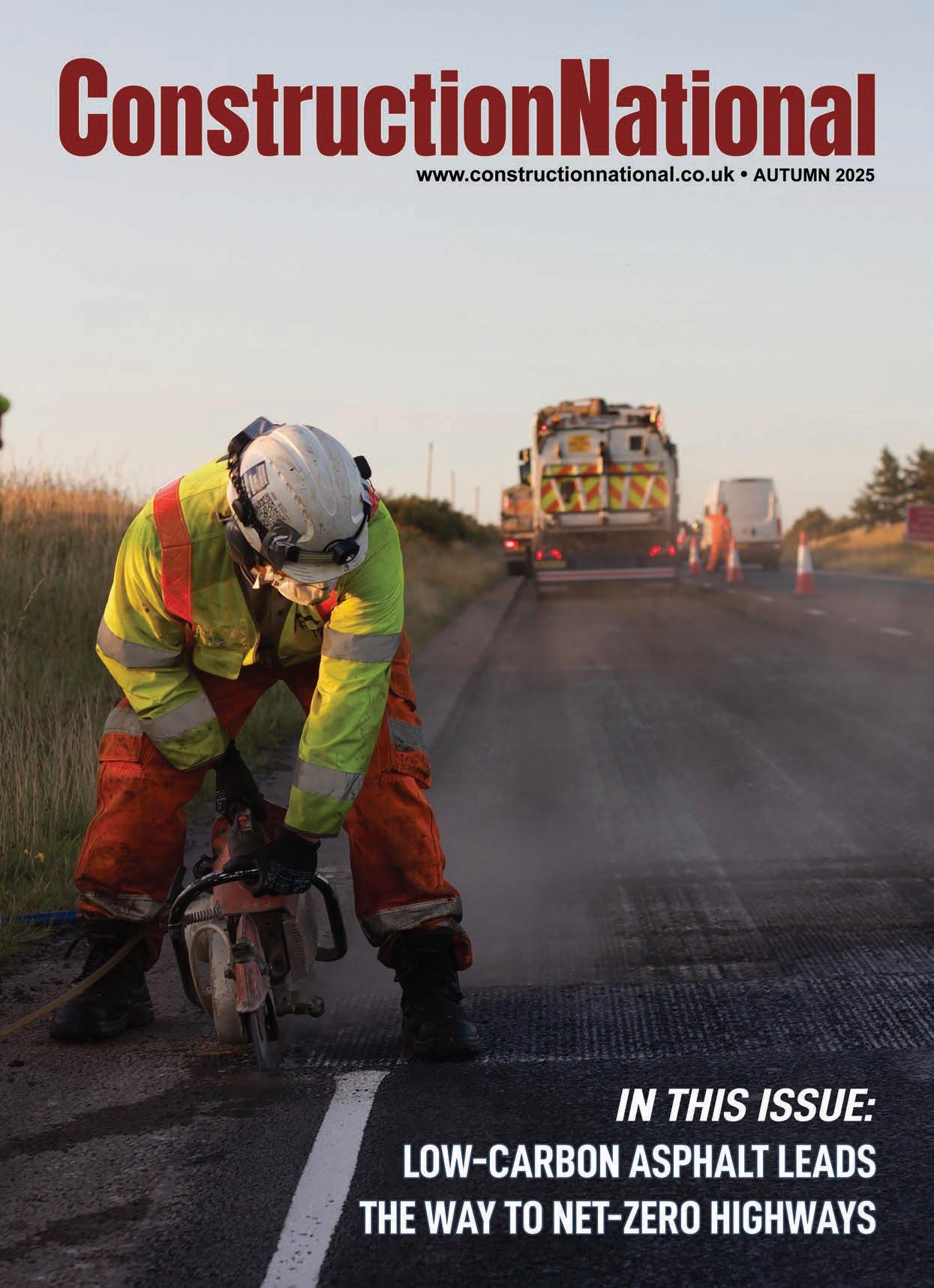

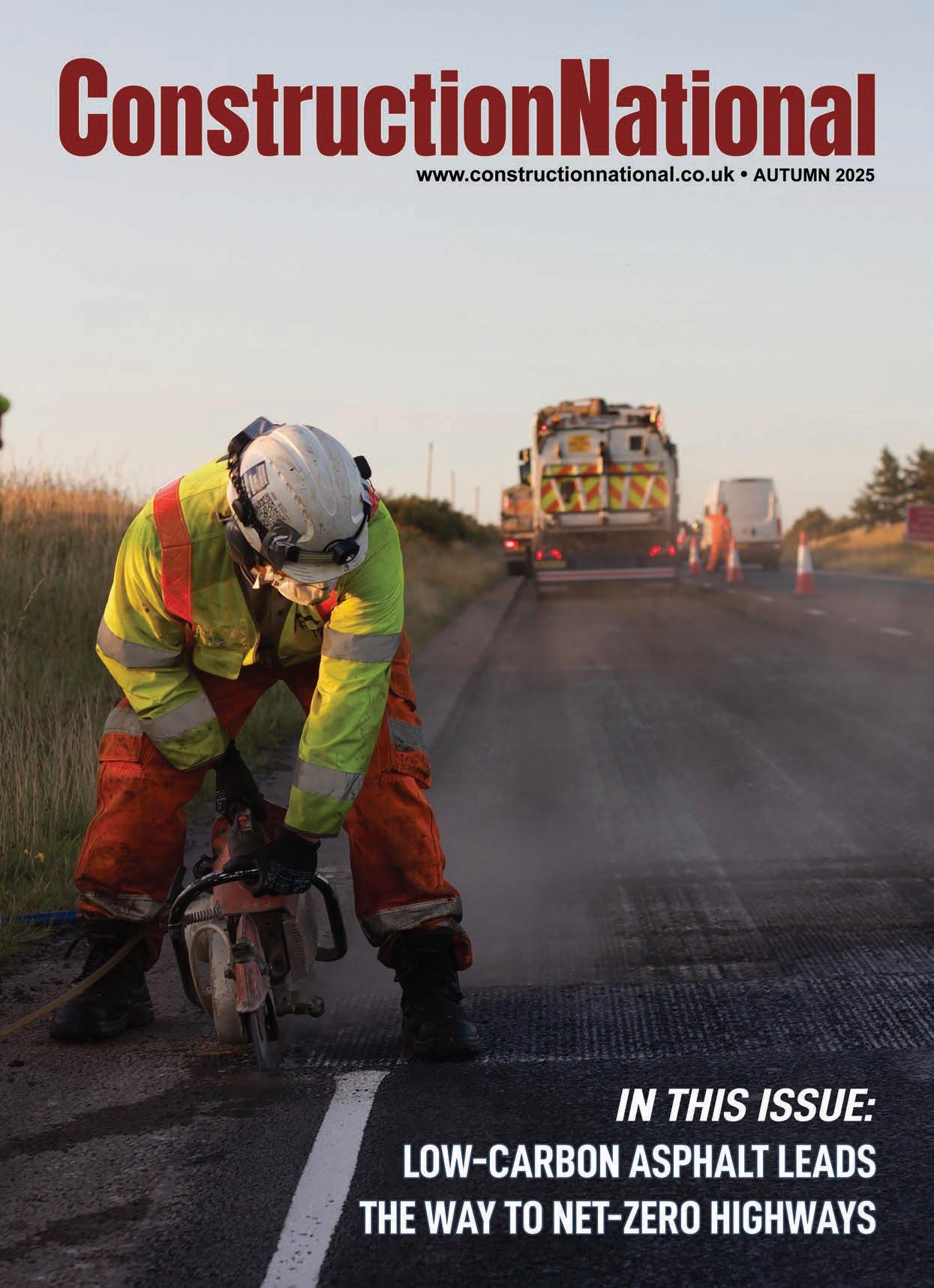

This issue’s front cover shows work underway to resurface a 12km stretch of the A30 in the South West with a new low-carbon asphalt. The two-layer surface, developed by sustainable building solutions specialist Holcim UK, was applied by highways contractor Tripod Crest.

The resurfacing project was carried out as part of National Highways’ demonstration funding scheme and came as the road, which is known as a link to the South West, was named the UK’s favourite road in the Strategic Road User Survey.

The surface course incorporated a long-life and high-grade polymer-modified bitumen, while the binder course incorporated the latest bio-component bitumen, reducing the carbon footprint by around 20% against traditional warm mix asphalts.

Read the full story on page 16.

