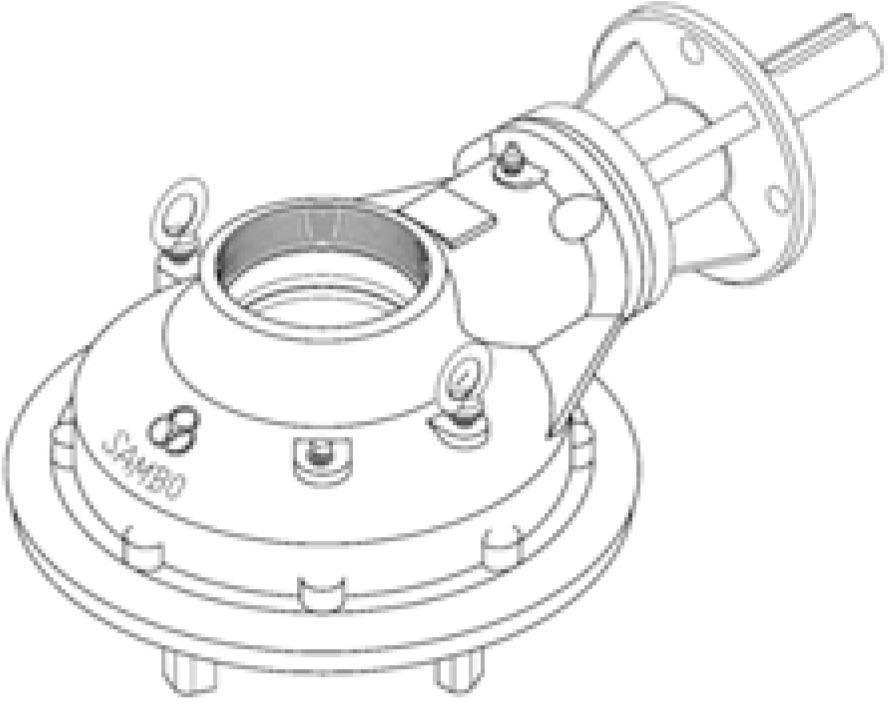

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (close) to 100% (open).

Bevel Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

Input can be equipped with a Handwheel locking device for IYlanually operated units.

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (close) to 100% (open).

Bevel Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

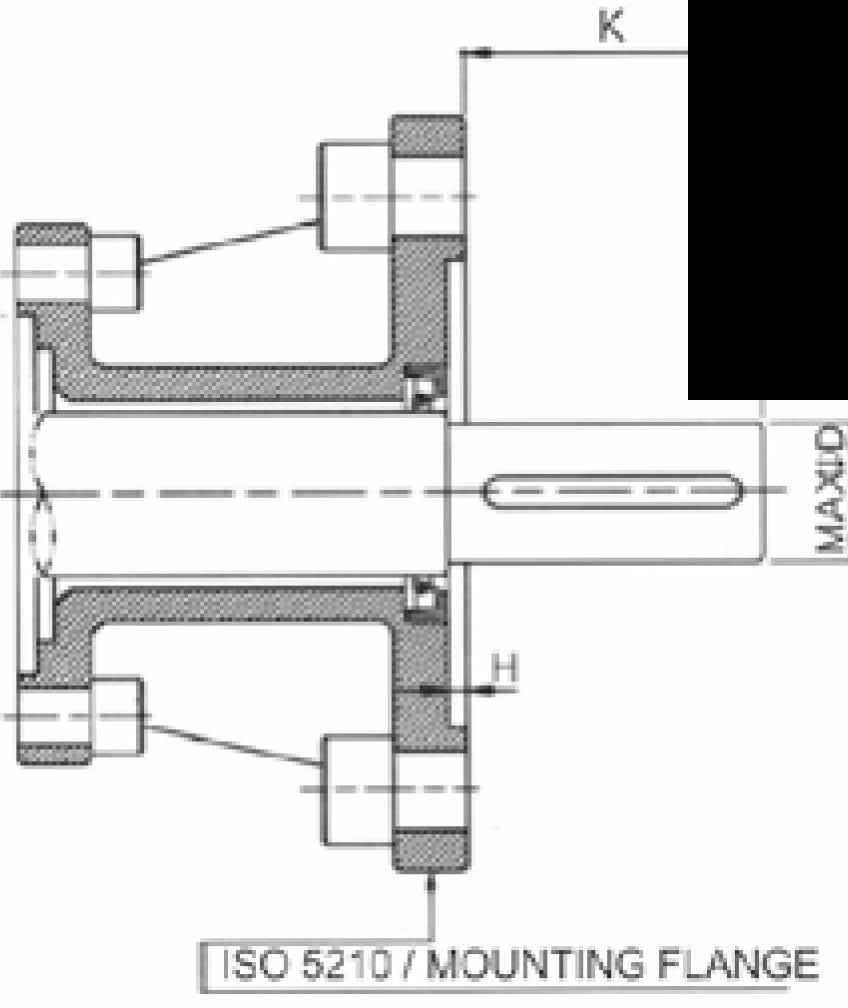

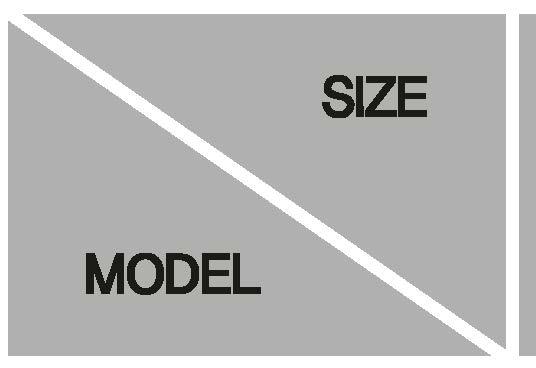

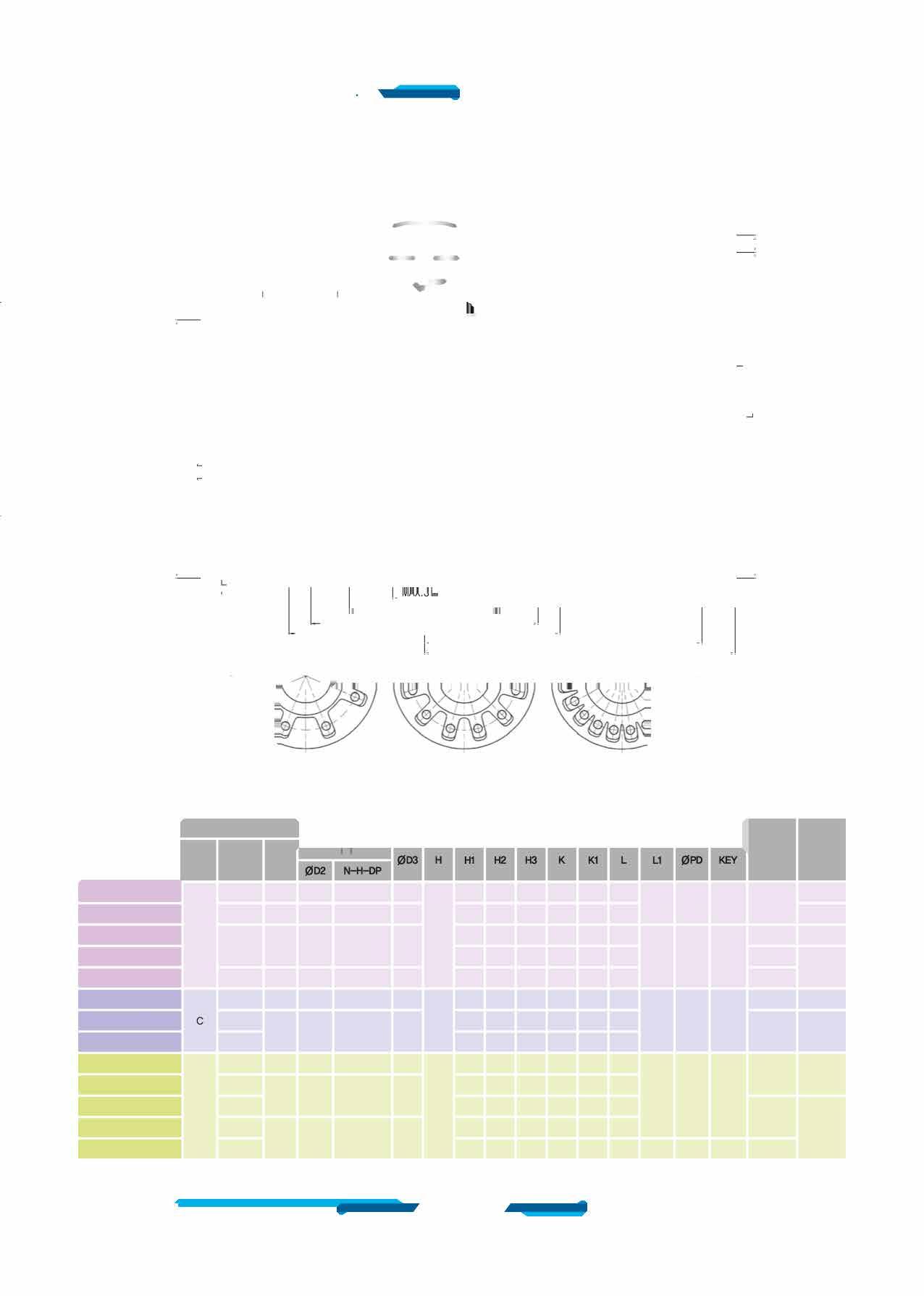

SB-V0-1S F-14 100

SB-VHS F-16 130

SB-V2-1S F-16 140 (F-20)

SB-V3-1S F-25 200

SB-V35-1S F-30 230

SB-V4-1S F-35 260

SB-V5-1S F-40 300

SB-V55-1S F-40 300

SB-V6-1S F-40 300

SB-V7-1S F-48 370

SB-V75-1S C F-48 370

SB-V8-1S F-48 370

SB-V85-1S F-60 470

SB-V9-1S D F-60 470

•SB-V10-1S F-80 670

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (close) to 100% (open).

