Beyond Conformal Cooling: 3D Metal Printing

What’s Ahead for Mold Manufacturing

MRO Control Strategies

Simplifying Mold Operations

“With every mold we build, we look to provide every advantage possible. ”

Steve Michon, Zero Tolerance LLC

What’s Ahead for Mold Manufacturing

MRO Control Strategies

Simplifying Mold Operations

“With every mold we build, we look to provide every advantage possible. ”

Steve Michon, Zero Tolerance LLC

The team at Zero Tolerance knows that a happy customer will be a repeat customer, and for Steve Michon, that includes designs with Progressive’s exclusives:

“We evaluate innovations that will benefit our customers. Our BOMs include Progressive exclusives like click-inplace Runner Turn Offs to prevent drift, reliable Slide Components, and uniquely designed Alignment Locks.”

Don’t build the same old, same mold. Visit procomps.com to build tooling that will deliver a performance edge.

Troy Nix,

Rachael Pfenninger, Director of Strategic Execution

Olivia Shotts, Public Relations Development Coordinator

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio PUBLISHED BY: 2150

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions

TYLER VANREE AMBA President, LEGACY PRECISION MOLDS, INC.

One book I’ve grown to love over the years is “The Go-Giver” by Bob Burg and John David Mann. It’s actually required reading for anyone who joins the Legacy Precision team. In the book, the authors share what they call the “Five Laws of Stratospheric Success.”

One of those laws is The Law of Value, which states: “Your true worth is determined by how much more you give in value than you take in payment.” This idea perfectly sums up what the AMBA represents and challenges each of us to remember the why behind what we do daily for our organizations to exist. It’s to add value to those we have the privilege of serving.

One of the ways AMBA continues to add value to its members is by keeping you informed and by representing you on Capitol Hill. The Association stays closely engaged with legislative activity, particularly around tariffs that are impacting its members and partners. Your perspective and active involvement matter to AMBA, so please don’t hesitate to reach out with questions or concerns. AMBA is here to serve you, strengthen your business and ensure your voice is heard. You’re always welcome to contact me directly or connect with the AMBA team.

AMBA has several events planned for the upcoming months. In December, don’t miss AMBA’s Industry Outlook and fourthquarter Advocacy Update, set for December 17. It’s filled with insights to help companies plan and prepare for the year ahead. In January, AMBA will host a webinar on AI and cybersecurity – two topics that are an increasing part of our everyday lives (whether we like it or not). Also, be sure to mark your calendars for MD&M West, taking place February 3-5, 2026. It’s a great opportunity to engage with peers and explore innovations shaping the industry. I look forward to connecting with many of you during these events as we begin a new year of learning and growing together.

As we prepare for 2026, I’ve been asking myself this one question, and I’d like to challenge you to do the same: What are some ways you can add more value to your team, your customers and your supplier partners? It could be something as big as a new product offering or as simple as a note of thanks to someone who’s made a positive impact on your life or business. Adding value to others doesn’t have to be complicated or costly – it just requires being intentional.

That’s exactly what AMBA will be focused on in the year ahead – finding new ways to deliver “value” into its member and partner organizations. Ultimately, the goal is to help you and your team become stronger, smarter and better equipped to face the challenges and opportunities that lie ahead – all in an effort to be even better in 2026 than you were in 2025. You just need to plug in, participate and grow with us. I trust I’ll see you at various points throughout the year as we navigate 2026 together.

You are the AMBA. We are the AMBA. Together, we are stronger.

OFFICERS

National President

Tyler VanRee, Legacy Precision Molds

Vice President Andy Peterson, Industrial Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Fiedlander, Coplan & Aronoff LLP

Treasurer

Hillary Thomas, Westminster Tool

Jeff Ford, BICO Steel

Justin Gregg, Dramco Tool Co., Inc.

Mike Hetherington, Franchino Mold & Engineering

Kyle Klouda, MSI Mold Builders

Scott Kraemer, Xact Metal

Steve Michon, Zero Tolerance

Troy Roberts, Tolerance Tool

Camille Sackett, Accede Mold & Tool

Scott Smith, Tessy Tooling

Todd Steging, Prestige Mold

Molders with non-standard requirements can order custom precision core pins, sleeves, ejectors, blades and punches from Regal Components. Custom components are used in molding a variety of medical, electronics and consumer products that require extreme precision, such as needles sheaves, closure s, nipples, pipettes, IV connectors, shavers, electronic components and writing instruments.

For greater control over thermal transfer, tensile strength, hardness and other physical proper ties, we can make components of a variety of materials including standard tool steel, powdered steels, stainless steel and copper alloys including M-2, A-2, H-13, S-7, PMM-4, PM 10V, 420SS

-Tolerances as tight as ±0.000050 inches

-Tips as small as 0.002 inches

-Lengths up to 14 inches

-Polished, coated and/or plated molding sur faces

-Custom details (e.g. tapers, rings, vents, ribs and spirals) can be shaped using wire EDM

By Lindsey Munson, editor, The American Mold Builder

As the plastics industry approaches the end of 2025, it stands at a crossroads – balancing innovation and technological advancements with ongoing supply chain disruptions, regulatory pressures, shifting market demands and more.

In this article, three industry veterans share their insights and perspectives on what lies ahead in 2026. Each professional has taken a moment to offer his or her expertise on the progress made throughout the prior year and the challenges that remain. With 2026 on the horizon, it is crucial that companies strategically align their operations to navigate and shift with a dynamic global landscape.

When looking to the future of mold manufacturing, it’s important to incorporate the perspective of an expert in advisory and consulting. It offers a bird’s-eye view of strategy and industry direction. Mike Devereux is a partner at Wipfli Advisory LLC, an accounting and advisory firm that helps closely held businesses achieve operational excellence, drive innovation and support growth. Devereux leads a national team that provides audit, tax and consulting services to the manufacturing sector.

Looking ahead, mold manufacturers will face a combination of familiar and evolving challenges that demand a sharper operational focus. Devereux said, “Beyond the longstanding challenges moldmakers face – such as workforce shortages and foreign competition – 2026 is expected to intensify cost pressures, making it essential to prioritize project margins, streamline lead times and delivery schedules, embrace technology integration and enhance overall operational efficiency.” With that, the economy also is playing a role. “External pressures, particularly trade and tariff policies, increasingly are influencing the market value and sourcing strategies for tooling packages. Tool shops that secure these projects can improve margin outcomes by driving operational efficiencies, leveraging data-driven decisionmaking and focusing on key performance indicators that directly impact profitability,” said Devereux.

Preparing for these pressures will require both short- and long-term operational adjustments of investments in technology and talent. The ongoing market volatility will remain a challenge for moldmakers, driven by factors such as tariff policies, broader economic shifts, reshoring activity, fluctuations in material costs and supply chain lead-time pressures.

Devereux said, “To succeed in 2026, mold shops must focus on controllable elements: managing cash flow, understanding capacity and utilization, and building discipline around processes like sales execution. Leveraging data through technology will be key to gaining deeper insights into profitability and driving smarter business decisions.”

While the molding industry faces ongoing economic and operational challenges, there are clear signs of progress and opportunity that point to an encouraging and positive year ahead. In Wipfli’s view, the outlook for 2026 includes strong areas of growth and innovation that position mold manufacturers for long-term success.

When asked, “What is Wipfli most optimistic about when it comes to mold manufacturing in 2026?,” Devereux responded, “Trade and tariff policies are expected to remain favorable for American mold builders in 2026, and with the passage of the One Big Beautiful Bill (OBBB) in July 2025, will encourage investment in US manufacturing. This landmark legislation reversed the prior punitive treatment of research expenditures, allowing companies to deduct domestic research and development (R&D) costs immediately – rather than amortize them over five years. Companies also can catch up their unamortized R&D expenses, hopefully freeing up cash flow for operations.”

Additionally, Devereux continued, “OBBB reinstated 100% bonus depreciation and significantly expanded Section 179 expensing limits. The bill also introduced incentives for new factory construction, providing mold builders with enhanced opportunities to invest in modern infrastructure and technology. These provisions collectively strengthen cash flow, reduce tax burdens and support strategic growth for US-based tooling operations.”

As 2026 approaches, a key area to explore is the supplierand service-focused side of the molding industry. Tony Demakis, president of Alliance Specialties and Laser Sales in Wauconda, Illinois, a company specializing in complete mold finishing and maintenance solutions, offers his insights and perspective on the future of the economy, the supply chain and more. A strong advocate for American manufacturing, Demakis has played an active role in Washington, pushing mold manufacturing into the spotlight to promote policy reforms that protect and strengthen the industry.

