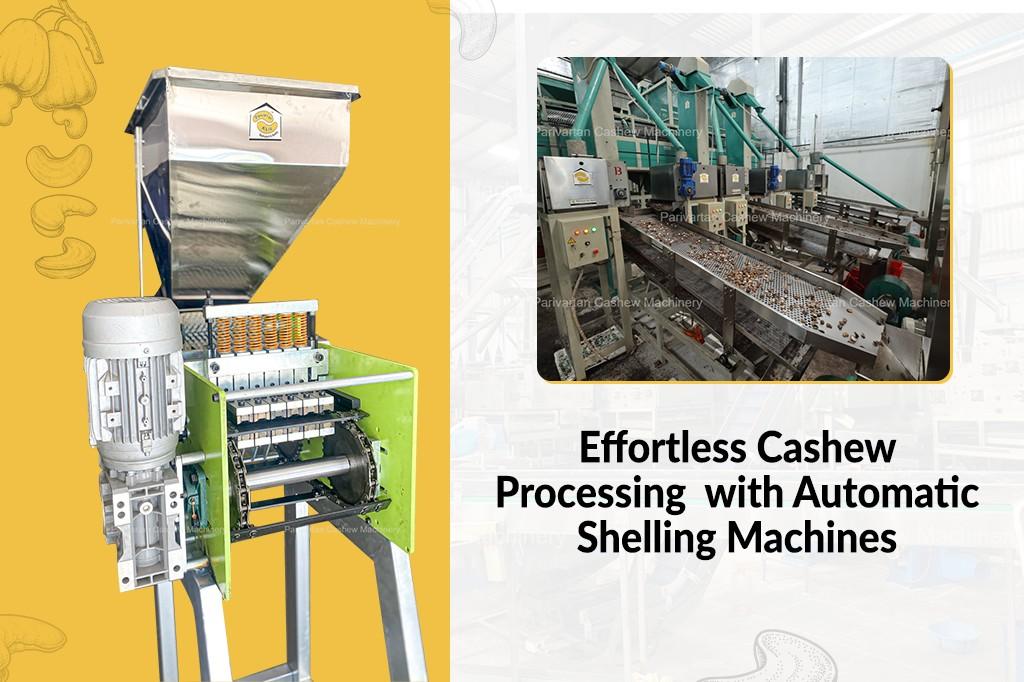

Cashew processing is an essential step in bringing high-quality cashew products to consumers around the world. With the advancement of technology, modern machinery has revolutionized the way cashews are handled, making the process more efficient, cost-effective, and precise. One of the most significant innovations in cashew processing is automatic shelling machines, which streamline operations and ensure consistent, high-quality results.

The Importance of Automatic Cashew Shelling Machines

Manual processing of cashews is time-consuming and prone to inconsistencies and kernel breakage. This is where automatic cashew-cutting machines come into play. These machines automate the process of removing cashew shells, ensuring that the kernels remain intact while minimizing breakage. As a result, manufacturers can produce higher-quality cashews with less manual effort and greater efficiency.

Benefits of Using Automatic Cashew Shelling Machines

1. Increased Efficiency: Automated shelling machines can process a large number of cashews in a short period. This significantly reduces processing time and labor costs.

2. Improved Quality: With precise shelling, there is minimal damage to cashew kernels, ensuring a higher yield of intact, high-quality products.

3. Consistency: Unlike manual methods, automatic machines provide consistent results, which is essential for maintaining product standards and satisfying customer expectations.

4. Cost-Effective: Automation reduces the need for extensive labor, thereby lowering operational costs and improving overall productivity.

5. Scalable Solutions: Whether managing a small or large cashew processing plant, automated shelling machines offer scalable solutions to meet growing demands.

Types of Automatic Cashew Processing Machines

1. Automatic Cashew Shelling Machine

An automatic cashew shelling machine is designed to crack and remove the cashew shell efficiently. These machines use advanced technology to ensure that the cashew kernels are extracted with minimal breakage, which is crucial for maintaining the quality of the final product. With adjustable settings, these machines can accommodate different cashew sizes and processing volumes.

2. Automatic Cashew Cutting Machine

The automatic cashew-cutting machine is responsible for the initial stage of shelling. It automates the cutting and splitting of cashew shells, preparing kernels for further processing. This machine is essential for reducing the workload and improving the speed of shelling operations.

3. Automatic Cashew Nut Peeling Machine

Post-shelling, a cashew nut peeling machine is used to remove the thin skin from the cashew kernels. This process ensures smooth, clean cashew kernels that retain their natural flavor and texture. It works seamlessly with other machines to provide a complete cashew processing solution.

4. Cashew Cooking System

The Cashew Cooking System is an essential step in preparing cashews for various culinary uses. By cooking cashews to the perfect temperature, this machine enhances flavor, texture, and shelf life. It ensures uniform cooking, reducing variability and maintaining high-quality standards.

5. Cashew Grading Machine

After processing, a cashew grading machine sorts kernels based on size and quality. This ensures that only the highest-grade cashews reach the market. Advanced grading machines use advanced sensors to ensure precision sorting, improving market value and customer satisfaction.

6. Cashew Dryer Machine

A cashew dryer machine is crucial for drying processed cashews to achieve the ideal moisture level. Proper drying prevents spoilage and maintains the natural taste and texture of cashew kernels, ensuring they meet quality standards for both local and export markets.

Why Choose a Reliable Cashew Shelling Machine Manufacturer?

When investing in automatic cashew machinery, choosing a reputable manufacturer is vital. A trusted manufacturer ensures that the machines are built with high-quality materials and offer cutting-edge technology. Whether you’re looking for a cashew shelling machine manufacturer or a fully automatic cashew cutting machine, partnering with industry leaders guarantees durable, efficient, and reliable solutions tailored to your specific needs.

Conclusion

Automatic shelling machines have transformed the cashew processing industry by making it more efficient and cost-effective. From shelling and peeling to grading and drying, these machines streamline operations, ensuring high-quality cashew products with minimal effort. By investing in advanced machinery, cashew processing plants can enhance productivity, reduce labor costs, and meet the highest industry standards.

Whether you are a small business or a large-scale processor, incorporating these innovative machines into your operations ensures seamless, high-quality cashew processing that meets both domestic and international demands.