EDITION 145 - 2024

E-JOURNAL OF PORTS AND TERMINALS

Maritime Safety Series: Port Edition, the virtual event taking place on the 3 - 4 December 2024 will discuss the critical importance of bringing safety to the forefront in port operations:

Our webinar platform will allow our audience to ask key questions, comment on the topics that matter to you and engage with our speakers!

The importance of port safety initiatives

What it means to instil a culture of safety

Mastering risk management principles

The power of effective leadership and safety training

Inevitable and essential: post incident response

The innovative technologies transforming safety

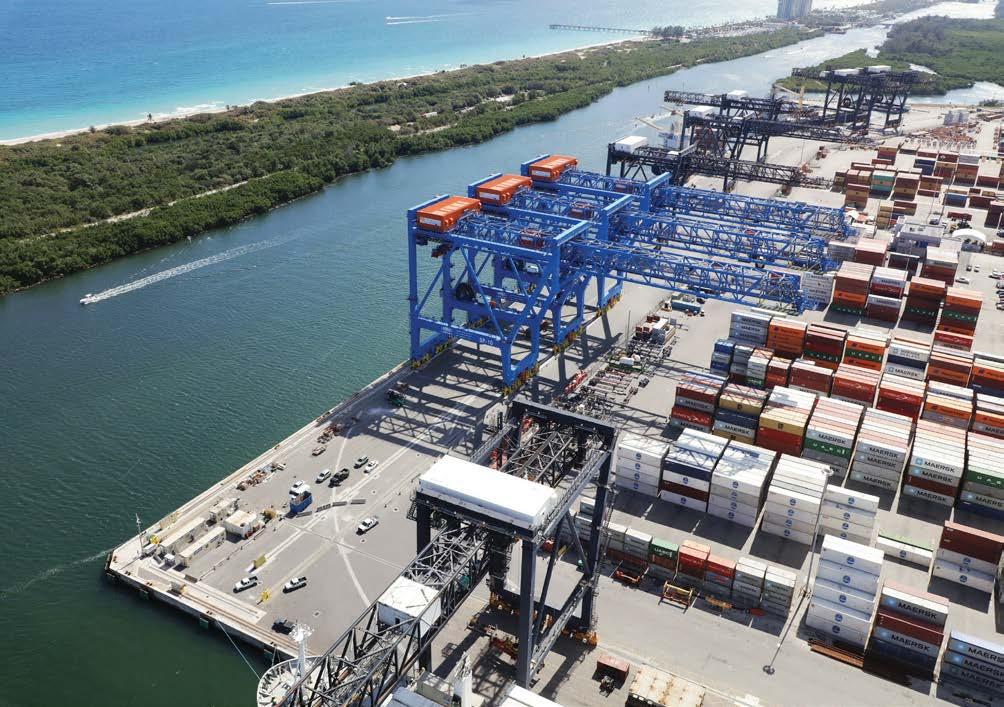

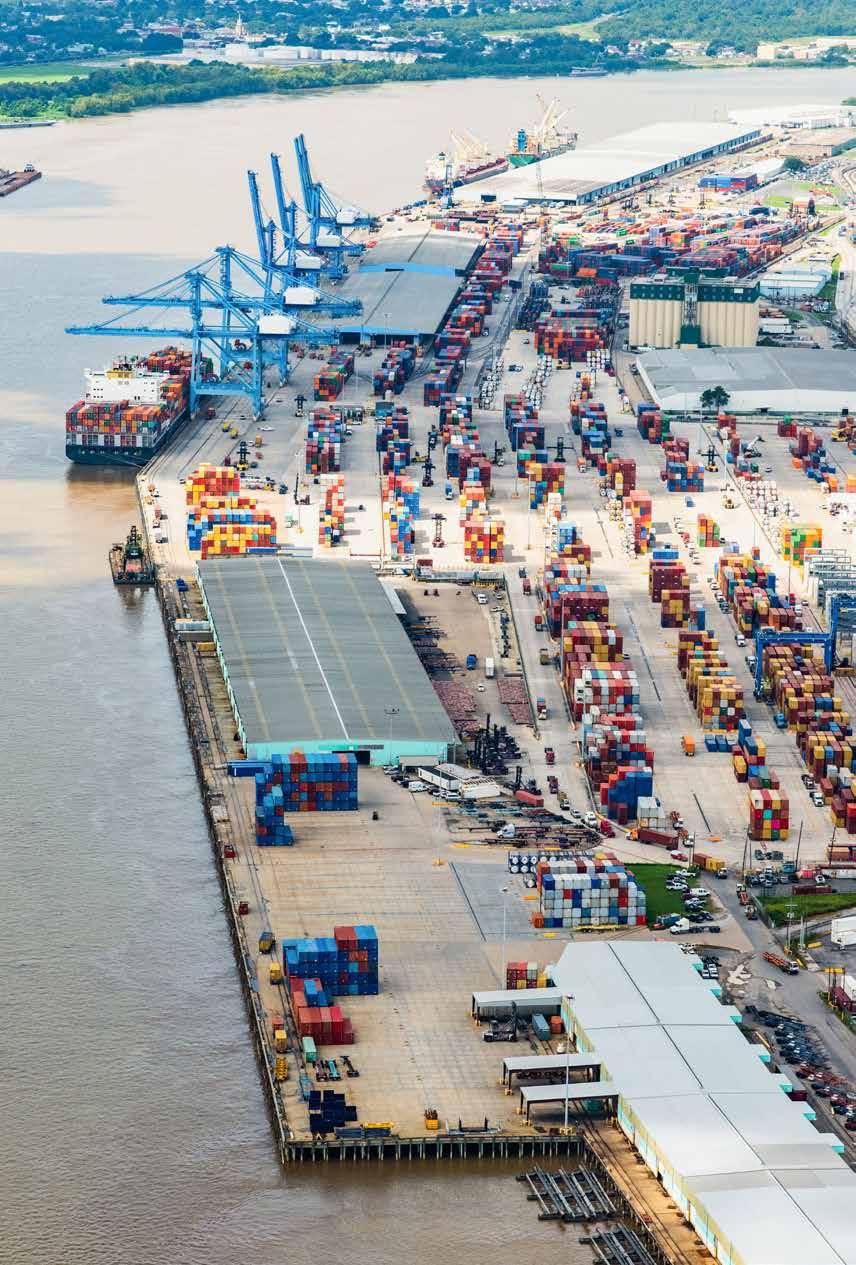

Welcome to the 145th edition of our e-journal, dedicated entirely to looking ahead at the future of port operations. In this issue, we’re exploring the trends and solutions that are transforming how ports operate and helping the industry stay ahead in an ever-evolving world.

We’ve asked the question: what will be the key trends and innovations that will shape next-generation port operations? To answer that, we’ve put together a collection of articles that examine various aspects of these changes, from automation to sustainability, giving you a full view of the exciting developments that are driving global trade forward.

We kick things off with a look at AI, thanks to an insightful article from INFORM. Dr Eva Savelsberg and Kaio Quinan provide an excellent overview of how AI is benefitting port operations, while also discussing its limitations. When used the right way, AI can support human decisionmaking and help make port operations more efficient. But, as Dr Savelsberg and Quinan point out, it all comes down

to using quality data and managing it carefully—AI can’t do it all on its own.

Moving on, we take a closer look at technologies that are making operations smoother. Kishor Arumilli from ATAI introduces ATLocation, a system that uses AI and sensor fusion to improve container tracking and yard management. Passify, with Marcel Lindemann, shows how its app is making truck handling at container terminals safer and more efficient, while Jean-Philippe Joassin and Angelica Nieto Lee discuss how Kalmar SmartRead can automate container ID reading, which cuts down on human error and boosts both safety and productivity.

We also dive into how advanced data solutions are helping make ports smarter. A brilliant article by Moffatt & Nichol and NextPort explains how Digital Twins and AI play a big role in improving decision-making, maintenance, and asset management at ports. Following the same theme, we had the pleasure of welcoming back Harrison Nguyen from RBS, who explains how the company promotes the use of similar technology to optimise

Margherita Bruno, Editor

resources and enhance safety. Innovation and technology must go hand in hand with safety — an aspect that can no longer be overlooked. In this context, Hiades introduces AMURA ControlBoard, a system that integrates sensor and radar data to enhance situational awareness, helping operators make safer, more informed decisions on the ground.

Finally, we turn our attention to the crucial role of sustainability in creating next-generation ports. Rocsys’ Paul Arms addresses the challenge of charging electrified port equipment by introducing a hands-free charging solution powered by robotics and AI. This innovative approach not only boosts safety and reduces inefficiency but also supports ports in achieving their sustainability targets.

A big thank you to all our contributors for sharing their insights. They’ve given us a clear look at an industry that’s evolving fast, with technology not only making ports more efficient but also safer, greener, and more resilient. We hope you find this issue as exciting and insightful as we do. Enjoy the read!

3.

AI: BEYOND THE HYPE TO A CLEAR UNDERSTANDING OF ITS POWER . . . AND LIMITS

Dr Eva Savelsberg, Senior Vice President, INFORM, and Kaio Quinan, Director of Sales Americas, INFORM

8.

ENABLING YARD OPTIMISATION. AN AUTOMATIC REAL-TIME TRACK, TRACE AND CAPTURE SYSTEM

Kishor Arumilli, Vice President – Engineering, ATAI

14.

HOW DIGITAL TRUCK HANDLING ENABLES MORE SECURE AND ADVANCED TERMINAL OPERATIONS

Marcel Lindemann, Co-Founder, passify

18.

KALMAR SMARTREAD CUTS DOWN ON CONTAINER HANDLING EXCEPTIONS

Jean-Philippe Joassin, Director of Process Automation, Kalmar, and Angelica Nieto Lee, Product Manager Automation Solutions, Kalmar

23.

INTEGRATION OF ASSET AND OPERATIONAL DATA: HOW DIGITAL TWINS AND ARTIFICIAL INTELLIGENCE CAN OPTIMISE PORT PERFORMANCE

Dr Oscar Pernia, Co-Founder & Head of Technology and Innovation, Nextport, Dr George Saad, Technical Director – Ports, Moffatt & Nichol, Miguel Angel Llorente, Technical Product Manager, NextPort, and Dr Ayçin Aykutalp, Software Engineer, NextPort

28.

FUTURE TRENDS IN TERMINAL MANAGEMENT: THE EVOLUTION OF INTELLIGENT SYSTEMS

Harrison Nguyen, Business Development Manager, Realtime Business Solutions

33.

AMURA CONTROLBOARD: ENHANCING SITUATIONAL AWARENESS FOR NEXT-GEN PORT OPERATIONS

Airam Rodríguez, CEO, Híades Business Patterns, Isaac González de Vega, Consultor, Híades Business Patterns, and Gerardo Alvarez Perez, Head of Maritime Operations, Valencia Port Authority

38.

