SYMBIOCENE ARCHITECTURE

“Our use of resources can be characterised as linear, wasteful and polluting, whereas in nature resources are maintained in closed-loop cycles.”

- Michael Pawlyn, Biomimicry

in Architecture -

We at PLP Labs, the research group of PLP Architecture, spent the last two and half years experimenting with mycelium bio-composites.

During this time, we converted a meeting room at our London headquarters into a makeshift lab to grow hundreds of mycelium samples including every prototype shown in this book. We cracked, crushed, and snapped three types of mycelium samples at an engineering lab. We became a node in the fungal network in London and beyond, by working in tandem with mushroom enthusiasts from local community groups to bio-oriented AI designers. In the process, we leaned into the symbiotic potential between architectural practice and nature.

This work is framed within the proposed ‘Symbiocene’ that envisions a future beyond the Anthropocene. It signals a shift in our relationship with the environment from parasitic and extractive to symbiotic and collaborative. The urgency to address environmental challenges, particularly the exploitation and depletion of natural resources, the rise in greenhouse gases, and the need for regenerative alternatives, necessitates this paradigm shift in architectural practice.

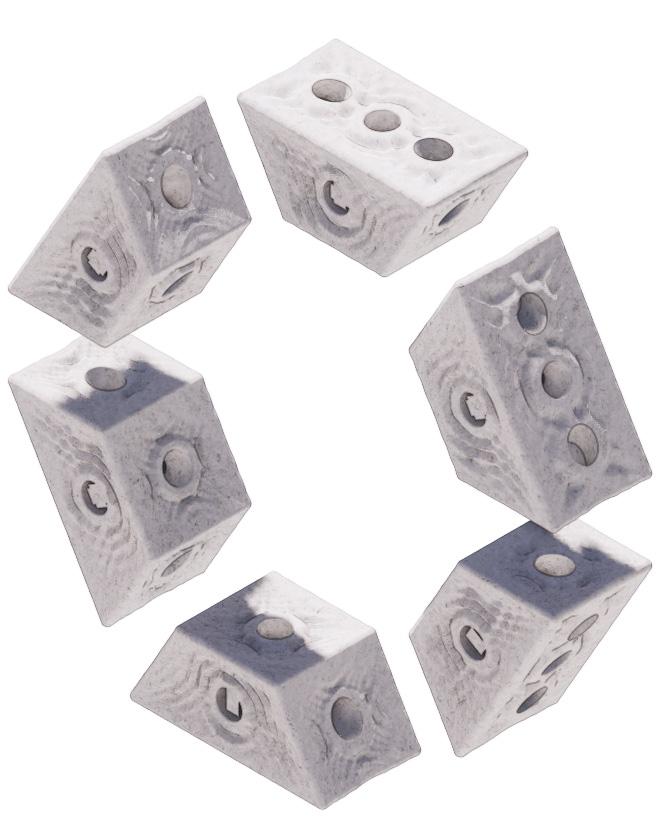

The research is documented in chronological order, from simple cubes and woodworking tests to 3D-printed configurations and material testing completed at the University of Cambridge. We showcased a novel 3D printed wood and mycelium modular system at major design festivals in London, including Clerkenwell Design Week, London Design Festival, and London Design Biennale in 2023.

Beyond PLP Labs’ interdisciplinary team of architects, modelmakers, product designers, and researchers, this work was made possible by the partners and friends we made along the way, many of which were directly involved in the making of this report.

We conclude with a scorecard that outlines the opportunities and challenges of the use of mycelium in architecture. The report is intended as a gateway and a milestone, not a finale, for those interested in mycelium’s potential to help steer the architecture and construction industry away from fossil fuel-based materials and towards a more ecologically sensitive future.

BY MERLIN SHELDRAKE PH.D MYCOLOGIST & AUTHOR

Fungi are a kingdom of life responsible for many of the vital metabolic processes that make life possible: metabolic wizards with a breathtaking capacity to arrange and rearrange the world. Fungi can digest anything from rock to kerosene, and without their powers of decomposition our lives would be inconceivable. If nothing decomposed, the Earth would pile up kilometres deep with the bodies of animals and plants. I remember trying to wrap my head around this as a child and feeling dizzy: our lives take place in the space that decomposition leaves behind. Composers make; decomposers unmake. And unless decomposers unmake, there isn’t anything that the composers can make with. It was a thought that changed the way I understood the world and one that continues to fuel my curiosity about these organisms which are responsible for so much, yet live largely out of sight.

Mushrooms are only the fruiting bodies of fungi: for the most part fungi live their lives as branching, fusing networks of tubular cells known as mycelium. Mycelium is how fungi feed and is the state in which they perform most of their chemical wizardry. Animals tend to find food in the world and put it in their bodies; fungi put their bodies in the food. To do so, they must ceaselessly remodel themselves, weaving their bodies into physical and chemical relation with their surroundings. This entanglement—with themselves, with their physical surroundings, and with other organisms—is their staple mode of existence. Fungi string their way through the soil, through sulphurous sediments on ocean beds, through coral reefs, inside plant leaves, roots and shoots.

Bacteria use mycelial networks as highways to navigate the wilderness of the soil. Nutrients circulate through ecosystems through fungal networks. Tug on a strand of mycelium and you’ll find it hitched to something else. Mycelium is a living seam by which much of life is stitched into relation.

In recent years, there has been an explosion of interest in the ways we can form generative partnerships with fungi to adapt to the crises and transformations of our times. One of these opportunities is myco-fabrication, in which fungi and their voracious appetites are invited to create useful materials. The basic idea is simple. Mycelium weaves itself into a dense fabric. The living mycelium is then dried into a dead material. The final product depends on how the mycelium is encouraged to grow. Bricks and packaging material are formed as mycelium ‘runs’ through a slurry of damp sawdust packed into formworks. Flexible materials are made from pure mycelium. Tan it, and you get leather. Dry it, and you get a foam that can be used to make anything from insoles for sports shoes to dock floats.

In this volume, an interdisciplinary team at PLP Labs present the results of their experiments with fungal building materials, including a novel 3D printed wood system to create the forms for fungal mycelium to grow into. There is a huge amount to discover in this fast-growing field and this enquiry should inspire others hoping to deepen and expand the art and science of myco-fabrication.

The Earth is a saga of geological, climatic, and biological transformations. Modern Homo sapiens occupy a fleeting moment within this vast history and yet our imprint on the planet reverberates across landscapes and ecosystems. We find ourselves amid the Anthropocene, epitomised by humanity’s dominion over Earth and characterised by climate change, urban sprawl, and biodiversity decline. Amidst growing environmental concerns, concepts like solastalgia and eco-anxiety underscore the emotional toll of ecological degradation, particularly among younger generations, and the urgent need for action.

In response, eco-philosopher Glenn A. Albrecht envisions a future epoch rooted in symbiosis. The Symbiocene heralds a paradigm shift towards collaboration with the natural world. Central to this vision is the emerging discipline of sumbiotecture, which emphasises collaboration over control in architecture and design.

At its core lies the integration of bio-based materials, with mycelium emerging as a standout contender. As a renewable, lightweight, and insulating resource, it offers a sustainable alternative for some elements of construction. Innovative projects, from pavilions to packaging, already showcase mycelium’s potential to reform extractive practises.

As humanity embarks on this journey towards the Symbiocene, humility and stewardship emerge as guiding principles to recognise nature as a living, evolving partner. Regenerative materials, like mycelium, are the literal and metaphorical building blocks of sumbiotecture, reshaping the natural and built environment in the process. Through collaboration and innovation, we may yet forge a future where human and non-human life coexist in harmony, drawing inspiration from some of Earth’s oldest inhabitants: plants and fungi.

“Humans, like all the species of the world, have been formed by nature and exist within nature.”

- Michael Weinstock, Hypernatural -

The Earth’s geological history is divided into several eras, each of which represents a period of time characterised by distinctive geological, climatic, and biological events. The time is further subdivided into supereons, aeons, eras, epochs, and ages, which provide progressively more specific and detailed insight into the evolution of life on our planet.

In the grand scale of Earth’s 4.6 billion years of history, modern Homo sapiens have only existed for a mere moment, evolving around 300,000 years ago.1 Despite this brief existence, humans have made an irreversible impact on the Earth’s land use, geology, climate, and ecosystems.

Within the larger and on-going Cenozoic Era and latest Quaternary Period, this report briefly touches on human intervention within the most recent epochs: Holocene and Anthropocene, and looks to human development during the plausible future epoch: the Symbiocene. These epochs frame and contextualise the conversation around development and the use of bio-based materials.

