AMBA Presents Three Distinguished Awards in Michigan

Byrne Tool Leverages Creativity over Capital

Manufacturing Supply Chains in Focus

Rising Healthcare Costs

AMBA Presents Three Distinguished Awards in Michigan

Byrne Tool Leverages Creativity over Capital

Manufacturing Supply Chains in Focus

Rising Healthcare Costs

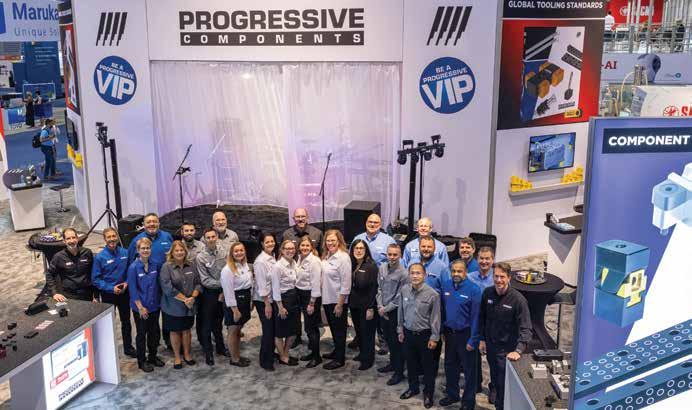

Our 11th NPE is in the rear-view mirror, and we are grateful for those who journeyed in person or visited online to see all of our new components and innovative monitoring solutions:

• New: Precision standard pins and mold base components

• New: Exclusive innovations now available off-the-shelf

• New: Mold Monitoring and Asset Management system

Thank you for searching out new methods, evaluating products, and utilizing them for your tools. As the only American-owned, independent full-line source for molders and mold builders, we’re driven to serve and assist our customer friends.

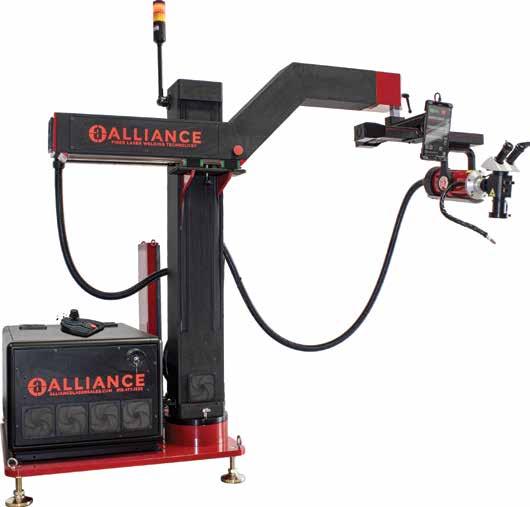

• MOLD FINISHING

• LASER WELDING

• LASER ENGRAVING

• HOT RUNNER REPAIR

• MOLD MAINTENANCE

• LASER MACHINE SALES

er mold finishing, laser welding, laser graving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom

Let Alliance make a di erence for you.

EVERY PART OF THIS MACHINE IS EASILY ADJUSTABLE TO ALLOW YOU THE VERSATILITY AND FLEXIBILITY YOU NEED TO MEET ALL OF YOUR DEMANDS

CONTACT US TODAY ABOUT AN IN-HOUSE DEMO, TO SEE THE ALLIANCE DIFFERENCE.

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio

Vice President, Editorial: Dianna Brodine

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann Opinions

TYLER VANREE AMBA President, LEGACY PRECISION MOLDS, INC.

TYLER VANREE AMBA President, LEGACY PRECISION MOLDS, INC.

Greetings AMBA! As I write this message, spring is in the air, everything is coming to life again and I’m reminded that each day is a fresh start with new beginnings, new opportunities and new experiences to grab ahold of. For many of us, the past months have provided plenty of challenges in business, some more than others. Wading through challenging seasons, whether professionally or personally, oftentimes can leave us clouded and lacking perspective, and we too easily can push aside what is most important in life. Regardless of where you find yourself today, I’d encourage you to take some time to step aside from the busy routine, reflect on the things that matter most and re-commit to making the most important things in your life a priority.

In late March, we wrapped up another successful AMBA National Conference in Grand Rapids, Michigan. Engaging in round table discussions with peers, learning from speakers on stage and networking with new (and old) friends always is a highlight for me at the conference. While there were many things I learned and grew from, two of the takeaways at the top of my list were “lean into the uncomfortable” and “why set a goal when you can make a promise.” I trust the conference was a beneficial time for you as well.

The conference also is a time when we get to celebrate the wins of individual AMBA members and their companies. Special shout-outs this year to Nick VanderZwaag from Legacy Precision Molds for winning the inaugural Emerging Leaders Rising Star Award, Roger Fox from Accede Mold for winning the Mold Builder of the Year Award and United Tool and Mold for winning the Tooling Trailblazer of the Year Award. I also want to shout out to Tom Barr, who finished his term as AMBA president and has passed the baton to me. His unwavering commitment to AMBA and his passion for the industry have been contagious and encouraging to me as I’ve served alongside him for the last several years.

As you read this, the NPE2024 Plastics Show in Orlando, Florida, has just wrapped up. If you weren’t able to exhibit or attend this year, I’d highly recommend considering it in 2027. NPE is a great opportunity to display and promote your American creativity, excellence and craftsmanship to the world. The AMBA team was active in its booth, working hard to promote US mold building companies as the best choice for tooling needs worldwide. AMBA also was instrumental in several networking events to help connect members to potential new prospects. This is just one more way that AMBA goes to bat for each of our organizations. Thank you, AMBA team, for your work in helping businesses have a competitive edge in today’s global marketplace.

In conclusion, I hope you will take the time to step back from the busyness, make a promise instead of a goal and engage with the multiple AMBA resources and offerings in the months ahead. You and your business will be better for it, and the AMBA community at large also will grow and become stronger as everyone stands together to face another day. You are the AMBA. We are the AMBA. Together we are stronger.

OFFICERS

National President

Tyler VanRee, Legacy Precision Molds

Vice President

Andy Peterson, Industrial Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Fiedlander, Coplan & Aronoff LLP

Treasurer Hillary Thomas, Westminster Tool

BOARD OF DIRECTORS

Tom Barr, TK Mold & Engineering

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume Engineered Diamond Products

Mike Hetherington, Franchino Mold & Engineering

Kyle Klouda, MSI Mold Builders

Chad LaMance, United Tool and Mold

Troy Roberts, Tolerance Tool

Camille Sackett, Accede Mold & Tool

John Stocker, Swiss Steel USA, Inc.

At Plastic Engineering & Technical Services, we are.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

“Iwant to thank everyone at Accede – we won this together!” said Roger Fox, president, Accede Mold & Tool, Co, Inc.

The AMBA Mold Builder of the Year Award, sponsored by Progressive Components, was created to recognize outstanding contributions as an industry leader and active AMBA member. Justin McPhee, Mold Craft, Inc., a Westfall Technik Company, and 2023 recipient of this award, presented the 2024 AMBA Mold Builder of the Year Award to Roger Fox, Accede Mold & Tool, and it was received on his behalf by his son, Mitchell Fox, at the AMBA Conference in March. As Mitchell Fox took to the podium to accept the award, he shared words written by his dad: “It’s not hard to succeed when surrounded by great people, like Camille Sackett who submitted this nomination.”

A few weeks before the conference, Tom Barr of TK Mold & Engineering, Inc. and Glenn Starkey of Progressive Components surprised Roger Fox at the Accede Mold & Tool facility in Rochester, New York, to present the award to him in person. Fox said, “I would like to thank AMBA for this prestigious award and express my regret for not being able to attend and receive it in person, and I would like to thank Tom Barr and Glenn Starkey, again, for making the trip to Accede and making it a truly memorable surprise … We will forever display this award with pride.”

Gathering together, the Accede family was there to celebrate Fox’s 2024 AMBA Mold Builder of the Year Award, and it was recorded for attendees to see at the AMBA Conference awards ceremony.

“MOLD

New York-based Accede Mold & Tool is a global leader that specializes in complex and precision state-of-the-art moldmaking for the plastics injection molding industry.

Under the leadership of Fox, Accede Mold & Tool has built a respected brand within the plastics industry for more than 40 years. But before a successful track record and decades in the industry, there was a younger, 21-year-old version of Fox and humble beginnings – starting his career in mold building under the guidance of his father. Within a few years, the company moved out of the suburban 10,000 sq. ft. warehouse and into its present location in 1987. With a mechanical curiosity and a fascination with manufacturing processes, Fox progressed from moldmaker to shop supervisor to vice president of manufacturing to general manager and finally, in 2012, to president and owner, during which he purchased the business from his father.

