A resource to evaluate packaging solutions 2023 BUYER’S GUIDE Learn more about our automation solutions at www.westrock.com/ automation

v yda s r v Our awar a v o r v ay ca nd r o r a

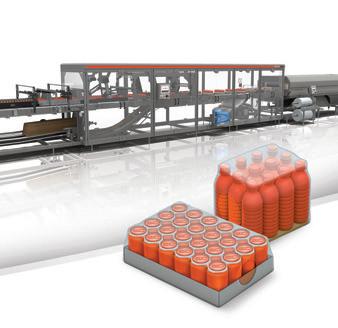

Liquid r ays

CONTENT

Joseph Derr Contributing Editor

David Bacho Creative Director

Filippo Riello Art Director

EDITORIAL CONTRIBUTORS

Matt Reynolds Chief Editor, Packaging World

Anne Marie Mohan Senior Editor, Packaging World

Sean Riley Senior News Director, PMMI Media Group

Casey Flanagan Editorial Assistant, PMMI Media Group

Elisabeth Cuneo Contributing Writer, PMMI Media Group

ADVERTISING

Wendy Sawtell Vice President, Sales wsawtell@pmmimediagroup.com

Lara Krieger Production Manager lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Client Success & Media Operations

Jen Krepelka Director, Digital Media

Mike Prokopeak Senior Director, Content & Brand Growth

Trey Smith Senior Director, Events

Sharon Taylor Director, Marketing

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

Lloyd Ferguson Founding Partner

Staff

2023 BUYER’S GUIDE FEATURES 2023 BUYER’S GUIDE STAFF • CORPORATE Go to this editorial section throughout 2023 for useful tips and advice on working with suppliers, designing for sustainability and navigating tech trends. FEATURES 6 What to Watch For in 2023 8 Checklist for Buying Packaging Equipment 9 Missteps to Avoid in Your Next Packaging Project 10 Design a Sustainable Package in Six Steps 11 Sustainability Beyond the Primary Package: Five Things to Think About 12 Emerging Technologies on the Horizon 14 Have You Tried PMMI ProSource? Packaging World • PMMI Media Group 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 Phone: 312/222-1010 • Fax: 312/222-1310 E-Mail: info@packworld.com • Web: www.packworld.com PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

at

Media

be

PMMI

Group can

contacted at info@pmmimediagroup.com

2 PW 2023 BUYER’S GUIDE

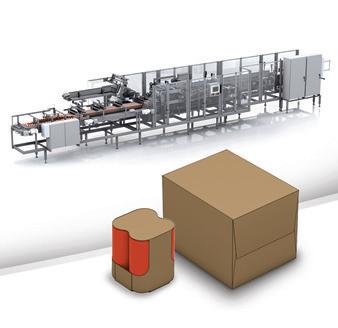

800.621.4170 | trianglepackage.com 100 YEARS OF KEEPING FOOD SAFE

2023 BUYER’S GUIDE • RESOURCES

comprehensive collection of company pro les, advertising,

all organized by category for easy reference in locating the

16 An alphabetical listing of leading vendors in packaging highlighted in the Packaging World 2023 Buyer’s Guide, organized by category.

COMPANY INDEX

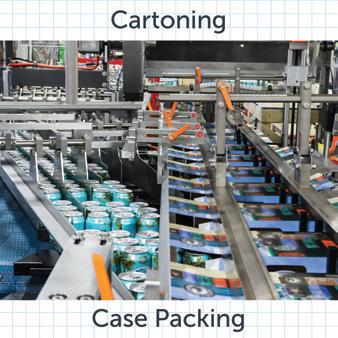

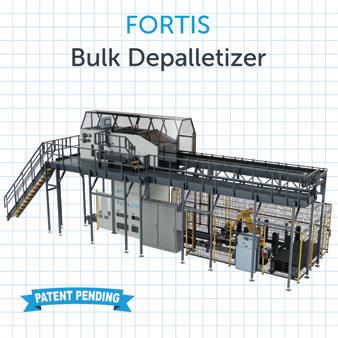

MACHINERY 20 Bagging, Pouching & Wrapping Products start on page 43 46 Cartoning, Multipacking & Case Packing Products start on page 85 92 Coding, Labeling & Printing Equipment Products start on page 121 126 Controls, Software & Components Products start on page 136 138 Converting & Package Forming Equipment 141 Conveying, Feeding & Handling Products start on page 165 170 Filling, Capping & Closing Products start on page 196 200 Inspection & Testing Equipment Products start on page 210 212 Palletizing & Load Stabilization Products start on page 226 229 Robotics Products start on page 239 240 Tray, Clamshell & Blister Packaging Equipment Products start on page 245 MATERIALS 246 Containers & Closures Products start on page 251 252 Flexible Packaging Products start on page

264 Labels Products start on page 267 268 Materials, Containers & Consumables Products start on page 278 BUSINESS DRIVERS 279 Business Drivers Products start on page 280 A

listings,

machinery, materials, containers, or services you

4 PW 2023 BUYER’S GUIDE

263

and product

packaging

need.

