Fulton & Fifth showcases PCE’s hyTower® system a modern high-rise solution delivering five residential and commercial towers, interlinked by podiums, with 876 apartments (40% affordable) across 105 storeys. The project exemplifies the benefits of Modern Methods of Construction (MMC): certainty in cost, programme, and quality, with enhanced safety and sustainability.

Over 17,500 hybrid components were assembled in just 23 months six months ahead of programme through coordinated offsite manufacturing across 12 factories in four countries. Precision-engineered with integrated façades, windows, M&E, and balconies, each component arrived ready for immediate installation.

PCE’s repeatable Kit of Parts and systemised DfMA approach enabled faster, safer, and more predictable delivery. PCE led the installation, logistics, crane planning, and finishing dramatically reducing site activity, risk, and disruption.

E’s hybrid DfMA (Design for Manufacture and em, delivering a complete structural solution for tall buildings. It combines offsite-manufactured components including structural frame, integral cores, internal walls, façades, and M&E zones into a coordinated, easily transportable system designed for rapid, safe, and accurate onsite assembly.

Inspired by modern automotive production, the system uses a repeatable ‘Kit of Parts’ approach, enabling components to be interchanged based on project requirements—without redesign or delay. Each component features precast fixings and smart connectivity, ensuring seamless integration during assembly.

hyTower® can also be combined with other PCE hybriDfMA systems, offering flexibility while maintaining full compatibility.

Overall, hyTower® provides a fast, safe, and highly efficient build solution, delivering certainty in quality, cost, and programme from concept to completion.

hyTower®’s systemised construction with standardised methodology and diligent preplanning helps deskill and substantially increase productivity.

With construction expertise and end-to-end control, just 13 multi-skilled PCE operatives were needed per block, achieving a 10-day cycle per level. Up to 500 tonnes of hybrid structural components were installed daily, despite requiring 80% less operatives compared with traditional construction. This streamlined process dramatically reduced on-site activity, improving safety, predictability, quality, and compliance throughout delivery, whilst minimising noise, traffic, and disruption to the local area.

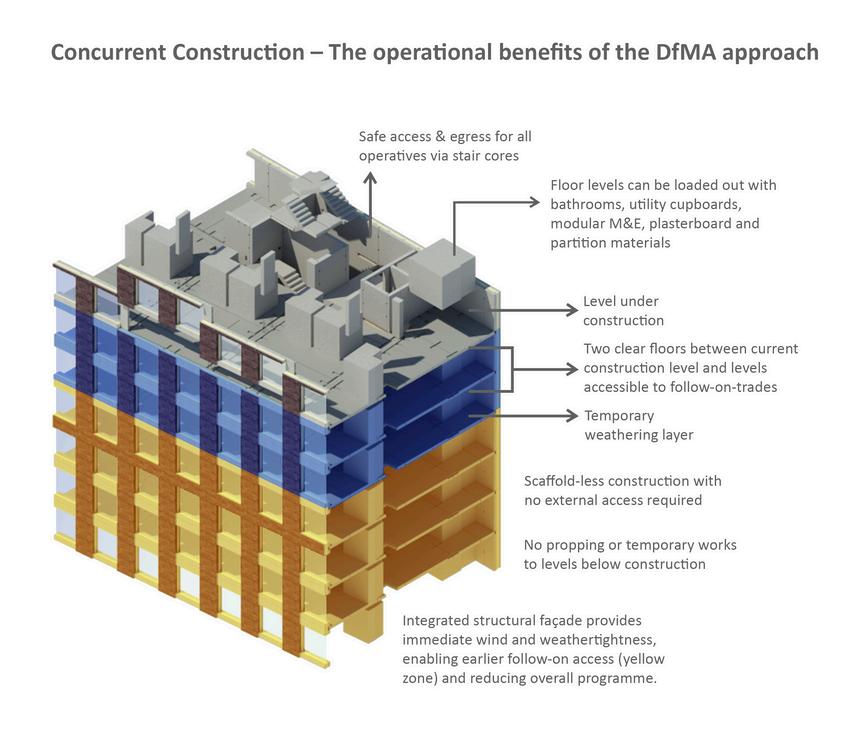

On-site, a 30% improvement in level cycle times saw structural floors delivered in just 10 days, with up to 500 tonnes of components installed daily. Early access for follow-on trades just two floors below active levels allowed units to be fit-out ready and occupied ahead of the completion of other blocks, accelerating the programme and maximising return on investment. Our scaffoldless solution reduced disruption to residents in earlier phases, enhancing the sales experience and process.

Offsite technology was central to delivering a high-performing, costefficient and resident-ready solution at scale. PCE’s componentised 3D model aligned with M&E from early design stages, enabling accurate cost forecasting, reducing rework, and supporting informed decision-making. Factory-manufactured components met the highest QA/QC standards, ensuring exceptional finish, performance and longevity offering longterm value.

