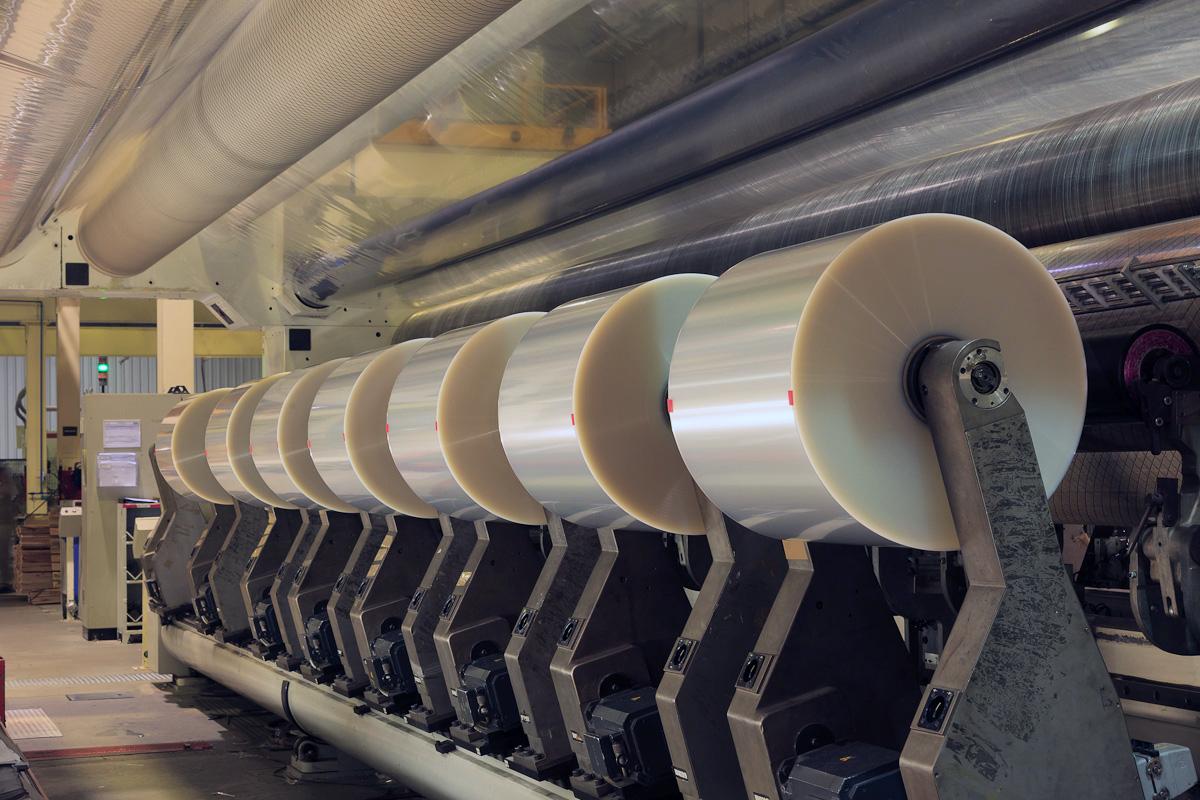

Transparent BOPP Film. Non heat-sealable.

Surface treatment for labels and stickers.

Non heat-sealable lm; Internal and/or external surface treatment; Excellent optical properties (gloss and transparency); Optimal performance in exographic printers and rotogravure printing.

Self-adhesive labels and tags (Pressure-Sensitive Labeling).

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability.

It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Opaque White BOPP Film. Surface treatment for printing and stickering. Pressure-Sensitive Labeling Application.

Heat-sealable starting from 112° C on the glossy surface; Internal and/or external surface treatment; A glossy surface, and a matte surface; High sti ness and low stretch; Cavitated lm with high opacity; Optimal performance in exographic printers, and in rotogravure, digital, ultraviolet and thermal transfer printing.

Self-adhesive labels and tags (Pressure-Sensitive Labeling) Magazine Labels (WAL Cut & Stack); Decorative applications in general.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Opaque White BOPP Film. Surface treatment.

Pressure-Sensitive Labeling Application.

Heat-sealable starting from 112° C on the glossy surface; Internal and external surface treatment; A high-gloss white surface, and a matte surface; High sti ness and low stretch; Cavitated lm with high opacity; Optimal performance in exographic printers, and in rotogravure, digital, ultraviolet and thermal transfer printing.

Self-adhesive labels and tags (Pressure-Sensitive Labeling) ; Magazine Labels (WAL Cut & Stack); Decorative applications in general.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability.

It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Transparent BOPP Film.

Heat-sealable.

Surface treatment for printing and/or lamination.

