11 minute read

INDUSTRY-SUPPLIED CONTENT

Analytics Overload: Why You’re Confused

And if you aren’t confused, you aren’t paying a ention!

By Michael Risse,

Vice President and Chief Marketing Offi cer, Seeq Corporation

Process manufacturing operations may be oversimplified as entailing raw materials, a production process, and finished goods. The same model can be applied to using production data to improve process and business outcomes: data, analytics, and insights.

The issue is the value of insights is so high that enthusiasm for claiming credit for the “analytics” between data and insights has gotten out of control. Analytics, the systematic computational analysis of data or statistics (according to Merriam Webster), derives from the Greek analýein, which means “to loosen, dissolve, or resolve into constituent elements.” Leave it to marketing to mess up what Aristotle taught almost 2500 years ago.

The result is “analytics” is now everything and everywhere in software products, platforms, and cloud services. You’d be hard pressed to find software that doesn’t claim analytics features or benefits as part of its offering. The abuse of this benign word means it’s difficult to tell what analytics means, what’s included, or what’s required. To overcome this, “analytics” is now frequently qualified to define the exact type of analytics, a trend which can be broken into three categories.

Advanced and augmented analytics

First, there is the trend towards modern analytics that taps innovation in data science and computing resources; for example “advanced analytics,” which has come into use in the last several years. McKinsey & Company defines advanced analytics as “the application of statistics and other mathematical tools to business data in order to assess and improve practices ... [users can use advanced analytics] to take a deep dive into historical process data, identify patterns and relationships among discrete process steps and inputs, and optimize the factors that prove to have the greatest effect on yield.

The issue with this definition is that it assumes a user has the skills for the statistics or machine learning or other technologies required to leverage advanced analytics. Therefore, Gartner has begun using the term augmented analytics, which taps the same innovation themes but puts the analytics in the context of the user experience with business intelligence applications or tools. As Gartner explains: Augmented analytics is the use of enabling technologies such as machine learning and artificial intelligence to assist with data preparation, insight generation, and insight explanation to augment how people explore and analyze data in analytics and business intelligence platforms.

Perhaps the best example of augmented analytics is the simple Google Search Bar— the user doesn’t have to know what computations are taking place behind the web page they use to get results.

Iteration required

The second transition in analytics language comes from recognizing that analytics is not a static end point or insight. I would get in trouble inserting a graphic from a vendor that uses this approach, but there are dozens of examples. This approach suggests a hierarchy, a “better than” analytics structure which starts with descriptive analytics (i.e., writing reports), then diagnostic analytics (root cause analysis), then predictive analytics (also predictive maintenance), and finally prescriptive analytics to tell the user what to do (see Figure 1). There may be other, intermediate steps included, but the point is there is a fixed path to greater analytics sophistication.

This hierarchical view of analytics may make for compelling marketing materials (“Find Your Analytics Maturity!”) but it’s simply not realistic. A realistic view of analytics is an iterative, looping, collaborative process where an engineer starts with one analytics type, switches

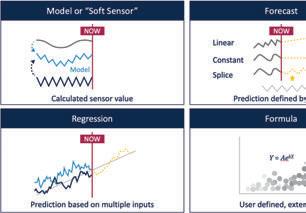

Figure 1: Even recognized types of analytics, such as predictive, can be further broken into specifi c types or methods. Source: Seeq

to another, goes back to the first, then does something else, or otherwise moves among analytics types to accommodate the changes in plant priorities, raw material costs, formula changes, and other factors.

Even in the most static environment, process engineers with experience in Lean or Six Sigma techniques knows that good enough today won’t be good enough tomorrow. Again, Gartner is leading the discussion on an iterative approach to analytics. The analytics aren’t static and hierarchical, they are circular and subject to impact from new requirements.

Improved outcomes

The third transition in analytics is in the desired outcome and impact of analytics. The static view, summarized in the prior paragraph, is defined both by its hierarchy and its defined outcome. The highest level, the brass ring, of this approach is “prescriptive” analytics, as if there was a way to define what the user should do given a certain set of data. This is simply not a realistic objective.

At any point in time there will be context known only to the user or subject matter expert, and only at the time of the analysis. This context must be considered when making the right decision for optimizing the production or business outcomes. If the analytic recommends a shutdown of the line when an asset is working but in need of maintenance, how does the decision get made in the context of production objectives and customer commitments? Only the process engineer or plant manager has the right business context to answer this type of question.

Therefore, the desired end point of analytics is not “tell me what to do” but instead “give me insights to inform my decision” based on the process engineer’s ability to tradeoff among outcomes. Another critical aspect of this optimization focus is insights must be achieved in time to make a decision that impacts the outcome. The unsatisfactory—and common—alternative occurs when the analytics take longer than the process to complete, with results delivered after the fact.

Analytics tools therefore need to be available as self-service, ad hoc solutions to plant personnel, and presented in time to make a difference. The boring and banal “actionable insights” from two decades of automation vendor marketing must give way to a focus on empowering and supporting the process engineer or subject matter experts inclusion and perspective in the trade-offs required for optimizing higher level outcomes.

Convergence

These three transitions in the language and innovation of analytics are not exclusive to each other; in fact they are converging in a new generation of software applications that assemble the key capabilities as one offering. Thus, innovative augmented analytics accessible to process engineers or subject matter experts in the plant will support all types of analytics—for past, present, and future data— to constantly tune and adjust the analytics to match plant requirements (see Figure 2).