As written on the award submission by Sackett, “He’ll take the time to give everyone else praise and recognition and give us everything we need to be set up for success … There are many easier ways to make money than owning a mold shop. But after being a family man, being an American moldmaker is Roger’s life’s work.”

Under his leadership and mission of “Mold Building Excellence,” the company built its first two-shot mold

in 1991, added a mold sampling lab in 1997, certified its Quality Management System in 1998, delivered its first turn-key systems in 2003, added the third-generation workforce in 2007 and built its first SpinStack cube mold in 2010. In 2015, it added a second facility known as the Systems Integration Center, which is used for turn-key and full systems integration around its plastic injection molds. Today, the company’s Quality Management System has been upgraded to meet ISO 9001:2015.

Accede Mold & Tool is continuing to nourish and create the building blocks that will support and develop the next generation of moldmakers, whether through internal apprenticeship programs, manufacturing day events, high school career fairs, robotics programs, technical trade colleges and more.

For Fox, inside and outside of the organization, mentorship is an integral part of developing and bringing the next generation into mold manufacturing. The company’s internal training program for moldmakers and machinists is designed not only to educate but to expose apprentices to various manufacturing equipment, processes and related activities used to manufacture custom injection molds. Externally, Accede Mold & Tool is committed to giving back to the community and the industry – investing time, resources and capital in local and global causes, including partnering with local high schools and technical colleges to promote the value of mold manufacturing, donating equipment to the local school district and sponsoring and volunteering in the FIRST® Lego® League global robotics program.

In concert with those efforts and striving to grow tomorrow’s next generation, Fox stated he plans to use the $5,000 scholarship money, given on behalf of Progressive Components, by investing it back into Edison Career and Technical High School with plans to reach as many young adults interested as possible in the mold manufacturing industry.

A quote by William Pollard, a physicist, can be found on Accede Mold & Tool’s website: “Learning and innovation go hand in hand. The arrogance of success is to think that what you did yesterday will be sufficient for tomorrow.” McPhee said, “Pollard’s quote perfectly sums up the mindset of Roger Fox. Always learning … always teaching, forever innovating.”

More information: www.accedemold.com

“It was exciting – Patrick and I were surprised, then had a ‘proud’ feeling for our entire team back home! We have put a lot of effort into being a part of local schools and creating opportunities for students to be involved in this industry, and it was nice to be recognized for that,” said Chad LaMance, COO for United Tool and Mold (UTM), Inc. Lemance was onsite at the AMBA Conference in March to receive the Tooling Trailblazer of the Year Award.

The AMBA Tooling Trailblazer of the Year Award, sponsored by Progressive Components, was established to recognize the accomplishments of an AMBA member company that have resulted in a notable impact in the area of education. This year’s award recipient is a company working hard to change the narrative of manufacturing in its region – shining a light on mold manufacturing and the available opportunities. Congratulations to United Tool and Mold, the 2024 AMBA Tooling Trailblazer of the Year.

“It means a lot to us to be awarded this through AMBA because there are a ton of great member companies who also do a lot to support education. United Tool is honored to be the one selected for the work done to create opportunities for students to get into this industry,” said LaMance.

For UTM, it is a small sign that its efforts in growing the industry are going in the right direction, continuing to push the company down the path of supporting and uniting the next generation in awareness, education and training.

United Tool and Mold is located in Liberty, South Carolina, and is a provider of engineering changes and repair services for the plastic injection, blow molding and die cast industries. Established in 1995, it was founded on the principle of “Keeping the Plastics Industry Running” and operates as a one-stop shop for all mold-servicing needs.

For more than 28 years, UTM has prioritized introducing high school and college students to the industry, but equally emphasized to its employees the importance of their active involvement in the careers of young adults. Employees are encouraged to support the various programs at the schools, be a part of facility tours, serve on advisory boards, and participate in career showcases, mentorship and more.

LaMance said, “In the last year, UTM has continued to make educational outreach an important part of its success through involvement with the local school system, including volunteering on advisory boards at the high school and technical college level, hosting over 100 high school students for shop tours and participating in a business showcase that allowed over 5,000 eighth grade students in the region to learn about the trade.”

UTM is striving to be a complete package by sharing, educating and developing the future of the industry, and being a sponsor and investing back into the local high schools is a huge part of taking students full circle.

The company sponsors several high school awards that celebrate excellence and accomplishments, such as the Most Improved Senior (at five local high schools) and The Scholar Technician. The Scholar Technician Award recognizes a technical high school student who excels at solving problems with her/his mind and hands, and is enrolled in one of the STEM programs at the Pickens County Career and Technology Center. With this award comes a monetary component that helps award winners purchase tools when they join the workforce or pay for tuition to further their education.

“We are very proud to have a younger workforce and to be able to see the individual and team growth as we move along. Seeing the transitions and helping develop young leaders and moldmakers are things the company values as very important for the future growth of the industry.

We are committed to every age bracket at UTM, and a key focus is continuing to help educate our young team in

technical and soft skills – all with the end goal of growing the NextGen workforce,” said Patrick Brisson, project manager at UTM, who also was in attendance at the Conference to accept the award.

“Providing hands-on opportunities for high school students is a great educational tool,” said LaMance, “and to that end, last year the company hired four rising junior high school students as interns to learn about the business and gain some trade experience.” UTM also has a registered apprenticeship program, and currently, three young men are enrolled who started the program in high school.

UTM knows that the future of its company and mold manufacturing is a continuous investment into the next generation, with plans to stay the course by offering full support back to local schools through sponsorships, internships, apprenticeships and more.

LaMance said, “Educational outreach has been and continues to be a very important part of our business. Almost 30% of the company’s 70 employees went through the Career and Technology Center as a part of their high school education. UTM started in 1995, and I was one of four students in the first class to co-op with UTM and the Center in 1996. I didn’t know what a mold was, much less any mold manufacturers at that time. I know firsthand that I wouldn’t be where I am today without UTM putting a priority on educational outreach 28 years ago.”

Whether a high school or college student or young mold builder who’s entering the industry, Brisson shared a key piece of advice: “You can learn a lot quick, but quickly learn how much you still have to learn… and always strive to be a better you.”

As for the $5,000 scholarship given on behalf of Progressive Components, UTM plans to use this monetary award by investing it back into Pickens County Career and Technology Center for use in several STEM classes. Twenty-eight years and going strong, it is UTM’s privilege to be a part of building the foundation and continued growth of the Center.

More information: www.utminc.com

In its inaugural year and presented at the 2024 AMBA Conference in March, the AMBA Emerging Leaders Rising Star Award is intended to recognize outstanding growth, leadership and/or contributions by an emerging professional in the AMBA community and a part of the US mold manufacturing industry. Based on recommendations provided by the AMBA Emerging Leaders Advisory Board, nominees for this award should exemplify one or more of the characteristics outlined, including integrity and accountability, adaptability and agility, leadership and initiative, collaboration and empathy, and dedication and a desire for growth.

This year’s first AMBA Emerging Leaders Rising Star Award was proudly presented to Nick VanderZwaag of Legacy Precision Molds, Inc., for the integrity displayed in his work, the willingness to try and learn new things, the ability to connect well with teammates, the proactive follow-through with projects and the continual desire to increase responsibility.

When asked what first came to mind when he heard his name at AMBA’s award ceremony, VanderZwaag said, “I was completely surprised! I had no idea I was even nominated until the big screen showed the list of nominees – and there was my name. I then internally experienced a mix of emotions since I am so new to the industry and, of course, gratitude for having received such a huge honor.”

In 2019, VanderZwaag was hired by Legacy Precision Molds, Inc., Grandville, Michigan, a full-service plastic injection mold builder, as general labor with minimal manufacturing experience but showed an interest in the opportunity to learn. In his first year at the company, VanderZwaag quickly jumped in cleaning the facility, performing maintenance, driving and cleaning trucks and helping in various light manufacturing projects. Tyler VanRee, president of Legacy Precision Molds and AMBA’s board president said, “There wasn’t anything he was asked to do that he wouldn’t be up for trying and learning. His willingness to learn or try something new and the humility he shows throughout that learning is highly commendable.”