9 Recommended new town sites revealed

9 HSE seeks views on LOLER and PSSR reforms

9 Safety notice issued around excavator operation

11 Stirling Prize shortlist announced

13 MP addresses construction’s pressing issues online

13 Poor fire door maintenance adds to battery fire danger

WJA TRADE SHOW

15 Water jetting industry celebrates second successful trade show

17 Milestone brings the Missing Link nearer to completion

17 Story shows how sinkholes can reveal the past

18 Homebuyers’ love of nature threatens govt’s housing aspirations

18 Former golf course site will provide much-needed homes

19 Affordable Passivhaus homes near completion in SW

19 Topping-out ceremony marks nine levels of construction in Wembley

20 Planning approval sought for Carlisle development

20 Scottish completions continue to fall, but private sector starts recovering

21 Solving the energy trilemma for UK housebuilders

LONDON BUILD 2025

23 London Build celebrates 10 years in style

ACCESS & LIGHTNING PROTECTION

25 Awards recognise top lightning and steeplejack apprentices

TRAINING, APPRENTICESHIPS AND EDUCATION

26 Scottish students urged to consider a career in construction

26 College plays a key role in supporting the Transpennine Route Upgrade

27 Exeter College to lead the way as Construction Technical Excellence College

28 Exciting news puts NCC at the heart of Britain’s skills revolution

28 Leading the way in green skills training

29 Reforms to grant system follow CITB listening to feedback

29 New plant training standards continue to rollout

30 College partners with Beard Construction to nurture future talent

31 Aiysha joins fellow girls to Open Doors into construction careers

31 Scotland’s first net-zero-ready campus set to open this year

33 Young elite head for November SkillBuild final

33 College’s deputy commends construction to “absolutely” everyone

WORKING AT HEIGHT

34 International body inaugurates at ScaffEx

34 Awards celebration brings ScaffEx to a close

35 Association carries out latest ladder safety checks

35 Accident reporting is not an option, IPAF says

ENVIRONMENTAL ISSUES

36 Fully-decarbonised cement production takes a step nearer

36 Innovation map helps source retrofit solutions

37 Firms fined for illegal housebuilding waste dumping

37 Military joins education and NHS in solar rollout HEALTH & SAFETY

38 Former football stars rally round to promote mental health on site

38 Wall collapses kill one worker, injure three LEGAL ISSUES IN CONSTRUCTION

39 Companies urged to counter skills card fraud

39 Fire engineers urged to prepare for new cladding test

40 London’s new museum gears up with offers for retail units

40 Restoration completes at Blackpool’s Grand venue

41 Calls for renewal of Grants Scheme follow HE research

41 Revamped stone show returns to Excel PLANTWORX 2025

42 Plant show has ‘em rocking in the aisles

[OUR COVER STORY this issue portrays a sight most people will have encountered many times. Resurfacing our highways is a never-ending task, but little attention has been paid to the materials used. The section of the A30 in point, however, has bucked that trend by utilising new low-carbon asphalt. It illustrates admirably the fact that the effort to decarbonise pervades all sectors of the industry.

The A30 has been voted the UK’s favourite road. Now there is even more reason to appreciate it.

• The big story on the subject of carbon has been the progress made towards construction of a carbon capture and storage facility for the production of decarbonised cement in North Wales. The production of cement is inherently carbon intensive. CO2 is produced as a by-product and cannot be avoided by using carbon-free fuels. Storing the stuff is, apparently, the only solution if cement is to continue to be produced.

• Environmental issues figure large throughout this issue. A survey of potential homebuyers has revealed a distinct trend towards wanting green space within reach. Most would expect to pay less for a home trapped in an unrelenting urbanisation. Interestingly, most homebuyers would also object to the introduction of the proposed Nature Restoration Fund, preferring any restitution to be carried out locally and not as part of a national fund.

That resistance is most pronounced among Labour supporters.

• Low-carbon heat is increasingly becoming de rigueur in the design of new homes. As Neal Herbert of GTC points out, heating accounts for a third of the nation’s greenhouse gas emissions. Where there is scope for networking of the heating, ground source heat pumps fit the bill better than any of the alternatives, he argues. With the impending introduction of the Future Homes Standard the proof of the pudding is set to be in the eating.

• The government’s new flagship energy company Great British Energy is expanding its installation of solar panels in schools and NHS premises – and including military premises within its ambit. The military sites will include remote installations, often difficult and expensive to supply with energy. The plan is to reinvest the savings into front-line operations.

• All things low-carbon in the construction industry will be on show at London Build in November. Over the show’s 10 years it has become increasingly environmentally conscious. Among the many goodies available at the show will be copies of this publication – but you quite possibly already know that.

• Attracting young people into the industry is the other theme running through this issue. The deputy head of the National Construction College has a simple message for youngsters thinking of joining the industry: Go for it! He explains how he became involved in the industry he now champions. In Scotland the CIOB addressed those getting their National 5 results, with the message that the industry is pivotal to Scotland’s future.

Attracting young women into the industry is the role of Girls Under Construction. One member, architecture student Aiysha Alli, recounts her visit to an Open Doors site.

• The national celebration of the best young people in construction is SkillBuild. Every year the most skilled apprentices and trainees in a range of trades compete in regional heats to reach the National Finals in November. This year’s finalists have now been announced.

• This wealth of new talent will be needed for the range of new towns this government is committed to. But when is a new town not a new town? When it’s an old one being refurbed, of course. And that is what it seems a few of the ‘new’ suggestions being put to the government are. Manchester and Leeds are among those being touted, alongside Milton Keynes! q

Chris Stokes Editor, Construction National

[THE GOVERNMENT has confirmed it will progress work on the next generation of new towns across England, following publication of an independent report that recommends 12 locations as potential new towns. The government is determined to begin building in at least three new towns in this Parliament and is prepared to progress work on a far larger range of locations if it proves possible.

The 12 recommended locations are: Adlington in Cheshire East; Brabazon and the West Innovation Arc in South Gloucestershire; Chase Park and Crews Hill in Enfield; the former airbase at Heyford Park in Cherwell; an urban development in Leeds; Victoria North in Manchester; Marlcombe in East Devon; a ‘Renewed Town’ in Milton Keynes; a ‘densified’ development in Plymouth; Tempsford in Central Bedfordshire; Thamesmead in Greenwich; and Worcestershire Parkway in Wychavon.

The government has also published an initial response to the report in which it

welcomes all 12 recommended locations and its wider recommendations on delivery and implementation. The government response also states that at this stage the sites at Tempsford, Crews Hill and Leeds South Bank look most promising.

A New Towns Unit will also be established by the government to progress development on new towns. The unit will work with all departments and their agencies to ensure new towns are a test bed for innovation and to unblock barriers to delivery.

The New Towns Taskforce, led by Sir Michael Lyons, was commissioned by the government to explore different approaches to large-scale development. In its report the taskforce has recommended a mixture of large-scale communities, including urban extensions, urban regeneration and standalone greenfield sites, should be built.

It says each new town should have at least 10,000 homes with an ambition for a minimum

of 40% affordable housing – half of which will be for social rent. The taskforce has also set out a range of recommendations for delivery, including the importance of accountable delivery bodies who are able to provide longterm certainty for communities in new towns.

A Strategic Environmental Assessment will be undertaken to understand the environmental implications of developing new towns. No final decisions on locations will be made until that assessment concludes and preferred locations could change as a result of the process.

The government will be looking for assurance that any location can be effectively and efficiently delivered in partnership with local communities, has a clear economic purpose and will support economic growth. Different delivery vehicles will also be tested to learn lessons for how future large settlements are delivered and to contribute to a wider transformation of housing supply. q

[ ON 1 OCTOBER HSE announced a Call for Evidence (CfE) to review the Lifting Operations and Lifting Equipment Regulations (LOLER), together with the Pressure Systems Safety Regulations (PSSR). HSE is inviting input from industry stakeholders, professional bodies and organisations with relevant experience and expertise, with the CfE running until 11 November.

The main objective of the CfE is to establish a comprehensive evidence base to inform viable opportunities for simplifying and streamlining regulatory processes. The review will reflect the current industry landscape, anticipate future innovation and maintain workplace health and safety standards.

Kate Haire, deputy director of direction and policy at HSE, said: “This review represents a targeted approach to regulatory reform rather than an overhaul of the frameworks. We want a regulatory system that not only protects those at work, but also encourages new investment, innovation and growth.

“We are focused on targeting amendments that will enhance clarity, simplify requirements and modernise processes. Our aim is to ensure that we deliver proportionate regulatory requirements, maintaining safety standards but minimising the unnecessary costs and compliance barriers faced by businesses.

“Our initial assessment indicates that LOLER and PSSR are generally founded on sound engineering principles, reflect wellestablished practices, and are deeply embedded across a wide range of sectors. However, we recognise that the emergence of new technologies, particularly those underpinning net zero transitions such as hydrogen, introduce new risk profiles, which is why we are looking to update our evidence base.”

HSE’s review is part of the organisation’s wider response to the government’s plans to support growth through the Regulation Action Plan. The CfE will serve as a preliminary validation of the practical implications of existing regulations, drawing on stakeholder insights to ensure no critical considerations are overlooked.

