30 minute read

NEWS

New Tool for Troubleshooting Industrial Ethernet

By David Greenfield

Editor-In-Chief/Director of Content, Automation World

The growing prevalence of Ethernet on the plant floor has been clear for years now, but the increase in remote work brought on by the pandemic has only served to underscore the importance of Ethernet in industry. Other drivers behind Ethernet’s wider use on the plant floor, such as connectivity to enterprise systems and the ability to transmit greater amounts of data, as well as the general push toward Industry 4.0 and Industrial Internet of Things applications, remain key reasons why Ethernet continues to replace many fieldbus installations.

Like any industrial communications technology, Ethernet requires specific maintenance tools to ensure the network remains up and running with minimal or no downtime. To help address specific Ethernet issues, Fluke Networks recently introduced the LinkIQ-IE Cable+Network Industrial Ethernet Tester, which is designed to troubleshoot network cabling.

To understand the effect of Ethernet cabling issues in industry, Indu-Sol, an industrial network support organization, reports that more than half of their industrial Ethernet service calls result from cabling-related issues.

Fluke Networks says that, by combining their state-of-the-art cable measurement technology and basic tests for industrial Ethernet switches, LinkIQ-IE speeds and simplifies the discovery of network failures via a touchscreen interface that’s similar to a smartphone.

“Troubleshooting industrial Ethernet problems often involves the use of complex tools such as protocol analyzers that require years of training or trial-and-error approaches such as running bypass cable in the hope of solving the problem,” said Walter Hock, vice president of products at Fluke. “We designed LinkIQ-IE to provide answers to key troubleshooting questions in seconds through an easy-to-use touchscreen interface and a price that puts it in the reach of factory teams.”

James Sinn, owner of Sinn Development, an Oakville, Ontario-based provider of design, installation, and troubleshooting services, said, “With the ability to display

switch port, VLAN, and PoE (power over Ethernet) information, LinkIQ-IE is a great addition to our toolkit. The first thing I did with LinkIQ-IE was to test the cabling for a face shield production line. It instantly showed me that the cause of the problem was a disconnected shield that made the cable susceptible to the EMI (electromagnetic interference) from a nearby machine tool with a large induction motor.”

According to Fluke, LinkIQ-IE is based on

a single-test approach that automatically provides the appropriate measurements based on what’s at the other end of the cable. For an open cable, it shows the length and pairing. If it’s terminated with the supplied remote, the test result shows the maximum data rate the cable can support—up to 10 Gb/s. If LinkIQ-IE Cable+Network Industrial the cable is connected to a

Ethernet Tester kit from Fluke. switch port, LinkIQ-IE shows the name of the switch plus the port name, speed, and duplex. If PoE is used, it will display the power and class (up to 90 W or Class 8) and then load the switch to verify the power can be delivered. The LinkIQ-IE has an RJ-45 type connector and includes cabling and adapters for connection to M12-D, M12-X, and M8-D connectors commonly used in industrial applications.

Improve Quality and Output

by streamlining applications with pallet-handling conveyor systems

Standard Products for Custom Solutions: Pallet loads up to 800 lbs./ea Pallet sizes up to 1,200x1,200 mm Repeat accuracy ± 0.1 mm Indexing or accumulation Now with ALL ELECTRIC devices

(860) 769-5500 | info@mknorthamerica.com

PMMI Executive Leadership Conference: How to Attract and Retain a Quality Workforce

By Melissa Griffen

Contributing Editor, PMG

At the 2021 Executive Leadership Conference (ELC) hosted by PMMI, The Association for Packaging and Processing Technologies, Gardner Carrick, vice president of strategic initiatives at The Manufacturing Institute (MI) and National Association of Manufacturers (NAM), presented technical workforce development trends, both in connection to and beyond COVID-19.

Results show that since 2010 there has been an increase of nearly a million and a half jobs in manufacturing, which decreased when the pandemic hit. Though recent studies suggest the numbers have rebounded and are returning to previous counts.