Demakis said, “My experience has shown me that it is incredibly difficult to try and forecast these sorts of things

because nothing is ever guaranteed and certain. That being said, I am optimistic about the future for both work and workers. More and more people are taking renewed interest in the manufacturing and service sectors of business, and with technology continuing to improve rapidly, the barriers to entry are significantly reduced. Companies like Westminster Tool are proving that you can hire for character and train for skill and be incredibly successful.” He shared that the industry’s outlook is positive – with continued growth and opportunities expected. While some companies may close or be acquired by private equity firms, those that “weather the storm, stick to who they are and focus on what they do best” likely are to continue succeeding.

Recent disruptions have tested the adaptability of companies across the molding industry, highlighting both vulnerabilities and opportunities for improvement. “They are just disruptions;” said Demakis, “they are not dead ends. What I mean is that there always is a way. When COVID-19 hit, some companies got scared, closed up shop and disappeared. Other companies took advantage of the opportunities that came from the disruption and adapted, evolved and grew into better versions of themselves. There always will be external forces that create challenges, but they don’t get to define how we do business. At Alliance, we looked at the challenges we have faced – shipping delays, price volatility and supply chain issues – and reinvested to ensure we have the proper inventory to meet the demands of our customers.”

Alliance adjusted its business operations, not out of fear, but to address any future concerns its customers might have. “We wanted to ensure that we could meet and, in most cases, exceed the needs of our customers and be able to come through for them. Our strategy is to make sure we have what we need for a good year. Don’t wait and see; be aggressive, trusting that we will have the year we are gearing up for, so we can continue to serve based on the reputation we have developed,” said Demakis.

To turn lessons into results, manufacturers need practical approaches to prepare for and manage these challenges. Demakis explained that leaders and management need to know their teams and companies to their core. Then, they can take actions and steps that are right for the operations, employees and customers – there is no one-size-fits-all solution. Depending on the company, some will advise caution while others will say, “Go all in!” Demakis said, “I can tell you that we are not making decisions based on external factors that are out of our control. Instead, we are bringing the best, most prepared version of ourselves to be bold and aggressive in 2026 and beyond.”

with nothing determined – it can be shaped into what manufacturers choose to make of it.

Looking ahead, Alliance is bringing a team ready to meet the challenges and opportunities in 2026. “We have dealt with the struggles and hardships of the last few years,” said Demakis, “and in each of those years, we have rallied as a team to not just maintain but have continued to grow, both personally and professionally.” Demakis gave four areas of optimism for 2026:

1. Customers are quoting more than ever before.

2. Industry peers share being so busy that they need additional support to get the work done.

3. Orders are being placed for 2026, showing an interest in manufacturing – and from the next generation coming into the industry.

4. The industry is an open playing field, with nothing determined – it can be shaped into what manufacturers choose to make of it.

With 2026 on the horizon, the pace of innovation and shifting market demands likely are to reshape what’s next for mold manufacturing. Thomas said, “While we are seeing an increase in quoting, higher costs across the board may mean less willingness and ability to invest in replacement or capacity tooling. The consolidation of the moldmaking industry (consumed by larger companies and private equity groups) continues to play a positive role in our growth and sustainability.” As Westminster navigates an evolving marketplace, the economic climate inevitably impacts its strategy and decision making. “We are proceeding with caution,” said Thomas. While Westminster’s pipeline The

Paul Patrash CEO Elite

One key perspective to consider as manufacturers look ahead to 2026 is that of mold builders. They understand what drives the industry forward, as well as the challenges and opportunities. To provide a look at “inside the shop” and the future of the industry, Hillary Thomas, vice president and strategic leader at Westminster Tool, shared her insights. Located in Plainfield, Connecticut, Westminster Tool is an injection moldmaker that specializes in complex plastic and composite parts.

remains strong and skilled moldmakers are in high demand, it recognizes that changes in factors such as interest rates or tariffs quickly could affect its 2026 sales.

Also, it was noted that overall company costs – including salaries, insurance and materials – are expected to rise over the next few months into 2026. Thomas shared, “We are being strategic about who and what we sell to cover the rising costs and remain competitive as an employer and a mold builder. We will continue to invest in technology that increases our capabilities and productivity, and build on our culture, which has attracted the best talent in the area.”

Facing these pressures, Westminster must both adapt and be ready to capitalize on new opportunities. “Staying true to what we have done for years,” said Thomas, “we are focused on diversifying our business through industries (medical, defense and industrial), services (Class 101 molds, mold components and low-volume contract machining and molding), locations (US and worldwide) and company level (OEM and contract manufacturers). While offsetting increasing costs, we are prioritizing profitable work by aligning with customers who value our capabilities and provide repeat business. As mold shops continue to be consumed by larger OEMS and private equity firms, our advantage as a small shop strengthens.”

As Westminster positions itself for the future, Thomas said, “For Westminster Tool, I am excited to see the investments we made in 2025 start to flourish. We brought on 10 new employees and four new key accounts. This next year is our chance to settle into growth and drive performance improvements.”

As the new year approaches, insights from three key perspectives across the mold manufacturing landscape –supplier, mold builder and advisor – offer a well-rounded view of the opportunities and challenges that await in 2026. Suppliers provide valuable guidance on material advancements and market trends. At the same time, mold builders stay focused on operational efficiency and customer demands.

In bringing these perspectives together, an industry advisor helps to connect the dots, offering strategic direction to navigate a changing landscape. Together, these insights help shape a clear and informed path forward for the year ahead in mold manufacturing.

More information: www.wipfli.com, www.alliancelasersales.com and www.westminstertool.com

By Liz Stevens, writer, The American Mold Builder

3D metal printing, a form of additive manufacturing (AM), has earned a reputation among mold builders for the complex conformal cooling channels that it can produce. Better cooling in molds yields faster cycle times and higher part quality. But beyond this increasingly common use, the technology is an affordable option for producing other mold insert parts, to speed up production, and for producing tools and fixtures. And mold builders find that having AM in the shop is attractive to young job applicants.

Steve Michon, owner of Zero Tolerance, LLC, Clinton Township, Michigan, is giving 3D metal printing a workout in his shop. Zero Tolerance offers plastics injection mold design, development and manufacturing for medical applications, complex aerospace applications, consumer products and military technical devices. The company is at the forefront of technology, using 5-axis machining as well as wire and sinker EDM. Its latest addition is an XM200G 3D metal printer from Xact Metal.

Xact Metal, State College, Pennsylvania, produces metal powderbed fusion 3D printers – including the XM200G family of printers – which use a laser to melt consecutive layers on a metal powder-bed. The finished parts can incorporate complex internal and external geometries. The company’s senior sales manager, Scott Kraemer, has a mold design and mold building background. He has known Zero Tolerance’s Steve Michon for years through common experience in molding building, mutual contacts and AMBA membership.

Photos on page 12 from top to bottom:

A set of parts, as first machined and cut open to reveal the inside. Photo courtesy of Xact Metal.

A set of parts, as printed. Photo courtesy of Xact Metal.

A mold core insert printed with Corrax stainless material, with support pillars shown at the bottom. Photo courtesy of Zero Tolerance.

Kraemer is collaborating with Michon to gain customer feedback and brainstorm mold building ideas. The pair recently presented a case study on 3D metal printing to the AMBA Emerging Leaders group. The American Mold Builder talked with them for insight into how mold builders can use this technology beyond its ‘no-brainer’ conformal cooling applications.

“Kraemer and I have connected over the years to explore new tooling, design and technologies,” said Michon. “Our latest partnership is about 3D printing – for conformal cooling, yes, but also for other parts which couldn’t be done in a traditional manufacturing style.” Kraemer sees Zero Tolerance as a great customer with whom to work. “In looking for a mold shop to help support the growing demand for printing mold inserts,” said Kraemer, “we wanted an owner who was open to adopting new technologies. Michon always has been progressive about new ways of getting things done.”

Their collaboration aids the greater mold building industry as well. “People take Michon’s vision and mindset seriously,” said Kraemer. “They see what he does to help educate the industry, and that he takes risks that not everyone is willing to take. Michon is incorporating additive manufacturing into his shop’s workflow and his success shows the industry that there are affordable 3D metal printing solutions that can deliver results from the day a new printer hits the shop floor.”

Michon has found many uses for 3D metal printing in his shop’s workflow. “For one job, I 3D-printed the rough inserts and the customer machined them afterward to fit into its tooling,” said Michon. “There are many things that can be made with 3D-printing that would be too expensive to machine.” Zero Tolerance also uses 3D metal printing for hand loads, tools, inserts, slides, lifters and even small cavity core blocks.

“Is this technology a panacea? No, not yet,” said Michon. “Is there a fit for it? Yes. It must be the right solution for

the right application. It’s like comparing an EDM machine to a mill; they are two different operations. 3D printing is another tool that allows us to do things that we would not or could not normally do, like making little fixtures that aren’t a big deal, but that add up as you use them. I’m always looking to find where this could work, where it makes sense to use it.”