Within the first year, VanderZwaag rose to the challenge of added responsibilities, including purchasing, outsourcing and managing vendor relationships – and he met those tasks with an initiative to listen, learn and develop, gaining confidence along the way.

Then, in his second year, he was instrumental in spearheading the initial certification of Legacy Precision Molds’ first Quality Management System, ISO 9001. VanderZwaag continued leading and collaborating with team members on those efforts, which ensured that metrics were well tracked so that customers received topnotch quality parts and on-time delivery. More recently, VanderZwaag took on a leadership role in a project to develop a new custom database solution for the shop floor. “I’ve had the privilege to be a part of the design and development of this unique system environment,” said VanderZwaag, “I’m really proud of how the overall system turned out. Legacy Precision hopes to see significant improvements in its ability to job cost, analyze data, report and adapt to changing market conditions.” His attention to detail and persistence in tackling this challenging project has not gone unnoticed by the Legacy Precision team as this database solution launched in April 2024.

VanderZwaag consistently has shown through his professional roles and responsibilities that he is dedicated to driving the mold manufacturing industry forward –but it doesn’t stop there. He was tasked with assuming a critical position of overseeing the CNC and moldmaker apprenticeships within the company. Taking this program head-on, he modernized it to reflect the needs and direction of today’s mold industry. And if that lineup of responsibilities isn’t enough, VanderZwaag is pursuing an MBA with a focus on data analytics, regularly attends AMBA online events and its annual conference and participates in the West Michigan Chapter fundraising events.

When asked how AMBA has supported him as an emerging leader, VanderZwaag said, “AMBA has been an incredible resource for me as I’ve been learning the industry. First off, though, a big thank you to Tyler and Tom at Legacy Precision for giving me many opportunities to use

AMBA’s resources. I’ve greatly benefited from the AMBA conferences and emerging-leader pre-conference sessions.”

He continued, “The sports world reality that ‘you get better when you play someone better than you’ also applies to business. Being saturated with the wisdom, experience and best practices of others in the mold building industry has made me a better person and employee. I hope to be able to return the favor to a certain degree throughout my career.”

Outside of his hard work, dedication and passion for his professional life, VanderZwaag hit a big personal accomplishment this year, sharing, “I completed my first sprint triathlon last summer. The swimming portion was one of the most challenging things I have done in my life, but it was a cool achievement to do with five of my Legacy Precision coworkers.”

VanRee completed the AMBA award submission on VanderZwaag, where he perfectly stated, “The integrity he displays in his work, his willingness to try and learn new things, his ability to connect well with his teammates, the way he is proactive and sees projects through to completion … are all characteristics that he displays with a high level of excellence.”

By receiving the Emerging Leaders Rising Star Award, VanderZwaag was given a financial contribution of $500 on behalf of the award sponsors Gesswein and Mastip, Inc. to be used toward his professional development. VanderZwaag shared, “This contribution has been applied to my student account at Davenport University where I’m currently working toward my MBA and is very much appreciated.”

In closing, VanderZwaag proudly said, “Aside from this award being an incredible honor, it also confirmed to me that the work I’ve been doing the last few years has been valuable and impactful. Finding meaning in work is so important, and one way I have experienced that is realizing how my work impacts Legacy Precision Molds and the industry. Both Tom and Tyler VanRee always have been exceptional at giving recognition when deserved to all at Legacy. This award reiterated how amazing the American mold building world is and has inspired me to be more willing to take on discomfort when called on to lead in various areas of my life.”

More information: www.legacyprecisionmolds.com

Byrne Tool + Design recently hosted an AMBA plant tour of the company’s Rockford, Michigan, operation, during which the manufacturer discussed and demonstrated an array of business practices to leverage creativity – as opposed to spending capital –to remain competitive and profitable. For this View from 30, The American Mold Builder followed up with Mike McLean, general manager at the company, for insight into the most valuable aspects of Byrne Tool’s efforts to use its existing resources and technologies to the fullest.

Byrne Tool + Design began in 1974 as Bylsma Tool, headed and staffed by founder Pete Bylsma. The company was moved to Rockford in 1984, purchased by Norman Byrne in 1997, initially called Byrne Tool & Die and renamed Byrne Tool + Design (BT+D) in 2015. The company produces injection mold tools for manufacturers of automotive, defense, medical and consumer goods. Byrne Tool has a 3D printing-equipped full-service design center, a range of injection molding presses for in-house sampling, a 17-strong day shift including two company veterans with 40 plus years of experience, and automation-enabled lights-out machining.

Top: Mike McLean and Nick Scheffler share lean manufacturing principles used at BT+D with AMBA tour participants.

Middle: Jackie Overley tells AMBA tour members about best practices for a self-directed workforce.

Bottom: AMBA tour attendees discuss digital transformation with Andy Baker and Mike Benstead from BT+D.

Photos courtesy of Jimmy Renallo, Creative Technology, www.creat.com.

McLean described his role at Byrne Tool and the company’s ethos. “As general manager,” said McLean, “I provide leadership and management to the organization so we can meet strategic objectives and operational excellence goals. I make recommendations for increasing our use of technology and resources, and I define initiatives for our team to meet established goals, often developing tools to increase company efficiency and reduce risk.” BT+D approaches workforce development and training, lean manufacturing and other resource enhancements with a long-held culture. “The company has a legacy of continuous improvement,” McLean explained. “We have a saying here – ‘Honor tradition and pioneer change.’ Lean manufacturing has been a staple of Byrne Tool’s growth for the last 25 years. We began with regular 5S and Common Sense Manufacturing events (multi-day problem-solving sprints). More recently, our initiatives have included automating the capture of realtime KPIs, and the use of the low-tech and highly effective SQDC boards (visual project management whiteboards).”

BT+D’s commitment to efficiency and excellence is found in every aspect of the company’s workflow, including marketing and customer communications. As McLean described it, “Byrne Tool has a brand promise of tooling done on time and right the first time. When we deliver on that promise it allows us to retain existing customers and win referral business from satisfied customers.” McLean asserted that a solid referral from a satisfied customer is the path of least resistance in finding qualified prospects for new business. “Once we gain an introduction to a new customer,” said McLean, “our goal is to have them visit our shop. Once they’ve visited us, we enjoy a high prospect-tocustomer conversion rate.”

The company gauges marketing success via tried-andtrue methods. “This is one area in which we really honor tradition,” McLean said, “Instead of putting money toward AdWords and PPC campaigns that convert form completions, we measure sales growth by segment and customer retention. Our new customer sales have increased 30% since 2019, in no small part due to referrals.” When it comes to customer communications, Byrne Tool provides detailed build schedules to its customers for all new tooling and larger engineering changes. BT+D taps technology to offer customers beyond-the-norm access and communication: “We developed an online customer portal that each customer can use to see its job status in relation to the agreed-upon schedule,” said McLean. “This wasn’t intended to reduce customer interaction, but rather to standardize how information is shared, so customer conversations are more productive and less ambiguous.”

McLean explained that cutting lead times is an additional factor that improves the customer experience. “We made significant improvements to our scheduling processes, planning each component of a tool complete through our facility,” he said. “The method of scheduling that we use allows us to identify critical paths for our projects to get them on schedule and highlight float time for different components. This makes it easier to see where drop-in repairs and engineering changes can be pushed forward or where we can compress lead times.”

At BT+D, job planning is another aspect of business that has been improved. “Our job planning has increased tremendously,” said McLean. “Instead of viewing a job as an individual unit in a silo managed by one mold builder, we document our routing and schedules digitally, bringing transparency to the organization’s core functions and improving team dialogue.” The software in use for job planning is Smartsheets. “The magic, however, is in the planning process, as opposed to the tool used,” McLean said. “We want to make better planners who can react dynamically when things change. Eisenhower famously said, ‘Plans are worthless, but planning is everything.’ I strongly believe that.”

The company also keeps an eye on outsourced work. “We generate reports to see what is planned to be contracted outside,” McLean said. “This has helped us increase efficiencies in logistics and improve our communication with vendors.”

The mix of lights-out manufacturing and operatormonitored production at BT+D is fluid and job-dependent. “Our scheduling and planning are not prescriptive,” said McLean. “That is, we don’t dictate down to the hour which components should be completed at which machine, so operators have the freedom to sequence as they see fit.”

Parts with multiple setups, for example, or parts that require operator interaction are run during the day, while longer programs are run at night to optimize lights out. This fluid strategy also gives the company the freedom to move jobs around to expedite repairs.