It aims to identify any unnecessary administrative or financial burdens that do not meaningfully contribute to risk reduction, assess whether regulations have become outdated in practice, and explore opportunities for reform that could enhance regulatory clarity, foster innovation and support economic growth.

Industry stakeholders, professional bodies and relevant organisations looking to participate can view the Call for Evidence webpages at consultations.hse.gov.uk q

[ THE HSE has published a safety notice aimed at excavator operators, slinger/signallers, site managers and supervisors, supporting personnel and anyone working near them.

They reference a case where, during a lifting operation, a slinger was fatally crushed between the quick hitch and a fixed structure. The excavator operator was leaning out of the cab to communicate with the slinger when they inadvertently made contact with the lefthand joystick, causing the excavator to slew. The safety control lever had not been applied to isolate the machine.

If there are people in the operational arc of an excavator, or similar mobile plant, the safety control lever should be applied, or other methods used to isolate the machine while no machine movements are being undertaken. Failure to do so means that there is a high risk that people can be struck by the excavator.

Dutyholders must, so far as is reasonably practicable, ensure the safety of people in the working arc of slewing plant and any load, with proper planning, management and monitoring of work activities.

Further information can be viewed at www.hse.gov.uk

The Plant Safety Group, managed by the Construction Plant Association, has guidance on the unintended movement of plant, as well as lifting operations with excavators. Both publications are clear on the use of the safety lever and ensuring supporting personnel are clear of the machine’s working danger zone during working activities.

They can be viewed at cpa.uk.net/document q

[ THE RESTORATION of one of the UK’s most recognisable landmarks, a pioneering new medical research facility and a contemporary almshouse designed to reduce isolation among older residents are among the six projects shortlisted for the RIBA Stirling Prize 2025, announced on 4 September. A university’s ‘factory for fashion’, an accessible home and a creative house extension have also been shortlisted. The six projects in the running for the UK’s highest accolade in architecture, are:

Appleby Blue Almshouse by Witherford Watson Mann Architects

Replacing an abandoned care home, Appleby Blue radically reimagines the traditional almshouse to foster community and reduce isolation among residents. The layout flips a centuries-old typology, placing communal spaces at its heart to encourage interaction, while bay windows at street level connect residents to the outside world.

Elizabeth Tower by Purcell

Housing the symbolic Big Ben bell – the timepiece of the nation – the most comprehensive restoration of Elizabeth Tower in 160 years is a conservation masterpiece. Traditional materials and bespoke craftspeople were sourced from across the UK to honour the tower’s original design: rectifying previous restoration missteps and repairing newly uncovered damage from the Second World War.

Hastings House by Hugh Strange Architects

Instead of demolishing an ageing hillside home, Hastings House reuses and celebrates the existing structure and materials to create a house of contrasts. A restrained, updated Victorian front gives way to a modern, timber framed rear, while a rough concrete courtyard celebrates its industrial character.

London College of Fashion by Allies and Morrison

Located in the cultural heart of the Queen Elizabeth Park in Stratford, the new home for the London College of Fashion brings together its 6,000 staff and students for the first time. A constrained site prompted a vertical campus rising to 17 storeys, with dramatic staircases unfurling through a shared ‘heart space’ to encourage collaboration.

Niwa House by Takero Shimazaki Architects

Meaning ‘Garden Home’ in Japanese, Niwa House is a pavilion-like oasis built on a previously derelict south London plot. This ‘horizontal home’ is a masterclass in craftsmanship and restraint. Subtle interventions, such as a flowing openplan layout and integrated accessibility features, create a seamless experience for its wheelchair-user resident while futureproofing it for later life.

The Discovery Centre (DISC) by Herzog and de Meuron / BDP

AstraZeneca’s Discovery Centre radically redefines the research facility, blending cuttingedge laboratories with welcoming public spaces.

Inside, 16 glass-lined laboratories are connected by clever interconnecting corridors that balance stringent security with transparency, putting science on display. Flexible lab stations and open-plan layouts foster innovation in a bold new prototype for research facilities.

RIBA president Chris Williamson said: “These projects demonstrate architecture’s unique ability to address some of the most urgent challenges of our time, responding with creativity, adaptability and care. From a monumental civic building that champions investment in arts and culture to the sensitive restoration of one the nation’s most iconic landmarks, and a cutting-edge medical research facility; each offers a blueprint for how architecture can enrich society.

“At a time when quality housing is urgently needed across the country, the residential projects stand out for their inventive, human-centred design; from social housing that combats isolation in later life, to a bold home extension that celebrates reuse and an accessible home that proves that beauty and accessibility can coexist.”

The winner of the RIBA Stirling Prize 2025 will be announced live at London’s Roundhouse on 16 October. q

[MIKE READER MP, chair of the All-Party Parliamentary Group for Infrastructure, has outlined his vision for addressing the construction industry’s most pressing challenges, while reaffirming the government’s commitment to its housebuilding targets. Speaking on the Federation of Master Builders’ (FMB) Build Up from the Basement podcast, he also voiced his support for licensing the industry.

The MP described the skills shortage as a ‘national emergency’. He advocated intensive boot camps: “I think actually either you do or don’t want to work in the sector…and you should be able to come in, try it and learn very quicky.”

Drawing inspiration from a military programme he took part in, Reader questioned: “Why haven't we got that for our sector?” He envisions a national recruitment campaign similar to military advertising, arguing that rather than “having every individual company doing their own engagement programme…we should have a national one.”

On engaging young people earlier, Reader suggested: “We should be looking at GCSE for the built environment…I think we engage too late. We should be introducing people a lot younger to the built environment.”

Reader expanded on the industry’s innovative capacity, while advocating for the balanced adoption of modern methods of construction alongside

[THE BRITISH WOODWORKING FEDERATION (BWF) has warned that poor fire door maintenance could put lives and property at risk given the surge in lithium-ion battery fires from e-bikes and e-scooters. The warning came during Fire Door Safety Week in September.

While media focus has largely been on domestic fires, the BWF’s research highlights that 19% of people charge e-bikes or e-scooters at work and 12% do so in public leisure facilities such as cafés, pubs, libraries or leisure centres.

Many employers have introduced facilities for e-bikes and e-scooters –such as indoor parking (31%), charging points (59%) and secure storage (27%) – yet nearly half of respondents (46%) had spotted problems with workplace fire doors, raising the question whether employers are giving the same attention to and investment into ensuring fire doors are properly installed and maintained to minimise risk to life.

Issues ranged from fire doors being propped open (18%) and blocked (13%) to having faulty closers (10%) or faulty hinges (10%). Yet just 13% admit to having reported fire door faults in the workplace.

Helen Hewitt, CEO of the British Woodworking Federation, said: “The findings highlight the essential role of fire doors in containing fires and protecting lives, while also exposing concerning gaps in awareness, maintenance and reporting. Fire doors are a critical line of defence, slowing the spread of fire and smoke to give people extra time to escape: time that is even more critical when dealing with the intense heat and speed of fires caused by lithium-ion batteries.”

Similarly, schools, colleges and universities have expanded storage and charging provision for e-bikes and e-scooters – and encouragingly, 39% of institutions have educated students on safe storage and the dangers of charging. Despite that, of the 40% of students who reported spotting issues with fire doors on campus, only 6% had ever reported a problem.

Helen Hewitt added: “We all have a role to play in spotting and reporting problems with fire doors and taking immediate action to protect lives and property. Fire Door Safety Week is an essential reminder that correctly installed, well-maintained fire doors save lives – but only if we all take responsibility for ensuring they can do their job.”

London Fire Brigade Deputy Assistant Commissioner Richard Field said: "Workplaces need to treat lithium battery fires with the same seriousness as they would in the home. Fires involving e-bikes and e-scooters can erupt suddenly and spread with alarming speed, producing intense heat and toxic smoke in seconds.” q

traditional skilled trades. He highlighted exciting developments in 3D printing technology, while acknowledging the continued critical need for specialist skills.

He said: “There is a place for these modern trades as well. It’s not going to work on every site…but we also will always have a need for specialist trades…I think we're a very innovative industry. What we’re not great at is adopting...There is a place to say we've got a product we can deliver now, let’s just get on and deliver it.”

He went on to announce significant progress on retrofit licensing following recommendations from the Energy Security Select Committee, with government committing to form an industry panel. That will aim to address consumer protection concerns while elevating trade recognition and professionalism, which the FMB has long campaigned for.

He said: “We need skilled trades like the building trades to be recognised for being the skilled craft people that they are and the quality that they deliver.”

