The Power Farming “Tractor of the Year”, an award, we started back in 1991 has uncovered many very worthy contenders for the current title at a time when tractor sales are reaching record highs and many makers are taking a new model release breather.

And, as the big makers take a little pause it has opened the floodgate to market unknowns who appear intend on replacing operators with joystick riders, such is the proliferation of driverless model reveals.

Also inside, take a look at some smart trailed sprayer models ideal for medium operations with a focus on accuracy.

In addition, see several good leads on how to move and store grain more efficiently. We also introduce the best value chemical and nutrient supplier, 4Farmers, who is expanding its operation into more eastern state locations. Find out how 4Farmers will save you heaps of money on all your herbicide and pesticide requirements.

Don’t miss our list of preferred farm equipment suppliers, as these makers are known to be trusted, along with select used models from the dealers that will look after you best. ■

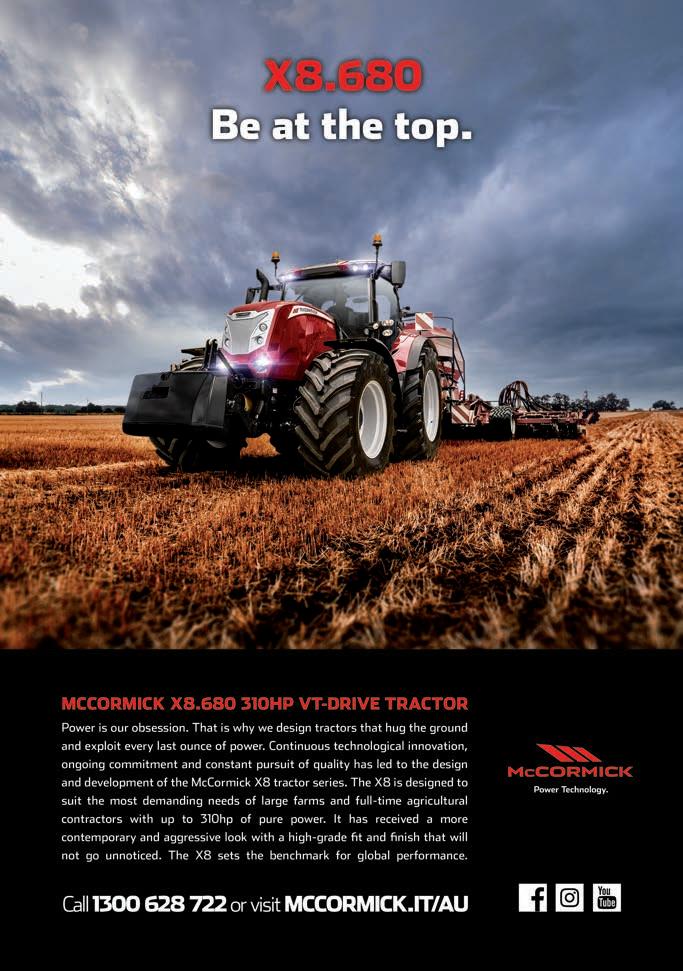

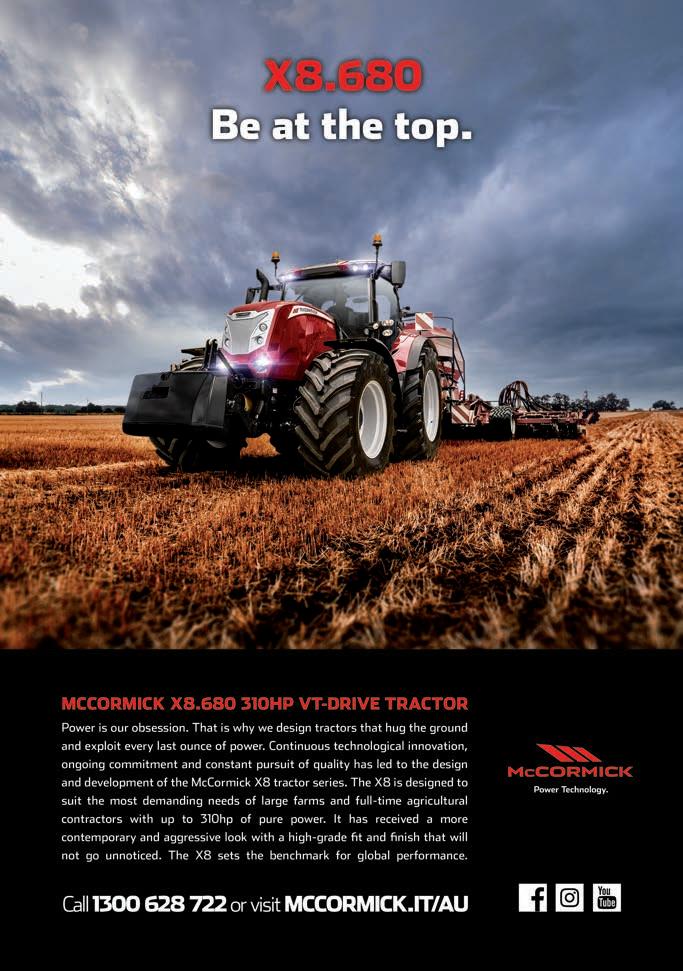

MCCORMICK X8 Functionality and technology has been combined in these models to meet performance and high comfort levels

SEEDER BUILDS Janke is offering growers a chance to order a custom build seeding system with a unique cost saving at the finish

LIQUID SYSTEMS How the inclusion of a Liquid Systems (SA) LQSAI120 Module to combat the loss of nutrients paid off for these growers

UNI TUBE EXPANDS Eagle i is providing more reach for grain growers with the Universal Industries manufactured Uni Tube conveyor

O’BRYAN SCRAPERS Atlas Industrial Holdings begins an expansion era for O'Bryan levellers with the purchase of the well-known model range

HAYTECH MONITORS A wireless monitoring system distributed by Farmscan is able to check heat and quality of hay bales to avert unwanted fires

THE SEAT SHOP See the range available from the leading local seat replacement specialist with all types of seats and for every industry

MASSEY FERGUSON MF 7S Equipped for operators seeking higher spec models as part of their regular daily duties from 103 to 154kW (140 to 210hp)

4FARMERS EXPANDS How farmers can now get more access to the best value herbicides, pesticides, seed dressings and trace elements

TARPFAST BLOWERS Smallaire has the ideal solution for keeping grain storage bunker tarps in a perfect position this season

TRAILED TRAILERS Specialist models for where it’s important to move quickly across crops and disperse product with a precision target approach

TRACTOR TRENDS How small unknown makers are plugging for a life of driverless tractors while the traditionalist fight for onboard operators

MASSEY FERGUSON 8S.305 The Power Farming Tractor of the Year 2022 expands the dream machines MF 8S Series to even greater power levels

FASTRAC iCON A redefine operator experience in control and comfort with integrate technology such as ISOBUS and GPS guidance

SOLIS S90 Ideal fit for livestock producers that need a hardy model to get around stock quickly and able to handle any feed carting requirement