BT+D has what it calls a self-directed workforce. “Our organization is flat,” McLean explained. “No one is dictating tasks or calling all the shots. We don’t have a foreman or supervisors.” The company’s work plans specify the required timelines and the milestones to be hit. “But if a CNC operator has four components to machine,” said McLean, “the operator has the freedom to sequence the job

to optimize the run time. Mold builders are given freedom to prioritize their jobs to create an efficient schedule.”

BT+D’s core business hours are 8 a.m. to 4 p.m. but with flexibility built in. “Some people,” McLean said, “start at 5 a.m. so they can get home in time to meet their kids at the afternoon school bus. Others like a later start time and work later accordingly. This allows us to have daily coverage through most departments from 5 a.m. to 5 p.m.; combined with our lights out, we have the operating efficiency of two shifts but with the staffing of only one. That is what we mean by a self-directed workforce - it is not other-directed.”

That kind of autonomy extends to the use of digital tools at BT+D. “Everyone has their own computer and the requisite skills to use technology effectively and professionally,” McLean said. “With design data shared throughout the organization, we foster collaboration amongst coworkers. This collaboration, in turn, allows for creative problem solving.” McLean acknowledged that there are risks associated with having technology so ingrained in the company’s operations. “We have quarterly cyber security training. We also have internal phishing campaigns designed to snare users and train them on how to spot and report these risks. This also highlights vulnerabilities to address before

they become a problem.” Effective job reporting also puts the company in a position to identify emerging problems as early as possible. “We have a daily huddle with department representatives and job leaders in which our goal is to identify risks to our projects and discuss how to keep them on track,” said McLean. “We have real-time reports on our schedules to see where projects could be slipping, but also to balance capacity.”

In addition, the company fosters its next generation of workers through an active apprenticeship program and offers tuition reimbursement for team members who would like to further their education. DiSC personality and communication style training and scientific problem-solving exercise programs have been conducted, and the company delivers annual CAD training and refresher courses for employees – all of which are a key part of building a self-directed workforce and striving toward one common purpose as a company.

It is no surprise that lean production is practiced at BT+D. The company has, for example, been paperless for over 10 years. “There are no job riders or other paperwork floating around containing technical data,” McLean explained. “Our experience is, once something is printed, it is no longer revision controlled. Instead, we maintain all data in the CAD model: the model data is the single source of truth, and all employees have training and access to the CAD model. If a feature exists in the mold, it exists in the CAD model. We use color codes and layers in the CAD system to communicate tolerancing and other information.”

How does the company measure success in this area? “We rigorously track scrap and rework, and follow back to the root cause for almost all issues,” said McLean. “Since going paperless, design revision-related rework has been reduced significantly by instantly giving access to the most up-todate specs.”

Through it all, says McLean, an important lesson has been learned. “Everyone must be a leader. This requires technical understanding of the operation, diligence to follow critical processes, courage to point out problems and vulnerability to ask for help.” What’s up next for Byrne Tool + Design? “We continue to sharpen the knife… We’ll be digging deeper into finding methods and resources to reduce non-value-added work. We will continue to improve our operations and financial analysis and reporting, and ultimately continue to deliver on our brand promise.” Kudos and many thanks to BT+D for its willingness to share valuable strategies and methods.

More information: www.byrne-tool.com.

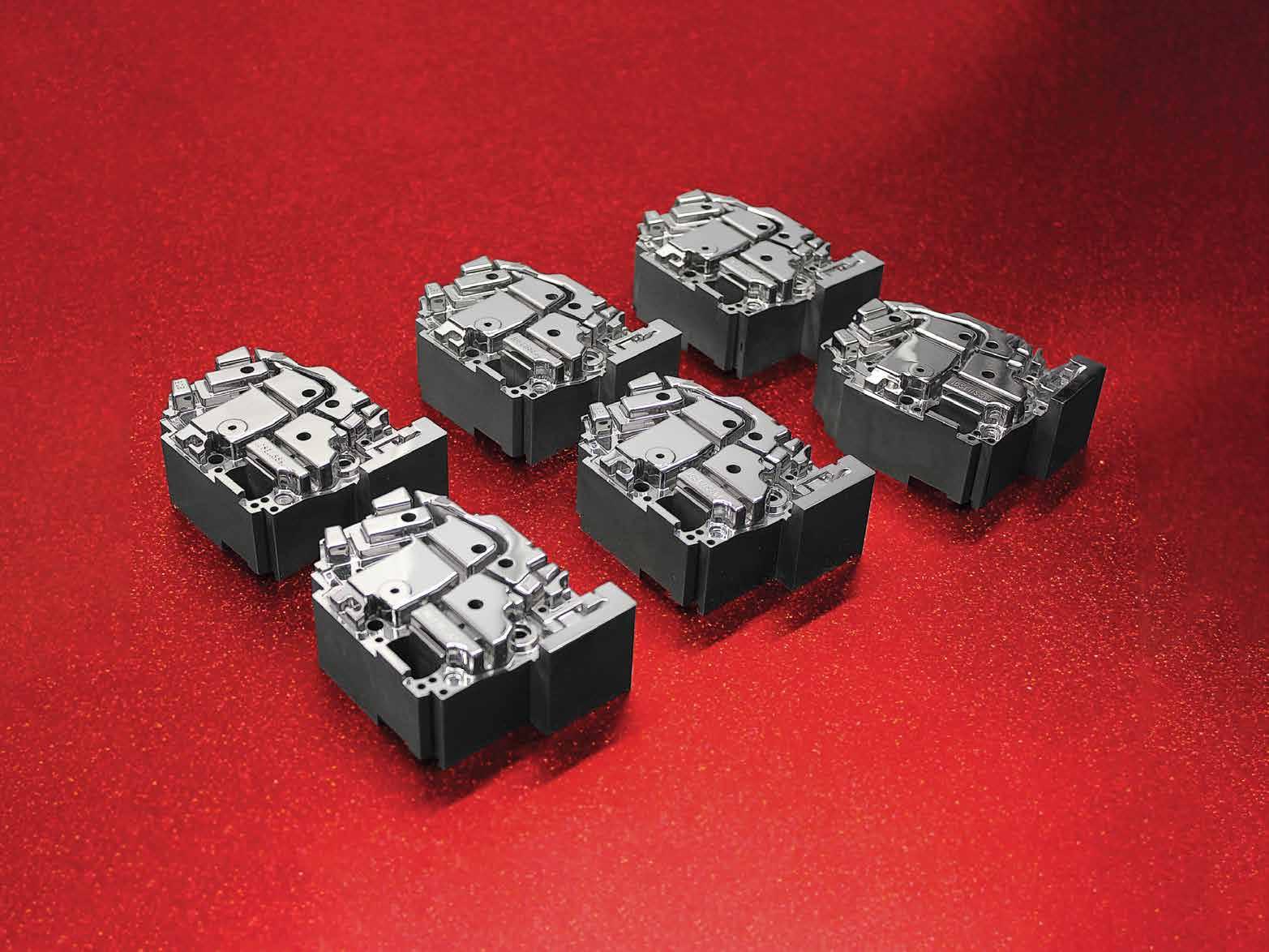

A look at mold bases used to support molds and tooling components in injection molding, compression molding and resin transfer molding.

Craftsman Tool & Mold

630.851.8700

www.craftsmanmold.com

Craftsman Tool & Mold, Aurora, Illinois, has created stack mold bases and rotational spin stack mold bases for the multi-shot injection mold industry across North and South America. Stack molds can double and triple the output of production. It all starts with a stable foundation, “the mold base,” giving customers peace of mind engineering their 2-, 3- and 4-level stack molds, to design parts with the most stringent of tolerances, many times to .0005". The photo represents two core plates (10.750x29.5x45) mounted on a clamp plate (2.625x45x72) all made from 420 stainless steel and the back side of the core plate is carved out with standing supports to house three sets of pin plates. The complete tool is a 32x32 stack mold. These bases are ideal for tools requiring In Mold Labeling (IML) and In Mold Close (IMC).

HASCO America, Inc.

877.427.2662

www.hasco.com/en

M&M Tooling, Inc.