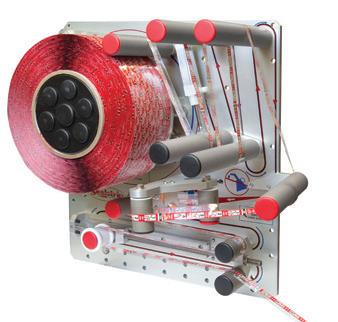

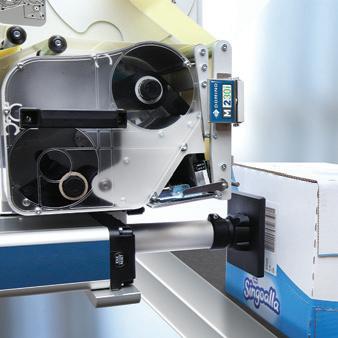

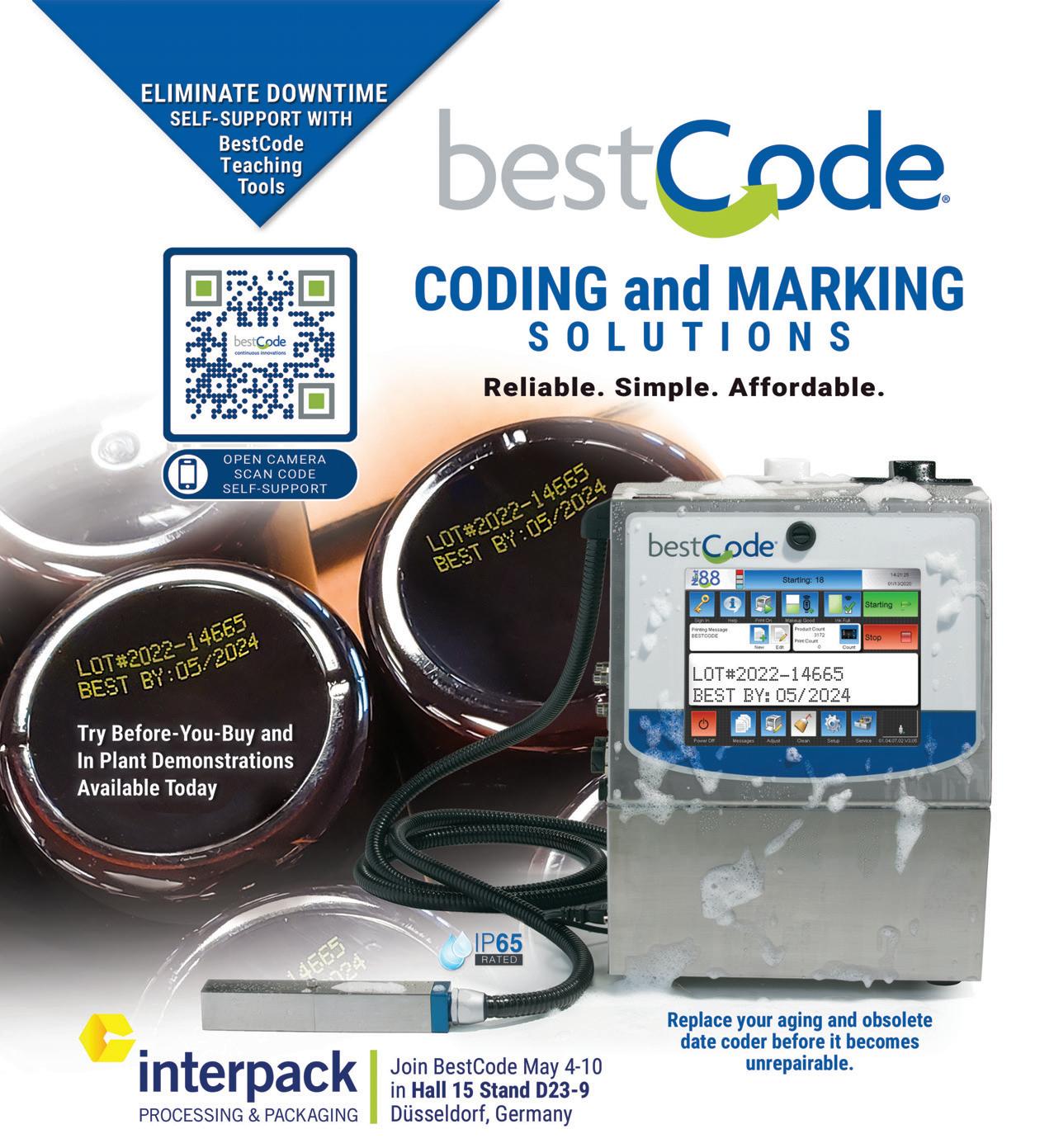

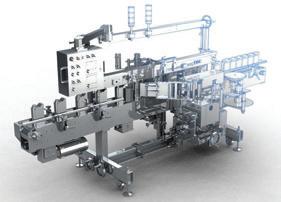

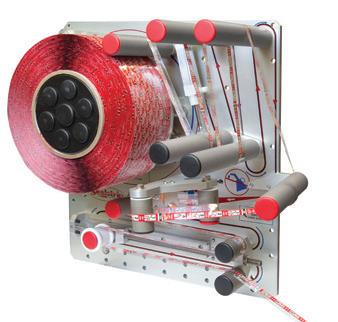

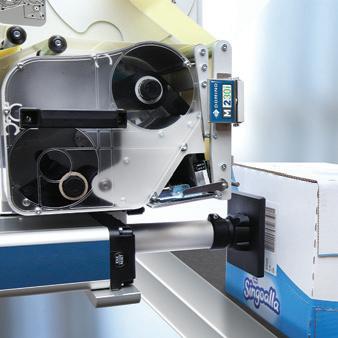

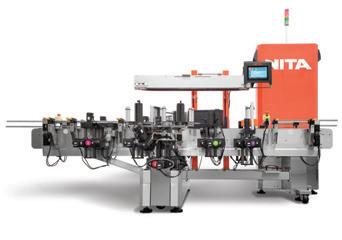

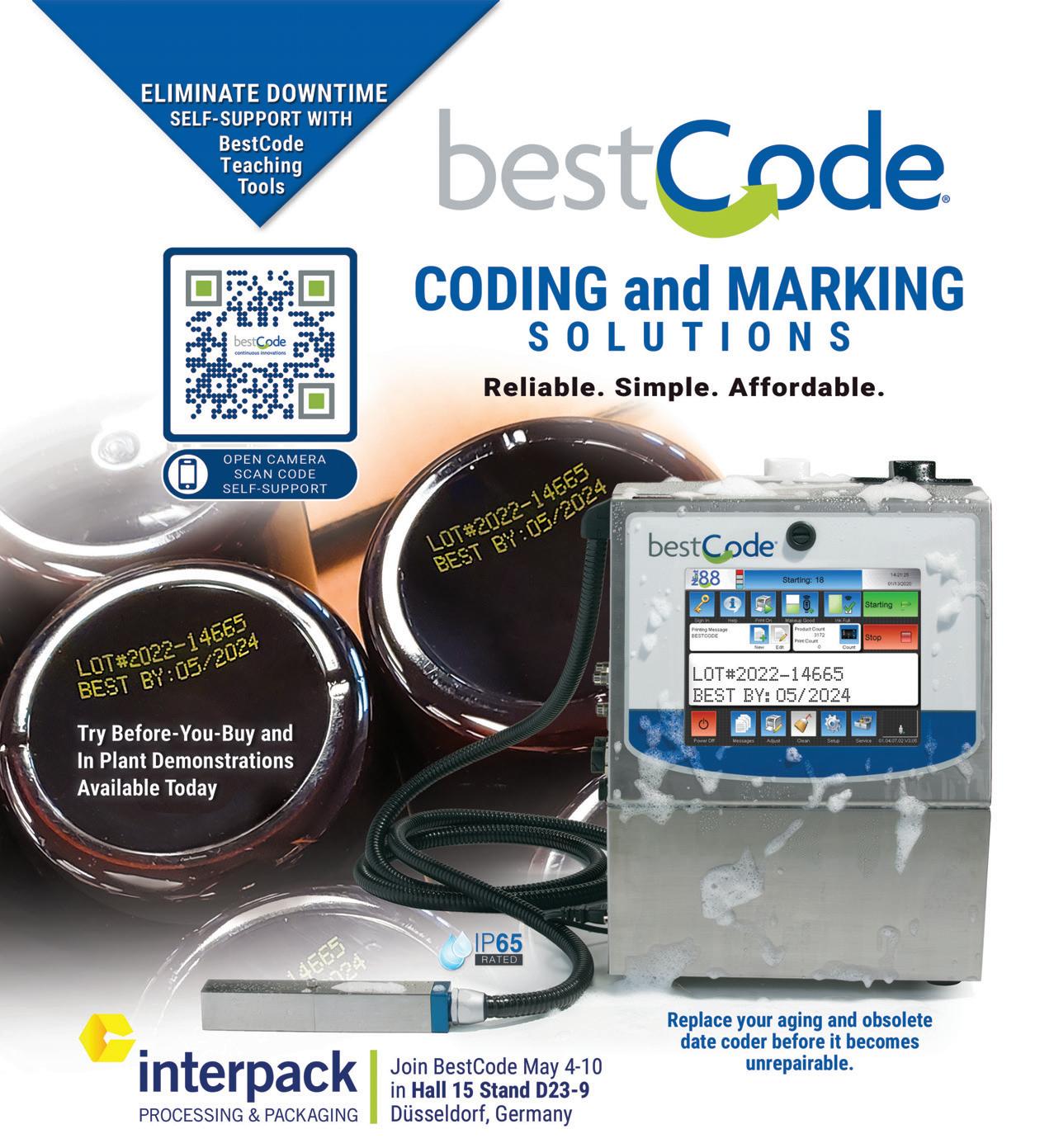

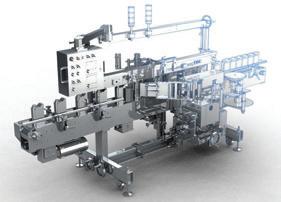

LABELING THAT’S SIMPLE, YET SOPHISTICATED

EPI’s MFlex™ pressure-sensitive label applicator systems are engineered to be simple to use, yet sophisticated enough to be the perfect choice for a wide range of applications. Designed and built in the USA, MFlex™ machines can be configured to handle many package types and meet the labeling needs of each customer.

• Singular touchscreen HMI interface for fast operator access to configuration adjustments and full machine control and diagnostics.

• Product setups easily saved in recipe database, ready for instant recall.

• Closed-loop servo system to ensure maximum synchronization and control.

• Built with stainless steel and non-corrosive materials, the MFlex™ is IP65 compliant as standard to thrive even in challenging environments.

• Zero-downtime option available for maximum efficiency and productivity.

• Multiple labeling solutions for top, bottom, c-wrap, wrap, and front and back labeling applications.

EPI@ProMachBuilt.com | New Freedom, PA | 717-235-8345 | EPILabelers.com UPGRADE YOUR LABELING CAPABILITIES CONTACT US AT EPI@PROMACHBUILT.COM OR VISIT EPILABELERS.COM To find your local EPI sales and service contact, scan QR code or visit: idtechnology.com/online-sales-and-service-directory © 2023 ProMach Inc.

What to Watch For in 2023

There is a lot of uncertainty about what’s ahead for consumer packaged goods (CPG) companies in the remaining three quarters of 2023. How will inflation and worries about a potential global recession impact consumers and businesses? Are supply chain disruptions— and the global pandemic that spurred them on—finally over? How will emerging automation technologies impact workforce issues and operations?

Though there is no crystal ball to peer into, three areas can be expected to shape the rest of this year: the consumer, the package and your facility.

Consumers: Changes Continue

Demographic shifts, changing preferences and economic factors, highlighted in Euromonitor International’s Top Ten Consumer Trends for 2023, are bound to impact consumer behavior—and the world of packaging—this year.

Gen Z now represents 25 percent of the population. Young Zoomers aren’t inherently loyal consumers and don’t like to be treated like transactions. They also have high expectations for brands. To earn their trust, CPG companies need to be transparent, honest and relatable, with packaging that communicates these traits.

Female shoppers also require fair representation and equality at the marketplace. They will be supportive of brands that advocate for a cause and personalize products to their size, age or life stage, all factors that impact packaging.

High transportation costs, record-high inflation and supply shortages will continue to drive up the cost of living. Budgeteer consumers may push brand loyalty aside in favor of private-label and store-brand products. These same factors are expected to continue driving e-commerce. CPGs may also feel the pinch as shrinking profit margins lead to SKU rationalization, updated pricing strategies and supply chain optimization. Look for

more brands to drive direct-to-consumer (D2C) models to help deliver savings while retaining customers. However, D2C will require CPG manufacturers to invest heavily in automation to meet expected demand, causing some growing pains.

Packaging: Sustainable Solutions

The packaging material landscape may see big shifts in coming years. Rigid plastic, flexible packaging and metal are expected to see the biggest gains by 2025 in the U.S., but the degree of growth will depend on the category they serve.

On the materials front, sustainable packaging remains top of mind for brands. CPGs will continue to find new and creative solutions that connect with the consumers who are demanding environmentally friendly packaging despite the challenges, such as the suitability of older machinery to new materials as well as longer sealing times and other packaging performance issues.

6 PW 2023 BUYER’S GUIDE

to the Buyer’s Guide.

Welcome

This resource is designed just for you – the specifiers and buyers of packaging equipment and materials. Here, you have the top industry suppliers at your fingertips, listed out by category of expertise. We hope you keep this reference and turn to it throughout the year when you’re looking for your next packaging solution.

Pay attention to the refill/reuse systems trend in beauty and personal care products happening now, which cuts across rigid and flexible packaging formats. Unilever is now well into its refill partnership trial with Asda in Europe, covering seven household-name brands and a model that emphasizes scaling refill-at-home innovations. Materials suppliers poised to help brands make the shift away from the single-use model include Aptar Beauty + Home and Quadpack, who developed a refillable wooden lipstick package and Mondi Group and Thimonnier, whose recyclable, monomaterial berlingot sachet is designed for liquid soap refills.

Watch for more surprises in the switch to paper-based formats, like KitKat’s ongoing experiment with curbside-recyclable paper as a replacement to plastic flow wraps in Australia. KitKat will gather feedback on how consumers like the new packaging via QR codes on the wrappers.

Another example of out-of-the-box thinking for sustainability is Spanish beer brewer Estrella Galicia, who launched a unique, adhesive-only multipack format it calls the No Pack, which uses a line of glue dots where one can abuts another in a six-

Facilities: Workforce and Automation Challenges

Facility managers have a lot on their minds these days, and with good reason. The workforce issues that have dogged manufacturing since the beginning of the pandemic show no signs of lifting. Automation continues to advance rapidly to help solve these issues, but new concerns, such as cybersecurity, are being added to the mix.

Your facility is not the only one being challenged to recruit and retain workers. The vast majority of CPGs are having di culty finding skilled machine operators, technicians and those familiar with complex equipment or digital automation technologies. In a recent study published by The Manufacturing Institute, 93% of respondents said they were struggling to find skilled applicants for vacancies within their companies. Finding enough workers to cover shifts, high turnover rates and technical training gaps are related concerns.

In response, brands are turning to automation for manual tasks and processes as the main remedy to reduce costs and demand for workers. But the benefits

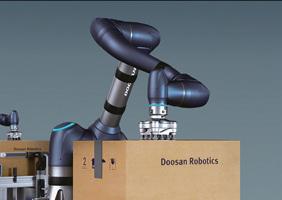

spotlight. While cobots are helping CPGs be more productive, they are also often seen as more complex to implement in a plant than robots, according to PMMI’s Business Intelligence report. Some CPGs noted they perceived that cobots were slower than manual processing. CPGs are looking for packaging technologies that are simple and user-friendly to accommodate lower skilled workers as well as being outright e cient.

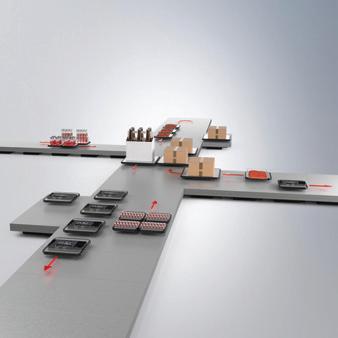

According to a majority of CPGs who responded to PMMI’s poll, packaging and processing have the most potential for automation among all stages of getting consumer packaged goods to market. Warehousing came in second. While the pandemic played a role in increased automation in 2021, it is now becoming clear that the drive to automation is likely to be permanent. Although warehousing and storage are lower on the list of automation priorities, there is still an opportunity for automation e ciencies here: 68% of CPGs who responded to the poll said packaging materials receiving and storage management is highly manual in their plants and 61% said raw material receiving and storage management is mostly manual.

pack format, completely doing away with paperboard can handles.

Brands will continue to promote their sustainability commitments, inspiring more healthy competition. At the same time, CPGs will have to keep another challenge in the balance: how to get consumers on board to pay for increased costs for the environmentally friendly products they demand without losing market share. In turn, CPGs will also be putting more pressure on their suppliers to provide clear solutions and e ciencies to help them meet their goals, not to mention the carbon emissions targets set by policymakers.

of automation do not end there. The recent PMMI Business Intelligence report on “Challenges and Opportunities for Packaging and Processing Operations,” which polled leading CPGs, noted that technology can assist with retention by automating repetitive tasks, making work more exciting, increasing the span of control of current operators and accommodating lower skilled workers. Emerging technology like augmented reality might also lead to better engagement and training of employees.

The turn to automation has put collaborative robots (cobots) into the

Remote access technology is another automation trend worth tracking. However, the top barrier for CPG companies adopting remote access technology is cybersecurity concerns, according to PMMI’s research. Surveyed OEMs also saw customer buy-in and acceptance of remote access by CPGs as a barrier to wider rollout, which is understandable based on companies’ security concerns. Suppliers who can help CPGs overcome these concerns should fare well in 2023.

7

Though there is no crystal ball to peer into, three areas can be expected to shape the rest of this year: the consumer, the package and your facility.

working with suppliers

Checklist for Buying Packaging Equipment

1 2 3 4 5 6 7

Know exactly what you need. An in-depth user-specification requirement document should always be priority number one before buying any new equipment. “You are going to be unsatisfied with a piece of equipment if you did not figure out exactly what you needed before buying,” says Christine Duncan, marketing manager for ProMach’s Matrix and Ossid brands. First, choose the suppliers who have the experience to help you select the right solution for your application. Once you find them, work closely with them to communicate your exact expectations.

Be bold and take risks. Early on, be open to new approaches and be ready to take risks. It may be easier and less risky to go with what you know, but replicating what you’ve done in the past won’t expose you to new technologies and new vendors who o er significant cost savings and time-to-shelf advantages for your package. You can always revise your risk assessment throughout the project. Thinking through potential pitfalls (see opposite page) and having the necessary contingency plans in place will prepare you for when problems crop up.

Get input from floor operators. Executives will usually make the final call on the machine to buy. But before presenting a recommendation to them, be sure to gather input from line-level personnel such as machine operators, technicians and mechanics to see what they think. Talk to your containers and materials suppliers, too. Collecting their feedback will bring valuable new insights that will inform the final decision. It will also help prevent missteps, such as having to refabricate parts mid-project. You can consider sending that same production team to the vendor’s factory later for in-depth equipment and safety training, during or even separate from the factory acceptance test (FAT).

Calculate speed thoroughly.

Throughput—nominal, jog and surge—as well as the conveyor speed all play into the equation of determining speed requirements. First, calculate the speed required to produce enough product for the initial launch. Then, determine the rates required for ongoing production. Look at the balance between the short and long term numbers and now you have a target for your overall strategy. A good rule of thumb for future growth: try to build in excess capacity of at least 15%.

Consider all costs. Don’t make the mistake of eliminating a machine based solely on cost. It’s important to put all costs in the proper perspective. For example, you may end up spending more money in the long run modifying an inexpensive machine or getting it to work for your application. One approach: ask your supplier if they are willing to customize the machine to your specific needs and factor that into one of your plans. Then, calculate the total cost of ownership for the cheaper option, the customized solution and any other options on the table.

Think about

flexibility

and growth. Many will buy a machine in 2023 thinking only of their 2023 product line. When you invest in new equipment, you’re not just looking at requirements for one package. Think about flexibility for future needs. How will the new machine be at running new package sizes and products you haven’t even thought of yet? Buy intelligently this year so that next year, when marketing comes knocking on your door with a request to go to a di erent package size, your equipment purchase won’t limit your capabilities and box you into a corner.

