Architect 2.0

The role of designers in a world where less is more

Modular marvel

Bio-based Offaly school arrives by truck Bay window Connemara scheme brings the Atlantic in

Architect 2.0

The role of designers in a world where less is more

Modular marvel

Bio-based Offaly school arrives by truck Bay window Connemara scheme brings the Atlantic in

Ireland’s largest developer goes passive at scale

Minimal Energy Usage. Maximum Living Comfort.

Read our position paper at cairnhomes.com/passive-house or scan the QR code.

Publishers

Temple Media Ltd

PO Box 9688, Blackrock, Co. Dublin, Ireland

t +353 (0)1 210 7513

e info@passivehouseplus.ie www.passivehouseplus.ie

Editor Jeff Colley jeff@passivehouseplus.ie

Reporter John Hearne john@passivehouseplus.ie

Reporter Kate de Selincourt kate@passivehouseplus.ie

Reporter John Cradden cradden@passivehouseplus.ie

Reader Response / IT Dudley Colley dudley@passivehouseplus.ie

Accounts Oisin Hart oisin@passivehouseplus.ie

Art Director Lauren Colley lauren@passivehouseplus.ie

Design Aoife O’Hara aoife@evekudesign.com | evekudesign.com

Contributors

Lenny Antonelli journalist

Caroline Ashe Brady KORE Insulation

Toby Cambray Greengauge Building Energy Consultants

Ellora Coupe Her Retrofit Space

Mhairi Grant Paper Igloo Architects

Kathryn Meghen RIAI

Marc Ó Riain doctor of architecture

Print GPS Colour Graphics www.gpscolour.co.uk | +44 (0) 28 9070 2020

Cover A rendering by 3D Design Bureau Ltd of Cooper’s Square, Seven Mills

Some of the most persistent myths about passive house, over the years, have been about its practicality and commercial viability. It’s all well and good for the committed enthusiast, the thinking goes, but once it interfaces with the real world of large scale property development, it won’t stack up.

When this magazine lobbied for a passive house planning requirement for all new buildings in Dún Laoghaire-Rathdown in 2015, both the then director general of the Construction Industry Federation and one of Ireland’s leading property journalists reached for the same metaphor in arguing against the plans: the luxury car. Sure, everyone might want to drive a Mercedes Benz, but most people can’t afford such a car.

I’ll do my best to avoid the rabbit hole of questioning the automotive metaphor –other than to say that it would be helpful in a climate emergency to move away from an oil age lexicon, where we no longer talk about concrete plans, steely determination, cementing relationships or putting the pedal to the metal. But I want to take issue with the substance of the argument: that passive house may be a nice thing to have for those who can afford it, but it’s not realistic for normal people. We built evidencebased arguments at the time that this was untrue, and that with expertise and care, passive house could be delivered at little extra construction cost and – if it became a condition on land – no net cost increase in terms of total development costs.

All the same, it is one thing to make an argument. It is quite another to see it become set in stone, to pick a less jarring metaphor. As this issue reveals, Ireland’s largest house builder, Cairn Homes, is currently on site with over 1,750 apartments

which are set to be certified to the passive house standard. Every one of these homes are social and affordable units, meaning that 1,750 households will not have to choose between heating or eating, and will not have to suffer the threats posed by damp, mould and poor indoor air quality.

And it gets better. Because they’re being delivered in sites aiming for biodiversity net gain, and with sustainable transport connections, and backed by the Irish Green Building Council’s rigorous Home Performance Index certification, they offer the real prospect of creating thriving communities which can show the way forward in terms of what property development in the 21st century must look like: places where people have the sanctuary and dignity of a quiet, comfortable home that is light on the pocket, with the delight of nature outside, and without the need to own a car to get around.

In so doing, projects like this show us the seemingly impossible: how to tackle the climate emergency, the biodiversity emergency, the energy crisis and housing crisis. The fact that Cairn have managed to do this without passing on any construction cost increases to their clients, is even more remarkable.

The cynic in me is still adjusting to praising a large-scale house builder. But I have no choice in this case. The leadership shown by Cairn Homes is game changing, and the entire construction industry in Ireland and the UK must sit up and take notice. If the largest house builder in Ireland can build at scale to the world’s leading low energy building standard, why can’t you?

Regards, The editor

If passive house is Everest, we’ve left base camp

The construction industry is moving in great numbers towards the passive house standard. In an adapted version of a speech at the Construction Industry Federation Conference in September, Passive House Association of Ireland chair Caroline Ashe Brady looks at the trek ahead.

Passive towers protect vulnerable Bronx seniors

How do you serve the needs of senior citizens who have fallen on hard times in the Big Apple? In Betances Residence, CookFox Architects have cooked up an extraordinary response, integrating the protective benefits of passive house with beautifully considered, user-tailored design.

Traditional homes retrofit grant pilot launched; £30m passive scheme launched in Down; and a pan-European consortium aims to kickstart the en masse greening and decarbonisation of Europe’s housing stock.

In the latest piece in his series on the development of low energy building, Dr Marc Ó Riain describes the evolution and Impact of EPCs in Ireland and the UK; and Ellora Coupe says our efforts to retrofit homes across the UK and Ireland will be severely hampered unless we engage meaningfully with and empower women homeowners and professionals.

Passive breakthrough

Ireland’s largest developer embraces passive house at scale

In September Cairn Homes lit the fuse on a passive house explosion, publishing a position paper on passive house and announcing the construction of nearly 1,800 apartments to the standard. But what’s behind the company’s bold move?

Bay window

Connemara passive scheme brings the Atlantic in Designing a passive house is one thing. Designing a scheme of passive houses to make the most of the views on an extraordinary coastal site is another. And designing that scheme to tie into the local supply chains and architectural vernacular – while ensuring the homes are set up for changing, potentially disengaged occupants – is the stuff of magic.

Offaly school uses volumetric modular timber build

Forgive the 80s hip hop house reference in the headline, but the volume of the walls in this volumetric modular school building in Birr was literally pumped up – with recycled newspaper insulation. Built to passive house principles, it’s a story of one Roscommon manufacturer reimagining the role that offsite methods can play in the delivery of highly sustainable permanent accommodation for schools – while delivering exceptionally low embodied carbon results.

Just what the doctor ordered

Stirling passive house blitzes RIBA 2030 targets What do you get when a clinician couple decide to build their dream family home? In the skilled hands of leading Scottish architects Paper Igloo, you get a forensically detailed, highly ecological, cosy home that wraps up low embodied carbon and passive house into a beautiful design.