Kraemer recalled an Xact Metal customer who spent 12 hours at his traditional machines to get a part machined to a satisfactory point, whereas by using AM, the job could have been done almost entirely through unattended processing. Kraemer also cited a customer who used AM in an innovative way. “This customer produces pistons,” he said. “They use 3D metal printing not for directly producing the pistons but, instead, for creating custom cutting tools needed for producing the pistons. That is a great example of using 3D printing differently than what moldmakers might expect.”

Kraemer noted that 3D printing can be used for replacing broken brackets on machinery, for holders, for mesh-type prints and for filters.

Kraemer is practical about where 3D printing fits into the big picture. “We promote 3D printing realistically,” he said. “We don’t promise the moon; we market a workhorse printer that can be used to make mold inserts or anything that fits within our build envelope. The industry needs an affordable solution in metal additive, and we offer that.”

The Xact Metal solution includes material options, such as alternatives to maraging steel, which has limitations as a material. “We partnered with Uddeholm,” said Kraemer, “to offer corrosion-resistant Corrax – which some mold shops use in plate form. We also have partnered with Sandvik to offer MAR55, which bridges the gap between H13 and maraging steel.”

At Zero Tolerance, Michon has found that working with 3D metal printing can be exciting, challenging or frustrating, depending upon its suitability for a job. Michon described one of the most exciting aspects. “It is incredible that it can make a watertight steel-printed insert,” he said. “It is made in layers, but no water comes through it. That is mind-blowing.” Michon also is enthused about 3D printing ceramics. “Ceramics can be useful for making prototypes affordably and quickly,” he said. “For a customer that needs only 100 injection-molded parts, we could print the cavity cores in ceramic and make the parts without destroying the cores. They can’t hold up like steel or aluminum, but ceramics provide a short-term prototyping solution.”

Michon described a challenging 3D metal printing job that nonetheless had a good outcome. “We had a mold with a cam-shaped arc,” said Michon. “We 3D-printed an insert for a curved shape – this whole tool turned with a cam action. Even after engineering changes that were laser-welded and re-machined, the insert proved to be amazing. There was more movement than normal but as it was machined, heat treated and processed further, it still worked well. That was definitely a success.”

In some cases, 3D printing is just a no-go. “For printing a whole cavity or core,” Michon said, “3D printing would be very time consuming. It is cost prohibitive unless it is needed for a small or complicated job. We find it best to use the conventional way to do most of the simple structure and use 3D printing for the complex sections.”

Michon and Kraemer see 3D printing as attractive to the workforce. “Nowadays, almost every student has done 3D printing,” said Kraemer, “and it is a good avenue for bringing more young adults into the manufacturing space.” At his shop, Michon has veteran workers as well as newbies on board. “3D printing won’t single-handedly fill the

workforce gap,” he said, “but if we use new technologies for making fixtures, etc., that’s useful.” He knows that he will lose his aging expert workers and is teaching new hires how to get the best-suited jobs done with AM methods. “The younger workers don’t see any limitations to this technology like we older guys may see,” said Michon. “I know what I can do with the traditional methods, but the young workers think that 3D is traditional. They don’t see limitations, and they are willing to try more things than an old-school tool maker would be willing to try.”

Michon is not moving away from traditional mold building techniques to exclusively teach 3D printing. “It still is important to teach the fundamentals so that the new workers understand how the technology evolved to this point,” said Michon. “They need to understand the traditional methods to appreciate the capabilities and limitations of additive manufacturing.”

Asked if Zero Tolerance was using 3D printing to its fullest potential, Michon replied, “Probably not. These are AM tools that we get comfortable using in a certain way and we may not learn about time-saving new features. The tools and software are getting better, faster than ever.” It requires time and continuous education to stay on top of the technological changes. “But we can’t afford not to explore,” said Michon, “because it could make or break a job.”

More mold builders are exploring and adopting new technologies. According to Kraemer, 3D metal printing is gaining traction among mold builders. “In 2024,” said Kraemer, “35% of our sales were to the molding industry; this year, they are projected to be about the same. We are having more discussions – weekly – with AMBA member mold shops, molders and OEMs on how they can adopt 3D metal printing for tooling. The interest is definitely growing.”

3D metal printing for mold builders is proven for conformal cooling. That, however, is just the most well-known application for this method of additive manufacturing. More mold builders likely will join Steve Michon and Zero Tolerance in exploring how this technology can be put to work in the shop – for inserts, fixtures, machine tools, slides, lifters, small-cavity core blocks and more.

More information: www.xactmetal.com and www.zerotolerancecnc.com

EMUGE-FRANKEN USA, West Boylston, Massachusetts, a manufacturer of high-performance end mills, taps, thread mills, drills and other rotary tools, has introduced EMUGE EvoGrip, a modular workholding solution that includes its first standard highperformance centering vise system. Designed to deliver maximum clamping force and full five-axis access in a compact solution set-up, EvoGrip is ideal for aggressive milling operations. Three basic vise widths include 70 mm, 100 mm and 120 mm, and EvoGrip offers 25 kN, 50 kN and an exceptionally high 75 kN clamping force. For more information, visit www.emuge-franken-group.com

Progressive Components, Wauconda, Illinois, a provider of solutions for tooling performance, with product lines consisting of standard and proprietary mold components, has released ProFile® v5, the latest evolution in cloud-based asset tracking and management software for the production tooling industry. ProFile v5 integrates asset management, real-time data analytics and comprehensive key performance indicator (KPI) reporting from Progressive’s suite of monitoring products. It can be used as a basic tracking system to organize and locate tools and equipment globally, or as a robust solution paired with Progressive’s CVe Monitor RT and ProFile v5 for complete real-time monitoring. For more information, visit www.ProFile-System.com.

HASCO, Fletcher, North Carolina, a full-service provider for tool and moldmaking, has launched marking stamps Z48600/… - Z48645/... The stamps are noted for their precise latching and accurate axial height control during arrow insert adjustment, thereby ensuring consistent component quality throughout the production process. The recessed engraving of the marking stamps guarantees a clean and precise reproduction of the injection-molded parts, thereby ensuring good readability and resistance of the labeling. For more information, visit www.hasco.com

Seco Tool, a Reynoldsville, Pennsylvania–based cutting tools solutions company, has launched the .38 Finishing Face Mill system, a selection of cutters engineered for high-precision surface finishing. The .38 Finishing Face Mill (SNFX1204) system offers three cutter variants – fixed pocket (R220.38-….-SN-..SA), hybrid (R220.38-….-SN-..CSA) and adjustable (R220.38-….-SN-..HSA), each tailored to different levels of control and performance. For more information, visit www.secotools.com.

Oerlikon HRSflow, San Polo Di Piave, Veneto, Italy, a manufacturer of hot runners, has unveiled its patented STARgate HRS® hot runner technology, featuring a completely redesigned gate unit. This technology uses a diaphragm-like element in the gate plane to manage melt flow into the cavity. Because its diaphragmatic concept delivers optimal cooling performance, STARgate HRS offers reduced cycle-time, resulting in higher productivity. Its design eliminates the need for actuator installation space, which typically is located axially above the needles in conventional systems, allowing for thinner back plates. Additionally, the pinless configuration allows for smaller nozzle diameters and reduced mold-pocket sizes, making the STARgate HRS a compact solution. For further information, visit www.hrsflow.com

Siemens, with headquarters in Washington D.C., is a provider of distributed energy systems, automation and digitalization for manufacturing. The company has introduced the SINUMERIK 828 CNC with new hardware and a digital twin to enhance flexibility, sustainability and cybersecurity. The SINUMERIK 828D is designed for the compact and mid-range machine tool market. Its Panel Processing Units (PPU), including PPU271.5, PPU270.5, PPU290.5 and PPU272.5, and the redesigned Machine Control Panel (MCP) operating concept offer a wide range of functions and options that increase the productivity, sustainability and efficiency of manufacturing processes. For more information, visit www.usa.siemens.com.

• MOLD FINISHING

• LASER WELDING

• LASER ENGRAVING

• HOT RUNNER REPAIR

• MOLD MAINTENANCE

• LASER MACHINE SALES

er mold finishing, laser welding, laser graving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom.

Let Alliance make a di erence for you.

EVERY PART OF THIS MACHINE IS EASILY ADJUSTABLE TO ALLOW YOU THE VERSATILITY AND FLEXIBILITY YOU NEED TO MEET ALL OF YOUR DEMANDS.