Commenting on the podcast, FMB CEO Brian Berry said: “Mike Reader’s commitment to driving forward a licensing scheme for retrofit work represents a significant step towards protecting consumers and raising standards across the construction industry. His understanding and personal experience in the industry and of the challenges facing our members, combined with his political position, makes him a valuable advocate for the professional trades. The FMB has long campaigned for proper licensing and regulation, and we’re pleased to see government taking these consumer protection issues seriously and we look forward to continuing to work with Mike in the future to better support the building industry.

“You’ve got a government that is pro-building and has just launched a small business strategy, and is really trying to change how the government engages with SMEs, particularly small builders, to make sure they’re part of the conversation.” q

[VISITORS AND EXHIBITORS at WJA Trade Show 2025 – the only exhibition in the UK dedicated exclusively to all forms of water jetting – have showered the event with praise, explaining how it provided unrivalled access to water jetting insights and expertise and opportunities to do business.

The event, organised by the Water Jetting Association, was held at StoneX in London on 11 September for the second year running, with a wide mix of products and services on show.

WJA chairman Lee O’Callaghan enthused: “Feedback from visitors and exhibitors has been very positive, with many saying they enjoyed WJA Trade Show 2025 and found it extremely useful. We had visitors looking to invest in new services and wanting to source new equipment, and exhibitors showing off new products. That’s a recipe for success. The event showed the value of providing a meeting place for our industry.

“I would like to personally thank all the exhibitors and our sponsors – Veolia, TST Sweden, Howden Insurance and Drain Trader Magazine – for supporting the trade show and making it such a success.”

for water jetting businesses when taking out a policy to cover their business risks.

He explained: “It’s been a fantastic event. For us, it’s all about keeping up to date with changes in the trade. That’s why being part of the WJA is very important, so when risk changes our policy can change and we can make sure we give customers the best cover.”

Annette Hessel, international sales manager at another of the event’s sponsors, TST Sweden, added: “All our products come from feedback from users, so attending WJA Trade Show 2025 allows us to meet our customers and drive our innovation.”

The event had more exhibitors than last year’s inaugural trade show and two external display areas, so more large equipment could be shown off. A speaker programme shared expertise on a range of topics, including robotic water jetting, health and safety and insurance issues relating to the water jetting industry.

Exhibition sponsor Howden Insurance, which is a member of the WJA, took the opportunity to demonstrate its expertise in the water jetting industry. Oliver Newport, a development executive at the global company, was one of the speakers, explaining commons pitfalls

James Coverdale, head of sales at iTouch Systems, which manufactures CCTV survey systems, was among exhibitors who were impressed with the event. He said: “We were busy all day, with a lot of interested visitors stopping at our stand. We’ve got some strong leads as a result. It’s been a very positive experience.”

Mark Stubbs, a director at Kelly’s Tanks, which manufactures concrete washout and water treatment systems, was equally impressed.

“WJA Trade Show 2025 has been exceptional for us,” he commented.

“It’s given us access new customers and visibility in the water jetting marketplace. The WJA must be thanked for bringing the industry together in such a constructive way.”

Event visitor Clive Reynolds, technical and compliance manager at high and ultra-high pressure water jetting services contractor Altrad Environmental Services, added: “WJA Trade Show is a fantastic place to meet suppliers and industry colleagues, to see new ways of working and share ideas.” q

[ AN EXTENSIVE major low-carbon surfacing trial has been successfully carried out on the A30 in a partnership between two industry-leading highways specialists, as part of National Highways’ demonstration funding scheme.

The completion comes as the road, which is known as a link to the South West, has topped this year’s Strategic Road User Survey, which ranks England’s major roads based on overall satisfaction according to UK road users.

Resurfacing work on the 12km stretch between Shallowater to Colliford was completed on 24 July, following extensive research and development work on new asphalt mixtures, drawing on a long-standing partnership between sustainable building solutions specialist Holcim UK and highways contractor Tripod Crest. The trial used a two-layer asphalt system comprising a 40mm surface course and a 60mm binder course to achieve its major low-carbon accreditation.

Holcim UK’s specially designed surface course featured around 2,500 tonnes of its SuperCurve asphalt, which incorporated a long-life and high-grade polymer-modified bitumen. This next generation asphalt aligns with National Highways’ latest standards and specifications, which focus on durability and making roads last longer.

The binder course used 400 tonnes of Holcim UK’s SuperLow Carbon asphalt, which incorporates the latest bio-component bitumen, reducing the carbon footprint by around 20% against traditional warm mix asphalts.

The asphalts were expertly laid by F&T Goodwin – part of the Tripod Crest Group. Working for National Highways on the Pavement Delivery Framework, Tripod Crest was appointed as principal contractor and worked in collaboration with Holcim’s technical and manufacturing teams to deliver the innovative trials.

Adam Vasey, commercial director of F&T Goodwin, praised the collaboration, saying: “This project has been a partnership to be proud of for both Tripod Crest and Holcim UK.

“Tripod Crest’s machinery helped speed up the laying process thanks to our state-of-the-art HAM HD 90 roller, which aids in density testing and allows for accurate installation. We also carried out HVO fuel testing to ensure our machinery aligned with the wider carbon reduction initiatives of the project.”

Neil Leake, national technical manager for contracting at Holcim UK, added: “The A30 project has allowed us to show what the future of low carbon roads in the UK look like in action. Not only this, but it has also been a fantastic opportunity for us to cross-collaborate with our trusted installer, Tripod Crest.

“The purpose of this trial, as part of National Highways’ demonstration funding scheme, is to show the capabilities of our low-carbon and longlife asphalt and how it can transform the way we build roads for the better.

“Not only has this been achieved through fantastic communication and partnership, but UK road users have voted the stretch of road as the most satisfying to drive on in the UK – which is another great accolade. This project shows what’s possible when innovation meets collaboration, and this is just the beginning.”

Angela Halliwell, National Highways’ head of carbon and air quality, said: “We’re changing the way we work to decarbonise construction on our roads: a crucial challenge of helping the UK to thrive as a low-carbon economy. National Highways has ambitious plans, backed by science, to decarbonise our corporate activities by 2030, to achieve net-zero across our maintenance and construction activities by 2040 and across our whole network by 2050.

“Our supply chain contains world-class talent and innovation and our message to our suppliers is clear: we are seeking your best ideas so we can scale up to meet the decarbonisation challenge. Our lowcarbon demonstrator fund is helping make these possible and later this year we are updating our standards to embed low-carbon innovations in our work.

“Together with our supply chain partners we’re taking positive steps towards a more sustainable future. Projects like this will pave the way for industry-wide changes, resulting in significant carbon savings, improved roads for drivers, and quieter roadworks for our neighbours.” q

[THE A417 MISSING LINK PROJECT has reached its next major milestone: building a new underbridge that will form part of a major new junction.

In September National Highways, along with contractor Kier, started lifting 53 20-tonne prestressed concrete beams into place that carry nine lanes of traffic over the new Shab Valley junction. Once in place, the beams will form an underbridge 20m wide and 62m long.

Concrete beams were chosen over steel beams as a construction solution due to their performance and practicality. The reduced weight of concrete enables construction using a smaller crane, which simplifies logistics, manages health and safety risks and lowers overall construction costs when compared with a steel girder construction. Longer term, it also reduces maintenance requirements by utilising an integral construction and concrete specification tailored to local environmental conditions.

Celine Acard, National Highways’ senior project manager for the A417 Missing Link, said: “We’re really proud of the progress we’re making on this major upgrade of the A417, and work taking shape on the new Shab Valley junction is a testament to our pace and efficiency on the scheme. We’re keen to make sure that this scheme benefits the local community as well as motorists and the new junction will ensure easy access to and from the main carriageway whilst minimising disruption.”

Colin Fowler, head of highways at Tony Gee, who designed the bridge, added: “The philosophy behind the junction design was to work with the natural topography, setting the underpass within the Shab Valley. This will reduce the elevation of the A417 carried by the

bridge, minimising visual and noise impact of the new road. A bridge set into the landscape in this way required a structural solution which would last.

“The integral bridge with precast, prestressed concrete beam deck will require only minimal maintenance through its lifetime and importantly will not require closure of the A417 above to do it.”

Following the beams being lifted into place, the new nine lanes of carriageway, five of which make up the main A417, will be built on top, along with entry and exit slip roads. The underbridge is a major milestone for the scheme, with its construction allowing National Highways to look towards a traffic switch from the existing A417 and onto the new stretch of road in early 2026.

The scheme has also recently achieved other milestones, including lifting in the steel beams for the 42m-long Cowley bridge, which will link Cowley to Stockwell Farm and the repurposed A417, and the creation of a new water course. Rather than diverting streams through culverts,

the scheme created a new watercourse as a more sustainable solution.

That was developed in close collaboration with the Environment Agency and ecological specialists, reflecting National Highways’ shared commitment to working with the landscape.