630.595.8834

www.mmtooling.com

M&M Tooling, Inc., established in 1999 in Wood Dale, Illinois, is a custom mold base builder specializing in manufacturing high-quality, tight-tolerance mold bases at all levels of intricacy and complexity. Its products range from NATO fighter pilot helmet face shields to first responders and medical personnel infectious disease face protection as well as medical molds to filtration systems, serving multiple sectors from industry to consumer. The photo illustrates a high-end, complex, medical, multicavitation, multi-parting line, unscrewing mold base. This tool is unique in its design and manufacturing, where external cam bars mechanically separate the plates in timing with the unscrewing mechanisms operated through hydraulics.

Vincent Tool Technologies Corp

715.720.8066 www.VincentTool.com

The modular system of standardized mold units, patented in 1960 and originated from HASCO, Fletcher, North Carolina, revolutionized the industry globally. This example of the HASCO modular mold plate system shows how easy it is to build a standard A-series mold base assembly. The quoting and order processes are further simplified online and offline at www.hasco.com/en with the HASCO Mould Base Assistant (online version) and the HASCO Standard Engineering Tool (SET) for moldmaking (offline version).

Vincent Tool is a 40 employee, family-owned company focusing on mold bases under 500 tons and prides itself on cultivating employee growth by embracing automation. The Makino, an advanced machine at Vincent Tool, is a fouraxis, two-pallet horizontal machining center that allows a machinist to work on three sides of a mold base in just one set-up, which reduces lead time while maintaining superior accuracy.With extra pallets the machine spindle can remain in nearly constant motion. Vincent Tool’s continued investment in technology enriches valuable manufacturing abilities right in Chippewa Falls, Wisconsin. Building a quality mold base with improved efficiency is a value Vincent Tool is proud to pass on to its customers.

In 2018, AMBA launched the AMBA Emerging Leaders Network, a program that provides professional development opportunities to innovative, creative and dedicated young professionals from across all AMBA member companies. These up-and-coming individuals come from all over the country and all areas of business and are defined primarily by their pursuit of a path toward leadership. Today, the Emerging Leaders Network – with the help of its advisory board – has played an integral role in the advancement of the professional development of over 150 up-and-coming professionals in AMBA’s community. This focused growth on the next generation not only is exciting but is imperative to the long-term survival of the domestic mold building industry.

To continue advancing the professional development of emerging leadership, the AMBA Emerging Leaders Rising Star Award was established to honor and celebrate the accomplishments of those either new to the US mold manufacturing community and/or their current roles. Characteristics exemplified by the Emerging Leaders Rising Star Award nominees include a focus on integrity and accountability, adaptability and agility, leadership and initiative, collaboration and empathy and a desire for growth.

The winner of the inaugural 2024 Emerging Leaders Rising Star Award was presented to Nick VanderZwaag of Legacy Precision Molds in early March at AMBA Conference 2024. To read about VanderZwaag’s journey as an emerging leader, visit page 11. AMBA is proud to have received eight nominations – all of which exemplify the characteristics of this award. In addition to VanderZwaag, a closer look at the seven nominees include:

Nick Ernst is the first “graduate” of the Dynamic Group’s apprenticeship program. Although a quiet observer, he is willing to step out of the one-on-one comfort zone he prefers and is quick to absorb instruction. Upon completion of the program, a new role, flex specialist, was created to foster Ernst’s continued skill development and to leverage his abilities wherever needed to meet the shifting schedule demands of the entire toolroom. Ernst has taken on additional mentorship responsibilities to help cultivate the next generation of mold manufacturers.

Scott Anderson is a driven individual who holds several qualifications, including his Journeyman Machinist, Moldmaker and Design Card. He has held a variety of positions at Franchino Mold and has embraced his most recent role in project management with character and humility. Through exemplification of key qualities, including professionalism, an ability to be detail-oriented and a willingness to share and apply his knowledge, he has earned the trust of the shop floor and communicates well with peers and customers.

Angel Hernandez has been involved in the moldmaking industry since high school as a student in Leyden’s Metals program, and continually advocates for the industry through educational channels. He regularly volunteers at local high school career fairs and builds a great rapport with students. Through his initiative, he has become a critical “go-to” leader in multiple areas within the company’s threeshift operation, and his efforts have been instrumental in initiatives to minimize downtime and increase capacity.

Jonny Salter started in the skilled trades back in 2014 and has worked his way from training on the manual boring mill to CNC programming and mold design. He has shown tremendous tenacity and grit, which has led to him taking on a leadership role at a young age while simultaneously completing his journeyman training and starting a family. He regularly impacts individual areas and the shop as a whole through such efforts as the creation of workload capacity tools, process improvements and the implementation of key principles drawn from the EOS framework.

Although, he joined the US mold manufacturing industry just two years ago, Noah Anderson already has made an impact. In addition to his professional development through AMBA events and the Connecticut Center for Advanced Technology, he drives student engagement through facility tours and industry events, like the recent plant tour workshop hosted by the AMBA Emerging Leaders Network. Also, Anderson has spearheaded 5S efforts in the toolroom, always is willing to “do more” and embodies the mantra of “Never Stop Improving.”

Victoria Rooke currently is responsible for CNC machining, inspecting, team improvements, job processing and project management support. As a shop floor leader, she not only leads by example but also motivates and inspires the team daily. She has stepped up to participate in a variety of panels at various manufacturing events, drive community engagement and has been an advocate for women in manufacturing.

MJ Belmont is an active contributor to both technical and professional skill development – inside and outside the company. Internally, he currently serves in a mentorship and training role, while externally, he is a frequent collaborator with Moldex3D Moldflow Simulation Software, helping other machine shops utilize this technology to troubleshoot moldmaking risks in the design phase. Belmont exemplifies leadership and a commitment to learning through his willingness to share knowledge with others, an innate ability to adapt in any technical field and an openness to peer collaboration.

More information: www.amba.org

The COVID-19 pandemic not only awakened OEMs but also senior government officials in Washington, D.C. to the need for a reliable domestic supply chain. Starting in April 2020, as a lobbyist for manufacturing associations, I began fielding questions about downstream industries as policymakers came to the realization that a robust and successful Tier I, II and III supply base are essential to national and economic security.

This is why the AMBA in April 2024 filed comments with the US Trade Representative (USTR) on promoting supply chain resilience. Government officials in Washington, D.C. have recognized the importance of a comprehensive supply chain strategy that does not only focus on the largest of corporations and single suppliers.

American mold builders and manufacturers of tools and dies are the backbone of manufacturing worldwide, without which few finished goods exist. As part of the USTR investigation, policymakers are asking for input to help strengthen the US manufacturing base and workforce and develop specific policy tools to achieve those goals.

In comments to the USTR, AMBA called on the Biden administration to adopt comprehensive trade policies that build from the ground up, supporting downstream industries. As the Biden administration looks to develop sector-specific remedies to support key industries, the AMBA is standing up for its members and for manufacturing in America.

AMBA is calling on the Biden administration to not only develop trade policies for today but to address the continued and oncoming onslaught of imports competing with US manufacturing. As AMBA and others succeeded in maintaining the 25% tariffs on imported molds and tooling from China, manufacturers and their supporters in the Chinese Communist Party continue to seek avenues to evade tariffs and duties.

In comments filed, the AMBA called upon the Biden administration to focus on the transshipment of goods from

China through third-party countries. A tactic often employed by importers is shipping goods from China, through Asia, Europe and even Mexico, in an attempt to mask its country of origin.

This form of transshipment allows importers to bring cheap goods into the US made in China but bearing the label of another country. The Biden administration in April 2024 began allowing companies to file trade cases against businesses receiving Chinese government subsidies even if they are operating in another country.

As AMBA-supported tariffs raised the price of Chinese imports, overseas companies worked to obscure the true source of their material and finished products. The AMBA, in its comments to USTR, reinforced the need to focus on the true origin of the manufactured product and the financial support often received from a foreign government. These illegal subsidies force AMBA members to compete against foreign governments – placing American workers and manufacturers at a significant disadvantage.

In the comments AMBA filed, the association made clear that member companies have the open capacity and capability to fill orders for a range of industries from defense to medical, infrastructure and automotive. As reported by members, the inability to provide a product is not a reason for customers to shop overseas and source from China, price remains the primary factor.

The “landed price” from China remains 30-50% below quotes from American mold manufacturers, even accounting for the existing 25% tariff levied under the Section 301 action on Chinese imports. This is why AMBA is calling on the Biden administration to not only retain the 25% tariffs on imported molds, tooling and dies from China but double the rate to at least 50%.