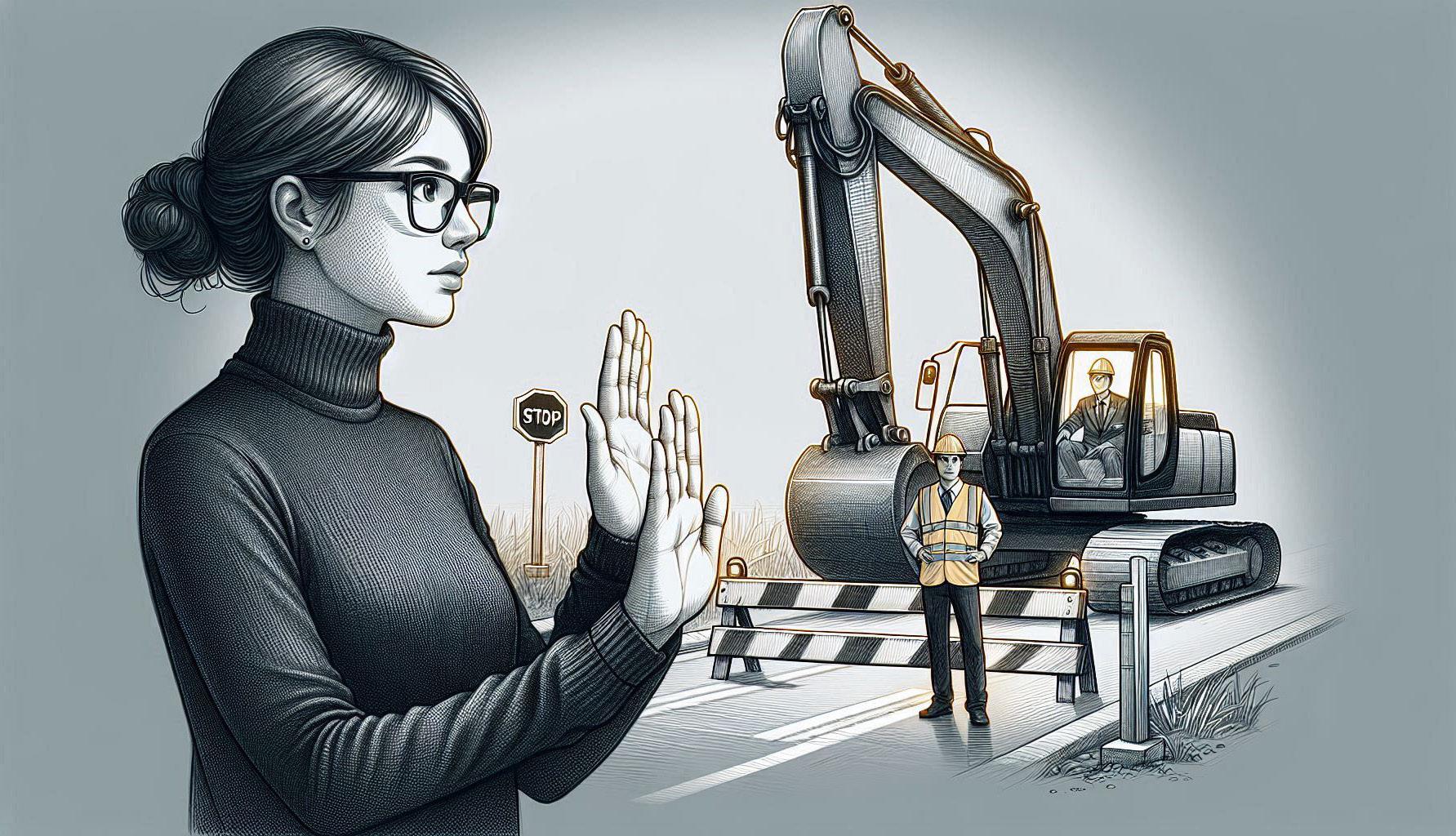

The role of designers in a world where less is more

It’s a radical idea: that to negate the environmental damage of construction, we don’t just need to build sustainably, we need to build less. However, most architects and building designers earn a living by doing exactly the opposite: by building stuff. So how can the design practice be reinvented for a world in which we need to do more with much, much less?

Keep up with the latest developments from some of the leading companies in sustainable building, including new product innovations, project updates and more.

Passive house doesn’t care about materials

One stubborn trope in some corners of green building is that passive house is so focused on energy performance that its advocates ignoring materials. Not so, argues Toby Cambray.

The construction industry is moving in great numbers towards the passive house standard. In an adapted version of a speech at the Construction Industry Federation Conference in September, Passive House Association of Ireland chair Caroline Ashe Brady looks at the trek ahead.

At present, many players in the construction industry are quietly investigating the passive house standard. With approximately 3,000 passive units in the pipeline in Ireland, on site or heading for site and in tandem with Cairn Homes’ recent announcement that they are adopting the standard and will add over 1,700 units, this has become a mega trend. So why the move to passive?

The rise of green finance and lower interest rates linked to Environmental, Social and Governance (ESG) has been a major driver. This source of finance is especially important to the construction industry given the investment required to make projects happen. If you cannot prove through reporting that you are delivering on your ESG outcomes, not being able to access lower interest finance puts you at a competitive disadvantage.

The raft of legislation from Europe is another key driver. The Corporate Sustainability Reporting Directive (CSRD) comes into play in Ireland this year for twenty-six companies.

both the embodied and operational carbon of the built environment. We need to look at how we design and build, the systems we use, and to engage with the entire supply chain – it is the collective effort from all that will deliver a lower embodied carbon result. This is no easy task and there is an industry view emerging that it will take some time, and that operational carbon interventions may more quickly deliver reductions. Operational carbon is the in-use carbon produced from the finished building. A target to reduce is easier to achieve because it is the output of the design and build activity. What happens on site following appropriate design, reduces the performance gap and therefore operational carbon.

is just the recipe for passive is slightly different. To be bold, we have the solution for zero energy building. If passive house is the summit of Everest, then NZEB is a base camp on that journey.

But what will it cost?

A study in the UK by Atkins in 2019 found that passive projects in the UK cost approximately an extra 4 per cent but reduce to nominal levels if adopted at scale. The reality is every time we want to do something different it costs money. Whether you build ZEB buildings today or in 3 years, you will incur the cost of doing so. The beauty of passive is that once you nail the process the cost difference is marginal.

We already use the ingredients, it is just that the recipe for passive is slightly different.

A further 2,000 companies must report next year, including many in construction, and this information will be data mapped, allowing the finance and investment industry to easily compare one company to another.

The recast Energy Performance of Buildings Directive was enacted in Europe in May, calling for zero emission buildings. Over the next couple of years government will be deciding what this looks like in Ireland.

Consider the E in ESG. We need to reduce

Why does passive house solve these problems? In the 1980s, Professor Wolfgang Feist wanted to prove that it was possible to build without a traditional heating system even in colder climates. The first building, built 33 years ago, is still being monitored and has been an intensive research project from day one. Feist set up the Passive House Institute, a not-for-profit independent research institute, and currently it offers the only internationally recognised, performance-based energy standard in construction. There are now nineteen affiliates globally, including the Passive House Association of Ireland, and as of June 2024, 43,800 units have been certified. To say that this standard is tried and tested is an understatement. It has proven effective through post occupancy evaluation and the institute continue to review, learn and always improve the standard. A science-based approach, the standard also speaks to the G in ESG. It reduces operational carbon compared to NZEB with no green washing. Outcomes are explicit because the performance targets are absolute, with metrics defined through a transparent evidence-based process. The passive house planning package (PHPP) is a robust, accurate and practical tool that supports compliance and design, and produces energy forecasts with an elevated level of accuracy. The performance gap is now in the margin of error. Our industry is on a progressive journey to zero and how we have done things to now has served us well. As Stephen O’Shea from Cairn Homes recently said, we already use the ingredients, it

There are so many more benefits, for homeowners, councils and housing bodies – passive house protects the value of your assets. Maintenance costs are lower, the building fabric is protected, and the need to retrofit new buildings to meet 2050 targets will be obviated.

The social advantages speak to the S in ESG. Passive buildings offer greater comfort, healthier buildings, improving the quality of life for the occupants. And because the performance gap is closed, the monetary savings are real. What would you do with the money you normally spend on heating if you had it in your pocket today?

Everything has its time

Consider Steve Jobs of Apple. In the 1980s he said that he wanted everybody on the planet to carry a computer in their pocket. In the apocryphal words of Henry Ford, who revolutionised the production of motor cars, “If I had asked people what they wanted, they would have said faster horses.” In the 1980s Wolfgang Feist designed a building without heating. So, as you get in your car and look at the little computer in your pocket, ask yourself – is now the time for passive house? n

How do you serve the needs of senior citizens who have fallen on hard times in the Big Apple? In Betances Residence, CookFox Architects have cooked up an extraordinary response, integrating the protective benefits of passive house with beautifully considered, user-tailored design.

Words by John Cradden

Betances Residence is a passive house classic-certified residential development located in the Bronx, New York City that provides supported housing for vulnerable and homeless senior citizens in what is now a thriving majority Hispanic community. Comprising two eight-storey towers with 152 units and around 10,000 sq ft of community space and amenities, this development had to meet a very challenging brief, and the team behind it has not only ticked all the right boxes, but executed it in a way that has surpassed expectations for energy efficiency, comfort and air quality.

The brief

The commissioning of Betances is the result of a collaboration between the New York City’s Department of Housing Preservation and Development (HPD) and Breaking Ground, a non-profit organisation that builds high-quality permanent and transitional housing for

the homeless using both public and private funding. The RFP (request for proposals) for the development on what was an open parcel of land owned by the City of New York was awarded to CookFox Architects, a local firm that specialises in mainly large-scale projects, most notably St John’s Terminal, Google’s 1.2 million sq ft headquarters in the city, and the 55-storey Bank of America Tower. The firm had previously worked with Breaking Ground on another supported housing project, the Hegeman in Brooklyn back in 2010, but for both organisations, Betances was their first experience of building to certified passive house standard.

The case for passive house

Aside from the energy savings, CookFox’s director of communications, Jared Gilbert, points to two of the biggest benefits of passive house for the residents of Betances: better air quality and superior

acoustic insulation. Located close to some of the busiest state and interstate highways in the city, the South Bronx has one of the highest asthma rates in the United States. “I don't know if it's more noisy than other neighbourhoods, but we often think of quiet as kind of a luxury product in New York City,” said Gilbert. “One of the benefits of passive house is that because you have to create an envelope that's so tightly sealed, you get really good acoustic performance.” He added that while taking pictures of some of the residents, the woman sitting at the window said: “I love this building. It's so quiet in here.”

Gilbert says the challenges of achieving passive house certification were complex “given the constraints for economy, construction sequencing and ambitions for architectural experience for a multi-unit design”, but a closely aligned team led by consultancy Steven Winters Associates, Monadnock Construction, and a steadfast client enabled them to achieve it.

The architecture along 143rd Street in New York City is very varied, with early 20th century brick-built town homes and some

When someone has not had a home of their own for many years, that sense of protection and permanence is important.

later 1920s and 1930s apartment buildings next door, not to mention high-rise public housing nearby. A neat design touch that enhances the sense of permanence of Betances is the use of deep window recesses, creating stronger shadows that bring a feeling of solidity and heft that apes older buildings but without the need to build walls that are thick and heavy. Many later 20th century buildings tend to have very flat facades that may not age well. “Our expression of the depth of our exterior wall is meant to reinforce the idea that this building will be lasting and permanent,” said lead architect Darin Reynolds. “When someone has not had a home of their own for many years, that sense of protection and permanence is important.”