The stream gently follows a natural, meandering path, encouraging the creation of habitats and supporting local biodiversity. There's also potential for tufa formations, which are calcium carbonate deposits that can form when spring water interacts with limestone. Those formations help create ideal conditions for aquatic invertebrates to thrive.

Zeke Mensah-Kessie, Kier’s environmental manager for the A417 Missing Link, explained: “Instead of the typical culvert diversion, we are delighted to have implemented a more sustainable solution, creating a naturally meandering stream across the landscape in keeping with the scheme’s environmental aspirations.

“The design enhances water quality via natural filtration, reduces flood risks and includes features to store and channel floodwaters. It also fosters habitats through diverse planting and captures local spring flows, supporting biodiversity and ecological health over time.

“This design exemplifies effective collaboration with the Environment Agency and other local stakeholders to minimise environmental impacts and develop a sustainable, resilient solution.”

The landscape-led A417 scheme is not only creating a vital transport link in the Cotswolds, but also incorporates world-class environmental practices that respect and enhance the surrounding landscape and habitats. q

[IN JULY the Highways Department of Buckinghamshire County Council posted a story of how it dealt with a sinkhole that opened up in the A413 in Great Missenden. Although not on the scale of the more widely-reported chasms in Merthyr Tydfil and Godstone, the story of the discovery of the cause and its repair are an illustration of ‘what lies beneath’.

On 1 July, Buckinghamshire Highways received an out-of-hours emergency call regarding a hole that had appeared on the A413 in Great Missenden. It was a large hole, that was potentially very dangerous for drivers on the busy road.

According to the post: “That evening, and through to the next day, detailed investigations were carried out, with the road and our crews protected by a lane closure using two-way traffic lights. This included the use of ground penetrating radar and CCTV. It appeared the sinkhole had been caused by localised water ingress – the unwanted presence of water in openings or structures. However, whilst investigating the sinkhole, we found what we believed to be an old defunct drainage channel almost 2m under the road surface, running across the A413.”

The discovery of the old defunct drainage channel (pictured left) led to the council’s archaeology officer becoming involved, to record and map the feature as part of the council’s Historic Environment Record.

“It was clear that the channel pre-dated the road and perhaps was associated with the formation of the turnpike road in the 18th century,” the post continued. “We did not consider there to be any immediate safety issues concerning the depth of the feature found. It was, however, important that this was addressed to preserve the future structural integrity of the A-road, so works were planned with immediate effect.

“Early on Saturday 5 July we closed the A413 to carry out a full repair of the sink hole and reinstate the old drainage channel. This required excavating down to 2.2m across the extent of the carriageway, filling in the old drainage channel and reinstating the road surface. We also worked closely with utility companies already operating nearby to coordinate efforts and minimise disruption and liaised with HS2Ltd/Align on the emergency works, recognising that this is a key construction route.”

On Monday 6 July the road was re-opened by 6am, in time for the morning rush-hour traffic. q

[A POLL by leading ecological consultancy Arbtech reveals two in three people (68%) currently buying a home would expect to pay less for their homes if they lacked access to green space. Moreover, more than half of prospective homebuyers said they would be much less likely to buy a property if they knew a developer had offset damage to nature by paying into a central fund.

The findings came as the government continues to push the Planning and Infrastructure Bill through Parliament, despite a number of Lords amendments to mitigate the Bill’s impact on nature.

Ministers are hoping to use the Bill to drive forward the government’s commitment to build 1.5 million homes over the course of this Parliament.

The nationally representative poll of 2,000 people found that 55% think being close to green spaces and nature is important to their property buying decisions. More than a third (37%) of the public would expect a discount of between 1% and 10% if their property was not within easy distance of green spaces.

For buyers looking to get on the property ladder imminently the issue is even more acute. A huge majority (88%) of those trying to buy a home now and 84% of those wanting to buy in the next 12 months say being close

to green space and the natural environment is important to where they would choose to buy. More than two-thirds (68%) of those trying to buy a home now said they would expect to pay less for their home without access to green spaces.

The Planning and Infrastructure Bill also includes proposals which allow developers to ‘offset’ damage to nature beyond the initial area of damage by paying into a central Nature Restoration Fund (NRF). That, in theory, enables nature to be offset elsewhere in the country.

Arbtech’s polling reveals that to be deeply unpopular among prospective homebuyers. Just under two-thirds of people buying now (62%) and in the next 12 months (60%) would be less likely to buy a property if a developer was known to have damaged the natural environment without restoring it locally.

For voters intending to vote Labour in the next election, 62% would be less likely to purchase a property if they found developers had used the NRF to offset nature destruction. That is far higher than Conservative voters (48%) and is close to the opinion of Reform voters, 57% of whom would be less likely to purchase a property if a developer had paid into the NRF.

The polling raises serious questions for the

government, which is seeking to significantly expand the UK's housing stock, if homebuyers are set to exit the market under the conditions that homes will eventually be built.

It comes as several amendments continue to be pushed through the House of Lords to make the Bill more nature-positive. One amendment, tabled by Lord Gascoigne, seeks to narrow the scope of the Bill so that it ensures that protected species cannot be destroyed by the Nature Restoration Fund. Another, tabled by Lord Curry, seeks to maintain the on-going role of site-by-site ecological assessments to determine the impact on the local natural environment.

Robert Oates, CEO and founder of Arbtech, said: “Pushing ahead with a law designed to build new houses will be worthless if nobody wants to buy them. The government still has the opportunity to improve this Bill by accepting the small, common-sense changes proposed in the House of Lords that would prioritise local nature protection whilst accelerating housing delivery.

“If the government chooses to push on, not only will it face disastrous ecological consequences, but it’ll face financial ones as homebuyers refuse to buy, or expect heavy discounts, on developments that destroy nature.” q

[IN AUGUST last year Anwyl Homes Lancashire applied to Preston City Council for permission to redevelop almost 27 acres of land that was previously part of Ingol Golf Course.

Preston City Council’s planning committee unanimously approved the application in February. A Section 106 agreement to provide investment in the local community was recently reached, which includes a contribution of more than £700,000 towards primary education and obligations on local employment skills and biodiversity net gain.

More than half of the 27-acre site will be public open space and woodland. A central play area will provide a focal point for the new neighbourhood. Reflecting the character of the site, with natural open, grassy areas and deciduous trees, the development will be marketed as Walkers Glade.

Anwyl Homes Lancashire’s MD John Grime commented: “The redevelopment of part of the former golf course site is an exciting project

as it’s our first scheme that features measures to achieve new standards in biodiversity net gain. This means ecology is at the heart of the design of the 164-home development. We’ll be providing 15 acres of open space, along with new homes, ensuring that wildlife and nature can thrive here. We’ve recently started infrastructure works to prepare the land for new homes with the aim of releasing the first homes for sale in spring 2026.”

Walkers Glade will provide 114 private sale properties, plus 50 affordable homes to cater for local housing need. The private sale properties will comprise a selection of three, four and five-bedroom semidetached and detached designs. The affordable housing will include a choice of two and three-bedroom apartments, mews, semi-detached and detached homes.

The homes have been designed to be modern with a distinct character, while being sensitive to the local context. q

[ELM GROVE in Nailsea is a landmark housing development, delivered through North Somerset Council’s Development Strategy. Homes at the site are now nearing completion, with residents already moving in and more properties available to reserve through shared ownership with housing association Alliance Homes.

A partnership between Alliance Homes, developer Stonewood Homes and North Somerset Council, Elm Grove comprises 52 highly energyefficient homes on council-owned land. They include 26 available for social rent and 26 offered through shared ownership – all built to the rigorous Passivhaus standard. The development is expected to be fully completed by Christmas and all homes will be affordable.

The homes, which comprise two, three and four-bedroom houses and bungalows, are designed to significantly reduce energy use and carbon emissions. Features include triple glazing, mechanical ventilation with heat recovery, solar panels and high levels of insulation – helping residents to cut their energy bills by up to 95% compared to the UK average.

Sarah McQuatt, service director for new homes at Alliance Homes, commented: “We’re proud to be delivering these high-quality, energyefficient homes in Nailsea. Passivhaus certification means our customers will benefit from lower bills and warmer homes, and we’re pleased to be offering these properties as affordable housing for local people.”

The Elm Grove scheme is the first Passivhaus development in North Somerset and one of the few in the South West to offer 100% affordable housing. The project has benefitted from funding support from Homes England and the One Public Estate Land Release Fund for site infrastructure.

James Petherick, land and planning director at Stonewood Homes, said: “Elm Grove is a flagship for sustainable housing in the region. We’ve worked closely with our partners to create homes that are not only energyefficient but also spacious, adaptable and built to a high standard. It’s exciting to see the first residents moving in and the community beginning to take shape.”