AMBA also recommended that the USTR focus on tracking a surge in imports of molds, tooling and dies as a result of increased tariffs on raw materials used to manufacture those products. The shifting of injury from one level of the

You’re INvited to our 138,000 ft2 state-of-the-art facility in Auburn Hills, Michigan, where we design, manufacture, assemble, test and service Hot Runner Systems for the North American Market.

In addition, INCOE, a USA family-owned business since 1958, offers engineering solutions, flow simulation, individualized training, 24/7 service and support that includes 300,000+ in-stock replacement components.

All to maximize your up-time and realize the most value from your INCOE Hot Runner System.

Welcome IN: Arrange your visit today - david.lange@incoe.com

• Finishes to all SPE-SPI standards

• Diamond Lapping

• Textured Surface Prep

• Benching

• Quoting from Drawings, Prints, Pictures and Parts

• On-Site Support

Capabilities

• 50+ Polishers

40 ton Capacity

• 24 hours – 7 days

• Pick-up and Delivery

• 3-D CAD File Capabilities

Partnerships

• Welding

• Plating Texturing

supply chain up to another often is the product of customers importing a more finished product into the US to avoid paying a higher price for American goods subject to higher input costs.

A system to monitor a surge in downstream product imports will assist policymakers in identifying in real time the increased shipments entering the US. It also will allow better insight into strategies used by overseas competitors to evade tariffs on those raw materials.

Omar Nashashibi is a founding partner at The Franklin Partnership, LLC, a bipartisan government relations and lobbying firm retained by the American Mold Builders Association in Washington, D.C. Services

The USTR supply chain review is an important factor as the Biden administration concludes its long-awaited review of the Section 301 tariffs on Chinese imports. Required by law after four years, and now in its second year of review, the USTR’s conclusions also could lead to increased tariffs on imports from China.

The Section 301 tariff action imposed by former President Trump covered roughly 60% of Chinese imports, including molds, tooling and dies. The Biden administration could use the information AMBA and other groups provide to address many of the ongoing challenges as China increasingly looks outward to stimulate its economy.

Evasion of tariffs and duties is not the only barrier from trade facing American mold manufacturers. Imports from Canada remain a concern, both for reasons related to transshipment but also to lower energy costs than those faced by US competitors.

Sources in Washington indicate that the USTR hopes to release a report on supply chains this fall ahead of the November elections. The results will clearly lead to discussions over the supply chain within the context of the 2024 election. However, the comments filed by AMBA, the leg work put in by the association and the mobilization of its members since 2019, will help instruct either administration on the steps it needs to take to use trade laws in a way that will strengthen downstream manufacturers.

AMBA members have had the opportunity to build upon advances in Washington over the past few years, and this is why the association is making its voice heard. Whether on tariffs, overseas subsidies or global supply chains, the US Government is focused on the downstream manufacturer and wants to hear from AMBA directly. Keeping the pressure beyond the election is how US mold manufacturers and the AMBA will continue to make a difference.

In an increasingly competitive landscape for hiring and retaining skilled employees, rising healthcare and benefits costs for employers in the United States manufacturing sector have become a significant concern. These employers often face challenges in providing affordable healthcare benefits to their employees while maintaining operational efficiency, competitiveness and profitability. The 2024 Health and Benefits Report, with data from Manufacturers Association for Plastics Processors (MAPP), Association for Rubber Products Manufacturers (ARPM) and American Mold Builders Association (AMBA), aims to provide US-based manufacturers with the most relevant data on the state of healthcare and benefits in the industry and to arm decision makers with the knowledge required to minimize costs while still providing maximum value to their employees.

Healthcare plan costs in the US have been on the rise over the past five years due to inflation, prescription drug price hikes and increased expenditures as the baby boom generation nears retirement age. This trend has disproportionately impacted small- to mid-size employers in the manufacturing sector, many of whom have older employee bases in comparison to other industries. These employers, often operating on tight budgets, face the daunting task of providing comprehensive healthcare

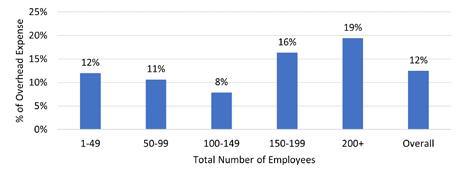

benefits to their employees while maintaining profitability. According to a 2023 nationwide survey conducted by the Kaiser Family Foundation1, the average annual premium for employer-sponsored health insurance plans in 2023 reached $8,435 (up from $6,896 in 2018) per employee for single coverage and $23,968 for family coverage (up from $19,616 in 2018). The findings in the 2024 Health and Benefits Report, while a different approach in tabulating the totals, show a similar upward trend, with overall healthcare plan costs per participating employee increasing 8% from 2022 to 2023 ($9,263 to $9,977, respectively, Fig. 1). These rising costs place a significant financial burden on smaller employers, making it challenging to offer comprehensive healthcare benefits to their employees without forcing costcutting measures in other areas of the business.

The surge in healthcare costs can strain the financial resources of small- to mid-size manufacturing companies, forcing them to make tough strategic choices. These decisions often involve weighing employee benefits and wages against investments in growth and innovation. Despite the 2024 Health and Benefits Report data indicating that organizations with less than 150 employees allocate a smaller portion of their overhead expenses to healthcare (Fig. 2, page 25), smaller operations generally have less tolerance for increased healthcare costs. A few highdollar medical expenditures significantly can impact their margins if self-insured or lead to a substantial rate increase in the next year if they are fully insured. A study by the National Association of Manufacturers (NAM)2 underscored that rising healthcare costs were a top concern for US manufacturers, with 58.9% of respondents citing it as a significant challenge affecting their competitiveness.

Similarly, in AMBA’s 2024 Business Forecast Report and in both MAPP’s and ARPM’s 2024 State of the Industry Reports, respondents listed rising healthcare costs (along with recruiting and retaining employees) among the top 10 “Challenges Interfering with Profit Margin Goals.”

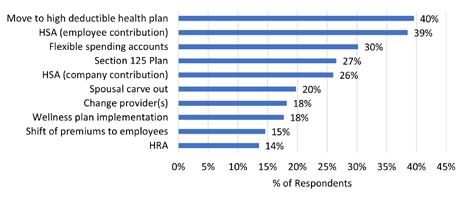

To mitigate the impact of rising healthcare costs, employers in the manufacturing sector have been exploring various strategies (Fig. 3), such as implementing high-deductible health plans (emphasizing employee contributions to HSAs or FSAs), offering wellness programs and changing insurance providers for better rates. This shift is further evidenced by nearly half (46%) of survey respondents providing at least one HDHP in their current plan year, while less than a quarter (21%) offer the once-ubiquitous HMO plan. Additionally, some companies are turning to alternative healthcare delivery models, like telemedicine and on-site clinics, to provide their employees with more affordable and convenient care options, though depending on the size of the operation and the funding methodology, this kind of solution may not be as feasible. Interestingly, survey respondents who had achieved decreased rates in the previous three years listed changing their healthcare plan carrier as the most common method of obtaining a rate decrease, indicating that constantly re-assessing the provider market could lead to savings over time compared

to remaining with the same carrier. However, shopping around each year can be a potentially repetitive and time-consuming process for decisionmakers (and a potential source of dissatisfaction for employees), as many carriers may initially ‘beat’ the incumbent carrier’s quote to land a new client, with the internal understanding that the new carrier likely will recoup any lost profit in the first year with the following year’s renewal unless the client is willing to switch providers again. Finding other strategic options, such as those listed in figure 3, to realize cost savings while remaining with the same carrier would be preferable to performing this taxing yearly exercise.

In conclusion, healthcare costs are poised to remain a pressing issue for small- to mid-size employers in the US manufacturing sector, potentially hampering their ability to offer competitive benefits and invest in their businesses. It is of the utmost importance for manufacturing executives to actively pursue strategies to manage and reduce these costs. This proactive approach is not only vital for the health and well-being of their workforce but also for mitigating cost and risk. Moreover, it provides a valuable benefit that can enhance the attractiveness of their business to prospective employees. In addition to the 2024 Health and Benefits Report and the annual Wage and Salary Report, AMBA offers resources and strategies that support its members through the annual renewal process by identifying potential threats and how to minimize them. Additionally, AMBA’s captive opportunity provides transparency and financial control, as well as strength from the aggregation of participating members.