Adjoining diagrams illustrate the span of Earth’s history, highlighting the diminutive timescale of the Anthropocene.

PHANEROZOIC EON (541 MILLION YEARS AGO TO PRESENT)

CENOZOIC ERA (66 MILLION YEARS AGO TO PRESENT)

MESOZOIC ERA (252 TO 66 MILLION YEARS AGO)

PALEOZOIC ERA (541 TO 252 MILLION YEARS AGO)

PROTEROZOIC EON

(2.5 BILLION TO 541 MILLION YEARS AGO)

ANTHROPOCENE EPOCH (~1900 TO PRESENT)

HOLOCENE EPOCH (11,700 YEARS AGO TO PRESENT)

PLEISTOCENE EPOCH

(2.6 MILLION TO 11,700 YEARS AGO)

PLIOCENE EPOCH

(5.3 TO 2.6 MILLION YEARS AGO)

MIOCENE EPOCH (23 TO 5.3 MILLION YEARS AGO)

OLIGOCENE EPOCH (34 TO 23 MILLION YEARS AGO)

EOCENE EPOCH (56 TO 34 MILLION YEARS AGO)

PALEOCENE EPOCH (66 TO 56 MILLION YEARS AGO)

ARCHEAN EON

(4.0 BILLION TO 2.5 BILLION YEARS AGO)

HADEAN EON

(4.6 BILLION TO 4.0 BILLION YEARS AGO)

The Holocene epoch is derived from the Greek terms “holos” (whole) and “cene” (new), signifying an entirely new era.2 The Holocene is known to be a relatively stable, yet cyclical period which prevailed over the past 11,700 years.3 During this time, human civilisation and technology advanced, which included the advent of agriculture and urbanisation.

Image generated with Midjourney AI; prompta landscape with rolling hills and a wide river flowing through it, surrounded by trees and vegetation. In the foreground, you see a group of humans farming the land, with domesticated animals grazing nearby. The sun is shining down on the scene, creating a warm and peaceful atmosphere

The Anthropocene epoch, coined by Nobel laureate Paul Crutzen, is derived from the Greek terms “anthropo” (human) and “cene” (new), is marked by significant human-driven planetary changes and defined by hubris.4

The Anthropocene is defined by domination over nature. Humans sought to tame, maintain, and rule over their environment at a scale never seen before. The known consequences of this behaviour have just begun, but the Anthropocene has already overstayed its welcome.

Image generated with Midjourney AI; prompta polluted cityscape, with skyscrapers towering overcrowded streets filled with cars and smog. The sky is grey and hazy, and there are few trees or green spaces to be seen. In the background, you can see factories belching smoke and pollutants into the air, contributing to the global climate crisis

* The official start of the Anthropocene is still disputed.

Construction alone is responsible for 30% of particulate matter (PM10) in London.5

Particulate matter can cause serious health issues like asthma attacks, heart and lung damage, high blood pressure, cognitive decline, and is linked to thousands of premature deaths in London.6

Buildings are responsible for 38% of annual global emissions 7

Carbon emissions are the primary driver of the global climate crisis, which claims hundreds of thousands of deaths per year, and has cost the global economy more than $2 trillion in the past decade.8,9

The construction industry generates 62% of the UK’s waste and 32% of all waste sent to landfill.10

Landfill waste is a risk to both human and environmental health. The volatile organic compounds (VOCs) emitted from landfills are connected to respiratory issues, cancer, and birth defects, as well as greenhouse gases and habitat destruction.11

Extractive processes are responsible for 90% of global biodiversity loss 12

Biodiversity loss has wide ranging impacts from increased zoonotic diseases like Covid-19 to food insecurity. The World Bank has reported that by 2030, the global GDP could lose out on $2.7 trillion due to loss of biodiversity.13

Construction, demolition and excavation account for 60% of material use and waste generation in the UK.

The linear economy exacerbates waste, biodiversity loss, and rise in greenhouse gases. The UK Green Building Council estimates by the circular economy offers a €1.8 trillion opportunity to the EU between 2015 and 2030.14

40% of the world’s land is degraded, due in part to resource extraction and soil erosion related to construction.15

Land degradation and the loss of fertile soil threatens food production, creates new deserts, pollutes waterways, and increases the risk of flooding.16 This places basic needs, like food, water, and safety in jeopardy.

GLOBAL BUILDING FLOOR AREA IS EXPECTED TO DOUBLE BY 2060.

The built environment is a driving force in the current climate crisis. As it stands, 38% of annual global CO2 emissions are attributed to the built environment. Concrete, steel, and aluminium make up 23% of those emissions.17 At the same time, there is a real need for development given global floor area is expected to double by 2060.18

Despite the built environment being a major contributor to carbon emissions, the demand for development continues unabated.

Solastalgia, a term coined by philosopher Glenn A. Albrecht in his book Earth Emotions, is a type of pain, grief, and suffering related to “the loss or lack of solace and the sense of isolation connected to the present state of one’s home and territory”.19 Similar to nostalgia, solastalgia is related to homesickness and stems from loss, distance, and inability to return.

The feeling of dislocation is often caused by humaninduced climate and landscape changes. Although the place may still physically exist in the same location, events like resource extraction, climate change, and political violence have caused irrevocable physical and emotional damage, permanently altering the landscape.20 In many cases, this negative feeling is also attributed to a sense of powerlessness to protect one’s homeland.

The Anticipatory Solastalgia Scale survey conducted in the United Kingdom reported participants’ current distress about expected future changes to the environment.21 Across the sample size of 509 participants, more than half were currently experiencing a form of anticipatory solastalgia.22

The Anticipatory Solastalgia Scale survey shown above, tracks the mean and standard deviations for each anticipatory solastalgia item in the UK.

The chronic fear of environmental cataclysm that comes from observing the seemingly irrevocable impact of climate change and the associated concern for one’s future and that of next generations.

- The American Psychological Association -

Google trends data above, shows a significant rise in search queries for “climate anxiety”, “eco-anxiety” and “solastalgia” over the last twenty years.28

Eco-anxiety is another Albrecht coined term that describes the growing worry of the consequences of climate change like extreme weather events, unhealthy pollution, biodiversity loss, and water shortages.23 Similarly, people may feel climate anxiety which stems from an awareness of climate change. In both cases, surveys show that children and younger people are disproportionately affected. In a 2020 survey of child psychiatrists in England showed that “..more than half (57%) are seeing children and young people distressed about the climate crisis and the state of the environment.”24

While not considered a medical condition, the American Psychological Association (APA) recognises that the internalisation of environmental challenges can have a range of psychological effects.25

Eco-anxiety and climate anxiety is on the rise and can lead to behavioural changes. Studies show that three-quarters of adults in the UK worry about climate change, and those worried are three times more likely to make changes to their lifestyle compared to those relatively unworried.26 It is anticipated that as climaterelated problems grow, so will the number of people experiencing eco-anxiety.27

The Symbiocene offers the prospect of deep mitigation of the causes of global warming and species extinction.

After the Anthropocene, Albrecht offers a more hopeful future epoch: the Symbiocene. It describes a period in which “human culture, habitat and technology will seamlessly re-integrate back into life cycles and processes”.29 In this future, the Anthropocene will gradually become a mere blip in the sediment layers, between the climatically stable Holocene and Symbiocene.

The epoch is defined by symbiosis. Humans will be proactively collaborating with non-human life to grow cities, participate in life cycles, and construct a better world for all species. This may look like combining human engineering and ingenuity with the capabilities of the natural world, a dominant circular economy, clean renewable energy, environmental justice, mutual aid, and symbiotic bonds.30

“The next era in human history is where we symbiotically reconnect to the rest of life. That strategy will bring the design and function of human culture, technology, food production and habitats into line with the long-term direction taken by the rest of interrelated life.”

- Glenn A. Albrecht -

PHANEROZOIC EON

(541 MILLION YEARS AGO TO PRESENT)

CENOZOIC ERA (66 MILLION YEARS AGO TO PRESENT)

MESOZOIC ERA (252 TO 66 MILLION YEARS AGO)

PALEOZOIC ERA (541 TO 252 MILLION YEARS AGO)

PROTEROZOIC EON

(2.5 BILLION TO 541 MILLION YEARS AGO)

ANTHROPOCENE EPOCH (~1900 TO PRESENT)

HOLOCENE EPOCH (11,700 YEARS AGO TO PRESENT)

PLEISTOCENE EPOCH (2.6 MILLION TO 11,700 YEARS AGO)

PLIOCENE EPOCH

(5.3 TO 2.6 MILLION YEARS AGO)

MIOCENE EPOCH (23 TO 5.3 MILLION YEARS AGO)

OLIGOCENE EPOCH (34 TO 23 MILLION YEARS AGO)

EOCENE EPOCH (56 TO 34 MILLION YEARS AGO)

PALEOCENE EPOCH (66 TO 56 MILLION YEARS AGO)

ARCHEAN EON

(4.0 BILLION TO 2.5 BILLION YEARS AGO)

HADEAN EON

(4.6 BILLION TO 4.0 BILLION YEARS AGO)

We believe architects and urban designers have a role in collaborating with nature to cultivate the urban landscape of the Symbiocene.