Cllr Mark Canniford, executive member for placemaking and economy at North Somerset Council, added: “This development shows what’s possible when local authorities take a proactive role and work with local partners to facilitate housing delivery. Elm Grove offers much-needed affordable homes for sale and rent: all built to the highest energy efficiency standards.

“North Somerset Council’s Development Strategy looks to deliver homes and jobs that meet the needs of our community now and in the future. These are the building blocks of thriving local communities, which is why it’s critical these sustainable Passivhaus homes are affordable and of quality.” q

[BRENT COUNCIL and award-winning developer Wates Residential have celebrated the topping out of the Cecil Avenue development in Wembley, where construction has now reached the ninth level.

The milestone marks the structural completion of Cecil Avenue at its highest point. Located at the junction of Wembley High Road and Cecil Avenue, the scheme will deliver 237 new homes, including 87 affordable homes and a range of properties available for private sale under the name The Pages.

The development will feature a publicly accessible garden and play area and commercial spaces to support local businesses, and is expected to create around 100 new job opportunities for the local community. A new community hall will offer residents a welcoming space for events, activities and social gatherings.

The achievement at Cecil Avenue follows ongoing progress at Zephaniah House (formerly Ujima House), where construction has now risen above ground level and the project is making steady headway. Once complete Zephaniah House will provide 54 affordable homes, alongside a new workspace and café. Both regeneration projects are due to be completed by the end of 2026.

Cllr Teo Benea, cabinet member for

regeneration, planning and property, said: “Brent, like many local authorities across the country, is facing a housing crisis. We are working closely with developers like Wates Residential to continue to find opportunities to deliver high-quality, affordable, safe and secure homes for local families. This development will also provide a community hall, garden and play area for families to enjoy. We look forward to families moving into their new homes at the end of the next year.”

Paul Nicholls, regional managing director for London at Wates, commented: “Wembley Housing Zone is a great example of what thoughtful regeneration can achieve. We're creating a place that brings together affordable housing, homes for sale, green spaces and opportunities for local people. With the topping out at Cecil Avenue, that vision is becoming reality and it’s one we’re proud to be delivering with Brent Council.” q

[ STORY HOMES has confirmed the submission of a full planning application for a new residential development comprising 65 high-quality homes in Houghton, Carlisle.

The application, submitted to Cumberland Council, proposes a mix of two to six-bedroom homes, including 20% affordable housing, to help meet local housing needs. The development will offer a wide range of property types suited to firsttime buyers, growing families and downsizers alike.

The new development would follow the success of Story Homes’ previous scheme in Houghton –Eden Gate – which delivered 99 new homes and is now a flourishing community. The new proposals build on that legacy, continuing the company’s commitment to delivering high-quality homes and meaningful investment in the local area.

David Hayward, Cumbria and Scotland land manager at Story Homes, said: “We’re excited to bring forward these plans for a thoughtfullydesigned new community in Houghton. Our proposals aim to deliver much-needed homes while also creating a central area of landscaped open space that seeks to provide lasting benefits for the wider area. We look forward to working in partnership with the council as we progress through the planning process.”

panels, supporting greener living and helping future residents reduce their carbon footprint.

As part of its investment in the area, Story Homes will provide on-site green open space as well as a new and improved equipped play area in a central location. That will create a safe and accessible environment for children and families to enjoy, encouraging outdoor activity and helping to build a strong sense of community.

The scheme also places a strong emphasis on environmental sustainability, featuring a comprehensive landscaping strategy and measures to protect and enhance local biodiversity. In addition, the development will incorporate sustainable technologies throughout, including electric vehicle charging points and photovoltaic solar

With internal layouts that offer flexible, open plan living spaces and exterior details that will create the unique street scenes for which Story Homes is renowned, the proposals for this development have been thoughtfully designed with modern customers in mind.

In addition to addressing local housing need, the scheme is expected to bring economic benefits to Carlisle, including the creation of construction jobs, the use of local subcontractors and increased demand for local services once the homes are occupied.

Story Homes anticipates a decision on the planning application by next summer, 2026. q

[ ACCORDING TO THE LATEST Scottish Government data on new housing supply, the total number of new build completions across private, social and affordable housing in Scotland has fallen by 6% in the year to the end of June 2025 – to 18,869 – with new build starts 3% lower than the previous year, at 15,202.

During that period the private sector completed 3.2% fewer homes (14,274), but started 12,247 new builds – 1.6% higher than the previous year. The social sector completed 14% fewer homes (4,595), with project starts down 20% at 2,955.

Overall, private sector completions were at the lowest level since 2018 and social sector completions were the lowest since 2017, excluding the pandemic in 2020.

Alan Aitchison, partner and head of real estate and construction in Scotland at middle market consultancy RSM UK, said: “The housebuilding data for Q2 2025 indicates a continuation of the sluggishness in Scotland’s housing sector amid market caution and on-going planning delays. The first sign of green shoots we’re all looking for may be present in the increase in private new build starts; however, the social housing sector continues to feel a

squeeze, with sharp declines in completions and starts indicative that delivery is being hampered by funding constraints, planning hurdles and labour shortages.

“With housebuilders having to absorb inflationary cost pressures, there is the added risk that the sector could fall further behind on meeting housing targets, especially in social housing where margins are tighter. Housebuilders are therefore facing tough decisions around project viability and timings. Pricing for new builds also remains subdued due to weak demand, and developers are increasingly having to scale up incentives for buyers in order to shift stock.”

It's not all gloom and doom, however. Alan Aitchison added: “Looking ahead, while the headline figures paint a gloomy picture, there are further reasons for cautious optimism. Funding announcements from the government’s spending review may begin to trickle through in Q3, potentially mobilising stalled projects and injecting some much-needed momentum into the sector. Mortgage approvals in Scotland also rose by 15.7% in Q2, indicating improving housebuyer sentiment.” q

Neal Herbert, managing director of housebuilding utilities partner GTC,

puts the case for the networked ground source heat pump

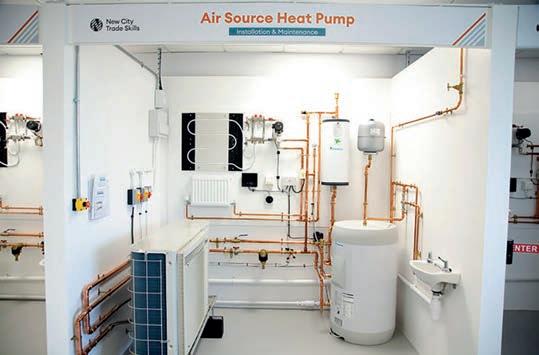

[AS THE UK transitions towards net zero, the pressure on housebuilders to deliver homes that are efficient, future-ready and compliant with evolving regulation has never been greater.

Heating accounts for nearly one third of the country’s greenhouse gas emissions, making it a critical area for intervention. With the Future Homes Standard timetable banning the use of gas boilers in new-build homes imminently, housebuilders and developers must now find sustainable alternatives that are not only environmentally sound but also commercially viable and operationally scalable.

Enter the funded, utility-grade networked ground source heat pump. These systems are redefining what’s possible in residential heating, addressing the threefold demands of the UK’s energy trilemma: ensuring long-term security of supply, keeping heating affordable for both developers and residents and supporting the urgent goal of environmental sustainability.

At the heart of this solution is a robust and resilient heat infrastructure that extracts warmth from the stable temperatures found beneath the ground. Unlike traditional gas-based systems or more weather dependent air source alternatives, networked ground source heat pumps provide consistent and reliable heating and hot water all year round. This reliability is especially valuable in the face of increasing strain on national energy systems and ongoing volatility in international gas markets. Decoupling heat supply from those risks ensures that both developers and homeowners benefit from secure, predictable performance.

Affordability is also central to decarbonisation. Rather than burdening developers with upfront capital costs, GTC designs, installs, owns and operates the solution – covering the entire underground heat network on a regulated utility basis. This model removes technical and financial risk from site delivery and provides developers with a single, accountable partner across all utility services. For residents, the result is access to a low-carbon heating system that delivers consistent comfort at a lower operational cost, without the need to understand or manage complex technology.

A key enhancement to these systems is the integration of smart thermostats. These intelligent control technologies work seamlessly with networked ground source heat pump systems to optimise heating schedules in response to live weather forecasts, user behaviour and occupancy patterns. By adjusting performance in real-time, these thermostats can significantly reduce

unnecessary energy use, typically cutting consumption by 15-20% while improving comfort. For developers, it also supports ESG reporting, evidencing operational carbon reductions and adding further value in a compliance-conscious market.

From an environmental perspective, networked ground source heat pumps represent a clear path to zero-carbon heating. These systems use electricity to power heat pumps that draw energy from the ground, offering up to five times the efficiency of gas and a 30% increase in efficiency compared to an individual air source heat pump.