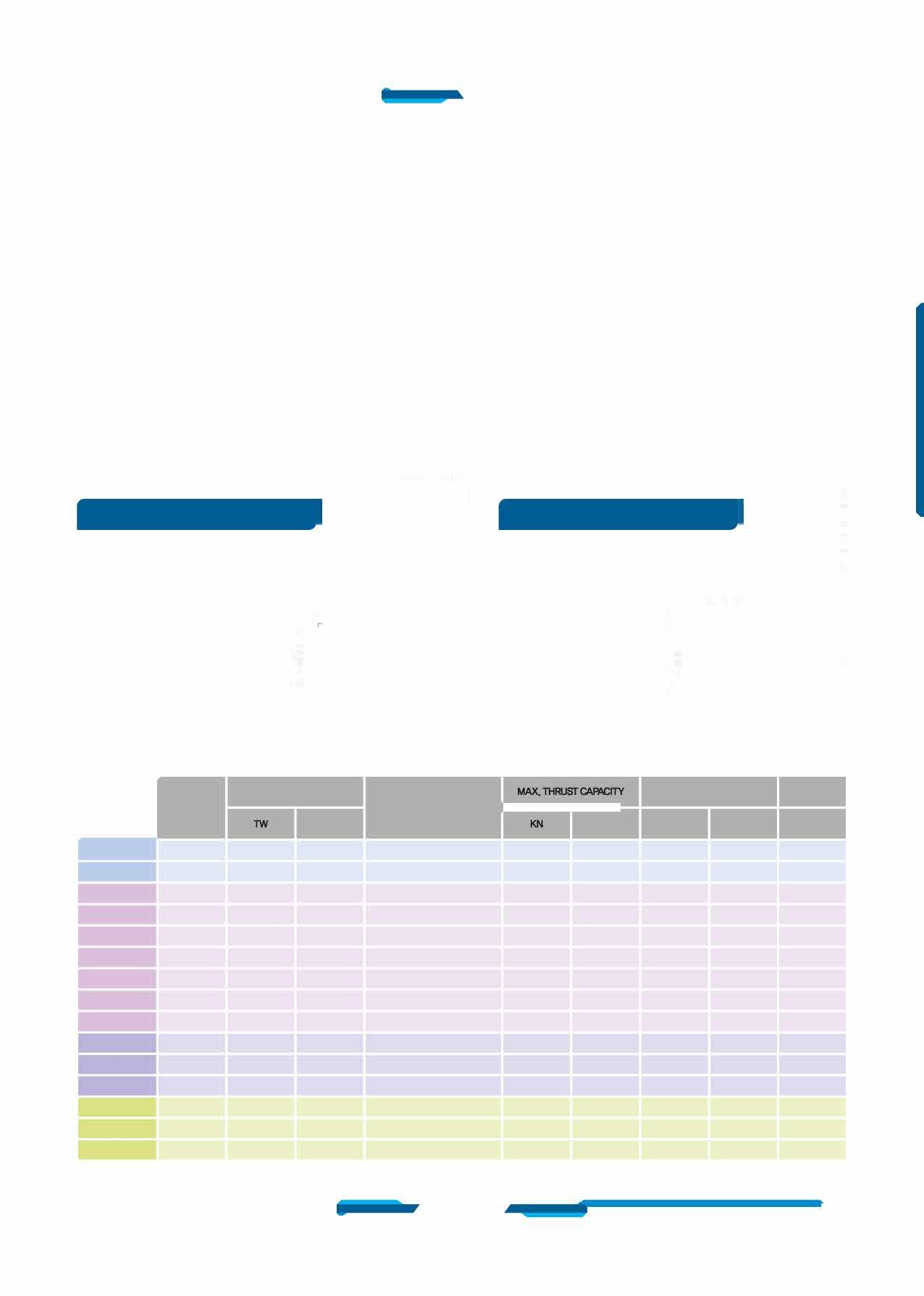

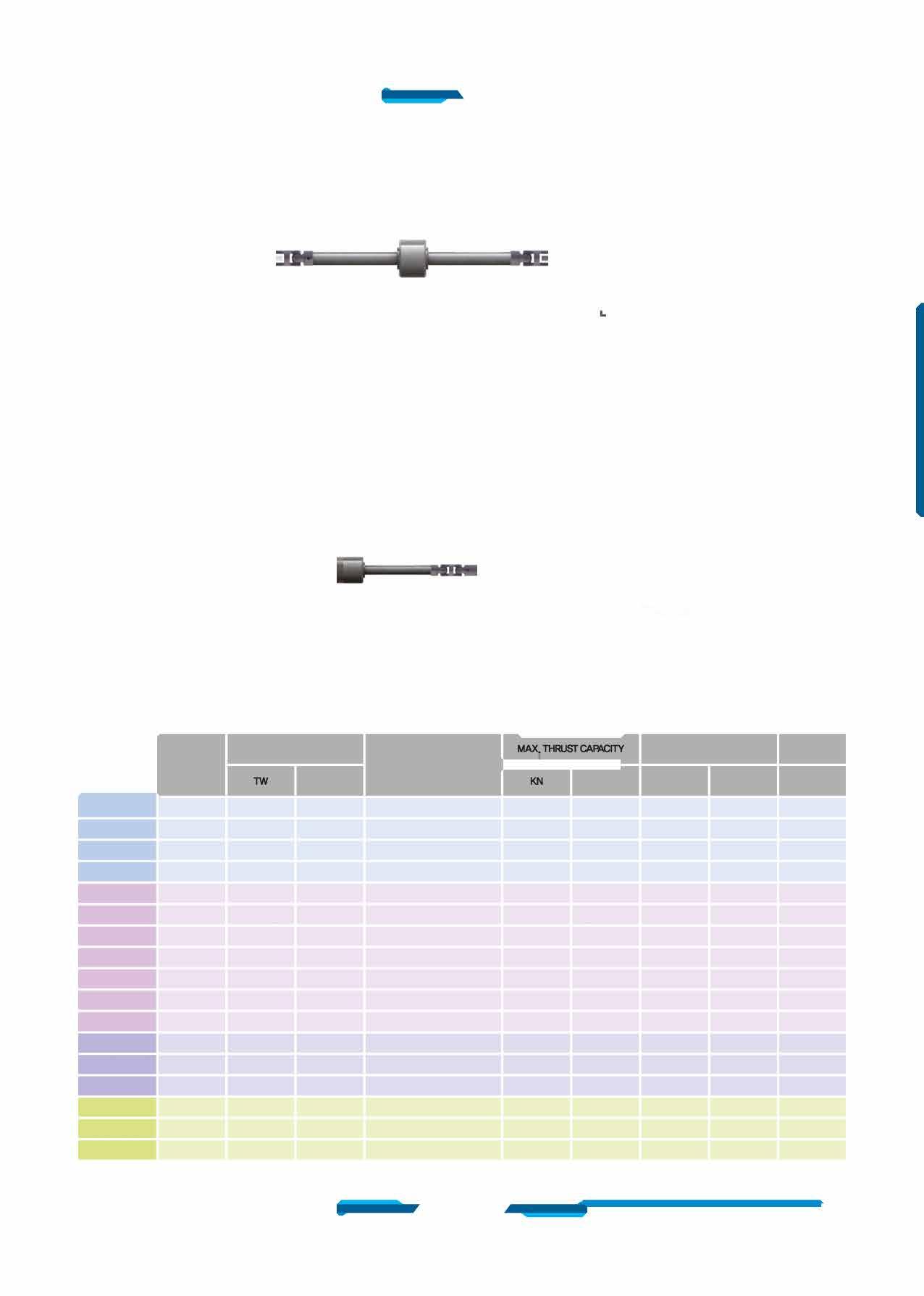

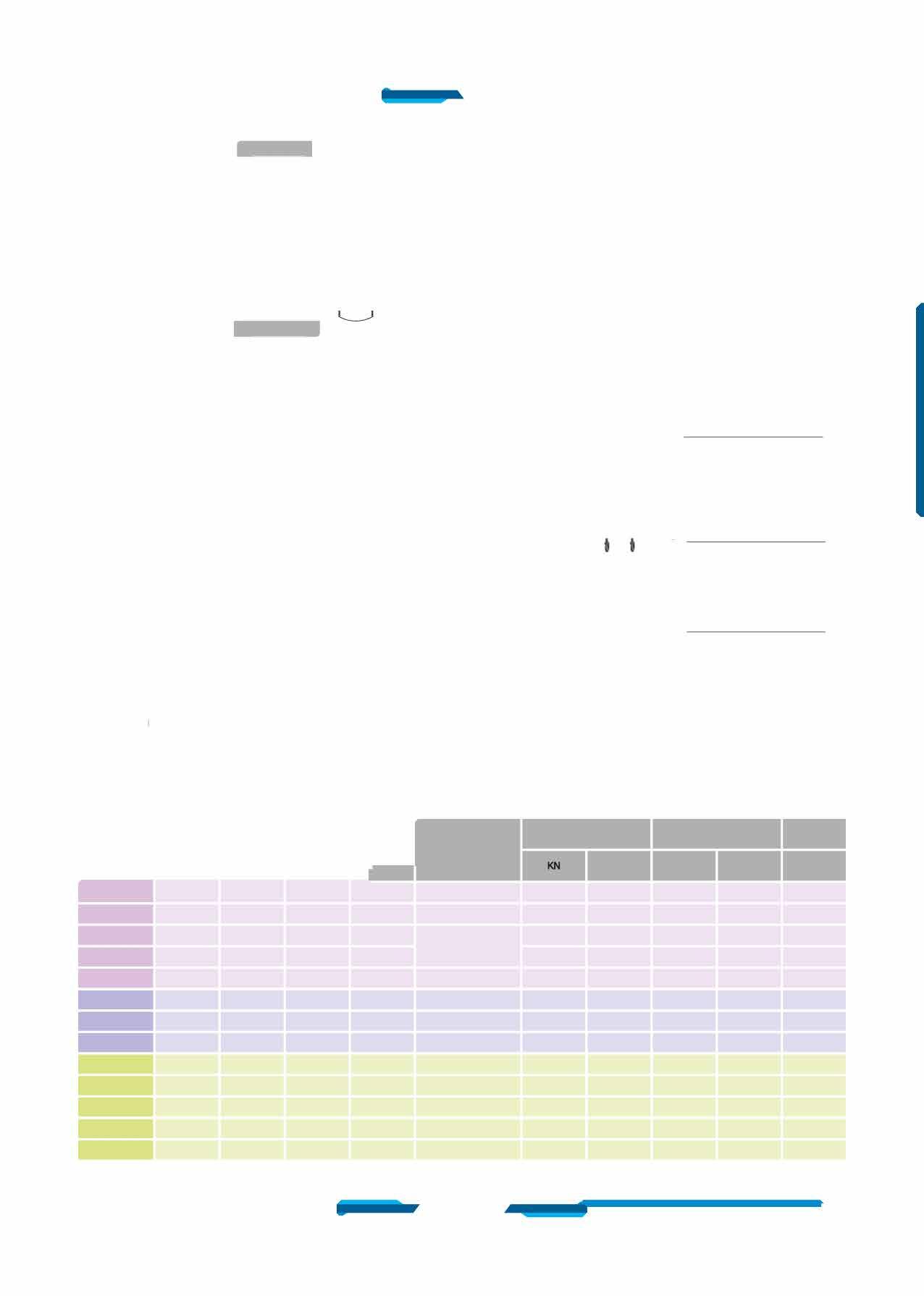

SB-V0-1S 6,5:1 46 38(12X8)F-10,F-12,F-1412728550600442

SB-VHS 7:15545(14X9)F-14,F-1614131700 980 723

SB-V2-1S 10,13:1 62 52(16X10)F-14,F-16,(F-20)1904271015001106

SB-V3-1S 12,66:17260(18X11)F-16,(F-20),F-252886475025001844

SB-V35-1S 16,5:1 85 72(20X12)F-25,F-303507868035002581

SB-V4-1S 18:1 98 84(22X14)F-25,F-30,F-354008992052003835

SB-VS--1S 22,94:111095(28X16)F-25,F-30,F-35,F-4051011465078005753

SB-V55-1S 24,5:1120105(28X16)F-30,F-35,F--401500337210104007671

SB-V6-1S 28:1130115(32X18)F-30,F-35,F--402310519300130009588

SB-V7-1S 30,22:1150130(36X20)F-35,F--40,F--4825005620201760012981

SB-V75-1S 40:1160140(36X20)F-40,F-48 3450 7755902100015489

SB-VS-1S 40:1180160(40X22)F-40,F-4841009217003200023602

SB-V85-1S 40:1190170(40X22)F-48,F-60515011577604000029502

SB-V9-1S 40:1200180(45X25)F-48,F-60545012251805500040566

•SB-V10-1S 40:1220200(50X28)F-60,F-60 7300 16411057500055317

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement. • IYlark has been changed and updated.