One way to reduce the carbon footprint of development is to replace energy intensive materials like concrete with regenerative materials like timber. Substituting traditional building materials for ones that store and sequester carbon will in turn help achieve climate goals.

Beyond energy use and carbon sequestration, biomaterials offer a wide array of benefits in construction and architecture in terms of insulation, specific strength, and air quality.

For instance, some biomaterials like sheep’s wool have insulation properties that help maintain consistent indoor temperatures while kerbing energy consumption for heating and cooling.31 In tandem with thermal insulation, many of these materials have inherent sound-absorbing attributes, reducing noise levels within structures.32

Regenerative materials have also been used in a loadbearing capacity. Materials, like bamboo, combine lightweight qualities with impressive strength, rendering them ideal for structural roles in buildings.33 Crosslaminated timber is another reliable and long-lasting option.34 These types of construction materials do not emit harmful volatile organic compounds (VOCs), leading to better indoor air quality, health, and well-being of building occupants.35

While biomaterials hold great promise for the construction industry, there are also challenges and limitations to consider, including meeting standards for durability, fire ratings, regulatory approvals, and market availability.36

By opting for renewable and less energy-intensive materials, we can pave a sustainable path forward that does not compromise the real need for urban development, where 68% of the world is projected to live by 2050.37

The integration of bio-based materials is part of the emerging field of sumbiotecture, also coined by Albrecht. The word is derived from “sumbiosis” (living together) and “techne” (build, craft, art). Sumbiotecture distinguishes itself by placing collaboration, rather than control, at the heart of design.38 In this manner, design and development are integrated within the natural order.

Circularity is indivisible from sumbiotecture. For every bio-based element in the structure and design there is an existing process for it to seamlessly be remade or returned to the soil. This cradle-to-cradle mentality is a necessary extrapolation of nature’s rhythms. Sumbiotecture reframes the concept of longevity, in which the temporal, biodegradable nature of its materials and time frame lends itself to the larger cycle of use and reuse.

Sumbiotecture also requires a sensitivity to scale and mass production. In this case, the question of “how” and “if”—at all—is a necessary conversation. It also encompasses a re-emphasis on localisation, craft, and sufficiency, in opposition to the aim of unconstrained and growth at all costs.

Working alongside nature in the manufacturing process of development, as equal partners, requires humility and celebration of unpredictability and uniqueness. Unlike working with non-living material, where it is possible to manufacture identical components en masse, the process requires sensitivity and each product likely will react, look, and perform within a range of variations.

Overall, sumbiotecture requires care, awareness, and respect when working alongside nature, as a living, evolving, adapting entity. Life is a survivor, first and foremost, as well as a mutator and adaptor. Therefore, it is critical to understand our role and the consequences of our actions when collaborating in the natural world. There is a gravity to the work, more so than working with a dormant material, which must be recognised.

In this new wave, we may see the rise of timber and stone office buildings, or bamboo, hemp, and rammed earth apartment complexes, algae powered buildings, and even self-healing facades. In this way, sumbiotecture moves towards the blurring of the lines between the built and natural environment, making them become one again.

Sumbiotecture and all its parts: bio-based materials, circularity, and ethical responsibility, is advantageous because it learns from one of the oldest and most resilient lifeforms on Earth—plants and fungi. By implementing this design philosophy, the built environment is no longer a liability for all future lifeforms.

“The architecture of mycelium resembles patterns predicted in string theory, and astrophysicists theorise that the most energyconserving form in the universe will be organised as threads of matter energy.”

- Paul Stamets, Mycelium Running -

All living things are divided into five categories or kingdoms: Animalia, Plantae, Protoctista, Prokaryotae, and Fungi.39 The fifth kingdom, the Fungi Kingdom, encompasses eukaryotic organisms that obtain nutrients through absorption, such as yeasts, moulds, and mushrooms.40

Mushrooms come in a countless number of different shapes, sizes, and colours, from the typical cap-and-stem structure exemplified by portobello mushrooms to rough, irregular knobby appearance of truffles. Despite the many variations, all mushrooms have mycelium.

Mycelium is part of the fungi that grows underground or in a substrate. It is composed of a network of tiny threadlike strands called hyphae which interconnect to form a network, forming the body of the fungi. Mushrooms, truffles, or crusts bloom from this network, acting as the fruit or flower of fungi.

In nature, mycelium plays an important role in the growth, maintenance, and reproduction of fungi. The mycelium’s hyphae enzymes break down complex organic compounds to absorb water and nutrients from decaying organic matter like wood, leaves, or soil. Through this process the mycelium creates a fibrous amalgamated matter in order to grow and reproduce.

Mycelium also serves as a communication network, allowing fungi to exchange information and coordinate their activities. Hyphae’s extensive branching structure creates complex interconnected networks known as mycelial mats or mycelial networks, which can be microscopic to colossal in size.

Fungi are ecologically important for nutrient and carbon cycling during the decomposition process. They help maintain biodiverse soils by breaking down organic matter, capturing and storing carbon, and recycling nutrients back into the ecosystem. Within this cycle, fungi are observed to have beneficial symbiotic relationships with other lifeforms 41

FIRE-RESISTANT

EASY TO PRODUCE FROM LOCAL

LOW COST

WATER REPE LLENT

Mycelium is beginning to be used for packaging, fashion, and within industrial design. It is garnering interest as a renewable and biodegradable material.42

Currently, mycelium is being used for everything from interior acoustic insulation to lighting fixtures to packaging and faux-leather. Within buildings, mycelium is sporadically used in a non-load bearing capacity.

As a lightweight, fire-resistant, and effective insulator, mycelium is a versatile material. With bio-resin or paint coating, mycelium may be protected against the elements and be used for a variety of applications.

MycoComposite

MycoTEX

5. ART INSTALLATION

The MycoTree was presented at the Seoul Biennale for Architecture and Urbanism in 2017, and designed by Dirk Hebel and Block Research Group.

6. ACOUSTIC PANELLING

Mogu offers a variety of acoustic panels for the workplace of different colours, textures, and shapes made from mycelium.

7. WALL INSULATION

Mykor offer insulation panels made of mycelium; however they are not suitable for the professional building industry yet due to lack of required certification.

8. FURNITURE DESIGN

Mycelium + Timber is a bio-based furniture collection by Sebastian Cox and Ninela Ivanova, made from scrap timber and mycelium.

Architectural installations, temporary structures, and experimental pavilions have begun to explore mycelium as a building material.

HY-FI

HY-FI

THE LIVING

THE LIVING

MOMA PS1

2014

MOMA PS1 2014

THE MYCELIUM MONOLITH JDO VAULTS

ATLANTA, GA, USA

2018

THE GROWING PAVILION

THE GROWING PAVILION

BIOBASED CREATIONS & PASCAL LEBOUCQ

BIOBASED CREATIONS & LEBOUCQ

DUTCH DESIGN WEEK 2019

DESIGN WEEK

Various innovative pavilions and art installations around the world have showcased mycelium. Designers of these structures have developed different ways to incorporate the material, from mycelium panels on timber frames, bio-bricks grown from corn stalks and mushrooms, to textiles embedded with mycelium spores.

These projects highlight the adaptability and sustainability of mycelium as a potential construction material, with an emphasis on experimentation and a symbiotic relationship with nature.

MY-CO SPACE

MY-CO-X

FRANKFURT, GERMANY

2021

IN VIVO: BELGIAN PAVILION

BENTO ARCHITECTURE & VINCIANE DESPRET

VENICE ARCHITECTURE BIENNALE

2023

INHABITING ECOLOGIES

NIKOLAJ EMIL SVENNINGSEN, SEAN LYON, SØS CHRISTINE HEJSELBÆK & JONAS RASK KALMAR HANSEN

CHRISTINE HEJSELBÆK JONAS KALMAR

CHART ART FAIR

2023

ART FAIR

HAYES PAVILION

SIMON CARROLL & LEKSI KOSTUR

GLASTONBURY FESTIVAL

2023

We gained a first-hand understanding of mycelium composites through experimentation. This was essential to begin to get a sense of the material’s capability and potential.