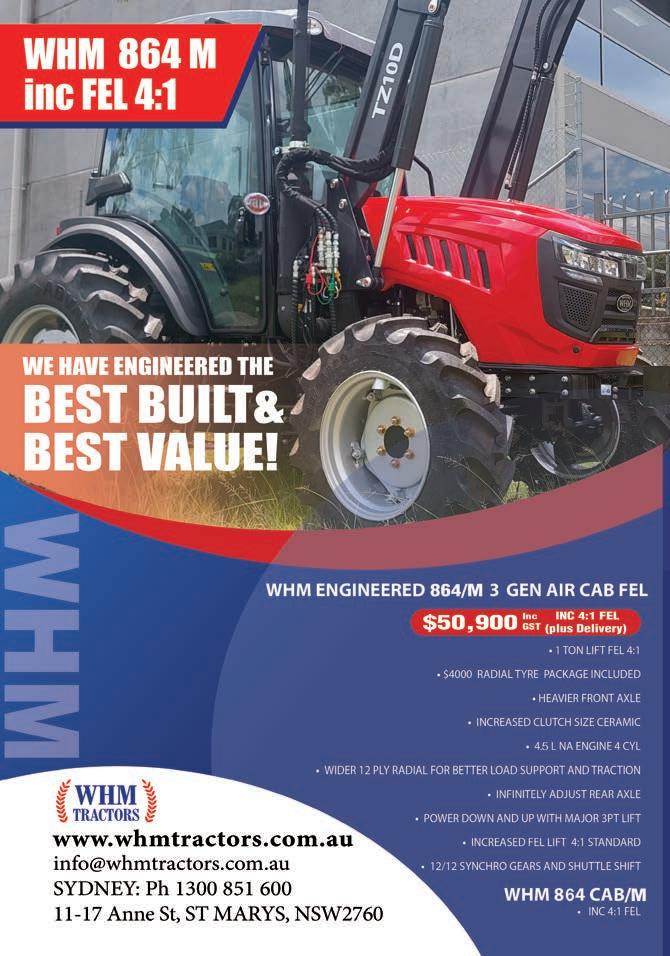

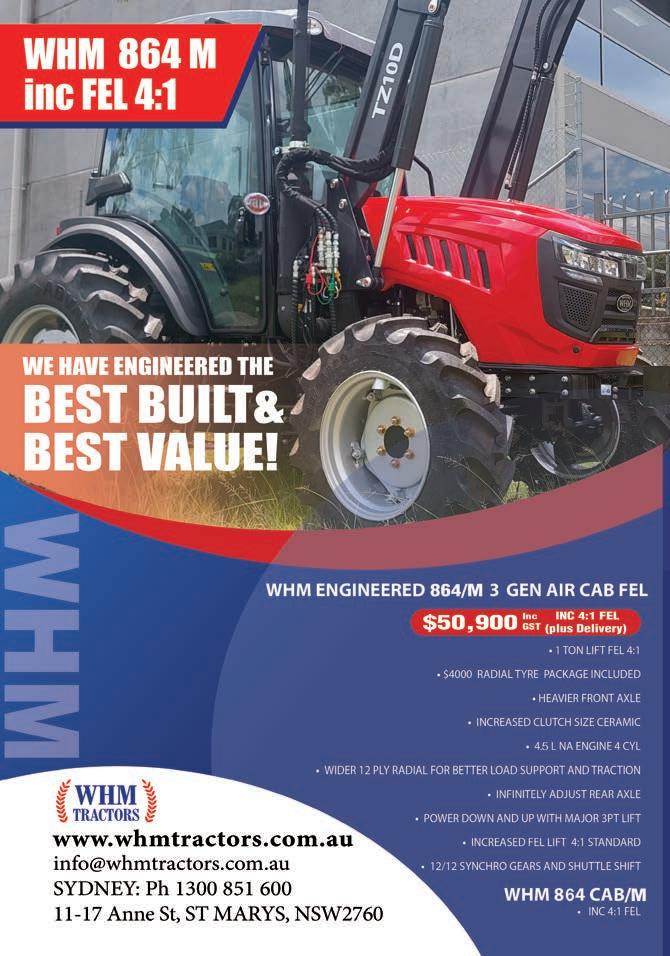

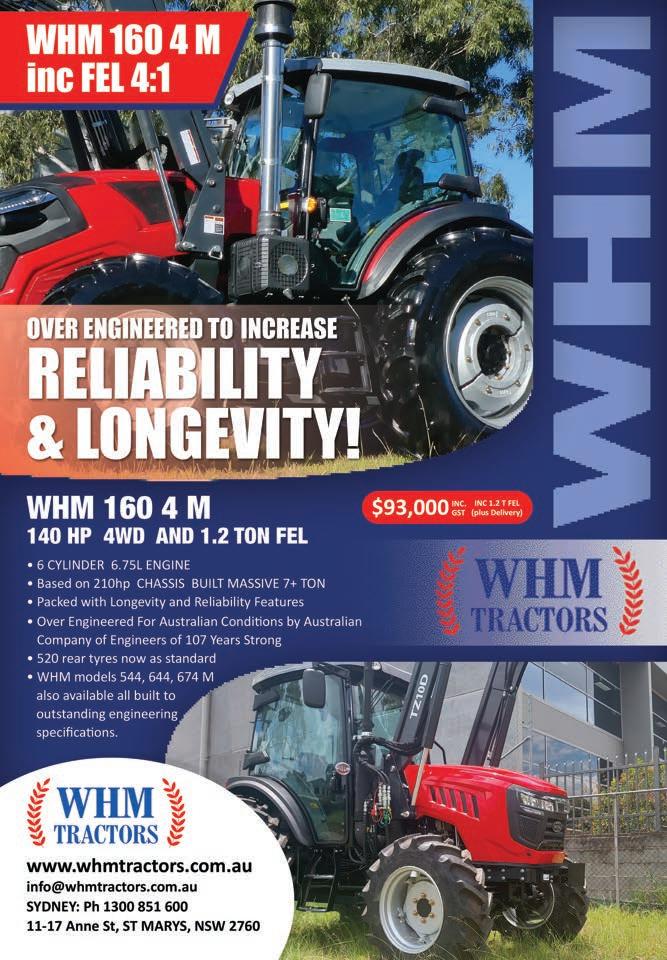

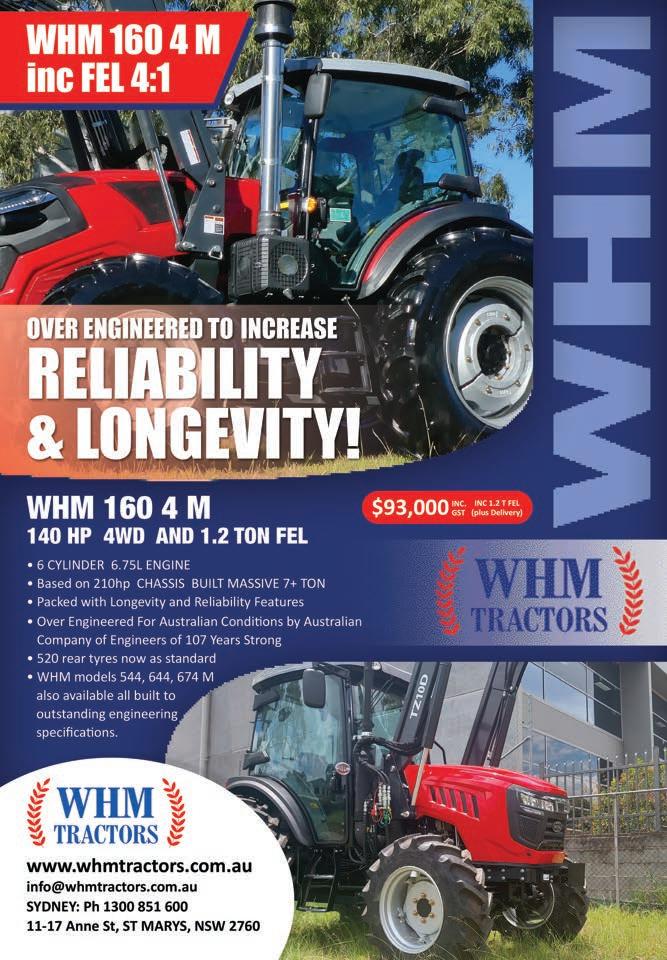

WHM 1604 M Outstanding tractor value with 119kW (160hp) and FEL and 4:1 Euro quick hitch available in ROPS or with full air-conditioned Cab PREFERRED SUPPLIERS

McCormick, one of the ARGO Tractors badges based in the province of Reggio Emilia, Italy, has recently completed a stylistic renewal of its entire range, estimated to cost in excess of A$120 million. Models in the brand now present with a more expressive and recognisable family feel. This is the result of the culmination of a journey that began several years ago, starting with the X8 VT-Drive, and which, step by step, has extended to the entire range.

One of the architects of this process is Fabio Leonardi, designer at the industrial group.

“Working for a leading and internationally renowned brand like McCormick is certainly very satisfying, but also a great responsibility, because you cannot disappoint or get it wrong; the design is often the first thing that people see and it is judged and appreciated”, he says, telling us about his experience at Argo Tractors. “What has guided me

in this sector”, continues Leonardi, “is my great passion for engines, for vehicles and especially tractors. It all started with the restyling of the X8 VT-Drive and that is where this great adventure began”. Design and branding are more closely linked with the tractor technology than many would realise says Fabio, as he goes on to underline his impressive knowledge of the process.

“For the McCormick brand, the design must convey the brand’s values and mission: the high power, the technological aspect, a quality product, comfort and safety. McCormick’s interior layout is always built around a person and the technology that governs the tractor’s power. Everything must revolve smoothly around the user. Great attention must therefore be paid to ergonomics.

“Unlike a car, there are several functional islands in a tractor: the dashboard, the left panel, the right panel, under the roof, the

Inside this issue, also catch the soon to be available to order McCormick X6.4 and X7 models now built to a higher level to meet the needs of all types of farming farm operations with boost power from 99 to 114kW (135 to 155hp) and 121 to 129kW (165 to 175hp) respectively

Much more goes into a tractor than the engine and driveline –style has to be right as wellThis is the model that started the McCormick tractor line transition to a more current look with added Power and torque to suit local large-scale farmers and contractors perfectly – the McCormick X8.680 VT Drive is currently the most powerful McCormick has ever built to date with engine power reaching 228kW (310hp)

Janke

For any grower or contractor looking for a special build you’ve had in mind for a while, your chance is now here for next season. Order a Janke bar now and fit the tynes and components yourself for a very considerable saving. Book your slot now, this is a unique opportunity, call on tel: 07 4693 7188.

Janke only has a few slots available and will be custom build from their invigorated range of Seed bars and Air-seeders. A range that Janke has firmly cemented in place from this major supplier going forward.

At the forefront of the current builds are individual row assemblies such as the Janke disc or tyne Parallelogram planter units. These bars allow growers to custom build equipment to suit any unique paddock conditions. An arena Janke has become a specialise in. Leading the initial charge is the FX range of spring parallelograms with breakout forces from 180 to 500kg (400 to 1100lbs). Replacement spring tyne units are also readily available in the same range. Standard hydraulic Parallelograms are available in 385kg (850lbs) and the popular 680kg (1500lbs) 3x1 tyne unit, that has been tested to planting depths of 250mm (10-inches).

At McCormick, functionality and technology must be combined with an attention to quality solutions in terms of forms, colours, detail and a high comfort level: all to create a classy environment to meet the very demanding customer’s expectations,” Fabio added.

“It is a delicate balance, between functionality and style, but the latter, Fabio clearly reiterates, must never become an unnecessary complication. Experience and awareness of technical aspects makes it possible to find the best solutions that guarantee both practicality and style. A result that is achieved to perfection in McCormick tractors in each new product family, Fabio concluded.

Inside this issue, take an exclusive look at the soon to be available McCormick X6.4 and X7 models now built to a higher level with the intention of meeting the needs of farm operations.