Plan for wear and tear. When specifying a machine, it’s important to not overlook factoring in the technical services that will be needed to keep it up and running. The big question on the plant floor these days is: “How quickly can I get spare parts from the supplier?” Set up good preventative maintenance practices and schedules to minimize downtime. “You’re making an investment in equipment that should last many years,” says Ben Vlieger, chief sales and marketing o cer at Felins. “Make sure that you spend those years with a supplier that understands your continuing needs and supports you.”

Consider

Buying the right packaging and processing equipment for your application is a big deal. There’s much to consider, from cost to capabilities, speed, flexibility and even future support. Refer to this checklist of best practices as you begin the purchasing journey for your next packaging machine. 8

Ask yourself if someone else—a contract packager—can do your project better or cheaper than you, which will ultimately save you the capital investment. Leaving a co-packing option on the table is particularly apropos when the launch window is extremely tight.

outsourcing as a solution.

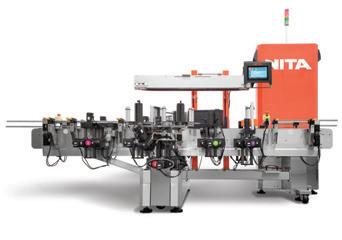

8 PW 2023 BUYER’S GUIDE

working with suppliers

Missteps to Avoid in Your Next Packaging Project

Integrating new or revamped packaging equipment into your packaging line takes time and understanding. To ensure the overall success of your next packaging project, it is critical to get the details of the project just right and adjust your expectations to the realities of your project. When planning your next packaging project, be sure to avoid these common pitfalls.

Unrealistic expectations

When a CPG sets the expectation for a higher level of performance than is necessary for a machine, either to justify the purchase or to pad the number with the assumption that the machinery supplier will fall short, it puts undue pressure on the equipment maker to commit to an unreasonable goal. All this does is set up both sides for disappointment. Here’s a better approach: have a frank discussion over real performance requirements and align expectations accordingly.

Vendor/application misalignment

Many equipment makers are founded or run by engineers, and most engineers have never met a problem they couldn’t solve— or so at least they think. It’s your job to filter through the vendor’s claims to make sure they can deliver on their sales pitch. Take the extra steps to make sure you are partnering with a vendor whose company values match yours. You will rely on them to provide a sustainable solution and support

for years to come. Vendors that contract to build machines outside their area of core competency will ultimately end up disappointing you, the CPG customer.

Incomplete project scope

Communicate the scope of your project clearly and completely. Do not assume your vendor will know your facility or packaging line, understand your upstream and downstream processes, or even know the ambient temperature in your factory—you have to tell them. “When talking about the full project scope, there is no such thing as too many details,” says Mike Brewster, vice president of sales and marketing at Schneider Packaging Equipment. “It is extremely valuable to understand what exactly is occurring up or downstream from your solution, even if it does not change your solution.”

Neglecting to consider future container sizes/shapes

No one can know the future, but CPGs should brainstorm with operations, engineering and marketing to at least think through all the possible containers you may run and communicate that to your equipment vendor up front. Include in this list what you run now and then account for what you may run in the future.

Counting on integration

It’s a mistake to assume a machine builder will serve as your engineering department and take responsibility for your entire line,

unless you explicitly hire them to do so. Never forget that the machine builder’s job is to build the machine, not to take responsibility for your line.

Being unprepared for machine delivery

As soon as you sign the contract to perform the FAT, you as a customer have work to do before the supplier’s truck rolls up with your new machine. Are all the utilities ready? Is there a clear path from the loading dock to the machine’s new location? Get your packaging materials ready, too. Sample products and packages are not only a requirement for the vendor during machine design, but they will also be needed in larger quantities later for internal testing and for the FAT. To test after the machine is installed, you will need still greater quantities. Be sure to include the costs for testing materials and shipping when setting up your budget.

Not validating at every step

When it comes time to validate your purchase, do you know what a successful implementation looks like? Failure is likely if expectations are unrealistic, or if vendor promises are not verified prior to purchase. You can only declare success at the end if you define it in the initial specifications you present to your supplier. Once you agree to how success will be defined, validate your progress towards it every step of the way.

9

Get Started on Your Sustainability Solution Design a Sustainable Package in Six Steps

Retailer demands. Machine and material technology. Public perception. Economic pressures. The regulatory environment. There are a lot of balls to juggle on the quest to design sustainable packaging, but here’s how to get started.

1. Ask questions first

Be aware of the challenges your current package faces in the sustainability puzzle. Is your package capable of being collected, sorted and processed? Is there a customer for your package at the end of its life cycle? If your package is currently going straight into a landfill, what other material options exist? When it comes to sustainable packaging, it’s important to learn about what you need to learn about.

2. Do a life-cycle assessment

Designing a sustainable package requires a comprehensive approach. Doing a carbon-emissions based life cycle assessment (LCA), the industry standard in informing sustainable packaging design, is often the first step. LCAs look at not only packaging materials but also through the wider lens of manufacturing practices, logistics considerations, consumer use and disposal. While numerous LCA options are out there, many of them may measure the same package in di erent ways, so it’s important to pick a program and stick to it.

3. Look at each component of your package

Sit down with your engineers and take a good, hard look at your package to discover any source reduction possibilities not previously considered. Brainstorm on bio-based material or recycled content you could introduce to the packaging components without compromising product integrity or detracting from shelf presence. Work with suppliers and technology developers who specialize in creating more sustainable containers, caps, labels and other components.

4. Evaluate monomaterials

Many materials, such as paper and PET, may be widely recycled, but oftentimes coatings, labels and other elements added to enhance package functionality or aesthetics may render them unfit for the recycling stream. This is the main reason why the spotlight is on monomaterials. Think big: could you pull o this package using only one, curbside recyclable material? Machining for monomaterials is a clear challenge, but it can be done. If you need inspiration, look to Colgate, whose monomaterial toothpaste tubes are finally a commercialized reality.

5. Design from the outside in

Look for space-saving opportunities in distribution when designing your package. Usually package design is focused on what the package will hold or contain—designing from the inside. But looking through the lens of how to minimize distribution logistics costs forces you to design from the outside in. To

right-size your package, look at any excess materials in your container that impact transport, handling and storage.

6. Look at renewable feedstock

Packaging based on renewable feedstock, such as bioplastics made from corn or sugarcane, has gained a presence in the packaging marketplace. For example, the polystyrene alternative protective packaging called MycoComposite from Ecovative is made from mushroom roots and designed to break down naturally after use. Switching to any material requires ample testing. When evaluating renewable feedstocks, consider a full life-cycle approach by looking at the materials’ performance in recycling, the supplier’s raw material sourcing and the material’s overall functionality for your product.

sustainability in package design today

10 PW 2023 BUYER’S GUIDE

PMMI Business Intelligence, 2022 Challenges and Opportunities for Packaging and Processing Operations

89% of CPGs polled are designing recyclable packaging, and 80% are minimizing packaging to reduce waste.

Over half of CPGs (56%) surveyed are redesigning packaging using more sustainable materials.

About a third (36%) of CPGs surveyed are implementing re-use packaging, while about a quarter (27%) are choosing renewably sourced materials.

Sustainability Beyond the Primary Package: Five Things to Think About

The sustainability discussion focuses most of its attention on the primary package: the unit that will ultimately go into a recycling stream or a landfill. Yet, there are many other sustainability considerations beyond the primary package itself. Sustainability touches all points in the production line. How the package is handled in the plant, how it is bulk-packed and how it is shipped all play into the sustainability equation. Use this checklist to think outside of the source-reduced box about the bigger sustainability picture.

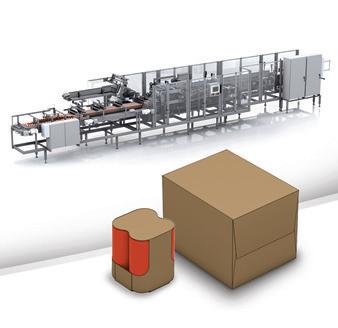

Think like a machine

The decision to go sustainable will impact not only your fillers but every inch of product handling system throughout the facility. Using the right-sized box requires machines to run di erent styles of boxes, cartons and cases. Opting for case packers with a minimal footprint will not only save energy but also help you hit sustainability targets. Don’t forget about conveyors and other secondary packaging machines; they should be able to adapt to lighter materials, like lightweight corrugated.

Think about secondary packaging

E ective primary packaging and shrink wrapping can greatly decrease the amount of shipping packaging needed. Whenever possible, try to eliminate secondary and

tertiary packaging. For example, some CPGs are now increasing the thickness of their solid bleached sulfate (SBS) materials from .16- to .22- or .24-in. to eliminate the need for secondary cases or other pallet stabilizing material. Make the most of volume savings. Even small reductions in height or width, such as 1/16 or 1/8 in., can result in significant savings across your product lines. And don’t just focus on your core product line, consider all the products that need packaging. By quantifying the amount of packaging being used, you can quickly estimate potential cost and waste savings.

Think about your pallets

Trimming fractions of an inch here or there o of your pallet can really add up. Look at primary package designs (see opposite) and how they fit into your case to discover where to shave excess space. Case and pallet-maximizing software will help you better understand how products and packages work together in di erent environments to find a space-saving solution. Be prepared for the possibility, though, that the software analysis may suggest changing the dimensions of the product itself.

Think about supply chain

Packaging typically makes up less than 10% of a product’s carbon footprint, with production, consumer use and transportation taking

up the lion’s share. To solve the sustainability puzzle, think about where you can make a di erence in shipping and logistics. Shipping packages that are mostly air over short distances is bad enough, but carbon footprints get multiplied quickly over the longer distances that products often travel. Identify local supply chain partners that share your mission. Research options carefully, because they may have a business model that is not compatible with yours.

Think about new models

When brainstorming about sustainability, think big. Have you considered new models like multiple-use or closed-loop packaging? Are there ways a shipping package can be used multiple times for the same function or can be used for another function before being discarded? The cost of the product decreases with each use. However, it’s important to factor in the cost of managing reusable, recycled or multiple-use packaging. You may be surprised to learn how much internal packaging you’re using and how easily it can be converted into reusable containers that have virtually unlimited life cycles.

11

Emerging Technologies on the Horizon

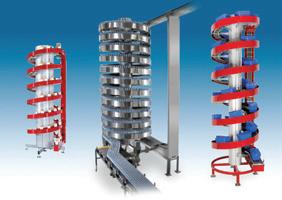

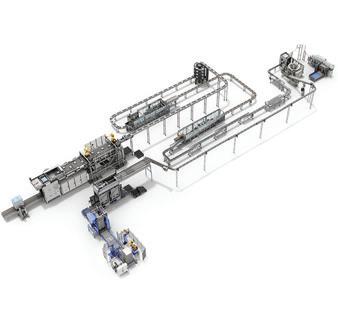

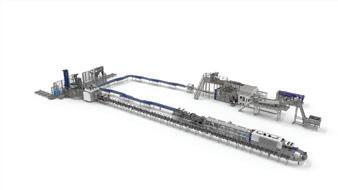

Automation emerged as a game changer during the pandemic, o ering a way for companies to respond to challenges on production lines and in supply chains, while also helping to address critical labor shortages. Companies are now realizing the potential of automated solutions to optimize production, storage and distribution processes.

But what’s on the technology horizon is more than just robots. Advancements and increasing adoptions in other areas, such as 3D printing, supply chain digitalization and materials technology will also grab their share of the spotlight this year.

Automation: full speed ahead

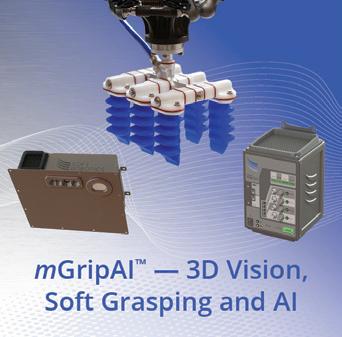

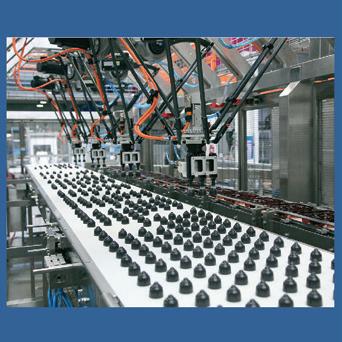

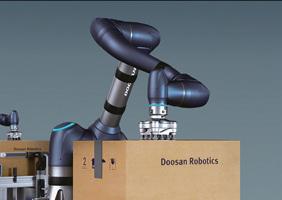

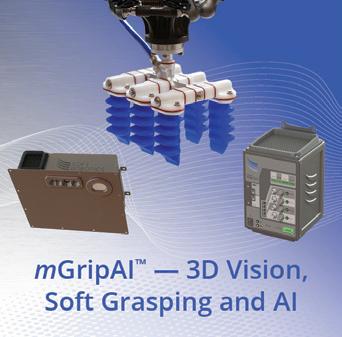

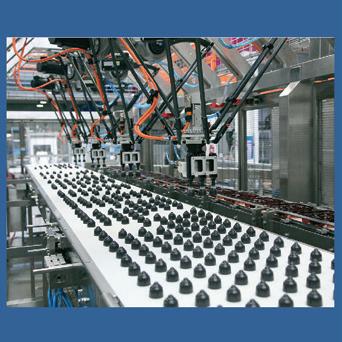

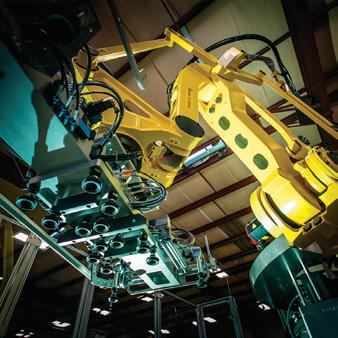

AI and machine learning are revolutionizing our industries, enabling robots to adapt to new scenarios by constantly learning from a growing amount of relevant data. Robots can now tackle complex tasks such as dynamic item picking and precise product inspections on a production line.