Aging gracefully

Above the ground floor level, Betances is clad in zinc, which aligns with the aim of using natural materials as much as possible as well as being relatively inexpensive. “The zinc we used on this project is pre-weathered, meaning that it come with patinated or oxidized surface, which causes its light, warm grey colour,” said Reynolds. “Over time, with additional weathering, the surface should darken slightly. This natural process allows the building facades to age gracefully and beautifully. It will look as good, or better in the future.”

Connection with nature

The use of zinc as a material that will age gracefully over time is but one example of the extensive application of biophilic design in Betances. Others – often done in conjunction with active design strategies to support health and wellbeing – include encouraging movement and activity by making the path through the building easy to navigate, lining it with plants and natural materials, and adding windows to the egress stairs to bring natural light and encourage the greater use of the stairs.

“As the building kind of took shape and began to be planted, we noticed that the neighbours started replanting the own backyards, with similar plants and things that we were using in these courtyards,” said Gilbert. “So, I love that idea that the building can make an impact on the neighbourhood in a positive way, and that there can be a relationship between not just the people, but the landscape in this building.”

The power of universal design

Given its central purpose as a building for senior citizens, it’s no surprise to see lots of examples of universal design, but they are all executed in a way that makes them feel

integral parts of the building, such as the discreet handrails along the ramp walkway. “The large entry ramp is a way to allow users with mobility issues to enter the building in the same way as someone without mobility issues,” said Reynolds. “The idea is that the experience is shared. By including natural materials and patterns, along with access to daylight and views, it actually elevates the experience of entering the building and makes it special for everyone.”

Gilbert adds that anytime he’s in the building for tours, most people tend to take the ramp rather than the stairs simply because they enjoy it more. “There's a slow descent towards that big glass where you're looking into the courtyard, so you just have this immediate connection to nature to the garden that's at the centre of the building and, as you sort of circle around that bend, you feel enveloped by the space.”

‘We got it right, here’

Brenda Rosen, president and CEO of Breaking Ground, says Betances meets a new standard for housing quality that everyone deserves, not just those who can afford it. “Whenever we begin a project, we approach it from the perspective of the tenants who

will call the building home. People experiencing homelessness deserve quality and sustainability in their housing, and we aim to ensure that people who are living with mental illness, long periods of homelessness, and other disabling conditions have everything they need to get and remain stable for the long term. And here we are also working with seniors, bringing another layer of complexity by ensuring that people can age-in-place in the community for as long as possible. One of my colleagues with deep experience opening our new projects said it best at the Betances ribbon-cutting: ‘We got it right here.’ I could not agree more.”

The digital version of this magazine includes access to exclusive galleries of architectural drawings.

The digital magazine is available to subscribers on passivehouseplus.ie & passivehouseplus.co.uk

Multi-award winning Belfast-based property developer, Fraser Millar, has launched Northern Ireland’s second large-scale residential passive house development – a 74-unit scheme of detached and semi-detached homes at a total project value of £30m.

Located on the Comber Road in Carryduff, Co Down, Beaufort Green follows the success of the company’s first passive house development, Lancaster Park, in south Belfast, which featured in issue 43 of Passive House Plus.

“The passive house standard has set a new benchmark for energy efficiency and sustainability in the housing market,” said Fraser Millar director John Carrigan, “The criteria for passive house certification significantly exceed Northern Ireland’s current building regulations – to the benefit of our homeowners”.

14 houses have initially been released with over three quarters booked. First completions are estimated for the first quarter of 2025.

While the construction industry has been slow to engage with monitoring the real world performance of buildings, Fraser Millar – who scooped Developer of the Year 2023 at the PropertyPal Awards – are proving to be an exception.

“We believe we are also the only property developers in Northern Ireland that collects monthly data to monitor the energy usage of our passive homes,” said Carrigan. “So far, we have received excellent feedback from our homeowners in Lancaster Park. Typical new homes, according to recent studies, are using nearly double the energy in their design projections. Whereas our passive homes are actually using slightly less than the calculated levels. This demonstrates that passive houses do what it says on the tin, which can result in considerably lower utility bills for the homeowner.”

Carrigan said Fraser Millar hoped to see sustainable building standards like passive house become more commonplace in Northern Ireland. “At Fraser Millar, we have cemented ourselves as the industry trailblazers, paving the way for a revolutionised way of living that is both better for the environment and for the health of occupants. The wider Northern Ireland housing industry is grappling with challenges and claims of low energy, but with passive house principles, the sector has the potential to be not only completely revolutionised but truly energy efficient.”

For more information visit www.frasermillar.co.uk •

The Sustainable Energy Authority of Ireland has launched a home energy upgrade for traditional homes pilot.

Owners of traditionally built homes can now apply for grant support through a number of SEAI’s registered one-stop-shop providers.

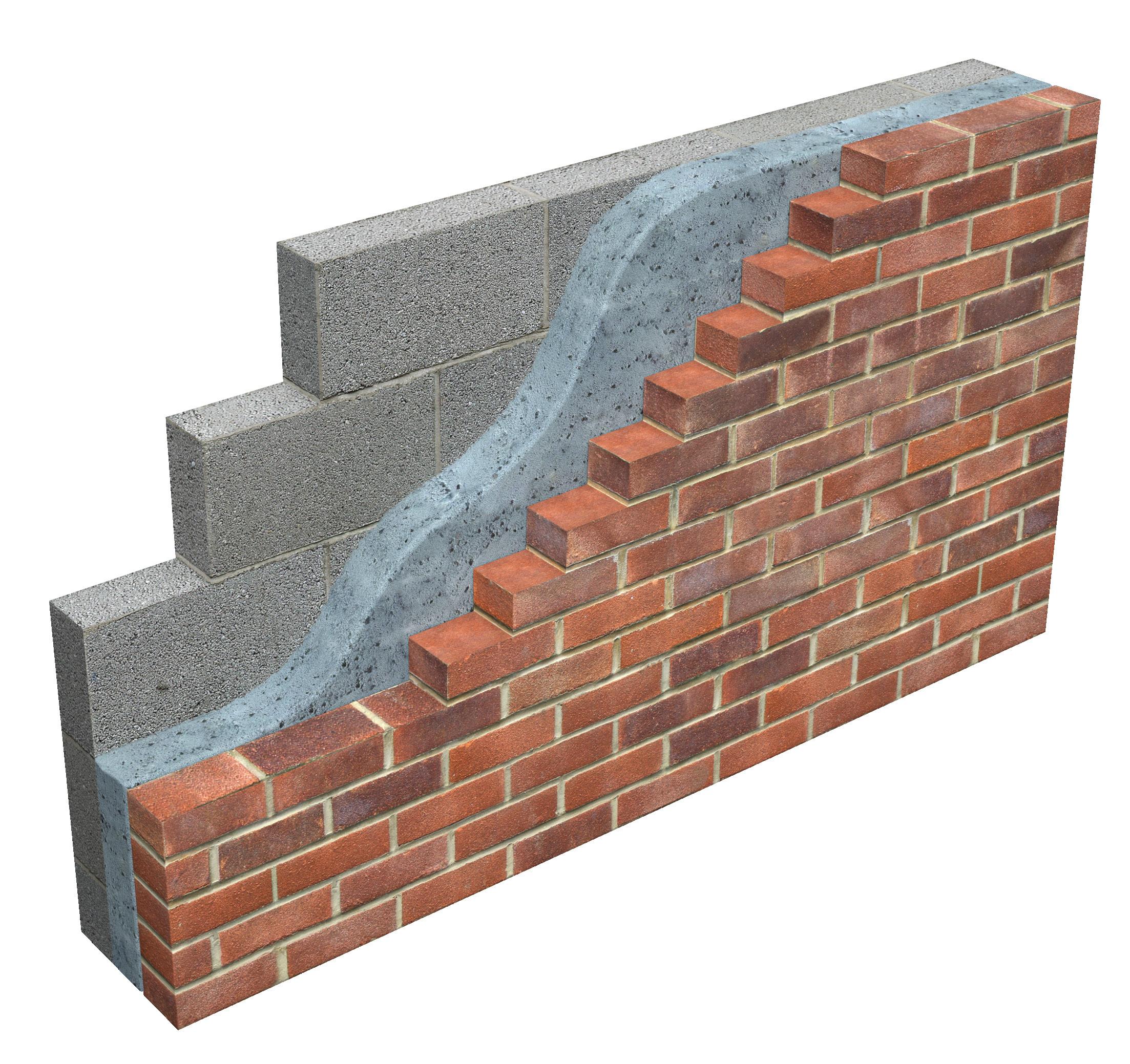

Typically, traditional homes differ significantly from homes built in the last century in one significant way: solid masonry external walls, built from traditional materials, with no continuous cavity. As few materials suitable for use in traditional buildings have been certified by bodies such as NSAI Agrément, the works in the pilot must involve homeowner-appointed traditional building professionals – including conservation-accredited architects, engineers or surveyors.