WHY THE PORT INDUSTRY NEEDS HANDS-FREE CHARGING

Paul Arms, Senior West Coast Business Development Manager, Rocsys

www.porttechnology.org linkd.in/porttech

Dr Eva Savelsberg, Senior Vice President, INFORM, and Kaio Quinan, Director of Sales Americas, INFORM

The hype surrounding artificial intelligence (AI) is anything but understated. As a new and evolving phenomenon, people’s ideas about AI often reflect their own imaginations as much as the reality of the technology itself. Upon listening to some popular sentiments, AI is on the verge of replacing humans in just about every conceivable function in business and society.

While AI is not the first technology to inspire overwrought expectations, the fever pitch is quite strong. Perhaps it has to do with the fact that it’s difficult for the average person—or even highpowered business leaders—to be sure what the limits of AI really are. It seems like it can do just about anything. And whatever your job is, it’s not implausible to think AI will soon learn to do it more cheaply and efficiently than you can.

However, optimising AI requires a realistic understanding of its power—which is considerable— and of its limitations. This article dives into the current explosion of AI in the marketplace, as well as the business community’s expectations of it and how these can be measured against some helpful reality checks.

Many tech companies are still getting up to speed on AI and machine learning. INFORM, however, has a long history of using algorithmic decision-making tools to bring innovation to the world and its major industries, including the maritime and intermodal industries.

“INFORM HAS GAINED UNIQUE INSIGHT INTO THE BEST USES OF AI, AND HOW IT CAN AUGMENT AN ORGANISATION’S EXISTING CAPABILITIES.”

This history started around 25 years ago in Hamburg, Germany, where we helped terminal operator HHLA to take its decision-making process to a higher level. A unique blend of tools, which was revolutionary in 1999, has continued to advance in the decades since. As a result, we have been able to improve dwell time prediction accuracy by 25 per cent in the North American intermodal transport market, while helping distribution centre operators harness data into better decisions and more effective strategies.

As we draw upon what we’ve learned, and work through the advances in this technology, we’re now being asked to improve congestion prediction algorithms for terminal operators and to boost the value of research into charging

optimisation of electric vehicles (EV). Some of our most valuable work has combined the power of AI with the value of operations research (OR) to deliver an extremely high level of information and insight.

Through this experience, we can say with confidence: INFORM has gained unique insight into the best uses of AI, and how it can augment an organisation’s existing capabilities. For that reason, when we look at the booming AI market, we are confident we can recognise some of the likely directions it will take—and how the industry will ultimately come to optimise it.

As recently as 2010, global investments in AI-based startups totalled $1.3 billion. By 2019, that

number reached $37 billion. According to the Stanford Institute for Human-Centered Artificial Intelligence, all global investments in AI totalled $70 billion in 2019. Goldman Sachs predicts that number could reach $200 billion by 2025.

This investment capital is certainly spurring plenty of activity, as the past decade has seen 4,643 AI startups in the US alone. That included more than a dozen startups in the maritime market, all claiming to use AI to solve operational challenges. In fact, most of these startups are focused on applications of machine learning, with decidedly mixed results.

One reason investments will continue to flow into AI startups is due to the rapid increase in the technology's power capacity. Consider the computing power of the average personal computer as far back as 1994, when computing technology was mainly used for word processing and games. E-commerce was in its infancy even as the very first website was published.

In the 30 years since then, the computing power of available

hardware has increased by a factor of 2,000. Yet that pales in comparison to the growing power of optimisation algorithms, which have grown in power over the same period by a factor of 1.74 million. When you combine the increased power of both the hardware and the optimisation algorithms, you’ll find that the capacity of AI has increased by a jaw-dropping factor of 3.48 billion.

That kind of power is sure to attract both investors and company founders determined to harness it to great effect. And as we assess the state of AI, it offers much to justify this kind of investment. AI as it stands today is:

Flexible. It can respond to diverse challenges, although it needs to be trained and proven on each challenge.

Disciplined. It excels at focused, niche applications and narrow, well-defined tasks. It can deliver high performance in specialised scenarios.

Relentless: It just keeps doing exactly what it’s programmed to do without ever getting tired.

Combined with the computing power of the hardware and the algorithms, these are characteristics of a very powerful business tool. But there's a risk that perceptions of AI will outpace its actual capabilities, potentially overlooking some of its pitfalls. Like any technology, AI is only as effective as its design and the data it processes.

AI is extremely data-dependent, and it needs the data it works with to be high in both quantity and quality. If very good data is available, and lots of it, AI will produce good outcomes. If not, it will sometimes produce bizarre outcomes.

To use a very simple example, we asked ChatGPT if it could name the protagonist of the book “The Hunt for Red October” by Tom Clancy:

“The protagonist of ‘The Hunt for Red October’ by Tom Clancy is Jack Ryan. He is a CIA analyst who plays a crucial role in the story as he tries to understand the motivations behind a Soviet submarine captain's decision to defect to the United States. The novel revolves around the tense and thrilling events surrounding the submarine

and its crew. If you have more questions about the book or its characters, feel free to ask!”

Exactly right. It’s a very famous book and the data to generate that answer is very good and easy to find.

At the same time, a friend of ours also wrote a book that didn’t become famous at all, although you certainly can find references to it on Amazon and other sites. We asked ChatGPT to name the protagonist of his book (whose name we happen to know is Clay Bender). The response?

“The protagonist . . . is a character named Nathaniel

‘Nate’ Thorne. The novel follows his journey as he navigates challenges and conflicts within a world that intertwines political intrigue and supernatural elements. If you have more questions about the book or its themes, feel free to ask!”

Not even close. Not only did ChatGPT not know the answer, it came up with a completely wrong answer. That’s because the available data was neither good enough nor voluminous enough to produce the information requested. Now consider the potential consequences of a decision-

making simulation in which AI doesn’t have good data (or enough of it) and generates an equally random output.

AI is very intelligent but it’s not perfect, and the quality of its algorithms is based heavily on the code and training data on which they are built.

MACHINE LEARNING IS STILL IN ITS INFANCY

While we have proven over the course of 25 years that machine learning can be a powerful driver of improvement, we have also

“AI IS EXTREMELY DATA-DEPENDENT, AND IT NEEDS THE DATA IT WORKS WITH TO BE HIGH IN BOTH QUANTITY AND QUALITY.”

“AI AT ITS BEST WORKS ALONGSIDE HUMANS TO ANALYSE AND SOLVE PROBLEMS, AND TO AID IN GOOD DECISION-MAKING.”

come to understand how much it requires to be effective. In many ways, machine learning remains a technology in its infancy.

The strongest point is the fact that, as its name suggests, machine learning (ML) doesn’t need human coaching to continue to improve. It accumulates and analyses information on its own, and gains a greater understanding of information as it goes along. Much as a human does, ML learns by doing.

Sometimes this is called trial and error, and both ends of that are important here. Without intense discipline, the data that drives ML can be unreliable and riddled with errors.

Remember, the machine will “learn” what it’s exposed to, but it won’t necessarily know if what it learns is wrong. Especially when we’re dealing with data that’s been manually entered, the risk of erroneous data compromising the ability of ML to help with decisionmaking is great. Small quantities of bad data can usually be filtered out, but large quantities are a bigger problem to manage and result in very poor models.

Managed correctly, ML can produce tremendous value to aid in information and decision-making. We’ve been doing it for many years. But it requires solid management, and it can go badly off the rails without it.

Full utilisation of AI requires strong processes, good data and a sound approach to defining and solving problems. An organisation that actively lives these characteristics can find AI to be a valuable tool because it’s designed to complement these strengths.

Crucial team members additionally need a strong knowledge of AI—its capabilities and its limitations—and the role it can play in augmenting the organisation’s decision-making processes. If the team possesses this knowledge and these skills, and the company has a robust management process, AI can work well within the structure.

The company should also be prepared with reasonable timelines and budgets to support the deployment of AI, and it must know who within senior management will be the primary sponsor of AI’s role. As much as many companies may feel they need to “get on the AI train” because that’s where things are headed, it’s more important to examine the organisation and be sure it’s ready to take full advantage of its capabilities.

Too many companies maintain their data in silos that don’t talk to each other, so there is little opportunity to see the complete data picture of the enterprise. Whether we’re talking about maritime and intermodal terminal operators, distribution centres or any other industry, the sharing and harmonising of data is critical to get the most out of AI. This demands the widespread embrace of data sharing and data cleaning to be sure we’re not developing AI systems that feed off biased and unreliable information.

Take, for instance, the use of Digital Twins for port infrastructure which can enhance monitoring and predictive maintenance. Blockchain technology could provide unparalleled transparency and security in supply chains, while 5G connectivity would support real-time data exchange and remote operations. Ensuring data quality and interoperability not only boosts the accuracy of AI models but also builds a foundation of trust and reliability in AI-driven insights.

As a leading developer of AI-based technologies, INFORM strongly believes in the power of AI. For that reason, we firmly advocate for it to be developed in effective, socially responsible and socially sustainable ways. What we also believe, is that AI at its best works alongside humans to analyse and solve problems, and

to aid in good decision-making. Its potential is enormous. We invite all conscientious companies, industries and individuals to join with us in continuing to shape it for the good of everyone.

Dr Eva Savelsberg is Senior Vice President of INFORM’s Terminal & Distribution Center Logistics Division. She specialises in optimisation Software that renders a wide range of operational processes which are more productive, agile, and reliable. Eva is also a lecturer at the University of Aachen (RWTH), where she received her Ph.D. in Mechanical Engineering in 2002. Eva has published five books and over 40 papers on innovation in freight transportation.

Kaio Quinan is Director of Sales Americas at INFORM’s Terminal & Distribution Center Logistics. In his seasoned career he gained a lot of experience in leading positions in the field of sales management and business development. Given his extensive background, he is interested in the field of AI, data science, ML and optimisation. Due to that and to deepen his expertise he has successfully completed several basis and advanced courses on these topics at Stanford University.

INFORM specialises in AI and optimisation software to improve operational decision-making. Based in Aachen, Germany, the company has been in the optimisation business for 50+ years and serves a wide span of logistics industries including ports, maritime, and intermodal terminals. With a broad range of standalone and addon software modules, INFORM’s unique blend of algorithmicbased software expertise, rich industry experience, and big-world thinking delivers huge value for its customers.

More Info: https://infrm.co/terminal

Container terminals are pivotal in the supply chain, facilitating cargo movement between producers and consumers. The terminals' efficiency in facilitating the container movement influences the cost and timely availability of the goods. Since 1990 terminals have focused on automation to enhance its efficiency and productivity, with gate automation and yard management as a major thrust area for automation. With the technological advancements, since the 2000s, terminals focused on automated terminal resource tracking, automated yard cranes (ASC), automated horizontal transports (AGV) and automated quay cranes. As a result, around 70 terminals are partially or fully automated with varying degrees of success.