Further analysis is available by purchasing the 2024 Health and Benefits Report through www.amba.org (the report is available free of charge to survey participants). The 2024 State of the Industry Report and 2023 Wage and Salary Report (updated rates as of July 2023) are also available at www.amba.org/publications.. If interested in becoming a member of AMBA, email info@amba.org

References

1. Kaiser Family Foundation, “2023 Employer Health Benefits Survey”

2. National Association of Manufacturers (NAM), “2024 First Quarter Manufacturers’ Outlook Survey”

Franchino Mold & Engineering Plant Tour Workshop

June 27, 2024 | 8 a.m.-2 p.m. EST

Join AMBA members for its next plant tour workshop, June 27, 2024, at Franchino Mold & Engineering. During this plant tour workshop, attendees will learn how a focused leadership philosophy has leveraged effective processes to build a positive, team-oriented culture and open the company up to opportunities and expansion. Tour highlights will include insight into the use of the Entrepreneurial Operating System (EOS) as a management and business development tool, key KPIs and their impact on the development of effective processes, workflow strategies featured in a recent expansion, 5-axis technology and more.

The AMBA 2024 Health and Benefits Report includes current benefit benchmarks from US plastics processors, mold manufacturers and rubber products manufacturers, as well as benchmarks related to health, dental, vision, ancillary and retirement benefits. With this report, AMBA executives will be able to better understand how other companies are utilizing new strategies to control healthcare dollars, contain costs and leverage benefits packages to attract and retain employees.

Member cost: $199. Non-member cost: $219. For more information and to purchase the report, visit www.amba.org/publications.

Member cost: $209. Non-member cost: $309. For more information and to register, visit www.amba.org/events.

June 25-26, 2024

AMBA has announced its second Emerging Leaders Leadership Retreat, which will feature a plant tour workshop at Hansen International, St. Joseph, Michigan, on June 25 from 11:30 a.m.-3:30 p.m.

EST, followed the next day by an in-person workshop, Team Building in Manufacturing, on June 26 from 8 a.m.-3 p.m. EST. Attendees also will be able to participate in an optional one-hour tour of Lake Michigan College Hansen Technology Center.

Facilitated by Senior Productivity Specialist Michael Wiseman of the Purdue Manufacturing Extension Partnership, this leadership workshop will highlight how effective leaders can drive and leverage team development, cohesion and employee engagement to impact organizational health and bottom-line profitability. Workshop content will tie in tour highlights from the previous day and explore how emerging management professionals can cultivate the leadership skills necessary to support similar results in their individual company environments.

Member cost: $499. For more information and to register, visit www.amaba.org/events.

Roundtable Discussion: Senior Leaders

June 11, 2024 | Noon EST

One of the most efficient ways for executive leadership to impact business operations immediately is to address challenges shared by peers in the domestic mold building industry. AMBA members are invited to participate in AMBA’s next virtual roundtable discussion with other senior leaders during its June event.

For more information and to register, visit www.amba.org/events.

Financial Literacy Series for AMBA Members

Continues this Summer

One of the most difficult aspects for new owners and professionals in finance roles in the US moldmaking industries is understanding which financial metrics to track and what that data represents once it’s gathered.

Join other members for AMBA’s next financial literacy session and take hold of the opportunities that will help drive measurable business growth, efficiency and profit.

For more information, visit www.amba.org/events.

One of AMBA’s most protected benchmarking initiatives is its annual Shop Rate Survey, now open to the US mold building industry. This survey collects charge rate data specific to services in engineering, moldmaking and specialty services, as well as current business conditions such as capacity, gross margins and more. Participate today by visiting www.amba.org/events; request a copy of the survey questions by emailing Rachael Pfenninger at rpfenninger@amba.org. AMBA members only will have access to the final report.

AMBA members now have access to the second report of the year via the ITR Economics Portal, a new benefit for AMBA members. This second quarter report provides leading-edge economic forecast data to help executives understand market optimism, consumer behavior, current economic growth and business tactics to consider in five major end markets. Valued at over $30,000, this new benefit is available to AMBA members at no cost.

Available: Learn how to leverage AMBA’s newest resource, the ITR Economics program, to increase company profitability and forecast industry conditions by listening to the recording of AMBA’s most recent webinar, ITR Economics Program – Member Application of Data. AMBA members will be able to access how AMBA member Tolerance Tool has utilized the 2024 data, as well as strategies, questions and challenges shared by other AMBA members. AMBA members can visit the Webinar Archives area on the AMBA website to access the recording.

AMBA’s newest virtual offering, its 2024 CNC Users Group, will continue through the second half of the year. This group connects CNC operators and related positions with functional area peers to discuss best practices, evolving technologies and more. Topics for each month are determined at the previous meeting; past topics have

included training strategies, CAD/CAM technologies, ERP system use and more.

Meetings will occur on the second Thursday of every month until the end of the year. Interested parties can register by emailing Rachael Pfenninger at rpfenninger@amba.org

Banner Mold & Die 251 Florence St.

Leominster, Massachusetts 01453

Main POC: Brian DeFelice, president

Email: brian@bannermold.com

Phone: 978.534.6558

Founded in 1946, Banner Mold & Die manufactures and repairs plastic injection molds with a wide range of applications. The team is committed to providing excellent customer service and its formula for success is simple: provide the best product available on the market with a smile. Banner’s technology, dedication and professional workmanship ensure that the company will continue to manufacture quality molds and dies in the future.

American Mold Builders Association (AMBA) delivered a power-packed three-day conference in early March, where attendees – engaged, elevated and evolved – in Grand Rapids, Michigan, by listening to inspiring keynote speakers, collaborating at roundtable discussions with peers, actively listening at breakout sessions and networking at the sponsor exhibit. In addition, AMBA brought new experiences to the conference from an Emerging Leaders pre-con session and a “Meet the Mentor” lunch to the Byrne Tool + Design plant tour workshop.

AMBA’s commitment to tackling the tough challenges faced by mold manufacturers was present throughout the conference, and as a team, they will continue to provide its membership and the industry with the latest trends, innovative ideas and advancements in technology and connection opportunities.

At the conference, there were several empowering and positive moments and to name a few:

● Troy Nix, AMBA’s executive director, lowered himself into a barrel full of ice and said, “Embrace the chill of change. Here’s to breaking through the ice and elevating yourself!” His message: To get uncomfortable because when there’s discomfort that is when a person experiences growth and development, both personally and professionally.

● Jason Hewlett, leadership expert and motivator, began singing Journey among other songs showing off his “signature moves.” According to Hewlett, “Denying these gifts to the world breaks a promise to ourselves and to those that surround us, and we each have a choice every day to bring our signature move or hide it.”

● David Atkins, keynote motivator, confidently tapped his chest and shared with the audience, “I have the courage to face my fears, to level up my life.” Then suggestively pointed at conference attendees as if he were asking, “Do you?” His message: That there is no warm-up in life.That life is a gift and a blessing, so when fears are faced, a person becomes stronger, which in turn pushes a team, department and company to be stronger together.

AMBA is honored to deliver this Conference each year – it serves as an investment and progressive effort to equip the industry with continuous learning and education, to deliver strategies and best practices and to open the door for networking and interactions with new and old friends.

The master of ceremonies for the AMBA Conference, Nix brought his enthusiasm, beliefs and two bags of ice to the stage with an opening address on leadership lessons. Throwing bags of ice down, he leaned into the microphone and said, “Leadership is breaking through the ice and finding the ability to enter an uncomfortable zone. Here’s to breaking through the ice and elevating yourself!” As a leader, whether in the front office or on the facility floor, it is easy to fall short in discomfort when the brain registers discomfort and signals to “stop” – this is a human’s fail-safe mechanism. It’s the brain’s trigger to stay in the “comfort zone” at all costs. When this happens, a leader sacrifices personal and professional growth. It’s important as a leader to know what it feels like to be “uncomfortable” and to learn to lean into the discomfort.

Nix said, “Research proves people who embrace discomfort

1. do better during (life) changes; 2. are more engaged, motivated and persistent and 3. can be motivated when viewed as a sign of making progress.”

By embracing discomfort and leaving the easy zone, the return is priceless – it’s in the experiences gained, lessons learned and growth personally and professionally. As Nix lowered himself into a barrel filled with ice and cold water, he said, “Embrace the chill of change because this is where innovation and inspiration reside.”

