INFORMATION AND ACCESSORY CARD

KAIR ECoCounter 4385 EC AIR HANDLING UNIT

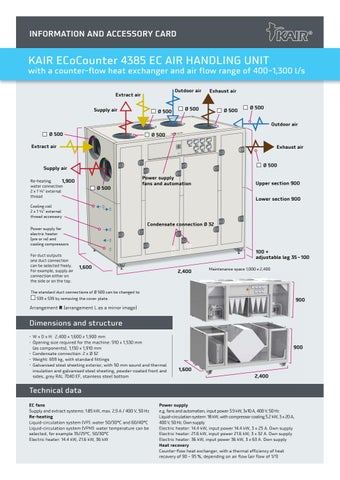

with a counter-flow heat exchanger and air flow range of 400–1,300 l/s Outdoor air

Extract air Supply air

Ø 500

Exhaust air

Ø 500

Ø 500

Ø 500 Outdoor air

Ø 500

Ø 500

Extract air

Exhaust air

Ø 500

Supply air Re-heating 1,900 water connection 2 x 1 ¼” external thread

Ø 500

Power supply fans and automation

Upper section 900 Lower section 900

Cooling coil 2 x 1 ¼” external thread accessory

Condensate connection Ø 32

Power supply for electric heater (pre or re) and cooling compressors For duct outputs one duct connection can be selected freely. For example, supply air connection either on the side or on the top.

100 + adjustable leg 35 - 100 1,600

2,400

Maintenance space 1,000 x 2,400

The standard duct connections of Ø 500 can be changed to 539 x 539 by removing the cover plate.

900

Arrangement R (arrangement L as a mirror image)

Dimensions and structure • W x D x H: 2,400 x 1,600 x 1,900 mm • Opening size required for the machine: 910 x 1,530 mm (as components), 1,130 x 1,910 mm • Condensate connection: 2 x Ø 32 • Weight: 659 kg, with standard fittings • Galvanised steel sheeting exterior, with 50 mm sound and thermal insulation and galvanised steel sheeting, powder-coated front and sides, grey RAL 7040 EF, stainless steel bottom

900

1,600 2,400

Technical data EC fans Supply and extract systems: 1.85 kW, max. 2.9 A / 400 V, 50 Hz Re-heating Liquid-circulation system (VP): water 50/30°C and 60/40°C Liquid-circulation system (VPM): water temperature can be selected, for example 35/25°C, 50/30°C Electric heater: 14.4 kW, 21.6 kW, 36 kW

Power supply e.g. fans and automation, input power 3.9 kW, 3x10 A, 400 V, 50 Hz Liquid-circulation system: 18 kW, with compressor cooling 5.2 kW, 3 x 20 A, 400 V, 50 Hz. Own supply Electric heater: 14.4 kW, input power 14.4 kW, 3 x 25 A. Own supply Electric heater: 21.6 kW, input power 21.6 kW, 3 x 32 A. Own supply Electric heater: 36 kW, input power 36 kW, 3 x 63 A. Own supply Heat recovery Counter-flow heat exchanger, with a thermal efficiency of heat recovery of 90 – 95 %, depending on air flow (air flow of 1/1)