ISSUE 1 2024 Advances in CNC Machining

Digital Textures in Moldmaking

THE OFFICIAL PUBLICATION OF THE AMERICAN MOLD BUILDERS ASSOCIATION

2024 US Regulatory Agenda New AMBA Member Benefit: Economic Forecasting

Registration is on us! Visit 2024.npe.org/1051 or... Join Progressive at NPE2024—our 11th NPE in booth W1543 to see new exclusive components and innovative technology solutions that will grow to become industry standards. Then, after walking the miles of aisles by day, we invite you back to our booth in the evening, where we will raise a glass together and enjoy a rockin’ good time... Progressive style! PRESENTING INNOVATIONS BY DAY... ROCKIN’ YOUR WORLD BY NIGHT!

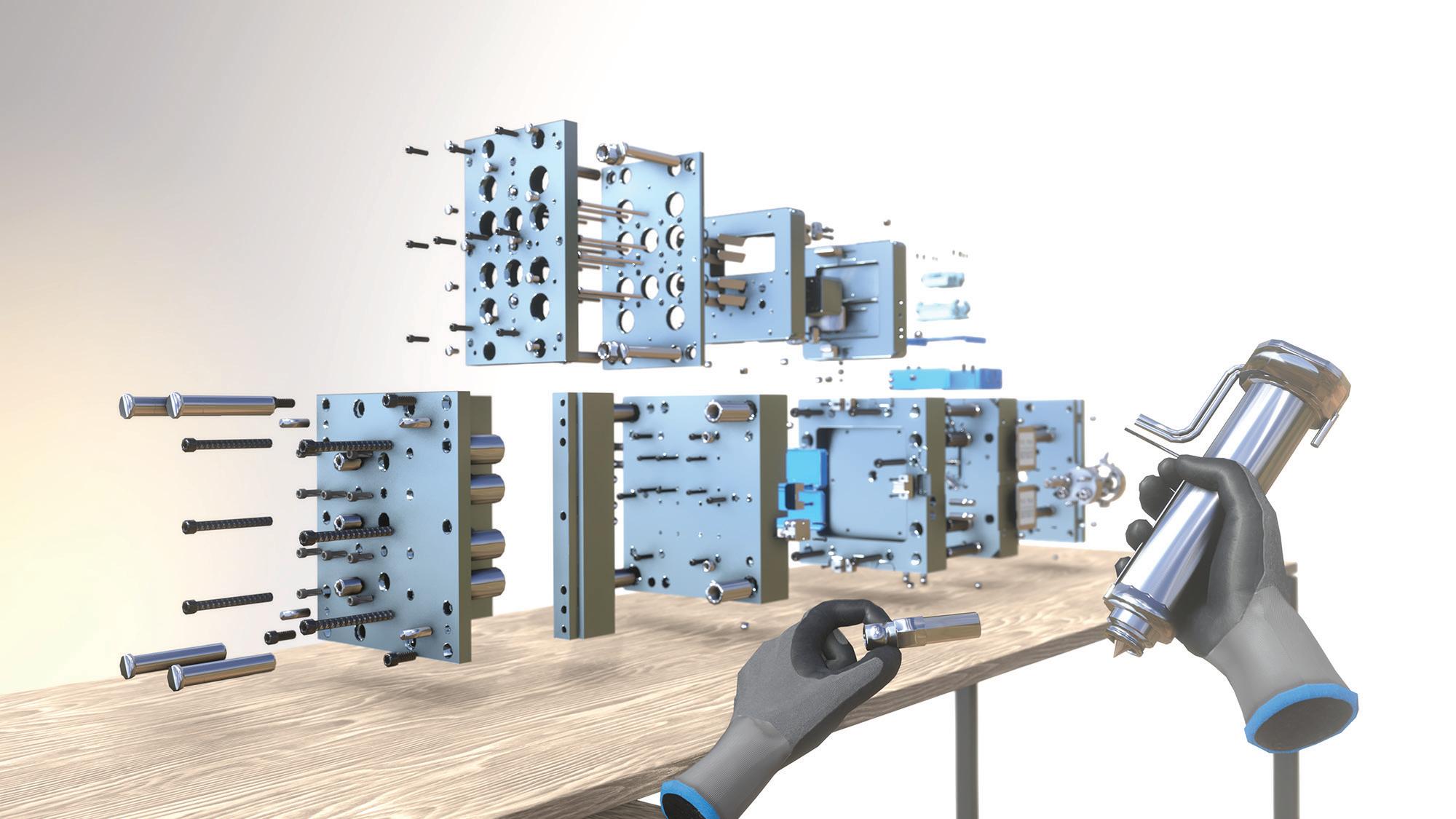

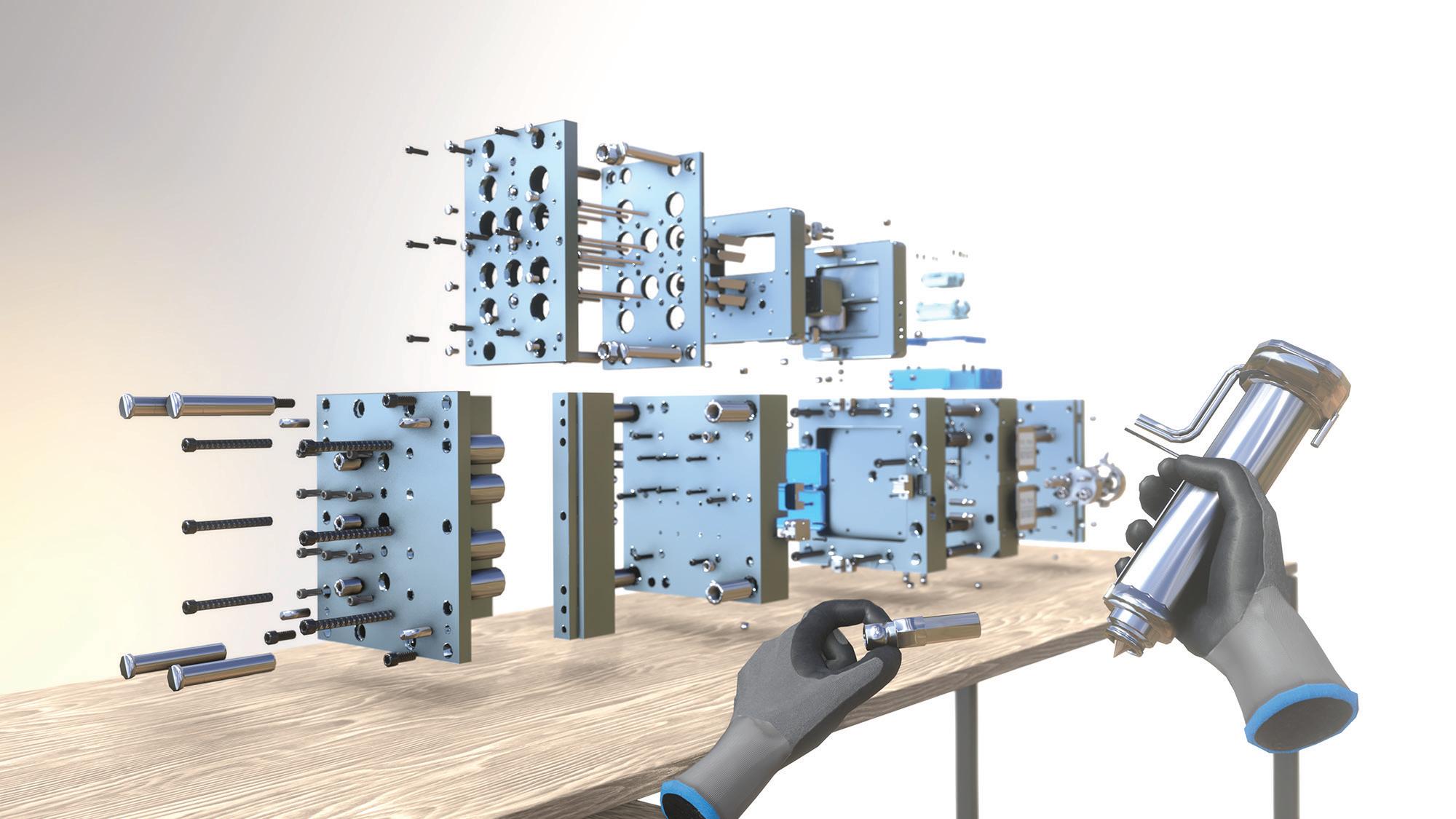

www.kruseanalysis.com New! Virtual Reality Mold www.molding-expert.com www.krusetraining.com

Training Molding Expert is developing the first fully functional virtual reality (VR) mold and molding facility training solution.

Circle of Knowledge

Training is an online interactive training program for part designers, mold designers, and senior process engineers. Innovative Simulation

Analysis provides innovative and full capacity filling-to-warpage CAE simulation services. Cutting Edge Injection Molding Simulation and Training Solutions

Next Generation

The

Kruse

Kruse

4 the american MOLD BUILDER | Issue 1 2024 Speak Out ................................................. 6 Industry ................................................... 19 Association ............................................. 24 Product .................................................... 34 Calendar .................................................. 46 Ad Index .................................................. 46 ISSUE 1 2024 Advances in CNC Machining Digital Textures in Moldmaking 2024 US Regulatory Agenda New AMBA Member Benefit: Economic Forecasting THE OFFICIAL PUBLICATION OF THE AMERICAN MOLD BUILDERS ASSOCIATION ISSUE 1 2024 8 EVENT AMBA Conference 2024 Engage. Elevate. Evolve. 10 TECHNICAL FOCUS Advances in CNC Machining Technology 16 MEMBERSHIP Partnership with ITR Economics Enhances Member Benefits 20 PREVIEW NPE2024 Delivers the Latest Technology 26 ADVOCACY The 2024 Regulatory Agenda for Manufacturing Cover image courtesy of Makino Inc.

AMERICAN MOLD BUILDERS ASSOCIATION

7321 Shadeland Station Way, #285 Indianapolis, IN 46256

P: 317.436.3102 • F: 317.913.2445 info@amba.org • www.amba.org

AMBA TEAM

Troy Nix, Executive Director

Kym Conis, Managing Director

Susan Denzio, Business Manager

Rachael Pfenninger, Director of Strategic Execution

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio

PUBLISHED BY:

2150 SW Westport Dr., Suite #101 Topeka, KS 66614

P: 785.271.5801

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions expressed in this publication may or may not reflect the views of the Association and do not necessarily represent official positions or policies of the Association or its members.