Implementing full automation in an operational terminal is highly disruptive and costly, often lacking a favourable return on investment (ROI). Therefore, fully automated terminals are more common in green field terminal sites. Partial automation presents a viable option for the existing terminals. The key to success for such an initiative will depend on the right automation strategy, appropriate technology selection and futureproofing for new technologies and operational strategies.

This paper focuses on enabling automation in the container yard of a terminal which is the central hub for all container movements and is also characterised as consisting of:

• Largest operational area vis-e-vis other sections of the terminal.

• Maximum number of container handling resources deployed

• High traffic levels due to gantry crane and horizontal transport vehicle movements. Consequently, yard automation for a brownfield requires certain innovative strategies for its success.

Adopting yard management automation, mainly due to advancements in Terminal Operating Systems (TOS), has provided most terminals with a basic level of decision-making automation in the planning phase of yard operations, namely, yard strategy, yard planning, stowage

planning, loading and unloading sequencing, etc. However, this is not sufficient as the on-ground operation may deviate from the plan and these deviations may not be updated in the yard management system, making the planning inefficient. Moreover, this approach lacks real-time dynamic decision-making capabilities.

ATLocation, a smart yard track, trace and capture system, overcomes this limitation as the following points illustrate.

When a container arrives at the yard, whether from the hinterland or foreland, it remains there until it is dispatched for onward transport. Typically, placement planning for the container upon arrival is done as part of the planning phase of yard management. However, during its

stay, the container may be subjected to further relocation due to housekeeping activities, unplanned shuffling or inspection needs. Tracking every movement of the container within the yard and maintaining accurate records is crucial for efficient container delivery operations. A reliable track, trace, and capture system should be able to:

• Capture the identity of the container being handled.

• Record the real-time location of the container

a. Represented in local terminal parlance if placed in the yard.

b. The pathway ID and transport ID, if the container is in motion (when being moved by horizontal transport)

Capture the context of the movement (pickup, placement, planned move, unplanned move, housekeeping, etc.).

Traditionally, the container movement was recorded by the operators (CHE crane operator or a tally clerk) using VMTs, but this method was prone to human error, data omission, and safety issues. Subsequently, many implementations of position

detection systems (PDS) came to the fore using GNSS or RFID technologies to automatically record the container location. These implantations required either container tagging or capturing geolocation based on (a) the proximity between the real location and the planned location or (b) based on the twist lock event trigger by tapping into crane PLC.

The PLC-based approach is reliable but not every crane supports this and is highly dependent on the manufacturing year or the make, nature of the CHE ownership, etc. The biggest flaw in this approach is that while capturing the location of a container being handled, the identity of the container is not reliably established.

ATLocation addresses these `challenges by:

• Developing a sensor fusionbased, deep learning-powered solution that is independent and compatible with all types and makes of CHEs and horizontal transport vehicles.

• Capturing container Identity using computer vision-based deep learning algorithms. Capturing the pick and place event of the container by sensing the twist lock events using a retrofit sensor, independent of crane PLC. This solution is compatible with every CHE make and type and makes use of ATAI’s innovation, to capture the twist lock events in real time.

• Capturing the precise location of the container based on the twist lock triggers with centimetre-level precision

“ATLOCATION CAN TRACE A CONTAINER IN THE YARD EVEN WHEN THE CONTAINER NUMBERS MAY BE DAMAGED/ERASED.”

using GNSS with RTK (real-time kinematic). The implementation accounts for the noisy signal environment of a typical container terminal.

Capturing the context of the move by tracking the TOS job instructions, and comparing and validating them against the actual move.

Enabling real-time decisionmaking and automatic synchronisation with the TOS to confirm or update the planned data, ensuring accurate data capture at all times.

As detailed previously, the CHE is equipped with location sensors, twist lock sensors and spreaderbased cameras to capture container location, container ID and twist lock events as well as the context of the movement. The continuous capture of accurate location data allows the system to track and locate every CHE equipment in the yard. The location data and context information enable ATLocation to provide:

Precise location of the CHE in the yard.

• The context of the operations being performed by the CHE.

• Navigation information to assist the operator in finding the optimal path to the destination.

• Interact with the TOS exchanging the above data to optimally allocate the CHE for the next operation.

Tracking and tracing horizontal transport is essential for (a) understanding the vehicle's current location to allocate jobs optimally and (b) ensuring the correct coordination between the truck and the CHE for accurate container delivery or receipt as per the plan. The ATLocation offers:

• GPS-based tracking of the horizontal transport within the yard.

• Navigational support to the transport operator for optimal route selection and navigation. A unique method for CHEs to identify horizontal transport.

ATLocation compensates for the GPS coordinate errors due to technology limitations by implementing an error compensation logic, thus providing accurate vehicle traceability within the yard.

ATLocation enables the advanced optimisation features of the TOS, such as Navis PrimeRoute or RBS SmartTrack, by providing real-time telematics for CHEs, trucks and containers with configurable data acquisition frequency without compromising other ATLocation functionality.

ATLocation captures all required and relevant data in real time without user intervention. This essentially allows the capture of real-time data digitally along with contextual data at configurable data acquisition frequency, enabling its further future use as and when new technology enables advanced services like Digital Twins, terminal simulators, predictive analytics, etc.

ATLocation as an independent solution provides a complete track, trace and capture of the yard operations and enables realtime decision-making support. Additionally, it is also capable of interacting with other terminal

automation modules like gate, rail, quayside automation and providing a holistic view of the terminal operations and enabling decisionmaking at the overall terminal level. Additionally, the ability to track the container beyond the terminal yard, allows ATLocation to trace a container in the yard even when the container numbers may be damaged/erased.

With ATLocation a terminal yard can automate the tracking and capture of all the terminal resources and operations enabling real-time operational decisionmaking; 100 per cent accurate location tracking and tracing enables the terminal to easily integrate with advanced yard planning and optimisation tools including digital twins.

A crane-agnostic system has now enabled the larger terminal community to adopt automation in the terminal yard.

ABOUT THE AUTHOR:

Kishor Arumilli, Vice President of Engineering at ATAI, has over 28 years of experience spanning from platform design to full solution development. At ATAI, he oversees product development from concept to production. With global experience in the IT industry working in various industry domains, he is a key member of ATAI's senior management. His research focuses on Smart IoT, Edge computing, Applied AI, distributed data & Compute, and Enterprise Servers & Storage.

ABOUT THE COMPANY:

ATAI is an applied AI company driving digital transformation in the maritime, logistics, and supply chain industries. Focused on improvements in productivity, sustainability, and cost efficiency, ATAI offers end-to-end problemsolving solutions powered by AI algorithms and cutting-edge technologies.

Head to atai.ai to learn more. www.atai.ai

Marcel Lindemann, Co-Founder, passify

The global logistics industry is at a pivotal moment. Increasing supply chain complexity and a driver shortage of 2 million by 2026 requires streamlined handling processes and optimised utilisation. With increasing pressure to optimise operations and enhance efficiency, innovative solutions that leverage digitalisation are crucial.

One such transformative innovation is passify, a software already in use at three of Hamburg's largest container terminals. Launched in 2024, it is designed to streamline terminal access and truck handling, replacing traditional physical trucker cards with a fully digital system.

The rollout at HHLA's container terminals—Tollerort, Altenwerder, and Burchardkai—has already demonstrated the platform's ability to deliver rapid benefits. Within months of the initial tests, the app has transitioned to full-scale use, proving its efficiency and effectiveness. In logistics, where time is critical, the short time to value stands out. Unlike comparable large-scale technological solutions that can take years to fully integrate, passify has quickly shown measurable improvements in terminal security and in enabling process automation.

The mobile app is designed to fully replace existing solutions such as RFID plastic trucker cards that truck drivers have historically used to gain access to HHLA container terminals. The manual nature of the old system caused inefficiencies, security risks, and ongoing hardware costs. By transitioning to a digital platform, passify eliminates these bottlenecks and enhances security significantly.

The implementation takes place without additional hardware and does not require time-consuming IT integration projects. High-level digital authentication ensures that only authorised drivers gain access, adhering to established standards from the International Ship and Port Facility Security (ISPS) Code.

Data security and compliance are fundamental, ensuring a smooth transition from the older, more vulnerable card system.

Truck drivers can now authenticate via the app, gaining instant access to terminals and significantly reducing waiting times. The app also provides drivers with real-time updates on their processing status, helping them plan more effectively.

SUPPORTING CHANGE: FOCUS ON DRIVER EMPOWERMENT AND CHANGE MANAGEMENT

While passify’s technological advantages are clear, its success also stems from its focus on the human element, specifically truck

“BY TRANSITIONING TO A DIGITAL PLATFORM, PASSIFY

“WHILE PASSIFY’S TECHNOLOGICAL ADVANTAGES ARE CLEAR, ITS SUCCESS ALSO STEMS FROM ITS FOCUS ON THE HUMAN ELEMENT, SPECIFICALLY TRUCK DRIVERS.”

drivers. Since changes always bring uncertainty, some companies may struggle with the adoption of new technologies due to resistance from end users who may be hesitant to change. Passify’s development and deployment have prioritised easing this transition with the users—in this case mainly the drivers—with a strong emphasis on their empowerment.

From the outset, the team ensured that the product was designed with truck drivers in mind. The intuitive user interface allows even those unfamiliar with digital platforms to easily navigate the system. During the initial implementation, several trucking companies tested the app and provided feedback, which was integrated into the final version to ensure it met drivers’ needs.

Additionally, the team worked closely with logistics companies and drivers during the rollout, providing detailed training and support. This approach highlights the importance of change management in the adoption of new technologies. By supporting drivers through the transition, passify has managed to avoid the common pitfalls of resistance to change, ensuring smoother and faster adoption across the board.

Marcel Lindemann, Co-Founder of passify, emphasised this in a statement: “The introduction of passify at the HHLA container terminals in Hamburg has been highly successful. Our collaborative work with the HHLA team, drivers, and trucking companies allowed us to move quickly in rolling out the app. We’re confident that by using our product, truck handling at HHLA and other terminals will become more secure and efficient.”

PASSIFY AS A BRIDGE-BUILDER: CONNECTING TERMINALS, DRIVERS, AND INNOVATION

Nowadays, truckers are often lining up at terminals and logistics hubs, struggling to keep their booked slots. They register manually at the terminal and have no on-site support during check-in. On the other hand, terminal truck handling has the problem of higher security requirements and loads often arrive late or do not arrive at all.

The communication barrier with international drivers also remains a challenge. This results in time delays and less flexibility as well as inefficient yard management and security gaps at terminals.

Passify positions itself as more than just an app; it is a bridge between terminals, drivers, and the digital future of logistics. By connecting stakeholders in the supply chain, it fosters collaboration between traditionally siloed operations.

