Fulton & Fifth

HybriDfMA hyTower System

Architectural

Structural

Architectural

Structural

PCE Ltd were delighted to once again partner with Regal as specialist design and build contractor for Fulton & Fifth - a landmark urban regeneration project in the heart of Wembley.

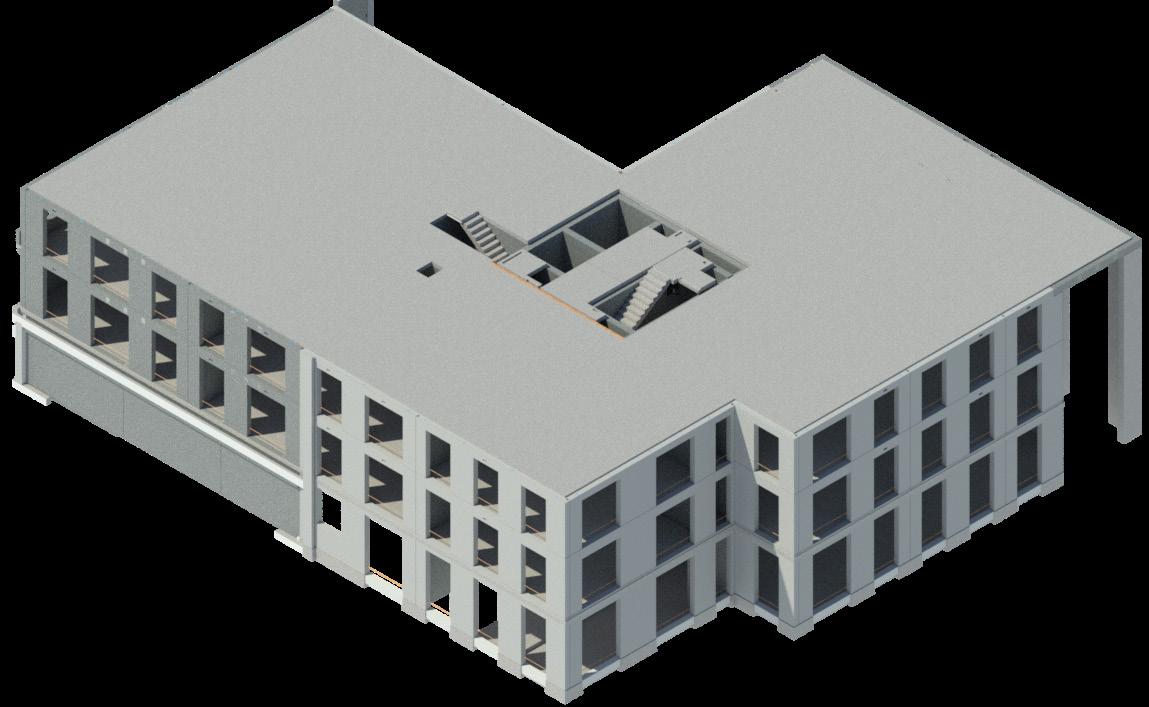

The development delivers 876 modern apartments, including 40% affordable homes, across five high-rise towers totalling 105 storeys. These towers sit above twoand three-storey podiums that provide a vibrant mix of retail, leisure, recreational, and light industrial spaceshelping to create a thriving new neighbourhood.

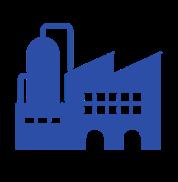

Designed by Concept Architects JTP and engineers Terrell, with Ryder Architecture and HDR Inc. supporting delivery, Fulton & Fifth was brought to life using PCE’s hyTower DfMA Structural System. This proven ‘kit-of-parts’ solution integrates the structural frame, internal finished walls, bathroom and utility pods, and the full building envelope — engineered offsite for optimal speed, safety, quality, and value.

The result: up to 50% faster construction, 90% less waste, and 80% fewer operatives and site deliveries. hyTower continues to demonstrate why it’s the trusted system for the efficient and assured delivery of high-rise residential projects across London and the UK.

239 kgCO2/m2 Embodied Carbon

30% Faster Programme

10 Days Per Level Installed

23 Months Constructing

876 Residential Units

21 Repeatable Components

13 PCE Operatives Per Block

17,300 Off-site Manufactured Components

40% Affordable Homes

500t Installed Daily

5 High-Rise Tower Blocks

12 Factories Used For Components

CLIENT

QUANTITY SURVEYORS

ARCHITECT

M&E ENGINEERS

CONSULTING ENGINEERS

Daniel Frett, Project Lead from Regal, noted:

’’PCE have worked tirelessly on achieving two huge milestones for Fulton & Fifth. Achieving the topping out of any structure is significant in its own right but to achieve the topping out of two blocks several weeks ahead of programme is testament to the team’s hard work and attitude. Fulton & Fifth, comprising 876 apartments, 294 of which are affordable, and more than two acres of landscaped public area, is a significant project, and with PCE’s help, we’re on track to deliver in 2026.’’

hyTower – PCE’s hybrid DfMA (Design for Manufacture and Assembly) system for complete tall building structures.

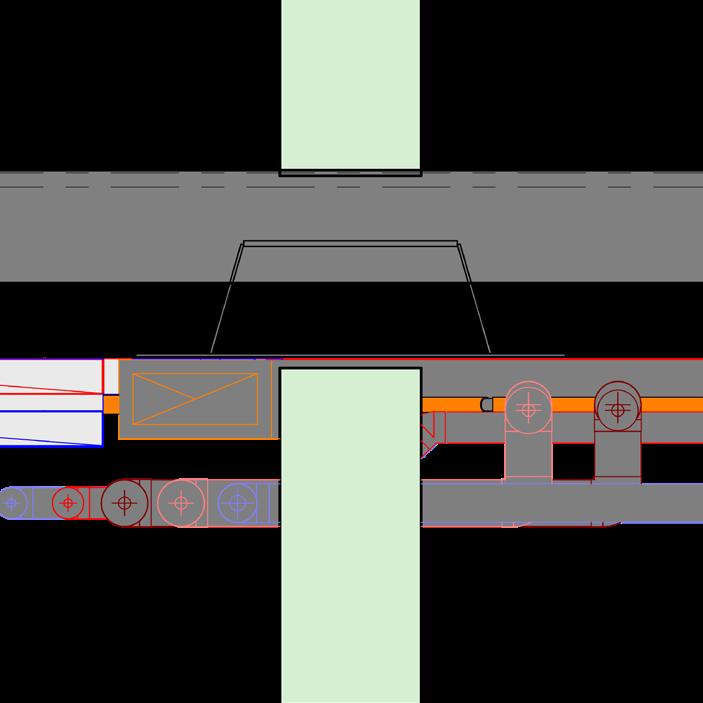

• Integrated Kit-of-Parts: Structural frame, cores, internal walls, façades, and M&E zones—offsite-manufactured for rapid, accurate assembly.

• Automotive-inspired: Standardised, repeatable components configured to each project, improving quality, accelerating delivery, and increasing certainty.

• Flexible supply chain: UK & Europe specialists; components can be preintegrated with façades, windows, balconies, M&E, bathroom pods, and utility cupboards

• Construction efficiency:

- No back-propping—safe early trade access two levels below active work.

- Scaffold-free assembly—enables earlier occupancy and improved sales experience.

• Sustainability benefits: Reduced on-site labour, waste, deliveries, noise, and carbon impact; minimal disruption to neighbours.

Result: A fast, safe, efficient structural solution delivering certainty in quality, cost, and programme—from concept to completion.