Beyond COVID-19, the second key business challenge of 2021 is the continuing struggle of attracting and retaining a quality workforce in manufacturing. Research proves that this issue is systemic and not transitory. There’s not a “strong enough pipeline of individuals desiring to go into a career in manufacturing, and not enough breadth of training programs to prepare them with skills to be successful in those careers,” said Carrick.

MI and NAM prioritize the success of manufacturers and their workforce, whether it be through fighting for manufacturer rights, providing news and intelligence about the industry, or through initiatives to support the diverse American workforce by providing skilled training programs.

The MI and NAM efforts, presented at ELC, are: 1. Creators Wanted, which exhibits in towns to invite high school students to enter the manufacturing field post-graduation.

MFG Day–when facilities open their doors on the first Friday in October–has been combined with Creators Wanted. It includes virtual tours and 3D maps, as well as an MFG Day webinar series. 2. Military and veteran recruitment starts these brave men and women on their next career. Individuals on their last six months of service can start training in the MI programs, which have recently been modified to include networking days with manufacturers. In addition, both non-commissioned and commissioned officers have shown increased

interest in leadership roles in manufacturing. These programs are available at five U.S. military bases. 3. The STEP Women’s Initiative, which includes training women to be role models in their community. More than 800 women have been recognized so far, with hundreds of companies participating. 4. The NAM Pledge of Action ensures broad-based recruiting strategies “to cast as many nets as wide as possible in order to fill the roles that we need,” said

Carrick. This allows for greater diversity in the workforce by reaching out to minority communities. 5. The Second Chance operation is for those with criminal records. Studies done on retention routes and productivity of individuals show that those in the

Second Chance program have a competitive drive to keep their positions.

Attracting and retaining a quality workforce in manufacturing is a systemic key business challenge.

Apprenticeships and credentials

Once a workforce is obtained, however, training is indispensable in making each individual’s manufacturing career a success.

Manufacturing-related positions focus on keeping machines working, which requires technical skillsets that go beyond the abilities of technical colleges. Carrick emphasizes that companies, with their up-to-date knowledge, need to be involved in educating future generations as well as the development of scholastic programs every step of the way, including apprenticeships. This is also a great opportunity to offer debt-free education and show the new workforce that the company is invested in them, which Carrick says will help gain their trust.

An apprenticeship program highlighted by Carrick at the ELC event is Toyota’s FAME, the Federation for Advanced Manufacturing Education. FAME is a multi-skilled maintenance technical program operated by a group of companies, which promotes professional behaviors in dress and speech, and educates workers on the culture of manufacturing; for example, how to think as a maintenance employee.

Another aspect of forming a quality workforce is credentialing. The credentials market is filled with credentials that are lacking, creating confusion on industry standards. NAM and MI have created tools to evaluate individuals and credentials in an attempt to rectify this confusion. Carrick said states are already lining up to back this standardization.

PMMI efforts to build the workforce

PMMI has invested in a single employer model with Amazon to develop an apprenticeship program. Amazon wanted to develop a program to upskill current employees, which would build a baseline to allow individuals to make a career in the industry. The company had been looking for different models and certifications to provide standards they could follow. PMMI’s mechatronics’ certification program became the base of Amazon’s apprenticeship program, which allows individuals to obtain certifications as well.

PMMI saw a huge increase of 223% in utilization of the certification program throughout 2020. This increase is expected to continue as more schools offer the certification program thanks to the Amazon apprenticeship program. Like the miltiary-focused MI and NAM programs mentioned above, PMMI is also working to make the military aware of the industry and become properly trained.

PMMI has also created a Skills Fund for the future workforce. This fund allows companies to work with local education programs to donate money or equipment. PMMI then matches company donations up to $50,000. According to PMMI, this fund is a key component in helping companies build stronger relationships with local education programs.

Learn more about PMMI’s workforce development programs at www.awgo.to/1211.