CONTACT US TODAY ABOUT AN IN-HOUSE DEMO, TO SEE THE ALLIANCE DIFFERENCE

By Andrew Carlsgaard, benchmarking and analytics director, AMBA

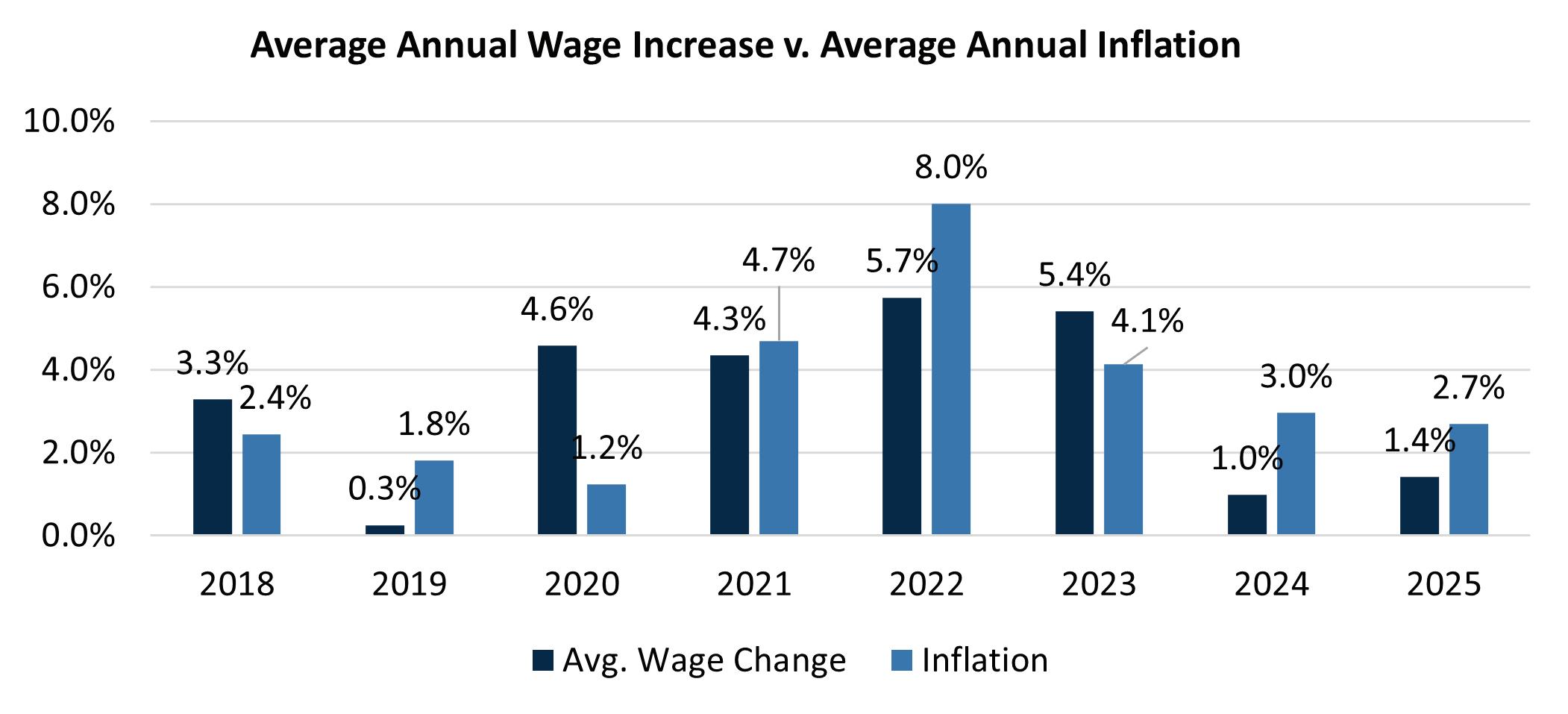

The 2025 AMBA Wage & Salary Report continues to show a familiar trend that mirrors last year’s results: rising wages and salaries across the US mold building workforce, albeit at a slower pace than inflation and the US manufacturing industry. The survey results of 88 mold builders, representing nearly 3,500 employees, once again indicate an upward wage trend, as 37 of the 53 industry job categories (70%) tracked year-over-year have reported increases from 2024 to 2025. These lower wage increases (an average of 1.4% wage growth from 2024 to 2025 across all positions) compared to some past years primarily are due to lower demand and competition for workers in 2025.

The elevated demand for manufacturing workers from 2020 to 2022 has declined since 2023 and continued into 2025. The US Bureau of Labor Statistics 1 reported that workforce participation and unemployment gradually have rebounded to pre-pandemic levels over the past few years. Low unemployment, plentiful job openings and lower participation rates have continued to create a favorable labor market for workers in the early post-pandemic years. However, progressively lower inflation and heightened economic uncertainty (and higher unemployment) in 2024 and 2025 have slowed this trend compared to the early post-pandemic era.

The 2025 report highlights significant changes in various roles across the US mold manufacturing industry. The average year-over-year increase for the 37 positions that saw growth was approximately 3.5%, down from 5.3% in the 2024 report. The remaining 16 positions had salaries that decreased or stayed the same, averaging about 4.0% lower in 2025 (compared to a 6.2% decrease in 2024). Notably, the largest salary increases were for customer service representatives (16.5%), gun drill operators (15.6%) and delivery drivers (9.3%). Conversely, the most significant median wage declines were seen in CEOs (9.9%), sales directors and managers (7.2%) and general machinists (7.1%). Given the top two declines, this data may suggest a reduced demand – and thus lower salaries – for some positions that contribute more to a mold builder’s overhead, such as leadership or back-office roles.

Average yearly wage increases for all tracked positions from 2024 to 2025 generally have risen, and for the second consecutive year, inflation likely is to account for most or all of this growth. The consumer price index – the main measure used by the US Bureau of Labor Statistics 1 to track year-over-year price inflation – surged in early 2021 and peaked in June 2022 at around 9.1%. However, the rate dropped to a three-year low of 3.0% in June 2023 and has stayed within the upper 2% to low 3% range over the past two years. To provide context, this still is higher compared to the pre-pandemic average rate of 1.8% in 2019. The average inflation rate for 2025 (through September) is 2.7%, while the average wage growth for all tracked positions in the 2025 Wage and Salary Report was only 1.4% – a third of that rate. That wage increase percentage is four points lower than two years ago (5.4% in 2023), but slightly higher than the previous year (1.0% in 2024) (Chart 1).

Additionally, this wage increase is lower than the wage increase data tracked by the US Federal Reserve 2, which reports yearly wage increases of 4.2% for US manufacturing jobs and 4.4% overall for US jobs as of August 2025. With these lower-than-expected year-over-year wage increases, mold builders report weaker hiring demand than just two years ago. In the 2022 AMBA Wage and Salary Report, 86% of mold builders said they would hire new employees over the next 12 months; however, this number dropped to 78% in 2023. It since has recovered and now stands at 84% as of the publication of the 2025 report (though 7% still are not hiring, compared to only 1% in 2022). This fluctuation in labor demand within the industry likely is caused by both economic uncertainty and the US government’s efforts to curb inflation by reducing consumer spending.

Additionally, results from the 2025 AMBA Business Forecast Report showed that increased overhead expenses, combined with lower sales figures, were among the mold builders’ most significant challenges in 2024, which impacted profitability and may have prevented lower hiring levels in the future.

the 2025 report are not surprising, considering the current economic conditions (and tariff policies), the domestic mold building industry and inflationary pressures. For manufacturing companies facing external pressures on their profits, such as higher energy and raw material costs, slower hiring of new or replacement roles than in recent years, maintaining steady employment levels or pausing pay increases might be necessary to sustain profitability and avoid layoffs in the near future. Unless economic conditions improve for workers, some decrease in wage growth likely is to continue.

Additionally, as noted in the previous report, lower inflation has been critical in preventing the upward trend in annual wages that has been common since 2020. Similarly, the labor market might keep shifting more in favor of employers as unemployment rises, and mold builders will need to adapt to the current market if it aligns with their business needs.

More information: www.amba.org/publications

While the survey results may favor employers’ financial outlooks somewhat, the wage and salary increases noted in

References

1. US Bureau of Labor Statistics

2. Federal Reserve Bank of Atlanta

May 12-14 | Grand Rapids, Michigan

The AMBA Conference 2026 – “Ideas Ignite” – is designed for US mold builders and industry suppliers looking to drive business growth, build executive connections and exchange insights with peers. For more information, visit www.ambaconference.com

• Wage and Salary Report Available for Purchase | Member Price: $399 / Non-Member Price: $899

• Industry Outlook Webinar | December 17, noon-2 p.m. (EST) | www.amba.org/events

• Business Forecast Survey | Deadline: January 23, 2026

• 2026 State of Indusrty Webinar | February 24, noon-1 p.m. (EST) | www.amba.org/events

AMBA unveils two new programs that offer members discounts on products and services in the office supply and IT arenas:

• Staples, a US-based office supply chain, offers significant discounts and rebates on products and services in categories such as technology, office supplies, print services, furniture, breakroom and more. Webinar: December 2, 1-2 p.m. (EST)

• CDW, a leading multi-brand provider of IT solutions for businesses, offers discounts on a wide range of products and project-based discounts, including infrastructure solutions, AI, training, security and more. Webinar: December 9, 1-2 p.m. (EST)

For more information, visit www.amba.org/membership/ cost-reduction-programs/ or register for upcoming webinars at wwww.amba.org/events

Don’t miss the opportunity to take advantage of new Grainger discounts in areas such as sealants and adhesives, as well as deeper discounts on frequently purchased products in the categories of safety, pneumatics and more! The expanded categories are designed to cover unplanned spot buys while enabling the consolidation and standardization of planned purchases. For more information, visit www.amba.org

Steve Michon is the founder of Zero Tolerance LLC, a plastic injection mold machine shop in Clinton Township, Michigan. Driven by a lifelong passion for innovation and

precision, he has built the company into a leader in the production mold industry over nearly 13 years. Michon leads a team focused on customer service and excellence, leveraging advanced software, machinery and tooling to deliver high-quality results. His career is defined by problemsolving, innovation and commitment to precision, ensuring that Zero Tolerance remains at the forefront of manufacturing technology.