And of course, insights from these new software applications will be accessible to end users so they can provide insights in time to improve production and business outcomes. Analytics has had a rough go of it in the last couple of decades with marketing abuse and over-saturation of messaging, but a new generation of solutions will deliver on the promises and potential of innovation.

Figure 2: Modern advanced analytics applications empower engineers to directly interact with data of interest to create insights quickly enough to optimize production outcomes. Source: Seeq

An interview with Hans Beckho , Beckho Automation managing director and founder, and Kevin Barker, president of Beckho USA, o ers insights into where industry is heading with automation technology.

By David Greenfield, Editor-In-Chief/Director of Content, Automation World

2020 was a year of change for everyone, and the industrial automation sector did not escape unscathed. After several years of growth and expansion, many industrial technology suppliers experienced significant downward impacts on sales and revenues. Even those suppliers that managed to have a year with positive earnings still felt the pinch compared to the levels of growth the industry had seen for years prior to the pandemic.

Automation World recently had the opportunity to speak with Hans Beckhoff, managing director and founder of Beckhoff Automation, and Kevin Barker, president of Beckhoff USA. The idea behind this interview was to get insights into Beckhoff’s experience as a global supplier of industrial automation technologies during a year that so dramatically changed personal and business perspectives and to get insights into what may lie ahead for the automation industry.

What 2020 wrought

Our discussion began with a review of Beckhoff’s business in 2020. Hans Beckhoff noted that his company had been experiencing an average growth rate of 14% since 2000. However, in 2020, that rate of growth shrank to about 2%, buoyed by a strong performance from Beckhoff China, which grew by 20% in 2020, as well as a good performance in the U.S., where the business grew by 5%. For 2021, Beckhoff sees positive business development worldwide based on its current double-digit growth rate. The company reportedly generates more than $1 billion in revenue worldwide.

Barker noted that Beckhoff’s “highly diversified” portfolio of products and industries it serves contributed to the company’s good performance in 2020.

“We don't have more than 15% of our business in any one particular vertical,” said Barker, “so when some of our existing customers did not invest in new theme parks or new oil and gas exploration, we still saw new projects with electric vehicles, semiconductor manufacturing, intralogistics, and packaging.” He added that Beckhoff’s technology portfolio, including TwinCAT control software, industrial PCs, I/O, drives and motors, contribute to the company’s ability to address a wide range of specific projects. “In the U.S., it's pretty evenly distributed and that’s because we are working with innovative companies looking to solve really important problems. And that starts at the control architecture and extends to the entire approach to automation. So, when we have these engagements, we see the revenue streams across all our different product families. We are leading the way with emerging technologies—like mechatronics—which have been a growth engine for us. But we see strong growth across all of our different product families.” Hans Beckhoff added that the Beckhoff automation architecture is “quite unified across I/O, bus terminals, CPUs, motors and drives, and software, which can be used to do very small applications like controlling a conveyor or very complex and big applications like machine building or logistical transportation projects. Regardless of the application, it's always the same hardware with basically the same TwinCAT software.” One differentiator that Beckhoff pointed to is that his company’s automation architecture is software-based and supported by modular hardware. “There are, of course, some differences in the software algorithms for different applications,” Beckhoff explained, “but control can be realized with this unified hardware, which helps us with a lot of different customers in different segments.”

Hans Beckho , managing director and founder of Beckho Automation (left), and Kevin Barker, president of Beckho USA.

At the IT/OT crossroads

Beckho EtherCAT terminals.

at the crossroads of IT and OT (operations technology)—an area that has gained increasing attention as the drive toward Industry 4.0 and Industrial Internet of Things applications brings these two technology worlds closer together.

“We’ve been doing PC-based control for almost 40 years, so having IT and OT integrated has been a part of our technology for all these years,” said Beckhoff. “Because we use a PC to control the machine, it's quite normal for us to collect and analyze data. And we are communication specialists; Beckhoff is the inventor of EtherCAT. We introduced the technology in 2003 and we knew that EtherCAT would be the perfect communication system for general automation, especially for demanding high-speed machine control applications with a lot of motion and measurement functions. Today EtherCAT is a global standard and has become the standard fieldbus for many automation architectures and device vendors. Nevertheless, Beckhoff supports an open control philosophy, which means that we support almost any communication interface in the industry, such as Profinet, OPC UA, EtherNet/IP, CANopen, and others—all of which is orchestrated through our TwinCAT software.” He contends that Beckhoff’s focus on industrial PCs, I/O communication technology, and its TwinCAT software provide a strong base for delivering edge intelligence, an aspect of Beckhoff’s business that has been growing rapidly as system integrators develop their own edge systems with Beckhoff hardware and “some big machine builders use our hardware to implement their own edge software concepts in different controllers on the machine.”

Beckhoff pointed to a particular feature of the company’s controllers as helping position the company well with integrators and OEMs when it comes to edge computing—the TwinCAT Analytics Logger inside the controller.

“This Analytics Logger works like a flight recorder, in that all signals from the machine are written in real time to a file or can be sent to the cloud. The complete operation of the machine is recorded,” said Beckhoff. “This allows you to do analytics and optimize the machine because you can see how the machine is working from your desk at home. So, if a machine is going down every two weeks in the middle of the night, you can see exactly what is going on. We also have the Analytics Workbench, which incorporates analytics tools like min/max comparisons, fast Fourier transforms, and it even has an interface with MatLab/Simulink for high-end analytics, all of which can be done via standard IEC 61131-3 languages. This means a controls engineer who programs the machine is also able to program the analytics.”