The move follows the Department of Housing publishing the guidance document, Improving Energy Efficiency in Traditional Buildings: Guidance for Specifiers and Installers.

The pilot, which will be open for 100 homes, seeks to gain a detailed understanding of the technical aspects, materials, products, and associated costs with the solutions required for traditional homes.

The announcement was welcomed by TU Dublin’s head of building performance and construction, Joseph Little, who called the news “the most significant government-led change in the energy efficiency of traditional buildings” since retrofit grants were introduced in 2008, adding that it would assert the importance of the role of conservation architects and other design professionals with expertise in ensuring the health of solid wall structures. “It’s going to reinvigorate the conversation about what is an appropriate specification and provide additional support for those seeking to move away from the narrow Agrément-approved approach.” Little said that once the pilot has concluded, the emphasis will be to move forward to a national scheme.

For more information, visit tinyurl.com/ tradpilot. •

Gas cooking is killing 40,000 European people a year in Europe, a major new study has revealed, with an average of almost two years taken off their life in the EU and United Kingdom due to exposure to nitrogen dioxide (NO2) emitted during gas cooking.The countries with the highest burden were Italy, Poland, Romania, France and the UK.

The European Climate Foundation-funded study, which was conducted by academics at Jaume I University, has calculated the first map of indoor NO2 concentrations in households according to cooking appliance for the European population. The annual concentrations inside the households of more than half of the countries exceeded the heath

guideline for NO2 proposed by WHO in 2021.

Gas cooking appliances are a significant source of household air pollutants, including NO2 , which is a harmful gas with known health effects. Gas hobs are present in 33 per cent of European Union households and in 54 per cent of households in the UK. Presence of gas cooking at home and exposures to NO2 have been associated with childhood asthma, premature mortality and other health outcomes in scientific studies.

Other pollutants emitted during cooking with gas appliances were not considered in the study. •

Europe’s burgeoning green homes market is a multi-trillion euros opportunity –but lenders must be wary of facilitating greenwashing, a pan-European consortium has warned.

According to Alexandra Hedesiu, managing partner at EnerSave Capital and spokesperson on the pan-European project Smarter Finance for EU: “The need to rapidly transition to a decarbonised, green European housing stock represents a multi-trillion euro opportunity –and it’s one that the finance community must embrace.”

With a range of drivers emerging to force the hand of finance to quantify and substantially improve the environmental and social performance of investments, Hedesiu warned against finance professionals seeking to do the bare minimum to meet the requirements for individual drivers in isolation.

“Investors who take a narrow interpretation of their obligations regarding any one green driver are heading for trouble,” said Hedesiu. “The EU taxonomy is one thing. But what about the Sustainable Financial Disclosure Regulations (SFDR), the Corporate Sustainability Reporting Directive (CSRD), or the recast Energy Performance of Buildings Directive? Property investments that barely meet the requirements of these drivers risk becoming stranded assets. The only prudent approach is to stop thinking about doing the bare minimum, and instead invest in property with credible green building certification.”

A European Union-funded consortium of

green building councils, energy agencies, NGOs and sectoral experts, Smarter Finance for EU is aiming to kickstart the en masse greening and decarbonisation of Europe’s housing stock by unlocking €100bn worth of EU taxonomy-aligned green homes – over €10bn of which has already been secured.

Green homes finance professional course launched

The consortium has developed a green homes-accredited finance professional training programme to upskill finance professionals on greening their portfolios, led by Hedesiu. “This comprehensive training initiative offers a robust curriculum,” said Hedesiu. “It encompasses key areas such as green homes certifications and EU taxonomy alignment, real estate loan portfolio assessment, reporting and governances, risk management, regulatory compliance and marketing strategies for residential green finance.”

Hedesiu said the training will play a key role in equipping finance professionals with specialized knowledge and skills in green financing, focusing on sustainable housing projects and green investment strategies.

Hedesiu announced the new training programme at the Smarter Finance for EU banking sector launch event, “Banking on green homes: exploring the world of sustainable finance”. Held in Brussels in May, the event focused on supporting the banking sector and the journey to “greenify” portfolios, and was attended by an audience of property financiers and investors.

The EU LIFE co-funded project, Smarter Fi-

nance for EU, is dedicated to driving the change Europe needs in the development of finance and credible green certification for homes.

Smarter has unlocked finance and green home certification for over 31,000 new homes across Europe, by taking a systemic, multidisciplinary approach to solving a systemic problem. The needs and motivations of all of the essential stakeholder groups that are critical to moving the green finance topic forward to promote greener homes for Europe’s are considered.

Co-ordinated by the Romania Green Building Council, the partners in Smarter Finance for EU include the Irish Green Building Council, Luxembourg-based sustainable finance facilitator EnerSave Capital, Passive House Plus publishers Temple Media Ltd, the association Energy Efficient Cities of Ukraine, Green Building Council España, Portuguese energy agency Adene, Habitat for Humanity International, and the European-Ukrainian Energy Agency. With energy poverty on the rise across Europe in the aftermath of Russia’s invasion of Ukraine, the consortium also includes a focus on developing hybrid green finance products to help lift vulnerable people out of energy poverty and provide healthy, comfortable homes with low exposure to energy price spikes.

A number of banking partners already offer finance products tied to green home certifications by partners in Smarter Finance for EU, and the EU Horizon 2020-funded programme which preceded it, Smarter Finance for Families. Tailored development finance discounts of 0.1 to 0.5 per cent are available in Ireland for housing schemes certified to the Irish Green Building Council’s Home Performance Index (HPI) certification by pillar bank AIB and Home Building Finance Ireland. A range of banks offer preferential green mortgages tied to Romania Green Building Council’s Green Homes certification, including Alpha Bank Romania, Banca Transilvania, BCR Erste Group, BRD Groupe Societe Generale, Garanti BBVA, Raiffeisen Bank Romania, Romanian Commercial Bank, Vista Bank and Libra Internet Bank, who also offer preferential development finance terms. Meanwhile, Smarter Finance for Families partner Polish Green Building Council has secured green mortgages on its Zielony Dom certified homes from BNP Paribas and BOS Bank.

For information on green home certification, finance for green homes visit www.smarter4. eu. For information on the courses offered by Smarter4EU partners including for green homes finance accredited professionals and a range of other courses, visit www.smarterfinance4.EU/ education •

New and tightening sustainability requirements are hitting the construction sector at an increasing pace. Irish Green Building Council membership engagement officer Lenny Antonelli goes through the main requirements – and offers clues on how to keep ahead.

How well do you know your CSRD from your SFDR from your CSDDD? Or even your EPBD from your EED? And do you know how these will impact your business? For those working in the built environment, it feels like there is an avalanche of new regulations and directives from Europe to get to grips with, each with its own confusing title.

The European Green Deal – the package of EU policy initiatives that aims to make the union climate neutral by 2050 – contains dozens of different laws, many of which will impact the building sector.

Some of the most important laws concern corporate finance and governance, rather than buildings explicitly. But their effect is quickly trickling down to the built environment. These are part of the EU’s Sustainable Finance Framework and could be grouped under the broad term ESG (Environmental, Social, and Governance). There is no strict legal definition of ESG, but the term is used to generally refer to corporate policy and regulation in these fields.

These new directives and regulations include:

› The Corporate Sustainability Reporting Directive (CSRD) requires companies to report on the impact of their activities on the environment and society. It applies to all publicly listed – as well as larger, non-listed – companies. It is expected to impact 50,000 businesses across Europe. The directive requires companies to collect more detailed and robust data on the environmental impact of their activities. For example, it is pushing companies in the building sector to measure the whole life carbon of their developments. Smaller companies not directly subject to the directive may also start to receive more requests for environmental information related to their clients’ CSRD reporting obligations. The CSRD was transposed into Irish law earlier this year, and the first Irish companies will begin reporting under the directive shortly.

› The EU Taxonomy Regulation (2020) is a classification system used to determine whether an economic activity is “environmentally sustainable”. It is designed

to prevent greenwashing. To meet the definition of sustainable, an activity must contribute substantially to at least one environmental objective, and do no significant harm to the other environmental objectives . Detailed sustainability criteria have been developed for buildings under the Taxonomy. Many investors, procurers, and developers are keen for their buildings to comply with the Taxonomy, as it will enable them to access ‘green’ finance at lower rates of interest.

› The Sustainable Finance Disclosures Regulation (SFDR) sets rules for how those who market and advise on financial products communicate sustainability information. In force since 2021, it requires these parties to evaluate any adverse sustainability impacts of their investment decisions or advice. The goal is to tackle greenwashing and make it easier to evaluate the sustainability of financial products. Real estate investors and other players in the property market may fall under the requirements of this directive.