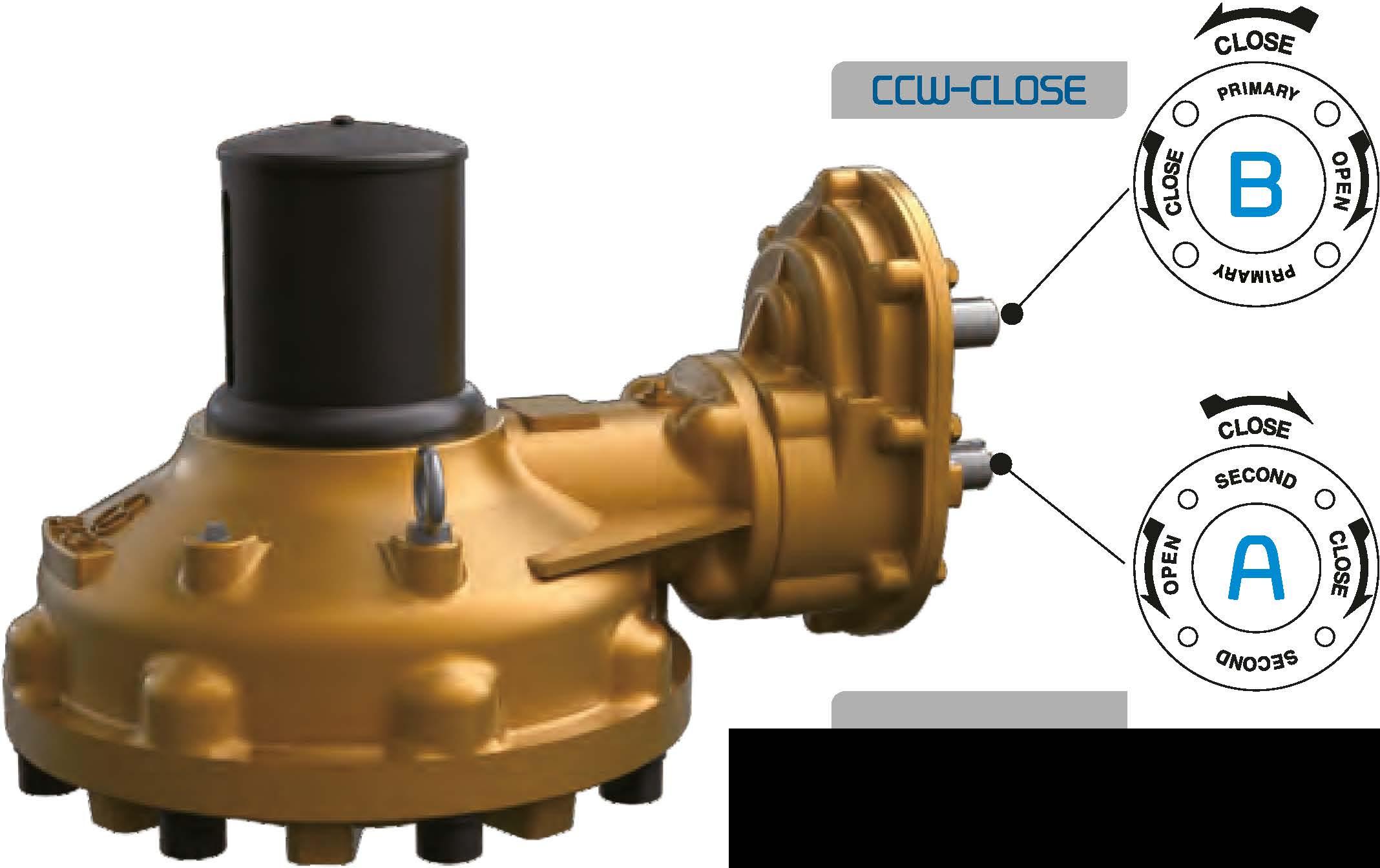

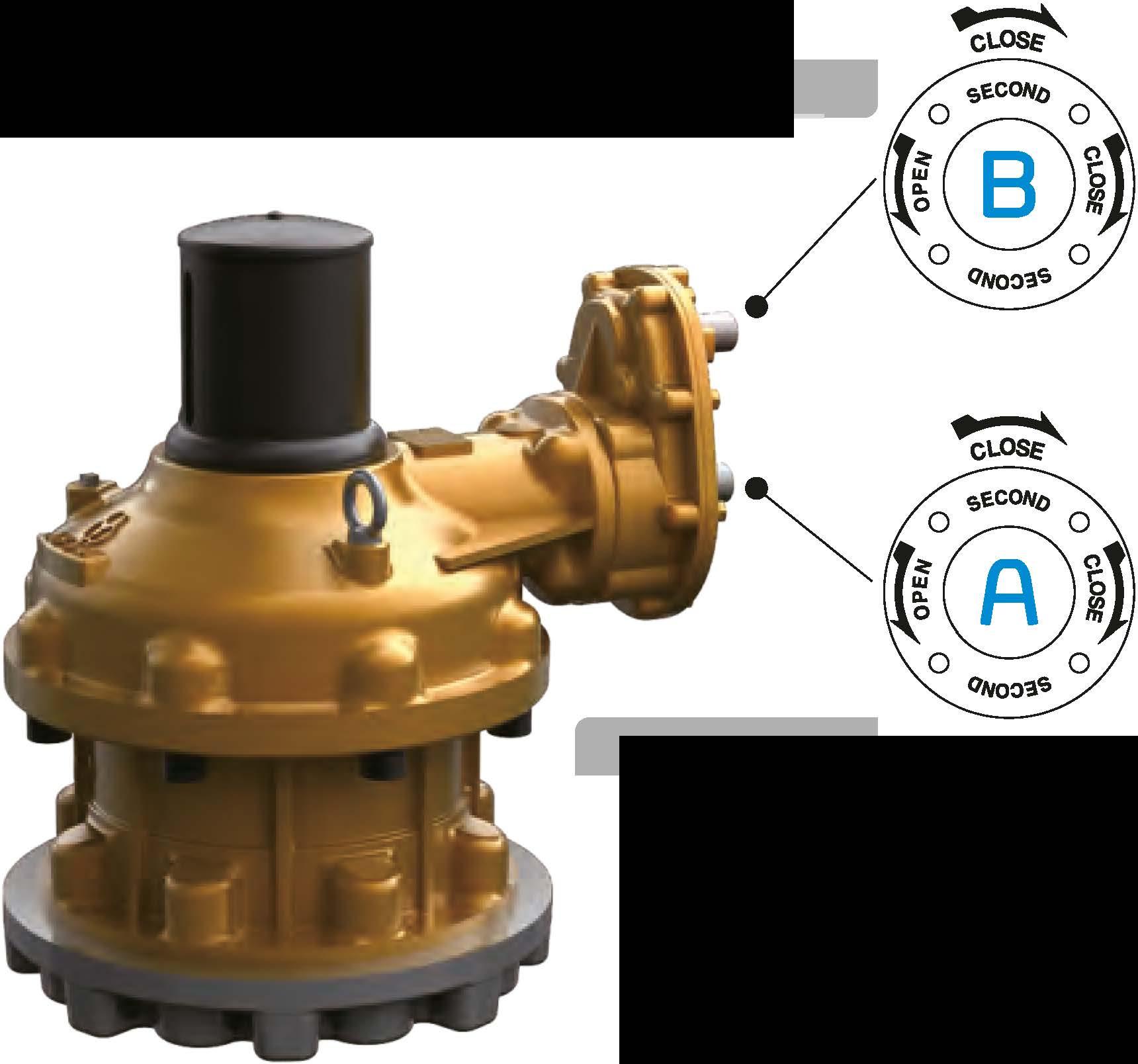

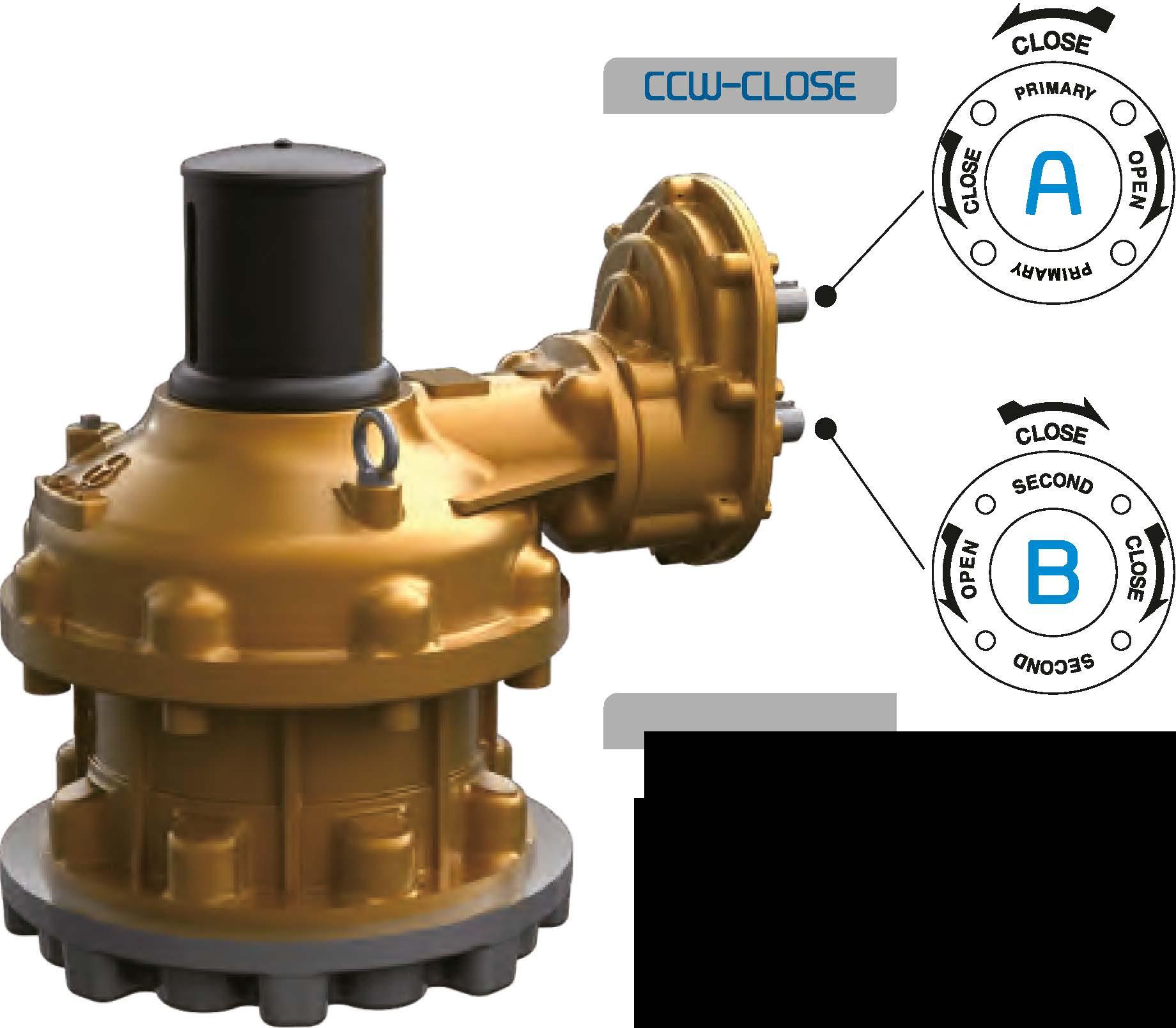

• This series suitable for use with Gate & Globe type valve. CLOSE Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available. m he World' Highest Quality!

A. Primary Input Shaft (High Speed Input Shaft) Allow for less turns after valve has been unseating.

8. Second Input Shaft (L□UJ Speed Input Shaft) Provides maximum mechanical advantage for seating and unseating of valves.

* SB-V0-1SD F-14 100 140

•SB-V1-1SD F-16 130 165

SB-V2-1SD F-16 140 205 (F-20)

SB-V3-1SD F-25 200 254

SB-V35-1SD F-30 230 298

SB-V4-1SD B F-35 260 356

SB-VS--1SD F-40 300 406

SB-V55-1SD F-40 300 406

SB-V6-1SD F-40 300 406

SB-V7-1SD F-48 370 483

SB-V75-1SD C F-48 370 483

SB-VS-1SD F-48 370 483

SB-V85-1SD F-60 470 603

SB-V9-1SD 0 F-60 470 603

•SB-V10-1SD F--80 670 813

4-M1&-24

4-M20-30 210 &-M1&-24 250 &-M1&-24 300

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent (close) to 100% (open).

Bevel Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

22,46:1 55 45(14X9) F-14,F-16

SB-V2-1SD 25.67:1 62 52(16X10) F-14,F-16,(F-20)

32,08:1 72 60(18X11) F-16,(F-20),F-25

SB-V35-1SD 49,5:1 85 72(20X12) F-25,F-30

54:1 98 84(22X14) F-25,F-30,F-35

SB-VS--1SD 80,31:1 110 95(28X16) F-25,F-30,F-35,F-40 510 114650 7800 5753

SB-V55-1SD 85,75:1 120 105(28X16) F-30,F-35,F--40

SB-V6-1SD 112:1 130 115(32X18) F-30,F-35,F--40

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement. • IYlark has been changed and updated.

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available. m he World' Highest Quality!

A. Second Input Shaft (Low Speed Input Shaft)

Provides maximum mechanical advantage for seating and unseating of valves.

B. Primary Input Shaft (High Speed Input Shaft)

Allow for less turns after valve has been unseating.

SB-V0-28 F-14 100

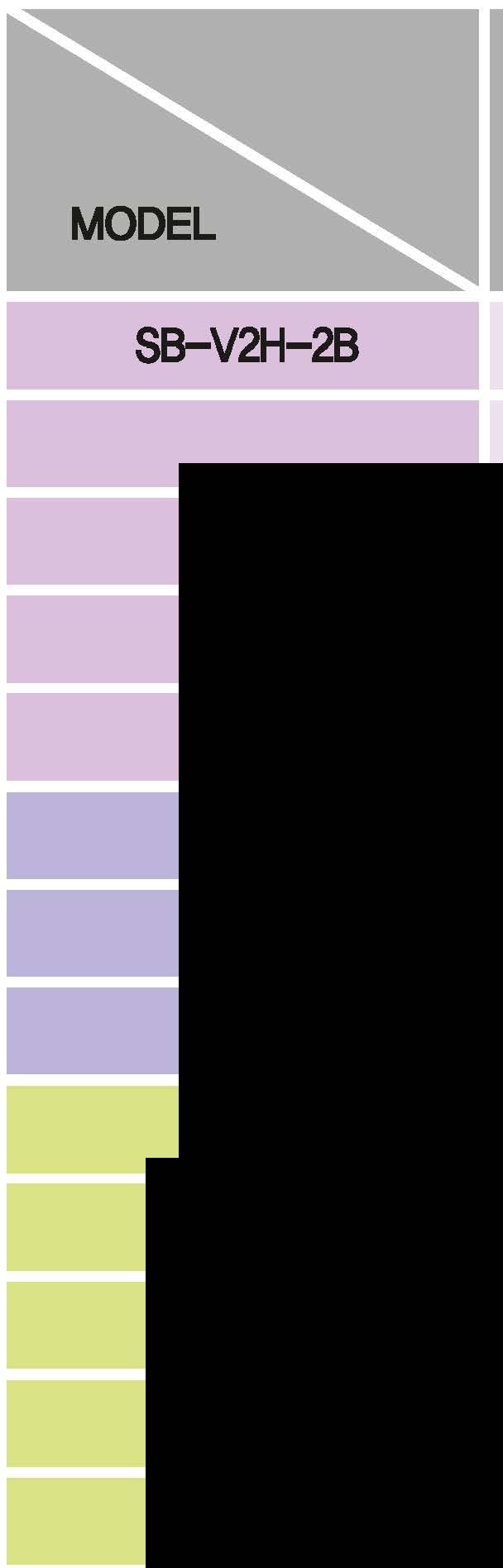

SB-V1-2B F-16 130

SB-V2-2B F-16 140 (F-20)

SB-V3-2B F-25 200

SB-V35-2B F-30 230

SB-V4-2B B F-35 260

SB-VS-28 F-40 300

SB-V55-2B F-40 300

SB-V6-2B F-40 300

SB-V7-2B F-48 370 I *SB-V75-2B C F-48 370 I SB-VS--28 F-48 370

SB-V85-2B F-60 470

SB-V9-2B D F-60 470 •SB-V10-2B F--80 670

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet IP67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (dose) to 100% (open).

Bevel Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

SB-V35-2B 17.87:1 85 72(20X12) F-25,F-30

SB-V4-2B 21:1 98 84(22X14) F-25,F-30,F-35

SB-V5-2B 26.22:1 110 95(28X16) F-25,F-30,F-35,F-40

SB-V0--1S2B F-14 100

SB-V1-1S2B F-16 130

SB-V2-1S2B F-16 140 (F-20)

SB-V3-1S2B F-25 200

SB-V35-1S2B F-30 230

SB-V4-1S2B B F-35 260

SB-V5-1S2B F-40 300

SB-V55-1S2B F-40 300

SB-V6-1S2B F-40 300

SB-V7-1S2B F-48 370 I*SB-V75-1S2B C F-48 370 I SB-V8-1S2B F-48 370

SB-V85-1S2B F--60 470

SB-V9-1S28 D F--60 470 •SB-V10--1S2B F---80

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet IP67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (dose) to 100% (open).

Bevel Gear can be provided with IYlotor actuator input flanges to accept standard ISO IYlounting Base.