Hewlett opened his keynote speech belting songs from Elton John, Journey and REO Speedwagon and, as music filled the conference room, attendees were mesmerized by his talent of sounding identical to the icons. These are his gifts – his “signature moves” – the thing that makes Hewlett uniquely him. Denying these gifts to the world breaks a promise, he explained, and we each have a choice every day to bring it or hide it. With humor and heart alongside his “signature moves,” Hewlett spoke about three areas of The Promise: Audience, Family and The One.

Hewlett opened with a story about an airport shuttle driver named T.J. He said her “signature move” was her specialty in customer service, showing up every day to deliver the promise she made to her passengers – the promise of delivering “Yee-Haw” moments. “If we make a promise every single day to show up to our performance, we will change the lives of the people we interact with,” he said. “It comes down to our signature moves. Think about the promise you’ve made to each of your customers. They are your audience, and that becomes your brand promise.”

The promises made to the family directly influence company culture. Being a leader who is present in the day-to-day with clear intentions and a direct promise to employees (to family) will ignite them to find their signature move and put it into action. This then drives retention, business results and positive customer experiences.

Hewlett said, “We keep promises to everyone else, but not to ourselves.” The promise made to oneself should showcase the gifts and talents that make “oneself” unique. This promise should be shared with the world. Photos courtesy of Jimmy Renallo, Creative Technology, www.creat.com.

American Mold Builders Association’s lobbyist in Washington, D.C., Omar S. Nashashibi addressed the uncertainty that comes with every presidential election year through a timely update on the state of tariffs on China, how elections already are impacting tax policy and navigating the 2024 election and if it will prompt a change in direction for regulators. “The Government impacts all of US manufacturing from the in action and action that is happening, and Washington needs to hear from manufacturers,” said Nashashibi.

David Atkins’ career included time spent on patrol, in investigations and undercover units with the New York State Police Department and was a first responder at Ground Zero on 9/11. While serving, he also built a million-dollar, international business with Beachbody. Adkins started his keynote by sharing, “Excuses are well-planned lies.” The ‘greats’ talk about the victor mentality, not the victim mentality.”

In addition to the update out of Washington, Troy Nix, AMBA executive director, Laurie Harbour, Wipfli (formerly Harbour Results, Inc.), and Nashashibi conducted a fireside chat on the conversations they're having with government officials on downstream supply base readiness and the implications for US mold builders. They encouraged attendees to set their companies up for success by building a profile on AMBA’s website, www.amba.org, under “Find a Mold Builder Tool,” utilizing the tool opens two doors; a door for a company to be found and a door for a company to find resources. Harbour said, “It is important to be accessible; matching moldmakers with mold builders is key to the manufacturing industry.”

Atkins encouraged attendees – to make a positive change and to not leave this conference as the same person. He said, “To engage, elevate and evolve as a person … to dominate!” It is important to be intentional in being the best version of yourself, Atkins said, “… you are robbing the world of you. There is no practice in life – all we have is today!” With that, Atkins shared The P3 Framework – Your Personal Perseverance Project:

Vision – It is having the vision within oneself to live it, breathe it and make it a reality.

Mindset – A mindset that isn’t strong will let life’s circumstances dictate the response, but if flipped the learning is a person cannot control what happens, but can control the reaction. A positive mindset is a powerful tool for success.

Urgency – “It’s the start that stops most people,” said Atkins. Tomorrow is not guaranteed and there is no perfect time to start; it’s in a person actively pursuing a goal and following through.

The AMBA Conference delivered a fulfilling three days for attendees offering opportunities to share in listening to seasoned mold manufacturing executives, holding peer-to-peer discussions, providing meaningful engagements at breakfast and lunch and closing the final day with a plant tour workshop at Byrne Tool + Design.

The Emerging Leaders Pre-Con Session faciliated by Kelly McDaniel, DeLisa Group, ended with a panel of seasoned mold manufacturing executives covering topics of dealing with tension and conflict, managing relationships and handling resistance to change.

The new topical rounds were 75 minutes of dialogue among peers broken down into specific topics, offering discussion on US mold manufacturing operations and the challenges being faced, best practices and new technologies.

Each day there was an allotted experience in breakout sessions, giving conference attendees time to listen to insights, advice and resources from presenters on a variety of topics ranging from business management to workforce strategies.

BRONZE EVENT SPONSORS

Troy Roberts, Tolerance Tool, LLC, and Troy Nix, AMBA executive director, presented AMBA’s newest members-only resource, the ITR Economics Program, which forecasts industry conditions and improves business stability.

As of January 2024, at no cost, members of AMBA have direct access to a full, simple-to-read quarterly report provided by ITR Economics that includes the US macroeconomic outlook, general direction of the economy and analysis of five major end markets (North America Light Vehicle Production, US Total Retail Sales, US Medical Equipment and Supplies Production, US Private Nonresidential Construction and US Agriculture, Construction and Mining Machinery Production).

To access the AMBA member-only webinar recording on the ITR Economics Program from Tuesday, May 21, 2024, visit www.amba.org/events.

PLANT TOUR AND SPECIAL EVENT SPONSORS

CNC specialists who join the TNC Club enjoy exclusive benefits, including news updates, free software options, and in-depth support with questions about all aspects of HEIDENHAIN controls. In addition, premium members receive regional training courses, special invites to HEIDENHAIN events, and on-site consultations tailored to their applications. And one unique benefit is the TNC Specialist certification program, which trains lateral entrants to become skilled CNC operators. Stay in dialogue with HEIDENHAIN and other TNC experts. At the TNC Club, we care about your opinion and invite you to shape our offerings.

www.tnc-club.com

BORIDE Engineered Abrasives, Traverse City, Michigan, a manufacturer and developer of abrasive products for industrial and consumer applications, has introduced its mounted ceramic super stones. The ceramic super stones mount a 3 mm high-quality stainless steel shank for durability and a wider range of use. This tool supports high-speed rotation for use in air grinders, electric grinders and ultrasonic polishers, providing versatility in various applications and suitable for a wide range of materials, including general steel, mold steel, stainless steel, various alloy steels and aluminum. For more information, visit www.borideabrasives.com.

HASCO, Fletcher, North Carolina, a full-service provider for tool and moldmaking, has launched its temperature control range in stainless steel with the US system ZI, including more than 30 product groups offering flexibility for customers and their applications. The cooling range made of stainless steel is used in clean rooms and medical technology, and the application of hot or cold water or cooling oil for the reliable cooling of injection molding tools. Its compatibility with the standard range allows the optimization of existing molds, switching from brass to stainless steel, and enables combinations with standard components, where required. For more information, visit www.hasco.com

Progressive Components, Wauconda, Illinois, develops and distributes components for the production tooling industry, has expanded its line of thousandth increment (TI™) ejector pins, including 267 new standard sizes and longer lengths. Progressive’s TI pins feature heads that are precision ground-to-mold tolerances. Designed to fit into small, crowded cavities and core inserts, the TI pins are manufactured with hardened M-2 steel and available in diameters from .060-.320" in both 2.5" and 5.5" lengths. In addition, Progressive introduced its M-2 Ejector Pins, which are suited for high wear resistance with abrasive materials, featuring tight tolerances held for sizing, roundness and straightness, and available in straight and shoulder versions. For more information, visit www.procomps.com

Mold-Masters®, Georgetown, Ontario, a developer and supplier of hot runners, controllers, auxiliary injection and co-injection systems for use in every market, has introduced the EcoONE-Series hot runner system. The EcoONE-Series is an economical solution suitable for processing commodity resins for simple, cost-sensitive applications such as consumer goods, small home appliances, basic automotive components, electronic peripherals/accessories and more. It offers a range of standard nozzle options with a nozzle shot range capacity of less than 5g up to 3,500g in lengths ranging from 50-300 mm. There are five standard nonvalved and five standard valved gating options. Manifolds are available in one to eight drop configurations with custom pitch options. For more information, visit www.moldmasters.com.

EMUGE-FRANKEN USA, West Boylston, Massachusetts, a manufacturer of high-performance taps, thread mills, drills, end mills and other rotary tools, has expanded its line of thread mills, including solutions for challenging threading applications and materials such as nickel alloys, titanium, high tensile strength steels, hardened high alloy steels, cast iron, cast aluminum and more. EMUGE offers five thread mill tool families, including THREADS-ALL™/MAX line, THREADS-ALL™/HEADED line, THRILLERMAX Thread Mills, VARIO-Z External Thread Mills and VARIO SKIP Tooth Thread Milling Cutters. An EMUGE Thread Milling Product Guide is available that provides specifications about the broad and expanded line. For more information, visit www.emuge-corp.com.