› The Corporate Sustainability Due Diligence Directive (CSDDD or CS3D) was formally adopted by the EU earlier this year but has not yet been signed into Irish law. It applies to EU companies with more than 1,000 employees and net worldwide turnover of about 450 million, and to non-EU companies that generate the same amount of turnover within the EU. It requires these companies to carry out due diligence to identify actual or potential adverse impacts of their activities, and their chain of activities, on human rights and the environment. These companies will have to introduce a climate change transition plan to ensure their business strategy is aligned with EU climate targets under the Paris Agreement.

All of this legislation is starting to impact buildings here in Ireland. “We are seeing the impact of the new European legislation and regulations in various ways,” says Neil Menzies, director of sustainability at leading Irish real estate group Hibernia, which specialises in the Dublin office

market. Menzies says these new laws are making their way into the due diligence processes of institutional investors and lenders, who are increasingly asking to see things like energy and carbon performance data for buildings, decarbonisation strategies, and green building certificates. “Hibernia's sustainability strategy to build and operate the most sustainable buildings with the performance and credentials to support this ensures that we are able to respond to these queries”.

“We also see the impact through the growing requests from occupiers for more sustainable spaces and the performance of these spaces to help support their own requirements to comply with this legislation,” he adds, “especially legislation that requires them to report on their own ESG related performance and key performance indicators, such as the CSRD and CSDDD.”

Leading Irish homebuilder and developer Cairn Homes is reporting a similar impact. “Cairn will be reporting under CSRD from the financial year 2025, and as part of that will be reporting the percentage of our activities which are aligned with the EU Taxonomy,” says the company’s head of sustainable construction and reporting, Stephen O’Shea. “However, we are already seeing our institutional customers request evidence that buildings we are selling this year –which are likely to have been designed in 2019 and procured in 2021 – are so aligned.”

“Thankfully our early commitment to science-based decarbonisation targets has meant that we have whole life carbon calculations to hand, and our biodiversity net gain targets ensure that we have the surveys, designs, and data required to evidence our efforts in that regard.”

We see the impact through the growing requests from occupiers for more sustainable spaces to help support their own requirements to comply with this legislation.

Besides these ESG directives and regulations, other new laws under the European Green Deal relate more directly to buildings and energy. These are beginning to trickle down and impact project specifications too.

› The Energy Performance of Buildings Directive (EPBD) is the most critical European law for the built environment. Previous versions of the EPBD led to the introduction of BER certificates and nearly zero energy building (NZEB) standards in Ireland. The latest version was adopted by the EU earlier this year. It places a stronger focus on renovation and includes rules on embodied carbon for the first time. The directive requires that all new buildings be “zero emission” from 2028, and that the life cycle global warming potential (GWP) of all buildings be disclosed, and limited, from 2030. The EPBD also requires member states to improve the energy efficiency of their worst performing buildings. The latest version of the EPBD must be transposed into Irish law within two years. The IGBC is currently working on a project to support this transposition.

› The Construction Products Regulation (CPR) aims to ensure the quality and safety of construction products. The latest version (2024) lays down more harmonised standards to help construction products circulate freely within the single market. For the first time, the regulation considers both the lifecycle global warming potential of construction products and their wider environmental impact.

› The Energy Efficiency Directive (EED) (2023) sets overall energy efficiency targets for member states. It requires EU countries to achieve an 11.7 per cent reduction in final energy consumption by 2030, and with regards to buildings, puts a stronger focus on alleviating energy poverty, and on delivering energy efficiency improvements for vulnerable householders.

› The Renewable Energy Directive, last revised in 2023, sets a binding target that 42.5 per cent of the EU’s energy supply be delivered from renewable sources by 2030 (up from a 32 per cent target in the previous version).

These regulations are starting to have an impact too, especially the EPBD. Even though it will be a few years before its requirements come into force, many developers and procurers are keen to ensure buildings under design now are ‘future-proofed’ and compliant with the EPBD.

“The EPBD and EED impact us directly by setting stricter minimum requirements for how

we develop new buildings – for example more onsite renewables, increased energy efficiency, and ongoing monitoring of performance etc,” adds Neil Menzies of Hibernia. “We are moving from a world of voluntary sustainability action to one where sustainability action and performance is now a mandatory licence to operate."

There is a way through this confusion: focus on delivering high quality, healthy, sustainable buildings whose environmental performance is backed by solid data.

For anyone designing, procuring or developing buildings, the European policy landscape can seem daunting. But there is a way through this confusion: focus on delivering high quality, healthy, sustainable buildings whose environmental performance is backed by solid data. While it might technically be possible to, say, define and meet the requirements of the Taxonomy in quite a narrow fashion, the combined effect of all these initiatives will require a robust and holistic approach to sustainability.

The EPBD for example, will require us to start measuring the whole life cycle carbon of buildings and to pay more attention to indoor environmental quality; the CSRD is already putting pressure on developers to gather data on whole life carbon, biodiversity, and circularity; while the Taxonomy is encouraging developers to be more ambitious on carbon on circularity. The CPR, meanwhile, will normalise reporting on the environmental performance of construction products.

So, taking a holistic and rigorous approach to sustainability will be the only path forward.

The Irish Green Building Council’s Home Performance Index (HPI) can help for residential buildings. It takes a holistic approach to sustainability across more than 30 indicators, covering energy efficiency, indoor environmental quality, embodied carbon, water efficiency, daylighting, acoustics, biodiversity, and transport.

The next version of HPI, v3.1, will embed compliance with the Taxonomy as a minimum requirement for certification. HPI v3.1 will be launched in November at the IGBC’s Better Homes Conference. The development of this update to HPI was funded by the Smarter Finance for EU project (www.smarterfinance4.eu).

The IGBC provides Home Performance Index training for those wishing to advise clients on HPI and submit assessments, see www.homeperformanceindex.ie for more information. •

What is the difference between a law, a directive and a regulation?

At European level, a regulation applies to all member states and becomes part of national law. Regulations come into force immediately once adopted by the EU. A directive sets more general goals that member states must achieve, but they devise their own national laws for reaching these goals. Once directives are passed, member states have two years to transpose them into their national legislation. Laws and legislation are more general terms that cover both regulations and directives.

I

n the #BuildingLife Ambassador Spotlight Series, Passive House Plus is profiling leaders who have endorsed the Irish Green Building Council’s call to address the environmental impacts of buildings across their lifecycle.

In this interview, RIAI CEO Kathryn Meghen tells us more about why she is supporting the #BuildingLife campaign, and what the institute is doing to address sustainability in architecture.

Why did you choose to become a #BuildingLife ambassador?

Kathryn Meghen: A central focus of the RIAI’s work is to support architects and architectural technologists in the delivery of high-quality sustainable buildings and places. This is not only for the benefit of the building users but for the wider society as an important contribution to climate change action. Our

We need to create an environment to support the delivery of better-quality buildings, surrounded by community-focused infrastructure.

RIAI Strategy 2023-2027 also places a strong emphasis on sustainability, and we support our members through training, promotion and advocacy. For example, we will be launching a new environmental accreditation for our members this year, to support their skills and expertise in design for sustainability.

The climate change challenge is, however, complex and solutions can only be delivered through collaboration with our built environment colleagues. The #BuildingLife ambassador programme is a great avenue to work across all sectors of the industry to deliver this ambition.

What are you hoping to achieve with the #BuildingLife campaign?

KM: Architects have a leadership role in the built environment, and the RIAI has brought our knowledge and expertise in sustainable building design to our work on external bodies such as the steering group for the National Policy on Architecture and the Construction Sector Group. But I believe that we need to go further – as a #BuildingLife ambassador, my key ambition is to build new platforms for collaboration across the built environment

professions.

These new platforms and initiatives can drive new research into sustainable methods of construction, which are necessary to deliver the number of homes we need to create – as part of liveable urban developments – to accommodate our rising population. Together, we need to create an environment which supports the delivery of better-quality buildings, surrounded by a community-focused infrastructure.

The #BuildingLife campaign provides a platform for the collaborative effort needed to drive change. One of the important outcomes has been the IGBC’s ‘Building a Zero Carbon Ireland’ roadmap, published in 2022. The roadmap outlines the key actions the building industry must take to reduce its emissions by 51 per cent by 2030, in line with our national climate targets. It includes a useful separate roadmap for each of the key disciplines within the building industry – architects, contractors, engineers, planners, surveyors etc.

Can you explain a few ways in which the RIAI is working towards a sustainable built environment?

KM: We have a range of initiatives underway that are all linked to the RIAI Strategy, which seeks to inspire excellence in architecture to deliver a sustainable and resilient future. Key elements of this are the upcoming Environmental Accreditation system, which recognises our members’ ability, knowledge and skill in sustainable design. We have an extensive CPD programme of courses in sustainable design for performance and are currently working with the Irish Green Building Council on a joint programme of research, support tools, guidance and up-skilling of professionals to address the much-needed decarbonisation of our built environment. The programme, Design4Zero, is funded by the Sustainable Energy Authority of Ireland (SEAI) under its National Energy Research Development and Demonstration Programme. We are also creating awareness of exemplars of sustainable design through our annual RIAI Awards programme with a dedicated award for Sustainable Design. This year’s winner was the Department of the Environment, Climate and Communications Headquarters – an exemplary retrofit project by the Office of Public Works. We believe that valuable lessons from this retrofit project can be applied to our existing building stock. We are constantly reviewing our training and support for our members to ensure that they are best equipped for their important role in the design, delivery and management of a sustainable built environment.