SB-V2-1S2B 20.26:1 62 52(16X10) F-14, F-16,(F-20)

SB-V3-1S2B 25.32:1 72 60(18X11) F-16,(F-20),F-25

SB-V35-1S2B 41_25:1 85 72(20X12) F-25,F-30

SB-V4-1S2B 45:1 98 84(22X14) F-25,F-30,F-35

SB-V5-1S2B 57_36:1 110 95(28X16) F-25,F-30,F-35,F-40

SB-V55-1S2B 61.25:1 120 105(28X16) F-30,F-35,F---40

SB-V6-1S2B 84:1 130 115(32X18)

SB-VS10C

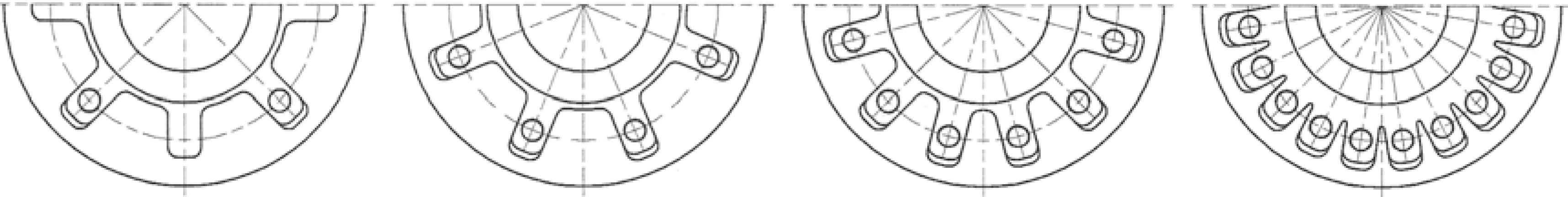

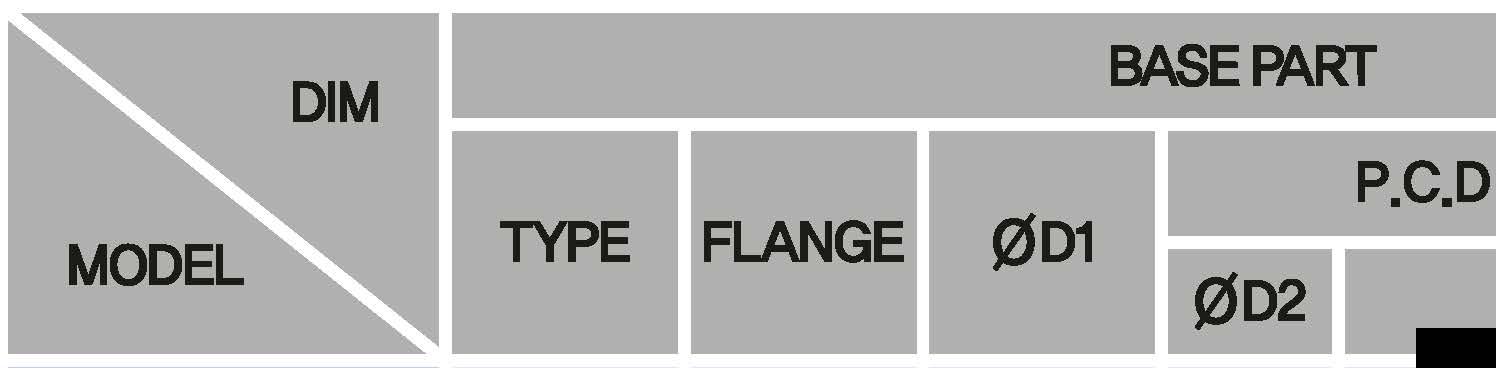

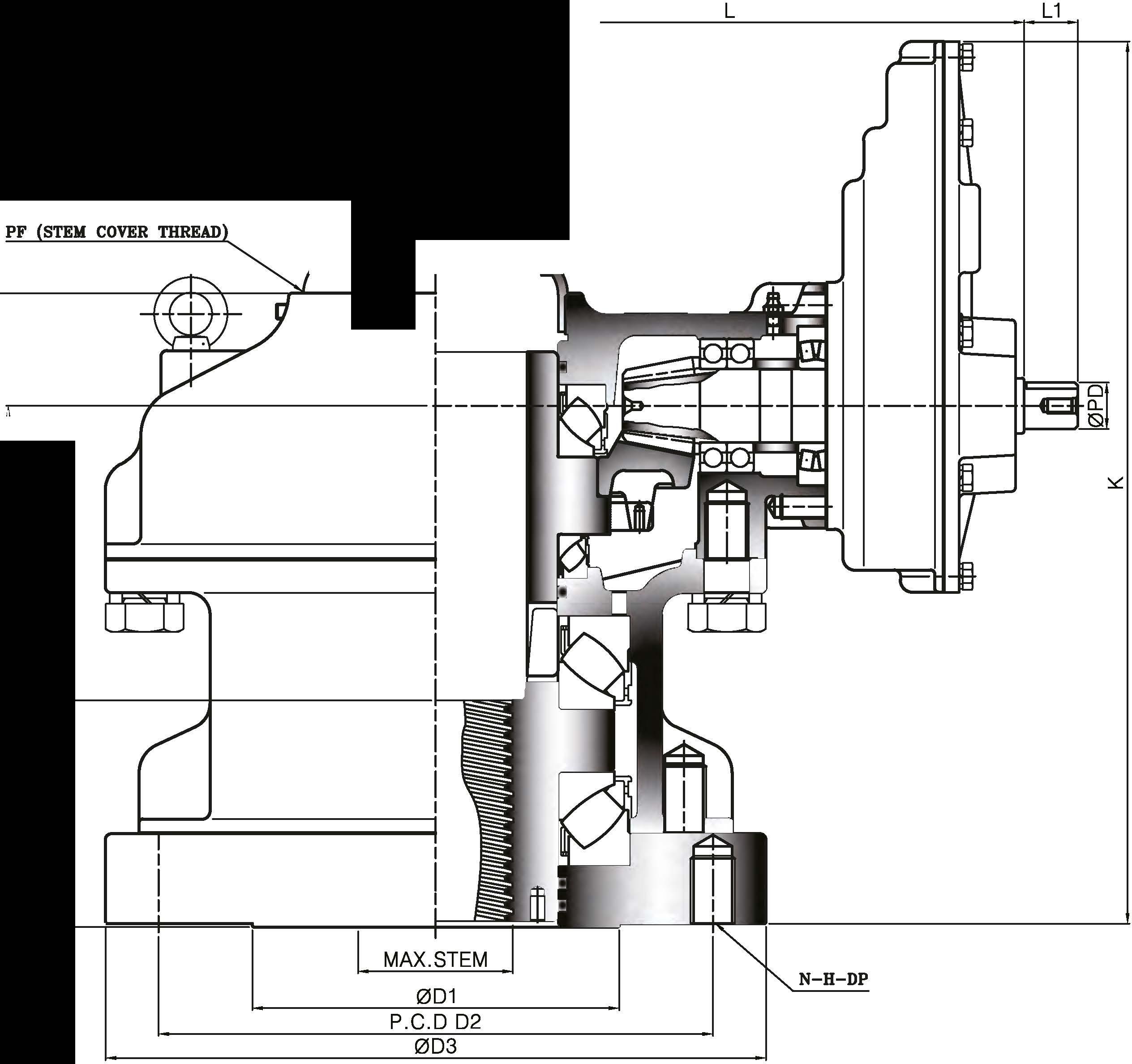

0D2 N-H-DP

F-14 140 8-3/8"-16UNC

F-16 165 F-16 165

8-1/2"-13UNC 190

8-1/2"-13UNC

SB-VS20C (F-20) 220 A 193.8

F-16 165 8-1/2"-13UNC

SB-VOC (F-20) 220 193.8 (F-20) 193.8 8-1/2"-13UNC 300

SB-V1C

SB-V2C

F-25 254 F-25 254 8-5/8"-11UNC

8-5/8"-11UNC

8-3/4"-10UNC 350 F-30 298

8-3/4"-10UNC F-30 298

SB-V3C 415

F-35 356 8-1"-8UNC F-35 356 8-1"-8UNC

SB-V35C B 8-11/4"-7UNC 475 F-40 406 F-35 356 8-1"-8UNC

SB-V4C

SB-V5C

F-40 406

8-11/4"-7UNC 475

F-35 356 8-1"-8UNC

F-40 406

8-11/4"-7UNC 480

Sizeandcomponentspeciticationinthiscataloguearesubjecttochangewithoutpriornoticeforqualityimprovement. •IYlarkhasbeenchangedandupdated

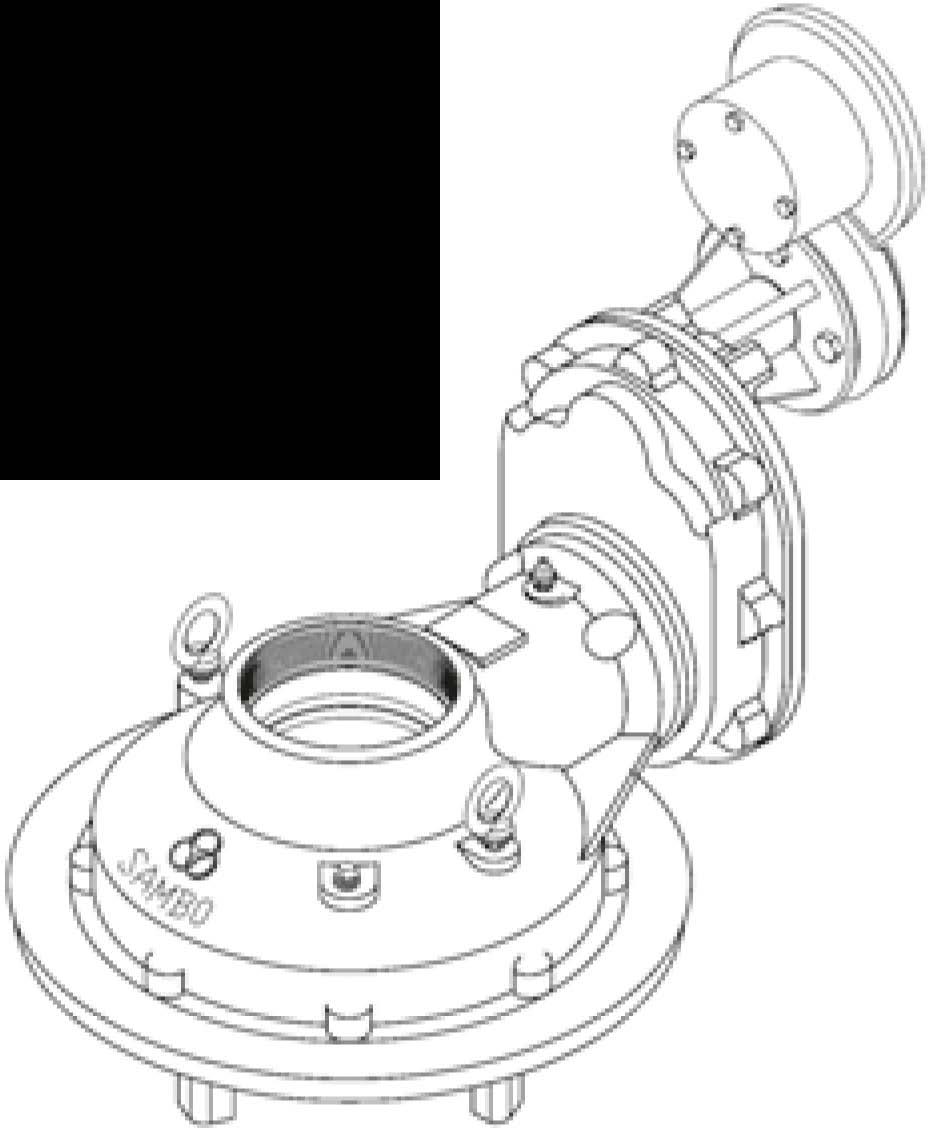

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet IP67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

Dimension>>> F-14 140

SB-VS10C-1S 8-1/2"-13UNC

F-16 165 F-16 165 8-1/2"-13UNC

SB-VS20C-1S (F-20)

91 105 A 193.8 F-16 165 8-1/2"-13UNC

SB-VOC-1S (F-20) 220 110 126 193.8 (F-20) 193.8 8-1/2"-13UNC 300 128 146

SB-V1C-1S 8-5/8"-11UNC F-25 254 F-25 254 8-5/8"-11UNC

SB-V2C-1S 8-3/4"-10UNC 350 146 166 F-30 298 8-3/4"-10UNC F-30 298

SB-V3C-1S 415 173 197 F-35 356 8-1"-8UNC F-35 356 8-1"-8UNC

SB-V35C-1S B 8-11/4"-7UNC 475 220 247 F-40 406 F-35 356 8-1"-8UNC

SB-V4C-1S 8-11/4"-7UNC 475 258 292 F-40 406 F-35 356 8-1"-8UNC SB-VSC-1S 8-11/4"-7UNC 480 266 306 F-40 406

Sizeandcomponentspeciticationinthiscataloguearesubjecttochangewithoutpriornoticeforqualityimprovement. •IYlarkhasbeenchangedandupdated.

• This series suitable for use with Gate & Globe type valve. Also sluice gates and any other type requiring linear motion for thrust and torque applications.

• Unique Top Entry Replaceable Stem Nut. High Tensile Aluminum bronze material providing corrosion and abrasion resistance.

•Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation Units are completely □-Ring Sealed suitable for temporary submergence to meet IP67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

A unique local position dial indicator is available. It is graduated in percent from 0% (dose) to 100% (open).

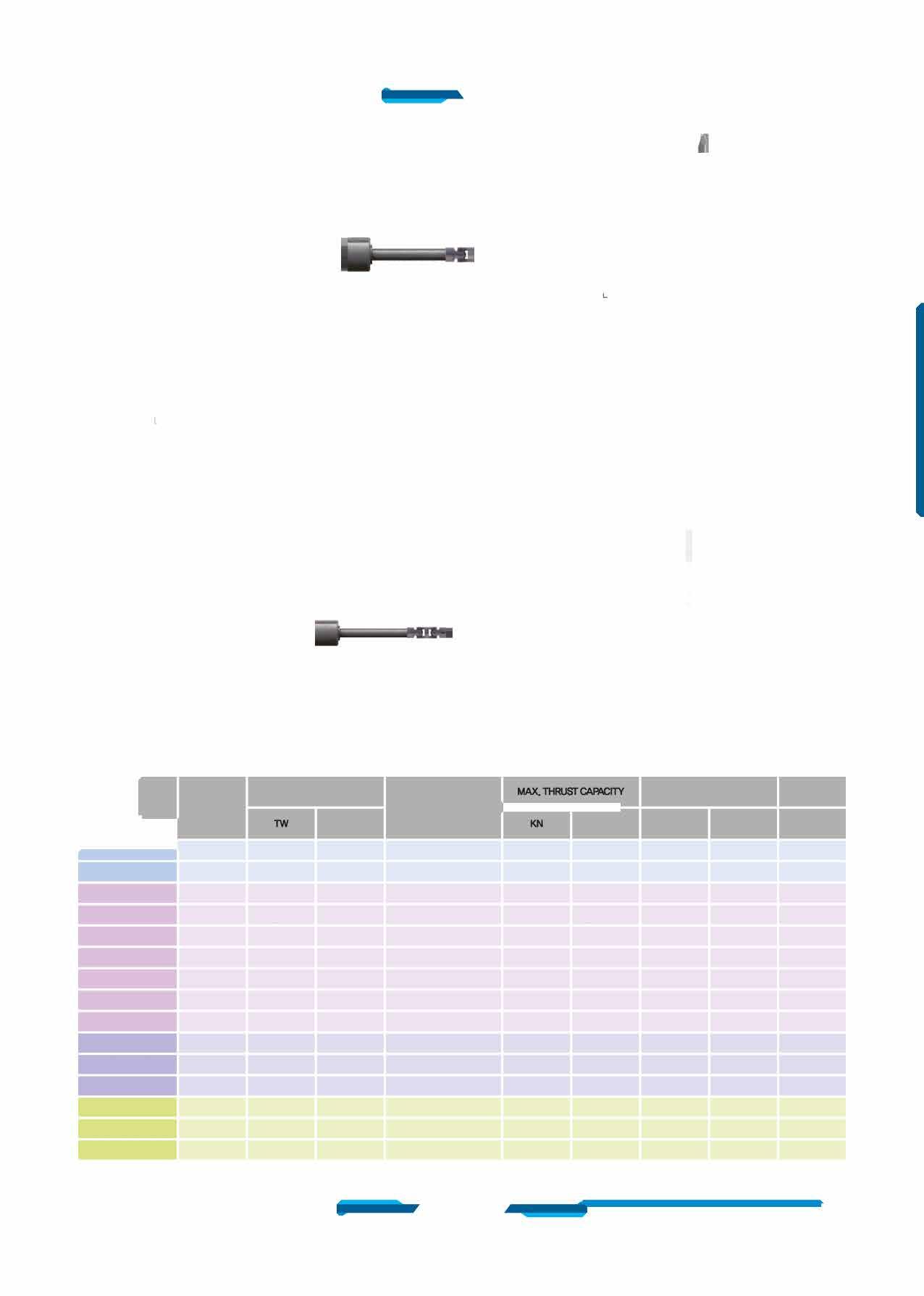

SB-VS10W F-10

SB-VS20W F-12 85 A

SB-VOW F-14

SB-V1W F-16

SB-V2W F-16 140 (F-20)

SB-V:ffl F-25

SB-V35W F-30

SB-V4W B F-35

SB-V5W F-40

SB-V55W F-40

SB-V&N F-40

SB-V7W F-48

SB-V75W C F-48

SB-Vfffl F-48

and component specitication in this catalogue are subject to change without prior notice for quality improvement.

IYlark has been changed and updated.

DualGearActuatorType (IYlanual Dial Indicator) >>> : Typical Arrangement for Two Spindles Application

1. This type is used for large size of sluice gates and designed for manufacturing type to operate efficiently using 2 spindles.

2. Local dial position indicator provides clear indication of gate position.

3. Samba can provide suitable interconnecting shafts and couplings if required. (Customer must state the center distance between the gate stems.)

DualGearActuatorType (Electric Actuators) >>>

: Typical Arrangement for Two Spindles Application

1. This type is used for large size of sluice gates and designed for manufacturing type to operate efficiently using 2 spindles.

2. Samba can provide suitable interconnecting shafts and couplings if required. (Customer must state the center distance between the gate stems.)

Sizeandcomponentspeciticationinthiscataloguearesubjecttochangewithoutpriornoticeforqualityimprovement. •IYlarkhasbeenchangedandupdated.

DualGearActuatorType (IYlanuaD >>> : Typical Arrangement for Two Spindles Application

1. This type is used for large size of sluice gates and designed for manufacturing type to operate efficiently using 2 spindles.

2. Samba can provide suitable interconnecting shafts and couplings if required. (Customer must state the center distance between the gate stems.)

DualGearActuatorType (Electric Actuators} >>> : Typical Arrangement for Two Spindles Application

1. This type is used for large size of sluice gates and designed for manufacturing type to operate efficiently using 2 spindles.

2. Samba can provide suitable interconnecting shafts and couplings if required. (Customer must state the center distance between the gate stems.)

*SB-V0W-1SD F-14 100 A

*SB-V1W-1SD F-16 130

SB-V2W-1SD F-16 140 (F-20)

SB-V3W-1SD F-25 200

SB-V35W-1SD F-30 230 B

SB-V4W-1SD F-35 260

SB-VSW-1SD F-40 300

SB-V55W-1SD F-40 300

SB-V6W-1SD F-40 300

SB-V7W-1SD F-48 370

SB-V75W-1SD C F-48 370

SB-V8W-1SD F-48 370

SB-V85W-1SD F-60 470

SB-V9W-1SD D F-60

*SB-V10W-1SD F-80

4-M1&-24

8-M16-24

8-M20-30 350 122

8-M30-45 410

8-M3&-55

8-M36-55

8-M36-55

12-M36-55

20-M36-55

DualGearActuatorType (Manual Dial Indicator) >>> : Typical Arrangement for Two Spindles Application

1. This type is used for large size of sluice gates and designed for manufacturing type to operate efficiently using 2 spindles.

2. Sambo can provide suitable interconnecting shafts and couplings if required. (Customer must state the center distance between the gate stems.)

DualGearActuatorType (Electric Actuators) >>> : Typical Arrangement for Two Spindles Application

1. This type is used for large size of sluice gates and designed for manufacturing type to operate efficiently using 2 spindles. 2. Sambo can provide suitable interconnecting shafts and couplings if