5 www.americanmoldbuilder.com | AMBA.org 20 30 SOLUTIONS What Do Digital Textures Offer the Industrial Mold Market? Opportunity! 36 TALENT Driving Organizational Excellence to Generate Business Growth 39 BENCHMARKING The State of US Mold Manufacturing: How Mold Builders Are Doing More with Less 42 OPERATIONS Addressing Tooling Labor Shortages with Automation 45 MANAGEMENT We Already Are Leaders 42

THOMAS W. BARR AMBA President TK MOLD & ENGINEERING

THOMAS W. BARR AMBA President TK MOLD & ENGINEERING

A MESSAGE FROM THE AMBA PRESIDENT

Hello AMBA Family – 2024 is underway! New for this year is the added member benefit of Economic Trend Reports from ITR Economics, which give businesses financial predictions and insights into our trade. Back in February, a webinar hosted by ITR explained how to navigate the specialized economic portal, access three-year forecasts for the top five markets, track rates-of-change to identify current business-cycle phases and benchmark data against key market indicators. The goal is to give AMBA executives a competitive edge. All AMBA members will receive this report quarterly. It's another tool in your toolbox!

The topic of fractional CFOs has come up in our AMBA Board strategy sessions as a way to help AMBA members who may not have the ability or the need to hire a full-time CFO. This past February, there was a webinar on Fractional (part-time) CFOs. AMBA is fortunate to have Troy Roberts on its Board, who has a lot of experience on the financial side of manufacturing. Roberts initially brought this topic up, and TK Mold already has Michigan CFO, so we thought it would be a great idea to demonstrate how a Fractional CFO can help your business. Although located in Michigan, the Michigan CFO team has the ability to work with clients out of state. (Likewise, Wipfli provides these services as well.) Todd Rammler, Dennis Weist and the Michigan CFO team are very well-versed in manufacturing and will share their knowledge at AMBA’s conference in March. This is another benefit to AMBA members!

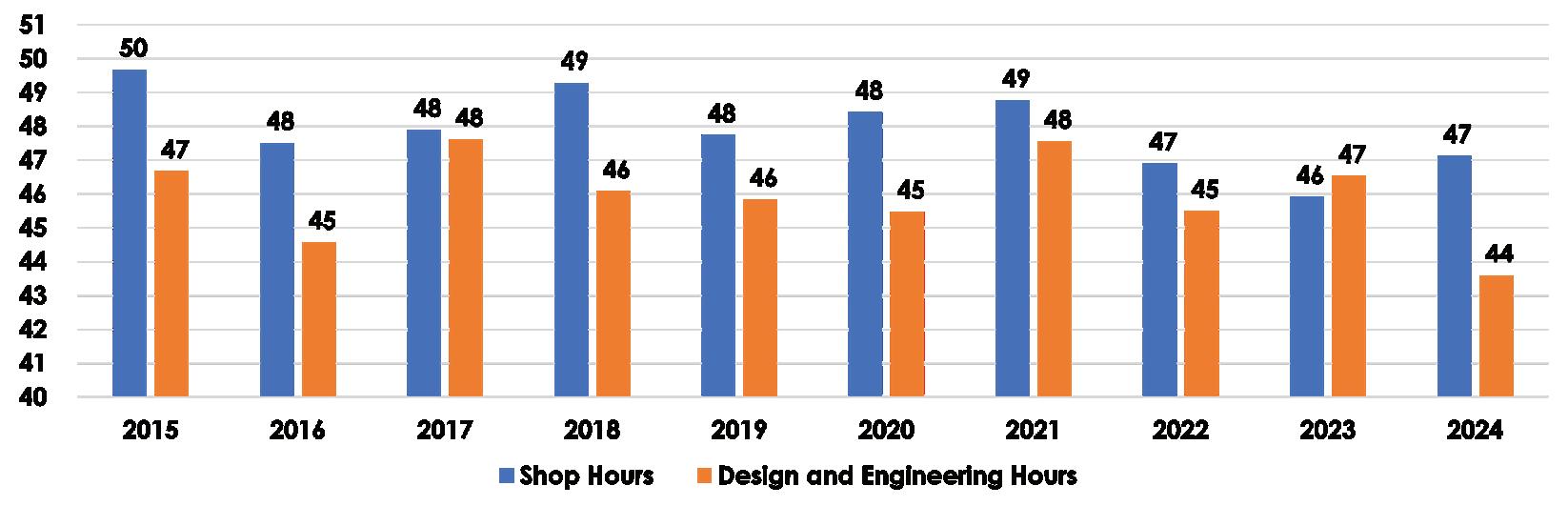

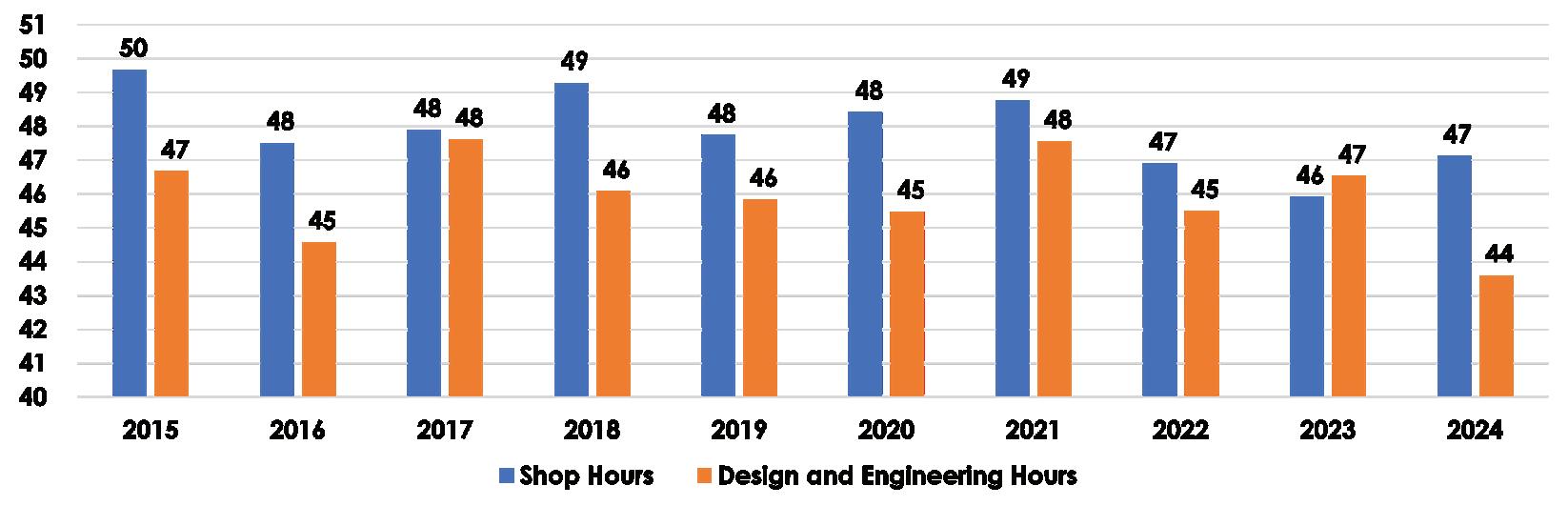

Roundtable discussions are a resource that has been valuable to members. Recently, AMBA created an “online” monthly CNC user group so that AMBA member CNC teams have their own roundtable discussions. The first meeting was about the use of test cutters, and the second meeting covered ERP systems and how they are utilized in the CNC area. My team has been very receptive to these roundtable discussions – gaining knowledge while sharing their own “pro tips!” What a great way for the moldmaking CNC community to introduce topics that are a challenge and to learn from peers who already have encountered those challenges. Make sure your CNC team signs up. This is another benefit to AMBA members!

By the time this edition of The American Mold Builder reaches your desk, AMBA’s 2024 Conference will be upon us. I’m excited to hang out with old friends and make new ones! Engage, Elevate and Evolve is the theme this year. Thinking back to when I started out in the trade in 1985, I could not have come up with three better adjectives to describe what it takes to be a moldmaker from that period until now! Learning how to engage, elevate and evolve “together” is another benefit to AMBA members! And, NPE is right around the corner. Please visit AMBA’s BRAND NEW booth (# S37129 South Hall) for a member reception on May 8, 3-5 p.m.

AMBA certainly delivers a lot of opportunities for us to grow and be successful. Please make sure you participate in the webinars and discussions. The goal is to keep giving members the tools that they need to thrive in an ever-changing trade. I certainly hope to see you all at the AMBA 2024 Conference in Grand Rapids, Michigan!

BOARD OF DIRECTORS

David Bowers, II, JMMS, Inc.

OFFICERS

National President

Tom Barr, TK Mold & Engineering

Immediate Past-President

Jim Sperber, Master Tool & Mold

Vice President

Tyler VanRee, Legacy Precision Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Friedlander, Coplan & Aronoff LLP

Treasurer

Andy Peterson, Industrial Molds Group

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume Engineered Diamond Products

Mike Hetherington, Franchino Mold & Engineering

Eric Karaman, Michiana Global Mold

Kyle Klouda, MSI Mold Builders

Chad LaMance, United Tool and Mold

Troy Roberts, Tolerance Tool

Camille Sackett, Accede Mold & Tool

John Stocker, Swiss Steel USA, Inc.

Hillary Thomas, Westminster Tool, Inc.

6 the american MOLD BUILDER | Issue 1 2024

You’re INvited to our 138,000 ft2 state-of-the-art facility in Auburn Hills, Michigan, where we design, manufacture, assemble, test and service Hot Runner Systems for the North American Market. In addition, INCOE, a USA family-owned business since 1958, offers engineering solutions, flow simulation, individualized training, 24/7 service and support that includes 300,000+ in-stock replacement components. All to maximize your up-time and realize the most value from your INCOE Hot Runner System. Welcome IN: Arrange your visit today - david.lange@incoe.com www.incoe.com North America | Europe | Asia | South America 3 2016-2023 8 © 2024 INCOE® 01/24 Your INCOE - AMBA Platinum Sponsor Experience begins here! May 6-10, 2024 - Orlando, Florida VISIT US AT BOOTHS W3761 & S30123

AMWAY GRAND PLAZA | GRAND RAPIDS, MI MARCH 19 - 21, 2024 Engage. Elevate. Evolve. Registration, hotel, programming and more at ambaconference.com. Registration Open! Assertiveness Skills New Customer Acquisition Advocacy Sales Insights People Management Strategies Automation Cyber Risk Profitabilty and Financial Structures Mentorship SESSION PROGRAMMING March 19-21 | Grand Rapids, MI 2024