A ground source heat pump is powered through electricity, delivering 3-4kW of renewable energy for every 1kW of electricity used. They represent the most energy-efficient heating technology available. As the UK grid continues to decarbonise, these systems become progressively cleaner over time.

Because the infrastructure is installed underground it is protected from the elements, requires less maintenance than surface-level systems, and has a lifespan exceeding 50 years: making them a long-term, low-impact investment in a sustainable future.

Although air source heat pumps have gained traction in recent years, they are often less suitable for dense residential developments or sites with ambitious sustainability goals. Networked ground source heat pumps outperform air source heat pumps in almost every category. They operate at higher efficiency levels throughout the year, particularly during winter months when air temperatures fall and demand for heat is at its peak. This higher efficiency translates directly into consistent running costs for residents and reduced grid demand during peak periods.

Unlike air source heat pumps, which require outdoor fan units that can be visually intrusive and produce noise, networked ground source heat pumps are quieter and hidden away once installed. That makes them particularly valuable in high-density or planning-sensitive environments, where aesthetic and acoustic considerations are paramount. Furthermore, the heat source in a networked ground source heat pump system is entirely external to the home’s thermal envelope, eliminating internal heat gains that can contribute to overheating – an important consideration under the latest Building Regulations.

That brings us to the question of compliance. With the recent updates to Part L and Part O of the Building Regulations, achieving regulatory approval is no longer just a box-ticking exercise; it’s a key part of a home’s value

proposition. Part L requires a 31% reduction in carbon emissions compared to previous standards. Networked ground source heat pumps contribute significantly to that target by reducing carbon emissions by 75-80% from day one. Part O, which focuses on reducing overheating risk, is also more easily met with ground source heat pumps, which avoid the need for indoor or roof-mounted units that generate excess heat within the home.

Looking ahead to the Future Homes Standard – due to take effect in late 2025 –networked ground source heat pumps are already fully compliant. Their low-carbon credentials and high efficiency ensure that homes built today can meet tomorrow’s expectations without retrofitting or technical compromise. This is particularly valuable on large-scale developments, build-torent schemes or high-rise projects, where consistent performance, simplicity and longterm viability are essential.

In shaping the homes of tomorrow, developers are also shaping the communities of the future. This approach embeds lowcarbon heat into the fabric of a development, transforming heating from a technical afterthought into a core element of placemaking and environmental stewardship. This infrastructure-first philosophy supports neighbourhood-wide carbon savings, lowers cumulative energy demand and helps developers tell a credible sustainability story to local authorities, investors and buyers alike. Low-carbon heat is no longer optional; it is essential. As regulation tightens, consumer expectations evolve and climate pressures intensify, and the need for scalable, highperformance solutions becomes ever more urgent. Networked ground source heat pumps meet that need head-on. They provide a future-ready answer to the UK’s energy trilemma: ensuring homes that are secure, affordable and sustainable by design. q

[LONDON BUILD EXPO returns to Olympia’s Grand and National Halls on 19-20 November – and this year marks 10 years of connecting the construction industry. To mark that milestone, this year’s event will offer more networking, innovation and community building than ever before.

As the UK’s leading and largest construction show, London Build attracts over 38,000 visitors, and offers more than 750 speakers across 12 CPD stages and more than 450 exhibitors.

This year, London Build Expo will bring together thousands of the UK’s leading contractors, architects, developers, civil engineers, housebuilders and construction professionals.

Visitors can meet the buyers and connect with top decision-makers and procurement teams from Tier 1 contractors. They can forge valuable relationships, explore tender opportunities and take business to new heights.

Among the 450 exhibitors are such varied companies as major contractors Wates Group and Laing O’Rourke, specialist suppliers Acrow Bridge and Howdens, developers Peel Ports Group and even Chelsea FC.

What’s on offer?

Visitors can head over to the London Build Government Hub to stay ahead of the curve with insights on the latest policies, procurement opportunities and initiatives shaping the future of construction. They can be part of the UK’s largest networking events for Women in Construction, Diversity in Construction, and Mental Health in Construction.

The more-than 750 inspiring speakers will dive deep into key topics such as AI, sustainability, fire safety, and diversity and inclusion –across 12 dynamic conference stages. Plus, with over 200 hours of CPD-accredited workshops, visitors will gain the knowledge and skills to cement their place as a leader in the industry.

Partner organisation the Construction Leadership Council (CLC) said: “Join us and the expected 38,000-plus visitors from contractors, architects, civil engineers, developers, local councils, house builders/ associations and construction professionals celebrating 10 years of London Build: plus over 750 inspiring speakers across 12 CPD conference stages, including Skyscrapers & Tall Buildings, Digital Construction, Fire Safety, Sustainability, D&I, Skills & Marketing and over 450 exhibitors showcasing the latest services, products and innovations transforming the industry.”

To register visit www.londonbuildexpo.com to receive a free attendee pass and access to the full event programme.

Among the many testimonials London Build can boast are:

“If you could you only attend one show a year in the UK, London Build is the one. I’ve been coming to the show since 2019 and I’ve seen the evolution of this great event. The growth of the sustainability focus at the show has been amazing, too.”

Juan A Morillas, head of sustainable design at John Sisk & Son Ltd

“That was the best show for us this year by far, great work! I appreciate your help and support and patience with members of the PlanRadar team. Personally, this is the flagship event of the year for PlanRadar in the UK and your support is always noticed.”

Robert Norton, UK regional leader at PlanRadar

Stop press!

The feedback from all exhibitors and attendees really speaks for itself. Attracting thousands of high-quality visitors from across the UK’s entire construction industry, it is your one-stop show to network with key buyers and acquire thousands of new business leads. The last few exhibition stands are being snapped up fast, so potential exhibitors need to act now. q

Welcome to our A to Z guide of the websites of some of the industry’s leading

If you are one of our many online readers simply click on any of the logos listed below and you will be automatically directed to that company’s website. To get your company’s website listed on this page just give us a call on

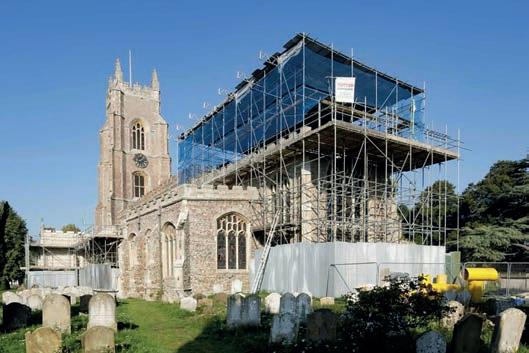

[THE INNSiDE by Meliá Manchester was buzzing on 26 June when the Association of Technical Lightning & Access Specialists (ATLAS) gathered for the 2025 ATLAS Apprentice Awards. The special evening celebrated the outstanding achievements of apprentices in the steeplejack and lightning protection industries, marking the exciting beginning of their professional journeys.

Over 70 guests attended the occasion, including apprentices, their partners, supportive employers and industry colleagues, who enjoyed an evening filled with camaraderie and entertainment. Hosting the event was comedian and actor Justin Moorhouse. Justin brought laughter and energy to the room, setting the stage for a memorable night.

ATLAS president John Jolly opened the evening with an inspiring speech, highlighting the importance of apprenticeships and applauding the dedication and hard work of all apprentices.

Certificates of completion were presented to the graduating apprentices, to enthusiastic cheers from the audience.

The highlight of the evening was the presentation of two prestigious awards, which are given to the best steeplejack and best lightning conductor engineer apprentice each year.

Three apprentices were shortlisted for the Ted Fuller Award, named in honour of a steeplejack legend. Junaid Hussan and Thomas Muldownie, both of Northern Steeplejacks Edinburgh, and Aaron Jones of Igoe Up were all recognised as having shown dedication to the course by going above and beyond standard requirements.

CITB instructors Bill Butcher and Will Wylie were invited on stage to explain the selection criteria before Bill announced the name of the winning apprentice: Junaid Hussan of Northern Steeplejacks Edinburgh.

Three apprentices were shortlisted for the A W Elliott Award, named after a truly remarkable figure in the lightning conductor engineering field. Jake Byrom and Thomas Halstead-Hughes, both of PTSG Electrical Services and Tyler Langan of Lightning Protection UK were

G & S Steeplejacks Ltd

Over 30 years experience in the Design & Installation of Lightning Protection Systems.

• Annual Testing • Inspection & Maintenance

Surge Protection • Height Safety Systems Schools, Hospitals, Universities, Colleges, Churches

T: 01761 437796 M: 07974 184449

all recognised for their dedication and exceptional performance.

CITB instructor Howard Wright was invited on stage to explain why the winner had been selected before ATLAS president John Jolly, who is also MD of premium event sponsor R C Cutting & Co, announced the name of the winning apprentice.

