COMING UP

24

FOREWORD

“Hydrogen is a future topic, and we really need a collective approach, so collaboration is key.”

With each passing month, the global hydrogen industry unlocks greater potential and further cements its role in the energy transition.

In this issue of the Hydrogen Industry Leaders eMagazine, we unpack groundbreaking research into how Scotland’s whisky industry could play its part in the nation’s hydrogen efforts, explore the Humber’s role in the UK hydrogen economy, and delve into the benefits of hydrogen powered vehicle training.

With the frequent movements in legislation, policy, and innovation, Hydrogen Industry Leaders brings you the latest advancements propelling the hydrogen economy to the forefront of net zero conversations.

Floyd March Editor

Floyd March Editor

f.march@peloton-events.co.uk

Hannah Wintle

Multi Media Journalist

Chelsea Bailey

Multi Media Journalist

Olivia

Staveley Graphic DesignerWHY THE HUMBER COULD BE THE MOST EXCITING REGION IN THE UK FOR THE FUTURE HYDROGEN

During the Hydrogen Industry Leaders’ Breakfast hubs that saw visits to Bristol, Durham, Manchester and Hull, it became apparent that the Humber region is in an excellent position to grow the UK hydrogen economy, with the vast array of pre-existing infrastructure and natural geography.

Home to over £15bn private investment set to be unleashed across the region, Tony Danker, Director General described the Humber as: “A critical piece of the jigsaw in decarbonising the UK” - An expression the private sector is clearly in tandem with.

In addition to this, it is evidently a blueprint for fostering economic clusters in the UK and is widely seen by the CBI as: “A demonstrator to champion and learn from in equal measure as the best way to bring private sector leadership to bear on levelling up.”

Historically, Humberside and Lincolnshire have been home to industry-leading facilities and infrastructure for energy production, storage and distribution; and the fact 80% of the UK’s licensed CO2 storage capacity is accessible from the Humber is proof that the geography and existing infrastructure makes the region extremely appealing.

THE CBI PREDICT 30% OF UK GOVERNMENT PRODUCTION TARGETS CAN BE

MET BY THE STRUCTURE

Looking to the future, and more specifically at the role hydrogen can play in this innovation hub, the CBI predict 30% of UK Government production targets can be met by the structure and 1 in 10 regional jobs will be safeguarded and thousands of new jobs created by decarbonising the Humber.

With a lot of pre-existing infrastructure for gas and CO2 storage, the region has been responsible for vast amounts of emissions, which adds to the growing need to decarbonise the region, placing the Humber in a win-win-win scenario for growing jobs, the economy and reducing emissions.

If all projects in development, construction and awaiting FID come to fruition, there could be a huge 80% CO2 emission elimination via the decarbonisation projects. These savings will only increase over time as the hydrogen used in these regions will help decarbonise other parts of the UK.

‘Hydrogen Hype’ has dominated the discourse in recent times, but the sheer volume of projects such as CCUS, BECCS and the recent Saltend approval could be the stepping stone to living up to the socalled ‘hydrogen bubble.’

SSE THERMAL AND EQUINOR ARE COLLABORATING ON WHAT COULD BE ONE OF THE WORLD’S LARGEST HYDROGEN STORAGE FACILITIES

H2H Saltend, headed up by Equinor, is a 600 MW hydrogen production facility which will initially reduce the emissions of Saltend Chemicals Park by 0.9 MT CO2 per annum while protecting 521 jobs and creating a further 97 permanent jobs.

As Zero Carbon Humber’s kick-starter project, this flagship low-carbon hydrogen production facility with carbon capture will fuel switch Triton Power station and reduce the emissions of local chemicals manufacturers.

H2H Saltend is located at Saltend Chemicals Park, one of the region’s most carbon-intensive sites, responsible for more emissions than the entire Merseyside region.

At least six local industrial operators could potentially use this hydrogen to lower the carbon footprint of their processes and products, one being the on-site Triton Power Station, seeking to fuel switch from natural gas to hydrogen, enabling low carbon power and steam to be supplied to local users.

In addition to this, East Yorkshire are getting in on the action; highlighting how the hydrogen economy is rapidly growing out of the Humber. The Aldbrough Hydrogen Storage project will be home to a capacity of 320 GWh of storage, the equivalent of powering 860 Hydrogen buses.