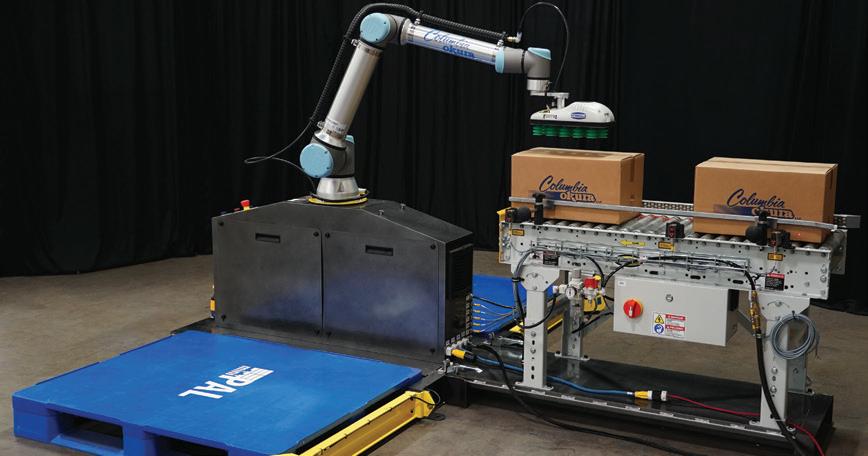

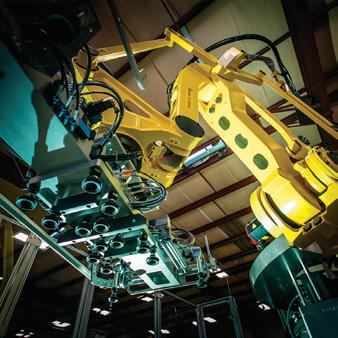

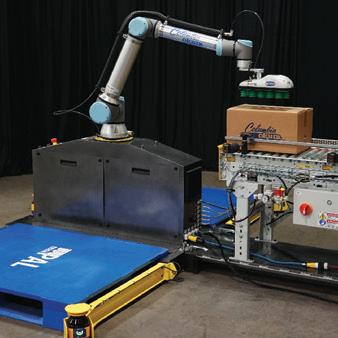

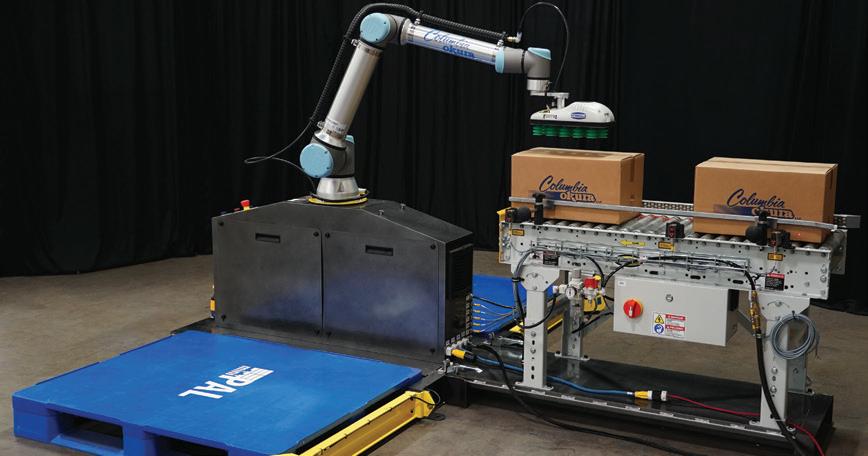

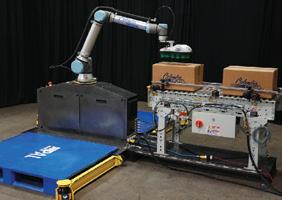

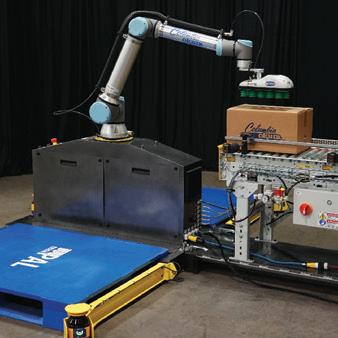

Advances in machine vision have made robots particularly valuable at the end of the packaging line, delivering more e cient pallet stacking that does not require extensive reprogramming to change product type or configuration.

In PMMI Business Intelligence’s 2022 report “Robots and Cobots: An Automated Future,” a majority of CPGs surveyed say they are now using robots at the end of line. The technology is especially useful for larger operations. “We could not operate without our robots and cobots due to the numerous products and packaging patterns,” says a process and automation engineer at a leading beverage company who is quoted in the report.

Survey respondents told us that they are using robots and cobots to reduce palletizing time, minimize gaps and o er measurable productivity, reconfigurability and increased

12 PW 2023 BUYER’S GUIDE

line flexibility during palletizing. Upstream applications for these technologies include case/tray handling, labeling, inspection and material loading. They are also deploying cobots in transport packaging, especially as cobot payload capacities increase.

Interestingly, respondents also thought that robotics growth will begin to plateau in the near future. Currently, 53% of surveyed CPGs use robots in end-of-line packaging, but those CPGs expect no change in that number in the next five years. For cobots specifically, participating CPGs expect a decline over the same timeframe, from the current 18% usage down to 16% in the next five years.

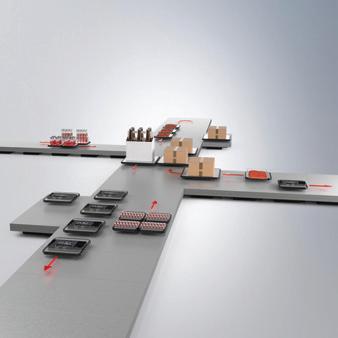

While autonomous guided vehicles (AGVs) have been in manufacturing facilities for years now, businesses are increasingly turning to autonomous mobile robots (AMRs) for internal transport solutions.

82,000 AMRs shipped in 2021, with shipments predicted to reach over 600,000 by 2025, according to an article by Mobile Industrial Robots. Look for more AMR innovations to be rolling on the plant floor soon. The newest generation of sensors and AI-driven data are making AMRs flexible enough to be easily redeployed and smart enough to navigate a facility without the need for guided wiring or magnets.

3D printing: a solution to the parts crisis?

Industrial 3D printing technology holds potential in new applications as prices of printers decrease, technological capabilities improve and adoption continues to rise.

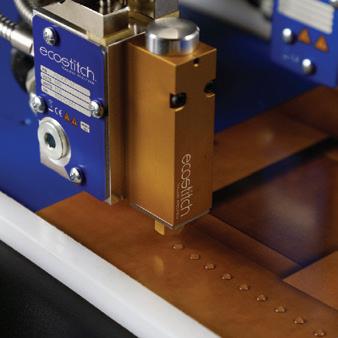

According to PMMI Business Intelligence’s “Future of Automation in Packaging and Processing” report, 25% of the CPG companies surveyed said that they are already using 3D printers to print spare parts, and that figure is expected to increase to one third in the next three years.

Traditionally, 3D printers have also been used to create designs and prototypes, saving time and money and having an immediate impact on ROI in product development. Now, 3D printing may be increasingly used in machine maintenance, helping CPGs keep downtime and maintenance costs low through on-the-fly spare parts generation.

Common applications they reported included printing non-moving parts that wear out quickly—rails, runners and wheels—as well as printing end-e ectors for robots. A ordable 3D printers can already print in metal, and the future is likely to

bring more material options to the market. Increased adoption throughout the industry will help CPGs reduce the cost of parts and circumvent potential supply chain problems, thereby reducing lead times and saving on administrative time and space.

The emergence of supply chain digitalization

The future growth of CPGs increasingly depends on their ability to mitigate the e ects of inflation on the supply chain, navigating rising energy and material costs. Digitalization o ers a tool to do just that.

According to GlobalData, the data and analytics company, digitalization incorporates technologies like artificial intelligence (AI), 5G, Internet of Things (IoT), augmented reality (AR) and virtual reality (VR) as a strategy to improve supply chain e ciency and reduce costs. GlobalData expects the integration of digital technologies will be a major development in supply chain management over the next decade.

What would a typical scenario for supply chain digitalization look like? AI can be used to predict changes in supply and demand, allowing for better inventory management, cost savings and supply chain e ciency. Increased automation across all stages of the supply chain can also aid in the shift from just-in-time to just-in-case delivery, reduce the risk of disruption and ensure product availability at all times.

The rise of maintenancepredictive

Perhaps the greatest disruption CPGs can experience is when a machine simply breaks down. Expect predictive maintenance systems to grow fast. PMMI Business Intelligence’s survey of attendees at PACK EXPO International in late 2022 found that 43% of the polled CPGs are currently using some form of the technology, while an additional 45% plan to implement predictive maintenance in the next three years. Details are published in the 2022 “Challenges and Opportunities for Packaging and Processing Operations” report.

CPGs are using predictive maintenance for implementing thermography solutions, full equipment monitoring and computerized maintenance management system software.

Increasingly, CPGs are looking to their suppliers for embedded or added predictive maintenance systems that handle parts room setup and organization, oil monitoring analysis, risk and reliability

software and machine level fault codes. They also need systems for tracking hours of use until downtime, outage planning and scheduled total productive maintenance and other factors.

Most respondents told PMMI that they are in the early exploratory stages with predictive maintenance, but the interest of respondents shows a significant and growing group adopting the technology, pointing to a technology trend to watch.

Active packaging

Technological advancements are also happening at the micro level, in materials. Advances in active and intelligent packaging (materials that include features to extend shelf life or monitor freshness) offer a chance to tackle the big problem of food waste, which has not only productivity but also environmental and humanitarian implications. About $400 billion is lost to food waste before products even reach the market each year, translating to 14% of all food produced, according to Angela Morgan, director of business development at Aptar.

Aptar’s InvisiShield is a three-phase polymer, an example of antimicrobial packaging that uses chlorine dioxide to protect produce from pathogens, extending the shelf life and reducing food waste. The Antipack from Handary is a commercial film that uses a coating of nisin to inhibit mold growth on solid food products like cheeses. Other examples from the developing sector of active packaging include:

• Edible coatings, applied directly to the product using spraying, dipping or brushing, are invisible to the consumer but can increase shelf life by providing gas barrier protection and e ective moisture barrier.

• Nanotechnology holds its own and is also intermixed with other categories. Danaflex-Nano supplies a flexible pack with a rigid top that uses silicate nanoplates to extend shelf life.

• Oxygen scavenging is an established active packaging category that already has several innovative examples in use, such as beer brewer Carlsberg’s ZerO2 scavenging material placed in the cap liner.

• Indicators built into packaging are another wide ranging category with several key functions depending on the product, from time temperature indicators to gas sensors.

13

Have You Tried

We hope this Buyer’s Guide will help you find the supplier for your next project. But chances are good that you will also be checking out potential vendors online. If you have ever tried to search for packaging machinery online you were likely overwhelmed by the sheer number of results. For example, a search for “cartoning equipment” on Google is returning about 36 million results.

What if you could connect to your next supplier by searching online through a curated, vetted list of the leading suppliers of packaging and processing machinery, materials and services? Now you can. PMMI ProSource is the online directory of PMMI members, representing the top suppliers in our industry who are experts in packaging and processing.

PMMI ProSource? three ways to find solutions

PMMI ProSource is a robust online directory with more than one way to navigate.

Drill down from the homepage

Start at Prosource.org and click through to the specific category you need. PMMI ProSource features illustrations and category definitions to help guide you through to the right solution.

Powerful search bar

At the top right of ProSource.org is a powerful search bar. Auto complete and common synonyms have been programmed in to help you find your solution faster.

Search by package type

Use the Package Type tool on the left hand side of PMMI ProSource to search for equipment by the packaging it runs: bags, bottles, cartons and more. Search results will display the suppliers who told PMMI their machines can handle those package types.

14 PW 2023 BUYER’S GUIDE

Cartoners Carton Erect/Load/Seal Carton Erectors/Formers quipment Category • 54 Companies quipment Category • 31 Companies quipment Category • 9 Companies See all Cartoning equipment categories Gabletop Cartoning Equipment Cartoning Equipment Search by Package Types:

Why PMMI ProSource?