• Configurable to existing and bespoke designs

• Flexible structural grid with long-span options for adaptable layouts

• Kit-of-parts design with flexible material interchangeability

• Optimised component geometry for structural and carbon efficiency

• Seamless integration of façade, M&E, utility, balcony, and window elements

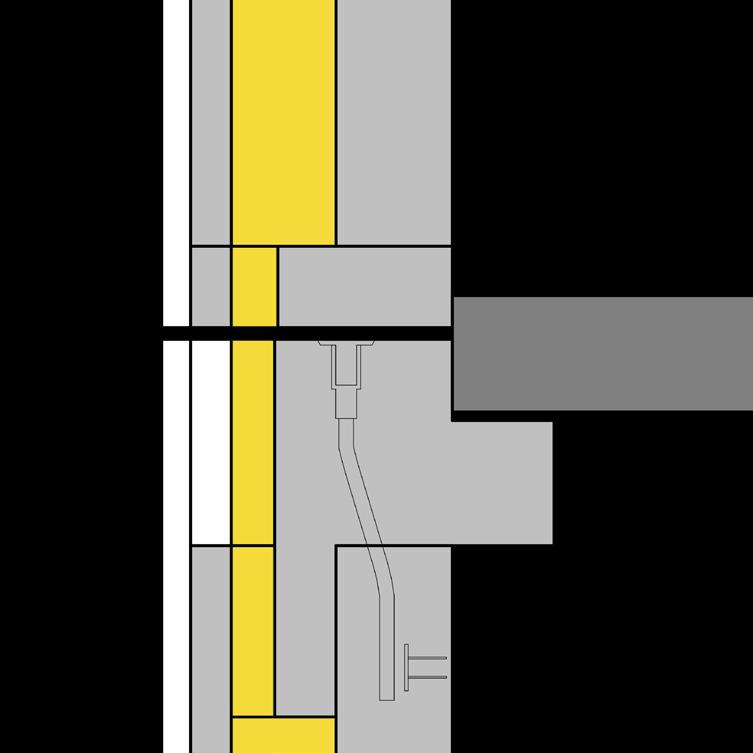

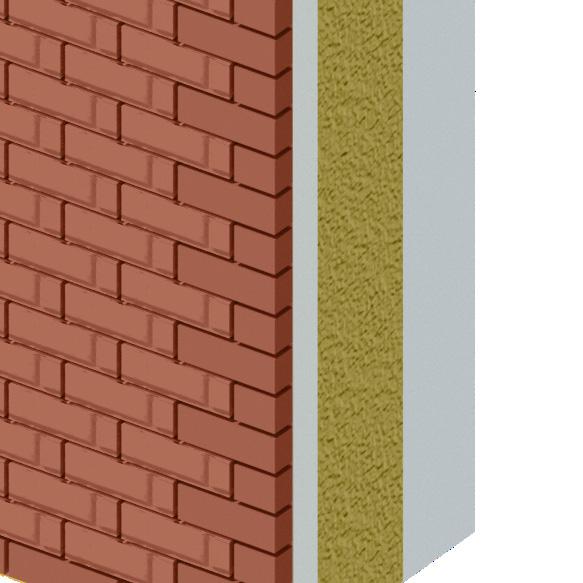

• Integrated, non-combustible (Class A1) façade system

• Smart connectivity for fast, accurate component interfacing

• Integrated MEP for efficient service coordination

• Fire-resistant system with excellent thermal and acoustic performance

• Digital twin and data-driven insight for precision and tracking

• Offsite manufacturing expertise ensures high-quality, controlled production

• 50% faster construction programmes

• 80% fewer site personnel improve safety and productivity

• Early access for fit-out just two levels below active construction

• No back-propping or scaffolding required, reduces risks, improves access, and improves site efficiency

• 90% reduction in site waste and 80% fewer deliveries

• 30%+ lower embodied carbon thanks to smart design and material efficiency

• Predictable quality and performance due to repeatable, systemised assembly

• Faster weatherproofing with integrated façades accelerates fit-out

• Better sales experience with clean, scaffold-free presentation of the structure

• Accelerated project completion allows earlier revenue generation and occupancy

PCE’s design for Fulton & Fifth showcases how systemised engineering and architectural creativity can work seamlessly together.

Collaborating closely with Roscoe and Ryder Architecture, the team configured the hyTower system to deliver both aesthetic intent and structural performance through targeted value engineering and component optimisation.

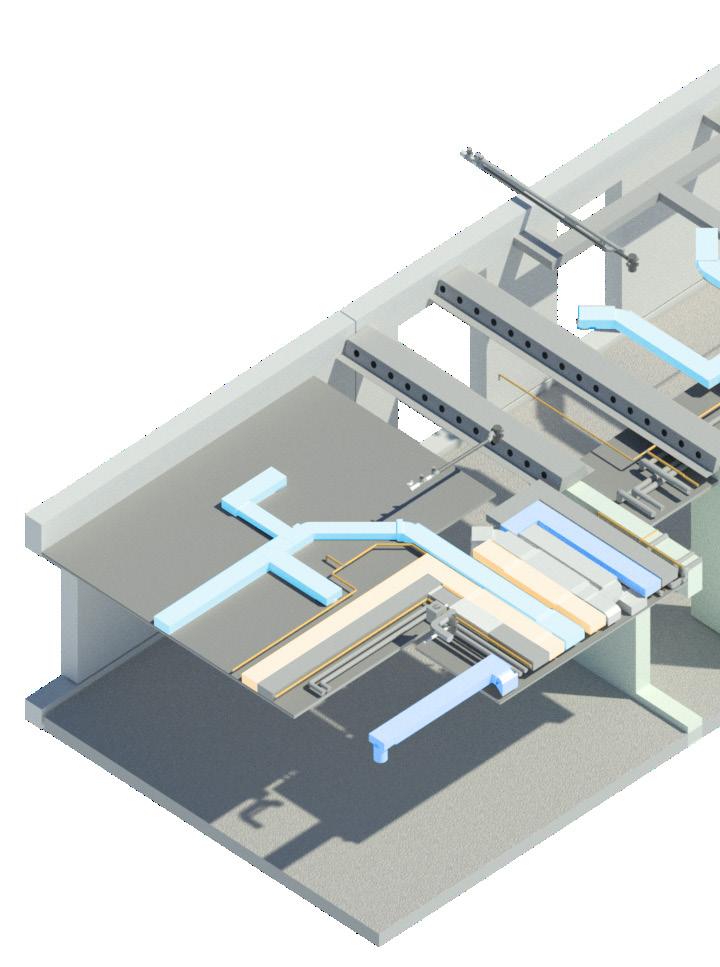

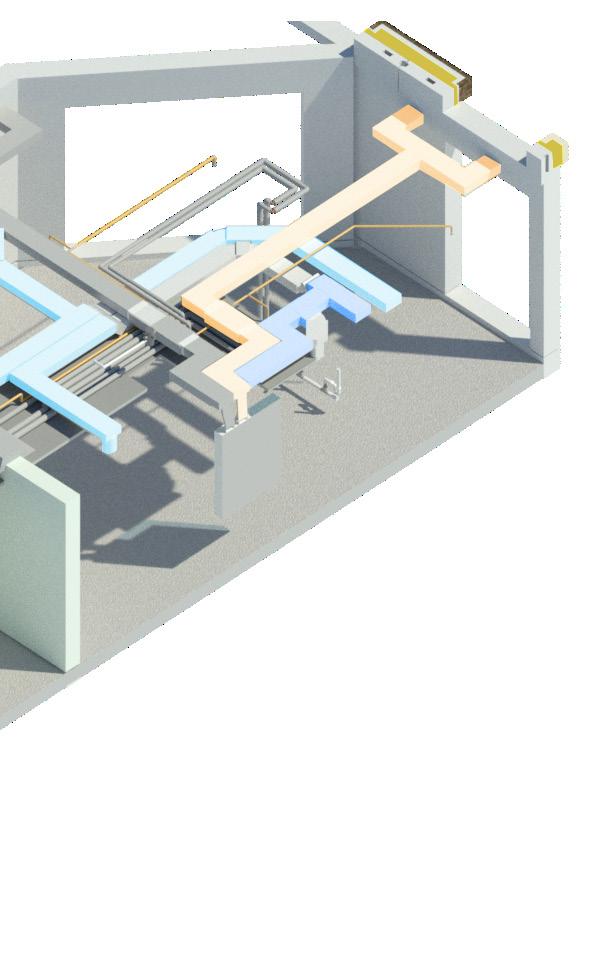

Using PCE’s ‘smart connectivity’ principles, standardised components and hybrid materials were combined to maximise efficiency, sustainability, and buildability. This approach enabled a flexible yet coordinated system that supports rapid on-site assembly and predictable results.