The Aldbrough Hydrogen Storage project plans to store low-carbon hydrogen either within the existing natural gas storage facility or at a new site adjacent to the Aldbrough Gas Storage facility in East Yorkshire. The project could be operational by early 2028.

SSE Thermal and Equinor are collaborating on what could be one of the world’s largest hydrogen storage facilities. The proposed Aldbrough Hydrogen storage facility could be in operation by early 2028, with an initial expected capacity of at least 320 Gigawatt hours (GWh), which is enough to power over 860 hydrogen buses a year.

The Aldbrough site is ideally located to store the low-carbon hydrogen set to be produced and used in the Humber region.

The benefit of the large-scale hydrogen storage at Aldbrough extends well beyond power generation. It would enable growing hydrogen ambitions across the region, unlocking the potential for green hydrogen, and supplying an expanding offtaker market including heat, industry and transport from the late 2020s onwards.

Hydrogen Industry Leaders will be exploring more projects such as these in our annual breakfast hub tour. This year we will be visiting Darlington, Nottingham, and Hull with more to be announced in the coming months.

EXPLORING INVESTMENT CHALLENGES IN HYDROGEN FOR MARITIME INNOVATION

Finding the appropriate pace of investment is crucial for a company’s longterm success, and when it comes to investing in hydrogen it is no different. Companies must analyse the barriers currently in place before exploring hydrogen investment opportunities.

Hydrogen will play a significant role across a range of end-use markets, including industry and transport, and could enable international trade of clean energy.

According to Marakon, a management consulting firm working with CEOs, their executive teams, and business leaders to help drive value transformation: “The deployment of hydrogen across the globe is gathering momentum and it is projected to meet 5-20% of final energy demand by 2050.”

To see this deployment become a reality, companies will need to invest in hydrogen. However, at the moment companies are debating whether they should invest in hydrogen, how to build capacity, and what the appropriate pace of investment should be.

BEFORE INVESTING COMPANIES MUST MAP OUT THEIR POSITION IN THE INDUSTRY

The way companies go about investing differs significantly by their different approaches due to the size of the company. Larger companies often have more financial flexibility, plus access to money and resources for research and development. This allows them to pursue a wide range of investment opportunities in hydrogen.

Typically, large companies have larger revenue base and more assets. This scale allows them to allocate more funds towards exploring new technologies like hydrogen.

In addition, large companies often operate in multiple markets, which can provide a more stable financial foundation, enabling them to absorb costs without having a big effect on its overall finance.

Using maritime as an example, Rod Davies, Hydrogen Lead at Marakon highlighted that though there are differences, there are some common features.

He said that these include creating a plan before beginning to think about investment: “To start with, there is a need for all companies to come up with a view internally around what the future might look like for the industry as a whole. From this, companies then need to figure out how they can participate and where.”

When it comes to making investment decisions, companies need to evaluate their current competitive position, where they are in the sector, and their ambition going forward.

On this, Rod explained: “It is all about questioning if they see hydrogen as an opportunity to lead and gain some competitive advantage through it, or alternatively if they’d rather be a fast follower. This will govern the extent to which they move forward.”

Evaluating these aspects could allow companies to make informed investment decisions that are aligned with their overall business strategy and aspirations. This will help them to prioritise opportunities, and mitigate risks.

“Making investment decisions comes down to analysing the company’s competitive position in the sector.”

-Rod Davies, Hydrogen Lead at Marakon

SHORTER SUPPLY CHAINS ARE NEEDED TO SEE HYDROGEN IMPLEMENTED INTO THE MARITIME INDUSTRY

One of the key issues for companies looking to invest in hydrogen is supply chain resilience, Rod said: “When you think about the maritime industry and the outlook for global trade, there are some interesting considerations to factor in. One is that internationally there is more of a push around supply chain resilience. With this, there is more incentive for local supply or shorter supply chains, which is rowing back on globalisation and the trade flows that result from that.”

As a result of the need for supply chain resilience and shorter supply chains, there is an increasing pressure on companies to reassess their sourcing strategies and explore more localised production and distribution networks.

Shorter supply chains and localised production will be key in reducing the vulnerability to disruptions in the global supply chain, helping to enhance energy security. This is due to long supply chains being susceptible to risks.

Therefore, by shorting supply chains, companies can mitigate these potential risks and create a more reliable and resilient supply of hydrogen. Companies could also see cost savings from the reduction of transportation costs, inventory carrying costs, and the need for buffer stocks.