Jeff Ford is vice president and minority owner of the BICO group of companies, including BICO Steel, Integrity Fab & Machine and BICO Metal Finishing, based in Grand Rapids, Michigan. Since 2017, he has led sales and marketing, bringing over seven years of executive leadership experience. Previously, he served as sales and marketing manager and as an outside sales representative at BICO Steel. Ford played a key role in the sale of BICO in 2018 and in the subsequent acquisitions of Integrity Fabrication & Machine (2022), RE Metal Finishing (2023) and Pioneer Steel/Die Sets (2025). He holds a Bachelor of Business Administration in marketing from Grand Valley State University.

Scott Kraemer brings a 35-year career in injection molding, tooling and product development across medical, automotive and consumer industries. Over the past 14 years, he has pioneered the integration of additive manufacturing for plastics and metal into mainstream production and tooling. Passionate about workforce development, Kraemer created the PTI Technical Academy program in Michigan, giving high school students hands-on training and exposure to careers in plastic injection molding. As of 2023, he works with Xact Metal to advance the adoption of metal 3D printing in production and tooling.

Todd Steging is general manager at Prestige Mold, Inc. in Rancho Cucamonga, California. He holds a BS and an MBA in business administration from Chico State. With over 20 years of leadership experience in aerospace, defense, automotive and medical device manufacturing, Steging specializes in technical processes, Nadcap and MedAccred accreditation, and quality system certifications. He has helped small- to mid-sized, minority- and women-owned

businesses achieve ISO/AS certifications and OEM approvals, including designing the quality system for PresTek Plastics. At Prestige Mold and Pres-Tek, he oversees operations, finance, HR, business development and strategic planning, with a focus on mentoring leaders, developing teams and improving processes.

Custom Molding Solutions

456 Sanford Rd. North Churchville, New York 14428

Main POC: Tanner Smith, plant operations

Email: tanner@custommoldingsolutions.com

Phone: 585.293.1702

AMBA members wrapped up the year with the 2025 United Tool and Mold Golf Outing in support of the iWarriors organization. Similar events also were hosted by M.R. Mold & Engineering and by Alliance Specialties and Laser Sales earlier in the year. All together, these community-led efforts included 300 plus golfers, featured 110 plus sponsors and raised over $78,000 to iWarriors, all of which will help the organization assist severely injured members of all branches of the Armed Forces. For more information, visit www.iwarriors.org

Dun-Rite Machine

4526 Adams St.

Zeeland, Michigan 49464

Main POC: Mitch Zuvernik, manager

Email: mitchz@dunritemachine.net

Phone: 616.688.5266

Dun-Rite Machine, founded in 1984 in Zeeland, Michigan, is a family-owned business now in its second generation. Dun-Rite specializes in custom plastic injection molds (press size: 30-300 ton), precision machining and laser welding – delivering high-quality work, on-time completion and a culture rooted in integrity and teamwork.

Mold

23155 15 Mile Rd.

Clinton Township, Michigan 48035

Main POC: Nick Mora, shop foreman

Email: nmora@eclipsemold.com

Phone: 586.709.9539

Since its incorporation in 1977, Eclipse Mold, Inc., has focused on investing in new technologies, the latest manufacturing techniques and expanded offerings to bring greater efficiencies to its worldwide customer base. From its cutting-edge facility, the experienced Eclipse team provides high-quality, high-precision molds, in-house prototyping and quick turnarounds, creating profitability for its customers.

Custom Molding Solutions specializes in engineered resins, over molding, insert molding and assembly. The company’s injection molding machines range from 33 to 610 tons, which are supported by its full-service toolroom. Purposely designed to minimize downtime between repair, maintenance and engineering changes – from concept to production – CMS does it all under one roof.

1235 Wall St. Ironwood, Michigan 49938

Main POC: Jake Zielinski, lead moldmaker

Email: jake.zielinski@ironwood.com

Phone: 906.932.7535

Ironwood Plastics specializes in producing precision injection-molded components for the defense, transportation, industrial and medical industries. Since 1979, high-tolerance components have been developed for complex, mission-critical programs. Ironwood proudly provides in-house tooling capabilities to support both quickturn and production solutions. The company utilizes RJG scientific decoupled molding technologies to establish a stable and repeatable process.

Unique Tool

15652 200th St. Hutchinson, Minnesota 55350

Main POC: Cody Lodes, president

Email: cody.lodes@uniquetoolllc.com

Phone: 320.587.5920

Unique Tool is a trusted Midwest-based precision mold builder with over 35 years of experience. Unique Tool specializes in injection mold tools for the medical, commercial, defense and electrical interconnector industries, and offers comprehensive services from concept design to complete build. The company’s advanced machining capabilities, including multi-axis CNC milling, CNC turning and EDM machining, enable its team to deliver high-quality, complex parts and tooling solutions.

MD&M brings together the entire manufacturing network in one location, offering access to innovation across five key industry sectors: MedTech, automation, design and manufacturing, plastics and packaging. Connect with leading companies in 3D printing, injection molding, coatings, furnishing and more as they showcase the newest in biocompatible polymers and injection molding technologies.

MD&M West will take place February 3-5, 2026, at the Anaheim Convention Center in Anaheim, California.

The event is expected to feature over 1,700 exhibitors presenting the latest innovations, along with more than 100 educational sessions offered through co-located conferences, workshops and theater presentations.

For attendees – whether developing next-generation medical devices, optimizing production efficiency or seeking sustainable manufacturing solutions – this event will provide access to the connections, insights, knowledge and expertise needed to advance projects and applications.

“To anyone who has never been, you need to take advantage and come. It’s an opportunity to see new things, meet people and interact with your fellow customers and competitors. It’s an opportunity to see the whole industry all at once,” said Octavia Banner, category manager, Cook Medical.

MD&M gives attendees the opportunity to attend and explore a single event that covers every aspect of the manufacturing process.

1. MedTech – Elite Medtech companies showcase innovations in cardiovascular care, medical device manufacturing, general healthcare and more.

2. Automation – The newest technology in robotics, sensors, motion control and automated systems to boost efficiency and meet demand for everyday goods domestically and beyond.

3. Design and Manufacturing – Connect with leading designers and engineers who are bringing advanced concepts to life through innovations in 3D printing, CAD/CAM software and testing equipment.

4. Plastics – Connect with top companies in 3D printing, injection molding, coatings, furnishing and more as they showcase the latest biocompatible polymers and injection molding innovations.

5. Packaging – From form-fill-seal systems to labeling, barcoding and protective materials, this is the place to meet suppliers, compare technologies and solve packaging challenges head-on. n

For more information on MD&M West and to find AMBA-member exhibitors, visit www.mdmwest.com.

The YCM Alliance brings together the very best machine tools, dealers, and solution experts to provide application-based systems designed to help grow your business.

• Die-Mold Solutions

• General Parts Machining

Milling

By Lindsey Munson, editor, The American Mold Builder

Mold builders’ customers face increasing pressure to optimize asset management – balancing uptime, traceability and compliance without overcomplicating processes or disrupting daily operations. Progressive Components, based in Wauconda, Illinois, is modernizing the mold industry through innovative, user-friendly solutions that streamline and advance operations under a simple, effective platform strategy. These new tools enable mold builders to provide their molders with an easier-tomanage asset.

In a recent webinar, “Simplify Asset Management Without Complicating Your Life,” Sujit Sheth, monitoring sales manager for Progressive, explored common challenges in mold asset oversight and shared practical digital strategies to simplify and strengthen asset management. His main message, “Simplifying,” does not mean cutting corners – it means redefining how companies treat their tooling assets. The American Mold Builder summarized the webinar, which offered insights into the obstacles companies face and how they can turn data into actionable strategies and expert solutions for creating a strong, streamlined asset management system.