AT11-19US | |

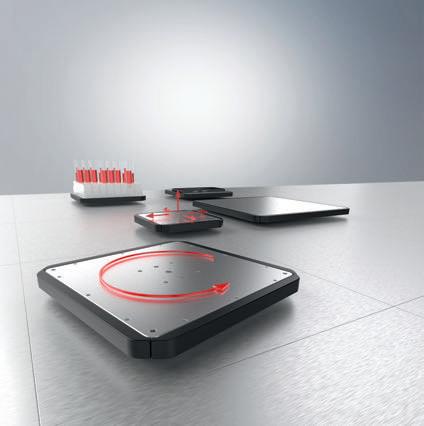

: Take flight with flying motion technology!

Flying 2D product transport with up to 6 degrees of freedom

kg

360°

5° Levitating planar movers

Scalable payload

360° rotation

Tilting by up to 5°

Lifting by up to 5 mm

Velocities up to 2 m/s

www.beckhoff.com/xplanar

XPlanar enables new dimensions of freedom in product and material handling: Levitating planar movers fly over flexibly arranged planar tiles accommodating nearly any track layout and path planning. Individual 2D transport at up to 2 m/s Processing with up to 6 degrees of freedom Transport and processing in one system Wear-free, hygienic and easy to clean Free arrangement of planar tiles enabling totally customized machine and process layouts Multi-mover control enables parallel and individual product handling Fully integrated into the powerful and standardized PC-based Beckhoff control system (TwinCAT, PLC IEC 61131, Motion, Measurement, Machine Learning, Vision, Communication, HMI) For use across all industries: assembly, packaging, food/bev, pharma, laboratory, entertainment, …

When Artificial Intelligence Comes to Control

Applications of machine learning and other forms of artifi cial intelligence have been recognized in robotics and analytics. Now the technology is adding some spice to basic control applications.

By James R. Koelsch, Contributing Writer, Automation World

Using your noodle to think things through tends to make things go much more smoothly—even if you’re just a high-speed food packaging machine wrapping instant noodles. That’s an important lesson gained from machine learning technology used by systems integrator Tianjin FengYuLingKong of Tianjin, China.

This form of artificial intelligence (AI) allowed the firm’s engineers to develop a multivariable inspection model for one of China’s largest producers of noodles. Relying on this model, the control system for the packaging lines can now deduce whether sachets containing spices and dried vegetables for flavoring were placed correctly on the precooked noodle blocks before each block is individually wrapped.

This ability is an example of how machine learning and other forms of AI are moving beyond applications like robotics and analytics and into control applications.

In Tianjin FengYu’s case, there was no other cost-effective way to check whether an occasional sachet of flavorings might have slipped between two blocks of noodles and been cut open by a cross-cutting tool. Although cutting a sachet generates measurable signals within the machine, other events such as vibration and changes in packaging material, conveyor speed, and cutting tension also affect those signals, making conventional forms of process monitoring unreliable.

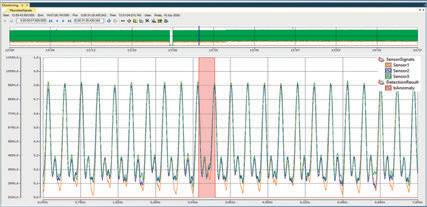

For this reason, Tianjin FengYu decided to develop, train, and deploy a mathematical model using TwinCAT Machine Learning from Beckhoff Automation. The integrator’s engineers collected sensor data via EtherCAT terminals and TwinCAT Scope View charting software. Then, the data were correlated into

a model using TwinCAT Condition Monitoring, and the model was trained using an opensource framework called Scikit-learn.

After being saved as a description file in a binary format suited for serialization in TwinCAT, the trained model was loaded into a CX5100 series embedded PC, which runs the model in real time. This embedded PC is integrated with the main controller on the packaging line.

The control system can run the model in real time as each packaging line wraps about 500 packages of noodles per minute. “A trained model actually runs fairly quickly,” notes Beckhoff’s Daymon Thompson. “And that’s what’s usually running in the controllers.”