For drivers, it simplifies every step of the terminal handling process. From authentication and verification at the gate to receiving updates on

cargo status, drivers have all the information they need in one place. With the digitalisation of manual processes, they can complete their handling without leaving the truck. The app also reduces the paperwork that drivers need to manage, further streamlining their experience. By focusing on both terminal efficiency and driver convenience, passify creates a holistic solution that benefits all parties involved in the logistics chain.

For terminal operators, the web application and its API offer full integration into their gate processes and overall software architecture. The app not only manages driver access and slot booking but also provides data insights that help optimise operations. Terminal operators can track the flow of trucks in real time, helping to avoid bottlenecks and ensure smoother processing. In addition, secure communication is ensured with an Admin-Driver-Chat.

Looking ahead, passify will integrate even further with other systems used in logistics and supply chain management. The modular functionality is tailored to individual customer requirements, making passify simultaneously agile and versatile. The app will be synchronised with other modes of transport, such as rail and sea freight, enabling better coordination across the entire logistics network. This will allow for more efficient data sharing and operational coordination, further optimising the supply chain.

Passify’s initial success in Hamburg is just the beginning. This year, the team has already grown from two Co-Founders to 13 logistics enthusiasts with a wide range of technical and industry experience. At four terminals, more than 150,000 trucks have already been handled error-free. Passify already laid out plans for further expansion, starting with a terminal in Romania. This will mark the app’s first step outside of Germany, setting the stage for a broader European rollout. By expanding to other major logistics hubs in Europe, passify aims to standardise terminal access and handling across the region, creating a more cohesive and efficient logistics network.

This expansion will be driven by partnerships with logistics companies and terminal operators ensuring that passify can address the unique needs of each market. By working closely with local stakeholders, the company can replicate its success in Hamburg while tailoring its solution to fit the specific requirements of each region. In the coming years, even more innovative features are expected to be added to passify. With plans for deeper integration with other logistics systems and expanded functionality for drivers, the app will continue to evolve, offering even greater value across the logistics chain.

ABOUT THE AUTHOR:

Marcel Lindemann, Co-Founder of passify, brings over 10 years of experience in transport and terminal logistics. Together with Nico Marks, he founded passify to tackle industry challenges like long wait times and manual processes by introducing innovative tech solutions. He previously worked for container depot operator HCCR and Hamburger Hafen und Logistik AG (HHLA).

ABOUT THE COMPANY:

Passify is a Hamburg-based logistics start-up which digitises and automates truck handling through a self-service app that enables drivers to book slots, check-in digitally and identify themselves securely via two-factor authentication. Through these functions, passify improves both security and efficiency in truck handling, contributing to more sustainable and cost-effective logistics processes.

For more details about passify and its ongoing development, visit the official website www.passifyapp.de.

Jean-Philippe Joassin, Director of Process Automation, Kalmar, and Angelica Nieto Lee, Product Manager Automation Solutions, Kalmar

Kalmar has recently unveiled its SmartRead technology, an Optical Character Recognition (OCR) system for container handling equipment that integrates with the Kalmar SmartPort solution to provide automatic, positive identification of containers from their external markings. Kalmar SmartRead helps reduce human errors in container handling processes at ports and terminals by minimising the number of exception cases and incorrect container transactions.

The Kalmar SmartRead solution utilises cameras on the spreader of the machine to read the ID number of the container being handled. This information is relayed to the Terminal Operating System (TOS) automatically, eliminating errors from incorrect or missing container identifications as well as productivity losses from time-consuming manual data input. Safety is thus enhanced as employees no longer need to be sent out into the yard to identify or locate misplaced containers, and fewer exceptions correlate directly to higher performance for the terminal.

"As terminal operators know, container handling exceptions are still a significant cause of lost productivity and operational bottlenecks," says Jean-Philippe Joassin, Director, Process Automation at Kalmar. "Misidentified containers are one of the key

reasons for exception cases, so Kalmar SmartRead was designed to allow operators to increase their productivity and streamline container movement, rather than spending time and resources on handling exception cases that happened during operation."

“KALMAR SMARTREAD REPRESENTS A COMPLETELY NEW LEVEL OF

Kalmar SmartRead was realised in partnership with Visy, a Finlandbased global leader in gate automation and OCR solutions. The solution is designed for challenging weather and operational conditions and incorporates cameras and cabinets engineered for rugged high G-force environments with IP67-rated ingress protection.

The Kalmar SmartRead solution is fully pre-integrated with the Kalmar SmartPort set of process automation modules. When combined with Kalmar's SmartStack, a solution for automated container tracking and position reporting, it enables highly accurate real-time tracing of every container in the terminal.

"We have done a lot of work over the years to help our customers

reduce the number of exceptions in their operations through the development of the Kalmar SmartPort solution," adds Angelica Nieto Lee, Product Manager Automation Solutions at Kalmar.

"Kalmar SmartRead represents a completely new level of accuracy. OCR has been utilised in gate and STS crane operations at ports for many years, but now the technology has reached sufficient maturity to be used on container spreaders in the challenging operating conditions for reachstackers."

For terminals already running Kalmar SmartPort, no changes to the TOS are required when deploying Kalmar SmartRead. The OCR solution can also be added to a wide range of TOS through Kalmar's easy-to-use application interfaces.

"The idea for the solution came from discussions with many of our customers, as we found they were looking for a way to further reduce exception cases," adds Joassin. "To address this need, we developed a solution that easily interfaces with Kalmar SmartPort without any additional software development or systems integration. Kalmar SmartRead complements our existing SmartPort offering, making it an even more comprehensive process automation solution than before."

Kalmar SmartRead can be installed on Kalmar toploaders and reachstackers as well as RTG and RMG cranes. The first impressions from early adopters have been overwhelmingly positive.

"Our pilot customers absolutely loved it," concludes Joassin. "Within a couple of months of testing,

they decided to purchase the technology to outfit all of their remaining fleet, as they realised the value the new solution is bringing in combination with the rest of the SmartPort offering."

Jean-Philippe Joassin is the Director of Process Automation at Kalmar, where he has passionately contributed to technological advancements for over a decade. With a background in automation and RFID, he leads a dedicated team in optimising automation processes. Prior to Kalmar, Jean-Philippe worked for Zebra Technologies mostly in Automotive manufacturing RFID solutions. Jean-Philippe holds a Bachelor of

Science in Computer Science from Lawrence Tech University.

Angelica Nieto Lee is a dedicated Product Manager for Automation Solutions at Kalmar, where she has worked for over seven years. In her role, she oversees the development and implementation of cutting-edge automation technologies, driving innovation within the logistics and cargo-handling industries. Angelica is studying for a PhD in Product Engineering and holds a Master’s degree in Machine Automation and a Bachelor's degree in Mechatronics, equipping her with deep technical expertise that informs her leadership in designing and improving automated solutions.

Kalmar (Nasdaq Helsinki: KALMAR) is moving goods in critical supply chains around the world, with a vision to be the forerunner in sustainable material handling equipment and services. The company offers a wide range of industry-shaping heavy material handling equipment and services to ports and terminals, distribution centres, manufacturing and heavy logistics.

Headquartered in Helsinki, Finland, Kalmar operates globally in over 120 countries and employs approximately 5,200 people. In 2023, the company's sales totalled approximately EUR 2 billion ($2.1 billion).

www.kalmarglobal.com

OF

Dr Oscar Pernia, Co-Founder & Head of Technology and Innovation, Nextport, Dr George Saad, Technical Director – Ports, Moffatt & Nichol, Miguel Angel Llorente, Technical Product Manager, NextPort, and Dr Ayçin Aykutalp, Software Engineer, NextPort

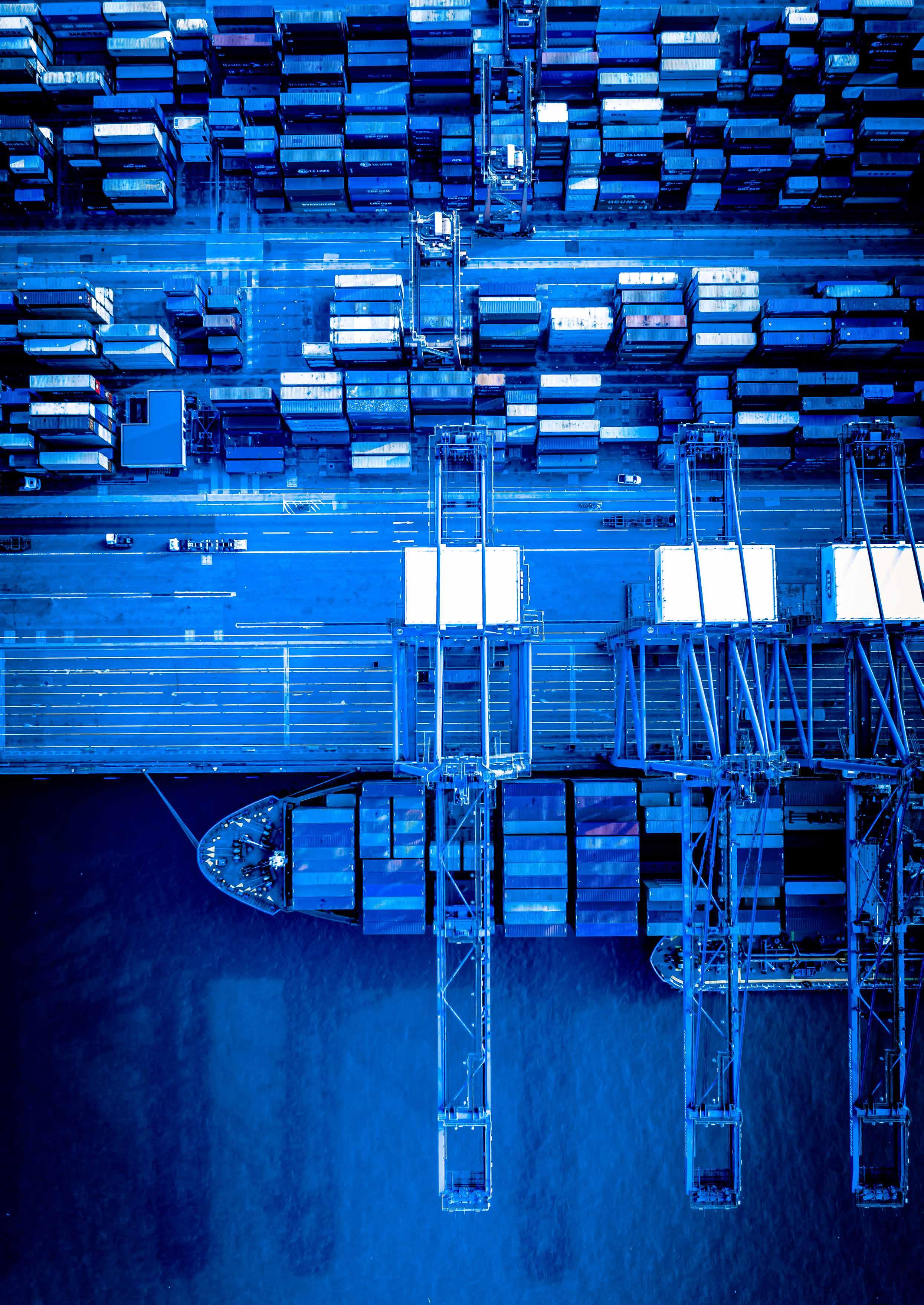

Harnessing the power of digitalisation within the maritime sector can streamline the exchange of data between shipping lines, port services, terminal operators and other stakeholders, resulting in significantly improved operations. It can also provide a vital link between infrastructure asset management and real-time operations. But to undergo this digital transformation effectively, a deep understanding of port and terminal operations is essential to capitalise on opportunities and tackle the challenges.