Early engagement and digital coordination ensured and architectural requirements, integrating key interfaces balconies — adding value across design, manufacture,

perfect alignment between structural interfaces such as M&E services, façades, and manufacture, and assembly.

The five towers, comprised of components designed in accordance with Eurocode 2, achieve 2-hour fire resistance, alongside robust thermal, acoustic, and environmental performance — delivering a safe, efficient, and high-performing solution that enhances comfort, sustainability, and long-term value.

Fulton & Fifth’s hybrid ‘Kit-of-Parts’ includes over 17,300 offsite manufactured recycled

Smart connectivity within the system means that key components can be easily interchanged, for configurability whilst enjoying the benefits a refined, proven system build solution brings. robotics. Components arrived on site complete with integrated façades, windows,

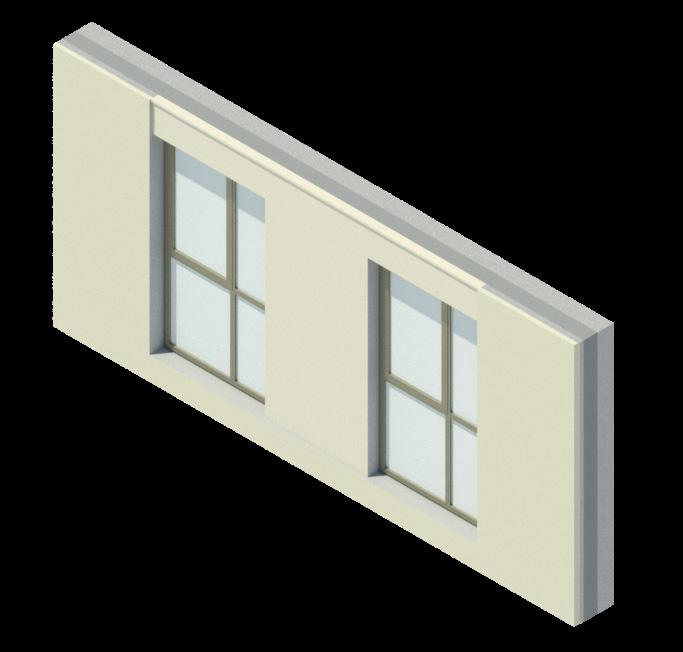

Structural Façade Panel

Sandwich panels were cast with a large diameter window fixed at the manufacturing factory along with various M&E items.

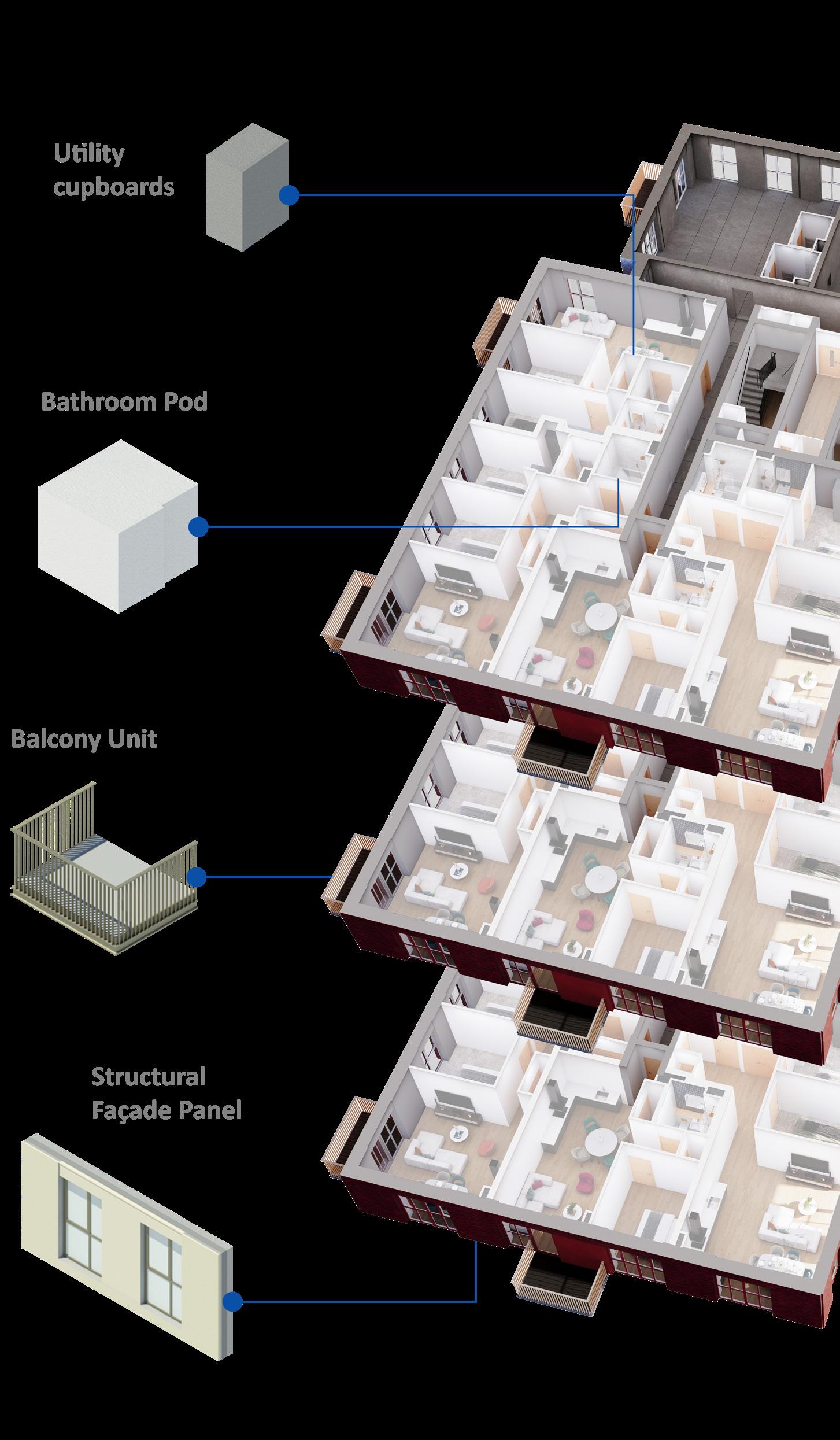

Structural Steel

Composite Beam

Steel beams were used compositely with reinforced structural concrete to support the floor structure without any down stands.