PMMI ProSource quickly connects you to your next supplier. How?

• Focused on our industry. Browse hundreds of categories of validated suppliers in key areas of machinery, materials and services, such as vertical form/fill/seal equipment, liquid fillers and conveyors.

• Authoritative. All companies listed are members of PMMI, the leading global association of packaging and processing that produces the PACK EXPO shows and this magazine. PMMI sta validate category listings.

• Less scrolling, more finding. Rather than spending hours scrolling through search engine results online, go to PMMI ProSource for a curated experience that connects you faster to the packaging and processing specialists who have the specific solutions you need.

Filter your results

Use PMMI ProSource’s filters during your search to sort through packaging solutions as you research, similar to the consumer sites you love.

• Say you are a start-up salsa company looking for your first machine. Once you are in the Liquid Fillers section, you can sort results to find suppliers that specialize in entry-level/budget models or hot fill machines machines using the panel on the left.

• Or, if you are a snack company looking specifically for stick pack machines, go to the Vertical Form/Fill/Seal section and select Stick Pack under the Bag Style section.

Make the connection

When you find a supplier that you are interested in, click on the preview blurb to be taken to their profile page. There, you can get an overview of the PMMI member supplier, their specialties, equipment categories and contact information.

Congratulations—rather than spending precious time digging through endless results on a search engine, you have just made a connection with a new potential supplier. And you did it all for free!

More than just listings

In addition to the directory listings, PMMI ProSource also offers many helpful howto articles to help you solve typical problems in the facility. Recent articles have included “Palletizing 101: An Overview of the Basics” and “Common Ways Labeling Projects Can Fail.”

15

Try out PMMI ProSource today and send us your feedback. We are always looking for ways to improve the site. Drop us a line at prosource@pmmi.org.

Visit www.prosource.org today.

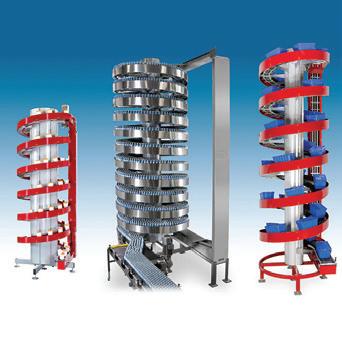

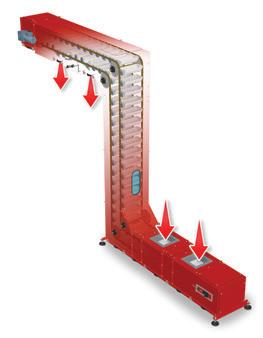

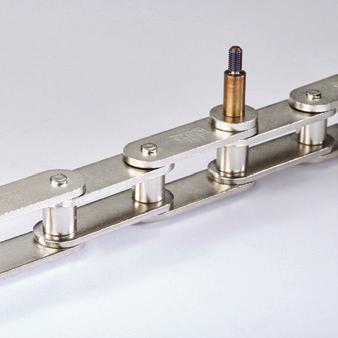

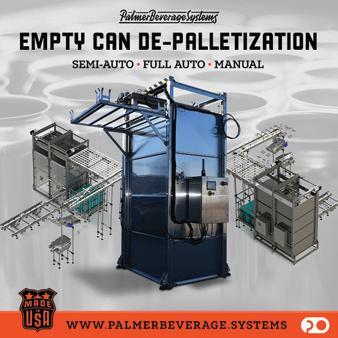

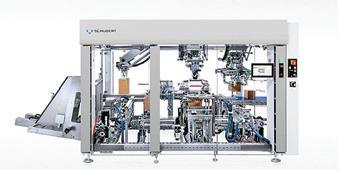

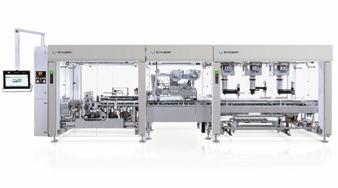

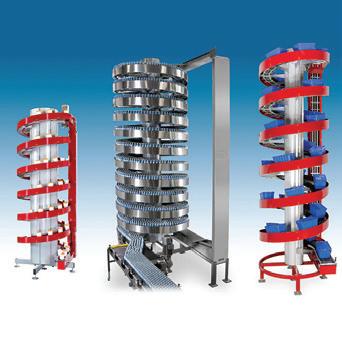

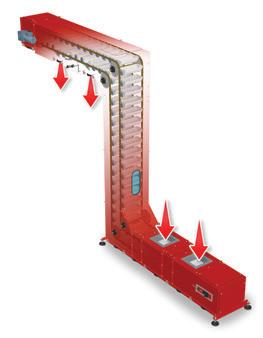

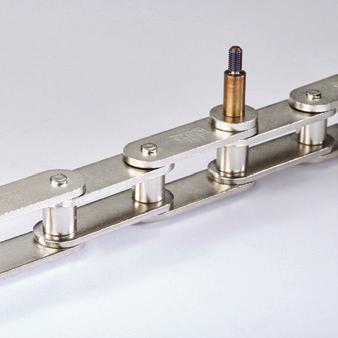

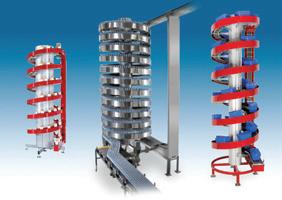

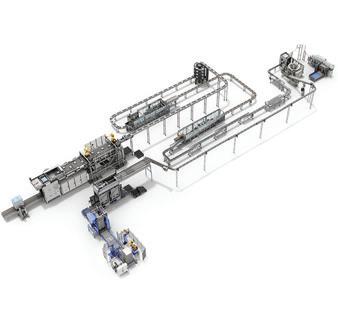

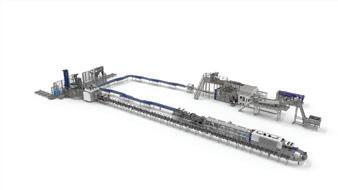

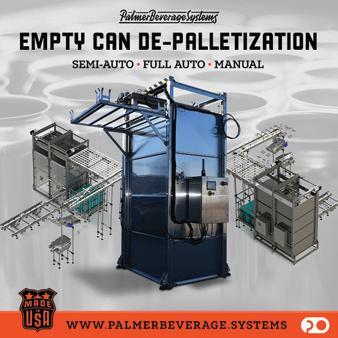

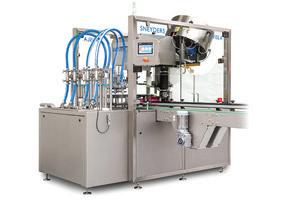

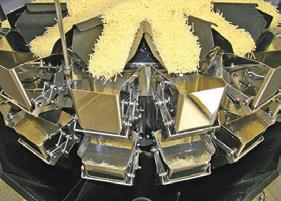

MACHINERY PAGE ADHESIVE APPLICATORS Dekka 51 Meler USA Corporation 66 Nordson Corporation 68 Robatech USA Inc. 73 Valco Melton 80 BAGGING, POUCHING & WRAPPING Formost Fuji Corporation 27 BAG & POUCH FILL/SEAL (PRE-MADE) All Packaging Machinery 22 ALLIEDFLEX Technologies, Inc. 21 BestCode 96 BW Flexible Packaging 253 FAWEMA Inc. 26 Formost Fuji Corporation 27 Frain Industries 58 Glenroy, Inc. 257 High Tek USA, Inc. 180 Mamata Enterprises, Inc. 30 Massman 65 Matrix Packaging Machinery, Inc. 31 PAC Machinery 33 Paxiom Group 34 Plan IT Packaging Systems Inc. 36 Shemesh Automation 190 Triangle Package Machinery Company 39 Uni ed Flex Packaging Technologies 40 Viking Masek Global Packaging Technologies 81 BLISTERS/CLAMSHELLS/ SKIN PACKAGING Klöckner Pentaplast, Food Packaging 272 Starview Packaging Machinery 244 U.S. Tsubaki, Inc. 161 BULK HANDLING/FILLING EQUIPMENT Duravant 219 ECORRCRATE 270 High Tek USA, Inc. 180 Ideal-Pak 181 Material Transfer & Storage, Inc. 150 National Bulk Equipment, Inc. (NBE) 154 Piab Inc. 232 Ryson International Inc 158 Uni ed Flex Packaging Technologies 40 Yamato Corporation 194 CAPPING BellatRx Inc. 173 New England Machinery, Inc. 156 Pneumatic Scale Angelus 187 Serac Inc. 189 Shemesh Automation 190 Shibuya Hoppmann Corp. 234 CARTONING Aagard Group, LLC 47 BluePrint Automation 48 BW Integrated Systems 215 Cama North America 50 Delkor Systems, Inc. 52 Doosan Robotics Inc 218 Douglas Machine Inc. 53 Econocorp, Inc. 55 Frain Industries 58 Graphic Packaging International 59 IXAPACK 63 JLS Automation 64 Mpac Group 67 Meler USA Corporation 66 Nordson Corporation 68 Paxiom Group 34 PMI KYOTO Packaging Systems 70 Propack Processing & Packaging Systems, Inc. 71 R.A Jones 72 Robatech USA Inc. 73 Schubert North America LLC 75 Serpa Packaging Solutions 76 Sourcelink Solutions, LLC 77 Syntegon Packaging Technology 79 Triangle Package Machinery Company 39 U.S. Tsubaki, Inc. 161 Viking Masek Global Packaging Technologies 81 CASE ERECT/SEAL A-B-C Packaging Machine Corp. 213 BW Packaging 175 Cama North America 50 Dekka 51 Delkor Systems, Inc. 52 Doosan Robotics Inc 218 Eastey 54 Econocorp, Inc. 55 Fallas Automation Inc 56 Focke & co 57 INSITE Packaging Automation 60 Intertape Polymer Group 61 Nordson Corporation 68 Norgren 131 ONExia 231 Propack Processing & Packaging Systems, Inc. 71 Robatech USA Inc. 73 Shurtape Technologies 276 Signode 222 WestRock 82 CASE/TRAY PACKING A-B-C Packaging Machine Corp. 213 Aagard Group, LLC 47 BluePrint Automation 48 Brenton 49 Busch Vacuum Solutions 241 BW Integrated Systems 215 Cama North America 50 16 PW 2023 BUYER’S GUIDE Company Pro les 2023 BUYER’S GUIDE COMPANY INDEX