Power outputs for the X6.4 Series start at 99kW (135hp) and peak at 114kW (155hp) from a 4.5-litre FPT four-cylinder engine, and there are updated controls in a revised cab but most of all there is an all-new semi-powershift transmission. McCormick X6.4 models now boast HD design, and a semi-powershift called P6-Drive, with six steps in both directions creating a 24x24 configuration – a very versatile layout. Also prominent in the new McCormick line-up is the X7 SWB Series of four-cylinder models with a power range starting at 114 to 130kW (155 to 177hp) that sit on a 2,651mm wheelbase. While two more models run more powerful six-cylinder engines to develop boost power of 121kW (165hp) and 129kW (175hp) respectively.

Offering the choice of four or six-cylinder engines in the X7 SWB Series shows the extent of matching purpose built models for all farm operations that McCormick has achieved to make the brand more compatible with just about every type of farm jobbing moving forward. Read more about all the current tractor releases, many before they reach our shores in the “Power Farming tractor of the Year” special inclusion in this edition.

planting conditions. And in addition, these units can also be locked up to be used as traditional tillage chisels. With the benefit of a Janke bar being able to run as either a plough or planter, this is a big cost saving for growers. There is no need to purchase a second machine for tillage – you already have two machines in one. From the Janke Air-seeder range are trailing Castering or Steerable Quad models in a range of product capacities up to 25000-litres in 2 or 3 bin configurations, running on a 2, 3, 4m wheel track. The metering unit is capable of double or triple shoot and offers easy access cleaning and servicing. Janke Trailing Air Seeders are offered with Ground Wheel Drive, Hydraulic or Electronic drive system. Janke Australia is located in the agricultural manufacturing hub of Dalby Qld, contact the sales team on tel: 07 4693 7188, fax: 07 4693 7185, email: sales@janke.com.au or see the website at: www.janke.com.au or facebook at Janke Australia. ■

Janke custom builds come with a unique choice to do it yourselfhas just a few slots available to custom build for a select group of growers for next season and that will range from Aircarts to upgrading an existing bar with more efficient Janke disc or tyne Parallelogram planter units, to a completely new Bar set up with tynes proven to achieve much higher yields

An investment in new planting equipment to apply liquid fertilisers is paying off for

Peninsula grain growers, Tim and Peter Edwards, and since they switched over, they’ve seen more vigorous early establishment, thicker canopies, healthier crops and yield gains.

About six years ago, Tim and Peter Edwards, Yorke Peninsula SA grain growers started using deep ripping to crack through subsoil layers in their soil. This allowed plant roots to explore to depths where they are exposed to more moisture for a higher yield potential.

Although this showed immediate and impressive results in crop performance, in the following seasons they often saw a nutrient ‘hangover’ that began to require higher macro and micro-nutrient inputs to maintain crop yields.

A new system was also needed to minimise the ongoing compaction of their newly deep ripped soils. After discussions with their agronomist, Chris Davey from YP AG, they made the switch to liquids at seeding and haven’t looked back.

“We sat down with Chris and said that we were thinking of going to a parallelogram seeder and controlled traffic system and also a liquids system because we feel we’re upsetting some of the nutrients in the topsoil as we deep rip, and he agreed,” Tim said. They replaced their Steiger tractor with a John Deere RT running on three metre centres and bought a second-hand John Deere 1910 aircart. They also picked up a demo model Air Cart that was already rigged for liquids to replace their old model.

The 12-metre bar was re-engineered to place the wheels at three metre centres and increase the strength of the frame to carry a 4000 litre liquids tank.

The only new piece of equipment they bought was a Liquid Systems (SA) LQS AI120 pump and control module for liquid application.

“The AI 120 pump and control module has been fantastic, it hasn’t missed a beat,” Tim added. Everyone I know who uses liquids uses Liquid Systems gear – they’ve been well made and no-one seems to have any trouble with them.”

Their usual upfront fertiliser program now includes 70 kg/ha of MAP and 30 kg/ha of Gran-Am applied with the seed in a 100mm wide root boot trench and 25 to 30kg/ha of EASY N with a trace element mix applied in a stream 50mm below the seed line.

The fertiliser program is fine-tuned each

season over three planning sessions in late spring, summer and after soil testing in March. “The updated equipment is giving us a lot more flexibility in what we can apply and how we apply it,” Tim explained. For example, they could apply higher rates of nitrogen upfront because the EASY N liquid nitrogen fertiliser is placed away from the seed line, compared with their previous knife point system. “Since we’ve unlocked our soils with deep ripping, we’re finding ways to push harder and achieve higher yields and we can’t do that without nitrogen to set that potential,” Tim said. Sulphur is another key nutrient they like to have available to the crop early, as well as copper, zinc, manganese, iron, cobalt and molybdenum. Flutriafol is added to the mix where needed. Although the input program is extensive, and more expensive, the cost has been more than offset by yield gains. “We changed a lot in one year, but we’ve certainly seen the benefits,Tim said, We noticed significant improvements in strike rates and germination. We’re seeing a lot better establishment and vigour and that’s been really valuable for weed competition. It surprised us how much a nice thick canopy can put pressure on brome grass and ryegrass and the early EASY N has played a large part in that.”

Tim said having higher rates of early nitrogen available to the crop gave them the flexibility to topdress urea or spray EASY N as required, rather than being under pressure to feed the crop early. There have also been a couple of incidents with missed strips and skipped applications to illustrate the value of their nutrient program.

“In the first year we used the new system we

skipped a few rows in the barley, and five or six weeks later, you could really see where the EASY N had gone out and where it hadn’t,” Tim added. The barley was green and gold – where there was no nitrogen applied it was significantly yellower, there wasn’t as much biomass, but where the liquid fertiliser was applied it was fantastic. Another situation was a liquid trace element brew to no liquid comparison in a lentil crop, resulting in a 250kg/ha yield increase. Even when they can’t point to a specific change in yields, Tim says setting up good crop health early is giving their crops the best opportunity to perform.

“The most rewarding thing is seeing all our crop yields trending the right way because we’re getting all that one percenter right,” Tim said.

Last season, Tim also installed two 30,000 litre tanks on-farm, allowing them to pre-purchase EASY N at a favourable price. He said the flexibility of being able to buy nitrogen at the right point in the price cycle and store it on farm from season to season was a major bonus. “The price difference between the first tank fill late last year and an equivalent urea purchase this year was more than the investment in the tanks,” he added.

Tim said they were planning to stick with their liquid seeding system for a few years, although they may consider adding a second tank to apply a wetter and are interested in latest release products like the new nitrogen and sulphur liquid fertiliser mix, EASY NS, planned for release next season.

See more on the full range of choices at www.liquidsystems.com.au or to find your nearest dealer call on tel: 08 8357 4437. ■

Tim and Peter Edwards made the switch to a Liquid Systems (SA) LQSAI120 Module with LQS-ASST3 LQS-AT5F x 43 outlets to combat the loss of nutrients from deep ripped soil and it has worked well for them Yorke

Uni

Eagle i Machinery is providing more reach for grain growers’ dollars with the Universal Industries manufactured Uni Tube conveyor.

Eagle i Machinery’s Peter Brunt said the Uni Tube is ideal for grain growers and bulk handlers, “The Uni Tube range covers models from 11 to 36.5m (37 to 120ft) long and with belt widths of 381, 457 and 559mm (15, 18 and 22-inches) that allow capacity handling up to 300 tonnes/hour making them ideal for outloading. “We’ve got over 150 Uni Tube’s operating in six states, from farms to commercial operations

and they’re providing excellent service for their owners.

Uni Tube offer a fingertip control self-propelled option that’s fully engineered and integrated, not just bolted on. The SP units give positive drive and excellent manoeuvrability in all conditions.

Peter Brunt said the hydraulic drive and self-propelled system made Uni Tube easy to position.

Peter Brunt continued, “We’ve had it go up and down some quite steep gradients and it handled them safely due to the unit being well balanced and the hydrostatic drive mechanism preventing the Uni Tube from

O’Bryan scrapers and land levellers have become part of the ATLAS group of companies and will move to an expanded state-of-art manufacturing plant in 2023

are ready for delivery now in a range of models from 11 to 36.5m (37 to 120ft) long and with belt widths of 381, 457 and 559mm (15, 18 and 22-inches)

“The Uni Tube rollers are fitted with a vulcanised rubber to positively drive the conveyor belt. Strength and reliability are built into the Uni Tube’s, which use shafts that run the full width of the belt rollers.

“This is instead of a welded shaft at each end of the roller, and this is where Uni Tube gets a big advantage, the superior belt alignment and running equal better longevity and performance.” Peter Brunt added.

Uni Tube is driven by a simple easy to maintain hydraulic system that is powered by a Kohler,

Honda or Yanmar engine in petrol or diesel depending on configuration. Uni Tube models are also available with electric or power take-off drive options for larger units or commercial operations.

Uni Tube is joystick controlled allowing the operator to move the conveyor and perform other functions such as raising and lowering.

There is a ‘deadman’ style button on the joystick and two safety switches provide an extra level of protection for the operator. There are also manual control levers as a back-up to the joystick.

The majority of models in the Uni Tube range come with a spring loaded universal hopper suitable for all conditions and Eagle i Machinery also offer a range of swing away and drive over hoppers.

Eagle i Machinery is based at Finley, NSW, and supplies a wide range of grain and fertiliser handling, tillage and irrigation equipment.