ENERGY COMMODITIES ARE BEING RESHAPED

Another barrier companies may face is the impact on maritime industry volume and mix.

Due to the growing concerns regarding climate change and reaching our net zero targets, there is a focus on transitioning to cleaner energy sources such as hydrogen.

However, as the maritime industry transitions towards implementing sources like hydrogen, there will inevitably be changes in the volume and mix of goods being transported, Rod revealed: “If you think about what is being transported by sea today, about a third is related to energy commodities like oil and gas. That is because much of the trade today is concerned with current fossil fuels. That is going to change over time in terms of the type of energy like hydrogen, but that is going to have a bearing on the volume and mix of the industry.”

These shifts will be driven by factors such as energy density, infrastructure requirements, and supply chain considerations.

Adapting to these changes will be crucial for companies across the maritime industry to ensure continued efficiency, competitiveness, and sustainability.

THE HYDROGEN TRANSITION WILL ENABLE NEW PLAYERS TO ENTER THE MARITIME INDUSTRY

It isn’t just the goods that are being transported as cargo that will need to be assessed but what gets used for fuelling the ships. As companies begin to focus on making sustainable choices, they are likely to decide on using cleaner fuel options like hydrogen for shipping fuel.

Companies operating in the maritime sector will need to adapt to implementing new sustainable choices into its day-to-day practices.

Rod stated that this transition could lead to the emergence of new players in the energy sector and changes in the traditional lines of commodities that are currently being transported by ship.

He said: “Industry structure is changing in some instances, for example iron ore reduction. This is a greater incentive to locate low-cost renewable energy sources. This will affect the lines of commodities.”

REGULATIONS WILL BE FUNDAMENTAL TO BUILDING INVESTMENT CONFIDENCE

The changes in the industry’s structure and operations may create uncertainty for investors regarding which technologies will emerge as more dominant in the future. Therefore, policy will play a crucial role when it comes to overcoming barriers and shaping the investment landscape for hydrogen in the maritime sector.

Rod stated that policy creates both challenges and opportunities for investors: “There are considerations around regulation and policy, and some of those things are right upon the industry. For example initiatives such as the EU Emissions Trading System (ETS) and carbon border adjustment mechanisms may impose financial and economic implications on the industry.”

These regulations will be fundamental in influencing and building confidence in investment decisions and future market dynamics.

Despite the challenges, hydrogen is becoming one of the most promising clean fuel options for the maritime sector, in particular shipping.

By addressing these barriers by investing in hydrogen, leveraging supportive policy frameworks, and embracing innovation, companies will be able to contribute to the advancement of more sustainable maritime transportation.

THE PATH TO FUTUREPROOFING HYDROGEN PROJECTS:

TACKLING HYDROGEN WEAR

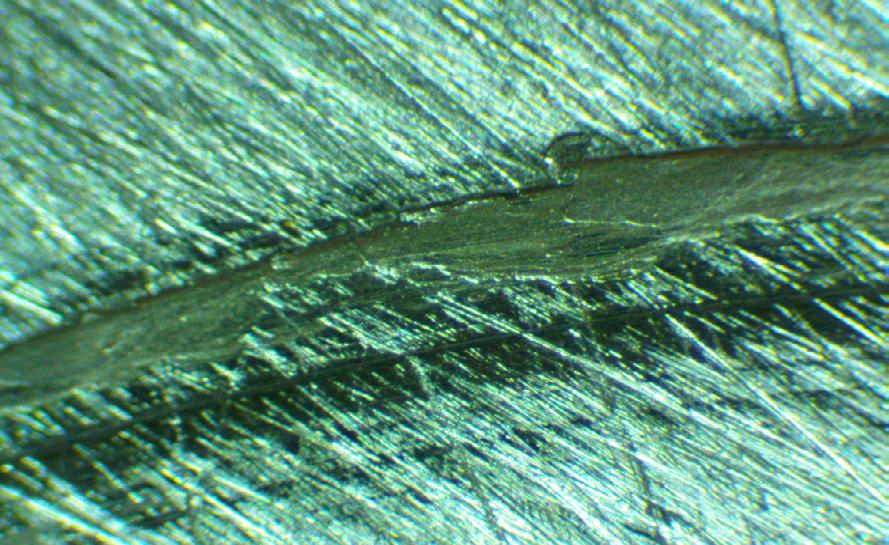

Hydrogen wear poses a significant challenge in industries such as aviation, automotive, and energy, where metals are commonly used in critical components in hydrogen-powered systems. Finding a way to combat this will be fundamental to the futureproofing of hydrogen projects.