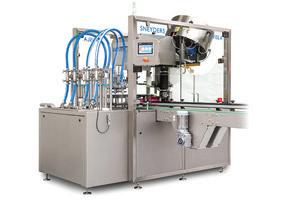

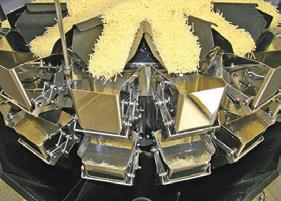

Delkor Systems, Inc. 52 Doosan Robotics Inc 218 Douglas Machine Inc. 53 Econocorp, Inc. 55 Fallas Automation Inc 56 FANUC America Corporation 230 Focke & co 57 Frain Industries 58 Garvey Corporation 145 Heat and Control, Inc. 179 ITW Hartness 62 IXAPACK 63 JLS Automation 64 Krones 182 Markem-Imaje 108 Massman 65 Meler USA Corporation 66 Mpac Group 67 Nordson Corporation 68 Paxiom Group 34 PMI KYOTO Packaging Systems 70 Propack Processing & Packaging Systems, Inc. 71 Robatech USA Inc. 73 Serpa Packaging Solutions 76 Schneider Packaging Equipment Co., Inc. 74 Schubert North America LLC 75 Sidel 191 Standard-Knapp, Inc. 78 Syntegon Packaging Technology 79 Viking Masek Global Packaging Technologies 81 WestRock 82 Yamato Corporation 194 Yaskawa America, Inc., Motoman Robotics Division 236 CODING/MARKING Bell-Mark 95 BestCode 96 Buskro Ltd. 97 Chase-Logeman 176 Diagraph Marking & Coding, An ITW Company 99 Domino Amjet Inc. 101 Encoder Products Company 129 ID Technology 104 Keyence Corporation of America 105 Label-Aire, Inc. 106 Leibinger 107 MFT Automation 148 Markem-Imaje 108 Nita Labeling Systems 109 Norwix 110 Novanta 132 Squid Ink Manufacturing 114 Universal Labeling Systems, Inc. 266 Videojet Technologies Inc. 116 Weber Packaging Solutions 117 WLS 118 CONTROLS & MACHINE COMPONENTS B&R Industrial Automation 127 Beckhoff Automation 128 Encoder Products Company 129 Eriez Magnetics 204 Fortress Technology Inc. 205 King Plastic Corporation 147 Lenze 130 Multivac Inc. 258 Nercon Conveyor Systems 155 Norgren 131 Novanta 132 Siko Products, Inc. 133 SMC Corporation of America 134 Soft Robotics 235 VDG (Van der Graaf) 162 Wipotec 209 Yaskawa America, Inc. 135 CONVERTING EQUIPMENT Buskro Ltd. 97 Encoder Products Company 129 IMA Dairy and Food USA 139 Novembal 183 Sidel 191 CONVEYING & ACCUMULATION B&R Industrial Automation 127 BW Integrated Systems 215 CASSEL Inspection 203 Columbia Machine 216 Columbia/Okura 217 Dodge Industrial, Inc. 142 Dorner Mfg. Corp. 143 DTM Packaging 177 Eastey 54 Encoder Products Company 129 Eriez Magnetics 204 Flexlink Systems, Inc. 144 Garvey Corporation 145 Heat and Control, Inc. 179 Intralox 146 ITW Hartness 62 Kaufman Engineered Systems, Inc. 220 King Plastic Corporation 147 mk North America, Inc. 149 Modular Conveyor Express 151 Morrison Container Handling Solutions 152 Multi-Conveyor 153 Nercon Conveyor Systems 155 Palmer Beverage Systems 185 PFlow Industries, Inc. 157 Phoenix Wrappers 35 PMI KYOTO Packaging Systems 70 Propack Processing & Packaging Systems, Inc. 71 Ryson International Inc 158 Ska Fabricating 223 Sleeve Seal 113 Span Tech LLC 159 Specialty Equipment 192 VDG (Van der Graaf) 162 DIGITAL PRINTING Bell-Mark 95 BestCode 96 Buskro Ltd. 97 Domino Amjet Inc. 101 Multivac Inc. 258 Squid Ink Manufacturing 114 Videojet Technologies Inc. 116 WLS 118 FEEDING/INSERTING/ UNSCRAMBLING All-Fill Inc. 171 BellatRx Inc. 173 BluePrint Automation 48 CASSEL Inspection 203 Eriez Magnetics 204 Garvey Corporation 145 MFT Automation 148 Morrison Container Handling Solutions 152 Multi-Conveyor 153 New England Machinery, Inc. 156 Serpa Packaging Solutions 76 Shibuya Hoppmann Corp. 234 FILLING/CAPPINGLIQUID & VISCOUS BellatRx Inc. 173 Bevcorp LLC 174 Busch Vacuum Solutions 241 BW Packaging 175 Chase-Logeman 176 DTM Packaging 177 Duravant 219 Enercon Industries 178 Frain Industries 58 Haver & Boecker USA, Inc. 28 Ideal-Pak 181 Krones 182 Matrix Packaging Machinery, Inc. 31 OPTIMA Machinery Corporation 184 Palmer Beverage Systems 185 Pneumatic Scale Angelus 187 Point Five Packaging 243 R.A Jones 72 Ronchi America 188 Serac Inc. 189 Shemesh Automation 190 Shibuya Hoppmann Corp. 234 Sidel 191 Specialty Equipment 192 Syntegon Packaging Technology 79 Uni ed Flex Packaging Technologies 40 Vacuum Barrier Corporation 261 Weightpack 193 Zima-Pack LLC 195 FILLING/CAPPING - DRY All-Fill Inc. 171 BellatRx Inc. 173 Enercon Industries 178 High Tek USA, Inc. 180 OPTIMA Machinery Corporation 184 Pneumatic Scale Angelus 187 R.A Jones 72 Specialty Equipment 192 Uni ed Flex Packaging Technologies 40 Yamato Corporation 194 Weightpack 193 FLOW WRAPPING Formost Fuji Corporation 27 Harpak-ULMA Packaging LLC 242 IMA FLX 29 Paxiom Group 34 Plan IT Packaging Systems Inc. 36 Schubert North America LLC 75 FORM/FILL/SEALVERTICAL All-Fill Inc. 171 ALLIEDFLEX Technologies, Inc. 21 All Packaging Machinery 22 BW Flexible Packaging 253 Harpak-ULMA Packaging LLC 242 Heat and Control, Inc. 179 High Tek USA, Inc. 180 IMA FLX 29 Matrix Packaging Machinery, Inc. 31 Norwix 110 Paxiom Group 34 Plan IT Packaging Systems Inc. 36 Syntegon Packaging Technology 79 Taisei Lamick USA, Inc. 37 Triangle Package Machinery Company 39 Uni ed Flex Packaging Technologies 40 Viking Masek Global Packaging Technologies 81 FORM/FILL/SEALHORIZONTAL ALLIEDFLEX Technologies, Inc. 21 Duravant 219 Formost Fuji Corporation 27 Harpak-ULMA Packaging LLC 242 High Tek USA, Inc. 180 IMA FLX 29 Mamata Enterprises, Inc. 30 nVenia, A Duravant Company 32 OPTIMA Machinery Corporation 184 Norgren 131 R.A Jones 72 INSPECT/VISION/TESTING/ CHECKWEIGH/X-RAY All-Fill Inc. 171 Anritsu Product Inspection 201 Bunting 202 CASSEL Inspection 203 Encoder Products Company 129 Eriez Magnetics 204 Fortress Technology Inc. 205 LMI Technolgies 206 Teledyne Taptone 208 Valco Melton 80 Wipotec 209 17 Continued on next page

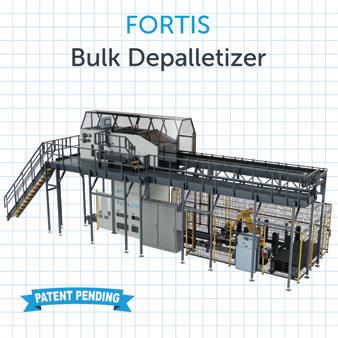

LABELING All-Fill Inc. 171 American Film and Machinery 93 Axon 94 B&R Industrial Automation 127 BellatRx Inc. 173 BestCode 96 Buskro Ltd. 97 BW Packaging 175 Chase-Logeman 176 CTM Labeling Systems Inc. 98 Diagraph Marking & Coding, An ITW Company 99 Domino Amjet Inc. 101 Encoder Products Company 129 EPI 102 Frain Industries 58 H.B. Fuller 271 ID Technology 104 Keyence Corporation of America 105 Klöckner Pentaplast, Pharma, Health & Protection and Durables 265 Krones 182 Label-Aire, Inc. 106 MFT Automation 148 Markem-Imaje 108 Meler USA Corporation 66 Multivac Inc. 258 Nita Labeling Systems 109 Nordson Corporation 68 Novanta 132 Panther Industries, Inc. 111 Pneumatic Scale Angelus 187 Precision Automation Company, Inc. 233 Quadrel Labeling Systems 112 Robatech USA Inc. 73 Sleeve Seal 113 Squid Ink Manufacturing 114 TRIPACK, LLC 115 Universal Labeling Systems, Inc. 266 Videojet Technologies Inc. 116 Weber Packaging Solutions 117 Wipotec 209 WLS 118 MATERIAL HANDLING AMCI 172 B&R Industrial Automation 127 Beckhoff Automation 128 Bunting 202 Busch Vacuum Solutions 241 Buskro Ltd. 97 Columbia Machine 216 Columbia/Okura 217 Dodge Industrial, Inc. 142 Doosan Robotics Inc 218 Dorner Mfg. Corp. 143 Duravant 219 FANUC America Corporation 230 Flexlink Systems, Inc. 144 Intralox 146 Kaufman Engineered Systems, Inc. 220 King Plastic Corporation 147 Material Transfer & Storage, Inc. 150 Mettler Toledo Product Inspection 207 mk North America, Inc. 149 Multi-Conveyor 153 National Bulk Equipment, Inc. (NBE) 154 New England Machinery, Inc. 156 Piab Inc. 232 PFlow Industries, Inc. 157 Pneumatic Scale Angelus 187 Precision Automation Company, Inc. 233 Ryson International Inc 158 Tawi USA 160 Yaskawa America, Inc. 135 MULTIPACKING/SHRINK BUNDLING/BANDING All Packaging Machinery 22 Axon 94 American Film and Machinery 93 BluePrint Automation 48 BW Packaging 175 Clysar LLC 255 Delkor Systems, Inc. 52 Eastey 54 EDL Packaging 25 Frain Industries 58 Krones 182 Meler USA Corporation 66 Morrison Container Handling Solutions 152 nVenia, A Duravant Company 32 PDC International Corp. 186 R.A Jones 72 Sleeve Seal 113 Standard-Knapp, Inc. 78 Syntegon Packaging Technology 79 Texwrap 38 PALLETIZING/ DEPALLETIZING A-B-C Packaging Machine Corp. 213 Aagard Group, LLC 47 Brenton 49 B&R Industrial Automation 127 BW Flexible Packaging 253 BW Integrated Systems 215 Columbia Machine 216 Columbia/Okura 217 Doosan Robotics Inc 218 FANUC America Corporation 230 Flexlink Systems, Inc. 144 Haver & Boecker USA, Inc. 28 Intralox 146 ITW Hartness 62 IXAPACK 63 Krones 182 Massman 65 Meler USA Corporation 66 Mpac Group 67 nVenia, A Duravant Company 32 Nordson Corporation 68 ONExia 231 Palmer Beverage Systems 185 Ryson International Inc 158 Schneider Packaging Equipment Co., Inc. 74 Ska Fabricating 223 Sourcelink Solutions, LLC 77 Specialty Equipment 192 TopTier Palletizers 224 Universal Labeling Systems, Inc. 266 Viking Masek Global Packaging Technologies 81 Yaskawa America, Inc., Motoman Robotics Division 236 ROBOTICS Aagard Group, LLC 47 B&R Industrial Automation 127 BluePrint Automation 48 Brenton 49 Busch Vacuum Solutions 241 BW Integrated Systems 215 Cama North America 50 Columbia/Okura 217 Delkor Systems, Inc. 52 Doosan Robotics Inc 218 Fallas Automation Inc 56 FANUC America Corporation 230 Flexlink Systems, Inc. 144 Garvey Corporation 145 Haver & Boecker USA, Inc. 28 ITW Hartness 62 JLS Automation 64 Multivac Inc. 258 nVenia, A Duravant Company 32 ONExia 231 Piab Inc. 232 PMI KYOTO Packaging Systems 70 Precision Automation Company, Inc. 233 Propack Processing & Packaging Systems, Inc. 71 Schneider Packaging Equipment Co., Inc. 74 Schubert North America LLC 75 Signode 222 Soft Robotics 235 Sourcelink Solutions, LLC 77 Syntegon Packaging Technology 79 TopTier Palletizers 224 Viking Masek Global Packaging Technologies 81 Yaskawa America, Inc. 135 Yaskawa America, Inc., Motoman Robotics Division 236 SHRINK WRAPPING Axon 94 Clysar LLC 255 Delkor Systems, Inc. 52 Douglas Machine Inc. 53 Eastey 54 EDL Packaging 25 PAC Machinery 33 PDC International Corp. 186 Standard-Knapp, Inc. 78 Texwrap 38 STRAPPING Signode 222 STRETCH WRAPPING/ PALLET LOAD CONTAINMENT Aero Rubber Company, Inc. 214 Columbia Machine 216 Duravant 219 Intertape Polymer Group 61 Kaufman Engineered Systems, Inc. 220 Orion Packaging Systems, Inc 221 Phoenix Wrappers 35 Signode 222 TopTier Palletizers 224 TAMPER-EVIDENT MACHINERY American Film and Machinery 93 Axon 94 Enercon Industries 178 Label-Aire, Inc. 106 Nita Labeling Systems 109 PDC International Corp. 186 Serpa Packaging Solutions 76 Sleeve Seal 113 THERMOFORM/FILL/SEAL Busch Vacuum Solutions 241 Harpak-ULMA Packaging LLC 242 JLS Automation 64 Klöckner Pentaplast, Food Packaging 272 Multivac Inc. 258 Starview Packaging Machinery 244 TRAY LIDDING/SEALING Harpak-ULMA Packaging LLC 242 Ideal-Pak 181 Multivac Inc. 258 Point Five Packaging 243 Starview Packaging Machinery 244 VISION INSPECTION SYSTEMS Mettler Toledo Product Inspection 207 Nita Labeling Systems 109 Propack Processing & Packaging Systems, Inc. 71 Soft Robotics 235 WEIGHING/ COMBINATION SCALES Anritsu Product Inspection 201 Heat and Control, Inc. 179 High Tek USA, Inc. 180 Mettler Toledo Product Inspection 207 nVenia, A Duravant Company 32 Paxiom Group 34 Triangle Package Machinery Company 39 Uni ed Flex Packaging Technologies 40 Yamato Corporation 194 Wipotec 209 COMPANY INDEX continued 2023 BUYER’S GUIDE 18 PW 2023 BUYER’S GUIDE