There are Uni Tube dealers in most states and they can easily be located on this link: www.eaglei.com.au or contact Eagle i Machinery direct to find a dealer to discuss more details on tel: 03 5883 2391. ■

expand the business when the company moves to new state of the art manufacturing facility in 2023.

Under new management, the O’Bryan Equipment team will have a big focus on innovation, engineering and the customer. "As a team we pride ourselves on being a forward-thinking group of people who understand the key requirements of each product we design, manufacture and support" said ATLAS Group Managing Director, Arne Joyce.

Atlas

O’Bryan Equipment has been designing and manufacturing land levellers for over 40 years and during that time has grown to become one of Australia’s most trusted manufacturers of earthmoving equipment.

Farmers and contractors are very familiar with well-known models in the O’Bryan range such as the 4.5 HD Highlift, one the largest scrapers with a 17cub.m capacity bowl and 4.3m (14ft) cutting edge, and the very popular O’Bryan 4.3 Farmer, a medium weight multi-purpose scraper ideal for land

owners with a 4.0m (13ft) cutting edge and 12 cub.m bucket capacity. Alreadt found on countless rural properties. This purchase expands the depth of manufacturing capabilities and product range for ATLAS who previously focussed on supplying construction equipment through APEX Equipment Group and had a specialist hire division through Yellow Hire. While a further strong supply chain within the group, Leader Cranes and Logistics was also a specialist in equipment rentals.

An ATLAS group representative confirmed they will keep the core strengths of O’Bryan Equipment in designing and manufacturing the quality earthmoving scrapers that O’Bryan was known for. And also intend to

“Since taking ownership of O'Bryan Equipment, it was a priority to register our O'Bryan Equipment's scraper range to the Australian Made Campaign, and that became a reality in March 2022. As an Australian owned and operated company, we feel the importance of a strong local supply chain and rely on the most reputable local manufacturers and suppliers for all raw materials and components.

ATLAS Group MD Arne Joyce added, "Management and staff look forward to working with our existing and new customers and the rural community now and into a very exciting the future."

Existing customers of O'Bryan Equipment land levellers will have access to all parts and components for any of the existing models and will be notified about the expanded model range that will become available to them as the new manufacturing plant begins its production line.

For further information on latest O’Bryan land leveller models contact ATLAS direct on 1800 847 272, or email sales@obryanequipment.com.au or scan the barcode shown in the picture above, on your mobile. ■

single-disc seeders make full use the PLR™ (ParaLink™ Row) Opener, as this newly designed single-disc opener utilises hydraulic downforce and parallel arms for increased travel, penetration and seed depth consistency.

Local growers are aware of the benefits and importance of accurate seed placement and are being drawn to Bourgault’s PLR™ opener system that uses a single gauge wheel running alongside the disc, to set the seed depth.

Consistent seed placement, even in undulating country, is achieved through the combination of 510mm of travel and hydraulic down-pressure on each individual opener. This

unique to Bourgault and provides growers with the most precise seed placement control for any disc seeder.

Good seed-soil contact for a fast and even germination is ensured with a rubber seed-firming wheel followed by a large semi-pneumatic press wheel. Adjustment of the packing pressure comes from a heavyduty torsion spring.

Repairs and maintenance costs are always at the forefront of disc machine operator’s minds.

Farmers can spend more time seeding and less time in the workshop with Bourgault’s PLR™ opener’s robust, low wear design. Greasable 25mm (1-in) diameter needle bearings, with seals and hardened and plated forged

the low 250-hour grease intervals mean greasing the machine is a once of season requirement for a lot of growers.

The PLR™’s independent hydraulic downforce system removes excess movement out of the operation of the unit. While designs using springs tend to bounce and vibrate when travelling over rough or uneven ground, the PLR™’s hydraulic cylinder on each opener reduces the vibrations, resulting in less wear and tear on the unit. With hydraulic downforce and a compound angle on the large 520mm (20.5-inch) disc, the PLR™ Opener has plenty of power to penetrate the toughest of ground conditions.

When seeder flotation is an important consideration for a farm operation, the optional HiFlotation™ package might be the right choice. It allows the operator to stay seeding for longer in soft or wet conditions with more rubber under your seeder. As much as 70 per cent of the weight applied from the drill to the tyres is transferred through the front running gear in a high draft scenario. Therefore, upgrading the rubber on the front of the drill is the main focus. Large single, lugged tyres provide 65 per cent more surface area on the mainframe.

Check availability of options and models with your local Bourgault Dealer on this link: www.bourgault.com/en-au/dealer-locator

The

crops

Designed and manufactured by Phillbourne of Merredin WA, the Retrodrum is a replacement feed auger that has made its mark as being able to handle the toughest of crops with ease. The Retrodrum actually started life as the Turbodrum and came into being during the 2016 harvest.

Phillbourne was asked by an Esperance farmer to develop a replacement feed drum for his MacDon harvester front based

on the very simple design the company used on its pickup fronts.

The drum developed to help this farmer was so successful that Phillbourne sold nearly 400 units in the next 14 months.

The name change to Retrodrum occurred in August 2018 when the Turbodrum name encountered copyright issues.

Since production of the Retrodrum began, a policy of continuous improvement has

resulted in a more refined product covering an ever-growing range of models – currently 5 brands and 13 models.

There are now over 1500 units working in Australia, New Zealand, Canada and the USA. It’s no surprise the Retrodrum’s first client was a Macdon owner as Macdon owners are known to suffer the frustration of slow harvest speeds in bulky crops, and blockages and breakdowns

caused by the standard feed drum in their fronts.

The Retrodrum can harvest canola or beans and then move to light feed crops with very little adjustment required.

Retrodrum became an instant fix for these problems, allowing operators to use the full width of their front, go faster and get crops off quicker.

Phillbourne has now developed a Retrodrum for John Deere, Honeybee, Midwest, Case IH and New Holland models.

Fitting the Retrodrum is a quicker operation than fixing the originals on many header fronts, and growers have found it comes at a fraction of the price.

Retrodrum’s heavy-duty design includes more than double the number of retractable fingers, with a much more aggressive pattern. It literally grabs crop and pulls it through in a constant and steady flow.

To eliminate harvesting issues, order your Retrodrum now for the next harvest.

For more information call the Phillbourne factory direct on tel: 08 9041 2066, or email phillbournes@wn.com.au

First-hand experience of a devastating hay shed fire on their Southern Mallee property in Victoria has prompted the Edelsten family to adopt some of the latest technology.

They have installed a Haytech wireless monitoring system purchased from Farmscan to monitor the heat and quality of hay bales, in addition to their existing moisture monitoring system.

Shane Edelsten farms with his brother, two nephews and his son, Blair, west of Hopetoun VIC in the region, where they grow export oaten hay and vetch hay, as well as cereal, canola and lentil crops.

The hay is grown over about 600 hectares, filling two sheds holding 2000 bales each and with any surplus hay, depending upon yields, remaining in the paddocks under hay cap covers. The premium export oaten hay is sold into Japan, China and developing new markets in Korea. Some can also be trucked to southern farms if quality is affected by adverse seasonal conditions.

“For us, it’s all about the quality. Colour is a major factor with oaten hay, so we bale it and get it in the shed as quickly as we can,’’ Shane said.

“We generally hold it for two to three months depending on end-user time-frames.’’

He said they lost a shed full of hay due to a fire several seasons ago, amounting to $360,000 for the hay and a cost of $140,000 for the shed.

“It was pretty horrific, but unfortunately, most hay growers experience a fire at some point in their lifetime, but it’s something I don’t want anyone to go through if they can help it.’’

Shane said they typically tested the moisture of every bale as they arrived into hay sheds, however this had since extended to the heat of bales using the Haytech wireless monitoring system purchased from Farmscan.

The system comprises robust 40cm (15.7-inch) hay probes that measure temperatures every hour and, via a base station, sends the data through to the Quanturi online service.

The online service is available on desktop computers, tablets and smart phones, to provide alerts when temperatures reach unsafe levels.

Shane said by using both the moisture and heat monitoring systems, they achieve a better overall view of how their hay is tracking.

“We still moisture test everything coming into the shed and will pull the higher moisture ones out and leave to the front if it is safe to do so, or leave them out – and we put the Haytech probes into the higher moisture bales.’’

“To maintain hay quality, it is also important to monitor the temperatures because it can cook it inside.’’

The Edelsten’s two hay sheds are 10 kilometres apart and as a result they run two separate Haytech wireless monitoring systems, sending real-time temperature data to the Quanturi app on their phones.

“It alerts us if there is a hot bale and we can then look it up to see what shed it is in,’’ Shane said.

“It’s an excellent system and has operated very well. With phones these days, I can be away and get an alert and there is generally someone around the farm. I can then say: ‘Go to shed B, there is a hotspot’.

“It’s huge for your peace of mind. Hay season starts first, before we get into the grain harvest, and you don’t want to be pulling sheds apart and monitoring hay in sheds while you’re harvesting.

“With this system, you can be in

the truck, flick over to the App on your mobile and see that the hay is all fine.’’

Distributed through Farmscan, the Haytech wireless monitoring system allows for multiple probes to be added as required and an optional repeater can enhance the signal strength between the probes to the base station, including from another nearby shed.

For sheds without 240-volt power, Farmscan can provide a purpose-built 3G/4G solar base station to connect to the Haytech base station.

Growers also have the option to take advantage of a premium data service with Quanturi, this service provides details of bale temperature history for up to a month for further assurance of hay quality.

The probes can be placed in a handy virtual storage locator to help find them easily in case of danger.