These opportunities lie in enhancing decision-making, leading to more efficient operations and troubleshooting, and improved resource allocation and asset management. The challenge is to bring together the many different factors influencing port operations’ efficiency, including sustainability, resilience, intermodality, and connectivity.

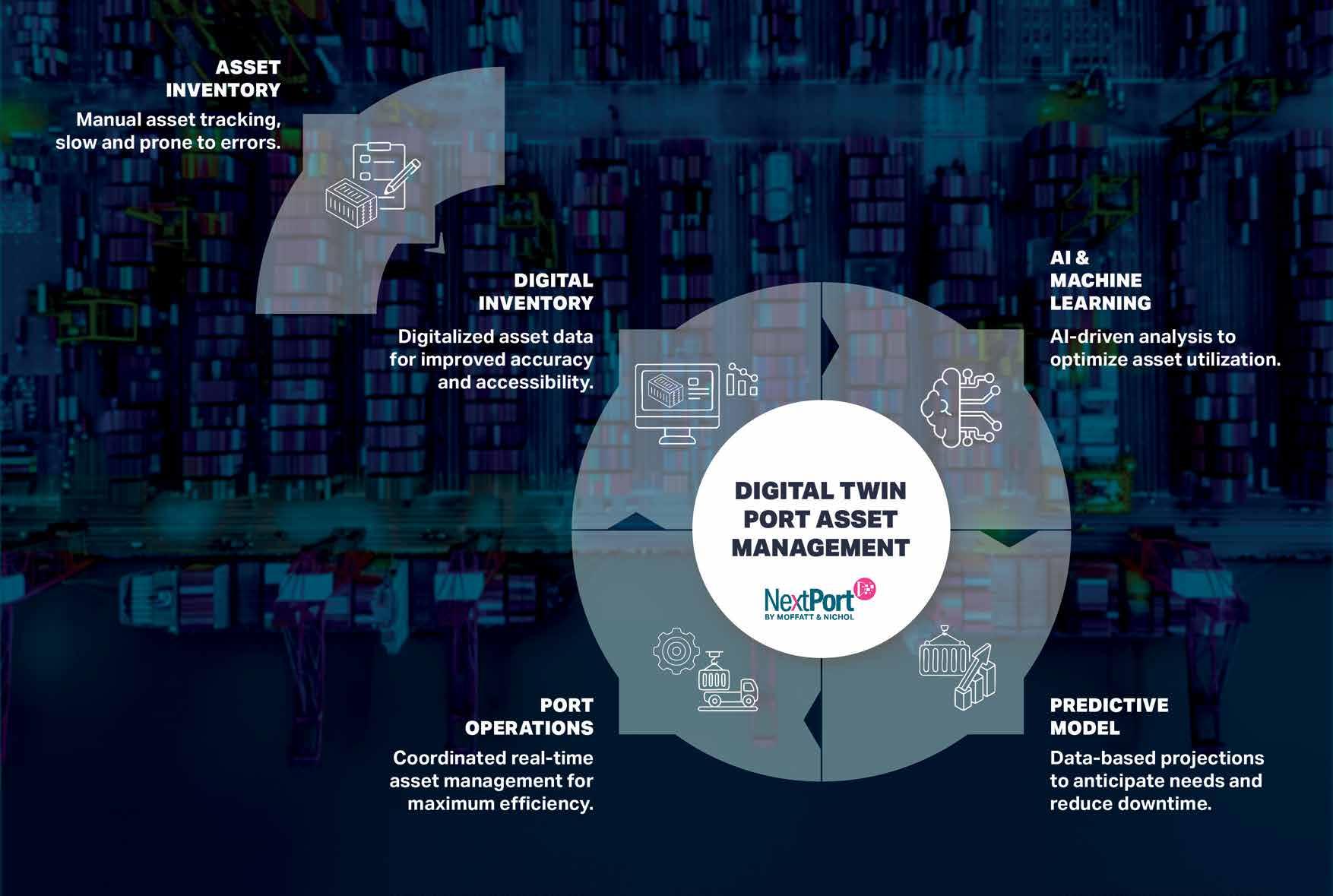

Ports are embracing the introduction of Digital Twins and artificial intelligence (AI) technologies to modernise their operations monitoring and asset management practice. As data starts being recorded, the next frontier is to apply those technologies that enable smart port design, planning

and maintenance. Together, data and digital applications will support targeted infrastructure investments which are aligned with a data evidence-based assessment of growth and with the port’s adaptation to the complex and changing industry dynamics.

TRANSFORMING AND INTEGRATING OPERATIONS AND INFRASTRUCTURE

Ports are complex ecosystems, with many stakeholders interacting across different activity domains in the supply chain, from marine or auxiliary services to logistics,

road and rail transport, or customs. Moreover, data is siloed and fragmented across multiple decision domains, and thus little value is being extracted from it. As a result, decision-making—both operational and strategic—within these different domains lacks the support of quality and timely data, and in many cases becomes a reactive process.

The risk comes when the physical and operational processes are not properly connected and integrated during the design phase. When this happens, later down the line we not only see variability in implementation but deviation from

the expected performance and tolerances.

Ports are beginning to realise the importance of digitalisation and leverage its potential to transform their way of working by connecting operations and infrastructure management more seamlessly. When assets are digitally monitored through sensors, we can predict when

repairs or maintenance will be needed. This enables port and terminal operators to model the impact that a particular asset’s unavailability can have on their operations, enabling them to build better troubleshooting and maintenance. It also reduces repair costs by shifting the focus to preventive rather than reactive maintenance.

As Moffatt & Nichol is well established with simulation and emulation, the Digital Twin was a natural next step in its technology strategy. Combining an extensive toolset with industry expertise to assist ports with truly data-driven decision-making throughout

an asset's lifecycle (design –implementation – operation – maintenance – optimisation), NextPort as its technology spin-off combines data on infrastructure and data science applications to leverage the potential of AI and machine learning (ML).

NextPort delivers a Digital Twin that integrates operational performance with information about physical infrastructure, enabling a continuous improvement function for asset performance. The solution provides port authorities and terminal operators with augmented monitoring and analytics features to optimise and troubleshoot operations, combining data from the different systems. Furthermore, the integration of data across operational and infrastructure domains extends the potential of technologies like Digital Twins and AI and establishes the foundation

to ensure ports are prepared for future applications and innovations at the asset management level. Digital port asset management (AM) encompasses docks, piles, terminal infrastructure, storage facilities, and cargo-handling machinery. At Moffatt & Nichol, we leverage our domain expertise in asset conditions to develop predictive models. In Figure 2, we provide a step-by-step workflow of how the digital AM system is connected to the port operations.

First, historical AM data is digitalised and cleaned up to be AI/ML-ready. Then, depending on the asset, different AI/ML predictive models are developed. AI and ML-driven models are integrated to ensure that all aspects of port operations are optimised and well-informed, resulting in improved outcomes and greater reliability.

Moffatt & Nichol has been investing in NextPort to develop innovative solutions that respond to ports’ and terminals' challenges to optimise operations and their supporting infrastructure and assets. Alongside its own simulation and emulations tool FlexTerm, these solutions generate a robust asset management framework, with tools that ensure seamless understanding between port operations and the underlying infrastructure and assets. The below table describes some port engineering competencies that will be inevitably transformed by technology and digitalisation in the short term.

In summary, leveraging Digital Twin technology with AI can transform port design, planning and maintenance by enabling data-driven decision-making. It can generate a foundation that promotes improved analysis and understanding of infrastructure,

Road maintenance represents a significant portion of asset management costs at ports, making it crucial to accurately predict future conditions and inform data-driven maintenance strategies. By analysing historical maintenance records, traffic (load intensity, movement frequency), and environmental conditions (weather, temperature) ports can develop robust AI/ML road deterioration models. These models provide early warnings (smoking guns) about deteriorating sections of pavement before the damage occurs. With accurate predictions of deterioration, AI/ML models enable the planning of cost-effective maintenance strategies, reducing overall maintenance costs.

Oceanography data involves understanding ocean currents, temperature, salinity, marine life, and seabed composition: data provides context such as sediment types, water column properties, and biological habitats. The integration of this data and the application of AI helps predict the best times for ship movements, considering the combined effects of tides, weather, and sea state on navigational safety and efficiency. The new regulations by IMO will enforce the digitalisation of this data to become an integral part of decisionmaking, generating the foundation for vessel systems like ECDIS and the ship-to-port interface to become a reality. Furthermore, climate change introduces challenges not only for navigation but for port authorities to truly digitise their dredging plans and associated surveys serving those.

At port facilities, effective management of cargo handling equipment such as quay or yard cranes relies on leveraging a combination of historical data, operational metrics, and real-time insights from sensors monitoring vibration, temperature, pressure, and electrical consumption. Combining all those sources of information into the Digital Twin helps not only optimise equipment assignment but also effective maintenance practices. By feeding this data into advanced AI/ML models, ports can gain valuable insights into equipment health and performance trends. This proactive analysis allows for the early identification of potential issues, enabling maintenance to be scheduled in a timely manner, and avoiding disruptions in overall port operations.

assets, and their behaviour and deterioration to optimise asset management and optimisation when the port is operational. This integration supports a more predictive, adaptive and responsive approach to managing port operations in a complex and dynamic environment, and ultimately optimises the overall performance and resilience of the port infrastructure and assets.

Dr Oscar Pernia holds an Industrial Engineering PhD, where he focused on Algorithms Design and Simulation applied to Marine Operations Optimisation. He has more than 20 years of international experience in Container Shipping, covering technology solutions and associated integrations across all processes in the ocean supply chain, with a specific focus on Ports & Terminals.

Dr George Saad is a Civil and Structural Engineer with extensive expertise in ports and terminals planning, design, operations, and simulations in a number of

countries. He works with clients globally to use tools such as data mining, data analytics and AI to efficiently solve complex engineering problems.