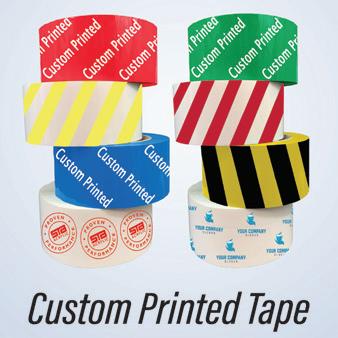

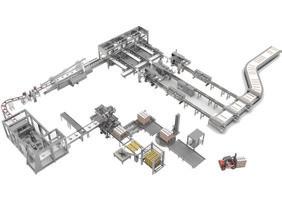

MATERIALS PAGE ADDITIVES, COATINGS & INKS Squid Ink Manufacturing 114 ADHESIVES/TAPE H.B. Fuller 271 Intertape Polymer Group 61 Sealstrip 260 Shurtape Technologies 276 STA, LLC 277 The Reynolds Company 275 BLISTERS/CLAMSHELLS/ THERMOFORMING MATERIALS Klöckner Pentaplast, Pharma, Health & Protection and Durables 265 WestRock 82 CARTONS AND BOXES Graphic Packaging International 59 Metsä Board Americas 273 WestRock 82 CLOSURES Independent Can 247 MRP Solutions 250 Novembal 183 Universal Labeling Systems, Inc. 266 CONTAINERS Bevcorp LLC 174 ECORRCRATE 270 Independent Can 247 Inline Plastics Corp 248 Klöckner Pentaplast, Food Packaging 272 Klöckner Pentaplast, Pharma, Health & Protection and Durables 265 Markem-Imaje 108 Novembal 183 Point Five Packaging 243 Printpack 259 FLEXIBLE PACKAGING American Flexpack Inc 23 Charter Next Generation 254 Formost Fuji Corporation 27 Klöckner Pentaplast, Food Packaging 272 FlexPak Services 256 Focke & co 57 Glenroy, Inc. 257 Mamata Enterprises, Inc. 30 Markem-Imaje 108 Norwix 110 Pregis LLC 274 Printpack 259 Sealstrip 260 Taisei Lamick USA, Inc. 37 Vacuum Barrier Corporation 261 LABELS American Film and Machinery 93 ID Technology 104 Klöckner Pentaplast, Pharma, Health & Protection and Durables 265 Universal Labeling Systems, Inc. 266 Weber Packaging Solutions 117 MULTIPACKS/HANDLES/ CARRIERS Axon 94 PakTech 69 PLASTICS/RESINS King Plastic Corporation 147 Klöckner Pentaplast, Food Packaging 272 Klöckner Pentaplast, Pharma, Health & Protection and Durables 265 PROTECTIVE/TRANSPORT PACKAGING Charter Next Generation 254 Eastey 54 ECORRCRATE 270 Focke & co 57 Intertape Polymer Group 61 Orion Packaging Systems, Inc 221 Pregis LLC 274 Signode 222 Sparck Technologies 140 RETAIL DISPLAY PACKAGING Aagard Group, LLC 47 Clysar LLC 255 ECORRCRATE 270 Focke & co 57 King Plastic Corporation 147 Metsä Board Americas 273 Sleeve Seal 113 Texwrap 38 Universal Labeling Systems, Inc. 266 REUSABLE TRANSPORT PACKAGING (BINS, CRATES, PALLETS, ETC.) ECORRCRATE 270 BUSINESS DRIVERS PAGE CONTRACT PACKAGING American Flexpack Inc 23 American Film and Machinery 93 Axon 94 BestCode 96 BW Packaging 175 Clysar LLC 255 James Alexander Corp. 249 Material Transfer & Storage, Inc. 150 Nita Labeling Systems 109 Pneumatic Scale Angelus 187 Ronchi America 188 Span Tech LLC 159 Specialty Equipment 192 Squid Ink Manufacturing 114 Taisei Lamick USA, Inc. 37 Texwrap 38 TRIPACK, LLC 115 E-COMMERCE BluePrint Automation 48 Clysar LLC 255 CTM Labeling Systems Inc. 98 Fallas Automation Inc 56 FANUC America Corporation 230 Intertape Polymer Group 61 Intralox 146 PAC Machinery 33 Panther Industries, Inc. 111 PFlow Industries, Inc. 157 Pregis LLC 274 Ryson International Inc 158 Schubert North America LLC 75 Shurtape Technologies 276 Sparck Technologies 140 Span Tech LLC 159 Specialty Equipment 192 Texwrap 38 The Reynolds Company 275 WestRock 82 Wipotec 209 PACKAGE DESIGN Metsä Board Americas 273 MRP Solutions 250 PACKAGING LINE INTEGRATION AMCI 172 BellatRx Inc. 173 Brenton 49 BW Integrated Systems 215 Cama North America 50 Columbia Machine 216 Columbia/Okura 217 DTM Packaging 177 Duravant 219 Formost Fuji Corporation 27 Harpak-ULMA Packaging LLC 242 Heat and Control, Inc. 179 Hitachi Industrial Equipment & Solutions America, LLC 103 ITW Hartness 62 JLS Automation 64 Krones 182 Leibinger 107 nVenia, A Duravant Company 32 National Bulk Equipment, Inc. (NBE) 154 Phoenix Wrappers 35 PMI KYOTO Packaging Systems 70 Serac Inc. 189 Serpa Packaging Solutions 76 Signode 222 Ska Fabricating 223 Sparck Technologies 140 Sleeve Seal 113 Yamato Corporation 194 SOFTWARE Beckhoff Automation 128 Markem-Imaje 108 SUSTAINABILITY Aagard Group, LLC 47 AMCI 172 American Film and Machinery 93 BestCode 96 Botani 269 Brenton 49 Busch Vacuum Solutions 241 BW Packaging 175 Charter Next Generation 254 Clysar LLC 255 Columbia Machine 216 Columbia/Okura 217 Digimarc 100 Eastey 54 ECORRCRATE 270 EDL Packaging 25 FANUC America Corporation 230 Focke & co 57 Formost Fuji Corporation 27 Fortress Technology Inc. 205 Glenroy, Inc. 257 Graphic Packaging International 59 H.B. Fuller 271 Hitachi Industrial Equipment & Solutions America, LLC 103 Independent Can 247 Intertape Polymer Group 61 ITW Hartness 62 Keyence Corporation of America 105 King Plastic Corporation 147 Klöckner Pentaplast, Food Packaging 272 Klöckner Pentaplast, Pharma, Health & Protection and Durables 265 Leibinger 107 Metsä Board Americas 273 MRP Solutions 250 Nita Labeling Systems 109 Novembal 183 Orion Packaging Systems, Inc 221 PakTech 69 Printpack 259 R.A Jones 72 Robatech USA Inc. 73 Ronchi America 188 Ryson International Inc 158 Schubert North America LLC 75 Sealstrip 260 Serpa Packaging Solutions 76 Sidel 191 Standard-Knapp, Inc. 78 Squid Ink Manufacturing 114 Texwrap 38 The Reynolds Company 275 Vacuum Barrier Corporation 261 Valco Melton 80 VDG (Van der Graaf) 162 Weightpack 193 WestRock 82 Wipotec 209 19

BAGGING, POUCHING & WRAPPING

MACHINERY 20 PW 2023 BUYER’S GUIDE

BAGGING, POUCHING & WRAPPING

ALLIEDFLEX® THE AUTHORITY in STAND UP POUCH PACKAGING

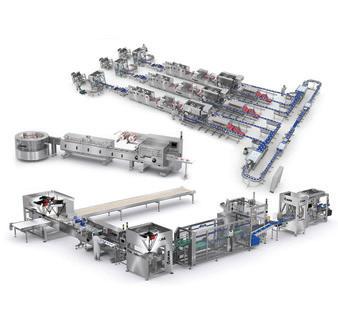

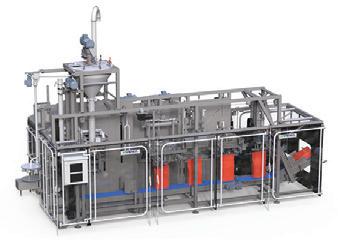

ALLIEDFLEX® is a leading North American supplier of Global Standup Pouch Packaging Machinery and Turnkey System Provider. We also provide integrated systems for Pouch Processing (Pasteurization, Cooling) & Automated Packaging including Flow Wrap, Flow Pack, Robotic Flex Picker, Multi pack Cartoning, Collating, and Case Packing Systems.

ALLIEDFLEX® specializes in Pouch & Bag Packaging Machinery for Standup

Zipper or “slider” styles, retort pouch, spouted pouch, die cut shaped pouch, side gusseted, stick pack, stand-up pouch, standing pouch and aseptic pouch machinery. Intermittent and continuous motion vertical form fill seal VFFS machinery technologies from the most respected suppliers in the world.

We offer: Fill Seal (pre-made), Fill through Spout, and Form Fill Seal (roll stock) HFFS Machinery Technologies, Horizontal Pouch Packaging, Vertical Pouch Packaging, Turnkey Robotic Automation for Pouch Processing and End Of Line Packaging, Semi & Automated Pouch Leak Detection Machinery to suit your present and future needs.

Markets Served: Beverage, Applesauce, Baby Food, Candy, Snacks, Dried Fruit, Meal Kits, MRE, Wine, Sauces, Cereal, Detergent Pods, Pet Treats, Pet Food, Shredded Cheese, Bakery Products, Cookies, Croutons, Coffee, Health & Beauty, Oil, Granola, Rice, Pasta, Yogurt, Poultry, Dairy, Alcohol, Chemical, Chocolate, Protein Powder, Nutraceuticals, Spices, Pharmaceutical, Puree.

Our Global Machinery Partners include:

VELTEKO | HDG Packaging Machinery | IMA ILAPAK | Aranow Stick Pack Machinery | IXAPACK Secondary Packaging Automation | Umbra Large Bag Machinery

www.alliedflex.com FL Sarasota dfc@alliedflex.com

941/923-1181

ALLIEDFLEX® Technologies, Inc. 21

BAGGING, POUCHING & WRAPPING

All Packaging Machinery Corp.

Expert Engineering for Superior Performance

All Packaging Machinery Corp. manufactures USDA-approved vertical and horizontal conveyorized band sealers for sealing pouches and bags. Our machinery is configured specifically for your unique packaging application. Every component is designed to run smoothly and require a minimum of maintenance. With over 75 years of successful packaging experience, our quality machinery is proudly made in the United States of America.

Vertical Conveyorized Sealing Systems

The ideal choice for products packaged in bags that can be sealed in an upright position. Model VCBSDM-1/8TX 6”x5’ includes a bag top trimmer, vacuum scrap removal, dual motor drive, and synchronized lower carry conveyor. Upgrade options and selective components are available such as a stainless steel frame or an embossing coder. Non-trim models are perfect for stand-up pouches! Model VBS-3/8-DH-10-V is supplied with verification ports for process validation of pressure, speed, and temperature. Includes self-contained compressed air. Seals Tyvek® pouches at up to 40 feet per minute.

Horizontal Conveyorized Sealing Systems

High speed production unequalled in the packaging industry! Model HCBS-1/8CT 12”x8’ includes a bag top trim feature with a vacuum scrap removal and is designed to support heavier or bulky packages. An optional overhead compression assembly is available for specific applications to remove air from the bag. Excellent for “lay-flat” packages such as tortillas, pizza, bakery, meat, poultry, and seafood.

www.allpackagingmachinery.com NY Ronkonkoma sales@allpackagingmachinery.com 631/588-7310

22 PW 2023 BUYER’S GUIDE

BAGGING, POUCHING & WRAPPING

920-430-1971

www.americanflexpack.com

American FlexPack is a contract packager specializing in single-use flexible packets and towelettes. We have over 20 years of experience with a multitude of products and industries served.

We are well versed in filling fluid products such as gels, creams, oils, and pastes of various volumes into a single use sachet. This format is perfect for trial sampling, retail packaging, and on-the-go applications.

Our towelette packets are an ideal format for travel and daily use. We are familiar with a wide range of towel and wipe materials and sizes to bring any product to the fingertips of the consumer.

In a growing nutraceutical industry, we are the premier choice for sachets of both liquid products as well as capusles, tablets, and gummies. This application if perfect for product sampling or daily doses of vitamins, minerals, and other essential nutrients in a convenient packette that appeals to consumers.

At American FlexPack, we pride ourselves on top notch quality, service, and fast production. With over 30 ultra efficient form-fill-seal lines in an EPA and FDA regulated facility, we are prepared for any packaging challenge. Our team of experts will guide you through concept to completion of a successful packaging launch. We are always excited about collaborating with customers to find new innovating packaging solutions, so please contact us to get started.

WI Green Bay info@americanflexpack.com

American FlexPack 23

BAGGING, POUCHING & WRAPPING

BROTHER USA MACHINERY

+1 (713) 485-5858

www.usabrother.com

For more than 28 years, Brother have been offering to the world the most affordable and practical packaging solutions, helping new businesses start like a Pro and empowering existing ones reach their potential, with automated fully multifunctional lines.

We provide a wide variety of machinery for any type of industry:

- Complete Automatic Packaging Lines with Z Conveyor , Multihead Weigher Scales, Vertical Packager or Doypack Sealing System, Finished Product Conveyor.