Training the model is a different story, however. Thompson says that training needs a lot of processing power, as much as 30 minutes to a full day, depending on the model and the computer training it. So, the initial training and any subsequent retraining are often done on a server or an offline controller. Besides in-process inspection, another application for machine learning in controls is the optimization of motion profiles. Consider a conveyor system that carries payloads around corners and coordinates motion with loading and other activities in a demonstration created by Beckhoff using its eXtended Transport System (XTS). “Instead of just running everything around as fast as we can to get in line for the next synchronized event, we want the motion to be optimized to minimize energy consumption and wear and tear on the mechanics,” explains Thompson.

The machine learning algorithm figures out exactly what the motion profile should look like. “Because the motors driving the system need to be coordinated in real time, the

motion profile really needs to be built into the machine control,” notes Thompson. “It can’t be done on a server or even an edge device.”

AI benefits closed-loop control

“Traditionally, PLC programmers would write ladder logic to tune systems with either creative rungs of arithmetic or PID control blocks,” says Kevin McClusky, co-director of sales engineering at Inductive Automation. “Today, closed-loop control with AI allows users to feed data into predictive models that can optimize output based on past performance or cost reduction, allowing far more complex algorithms to be applied to achieve efficiency or productivity goals.”

He reports that the catalogs of several PLC manufacturers now offer AI modules for closed-loop control. Although not every application needs the technology, these modules are another set of tools in the toolbox. McClusky compares them to a simple PID block in ladder logic. “It’s not needed in a lot of applications, but it sure is handy in applications that can benefit from it,” he says.

“Model outputs can be integrated into the control scheme to extend the capabilities of classical control methods,” adds Jennifer Mansfield, marketing manager—analytics at Rockwell Automation. “Challenging problems, like enabling predictive maintenance or dynamic control, are better addressed with machine learning than classical control.”

Illustrating her point is the model predictive control (MPC) that EnWin Utilities Ltd. implemented to mitigate pressure spikes in the water distribution system in Windsor, Ontario. These spikes had been contributing to an increasing number of watermain breaks in the aging system.

The old control scheme had depended upon PID logic that maintained a flow setpoint based upon outlet header pressure. Pressure would vary whenever operators would start and stop pumps at the two pumping stations and an auxiliary booster station to adjust flows to compensate for fluctuating demand.

To even out pressure, EnWin chose an MPC-based system that could handle more variables than just flow and outlet header pressure. Working with engineers from Rockwell Automation, EnWin began by creating 17 remote pressure stations throughout the water distribution system. The team also installed server-based MPC on its existing supervisory control and data acquisition (SCADA) system. The system now maintains the lowest possible pressure for producing adequate flow as demand changes.

To optimize pressure and flow control further, the main campus uses a new ControlLogix controller with onboard MPC. “We knew we could optimize the system by incorporating pump start-stop functionality and flow control valves,” explains Quin Dennis, an application engineer at Rockwell Automation. “But given the existing interval speed, [server-based] MPC would not be able to make system adjustments quickly enough to mitigate the rapid pressure spikes from pump starts or stops.” Onboard MPC, however, reduced the 15 to 16 second interval speed down to 0.5 to 1 second.

The system is now responsive enough to regulate the speed of the pumps and adjust

Real-time inference results

Artificial intelligence used on noodle packaging machines by Tianjin FengYu detect an anomaly (highlighted in red). Real-time inference results like these are displayed in TwinCAT Scope View. Image courtesy of Beckho Automation.

control valves to offset any pressure spikes. By replacing PID logic with MPC at the controller level, as well as at the server level, EnWin was able to reduce watermain breaks by 21%. It also reduced average pressure by 2.8 psi and standard deviation by 29%, saving the company $125,000 in annual energy and leakage costs.

Predictive applications

Another benefit of AI is that it can help users peer deeper into their processes than controllers would otherwise permit. This is especially true in applications that require processing large amounts of data.