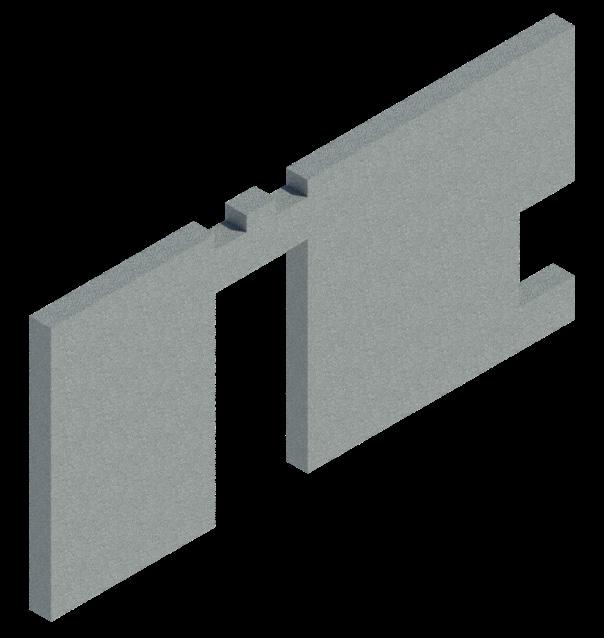

Precast solid wall

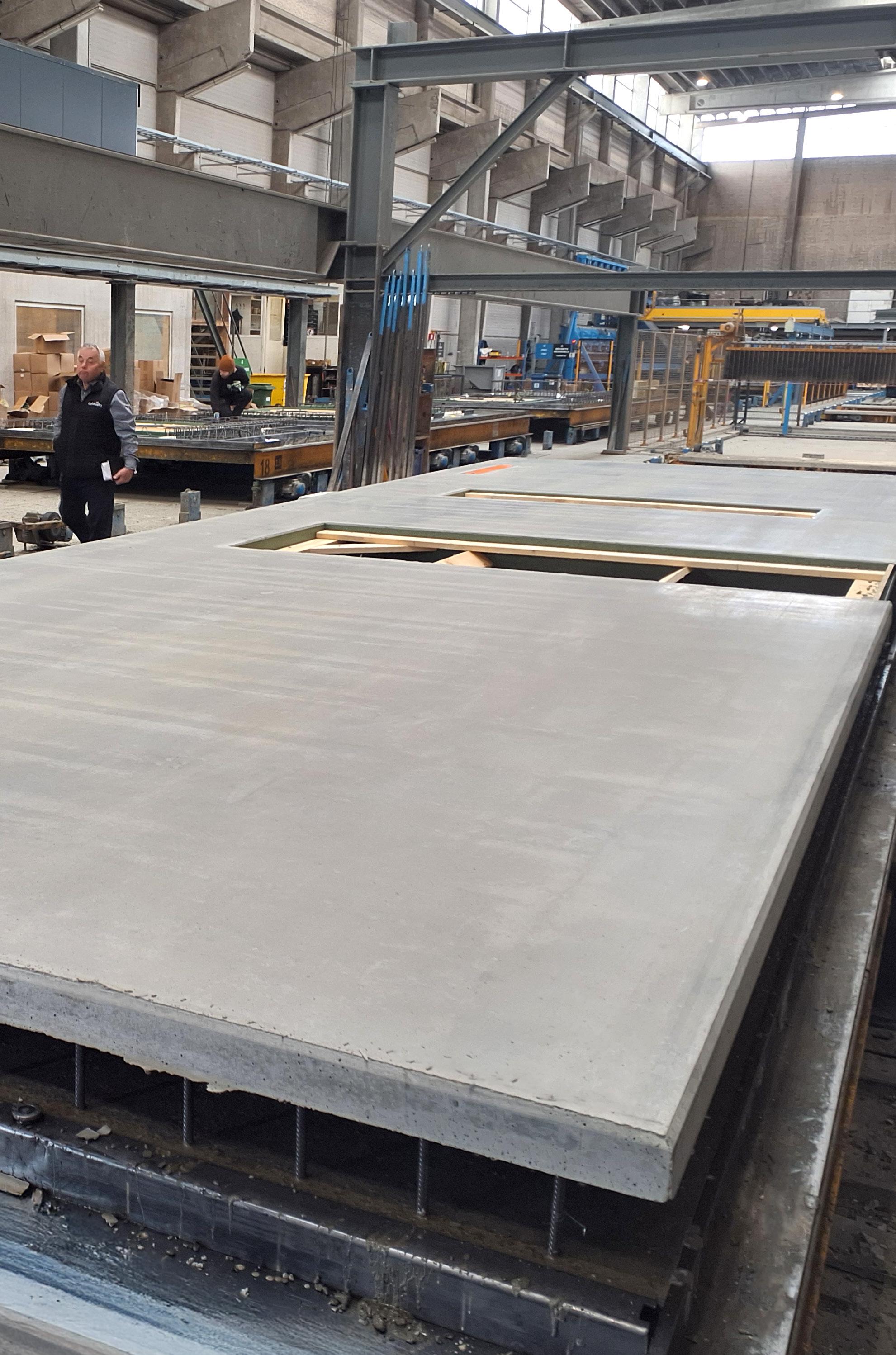

Precast solid walls were cast flat on variable steel tilt tables, ensuring a high-quality finish. Tilt tables were used to minimize unnecessary handling reinforcement.

Pre-stressed Floor Unit

Pre-stressed floor units were designed to work compositely with the reinforced screed.

manufactured components, comprised of precast concrete, insitu concrete, and recycled steel.

interchanged, without design changes and delays to adjacent components and connections. This allows brings. Each component was precision-engineered offsite using advanced automation and windows, M&E elements, balcony connections and more - ready for immediate installation

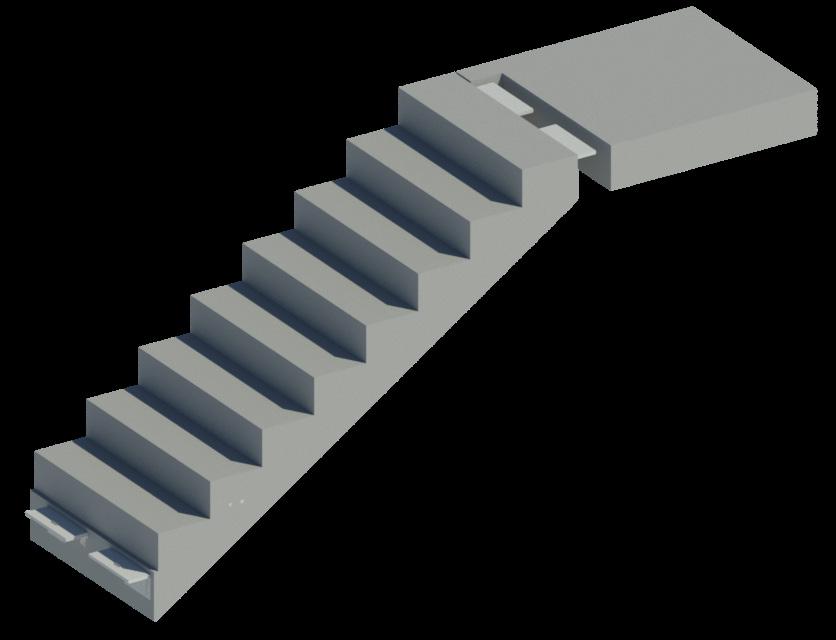

Stair units were pre-fitted with handrails at the factory for safety.

Twin wall cores provide stair and lift shafts as well as structural stability. They provide a more efficient structural design over traditional solid wall precast units.

Pods and cupboards including modular M&E components are preloaded onto the construction deck prior to the next floor plate being assembled.

Balcony units are integrated with smart connectivity in the sandwich panels. These were premanufactured with balustrade, soffit and deck finishes already in place.