In the beginning we started out small, by growing mycelium cubes in casts. The initial experiments helped us understand the growing process, its ability to fuse together (a success!) and if it could be cut apart (not so easy). The experiments gradually incorporated organic materials in the growing process, from wooden dowels to muslin cloth. From there, we were able to test and observe the tolerance, control, and webbing properties of mycelium bio-composites. The research took a turn when it became apparent that mycelium could be grown within 3D printed wood formwork, instead of a cast, into countless, complex shapes.

With this new technique in hand, it was time to put it to the test. We conducted compression and 3-point bending tests on three types of mycelium samples at the engineering fatigue laboratory at the University of Cambridge. Key differences between mycelium and the 3D printed wood filament mycelium bio-composites became even more clear during CT micro scans and sinograms.

We tested the 3D printed wood + mycelium’s environmental merits by conducting a life cycle assessment of the process. This experimental era ends with a comparative study on carbon of mycelium, concrete, and brick blocks.

“Architecture will be brought to its fullest realisation only when the deepest knowledge of human life in the biological whole is available.”

- László Moholy-Nagy -

During the initial experiments we grew and cast mycelium into simple geometric shapes in order to understand the growing process.

We experimented bonding mycelium with organic materials, like wood and organic fabric.

Our understanding of the growing and bonding process led us to discover how to bond 3D printed wood and mycelium. By using a 3D printed wood formwork, our mycelium samples began to take on more complex geometric shapes.

The experiments started with growing mycelium cubes in Perspex-based formwork to study the effects of size, volume, growing time, and conditions on structural integrity.

We first grew cubes and cuboids of different sizes with a Perspex based formwork that is easily removed.

These initial experiments were useful for understanding the relationship between size and volume, as well as growing time and conditions.

These samples were tested for strength by applying manual pressure. Due to the fibrous nature of the material, we found at least five to seven cubic centimetres of material is required to maintain structural integrity.

For the second round of experiments, we explored complex and double-curved formworks made with 3D printed PLA. In doing so, we observed how difficult it is to remove formworks that have overhangs and complex curvature. For mycelium samples of 2.3-3 cm thickness, double curved geometry samples appeared to be stronger than flat samples.

We experimented how 7.5 cm mycelium cubes fared with woodworking techniques. This included cutting the mycelium with a band saw and hot wire cutter, plus drilling holes of two sizes.

Bandsaw: The internal section of the mycelium block becomes highly flaky when a band saw cuts the mycelial matrix that holds the hemp fibres together. Once the outermost skin is compromised, the inherent stability of the composite material is decreased, and the material starts to disintegrate and flake.

Hot wire cutter: When cut with a hot wire cutter, the material produces a burning smell and a clear score line can be seen on the block. However, no smoke or fire is produced.

Drilling: In the case of drilling, a clean drill hole is hard to produce as the composite material is made from 3-10 mm fibres and chips that start to flake. The integrity of the block is compromised once the holes are drilled, making it highly susceptible to tearing and breakage.

We briefly experimented with imparting colour onto mycelium composites using natural colouring additives. In doing so, we tested to what extent mycelium composites assimilated or bonded with organic and inorganic substances.

We carried out these experiments by adding natural food colouring, terracotta, coloured salts as well as Plaster of Paris. The coloured salts and dyes assimilated, but the terracotta did not.

The Plaster of Paris sample assimilated and bonded to the mycelium, and the plaster hardened due to the moisture that is produced during the growing process. This process created a white block with a texture that is somewhere in between that of mycelium and plaster. The material becomes harder than the other samples, but retains a slightly brittle and less fibrous quality.

We also fused two separate mycelium samples together. During the growing process, two separate mycelium cubes grew in close proximity. Overtime, the distance between the two samples began to shrink as the samples grew, to the point the two fused together and became one.

The strength of the fused bond is high. It becomes impossible to manually separate one block from the other.

It was hypothesised that mycelium would bond with industrially produced organic materials used commonly in architecture, because the substrate for the mycelium composites is also made of various organic materials.

To test this hypothesis, we strategically grew mycelium in the vicinity of various timber-based materials, including basswood dowels, plywood panels, and MDF samples.

In these tests, a grid of wooden dowels or panels were slotted into cube and rectangular casts. During the growing process, mycelium successfully bonded with bass wood dowels and plywood panels.

Bonding mycelium to MDF samples was less successful. The chemical treatment of the MDF hinders the growth of mycelium and absorbs the ambient moisture content. This results in a very weak material that crumbles and does not grow near the MDF panels.

In a corresponding test, we grew mycelium in the vicinity of two different types of wood based 3D-printing filament. The mycelium only successfully bonded with the filament that had a higher wood to plastic ratio. The test confirmed mycelium is best bonded with materials of a higher organic quality.

Our hypothesis was proven correct: it is possible for the mycelium to bond and even grow on to timber materials like wooden dowels, plywood panels, and 3D printed wood filament as long as it is directly interfacing with the colonised substrate.

We experimented with bonding mycelium with different types of fabrics, including unbleached cotton, muslin cloth, and hemp. The muslin cloth worked best, as not only did the mycelium bond to the fabric but it also did not crack while drying, unlike the hemp fabric. The mycelium bonded more effectively with fabrics having a higher content of natural ingredients.

We bonded the mycelium to fabric by first creating either a square plywood box or 3D printed wood circular frame. We attached the fabric to the frame and grew mycelium in the cavity of the box or doughnut. The mycelium first grows around the frame, before latching on the cloth. An agar solution was sprayed on the fabric to facilitate growth.

We began to experiment with tolerance and control of mycelium when bonded with wood filament. Typically, a mycelium composite sample shrinks and contracts while losing moisture during the drying process, and in some instances losing up to between 35%-40% of their original weight. However, we found when bonded with the 3D printed wood it tends to resist the shrinkage and bow in towards the centre of a face.

Reducing shrinkage is important for growing blocks for a modular, interconnecting system. In order for this type of system to work, each of the modular pieces must closely resemble each other in size and shape. A mycelium and 3D printed wood composite provides greater control over the tolerance so that the modular pieces are relatively similar across the board.

The trade-off of combining mycelium with 3D printed wood filament is that it generally takes longer for the two composites to bond and dry. While a typical mycelium sample takes approximately ten days to two weeks to fully grow, this technique requires between three and four weeks. The drying also must be done at a lower temperature otherwise the outermost mycelium layer will start to crack. Hence, the mycelium 3D printed wood composite samples were dried at a constant temperature of 35 °C for 12-16 hours.

Once we discovered mycelium could bond with wood, we attempted to grow mycelium onto a grid made of 3D printed wood filament. The mycelium took well to the wood tray, infilling the grid. From here, we begin to hypothesise whether mycelium could grow across on a grid or a perforated structure made of 3D printed wood filament.

First, we grew mycelium in interlocking shapes using a removable plastic formwork. The interlocking samples were designed to fit together like puzzle pieces. However, after the cast was removed, we found the interlocking mycelium shapes did not fit together due to the difference in undercuts, overhangs, and curvatures of each sample after shrinkage. We then attempted to grow mycelium in interlocking shapes using 3D printed wood filament. This worked far better as there were less issues with the tolerance and cast removal.

We discovered, by accident, that mycelium was able to bridge large distances while growing organic shapes. In this case, the growing sample was wrapped in a sheet of plastic. Incidentally, the mycelium used the plastic to grow from one protrusion to the next, creating a mycelium web between the two.

We experimented with three types of coating: Bioseal Mycelium coating from Impershield, Jesmonite, and epoxy resin.

The Bioseal sample provided adequate coverage for the mycelium so that it would not flake off, while retaining its natural texture.

The Jesmonite created a glossy and smooth finish, in which the mycelium colour was preserved but concealed its natural texture.

The epoxy resin created a thick and smooth envelope around the mycelium, completely encapsulating and obscuring all natural qualities of the mycelium sample.

Previous tests hinted that mycelium could grow over holes and between gaps, and even “climb up” organic materials like wood. These ideas were put to the test. The experiment involved growing mycelium onto a complex morphology made with 3D printed wood filament. We hoped to determine the size of gaps mycelium could bridge and whether the mycelium would grow vertically on the perforated structure.