The Elliott Award recipient was Jake Byrom of PTSG Electrical Services.

In closing, Justin Moorhouse expressed best wishes for the apprentices’ promising futures, underscoring their critical role in shaping the industry’s future and the privilege of having the industry recognise those apprentices by hosting an awards evening. The ATLAS Apprentice Awards served as a testament to the commitment and excellence of the apprentices, highlighting the industry’s bright future. q

[ THE Chartered Institute of Building (CIOB) in Scotland took the opportunity of thousands of young people receiving their National 5 results on 5 August to encourage them to consider a career in construction.

Not only does the sector offer meaningful and well-paid work, the world’s leading professional body for construction management and leadership pointed out, but it is also vital to achieving Scotland’s housing and climate goals. In fact, CIOB believes Scotland’s ambitious plans to tackle the housing emergency and meet net zero targets risk falling short unless more is done to steer young people toward the industry.

A recent CIOB survey found that nearly three quarters (74%) of 16 to 24-yearolds in Scotland view construction careers positively, and over a third (36%) would consider working in the sector. However, almost half (43%) of respondents said construction was not included in the careers advice they received during school – a missed opportunity to engage students at a critical decision-making stage.

Jocelyne Fleming, senior policy and

public affairs officer for CIOB in Scotland, said: “Results day is a time of reflection and decision-making for young people across the country. For Scotland’s construction sector the simple fact is that, unless more young people are guided into roles such as architects, surveyors, site managers, skilled tradespeople and technicians, the country’s infrastructure and climate goals could be at risk.

“With demand for skilled workers in construction continuing to rise, there’s never been a better time to consider a career in this rewarding industry, so we’re encouraging as many young people as possible to give a role in construction some serious thought.”

A parallel CIOB survey of parents of 16 to 24-year-olds in Scotland revealed 77% would support their child working in construction, with over a third (39%) preferring the ‘earn while you learn’ approach of apprenticeships over university: reflecting concerns about student debt and uncertain graduate job prospects.

Jocelyne added: “Three quarters of the young people we surveyed in Scotland

already have a positive view of construction, but we’re not doing enough to encourage them into the sector – and we believe a lack of clear careers guidance plays a part in this.

“As young people across Scotland weigh their next steps after N5 results, we’re urging students, parents, teachers and careers advisers to take a fresh look at construction – not just as a job, but as a rewarding, future-proof profession that builds communities and shapes a better world.”

The construction skills gap remains a critical challenge. Recent analysis from CITB shows the Scottish construction sector will need almost 3,600 new workers each year between now and 2029 just to meet expected demand. Young people interested in pursuing a career in the construction sector can find free resources at www.goconstruct.org q

[ KIRKLEES COLLEGE is proud to be playing a key role in the Transpennine Route Upgrade (TRU). The TRU is an ongoing upgrade to the North’s railway systems that will see major improvements in rail services, including cutting down journey times between major locations across northern England. The college is playing a key role in supporting the upgrade, through the new Kirklees Operator Skills Hub, which opened earlier this year.

The hub is a state-of-the-art facility for plant machinery operations upskilling, funded by Flannery Plant Hire, Kirklees College and Kirklees Council, and supported by the TRU and BAM Construction. It is a work-based training unit for plant operatives to upskill on new equipment and the latest technology including GPS, mobile simulators and digital infrastructure, all of which support the delivery of skills bootcamps, study programmes and apprenticeships.

The TRU and Mass Transit projects announce by the West Yorkshire Combined Authority guarantees that there will be an acute need for plant operatives and groundworkers for the next decade. Therefore, equipping local people with these skills is of significant strategic importance to the regional economy. Kirklees College is proud to be at the forefront of filling this skills gap.

Steve Plumstead, Director of Curriculum at Kirklees College, said: “This facility has allowed adult learners in Huddersfield and surrounding areas to gain vital plant machinery operation skills that directly support the skills needed to implement the TRU.

“Kirklees College will be extending learning opportunities at the hub to young people in September and we are excited to be

empowering local people with the training required to support the work of the TRU.”

The Transport Select Committee recently visited the hub on an official visit to see the ongoing work of the TRU in Huddersfield and West Yorkshire. Shortly after this, the government announced the completion of one of the upgrade’s biggest milestones on time – the electrification of the line between Church Fenton and York. As the government continues to support this £11bn project, Kirklees College will continue to educate and inspire the workforce who will see through its completion. q

• For further information visit www.kirkleescollege.ac.uk

[

EXETER COLLEGE is proud to announce it has been chosen as one of 10 Construction Technical Excellence Colleges by the Department for Education, an accolade that underscores the exceptional quality, innovation and impact of its construction provision.

This prestigious recognition is a testament to the outstanding expertise and dedication of Exeter College’s construction team, whose tireless work continues to set the benchmark for excellence in technical and vocational education. It positions the college as a national leader in construction training and opens exciting opportunities to collaborate with providers across the country, share best practices and drive further investment into the South West region.

John Laramy CBE, principal and CEO at Exeter College, said: “We are absolutely delighted to be selected as the one of the Construction Technical Excellence Colleges. We look forward to working with our students, staff, stakeholders and employer partners across the region to turbo charge construction training.

“It is a particular personal privilege, as an education leader who began their career in construction, to be part of a national initiative to ensure our region benefits from the career opportunities that excellent technical education enables. No education system can be better than the quality of its teachers and it is brilliant to see their professional development as a key part of this initiative.

“We are excited about working with colleagues in the DfE and wider government to ensure this national policy has meaningful impact and benefits for the South West and beyond.”

The college’s exceptional track record of collaboration with regional and national employers has created a vibrant construction network that is impacting significantly on the national construction skills shortage. The Technical Excellence status recognises the eco system Exeter has in place. Through initiatives like Building Greater Exeter and the Green Skills Advisory Panel, the region is working to make a real impact on the government initiative to ‘Get Great Britain Building Again’.

Steve Race, Labour MP for Exeter, commented: “Awarding Construction Technical Excellence College status to Exeter College means brand new skills training in construction for young people and will help others already in the construction sector to upskill. This new approach will help us deliver the new homes and the economic growth we need across our region, in partnership with the construction sector. It’s a testament to the hard work and educational excellence of the college team, and I’m excited about this new future for skills training in Exeter.”

In securing Technical Excellence status, the college received

an impressive 120 endorsements from local organisations and stakeholders, including FE colleges, schools, councils and construction employers, reflecting strong community backing.

Pete Sadler, managing director for Vistry South West, said: “Vistry is delighted to see the roll out of Construction Technical Excellence College’s across the country – they will provide a significant boost to skills, innovation and developing the future workforce our country needs. At Vistry, we’re deeply committed to skills development and building strong industry partnerships.

“This achievement will not only strengthen our collaboration with Exeter College but also help ensure we have a pipeline of talented, work-ready individuals to support the future of construction and housebuilding across the region.”

This is a timely investment as the college has seen unprecedented growth in construction in recent years. Full-time learner growth surged by 32% in the last academic year, while apprenticeships have also seen consistent increases, with over 650 trade and professional construction apprentices enrolled for the 2024/25 academic year. The total of over 1,150 construction learners will help to provide a solution to the UK’s construction skills shortage over the next few years.

Furthermore, the faculty’s achievement rates significantly surpass national averages, underlining its dedication to high quality teaching, learning and student success.

Councillor David Thomas, chair of the Devon and Torbay Combined County Authority (DTCCA), said: “Exeter College’s appointment as a Technical Excellence College in construction is welcome news for our region. This will strengthen local skills and help Devon and Torbay contribute to the government’s 1.5 million homes target.

“To meet these ambitions, we must expand construction training across the whole of our region. The DTCCA looks forward to working with Exeter College to address local needs and challenges.

“We are also committed to collaborating with the West of England Combined Authority, Plymouth and Cornwall, to align skills strategies and share expertise with other training providers, ensuring a joined-up approach to building a skilled workforce across the South West.”

As a Construction Technical Excellence College, Exeter College is excited to lead the way in tackling the skills shortage, driving innovation and building a stronger future for the South West, and looks forward to sharing more exciting developments on this initiative in the near future. q

[ NEW CITY COLLEGE (NCC) has been confirmed as one of just 10 Construction Technical Excellence Colleges (CTECs) across the country and will receive part of a £100m government investment to train thousands of construction workers.

This announcement will benefit students, employers and communities as the college – with construction training centres in Rainham, Epping Forest and Hackney –will receive extra funding to deliver training in sectors where there are skills shortages.

Local aspiring builders, electricians, carpenters, bricklayers and roofers will be able to take advantage of cuttingedge training for skills that are in demand from employers and for jobs within the construction industry in the years to come.