#BuildingLife is a project led in Ireland by the Irish Green Building Council. The initiative aims to achieve the mix of private sector action and public policy necessary to tackle the whole-life impact of buildings. Learn more and endorse the Building a Zero Carbon Ireland Roadmap at www.igbc.ie/ building-a-zero-carbon-ireland/. •

Make the greener choice for your home, upgrade your existing central heating with an eco-friendly, low noise Midea Heat Pump. Air source heat pumps are the low-carbon future of home heating which integrates heating and domestic hot water into one system.

The future of heating, renewable energy is the greener, cleaner way to heat your home. Midea’s air source heat pumps are the costeffective way to lower your energy bills and switch to a low-carbon way of heating your home. Make yourself at home and start saving with Midea Heat Pumps.

OUR MIDEA MONOBLOC HEAT PUMP COMES WITH A MARKET LEADING 10 YEAR WARRANTY.

In the latest piece in his series on the development of low energy building, Dr Marc Ó Riain describes the evolution and Impact of EPCs in Ireland and the UK.

The introduction of energy performance certificates (EPCs) in 2007 represented a pivotal moment in enhancing consumer awareness of home energy efficiency in both Ireland and the UK. The concept of energy performance ratings dates back to Energy World’s initiatives in Milton Keynes in 1985 and the UK's National Energy Rating Scheme developed by the Building Research Establishment (BRE) in 1990. However, it was the global Kyoto Protocol of 1998 that spurred the EU to introduce its first Energy Performance of Buildings Directive (EPBD) in 2002. This directive laid the groundwork for integrating energy conservation targets into national regulations, prompting Ireland and the UK to revise their respective requirements for energy performance under building regulations, called Part L in both Ireland, and England and Wales.

In 2007, Ireland and the UK launched EPCs for residential buildings, extending to public buildings in 2008 with the introduction of Display Energy Certificates (DECs). Both rating systems evaluate and rate a building's energy efficiency on a scale from A to G.

Although methodologies for calculating energy performance differ between the two countries, they both comply with the EU’s Energy Performance of Buildings Directive. In the UK, the Standard Assessment Procedure (SAP) is used to generate EPCs, while Ireland uses the Domestic Energy Assessment Procedure (DEAP) to produce Building Energy Ratings (BERs). Both procedures focus on fixed energy loads such as heating, cooling, hot water, and lighting. However, they exclude the impact of household appliances, such as refrigerators and washing machines, which are classified as "loose" or "plug" loads.

Unlike the DECs for public buildings, which are based on actual energy consumption, residential EPCs and BERs are based on theoretical models and fixed assumptions. This theoretical approach has led to a discrepancy between calculated and actual energy consumption. Studies, such as those conducted by O’Driscoll (2014), have highlighted the growing importance of plug loads in energy consumption, particularly in net zero-energy buildings.

Prior to 2005, compliance with Part L was relatively straightforward, based on standard U-values for building components. However, the introduction of BERs/EPCs necessitated signif-

icant revisions to Part L in the UK in 2006 and in Ireland in 2007. These updates incorporated new factors, including thermal bridging, airtightness, and – in the case of Ireland – contributions from renewable energy sources. While these changes aimed to improve energy efficiency and sustainability, they also added complexity to the design and compliance processes. As a result, energy consultants became crucial, using simulation tools to help architects achieve compliance through design modifications and the integration of renewable technologies such as solar pan-

renovations of existing buildings. In Ireland, a new coalition government in 2020 introduced a commitment to upgrade 500,000 homes to a B2 rating by 2030, with grants of up to 50 per cent available to improve eligible homes. The DEAP software was also updated and converted into a web tool, with periodic updates to primary energy factors for the electricity grid meaning that electrically heated homes achieved BER improvements even without fabric improvements – a shift which helped turbocharge the rise of the heat pump.

The surge in energy prices underscores the growing significance and awareness of energy performance certificates as a vital tool for assessing building energy efficiency, benefiting homeowners and investors alike.

els, heat pumps, and wood-burning stoves. The introduction of BERs, EPCs and DECs increased public awareness and influenced both individual behaviour and market dynamics. Reports from 2013 onwards revealed that properties with higher energy performance ratings commanded higher purchase prices, reflecting an energy efficiency premium. For example, the study by Duarte & Chen (2022) found that A-rated homes in Ireland saw a 9.5 per cent increase in value compared to D-rated homes, whereas F/G-rated properties experienced a 10.6 per cent decrease. In England, A-rated homes saw a 5 per cent premium, while F/G-rated homes saw similar levels of price reductions. Other countries, such as Norway and Denmark, reported even more pronounced premiums and reductions, highlighting the growing importance of energy efficiency in property valuation.

A 2010 recast to the EU Directive on the Energy Performance of Buildings introduced a new target for new buildings, the Nearly Zero Energy Building (NZEB), which member states had to define and implement by 2019. The directive also required member states to set minimum energy performance targets for major

The global energy crisis triggered by the war in Ukraine in February 2022 led to a dramatic rise in energy prices, with heating and electricity costs increasing by 70-80 per cent. This surge has driven a significant rise in building retrofits and solar panel installations. In Ireland, building retrofits increased by 53 per cent since the first quarter of 2023, and domestic rooftop solar production rose by 42.6 per cent over the same period. This surge underscores the growing significance and awareness of energy performance certificates as a vital tool for assessing building energy efficiency, benefiting homeowners and investors alike.

In the next article I will tackle the definition of Nearly Zero Energy Buildings a decade ago and whether these standards are still fit for purpose. n

Dr Marc Ó Riain is a lecturer in the Department of Architecture at Munster Technological University (MTU). He has a PhD in zero energy retrofit and has delivered both residential and commercial NZEB retrofits In Ireland. He is a director of RUA Architects and has a passion for the environment both built and natural.

At NorDan Vinduer, we firmly believe in the power of strength and resilience. Our roots are deeply embedded in Norway, where we engineer our doors and windows to withstand the harsh, unforgiving weather. This makes our products the ideal choice for Ireland’s diverse and challenging climate.

We have faced countless storms and emerged victorious, leading the way in sustainability, carbon reduction, and quality in every product we offer. Our dedication to excellence has established us as a leader in sustainable manufacturing of windows and doors.

Choosing the right windows and doors can be a challenging task, especially since it's not something we do frequently. This rarity makes the decision even more crucial. Our expert team are on-hand to guide you through key considerations to help you make informed choices.

Whether it’s a new build or refurbishment, each requirement is unique and the NorDan team are the perfect partners to help you find the ideal solutions for your project.

Our efforts to retrofit homes across the UK and Ireland will be severely hampered unless we engage meaningfully with and empower women homeowners and professionals, writes Ellora Coupe, founder of Her Retrofit Space.

Irecently sat down and felt compelled to ask ChatGPT to "name a process undertaken by women that has been made more efficient and stress-free through innovation and process changes." The results that came back were about washing machines, robotic hoovers, kitchen appliances, automatic dryers, laundry detergent, stain removers, and ironing. I had not mentioned anything in relation to cleaning or housework, but it still showed inherent biases and lacked the variety of skills involved in women’s lives today.

I asked the same question with "men" in place of "women," and the innovations listed were financial tracking, investing, online banking, and budgeting software.

My job is to constantly evaluate how to better support women homeowners in embracing retrofit projects. Women homeowners today require a multitude of skills including data analytics, financial tracking, procurement, cleaning, buying, designing, technological competence, scheduling, cooking, specification, and parenting, all while often managing another career.

Observing the pitfalls in the renovation or retrofit process through the lens of thousands of women in the community I run is disheartening. I spend every day listening to a multitude of stories from women around why and how things go wrong, how to try to mitigate risk and how to resolve disputes.

This experience has had two clear effects. It has only further inspired me to hone my focus on identifying the hidden opportunities to better support women. And it has made me conclude that the retrofit industry has an opportunity to create a better framework to improve the project journey for women homeowners. However, another dependency of this journey is whether the appetite to embrace retrofit exists amongst women homeowners.

So where do we look for solutions? With over 10 years working within the branding industry in the UK, there is still a misunderstanding that it is about selling products, ideas, and lifestyles to people that they do not need. If anyone thinks that pretty designs, well-written words, and compounding data are enough to convince a woman today to buy anything, then we have made the first significant mistake. In the retail

industry and consumer markets, they have to work exceptionally hard, invest significant time, and ensure they don’t underestimate women’s ability to grasp the truth about something and whether it actually benefits them profoundly.