SB-V5W-1SD 80.31:1 110 95(28X16) F-25,F-30,F-35,F-40

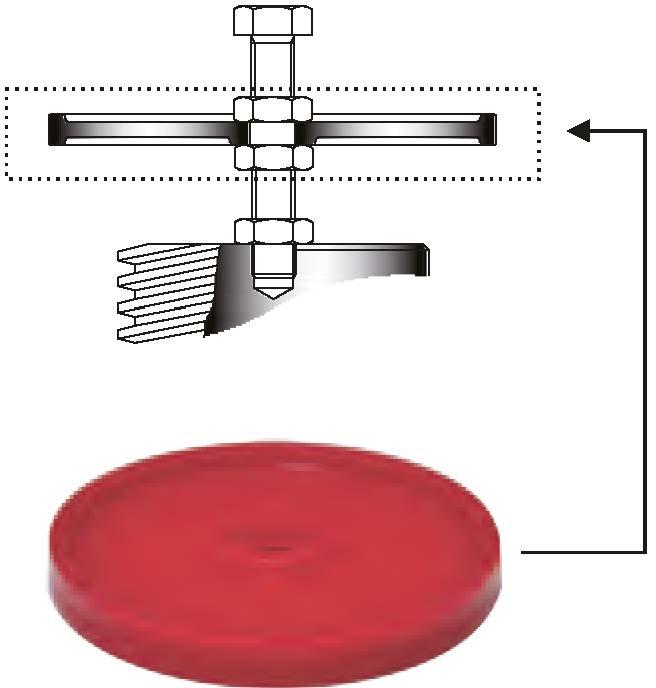

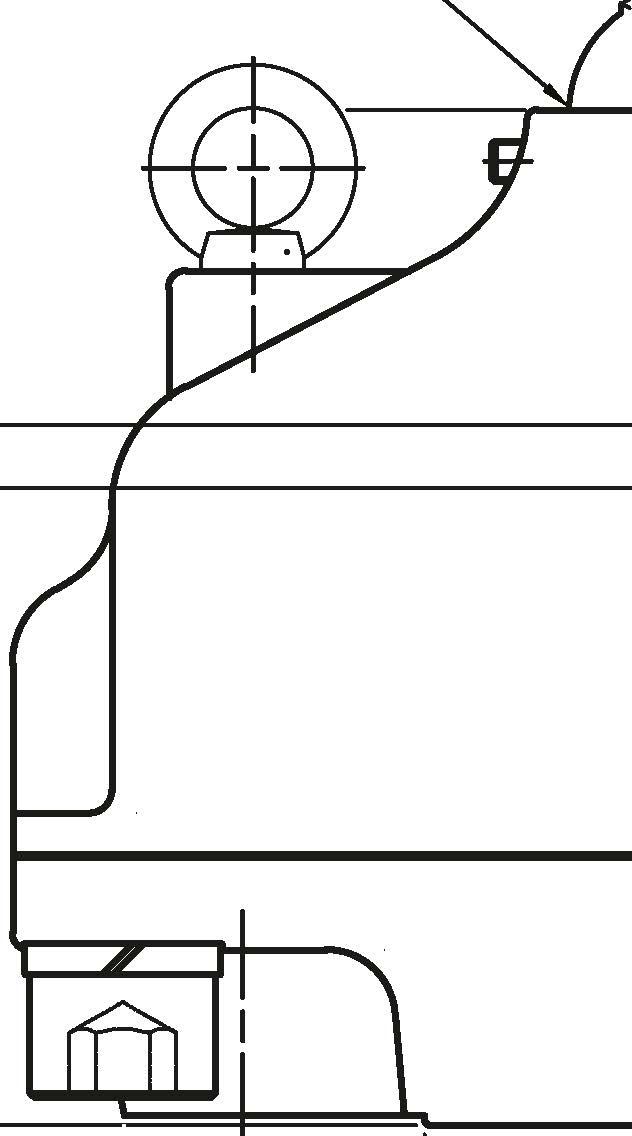

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

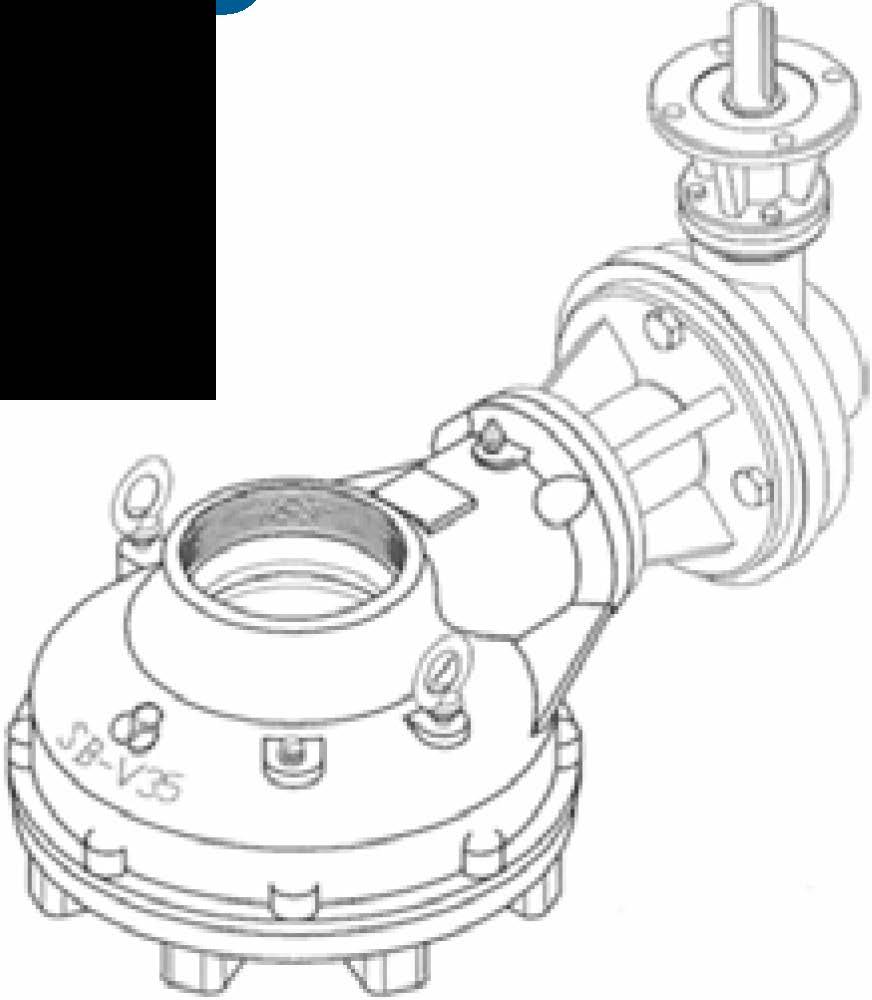

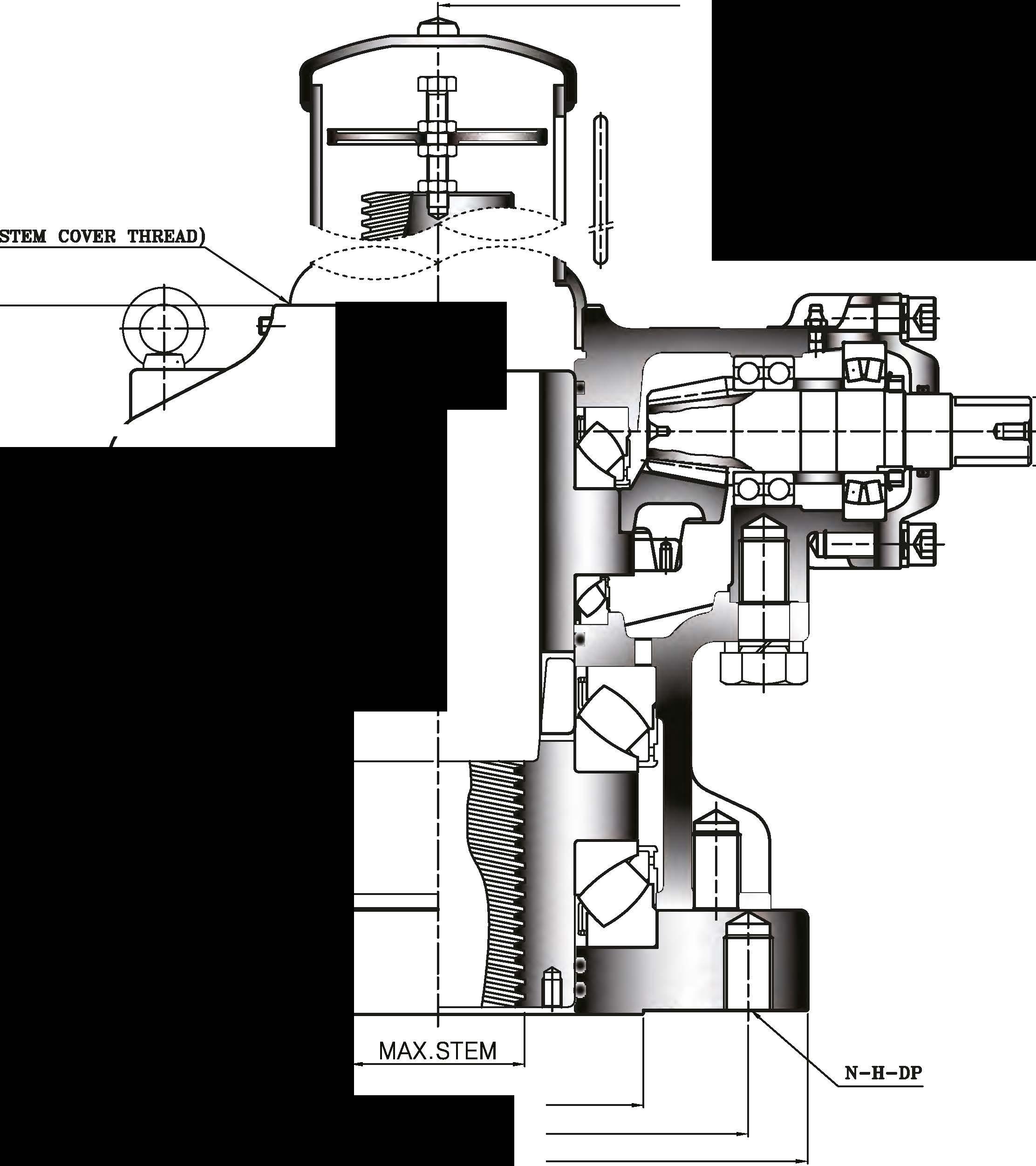

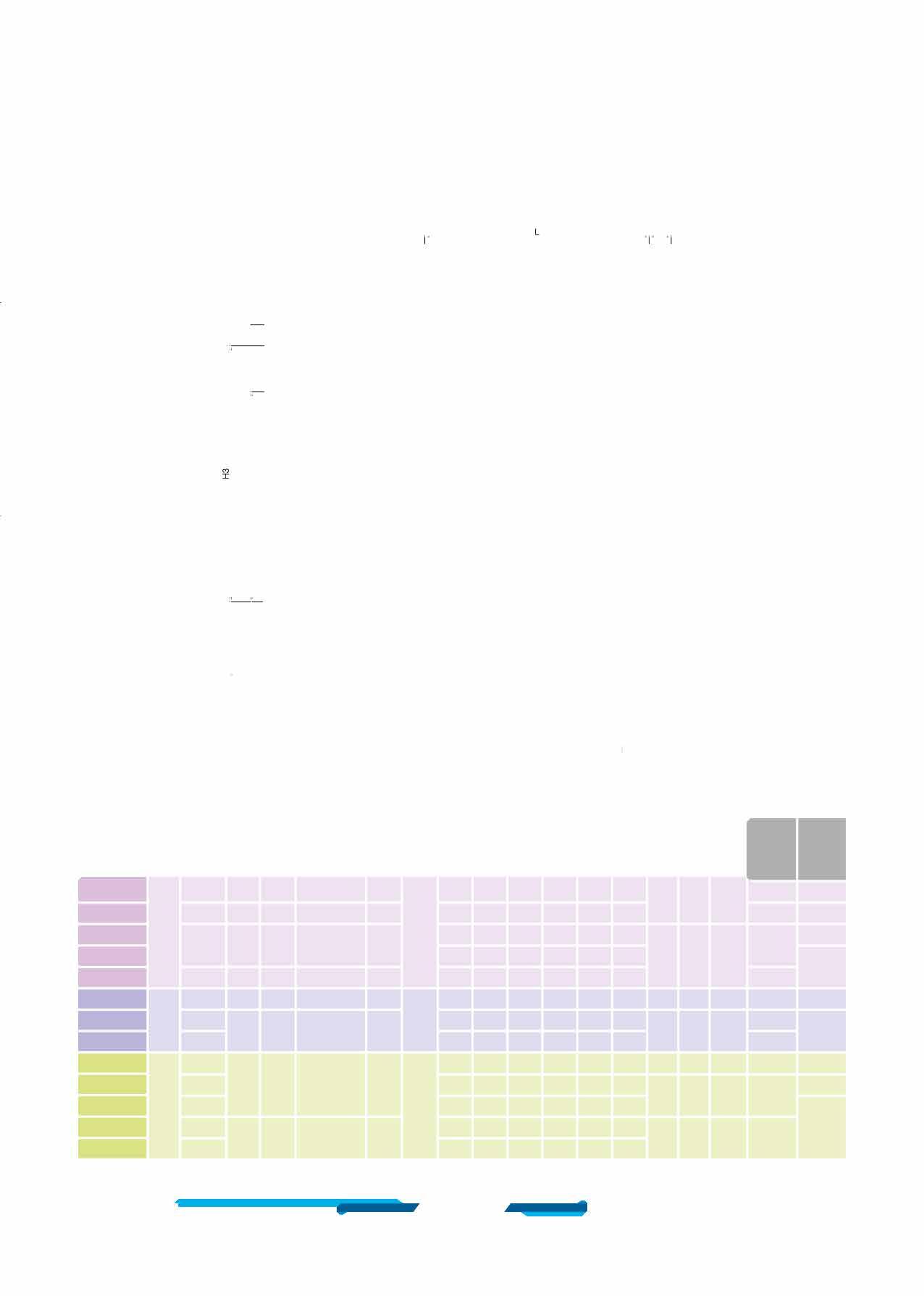

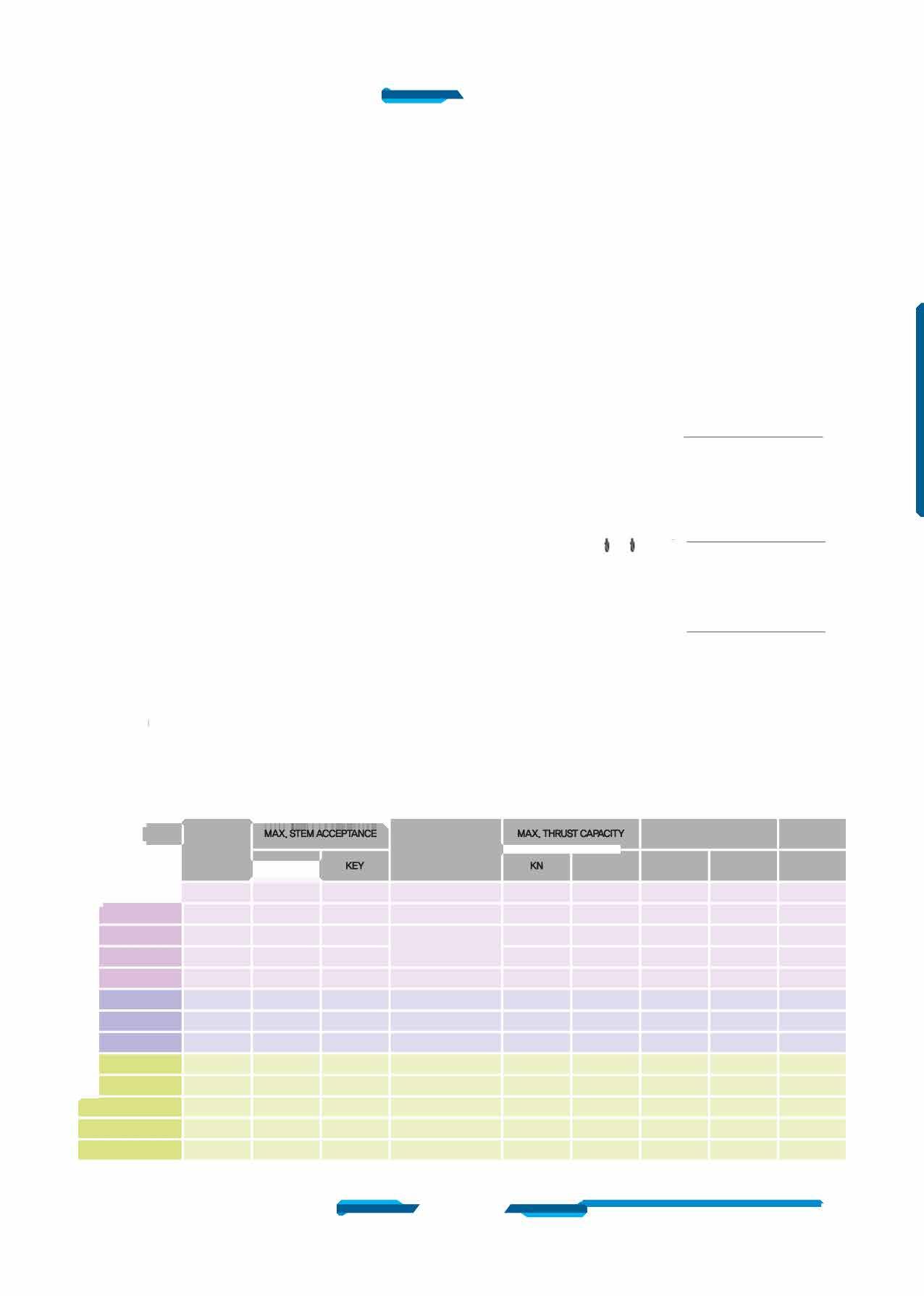

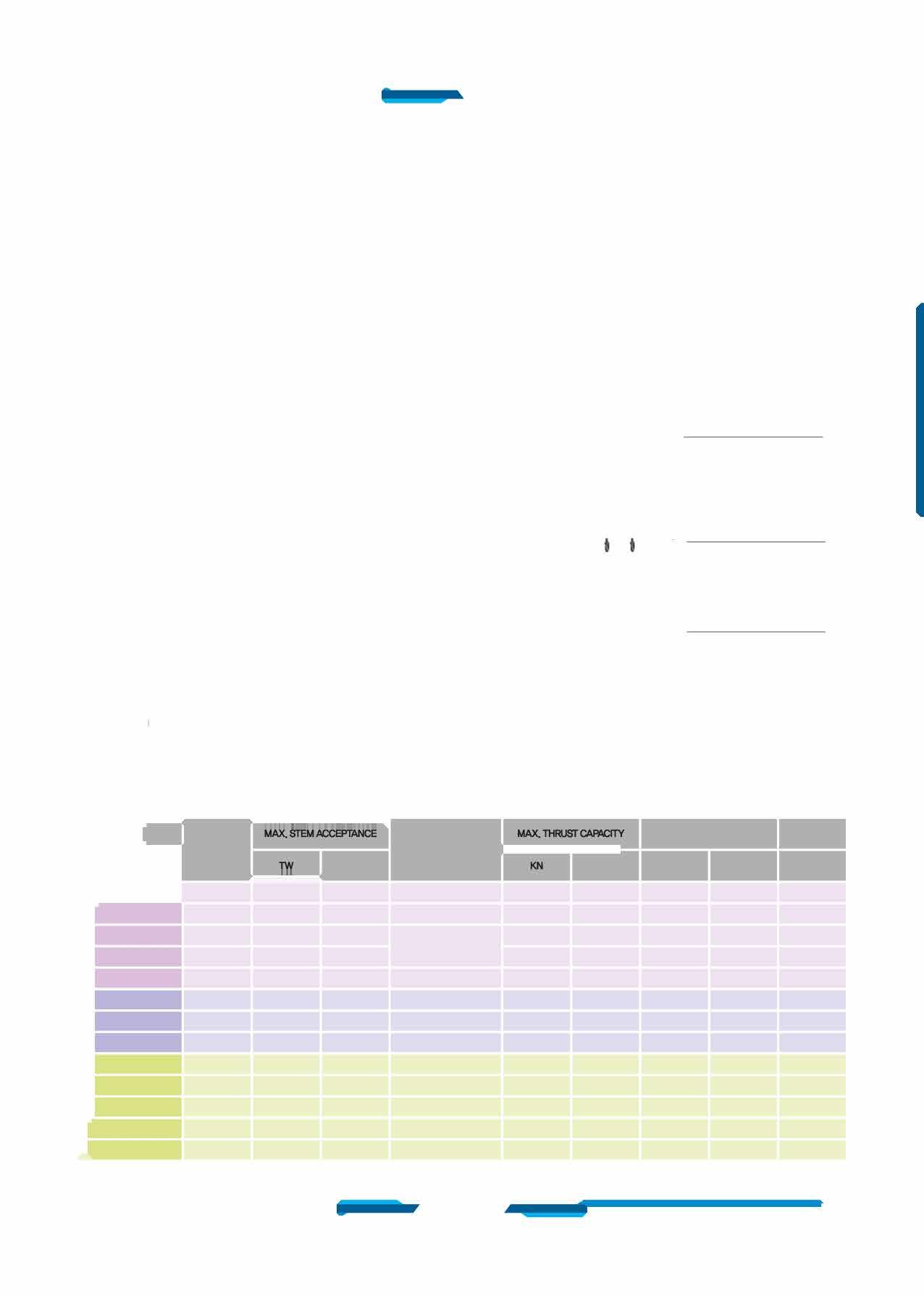

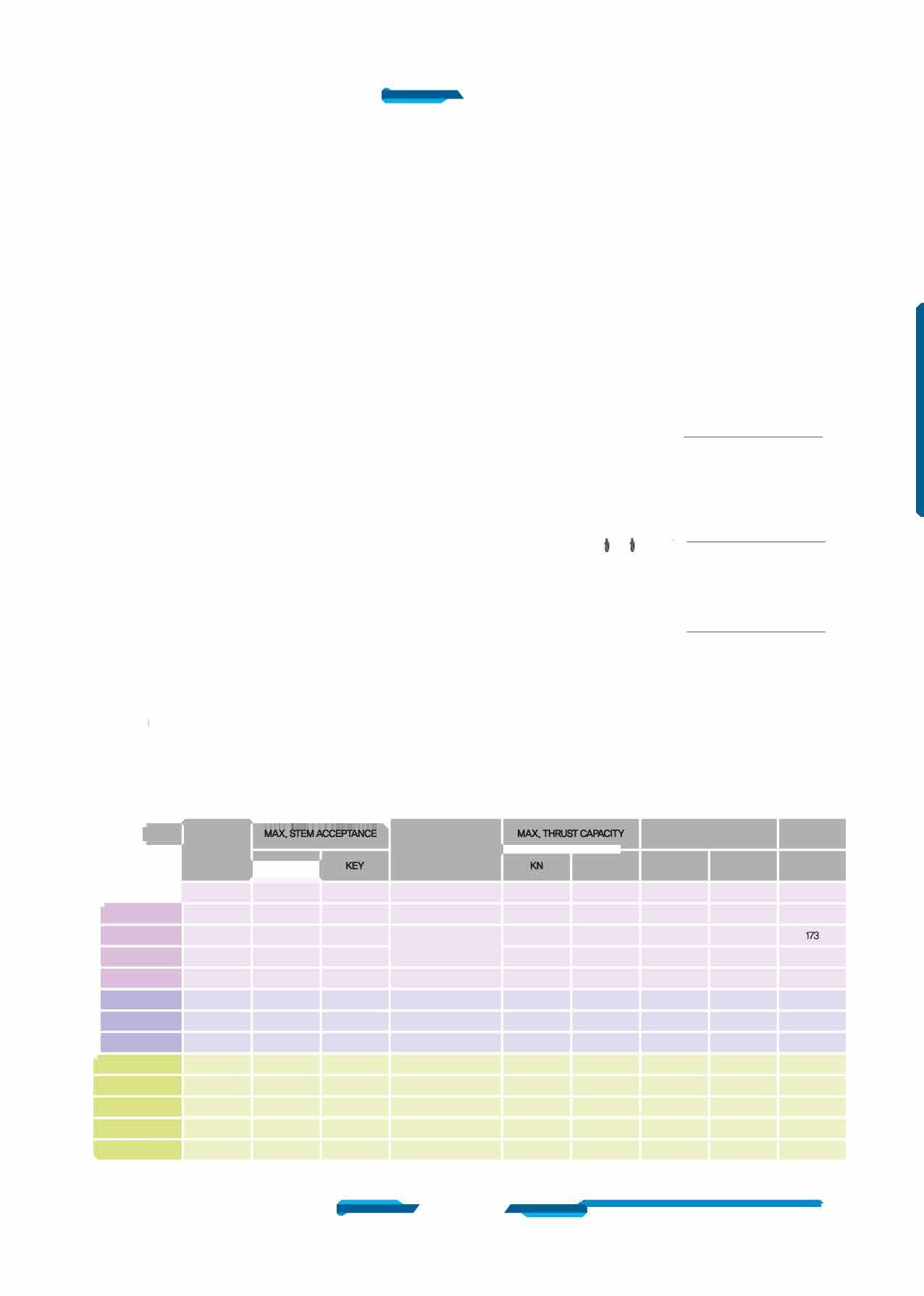

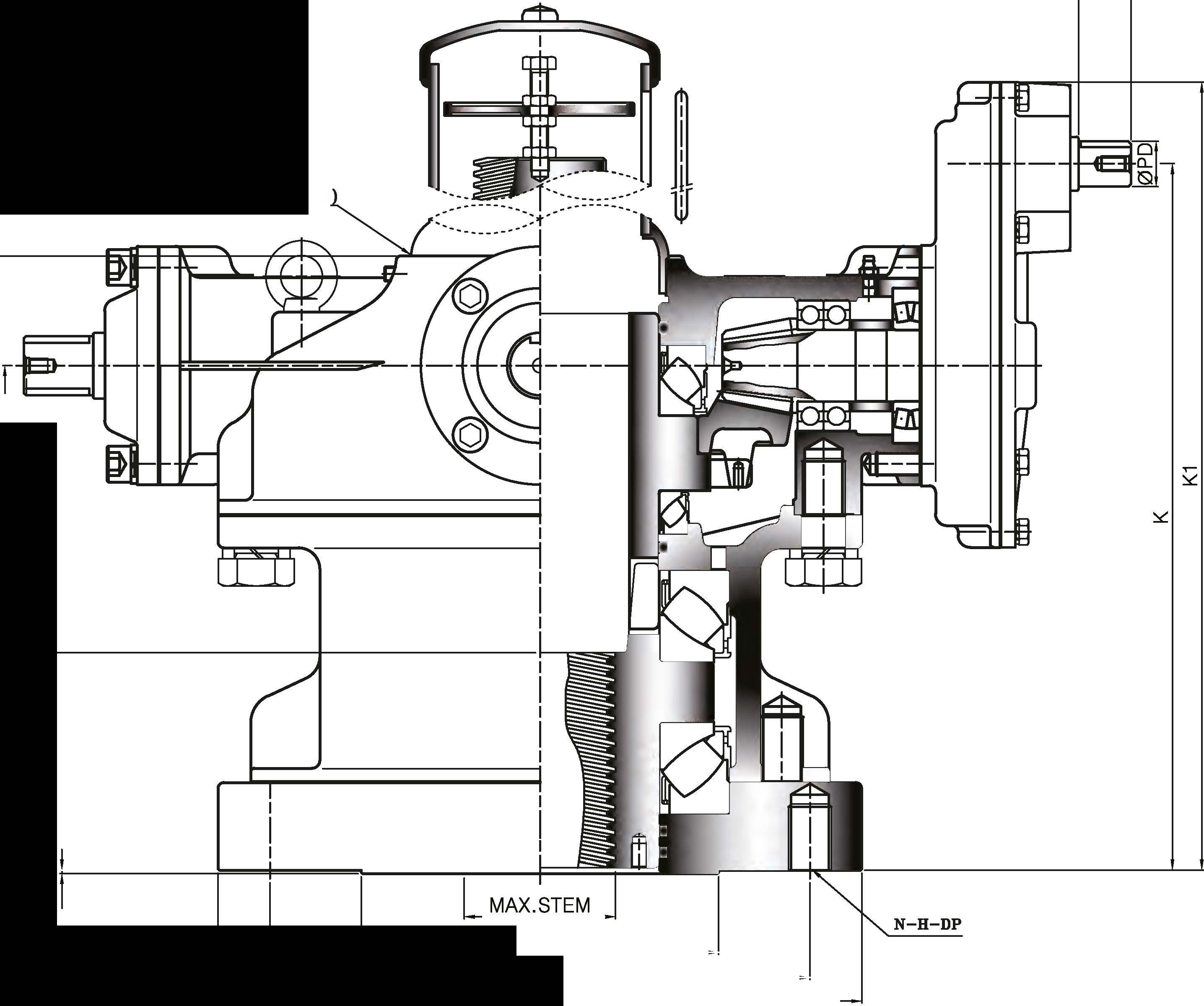

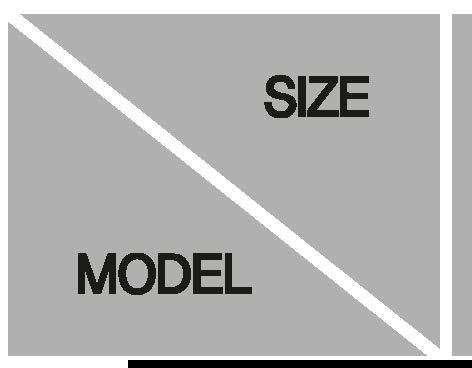

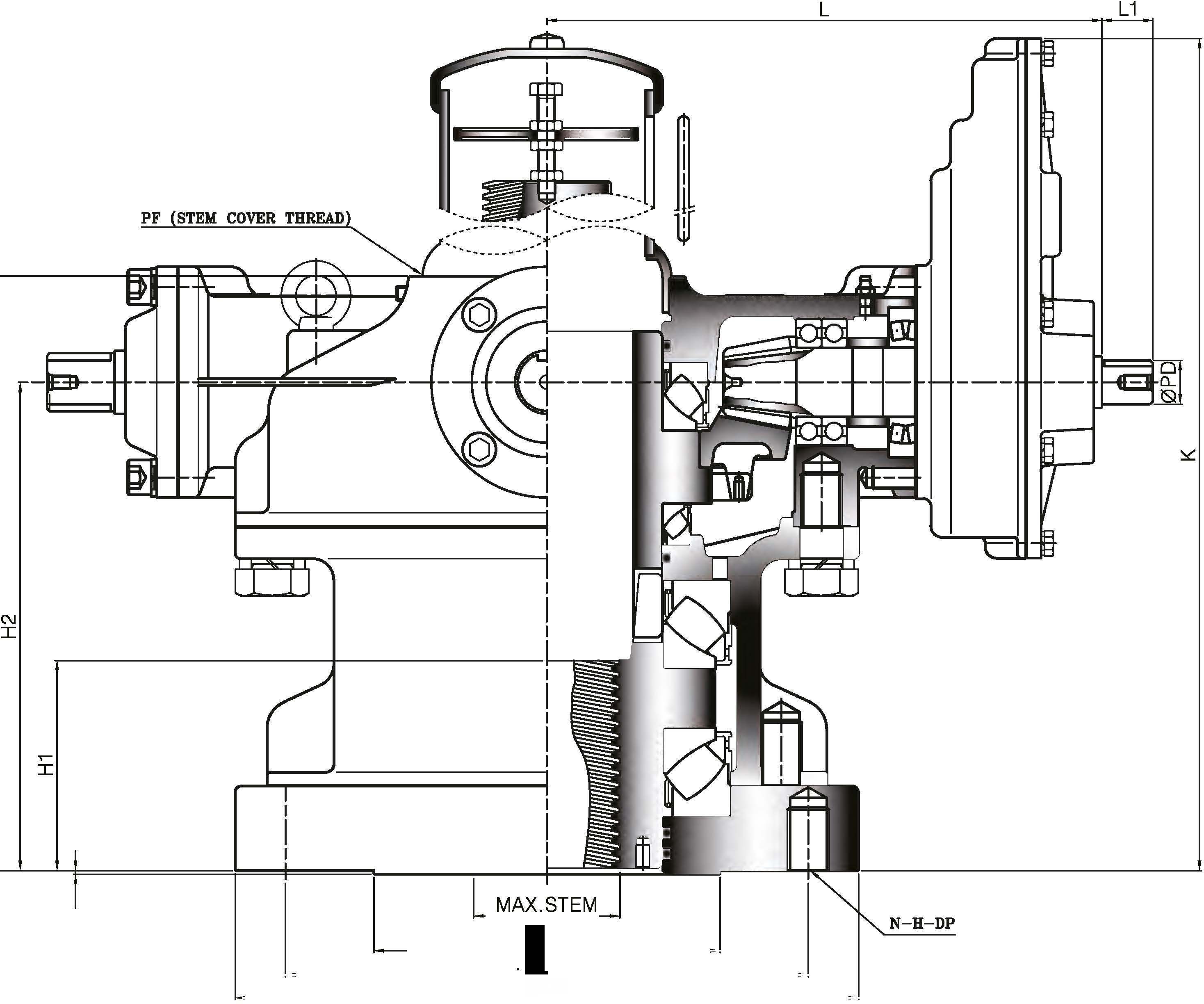

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

SB-V2H-1S F-25

SB-V3H-1S F-30

SB-V35H-1S B F-35

SB-V4H-1S

SB-VSH-1S F-40

SB-V55I-HS F-48

SB-V6H-1S C F-48

SB-V?H-1S F-48

SB-V75H-1S F-60

SB-V8H-1S F-60

SB-V85H-1S D F-60

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

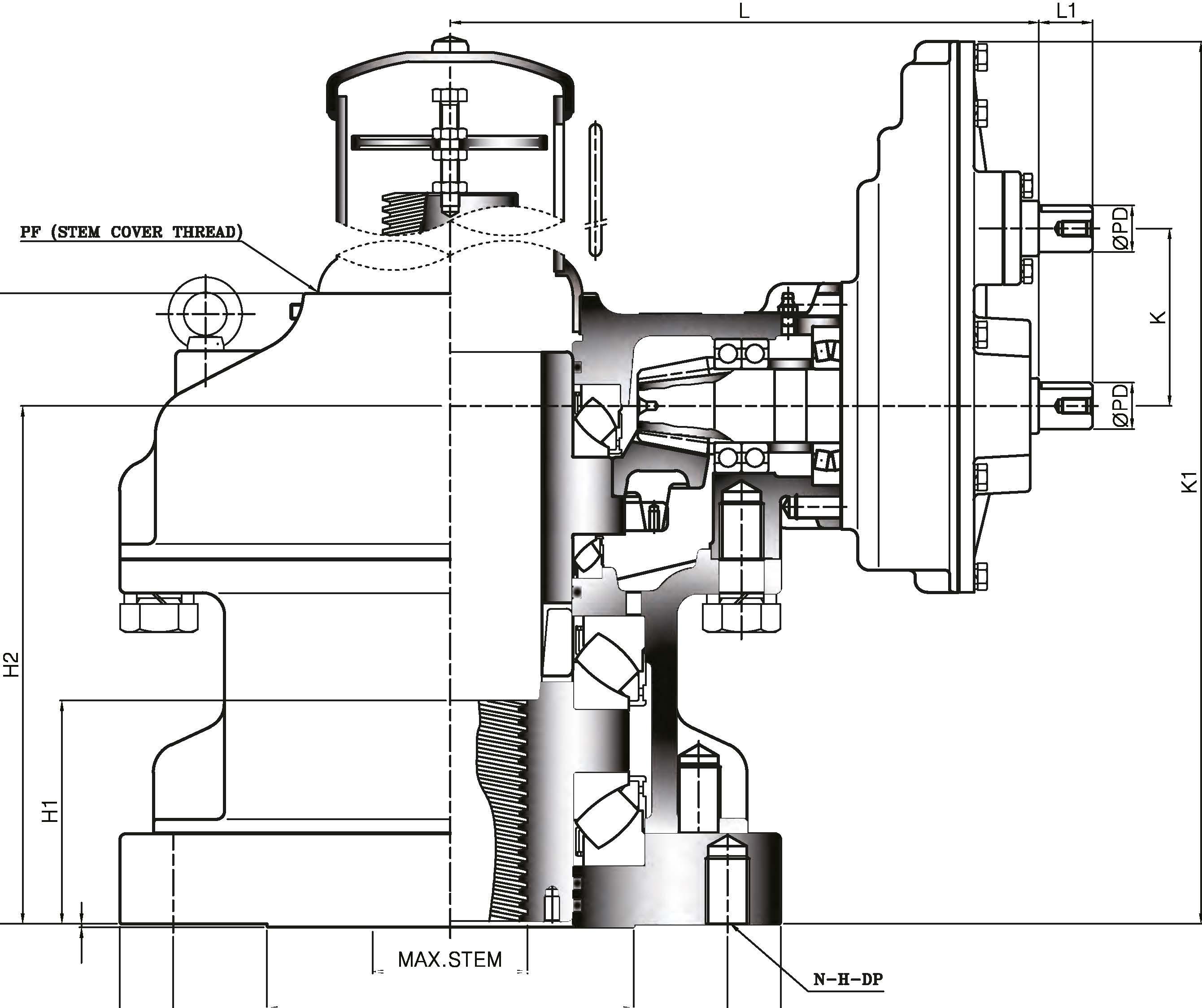

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available. Global .eader �����1}}�I1L:�a/ues

10.13:16555(16X10)(F-20),F-251080242800

SB-V3H-1S 12.66:18070(20X12)F-25,F-301710384400

SB-V35H-1S 16.5:19585(22X14)2450550800 F--25,F-30,F-35

SB-V4H-1S 18:111095(25X14)2900651900

SB-V5H-1S 22,94:1130115(32X18)F-30,F-35,F---403500786800

SB-V55H-1S 24,5:1140120(32X18)F--35,F-40,F---484200944197

SB-V6H-1S 28:1150130(36X20)F--35,F-40,F---4847001056600

SB-V7H-1S 30.22:1170150(40X22)F---4852001169000

SB-V75H-1S 40:1190170(40X22)F--48,F--6068001528701

SB-VSH-1S 40:1215185(45X25)F-48,F--6076501719800

SB-V85H-1S 40:1225195(45X25)F-48,F--6091002045760

•SB-V9H-1S 40:1240215(50X28)F--60,F--8094002113200

*

SB-V10H-1S 40:1270240(56X32)F--60,F--80115002585300

SB-V21+-1ST F-25

SB-V3+-1Sf F-30

SB-V3!i-l-1Sf B F-35

SB-V4H-1ST

SB-V!it-1Sf F-40 F--48

SB-V&+-1ST C F-48

SB-V71+-1ST F-48

SB-V75H-1ST F-60

SB-va+-1ST F-60

SB-V85H-1ST D F-60

*SB-V9+-1ST F--80

*SB-V10+-1Sf F--80

CW-CLOSE

CW-CLOSE

Disassembly flow chart of thrust bush for processing of stem thread

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

8. Re-assembly in reverse order.

A. Primary Input Shaft (High Speed Input Shaft) Allow for less turns after valve has been unseating.

B. Second Input Shaft (Low Speed Input Shaft) Provides maximum mechanical advantage for seating and unseating of valves.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers,position dial indicators are available.

SS-V2tHSD F-25 200

SS-V3H-1SD F-30 230

SS-V35H-1SD B F-35 260

SS-V4H-1SD

SS-V5H-1SD F--40 300

SS-V55tHSD F--48 370

SS-V6tHSD C F--48 370

SS-V7tHSD F--48