Over a period of three weeks, the mycelium did bond with the wood filament and did indeed “climb” onto the perforated shape, which acted akin to a scaffold. It was observed that the mycelium was able to grow over and cover some of the perforations of between five to seven millimetres in diameter. This is a turning point in our understanding of the relationship between 3D printed wood and mycelium.

An organic-inspired sample from this era was a rootinspired vase. It seamlessly combines the beauty and materiality of biophilia, through engineering.

The 3D printing technique offers defined and precise control over design from the onset of the growing process. This becomes most apparent when growing mycelium into organic shapes.

If exposed to light and air, the mycelium will begin to fruit mushrooms.

One of the most common questions asked about mycelium’s potential as a material is “will it keep growing?” Heating mycelium, even for a few hours, will effectively cause it to become inert and no mushrooms will fruit. The only samples which fruited mushrooms, as seen here, were exposed to light, air, and not heat treated. In the case of blue oyster, the mushrooms sprouted within eight to twelve weeks.

In comparison, the pink oyster samples went through three to four stages of pinning, before fully fruiting over two to three months. This happened only after being exposed to light and air.

At the University of Cambridge Fatigue Laboratory in the Department of Engineering, we tested three types of mycelium-composite samples: (1) loosely packed substrate [LP], (2) densely packed substrate [DP], and (3) densely packed substrate in the 3D printed wood formwork [3DP]. Five samples were created for each type with each sample measuring 100 mm x 100 mm x 100 mm. Each test sample was compressed by a load of up to 10 kN (equivalent to roughly 1000 kg of force) over a period of approximately five minutes to failure.

The compression tests were conducted following the ASTM D1621 standard using an Instron 5985 testing machine with a 250 kN load cell. Each test used a 100 mm x 100 mm square sample area, with five specimens tested at a speed of 10 mm/min until they were compressed to at least half their original thickness (50 mm). We measured the apparent compressive modulus (Ec) within a 2%-3% strain range and the compressive strength at 10% deformation from the stress-deformation curves. ASTM D1621 is the standard test method for compressive properties of rigid cellular plastics and structural foams.

The samples had a fibrous texture and occasional small pores. At peak loads, the samples split open like a fabric seam. Post-test observation revealed the samples to spring up slightly after being compressed.

The densely packed samples reacted similarly during compression testing, albeit able to withstand a heavier load. The compressive strength is likely influenced by density and internal structure.

These samples were the same hue, but had a smooth, uniform surface. At peak load, the sample fractured along the seams of the 3D printed formwork. The compression was contained within the formwork.

Five samples were created for each type of mycelium composite in order to collect sufficient data for the study. For each, the weights were recorded at the time of being packed into the formwork (Wet Weight) as well as after drying. There is a fairly uniform weight reduction of 75 to 80% between the two phases. In terms of compressive behaviour, all three MBCs exhibited three key stages in their load-displacement curves, that are also characteristic of cellular foam materials: (a) an initial elastic region (0.25-2.5% strain) where deformation was (probably) recoverable, (b) a plateau region where plastic deformation took place (up to 15% to 25% strain), followed by (c) a densification region where significant plastic deformation took place with a substantial increase in load (over 15% to 25% strain).

Looking at the Force vs. Deformation graphs for the samples, although there is similar behaviour across the three types, there are noticeable variations in their load capacities. As expected, the densely packed

samples exhibit much higher load bearing ability, with the compressive strength being directly proportional to the density of the material. Moreover, there is uniform trending behaviour within each type.

The 3D printed samples display a distinct kink, this corresponds with the points at which the 3D printed formwork fractures. As the 3D printed formwork samples display a significantly lower load bearing capacity than the densely packed samples it may be inferred that there are gaps or discontinuities between the packed substrate and the 3D printed walls which lead to uneven packing. Further testing is required to study different packing strategies in the case of 3D printed ‘lost’ formwork-based fabrication. The three types of samples display a low standard error from the mean for density and a higher error for stiffness which may indicate that even though the manual packing process results in fairly uniform density across samples, there are higher inconsistencies in their physical performance. This may be addressed by automating the packing process.

SAMPLE 02 WET WEIGHT - 576 g DRY DENSITY - 123 Kg/m3

SAMPLE 01 WET WEIGHT - 497 g DRY DENSITY - 118 Kg/m3

SAMPLE 04

WET WEIGHT - 473 g DRY DENSITY - 113 Kg/m3

SAMPLE 05

WET WEIGHT - 458 g DRY DENSITY - 117 Kg/m3

SAMPLE 03

WET WEIGHT - 497 g DRY DENSITY - 116 Kg/m3

Displacement (mm)

SAMPLE 02 WET WEIGHT - 606 g DRY DENSITY - 141 Kg/m3

SAMPLE 01

WET WEIGHT - 589 g DRY DENSITY - 143 Kg/m3

SAMPLE 03

WET WEIGHT - 596 g DRY DENSITY - 133 Kg/m3

SAMPLE 04

WET WEIGHT - 575 g DRY DENSITY - 127 Kg/m3

SAMPLE 03

WET WEIGHT - 462 g DRY DENSITY - 154 Kg/m3

SAMPLE 01

WET WEIGHT - 440 g DRY DENSITY - 153 Kg/m3

SAMPLE 05

WET WEIGHT - 463 g DRY DENSITY - 159 Kg/m3

SAMPLE 04

WET WEIGHT - 447 g DRY DENSITY - 148 Kg/m3

SAMPLE 02

WET WEIGHT - 551 g DRY DENSITY - 145 Kg/m3

Displacement (mm)

SAMPLE 05 WET WEIGHT - 661 g DRY DENSITY - 149 Kg/m3 Displacement (mm)

The three types of mycelium-composites, (1) loosely packed substrate [LP], (2) densely packed substrate [DP], and (3) densely packed substrate in the 3D printed wood formwork [3DP], were also tested for bending strength at the University of Cambridge. This was done through a 3-point bending test performed on five samples for each type, with each sample measuring 200 mm x 30 mm x 30 mm.

3-point bending flexural tests were performed according to ISO 178:1997 using an Instron 5985 testing machine equipped with a 3-point bending fixture and 10 kN calibrated load cell. Distance between rollers was maintained at 120 mm, and a cross-head speed of 2 mm/ min was used. The flexural modulus, flexural strength,

and ultimate flexural strain at maximum stress were measured from the stress–strain curves, where stress and strain were calculated at the outer surface (i.e. convex or tension side) of the test specimen at midspan. BS EN ISO 178:1997 is the standard method for determining flexural properties for plastics.

The load was applied by the middle roller while the two side rollers held the sample in place. Each test sample was bent by a load of up to 35 N (equivalent to roughly 3.5 kg of force) over a period of approximately two and a half minutes to failure. Due to the nature of the bending flexural test and the standard dimensions of the samples, the loads used here were much smaller than those of the compression tests.

The samples had a fibrous texture that was often smooth. During the testing, samples deflected quickly under low loads. Subtle bending and a minor surface crack on the bottom centre of the sample was observed.

The densely packed samples reacted similarly during the 3-point bending testing, albeit able to withstand a greater bend. The flexural strength values were consistent across the mycelium samples.

The wood and mycelium composites had a smooth, uniform surface. At peak load, the sample also fractured around the bottom centre. The sample was more resistant to bending deformation and fracturing.

As with the compression test, five samples were created for each type of mycelium composite in order to collect sufficient data. Each of the weights were recorded at the time of being packed into the formwork (Wet Weight) as well as after drying. There is a fairly uniform weight reduction of 75% - 80% between the two phases for sample types LP and DP. For the 3D printed sample type 3DP, it is noted that the weight reduction is uniformly around 33% of the wet weight.

For flexural behaviour, a strong correlation between density and bending stiffness and strength was observed. The DP samples exhibited much higher load capacities compared to the LP samples, and the 3DP outperformed the other two sample types by a large margin. This may suggest that the sacrificial shell offered some amount of tensile reinforcement due to the flexible nature of the wood-PLA filament. Further testing is required to study the different strategies that may enhance the reinforcement capability of this method.

The Force vs. Deformation graphs for the samples show similar behaviour across the three types, but with noticeable variations in their load capacities.

Although there is similarity in trends between the three sample types, the 3DP samples display some additional behaviours, not shown by the non-3D printed samples. The 3DP samples, once again, display a distinct kink that corresponds with the points at which the 3D printed formwork fractures.

SAMPLE 04

SAMPLE 03

SAMPLE 02

SAMPLE 01

SAMPLE 05

SAMPLE 03

SAMPLE 05

SAMPLE 01

The scan shows a porous material, with flecks of the substrate enveloped by the hyphae of the mycelium.