For processors, the mold is one of their most complex assets, as it is highly costly to build or modify, has serious consequences if it underperforms or fails, and often has a long service life. Sheth said, “Molds are indisputably valuable assets. If those assets are not being maintained, one can’t expect that they’re going to consistently get the productivity of Day One two years down the road. Also, having the right amount of tooling is critical. No molder wants to have extra tooling, and yet no molder wants to be short on tooling – so understanding how much you have, what it’s producing, where it’s located and total capacity is important to running a business effectively.” For a mold builder, that means not only designing and building the mold, but also providing the ability to monitor lifecycle data, review maintenance tracking, view the mold’s location and access performance metrics needed by the molder and OEM.

An everyday reality is that many companies end up managing tooling assets with spreadsheets, logbooks or

fragmented ERP modules, leading to unseen gaps (i.e., unknown locations, undocumented PM work, hidden downtime and untracked tooling history) that become hidden costs. Sheth said, “You cannot manage what you cannot see, and the system makes it easy to track GPS locations, maintenance and documents efficiently from a single platform, from anywhere.” For mold builders, offering asset visibility as part of the tooling hand-off can differentiate by helping reduce downstream issues.

To help mold builders turn insight into action, Sheth outlined four pillars that form the foundation of a simplified tooling-management system:

1. Visibility and Centralized Data – Establish a comprehensive asset platform with location, serial number, maintenance history, cycle count, spare parts and condition information.

2. Strategic Prioritization – Not all molds are equal. Identify those critical to quality, uptime or customer programs, and focus resources where impact is highest (with preventive maintenance on high-risk tools, monitoring of high-cycle molds and tracking of molds that move between sites).

3. Standardized Process and Workflow – Define triggers, workflows and ownership. Clarify when preventative maintenance or replacement is due, who approves downtime and where documents are stored.

4. DataDriven Continuous Improvement – Once visibility and workflows are in place, companies can use data to benchmark and improve cycle counts, downtime, maintenance cost per tool, reject rates and more.

Understanding the pillars is essential, but it’s only the starting point. The real value comes from applying them inside the company. To help molders take action, Sheth said, “Start small and scale by testing the asset-tracking or mold-monitoring system on the top 10-20% of molds by value or risk. This allows companies to show early wins, refine deployment and build organizational buyin. Equally important is engaging internal stakeholders, including tooling, mold maintenance, production planning, procurement and IT.”

Technology should be accessible and easily integrated into companies, not an added complexity. While fully featured systems may be attractive, many companies can make significant progress with simpler tools like QR-code asset tags, cloud-based dashboards and mobile-enabled platforms. Sheth said, “It is important to include all tooling assets – not just the molds themselves. The ‘non-mold’ assets, such as auxiliaries, gauges, end-of-arm tooling and more, directly affect uptime and profitability. Including them in the same asset management framework provides a complete view of the total tooling cost of ownership.”

Finally, Sheth said, “It is key to link the asset-management system to the mold builder hand-off. When a mold is delivered to the molder or OEM, providing the asset tag, documentation, cycle-history baseline, and recommended maintenance schedule and service tasks not only adds value but also reduces downstream disputes and reinforces the partnership.”

For mold manufacturers, partnering with their customers to assist in their asset management doesn’t have to be complicated. Sheth’s approach proves that it can be modern,

1. Automate data collection to reduce manual effort and errors.

2. Centralize information so teams can access what is needed under one platform.

3. Trigger actions based on asset usage to be proactive.

4. Keep adoption easy so the “system” becomes part of daily operations.

actionable and, most importantly, simple enough to be sustainable for any company.

By assisting with these key tactics – starting small, engaging stakeholders, standardizing technology and including all assets to better integrate the mold hand-off – mold builders can help molders transform how they maximize their tooling investments. The result goes beyond efficiency; it delivers clarity, control and confidence across the entire supply chain.

More information: www.procomps.com/monitoring

Beanstalk Collaborative Community Wealth (BCCW), a mission-driven investment organization focused on preserving and growing US small manufacturing businesses, has announced that its subsidiary, DTE LLC, Bertha, Minnesota, has acquired the assets of Diamond Tool & Engineering, Inc. (DTE). DTE is recognized as a precision mold builder serving demanding industries, including medical devices, aerospace and consumer products. For more information, visit www.beanstalkccw.com.

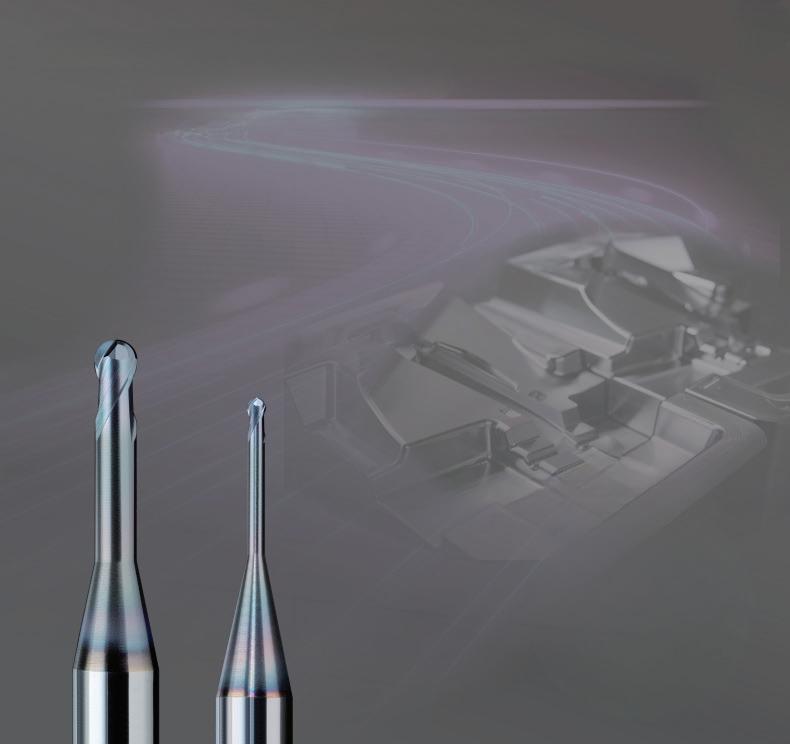

EMUGE-FRANKEN USA, West Boylston, Massachusetts, a manufacturer of high-performance end mills, taps, thread mills, drills, gauges, tool holders and now standard workholding, has donated EMUGE Made in the USA TOP-Cut VAR End Mills to Utah Tech University for its Modern Machining course. This reaffirms its commitment to help grow a skilled workforce in America. Multipurpose, high-performance TOP-Cut VAR end mills

are the industry’s most versatile variable helix carbide tool solution. Undergraduate engineering students can gain first-hand experience with high-performance, industry-leading cutting tools and apply best-practice machining techniques, thereby honing their critical thinking skills and preparing them for a career in the manufacturing industry. For more information, visit www.emuge-franken-group.com/us/en/.

The Plastics Industry Association (PLASTICS), Washington, D.C., has announced that “NEXT IS NOW” will serve as the official theme for NPE2027: The Plastics Show, the largest plastics tradeshow in the Americas. NPE2027 will be defined by its impact on business growth, innovation, sustainability and the perception of plastics. The “NEXT IS NOW” theme emphasizes adoption over aspiration, positioning the plastics industry as forwardthinking and actively shaping its future. For more information, visit www.npe.org

•

•

•

Slide Products, Wheeling, Illinois, a developer and producer of products for the plastics molding industry, has introduced Aaron Gibson as the new company president. Gibson’s legacy traces back to 1993, when Slide was just starting to expand, when he began his career as a part-time production line worker. Throughout the 30 years he’s been with the team, Gibson has had the opportunity to work in various positions. His professionalism and extensive industry knowledge make him a perfect leader to take Slide to the next phases of growth. For more information, visit www.slideproducts.com.

Triangle Tool LLC, Milwaukee, Wisconsin, a precision moldmaking and machining company, has announced the promotion of Bryce Ristow to operations manager. After two decades with Triangle Tool, Ristow will oversee dayto-day operations, while continuing to drive efficiency and process improvement throughout the organization. This transition reflects Triangle Tool’s long-standing commitment to developing talent from within. For more information, visit www.triangletoolllc.com.

At Plastic Engineering & Technical Services, we are.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs.

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance.

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

By Shelby Lasley, GPO director, AMBA

In the world of manufacturing, most companies can quickly identify their biggest cost drivers: labor, raw materials and energy. But tucked behind the scenes, in storerooms and tool cribs, lurks a category that often goes unnoticed until something breaks – maintenance, repair and operations (MRO) supplies. More than 40% of MRO purchases were unplanned – and overbudget.

For years, one AMBA member – a mid-sized mold manufacturer – had approached MRO the way many do: reactively. When equipment failed, someone ordered parts. When maintenance techs needed gloves, they grabbed what was available or sourced it locally. The purchasing team, focused on direct materials, rarely had time to chase down minor expenses like filters, bulbs or fasteners. Yet, by the end of the fiscal year, MRO expenses had quietly ballooned beyond budget, with little clarity on where the money had gone.