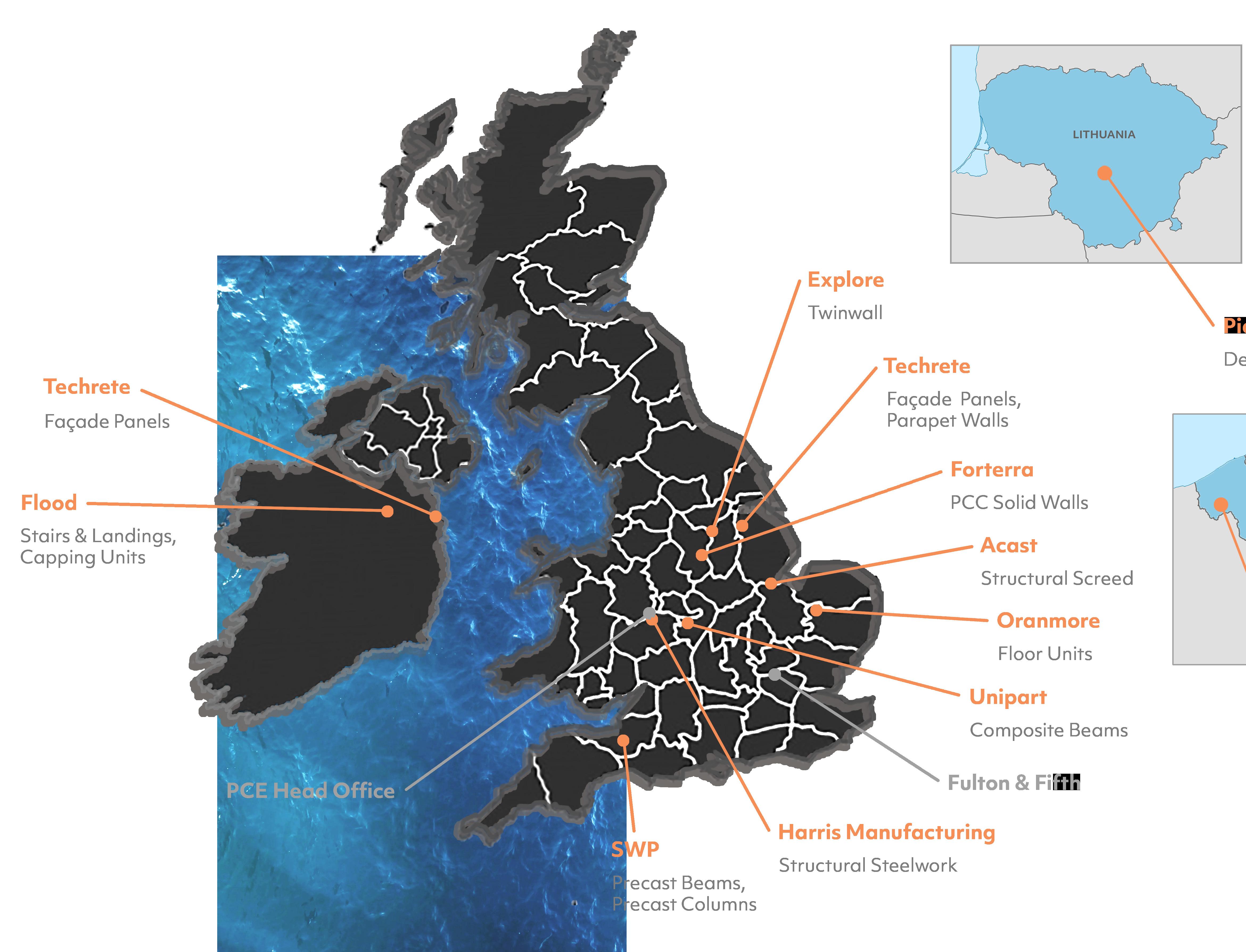

Using PCE’s adaptable and flexible supply chain model, 11 specialist offsite manufacturers from four countries across the UK and Europe were selected from the supply chain for Fulton & Fifth, using 12 contemporary factories. Each supplier was carefully selected based on the qualities each brought specifically to the project, based on required structural integrity, embodied carbon, and performance characteristics.

Component quality standards, aesthetics and tolerances were defined and agreed with the input from key stakeholders, including PCE, Regal, architects Ryder, and the allocated supply chain. This benchmark standard ensured all subsequent offsite manufactured components were delivered to the agreed highest quality standard, without exception.

Close engagement with the supply chain ensures full alignment on these standards. PCE’s Precast Quality Coordinators were embedded in factories to provide handson guidance and ensure every component meets the agreed specification - without exception.

Offsite technology was key to delivering a high-performing, costefficient, and resident-ready solution at scale.

PCE’s componentised 3D model integrated M&E from early design stages, enabling accurate cost forecasting, reduced rework, and better decision-making. Factory-produced components met the highest QA/ QC standards, ensuring a high-quality finish, long-term performance, and value.

An optimised hollowcore design cut structural weight by 17,500 tonnes - reducing material use and improving spatial efficiency. The hyTower system reduced deliveries by 70% and waste by up to 90%.

Inherent material properties ensured fire resistance, robust thermal, acoustic and air-tightness performance - delivering safe, comfortable homes with low running costs. Fulton & Fifth targets a ‘Beyond Best Practice’ Considerate Constructors score - proving that quality, sustainability, and speed can be achieved through precision hybrid offsite delivery.

At Fulton & Fifth, PCE delivered precision and consistency through a tightly controlled quality assurance process, fully integrated from design to client handover.

At the heart of this approach was a coordinated 3D digital twin, linking every component to real-time quality data throughout the design, manufacture, and construction phases. This created a live, transparent record of complianceaccessible to all project stakeholders.

• A fully integrated and coordinated structural and M&E model enabled early clash resolution and design validation.

• Fabrication data was extracted directly from the model, ensuring manufactured elements aligned precisely with architectural intent.

• Each unit underwent thorough inspections before and after casting, with dimensional data and photographic evidence captured in the digital system.

• ‘First-off’ samples established clear quality benchmarks, with repeatability ensured through a combination of in-house QA checks and automated monitoring.

• PCE’s dedicated factory expeditors independently audited 10% of components to verify compliance.

• All components were inspected on arrival, with any delivery damage digitally logged.

• Positioning was managed using survey control grids, with placement accuracy recorded against tolerances.

• Hold-point inspections and multi-party sign-offs were required for key activities like grouting and reinforcement.

• Consistency in finish was maintained through reference samples and documented quality standards.

• A dedicated Handover Manager led the final inspection and detailing process, coordinating client engagement to ensure a clear, well-documented quality close-out.

