Proto PCB and Circuit Board Parts: Essential Components for Prototyping

and Development

In the fast-changing world of electronics, a fast prototyping has become quite important since it pushed the innovation. Many-a-time, Proto PCB helps the engineers and designers in trials with their idea before scaling it up to mass production. High-quality connectors guarantee that stable signals are transmitted between the board and its external devices. At PCBAndAssembly, we know that, in any developmental phase, the quality of components matters.

Understanding Proto PCB

It is a testing and validation version of a circuit board. It picks the minds of engineers for circuit performance, design problems, and changes to be made before large-scale manufacturing. Prototypes help in conducting refinements in design, whether for consumer electronic devices, industrial purposes, or auto systems.

Why Prototyping Matters

By permitting manufacturers to:

• Investigate circuit behavior;

• Early indication of defects;

• All facilitate the lowering of costs when design is at fault;

• Allow for a rapid transition in other new products toward commercialization.

A well-laid-out Proto PCB mitigates risks and contributes to reliable products in the development process.

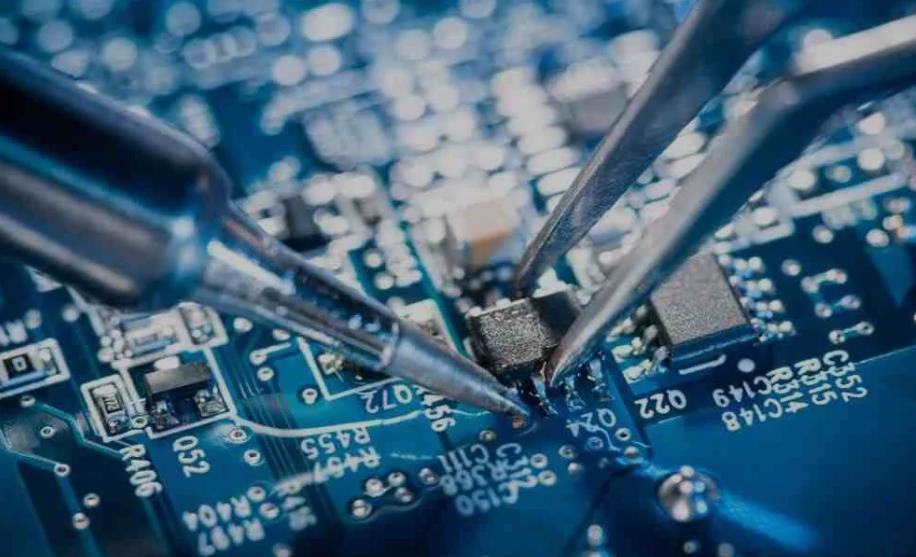

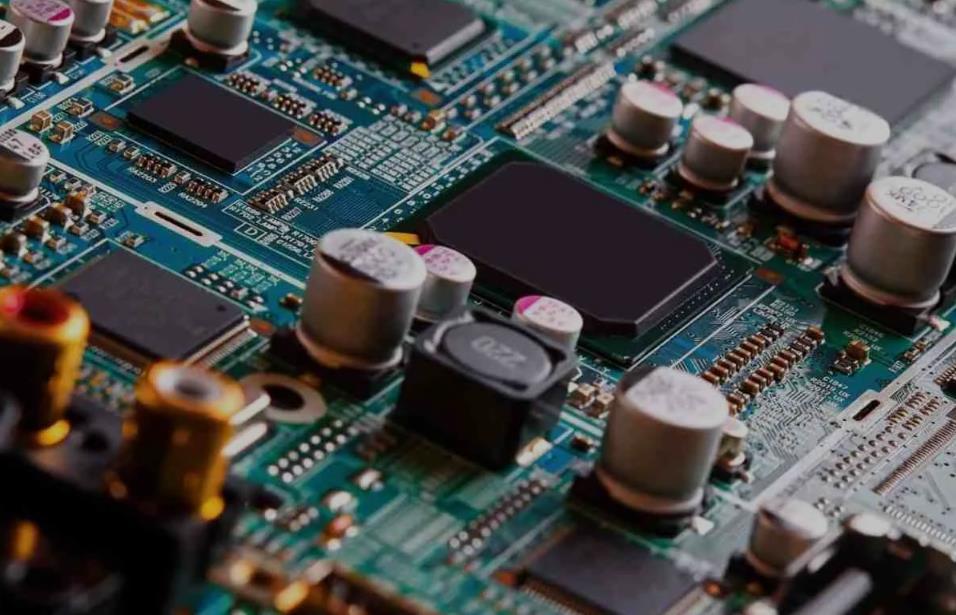

Key Components in Prototyping Circuit Boards

It is made of components vital for circuit board operation. High-quality component selection allows for smooth operations during testing and thereafter.

1. Substrate Material

Any circuit board stands on its substrate. FR4, polyimide, or metal-core laminate material gives properties like thermal resistivity, flexibility, and durability to the substrate. The correct choice for substrate improves signal integrity and reduces overheating.

2. Conductive Traces

Copper traces provide the electrical path(s) on the board. Their thickness and configuration will affect the transmission of signals, power distribution, and EMI control, with a properly designed trace improving efficiency and minimizing signal loss.

3. Passive and Active Components

Resistors, capacitors, and inductors control voltage and current flow, whereas semiconductors such as transistors and diodes handle the signal. The selection of reliable components ensures equally reliable performance during prototyping.

4. Connectors and Terminals

Secure and efficient connection is required in PCB prototyping. Proper placement of terminals provides good accessibility for testing and debugging.

5. Solder Mask and Silkscreen

The solder mask shields copper traces from oxidation and prevents unintended solder connections. A silkscreen layer applied well authorizes proper component labeling for easy assembly. These elements enhance usability and longevity for the board.

Best Practicing for Effectiveness in PCB Prototyping

To further ensure the success of it, engineers should:

• Use design software to accurately lay out components and place them.

• Apply DFM-software practices to enhance the manufacturing process.

• Subject the prototype to rigorous testing in functional and environmental domains.

• Source high-quality circuit board parts from trusted suppliers.

A strategic approach to prototyping aids in curtailing errors, enhancing efficiency, and quickening transitions into volume production.

Final Thoughts

Prototyping is the bedrock of successful electronic products. The choice of Proto PCB, supplemented by premium circuit board parts, goes a long way toward ensuring innovation and quality. With the right components and expertise, the engineers will transition concepts into dependable and high-performance products.

Put your faith in PCBAndAssembly for expert PCB solutions to support your development needs. For other information, please consult www.pcbandassembly.com