Shane said support for the Haytech monitoring system from their local Farmscan dealer and through to the distributor in WA had been excellent, highlighted by strong technical expertise, and he encouraged other growers who may be considering the system to take the step.

“Upgrading to a system like this for the peace of mind is money well spent. If you look at the cost of how much it is per bale over 10 years, it is negligible,’’ he said.

Farmscan is delivering the Haytech wireless monitoring system through their extensive dealer network, Australia-wide.

Call Farmscan direct on on tel: 08 6102 3200 or check for your local dealer at: https://farm scan.com.au/a/storelocator or see the full product range at: farmscan.com.au

Take a minute to familiarise yourself with the leading seat replacement specialist in Australia, The Seat Shop, as the next seat you buy should come from this local supplier.

The Seat Shop sells and services all types of seats and for every industry. And has built up the best selection of quality replacement seats currently available.

They specialise in original equipment seats for many of the leading Tractor and Truck brands and in addition will often recommend a seat that far excels what was fitted in many

older models. To the delight of the operator.

The Seat Shop always has seats in stock from major brands including KAB Seating, National, Stratos and Buro to mention a few. And while they specifically focus on agricultural seats, construction, mining, and truck seats they have the capability to supply a seat for any vehicle or model type.

In addition, they specialise in custom seat builds and rebuilds from their branches in Biloela, Mackay, Toowoomba and the Gold Coast from where they deliver Australia-wide and

internationally.

And while The Seat Shop has excelled in stocking a wide range of seats since they were founded in 2004, they also supply spare parts and a seat repair service Australia-wide.

As part of the service, The Seat Shop has a wide range of seat covers to choose from to suit all types of work applications. And because their covers are custom made to an exact template of the seat and cut and sewn to suit, you can expect a perfectly cover. We make an. They also have in stock the most current popular fabrics in

both industrial canvas and industrial black denim finishes. Often seat replacements or updates need a new set of seat belts, and The Seat Shop can help here as well by providing a wide range of replacements for every different application including all agricultural machinery, for construction and mining vehicles, as well as all 4WD vehicles.

If you are seeking a simple part for your seat, talk to The Seat Shop about that as well, because they stock a massive range of spare parts. Includes airbags, shock absorbers, air compressors, bearing kits, buttons, levers, armrests and more. Take a look at their spare parts range on their website shown below.

The Seat Shop can provide floor stock seats for sale from their branches in Biloela, Mackay, Toowoomba and Gold Coast. And will ship seats to any destination throughout QLD, NSW, VIC, ACT, TAS, SA, WA, NT and internationally.

Get in touch with The Seat Shop and they will provide expert advice on the right seat to suit your machine or vehicle. Call direct on 1300 146 294 to receive your free quote or look at the full range from farm machines to trucks Online at: www.theseatshop.com.au ■

Massey Ferguson’s MF 7S Series tractors are ready to be equipped for operators seeking a higher specification model as part of their regular daily duties in a maximum power range from 103 to 154kW (140 to 210hp). With another vital surge on standby when Engine Power Management (EPM) kicks in.

Many operators will be drawn to this range based on the level of customisation that is available to make the tractor truly representative for the work it is bound to perform.

As these MF7S models offer the chance for the operator to select a transmission, level of cab comfort, automation and control technology to suit the specific farm jobbing they will undertake.

The first task for the operator will be to select a power range.

This task is straight forward with Massey Ferguson’s model designations show numbers that denote the maximum draft power of the tractors. In this case being, MF 7S.145, MF 7S.155, MF 7S.165, MF 7S.180, MF 7S.190 and MF 7S.210.

In general, all MF 7S Series tractors deliver up to an extra 22kW (30hp) with Engine

Power Management (EPM) –depending on the model.

All tractors in the MF 7S Series have a long 2.88m wheelbase that sits on a very stable robust chassis with the ability to manoeuvre through a 4.93m turning radius.

These tractors are also able to work comfortably hauling heavy loads of up to 9600kg at the rear and 4000kg on the front linkages.

The overall design is highly determined as it encompasses the tractor’s gross vehicle weight of 14 tonnes with a gross combination weight of up to 44.5 tonnes.

Obviously, you need some propulsion power behind this build and Massey engineers have opted for powerful and straightforward 6.6-litre, sixcylinder Tier 2 engines that deliver draft power from 107 to 154kW (145 to 210hp).

And as all models are capable of generating extra power and torque with the EPM as required they are capable of maintaining high productivity in all working conditions.

The choice of customised build starts with selecting the transmission. There is the new and improved Dyna-VT Super

ECO transmission on offer or the very efficient and easy to use Dyna-6 Super Eco with Automatic Mode on tractors up to 132kW (180hp).

Then there is the level of finish to consider. And while many operators will find the standard specification is a much higher level than their current model, there is also the choice to upgrade to either an Essential or Efficient finish.

The choice of standard, Essential or Efficient finish finds its way into the current profile cool and quiet cab with a high level of operator comfort and controls offering upgraded technology that come straight out of the award-winning MF 8S Series tractors.

A bonus for operators that opt for the Efficient finish there is a new Multipad waiting for them to provide single lever, comprehensive control on a comfortable armrest-mounting.

And there is the very easy and logical to use Datatronic 5, a 230mm (9-inch) terminal with a bright and clear touchscreen that also offers MF E-loader options.

Personal preferences that lead to a unique build is where the MF 7S Series will have an

edge over its power segment competitors.

And once the customised model reaches the tractor fleet exactly as the operator has specced, it’s going to stay in work for many more hours than a standard model.

Let’s take a look at what was behind the thinking of the MF 7S Series build.

The six tractors in the MF 7S Series are all built on a 2.88m long wheelbase to attain an optimum level of stability and traction.

A lot was always going to be expected from these next generation utility models so it was necessary to anchor more powerful six-cylinder, 6.6-litre engines that would deliver the high level of concentrated power and torque operators would be calling upon.

It was also important to realise many operators would be tempted to carry and haul heavy loads, so some robust engineering was added to enable these tasks.

While out in the paddock there would be no let-up for these models with expectations to deliver a high performance,

Massey Ferguson MF 7S Series

Massey Ferguson MF 7S Series

Engine Power Management (EPM) was therefore a must to keep the revs up.

And on the road during transport these models would need to get between jobs quickly, and also while being capable of yard work with a tight turning circle, these high productivity tractors are expected to be easy to manoeuvre.

To mark all these points with a tick, it was necessary to build the MF 7S Series with the ability to provide enhanced performance by equipping them with a range of automated functions for the operator with controls connected to the most current technology.

MF 7S Series tractors will be expected to perform well above their weight, and they will achieve this with the advanced AGCO Power 6.6-litre, six-cylinder engine positioned at their heart.

And while the draft power registers in a range from 103 to 154kW (140 to 210hp) there is back-up standby power when the EPM kicks in to take the ultimate power surge to 118 to 162kW (160 to 220hp)

All MF 7S Series tractors benefit from this generous extra power and torque, that are generated automatically when required for transport, PTO work or more demanding hydraulic requirements.

And while the standard load sensing hydraulics are 110litres/min, there is the choice of fitting an optional hydraulic system of either 150-litres/min or 190-litres/min.

inspireFor simplicity, Massey Ferguson continues to offer the range in Tier 2 emissions for straightforward, dependable operation and a very low cost of ownership.

Farmers will appreciate the chance to select a transmission

that will be a perfect fit for their own unique operation.

At the starting point is Massey Ferguson’s highly efficient and easy to use DynaVT ECO transmission that offers seamless shifting and is available on all models.

The Super Eco version of the Dyna-VT further improves efficiency by allowing the tractor to achieve 40kph at just 1,450rpm.

In addition, the highly regarded Dyna-VT continuously variable transmission has been upgraded with an automatic mode. This allows operators to use either the Multipad lever or foot pedal to alter forward speed, while it automatically sets the optimum engine setting to the load and speed.

An added bonus from the transmission upgrades is a much smoother operation and a noticeable improvement in fuel efficiency.

Alternatively, for MF 7S Series models up to the 132kW (180hp), MF 7S.180, there is the choice of the renowned, highly efficient and reliable Dyna-6 Super Eco 24 x 24 semi-powershift transmission.

Paddock proven for more than 20 years, this engine achieves a top speed of 40kph at a low 1,500rpm and as a result is also a better than average fuel saver.

Automatic Mode, standard on all Dyna-6 models, controls the role of speed shifts most relative to the engine load and speed.

While operators can also manually set the engine rpm at which changes are made.

All models are also equipped with the useful brake-to-neutral function, that is easily activated with a switch on the pillar.

For operators working in specialist crops they will welcome the Super Creeper option, that provides precise control with speeds down to 70metres/hr at 1,400rpm.

All MF 7S Series operators will benefit from significant cab improvements that provides more comfort and better control over any previous models they have worked with in this power range.

MF 7S Series operators are getting the benefit of the plush surroundings enjoyed by the market leading range of MF 8S Series tractors, including the

most current and efficient armrest available, Multipad controller and backed-up with enhanced connectivity.

With the additional of a newly designed air conditioning system the cab is now up to 4C° cooler than any previous model and offers a very high quality trim with a chrome steering wheel and black dashboard on Efficient versions for instance.

Operators also benefit from a more comfortable, standard inclusion air-suspended seat.

With a heated seat option and high level of ventilation, it is equipped with the DDS –Dynamic Damping System that responds automatically to the severity of any bumps with a lateral stability suspension.