SS-V75H-1SD F-60 470

SS-V8H-1SD F-60 470

SS-V85H-1SD D F-60

*SS-V9H-1SD F-80 670

* SS-V10H-1SD F-80

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

Global .eader

25.67:16555(16X10)(F-20),F--251080242800

SB--V3H-1SD 32.08:18070(20X12)F-25,F-301710384400

SB--V35H-1SD 49.5:19585(22X14)2450550800 F--25,F-30,F-35

SB--V4H-1SD 54:111095(25X14)2900651900

SB--VSH-1SD 80.31:1130115(32X18)F--30,F--35,F---403500786800

SB--V551-HSD 85_75:1140120(32X18)F--35,F-40,F---484200944197

SB--V61-HSD 112:1150130(36X20)F--35,F-40,F---4847001056600

SB--V71-HSD 120.88:1170150(40X22)F---4852001169000

SB--V751-HSD 200:1190170(40X22)F--48,F--6068001528701

SB--VSH-1SD 200:1215185(45X25)F--48,F--6076501719800

SB--V851--HSD 200:1225195(45X25)F--48,F--6091002045760

*SB-V91--HSD 200:1240215(50X28)F--60,F---8094002113200

*SB-Vl0H-1SD 200:1270240(56X32)F--60,F---80115002585300

42778 1055

SB-V21-HSDT F-25 200

SB-V3H-1SDT F-30 230

SB-V35H-1SDT B F-35 260

SB-V4H-1SDT

SB-V51·-HSDT F-40 300

SB-V55H-1SDT F-48 370

SB-V6H-1SDT C F--48 370

SB-V7H-1SDT F--48

SB-V75H-1SDT F--60 470

SB-V8H-1SDT F--60 470

SB-V85H-1SDT D F--60

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement.

• IYlark has been changed and updated.

CW-CLOSE

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

A. Prima� Input Shaft (High Speed Input Shaft)

Allow for less turns after valve has been unseating.

B.Second Input Shaft (Low Speed Input Shaft)

Provides maximum mechanical advantage for seating and unseating of valves.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

SB-V2H-28 F-25

SB-V3H-2B F-30

SB-V35H-2B B F-35

SB-V4H-2B

SB-V5H-2B F-40

SB-V55H-2B F--48

SB-VSH-28 C F--48

SB-V71+-28 F--48

*SB-V75H-28 F-60

SB-VSH-28 F-60

SB-V85H-28 D F-60

F--80

F--80

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

.eader

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

High Load Thrust & Torque Horizontal Input with Single Reduction Gear Attachment

Dimension

SB-V2HW-1S F-25

SB-V3HW-1S F-30

SB-V351fN-1S B F-35

SB-V4HW-1S

SB-VSHW-1S F-40 F-48

SB-VSHW-1S C F-48

SB-V7HW-1S F-48

SB-V75HW-1S F-60

SB-V8HW-1S

SB-V85HW-1S D F-60

*SB-V9HW-1S F--80

*SB-V10HW-1S F--80

Size and component specitication in this catalogue are subject to change without prior notice for quality improvement.

IYlark has been changed and updated.

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

SB-V7HW-1S 30.22:1 170 150(40X22) F--48

SB-V75H'W-1S 40:1

SB-V2H\N-1SD

SB-V3HW-1SD

SB-V35HW-1SD B

SB-V4HW-1SD

SB-VSHW-1SD