It wasn’t until the company’s operations director decided to explore the AMBA Grainger Program that things began to change.

What started as an interest in accessing some decent product discounts turned into a deeper conversation about procurement strategy. Through the program, the company gained immediate access to competitive pricing on thousands of items across Grainger’s extensive catalog. But the real value came from what followed: an invitation to rethink how the company managed its MRO approach.

Working with both the AMBA team and a dedicated Grainger account representative, the company began a full spend analysis. It discovered that the same items were being purchased under different names at different prices, depending on the location or buyer. A staggering number of SKUs had been added over the years with no real oversight. Worse, more than 40% of MRO purchases had been made on an unplanned basis – ordered overnight or rushed through at a premium when critical equipment failed. With guidance, the company created a plan to consolidate vendors, standardize common products and set up a system for planned purchasing. Inventory management tools like KeepStock® were introduced to automate restocking and

reduce downtime risk. Safety consultations helped ensure compliance while uncovering areas for additional savings through bulk purchasing and more efficient sourcing.

While cost savings were a clear benefit – category discounts ranged up to 30% depending on the item – the company quickly realized this wasn’t just about cheaper gloves or faster shipping. It was about visibility, control and data. Regular reports from Grainger began revealing patterns, including which departments were overspending, which products had cheaper alternatives and which items could be entirely eliminated.

The company’s procurement team went from firefighting to forecasting.

Now, MRO expenses are budgeted, tracked and reviewed quarterly. Unplanned purchases have dropped dramatically, and the plant manager no longer wastes time hunting down supplies. The company continues to leverage Grainger’s value-added services to support training, compliance and long-term operational goals.

Throughout the process, AMBA served as more than a passthrough to a discount. The association provided context, shared best practices from other members and helped troubleshoot implementation challenges. For companies just getting started, the AMBA team offers a simple onboarding process and a free spend analysis – helping members identify immediate opportunities to save and streamline.

For more information, email AMBA at info@amba.org to schedule a complimentary spend analysis.

Shelby Lasley is the GPO director for AMBA, providing members with strategic guidance and tailored support as they work towards improving their MRO strategy. Lasley joined the AMBA team after 13 years at Grainger, where he specialized in supply chain optimization and cost reduction. His deep industry knowledge and member-focused approach make him a key resource for companies looking to streamline procurement and drive operational efficiency.

By Susan Quinn, CEO, circle S studio

In today’s business landscape, competition is relentless. Disruptions emerge overnight. Customer expectations rapidly evolve. Talent is harder to retain than ever. Yet, some companies consistently outperform their peers –growing faster, attracting top talent and building unshakable customer loyalty.

What sets these companies apart?

An in-depth study was conducted with companies to identify the characteristics of top performers. The findings revealed a critical truth: high-performing companies aren’t just lucky. They operate with a set of core traits that drive sustained success. These organizations don’t merely aim to be “best in class” – they execute a repeatable, scalable and measurable strategy that fuels their growth.

What are these nine traits, and how can companies embed them into their DNA?

1

High-performing companies don’t drift. They operate with a clear purpose that drives their strategy, decisions and culture. Their guiding principles – vision, mission and core values –aren’t just corporate jargon. They’re actively demonstrated at every level of the organization.

What makes them different? Leaders continuously reinforce these principles in communication, hiring and decision making. Employees understand how their roles contribute to the company’s broader mission. This alignment creates a culture of accountability, engagement and trust – three factors that significantly impact performance.

2

Talent is the fuel that drives a business forward, and high-performing companies treat their employees like their most valuable assets. They don’t just offer jobs; they create environments where employees thrive.

These companies invest in professional development, employee well-being and company culture. They prioritize

engagement, conduct regular satisfaction surveys and actively act on feedback. As a result, employees become brand ambassadors, delivering superior service, innovating and staying loyal to their companies.

3

For high-performing companies, customer satisfaction isn’t enough – they aim to create customer advocates.

They analyze customer journeys, remove friction points and proactively seek feedback. More importantly, they act on that feedback, refining their offerings and personalizing experiences to create deep relationships.

Data from a global management consulting company shows that fluctuations in a company’s Net Promoter Score (NPS) can explain 20%-60% of its organic growth. This statistic alone highlights why top companies prioritize customer experiences – it directly impacts revenue.

High performers don’t just meet quality standards – they set them.

They integrate quality into every process, ensuring it’s not just a final checkpoint but a guiding principle from the start. This commitment to excellence builds trust and differentiates them from competitors.

Apple, for instance, isn’t just known for technology but for its meticulous attention to detail. High-performing companies operate with the same mindset – whether it’s in service delivery, internal processes or employee training.

4 5

Disruption is inevitable. The question is: Will a company adapt fast enough to stay ahead?

High-performing companies don’t resist change; they embrace it. They anticipate market shifts, monitor industry trends and pivot when necessary.

Research has shown that many companies failed during crises like the COVID-19 pandemic – not because they lacked resources but because they failed to adapt. Meanwhile, organizations that were agile in their strategies and executions thrived.

6

Top companies leverage data to make strategic decisions and track real-time key performance indicators (KPIs) through dashboard systems that are visually engaging. Through the utilization of AI and other software programs, they aggregate information across the enterprise for a holistic view and understanding of how all elements fit together. This ensures that leaders have access to clear information and actionable insights. More importantly, they align their data collection with business objectives, avoiding “data for data’s sake.”

7

The best companies don’t just monitor their competitors – they understand the full ecosystem in which they operate.

They recognize that value creation often requires collaboration. Whether through strategic partnerships, industry alliances or supplier relationships, they position themselves at the center of innovation and market shifts.

Complexity slows companies down. High performers know this and focus on making operations lean and efficient.

Steve Jobs famously said, “Simple can be harder than complex. You have to work hard to get your thinking clean to make it simple.”

Top companies take this to heart. They continuously refine workflows, eliminate unnecessary steps and automate where possible. The result? A more agile, cost-effective and scalable operation.

8 9 t

Perhaps the most defining trait of highperforming companies is their relentless pursuit of improvement.

They don’t assume they have all the answers – they continuously learn, evolve and refine their strategies. They

invest in leadership development, create knowledge-sharing platforms and encourage experimentation.

These organizations view failure as a stepping stone to progress, not a setback. This mindset allows them to stay ahead of industry changes and maintain a competitive edge.

If a leader wants to build a company that stands out, start by assessing where the company currently stands on these nine traits. Questions to ask include:

y Are the company’s purpose and values deeply embedded in everything it does?

y Does the company treat employees as its greatest asset?

y Is the company truly customer-centric or does it just say it is?

y Is quality a guiding principle in all areas of the business?

y How adaptable is the company to change?

y Does the company make decisions based on data or gut instinct?

y Does the company understand its industry ecosystem and leverage partnerships?

y Has the company eliminated unnecessary complexity in its operations?

y Does the company foster a culture of learning and continuous improvement?

Achieving high performance isn’t about making one major change – it’s about consistently refining these areas over time. The question isn’t whether these traits matter. The real question is: How quickly can an organization begin embedding them into its DNA?

Susan Quinn has worked for 30-plus years with Fortune 500 to middle market firms across the country, developing strategies that spur growth. As CEO of circle S studio, she supports companies in their quest to ‟better their best” and brings a keen understanding of how to create a winning strategy. Quinn is the author of “Does Your Business Show Up or Stand Out?,” a leader’s playbook for implementing the nine traits.

More information: www.circlesstudio.com/business-playbook

By Rachael Pfenninger, director of strategic execution, AMBA

Company culture was alive and well during the Dynamic Group’s plant tour workshop for AMBA’s emerging leadership and MAPP’s young professionals. Hosted in conjunction with MD&M Midwest, Minneapolis, Minnesota, this two-facility event highlighted how strong values, communication and next-level leadership can lead to a company environment where employees thrive personally and professionally.

Dynamic Group, a company with both molding and tool building capabilities, has a long history of strong partnerships. Founded by two friends and now run by their sons, the company has a reputation for its strong culture that continues to grow in notoriety today. This was evident from the first step into each facility as, during the tour, employees and guides spent as much time highlighting best practices related to new hire development, employee growth and department relationships as they did on machines, technology and processes.

From phrases like “Own the Zone,” where each employee is assigned an independent area to manage weekly, to “Code Orange,” where quality reps work alongside other departments to understand and rectify defects, tour representatives emphasized the role that accountability and shared priorities play in what gets accomplished on a daily and weekly basis.

Through reliance on management methodologies like Six Sigma (a quality management methodology that uses a data-driven approach) and the EOS framework (a practical set of tools for businesses to simplify operations, achieve clarity and drive accountability and execution), employees

demonstrated how they constantly seek to improve and evolve. Whether it was through elements like the company “UN-Profit” table, where mistakes are “celebrated” and reviewed for improvement, or its detailed, employee-driven continuous improvement initiative and prize wheel (a popular tool through which employees and departments can be rewarded), it was clear that every employee was willing and unafraid to fail if it meant progress and improvement.