All control positions have been well planned and within easy reach, arranged in a convenient and logical layout.

Depending on the model specification selected, the new armrest and Multipad provide simple, comprehensive control along with a keypad for lesser used functions.

Outside the cabin the LED light design along with the bonnet lightbar produce a bright signature, with the option to fit up to 16 LED worklights.

For loader operations there is also the option to fit a Visio Roof to provide a direct visual of the load right through the whole lift process.

There are plenty of choices to improve cabin and operational comfort by adding the optional mechanical or active mechanical cab suspension, as well as a suspended front axle.

The Efficient specification includes the Multipad lever and comprehensive control

Attention is grabbed at first sight as MF 7S Series tractors have the most sculpted cutaways for the greatest visibility of any model to date but still incorporate the family look with the iconic MF grey sabre stripe along the side and horse collar motif that dates back to the MF 100 Series Any loader operation is a cinch with MF 7S Series tractors if the optional Visio Roof is fitted the operator gets a direct visual of the load right through the lift processarmrest, linked to the seat, as standard equipment.

This easy to use, ISOBUS compatible controller places everything conveniently to hand, including linkage control rocker switch, cruise settings, driving mode pre-sets and MF Guide activation. It also houses a micro joystick to operate two electric spool valves.

A unique multifunction lever option provides easy control of a loader and front linkage. As well as operating the spool valves, this also allows operators to change direction and tractor speed.

Operators will appreciate the latest upgrades to the Datatronic 5 terminal with a much brighter and clearer touchscreen to reduce glare.

Higher definition colours and a black background, along with new shortcuts on the homepage also make it easy to use.

Also new is the MF E-Loader option that helps to increase loading accuracy, productivity and safety and provides control and setting of the Bucket Shake facility.

This enables operators to weigh individual fork or bucket loads and record the total, load or job, then transfer these to a simple spreadsheet.

It’s also possible to set-up and save upper and lower limits as well as automatic sequences for different loading cycles.

Also for Efficient versions is an option that enables the radio, mobile phone and media to be operated through the Datatronic 5 screen, with inputs via Bluetooth, USB or Aux cable.

Operators are alerted to incoming calls by a pop-up on the screen.

Datatronic 5 manages all the tractor functions and also with ISOBUS connectivity and GPS signal it is able to run the MF Technologies’ Precision Farming suite.

These include MF Guide, with its fast set-up ‘Go-Mode’ as well as MF Section Control to reduce overlaps and precisely target inputs with variable rate applications using MF Rate Control.

Data gathered and recorded automatically on MF TaskDoc is transferred with an USB memory card.

With the MF Task Doc Pro option it allows the operator to create application plans and wirelessly synchronises with farm management software.

MF Telemetry is standard on all MF 7S Series models.

With its 2.88m wheelbase and strong, sculpted chassis, MF 7S Series models combine stability with manoeuvrability – offering a turning radius of just 4.93m.

Perfectly balanced, they also provide an excellent power to weight ratio and afford an impressive 44.5 tonnes Gross Combination Weight.

Three-point linkage lift capacities of 9,600kg on the rear and 4,000kg up front and up to 14 tonnes Gross Vehicle Weight (GVW) make them ideally suited to operating output boosting front and rear combinations.

The long 2.88m wheelbase also helps increase traction and stability. And that design advantage can be enhanced further by specifying up to

1066mm (42-inch) diameter rear tyres, to help reduce the ground pressure.

For heavy duty work there is a wide range of ballasting options, that are easily removed to take advantage of the MF 7S’s agility for handling wide implements and transport work.

Massey Ferguson’s MF 7S Series tractors have just launched in AU and NZ with the expectation to set the benchmark for the easiest to maintain and most versatile utility models in the 103 to 154kW (140 to 210hp) power segment.

Contact your local Massey Ferguson dealer on this link: www.masseyferguson.com.au

Take a look at all the most inspiring model releases for 2022, starting on page 36. ■

Growers in eastern states will soon have better access to well-priced chemicals through the 4Farmers network where they will find their farm operation will run more efficiently by organising product orders they are likely to need well in advance at a keener price

4Farmers was established in 1994 with one simple goal in mind, and that was to supply farmers with the best value agricultural herbicides, pesticides, seed dressings and trace elements available and this goal is still foremost in their operation

While growers and producers in the eastern states may not be as familiar with the name 4Farmers, as those operating in the west, the aim is for that situation to change.

4Farmers has previously had minimal representation in the east but are now on a drive to appoint additional supply outlets and renew the expansion operation into more eastern cropping regions.

This expansion by 4Farmers will provide more local access to low ag-chem prices.

Today, access is as simple as opening an account directly with 4Farmers, but then if you can nominate a local distributor and request a delivery from a local warehouse, the delivery or pick-up becomes easier.

When 4Farmers was formed in 1994, it concentrated its efforts on WA farmers and went about the business of supplying herbicides, pesticides and adjuvants at a much fairer price than farmers had ever accessed previously.

For many growers bearing the brunt of high prices at the time, it appeared suppliers worked off the principal of a price point of “what the market will bear” and it was this practice that enabled 4Farmers to supply Chlorsulfuron in 1995 at half the price of other suppliers.

Through the efforts of 4Farmers to provide low-cost chemicals, growers were able to adopt a whole new range of crop protection strategies that were previously too costly to contemplate particularly in the eastern regions of the WA wheatbelt.

Looking at the current 4Farmers operation, it is solidly backed by a team of professionals with background in Agriculture, management, distribution, and technical support.

This support derives its roots from current and ex farmers, agribusiness professionals and scientists. 4Farmers offers a unique blend of practical experience and technical skills at hand.

Armed with a broad product range, and with a widespread distribution network of local agents and small, flexible management team, 4Farmers is well equipped to get the right product to the right place when it is required.

There is already a quality widespread network of around 30 local 4Farmers agents and distribution locations throughout regions of WA, SA and Victoria.

It is envisioned that with any expansion into New South Wales and Queensland, 4Farmers can offer some of the best industry knowledge and input pricing Australia-wide.

With emphasis on balancing price with quality through bulk buying and in-house production, 4Farmers was an instant hit when it first began its operation, creating a much-needed impact on high costs in the marketplace.

As a result, the increased competition immediately brought down prices in several lines that 4Farmers was offering.

The people behind 4Farmers were and remain farmers and understand the importance of agronomy, working with local conditions and looking for ways to improve production.

The experience 4Farmers has gained is passed onto their clients, including on-going paddock trials from where information goes back to the 4Farmers agronomists and lab technicians, and they weigh-up different ways to improve their product effectiveness whenever required.

Another way of achieving a

4Farmers is recognised as beginning the supply of much more reasonably priced herbicide and pesticide in Australia. They are ever keen on expanding that operation into more supply locations where growers can get regular easy access

significant improvement in value is to have a more thorough discussion on input requirements, such as a more exact chemical level with a 4Farmers rep.

For example, a grower aiming to save $2.50/ha of costs, and spending $50/ha on chemicals, only needs to trim their bill by 5 per cent to achieve a real saving.

This translates across a cropping program of 2000ha into a $100,000 chemical bill, and if more carefully planned the cost can easily be reduced by $5,000.

Of course, buying quality is imperative, but 4Farmers also look to supply quality, cheaper. 4Farmers chemicals are lower cost and great quality, therefore better value.

In addition, beyond the savings made, 4Farmers backs its products with access to experienced expert technical advice to help growers objectively weigh switches to more economical generic chemical strategies.

There is a team in place at 4Farmers that can give qualified advice and support growers at all stages of crop development.

Sales team members are experienced in the ways of Australian ag and in-house agronomists are experienced and accessible by phone.

The service doesn’t stop there as 4Farmers will often deliver direct to farms and aims to have extra product on hand in case of high season

demand. They understand the importance of having product available in a timely manner.

Working with customers 4Farmers emphasise just how important it is for their staff to know paddock rotations and expected planting area well in advance and from there the appropriate chemical levels can be secured.

From this knowledge, an early order is the best strategy to make sure 4Farmers will have all the product on hand that you require.

All suppliers want to avoid supply and production issues such as local production bottlenecks due to the shortage of some ingredients like solvents or even packing materials or drums. 4Farmers is no exception.

Seasonal conditions such as the rain breaks that came in the eastern states following three years of drought, saw Glyphosate supplies flip from feast to famine.

In both these cases, early indications, forecasts, and orders can all help to alleviate or at least, manage this situation if it arises.

The solution is to deal with 4Farmers early so that product requirements are known well in advance, and supply can be guaranteed.

Farmers can buy with confidence from this locally owned company that also sources Australian made whenever possible throughout its supply chain.

A recent survey by 4Farmers confirmed how 88 per cent of farmers want to buy from from an Australian owned company, they ranked it as highly important.

A similarly high proportion of respondents indicated that buying Australian made had a significant influence on their purchasing decisions.

It’s time for Aussie farmers to back the all-Australian owned 4Farmers.

The effective reduction of Aussie owned companies from competition has been a longterm concern and the situation will only improve if farmers make a conscious effort to support local companies and keep strong competition alive.

If you take a look at some of the big names on plastic containers around the farm, it’s easy to see how the bulk of Aussie farm profits is going overseas. FMC – USA, ADAMA and Syngenta – Chinese, Bayer and BASF – German.

But make no mistake, 4Farmers welcomes free trade, competition and innovation. 4Farmers doesn’t agree with protectionism that adds to the costs of Aussie farmers; like Nufarm’s 35 per cent protection duty on Chinese 2,4-D products, or tariffs on some international Trifluralin.