Hydrogen embrittlement, also known as hydrogen wear, occurs when hydrogen atoms infiltrate the structure of certain metals, rendering them brittle and prone to cracking or fracturing under stress.

The infiltration of hydrogen atoms into the metal lattice weakens the metallic bonds, therefore, increases susceptibility to failure, compromising both the integrity and safety of critical engineering structures and components.

COPPER-BASED ADDITIVES HAVE ANTI-WEAR PROPERTIES

In response to this pressing challenge, research has led company NEOL Copper Technologies to develop CuGlide, a copper filming technology that helps to eliminate hydrogen wear. This has been developed through decades of research in tribology (the study of friction, wear, and lubrication).

Leyla Alieva, CEO and Co-founder of NEOL Copper Technologies explained CuGlide leverages the properties of copper to create a protective film that shields metal surfaces from the detrimental effects of hydrogen exposure.

She said: “Why we stand apart is because we developed our own anti-wear technology which is different to the one that has been used conventionally by the lubricants industry over the last 50 years, and it is based on scientific knowledge about hydrogen wear of metals.”

The additive forms a self-healing low-friction copper film that helps to reduce both friction and wear. Unlike traditional lubricants like ZDDP that may contain chemically-active additives, such as sulphur and phosphorus, CuGlide is free of harmful substances, making it a sustainable choice and safe for use with modern catalytic converters and diesel particulate filters.

ADDRESSING HYDROGEN WEAR IS KEY TO THE WIDESPREAD ADOPTION OF HYDROGEN

Despite its significance, hydrogen wear remains relatively obscure outside certain scientific and engineering communities. This is largely due to its limited coverage in mainstream media compared to other aspects of hydrogen technology.

Leyla emphasised the need for heightened awareness, stressing the importance of sharing scientific knowledge of hydrogen wear to a broader audience: “You’d be surprised how few people actually know about the phenomena of hydrogen wear, even some people who have developed hydrogen internal combustion engines. There is a process of friction inside the engine and during this process hydrogen wear happens. It is very important to realise that this does happen.”

“We need to make people more aware of the scientific discoveries and the scientific knowledge of hydrogen wear to see it become more publicly aware.”

- Leyla Alieva, CEO and Co-founder of NEOL Copper Technologies

Recognising and addressing hydrogen wear is essential to better educate and equip stakeholders, policymakers, and the public to understand and mitigate the challenges that are associated with hydrogen wear. This will ultimately help to advance the widespread adoption of hydrogen.

By understanding the challenges and benefits of hydrogen wear, industry leaders can integrate preventative measures into the design, manufacturing, and maintenance of their hydrogen-powered systems and projects.

When it comes to policymakers, this knowledge will help them to enact robust policies aimed at safeguarding against failures from hydrogen embrittlement, therefore, amplifying the confidence in the reliability and safety of hydrogen.

CURRENT HYDROGEN PROJECTS CAN BE FUTUREPROOFED THROUGH CHANGING THE LUBRICANT USED

In addition to educating key industry leaders, addressing hydrogen wear will support the reliability and longevity of equipment and infrastructure in hydrogen projects. This will be fundamental as the widespread adoption of hydrogen relies heavily on not only current hydrogen project’s success but also their long-term viability and resilience.

Addressing the issue of hydrogen wear is imperative for futureproofing current hydrogen projects and ensuring their role in facilitating the energy transition.

“By using a different lubricant, we can talk about potentially extending the resource of those engines, which is going to make them more commercially viable.”- Dr Sergei Mamykin, Tribologist, Copper Filming Technology Developer at NEOL Copper Technologies

Dr Sergei Mamykin,

Tribologist, Copper Filming Technology

Developer

at NEOL Copper Technologies highlighted that reducing hydrogen wear is paramount and by doing so, it could strengthen the foundation for hydrogen project’s success for years to come.

He said: “For current projects, we can futureproof them right now by changing the lubricant. Developers of hydrogen internal combustion engines working with copper-based lubricant rather than standard ZDDP based lubricants can extend the life of hydrogen combustion engines.”