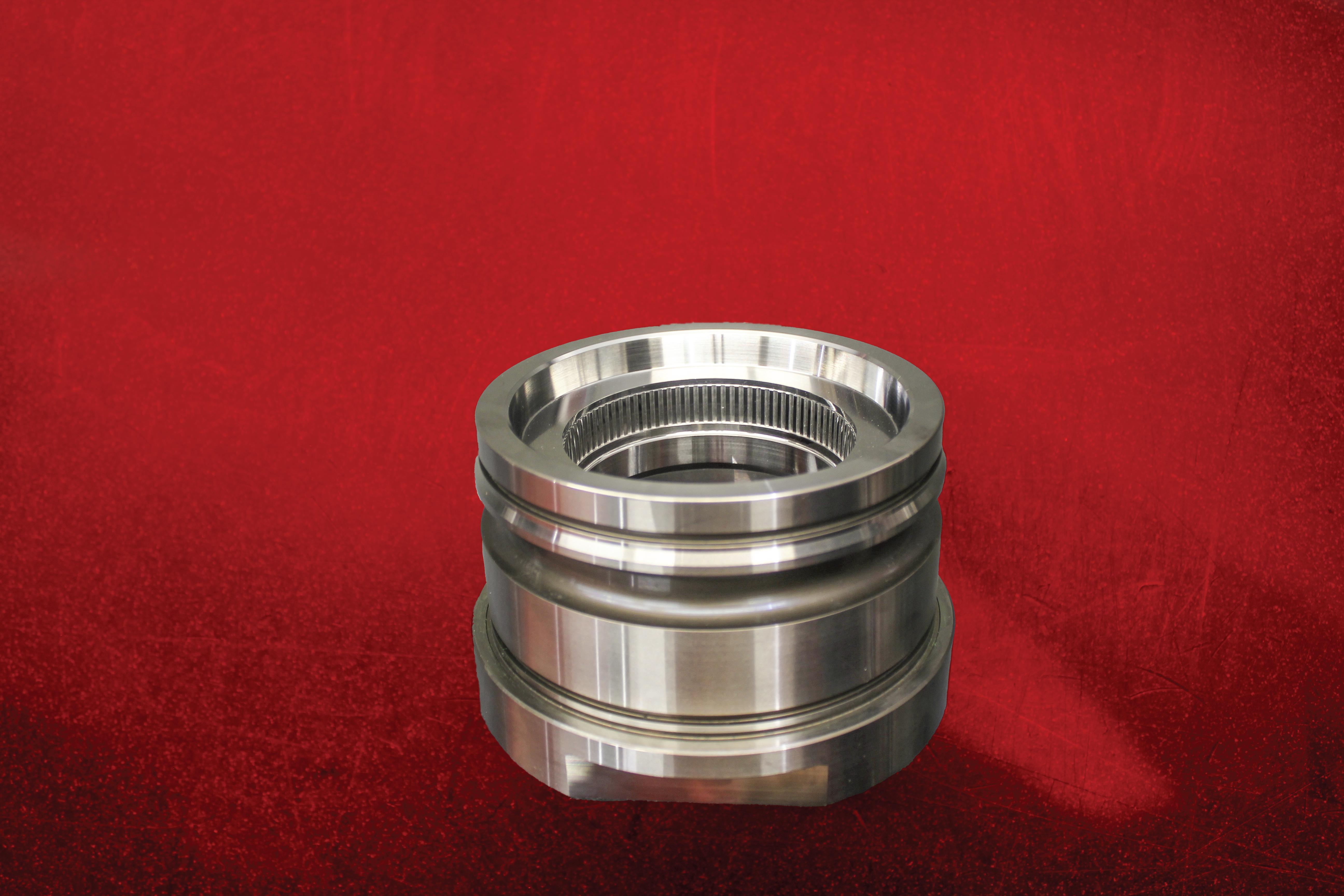

ADVANCES IN CNC MACHINING TECHNOLOGY

By Liz Stevens, writer, The American Mold Builder

CNC machining was developed in the late 1940s and early 1950s. Like the computing equipment that controls a CNC machine and drives CAD and CAM technologies, CNC machining has evolved dramatically since its early days and continually is improved to meet the industry’s latest needs. CNC equipment manufacturers respond to requests from their customers for new features and expanded capabilities. They respond to technological advances such as Industry 4.0, the Internet of Things and additive manufacturing, while keeping a watchful eye on local, regional and global developments that may impact the machining and mold building industries.

The American Mold Builder interviewed representatives from two CNC equipment companies to learn about new developments, integration with other technologies, security issues and more. Makino Inc., established in Japan in 1930, has its Americas headquarters in Mason, Ohio. Makino offers a family of CNC machining centers with metalcutting and EDM machines in configurations with 3-, 4- and 5-axis machining. PROMAC North America Corp., with US headquarters in Troy, Michigan, was established in Italy in 1995. PROMAC offers four lineups of CNC machine tools – fixed portal, gantry machine with fixed table, rotarytranslating table and horizontal travelling column machines – in completely customizable working centers. The American Mold Builder also gathered insight from Siemens on the company’s newest CNC control features.

WHAT NEW TECHNOLOGY DEVELOPMENTS ARE COMING IN THE NEAR FUTURE FOR CNC MACHINING/EQUIPMENT? WHAT ABOUT IN THE LONG-TERM?

Sean Shafer, market segment manager, Makino Inc.: “5-axis technologies, advanced tooling and ease of programming have been huge improvements in the last 10 years, enabling higher utilization of 5-axis CNC machines. Cutting machine tool technologies have peaked in terms of maximizing machining speeds; further speed increases would not bring significant cycle time reduction and likely would cause inaccuracies due to thermal heat and mechanical vibrations.” Shafer cited digital twins as the future for manufacturing. “Digital twins incorporate a CAD model of the entire shop, and the machines, processes and skillset efficiencies, allowing machine kinematic selection for the parts through AI.”

Giulia Carraro, administrative manager, PROMAC North America: “PROMAC’s machining centers are known for their flexibility of use due to their characteristics, some of which are patented, and to our in-house development and production of automatic heads and related electro spindles.”

The PROMAC features meet machining requirements in a variety of fields, including moldmaking, special general mechanics and the aerospace sector. “With these features that set us apart,” said Carraro, “PROMAC machining centers can be configured to integrate combined machining – such as turning and milling – in a single set-up and

10 the american MOLD BUILDER | Issue 1 2024

with automatic head and pallet changing systems. These machining centers also are suitable for large dimensions pieces and can allow unmanned production over long periods.”

Siemens Corporation: “Siemens is expanding its offering on the SINUMERIK ONE ‘digital native’ CNC. This new control generation now is being offered with innovations in hardware and software. With the new system software SINUMERIK V6.20, there are new technology functions for SINUMERIK ONE that simplify machine tool operation, reduce machine wear and increase manufacturing productivity. With these developments, Siemens is demonstrating how the SINUMERIK control system can be optimally used for digital transformation in a highly productive, flexible and modular way.”

HOW DOES INDUSTRY 4.0 PLAY A ROLE IN EQUIPMENT ADVANCES? WHAT IS AN EXAMPLE OF HOW INDUSTRY 4.0 FEATURES ARE INCORPORATED INTO EQUIPMENT? HOW ARE THE CYBERSECURITY CONCERNS THAT COME ALONG WITH DIGITAL CONNECTEDNESS AND REMOTE ACCESS ADDRESSED?

Sean Shafer, Makino Inc.: “Makino offers Machine Condition Monitoring software, which provides predictive maintenance actions for uptime reliability. It also provides for managed maintenance to best work around any downtime.” Shafer explained that the software includes three levels of connectivity – standalone control, company private network or cloud-based connectivity.

Makino is very aware of the cybersecurity issues that come with increased connectivity. “Many shops remain nervous about storing their data and intellectual property in the cloud,” Shafer said. Some companies are ITARcertified – dealing with defense-related items – and so they are restricted as to what they can do with their data. “With so much data now coming from the machine tools,” said Shafer, “the current issue is how to manage the massive amount of data. We expect that AI will assist with that issue.” To safeguard systems while allowing authorized remote access, Makino’s controls use white list antivirus protection and will only run programs on a control that the customer has authorized.

Giulia Carraro, PROMAC North America: “The interconnection of work centers with management and data analysis software makes it possible to analyze and improve production processes and achieve maximum yield both in terms of production process and return on investment.” PROMAC believes that in today’s production system where the comparison with competitors is global, Industry 4.0 integration is crucial for efficiency which, consequently, improves competitiveness. “The system of connections, stored data and related processing is part of the company’s assets,” Carraro asserted, “and therefore must be managed with appropriate secure access and safeguarded storage systems. PROMAC uses remote connection systems and software from specialized companies that provide secure, protected connections based on the specific authorization of the end customer.”

11 www.americanmoldbuilder.com | AMBA.org

t

Photo courtesy of Makino Inc.

Siemens Corporation: “SINUMERIK ONE plays a central role in the transformation of machine tools in the age of Industry 4.0, outperforming previous generations of controllers in terms of PLC and CNC performance in machine operation, cutting speed, data capture and processing power. With its integrated SIMATIC S7-1500F PLC, it offers up to 10 times faster PLC cycle times. With the SIMATIC S7-1500F PLC, SINUMERIK ONE now is fully integrated into the Siemens TIA Portal engineering framework, enabling standardization of all engineering tasks for operators of larger plants.”

AS AN EQUIPMENT MANUFACTURER, WHAT IS THE BIGGEST “ASK” RECEIVED FROM CUSTOMERS FOR NEW FEATURES OR EXPANDED CAPABILITIES (I.E., EQUIPMENT SPEED, CHANGEOVER RATES, ETC.)?

Sean Shafer, Makino Inc.: “As already mentioned, increased speed is no longer a request that we receive from customers. Nowadays, the requests are more about reliability, repeatability and consistency.” In response, Makino offers Machine Condition Monitoring software to address these issues. “And,” said Shafer, “most of our 5-axis machines now feature Collision Safeguard to avoid spindle collisions.”

Giulia Carraro, PROMAC North America: “In addition to building precise and reliable machining centers, our customers increasingly are turning toward flexible manufacturing systems, complete with automatic pallet or head change systems so they can be used continuously and unattended. The new generation of PROMAC machining centers is available with systems for monitoring machining status and usage so that they can continuously check whether they are within the set parameters. Special sensors in the various electronic and mechanical components allow maintenance to be managed in a predictive manner.”

FOLLOWING THE SUPPLY CHAIN MELTDOWN DURING THE PANDEMIC AND WITH A CURRENT POLITICAL FOCUS

ON EMPOWERING AMERICAN DOMESTIC MANUFACTURING, WHAT KIND OF BUSINESS DECISIONS ARE BEING SEEN BY CUSTOMERS AND PROSPECTIVE CUSTOMERS? IS THERE A PUSH TO RESHORE MOLDMAKING?

Sean Shafer, Makino Inc.: “We are not seeing an increase of moldmaking reshoring to the USA. Most of the large die/mold shops still are using overseas resources, and most of them also have facilities in Mexico. The Big Three, however, now are requiring supply chain resiliency. They are shifting sourcing from China to alternatives like Mexico, Vietnam and India.”

Giulia Carraro, PROMAC North America: “Undoubtedly, we are facing a new industrial era where innovations often are slowed down by obsolete and slow production

processes, and influenced by issues that are not just industrial but also by political, climate-related, and health or social concerns as well.”

“Shortening the supply chain is a solution that helps a lot,” said Carraro, “but it is not always enough. It also is important to have a technical support system, available remotely and in person to the customer, to reduce any possible downtime. PROMAC has invested in this from the start, by having a local office in Michigan and by thoroughly preparing and training our dealer technicians.”

HOW ARE COMPANIES EVOLVING TO INCLUDE ADDITIVE MANUFACTURING (AM) EQUIPMENT OPTIONS AND TO INCORPORATE AM AS ANOTHER TOOL IN OVERALL SYSTEMS?