Instead 4Farmers would prefer to get behind Australian companies competing on their own merits, beating foreign competition with better value and no government props.

In the case of 4Farmers. The company is 100% Australian owned and all the profits stay

on our shore. These profits are generally reinvested into the next cost saving chemical that needs development, trialling and production. Again, most of this is done in house.

Additionally, approximately 70 per cent of the chemicals sold by 4Farmers are formulated in their own plant in Perth.

That supports more local jobs and local community spending. If farmers care about buying from a local company that makes a lot of its product in Australia, clear choice for farm chemicals is 4Farmers.

The 4Farmers visions remains as it was at the start of its operation over 25-years ago, a company dedicated to the needs of local farmers in every location.

With the core business of manufacturing and distributing as directly to farmers as possible, a wide range of quality agricultural chemicals, 4Farmers emphasis remains on working with low overheads and tight margins to ensure local farmers get a fair and competitively priced product.

Make the switch to an Aussie owned chemical supplier, as 4Farmers welcomes all the new customers from the eastern states they will be working with this season.

Contact 4Farmers Australia about your farm chemical requirements with a Freecall on 1800 038 445, by email: sales@4farmers.com.au or by fax: +61 (8) 9356 3447.

See the full product range at: www.4farmers.com.au/products/

4Farmers has expanded its operation in supplying more eastern states growers in this near record breaking season

In addition to keener priced product lines 4Farmers also supplies a wide array of self-help procedure brochures to ensure farmers get the best results from their applications

4Farmers has expanded its operation in supplying more eastern states growers in this near record breaking season

In addition to keener priced product lines 4Farmers also supplies a wide array of self-help procedure brochures to ensure farmers get the best results from their applications

Smallaire has the ideal solution for keeping grain storage bunker tarps in a perfect position this season with the release of the Smallaire Tarpfast blower.

The Tarpfast blower works by creating a negative pressure under bunker tarps as it gently sucks the tarp to the grain.

This stops the tarp from flapping and tearing in windy conditions and avoids costly tarp repairs and any downtime labour.

Your tarp will stay in position and as result the grain it is protecting will come out in much better condition, with no grain spoilage.

Tarpfast has proven to be the ideal solution for growers that ran this blower system last season.

Brett Moore from Moore Bulk Haulage in Horsham VIC said, “I would highly recommend

the Smallair Tarpfast. After having used these units, we have found that our tarps last longer and suffer no ripping or ballooning in windy conditions.

“By using the Tarpfast blower, they have prevented any tarp losses in severe winds.

“Another benefit of these units is their compact design and low power consumption. With just a 0.37kW (1/2hp) motor these blowers are capable of holding a 10,000 tonnes bunker tarp in place.” Brett concluded.

With a 10,000 tonnes bunker tarp costing upwards of $38,500 it is estimated that a Tarpfast blower will extend the life of the tarp at least three times the average expected lifespan.

This makes a Tarpfast blower very cost effective, with the added benefit that Tarpfast is Australian made and designed

Smallaire grain drying and aerating blowers feature strong pressed steel casings and a durable hot-dipped galvanized finish (a powder coating option is available upon request). Units are lightweight and manoeuvrable and balanced to prevent vibration. A single fan can be moved around a number of sites to save on the cost of multiple

for local storage conditions.

Tarpfast blowers come in kit form, ready for operation.

Just choose the blower unit engine drive power that will suit your operation from a choice of .375kW to 2.2kW electric power. Or a 4.4kW (6hp) Yamaha petrol engine, or a 4.9kW (6.7hp) Yanmar diesel engine.

In addition, the standard Tarpfast blower kit includes a blower stand of 1.6mm in a galvanized construction, a suction plenum of 1mm galvanized construction.

And five metres of 200mm Extractaflex hose, 200mm of duct end connector and a 200mm lever lock.

The Tarpfast blower comes as a fully functional unit with kits priced from $4,155.27 plus GST, depending on the power source selected. The price can be confirmed with Smallaire at

the time of ordering.

In addition to the Tarpfast blower to keep stored grain in top condition, Smallaire is already well known to growers for its leading Grain Aeration Systems that are ideal to bring into every harvest operation for their ability to extend the harvest window.

This family-owned business specialises in providing air movement systems for grain growing operations and since its inception in 1974, the company has grown to become an award-winning manufacturer and exporter.

From its base at Horsham VIC in the grain growing Wimmera region, it was almost inevitable that Smallaire would find itself providing aeration systems for grain storage.

Today, the company’s grain aeration systems can be fitted to new or existing silos, either

Petrol powered 1000LPS blower is available from Smallaire for faster drying

damage and grain loss in severe winds are kept in check with the Smallaire Tarpfast blower

elevated or flat-bottomed, and provide users with the ability to dry and cool grain as well as prevent insect infestation.

The knowledge that grain can be dried successfully in the silo provides growers with a greatly extended harvesting window.

Grain can be brought in earlier in the season as even if there are some green patches in the crop, and with higher moisture content, there is no risk of spoilage.

Growers can also take advantage of earlier starts in the morning and be able to harvest longer into the night.

Even if a storm is on its way, the decision can still be made to get the crop off with the added confidence it can be dried later in the silo.

In addition, harvesting grain with higher moisture content assists in the cooling cycle as it is the same principle as an evaporative air conditioner, but in this case with the grain acting as the wet filter.

The presence of insects and vermin will also be minimised (possibly even eliminated) and chemicals are not required to keep insects out.

Smallaire grain drying, and aerating blowers are built with

strong pressed steel casings and come with a durable hotdipped galvanized finish, while a powder coating or stainless option is available on request.

Units are lightweight and manoeuvrable and computer balanced to prevent vibration.

A single fan can be moved around a number of sites to save on the cost of multiple blowers. Fans are also covered by a 12-month warranty.

Diesel fired heaters are also available for faster drying.

The other half of the Smallaire system is the galvanized steel plenum fitted horizontally across the bottom of the silo.

When the silo is filled, the void underneath the v-shaped plenum remains as open-air space and acts as the conduit for the introduction of fresh air flow from the exterior fan.

In an elevated silo this air is first forced downward from the plenum to the base of the silo cone, and then rises upward and is distributed evenly throughout the silo for consistent drying and aeration.

For flat-bottomed silos, perforated flat floor ducting takes the place of the v-shaped plenum and air is forced directly upwards through the

perforations.

Multi-silo systems with a single blower can also be set up with the use of manifold ducting so that individual silos can be turned on or off at any time.

Rounding out the Smallaire system are air temperature and humidity controllers.

Controllers allow growers to set humidity and temperature for drying grain in the best climatic conditions. Dials can then be reset for aeration to blow cold, dry air through the grain.

These units take the guesswork out of grain drying and allow growers to get on to other jobs while the fans are monitored by the controller.

Smallaire stock the most inexpensive controller on the market and the only one with the humidity and temperature functions all in one. The unit is fully portable and only the size of a shoe box.

An extension to the Smallaire aeration system is the inline fumigation cabinet.

Ideal for use with existing fans, these units hook in-line with an existing system for minimal fuss and easy setup.

With this system, phosphine tablets are placed in the

Fumigator cabinet tray provided and once the tablets are spent, the powder form drops through the mesh grate ready for easy disposal.

An added advantage is that no residue is left in the grain.

Smallaire also provides easy to install temperature probe kits that can be fitted to any silo to provide a digital readout of the internal temperature without the need to enter the silo.

The probe also measures ambient external temperature and humidity so users can decide when to turn blowers on or off.

As well as its grain aeration systems, Smallaire’s renown air movement expertise is also in hot demand for airseeder setups.

In addition the Smallaire company provides blowers, components and offers an exclusive Airseeder CAD (Computer Aided Design) design program to aid in the design of systems to meet the requirements of any size grain operation.

For more information call Smallaire on tel: 03 5382 5688, email info@smallaire.com.au or to see the full range go to www.smallaire.com.au ■

Galvanized steel plenums are fitted horizontally across the bottom of the silo. When the silo is filled, the void underneath the v-shaped plenum remains as open air space and acts as the conduit for the introduction of fresh air flow from the exterior fan

temperature

An extension to the Smallaire aeration system is the inline fumigation cabinet. Ideal for use with existing fans, these units hook in-line with an existing system for minimal fuss and an easy setup

KUHN has concentrated on offering specialist trailed sprayer models for farm operations where it’s important to move quickly across crops and disperse product with a precision target approach.

In offering sprayers for specialist application KUHN has developed a range of trailed, mounted, and front tank spraying models that can guarantee maximum crop protection, with the advantage of reduced application costs.

Currently proving popular in our local market are two of KUHN’s trailed sprayer ranges, the METRIS 2 and LEXIS Series.

These models are sought after for their compact design and efficiency that combines the most current precision spraying techniques.

KUHN has been a long-term manufacturer of booms and has progressed to a stage where they offer the most current lighter weight aluminium variants with a more natural resistances to corrosion and chemical aggression.

The weight advantage of these aluminium booms is in being almost three times lighter than steel, but still offer the strength of build levels that will withstand sometimes very harsh paddock applications.

When these aluminium booms come into contact with fertilisers, crop protection products or other chemicals they that remains unaffected by corrosion.

Both the Metris 2 and Lexis models can be equipped with aluminium booms, resulting in lightweight machines for specialist applications.

Metris 2 models are the big guns in KUHN’s small to medium sprayer range.

Available in 3200 to 4100litre product capacity tanks, these give precision coverage across 18 to 36 metres with the most current design aluminium bi-fold booms.