CuGlide’s compatibility with modern catalytic converters and diesel particulate filters means that it can seamlessly integrate into existing infrastructure, saving on costs.

THE REDUCTION IN WEAR COULD HELP HYDROGEN TO BE COMPETITIVE WITH OTHER ENERGY SOURCES

Continuing, Dr Mamykin added that combating hydrogen wear is essential to enhancing the reliability of equipment used in hydrogen projects: “At the moment a big issue is that nobody knows how long these engines can live and the resources of those engines.

By using a different lubricant, we can talk about potentially extending the resource of those engines, which is going to make them more commercially viable.”

Ensuring that the infrastructure and equipment used in hydrogen projects remain durable over time is crucial for the long-term viability of hydrogen technologies as it reduces the need for frequent repairs or replacements.

The reduction in wear and tear could see maintenance costs associated be significantly lowered. This cost-effectiveness is needed to amplify the economic viability of hydrogen, helping it to become more competitive with other energy sources. Lower operational costs could also be seen, contributing to the attractiveness of hydrogen projects to investors.

In addition, minimising wear will also help to mitigate safety risks, amplifying the safety of hydrogen projects for workers, local communities, and the environment. This enhancement of safety will also boost the public’s confidence in hydrogen.

By addressing hydrogen wear, companies can ensure the reliability, longevity, and safety of hydrogen projects, whilst also helping to accelerate the adoption of hydrogen as a key driver of the energy transition.

From Whisky Wastewater to Green Hydrogen: A Scottish Solution

Think about Scotland and you might begin to conjure mental images of the Loch Ness Monster, tartan kilts, and whisky. While these may be basic stereotypes of a country that aims to reach a total installed capacity of five gigawatts of low-carbon or renewable hydrogen production by 2030, the latter could well have a part to play in getting there.

With the green hydrogen production process currently consuming 20.5 billion litres of fresh water every year, scientists at HeriotWatt University have set their sights on the nearly 150 whisky distilleries in Scotland which produce approximately one million litres of wastewater a year.

Hydrogen Industry Leaders spoke to Dr Sudhagar Pitchaimuthu, Associate Professor in the University’s Institute of Mechanical, Process & Energy Engineering within the School of Engineering & Physical Sciences, to explore the practical uses for whisky wastewater in green hydrogen production.

WHISKY WASTEWATER COULD PROVE ITS USE AND VALUE AS A FEEDSTOCK

Most commercial electrolysers are based on freshwater systems, with nine kilograms of fresh water required to produce just one kilogram of green hydrogen.

“The volume of freshwater required is huge,” Dr Pitchaimuthu expressed, “So we started to test with the different types of wastewater. Scotland is blessed with hundreds of whisky distilleries, so why can’t we apply this wastewater to the electrolysis system?”

Through their research, the team at HeriotWatt developed a nanoscale material, with a particle size 10,000 times smaller than the diameter of a strand of human hair.

The nanoparticle, called a nickel selenide, can withstand wastewater for a long period of operation, while its commercial catalyst counterparts such as iridium, platinum, and ruthenium, don’t perform well in wastewater environments.

Furthermore, these materials come at an incredibly high price point – just one gram can cost thousands of pounds. The nanoscale material developed at Heriot-Watt, however, comes in at around fifty-times cheaper.

Dr Pitchaimuthu and his team also found that, as well as producing green hydrogen through electrolysis, the process can simultaneously extract other commercially valuable products.

He explained: “The whisky wastewater contains a lot of biomass substances due to the fermentation process, so in the electrolysis process, we are simultaneously, in the anode compartment, oxidising these small molecules.

“For example, lactic acid is one of the high quantity, highly concentrated small organic molecules present in the whisky wastewater. During the electrolysis process, these acid molecules are oxidised and produce a commercial product that can be sold for different purposes.

“In the cathode compartment, it obviously produces the green hydrogen, so two birds with one stone, simultaneously wastewater treatment, and on the other hand, you’re getting the green hydrogen.”

THE INNOVATION COULD HELP TO DECARBONISE THE WORLDWIDE DISTILLERY INDUSTRY

On a global scale, the whisky distilling industry produces approximately one billion litres of wastewater a year. Scale up this technology, and the implications for green hydrogen production become clear.

“Every country has distillery industries,” Dr Pitchaimuthu said. “They are producing a huge amount of wastewater. We can sit on-site hydrogen generation in particular distillery industries, and if you have any renewable energy systems in a particular location, like a windmill or solar farm, you can connect it. It’s free renewable power.”