Darker and lighter concentrations illustrate the density of the mycelium.

The outer edge of the mycelium can be seen flaking from the main body of the sample.

CT scans are commonly used to scan internal organs, but they can also show the internal structure of materials. The samples underwent a micro-computed tomography (CT micro) scan. This is a non-destructive imaging technique that provides detailed, three-dimensional visualisations of the internal structure of small objects at a microscopic scale.

The barrier of the 3D printed wood is clearly visible in contrast to the mycelium.

The mycelium hyphae have grown through and around the 3D printed wood formwork.

Flecks of the substrate can also be seen in this sample.

The object binds together in a removable cast during the growing phase, so no formwork is present.

The structure is loose and varies in density.

Sinograms are a special type of image created by a CT scan. During the scan, the machine takes an X-ray picture or “projection” of an object from many different angles. The sinogram is made by lining up all the projections side by side in a single image.

Sinograms provide information on the object’s structure or any anomalies present.

The 3D print formwork is characterised by the dark edges.

The internal structure is comparatively more defined and denser.

Life Cycle Assessment (LCA) of a building evaluates and quantifies the environmental impact by comparing the environmental performance of the different elements of a building. The assessment measures the carbon footprint over a building’s lifespan and may be used to optimise and reduce its impact. The various life stages of a building that are considered, from the production and transport of raw materials to demolition and recycling.

Measuring the carbon footprint takes place in multiple stages. The diagram below details the various stages and the whole life carbon cycle of buildings. The embodied carbon stages at production (A) and end of life (C), and circular construction (D) methodology are considered for the purpose of this calculation. However, the type of consideration differs at all stages. Over the course of this research, the inoculated substrate was acquired from a vendor, while the formwork production, growing, and drying were done in-house. Thus, the product stage of the assessment has been quantified through the review

of existing literature. The use stage was not considered and included assumptions about the end-of-life and beyond stages because of the infancy of mycelium-based composites in architecture.

A1- Data procured from external sourcing

A2- Manual calculation based on delivery pick-up and drop-off locations

A3- Manual calculation based on machines used in-house

A4- Not considered

A5- Assumptions

B- Not considered

C- Prospective Assumptions

D- Prospective Assumptions

In the construction industry, the business-as-usual approach forms a linear economy that leads to landfills and climate pollution. Inversely, the mycelium block reinforces the idea of a circular economy that synchronises with nature and generates no waste.

A1-A3: Product Stage

Raw material extraction, transport and manufacturing

A4-A5: Construction Stage

Transport and Installation

B1-B5: Use Stage

Maintenance, replacement, repair and refurbishment

C1-C4: End of Life Stage

Deconstruction, demolition, waste processing

D: Beyond building life cycle

Circular Economy

SUBSTRATE MYCELIUM

A1

Sterilisation of the substrate*

INOCULATION & PACKING

IN-HOUSE DEVELOPMENT

* For these studies the inoculated substrate has been sourced from our partners Osmose Studio, and associated emissions are unknown. Therefore, the carbon factors for these stages are extracted from the paper academic literature reviews.43

A2

Transport of the procured Mycelium to the substrate preparation laboratory.* Transport of the prepared substrate to the PLP Labs facility - Nottinghamshire to Central London.

Transport of the wood filament required to manufacture the formwork - Bradford to Central London.

A3

3D Printing of the formwork. Packing the Substrate into the formwork.

Growth of the substrate over the formwork.

Dehydration of the block

The Mycelium Block’s Carbon Emissions are measured for a block of the following characteristics

Dimensions: 10 x 10 x 10 cm

Density: 153 g

Carbon emissions calculations are subject to changes in these above mentioned values.

SUBSTRATE PREPARATION

Soaking substrate in water (manual) Draining (manual)

Sterilisation

LAB: 32L autoclave IND:5000L autoclave

STERILEWORK AND PROCESSING

FURTHER PROCESSING FORMWORK FABRICATION

Controlled environment

LAB: Laminar flow cabinet IND:Sealed room (mushroom farm)

Inoculation (formwork filling)

LAB: Manual IND: Automatised

Formwork removal

LAB: Manual IND: Automatised

LAB: Passive solar heating

Walk-in drying room

LAB: Polyethylene IND: Glass fibrereinforced plastic

Laser cutting of formwork

Sealing (manual)

Cleaning (manual)

A1

Sterilisation of the substrate*

A3 - 3D Printing of the Formwork

Printer model Ultimaker s5

Approx. 0.35 kW power usage

Print time of 1 hour per block

A3 - Dehydration of the block

Buffalo 6 Tray Mini Dehydrator

Max. 1.1 kW power usage

Conservative drying time of 10 hr per block

The Mycelium Block’s Carbon Emissions are measured for a block of the following characteristics

Dimensions: 10 x 10 x 10 cm

Density: 153 g

The methodology followed at each stage is described in the previous pages, and detailed in-house calculations have been conducted for the A2 Transport and A3 Manufacturing stages.

A2 Transport Emissions are from the transport of the Substrate and Filament for 3D printing. Due to the low density of these materials, the transport emissions are nominal with respect to the rest.

A3 Manufacturing Emissions are from the preparation of the formwork, and the sterilization/dehydration of the finished product. This stage has the largest carbon emissions due to the energy involved for long periods of time. Stage-wise assumptions and the calculation formulae are detailed as follows and elaborated further in the supplementary documents in the appendices.

The Carbon Emissions calculations are conducted for a functional unit of one block. These values are subjected to changes in the dimensions and density. The Carbon Factors are obtained from Defra.44

On the basis of these calculations: the Embodied Carbon of our mycelium composite material is 5.8 kgCO2/m2

A1

Extracted Data from Paper and matched to UK equivalencies

Biogenic Carbon

Electricity in sterilization of substrate

A2

Luton Van of ~800kg capacity

Carbon Factor 0.14

Substrate Transport- Nottinghamshire to Central London

18l of Diesel for an ~209km distance

Mass per block: 0.473kg

Filament Transport - Bradford to Central London

30l of Diesel for an ~347km distance

Mass per block: 0.039kg

A3

Electricity Factor 0.2

Transport and Distribution Factor 0.017

3D Printing for the Formwork

Power Usage: 0.35 kW (Printer model

Ultimaker s5)

Print time per block: 1 hour

Dehydration of the block

Power Usage: 1.1 kW (Buffalo 6 Tray Mini

Dehydrator)

Drying time per block: 10 hours

Calculations45,46:

Carbon Emissions (KgCO2) vs Life Cycle Stages

A5

Loss/wastage in bespoke use at site

~5% of the total carbon emissions

C1

Mishandling of the deconstruction process

~10% of the total carbon emissions

C4

Disposal into the earth

All remaining elements of the material

D

Potential for re-use

70% of the remainder of the elements

- Can be recycled to use the broken down substrate into new blocks

- Repurpose the blocks for a new use case

Calculation for A2 (Transportation; Van):

Transport Distance x Carbon Factor x Mass per block

Total Van Capacity

Calculation for A3 (Manufacturing; 3D Printer):

Power Usage x Carbon Factor of (Electricity + Distribution) x Time

Calculation for A3 (Manufacturing; Dehydrator):

Power Usage x Carbon Factor of (Electricity + Distribution) x Time

Total Dehydrator Capacity

For the life cycle assessment, we compared the construction materials: mycelium composites, clay bricks and concrete blocks. Although mycelium composites have a lower load bearing capacity in comparison, the strength to weight ratio is very high. Thus, an argument may be made that mycelium composites, with adequate support and reinforcement may be a viable natural alternative. The production lifecycle of each material varies based on the method of extraction at A1 stage for the raw materials, the distance and method of transport to the manufacturing lab/industry for at A2 stage, and the quantum of energy intensity based on methodology at the manufacturing stage A3. Therefore, the processes for bricks/blocks made using mycelium, clay and concrete are outlined in the adjoining diagrams.

A mycelium block nearly produces zero carbon emissions per block and has the potential to be carbon negative. The carbon capture by plant growth at A1 stage mitigates the emissions of energy required in later stages. Additionally, if the mycelium block is recycled or is returned to the soil it could have a negative carbon impact. A mycelium

block has a clear carbon advantage compared to a clay brick and a solid concrete block, based on its standard size in cubic metres. However, comparing the carbon emissions produced by a mycelium block, clay brick, and solid concrete blocks is not a perfect apples-to-apples comparison for two reasons. The first, it is difficult to compare the carbon emissions from materials that are widely used, like clay and concrete, to more niche materials, like mycelium. Secondly, the carbon emission of clay or concrete, as reported by EPDs, which are produced on an industrial scale unlike mycelium.