Sean Shafer, Makino Inc.: “Makino has an Additive Manufacturing Services Group in Singapore that is dedicated to developing the entire AM solution, including

12 the american MOLD BUILDER | Issue 1 2024

The new keyboard and machine control panels for Siemens’ SINUMERIK ONE.

t t

Sharav HGVT, one of PROMAC’s gantries.

tremoving part fixturing, machining and automation. They are developing additive machines, laser machines and materials to support AM. We are seeing additive manufacturing as a process that can create unique, unmachinable cooling inserts to provide 25 to 35% faster cycle times.”

Giulia Carraro, PROMAC North America: “In keeping with PROMAC’s logic of integrating into machining as many processes as possible so that they can be executed in sequence with a single workpiece placement, the company makes additive processes available in addition to subtractive processes, at the customer’s request and in conjunction with our technical evaluation.”

As an indispensable technology for mold builders, the manufacturers of CNC machining equipment will continue to expand the equipment’s capabilities, finetune its operations and incorporate automation to meet the industry’s evolving needs.

For more information, visit www.makino.com, www. promac.eu and www.siemens.com. For information about the AMBA CNC Users Group, visit www.amba.org/events

AMBA CNC USERS GROUP DEBUTS

As Tom Barr mentioned in his president’s message in this issue of The American Mold Builder, AMBA created a new benefit at the end of 2023 for CNC companies and teams – an online CNC users group has roundtable discussions and meetings the second Thursday of every month. Barr was enthusiastic about the group’s initial meetings and its value to CNC companies. “The first meeting was about the use of test cutters,” said Barr, “and the second meeting’s topic covered ERP systems and how they are utilized in the CNC area.” Barr’s team was very receptive to the roundtable discussions – an opportunity to gain knowledge while sharing their own ‘pro tips.’ “What a great way for the moldmaking CNC community to introduce topics that are a challenge and to learn from someone who’s already encountered those challenges,” said Barr.

14 the american MOLD BUILDER | Issue 1 2024 PCS_ProductLine_HalfPgH_7_5_x_4_875_050923_Final.indd 1 5/9/23 7:29 AM

C C

PARTNERSHIP WITH ITR ECONOMICS ENHANCES MEMBER BENEFITS

By Lindsey Munson, editor, The American Mold Builder

On the rise and expected to grow over the next decade, mold manufacturing companies are challenged with meeting their operational expectations no matter the external market trends and economic impacts. Management teams are pressured now more than ever to assess, plan and respond based on environmental impacts and shifts – and to meet these demands head-on, they must be provided with the proper tools to make strategic business moves and sound decisions.

For the American Mold Builders Association (AMBA), it’s setting its membership up for success and giving them the economic know-how and foresight to navigate these pressures by forming a partnership with ITR Economics.

Troy Roberts, CEO and co-founder of Beanstalk Collaborative Community Wealth LLC and CEO of Tolerance Tool LLC, currently serves on the AMBA Board of Directors and has first-hand knowledge with how the ITR program can impact companies in the molding industry. Roberts said, “Before starting Beanstalk, I worked for a prior company that was a member of the Precision Metalforming Association, which implemented the ITR Economics program. We used the ITR information (e.g., ITR’s Economic Trends Report) to understand where our customers were in their business cycle (i.e., recovery, accelerated growth, slowing growth and recession). This enabled our leadership and management team to proactively anticipate, forecast and plan. As such, we were ahead of the curve in our planning, and not behind the curve. We knew when to conserve vs. invest, when to expand vs. contract.”

As of January 2024, at no cost, members of AMBA will have direct access to a full, simple-to-read quarterly report provided by ITR Economics that includes the US macroeconomic outlook, general direction of the economy and analysis of five major end markets (North America Light Vehicle Production, US Total Retail Sales, US Medical Equipment and Supplies Production, US Private Nonresidential Construction and US Agriculture, Construction and Mining Machinery Production).

CORE OBJECTIVES AND METHODOLOGY

Founded in 1948, ITR Economics is the oldest privately held, continuously operating economic research and

consulting firm in the US. Its mission and ultimate objective is to provide the best economic intelligence to reduce risk and drive practical and profitable business decisions. ITR Economics’ highly regimented training program cultivates the economists who build the forecasts, which also are supported by a rigorous review process. Jeremy Bess, one of the firm’s economists and business consultants, took a moment to elaborate and share key program details, explaining that ITR Economics is one of very few economic forecasting firms that publishes forecast accuracy results, which gives full transparency to its clients and, in turn, helps build trust in its partnerships.

Bess shared, “Our overall forecast accuracy rating since 1985 is 94.7% at one year out! Our business-minded economists provide market forecasts, company forecasts and actionable advice to help business leaders stay ahead of the economic turns that will directly impact their business. We surpass the conventional regression-based approaches employed by other forecasting companies, which contributes to our consistently high forecast accuracy rating.”

ITR Economics’ methodology stands on four key pillars:

● Internal trends – ITR Economics looks at rates-ofchange and various statistics to define the bounds of normal for a data series.

● Leading indicators – These predictive datasets provide forward-looking insights based on the correlative and causal relationships between the subject series and various components of the economy.

● ITR Economics’ Long-Term Business Cycle Theory

– This theory dates back decades and quantifies the various phases of the business cycle, providing extended views of core macroeconomic indicators.

● News and market observations – These data points, which may include new regulations, black swan events and other factors, are considered as they arise.

MEMBER BENEFITS AND PROGRAM INTEGRATION

In working with ITR Economics, AMBA members will have access to many benefits. They will be subscribed to customized reports that include three-year forecasts for preselected industries and markets that impact their businesses. Through the Business Cycle Dashboard, members will

16 the american MOLD BUILDER | Issue 1 2024

have the tools to understand where the macroeconomy is headed and access to supporting text analysis for additional insights that support the outlook. “This gets to the heart of understanding the economic playing field,” said Bess.

In addition, there will be access to the Alliance Powered by DataCast™ portal for customized reports. Bess elaborated, “It puts members in the driver’s seat, letting them plot their company’s data against any markets covered in their customized report. This real-time experience will strengthen members’ understanding of where their business fits within their specific markets and the overall economy.”

It is key for management teams to understand the trajectories of the economy, selected industries and their own companies. Such insights are pivotal in guiding present-day decisions. Through the various services offered, ITR Economics equips companies with a precise and actionable roadmap that facilitates confident business planning. For association members specifically, ITR Economics crafts market forecasts that empower members to discern the prevailing trends, which in turn helps them make timely business adjustments.

In addition to providing insights into the trajectories of various industries and markets, ITR Economics furnishes associated action items. Bess said, “These are known as Management Objectives; these comprehensive action items are organized according to their optimal deployment in the

CASE STUDIES FROM ITR ECONOMICS

Case Study A

A client that receives company-specific forecasts attended a conference at which ITR Economics provided a keynote speaker. The client already was acquainted with ITR Economics’ outlooks, had a solid understanding of its forecasts and had proactively taken measures to prepare for an imminent recession in its industry. By contrast, the client’s competitors in the audience were caught off guard by ITR Economics’ projections, and they had accumulated excess inventory as demand decelerated.

Meanwhile, ITR Economics’ strategic foresight empowered its client to capitalize on a more favorable pricing environment, which has enabled the client to augment inventory selectively, while its competitors found themselves unable to do the same.

Case Study B

Another client got ahead of a forecasted slowdown in its business by building cash reserves during the growth phase. When demand softened, the client was able to deploy that money and is leveraging the current period of slower

phases of the business cycle. Developed collaboratively with our clients over many business cycles, this evolving catalog is a strategic guide focused on preparing for future developments by taking the right actions at the right times.”

In partnership and utilizing these tools, AMBA and ITR Economics are confident that if members integrate and apply the available benefits, they will help drive practical and profitable business decisions.

FORECASTING FOR SUCCESS

In closing, Bess said, “The encouraging news is that the association already has taken a significant stride in providing members with a valuable resource for decisionmaking. Now, the onus is on individual members to leverage these available tools and services. Integration requires active involvement and utilization.”

By incorporating ITR Economics’ insights, program members stand to enhance their internal forecast accuracy, more effectively benchmark for success and further refine their marketing strategies. Members are encouraged by both AMBA and ITR Economics to stay updated on releases from both organizations so they can familiarize themselves with the advantages of tailored reports and the Economic Portal, where powerful and actionable insights are just a click away.

More information: www.amba.org, www.itreconomics.com

growth to improve its efficiencies, including making a key upgrade to its ERP system.

Case Study C

ITR Economics has observed a prolonged trend of labor market tightness and, in response, has formulated crucial Management Objectives advocating for investment in automation. One of the firm’s clients enthusiastically embraced this advice and committed to robotics investments to assist with more labor-intensive tasks.

Additionally, the client implemented software that automated processes suitable for overnight execution, resulting in by-morning completion. These initiatives significantly elevated the productivity of the client’s current workforce, mitigated the risk of burnout and improved retention amid post-COVID labor market pressures.

For additional case studies, visit https://itreconomics.com/ kenneth-brown-case-study/, https://itreconomics.com/ sekisui-kydex-case-study/, https://itreconomics.com/vallendistribution-case-study/.

17 www.americanmoldbuilder.com | AMBA.org

DON'T LEAVE MONEY ON THE TABLE

amba members saved an average of $6K in mro spend in 2023 -

$4,800 more than average member dues.

Get involved to start saving today.

AMBA.org.

HASCO CELEBRATES 100 YEARS

HASCO, the Lüdenscheid/Germany-based manufacturer of standard mold units, has written history from 1924-2024 –celebrating its 100th anniversary. In 1924, HASCO founder Hugo Hasenclever built the first molds for processing the then-new material Bakelite in a cellar workshop. It was a history that later underwent a decisive turning point through his son, Rolf Hasenclever, when the latter invented the modular system for standard mold units and, in 1960, had it patented. It was a milestone that paved the way for advancing from a small crafts enterprise to a globally operating company. HASCO’s history is recounted in a fascinating publication, namely a two-language book (German and English). For more information, visit www.hasco.com.

ACCEDE PROMOTES COREY FOX, MITCHELL FOX

IWARRIORS WEST COAST OUTING RAISES $17,500

Accede Mold & Tool Co., Inc., Rochester, New York, a family business that is an independently owned injection mold builder, has promoted Corey Alton Fox to operations manager and Mitchell Fox to manufacturing specialty department manager. Corey Alton Fox will oversee and continue to improve manufacturing operations and establish and drive manufacturing production goals. Mitchell Fox’s responsibilities include overseeing manufacturing operations such as CNC milling, CNC turning, grinding, conventional EDM and wire EDM, while leveraging his extensive experience to optimize manufacturing operations. For more information, visit www.accedemold.com

GROB EXPANDS OHIO FACILITY

GROB Systems, Inc., Bluffton, Ohio, a developer of manufacturing systems and machine tools, announced it broke ground in December 2023 on a 135,000 sq. ft. expansion project to its main facility. It will add approximately 35% more space for production and shipping as well as add 200 new jobs. With 33 years in the US along with increased growth in North America, the expanded space will house many of GROB’s sub-assembly departments to support final production. The expansion project, which is located on the east side of GROB’s main facility footprint, is slated for completion in March 2025. For more information, visit www.grobgroup.com/en/

The iWarriors 2024 Annual West Coast Golf Outing organized by M.R. Mold & Engineering, Brea, California, was held on February 9, 2024, at the Navy Golf Coast at Seal Beach and raised $17,500 to support wounded combat veterans. The event was made meaningful with a vet onsite who received his tablet, and he shared his experience overseas that qualified him for two Purple Hearts. This was the second annual West Coast event and joins an annual golf outing organized each September in northern Illinois by Alliance Specialties and Laser Sales, as well as an outing each October in South Carolina hosted by United Tool & Mold. iWarriors is a registered 501C-3 entity organized by Progressive Components, and funds are raised throughout the year to provide wounded vets with an iPad containing resources. For more information, visit www.iwarriors.org.