Miguel Llorente is a Technical Product Manager with over 14 years of experience in software engineering, product management, and leadership roles. He currently leads Data Platform development at Nextport. ai by Moffatt & Nichol, defining platform functions and focusing on areas like cybersecurity, data management, and AI innovation.

Dr Ayçin Aykutalp is an astrophysicist with a strong background in software development, Big Data and ML. She has over 15 years of experience in conducting cutting-edge research. At M&N, she is leading the development of AI/ML models for digital asset management systems.

Moffatt & Nichol (M&N) is a global infrastructure advisory firm with more than 1,000 employees based

in offices around the world. They provide practical solutions to clients in the ports, transportation, and water markets. M&N is a multidisciplinary professional services firm with specialised expertise in structural, coastal, and civil engineering, as well as environmental sciences, economics analysis, inspection and rehabilitation, and programme management solutions.

NextPort® is a European trademark registered by M&N, a firm with 75 years of experience in port engineering, port planning, simulation, TOS emulation and operations improvement. With the investment and launch of NextPort® as a Technology & Innovation brand, M&N seeks to spin off and accelerate the development of SmartPort solutions, leveraging the potential of technologies like cloud computing, Digital Twin or AI, as well as the productisation and strengthening its capabilities for digital transformation and automation at ports and terminals.