Designed for stability, Metris 2 aluminium booms are integrated into the overall tank design, and fold into three sections.

This compact design limits the overall height when the boom is folded, to allow for efficient transport.

The short length of the Metris ensures flexible maneuvering and improves tracking, making it easier to enter the paddock and reverse in paddock corners. This also

limits any crop damage.

Maintaining machine stability is crucial to keep the boom as close as possible to the target.

With the drawbar and axle suspension using Strathane pads, all movements are absorbed when travelling over uneven terrain in paddocks and during transportation on the road.

A suspended axle improves the machine’s service life, and ensures stable, while offering precise spraying.

Metris 2 booms have four levels of suspension, ensuring operators can keep their machine stable and suspended at all times with the effect of smoothing out uneven terrain.

For small to medium farm operations that grow specialist crops and produce livestock

KUHN offers economical trailed sprayers for small to medium operations in a selection of models with product capacities from 2400 to 4100-litres in the METRIS 2 and LEXIS range

feed, Lexis spraying models are available in 2400 and 3000litre capacities. With boom options of 18 to 24 metres in either steel or aluminium bifolds.

Lexis is the perfect model for entry level spraying requirements, offering all the key functions farm operations need to protect crops to the highest level effectively.

Similar to the Metris 2 range, the Lexis’ tank is designed to incorporate the booms into the machines overall outline.

And with a short hitch-toaxle length of just 4 metres and a height of 3 metres, these Lexis models are obviously very compact.

Both Metris 2 and Lexis models are equipped with simple, easy to use operator stations.

The manual MANUSET operation offers complete

control of all sprayer functions from a centralised station, while the DILUSET+ operation means rinsing functions can also be performed from inside the tractor cab.

Operators can choose to rinse the sprayer, or the boom only, through an easy to use terminal while sitting inside the tractor cab.

Simply indicate the type of rinsing required, and the automatic rinsing system will take care of the rest.

The terminal has the further function of being able to display the volume remaining in the tank in real-time throughout

the entire spraying operation.

KUHN’s wide range of trailed, mounted and front tank sprayers allows farm operations to protect crops at all levels, with a model designed to fit into their unique requirements.

Whether it’s grain or multicrop production, precision spraying is guaranteed with KUHN’s compact designed sprayers, armed with a simple to use operator systems.

For more information on the KUHN broadacre sprayer range, see more on at this link: www.kuhn.com.au and check for your nearest dealer. ■

First revealed last year on the range topping Hardi Rubicon 9000, GeoSelect is now available on the Hardi Commander trailed models..

Many growers took notice when the installed GeoSelect was first trialed with the fed information gathered from a drone into an onboard monitor to develop a clear record of every weed in the paddock.

Growers were introduced to a method that seeks out weeds, targets them with spot spraying and is then able to eradicate the weeds using only 10 per cent of product, when compared to blanket spraying.

With a system able to save 90 per cent on chemicals costs when compared to previous weed seeking systems it has amounted to a big saving for growers.

The Hardi GeoSystem difference starts at the very foundation of identifying the problem weeds in the paddock and once armed with that vital information it’s a matter of seek and destroy with limited wastage.

Instead of running a vehicle across the paddock for mapping, Hardi GeoSelect takes full advantage of the most current information seeking device

available, a farm drone.

By using a farm drone to scan the full paddock and produce hi-res imagery, this information is fed into GeoSelect and it enables the program to identify and number every weed in the paddock.

Once loaded into the system that information is used to arm the sprayer to spot spray with pinpoint accuracy.

The sprayer operator is guided through a mission of accurately spraying all problem weeds.

Through the GeoSelect weed management monitor, the operator knows exactly

how much chemical to mix, what rows to skip and where to slow down to get the best efficiency from the chemical application.

Just to show how much time GeoSelect can save, during the concise paddock run the operator will be instructed to speed up over ground that contains no weeds, but then be instructed to slow down where a heavy belt of weeds exist.

All the while making sure that every weed marked is sprayed with an effective chemical application within a centimetre of accuracy for entire eradication.

To further back up application accuracy GeoSelect works with Hardi’s H-Select 3+1 nozzle system to precisely co-ordinate four different nozzles at each nozzle body.

These four nozzles work in conjunction with one to spot spray while the other three rapidly switch between nozzle combinations to maintain the required dose set point right across a wide, turning boom.

Now farm managers can immediately see the benefit of using pre-scanned imagery that eliminates unwanted

Hardi has expanded GeoSelect advanced weed seeking spot sprayer system claimed to save 90 per cent of chemical costs to Commander trailed models

spraying for a herbicide product saving of up to 90 per cent in certain conditions. This targeted approach also saves on operator time.

During the targeted spraying process farm mangers will also have the benefit of collecting real time data from the multiple, light-weight GNSS antennas mounted along the boom.

This also helps to ensure precision accuracy is maintained throughout the weed spraying run.

GeoSelect has also been engineered to automatically adjust for boom deflection and changes in ambient conditions, allowing it to be accurate in any spraying environment.

Hardi research shows that application accuracy can easily be maintained at an operating speed of 25 to 30kph, and there is also the added advantage of working at night with the confidence no weed has been missed.

At the end of the paddock run Hardi estimates that more than 90 per cent of weeds will have been targeted and eliminated with the GeoSelect system.

For more information on

contact

for your nearest

on Tel: 08 8343 9999, email: info@hardi-aus.com or see more at: www.hardi.com.au ■

Shown here is HARDI’s latest release self-propelled Saritor with Geoselect onboard –– from the high-resolution scans gathered by the farm drone, the spray strategy is formed and every weed is marked and all spray directives are made even before the operator steps foot into the sprayer

For the most economical and accurate spray methods there is a specially built range of HARDI’s trailed sprayers.

These models are well known to deliver reliability and performance that you can count on to get the application done fast and efficiently.

Most farm operations view spraying as such an important process that you just cannot take chances.

HARDI’s range of small to large trailed sprayers have been built over time to meet all the diverse topography that operators will encounter, from flat land to rolling steep hills.

HARDI’s trailed sprayer range includes the COMMANDER, NAVIGATOR, RANGER, and GRASSLAND with all of these models able to provide flexibility and usability to suit every farm operation, with a wide selection of boom sizes on offer.

The COMMANDER is one of the most successful and awarded sprayers. It is the largest trailed sprayer at HARDI Australia and is designed as a high quality, high capacity, and user-friendly machine.

The HARDI COMMANDER is widely regarded as one of the world’s top trailed sprayer, with tank capacities ranging from 6,500 to 10,000-litres and height controlled booms extending from 30m, right up to 48.5m.

Optioned with the trusted H-SELECT, the proven nozzle switching technology pushes the HARDI COMMANDER to outdo itself once again.

The COMMANDER is built around intelligent control

technology and convenient operation, to deliver a precise chemical application for hectare after hectare and year after year.

COMMANDER is the first HARDI trailed sprayer line to be optioned with GeoSelect to accurately pinpoint and spot spray to eliminate all weeds while saving 98 per cent on chemical costs.

NAVIGATOR by HARDI is based on a foundation of simple, dependable solutions combined with ease of use and great serviceability.

Versatile choices include tank sizes of 3000, 4000, 5000, and 6000-litres, as well as superior electronics, making the NAVIGATOR the obvious choice in a wide range of applications, from row cropping to small broadacre operations.

The versatile NAVIGATOR range is enhanced by a flexible choice of boom options, to help drive efficiency and productivity on every farm, with boom sizes designed to suit operators needs, ranging in sizes from 18 to 36.5m.

The NAVIGATOR range is the key to precision, efficiency, and productivity, with a proven HARDI diaphragm pump and a choice of sturdy, broad booms in steel or aluminum.

The RANGER’s success has been greatly established over the world since it was launched to answer the requirement for a simple and reliable sprayer.

This 2500-litre class-leading sprayer is a design ideally suited to row crops, cereals,

pasture renovations, and horticulture.

You can adjust the boom from within the cab as well as modify the boom height on the run, which is great for those paddocks where you need to get the boom up and out of harm's way quickly.

The RANGER’s intelligent tank and frame design deliver strength and stability, while quality components ensure high performance and ultimate durability. A wide choice of booms means the sprayer can be set up for almost any type of operation.

The 1200-litre GRASSLAND sprayer is a low-cost, simple sprayer that is ideal for spraying light areas and minor crops.

The HARDI GRASSLAND has a fully integrated design with a low centre of gravity with 48cm crop clearance.

It can be adjusted for all purposes with a choice of 6, 8, 10, and 12m booms, making it a versatile alternative to larger sprayers.

The boom fold on all the equipment is handled manually, with hydraulic boom height control offered as an option.

HARDI Australia has spent years perfecting its trailed sprayers, and in many cases to meet the needs that farmers were not even aware they required until added by HARDI.

These trailed models are now loaded with many special features to make them effective in the paddock and further adding to their productivity and reliability.

With the various models of trailed sprayers designed to suit all spraying requirements, HARDI Australia is a market leader in trailed sprayers.

With a range of operational use and sizes, HARDI’S trailed sprayers are built on a platform of simple, reliable solutions combined with ease of use and excellent serviceability.

For more product range information, contact your local HARDI-approved dealer at www.hardi.com.au/about-hardi/ourcompany/dealer-locator-2 or go to: hardi.com.au ■

AgXeed is a Dutch start-up tractor manufacturer specialising in driverless technology and is pressing ahead with commercial agreements that support the distribution and sales of its recently-expanded range.