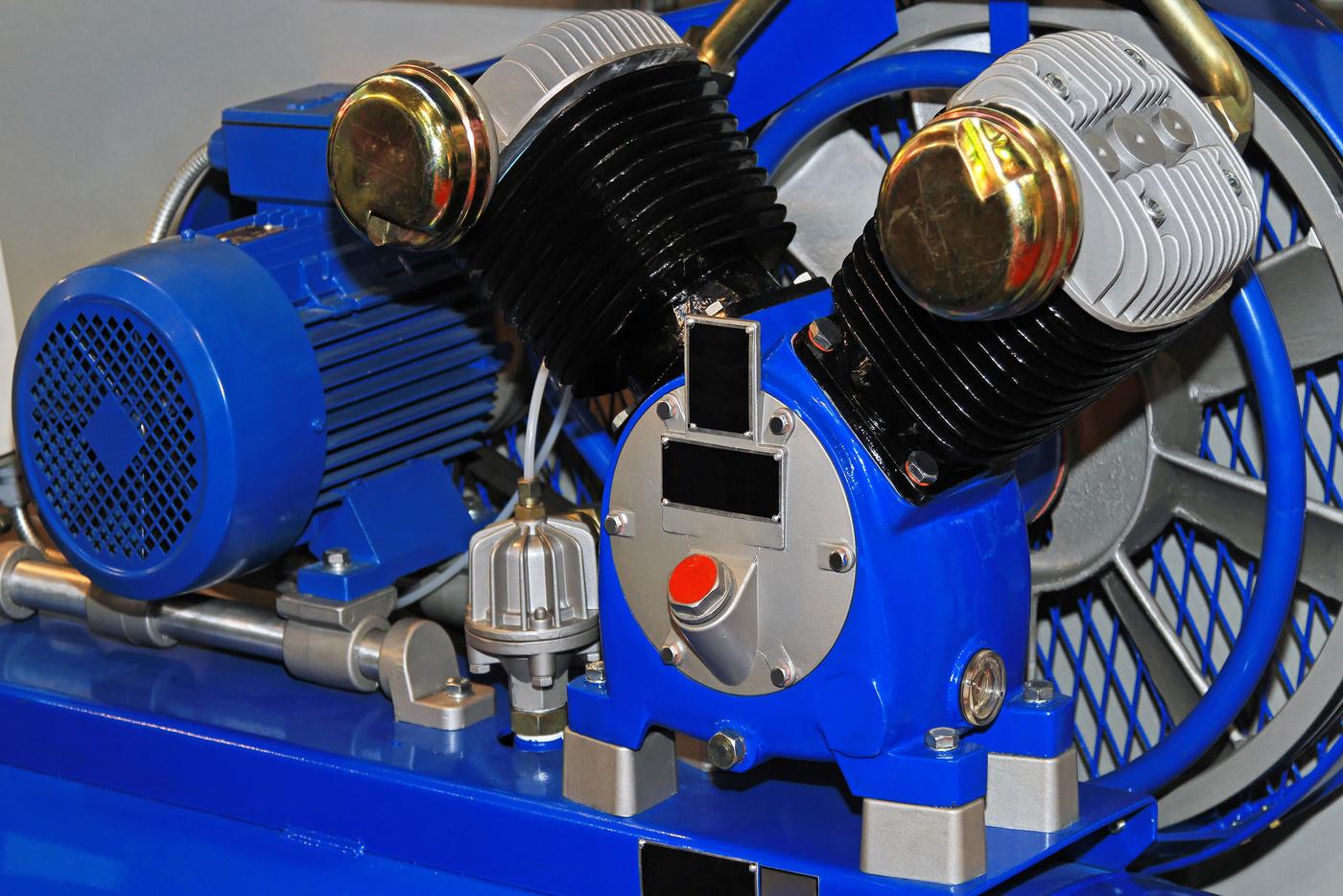

A rotary screw air compressor is a type of air compressor that uses a rotary-type positive-displacement mechanism to compress air. This type of compressor is commonly used in industrial applications where high volumes of compressed air are required.

One of the advantages of a rotary screw compressor is that it can deliver a continuous supply of compressed air, which is useful in applications where a steady flow of air is required. Another advantage is that rotary screw compressors are relatively compact and can be easily installed in a variety of settings.

Rotary Screw Air Compressor are available in a range of sizes and capacities and can be used in a variety of applications, including manufacturing, construction, and automotive repair. They are also available in oil-injected and oil-free models, depending on the specific needs of the application.

Here are some tips for maintaining a rotary screw air compressor:

screw air compressor:

Add Check and change the oil: The oil in a rotary screw compressor is critical to its performance and should be checked and changed regularly. Follow the manufacturer's recommendations for the type and frequency of oil changes.

Inspect the belts and pulleys: Belts and pulleys can wear out or become misaligned, causing the compressor to operate less efficiently. Inspect the belts and pulleys regularly and replace or adjust them as needed.

Monitor the operating temperature: A rotary screw compressor can overheat if it is operating at too high of a temperature.