SB-V55HW-1SD

SB-V6HW-1SD C

SB-V7HW-1SD

SB-V75HW-1SD

SB-V8HW-1SD

SB-V85HW-1SD D

*SB-V9HW-1SD

*SB-V10HW-1SD

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

SB-V55HW-1SD 85_75:1 140 120(32X18) F-35,F-40,F-48 4200 944197

SB-V6HVv-1SD 112:1 150 130(36X20) F-35,F-40,F-48 4700 1056600

SB-V7HVv-1SD 120.88:1 170 150(40X22) F--48 5200 1169000

SB-V75HW-1SD

SB-VSHW-28

SB-V55HW-2B

SB-V6HW-28

SB-V7HW-28

SB-VBHW-28

SB-V85HW-28

1. Remove base plate socket head cap screws and base plate.

2. Remove Gasket

3. Use eye-bolts from housing and thread into tapped holes on end of the drive bushing.

4. Lift drive bushing with lower roller bearing.

5. Remove roller bearing from drive bushing.

6. Thread bushing as required.

7. Add grease as necessary.

B. Re-assembly in reverse order.

• This series suitable for extreme high thrust loads for use with Gate & Glove type valves. Also sluice gates and any other type requiring linear motion for high load thrust and torque applications.

• Bottom entry type stem nut. High tensile aluminum bronze material providing corrosion and abrasion resistance.

• Castings are Ductile Iron, class 65-45-12 providing high strength and impact resistance.

• Heavy duty roller bearings supporting both radial & axial thrust loads.

• Gears are IYlachine cut, heat treated and ground for optimum operation, Units are completely □-Ring Sealed suitable for temporary submergence to meet Ip67 class.

• IYlany options, such as hand wheels, chain wheels, stem covers, position dial indicators are available.

SB-V6HW-2B 35:1 150 130(36X20) F-35,F-40,F-48 4700 1056600

SB-V7HW-2B 37.77:1 170 150(40X22) F---48 5200 1169000

*SB-V75HW-2B 44:1 190 170(40X22) F-48,F--60

Contact your local CDC sales representatives:

Serving OH, MI, W.PA, WV, E.KY, VA

143 S.Thomas Rd. Tallmadge, OH 44278

Tel: 330-253-4800

Email: sales@portersvilleprd.com

7707 Cole Lane Midland MI 48642

Tel: 586-764-4336

Email: sales@portersvilleprd.com

www.portersvilleprd.com

2680 New Butler Rd. New Castle, PA 16101

Tel: 724-368-8725

Email: sales@portersvilleprd.com

700 Southlake Blvd. North Chesterfield VA 23236

Tel: 804-593-2384

Email: sales@portersvilleprd.com

1500 E. Burnett St. Signal Hill, CA 90755

Tel: 562-424-8108

Email: Sales@BV-BM.com

www.bv-bm.com

403 Technology Dr South Point, OH 45680

Tel: 740-377-0012

Email: sales@portersvilleprd.com

3800 Fruitvale Avenue Bakersfield, 93308

Tel: 661-589-6801

Email: Sales@BV-BM.com

3195 Park Road, Benicia, CA 94510

Tel: 707-590-6688

Email: Sales@BV-BM.com