GUILL OPENS IN-HOUSE LAB

Guill Tool & Engineering, Co., West Warwick, Rhode Island, a global supplier of extrusion tooling, announced that its rheology lab is open for commercial services with a fee. The in-house lab provides faster turnaround on test results, reduces delays during the design process and offers better control over the testing parameters. The result is a high-quality part delivered on time. In addition, tooling geometry is virtually optimized, and the project can be viewed in 3D CAD. Machines used include a rotational rheometer, scanning calorimeter, thermal conductivity meter and a new CT scanner. For more information, visit www.guill.com.

IN MEMORIAM: TIM KATEN

Tim Katen, one of the cofounders of Micro Mold Co. Inc. and Plastikos Inc. in Erie, Pennsylvania, passed away on January 29, 2024, just weeks after he was diagnosed with mesothelioma. He was 76 years old. Katen and David Mead founded toolmaker Micro Mold in 1978 and injection molder Plastikos in 1989. Katen’s sons Phil and Ryan are on the executive team for the companies. Katen graduated from McDowell High School in 1965; then he enlisted in the US Navy at age 17 and served on active duty during the Vietnam War. After his service in the military, he enrolled in trade school and started his moldmaking career at Seaway Tool & Die. Katen retired in 2010.

19 www.americanmoldbuilder.com | AMBA.org

NPE2024 DELIVERS THE LATEST TECHNOLOGY

By Lindsey Munson, editor, The American Mold Builder and Susan Denzio, business manager, AMBA

After a six-year hiatus, one of the plastics industry’s largest tradeshows is preparing for a big return. NPE: The Plastics Show will take place May 6-10, 2024, in Orlando, Florida – three years after COVID-19 forced the cancellation of the triennial show’s 2021 event. With the theme “Made for You,” the 2024 show will offer attendees demonstrations of the latest machinery and equipment, opportunities to network with industry experts, collaboration around some of the biggest challenges facing the industry and a redesigned educational program. Organizers expect more than 2,000 exhibitors and 55,000 attendees to fill the halls at the Orange County Convention Center over the five-day event.

NPE2024 will feature six Technology Zones, including the advanced manufacturing zone and moldmaking zone, to consolidate the most cutting-edge advancements, tools, materials and processes in one central location. In addition, organizers have unveiled over 100 sessions, 60 industry speakers and access to the three Spark Stages on the show floor. While attending NPE2024, be sure to visit the booths of AMBA's members and partners:

ACCEDE MOLD & TOOL CO., INC. BOOTH W381

Established in 1981, Accede Mold & Tool is an independent full-service Class-101 plastic injection moldmaker and systems integrator. ACCEDE serves the molding industry globally by providing innovative and precision highcavitation, stack and two-shot mold solutions, including cube platforms. Sampling capabilities: 120-720 tons. ISO9001:2015 certified QMS. Made in the USA.

ADLER INDUSTRIAL SOLUTIONS

BOOTH S31151

Including the family of companies: R&D/leverage US and Europe, Pinnacle Molds and Rapid Mold Solutions, Adler designs and manufactures injection molds, injection blow molds and injection stretch blow molds. From new product tooling to keeping existing molds running, Adler’s team gets customers there faster. Adler “Knows Molds!”

ALLIANCE SPECIALTIES AND LASER SALES BOOTH S31038

Alliance is the home for American-made laser welding and engraving solutions – mold builders who don’t build molds. Its expertise is complete injection mold finishing and maintenance needs, specializing in polishing, laser welding, engraving, mold maintenance and hot runner manifold repair.

AMERICAN MOLD BUILDERS ASSOCIATION BOOTH S37129

THE AMERICAN MOLD BUILDER MAGAZINE

American Mold Builders Association (AMBA) has been dedicated exclusively to the US mold manufacturing industry for over 50 years. Its mission is to provide resources, peer connection opportunities that drive profitability, develop internal leadership and build resilent, more adaptable

organizations. TAMB is the official magazine of AMBA.

AMERICAN MOLD BUILDERS ASSOCIATION – BOOTH S38128

WEST MICHIGAN CHAPTER

Showcasing all 19 AMBA member shops located in West Michigan in one stop. Manufacturing a variety of plastic injection and diecast molds, from small to large, along with supporting fixtures, EOAT, 3D printing and more. Discover how these shops meet a wide range of tooling needs.

AMERICAN TOOL AND MOLD BOOTH S10065

American Tool and Mold specializes in injection molding and tooling in the same facility, emphasizing precision tooling for industries including medical and aerospace. Its advanced CNC machining and EDM processes adhere to stringent standards, including ITAR and AS9100, ensuring close-tolerance parts and delivering precision and innovation through expert machining for critical applications.

BMG FREEMAN BOOTH W232C

BMG is the gold standard for thermoform tooling for both plastic and paper thermoforms. Manufactured in a climatecontrolled facility, tools are produced with the highest precision. BMG designs and manufactures mold and trim tools for paper, post-trim, steel rule, form/cut/stack and form/fill/seal thermoforming machines.

BORIDE ENGINEERED ABRASIVES BOOTH S28023

BORIDE Engineered Abrasives manufactures abrasive products for industrial and consumer applications, including 20-plus unique mold polishing stone formulations and a

20 the american MOLD BUILDER | Issue 1 2024 the american MOLD BUILDER | Issue 2 2022

t

Whether you want to expand your plastics knowledge, build your professional network or find the hottest innovations, there’s no better place than NPE: The Plastics Show. Advance your business by coming together with everyone (and we mean everyone!) in the plastics ecosystem.

Don’t miss your chance to leverage new ideas from the people who know plastics.

Learn more and register at NPE.org/AMBA

NPE2024 IS MADE FOR YOU

tvariety of diamond compounds. The offering is complemented by working with industry experts to provide a full line of polishing accessories, including equipment, mounted points, coated abrasives and more.

CUSTOM ETCH, INC.

BOOTH S25027

Custom Etch has over 12 years of laser experience in 5-axis operations. CE is the largest laser texture supplier in North America with 10-plus machines, servicing aerospace, automotive, consumer products, packaging, medical and defense. Specializing in texturing services (laser or chemical etching), CE offers engraving, marking, anti-counterfeiting, digital watermarks and electrode manufacturing.

DME BOOTH W1601B

DME is committed to earning business every day by bringing new, innovative and cost-effective products and services. Time-earned knowledge, molding industry expertise and cutting-edge technology make DME the company to partner with for a molder’s next project.

DMS BOOTH S28023

DMS will be showcasing, hydraulic edge gate cutting, dynamic gas venting technology, best-in-class 3D printed hot sprues and energy-saving hot runner systems, best-inclass micro welding, the latest mold polishing products from Boride and much more!

DYNAMIC TOOL

BOOTH S26177

Dynamic Tool will showcase its extensive injection mold engineering, design, build and scientific sampling capability.

GESSWEIN

BOOTH W4261

Providing high-quality precision metalworking tools, equipment, training and service to metalworking trades for over 100 years, Gesswein’s extensive product line includes laser welders, engravers, polishing consumables, ultrasonic polishers and much more. Gesswein manufactures Gesswein Polishing Stones, offers tailored mold and die polishing training and provides personalized technical support.

HASCO AMERICA INC.

BOOTH S35049

Hasco looks back with pride on 100 years of success as the pioneer of moldmaking. With the invention of the standardized modular system in the 1960s, HASCO revolutionized the plastics industry worldwide. The goal is to set further innovative milestones in the next 100 years.

INCOE CORPORATION

BOOTHS W3761/S30123

A must-visit hot runner technology destination to book as a part of the NPE itinerary. Hours 9-5 p.m. on Monday through Thursday and 9-3 p.m. on Friday. Reservations are not required but recommended. People-Product-Sustainability,

since 1958. A member of PLASTICS (formally SPI) since 1970. Your INCOE, Welcome IN.

KRUSE ANALYSIS

BOOTH W4488

Kruse is committed to providing in-depth CAE simulation services and eLearning for injection molding – focused eLearning, including virtual reality-supported training for the next generation of engineers. Kruse’s ATR (Attract –Train – Retain) framework will support the entire injection molding industry.

M.R. MOLD & ENGINEERING

BOOTH W3789

M.R. Mold & Engineering is excited to announce it will be exhibiting in booth W3789. Since 1985, M.R. Mold has been building high-precision plastic and LSR injection molds. M.R. Mold is pleased to partner with Milacron in booth W1601, Shibaura in booth W2743, Sumitomo Demag in booth W3343 and Zeiger Industries in booth W4281.

MANTLE BOOTH S27055

Mantle is the only metal 3D printer built for precision tooling. Mantle automates the production of precision tooling and delivers the accuracy, finish and steel properties required for demanding tooling applications. Tools made with Mantle have molded millions of parts while reducing lead times, cutting costs and solving labor shortages.

MASTIP BOOTH W3089

Mastip, a leading designer, manufacturer and supplier of innovative, cost-effective hot runner solutions to the global plastic injection molding industry, believes in providing exceptional service and support throughout the life cycle of the hot runner, ensuring spares and technical support are available. See Mastip’s latest innovations, including the Aquilo LSR System and MetiCom Temperature Controllers.

THE MINCO GROUP BOOTH W4949

The Minco Group, located in Dayton, Ohio, is comprised of Minco Tool and Mold and All Service Plastic Molding (ASPM) – which specializes in product design, precision machining, tooling and molding. The Minco Group offers a global tooling strategy and injection molding capacity ranging from 55 to 1,100 clamp tonnage.

MOLD CRAFT (A WESTFALL TECHNIK COMPANY) BOOTH W3581

Come see a demonstration of micro molding in the Sodick Plustech booth, W3581. Mold Craft dba Westfall Technik will be demonstrating micro molding using the Sodick Plustech GL30A injection molding press with two-stage plunger injection.

MOLDMAKING TECHNOLOGY BOOTH S30135

MoldMaking Technology addresses what’s new and what works in mold manufacturing. MMT comes to life through a

22 the american MOLD BUILDER | Issue 1 2024

physical magazine, a digital edition, comprehensive website, MMT Chats video series, MMT Today e-newsletter, social media, webinars and flagship events: the MoldMaking Conference and Amerimold.