The green hydrogen produced on these sites can then be sold outside of the industry though either exporting to pipelines, or stored in cylinders and transported to offtakers. However, Dr Sughagar offered an alternative use.

“Most of the distillery industry is currently running the fermentation process using the fossil fuel-based heating system, so it’s a huge carbon emission. This on-site green hydrogen can be fed back into the fermentation process, more like a hydrogen powered fermentation process or hydrogen powered heating system.”

This circular energy system could therefore make use of the vast quantities of wastewater produced each year by the distillery industry, and in doing so produce clean energy to fuel its operations.

CONTRIBUTING TO SCOTLAND’S HYDROGEN TARGETS THROUGH SCOTTISH INNOVATION

On a more local level, this inherently Scottish research could help the country progress towards its hydrogen targets by going some way to solving challenges unique to the country.

With plans to build a hydrogen sector and achieve 5 GW of hydrogen production capacity by 2030, scaling up to 25 GW by 2045, the Scottish Government has also acknowledged the remote nature of distilleries and accounted for the use of hydrogen in circumstances where the grid is a limiting factor.

Interestingly, while the potential for hydrogen to serve distilleries has been considered, Dr Pitchaimuthu is considering the inverse. He said: “The Scottish Government are really working very well. They’re in a very early stage, but still the water footprint is really scary. In Scotland, we are blessed with a huge amount of wind energy, but the water is a scarcity, even though we are blessed with a lot of lakes. But in the future, it’s really a big question mark.

“So in this context, our research into the feasibility of introducing the whisky wastewater feedstock into the electrolysis system will be complementary to the Scottish Government’s hydrogen action plan.”

Keen to expand upon the potential discovered through their research, the research team are looking to translate their research into other industry wastewater with hopes to complement the Scottish Hydrogen Action Plan in the long term.

Now, Dr Pitchaimuthu is seeking collaborators and funding partners to build upon the successes of their research: “We have a lot of challenges, not only funding, we also need different types of water samples.

“We are open to collaboration with regional industries from Scotland and the UK, and are looking for collaboration with the academic area where similar distillery research is going on in Europe or some Asian countries.

“We are also working on different funding applications and we really need an outreaching partner, particularly to reach the industry as well as laymen.

“Hydrogen is a future topic, and we really need a collective approach, so collaboration is key.”

With appropriate funding avenues and collaboration, the use of whisky wastewater as a feedstock for electrolysis could prove a valuable advancement in the hydrogen industry.

This research, undeniably Scottish in its nature through institute and subject matter, has impressive potential to both bring Scotland closer to its hydrogen targets, and showcase the nation’s prowess on the global hydrogen stage.

How Electric Vehicle Training Can Drive Business Growth

With new zero emission vehicle registrations rising sharply, the growth of electric vehicles (EVs) offers opportunities for businesses that are ready to embrace the change. To be ready, they must invest in EV training to ensure their employees have the necessary skills and knowledge to accommodate future demand.

To support making the transition to EVs more streamline for businesses, Blackburn College has become the first Further Education centre in England to be providing hydrogen fuel cell electric vehicle (FCEV) training.

The fully-interactive Toyota Mirai training rig from Block Automotive is the latest addition to the college’s Hybrid Electric Automotive Training (HEAT) facility, which opened in November 2022 as a dedicated centre to develop and deliver training to bridge skills gaps and meet the demands of greener vehicle technologies, including hybrid, electric, and now hydrogen.

BLACKBURN COLLEGE IS DELIVERING SPECIALIST EV AND HYBRID VEHICLE COURSES

HEAT is part of the £1.3 million Lancashire Automotive Skills Accelerator Project (LASA), a partnership project led by Blackburn College aiming to support businesses across Lancashire to respond to the growth of renewable energy sources, particularly focusing on low-emission vehicles and infrastructure within the light vehicle maintenance, service and repair, plant machinery and motorsport industries.

Hydrogen Industry Leaders spoke to Michael Yerbury, Advanced Automotive Technical Trainer, HEAT at Blackburn College about the facility and how it will help to create the next generation of motor vehicle professionals.

Michael explained that at Blackburn College’s HEAT facility, they have two hybrid rigs and two electric rigs: “The rigs we have at the facility have all of the running gear needed but in a classroom or training environment and are static. We can carry out all of the service procedures, testing, and diagnostic procedures on the rig rather than have a car that takes up a lot of space.”