“AI is now being implemented on the edge in situations where large volumes of data must be analyzed quickly before being sent to the cloud,” observes Joe Berti, vice president of AI applications at IBM Corp. “As a result, smart technology is broadening engineers and technicians’ understanding of their assets’ health by capturing and interpreting more information faster than any human could.”

Consequently, Berti thinks that the biggest contribution AI and machine learning are making to controls technology is the ability to streamline detection and resolution of developing problems before they have a chance to escalate. “In the past, an asset might have been inspected on an annual basis,” he says. “Now, IoT sensors and enterprise asset management systems can detect patterns in asset data and then translate those findings into potential problems.”

An example of this kind of application can be seen in the use of AI to discover oil degradation on a food packaging line installed by Novate Solutions Inc., an engineering and technology services firm based in West Sacramento, Calif. The clues to the problem came from IBM’s cloud-based AI technology and Maximo Monitor software, which Novate uses to provide a process monitoring service. The AI noticed that the average torque of a servomotor had been increasing over time, so the Novate solution flagged the equipment for inspection.

Upon being alerted by Novate engineers, the production crew at the food producer checked the packaging equipment and found that the oil had not been changed as the maintenance log had suggested. The oil had completely degraded, causing the motor to work increasingly harder over time.

Trained for decision-making

Another application for AI in basic control is the automation of decision-making in continuous processes. “Here, an AI system controls a part of a facility or operation, sending signals to do basic control of different pieces of equipment,” says Inductive Automation’s McClusky.

He points to the way a type of machine learning known as reinforcement learning is being deployed by Andritz Automation, a worldwide systems integrator headquartered in Graz, Austria. In reinforcement learning, models are trained to make a sequence of decisions by means of a trial-and-error method that strives to maximize a cumulative score of rewards and penalties.

In what may have been the first implementation of this AI technology in continuous industrial processes, Andritz engineers in Canada and Germany collaborated on developing prototype software. They then implemented the prototype in a pilot program at Newmont GoldCorp., a Vancouver-based goldmining company.

This prototype uses the integrator’s process simulation software as the training ground for machine-learning algorithms. The AI engine learns by interacting with several simulations as they run. A user can set up batches of training scenarios, such as particular plant malfunctions that the AI engine needs to know. After the training exercises are performed, the algorithms are stored and used for automatic plant control.

A key technology for developing and implementing this AI engine was Inductive Automation’s Ignition development environment for SCADA. Ignition provided a bridge between the AI engine and either the integrator’s process simulation software or the real plant, using scripted HTTP calls on one side and OPC on the other.

Ignition’s sequential function charts control the dispatch of training scenarios. All scenario configuration and training results are stored in a SQL database. During the training process, the two teams in Canada and Germany were able to work on the project at the same time because the training environment was deployed on a small virtual network on a Microsoft Azure cloud server in Europe. Each team could run Vision clients simultaneously and access the database gateway and simulation machines.

Industrial Ethernet Advances Broaden the Network’s Value Across Industries

Not so long ago, many doubted that industrial Ethernet could ever take the place of legacy fieldbus on the plant floor. Prior to the rise of deterministic Ethernet communication protocols such as EtherCAT, EtherNet/IP, and Profinet, Ethernet simply wasn’t capable of accommodating the extremely rapid cycle times mandated by complex motion control applications, which often require control loop updates to take place within the space of mere milliseconds to function properly. However, with these issues solved, Ethernet has increasingly become the preferred industrial network, particularly in discrete manufacturing.

According to Michael Bowne, director of technology marketing at PI North America, four Profinet nodes are now sold for every one Profibus node sold; just a decade ago, those numbers were reversed.

Despite the rise in preference for industrial Ethernet networks, many fieldbus installations remain in place, particularly in the process industries where the shift to Ethernet has been more challenging. One of the reasons for this is that longer cable runs are often needed in large, outdoor environments common to the oil and gas industry. With typical industrial Ethernet being limited to a maximum length of 100 meters to prevent signal decay, this can present an issue. Moreover, with many process industry applications taking place in areas classified as hazardous zones and divisions by the National Electric Code, costly safety measures that require specific expertise must be undertaken to ensure Ethernet cabling and connectors will not ignite a flame.