MSI MOLD BUILDERS

as well as the new P-Bas technology for making custom conformal cooling components in the MoldMaking Zone.

SELFLUBE

BOOTH S35065

MSI Mold Builders’ passion is to be its customers’ competitive advantage. MSI specializes in building and repairing large steel and aluminum molds for high- and low-pressure plastic injection. Please visit MSI at South Hall Level 1 – S35065.

OMEGA TOOL

BOOTH W1588

Omega Tool is a third-generation, family-owned plastic injection mold builder for the medical, packaging and light industrial markets. With over 3.5 million in new machinery to meet the fully interchangeable, tight-tolerance requirements, its Molding Technology Center recently was updated to perform full mold validations.

OERLIKON HRSFLOW

BOOTH S25183

Oerlikon HRSflow, part of the Swiss technology group, is specialized in the development and production of advanced hot runner systems for the injection molding industry in automotive, logistics and environmental, houseware and gardening, medical, beverage and home, thin wall packaging, beauty and personal care markets. Oerlikon HRSflow manufactures hot runner systems in Italy, China and USA.

PCS COMPANY

BOOTH W3801

PCS Company will feature its latest products and solutions for the plastics injection molding, moldmaking and die casting industries at NPE. New products at the show will include hot runner systems and controls, mold bases, mold components, molding supplies and more.

PRESTIGE MOLD INCORPORATED

BOOTH W1129

Specializing in high-cavitation, fully interchangeable molds, Prestige Mold utilizes robotic automation to maximize efficiency, reduce costs and ensure ultimate quality for its global customer base. Also providing mold sampling, process development and validation, production molding and complete turnkey integration through its sister company, Pres-Tek Plastics.

PROGRESSIVE COMPONENTS BOOTH

W1543

Progressive is the only American-owned, independently operated developer and full-line global distributor of mold components and mold monitoring technology. At NPE, introductions include new, exclusive mold mechanisms and advancements to the ProFile v4 mold management platform.

PUNCH INDUSTRY USA INC.

BOOTH S39137

PUNCH INDUSTRY USA INC. will exhibit precision round core pins, micro pins, ejectors, blades, and sleeves,

BOOTH W4215

SelfLube’s custom wear strips are made to exact requirements. They’re furnished complete and ready to install, saving time and money. This frees up resources that can be redirected to higher value-added activities. SelfLube also has a proven track record for quality and on-time shipping.

SLIDE PRODUCTS, INC.

BOOTH S33083

Slide Products offers moldmakers and plastic processors the most complete line of processing aids, all formulated to help improve efficiency and profitability. Offering on-site production assessments and free samples of mold releases, mold cleaners, rust preventives, ejector pin greases and purging compounds, Slide will help ensure facilities are operating at peak performance.

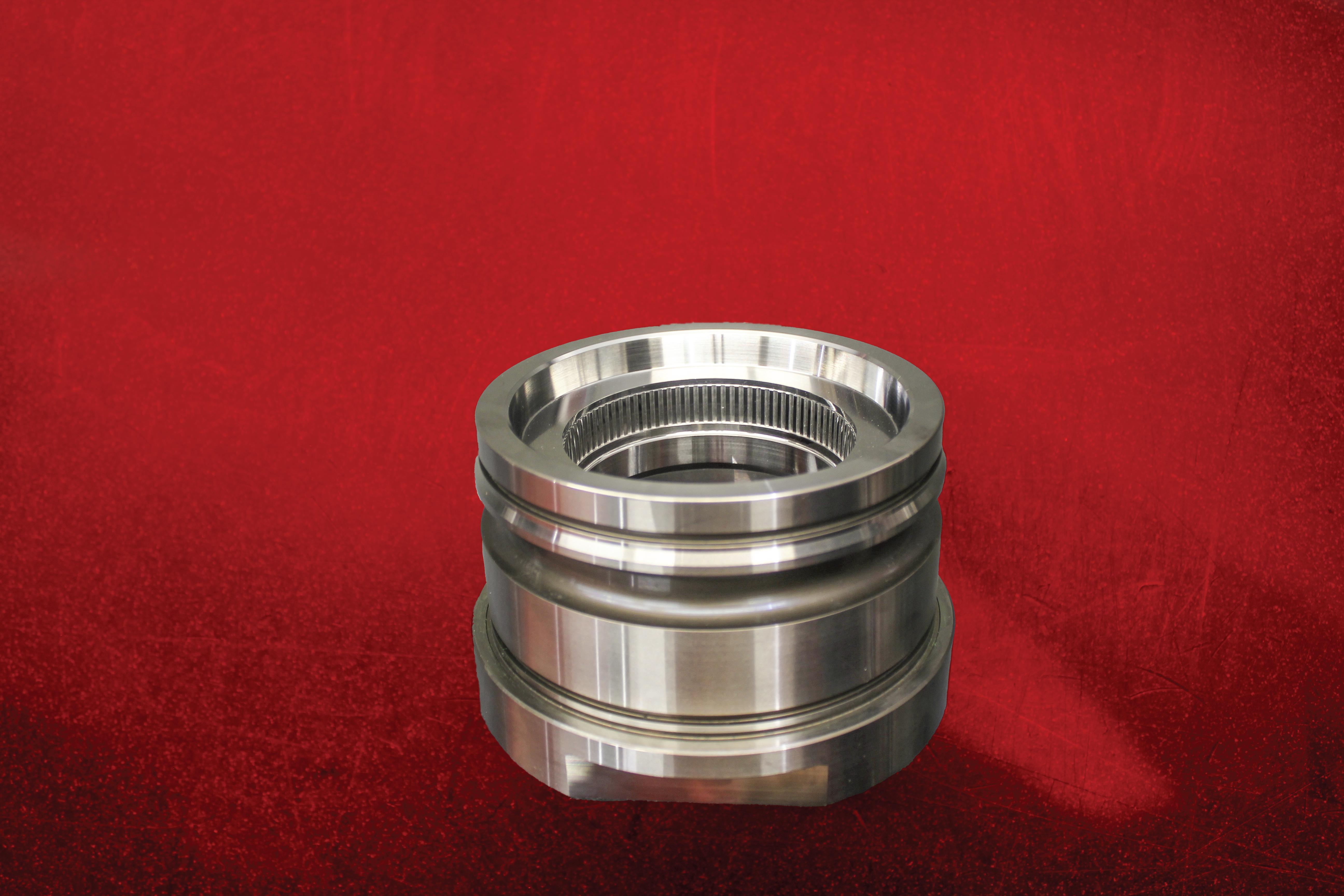

SWISS STEEL USA

BOOTH S34143

Swiss Steel USA, part of the Swiss Steel Group, and its in-house production at Deutsche Edelstahlwerke and Finkl Steel, supplies premium mold steels, vacuum heat treatment and machining services, with six service centers throughout the USA and Canada. Its line of stainless mold steels is for applications including mold base, core and cavity.

WESTMINSTER TOOL INC.

BOOTH W2691

Westminster Tool Inc. is a Connecticut-based Class 101 injection mold manufacturer specializing in particularly challenging tolerances. In addition to serving the packaging and defense industries, Westminster Tool excels in medical device production where quality is critical. Westminster will highlight its latest projects utilizing new metal additive technology and molding machines for mold qualification.

WIPFLI

BOOTH S26197

Helping manufacturers achieve their goals takes imagination, discipline and a process that delivers results today while anticipating tomorrow’s demands. That’s Wipfli. From tax incentives to operational improvements and performance enhancements to large-scale digital transformation, it helps clients achieve lasting results. Learn more about analytics dashboards and machine monitoring software.

XACT METAL, INC.

BOOTH S25196

Xact Metal is a designer and manufacturer of affordable metal 3D printers, built here in the United States. 3D printing can provide the tools to make inserts with conformal cooling and Xact Venting with tooling steels to reduce cycle times and yield better parts.

23 www.americanmoldbuilder.com | AMBA.org

PROFESSIONAL DEVELOPMENT ABOUNDS FOR TEAMS AT AMBA CONFERENCE 2024 – ENGAGE. ELEVATE. EVOLVE.

At this annual event, US mold manufacturing executives and emerging professionals alike will have the opportunity to embrace growth and learning opportunities through peer connection, guided dialogue and best practices sharing. Don’t miss out on sessions like those designed for emerging professionals, breakouts highlighting best practices in sales, workforce development, cybersecurity, automation and financial preparedness and NEW peer networking connections, like AMBA’s topical rounds.

For more information about how executives, management teams and up-and-coming professionals will benefit from AMBA Conference 2024, visit pages 8-9 or www.ambaconference.com

PROFITABILITY, MARKET OPTIMISM AND MORE – AMBA 2024 BUSINESS FORECAST REPORT NOW AVAILABLE

AMBA has released its annual 2024 Business Forecast Report, which highlights economic and industry-specific trends that US mold manufacturing executives can use to plan for the months to come. From profitability, capacity utilization and shipment levels to jobs won, workforce strategies and reshoring activity, industry professionals won’t want to miss what this report has to offer. Member cost to purchase the report is $299; non-member cost is $499. To purchase the 2024 Business Forecast Report, visit www.amba.org/ publications.

AMBA HEALTH AND BENEFITS SURVEY RETURNS IN 2024

AMBA once again has launched the Health and Benefits Survey to the US mold manufacturing industry. Last published in 2022, this survey will benchmark benefits offered by manufacturers in mold manufacturing, plastics processing and rubber processing, including health, vision, dental, life insurance and retirement programs. The final report will include some aggregate data for all surveyed manufacturers, as well as data specific to each industry. To complete the survey, visit www.amba.org. The survey deadline is March 15, 2024.

DRIVE BUSINESS GROWTH WITH NEW ITR ECONOMICS REPORTING

New this year, AMBA members have access to leading-edge economic forecast data from ITR Economics to assist in making better, overall strategic decisions – a new benefit at no cost. Members now can log in to a members-only portal, where they can access a full, simple-to-read report detailing the US macroeconomic outlook, the direction of the general economy, growth rates and business tactics to consider in five major end markets: North America Light Vehicle Production, US Total Retail Sales, US Medical Equipment and Supplies Production and more.

In addition, ITR’s online portal provides more data and a Rate of Change calculator to align company historical data with over 50 other indices in order to draw correlations between economic activity and business results. For more information, visit www.amba.org under the Member Resources tab.

AMBA LAUNCHES 2024 CNC USERS GROUP FOR TOPICAL DISCUSSION

AMBA has launched a CNC users group that meets on the second Thursday of every month. This group connects CNC operators and related positions with functional area peers to discuss best practices, evolving technologies and more. So far, the group has met to discuss new tooling and techniques, as well as ERP system use, challenges and best practices. The group will continue with a new topic during its March meeting on March 14, 2024, at 11 a.m. EST. For more information and to register, visit www.amba.org/ events.