Heat-sealable on both surfaces, starting from 105° C on the NT surface; Corona surface treatment on one side; Excellent optical properties (gloss and transparency); Optimal performance in vertical and horizontal packing machines;

Flexible packaging for foods: biscuits, snacks, chocolates, cereal bars, and packaging for printed clusters; Flexible packaging for non-foods: monolayer or laminated options; Continuous labels, laminated or monolayer options, WAL Roll Fed type.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Transparent BOPP Film. Non heat-sealable. Surface treatment for printing and/or lamination.

Non heat-sealable lm; Internal and/or external surface treatment; Excellent optical properties (gloss and transparency); Optimal performance in horizontal or vertical lling machines; Medium thermal resistance.

Flexible packaging for foods: doughs, co ees, chocolate products, dried soups, nutritional powders; Flexible packaging for non-foods: pet food; paperboard lamination and graphics applications in general;

Continuous labels (WAL Roll Fed), laminated or monolayer options, and Magazine Labels (WAL Cut & Stack);

Designed for HFFS - Horizontal Form Fill Seal and VFFS - Vertical Form Fill Seal lling processes.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Metallized Opaque White BOPP Film

Heat-sealable Surface suitable for printing

Heat-sealable starting from 105° C on the non-metallized surface; Metallized surface suitable for printing; High sti ness and low stretch;

Metallized cavitated lm with very high opacity; Excellent performance in high-speed labeling machines.

Continuous labels (WAL Roll Fed), laminated or monolayer options; Decorative applications in general.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Metallized BOPP Film. Heat-sealable. Medium Barrier.

Heat-sealable starting from 105° C on the non-metallized surface; Medium Barrier to water vapor; Excellent barrier to light; Optimal performance in vertical and horizontal packing machines.

Flexible packaging for foods: biscuits, snacks, chocolates, ice creams, cereal bars;

Flexible packaging for non-foods: decorative applications in general Continuous labels, laminated or monolayer options, WAL Roll Fed and magazine labels - WAL Cut & Stack.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Opaque White BOPP Film. Heat-sealable. Surface treatment for printing and/or lamination.

Corona surface treatment on one side; High gloss on both surfaces; High sti ness and low stretch; Cavitated lm with high opacity; Excellent performance in very-high-speed labeling machines.

Roll-label type labels; Decorative applications in general.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Opaque White BOPP Film. Surface treatment for printing. In Mold Label - IML Application.

Corona surface treatment on the glossy surface and blaze treatment on the matte surface; A glossy surface, and a matte surface; High sti ness and low stretch; Cavitated lm with high opacity; Optimal performance in exographic printers, and in rotogravure, digital, UV and thermal transfer printing.

IML (In Mold Label) type labels for decorative applications in general.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Transparent BOPP Film. Non heat-sealable.

Surface treatment for printing and/or lamination.

Non heat-sealable lm; Internal and external surface treatment; Excellent optical properties (gloss and transparency); Optimal performance in exographic printers and rotogravure printing.

In Mold Label - IML Labels.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Transparent BOPP Film. Heat-sealable.

Surface treatment for printing and/or lamination. In Mold Label - IML Application.

Heat-sealable starting from 105° C on the untreated surface; Internal and external surface treatment; Excellent optical properties (gloss and transparency).

In Mold Label - IML Labels.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Transparent BOPP Film. Non heat-sealable.

Surface treatment for printing and/or lamination.

Transparent Non-Sealable Film

Corona surface treatment on one side; Excellent optical properties (gloss and transparency); Optimal performance in packing machines; Medium thermal resistance.

Flexible packaging for foods: doughs, co ees, chocolate products, dried soups, nutritional powders; Flexible packaging for non-foods: pet food; paperboard lamination and graphics applications in general. Continuous labels, laminated or monolayer options, WAL Roll Fed and magazine labels - WAL Cut & Stack.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.

Opaque White BOPP Film. Surface treatment for printing and stickering. Pressure-Sensitive Labeling Application.

Corona surface treatment on the glossy surface and blaze treatment on the matte surface; A glossy surface, and a matte surface; High sti ness and low stretch; Cavitated lm with high opacity; Optimal performance in exographic printers, and in rotogravure, digital, UV and thermal transfer printing;

Labels and self-adhesive tags (Pressure-Sensitive Labeling) Decorative applications in general.

All products are stored in dry, protected and clean environments, and are shipped under the same conditions in any mean of transportation. It is recommended that storage and transportation are carried out at a temperature of around 30° C and relative humidity of 60%.

If the temperature is not at the recommended level, the following problems might occur:

- Surface treatment level reduction which, at a later stage, might hinder printing and/or lamination;

- Film transparency reduction;

- Excessive CoF reduction, which might hinder processing and machinability. It is recommended that BOPP lms are kept at operating room temperature for 24 hours before use.