Recent innovations in Ethernet’s physical layer—the first tier of the Open Systems Interconnection (OSI) model, a conceptualframework used to describe the various functions of a networking system—may help to surmount these obstacles.

Single Pair Ethernet (SPE) and Ethernet Advanced Physical Layer (APL) are two Ethernet innovations currently leading the way for greater expansion of Ethernet in industry, and both bring with them an assortment of potential benefits. Simply put, SPE is a form of Ethernet that uses a single twisted-pair of wires, whereas other forms of ethernet use two or three. Similarly, APL is a type of SPE combined with IEC 60079 Two-Wire Intrinsically Safe Ethernet (2-WISE) capable of being deployed with pre-existing Fieldbus Type A cabling for use in hazardous environments. While the distinction may seem minute, many industry insiders are hailing the development as having significant implications for industrial networking deployments.

“This is going to be the same type of step change that happened in factory automation when we moved from fieldbuses to industrial Ethernet,” Bowne says. “All those benefits we gained from that—the same thing can happen in process control.”

By David Miller, Senior Technical Writer, Automation World

SPE uses a single twisted pair of wires, as opposed to the two or three used in other forms of industrial Ethernet. Recent innovations in industrial Ethernet’s physical layer—Single Pair Ethernet and Ethernet Advanced Physical Layer—are being heralded as game-changers for their ability to extend Ethernet cabling lengths and address hazardous environment concerns.

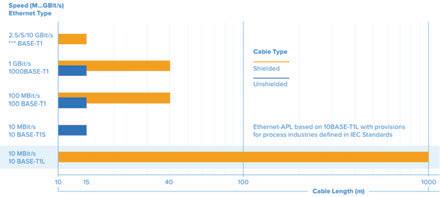

SPE: Single Pair Ethernet

Several qualities possessed by SPE make it ideal for use in process industry environments. First, its maximum length is 1,000 meters—10 times that of previous industrial Ethernet forms. That said, this extension isn’t accomplished without some trade-offs. SPE’s communication speed is 10 Mbit/second, while four- and eight-wire Ethernet can reach speeds ranging from 100 Mbit/second to as high as 10 Gbit/second. Still, this represents a marked improvement over both fieldbus, which has a maximum communication speed of 31.25 Kbit/second, and HART,

One of SPE and APL’s primary advantages for the process industries is their substantially greater cable length compared to other forms of industrial Ethernet.

which has a maximum communication speed of 1,200 bits/second.

In this way, SPE represents a kind of middle-ground between legacy fieldbus and other forms of industrial Ethernet. While fieldbus might not currently offer data transmission speeds that can fully tap the larger quantities of data being produced by Internet of Things (IoT)-equipped devices, four- and eight-wire Ethernet may provide more than is necessary, says Guadalupe Chalas, senior marketing specialist at Phoenix Contact.

“For these field devices, you might need longer cable distances but less bandwidth. So, what happens is if you’re talking about bandwidth specifically, you don’t want to put a standard Ethernet connection of 100 Mbit/ second on something that only needs eight or 10 Mbit/second. That would be overdesigned,” Chalas says. “In that case, you’re using an expensive connection on an application that doesn’t need it.”

In addition, SPE has swapped the RJ45 connectors native to most Ethernet cables. Not only are SPE’s connectors more rugged, and thus better suited to harsh industrial conditions, but they are significantly smaller and match ports commonly available on existing sensors and other field instrumentation. "The number one reason that standards organizations are heading in this direction is to ensure greater interoperability," says McKenzie Reed, technology manager for standards development at Harting. "The RJ45 is a commercial product that migrated into the industrial market, and that is what standard organizations working on SPE are putting a ton of time and attention into making sure doesn't happen again because of the quality, compatibility, and performance issues that surround the RJ45 connector when used in industrial environments.”