- Vertical Packagers and Horizontals Flowpack Wrappers.

- Fillers by Volume, Piston , Auger or Single/Multihead weighing systems that can be combined with a Packager or Doypack.

- Thermal Shrink Packaging .

- Tape Box Closer/ Carton Erector Lines.

- Strapping Systems

- MAP / Vacuum systems

- Tray/Cup Fill Seal,

- Blister- Skin,

- Conveyors : Belt, Rollers, Chain , 90 degrees, Extendable

- Printing: Hot Stamp, Hot Roll, OPP, Ink Jet .

- Robotics Arms and Spiders , etc.

Brother machines are designed to support and keep your business moving to the next level, with the best quality , service , parts, at affordable cost.

TX Houston salesla@usabrother.com

24 PW 2023 BUYER’S GUIDE

BAGGING, POUCHING & WRAPPING

EDL Packaging, a Massman Company

920/336-7744

OVERVIEW

At EDL, a Massman Company, we understand that secondary and end-ofline packaging decisions are driven by multiple factors: consumer demand, distribution requirements, cost reduction, and packaging design. This is why we do not believe in a one-size-fits-all packaging solution. Instead, we apply our ~60 years experience in the food, personal care, building supplies, carpet, dairy, grain, and pet food industries to manufacture shrink bundling, multi-packaging, and tray wrapping equipment designed to meet customers unique requirements.

SOLUTIONS

EDL systems are designed to collate and bundle consumer and industrial products for shipment in Low Density Polyethylene (LDPE) film. Our complete line of equipment includes:

As part of the Massman Companies, we provide packaging solutions from . sampling of additional solutions we build.

www.edlpackaging.com WI Green Bay sales@edlpackaging.com

25

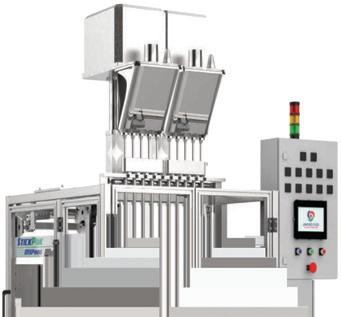

POUCHING

FAWEMA for over 100 years has been manufacturing the best powder packaging machinery for our customers around the world. We have a great variety of solutions for your packaging needs no matter how big or how small the job at hand. Our team of engineers / managers and sales agents will always find the best packaging solutions. We are always delivering to our customers the best packaging Machinery products, permitting us to compete more efficiently that other industry competitors in the market.

From sugar, flour, concrete powder, pet food, sweets we can pack anything without sacrificing quality and speed of Customer final package with our high-speed lines. If you want it / then FAWEMA can pack it !

FAWEMA has evolved to become a market specialist for complete packaging solutions for the filling of bags and sacks. Today the FAWEMA brand reaches every corner of the globe and is renowned for German reliability, efficiency ultra strong build quality in each and every machine produced. Our product range comprises machines and lines for filling and packaging dry products for almost all areas of application. FAWEMA brings you the entire know how of packaging technology. We draw up overall design proposals – from product feed to palletizing. Moreover, FAWEMA is always open to new developments – new applications, new industries, new packaging technologies. We do this by investing time and energy, bringing together the most innovative minds and giving our younger engineering talent the tools and ability they need to solve the packaging challenges of tomorrow. Choosing FAWEMA means buying into a wealth of know how, experience and ethical business values which are paramount in delivering success on each and every project that FAWEMA undertakes on behalf of our clients worldwide. We truly are a global company. FAWEMA are synonymous for reliability and punctual delivery, thanks to the commitment of our employees at our factory in Germany.

Since 2019, FAWEMA, HDG and WOLF has been part of the group of companies TPG, which was founded by the merger of the established companies FAWEMA, HDG and WOLF. Packaging solutions from a single source, worldwide and any time.

www.fawema.com IL Chicago r.ballesteros@the-packaging-group.com 941-302-7320 FAWEMA Inc. BAGGING,

& WRAPPING 26 PW 2023 BUYER’S GUIDE

BAGGING, POUCHING & WRAPPING

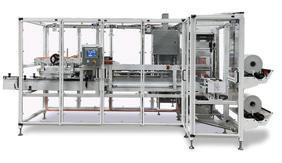

We are here to help you design a packaging solution that is EFFICIENT, RELIABLE, and SUSTAINABLE.

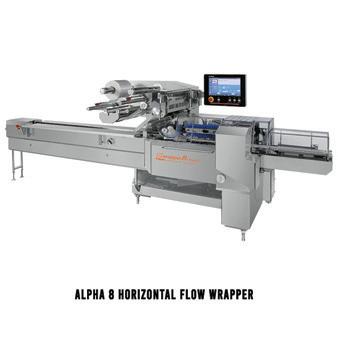

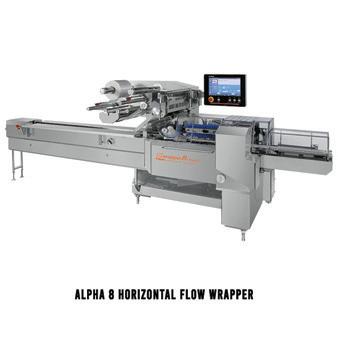

Equipment EFFICIENCY is the result of many different options. The features of a Formost Fuji standard wrapper include a vision system that controls registration and makes for a faster film change and an operation panel with a tablet-like, intuitive user interface that helps reduce labor hours. The ALPHA 8 flow wrapper center seals are designed with induction heat technology that provides fast and consistent sealing, which in turn increases output and saves energy. These are just a few standard features to improve your packaging line’s efficiency.

RELIABILITY has been proven time and time again with our bagging and wrapping machines. Formost Fuji equipment is designed and built for years of dependable operation. In-house dedication to the design and manufacturing of our equipment has positioned Formost Fuji as a leader in quality horizontal flow wrapping and bagging machines as well as automation systems that remain the most reliable in the industry.

Formost Fuji is a leader in providing SUSTAINABLE packaging lines for our customers. With eco-friendly and recyclable materials continually improving and becoming more readily available, we provide free testing in our lab with your product and new films. This allows you to determine if the materials you are considering will align with your product, package integrity, and marketing efforts. Other innovative solutions, such as eliminating foam trays within flow wrap packaging, help meet consumer demand for better sustainability.

You can count on your partnership with Formost Fuji to provide you with excellent customer service from the beginning of the sales cycle, through the build and delivery, and continuing with support, training, and onsite service for years to come.

www.formostfuji.com WA Woodinville sales@formostfuji.com

425/483-9090

Formost Fuji Corporation 27

BAGGING, POUCHING & WRAPPING

HAVER & BOECKER USA

770/760-1130

www.haverusa.com

Haver & Boecker is a global leader in bagging equipment, liquid fillers, palletizers and material handling. The Haver & Boecker technologies include silos, mixers, lump crushers, flow control gates, valve bag packers, open-mouth baggers, FFS baggers, big bag fillers, drum and tote fillers, can and pail fillers, conventional and robotic palletizing, and complete automation capabilities.

We strive to provide the best service experience through on-site and hands-on training, spare part availability and technical support. We serve all markets from start to finish.

Technology Solutions:

Storage Silos

Material Handling Components

Valve Bag Packers

Form-Fill-Seal Baggers

FIBC baggers

Drum/Pallet Liquid Fillers

IBC/Tote Fillers

Pail/Canister Fillers

Low/High Level and Robotic Palletizers

Are you experiencing performance issues with your bags? Let us help analyze your bags and come up with a plan to increase your production and reduce product loss.

GA Conyers info@haverusa.com

28 PW 2023 BUYER’S GUIDE

POUCHING & WRAPPING

www.ima.it/flexible-packaging-hub

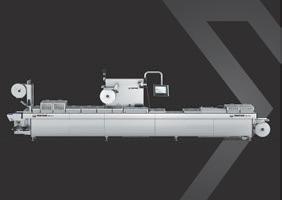

ABOUT IMA FLX

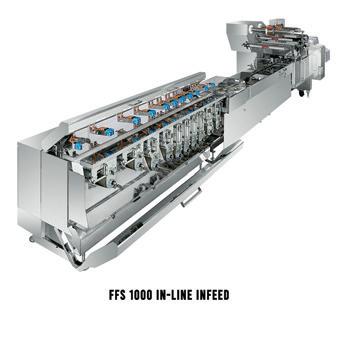

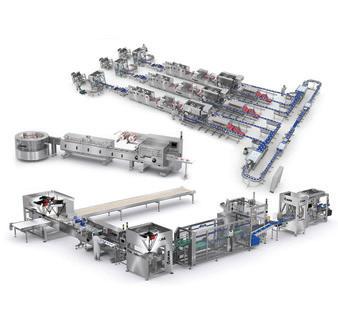

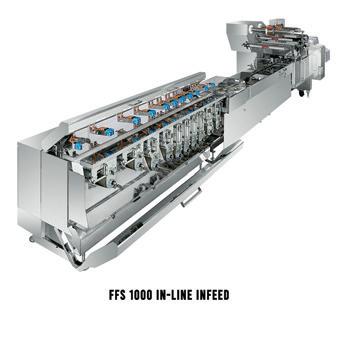

The new IMA FLEXIBLE PACKAGING hub is where the production of all machines in the flexible packaging chain converge. Everything needed to process all types of flexible packaging for the Food, Pharma, Wet Wipes and Pet markets is right here.

PRODUCT SUMMARY

HFFS flow wrapping machines, VFFS vertical baggers, 4 side seals multilane and sticks machines, HFFS Doy pouch lines, systems for MAP and vacuum, fold pack and sandwiching solutions, product handling, automatic feeding and loading systems, counting and weighing solutions, end-of-line, carton packaging machines and complete, fully automated lines.

IMA FLX. THE ONE STOP SUPPLIER FOR FLEXIBLE PACKAGING.

The full array of leading technologies brought together in one facility, where a one-stop supplier drives the quest for excellence, sustainability, constantly researching innovative solutions and new eco-compatible materials.

TURN-KEY PACKAGING SOLUTIONS

IMA FLX HUB, taking advantage of synergies and integrations with IMA Group companies and thanks to proven expertise gained in food & non-food industries’ key applications, o ers fully engineered solutions delivering highly e cient flexible packaging lines to maximise your line’s OEE, with real time operator-specific production and diagnostics data.

From automatic loading systems to cartoning, from product feeding and handling to single and multiple flow wrapping. Weighing solutions coupled with vertical baggers and end of line equipment.

IMA FLX HUB is your perfect partner for delivering turn-key packaging solutions. Its high-speed flexible automation systems are capable of the highest production throughput requirements.

info.flxhub@ima.it +1 215 579 2900 IMA FLX

29

PA Newtown, 18940

BAGGING,

BAGGING, POUCHING & WRAPPING

Mamata Enterprises, Inc.

At Mamata, we understand your needs and provide solutions to increase your productivity and reduce changeover times and footprint.

Our machines are based on conventional servo technology. They are designed to offer the best OEE in the simplex pouch packaging segment.

The key features address the crucial areas in terms of efficiency, hygiene, product quality and flexibility.

HFFS Rollstock machines: Our Simplex HFFS machines allows brands to produce and package pouches at upto 120 ppm and are to a Duplex machine. It’s ideal for lay-flat pouches, stand-up pouches with and without zippers, and single-serve sample packs in the range of 80 to 300 mm. Its ability to produce pouches from recyclable mono-material films makes it unique in the industry.

Premade Pouch filling systems: These machines are designed for highspeed premade pouch-filling applications, allowing you to trade old semi-automatic or manual operations for a highly efficient packaging machine. At 65 ppm, it delivers comparable speeds to a Duplex premade pouch system or a Simplex roll stock HFFS. An ideal machine to package trail mixes and nuts, fresh and frozen produce, snack foods, powders, Pet foods, etc. It’s designed to package both PE/PE recyclable mono-material pouches & laminated pouches.

VFFS baggers: Our Vertical Form Fill Sealing (VFFS) system achieves exceptional seal integrity and optimal precision across a large range of films at up to 220 ppm, making it the fastest system in the industry for single lane pouch filling.

All above and many more that will ease your packaging process and rise above getting competition.

For your pre-sales and after-sales support, our Florida location is equipped with spare-parts, local technical support, and sales consulting.

www.mamata.com FL Bradenton sales@mamatausa.com (941) 205 0227

30 PW 2023 BUYER’S GUIDE

262/268-8300 Matrix Packaging

www.MatrixPM.com

World Class Flexible Packaging Solutions

Matrix, a leader in vertical form fill seal packaging equipment, delivers rugged, well-engineered, easy-to-use packaging systems backed by a large world-class service and parts teams. Our VFFS machines can produce a variety of bag styles; pillow, gusseted, flat bottom, and modified doy. We have the ability, knowledge, and commitment to tailor highly efficient and profitable packaging systems for our customers on a global scale. We work collaboratively, as part of a team with our customers to assess and determine their needs to customize a packaging solution specific to their project.