SAVE THE DATE FOR AMBA SUMMER 2024 EVENTS

Save the date for two notable in-person events approaching summer 2024! On June 25-26, 2024, AMBA Emerging Leaders Network will host its second Leadership Retreat. This event will feature best practices and strategies related to professional development and growth and will be complemented with connection and peer networking opportunities. All professionals (regardless of age) emerging in their roles and interested in professional growth are encouraged to attend this facilitated workshop. Details on the event speaker, location, agenda and more will be announced in late March 2024.

24 the american MOLD BUILDER | Issue 1 2024

Following the AMBA Emerging Leaders 2024 Leadership Retreat, AMBA will host a plant tour workshop at Franchino Mold & Engineering on June 27, 2024. Located in Lansing, Michigan, this event will follow the traditional plant tour workshop format. Details on the host and tour agenda will be announced in early April 2024.

JOIN AMBA AT NPE2024

Every three years, bold leaders, creative thinkers and visionaries from every industry in the world gather at NPE® to advance their business through innovations in plastics. In just five days at NPE2024, May 6-10, attendees will build new partnerships, experience the latest technology and unlock new opportunities to drive exponential growth for their organizations.

Join the AMBA team at Booth #S37129 to celebrate the event in style for a member reception from 3-5 p.m. EST on Wednesday, May 8, 2024, and see what the association has planned for the second half of 2024.

NEW MEMBERS

D1 Mold & Tool

8201 N. St., Rd. 9 Alexandria, Indiana 460021

Main POC: Mark Whybrew

Email: mwhybrew@d1moldandtool.com

Phone: 765.378.0693

Website: www.d1moldandtool.com

D1 Mold & Tool is a full-service design and build mold shop that services several industries. In 2022, the company celebrated its 20th anniversary and relocated to a larger facility, which in turn expanded its capacity through the introduction of new equipment. By utilizing high-quality materials, D1 Mold & Tool provides its customers with the most reliable tooling.

Quality Mold Inc.

8130 Hawthorne Dr. Erie, Pennsylvania 16509

Main POC: Darren Hakel, vice president

Email: darren@qualitymolderie.com

Phone: 814.866.2255

Website: www.qualitymolderie.com

Founded in 1985, Quality Mold is a privately held plastic injection mold manufacturing company that specializes in medical, automotive and consumer products. From singlecavity prototype tooling to high-cavitation production molds, the company’s customer-first approach and highquality standards, paired with expert precision, allow its customers to have a competitive advantage.

NEW PARTNERS

King Commercial Capital, Inc.

2521 Cirtrine Brook Crossing

Ft. Wayne, Indiana 46845

Main POC: Gerald King, president

Email: gking@kingcommercialcapital.com

Phone: 260.969.1487

Website: www.kingcommercialcapital.com

King Commercial Capital is an independent equipment finance brokerage, that breaks free from rigid traditional bank guidelines and goes beyond by tailoring equipment financing solutions for small- to mid-size businesses in the injection molding industry. With an extensive funding network, the company specializes in diverse financing, including tooling finance solutions and addressing AMBA member needs. King Commercial Capital’s mission is to pioneer inventive equipment and tooling financial solutions, enhancing cash flow dynamics for sustained business success.

“A perfectly balanced stone; optimal breakdown paired with superb finishing capabilities.”

25 www.americanmoldbuilder.com | AMBA.org

New AS-9 PLUS stone formulation now available! Get to the finish you need faster & with better results! AS-9 PLUS EDM POLISHING STONE BorideAbrasives.com • info@borideabrasives.com • 231.929.2121 NEW! AVAILABLE NOW! • NEW! AVAILABLE NOW!

THE 2024 REGULATORY AGENDA FOR MANUFACTURING

By Omar S. Nashashibi, co-founder, The Franklin Partnership, LLC

Twice a year, the US government provides manufacturers with a preview into what it has in store for them. This comes in the form of the Fall 2023 Unified Agenda of Regulatory and Deregulatory Actions, which the Biden administration released in December 2023. The Regulatory Agenda, as it is known, is a list of proposed and final rules agencies intend to release in the coming months.

The Fall 2023 Regulatory Agenda included 2,524 entries of new and potential regulations coming from virtually every agency, including some that many readers may not know even existed. As a lobbyist for AMBA and manufacturers around the US, my firm filters through regulatory agenda twice a year to help businesses anticipate how a proposed or final rule may impact their operations and industry.

Most members by now are familiar with OSHA’s activities related to a possible rule regulating indoor and outdoor workspaces when the heat index exceeds 80° F. The agency issued a draft framework for a potential rule in 2023 that would require 10- or 15-minute breaks every two hours depending on the temperature at the workstation, increased supervisor monitoring of workers, installation of temperature-monitoring equipment, engineering controls and potentially administrative controls if the shop is unable to reduce the temperature. OSHA listed in its Regulatory Agenda that it would spend January 2024 reviewing stakeholder input following the release of its draft framework as it considers releasing a proposed rule possibly later this year.

One of OSHA’s top 10 citations annually is Lock-out/ Tag-out and addressing uncontrolled hazardous energy in machinery. The agency stated in the Regulatory Agenda that it plans to release a Notice of Proposed Rulemaking (NPRM) in August 2024. Depending on whether a proposed rule maintains certain exemptions, OSHA could significantly alter how thousands of manufacturers operate their machines.

The Wage and Hour Division at the Labor Department revealed that it intends to release a Final Rule in April 2024 increasing the exemption threshold for overtime pay that would make an estimated 3.6 million workers eligible for time and a half. Currently, full-time salaried employees earning below $35,568 annually are eligible. The proposed rule indicated that the Department could increase the limit to $60,209, a threshold which would take effect 60 days following publication of the final rule. A possible change this summer could impact thousands of payrolls for manufacturers across the country.

The Department of Labor already has released one of the proposed rules listed in the Regulatory Agenda –one to change the federally registered apprenticeship programs, with comments due March 18, 2024. The Biden administration is proposing to “eliminate the tripartite onthe-job training.” This would eliminate the ability to use competency-based and time-plus competency for registered apprenticeships that the Labor Department began allowing in 2008. Many manufacturers already are raising concerns that a time-only apprenticeship with 2,000 hours annually could slow the progression of apprentices, turn away potential apprentices and cause employers to drop registered apprenticeships altogether.

The EPA has among the longest sections in the Regulatory Agenda, with 119 proposed and final rules listed. This is especially notable in an election year as administrations typically work quickly to push through regulation in the event the sitting president or their party loses control of the White House.

In March 2024, the EPA listed in the Regulatory Agenda that it would issue a Final Rule for Greenhouse Gas emissions standards for heavy-duty engines and vehicles (Phase 3) and also Multi-Pollutant Emissions Standards for Model Years 2027 and Later Light-Duty and Medium-Duty Vehicles.

26 the american MOLD BUILDER | Issue 1 2024

t

ESSENTIAL WHEN YOUR MOLD MATTERS er mold finishing, laser welding, laser graving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom Let Alliance make a di erence for you. • MOLD FINISHING

LASER WELDING

LASER ENGRAVING

HOT RUNNER REPAIR

MOLD MAINTENANCE • LASER MACHINE SALES P R O U D PA R T N E R M E M B E R 2 6 5 I N D U S T R I A L D R W A U C O N D A , I L 60 0 8 4 PHONE ADDRESS ALL I A N C E L A S E R SA L E S . C O M ONLINE 847 487.1945 AK E RS FOR M OLD MA KER S EVERY PART OF THIS MACHINE IS EASILY ADJUSTABLE TO ALLOW YOU THE VERSATILITY AND FLEXIBILITY YOU NEED TO MEET ALL OF YOUR DEMANDS CONTACT US TODAY ABOUT AN IN-HOUSE DEMO, TO SEE THE ALLIANCE DIFFERENCE. ALLIANCE SPECIALTIES CORP. / ALLIANCE LASER SALES, INC. • FIBER LASER TECHNOLOGY • MADE IN AMERICA • HIGH PRECISION LASER WELDING • NO MAINTENANCE NEEDS

•

•

•

•

tThe next month, in April, EPA will release a Final Rule repealing former President Trump’s Affordable Clean Energy rule regulating power plant emissions. Another significant Final Rule from EPA expected in April is officially known as Secondary National Ambient Air Quality Standards (NAAQS) for Ecological Effects of Oxides of Nitrogen, Oxides of Sulfur and Particulate Matter. Thousands of manufacturers, their suppliers and customers fall under the NAAQS regulations covering emissions from their facilities.

On the supply chain side, the Departments of Defense, Transportation and others are finalizing and proposing actions to strengthen Buy American requirements as part of federal acquisition regulations. Build America Buy America (BABA) is a top personal priority for President Biden, who issued an Executive Order increasing the US content requirements for federally backed projects.

The Commerce Department could consider changes to the Manufacturing Extension Partnership program (MEPs), the process by which importers request exclusions from tariffs on steel and aluminum, and how Commerce factors in market conditions when determining antidumping and countervailing duties on imports from countries such as China.

•

From non-competes to corporate climate disclosures and forever chemicals, manufacturers have no shortage of regulations to track and possibly comply with coming from Washington, D.C.

The National Association of Manufacturers last year released a study showing federal regulations cost an estimated $3.079 trillion in 2022, with the annual burden for an average firm being $277,000. Smaller manufacturers bear the burden, with those having fewer than 50 employees averaging a regulatory cost of $50,100 per worker.

Regulations play a critical role in health, safety and productivity, and are an important part of what governments do in partnership with the regulated community. The goal of reviewing the Regulatory Agenda twice each year is to help businesses anticipate, and possibly adapt as necessary' to the changing regulatory environment. While lawmakers and politicians receive the most media attention on a daily basis, it is the regulators who often have a greater impact on day-to-day operations.

Omar Nashashibi is a founding partner at The Franklin Partnership, LLC, a bipartisan government relations and lobbying firm retained by the American Mold Builders Association in Washington, D.C.

28 the american MOLD BUILDER | Issue 1 2024 Services • Finishes to all SPE-SPI standards • Diamond Lapping • Textured Surface Prep • Benching • Quoting from Drawings, Prints, Pictures and Parts • On-Site Support Capabilities

50+ Polishers

40 ton Capacity

24 hours – 7 days

Pick-up and Delivery

•

•

•

•

3-D CAD File Capabilities Partnerships

Welding

Plating Texturing Ph: 847-352-5249 Fx: 847-352-4052 1320 Holmes Rd., Elgin, Illinois sales@ultrapolishing.com www.ultrapolishing.com ISO 9001-2015 CERTIFIED GETS YOU TO MARKET FASTER 2023_Ultrapollishing_AMBA_quarterpgV1.indd 1 2/14/2023 3:42:12 PM

•

•

Don't miss the opportunity to make new business connections and celebrate the return of NPE with other industry professionals.

Learn more about AMBA and its NPE presence at AMBA.org Visit AMBA at NPE2024!