Finally, SPE enables power over data line (PoDL), which is capable of transmitting up to 50 watts of power over the same twisted pair of wires that transmits data. According to Reed, this can be used to deliver power to small sensors and other forms of simple instrumentation in the field, allowing endusers to further cut costs by eliminating secondary power supplies.

APL: Advanced Physical Layer

APL refers to an installation architecture that can be used to render SPE intrinsically safe for applications in hazardous environments. This is achieved in conformity with IEC technical specification 2-WISE, which defines port profiles for multiple power levels to limit the flow of current in areas where explosions may occur. According to Al Beydoun, president and executive director of ODVA, while other forms of industrial Ethernet can be used in hazardous environments, they require additional precautions be taken, such as installing mechanical cable protections, using shorter cable runs that must be determined using appropriate calculations, and sheltering connections in additional cabinets and enclosures. By eliminating these needs, APL cuts costs, reduces complexity, and allows for longer cable runs without compromising safety. Moreover, APL is designed to be compatible with pre-existing Fieldbus Type A cabling, which may significantly ease the process of adoption. This is possible because, while APL is a change to an Ethernet cable’s physical layer, its increased data transmission capacities are enabled by a compatible device’s network interface controller (NIC) and physical transceiver (PHY), rather than the cabling itself. As a result, industries such as oil and gas or wastewater management in which existing cabling may be buried, encased in concrete, or otherwise difficult-to-reach locations can easily make the transition by updating devices and connectors without needing to rip and replace their entire cabling infrastructure.

More data for modern applications

Perhaps the greatest benefit of bringing SPE and APL to process industry applications is the ability to transmit larger quantities of richer, more granular data from sensors and devices to higher level systems due to Ethernet’s greater bandwidth compared to fieldbus. In addition, where fieldbus only offers half-duplex or unidirectional communication, SPE and APL, like other forms of industrial Ethernet, are full-duplex, meaning they can simultaneously transmit data to and from connected devices. With this functionality, real-time, continuous visibility for use in digital twins and other advanced technologies can be made possible.

SPE and APL are also protocol agnostic, meaning that they can be used in conjunction with any other higher-level industrial Ethernet communication protocol, allowing for top-to-bottom Ethernet use without the need for network gateways or protocol conversion that raise costs and increase complexity. According to Reed, this will also make commissioning easier to manage, especially as fieldbus expertise wanes among newer members of the workforce.

However, ubiquitous adoption won’t occur overnight, says Sri Senthamaraikannan, product line manager for industrial Ethernet and electronic cables at Belden. Because devices must be manufactured with the appropriate

PHY in order to be compatible with SPE and APL, it could take three to five years before deployment gains momentum. That said, the first SPE and APL compatible devices are going into production this year.

It’s also important to note that SPE and APL are not replacements for, but rather complements to existing forms of industrial Ethernet, and have been designed specifically to bring Ethernet connectivity to select applications, particularly those in the process industries.

“SPE offers many benefits, but it’s not going to [entirely] replace existing four- or eight-wire industrial Ethernet because it still has strong advantages over SPE, such as a higher data transmission rate; but it is definitely going to be the case that SPE will be a cost-effective solution in specific applications where it has an important role to fill,” Senthamaraikannan says. “We see SPE being a critical enabler of adoption of Ethernet in process control environments.”

SPE and APL use smaller, more rugged connectors, which can result in material footprint reductions of up to 80% over previous RJ45 connectors.

U.S. Air Force F-16 fi ghter craft. Source: GE Aviation

U.S. AIR FORCE LOOKS TO FLY WITH 3D PRINTED PARTS

Metal additive manufacturing is being applied to the production of oil lubrication system parts for the GE F110 engine, which powers the Air Force’s F-16 jet fi ghter.

By Jeanne Schweder, Contributing Writer, Automation World

Adopting new manufacturing technologies has often proven to be a game changer for companies seeking to enter a new market or retain their leadership in an existing one. For GE, 3D printing is the latest tool for staying ahead of its competitors in the aircraft industry.