Optimised hollowcore design reduced structural weight by 17,500 tonnes, cutting material use and enhancing spatial efficiency crucial for affordable housing. The hyTower® system reduced labour by up to 80%, deliveries by 70%, and waste by up to 90%. Standardisation enabled scalable delivery with minimal disruption.

Inherent material properties ensured robust thermal, acoustic and air-tightness performance delivering safe, comfortable homes with low running costs. Fulton & Fifth targets a ‘Beyond Best Practice’ Considerate Constructors score proving that quality, sustainability, and speed can be achieved through precision hybrid offsite delivery

A major advantage of the hyTower® system is the early access it provides to follow-on trades. With no back-propping, weatherproofing through integrated façades, and precast cores offering safe access from the outset, fit-out work could begin just two levels below the active assembly level.

PCE’s scope also included lifting and placement of prefabricated bathroom pods, utility cupboards, and alignment with full M&E coordination. This allowed for earlier occupation of completed blocks even while other towers were still under construction demonstrating the high level of control and programme certainty made possible by our systemised offsite approach.

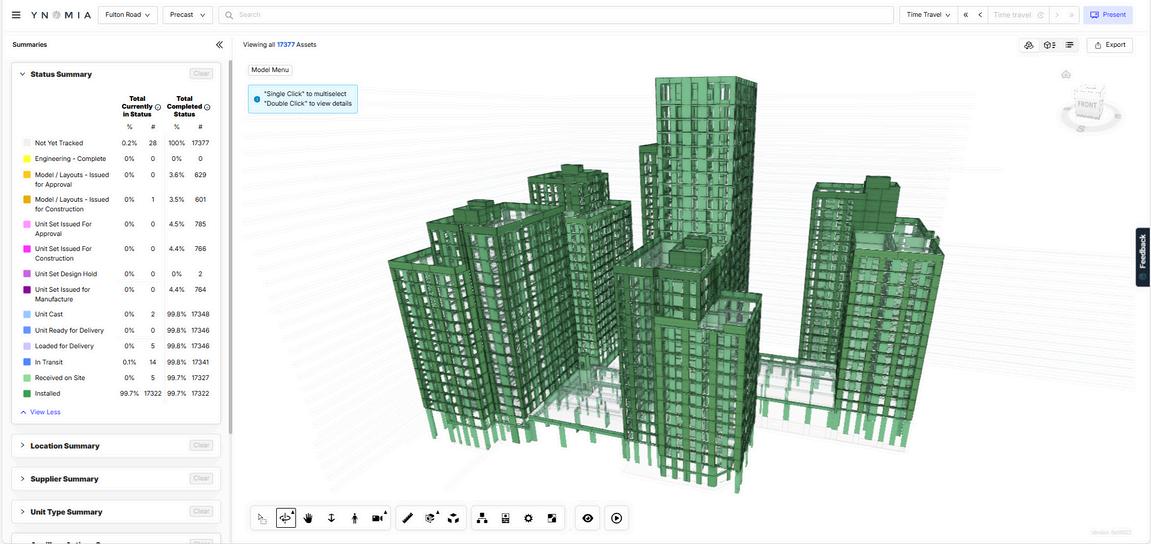

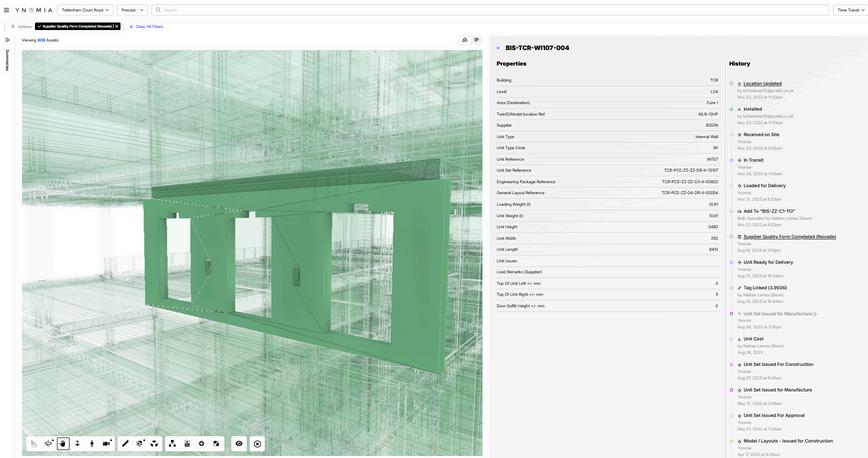

Crucial to residential delivery under the Building Safety Act Gateways, PCE used an interactive 3D digital twin to track every component through a real-time 14-stage status process, complete with QA and engineering insight. This centralised, transparent system ensured full traceability, safety compliance, and alignment with the Golden Thread underpinning a more accountable and

Regal & PCE have achieved a huge milestone. Fulton delivers not only the tallest block in the London Borough of Brent but also in Regal’s history.

Due to a collaborative working relationship, we have overcome the odds, achieving this significant feat, ahead of programme. Thanks go to the team at PCE for making this happen on site and working with their supply chain to enable the manufacture and delivery of all components to achieve an early completion