Having this technology available means that Blackburn College’s HEAT facility is able to deliver specialists EV and hybrid vehicle courses accredited by the Institute of the Motor Industry (IMI) TechSafe.

YOUNG PEOPLE MUST BE ENCOURAGED TO JOIN THE AUTOMOTIVE INDUSTRY

The automotive industry currently faces a skills shortage, and is struggling to find people with the ability to learn the technical skills needed.

There is a particular skills shortage when it comes to vehicle servicing, with the IMI stating that research has suggested that around 175,000 people work as automotive technicians in the UK. However, more will be required to meet the demands of future EV technologies.

To futureproof the automotive industry, it must focus on encouraging young people to want a career in it.

We’re trying to educate people across the country, so that they are ready for the new generation of vehicles.

Michael Yerbury, Advanced Automotive Technical Trainer, HEAT at Blackburn College

On this, Michael said: “Delivering these courses and modules means that people can have a better chance at getting a job in the industry because no other college in the area is giving students this opportunity. Our students are becoming more confident with working on these new vehicles and it puts them in a great career position.”

Ensuring that it is helping to create the future generation of motor vehicle professionals, HEAT is also working with schools, Michael expressed: “We have good relationships with local schools, and we have various stem days where school children come to the college. They look at the hydrogen FCEVs and they’ve never seen anything like it before. Then they go home and tell their family and friends about it.”

Not only does this help to get school children interested in the industry, but through sharing their experience with others, they are raising awareness of hydrogen technology.

SMALL COMPANIES AND GARAGES NEED TO BE SUPPORTED SO THEY DON’T GET LEFT BEHIND

Educating young people is essential to the future of the industry, but Michael stated that the industry also needs to ensure that it is upskilling the existing workforce: “As well as encouraging students to become more confidence in this technology, it is about educating garages and employers to take hydrogen vehicle training.”

Although the ban on new petrol and diesel car sales in the UK has been extended to 2035, Michael said that it is paramount that gaining knowledge of hydrogen FCEVs doesn’t come to a hault.

“Changing the goalpost to 2035 has confused many customers because some people were ready for this revolution. However, on the flip side, manufacturers haven’t stopped producing EVs and the production of these cars won’t just stop. They will continue to build, therefore, the industry need technicians.”

GARAGES NEED TO GET AHEAD OF THE GAME

One of the opportunities that HEAT offers for those already working within the industry is its skills Bootcamp that takes place in the evening. Its Electric and Hybrid Vehicle Bootcamp is aimed at upskilling and building on sector-specific skills within the automotive industry.

On the benefits that garages will gain from the Bootcamp, Michael revealed: “From the training they get to do via the Bootcamp, it allows them to expand. They might look at servicing more heavy vehicles, making repairs, or dealing with the safety aspects of them. Our technology and rigs reflect what is currently out there in the market, and show what can be done.”

By providing the Bootcamp, HEAT at Blackburn College highlights that these cars are here now and will continue to be part of the future. People are going to want to get their cars serviced and repaired. Therefore, getting ahead and gaining the knowledge needed to be able to work on these cars will be crucial in futureproofing the industry.

HEAT AT BLACKBURN COLLEGE IS AIMING TO INTRODUCE MORE HYDROGEN TRAINING

Going forward, Michael explained that training technicians on hydrogen FCEVs feels like the next natural step for HEAT: “Once the products are out there, I think there’ll be a big demand

for the hydrogen qualification. In the future, we are hoping to diversify our Bootcamp into a hydrogen Bootcamp too.”

Many technicians haven’t seen a hydrogen FCEV before, so in order to amplify confidence with the technology, they must be provided with the knowledge needed for them to get ahead of the game.

With this knowledge and confidence, technicians can start advertising that they can do repairs on these vehicles, and they will be able to be a specialist and cater for people who need them the most. This will not only help to meet the demand needed for technicians skilled in hydrogen FCEVs but also help technicians to see their business thrive.

The Hydrogen Industry Leaders Roundtables are set to ignite dynamic conversations, foster collaboration, and pave the way for a sustainable hydrogen-powered future. Our distinguished roundtables will cover legislation, law, and private finance, each bringing their unique perspectives to the table. These roundtables can be tailored to your specific business objectives and needs.

Private Finance Legislation