We could revisit the stories about misogynistic tradespeople overlooking women to talk to the man, or the perception that women won’t understand construction, technology, or metrics, or that they get taken advantage of when it comes to costing, but I think it would do a disservice to the subtle, overlooked lesson: don’t underestimate women.

The real focus should be on highlighting the significant opportunities and misconceptions about women homeowners today that are blocking the pathway for women to embrace retrofit.

A recent report on retrofit by the Federation of Master Builders stated, "There is low consumer demand for work to reduce the carbon impact of existing homes, with consumers typically showing little or no interest in energy efficiency or low/zero carbon technologies."

I did think immediately that it hadn’t caveated that little to no public engagement had been made on any significant scale to enlighten, educate, and inspire consumers on the benefits and opportunities to retrofit their homes.

Are there lessons to be made from the growing number of significant sustainable decisions women make today? Did the dramatic rise in women buying more second-hand clothes come from a rise in living costs? Or was it a very clever platform called “Vinted” which improved the process, making buying and selling second hand clothes suddenly very easy?

Deloitte's 2023 report, The Boston Consulting Group (BCG), and McKinsey's findings highlight an exponential growth in sustainable purchasing behaviours among UK women, driven by environmental awareness, ethical considerations and a desire for durable, repairable products.

How can one presume a lack of appetite when the level of conversation with women homeowners around a retrofit approach or energy efficiency upgrades is at opposite ends of the scale compared to food, health, and beauty?

To address this, how should we engage better and capture the attention of women homeowners? Well, we can learn from the many

consumer-focused businesses that have made significant shifts in consumer behaviour, such as the non-alcoholic beverage industry or natural cleaning products industry.

Olio, the giving away instead of throw away app that lets you simply offer an item of very little value to anyone who can re-home it, has gone from 2.3 million users in November 2022 to 4.8 million in November 2023. Seventy percent of its users are women in the UK. There is absolutely no financial or social gain from giving away these items, but users understand that not throwing something away is better for our planet and are prepared to take up time in their day to offer items for free to someone in their local area. No one would know if they had thrown it away except them, so if the system is in place to do the right thing, people do.

It comes back to making assumptions, and this is also the case with the presumed adversity that women have to technology adoption. Women use technology for what it can do, not for the sake of it, and research shows that women can be early adopters of many systems and processes when they work really well. They have less tolerance for bad user interfaces; if it is hard to use, they will not use it, not because they cannot. Marketers and manufacturers have data to support that women do more research than men before making a purchase.

To truly enable women to adopt retrofit, the industry should focus on developing better project process-driven frameworks to improve the journey, design technology with intuitive interfaces, build robust support networks, and promote gender-inclusive policies and practices. We just may need to call on a different set of professions to enable women homeowners to lead the way, rather than perceive them as a barrier. n

more information visit www.herownspace.com

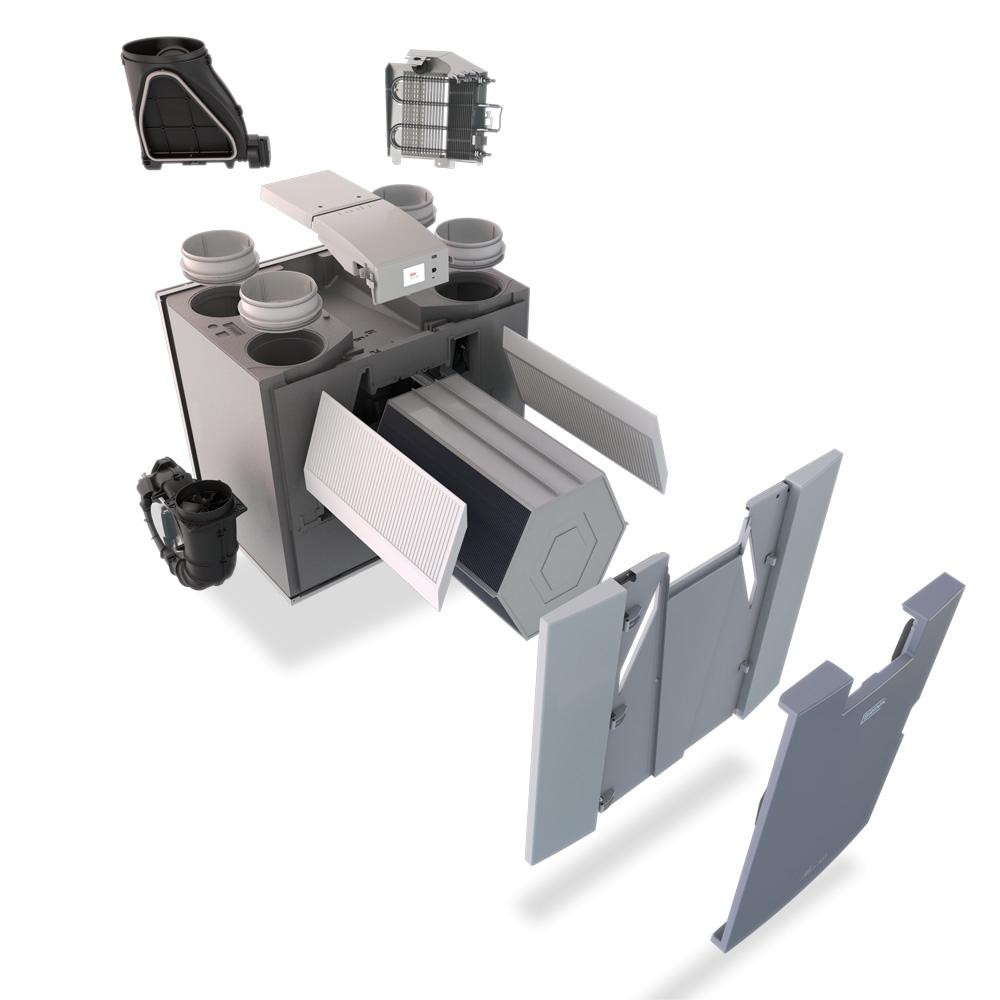

MVHR FOR RESIDENTAL APPLICATIONS

Elevate your indoor experience with InspirAIR Top MVHR system, a connected marvel of innovation designed to prioritise air quality, performance, comfort, and user interaction.

With Passiv Haus certification and recognition in the PCDB database, InspirAIR Top is your ultimate choice for top-tier indoor air quality, performance, and comfort.

Connec tivit y

VENTILATION FOR SCHOOLS AND COMMERICAL SETTINGS

DEX3000 - Decentralised Ventilation

A decentralised ventilation unit is a simple solution where one ventilation unit is placed in each room with separate connection through a wall or ceiling/roof.

The installation can be carried out classroom by classroom,

CX3000 - Ceiling units

The CX3000 is designed for integration into a suspended ceiling, or fitting into a ceiling or floor partition.

suitable for renovation or new build projects.

IRELAND’S

In September Cairn Homes lit the fuse on a passive house explosion, publishing a position paper on passive house and announcing the construction of nearly 1,800 apartments to the standard. But what’s behind the company’s bold move?

By Jeff Colley

In The Devil’s Dictionary, Ambrose Bierce defined the corporation as “An ingenious device for obtaining individual profit without individual responsibility.” Though Bierce’s masterwork dates back to 1906, these words could have been written yesterday. For more than a hundred years the perception has endured: Big Business Does Bad Things.

So what on earth, you might quite reasonably ask, is Ireland’s largest house builder, Cairn Homes PLC, doing building over 1,750 certified passive houses, with a further 1,250 in the pipeline for next year?

And it gets worse. It’s not just passive houses. It’s passive social and affordable housing, which is also aiming to integrate several other aspects of sustainability via using the Irish Green Building Council’s Home Performance Index (HPI), on sites which are aiming for biodiversity net gain, with sustainable transport options. It begs the question: who are we supposed to rail against, if house builders start acting like this?

Cairn’s passive house rollout is breathtaking in its speed and scale, with four large apartment schemes being built simultaneously around Dublin. The first two, Pipers Square in Charlestown, and Cooper Square in Seven Mills, are slated to have the first units ready to occupy (RTO) by the end of 2025, totalling 590 and 607 units each. Two smaller projects in Santry – 255 units at Whitehaven and 303 units at Niven Oaks – are due to have first units RTO by the end of 2025 and April 2026 respectively, with all four schemes set for final completion in the first half of 2026. This totals 1,755 units on site, all targeting passive house certification.

What’s more in the midst of implementing this change Cairn pulled together a position paper on passive house – which, full disclosure, I had the pleasure of co-authoring via my new communications consultancy, Zero Ambitions Partners – to explain why Cairn were throwing their considerable weight behind passive house, what benefits it would bring for everyone from residents to building owners to construction workers, and in the process reassure their clients that they hadn’t lost the run of themselves.

The anatomy of a transition How did Cairn’s decision to go passive come to pass? The answer, in part, starts with a positive-sense single-stranded RNA virus: SARS-CoV-2.