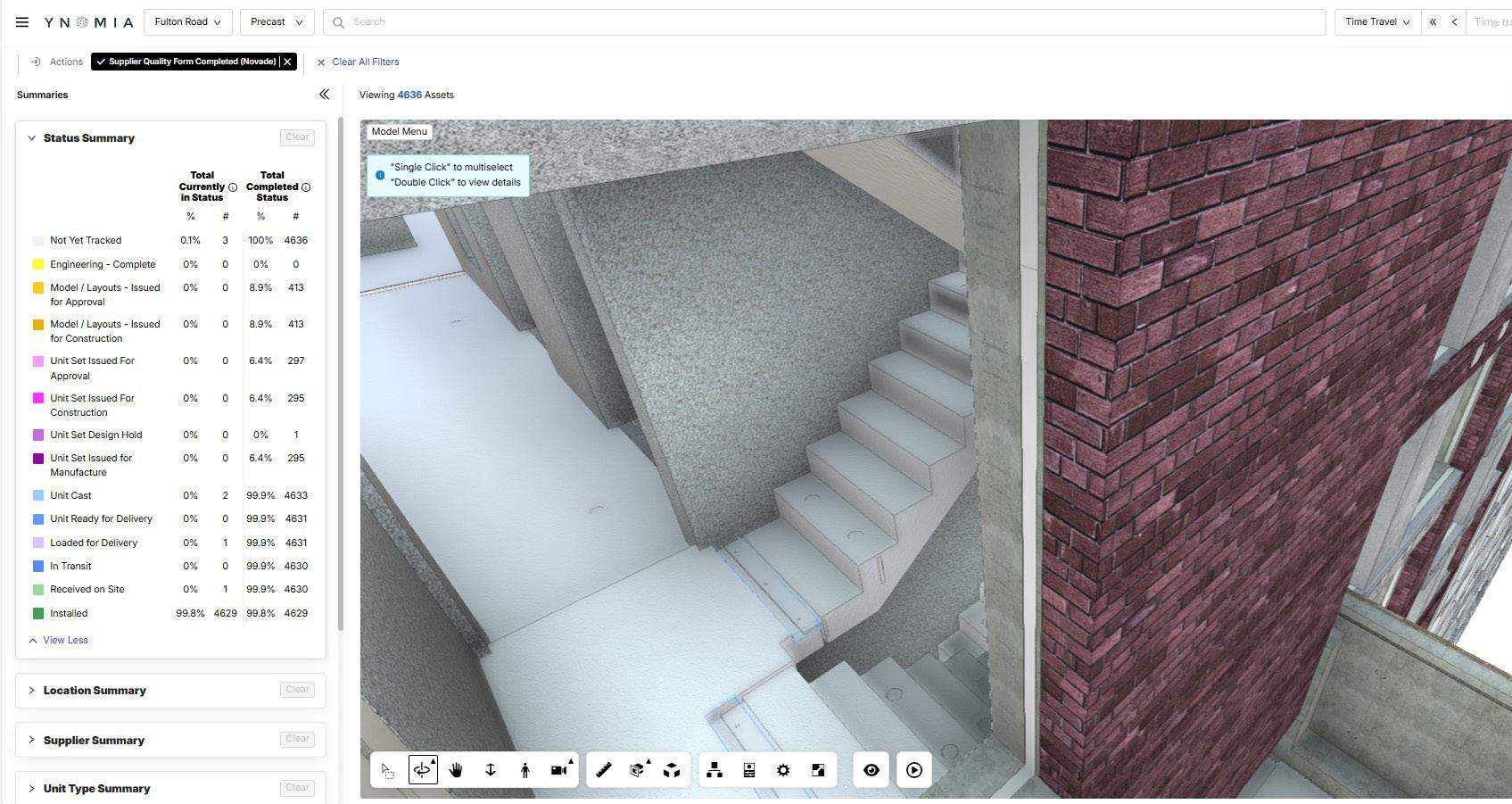

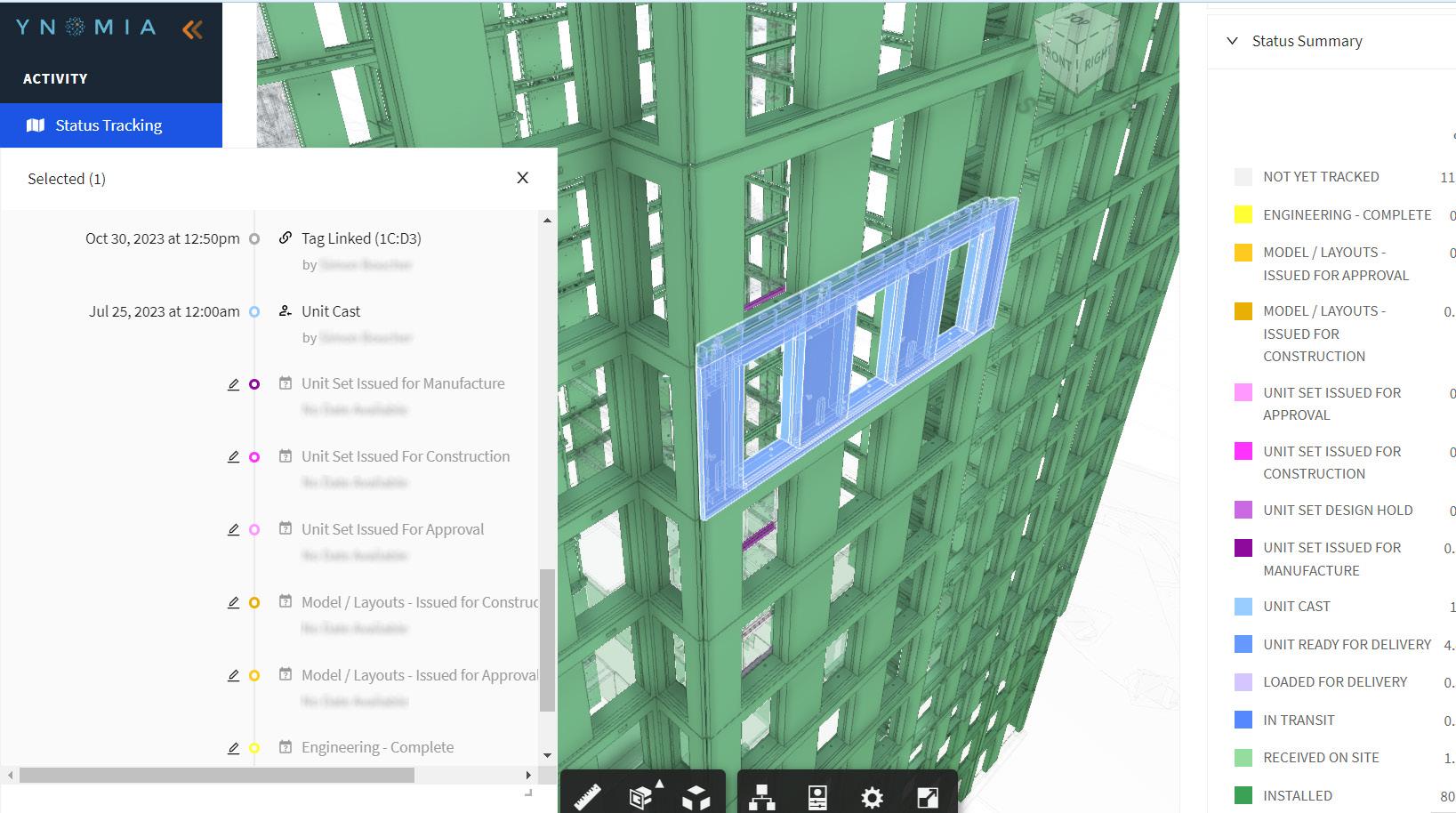

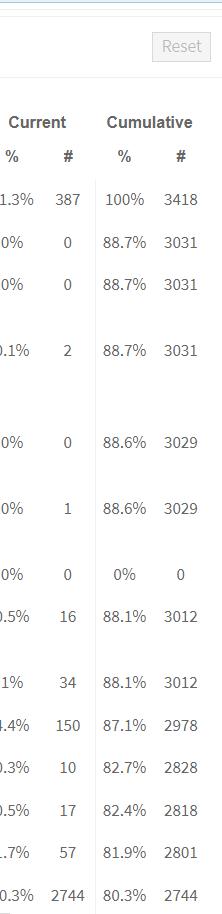

At Fulton & Fifth, PCE leveraged Ynomia’s advanced digital twin platform to deliver a fully transparent, traceable, and accountable structural solution.

Every component was tracked in real-time through a 14-stage status process, enriched with quality assurance data and engineering insights.

By linking the BIM model to a live, interactive digital twin, each structural element was assigned a unique location identifiercreating a single source of truth throughout its lifecycle. This approach not only enhanced coordination and clarity across the project team, but also supported compliance with the Building Safety Act’s Gateway process and Golden Thread requirements.