Hypothetically, industrially manufactured mycelium building blocks would require higher electricity loads, but equally likely, the process would receive benefits of scale from renewable energy and vertical farming. In the same way the industrialised production of clay bricks and concrete blocks has been refined for over a century through automation and prefabrication pipelines, we assume with enough time and development similar efficiencies can be developed for biomaterials.

INSTALLATION

TRANSPORT

MANUFACTURE

TRANSPORT INSTALLATION

MANUFACTURE

INSTALLATION

TRANSPORT

MANUFACTURE

DEMOLISH

LANDFILL LANDFILL RECYCLE

DEMOLISH RECYCLE

CO2 EMITTED

CO2 STORED

DE-CONSTRUCT USE

RECYCLE

94.8 KgCO2/m2

5.8 KgCO2/m2

We showcased our novel mycelium-3D printed wood technique at major design festivals in London, including Clerkenwell Design Week, London Design Festival, and London Design Biennale in 2023.

At Clerkenwell Design Week, we debuted as what Glenn A. Albrecht described as a “Symbiocene Demonstrator” featuring a modular system of 84 mycelium bio-composite blocks grown over the course of three months. The unique block shapes allowed for various configurations such as partitions, seating, planters, and tables showcased at the event.

The mycelium bio-composite blocks were incorporated in the “Ephemeral” pavilion at Somerset House for the London Design Biennale 2023. The Centre for Natural Material Innovation at the University of Cambridge and PLP Architecture organised the exhibit to illustrate innovative, flexible living concepts using natural materials.

PLP Labs also partnered with Studio Snoop and their AI designer, Tilly Talbot, to create an AI-designed mycelium stool named GUS for the London Design Festival 2023. Showcased at Tom Dixon’s Studio, GUS pushed the boundaries of traditional design and material use, and illustrated the evolving role of AI, collaboration, and natural materials in design.

During these showcases, we shared our journey of experimentation and collaboration with the broader public, introducing many to the Symbiocene.

“It is a recognition that, life is all about the sumbios, or “living together” with each other and other types of beings. Life works with life to further life.”

- Glenn A. Albrecht, Earth Emotions -

We debuted the mycelium bio-composite building blocks in late May at Clerkenwell Design Week (CDW) 2023 hosted in London, United Kingdom. The installation took place in the heart of the event, just off Clerkenwell Road in St. John’s Square. The event was attended by 37,725 visitors, a record-breaking number for CDW.47

CLERKENWELL & SOCIAL

ST. JOHNS SQUARE ST. JOHNS GATE

The site was located in front of Clerkenwell & Social at St John’s Square, London EC1M 4DE.

The site measured 7 m x 3 m, spanning multiple parking spaces. As a part of the outdoor exhibition within St. Johns Square, the site sits on cobblestone paving while being framed by tall trees. No permanent fixtures or changes were allowed.

CLERKENWELL & SOCIAL

CLERKENWELL & SOCIAL SITE SITE

The installation was made up of three layers from the ground up. A foam tile layer and MDF board was placed underneath to even out the cobblestone ground and stabilise the installation. Next, a cork pattern was laid over the MDF board for aesthetic purpose, which matched the modular mycelium biocomposite structures.

The largest structure on site was the partition, which was made of 38 mycelium bio-composite blocks. The partition was formed using a repeating and interlocking hexagon pattern. The short side of the blocks were connected to create a hexagon.

The installation was made up of a modular system using mycelium bio-composite blocks. The unique shape of the block allowed for many more configurations than the partition, seating, planters, and table showcased on site.

step 01

Obtain and sterilise a substrate.

Common substrates include agricultural waste such as straw, wood chips, or sawdust.

step 04

Preparing the block.

We packed the 3D printed wood formwork with sterilised substrate mushroom spores.

step 02

Obtain a fungal culture.

This process often requires a lab environment due to the level of sterilisation and control.

step 03

Inoculate the substrate with mushroom spores.

We obtained a pre-inoculated substrate and mushroom spores from Osmose Studio.

step 05

Grow!

We let the mycelium colonise the substrate in a dark and humid environment over the course of three to four weeks.

step 06

Heat the mycelium.

We placed the fully colonised mycelium into a heating chamber. The mycelium was heated at 40 °C for a few hours.

step 07

Mycelium block!

Once fully dried, the mycelium composite block process is complete!

step 08

Mycelium modular system.

The mycelium composite blocks are arranged in various configurations.

connection

angled one plane connection

two plane connection

The modular system is connected via wooden dowels that run through the mycelium blocks. The blocks are designed to be connected in a straight line, an angled connection as well as an angled two plane connection, allowing for 3D aggregation.

The modular system can be connected in an infinite number of configurations to best suit the needs of the user.

The mycelium block was grown using a method of lost formwork, instead of a cast.

The wood filament facilitates mycelium growth, the hyphae expand from inside the formwork to the outer shell.

The 3D printed wood form is enveloped by a thin skin of mycelium, becoming a lost formwork.

It took approximately three months to grow 84 blocks from start to finish in Meeting Room 7 of our London headquarters.

The ripples that decorate the block represent mycelium’s ability to connect and communicate with itself and other lifeforms.

The design language of mycelium is in its infancy. This block is an attempt to explore the visual identity, characteristics, and principles of mycelium-based design.

The finish is mostly white with patches of beige. The texture is soft and fuzzy.

The finish develops a more yellow and beige colour. The texture becomes more rigid and foam-like.

The finish has a marbled quality to it, with different areas of white, yellow, beige, and brown. The texture is smooth, hard, and cracks easily. 1

The “Ephemeral” exhibition at the London Design Biennale 2023 held at Somerset House, showcased innovative, flexible living concepts using natural materials.48 Organised by the Centre for Natural Material Innovation at the University of Cambridge and PLP Architecture, the exhibit highlighted research into sustainable and adaptable housing solutions, including mycelium building blocks and engineered timber partitions. The exhibit is a continuation of the ideas developed by Dr. Ana Gatóo’s during her Ph.D thesis, which was sponsored by PLP Architecture. These modular, affordable components allow for customisable living spaces that evolve with residents’ needs. The exhibition emphasised the importance of sustainable practises, such as prefabrication and the use of timber, in combating climate change and addressing urban housing demands. It also explored the future of construction through digital fabrication with natural materials, promoting a re-integration with nature in the era of the Symbiocene.

The installation consisted of a solid timber structural frame and 12 mm plywood sheets. Through the process of kerfing, the flat sheets were made flexible. The lengths and widths of the cuts drive the amount of material that is removed, thus directly influencing the amount of flexibility and strength of the resulting panel. This was achieved through a series of physical prototypes and computational models to finetune and optimise the kerfing patterns.

SYMBIOCENE FURNITURE

PLP

Labs partnered with Studio Snoop and their AI designer, Tilly

Talbot, to create an AIdesigned stool for the London Design Festival 2023, showcased at Tom Dixon’s Studio.

In exploring the human role in an AI-driven world, PLP Labs brought one of Tilly’s designs, a mycelium stool named GUS, to life.

GUS highlighted the potential of combining advanced technology with sustainable resources, pushing the boundaries of traditional design and material use. The stool speaks to the evolving role of collaboration, natural materials, and AI in the design world.

Tilly has been created by Studio Snoop to be a part of their team as a ‘design innovator’ with their training intentionally biased to prioritise a ‘human-centred’ and environmentally conscious approach towards design. This involved overlaying the traditional principles of Bauhaus with aspects of bio-mimetics and natural materials.49

To bring GUS to life, the first step was to extrapolate a formwork template from the 3D model created by Tilly and Studio Snoop. As the shape contained areas of high double curvature as well as undercuts, special consideration was given to discretising the formwork for efficient removal. This was done by splitting the stool into four sequential levels that were packed in layers. The maximum sizes of the elements were dictated by the bed sizes of our inhouse 3D printers.

The formwork consisted of 30 individual pieces with a flap-based joinery system on its periphery that attaches it to the adjoining piece. Due to the cantilevering nature of the stool, the formwork was made from PLA instead of wood as it would offer easier joinery and provide additional rigidity during the growing phase.

After three weeks of growing, the screws on the formwork were loosened to let fresh air in. As the composite slowly hardened, pieces of the formwork were incrementally removed over the next four to five days. The stool was then dried off at 40 °C for almost 16 hours before being rigid enough for use.