Cairn’s passive journey began during Covid lockdown in 2020. And though it is hard for me to process, Passive House Plus had a part to play in it. Cairn’s senior creative manager, Donal Thornton, rang me up out of the blue in October 2020, asking about the passive house standard, and evidently keen to learn what the

Source: MosArt

company could do to improve the sustainability of its projects. I remember being startled –pleasantly – that such a big housebuilder was asking these kinds of questions, and having a characteristically long and sprawling conversation on passive house and some quick wins Cairn could implement to specify low carbon building materials. Donal contributed to a presentation on the benefits that passive house could bring at Cairn’s Innovation Forum, and the seeds were sown. And then it went quiet.

In January 2022 Stephen O’Shea, an architect with twenty five years of private practice under his belt, joined Cairn – first as design manager, before becoming the head of sustainable construction and reporting in 2023.

By his own admission O’Shea had been “quite sceptical” about passive house for many years, before the opportunity to probe the standard arose when he sat the post graduate course in building performance (energy efficiency in design) at TU Dublin. “I came to respect its rigour, but it seemed very far removed from the cut and thrust of ‘normal’ building projects,” he says. “Then when I came to Cairn and learned about their attitude towards efficiency in their operations, their methods, processes and products, their passion for sustainability, and their focus on the customer journey I realised that there was the potential for a meeting of minds."

O’Shea commissioned feasibility studies on passive house for low density and high density schemes from seasoned passive house experts MosArt, drawing on the Wicklow company’s 20 years of experience in passive house consultancy, certification and training throughout Ireland, the UK and North America on projects of all shapes and sizes.

“We’re not new to big projects,” says MosArt MD Tomás O’Leary. The firm’s high density passive track record includes the likes of a 26-storey skyscraper for Cornell Tech in New York in 2016, and a current project that’s set to dwarf it not once, not twice, but three times: Urbanest’s 2 Trafalgar Way in London’s Canary Wharf, with three towers coming in at 28, 36 and 46 storeys each.

If there’s one thing passive house enthusiasts love it’s a graph, and a graph of Irish residential passive house projects involving MosArt outlines the Irish passive house story in stark terms, ironically evoking the infamous hockey stick graphs showing the rapid growth in recent and projected future warming arising from climate change. From 2004 to 2020, the line was pancake flat, except for a couple of bumps in 2008 with UCD’s Roebuck Castle student halls and in 2017 with Durkan Residential’s 59-unit Silken Park housing scheme. The figures started to tick up from 2021-2023, with projects like Fraser Millar’s 219 homes at Lancaster Park in Belfast and Durkan Residential’s 47-unit Egremont scheme in Killiney, before a near vertical rise in 2024, with almost 2,500 units on site this year.

Stephen O’Shea says Cairn took great com-

fort in MosArt’s long track record in passive house. “Having someone with Tomás’s breadth and depth of experience was absolutely key,” he says. “Knowing that he had been a member of the team that delivered the tallest passive house building in the world really gave us comfort that he had been there, done that, and he was very open to embracing a developer mindset. He knew that was key to making any largescale.

More reassuring still was the fact that MosArt were working on Shanganagh Castle, a social and affordable homes currently approaching completion which includes 546 passive apartments. Developed by Dún Laoghaire-Rathdown County Council and the Land Development Agency, the project will be the enduring legacy of the passive house clause in Dún Laoghaire Rathdown’s 2016 County Development Plan, which this magazine helped to push through.

“Shanganagh was a huge influence for us,” says Stephen O’Shea. “It answered the ‘Can this be done at scale in Ireland with Irish supply chains?’ question, and now we just had to decide how it could best be done for Cairn. We wanted to use our own methodology, which is very different from the precast solution being used there.

Stressing Cairn’s “openness to innovation and a trust in data”, O’Shea paints a picture of a company culture which encourages new ideas to be sought out, aired, discussed and fleshed out. “Through our Innovation Forum we were able to give the idea time and space to be considered and thoroughly researched,” he says. “What we found is that the benefits were considerable, and the difficulties were not insurmountable. Passive house had struggled with the image of being too difficult, too bespoke. But when we really examined the changes that would be required to our standard methodology, we found that they weren’t seismic.”

By happenstance or design, feasibility studies showed that Cairn’s quality assurance focus and approach to meeting the nearly zero energy building (NZEB) standard required under Irish building regulations made passive house surprisingly attainable. The apartment buildings needed no extra insulation, though Cairn’s house types needed extra floor and roof insulation, and all buildings would require triple glazing. The company was already using mechanical ventilation with heat recovery (MVHR) on some and the lower heating demand enabled a switch to a simpler, lower capital cost heating package: direct electric heaters and individual hot water heat pumps.

Following all of this early engagement and the formation by MosArt’s Stephen Donoghue of a study group of developers working on or considering passive house projects, Cairn bit the bullet and took the decision to commit to passive house on the Pipers Square site.

“We acquired Pipers Square with planning permission and started straight into pre-construction,” says Stephen O’Shea. “It was never designed with passive in mind. But the decision was made when we started on pre-construction.

In July 2023, just before Cairn had agreed to push the button on this project, I met O’Shea at an IGBC event in our roles as BuildingLife ambassadors under the World Green Building Council’s BuildingLife Campaign. At this stage there was – quite reasonably – uncertainty from some in the company about stepping into the unknown. O’Shea invited me to come in and give a corporate version of my TEDx talk to Cairn’s senior leadership team (SLT), to help tackle any nagging concerns. I had recently launched a sustainable building comms/strategy business, Zero Ambitions Partners, with my magazine co-founder and podcast co-host Dan Hyde, who used his corporate communications background to help me piece a presentation together. According to Stephen, it made

Passive house has the image of being too difficult. But the changes required to our standard methodology weren’t seismic.

a decisive impact.

“The change process has been a long one, so even though the strategic decision had been made to go passive for Pipers Square, bringing the SLT and other senior figures together in an open forum was critical,” he says. “We all know the myths around passive house, and we have all felt the fear of trying something new. So having that group addressed by a real subject matter expert who tackled those myths head on was a real turning point.”

My enduring memory of that day was the high level of technical questions coming from Cairn staff in the questions and answers session after my talk – and a clear focus on the customer which went right up to the top of the company, and CEO Michael Stanley.

While the company is implementing a number of decarbonisation strategies, the prospect of better outcomes for customers made passive house stand apart. “Michael Stanley very quickly saw the tangible benefits and added value that it would bring to our customers, and that made a big difference,” says O’Shea. “Other decarbonisation initiatives such as switching to HVOs for site machinery or using GGBS in concrete mixes don’t have such benefits and can feel somewhat academic as a result,

but passive delivers day-after-day, year-afteryear in ways that make real positive differences to people’s lives.”

Virtuous though Cairn’s efforts are, they’re not happening in a vacuum. The business community is coming under exponentially increasing pressure to engage with environmental, social and governance (ESG) investment principles and report on the positive and negative impacts of their activities, including reporting on emissions upstream and downstream of their operations. In the case of a developer, “upstream” means embodied carbon, and “downstream” means sixty years of projected emissions from operational energy use after the buildings are handed over – but all counted in year one in Cairn’s figures. “We measured our carbon footprint in accordance with GHG Protocol and realised how great a proportion of our total – over 50 per cent – comes from the use of the homes we sell.

But while large companies like Cairn are in the first wave of companies subject to the rigours of sustainability reporting obligations under the Corporate Sustainability Reporting Directive (CSRD), O’Shea stresses that the company’s actions are driven by its values, rather than carbon accountancy. “We strive to do the right thing, and then we report on those actions,” he says. “We try to actively avoid letting reporting dictate what we do – it can never be the driving force.”

He does concede, though, that passive house offered an advantage for their reporting. “We were aware that passive house could improve the accuracy of our reporting. We currently apply a substantial ‘penalty’ to our BER data when reporting on our emissions to allow for the performance gap, but if the data was coming from PHPP and the homes were being certified to the passive house standard then we could all but eliminate that safety factor.”

Grand plans are one thing, but putting in place a strategy to actually deliver are quite another. According to Tomás O’Leary, Cairn aren’t taking any chances.

“Cairn are throwing resources at upskilling and educating their staff at various levels,” he says. “They have set quite a few of their senior technical team to do the passive house designer course. We’re currently working on a tailored course for site supervisors.”

With all four sites progressing at a rate of knots, O’Leary is impressed by what he’s seeing. “We’re dealing with their site staff and site supervisors,” he says. “Our experience is that they’re really up for it. You don’t normally get total buy in, but they’ve bought in 100 per cent. They’re all in. Jamie Lacey, a technical manager. The intensity in his eyes – he’s hanging on every word, and he wants to deliver not just passive house but the best passive house in the world. It’s just such a joy to work with people like that.”

While the prospect of meeting passive house is in sight, O’Shea isn’t counting his chickens just yet. “We are now live on four projects, so every day brings new challenges. But our technical teams and consultants are working through them. We’re far from thinking ‘We have this licked’, but very confident that we’ll get there.”