PCE’s advanced digital construction capabilities ensured Fulton & Fifth benefited from:

• Real-time tracking of all components from design to assembly

• Comprehensive data insight including QA

• Historic traceability

• 3D digital twin technology

• Autonomous system integration

• Coordinating project team – site, office, supply chain

• Supporting the Golden Thread

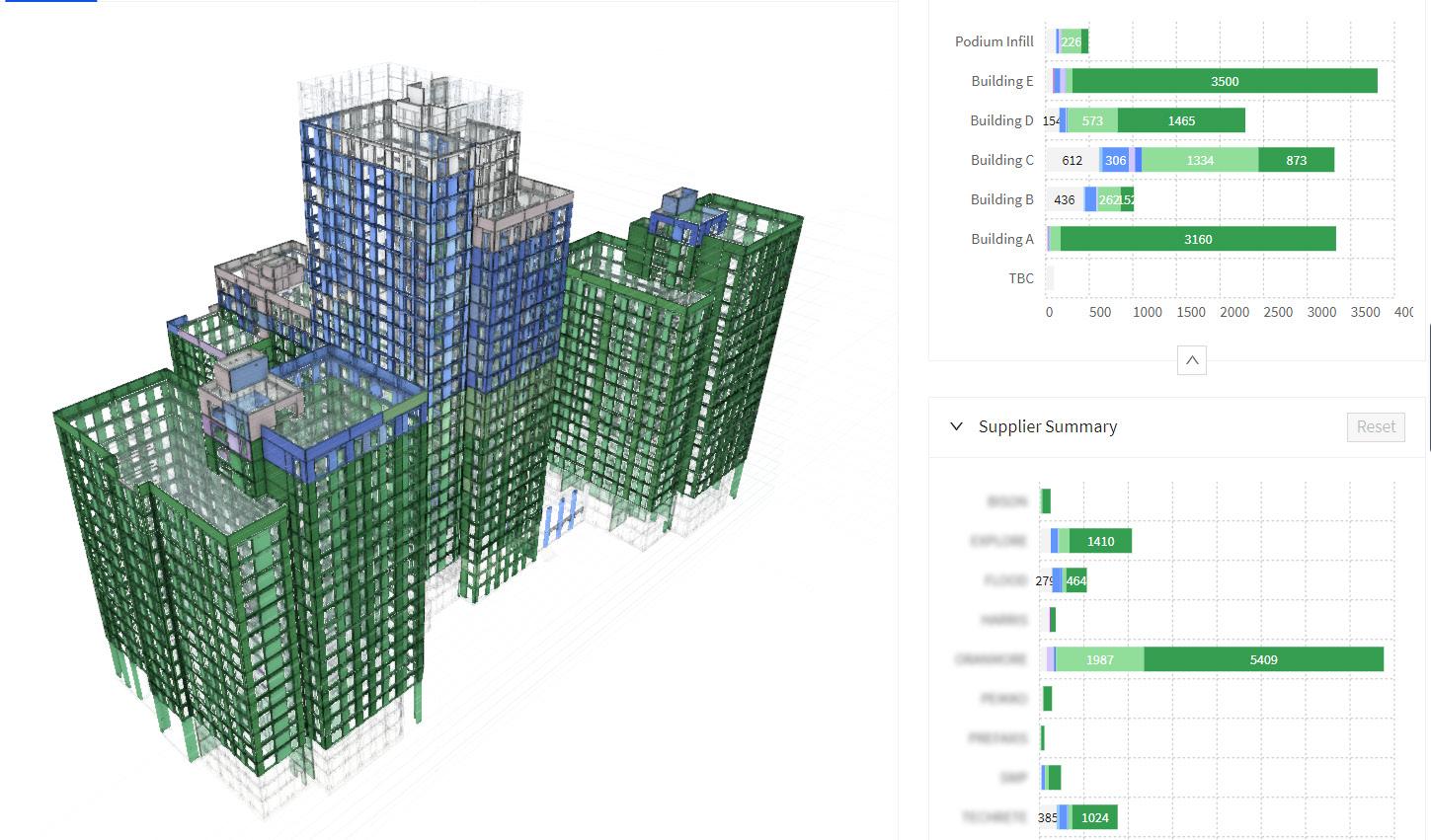

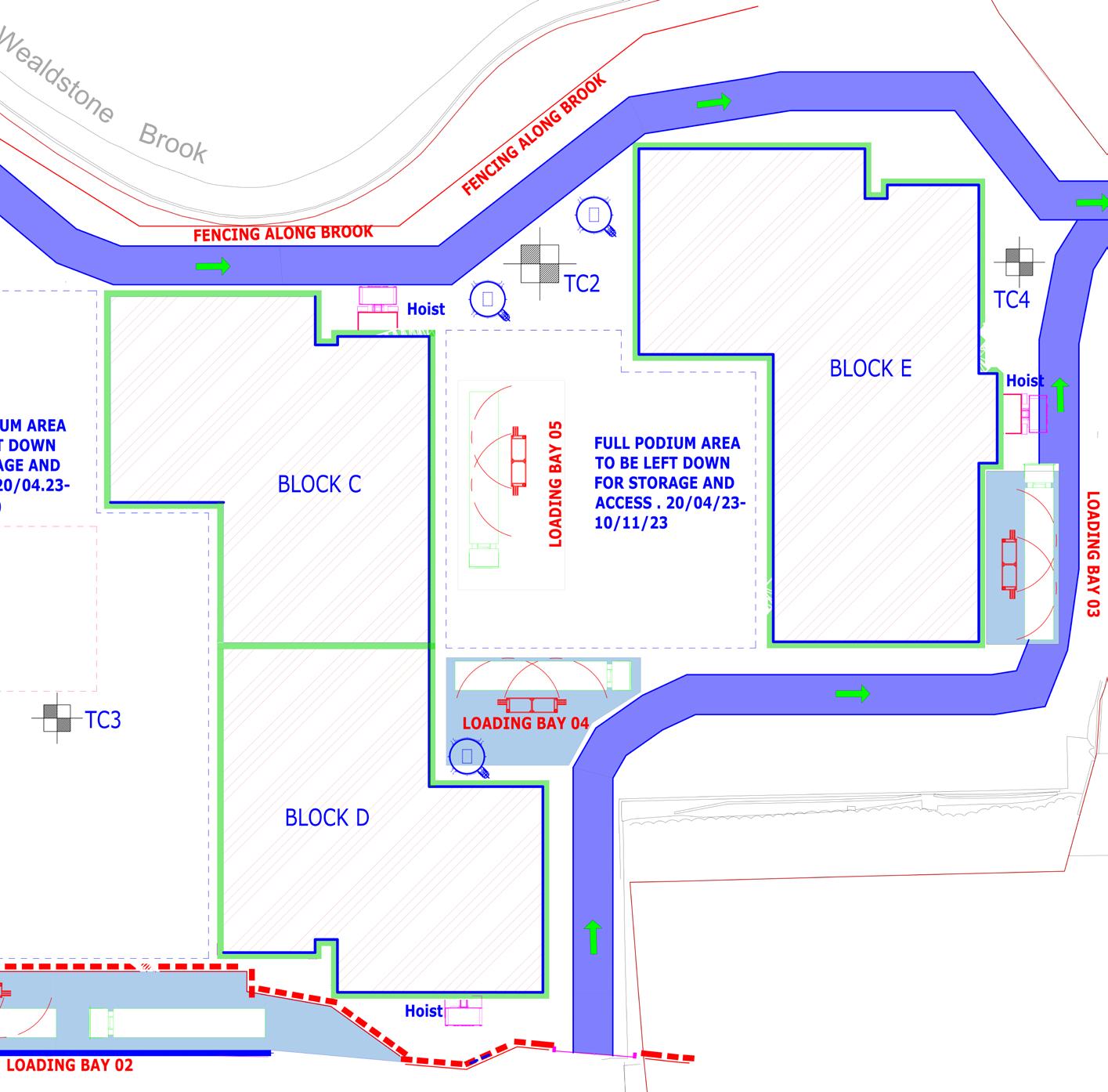

Precise planning was essential to ensure speed, accuracy, and quality on a constrained urban site.

At Fulton & Fifth, a robust just-in-time logistics strategy enabled the smooth delivery and installation of up to five loads per crane per day - totalling 500 tonnes of structural components - despite the challenges of a busy Wembley location.

With windows and façades pre-integrated during manufacture, components arrived ready for immediate installation. Careful coordination of casting, delivery, and load sequencing with the assembly strategy meant components were lifted directly from wagons into place - minimising handling and maximising efficiency.