Though GE engineers had originally developed the engine for the B-1 supersonic bomber, by 1970 it was no longer seen as a leading supplier. That opinion changed in the 1980s when GE designed a new engine around the B-1 core to provide the U.S. Air Force with propulsion systems for its F-16 and F-15 fighter aircrafts. Decades later, that F110 jet engine still powers most frontline F-16 fighters.

To keep its fleet flying, the U.S. Air Force continually searches for the best ways to procure parts, including crucial spare parts for planes that have been in service for decades. That’s why the Air Force’s Rapid Sustainment Office (RSO) was receptive when representatives from GE Additive approached them last year with the idea of making some parts with 3D printing.

That collaboration is now bearing fruit. GE’s engineers are building a 3D-printed sump cover for the GE F110 engine. The sump is part of the oil lubrication system, and the sump cover is basically a cap, yet still a key part of the engine, says James Bonar, engineering manager at GE Additive. “Compared to other parts on the F110 engine, the sump cover might have lower functionality, but it is incredibly important. It needs to be durable, form a seal, and it needs to work for the entire engine to function. That’s critical, of course, on a single-engine aircraft like the F-16.”

Intricate shapes

technology. Also known as additive manufacturing, the process works by fusing thin layers of metal powder with a laser or electron beam to make a final product. The technology allows engineers to create shapes that would otherwise be too expensive, or too intricate, to make by casting or stamping.

According to Antroine Townes, site leader for GE Aviation’s Additive Technology Center (ATC), “The beauty and the value of additive manufacturing comes in the flexibility of design and the speed of innovation.” And it has been a particular boon for GE’s work in aviation.

Engineers at the ATC, for instance, were able to use the technology to combine more than 300 engine parts into just seven 3D-printed components in the new GE9X engine, which GE claims is the most powerful jet engine in the world. Thanks to 3D printing and other technologies, this engine is 10% more fuel-efficient than its predecessor, the GE90.

GE Aviation also relied on 3D printing for its Catalyst, the first “clean-sheet” design of a turboprop engine to make it to the aviation market in more than a half-century, according to GE Aviation. With 3D printing, GE’s engineers distilled about 800 parts down to a dozen or so, while reducing the Catalyst’s weight and improving its fuel consumption.

3D-printed sump cover

GE’s collaboration with the Air Force RSO builds on this experience. “The Air Force wanted to go fast from day one and gain the capability and capacity for metal additive manufacturing as rapidly as possible in order to improve readiness and sustainability,” says Lisa Coroa-Bockley, general manager for advanced materials solutions at GE Aviation. “Speed is additive’s currency.”

The first print run of the sump covers, which are conventionally cast from aluminum, happened at the ATC, where engineers created the parts from cobalt-chrome powder using GE Additive’s Concept Laser M2 machine.

“Part of that process involved exploring how to quickly eliminate the associated risks with castings, and how metal additive might replace it for those parts that are either no longer in production or where we need smaller production runs to keep our platforms flying,” explains Melanie Jonason, chief engineer for the propulsion sustainment division at Tinker Air Force Base in Oklahoma.

For this collaboration, the Air Force and GE are using a spiral development model common to fields like software. This process begins with lower functionality individual parts, like the sump cover, and then advances to tackle complex components and systems such as heat exchangers. With Phase 1a of the sump cover project underway, the teams are moving on to Phase 1b, which focuses on a sump cover housing—a family of parts on the TF34 engine. This engine powers the Air Force’s Fairchild Republic A-10 Warthog, which has been in service for more than 40 years.

“The program with GE is ahead of schedule and the preliminary work already done on the sump cover has allowed us to move forward quickly,” says Beth Dittmer, division chief of propulsion integration at Tinker Air Force Base. “As we build our metal additive airworthiness plan for the Air Force, the completion of each phase represents a significant milestone as we take a step closer to getting an additive part qualified to fly in one of our aircrafts.”

Additively manufactured cobalt-chrome sump cover for F110 jet engine. Source: GE Additive