“‛Going Pro’ means that we set the highest expectations for our workforce. But if we expect our employees to achieve the goals we set forth, we have to prepare them in a way that enables them to be successful,” explained Matt Walters, who specializes in technical sales for Dynamic Group.

“I believe I have something to learn from everyone. The journeyman toolmaker with 40 years’ experience and the high school apprentice both bring great ideas to the table if empowered.”

More than just a tour, this event highlighted the valuable roles up-and-coming leaders are capable of playing in the workforce today, particularly when provided with openminded leadership that encourages the exploration of new ideas, sound processes and the safety to fail.

AMBA will continue its partnership with MAPP on March 19-20, 2026, in Rosemont, Illinois, as industry leaders come together for both associations’ first co-hosted Leadership Retreat (in conjunction with PTXPO 2026). To learn more about this event and other leadership development opportunities with the AMBA, visit www.amba.org/events.

A look at custom mold components tailored to specific applications that improve efficiency, functionality and mold quality.

individual requirements, with intuitive user guidance. By simply entering the desired parameters, customers are guided step by step through the configuration process. During the design process, a configuration code is generated that can be called up again at any time. The result is a ready-to-use hose assembly.

DME Company, Harrison Township, Michigan, is a designer and supplier of standard and custom mold components, mold bases, hot runner systems and process controls designed for demanding industrial molding applications. DME also offers an extensive catalog of maintenance, repair and operations products and equipment for a wide range of applications. DME has supported the molding industry for over 80 years, providing reliable products and services to its global customer base.

DMS / Ermanno Balzi

519.737.6743

www.dmscomponents.com

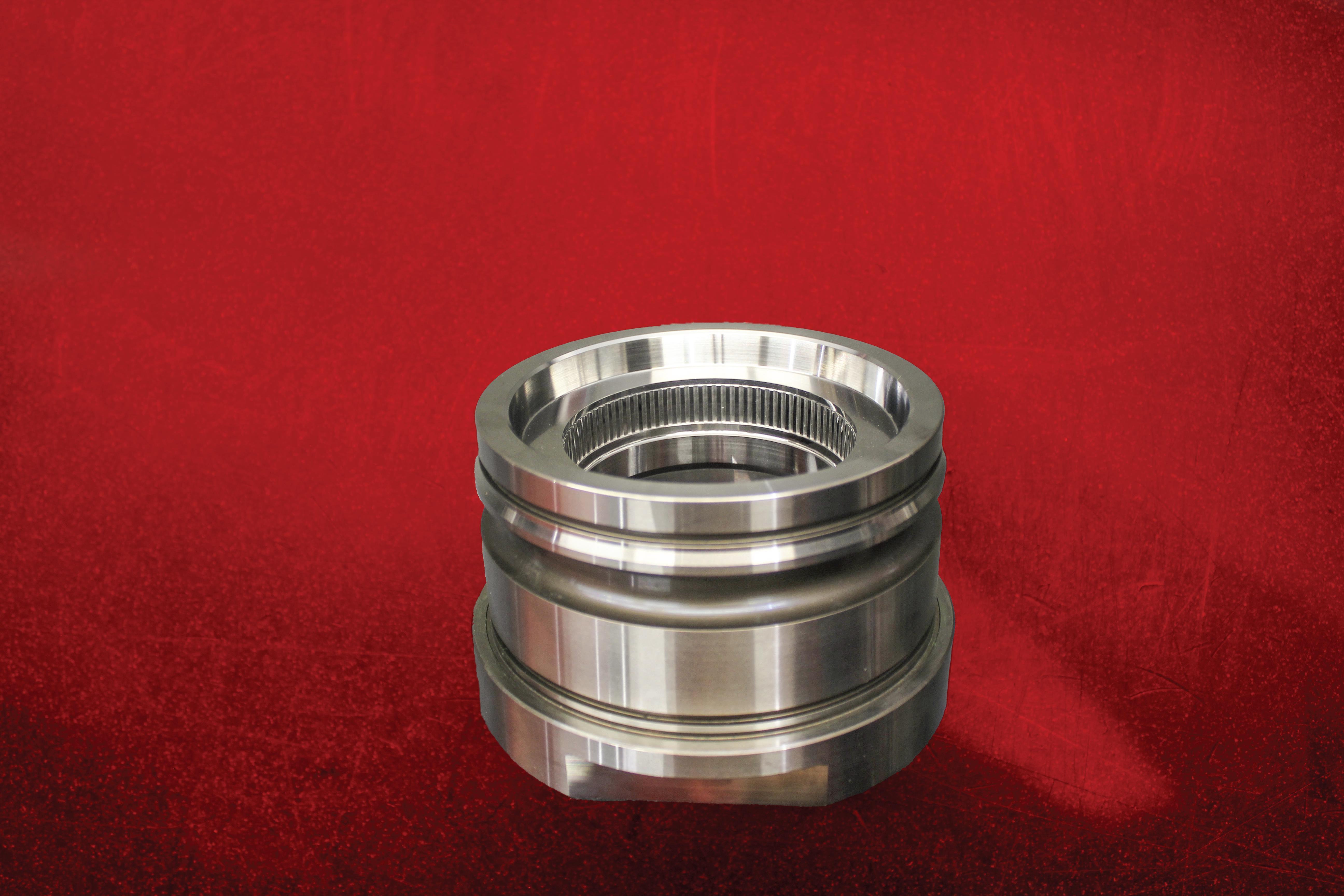

Ermanno Balzi, based in Italy, designs, manufactures and distributes components and accessories worldwide for the construction of molds for plastic material injection. DMS, Oldcastle, Ontario, is the North American distributor of Ermanno Balzi products. The MechIndex system is a mechanical device designed to perform rotary movements of plates within plastics injection molds. It is suitable for use in both multi-material molds and molds where it is advantageous to have multiple stations for insert placement or part extraction. The integrated helical guides convert the linear motion of the press ejector into a rotary movement of the plate by 90°, 120° or 180°, depending on the selected configuration.

Progressive Components 1.800.269.6653

www.procomps.com

828.650.2619 www.hasco.com

HASCO, Fletcher, North Carolina, a full-service provider for tool and moldmaking, has launched a new online hose configurator. The hose configurator is a web-based tool that enables customers to create custom hose lines according to

Progressive Components, Wauconda, Illinois, offers advanced solutions for tooling performance, including product lines of standard and proprietary mold components, mold monitoring devices and software, and innovations to improve mold maintenance. Progressive has introduced a Mold Safety Strap that offers safe, assured securing of parting lines during mold transport and storage. The Safety Straps feature an engineered break point to prevent the shearing of bolts. Available in three-inch and metric sizes, each powder coated in OSHA Yellow, assigned a safety factor of two and compatible with previous standards: SAFT-88 / SAFTM-22 = 7/8" bolt centers, SAFT-150 / SAFTM-38 = 1-1/2" bolt centers and SAFT-200 / SAFTM-50 = 2" bolt centers.

PUNCH INDUSTRY USA, Inc. 630.625.8080 www.punch-us.com

PUNCH INDUSTRY USA, Itasca, Illinois, is the North American subsidiary of the mold/die components manufacturer PUNCH INDUSTRY CO., LTD., Tokyo, Japan. Specializing in small-diameter, precision-ground rounds and custom pins made per a customer’s print, PUNCH’s quality and diamondground finish are trusted by mold and die makers in the medical, food and beverage, and other industries. PUNCH can support both low- and high-cavitation molds. The drawing is courtesy of B.A. Die Mold in Aurora, Illinois, which partnered with PUNCH on a challenging mold build.

DECEMBER

Webinar: Staples Program Launch, December 2, www.amba.org/events

Roundtable Discussion – Sales and Marketing, December 3, www.amba.org/events

Webinar: CDW Program Launch, December 9, www.amba.org/events

Webinar: Industry Outlook and Fourth Quarter Advocacy Update, December 17, www.amba.org/events

JANUARY

Webinar: AI, Cybersecurity and the Law – Strategies for Risk Management, January 22, www.amba.org/events

Roundtable Discussion – Sales and Marketing, January 28, www.amba.org/events

FEBRUARY

MD&M West, Anaheim, California, February 3-5, www.mdmwest.com

Webinar: AMBA State of the Industry Webinar, February 24, www.amba.org/events

Roundtable Discussion – Senior Leaders, March 11, www.amba.org/events

PTXPO 2026, Rosemont, Illinois, March 17-19, www.plasticstechnologyexpo.com

EL Leadership Retreat, March 19-20, www.amba.org/events

MAY

AMBA Conference 2026, Grand Rapids, Michigan, May 12-14, www.ambaconference.com