As real-time learning had not been possible, Tilly was only able to respond to working with mycelium composites based on the LLM’s extent of knowledge. This proved to be a challenge as fabrication with mycelium composites is also in its nascent stages with most of the information only available through academia and hobbyist forums.

5mm DIA. M5 WASHER

M5 SCREW

1. 3D CAD Model 2. 3D Printed Formwork 3. Assembly Sequence S_C_03 S_C_04 F_B_02 F_B_03 S_B_01 S_B_04 F_B_04

F_A_04 S_A_02 S_A_03 F_B_01 F_B_04 S_C_02

F_A_03 F_C_02

“It will be soft and hairy.”

Salvador Dali on the future of architecture, in response

Mycelium bio-composites prove to be a promising gateway into utilising biomaterials in architectural design and construction. Although there are several challenges towards widespread commercial adoption, there is great potential for further development. Interest in mycelium bio-composites is growing in architectural practise and universities as seen by the ever-increasing number of academic studies and design experimentation. However, despite initial interest, consumer trust and industry validation remain formidable obstacles as doubts persist regarding the material’s fire rating, structural performance, and aesthetic appeal, including concerns about allergic reactions and odour.

External durability, fire rating, and waterproofing are some of the major hurdles to be overcome before these products can be used globally. Thus, it is only logical to consider using mycelium materials in tandem with other, more familiar, natural materials such as timber and clay. Further research into bio-based coatings and genetic engineering may provide viable solutions for some of these issues in time. But an industry wide shift away from fossil fuel-based materials will only occur if there is demand from the ground up.

Mycelium remains an intriguing opportunity. For instance, carbon-neutral, large-scale commercial mycelium production may be possible as the process requires little energy. Mycelium bio-composites can also be mass produced across the globe, using locally available agricultural waste and regional mushroom species. The growing conditions are relatively simple to replicate with the right know-how. Moreover, the material may be fabricated into various shapes and sizes making it form agnostic, which offers an exciting opportunity to designers.

However, at present, mycelium is best suited for thermal and acoustic insulation, as well as low density construction, showcased by Mogu’s Foresta system50 and the MycoHab by Red House Studio Architecture.51

This score card is a benchmark, not a conclusion, of the capacity of mycelium bio-composites in architecture and design. We look forward to the continuation of this work and the dawn of the Symbiocene.

CONSUMER INTEREST CONSUMER TRUST

BIODEGRADABLE

WEATHERING COATINGS

SCALABILITY

BIOPHILIC QUALITY

COMPRESSIVE STRENGTH

ENERGY FOR PRODUCTION

SURFACE DURABILITY

WEATHER RESISTANCE

PRODUCTION COST

NEW AESTHETIC

TENSILE STRENGTH

DISCONTINUOUS PROCESS

WEIGHT ODOUR

ACOUSTIC PERFORMANCE

BY GLENN A. ALBRECHT PH.D PHILOSOPHER & ENVIRONMENTALIST

It might be the case that architects are in the vanguard of the urge to make a fundamental change from the dictates of the Anthropocene or period of human dominance on this Earth. Continuing to design and build the superstructure of human dominance over the rest of life comes at an emotional cost. A recent survey of the wellbeing of architects in Australia found that a large proportion of those surveyed (42%) felt dissatisfaction with their work and experienced a loss of well-being.52

Solastalgia can be experienced within the built environment as much as that inflicted by negatively perceived and felt change to rural or natural environments (e.g., by open-cut mining or the clearcutting of forests).

If one belongs to a profession that is core to building the built environment, then solastalgia sits on one’s shoulders as a chronic, painful weight. It is also the case that while the burden of architectural solastalgia is personal, the solution or remedy is structural and, as concluded by the authors of The Wellbeing of Architects concluded, “… is certainly not something that can be fixed with individual self-care.”53

The largest ‘structure’ within which the profession of architecture sits is the Anthropocene. In the name of increasing economic growth and wealth accumulation, the main characteristics of this period in human history include massive damage to the Earth due to extraction of inorganic raw materials, ecosystem-wide pollution due to accumulation of toxins, a massive loss of biodiversity, chaotic global climate warming, loss of health in ecosystems, and loss of mental and physical health in human and non-human populations.

As ‘architects’ of the Anthropocene, the etymological emphasis can be interpreted as one of dominance or rule as the derivation of the word ‘archi-’ is a noun “denoting individuals who direct or have authority over others of their class”.54 Hence the implication of rule over the design and construction of a building (tektõn = to build). In a hierarchy of responsibility for the material existence of the Anthropocene and its design and construction (cities, houses, etc), architects must reside near the top. No wonder that as a profession, that burden can be easily transferred into solastalgia and other indicators of a loss of well-being in a time of biophysical and social crisis.

There is another possible interpretation of the ‘archi’ in architecture that just might take the profession in a different direction. Here the emphasis is on ‘archi’ as a “first, principal” or that which is primary or comes first. The creation of a plan before a building is erected would be the meaning here. As such, the emphasis in architecture would be more on ‘birth’ or creation than rule or dominance.

To take the creation line of reasoning further, I suggest a new derivation for those who design then build. Architecture can morph into ‘sumbiotecture’. Here, the derivation is from the Greek, ‘sumbios’, meaning companionship or living together. The bio-scientific term, ‘symbiosis’, is derived from this very powerful word. The full derivation is from the Greek sumbiosis, meaning companionship (from sumbioun, to live together, from sumbios, living together).55

Sumbiotecture is to design and build with others (human and non-human) for the purpose of harmoniously living together. Instead of hierarchy, an egalitarian principle is introduced where there is what the social ecologist, Murray

Bookchin, called “an equality of unequals”.56 The notion of equality is central here because in symbiotic relationships, no one component is more important than another, as the whole is always greater than the sum of the parts. We are all holobionts!

Design and building for symbiosis (healthy connections), rather than dysbiosis (disease outcomes), becomes the primary aim of the ‘sumbiotect’. This idea might seem new, yet Ian McHarg in 1969 published ‘Design with Nature’ which included a simple diagram for the evolution of life and its relevance for design.57 He saw ‘retrogression’ in life as involving (amongst other factors) “low number of symbioses” and ‘evolution’ as engaging a “high number of symbioses”.58 He also saw the process of apperception as vital to the role of humans as good stewards of nature having the primary role of “the agent of symbioses”.59

Sumbiotecture now has a vital role in directing the future of humanity out of the Anthropocene and into the Symbiocene.60 We have grossly failed as agents of symbiosis in the Anthropocene. In addition to the failures outlined above, the most egregious, the most devastating, have been the symbiosis-busting activities of humans. Failure to even acknowledge symbiosis as a factor in evolution has seen, for example, outcomes of huge magnitude such as early 2024, 70% bleaching, caused directly by global warming, of the largest structure formed by symbiosis on planet Earth, the Great Barrier Reef.61 This is symbiocide writ large.

To design with nature and its foundation of symbiosis becomes the most important role creative thinkers and makers can have in any profession, trade or enterprise. The dysbiotic structure of the Anthropocene must be completely replaced. In the translation of theory to praxis

this means that the foundations of human society must return to a relationship with the rest of extant life. Life supports life and this has been a feature of life-existence for 3.5 billion years of evolution.

For humans to use life to support their own lives now requires that we use the building blocks of complex life such as algae, bacteria and fungi to support our future. Every aspect of the Anthropocene that relies on extraction, toxic waste and pollution of Earth’s biogeochemical systems and life has to be replaced by its Symbiocene opposites and re-integrated seamlessly back into life. Toxic artefacts can all be replaced by benign symbiofacts.

Sumbiotects have realized this truth. They are now innovating foundational construction materials made from the mycelium of fungi. ‘Infrastructure’ is now being made from mycelium bricks that are part of the cycles of life, it is being transformed into ‘symbiostructure’. Our domestic “stuff”, formerly made mainly from toxic petro-chemical plastics, is now being replaced by algae and cellulosebased substances. The revolution is not just conceptual, it is also material and emotional. Sumbiotects will, along with the rest of humanity, find that their well-being and happiness come from co-designing a Symbiocene that unites humanity with the rest of life.

Abhinav Chaudhary, Associate Partner

Alex Davidson, Associate Partner

Deepthi Ravi, Sustainability Design Lead

Dila Batmaz, Architectural Assistant

Dominic Do, Model Maker

Principal Authors:

Abhinav Chaudhary, Savannah Willits, & Deepthi Ravi

Harjit “Ram” Sembi, Senior Associate Partner

Jenya Andersson, Senior Associate Partner

Michael Polisano, Industrial Designer

Ron Bakker, Founding Partner

Savannah Willits, PLP Labs Team Lead