This streamlined approach reduced onsite activity, improved safety and quality, and ensured consistent compliance - while significantly cutting noise, traffic, and disruption to the surrounding community.

Fulton & Fifth sees PCE combine two of its structural systems; hyTower, and HybriDfMA Frame.

With hyTower used for the majority of the build, HybriDfMA Frame was deployed for the two-three storey podiums. To accommodate misaligned column grids between tower and podium, deep precast transfer beams - up to 1.6m - were designed. In one high-load zone, a bespoke hybrid concrete beam was created: 24m long, 2.0m wide, and 2.2m deep. This complex solution used three offsite-manufactured reinforced concrete U-sections, each with 150mm thick walls and base. Final reinforcement and concrete were cast insitu, resulting in a single beam weighing over 250 tonnes.

The podium also featured 9.5m tall precast columns, pre-stressed hollowcore slabs (200–400mm thick), and over 1,200m³ of insitu concrete - delivering a robust structure compliant with robustness Class 2B.

Safety was embedded in every stage of Fulton & Fifth’s delivery.

In addition to standardised and well-versed construction methodologies, PCE’s hyTower system enabled safer, faster assembly with components arriving pre-fitted with features like edge protection and handrails - minimising on-site risk from the outset.

To further enhance safety during unloading, PCE used its SlingSafe system: a gated platform with a mobile boom providing full fall arrest protection via harness and inertia reel.

hyTower also eliminated the need for backpropping and minimised temporary works, while integrated stair cores provided safe access throughout construction - removing the need for scaffolding.

Independent safety audits ensured continuous improvement, while offsite-installed façades created a weatherproof, secure structure during assembly. This allowed follow-on trades to work safely just below the leading edge, accelerating fit-out and programme delivery.

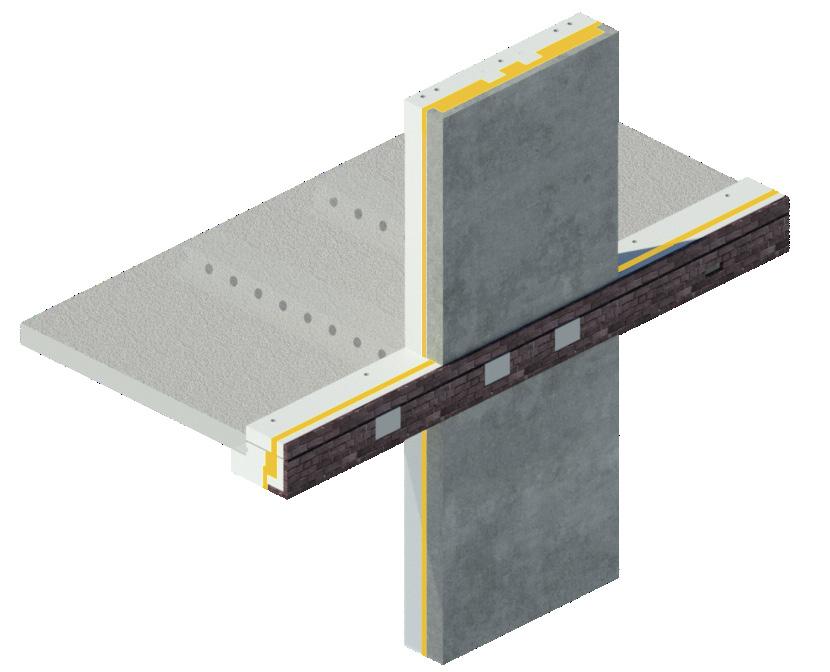

A standout feature of PCE’s integrated façade, built in structural frame.

This approach enables the building tight as it rises, allowing internal floors below active construction and envelope from the critical path accelerating the overall programme.

Façades, windows, and balconies offsite, eliminating the need for scaffolding. improved safety by reducing work the sales experience, showcasing architectural façade throughout the included balcony connectors that accommodated movement, along and sockets to minimise on-site labour.

Featuring three distinct finishes, bearing panels were enhanced with exposed architectural concreteAcross the five towers, 1,500 sandwich were installed, delivering design assembly.

PCE’s system is its in tandem with the building to become weatherinternal trades to start just two - removing structure path much earlier, and programme.

balconies were all installed scaffolding. This work at height and elevated showcasing a clean, finished the build. Panels that transferred loads and along with cast-in conduits labour.

the insulated, loadwith brickwork and all completed offsite. sandwich panel units consistency and rapid

The five towers were engineered to meet the required 2-hour fire resistance for residential buildings, with PCE’s integrated façade panels delivering more than just compliance. The design ensured high levels of thermal, acoustic, vibration, air, and water performance - creating a robust, efficient building envelope. This holistic approach not only enhanced safety but also improved long-term cost efficiency and comfort for residents.

hyTower’s systemised construction with standardised methodology and diligent pre-planning helps de-skill and substantially increase productivity and predictability.

The speed gains achieved using this systemised approach enabled structural completion of the five towers in just 23 months.

With construction expertise and end-to-end control, just 13 multi-skilled PCE operatives were needed per block, a, with repeatable efficiencies enabling a 30% increase to level completion time, which was achieved in a 10-day period. Up to 500 tonnes of hybrid structural components were installed daily, despite requiring 80% less operatives compared with traditional construction. This streamlined process dramatically reduced on-site activity, improving safety, certainty, quality, and compliance throughout delivery, whilst minimising noise, traffic, and disruption to the local area.

Beyond earlier access for follow-on trades and the enhanced sales experience of a scaffoldfree build, PCE’s scope extended to lifting and placing prefabricated bathroom pods, utility cupboards, and integrating full M&E coordination. The hyTower system provides a truly comprehensive structural solution, supporting wider delivery activities such as setting internal partition walls, installing SVPs, window dressing, vapour barriers, ductwork, and screeding.

This seamless integration accelerated construction, enabling earlier occupation of completed blocks while other towers were still in progress - showcasing the programme certainty and control achievable through our systemised offsite approach.

The hyTower system brought a number of sustainability benefits to the project.

Through carbon conscious pre-engineering, Fulton and Fifth’s ‘kit-of-parts’ components had up to 50% cement replacement within concretes and 100% recycled steel reinforcement.

Offsite manufacturing enabled precise quality control, eliminating the need for additional finishes or decoration. For example, precast twin walls in the stair and core areas were left fully exposed - avoiding plasterboard and saving 75 tonnes of embodied carbon, while also reducing time, cost, and increasing usable internal space.

The system’s hybrid flexibility, standardised connection principles, and value engineering ensured the right materials were used efficiently and effectively. As a result, Fulton & Fifth achieved 239 kgCO₂e/m² (A1–A5), meeting LETI 2020 targets, and delivered a 32% embodied carbon reduction compared to traditional construction methods.

Our highly trained, multi-skilled construction teams are committed to delivering the highest levels of professionalism, workmanship and quality in every aspect of what they do both on and off site.

Completing Fulton & Fifth was a monumental team effort and a project we are proud to have achieved ahead of schedule. From the very early stages of pre-construction, the quality standards of offsite manufacturing, the detailed work of our design teams, and the tireless efforts on-site by the project team, supply chain, site crew, and subcontractors – this achievement is a testament to everyone’s dedication, hard work, and commitment.

Being an EOT business means PCE are equally owned by its employee partners.

As business owners, our people take ownership for PCE’s continued success and enjoy the rewards that come with it; the more successful our business, the more reward we collectively enjoy.

We recognise that for PCE to be successful, we need our people to be at their best, which is why we have established a culture built around development and succession planning, investing into our workforce and providing challenging, inspiring and rewarding careers for our people to realise their potential.

Our people are given the tools and support to develop their careers, increase their knowledge, skills and experiences to help drive our EOT forward, and ultimately, enjoy the rewards we share for our collective success. It’s this culture that has been installed, that enables us to deliver great projects.