AMBA Member Reception

8, 3-5pm | Booth S37129

May

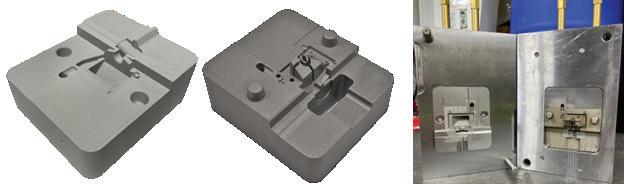

WHAT DO DIGITAL TEXTURES OFFER THE INDUSTRIAL MOLD MARKET? OPPORTUNITY!

By Chad Hase, director of advanced manufacturing, Custom Etch Inc.

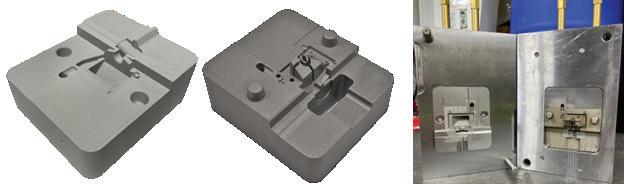

Five-axis laser machining makes digital mold textures possible for all moldmaking processes.

Mold manufacturers using laser technology can play a vital role in brand protection, recyclability and traceability efforts with new digital mold textures.

Laser texturing has opened the door to new possibilities in design, engineering and moldmaking with the development and implementation of five-axis laser machining.

EVOLUTION

The first evolution of laser technology focused on cosmetic texture applications that yielded unprecedented geometric and homogeneous patterns for products across the automotive, aerospace, consumer products, defense and medical industries. These engineered patterns demand full five-axis laser CNC machining, as they are impossible to achieve with traditional chemical etching.

Custom Etch collaborates with DIGIMARC to embed digital watermark technology into textures applied by its laser systems. Every code is unique and is a string of numbers that points to a database able to carry a wide range of attributes for a variety of use cases.

The second evolution involved the development and incorporation of functional textures. This application gives products a physical property while maintaining the cosmetic appearance required. For example, adding a gripping effect to ease handling for touch or grab products or promoting a new surgical procedure to help bone growth on implants. Laser texturing has no limitation on design because it is a 100% digital process.

The new evolution of today is digital watermarking. This application places a unique digital code within a texture, completely hidden to the naked eye but fully readable by machine vision systems, including smartphones. This embedded digital watermark is applied directly into textures and creates an invisible code that is the size of a postage stamp. This process only can be done using laser technology.

THREE REASONS TO USE DIGITAL WATERMARKING TEXTURES

Here are three benefits of digital watermarking textures:

1

Brand Protection

● Counterfeiting impacts trade, jobs and brand reputation, making anti-counterfeit solutions attractive. For example, a laser digital watermark texture ensures product authenticity and aids in identifying knockoffs.

● A strategically placed digital texture offers digital tracking that can improve brand safety and anticounterfeiting measures critical to regulatory compliance in the medical and pharmaceutical markets.

● Most products have no digital presence, making their lifecycle unknown. Laser digital watermarks confirm data effortlessly with digital authentication and analysis.

2Recyclability

● Digital textures act as a digital passport for a circular economy and show consumers a company’s alignment with sustainability initiatives.

30 the american MOLD BUILDER | Issue 1 2024

t

WHO’S BRINGING NEW LEVELS OF PERFORMANCE TO COMPACT HOT RUNNER/MANIFOLD SYSTEMS?

At Plastic Engineering & Technical Services, we are. We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

ENGINEER BUILD MAINTAIN Industry Insights Straight from the Source moldmakingtechnology.com/videos/mmtchat

Our Latest MMT Chat or visit youtube.com/moldmakingtechnology Each week, MMT Editorial Director, Christina Fuges, sits down with industry insiders for quick, casual conversations on topics impacting the industry today. Enjoy actionable insights on new tech, tips, trends and issues you can put to work in your shop. Stay Informed and Stay Inspired CASTING CALL! Want to be a guest? Reach out! We’re always looking for fresh new faces and perspectives from the industry. Email us at: cfuges@gardnerweb.com MMT24_MMTChats_Ads.indd 1 12/11/23 1:46 PM

Scan To Watch

In 2011, Custom Etch expanded its customers’ needs by installing the addition of 5-axis laser texturing technology.

● Digital textures offer label-less design, making it easier to recycle.

● Digital textures are a solution for the regulatory scrutiny and consumer sentiment that dictates manufacturers’ responsibilities to manage plastic waste better. An example is the packaging industry’s ‟Holy Grail 2.0” initiative, which involves more than 170 companies and organizations in Europe, focused on using digital watermarks to improve sorting accuracy.

● Digital textures deliver data about packaging attributes, such as reusable post-consumer recycled (PCR) material.

3Traceability

● Digital textures play a vital role in Industry 4.0 by delivering product digitization that illuminates more about the manufacturing process and business. This digitally scanned data eliminates manual documentation and human error of vital product information; for example, tracking product transportation.

● Digital textures digitally structure and streamline regulatory compliance (FDA, OSHA, ISO, etc.).

● Digital watermarks identify the manufacturer, resin type, color, weight, use, recyclable vs. nonrecyclable, monolayer vs. multi-layer packaging, carbon-black, opaque, difficult-to-recycle packages and new material introductions (PCR vs. virgin).

ADDITIONAL FACTS ABOUT DIGITAL TEXTURES

Unlike a static QR code, digital textures are dynamic and point to a new source of information at any given time –making them 100% customizable.

Information via internal and external data retrieval means that product intelligence can be sent for deeper business

insights on a product’s complete lifecycle, better brand integrity, accuracy, efficiency, security and supply chain traceability.

Laser texturing is widely accepted in today’s manufacturing process, as it offers product improvement and higher quality. Laser digital textures give mold builders a new, innovative solution to meet customer needs and open the door to new business opportunities across all end markets.

Chad Hase is director of advanced manufacturing at Custom Etch Inc., a design company based in New Castle, Pennsylvania. He has over 25 years of experience in tool and die manufacturing and has been instrumental in bringing new laser technologies to North America. Hase’s current research involves the study of digital watermarks and continued studies on surface treatment from different laser sources on medical and aerospace materials and microstructures. Since 1982, Custom Etch has provided its customers with experienced support to develop their texture ideas and expertise to create the best possible aesthetic and functional textured surfaces.

More information: www.custometch.com

33 www.americanmoldbuilder.com | AMBA.org

t

ANCA RELEASES TAPX

ANCA, Melbourne, Australia, a manufacturer of CNC grinding machines, has released the TapX machine that specifically is designed and integrated with automation to ensure high productivity in mass production. TapX integrates the various processes into one machine. The specially designed machine and powerful ToolRoom software ensure a vast range of tap types and sizes can be designed and manufactured under a single set-up. The TapX uses ANCA’s own LinX motor technology for all linear axes and direct drive technology for all rotary axes. The TapX one-machine grinding concept provides faster tap design, set-up and changeover to reduce lead times and boost competitiveness. For more information, visit www.machines.anca.com.

introducing a new five-inch-tall version for larger tools and plates. Independently tested to hold 15,000 lbs each and designated a safety factor of three, a 60,000 lbs mold can be elevated with four five-inch RhinoFeet. Released in 2020, the product line is offered in two-, three- and four-inch heights –established as a simple, safe and efficient solution for elevating and storing heavy items within the shop. When used under molds, RhinoFeet eliminates the trip hazard of wood and skids strewn about the plant and improves 5S continuous improvement efforts. For more information, visit www.procomps.com.

FAULHABER PARTNERS WITH IPR

FAULHABER

MICROMO

CETEC SHARES ERP SOLUTIONS

Cetec ERP, Austin, Texas, a cloud-based ERP software provider, has started sharing its tailored ERP solutions with machine shops, metal fabrication and contract manufacturing industries. Cetec ERP software features include intelligent scheduling capabilities that optimize production timelines, ensure on-time deliveries and streamline resource allocation for increased efficiency. The ERP’s advanced scheduling system schedules work orders according to available machine capacity and assigned job priority. Its shop floor control capabilities enable operators to access real-time data, efficiently manage work orders and improve production workflow. With comprehensive inventory management and traceability, manufacturers gain real-time visibility into inventory levels and shortages that report back to production management. The robust quality management module ensures adherence to stringent quality standards such as ISO 9001, ISO 13485 and AS9100. For more information, visit www.cetecerp.com.

PROGRESSIVE EXPANDS RHINOFEET™ LINE

Progressive Components, Wauconda, Illinois, a developer and supplier of components for the production tooling industry, has expanded its RhinoFeet™ product line by

LLC, Clearwater, Florida, supplier of high precision miniaturized and miniature drive systems, servo components and drive electronics, worked closely with Intelligent Peripherals for Robots (IPR) in Eppingen on its TKX Changer Series which features FAULHABER’s motor in the electric drive of the automatic changer. A brushless motor from the FAULHABER BXT family provides the driving force for opening, closing, and holding. With its external rotor technology, it achieves a ratio of torque to weight and volume that is unrivaled on the market. This power density is one of the prerequisites for the unique selling point of the IPR’s TKX Changer Series. IPR procures all micromotors from FAULHABER. For more information, visit www.faulhaber.com.

HASCO LAUNCHES ECO-FRIENDLY SUBSTANCES

HASCO, Fletcher, North Carolina, a full-service provider for tool and moldmaking, has launched a new range of chemical working substances, including a heavy-duty lubricant spray Z2610/..., anti-corrosion spray Z2620/..., multi-purpose cleaner spray Z2630/..., metal-based assembly paste Z2660/... and all-synthetic creepfine oil spray Z2670/... . The all-synthetic premium working substances function well and have environmental compatibility. Nearly all the products have

34 the american MOLD BUILDER | Issue 1 2024

NSF certification for the food segment. The chemical working substances are produced in Germany and subject to the strictest of controls concerning production and raw materials and are produced without mineral oils. For more information, visit www.hasco.com.

IKO INTRODUCES CAM FOLLOWERS

IKO International, Parsippany, New Jersey, designs and manufactures quality needle bearings, linear motion rolling guides, precision positioning tables and machine components, has introduced its CFC…B Series of short stud-type cam followers. The cam follower’s mounting structure consists of a hexagon socket head bolt and a dedicated flange nut that not only creates a more compact cam follower but also reduces the required mounting space on the stud side by up to 34%. By providing greater design freedom, this enhances production efficiency for a wide range of applications across many industries such as robots, electronic devices, manufacturing and automated equipment. For more information, visit www. ikont.com

MEUSBURGER EXPANDS PRODUCT RANGE

Meusburger, Mint Hill, North Carolina, a provider of highprecision standard parts, has expanded its product range to include the single nozzle easyFILL EH 4010 for selected applications. It has been developed as a cost-effective alternative to the single nozzle smartFILL EH 4000 and is available with two flow channel diameters and in four lengths. The one-piece, coated nozzle tip allows problemfree processing of most plastics. Different nozzle heads and contact radii in the sprue bush allow an individual selection of the nozzle to suit the injection situation on the item or in the mold and the connection to the machine nozzle. The modular design of the nozzle allows individual nozzle components to be replaced at any time so that repairs are efficient and economical. For more information, visit www.meusburger.com

MITSUBISHI ELECTRIC LAUNCHES FA TOOL