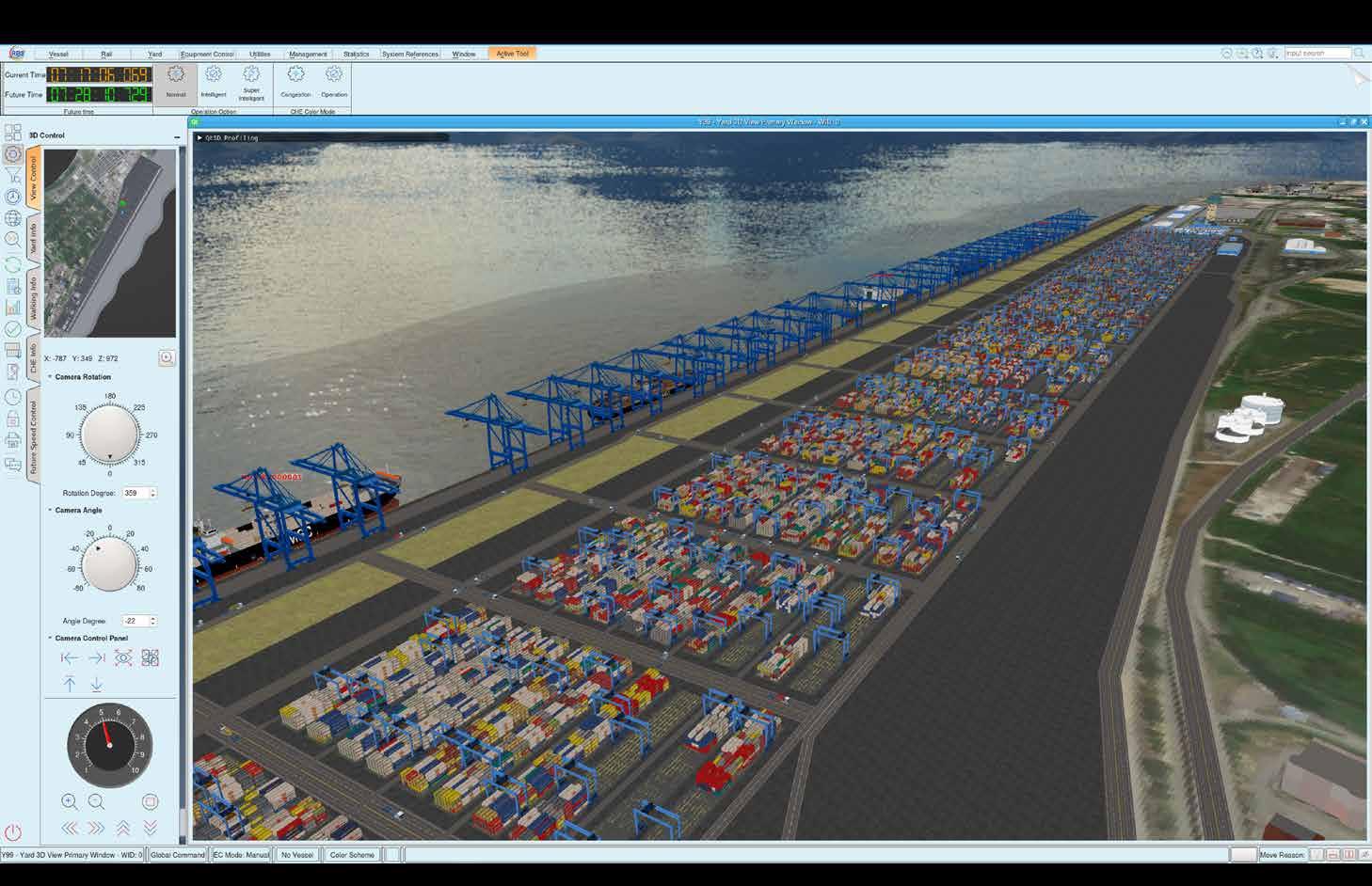

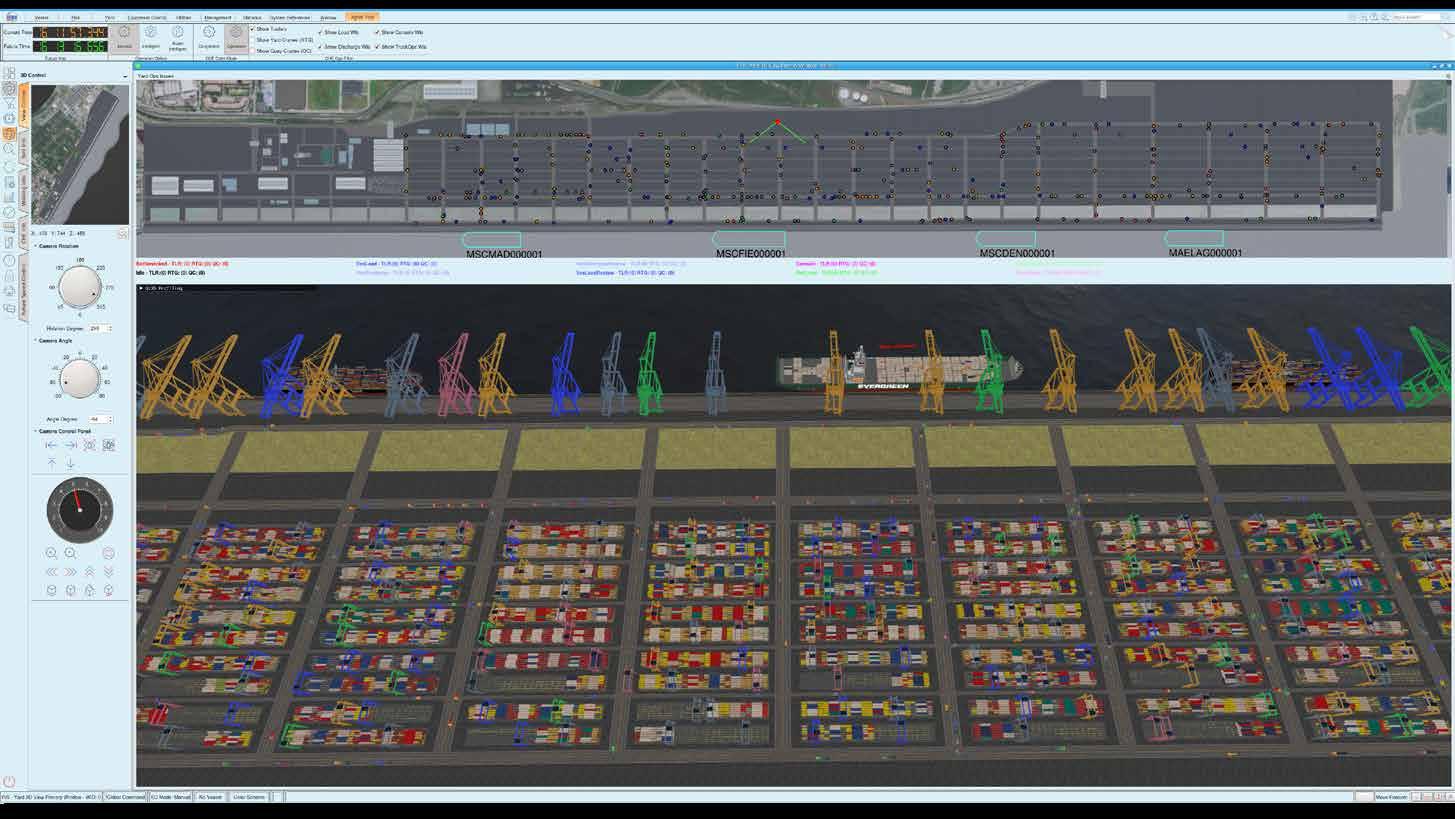

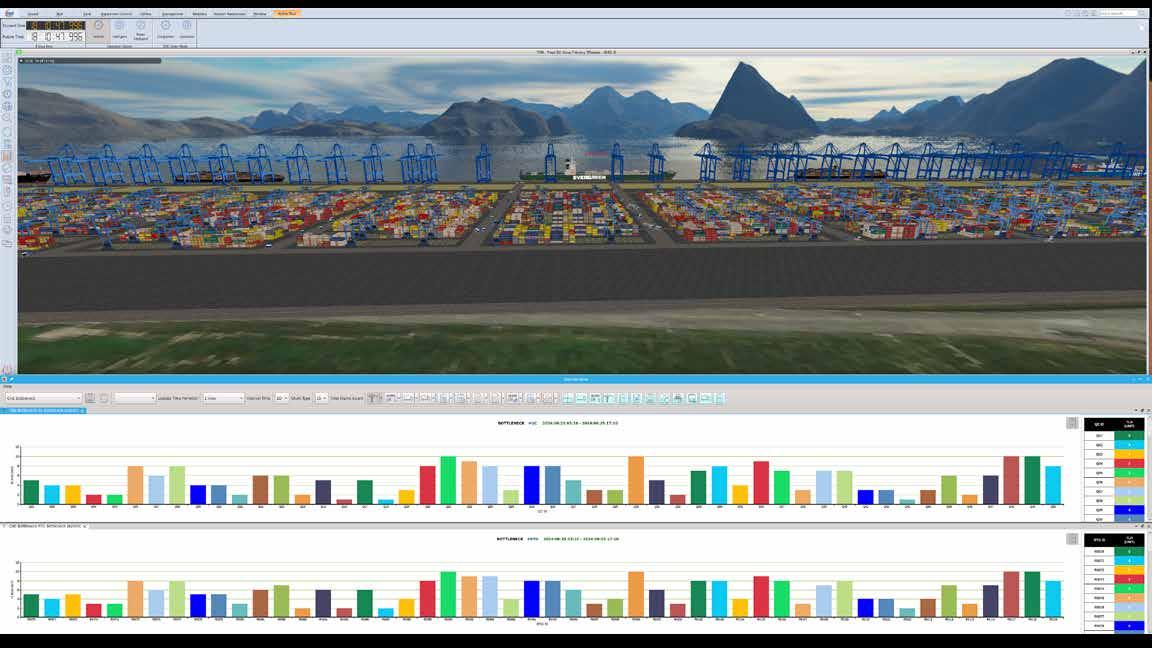

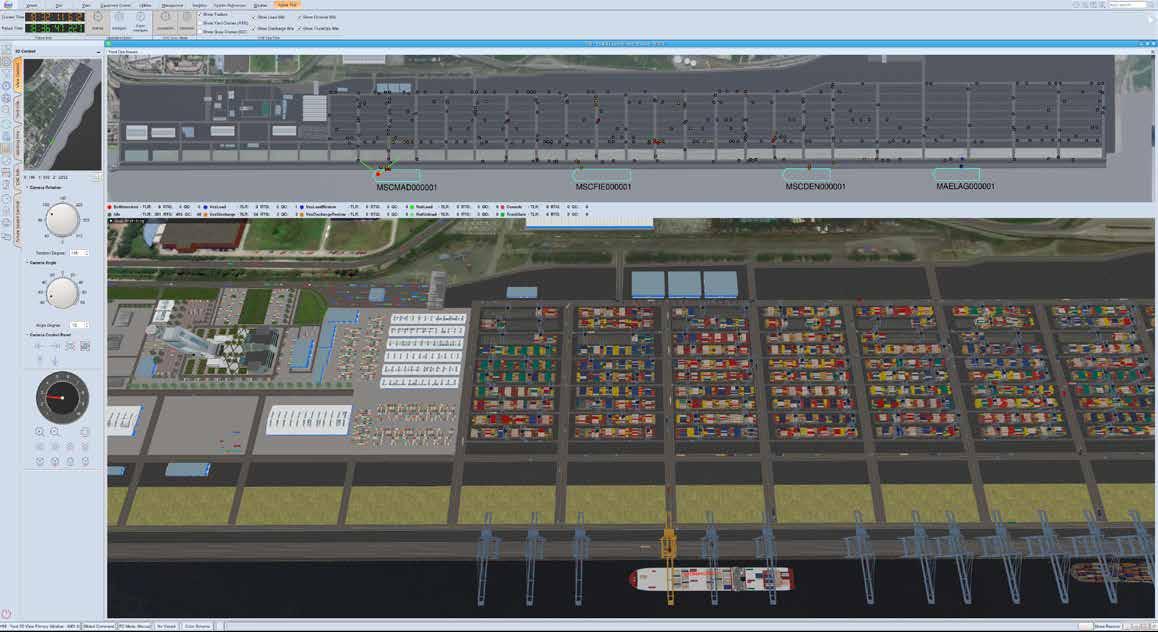

Nguyen, Business Development Manager, Realtime Business Solutions

Now more than ever, the future of terminal management systems is focused on advancements in technology, especially regarding the topics of Digital Twin, AI, and automation. The rise of Digital Twin technology marks a significant evolution in terminal operation, driven by the need for improved performance, efficiency and safety. By creating a virtual 3D replica of a terminal, Digital Twins provide comprehensive visibility into the terminal environment, encompassing equipment, container inventory, and more. However, the true potential of a Digital Twin is only realised when it is integrated with a super-intelligent engine that provides real operational benefits to enhance terminal operations. This is also used to facilitate the effective use of automation and more advanced equipment.

The following outlines the key benefits of such an integration, providing insights into its implications for future terminal management.

The implementation of a Digital Twin provides a real-time, 3D representation of terminal operations, allowing stakeholders to oversee resources and activities

“THE

effectively. A traditional Terminal Operating System (TOS) may lack the comprehensive visualisation capabilities needed for optimal decision-making. In addition, a Digital Twin, combined with an intelligent engine, facilitates not only real-time monitoring but also predictive capabilities to preemptively address potential issues. The ability to visualise both current operations and future scenarios empowers terminal operators to optimise planning and decision-making processes. Accessibility throughout the terminal enhances the monitoring and control of operations, ensuring timely interventions when necessary.

TECHNOLOGY

Ultimately, this becomes a necessary feature as terminals continue to grow in size and complexity.

A super-intelligent Digital Twin's ability to analyse and forecast resource allocation proves invaluable in lowering operational costs. By calculating optimal berthing times, minimising equipment downtime, and choosing better slots for containers, terminals can maximise resource utilisation like never before. Furthermore, incorporating real coordinate data for container handling equipment (CHE) and

containers enables precise movement calculations, reducing fuel consumption and time spent. The integration of AI enhances this process, allowing for the anticipation and resolution of potential issues before they escalate, ultimately resulting in substantial cost savings. The combination of Digital Twin technology, AI, and automation presents an opportunity for terminals to streamline operations and reduce financial burdens.

The continuous forecasting capabilities of a Digital Twin significantly mitigate risks and enhance performance metrics. By offering a complete 3D view of the terminal, Digital Twins enable proactive identification of safetycritical events, thereby reducing the likelihood of accidents. Moreover, predictive analytics allow terminals to anticipate and resolve bottlenecks, improving overall efficiency.

Integration with a TOS facilitates optimal management of CHE, minimising unladen movements and effectively distributing traffic to prevent congestion. This predictive capability extends to vessel operations, where accurate ETA/ ETD predictions lead to increased terminal efficiency. Therefore, the combination of a Digital Twin and a super-intelligent engine fundamentally transforms risk management and operational efficiency in terminal environments.

The comprehensive visualisation offered by Digital Twin technology empowers decision-makers with critical insights into terminal activities. Predictive maintenance, driven by real-time data analytics, enables the identification of potential risks and resource use, thus enhancing both operational and financial decision-making.

By leveraging advanced analytics, stakeholders can make timely, informed decisions that drive business performance improvements.

The predictive and preventative capabilities of a super-intelligent Digital Twin further support the decision-making process, allowing for data visualisation through charts and dashboards that highlight terminal performance and areas for improvement.

Effective utilisation of a Digital Twin fosters enhanced collaboration among terminal personnel. The shared 3D visualisation facilitates transparency and integration among team members, optimising workflow and operational efficiency. Displaying the Digital Twin on a large screen within the terminal encourages real-time interaction and collaboration, allowing team members to monitor operations collectively. This heightened level of collaboration not only enhances productivity but also leaves a positive impression on visiting customers, showcasing the terminal's commitment to innovation and efficiency.

The integration of new and advanced technology within terminal management is poised to revolutionise the industry. By pairing Digital Twins with advanced super-intelligent systems, terminals can achieve significant competitive advantages through risk reduction, cost savings, enhanced visualisation, improved decision-making, and better team collaboration.

As the container handling industry continues to evolve, the investment in a super-intelligent Digital Twin will undoubtedly yield extensive benefits, positioning terminals for future success.

ABOUT THE AUTHOR:

Harrison Nguyen is Business Development Manager at Realtime Business Solutions (RBS) and is passionate about how software can revolutionise industries. He graduated from the University of New South Wales with a Bachelor of commerce and computer science with distinctions. With his fresh ideas and burning ambition, Nguyen is dedicated to helping terminals find the best solutions to optimise their operations.

ABOUT THE COMPANY:

Realtime Business Solutions (RBS) specialises in developing state-of-the-art TOS solutions and has worked exclusively in the Container Handling Industry for over 30 years. Over this period, RBS has carried out the installation of the RBS TOPS software to many Container Handling operations around the globe. RBS’ most recent products include TOPS Expert and TOPX Intelligent 3D, which is a super-intelligent Digital Twin. For more information, please visit www.rbs-tops.com.

“THE CONTINUOUS FORECASTING CAPABILITIES OF A DIGITAL TWIN SIGNIFICANTLY MITIGATE RISKS AND ENHANCE PERFORMANCE METRICS.”

Transform your terminal operations with our super intelligent digital twin technology, designed for both manual and automated terminals. This innovative solution offers significant cost savings and optimizes nearly every operational aspect, handling terminals of any size up to 10 million TEUs and beyond. Ideal for integration with our state-of-the-art RBS Terminal Operating System (TOS) or any existing TOS, our digital twin ensures seamless and efficient management of your terminal. www.rbs-tops.com

Airam Rodríguez, CEO, Híades Business Patterns, Isaac González de Vega, Consultor, Híades Business Patterns, and Gerardo Alvarez Perez, Head of Maritime Operations, Valencia Port Authority

The increasing complexity of operations in port environments demands advanced monitoring and control tools that enhance safety and efficiency.

Situational awareness is essential to become a smart port, enabling real-time management of multiple operational and business variables, minimising risks, and facilitating interoperability with third-party information to comprehensively address the needs of maritime and port authorities.

This article explores how platforms such as AMURA ControlBoard developed by Híades Business Pattern enable integrated and standardised management of the port environment, facilitating the anticipation of routine situations and effective responses to unexpected events, thus paving the way for next-generation ports.

Situational awareness refers to the ability to perceive, understand, and anticipate the state of a complex operating environment.

In ports, this capability is essential due to the constant interplay between physical (weather, sea state), dynamic (vessel movement), and logistical (availability of berths and anchorages).

Situational awareness in the port environment implies constant monitoring to make quick and accurate decisions on docking, anchoring, and undocking manoeuvres as well as responding to emergencies, such as pollution incidents or collisions.

To become a smart or nextgeneration port, it is essential to achieve an effective level of situational awareness. Operators require access to a platform that compiles real-time information on these factors. Real-time visual and positioning data enable operators to quickly analyse situations, identify risks, and take preventive or corrective actions. The application of artificial intelligence

in the collection and analysis of this data enhances the system's predictive capabilities, which is crucial in a port environment.

The AMURA ControlBoard is an advanced tool designed for the integrated management of port operations, enabling operators to have a comprehensive, real-time view of the environment. The platform collects data from sensors, radars, and geospatial information systems, consolidating them into an intuitive interface that facilitates the monitoring and control of every aspect of the operation.

“ONE OF AMURA’S ADVANTAGES IS ITS ABILITY TO VISUALISE SCENARIOS IN REAL TIME AND ALERT OPERATORS OF POTENTIAL RISKS, SUCH AS SUDDEN WEATHER CHANGES OR TRAFFIC INTERFERENCES.”

The tool provides a visual interface that aids in the detection of anomalies and the monitoring of routine operational situations, such as anchorage zones and loading/ unloading manoeuvres.

One of AMURA’s advantages is its ability to visualise scenarios in real time and alert operators of potential risks, such as sudden weather changes or traffic interferences. Through graphical representations, operators can view areas where ship movements or environmental changes are occurring, enhancing decisionmaking effectiveness.

The tool further enables realtime collaboration among various port stakeholders, such as harbour masters, pilots, and terminal operators. Its interface allows all involved parties to access the same up-to-date, standardised information, minimising communication errors and promoting a more coordinated and efficient response.

These systems must be supported by scalable, nextgeneration architectures that can efficiently manage large volumes of data—both real-time data with non-transactional databases and historical data for statistical and predictive purposes using transactional databases. Each layer included in our situational awareness management system provides new information and insights that enrich every data point entering the platform.

These standards are fundamental for creating uniform spatial data models that improve the precision and consistency of information within systems like these. They facilitate the integration of data from multiple sources, including bathymetric maps, meteorological data, traffic information, and oceanographic prediction models.

Another essential concept in this environment is interoperability with other systems. The architecture must not only be scalable but also open, making data sharing essential and enabling the exchange of data following international standards that support this function.

At AMURA, the adoption of these standards allows operators to visualise information with a high degree of precision and detail. The platform can display detailed and real-time maps of port bathymetry, identify recommended traffic routes, and show wind and wave conditions in each area.

By operating within a standardised framework like S-100, AMURA ensures that all geospatial data is compatible and reliable, facilitating its integration with other port information systems and enabling effective interoperability between platforms.

S-100 also enables AMURA to implement predictive models that

project the future behaviour of factors such as tides and vessel movement. This is particularly useful for traffic and anchorage planning, ensuring that port operation areas remain free of interference and minimising the risk of collisions or accidents.

AMURA’s visual representations of common situations offer a significant advantage in the training and preparation of port operators. Through the analysis of frequent operational patterns, such as docking manoeuvres, anchorage, and navigation through narrow channels, AMURA can store

and display typical scenarios that help operators better understand the flow of operations.

Using artificial intelligence algorithms to analyse these patterns and anticipate potential irregularities is key to ensuring safety in maritime operations. For example, if unusual vessel movements or unexpected traffic changes are detected in an anchorage area—such as abnormal drift or swing radii—, the system can alert operators and recommend corrective actions, such as redirecting a vessel or adjusting the assigned anchorage space. This ability to learn from past situations and apply that knowledge in real time enhances

response effectiveness and operational safety.

Moreover, operators who familiarise themselves with these common scenarios contribute to a quicker and more efficient response in case of emergencies. With detailed images and standardised data, operators can rely on the accuracy of the information to assess risk situations and make informed decisions based on solid, verified data. Another essential use case is the planning and forecasting of atypical situations that periodically arise in ports, such as expansion and modification projects for port infrastructures, docks, dredging work, etc., which alter the normal

use of the port. This brings into play concepts like no-go zones and temporary work windows to maintain port optimisation and enhance its safety.

The principles of situational awareness and operational standards have proven to be powerful tools for modern port management. These platforms enable not only real-time monitoring of all aspects of operations but also an advanced capacity to anticipate risks and optimise safety. The system’s visualisation of common situations helps operators prepare for and respond effectively to various operational scenarios. In a port environment where safety and efficiency are paramount, these systems represent a crucial advancement. Their continuous evolution provides ports with a competitive

advantage by enhancing their response capabilities and ensuring safer, more controlled operations.

ABOUT THE AUTHORS:

Airam Rodríguez is a business leader who holds a Master's degree in Big Data. He founded Híades and developed AMURA, a smart port ecosystem that operates in 17 ports. Airam is dedicated to driving innovation and has received over 20 awards for his international efforts.

Isaac González de Vega is a business development expert with extensive experience in technology, strategy, and international market expansion. He holds degrees in Business Intelligence, Big Data, and an MBA. Currently, he holds strategic roles in Pleyone and Híades Consulting focusing on commercial strategy, project management, and team leadership across the Latin American and Spanish markets.

Gerardo Alvarez Perez is an experienced maritime operations

leader with over 20 years of experience in the sector. Currently, he serves as Head of Maritime Operations at Valencia Port Authority and previously held the role of VTS Supervisor. His expertise is backed by extensive maritime service and advanced studies in port management, logistics, and integrated management systems.

ABOUT THE COMPANY

Híades Business Pattern SL, with over 14 years of expertise, designs advanced systems to optimise port operations. Through its innovative AMURA solutions ecosystem, Híades enables real-time port management, fostering safety and innovation. Híades’ collaborative innovation model turns clients into strategic partners, ensuring tailored solutions and mutual growth.

ENQUIRIES:

info@hiades.es igonzalez@amurasolutions.com

Paul Arms, Senior West Coast Business Development Manager, Rocsys

The port industry is blazing new trails in sustainable practices, as terminals around the world seek out new ways to lower carbon emissions in ports and nearby communities. The first—and usually easiest—step towards cleaner, more efficient terminals is with new, all-electric container handling equipment, like electric yard trucks and container stackers. As more manufacturers roll out new models of electric equipment every year, terminals are supplementing or even altogether replacing their existing equipment with these new electric models.

While electric equipment is a step in the right direction, it’s critical that terminals take a holistic approach to their new fleet equipment, taking into account not only the equipment itself but how charging electric equipment will impact their day-to-day operations. In an industry where a single dead battery can create a significant bottleneck in efficiency, terminals need to consider how they’ll keep their new electric equipment charged while still meeting the high demands of a modern port terminal.

In this paper, we’ll explore the challenges of manually charging electric equipment fleets and how new innovations in handsfree charging technology might provide the solutions terminals are looking for as well as yield some unexpected benefits that they might not have considered.

At first glance, manually charging electric equipment seems like a non-issue. You just plug it in, right? But heavy-duty port equipment isn’t

“THE FIRST—AND USUALLY EASIEST—STEP TOWARDS CLEANER, MORE EFFICIENT TERMINALS IS WITH NEW, ALL-ELECTRIC CONTAINER HANDLING EQUIPMENT.”

like a Tesla parked at your home. Port equipment needs to be ready to roll at a moment’s notice, often in operation 24 hours a day, with sometimes limited opportunities to charge. Terminals need to constantly monitor the charging process of their electric equipment, ensuring that they have adequate battery life to perform the necessary tasks required to meet the demands of the industry. And that’s for every piece of electric equipment in the fleet. For terminals with sizable electric port equipment fleets, manual charging alone just isn’t a feasible option.

In recent years, new innovations in hands-free charging technology have begun to develop the solutions that terminals with large electric equipment fleets have been looking for. These emerging technologies utilise advanced computer vision, algorithmic learning, and mechanical actuators to create an effortless charging process for electric equipment. Once the equipment arrives at the charger, the charging process begins, automatically plugging

“A

CONDITIONS FOR ON-SITE PERSONNEL, REDUCING THE

the charger into the equipment. Once the charging cycle is completed or the equipment has an adequate charge to be put back into operation, the system unplugs the charger, and the equipment is ready for duty again.

But what are the benefits of hands-free charging?

By implementing hands-free solutions into your fleet charging processes, terminals gain peace of mind knowing that the risk of a dead or low battery due to an improperly pluggedin charger is minimised compared to manual charging. Equipment

operators no longer need to bother with plugging in charging equipment themselves or call a dedicated person to facilitate the charging process, leading to significant time savings and allowing terminals to refocus those resources elsewhere. In addition, equipment can charge during idle periods like when the operator is taking a break or during shift changes. This allows terminals to streamline their fleets and enables them to run more efficiently.

Safety remains one of the top priorities in the port industry. Inclement weather, low-light conditions, and high-traffic areas all pose possible safety risks to on-site personnel working in port terminals. Manual charging requires a human operator to facilitate the charging process, exposing them to these potential safety risks. A hands-free charging process improves safety conditions for on-site personnel, reducing the need for a human operator to handle heavy charging equipment in unsafe conditions, ensuring that charging cables are not damaged by being accidentally run over or due to accidental drive-offs when a charger is still plugged in while the equipment is in motion—a frequent occurrence with electric equipment in a busy industry.

As the industry pivots towards more sustainable practices to meet emissions goals and improve environmental conditions for those working in and living near port terminals, new opportunities for business begin to emerge. Industry organisations looking to decrease their carbon footprint might seek to align with modern ports that have implemented sustainable processes that lower carbon emissions, like electric equipment fleets with handsfree charging solutions. Additionally, new grant opportunities may be available for terminals investing in vehicles and infrastructure that lower their overall carbon footprint and

“MOST HANDS-FREE CHARGING SOLUTIONS INTEGRATE WITH EXISTING STANDARD CHARGERS AND REQUIRE NO COSTLY RETROFITS TO EITHER EQUIPMENT OR CHARGING INFRASTRUCTURE.”

support global sustainability goals and regulatory requirements.

Electric equipment with handsfree charging solutions can open new avenues for growth that extend beyond just day-to-day port operations.

As electric equipment adoption continues to rise in the port industry, terminal operators need to consider how expanding their fleet will impact operations. Most hands-free charging solutions integrate with existing standard chargers and require no costly retrofits to either equipment or charging infrastructure. This allows terminals to expand their fleets with new equipment without sacrificing efficiency or dedicating significant resources to new charging assets.

Future-proof port fleets are essential in the evolving logistics landscape and to ensure that your terminal can meet the changing needs of a growing industry will ensure success in the future.

With 90 per cent of all commercial goods transported via ship, ports make up a crucial lynchpin in the global supply chain. As the industry continues to prioritise sustainability, it’s important that terminals adapt accordingly to meet the needs of an evercharging ecosystem.

Adopting electric container handling equipment is the first step for many ports looking to reduce carbon emissions, but as electrification continues to play a greater role in fleet management, ensuring that fleet equipment is adequately charged and able to meet the high demands of the modern port industry is essential for successful port operations. Hands-free charging technology can help terminals by improving efficiency, increasing safety, and planning for future fleet expansions, all without a significant impact on day-to-day operations.

Paul Arms is the Senior West Coast Business Development Manager at Rocsys. Based near the Los Angeles Port, Paul focuses on building efficiency and long-term profitability in logistics operations. With extensive experience in mobility and EV charging infrastructure, he brings handsfree charging solutions to logistics projects. As part of Rocsys, a global leader in seamless electric vehicle charging, Paul helps terminal operators and logistics companies unlock greater value and efficiencies from their electric cargo handling infrastructure.

Rocsys is the global leader in hands-free charging solutions for electric vehicles. The company’s cutting-edge technology, including next-generation soft robotics, AIdriven computer vision, and datadriven services, unlocks greater efficiency, safety, seamlessness, sustainability and scalability for the world’s leading port operators, logistics companies and automotive brands.

With operations in Europe and the United States, Rocsys plays a leading role in shaping standards that will unify a powerful EV ecosystem through industry consortiums and strategic partnerships with multinational corporations and OEMs.

www.rocsys.com